Method and device for removing gaseous pollutants from exhaust gases

A pollutant and exhaust gas technology, applied in the field of removing gaseous pollutants, can solve problems such as large pressure loss, low utilization rate of reaction reagents, and problems caused by control operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

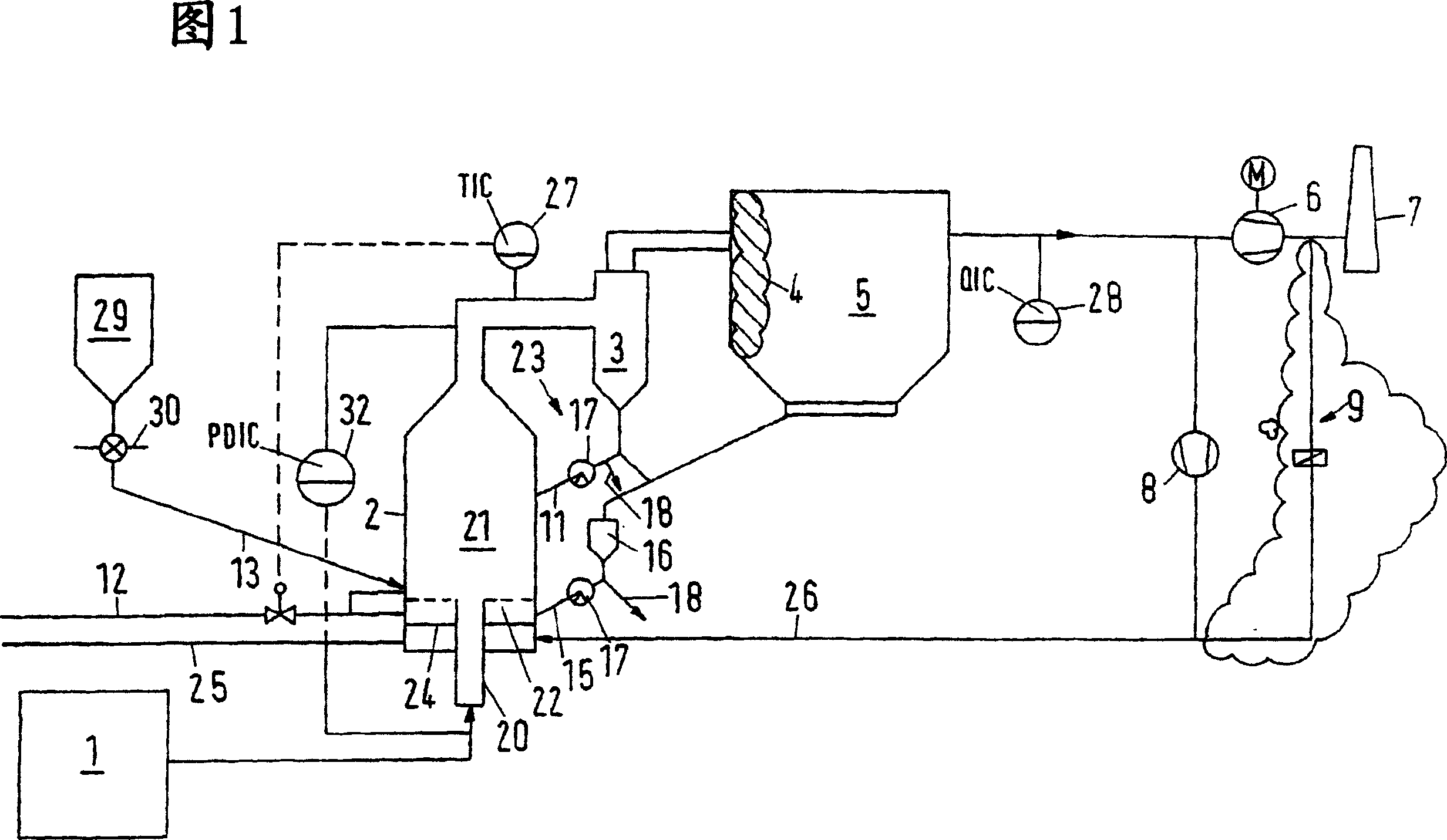

[0054] Because the high turbulence and associated good mass and heat transfer conditions create good reaction conditions in the mixing chamber 21, and because the reagents have a long residence time in the fluidized bed, the reaction with almost stoichiometric consumption The reagents then allow the dry exhaust gas cleaning reaction to proceed to very low cleaning gas concentrations according to the invention. In this way, a particularly effective exhaust gas cleaning can be achieved with a very low consumption of reagents. In addition to the above-mentioned applications, the gas cleaning method of the present invention can also be used to clean the SO-containing gas discharged from the sintering plant 2 exhaust gas. Example 1 (removal of hydrogen fluoride from the waste gas stream discharged from an electrolytic cell for the production of aluminum)

[0055] When the electrolytic aluminum is melted, a large amount of gaseous hydrogen fluoride (HF) is released. This pollutan...

Embodiment 2

[0066] Embodiment 2 (removal of acid gas from the flue gas flow of combustion plant)

[0067] During the combustion process, the sulfur, fluorine and chlorine compounds in the fuel are basically converted into sulfur dioxide (SO) through various equilibrium reactions 2 , hydrogen fluoride HF and hydrogen chloride HCl. This occurs, for example, in power plants and incineration plants for waste or special waste. These gaseous compounds exit the combustion zone 1 with the exhaust gas, from which they must be removed before being released into the atmosphere.

