Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

75results about How to "Reliable shifting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

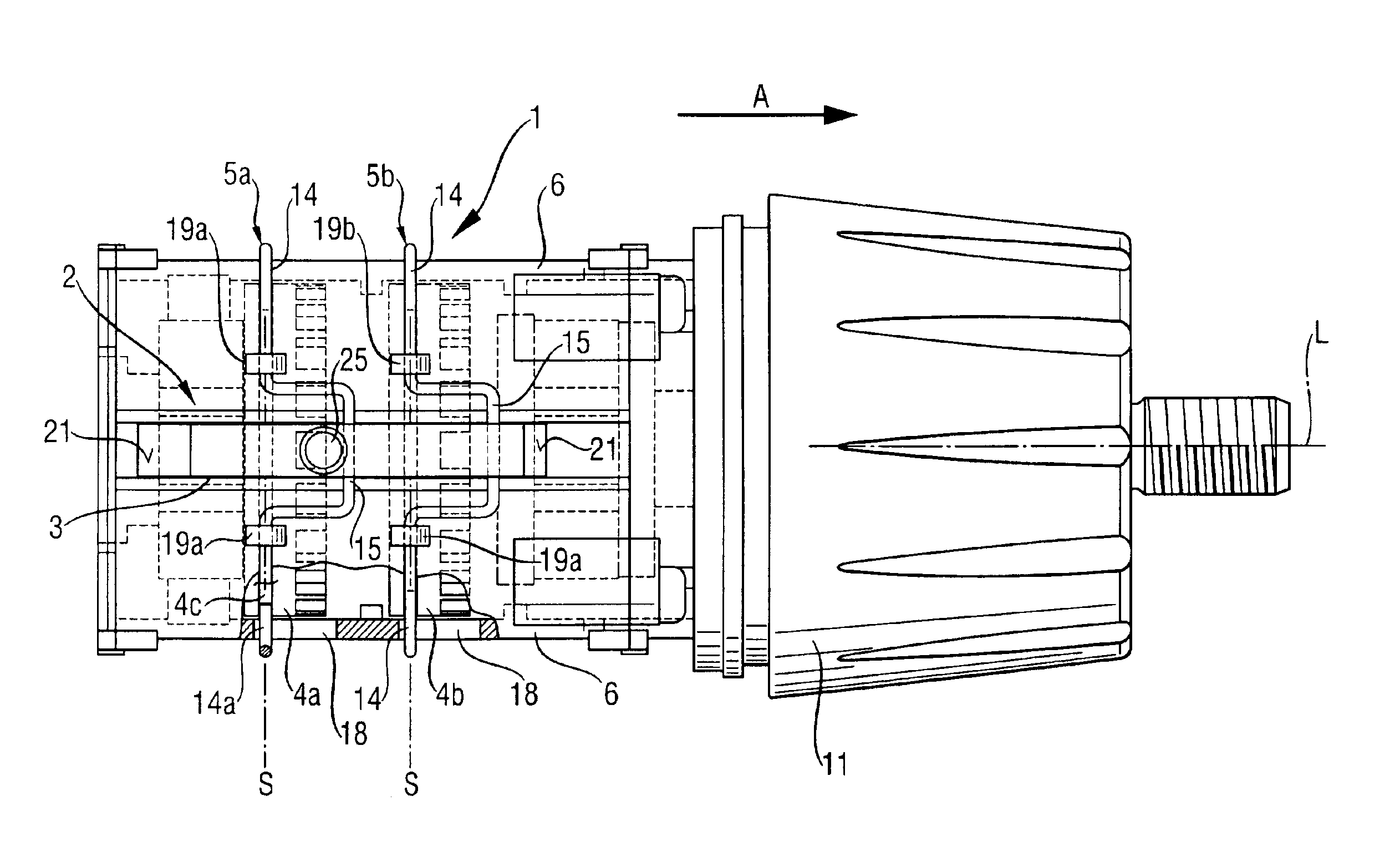

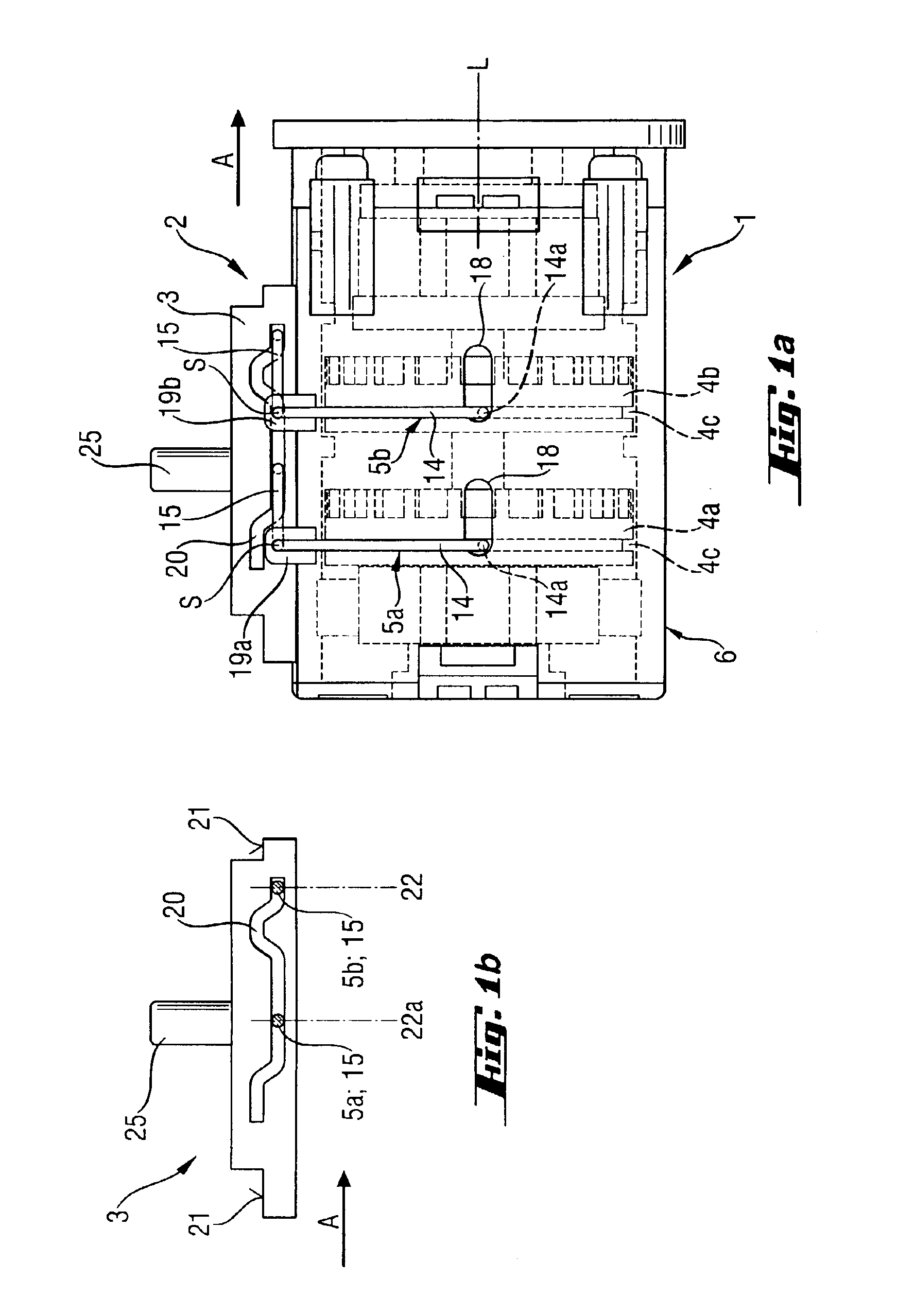

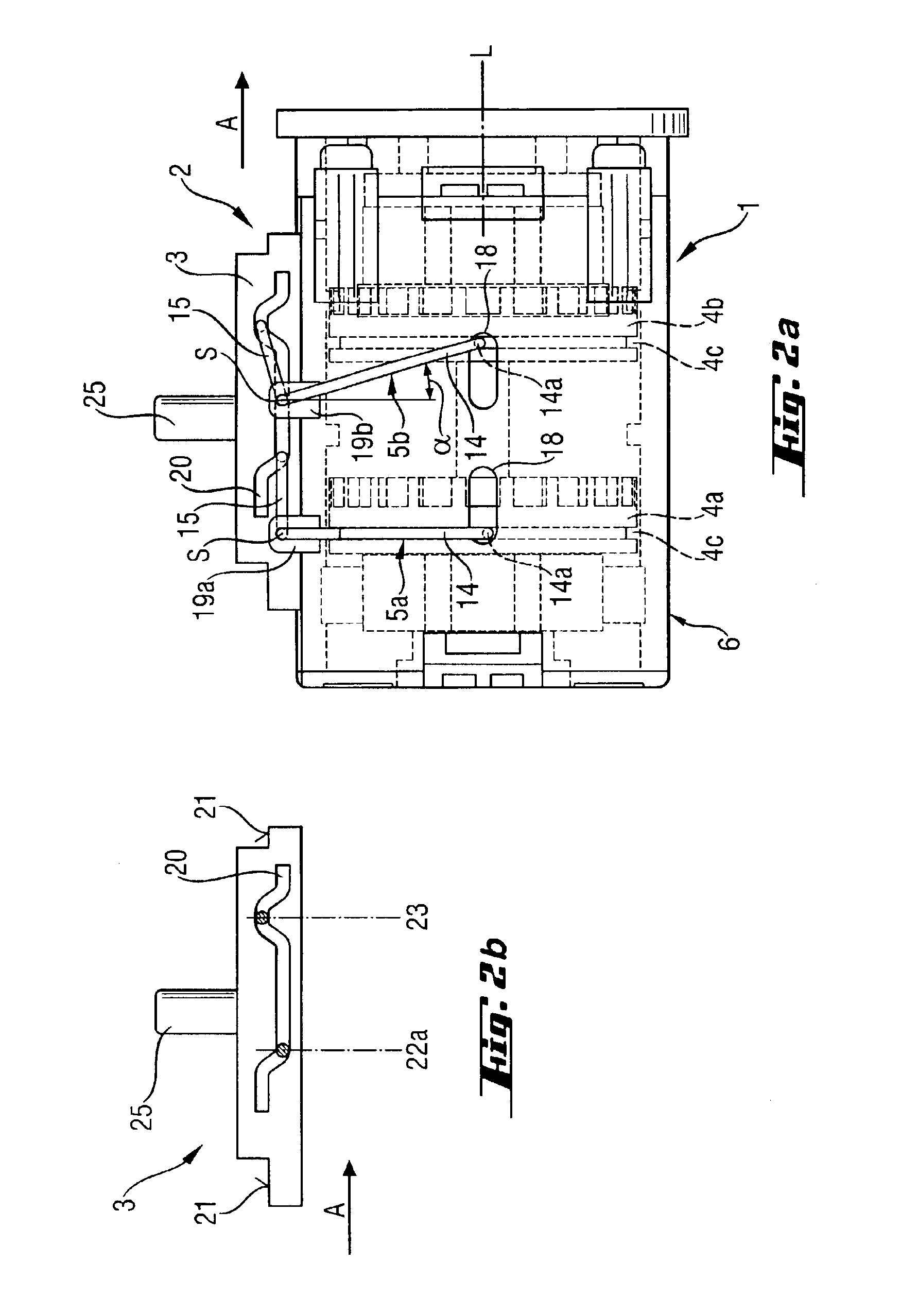

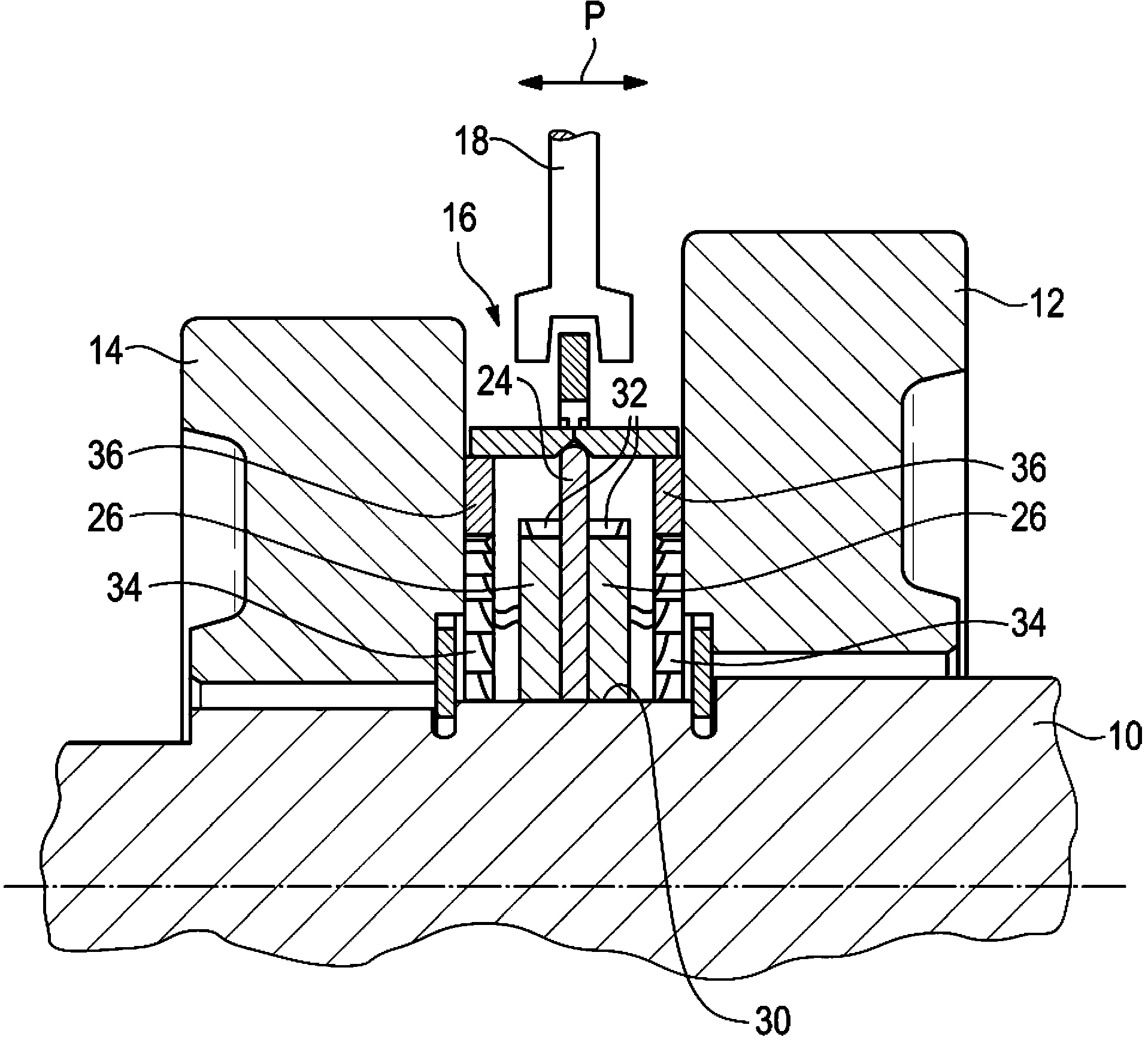

Gear transmission assembly for electrical power tool

ActiveUS6860341B2Easily formFacilitate assemblyDrilling rodsBorehole drivesPower toolGear transmission

A gear transmission assembly for an electrical power tool includes a housing (6), a multi-stage gear train (1) located in the housing and having a plurality of axially displaceable indexing gears (4a, 4b) associated with respective stages of the gear train (1) and a shift device (2) for shifting the gear train (1) from one stage to another and having a shifting slide (3) displaceable from one shift stage to another, and a plurality of springable shifting stirrups (5a, 5b) connected with the shifting slide (3) and cooperating with respective indexing gears (4a, 4b) for displacing same in response to displacement of the shifting slide (3) between shift stages.

