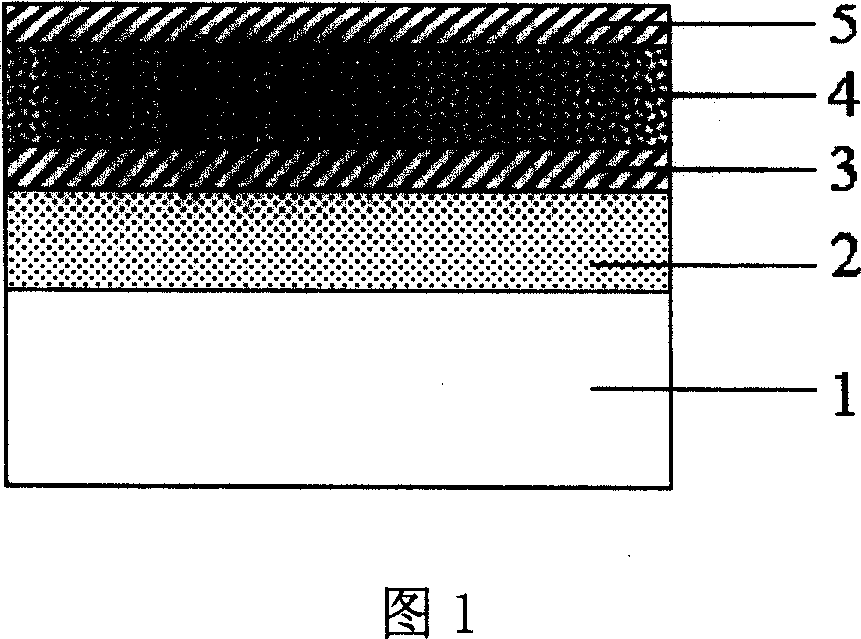

Nd-doped Bi4Ti3O12 ferroelectric thin film for the ferroelectric memory and its low temperature preparation method

A ferroelectric memory, neodymium bismuth titanate technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, static memory, chemical instruments and methods, etc., can solve the problem of unfavorable compatibility between ferroelectric films and CMOS circuits, preparation of High temperature and narrow ferroelectric film thickness range, to achieve the effects of excellent fatigue resistance, large polarization strength, and wide film thickness range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The low-temperature preparation method of the above-mentioned film proposed by the present invention is characterized in that it consists of two parts: preparing Nd-doped bismuth titanate precursor sol and preparing Nd-doped bismuth titanate ferroelectric thin film, including the following steps:

[0028] 1) Preparation of the Nd-doped bismuth titanate precursor sol:

[0029] 11) Dissolving neodymium acetate (commercially available product) in ethanolamine (commercially available product) (ethanolamine is both a solvent and a complexing agent), so that it is completely dissolved into a neodymium acetate solution;

[0030] 12) Dissolve bismuth hexanoate (commercially available product) or bismuth acetate (commercially available product) or bismuth nitrate (commercially available product) in caproic acid (commercially available product) or acetic acid (commercially available product) to make it completely dissolve into caproic acid Bismuth solution or bismuth acetate solu...

Embodiment 1

[0044] The neodymium-doped bismuth titanate Bi of the present embodiment 4-x Nd x Ti 3 o 12 The composition and components of the ferroelectric thin film are: Bi 3.15 Nd 0.85 Ti 3 o 12 , the x in the Nd is 0.85; the Bi in the neodymium-doped bismuth titanate, relative to the composition formula Bi 3.15 Nd 0.85 Ti 3 o 12 The content of Bi should be added in excess, the excess percentage of the Bi element is 20%; the thickness of the film is 20nm.

[0045] The preparation method of this thin film comprises the following steps:

[0046] 1) Preparation of the Nd-doped bismuth titanate precursor sol:

[0047] 11) Dissolving 1.366g neodymium acetate (commercially available product) in 10ml ethanolamine (commercially available product) is mixed with completely dissolved neodymium acetate solution;

[0048] 12) 15.422g bismuth hexanoate (commercially available product) is dissolved in 25ml hexanoic acid (commercially available product) and is made into completely dissolved...

Embodiment 2

[0061] The neodymium-doped bismuth titanate Bi of the present embodiment 4-x Nd x Ti 3 o 12 The composition and components of the ferroelectric thin film are: Bi 3.75 Nd 0.25 Ti 3 o 12 , the x in the Nd is 0.25; the Bi in the neodymium-doped bismuth titanate, relative to the composition formula Bi 3.75 Nd 0.25 Ti 3 o 12 The content of Bi should be added in excess, and the excess percentage of the Bi element is 5%; the thickness of the film is 500nm.

[0062] The preparation method of the neodymium-doped bismuth titanate ferroelectric thin film comprises the following steps:

[0063] 1) Preparation of the Nd-doped bismuth titanate precursor sol:

[0064] 11) Dissolving 0.402g neodymium acetate (commercially available product) in 10ml ethanolamine (commercially available product) is mixed with completely dissolved neodymium acetate solution,

[0065] 12) 13.942g bismuth nitrate (commercially available product) was dissolved in 50ml acetic acid (commercially available...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com