[0068] For the removal of acidic components from exhaust gases (flue gases), various wet, dry and semi-dry methods have been developed. What all methods have in common is the simultaneous removal of acidic components with alkaline reagents.

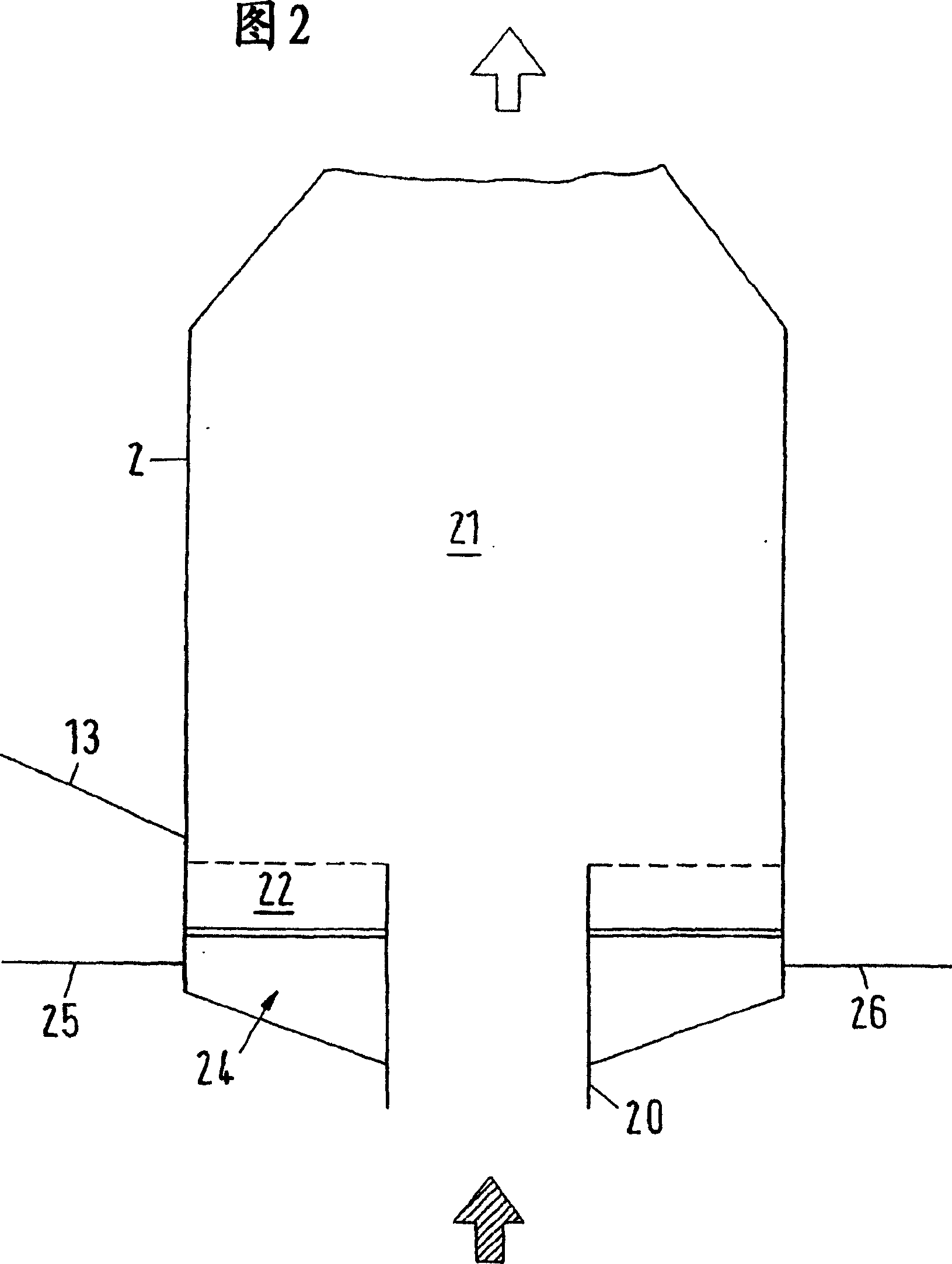

[0069] The exhaust gas flow discharged from the combustion device 1 is supplied to the center pipe 20 (central tuyeres). The temperature at the inlet of the central tube 20 is abou...

Embodiment 3

[0079] Example 3 (removal of sulfur dioxide, hydrogen fluoride and hydrogen chloride from the exhaust gas stream of the heat generating process)

[0080] In some production processes, such as glass production, cement production, sintering devices and metallurgical processes, clean harmful gases are released during the production process. For cleaning the gas, a method substantially similar to that described above for the combustion device is used. But in many industrial fields, lower efficiencies or higher emissions are allowed.

[0081] In this example, the exhaust gas stream discharged during the production process is supplied to the central pipe 20 of the reactor 2 . The temperature at the inlet of the central tube is about 200-600°C. The annular fluidized bed 22 is supplied with recirculated clean gas or particle-free off-gas from parallel ducted gas streams, if available.

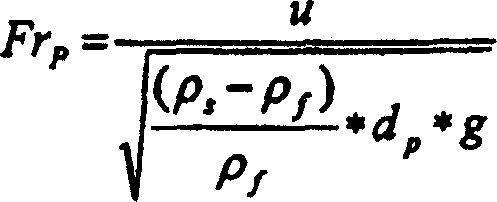

[0082] Particle Froude number Fr in central tube 20 p About 77, the particle Froude number Fr i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com