Owner:HILTI AG

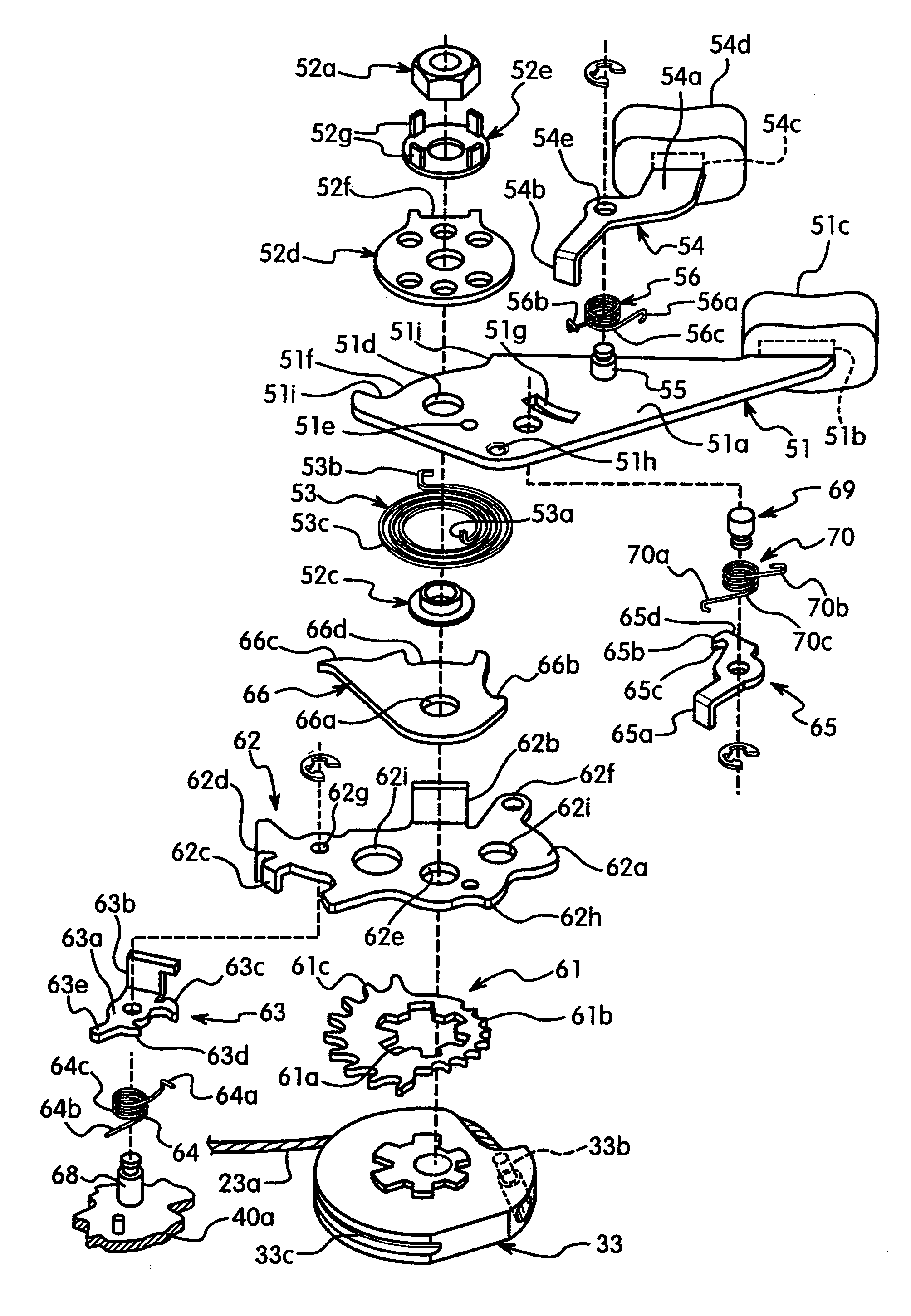

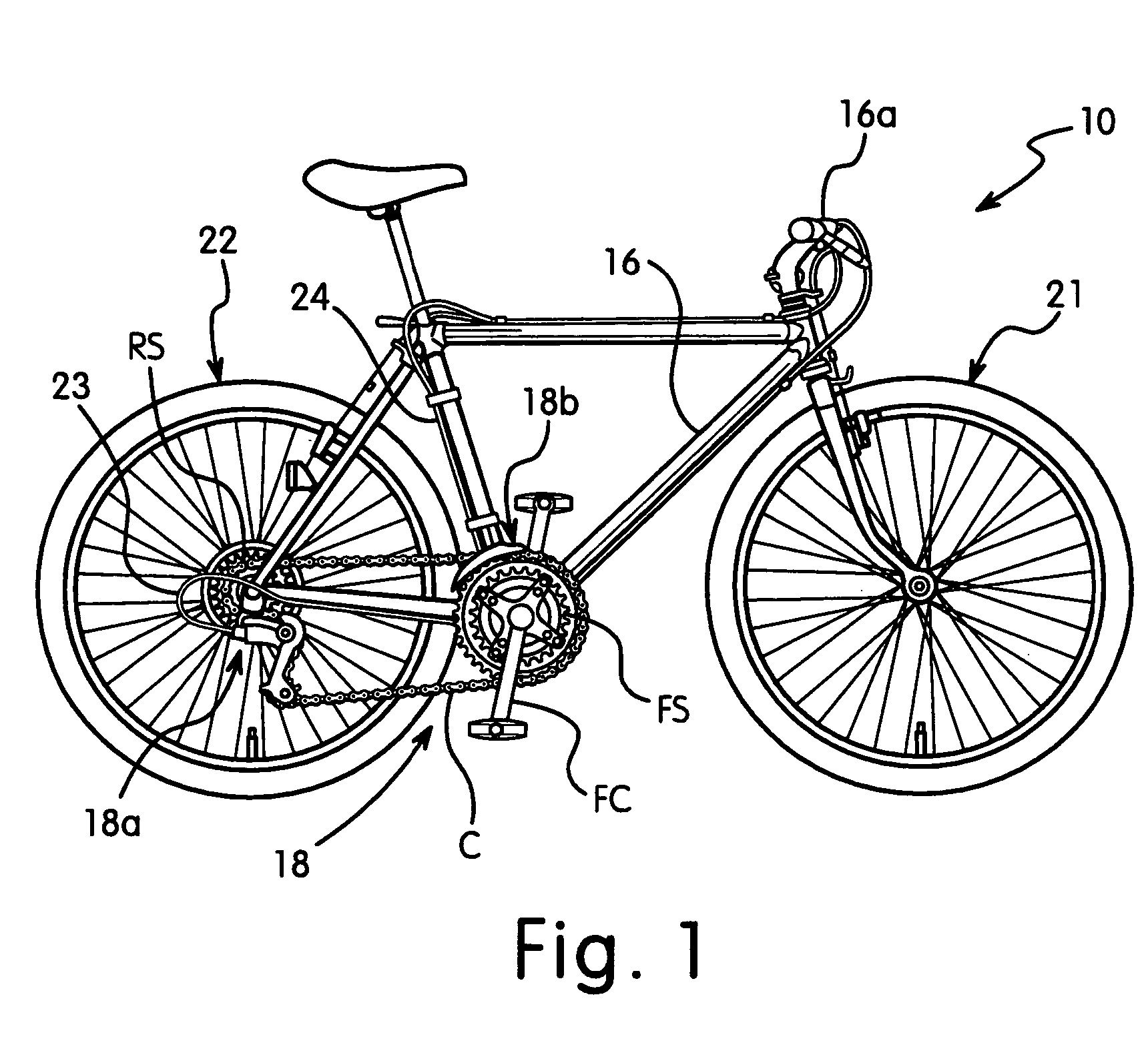

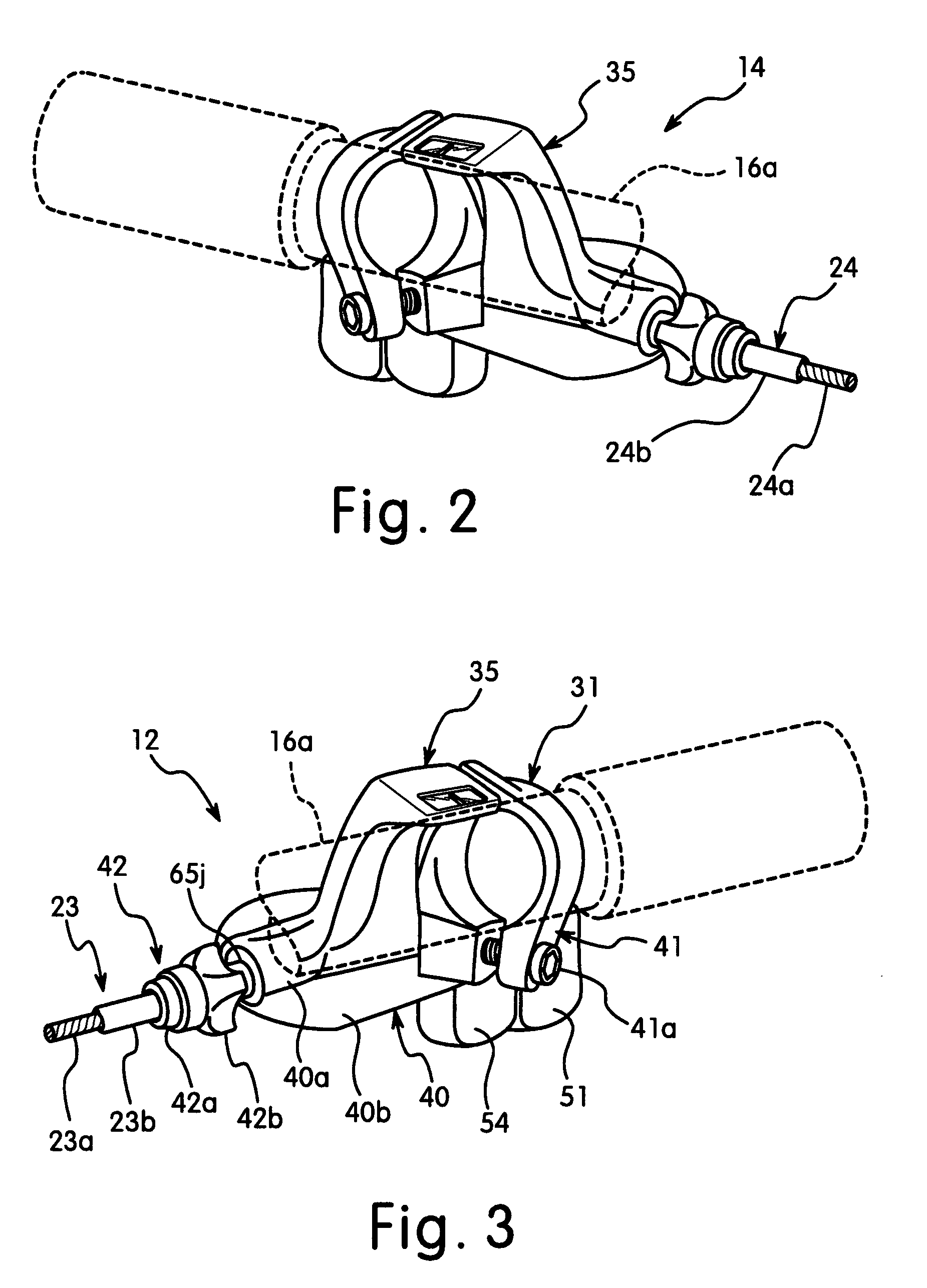

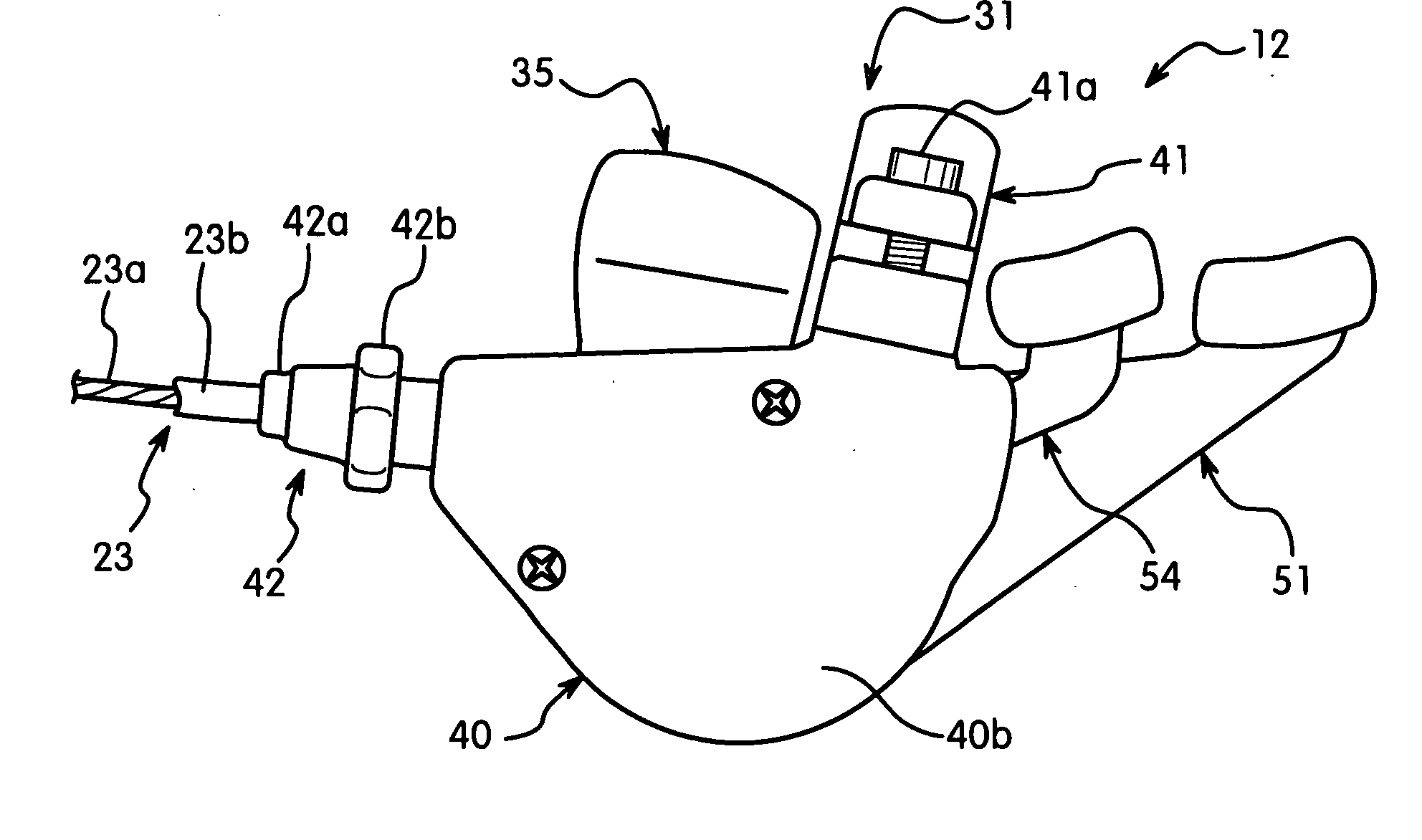

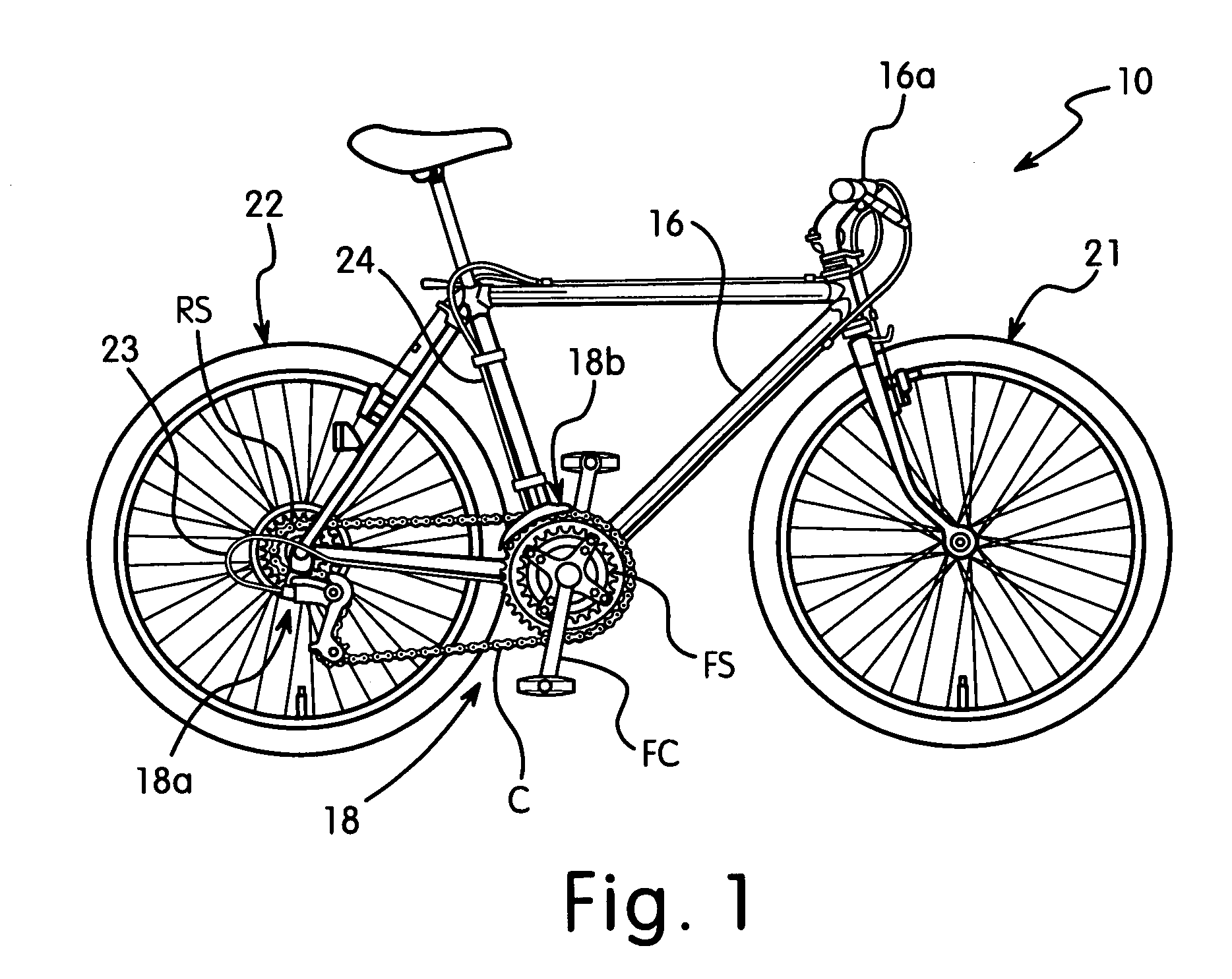

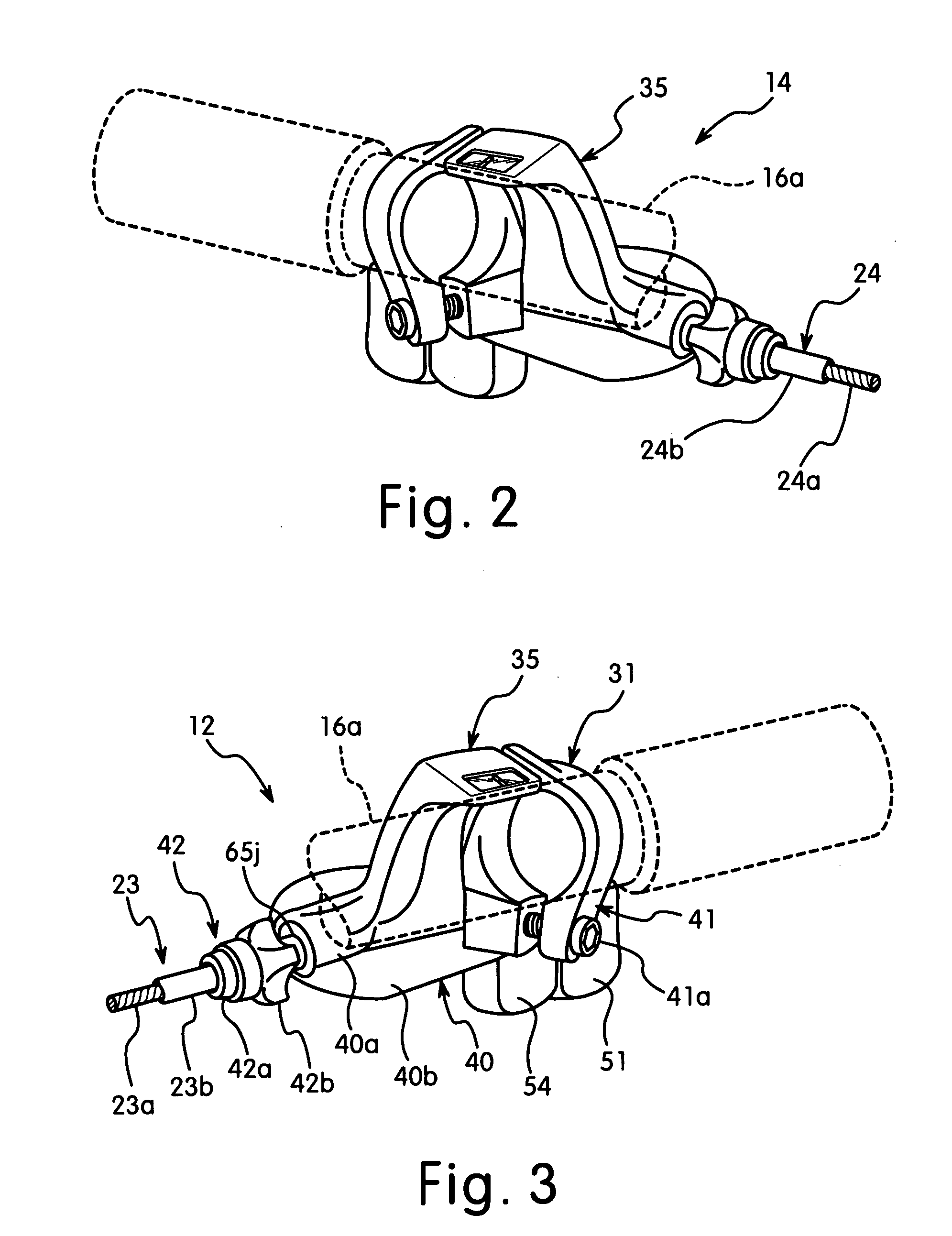

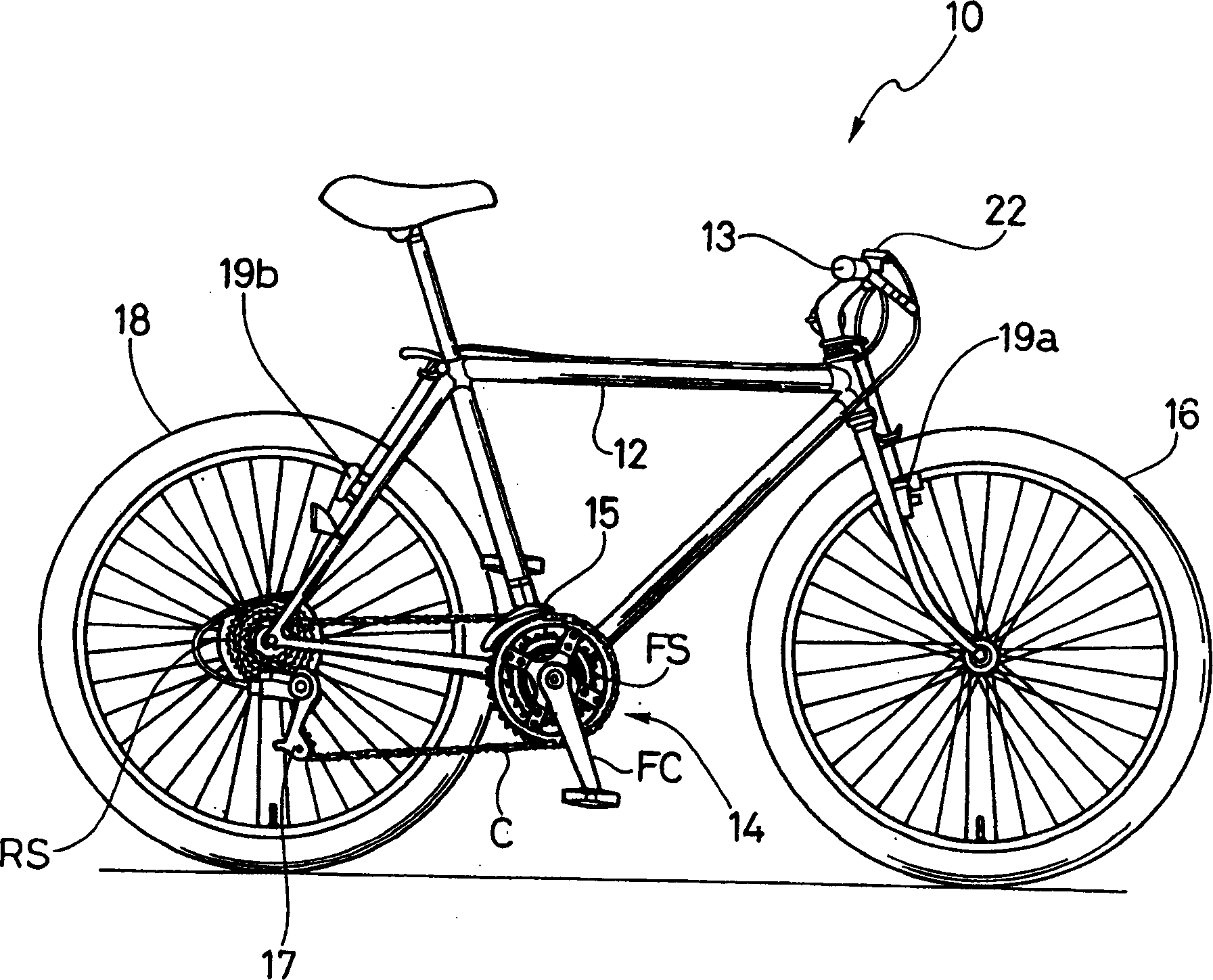

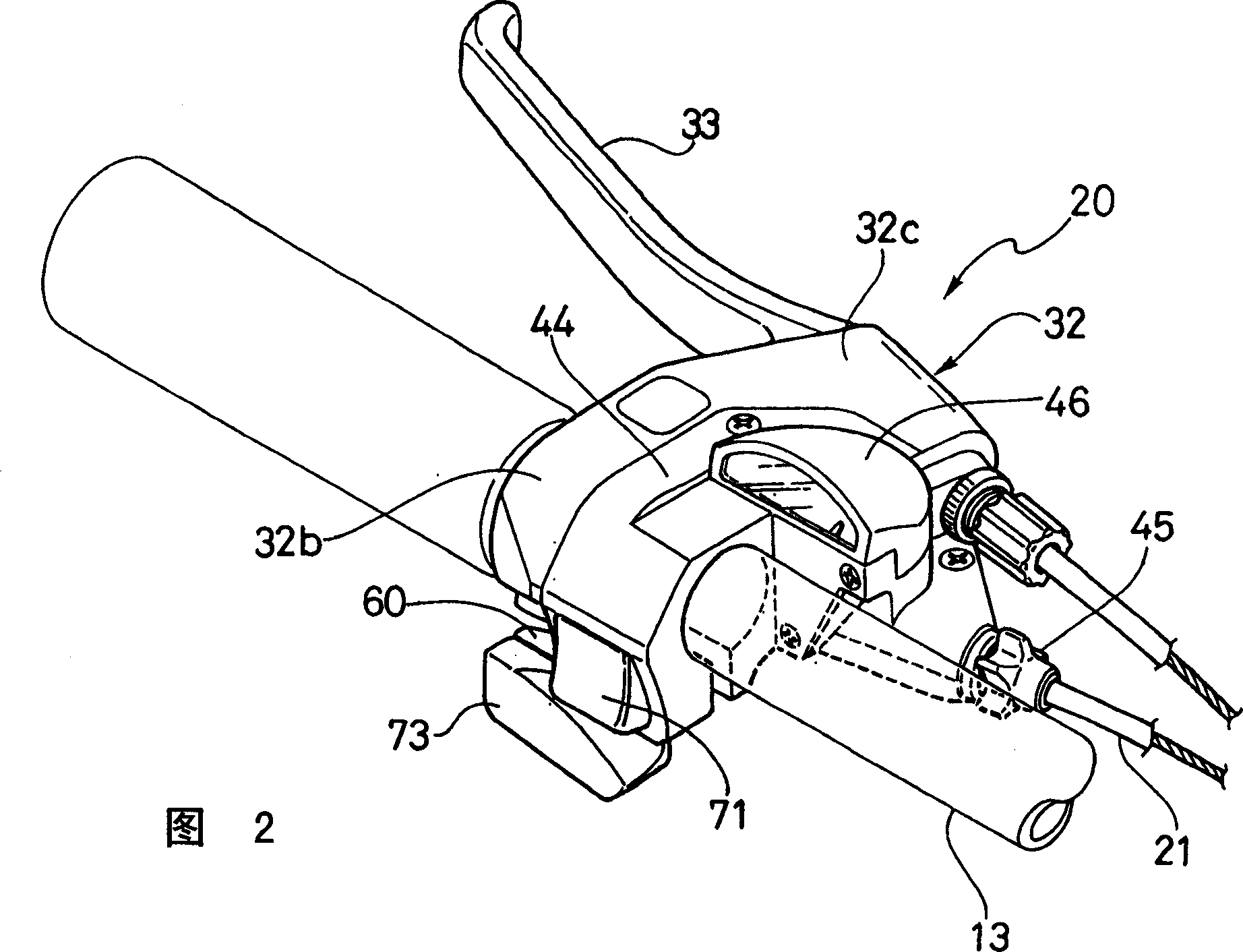

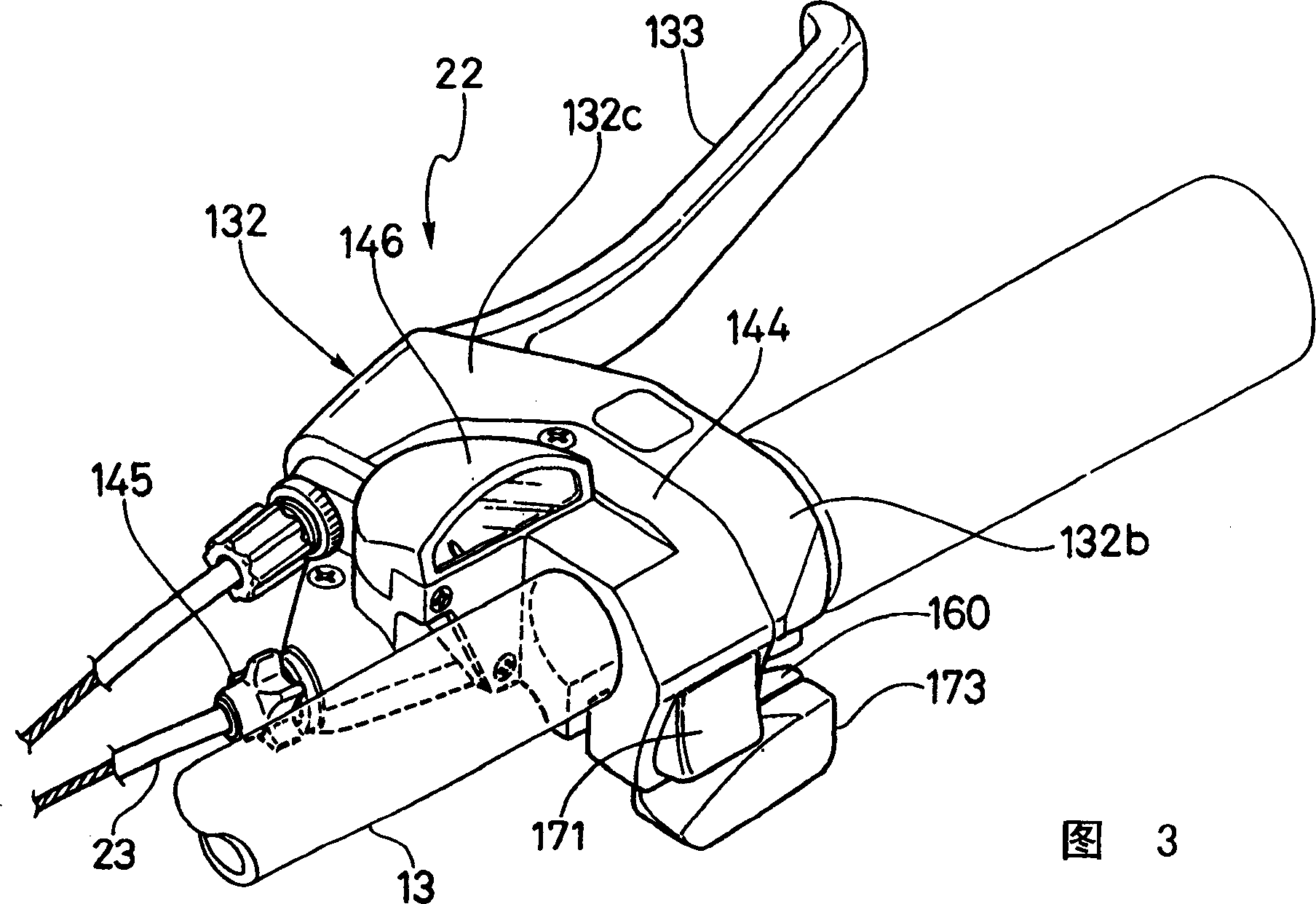

Bicycle shift operating device

InactiveUS7194928B2Easy to operateSimple and inexpensive to manufactureGearing controlShaft for linear movementEngineeringConductor Coil

