Drop pills of amlodipine maleate and preparation method thereof

A kind of technology of amlodipine maleate and maleic acid, which is applied in the fields of medicines with special dosage forms, medicines for the treatment of hypertension and angina pectoris, and medicines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

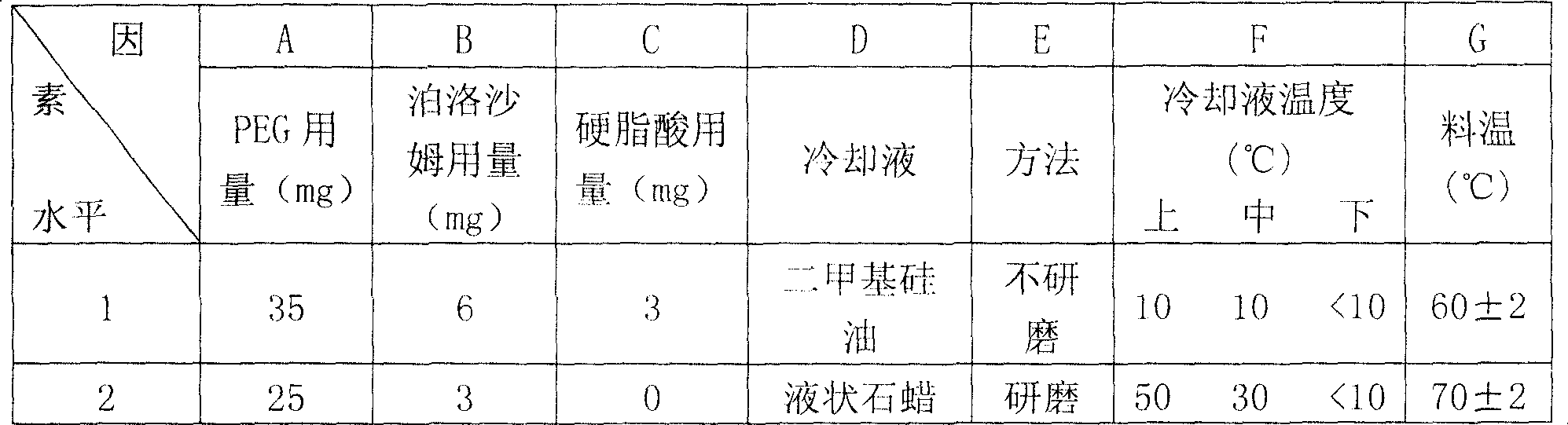

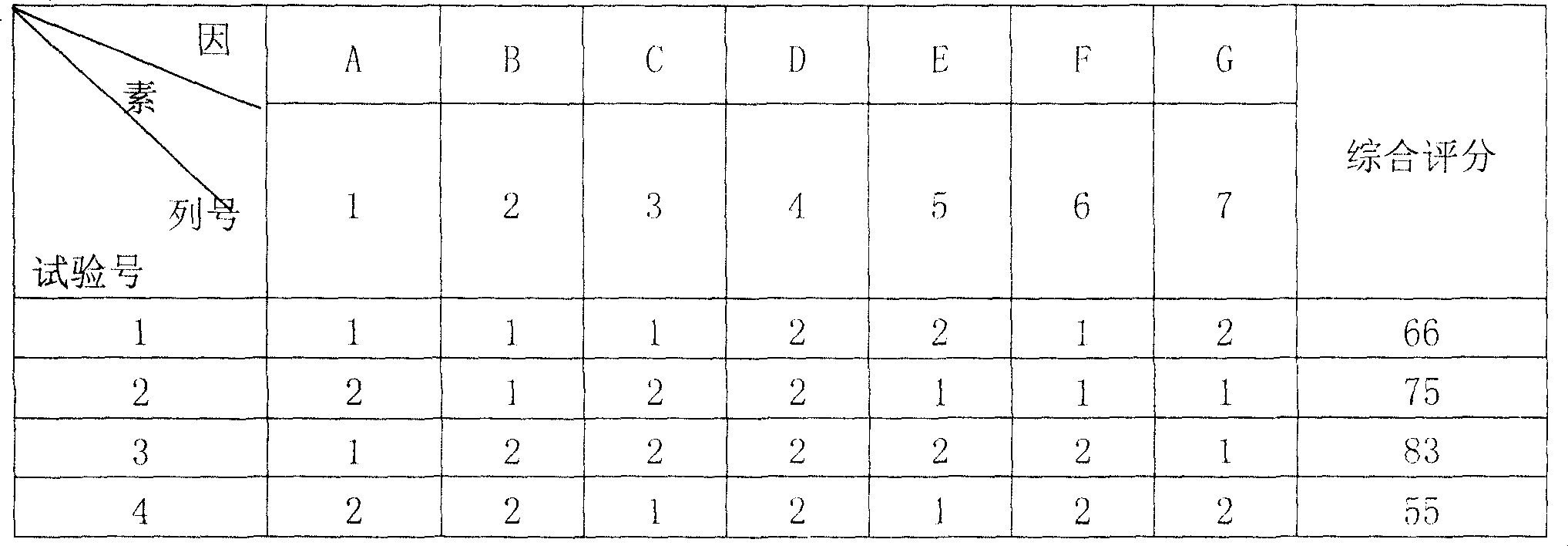

Method used

Image

Examples

specific Embodiment approach 1

[0071] (1) material preparation

[0072] According to the active ingredient of the drug is amlodipine maleate, the matrix is polyethylene glycol-6000, stearic acid, sodium stearate, glycerin gelatin, poloxamer, polyoxyl 40 stearate, shellac, Any one of polyoxyethylene monostearate, polyether, sodium carboxymethyl starch or sodium lauryl sulfate pharmaceutical excipients or a mixture of two or more of them in any proportion, ammonium maleate The ratio of lodipine to the matrix is 1:2-10 in g or Kg; according to the composition of the membrane material, it is hypromellose 1.0-1.2g, titanium dioxide 0.8-1.0g, talcum powder 1.0 -1.2g, iron oxide yellow 0.10-0.15g, polysorbate-800.4-0.5g plus 80% ethanol to 50ml ratio to prepare raw materials;

[0073] (2) Preparation of dropping pills

