Direct bonding method for indium phosphide and gallium arsenide materials

A direct bonding, direct technology, used in lasers, electrical components, circuits, etc., can solve problems such as large limitations and poor conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

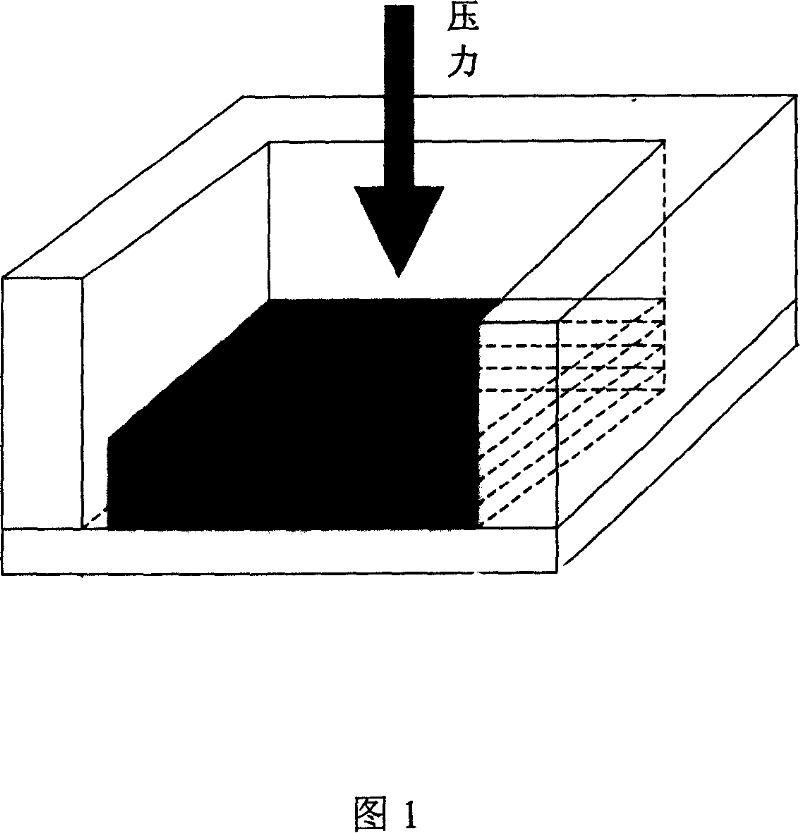

Image

Examples

Embodiment 1

[0027] The process steps for the direct bonding of InP and GaAs are:

[0028] 1. Cleavage the InP and GaAs substrates into a square with a side length of 2.5cm;

[0029] 2. Cleaning the substrate: use isopropanol, acetone and absolute ethanol to ultrasonically clean the sample piece 3 times each for 5 minutes, and then rinse with deionized water for more than 3 minutes;

[0030] 3. To remove surface oxides: InP is at rest H 2 SO 4 +H 2 O 2 +H 2 O (volume ratio is 3:1:1) in the corrosion for 10 seconds, GaAs in the static H 2 SO 4 +H 2 Etch in O (volume ratio 1:20) for 40 seconds. Before etching, both InP and GaAs need to be blown dry with high-purity nitrogen. After the etching is completed, rinse with deionized water for more than 5 minutes; Blow dry with high purity nitrogen and immerse directly into HF+H 2 Soak in O (volume ratio 1:10) for 30 seconds, and then rinse with deionized water three times; the above corrosion processes are all completed at room temperature (20~25℃);

...

Embodiment 2

[0037] In this embodiment, InP and GaAs are cleaved into a rectangular shape, with side lengths of 1.5 cm and 2.5 cm, respectively, and the edge-to-side alignment overlap angle is 1°. The bonding temperature is 680℃, and the pressure applied after keeping for 30 minutes is 2Kg / cm. 2 , The cooling rate in the temperature range of 680-450℃ is 3.5℃ / min, the cooling rate in the range of 450-300℃ is 2℃ / min, and the rest is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com