Owner:SHIMANO INC

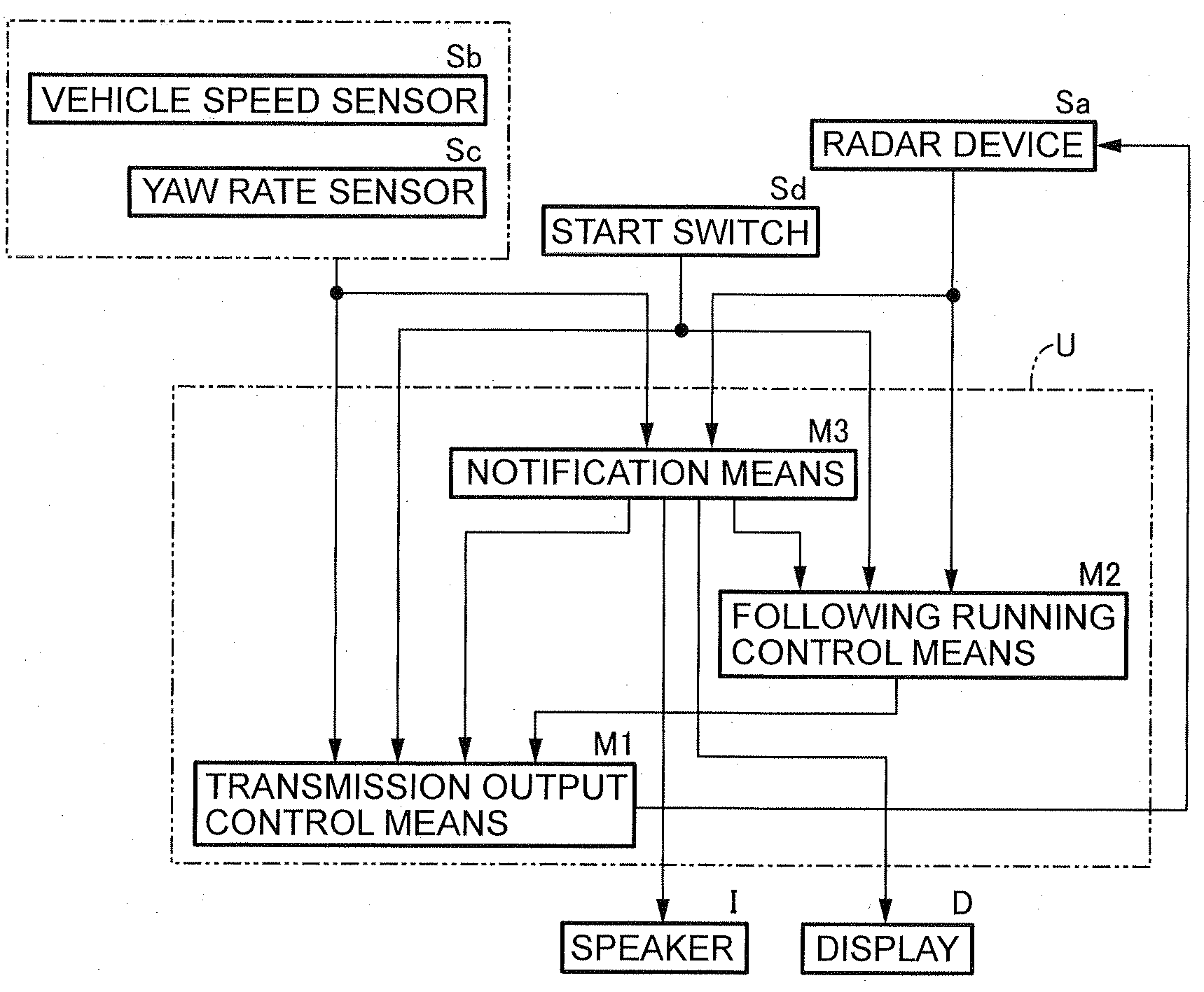

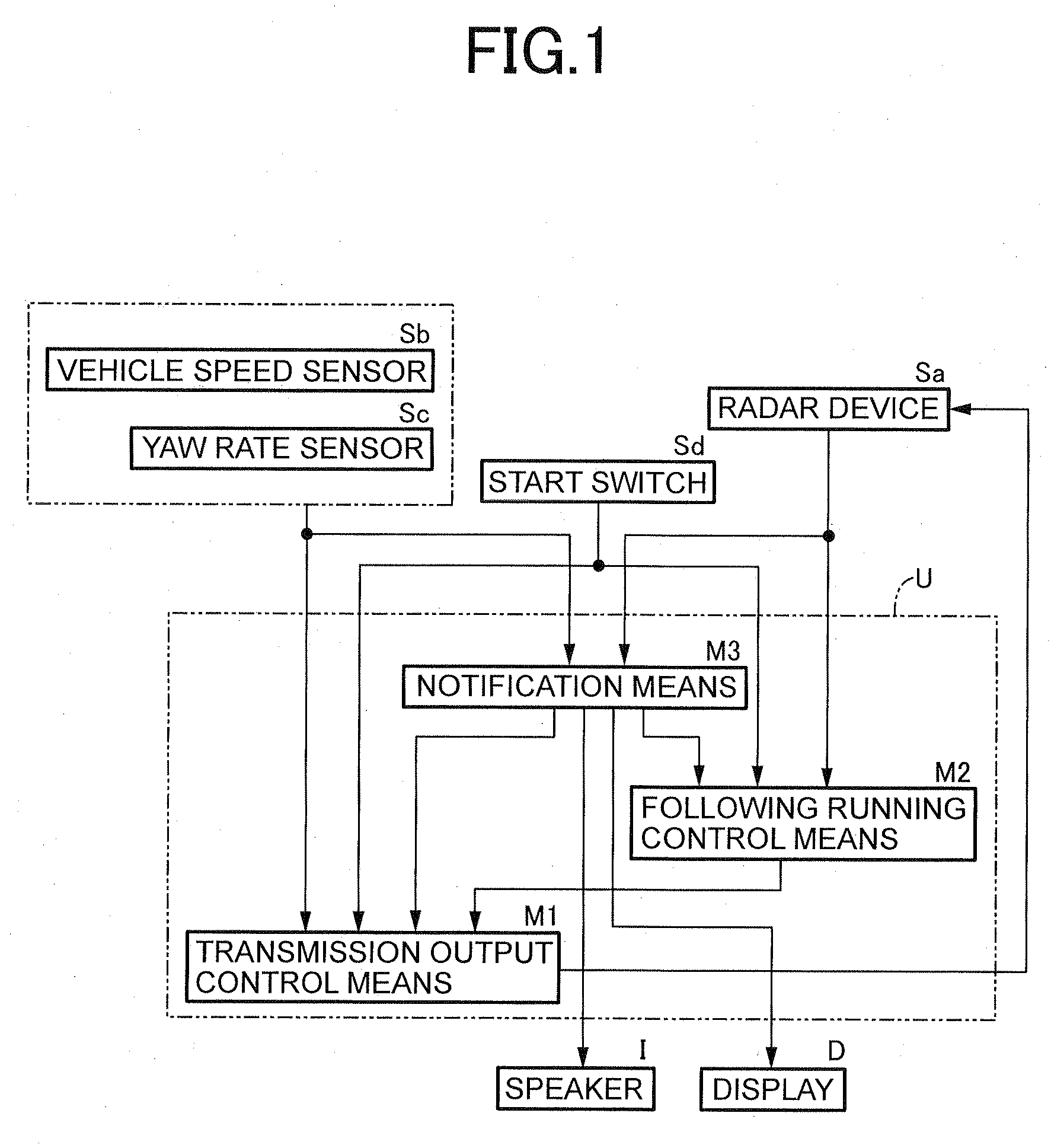

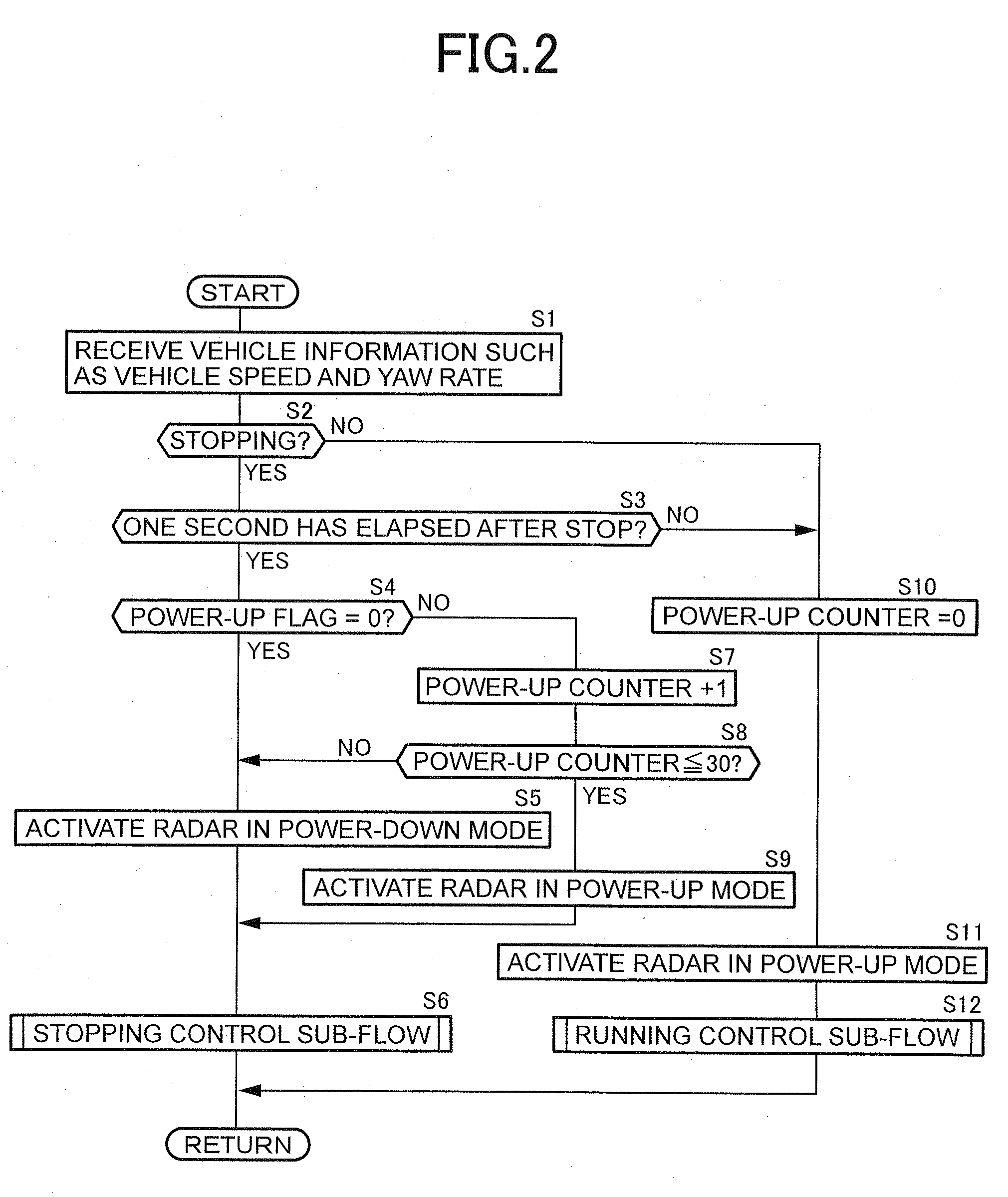

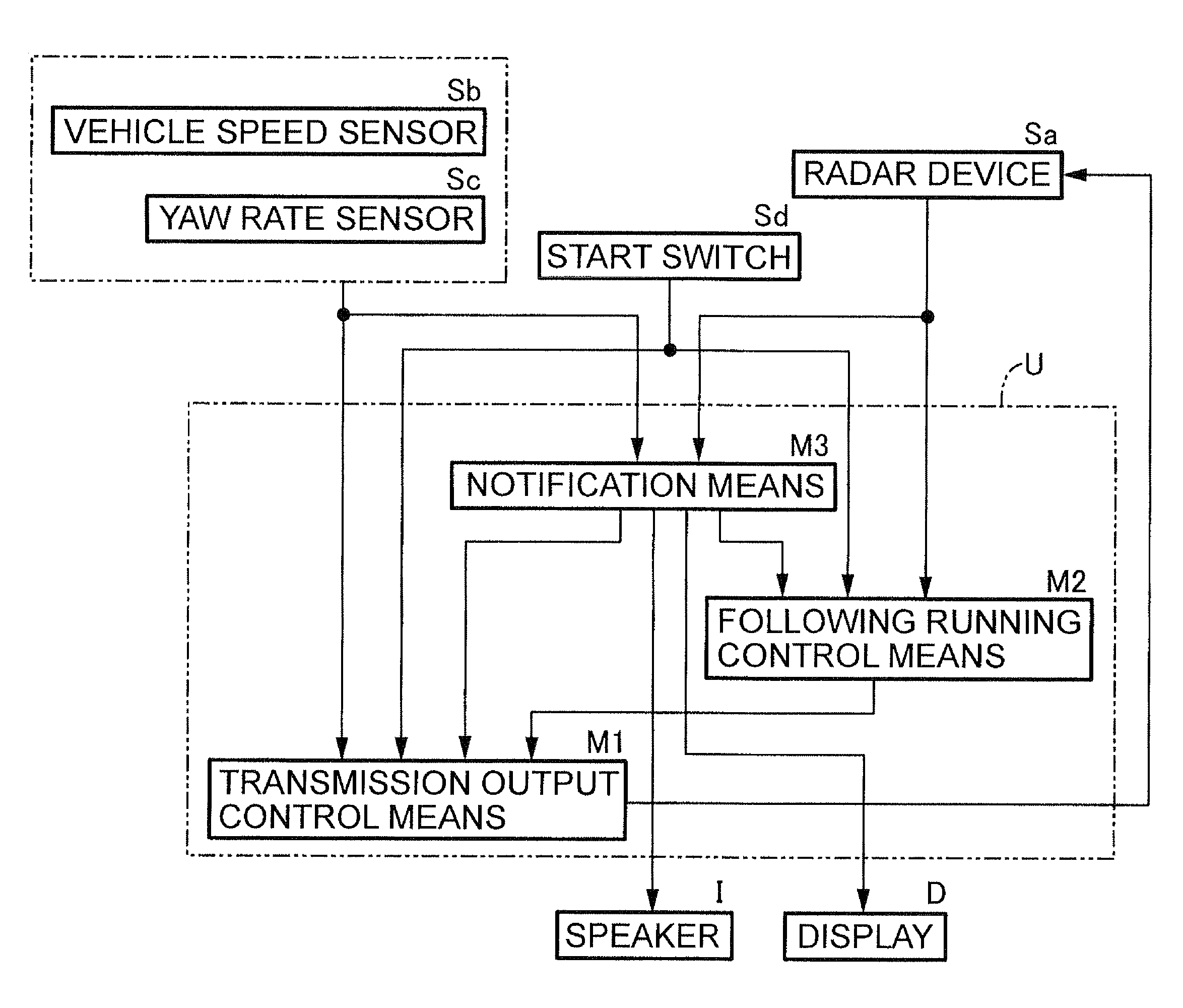

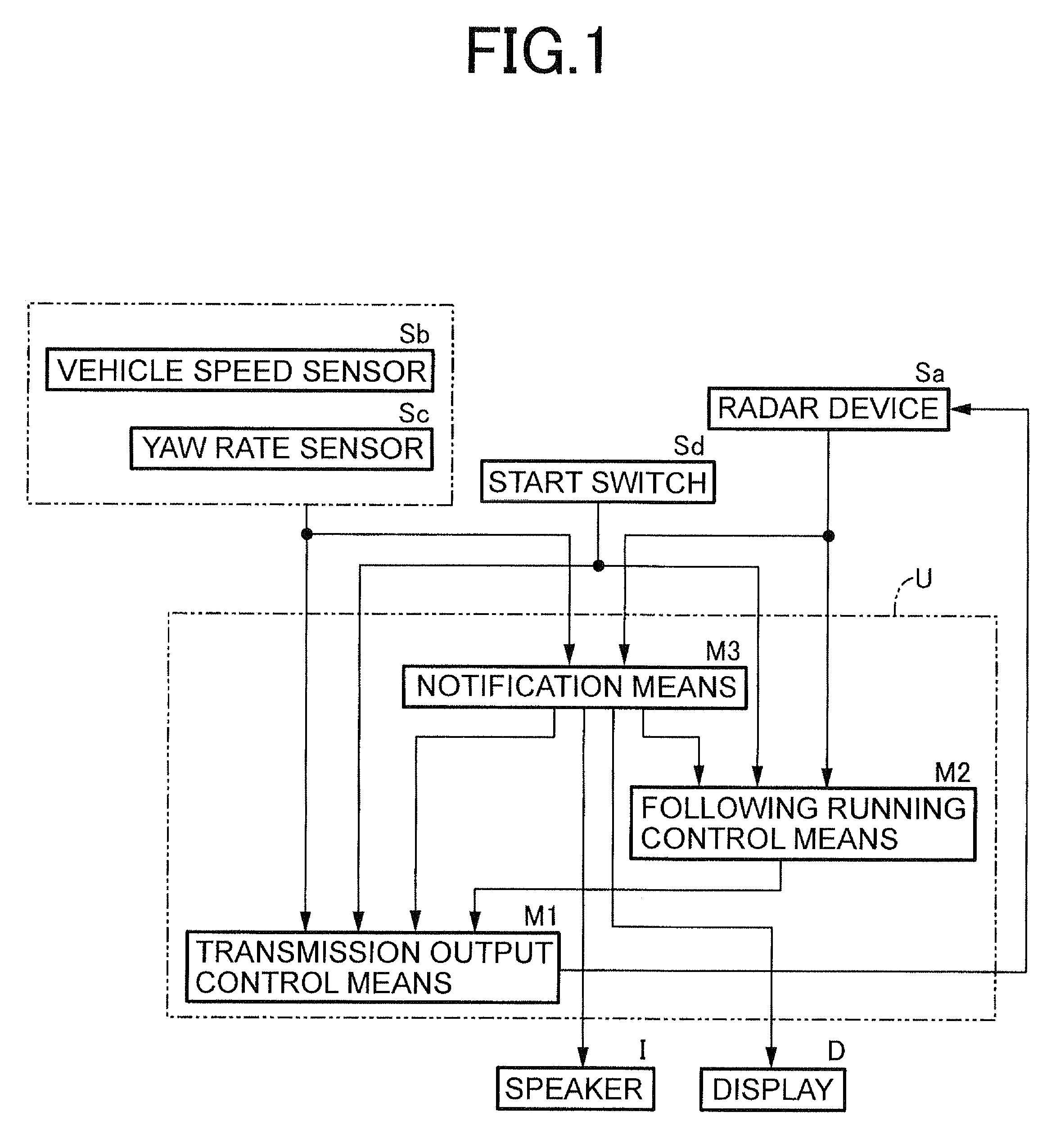

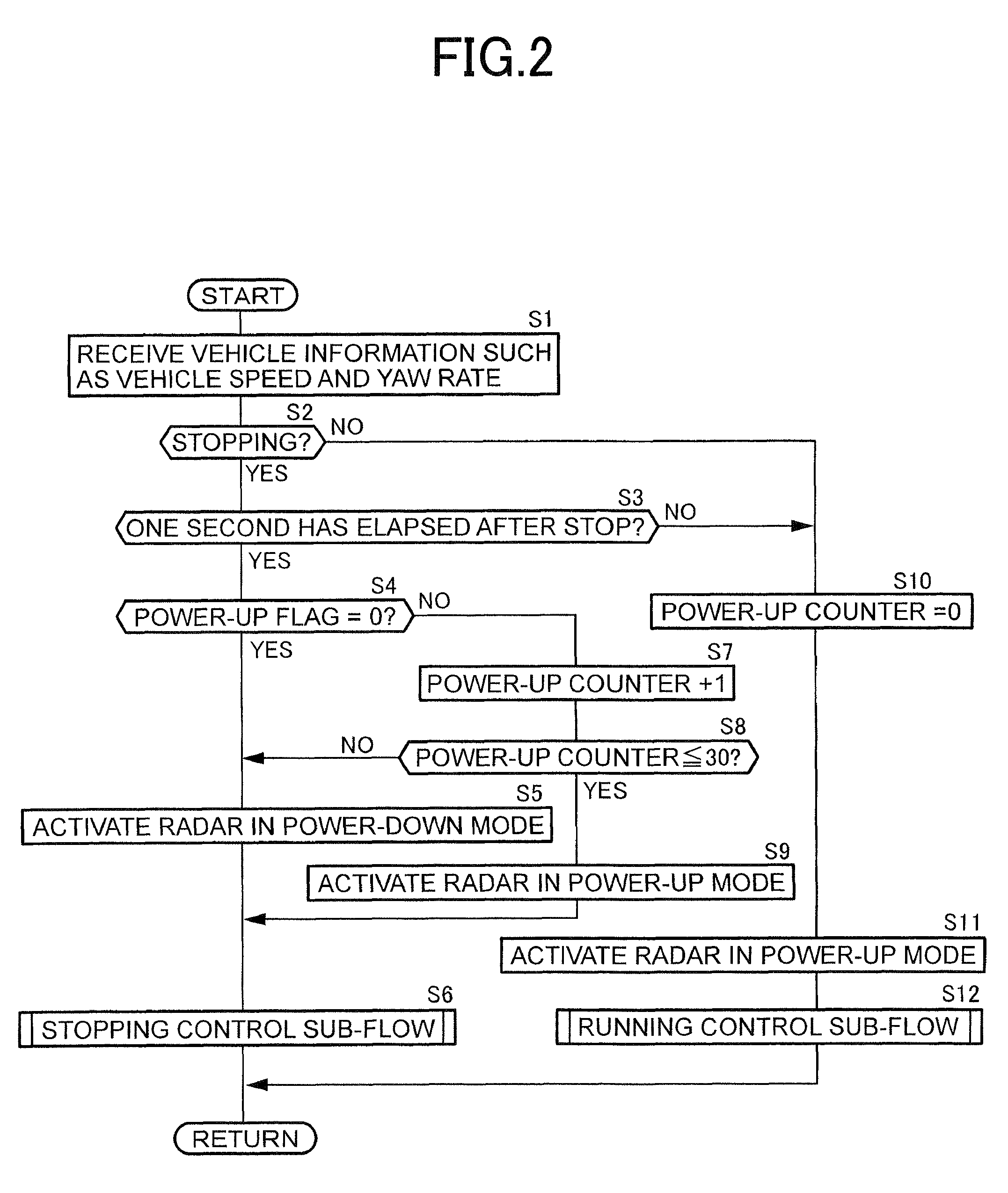

Running control system for vehicle

InactiveUS20090135049A1High outputReliable shiftingVehicle fittingsSpeed/accelaration controlRadarControl system

A running control system having a radar device that detects a distance between a subject vehicle and a preceding vehicle. When a vehicle speed sensor detects the subject vehicle has stopped, a transmission output controller sets a transmission output of the radar device to a stopping time transmission output lower than a running time transmission output. When the radar device detects an increase in the distance between the subject vehicle and the preceding vehicle while the subject vehicle is stopped, or when the distance between the subject vehicle and the preceding vehicle detected by the radar device while the subject vehicle has stopped is longer than a predetermined value, a notifying device notifies an occupant of the subject vehicle that following running control is possible.

Owner:HONDA MOTOR CO LTD

Bicycle shift operating device

InactiveUS20070151394A1Easy to operateSimple and inexpensive to manufactureShaft for linear movementCycle actuatorsEngineeringConductor Coil

Owner:SHIMANO INC

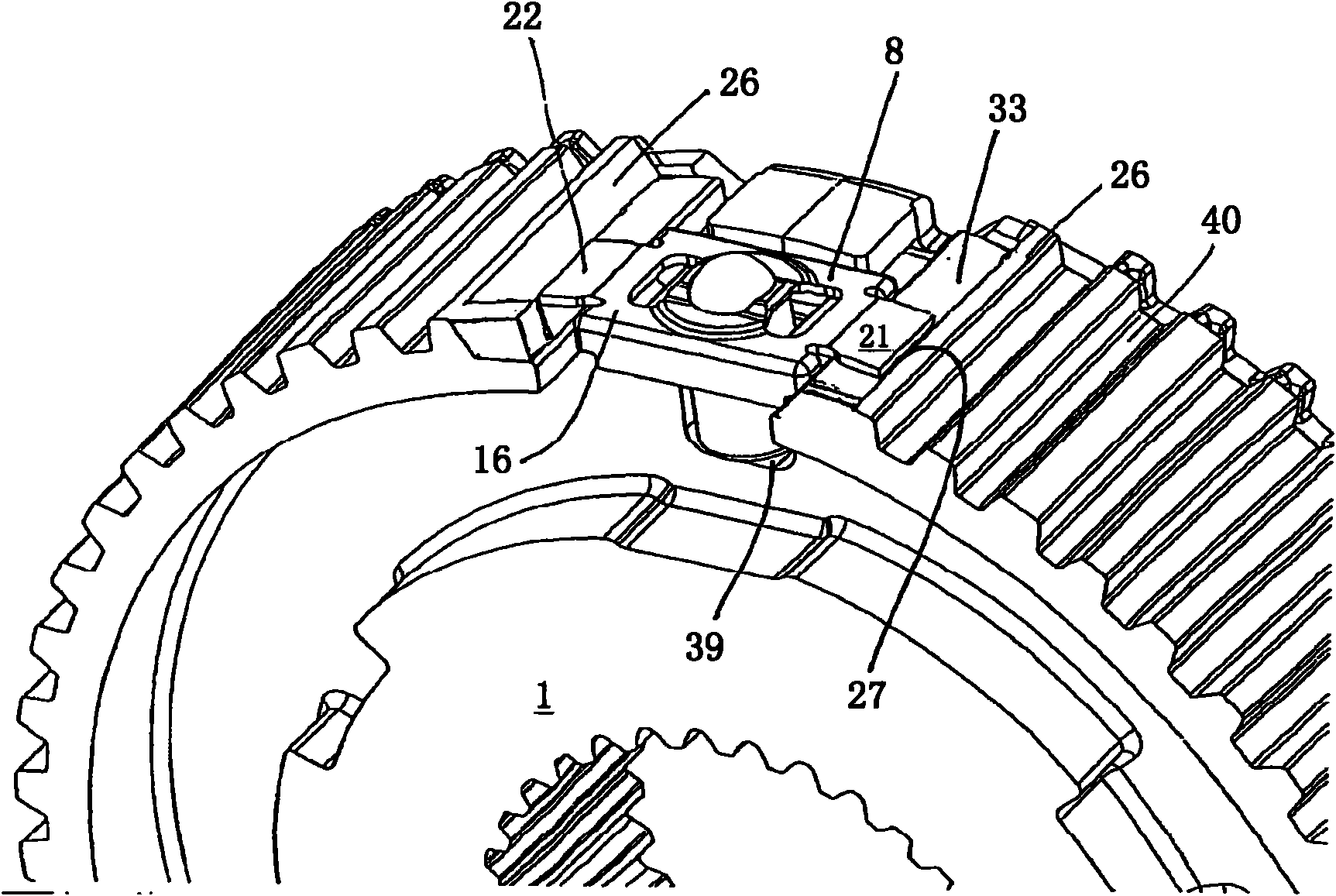

Catch

ActiveCN101965462AIncrease the number ofAchieve preparationMechanical actuated clutchesRest positionEngineering

The invention relates to a catch (6) of a synchronization device (27) that can be axially displaced in the installed state with regard to a synchronous body (1) comprising teeth at the outer circumference thereof, wherein the catch (6) comprises a catch element (8) acted on by an engagement element (15) for engaging in a rest position and a housing (14) having an approximately rectangular radial surface (16) having axial edges (17, 18) aligned outward and side edges (19, 20) oriented in the circumferential direction, wherein the catch element (8) is disposed in the interior of the radial surface (16), the wings (21, 22) being formed flush with the radial surface (16) as seen in the radial direction, and the axial width of the wings (21, 22) being smaller than the minimal axial width of the radial surface (16), and a method for producing the same.

