Three-element compound metallic oxide catalyst and its preparation method

A noble metal oxide and ternary composite technology, applied in chemical instruments and methods, separation methods, dispersion particle separation, etc., can solve problems such as unreachable and lower catalyst light-off temperature, achieve low light-off temperature, high temperature aging resistance The effect of good performance and wide selection range of precious metal components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

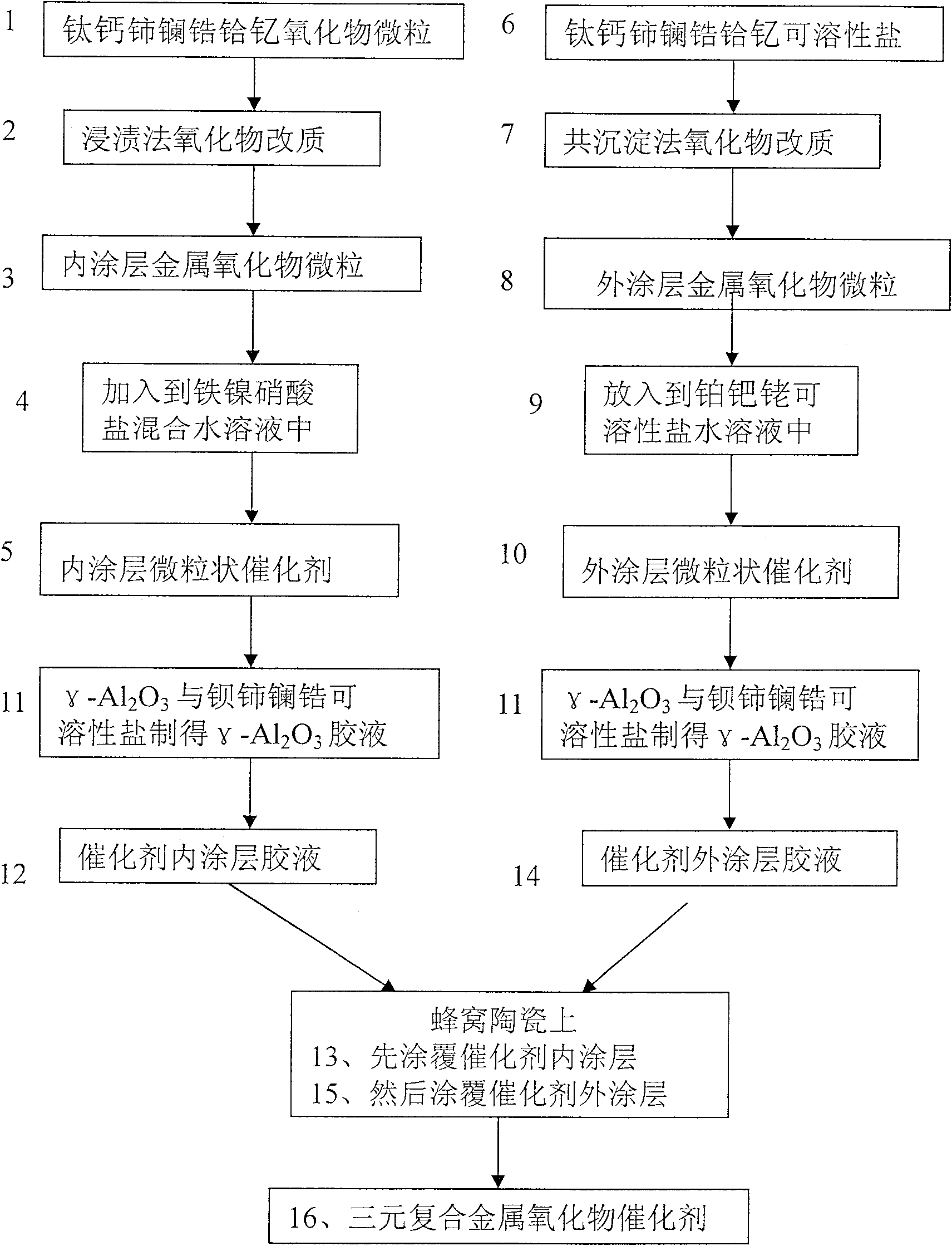

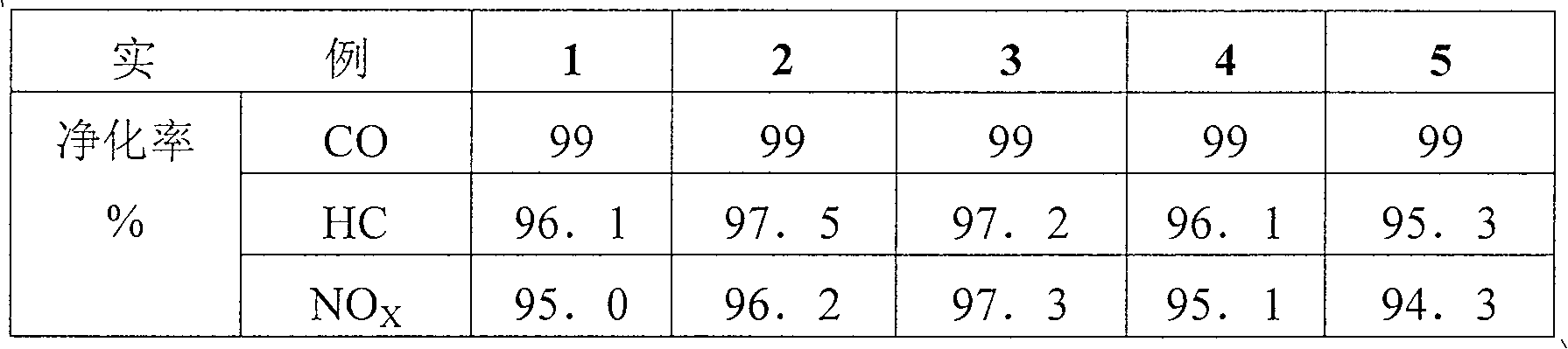

[0030] Example 1: Preparation of ternary composite metal oxide catalyst.

[0031] Such as Picture 1-1 , 2, take 100 grams of titanium dioxide and 61 grams of calcium nitrate, dissolve them in water, impregnate the aqueous solution of calcium nitrate on the titanium dioxide, evaporate to dryness, then dry at 120 ° C for 5 hours, and roast at 600 ° C for 3 to 5 hours to control the average particle size of the powder. diameter of 4um to obtain inner-coated metal oxide particles 3 . Such as figure 1 As shown in -4, take 200 grams of ferric nitrate and 200 grams of nickel nitrate, dissolve them in water, and the mass ratio of oxides is Fe 2 o 3 :NiO=1:1.3. Dissolve ammonium carbonate in water to make 0.2 mole (NH 4 ) 2 CO 3 Solution; 100 grams of prepared inner coating metal oxide particles 3 are added to iron, nickel nitrate mixed aqueous solution 4, and 0.2 moles (NH 4 ) 2 CO 3 solution, add ammonia water dropwise at pH=7, adjust pH=10, let it stand for 1-2 hours, the...

Embodiment 2

[0038] Example 2: Preparation of ternary composite metal oxide catalyst.

[0039] The preparation and coating method of the catalyst inner coating glue solution 12 are the same as those in Example 1.

