Device for preparing environment-friendly type bast fiber film

A preparation device and technology of hemp mulching film, which can be used in plant protection covers, textiles and papermaking, fiber treatment, etc., can solve the problems of difficult stable production, difficult spraying waterproof, insect prevention, weed control, hindering the industrialization and promotion of invention patents, etc. problems, to achieve the effects of stable quality, improved flatness and waterproof performance, and low surface density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

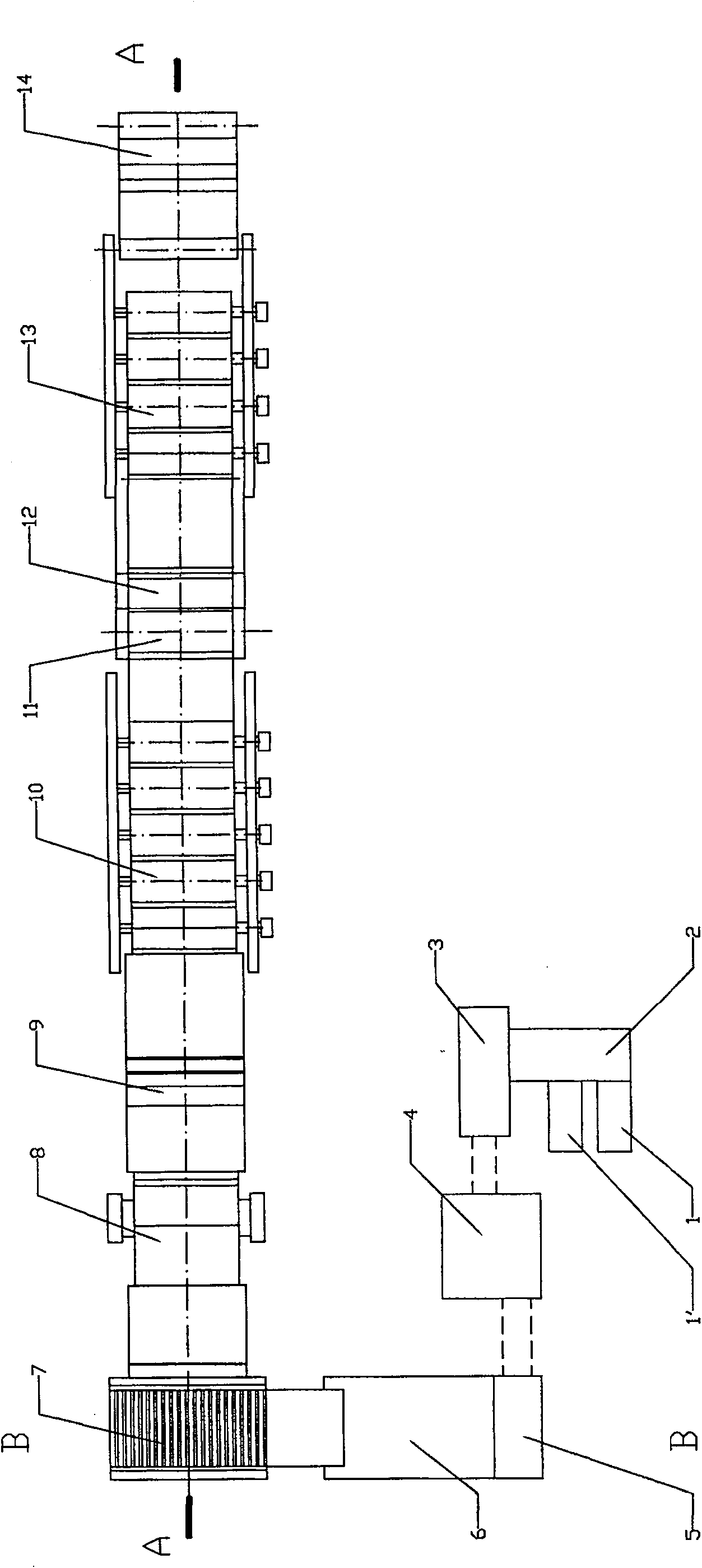

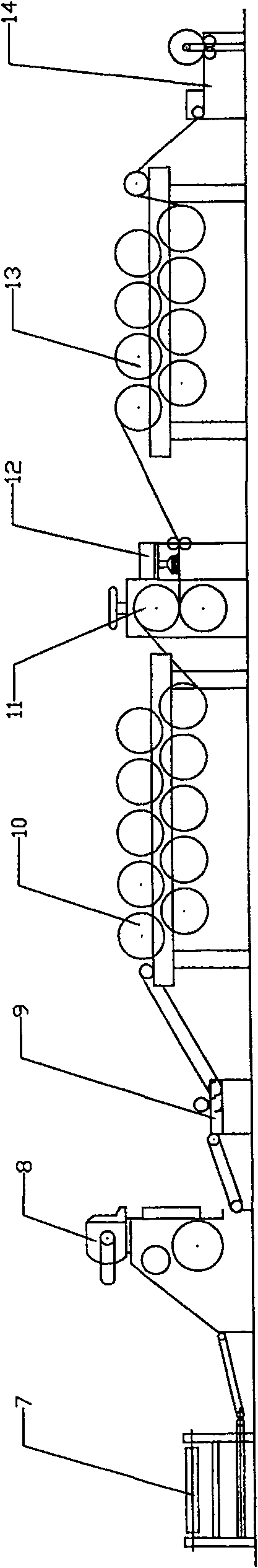

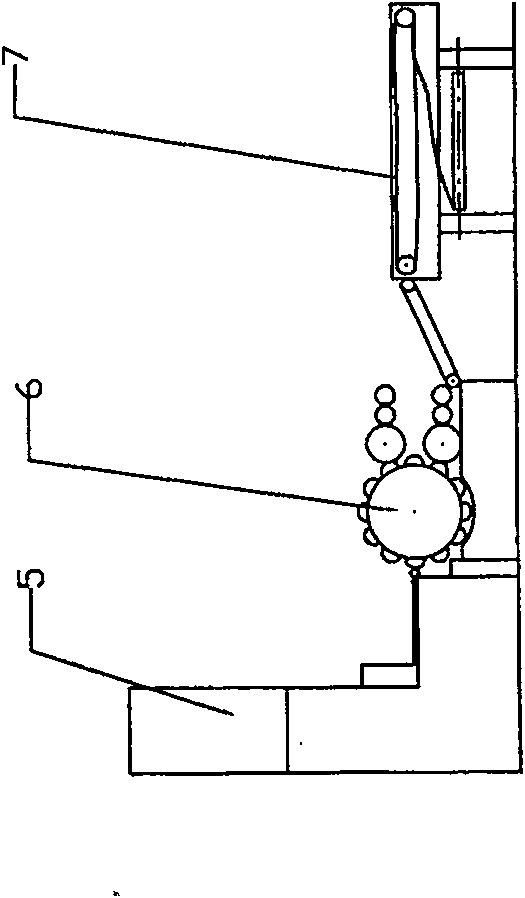

[0012] The environment-friendly hemp mulch film preparation device of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0013] The environment-friendly hemp mulching film preparation device of the present invention includes feeders 1 and 1', a material mixer 2, a rough opener 3, a fine opener 4, a vibrating air pressure feeding box 5, a carding machine 6, and a mechanical cross-lapping machine. machine 7, air-laid machine 8, dipping machine 9, drum-type pre-drying machine 10, pneumatic double-roll calender 11, surface spray coating machine 12, drum-type drying and setting machine 13, drafting and cutting Side lapping machine 14 and other operating unit machines, and the selection of equipment should be suitable for processing natural fibers as the main technical parameters.

[0014] When the device of the present invention works, the hemp raw materials are transported to the mixer 2 by two feeders 1 and 1' for mixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com