Owner:SCHAEFFLER TECH AG & CO KG

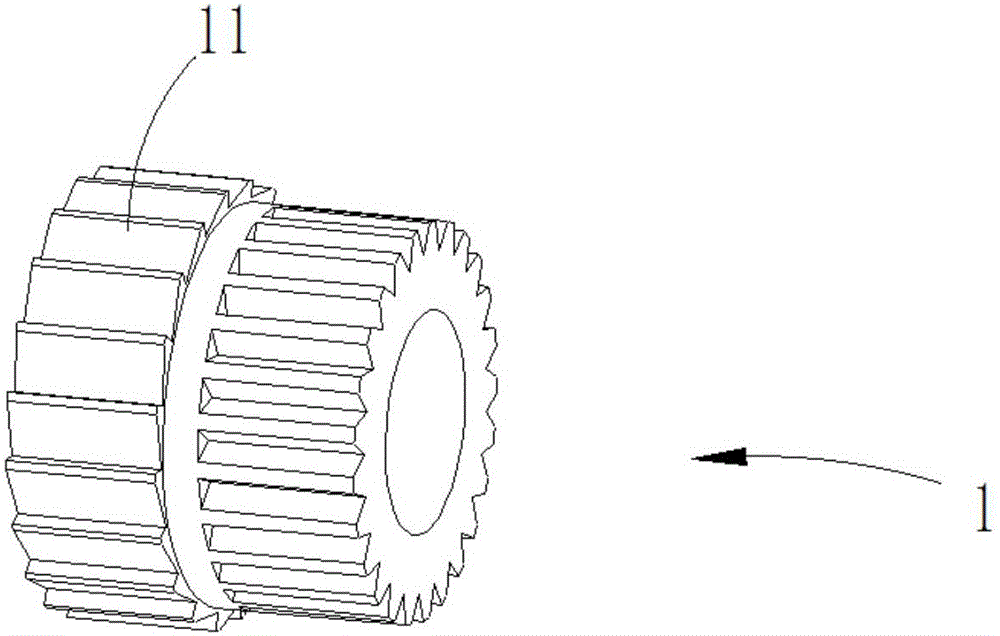

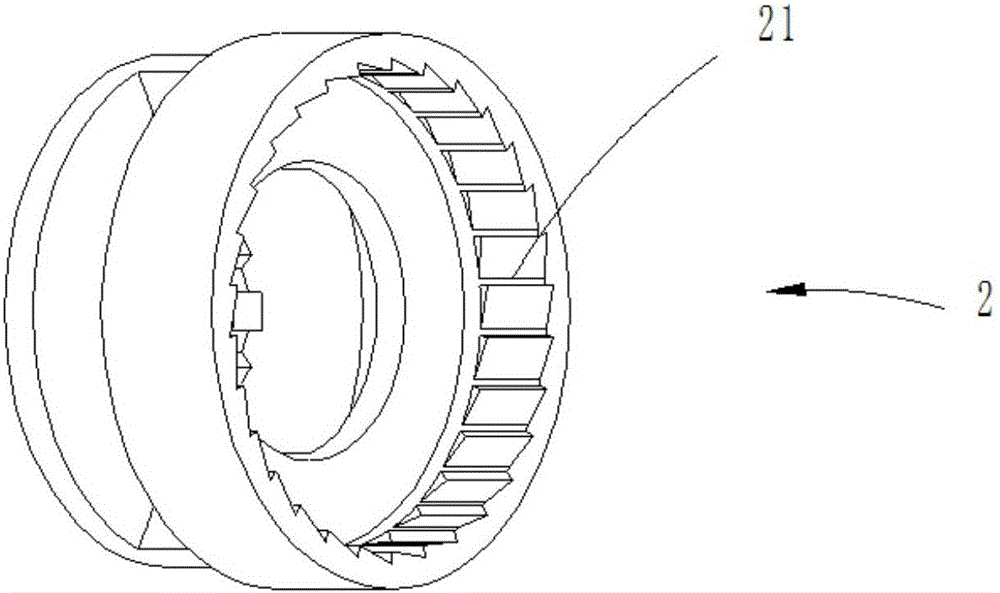

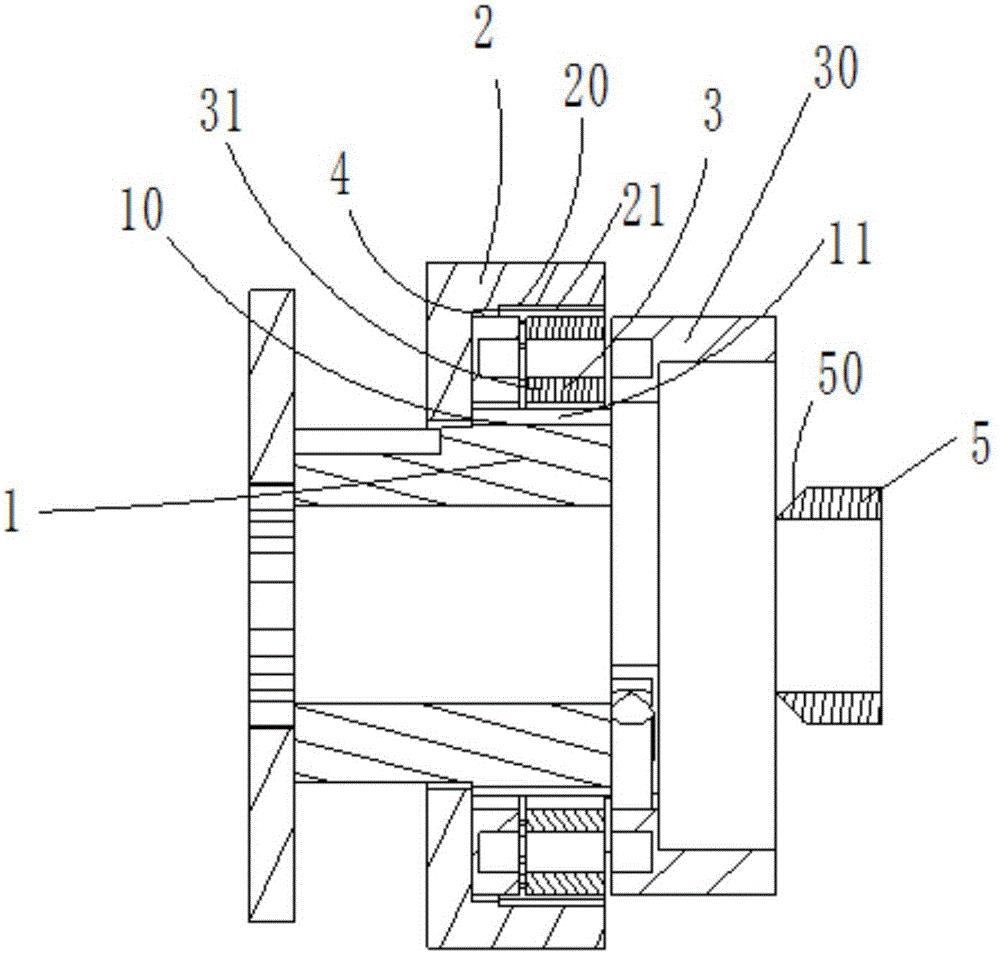

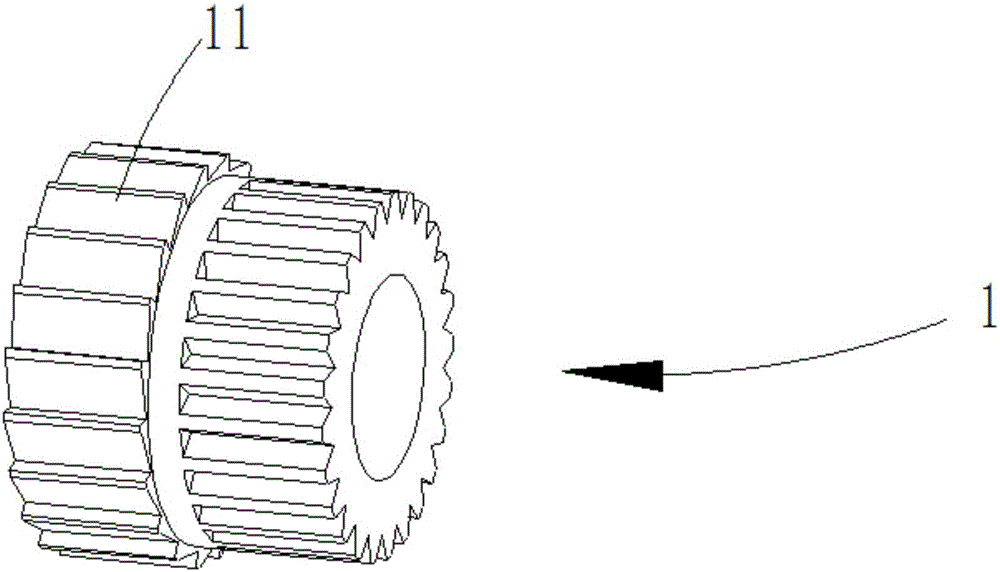

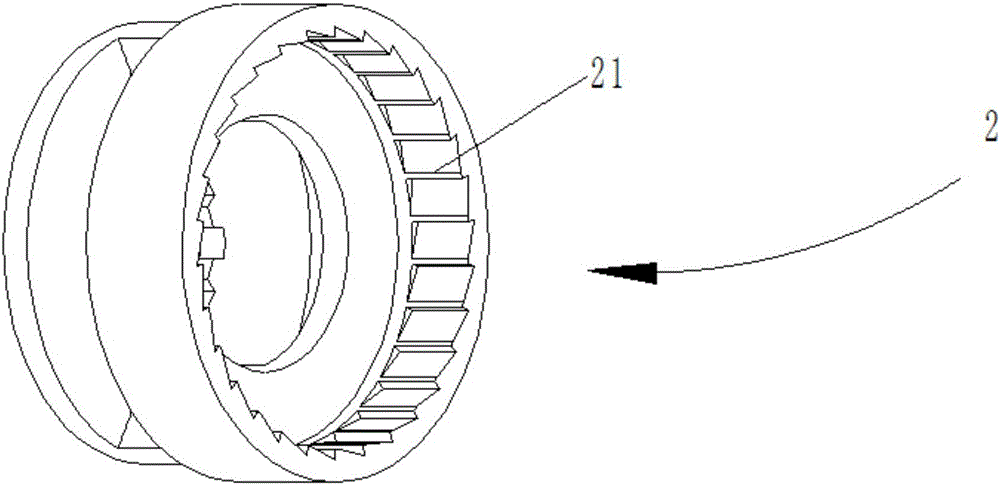

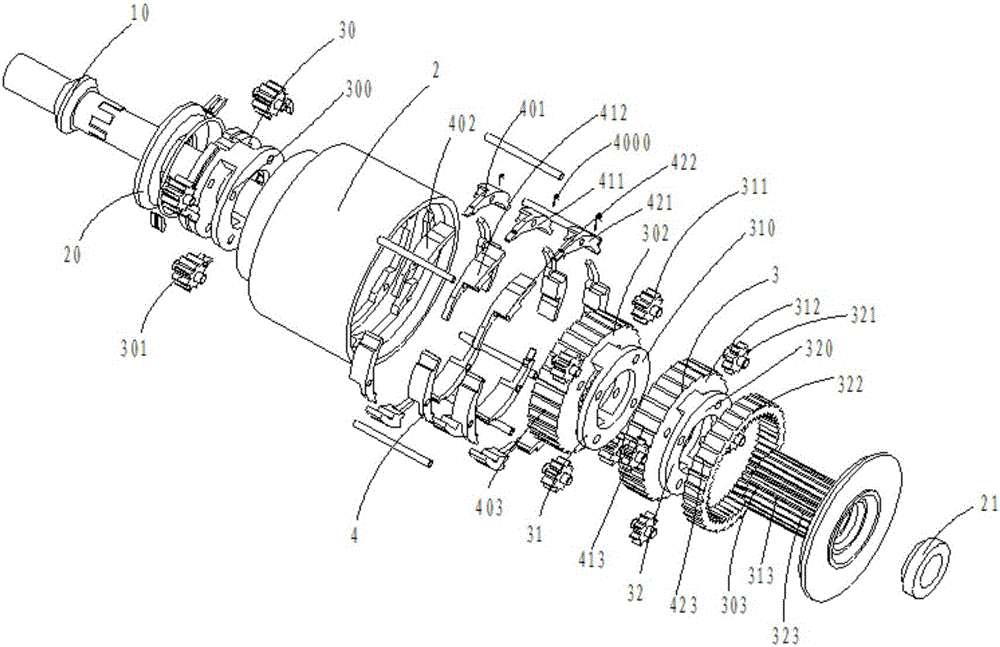

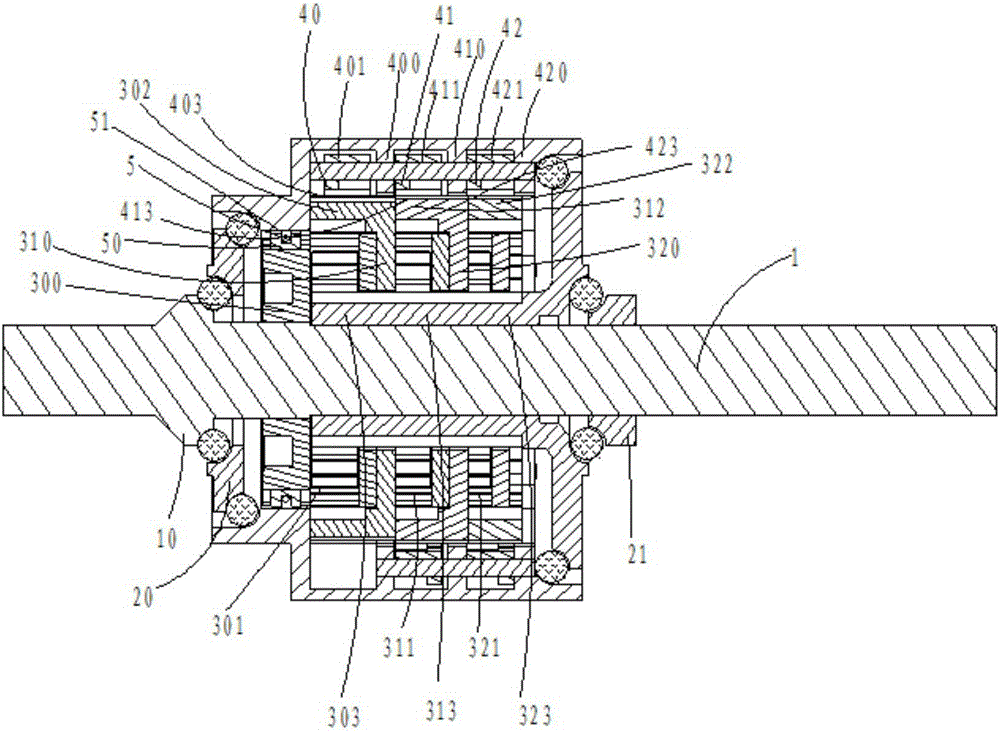

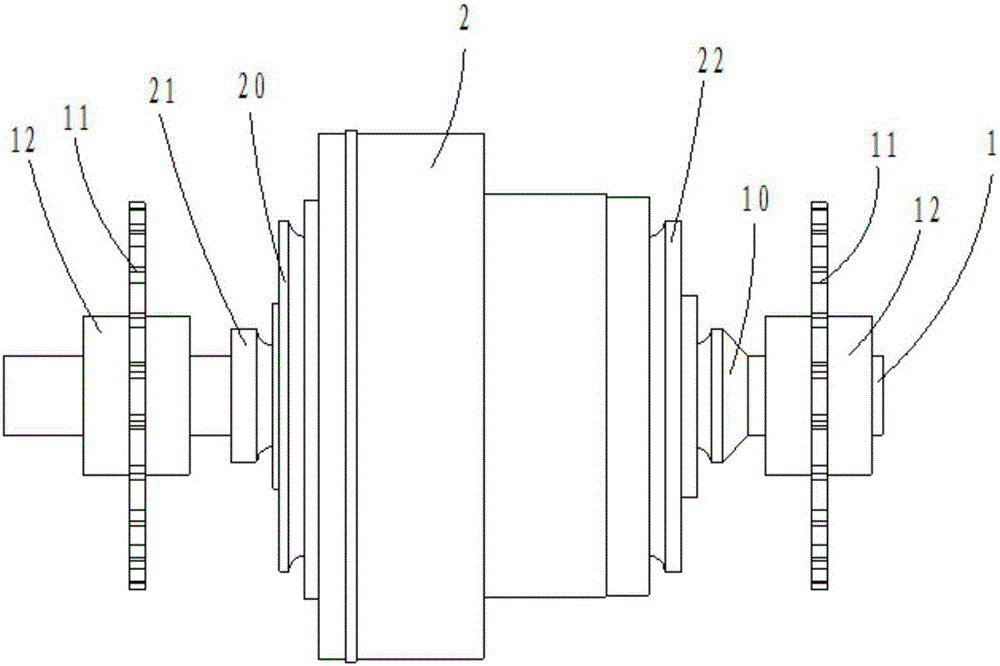

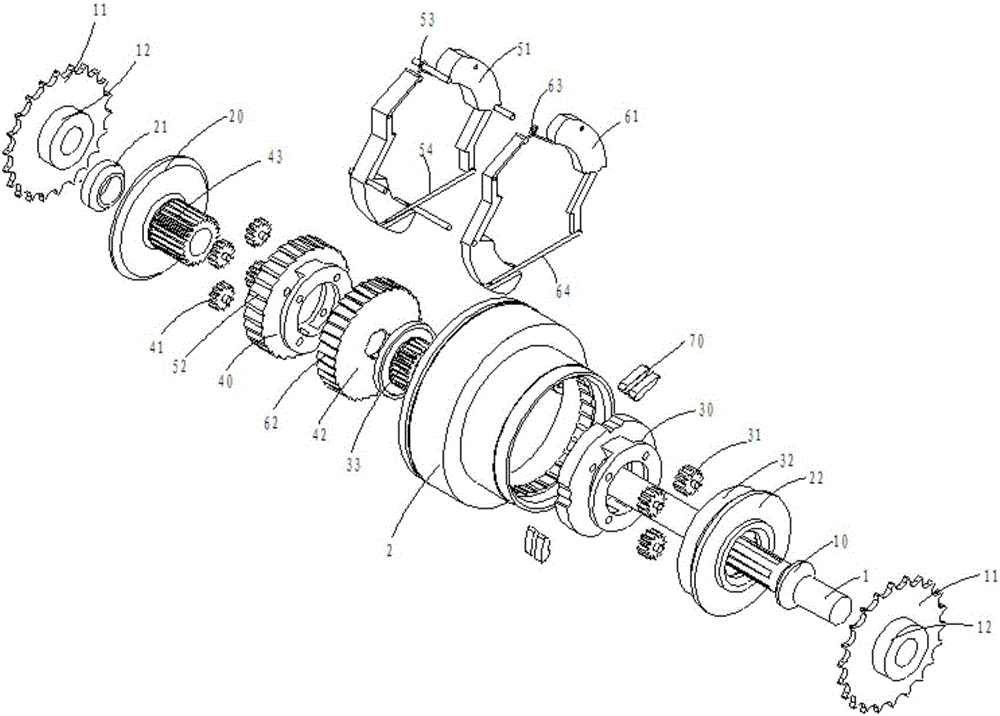

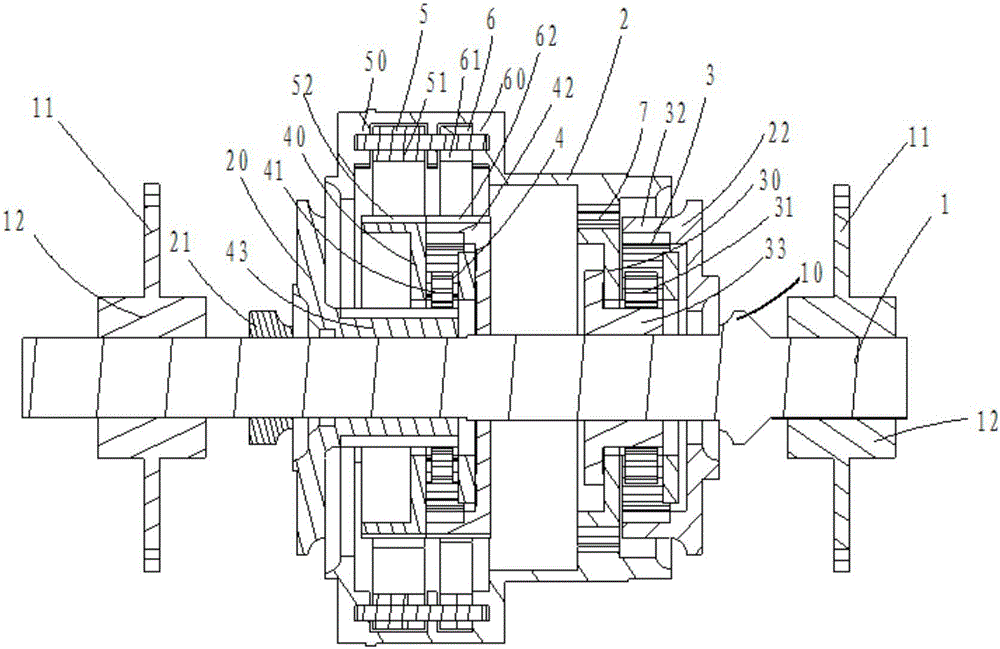

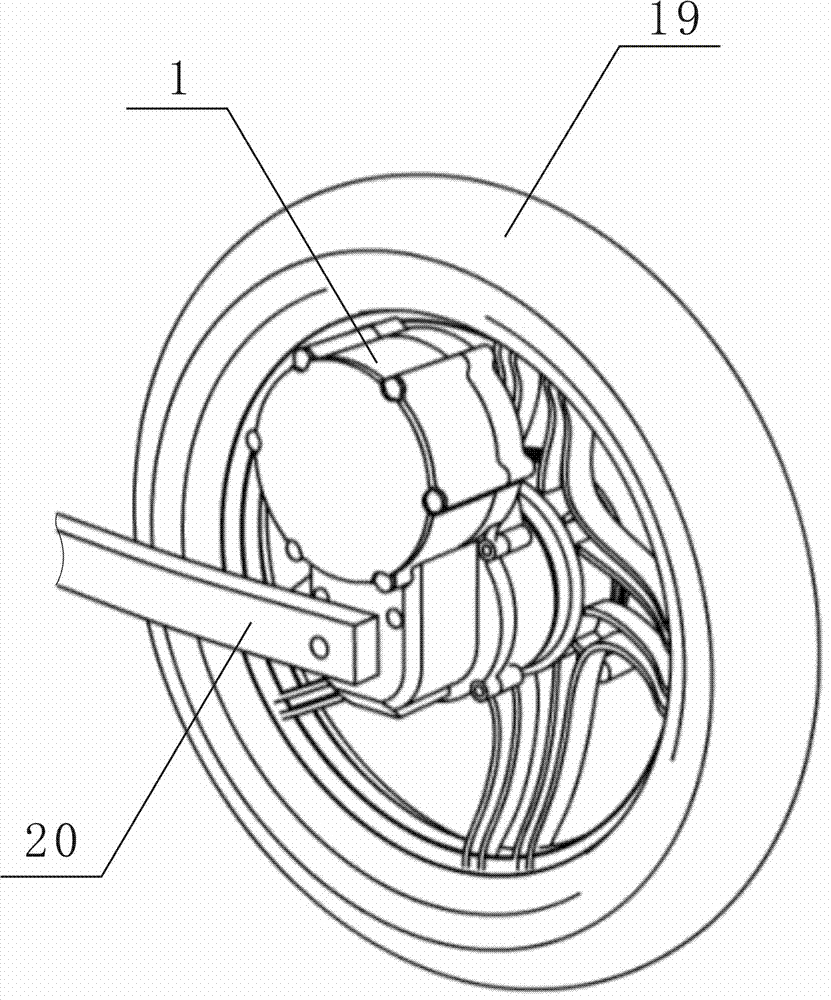

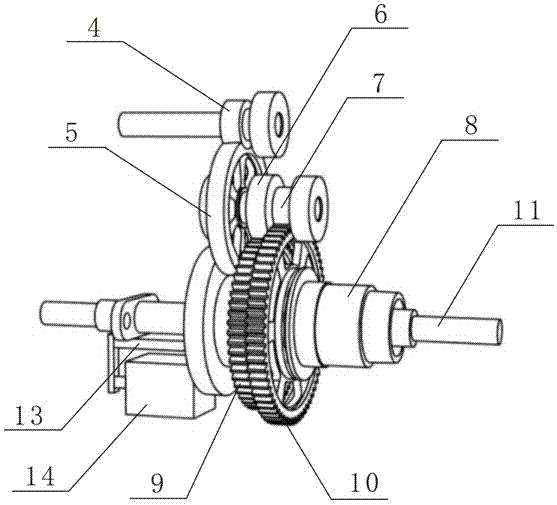

Centrifugal gear shifting device

The invention relates to a centrifugal gear shifting device, which comprises a first transmission element, a second transmission element and a gear shifting mechanism, wherein an accommodating cavity is formed between the second transmission element and the first transmission element; the second transmission element is provided with an inner wall positioned in the accommodating cavity; the first transmission element is provided with an outer wall positioned in the accommodating cavity; a first ratchet wheel is arranged in the outer wall position of the first transmission element; a second ratchet wheel is arranged in the inner wall position of the second transmission element; the gear shifting mechanism comprises a gear shifting element frame and a gear shifting element device; the gear shifting element device comprises a plurality of gear shifting elements; the gear shifting elements are connected through balancing elements; each gear shifting element comprises an installing part and a weight balancing block; the installing part comprises an inner surface and an outer surface; the first pallet is arranged on the inner surface of the installing part; the second pallet is arranged on the outer surface of the installing part; an elastic element used for controlling the initial position of the first pallet and the second pallet is arranged on the gear shifting element frame. The centrifugal gear shifting device can realize the automatic gear shifting in the running process.

