Method for manufacturing dye sensitized nano crystal solar cell photo-anode membrane

A technology for solar cells and manufacturing methods, which is applied in electrode manufacturing, capacitor electrodes, and final product manufacturing, and can solve problems such as easy cracks in the film, pores in the film, weak bonding between the film and the conductive glass substrate, and particles in the film. , to achieve the effects of improved film uniformity, excellent bonding, and low mass production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] Nanostructured composite TiO 2 The preparation method of the powder is: the nanocrystalline TiO 2 Disperse in a solution containing organic matter to form a uniform slurry, then dry and crush to prepare TiO with nanostructure characteristics and an overall size in the order of microns and submicrons 2 powder.

[0042] Nanostructured composite TiO 2 The organic matter contained in the powder is in a solid state at room temperature, and is selected from organic carboxylic acid, polyethylene glycol, polyvinyl alcohol, polyacrylamide, polyvinylpyrrolidone, polyacrylic acid, polymethacrylic acid, two or both of the above A mixture of the above organic compounds.

[0043] The above-mentioned treatment is to remove the organic matter from the inside of the film by evaporation or decomposition, and is selected from heat treatment, UV irradiation treatment, microwave irradiation treatment, electron beam irradiation treatment or two or more methods thereof.

[0044] After ste...

Embodiment 1

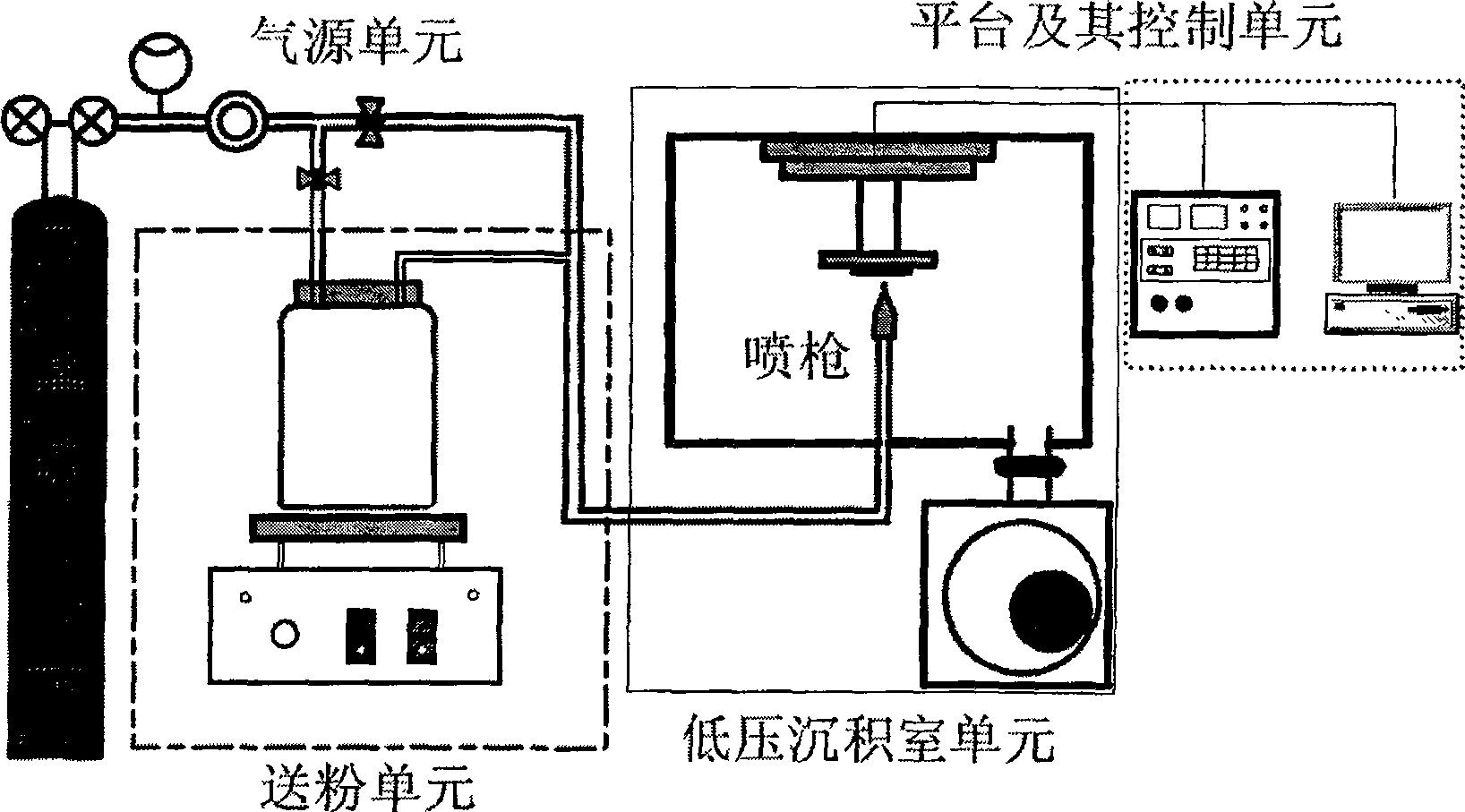

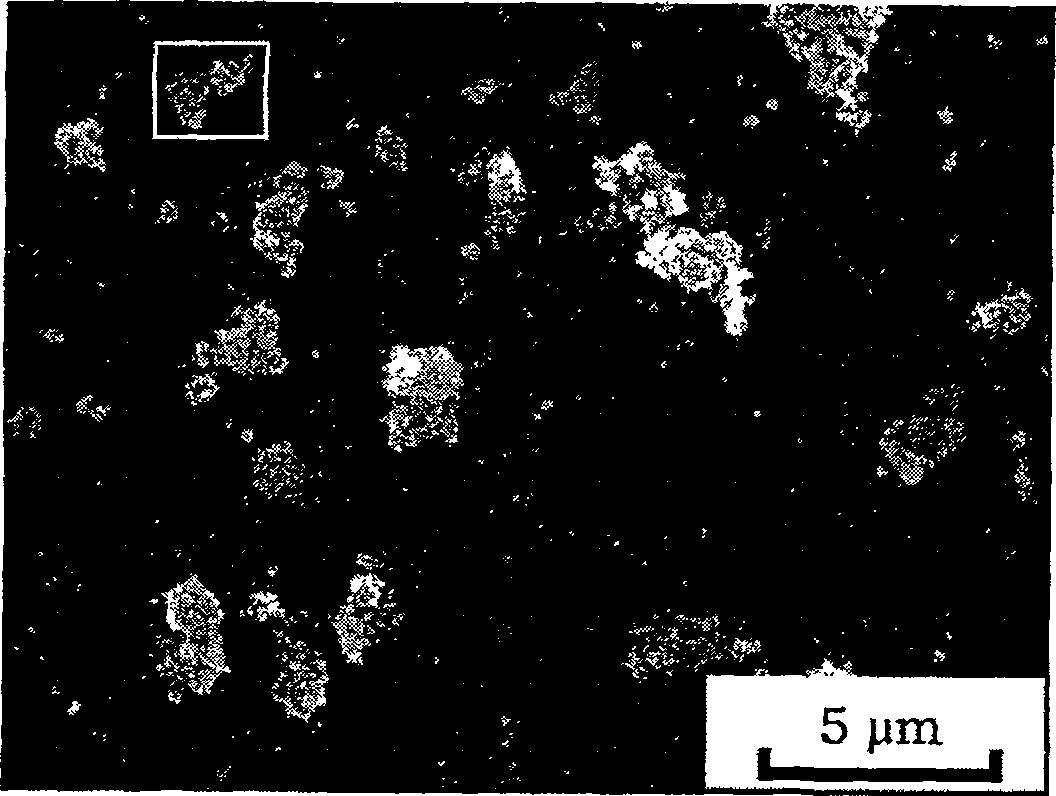

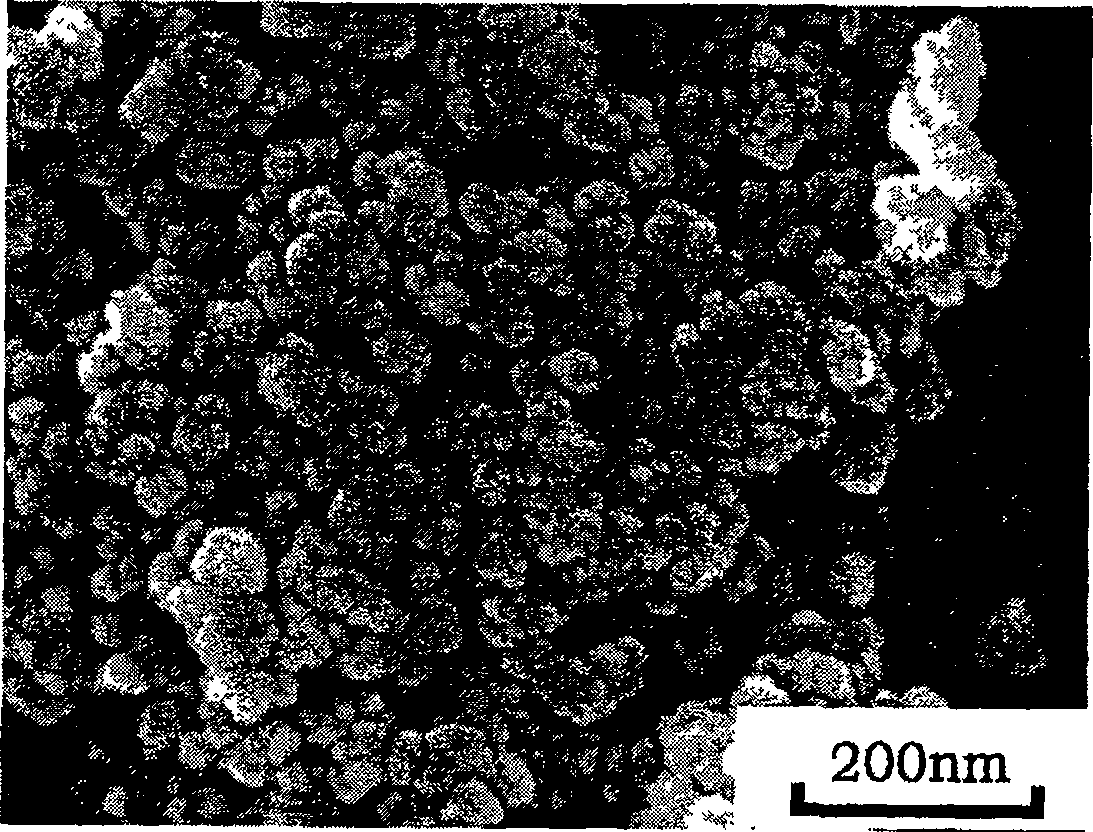

[0047] Dissolve 4g of polyethylene glycol in 50mL of ethanol, and add to the solution containing 10g of P25 TiO under ultrasonic vibration 2 Suspension of the powder in 100 mL ethanol. After rotary evaporation and drying, grinding and sieving to obtain nanostructured composite TiO2 treated with polyethylene glycol 2 powder, see figure 2 , image 3 .

[0048] Using this spray powder, TiO was prepared by vacuum cold spraying on FTO conductive glass 2 film. Typical vacuum cold spray parameters are: vacuum chamber pressure 0.23KPa; He is accelerating gas, flow rate 2L / min, pressure 1MPa. The cross-section and surface morphology of the film are shown in Figure 4 , Figure 5 ,As a comparison, Figure 7 The surface morphology of the films prepared by the traditional knife coating method is given. It can be found from the figure that this film has no defects such as cracks and pores.

[0049] The prepared film was heat-treated at 450°C for 30 min to remove organic matter. ...

Embodiment 2

[0052] In the case described in Example 1, after removing the organic matter, the film was soaked in 0.05mol / L, 70°C TiCl 4 In the aqueous solution for 30 minutes, then heated to 500 ° C for 20 minutes, so as to treat TiO 2 Strengthening of connections between primary particles. Then according to the dye adsorption and battery assembly method of Example 1, the battery was assembled into a battery at AM1.5 (100mW / cm 2 ) under the xenon lamp light source to simulate sunlight, the measured short-circuit current density of the battery is 17mA / cm 2 , open circuit voltage 0.66V, energy conversion efficiency 6.5%, see Figure 8 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com