[0040] The making of palladium-containing outer coating particulate catalyst 10: get 100 grams of cerium, zirconium outer coating metal oxide particles 8, put into and stir in the aqueous solution 9 that is dissolved by 10.71 grams of palladium chloride, drip into with 1 mole of sodium carbonate When the pH value = 10, let stand for 1-2 hours, filter, wash with deionized water, then dry at 120°C for 5-6 hours, and roast at 500°C for 3 hours, and control the crushing average particle size to ≤5um to obtain a palladium-containing outer The coated particulate catalyst 10 contains 6% palladium.

[0041] The preparation method of rhodium-containing outer coating particulate catalyst 10 is the same as in Example 1.

[0042] Preparation of catalyst outer coating glue solution 14: tak...

Embodiment 3

[0043] Example 3: Preparation of ternary composite metal oxide catalyst.

[0044] The preparation and coating method of the catalyst inner coating glue solution 12 are the same as those in Example 1.

[0045] The making of platinum-containing outer coating particulate catalyst 10: get 100 grams of cerium and zirconium outer coating metal oxide particles 8, quantitatively impregnate them with 3% chloroplatinic acid solution 9, and dry them at 120° C. for 5 hours after each impregnation. Then roast at 200°C for 1 hour, and roast at 400°C for 3 hours. After crushing, impregnate again, dry, roast, and crush until the solution dissolved by 17.36 grams of chloroplatinic acid is used up, then dry at 120°C for 2 hours, and then dry at 200°C. Calcined for 1 hour, 400° C. for 1 hour, and 600° C. for 3 hours to prepare an outer-coated particulate catalyst 10 with a platinum content of 6%.

[0046] The preparation method of rhodium-containing outer coating particulate catalyst 10 is the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com