Owner:ZHANGJIAGANG CHUANJUN VEHICLE IND CO LTD

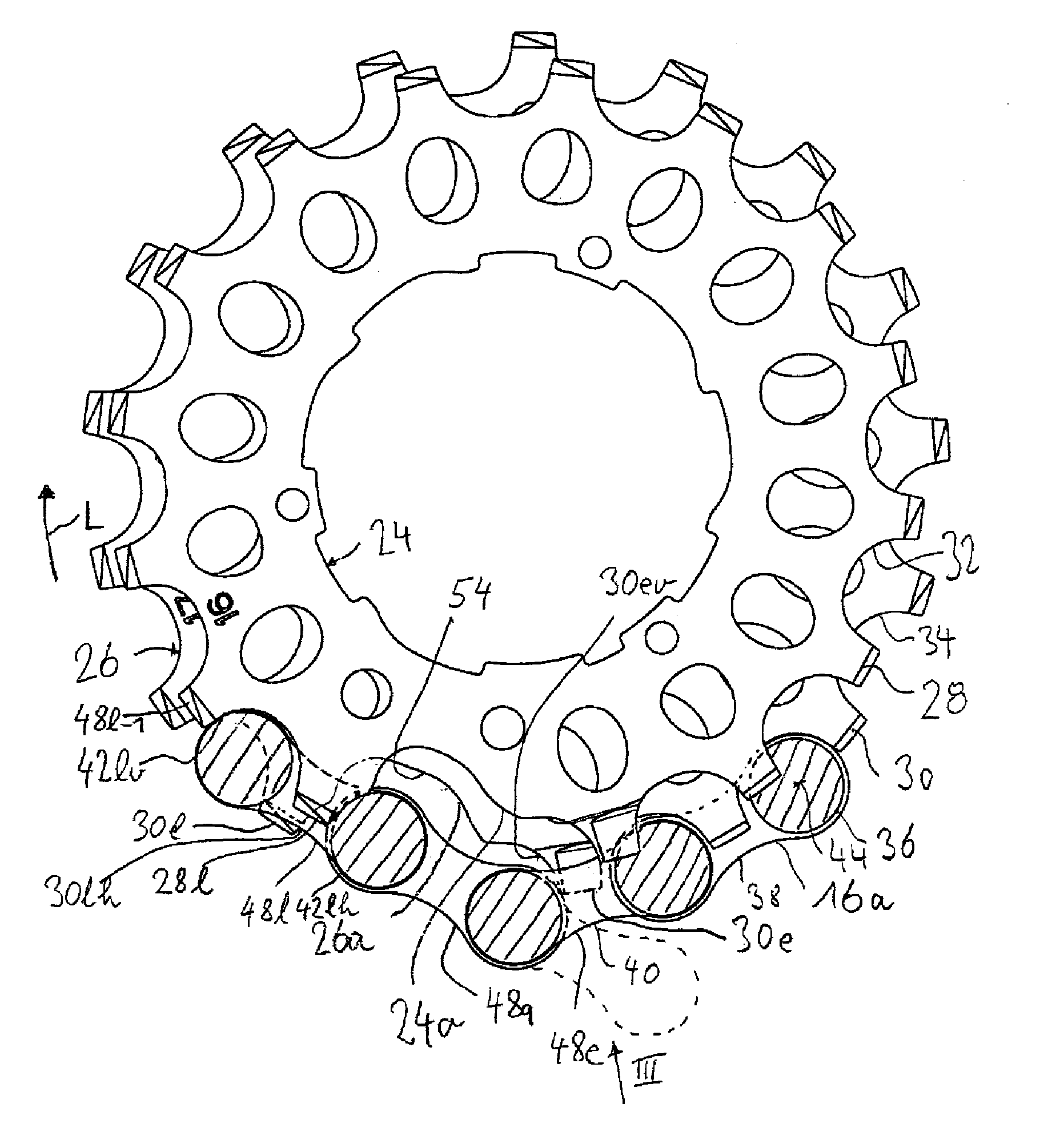

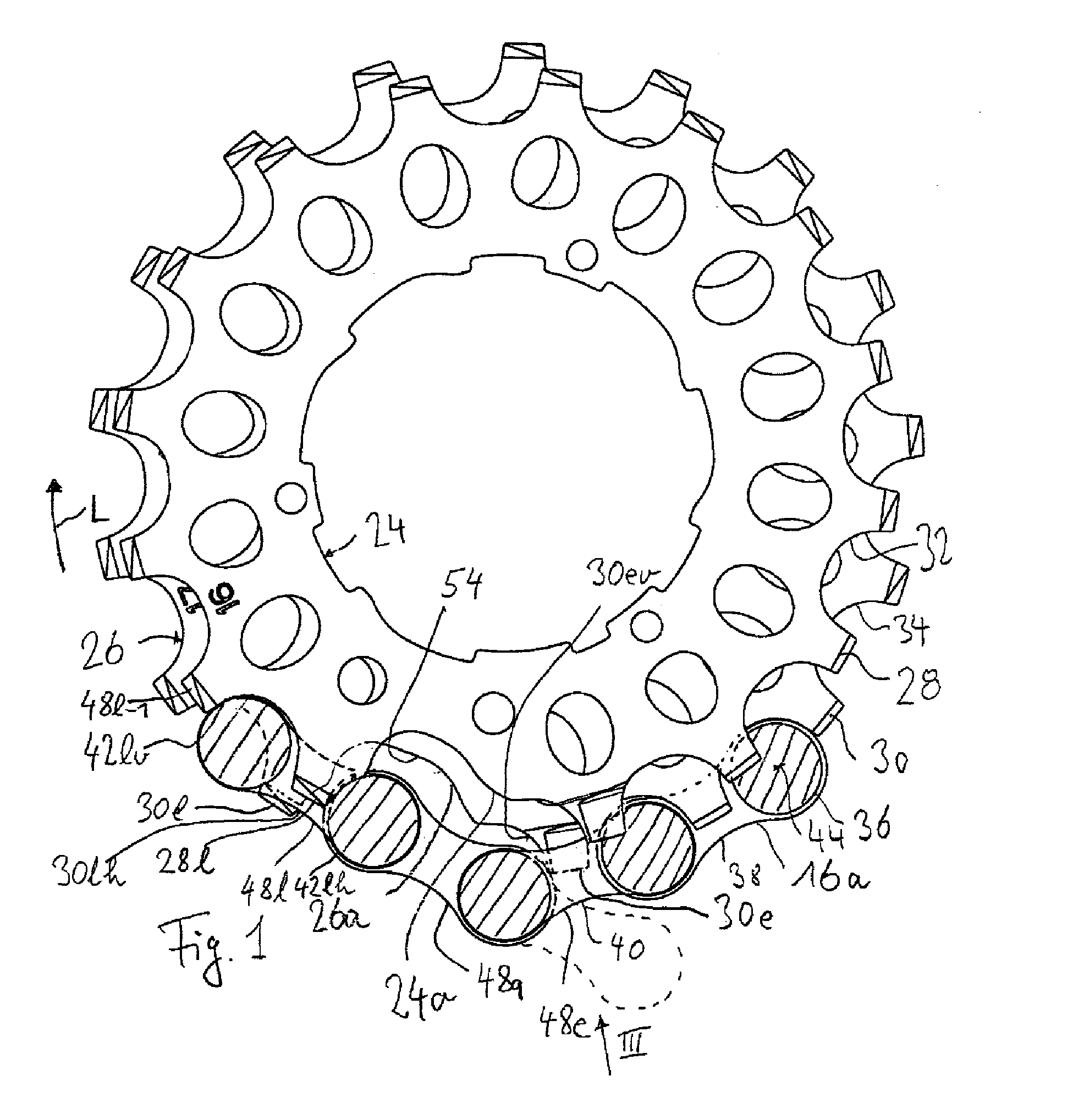

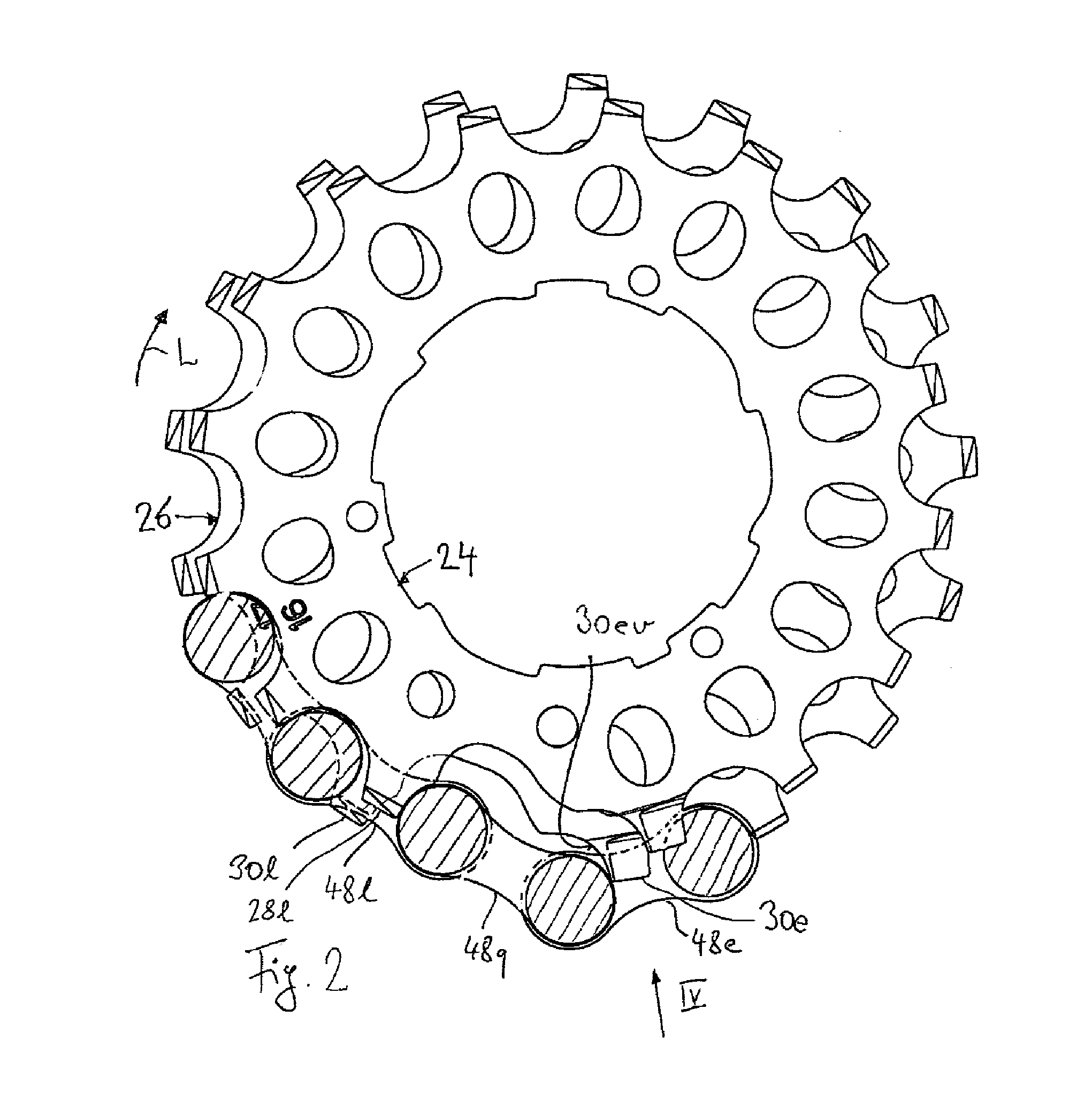

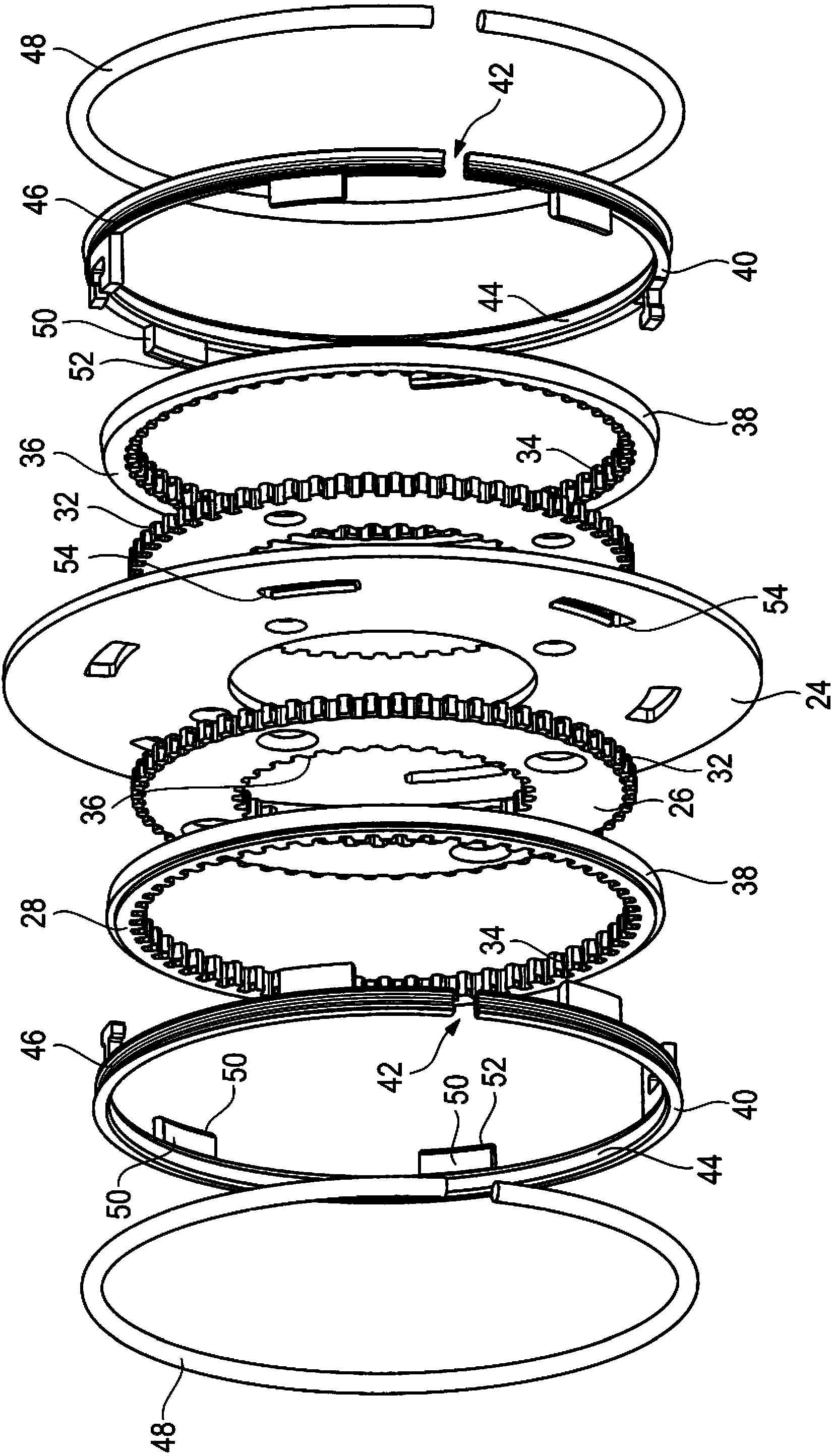

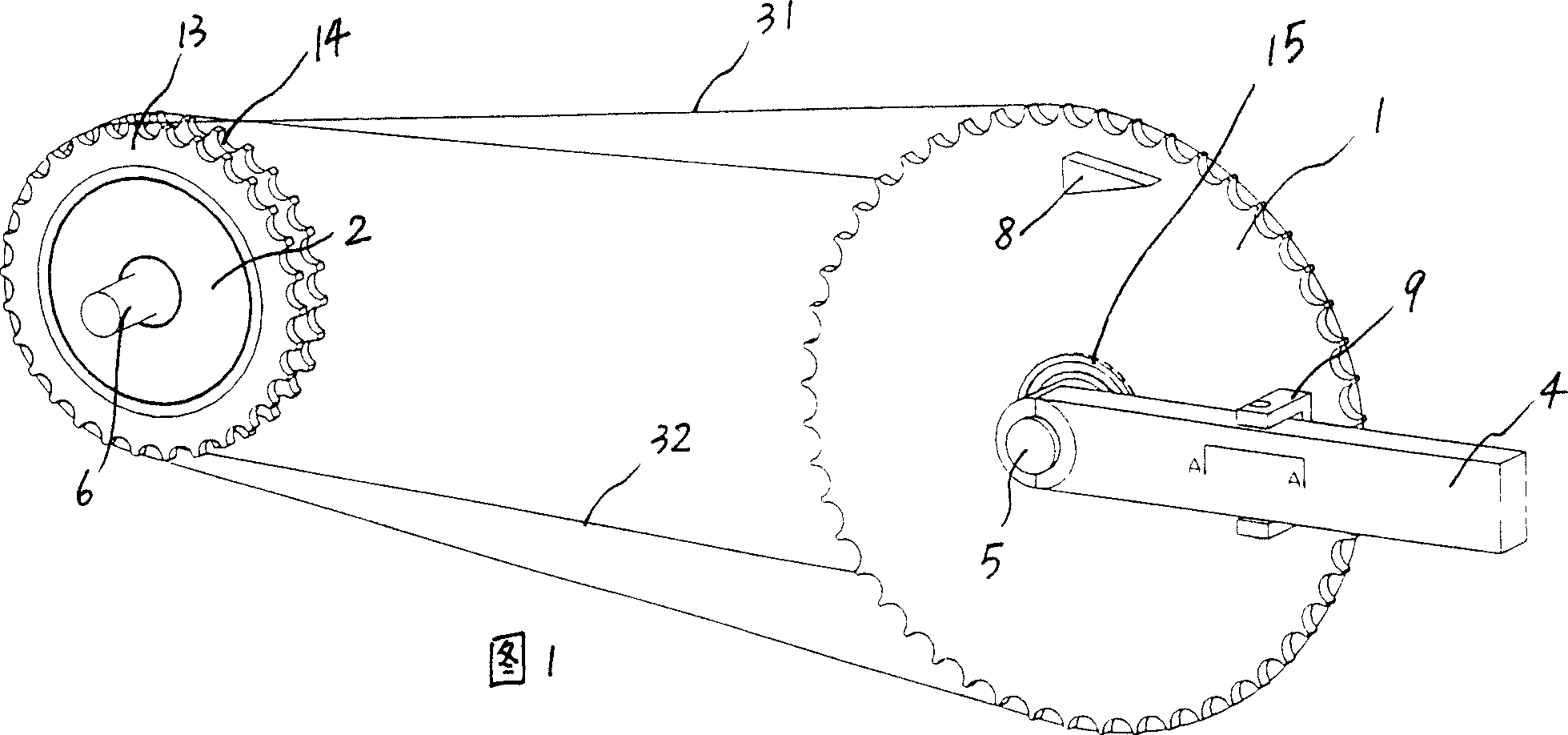

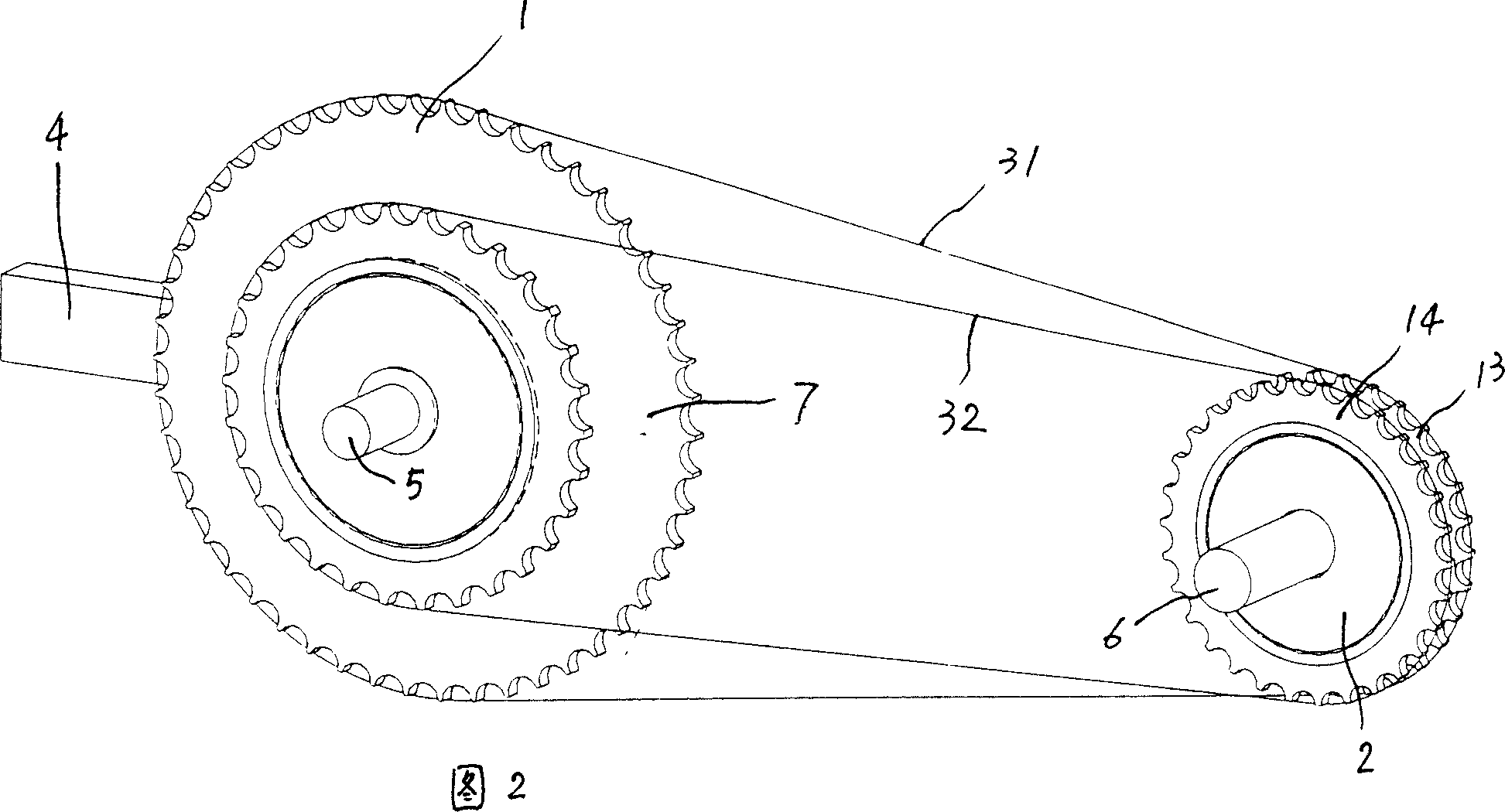

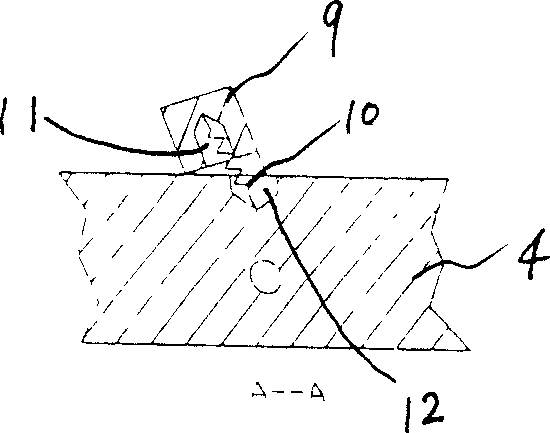

Multi-Speed Sprocket Assembly

InactiveUS20070213155A1Not sensitive to dirtReliable shiftingChain/belt transmissionPortable liftingTransitional RegionEngineering

A multi-speed sprocket assembly is suggested, including at least two sprockets, with both sprockets having at least one common upshift transitional region in which, when the chain is displaced from the smaller sprocket to the larger sprocket for the purpose of shifting gears, the chain leaves the smaller sprocket, with a trailing tooth of the smaller sprocket being the last to engage between a trailing link plate pair of the chain, and moves onto the larger sprocket, with a leading tooth of the larger sprocket either being the first to engage between a first outer link plate pair or being located adjacent to a first inner link plate pair, and with at least the larger sprocket having in its upshift transitional region a double spacewidth created by omitting a tooth, which is immediately followed by the leading tooth. Only one chain link crossing from the smaller sprocket to the larger sprocket is located between the trailing chain link and the leading chain link. The chain roller of the link connection between the crossing chain link and the trailing chain link is located directly across from a rear tooth flank of the trailing tooth of the smaller sprocket. The leading tooth cooperates with a circumferential surface of a link plate of the crossing chain link using its front tooth flank, with the leading tooth being in contact with either the inner surface of an outer link plate or with the outer surface of an inner link plate of the leading chain link. In the region of the double spacewidth, the larger sprocket is embodied in such a way that the crossing chain link comes into contact with the larger sprocket only in the region of the leading tooth.

Owner:SRAM

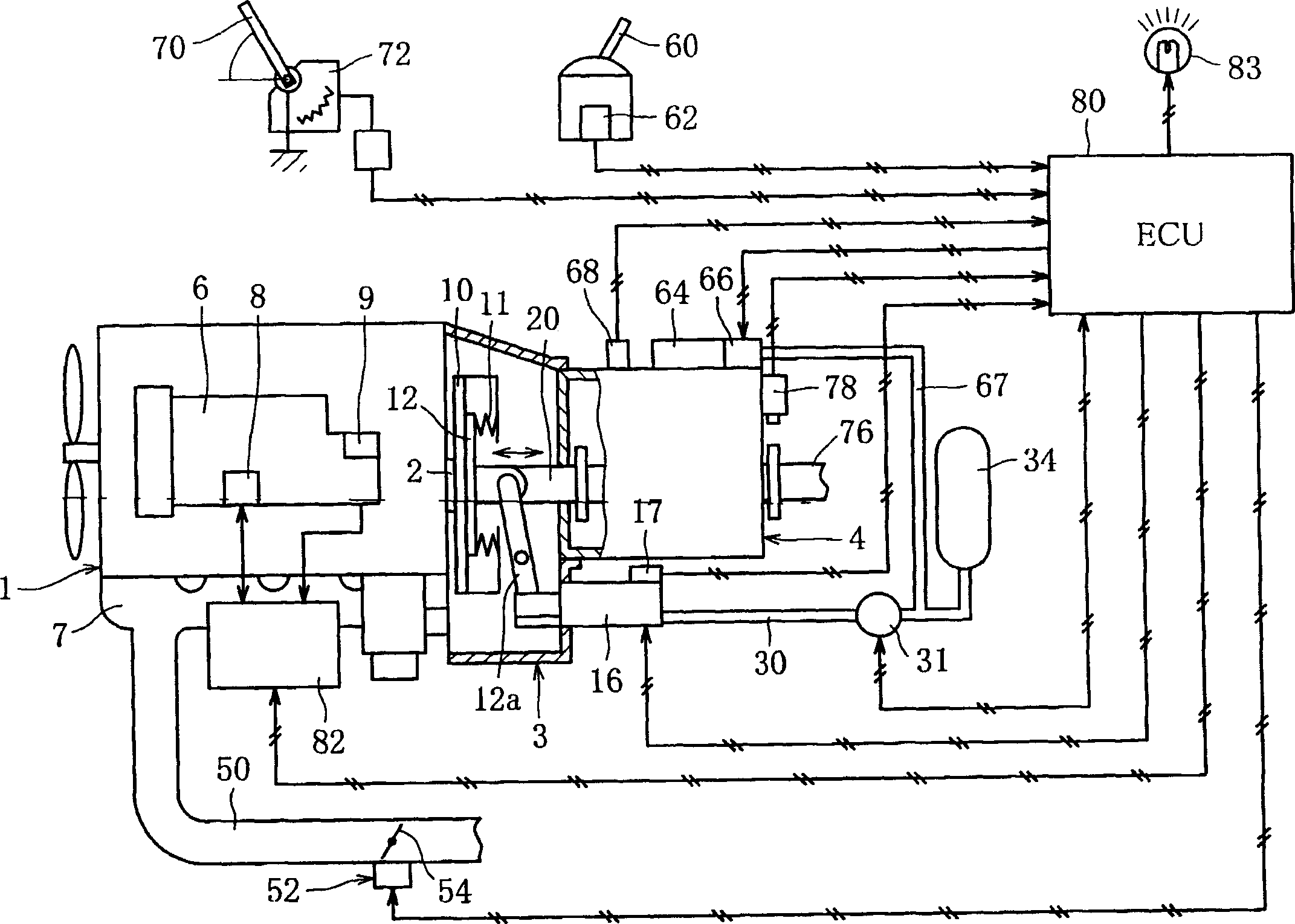

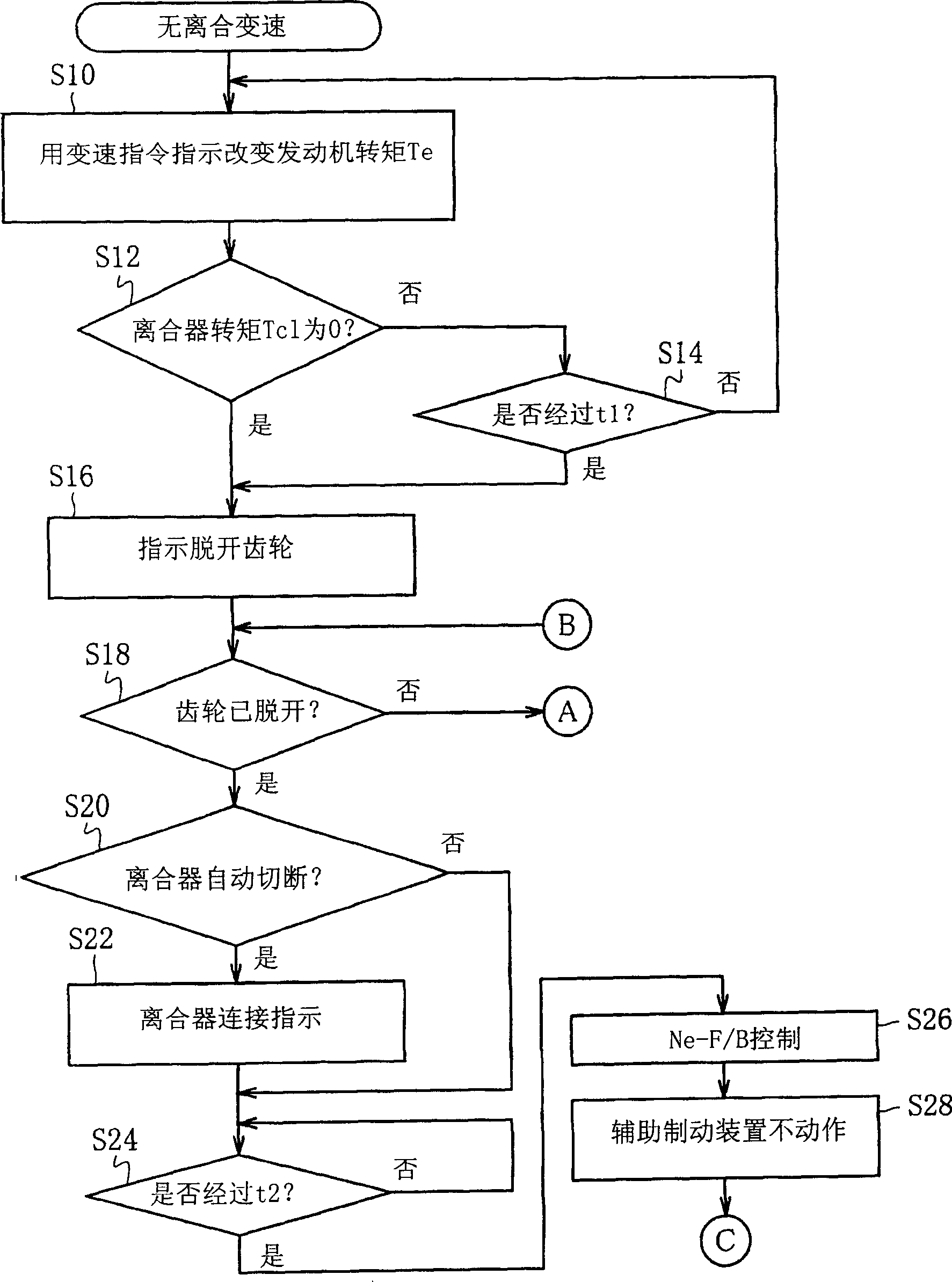

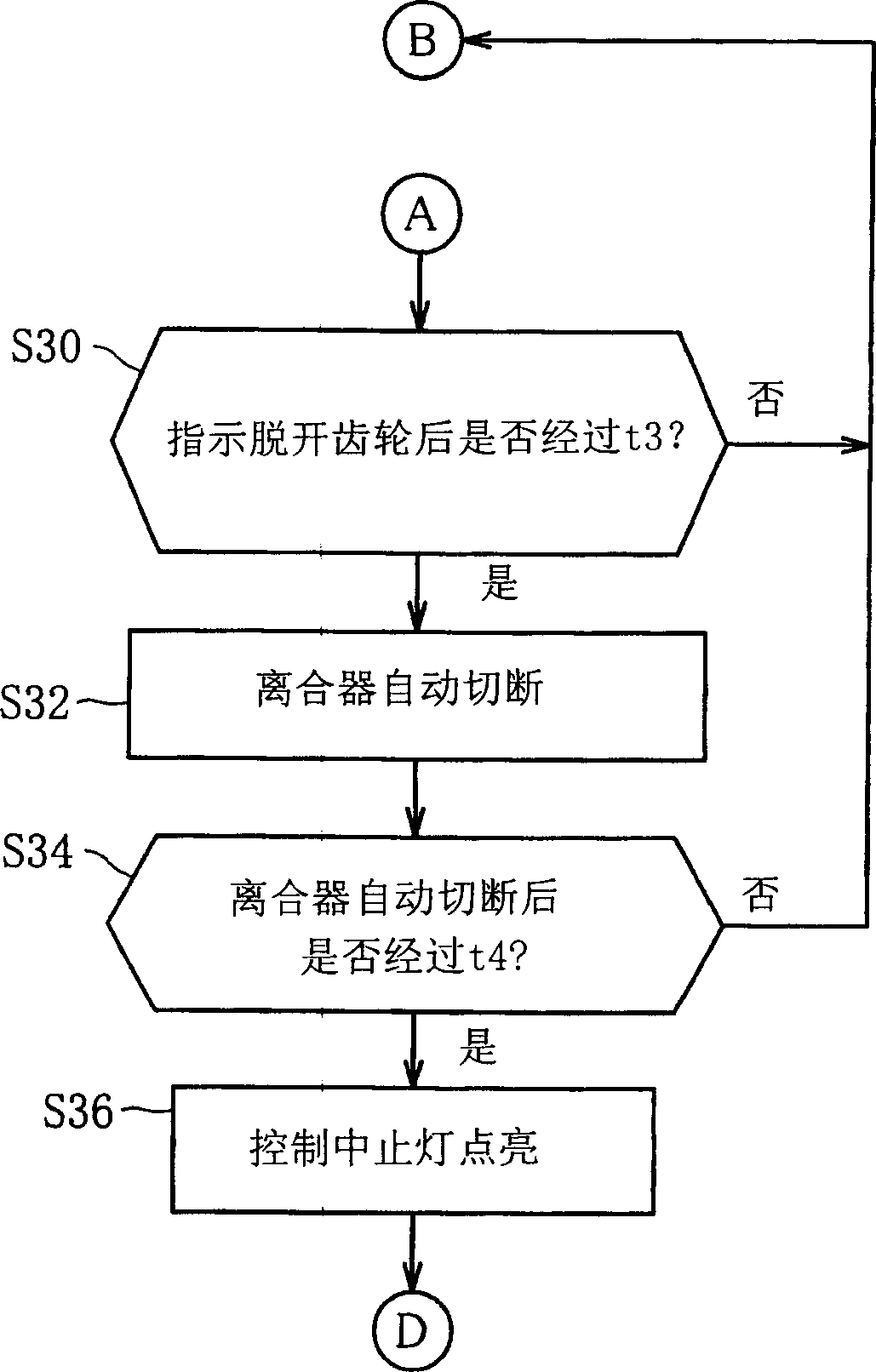

Method and device for controlling gear shift of mechanical transmission

InactiveCN1711183AHang up smoothlyReliable shiftingElectrical controlGearing controlCombustionExternal combustion engine

Owner:MITSUBISHI FUSO TRUCK AND BUS CORPORATION

Gear shifting device

ActiveCN106005234AReliable shiftingCompact structureWheel based transmissionCycle actuatorsEngineeringPallet

The invention relates to a gear shifting device, which comprises a first transmission element, a second transmission element and a gear shifting mechanism, wherein an accommodating cavity is formed between the second transmission element and the first transmission element; the second transmission element is provided with an inner wall positioned in the accommodating cavity; the first transmission element is provided with an outer wall positioned in the accommodating cavity; a first ratchet wheel is arranged in the outer wall position of the first transmission element; a second ratchet wheel is arranged in the inner wall position of the second transmission element; the gear shifting mechanism comprises a gear shifting element frame and at least one gear shifting element arranged on the gear shifting element frame; the gear shifting element comprises a main body part and an extending part; an elastic device is arranged in the extending part or the gear shifting element frame; one end of the main body part is provided with a double-side pallet; the other end or the middle section of the main body part is provided with a positioning hole; a manual gear shifting part matched with the elastic device is arranged on the axial line of the gear shifting element frame. The gear shifting can be realized through axially moving the manual gear shifting part; meanwhile, the function of an overrun clutch can also be realized through the transmission of the ratchet wheels and the pallet.

Owner:ZHANGJIAGANG CHUANJUN VEHICLE IND CO LTD

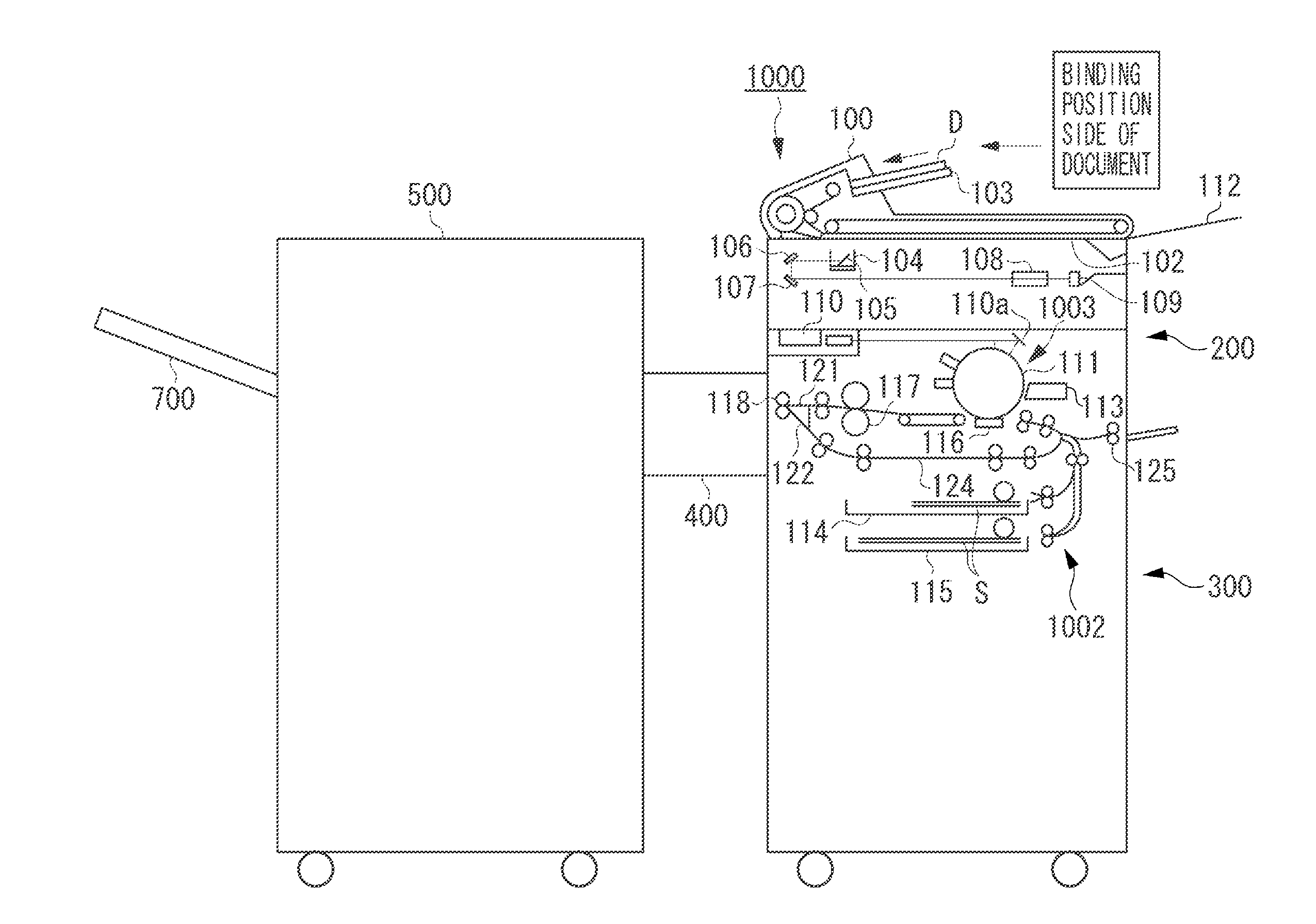

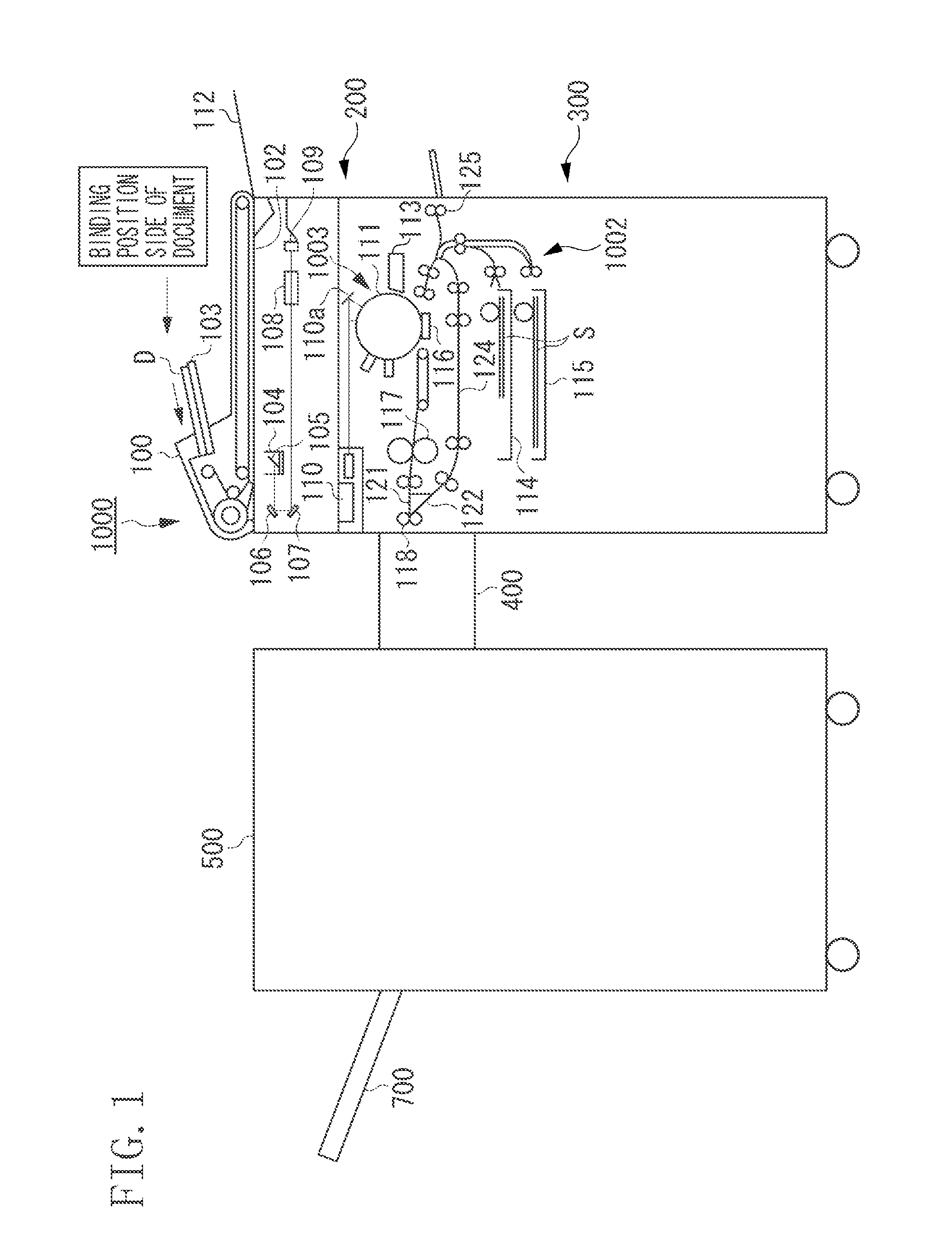

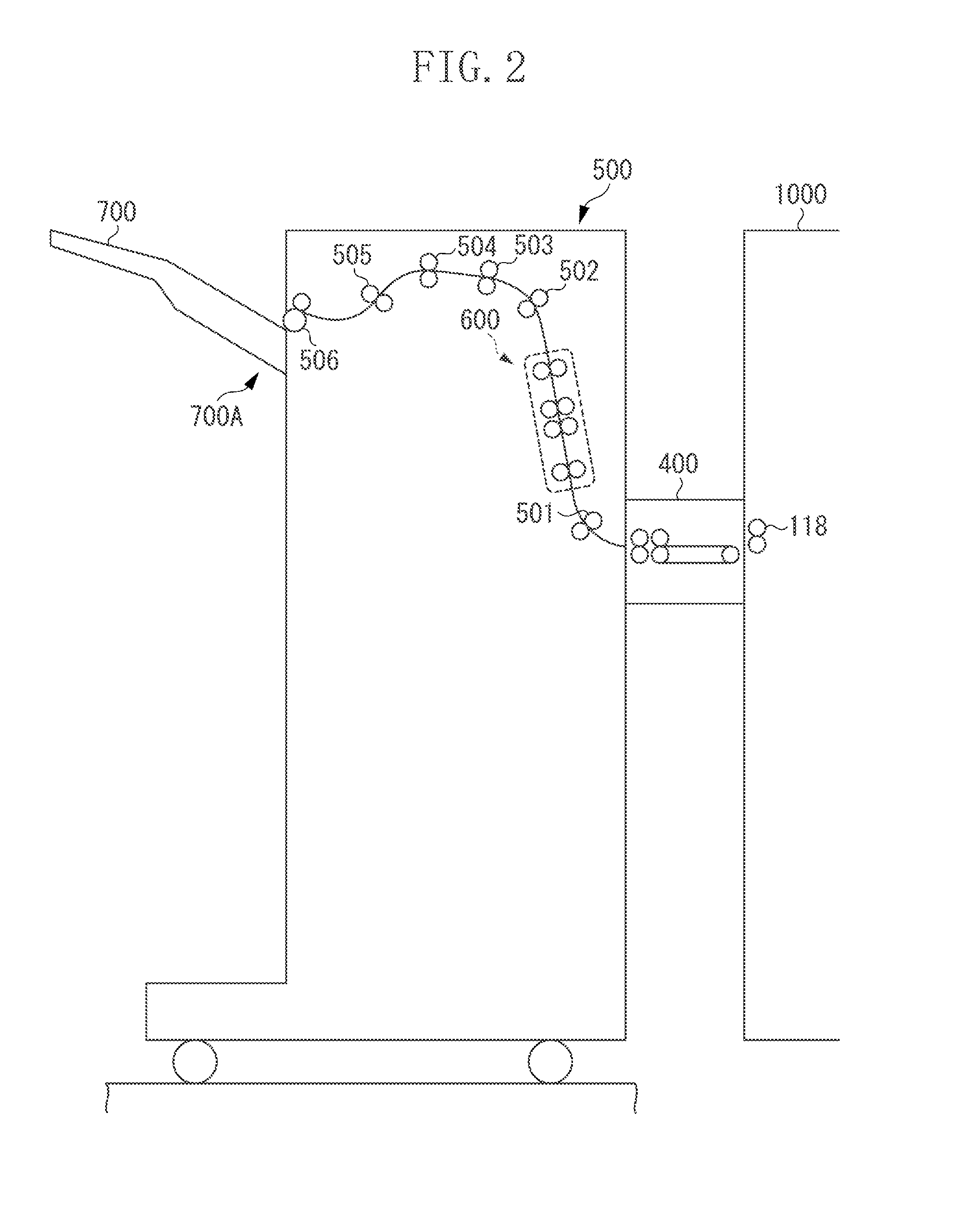

Sheet conveyance apparatus and image forming system

InactiveUS20130249166A1Reliable shiftingFunction indicatorsOther printing apparatusSeparated stateEngineering

Owner:CANON KK

Center wheel fixed single-wheeled direct drive multi-speed full-automatic transmission

PendingCN106763570ACompact structureEasy to installToothed gearingsTransmission elementsVariatorEngineering

The invention discloses a center wheel fixed single-wheeled direct drive multi-speed full-automatic transmission which comprises a center shaft, a wheel hub and a speed change mechanism, wherein the speed change mechanism comprises at least two sets of planetary transmissions and at least one set of automatic centrifugal gear-shifting mechanism; each set of planetary transmissions comprises a planet carrier, a planet wheel, a gear ring and a center wheel; in every two adjacent sets of planetary transmissions, the gear ring of one set of planetary transmissions and the planet carrier of the other set of planetary transmissions form an assembling unit; the planet carrier of an initial set of planetary transmissions and the center shaft are fixedly connected or integrally molded with each other; each set of automatic centrifugal gear-shifting mechanism comprises a pawl piece rack, a ratchet wheel and at least one pawl piece; the pawl piece rack is arranged in the wheel hub; the ratchet wheel is arranged on the assembling unit or the gear ring; and an overrun clutch is arranged between the planet carrier and the wheel hub, or the overrun clutch is arranged between the assembling unit and the wheel hub. According to the transmission disclosed by the invention, the requirement on stepping frequency can be reduced at a medium / high gear.

