Nano-structured aggregate powder of AI/Yt/Zr ternary compound oxides and its production method

A ternary composite and nanostructure technology, which is applied in metal material coating process, fusion spraying, coating, etc., can solve the problems that the actual application of production is too far from the scale, it is difficult to achieve scale, and the production cost is increased. , to achieve the effect of easy control of process parameters, easy promotion and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

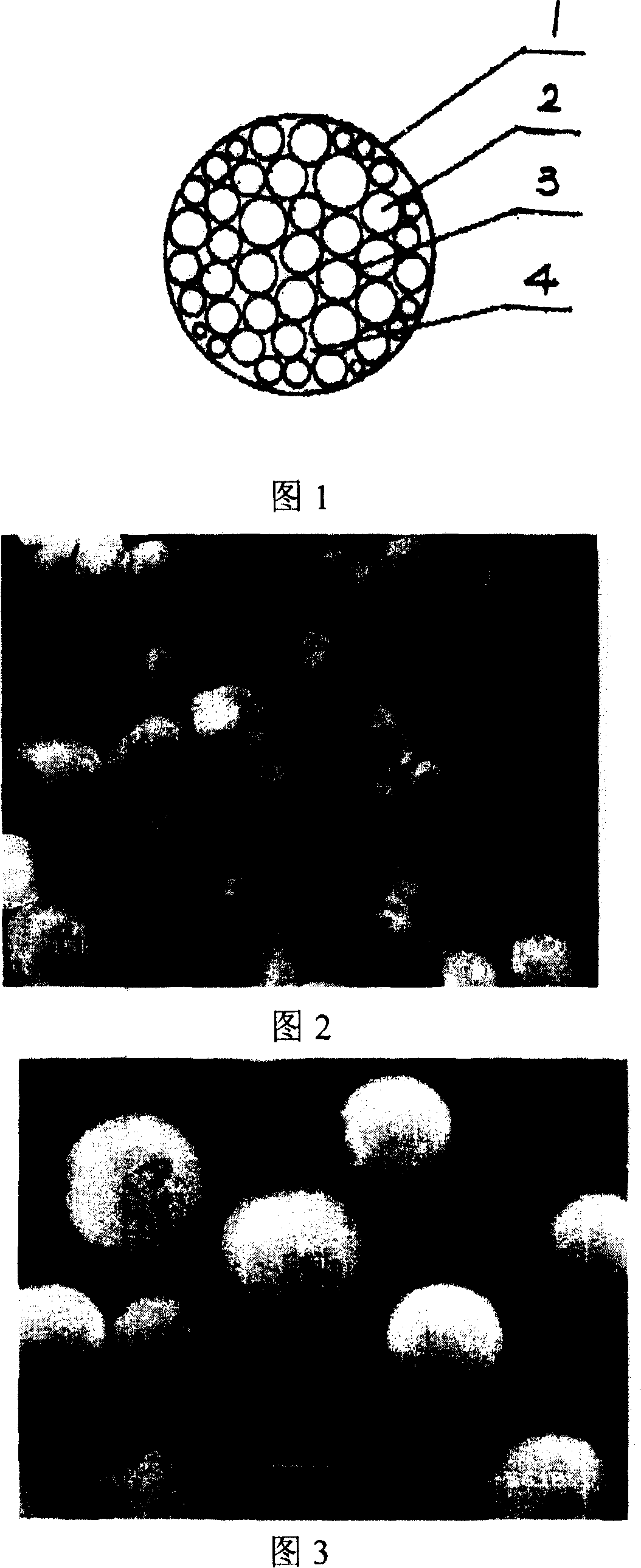

Embodiment 1

[0045] Take 20 kg of zirconium oxychloride and dissolve it in 100 liters of water, add 0.1 mol / liter of aluminum nitrate and yttrium nitrate solution, control Y 2 o 3 in ZrO 2 The doping amount in the powder is 4wt%, Al 2 o 3 The doping amount is 2wt%. A certain amount of ethanol is added, and 50% ammonia water (volume ratio) is added dropwise under strong stirring until the pH value of the solution is greater than 9. A ceramic membrane separates the hydroxide precipitate, and the precipitate is washed with distilled water until no chloride ions are detected in the filtrate (silver nitrate test). The precipitate is centrifuged or filtered, and the hydroxide precipitate is mixed with 2 times of butanol (weight ratio), treated with a colloid mill or vigorously stirred. Place in a distillation drying dehydration device, dehydrate at 150°C until the powder is completely dry, and calcinate the powder in a high-temperature furnace at 800°C for 2 hours. A ternary composite nano...

Embodiment 2

[0054] Prepare ternary composite oxide powder according to the method of Example 1, take 10 kg of powder, add 15 kg of ultra-pure water, stir evenly, disperse evenly with a colloid mill for 10 minutes, and prepare a stable suspension slurry for use.

[0055] The slurry is sprayed into the drying tower with a centrifugal atomizing disc. The rotational speed of the centrifugal atomizer is 10000r / min. The atomized slurry particles shrink into a conglomerate spherical shape by virtue of their own surface tension. They are dried in the hot air and heated by the drying tower. The heating temperature of the device is controlled at 180°C to quickly evaporate the water in the mist droplets, and the dry agglomerate powder is collected by a cyclone separator. Sieve the collected powder with a mechanical sampling sieve, keep the particle size range between 40 and 100 μm, and use the powder with a particle size greater than 100 μm and less than 40 μm as the recycle material, and make it int...

Embodiment 3

[0061] Prepare ternary oxide nanopowder by the method for embodiment 1, wherein Al 2 o 3 The content is 3wt%, Y 2 o 3 The content is 8wt%, the calcining temperature is 600°C, and the average particle diameter of the crystal is 10nm.

[0062] Take 10 kg of nano-oxide powder, add 20 kg of ultra-pure water, stir evenly, disperse evenly with a colloid mill for 10 minutes, and prepare a stable suspension slurry for use.

[0063] Purified compressed air is used as the carrying gas, the gas pressure is controlled at 0.3-0.8MPa, and the slurry is sprayed into the drying tower by a two-fluid nozzle. The temperature of the air inlet is controlled at 200°C, and the temperature of the air outlet is controlled at 130°C, so that the aerosol droplets are fully dried in the hot air. The dried agglomerate powder is then drawn by suction into a cyclone separator for collection.

[0064] The collected powder is sieved with a mechanical sampling sieve. The particle size range of the finished...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com