Drop pills of vepeside and preparation process thereof

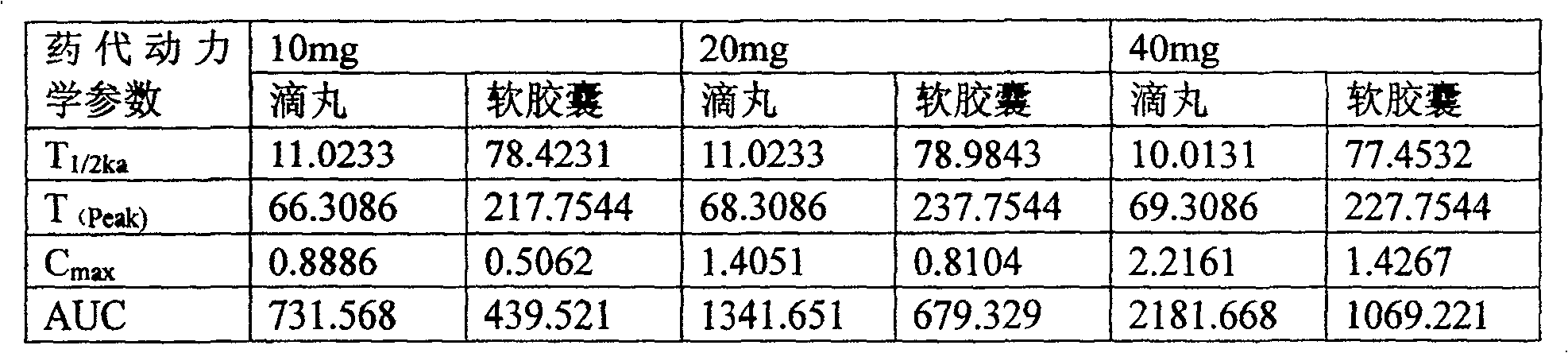

A technology of etoposide dropping pills and etoposide, which can be applied in the directions of pill delivery, medical preparations containing active ingredients, organic active ingredients, etc., and can solve the problems of low bioavailability and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] The present invention adopts the following preparation method: take the pharmaceutical adjuvant according to the formula quantity, which can also add other pharmaceutical adjuvants such as Tween-80, CMS-Na, etc. that help the drug release in the dripping pill, heat and melt, add The etoposide in the formula quantity is fully stirred to make it melt completely and disperse evenly to obtain a molten liquid; or weigh the etoposide according to the formula quantity, add an appropriate amount of cosolvent, dissolve it with slight heat, and then add the medicine in the formula quantity Use the auxiliary agent molten liquid, stir and mix evenly, evaporate the auxiliary solvent, and disperse evenly to prepare the molten liquid; put the molten liquid in the liquid storage cylinder of the dropping pill machine, keep it warm, and drop it at a certain dropping speed at an appropriate temperature In the condensate, condense into pills, collect the dripping pills, remove the coolant, ...

Embodiment 1

[0037] Prescription (Specification: 10mg / pill)

[0038] Etoposide 10g

[0039] Macrogol 4000 30g

[0040] A total of 1000 capsules

[0041] Preparation:

[0042] Weigh according to the weight ratio of each component, heat polyethylene glycol 4000 to make it melt, add etoposide fine powder, stir continuously to make it all melt, put it in the liquid storage bottle of the dropping pill machine, and keep it warm at 80°C 30 minutes to serve. Adjust the drop distance to 3cm, and drop it into the liquid paraffin condensate containing methyl silicone oil at a constant speed of 50 drops / min. The temperature of the upper 20cm of the condensate is 20±2°C, and the temperature of the lower 30cm is 0±1°C. Collect the dripping pills, remove the condensing agent on the surface of the dropping pills, dry, and select the pills to obtain the finished product.

[0043] Determination of dissolution time: According to the 3rd method of appendix X11A of the Chinese Pharmacopoeia 2000 edition, ...

Embodiment 2

[0048] Prescription (Specification: 10mg / pill)

[0049] Etoposide 10g

[0050] Macrogol 6000 30g

[0051] Tween-80 0.25g

[0052] A total of 1000 capsules

[0053] Preparation:

[0054] Weigh according to the weight ratio of each component, heat polyethylene glycol 6000 to melt, add etoposide fine powder and Tween-80, stir continuously to melt all, put in the liquid storage bottle of the dropping pill machine medium, 86°C for 30 minutes and set aside. Adjust the drop distance to 4cm, and drop it into the liquid paraffin condensate at a constant rate of 60 drops / min. The temperature of the upper 20cm of the condensate is 23±3°C, and the temperature of the lower 30cm is 5±1°C. Collect the dripping pills, remove the condensing agent on the surface of the dropping pills, dry, and select the pills to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com