Owner:ZHANGJIAGANG CHUANJUN VEHICLE IND CO LTD

Bicycle gear controller for bicycle driving gear

InactiveCN1431121AEasy to makeEasy to assembleCycle control systemsGearing controlElectrical and Electronics engineeringReciprocating motion

Owner:SHIMANO INC

Liner treading single-wheel direct-drive tooth ring center wheel fixing transmission

The invention discloses a liner treading single-wheel direct-drive tooth ring center wheel fixing transmission. The liner treading single-wheel direct-drive tooth ring center wheel fixing transmission includes a central shaft, input wheels, a wheel hub, and a transmission mechanism; the transmission mechanism includes a first planetary transmission, a second planetary transmission, a first automatic centrifugal shifting mechanism and a second automatic centrifugal shifting mechanism; the first planetary transmission includes a first planetary carrier, a first planetary wheel, a first tooth ring, and a first central wheel; an overrun clutch is arranged between the first planetary carrier and the wheel hub; the second planetary transmission includes a second planetary carrier, a second planetary wheel, a second tooth ring, and a second central wheel; the second central wheel is fixedly connected to a frame; the central shaft is fixedly connected to the second planetary carrier or the second tooth ring; the first automatic centrifugal shifting mechanism is arranged between the wheel hub and the second planetary carrier; the second automatic centrifugal shifting mechanism is arranged between the wheel hub and the second tooth ring; and in this way, the demand for the treading frequency is lowered at a medium-high speed.

Owner:ZHANGJIAGANG CHUANJUN VEHICLE IND CO LTD

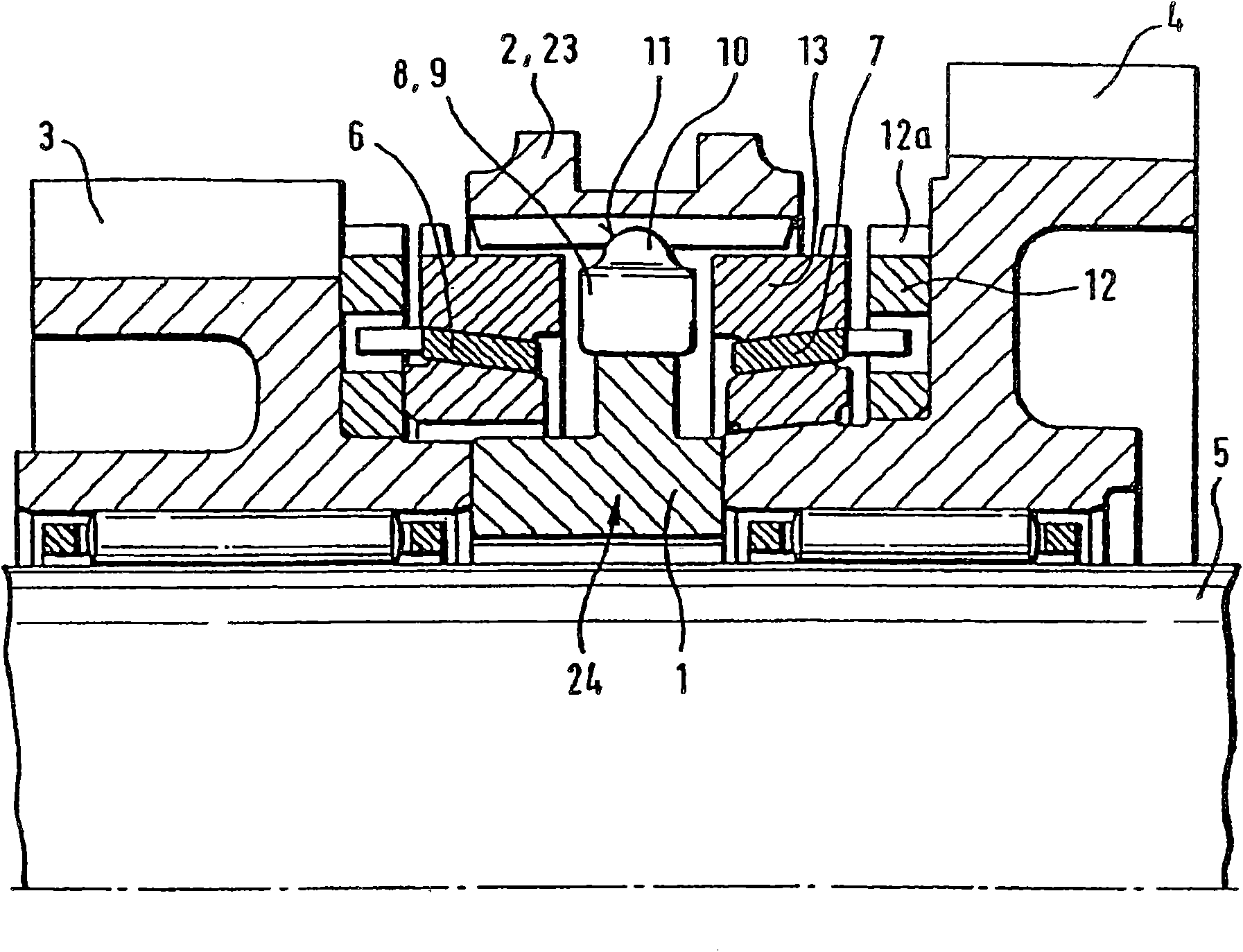

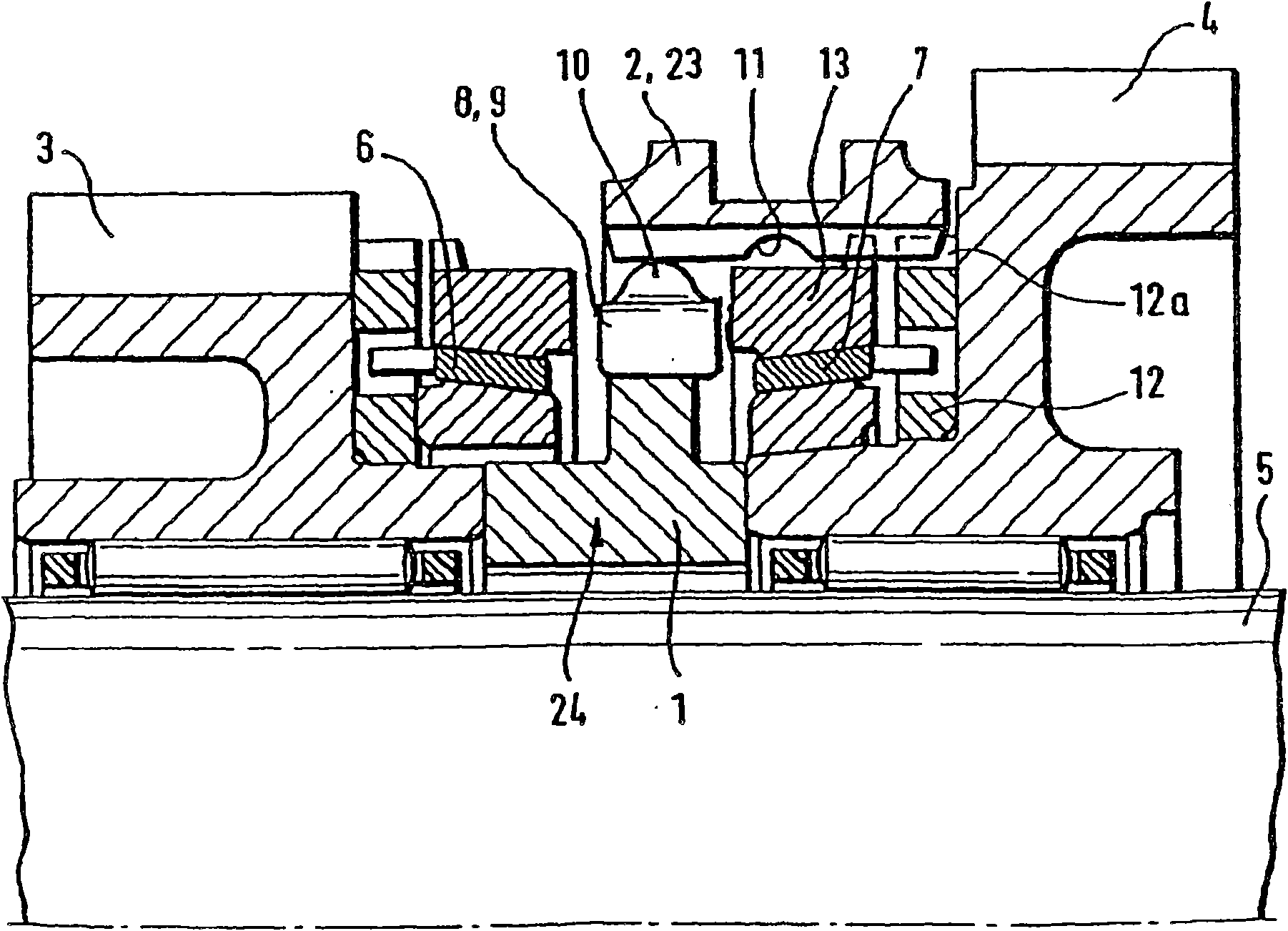

Comfortable jaw clutch

ActiveCN103573842ACompact configurationResist getting connectedInterengaging clutchesDrive wheelGear wheel

The invention relates to a jaw clutch transmitter for a transmission, which includes a transmitter body, at least one torque transmission element which is connected to the transmitter body in a torsion-proof manner and is displaceable in the axial direction of a transmission shaft, and at least one clutch formation which is connected to the transmitter body in a torsion-proof manner and can be brought into engagement with a complementary driven wheel clutch formation of a gear wheel,and at least one slotted friction ring is provided which can be brought into engagement with the friction surface associated with the driven wheel. The invention also relates to a gearbox with at least one transmission shaft, at least one jaw clutch transmitterwhich is arranged displaceably on the transmission shaft, and at least one driven wheel provided with a driven wheel clutch formation which is engageable to the clutch formation on the transmitte, whereby the driven wheel is coupled with the transmission shaft in a torsion-proof manner, and the driven wheel is provided with a friction surface which can cooperate with the friction ring of the transmitter.

Owner:HOERBIGER ANTRIEBSTECHN HLDG +1

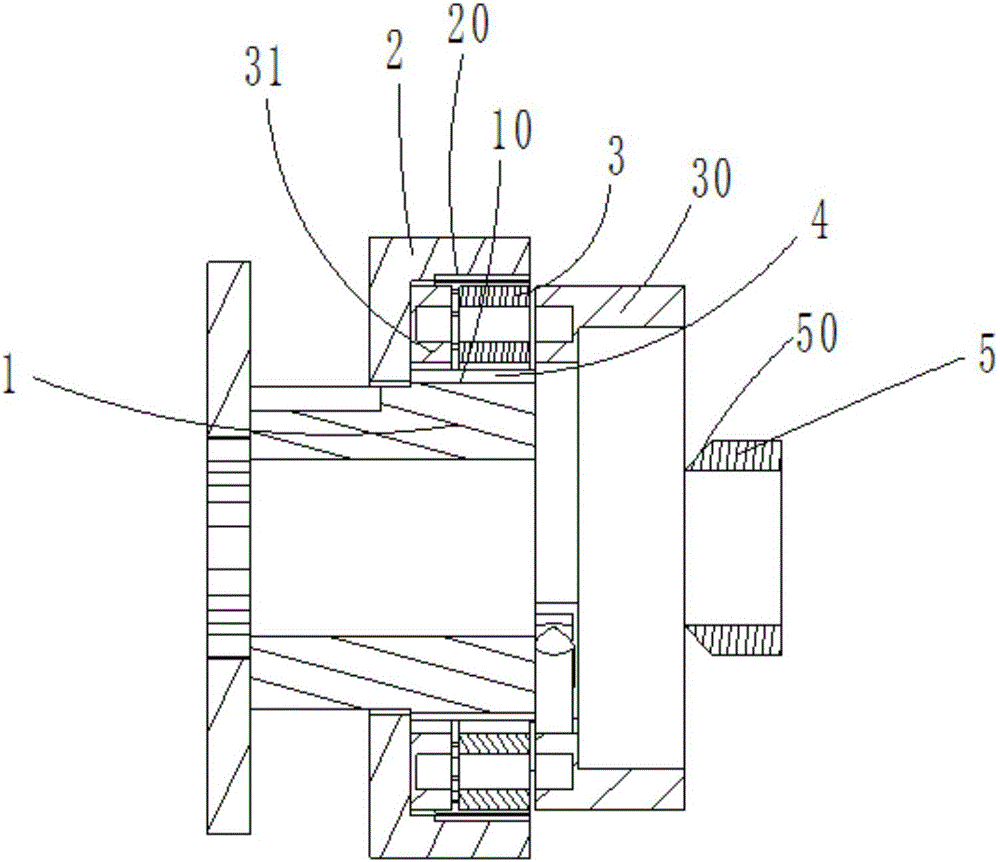

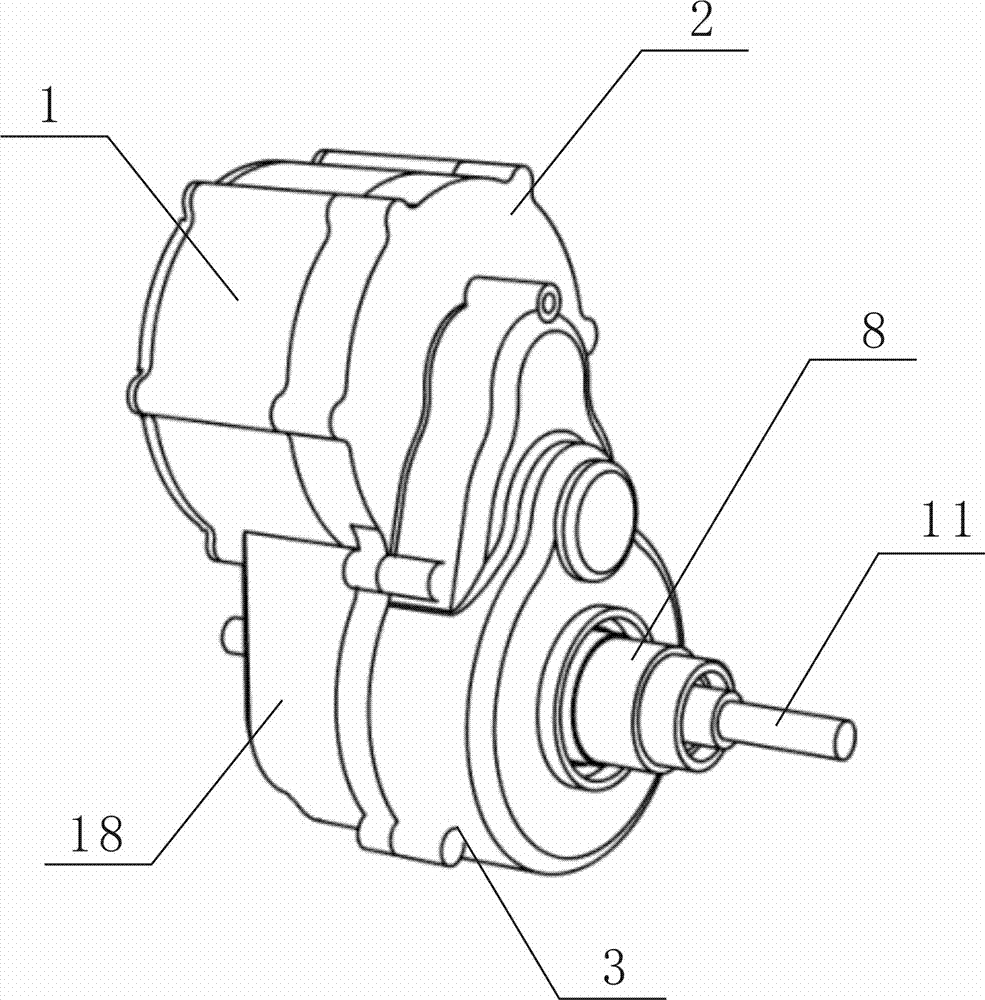

Linear pedaling single-wheel direct drive transmission

ActiveCN106627975ASmooth shiftingCompact structureWheel based transmissionEngineeringElectrical and Electronics engineering

The invention discloses a linear pedaling single-wheel direct drive transmission which comprises a center shaft, an input wheel, a wheel hub, two sets of planetary transmissions and two sets of automatic centrifugal gear-shifting mechanisms, wherein the planetary transmissions comprise a first planetary transmission and a second planetary transmission; the first planetary transmission comprises a first planet carrier, a first planet wheel, a first gear ring and a first center wheel; the second planetary transmission comprises a second planet carrier, a second planet wheel, a second gear ring and a second center wheel; the center shaft is fixedly connected with the first gear ring or is simultaneously and fixedly connected with the first planet carrier and the second gear ring; the automatic centrifugal gear-shifting mechanisms comprise a first automatic centrifugal gear-shifting mechanism and a second automatic centrifugal gear-shifting mechanism; the first automatic centrifugal gear-shifting mechanism is arranged between the wheel hub and a second assembling unit; the second automatic centrifugal gear-shifting mechanism is arranged between the wheel hub and the first gear ring. According to the transmission disclosed by the invention, the requirement on the pedaling frequency can be reduced at a high gear.

Owner:ZHANGJIAGANG CHUANJUN VEHICLE IND CO LTD

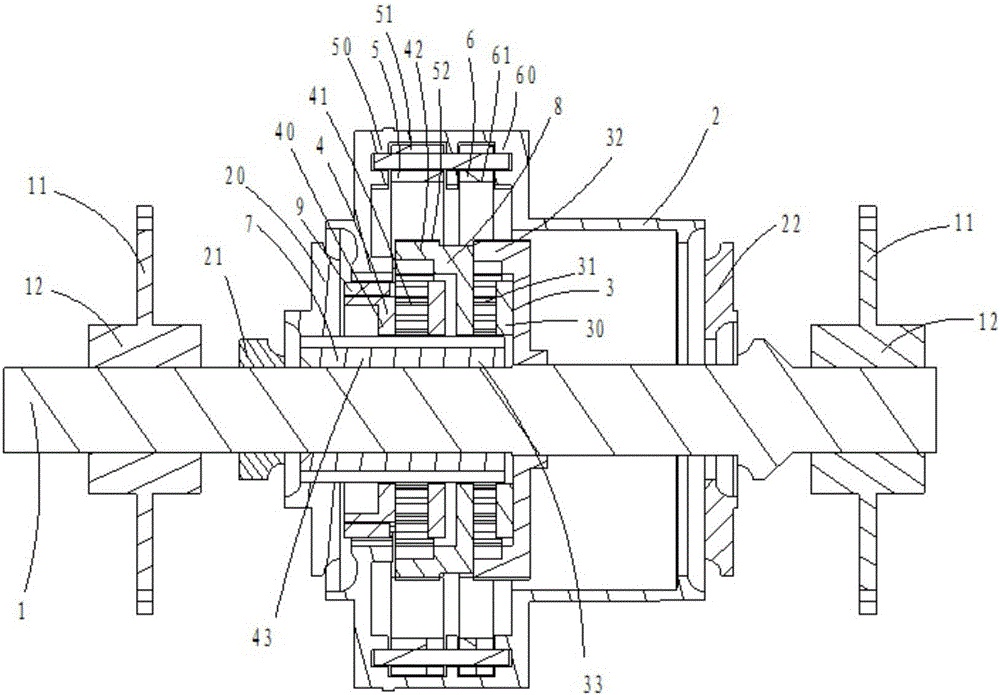

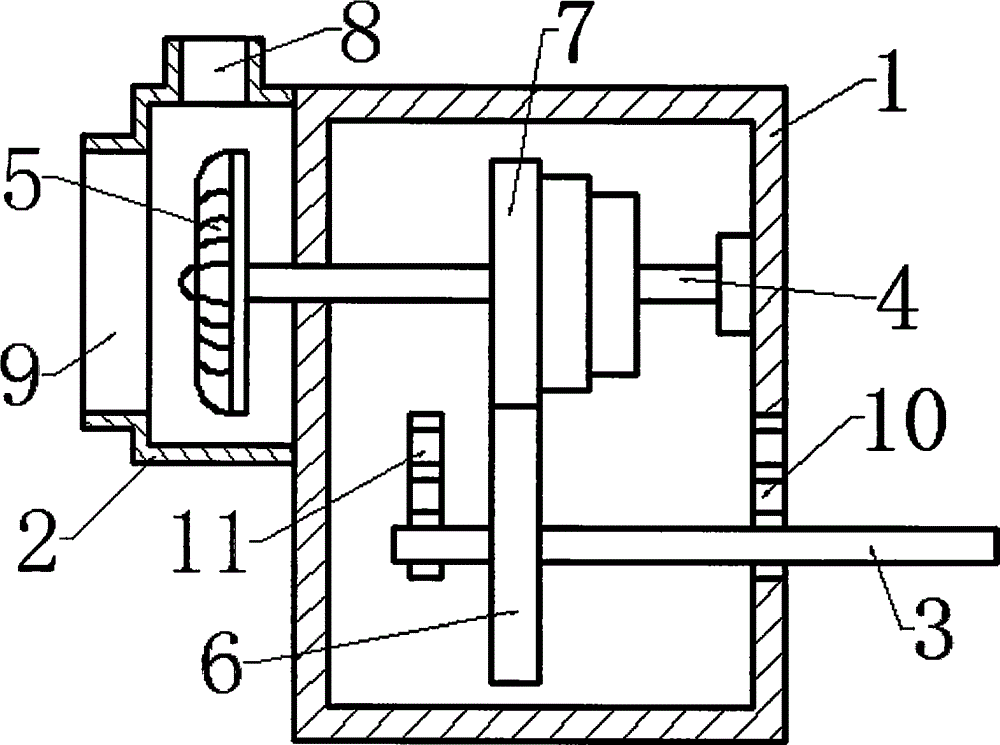

Drive device of electric motor car

InactiveCN102826191ACompact structureEasy to installWheel based transmissionToothed gearingsLow speedEngineering

The invention discloses a drive device of an electric motor car. The drive device comprises a shell, a motor, a speed change mechanism and a gear-shifting self-holding electromagnet, wherein the speed change mechanism comprises an output shaft sleeve, a high-speed driven gear and a low-speed driven gear are sleeved on the output shaft sleeve, and mutually matched ratchet mechanisms are arranged between the output shaft and the high-speed driven gear and between the output shaft sleeve and the low-speed driven gear. The drive device also comprises a wheel axle, wherein the output shaft sleeve is sleeved on the wheel axle through a bearing, a gear-shifting shaft sleeve capable of moving along the axial direction is sleeved on the wheel axle, the gear-shifting shaft sleeve is matched with the ratchet wheel mechanism by moving the gear shifting shaft sleeve, thus switching between high speed and low speed can be realized. The drive device provided by the invention has the advantages of high gear shifting speed, accuracy and reliability, convenience for maintenance, capability of automatically carrying out power upgrading, low cost, and capability of increasing bearing capacity of the electric motor car.

Owner:CHONGQING CHENGMOU TECH CO LTD

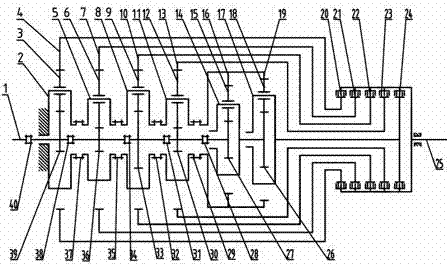

Transmission, power drive system and vehicle

ActiveCN110657203ASimple structureEasy maintenanceElectric propulsion mountingToothed gearingsGear wheelControl theory

The invention discloses a transmission, a power drive system and a vehicle. The transmission comprises a first planetary gear mechanism, a second planetary gear mechanism, an input shaft, an intermediate shaft, a first synchronizer and a second synchronizer. A second planetary carrier of the second planetary gear mechanism is connected with the output end of the transmission. The input shaft is connected with a first sun gear. A first toothed ring is connected with the intermediate shaft. The intermediate shaft is connected with the second sun gear. The first synchronizer enables the first planetary carrier to be fixed to a shell of the transmission or to be connected with the first sun gear. The second synchronizer enables a second toothed ring to be fixed to the shell of the transmissionor to be connected with the first toothed ring. According to the transmission, by arranging the double-planetary-line double-synchronizer structure, rapid, smooth and reliable gear shifting can be achieved; and the transmission is simple in structure and convenient to maintain.

Owner:BYD CO LTD

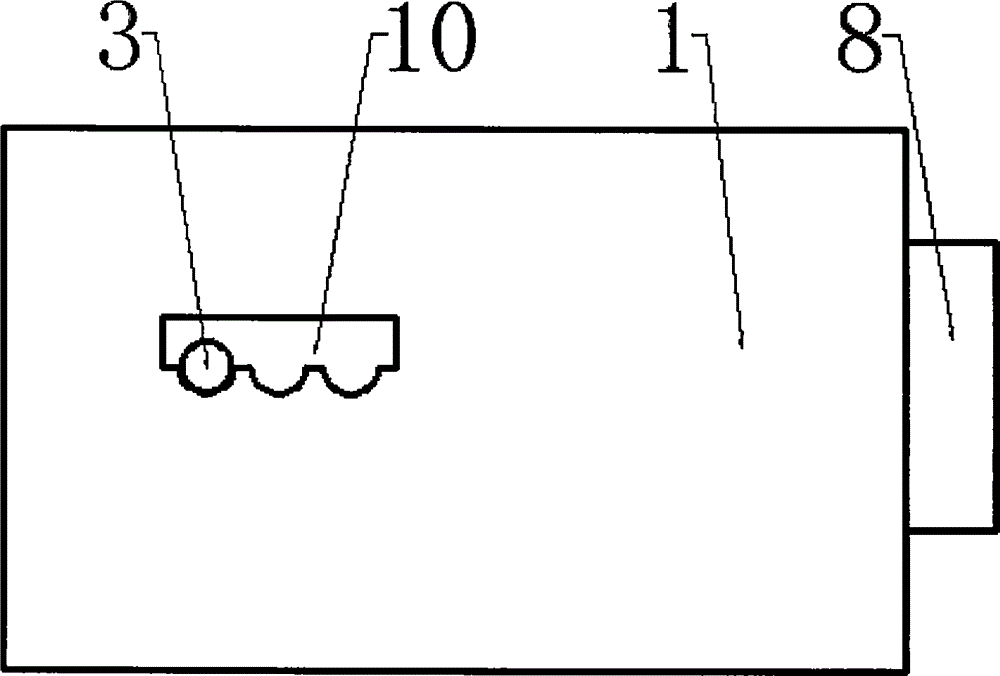

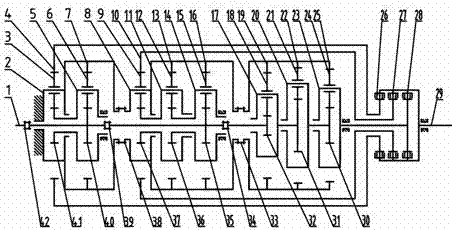

Multi-stage high-speed centrifugal type vapor compressor

InactiveCN105179266AMeet the requirements of multi-stage transmissionTo achieve the purpose of multi-stage gear shiftingToothed gearingsGearing detailsDrive shaftGear wheel

The invention discloses a multi-stage high-speed centrifugal type vapor compressor, and relates to the field of chemical mechanical equipment. According to the multi-stage high-speed centrifugal type vapor compressor, a gear shifting hole is formed in the side surface of a box body of a gearbox; a gear-shifting supporting frame is arranged on a position, corresponding to the gear shifting hole, in the gearbox; a drive shaft is arranged between the gear shifting hole and the gear-shifting supporting frame; a drive gear is fixed on the drive shaft; a driven shaft is further fixed in the gearbox; a driven multi-stage gear is fixed on the driven shaft; the driven multi-stage gear is mutually engaged with the drive gear; and the drive shaft is manually shifted between the gear shifting hole and each semicircular hole corresponding to the gear-shifting supporting frame to achieve the multi-stage gear-shifting transmission purpose. The multi-stage high-speed centrifugal type vapor compressor is convenient in operation, reliable in gear shifting, and can meet multi-stage transmission requirements of the vapor compressor.