[0074] a. Pass the raw materials through a 100-120 mesh sieve, weigh polyethylene glycol-6000 and poloxamer in proportion, heat and melt them in a water bath at 80°C, cool to 65°C and add the...

specific Embodiment approach 2

[0080] (1) material preparation

[0081] Containing amlodipine maleate 6.42g, polyethylene glycol-600035g, poloxamer 6g in the drop pill that every 1000 pills, every pill weight is 47.5mg Ratio, prepare raw and auxiliary materials; According to every 1000 pills, every Dropping pills with a pill weight of 47.5mg require 1.0g of hypromellose, 0.8g of titanium dioxide, 1.0g of talcum powder, 0.15g of iron oxide yellow, 0.4g of polysorbate-800.4g, and 80% ethanol to 50ml. Membrane material;

[0082] (2) Preparation of dropping pills

[0083] a. Pass the raw materials through a 100-120 mesh sieve, weigh polyethylene glycol-6000 and poloxamer in proportion, heat and melt them in a water bath at 80°C, cool to 65°C and add the prescribed amount of ammonia maleate Clodipine, heat and stir at 60°C until uniform.

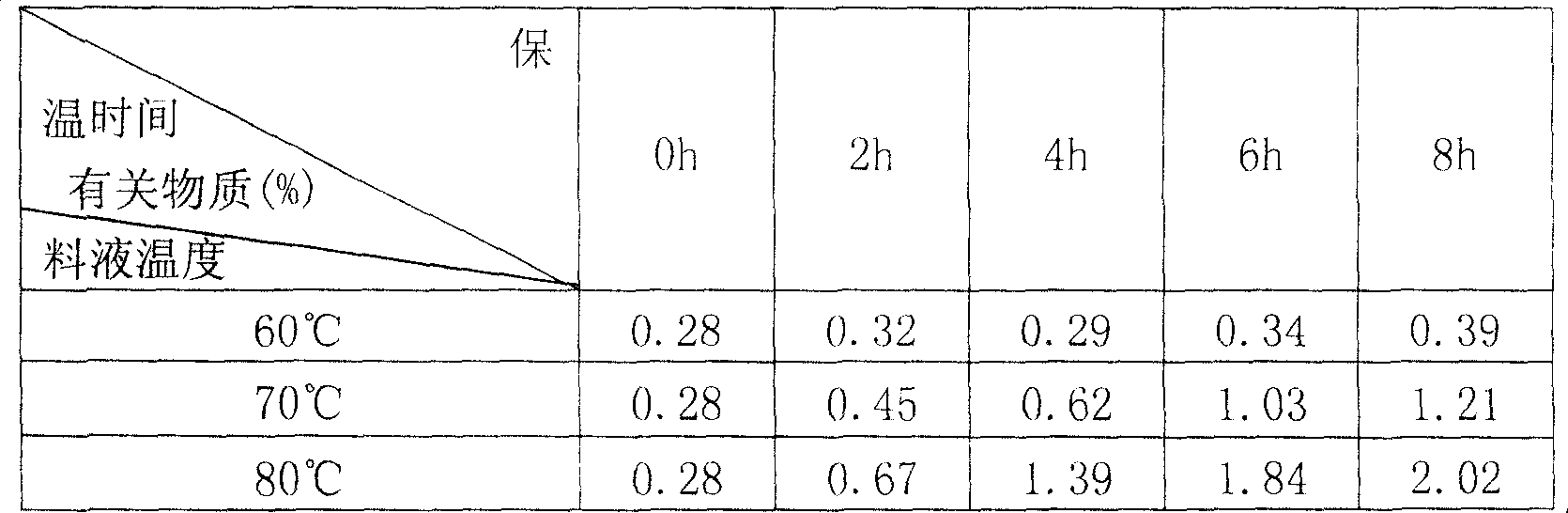

[0084] b. Keep warm at 60°C. After adjusting the temperature of the cooling liquid, adjust the weight of the pellets to reach the specified weight. Drop them into the simet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com