Ultrasonic leaching-extracting separation method for sulphating roasting rare earth mine

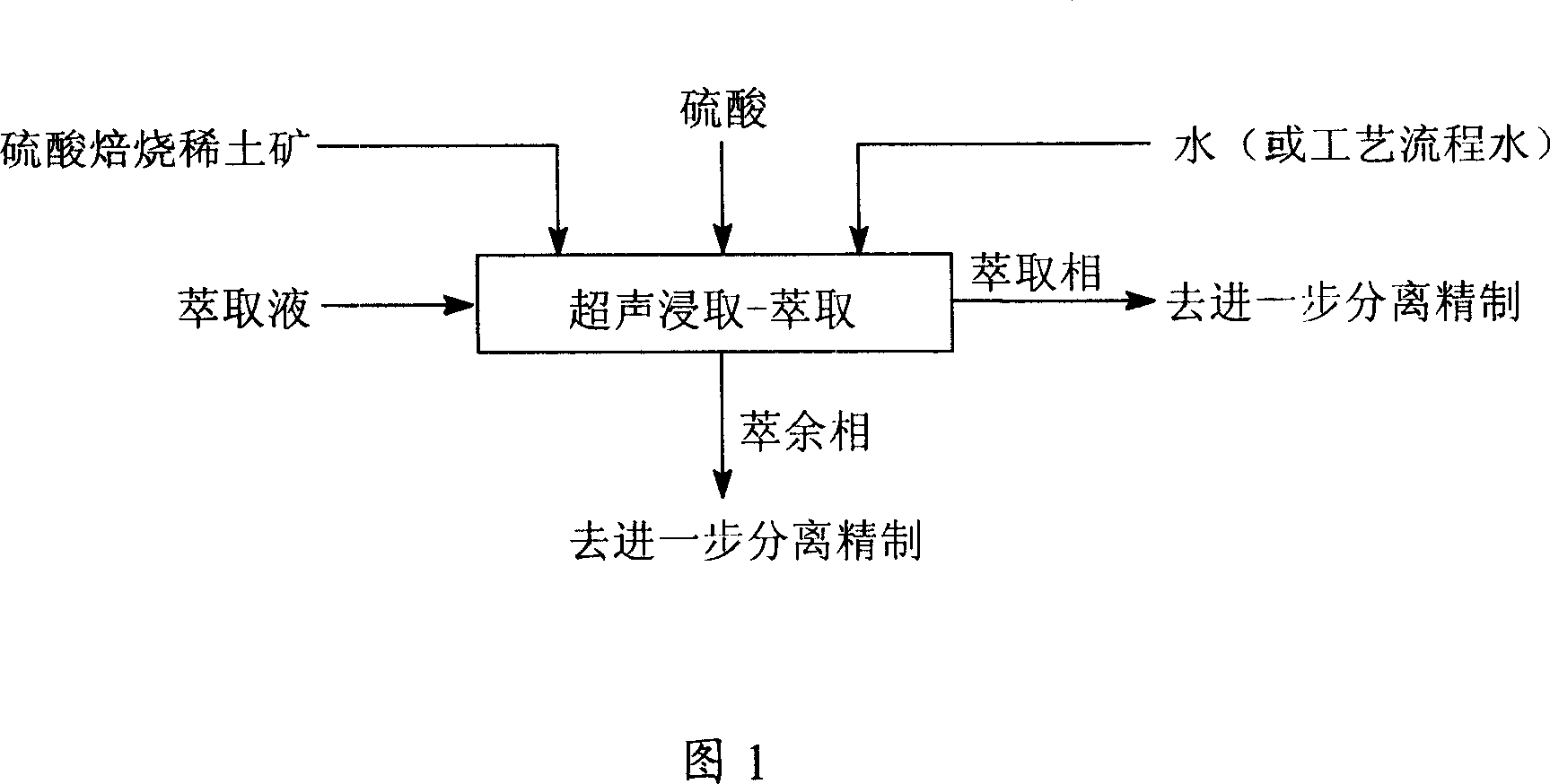

A technology of sulfuric acid roasting and separation method is applied in the field of separation of rare earth ore roasted by sulfuric acid, and can solve the problems of increasing the load of evaporation and concentration, long separation process route, low leaching and extraction rate and efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: main production equipment: probe type ultrasonic generator, 1L stirred tank, analytical testing instrument;

[0025] Main raw materials: water, sulfuric acid, P204 extractant, sulfuric acid roasting rare earth ore;

[0026] The separation steps are as follows: put sulfuric acid roasted rare earth ore, leaching solution, and extract into a 1L stirring tank at a ratio of 1000g:5L:0.1L, sulfuric acid roasted rare earth mineral material 100g, sulfuric acid aqueous solution 0.5L and extract P204 and kerosene are mixed Solution 0.01L, put the probe of the probe-type ultrasonic generator in the mixed material, control the operating temperature to 5°C, adjust the ultrasonic frequency to 19kHz, and the ultrasonic action intensity to 0.2W / cm 2 , ultrasonic leaching-extraction separation operation was carried out under the action of ultrasonic waves. After ultrasonic leaching-extraction separation for 30min, the raffinate phase was light rare earth sulfate enrichment...

Embodiment 2

[0027] Embodiment 2: main production equipment: probe type ultrasonic generator, 5L stirring tank, analytical testing instrument;

[0028] Main raw materials: water, sulfuric acid, P204 extractant, sulfuric acid roasting rare earth ore; separation steps are: put sulfuric acid roasting rare earth ore, leaching solution, and extracting solution into a 5L stirring tank at a ratio of 1000g:20L:5L, and sulfuric acid roasting rare earth mineral 150g of material, 3L of sulfuric acid aqueous solution and 0.75L of the mixed solution of extract P204 and kerosene, place the probe of the probe-type ultrasonic generator in the mixed material, control the operating temperature to 40°C, adjust the ultrasonic frequency to 25kHz, the ultrasonic intensity 2.0W / cm 2 , ultrasonic leaching-extraction separation operation was carried out under the action of ultrasound. After ultrasonic leaching-extraction separation for 15 minutes, the raffinate phase was light rare earth sulfate enrichment, mainly...

Embodiment 3

[0029]Embodiment 3: main production equipment: probe type ultrasonic generator, 10L stirred tank, analytical testing instrument;

[0030] Main raw materials: water, sulfuric acid, P204 extractant, sulfuric acid roasting rare earth ore;

[0031] The separation steps are as follows: put sulfuric acid roasted rare earth ore, leaching solution, and extract into a 10L stirred tank at a ratio of 1000g:50L:10L, sulfuric acid roasted rare earth mineral material 100g, sulfuric acid aqueous solution 5L and extract solution P204 and kerosene mixed solution 1L , place the probe of the probe-type ultrasonic generator in the mixed material, control the operating temperature to 60°C, adjust the ultrasonic frequency to 80kHz, and the ultrasonic action intensity to 20.0W / cm 2 , under the action of ultrasound, ultrasonic leaching-extraction separation operation was performed. After ultrasonic leaching-extraction separation for 30min, the raffinate phase was light rare earth sulfate enrichment, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com