Owner:成浩

Coaxial line planetary transmission gear ring output multi-gear speed change mechanism

InactiveCN107143623ASimple shiftingReliable shiftingToothed gearingsCoaxial lineMechanical engineering

The invention provides a coaxial line planetary transmission gear ring output multi-gear speed change mechanism. The gearshift mechanism can adopt a planetary mechanism to realize gearshift in one direction, that is the gearshift mechanism is only provided with a forward gear, in addition, the gearshift mechanism can realize gearshift in two directions as needed, that is the gearshift mechanism is provided with both a forward gear and a reverse gear; the coaxial line planetary transmission gear ring output multi-gear speed change mechanism is provided with an input end and an output end; an input shaft inputs power; the final gear can be gear ring output and planet carrier output, and other gears are gear ring output; the rotating speed of the output end is low, so that compared with an input end gearshift mechanism, the output end gearshift mechanism is easier and more reliable in gearshift and higher in efficiency; and compared with a parallel-axis gearshift mechanism, the gearshift mechanism has the advantages of being small in occupied area, large in transmission ratio range, high in bearing capacity and capable of realizing speed change with a high speed ratio.

Owner:TAISHAN MEDICAL UNIV

Transmission, power driving system and vehicle

ActiveCN110657201ASimple structureEasy maintenanceToothed gearingsTransmission elementsGear wheelEngineering

The invention discloses a transmission, a power driving system and a vehicle. The transmission comprises a first planetary gear mechanism, a second planetary gear mechanism, an input shaft, a middle shaft, a first synchronizer and a second synchronizer. The first planetary gear mechanism comprises a first sun gear, a first planet gear, a first planet carrier and a first gear ring; the second planetary gear mechanism comprises a second sun gear, a second planet gear, a second planet carrier and a second gear ring; the second gear ring is connected with the output end of the transmission, the first synchronizer makes the first gear ring fixed with a shell of the transmission or the first gear ring connected with the first sun gear, and the second synchronizer makes the second planet carrierfixed with the shell of the transmission or the second planet carrier connected with second sun gear. According to the transmission, through the arrangement of a double-planet-row double-synchronizerstructure, gear shifting can be achieved quickly, smoothly and reliably, and the transmission is simple in structure and convenient to maintain.

Owner:BYD CO LTD

Transmission, power driving system and vehicle

ActiveCN110657206ASimple structureEasy maintenanceToothed gearingsGearing controlGear wheelControl theory

The invention discloses a transmission, a power driving system and a vehicle. The transmission comprises three planetary gear mechanisms, an input shaft, a first middle shaft, a second middle shaft, afirst synchronizer and a second synchronizer. A first gear ring of the first planetary gear mechanism is fixedly connected with a shell of the transmission, a second planet carrier of the second planetary gear mechanism is connected with the output end of the transmission, a third gear ring of the third planetary gear mechanism is fixedly connected with a shell of the transmission, a third planetcarrier of the third planetary gear mechanism is connected with a second gear ring, the first synchronizer enables the first middle shaft and a first planet carrier to be connected or enables the first middle shaft and a first sun gear to be connected, and the second synchronizer enables the first middle shaft and a second sun gear to be connected or enables the first middle shaft and the secondplanet carrier to be connected. According to the transmission, through the structure of three planetary lines and dual synchronizers, rapid, smooth and reliable gear shifting can be achieved, and thetransmission is simple in structure and convenient to maintain.

Owner:BYD CO LTD

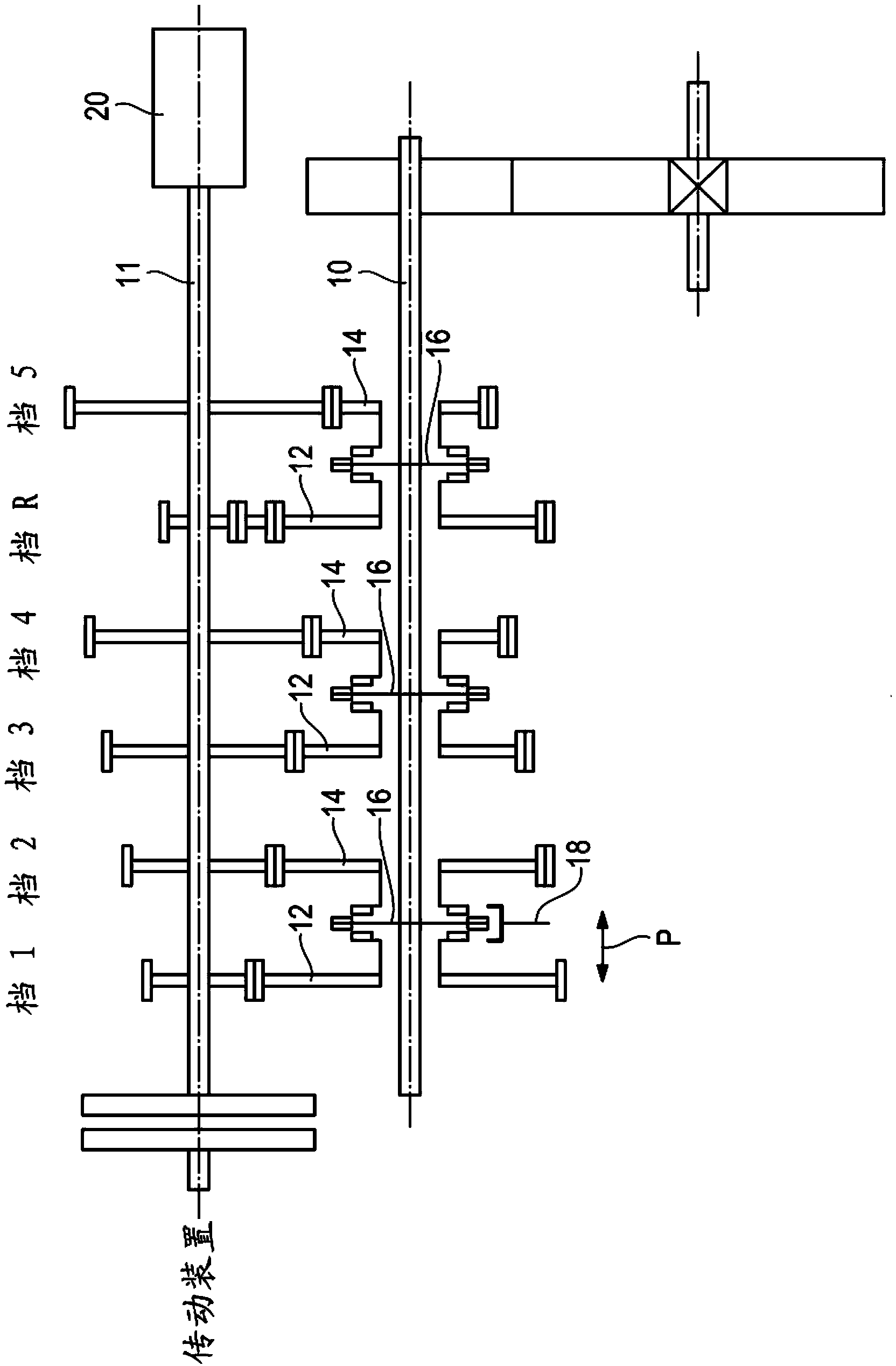

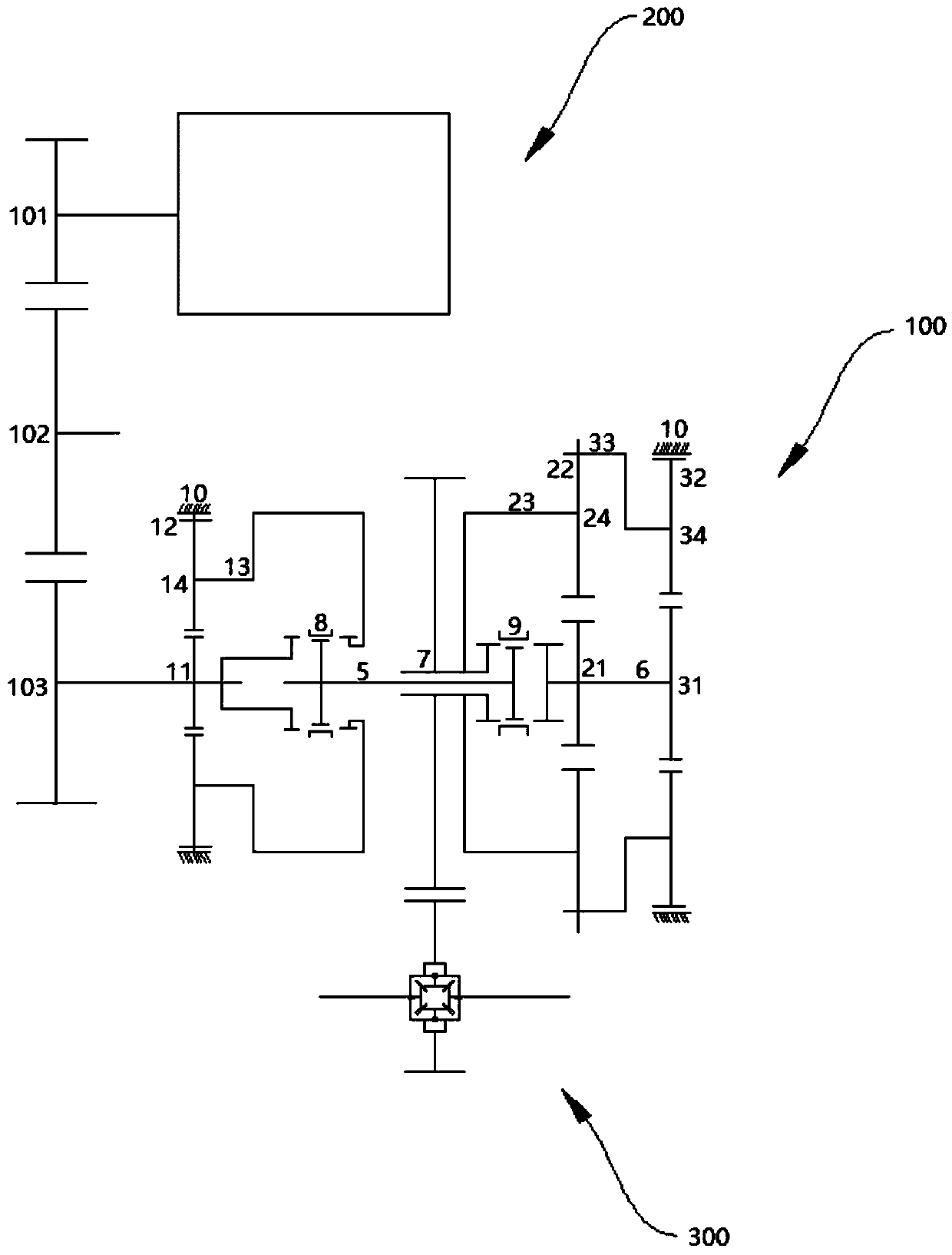

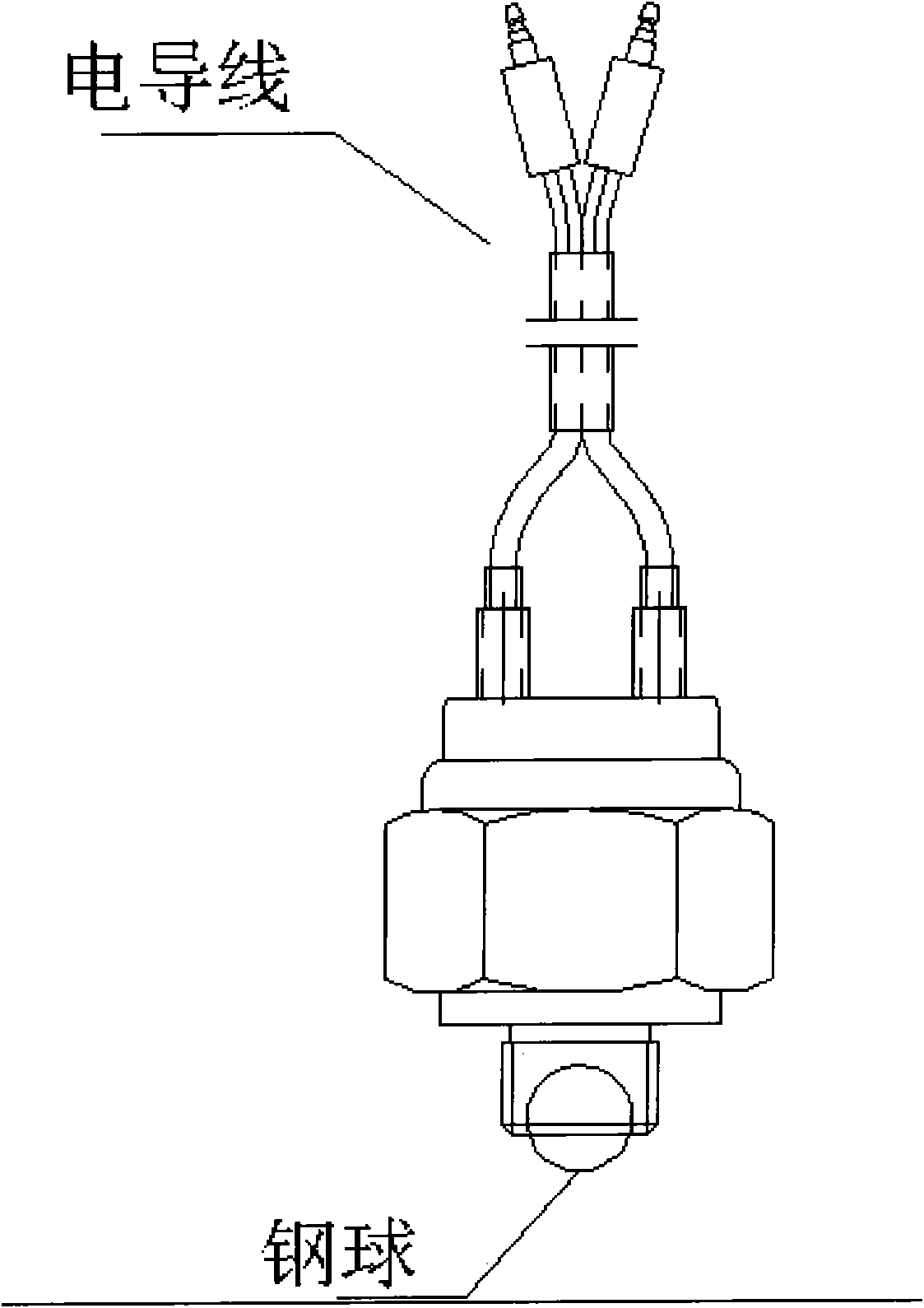

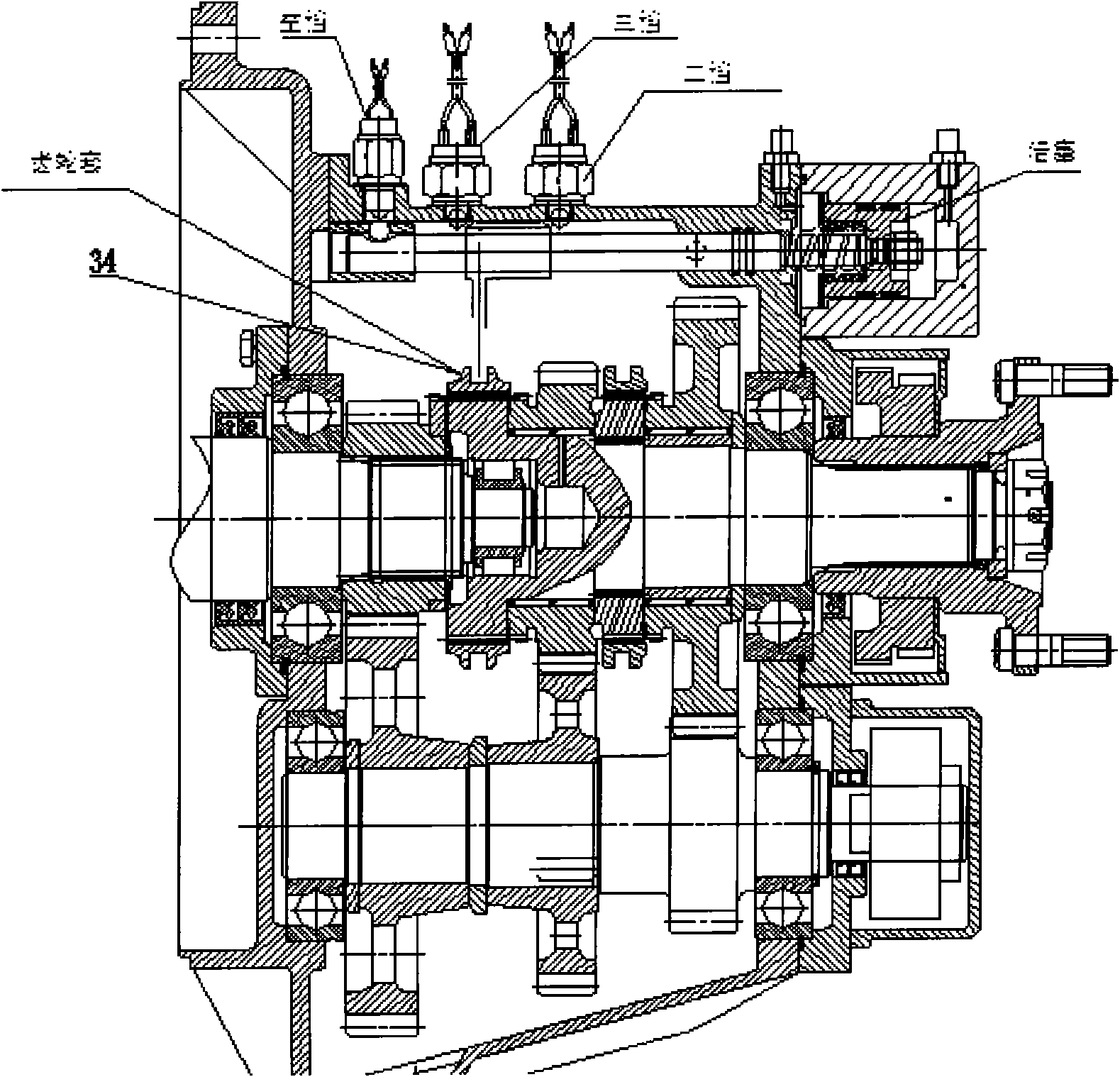

Electric-drive mechanical type variable-speed power transmission system and control system thereof

The invention discloses an electric-drive mechanical type variable-speed power transmission system for electric vehicles, which comprises a vehicle motor (2) and a speed-changing gearbox (1), wherein the speed-changing gearbox (1) comprises a power input shaft (27), a power output shaft (28), an intermediate shaft (29), gears (35, 36, 37, 38, 39 and 40) and an air cylinder (30), the air cylinder (30) is connected with a shifting fork through a piston (31), the shifting fork is correspondingly connected with the gears, and the output shaft (27) of the vehicle motor (27) and the input shaft (27) of the speed-changing gearbox share the same shaft. The speed-changing gearbox is provided with a gear shifting interlocking device formed by an ejector rod (53), positioning steel balls (51 and 52) on two sides of the ejector rod (53), and the shifting fork; and the shifting fork is provided with a positioning groove matched with the positioning steel balls. Due to the function of the gear shifting interlocking device, the phenomena of gear disorder, gear misoperation and gear striking generated by the traditional speed-changing gearbox without a synchronizer during speed changing can be avoided, and gear shifting is smooth and more reliable.

Owner:襄阳宇清电驱动科技有限公司

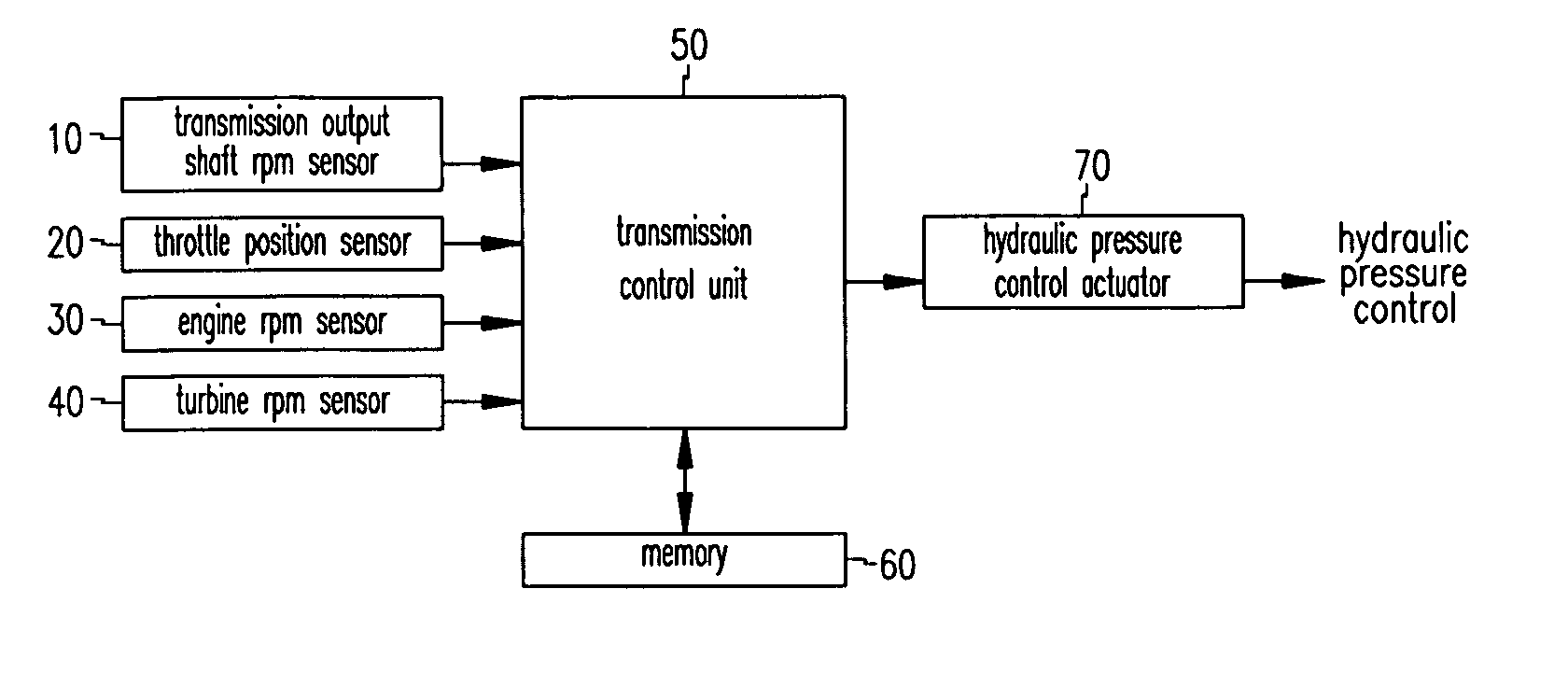

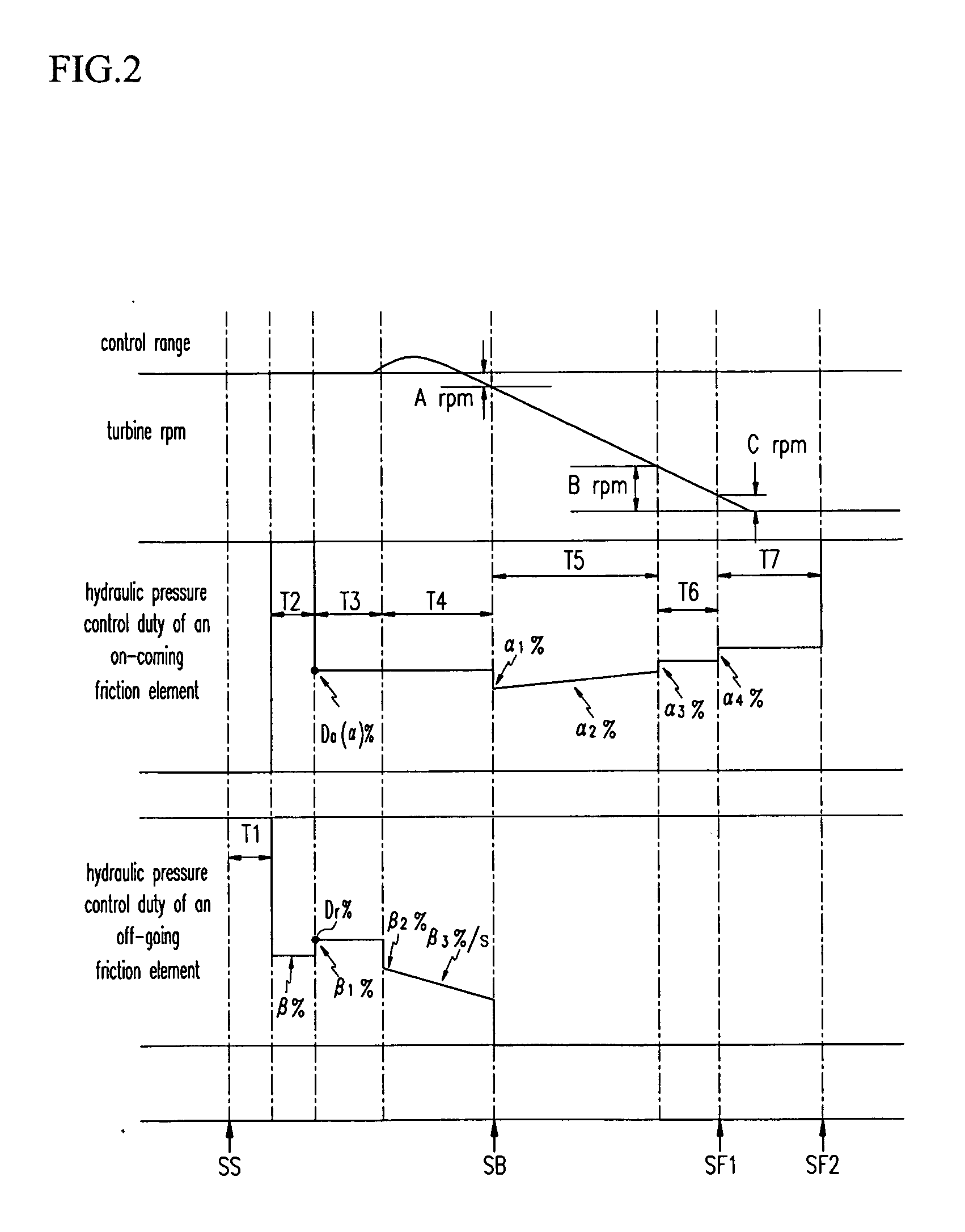

Upshift control system of automatic transmission and method thereof

InactiveUS20050125130A1Reliable shift controlReliable shiftingDigital data processing detailsGearing controlAutomatic transmissionControl system

A power-on 2-3 upshift control method for an automatic transmission comprises: determining whether a power-on 2-3 upshift condition exists; extracting an initial hydraulic pressure control duty and hydraulic pressure control duty depending on an input torque from a map table for an on-coming friction element and an off-going friction element, if it is determined that the power-on 2-3 upshift condition exists, and performing a shift control for the upshift; and completely releasing a hydraulic pressure of the off-going friction element at a point at which a hydraulic pressure for the on-coming friction element is capable of tolerating a turbine torque.

Owner:HYUNDAI MOTOR CO LTD

Running control system for vehicle

InactiveUS7965224B2High outputReliable shiftingVehicle fittingsSpeed/accelaration controlRadarControl system

A running control system having a radar device that detects a distance between a subject vehicle and a preceding vehicle. When a vehicle speed sensor detects the subject vehicle has stopped, a transmission output controller sets a transmission output of the radar device to a stopping time transmission output lower than a running time transmission output. When the radar device detects an increase in the distance between the subject vehicle and the preceding vehicle while the subject vehicle is stopped, or when the distance between the subject vehicle and the preceding vehicle detected by the radar device while the subject vehicle has stopped is longer than a predetermined value, a notifying device notifies an occupant of the subject vehicle that following running control is possible.

Owner:HONDA MOTOR CO LTD

Bicycle speed variator and variable speed bicycle

InactiveCN1673026ANot easy to drop the chainReliable shiftingChain/belt transmissionBicyclesVariatorFlywheel

The bicycle speed variator includes front chain wheel installed via a bearing on pedal rocking arm, back flywheel on the back wheel and with two back chain wheels, double chain, front flywheel coaxial with the front chain wheel, push block fixed onto the front chain wheel, swinging stopper hinged to inside of the pedal rocking arm, and spring compressed between the pedal rocking arm and the swinging stopper. The swinging stopper under the control of the spring has two stable work positions; the push block has one bevel and moving track crossing with that of the swinging stopper in one of its stable work positions. When the middle shaft rotates reverse, the swinging stopper under the action of centrifugal force or push block pressure can convert between two stable work positions. The present invention also discloses the variable speed bicycle with the speed variator.

