Flame type deiinted cotton seeds processing technology and dedicated combustion furnace thereof

A technology for delinting and processing cotton seeds, which can be used in application, seed and rhizome treatment, separation of plant fibers from seeds, etc., and can solve problems such as environmental pollution, increased production costs, and large acid consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

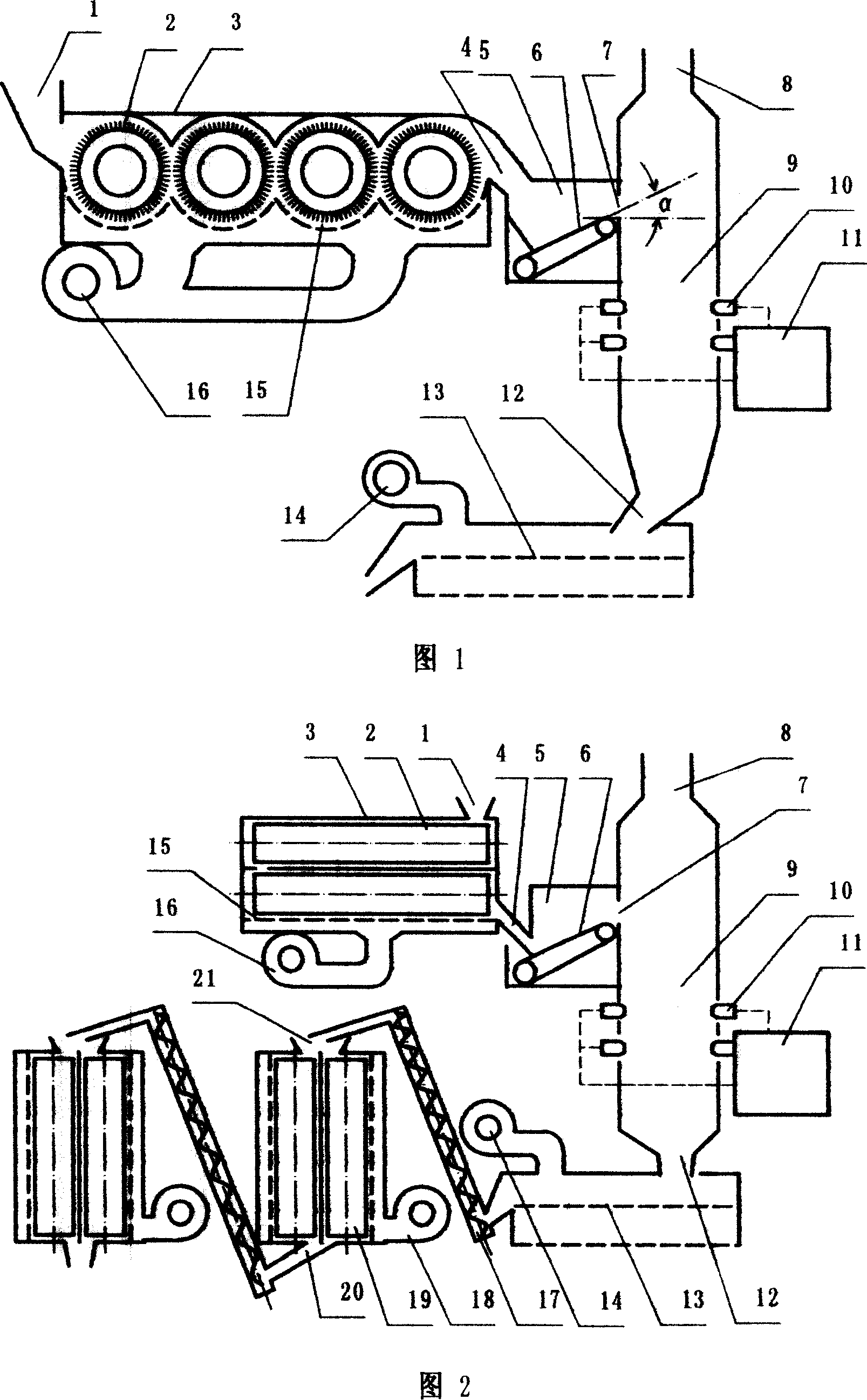

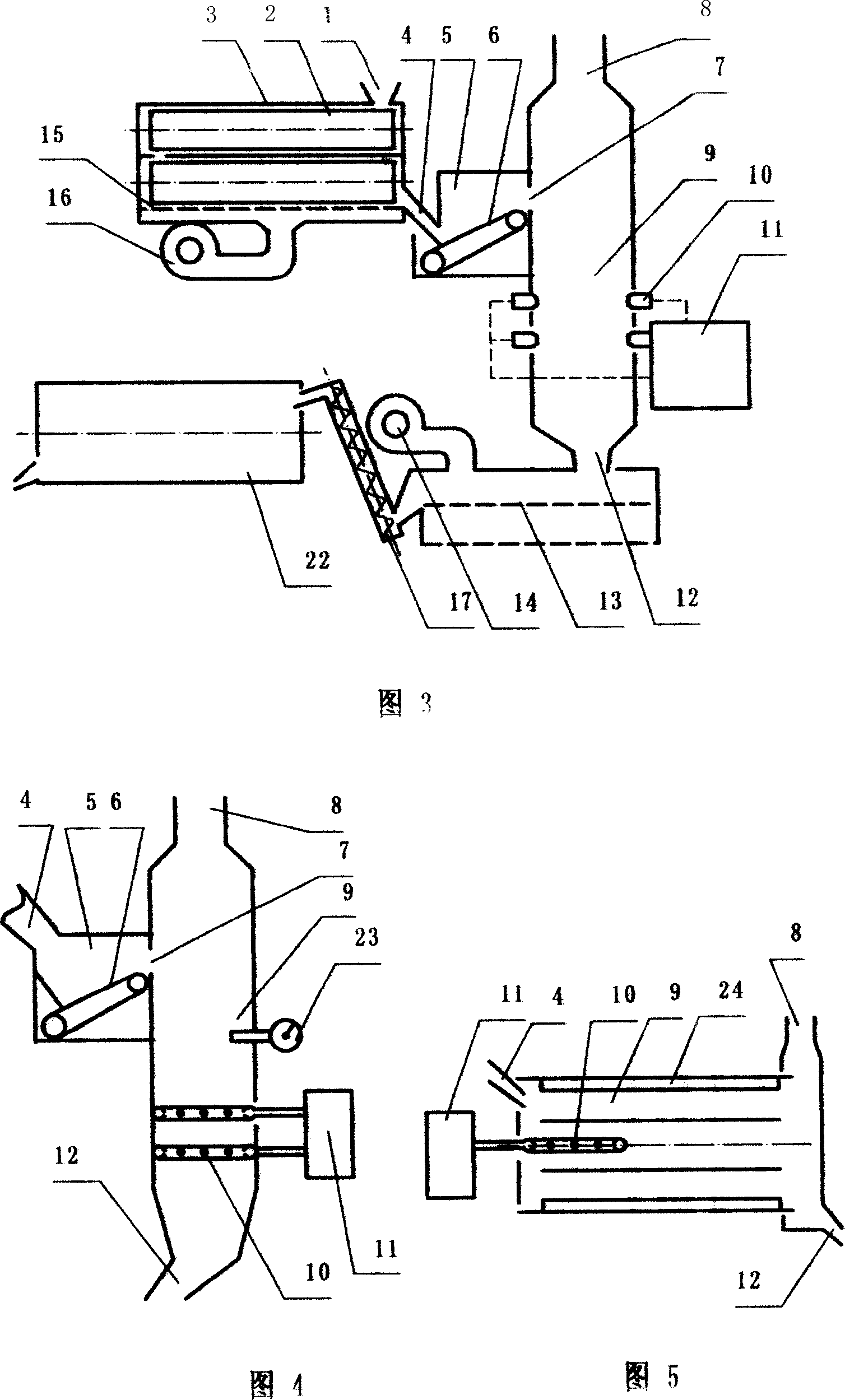

[0021] Embodiment 1: With reference to Figure 1, it is a schematic diagram of Embodiment 1 of the present invention and its equipment structure.

[0022] The carding in this embodiment uses a flat push parallel carding machine 3 to comb the wool seeds and pre-de-hairing. The carding machine includes an inlet 1, an outlet 4, and 4 sets of cards that rotate in the same direction are installed in the carding machine. Roller 2, carding roller 2 is equipped with a combing wire brush. Feeding port 1 and discharging port 4 are respectively located at the first and fourth carding rollers side by side. The lower part of carding roller 2 has a sieve plate 15 and linters. The discharge fan 16 and the short lint discharge fan 16 are negative pressure fans. A burnt lint feeder 5 is provided at the outlet 4 of the carding machine. The front end of the conveyor belt 6 of the burnt lint feeder is inclined upward at an angle α of 30°. The seed inlet 7 of the combustion chamber 9 is opposite, the c...

Embodiment 2

[0028] Example 2: Compared with Example 1, the difference of this example is that the process of the present invention is the pre-process of measuring the acid cotton seed delinting process: the wool seed is pretreated by this process, so that the acid The amount of wool seed lint before the treatment process is between 7 and 8%, and then enters the metering acid delinting process. At this time, the amount of acid is easy to grasp, thereby ensuring the quality of seed processing.

Embodiment 3

[0029] Embodiment 3: Compared with Embodiment 2, the difference of this embodiment is that the burner is a gas type.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com