Viscosity reduction bacteria for increasing recovery ratio of petroleum, and application

A technology for application and oil recovery, applied in the direction of bacteria, drilling composition, and microbial-based methods, can solve problems such as poor hydrocarbons, unsatisfactory effects, and application constraints, so as to reduce fluidity and improve crude oil flow capacity , Improve the effect of the sweep coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1, Streptococcus zooepidemicus (Streptococcus zooepidemicus) CGMCC NO.1988 to crude oil (oil-water ratio is 5-0.2, crude oil comes from Xinjiang Karamay Oilfield, Henan Zhongyuan Oilfield, Heilongjiang Daqing Oilfield) degradation

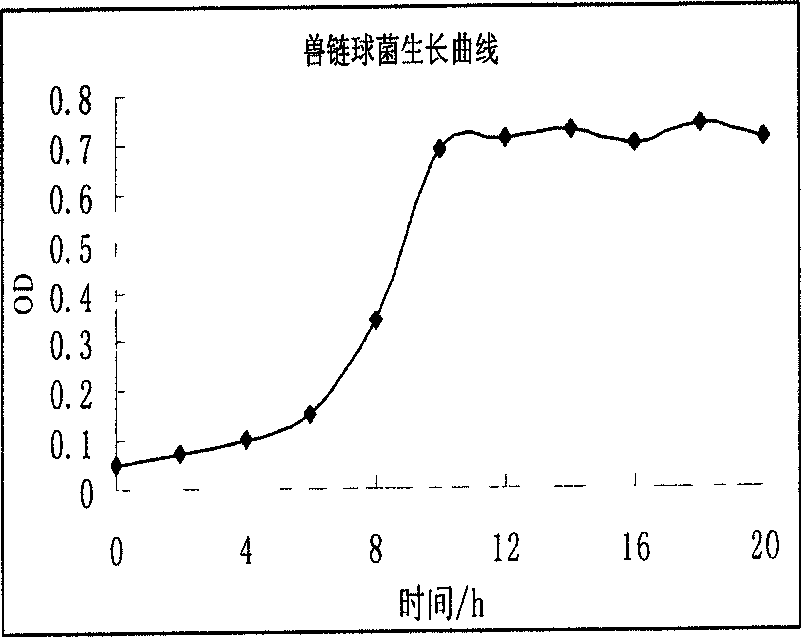

[0049] (1) Growth curve

[0050] Inoculate Streptococcus zooepidemicus CGMCC NO.1988 directly into 100ml of crude oil, culture it on a shaker at 20-60°C, 120-180r / min, and regularly measure the density (OD value) of bacteria in the crude oil. is the abscissa, and the OD value is the ordinate to draw its growth curve, and the results are shown in Figure 2. It can be seen from the growth curve that the bacteria enter the logarithmic phase at 4 hours of crude oil, and enter the stable phase at about 10 hours, which shows that the bacteria multiply very quickly in crude oil, which is beneficial to practical applications.

[0051] (2) Dispersion and emulsification effect

[0052] Take 5ml of Streptococcus zooepidemicus (Streptococcus...

Embodiment 2

[0083] Embodiment 2, the analysis of Streptococcus zooepidemicus CGMCC NO.1988 strain fermented liquid

[0084] (1) Qualitative and quantitative analysis of organic acids in fermentation broth

[0085] ① Qualitative analysis results of organic acids

[0086] Using Shimadzu GC-14C gas chromatography: FFAP quartz capillary column (0.250×30m), the carrier gas is high-purity nitrogen, the flow rate is 1ml / min, the temperature of the vaporization chamber is 220°C, the column temperature is programmed to rise, and the starting temperature is 90°C. The rate is 3°C / min, the final temperature is 200°C, and the injection volume is 1.0 μl. The organic acid is qualitatively determined according to the conventional method. The chromatogram of the organic acid standard sample is shown in Figure 6a, and the retention time under the chromatographic conditions is shown in Table 5. shown. The organic acid gas chromatograms of crude oil samples before and after the treatment of Streptococcus z...

Embodiment 3

[0104] Embodiment 3, subsequent treatment of the oil produced by Streptococcus zooepidemicus CGMCC NO.1988

[0105] Subsequent treatment of crude oil includes: dehydration and desalination.

[0106] (1) Dehydration

[0107] Water-containing crude oil must be dehydrated before being transported from the oil field to reduce transportation costs. To separate the crude oil from water, the crude oil needs to be demulsified. Demulsification is the process of transforming a relatively stable system into a relatively unstable system. At present, the commonly used demulsification methods include mechanical demulsification, electric demulsification and chemical demulsification.

[0108] Mechanical demulsification includes gravity sedimentation, centrifugal separation, fiber bed filtration, super filtration, etc. Due to its slow demulsification speed and high equipment investment, large-scale application of mechanical demulsification is limited; electric demulsification is performed un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com