Owner:徐守则

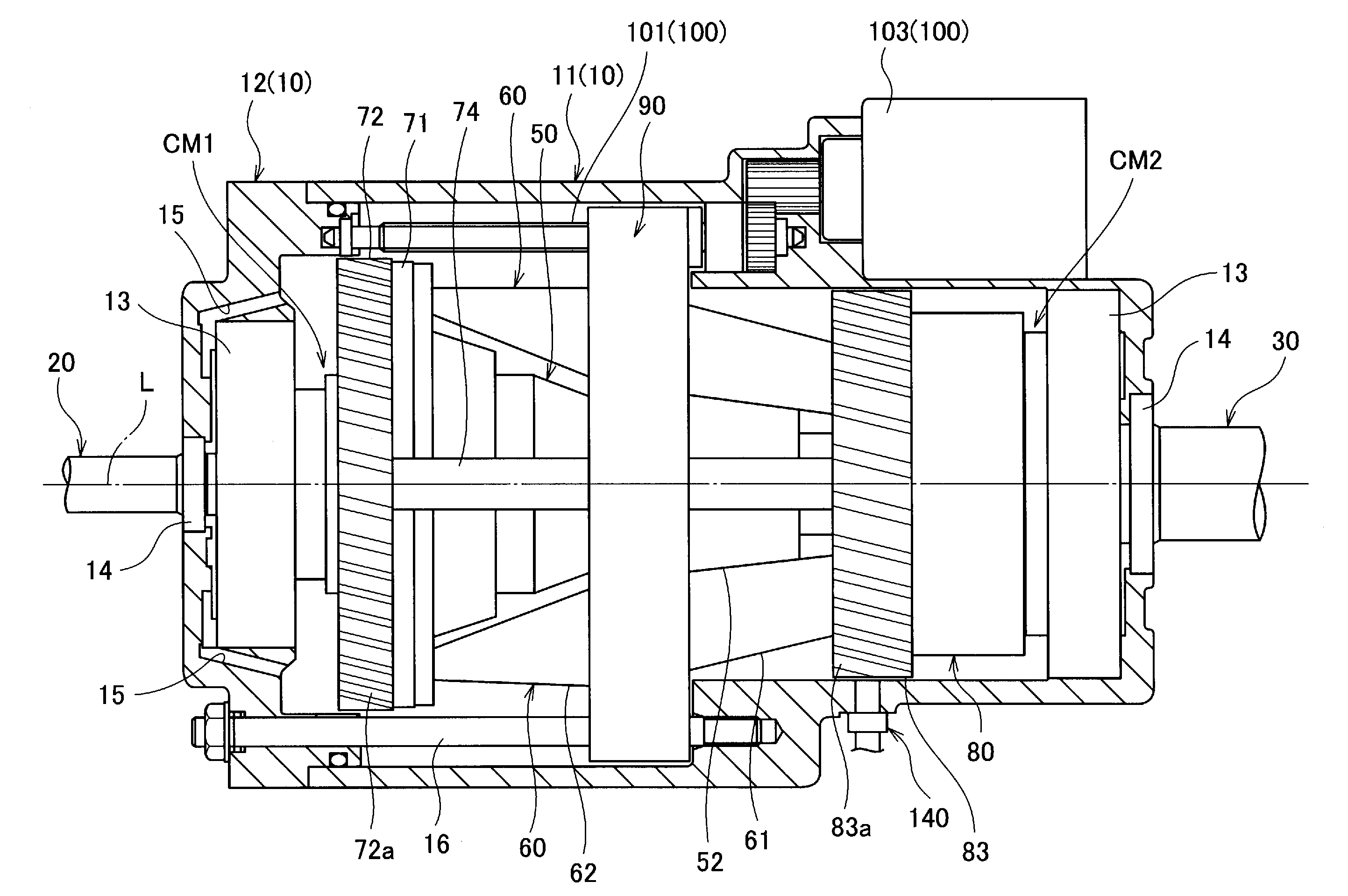

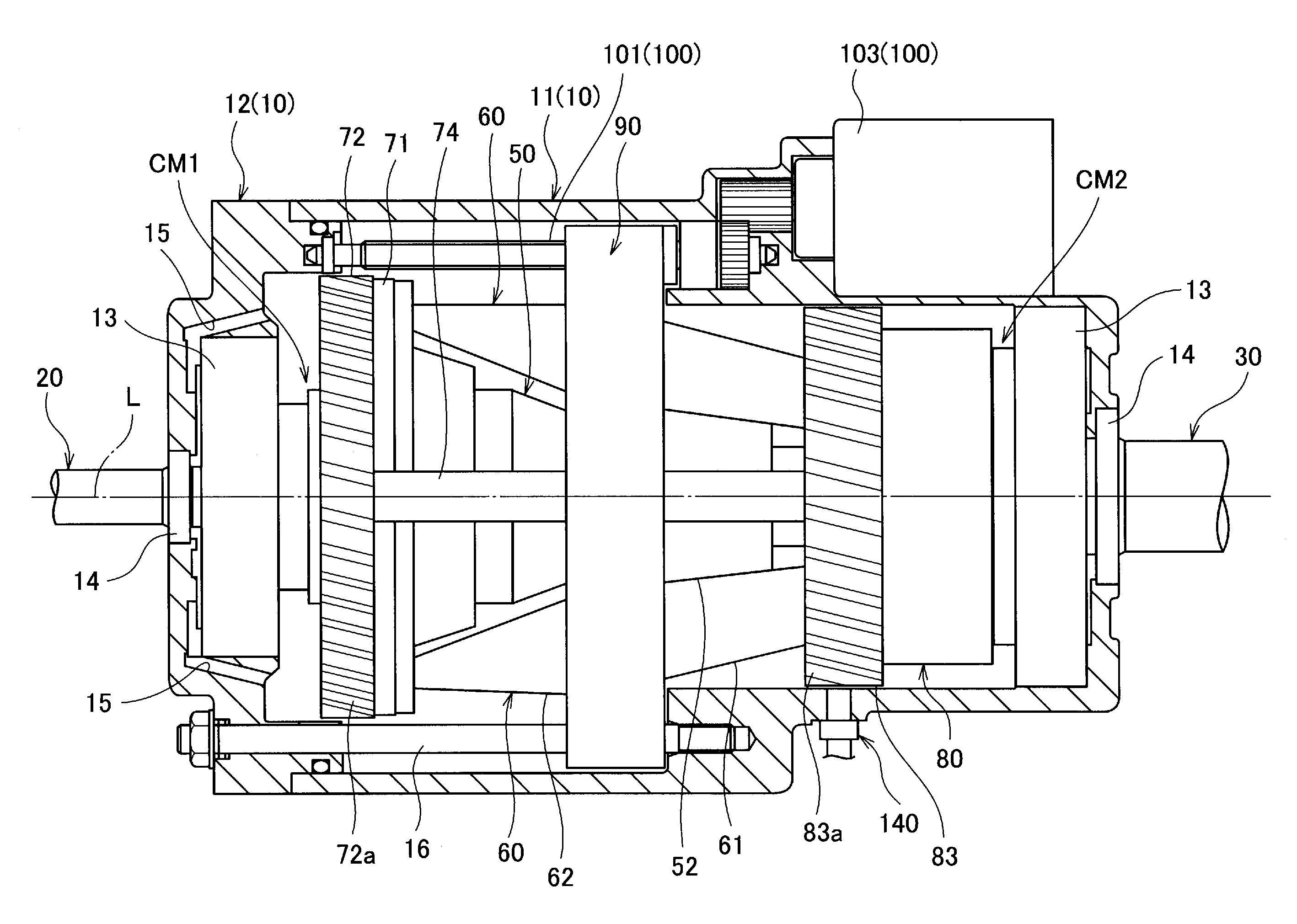

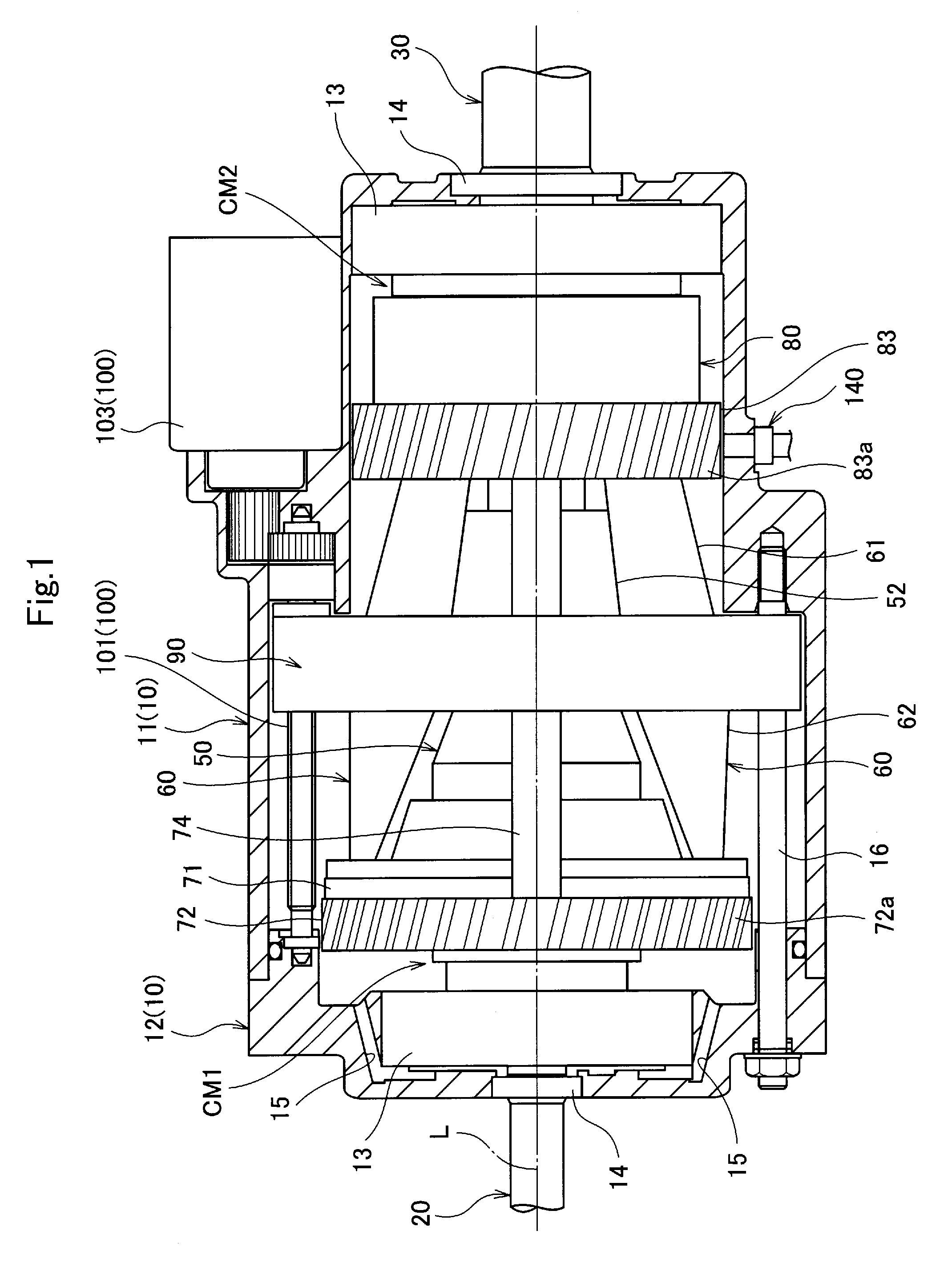

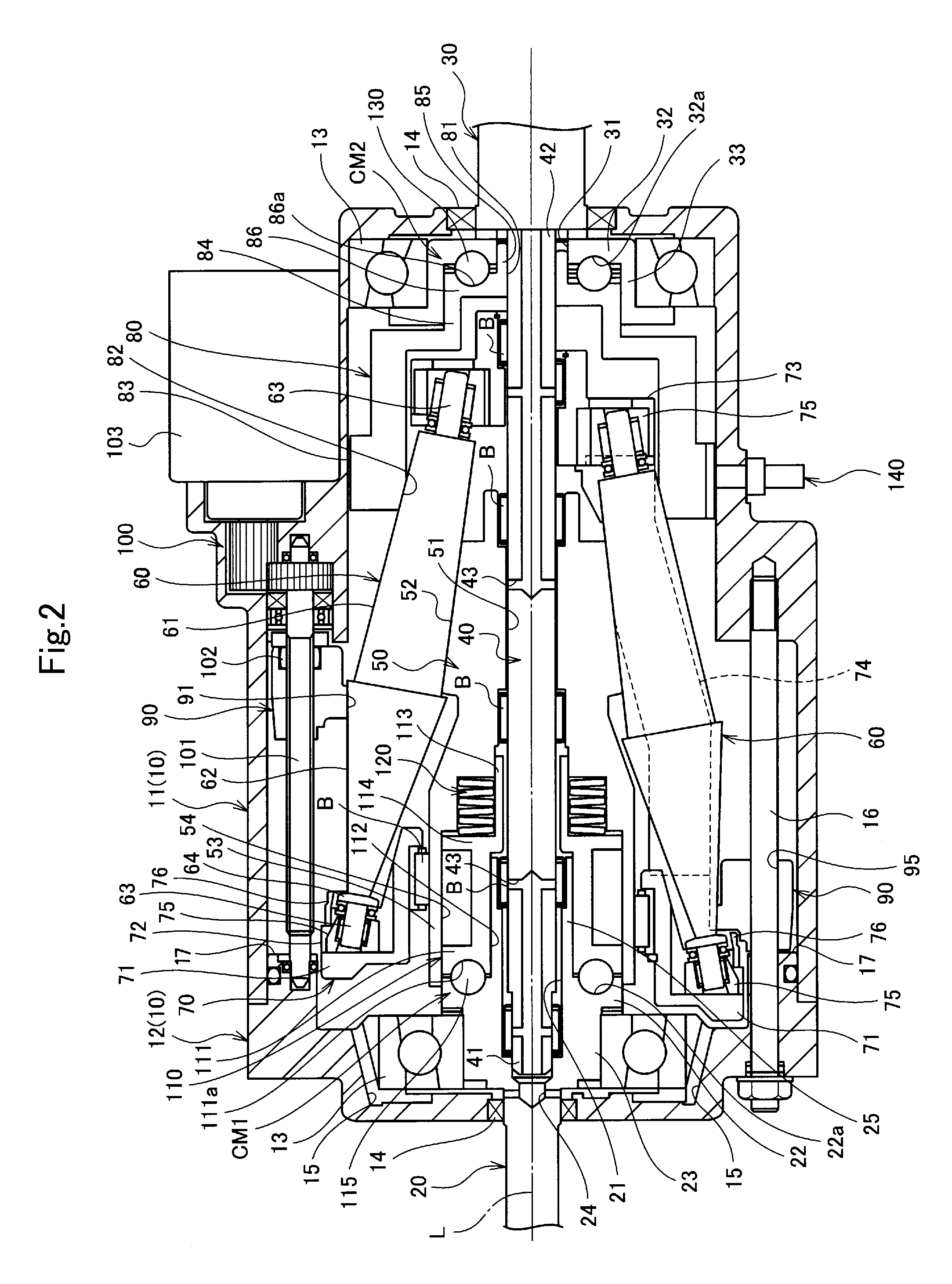

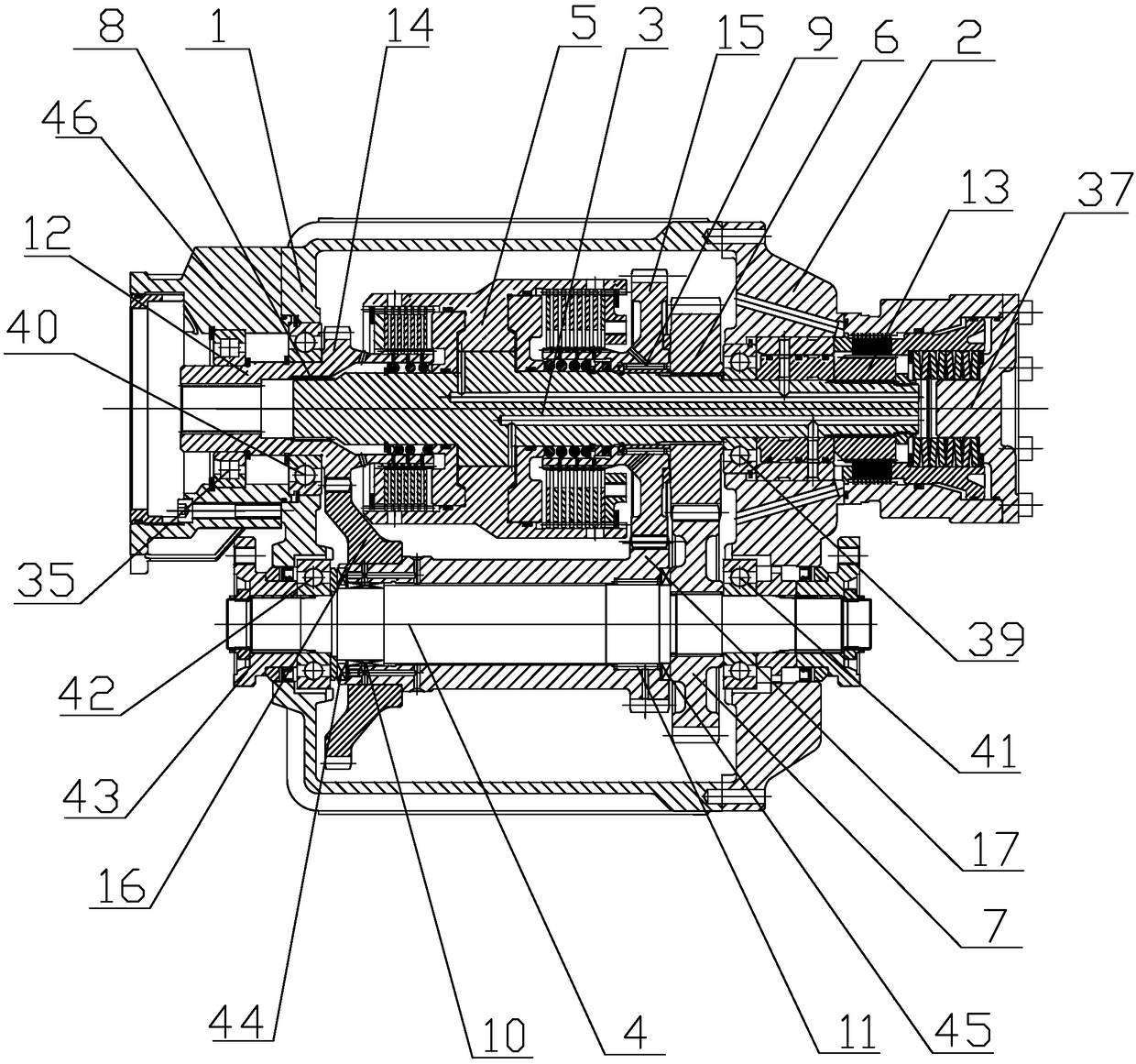

Continuously variable transmission device

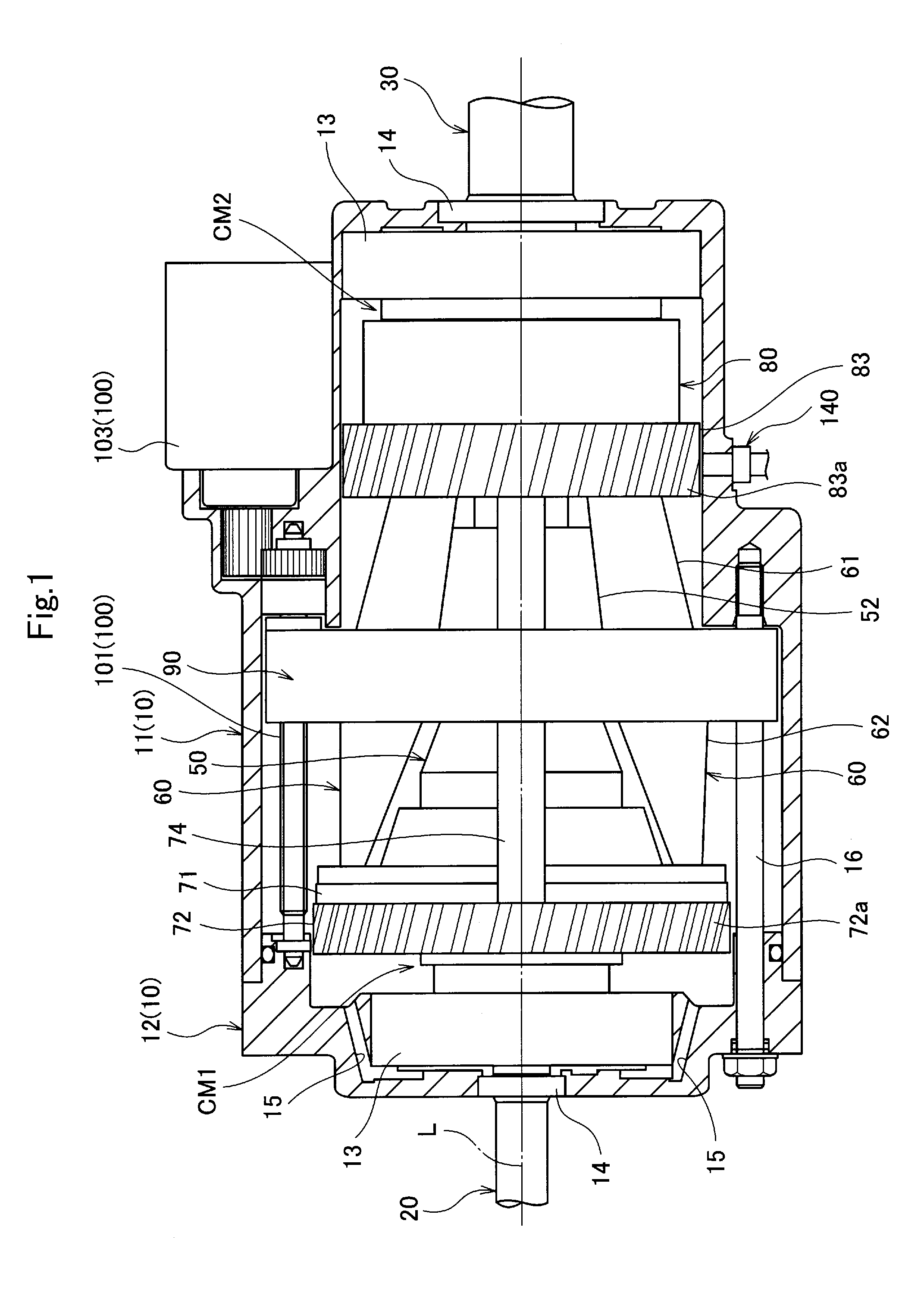

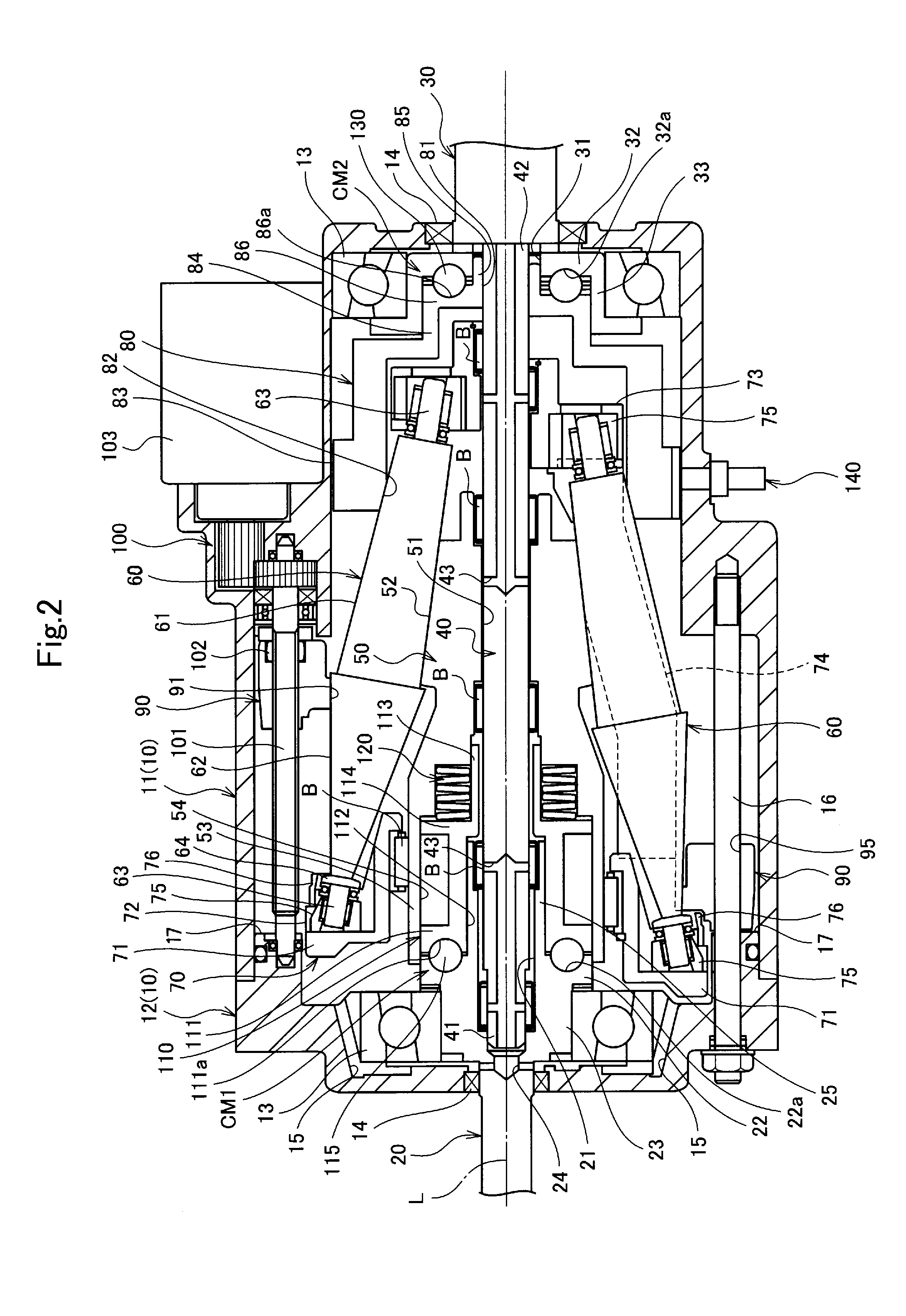

A continuously variable transmission device includes an input shaft, an output shaft, an input roller, an output ring, a transmission ring, a plurality of planetary rollers including a first conical portion externally contacted to the input roller and internally contacted to the output ring and a second conical portion internally contacted to the transmission ring, a movable holder which holds the plurality of planetary rollers to be capable of rotating about each rotating axis line and revolving about the center axis line, and a loading cam mechanism (CM1, CM2) which generates a thrust load. The input roller, the output ring, and the transmission ring are formed so that each face being contacted to the planetary roller is formed to have a convex curved face. The planetary rollers are supported by the movable holder so that an inclination angle of a rotation axis line against the center axis line is variable.

Owner:MIKUNI CORP

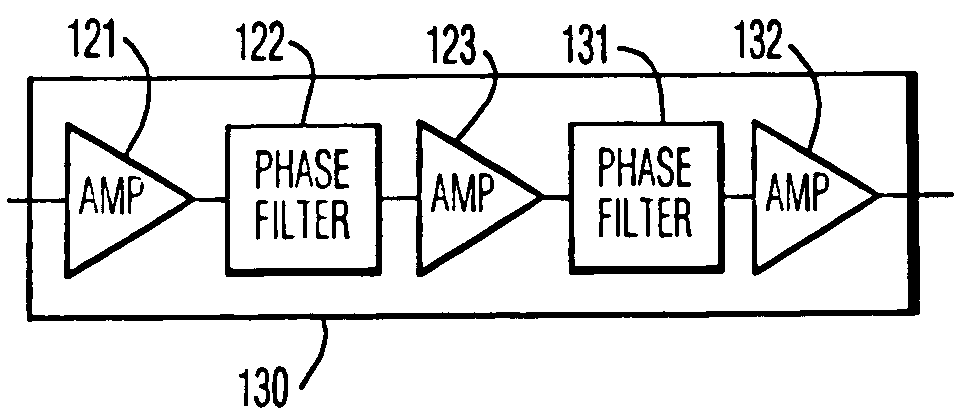

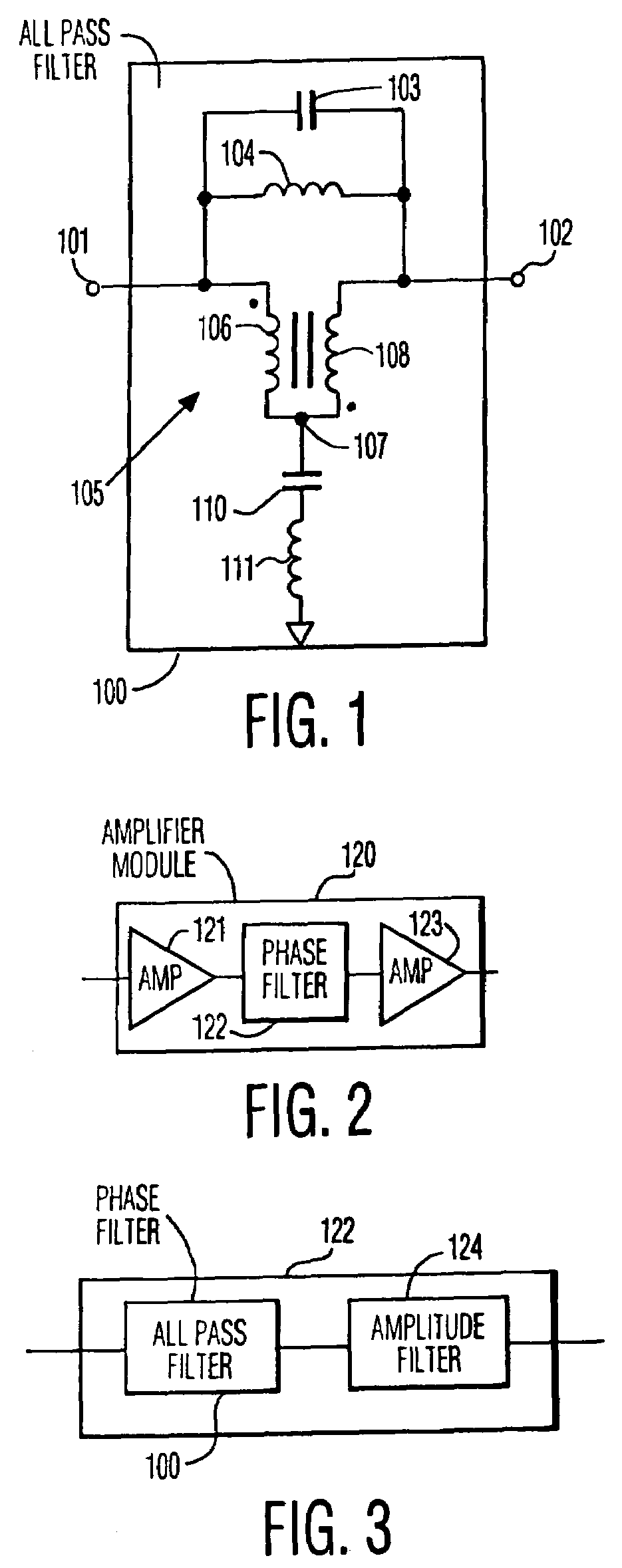

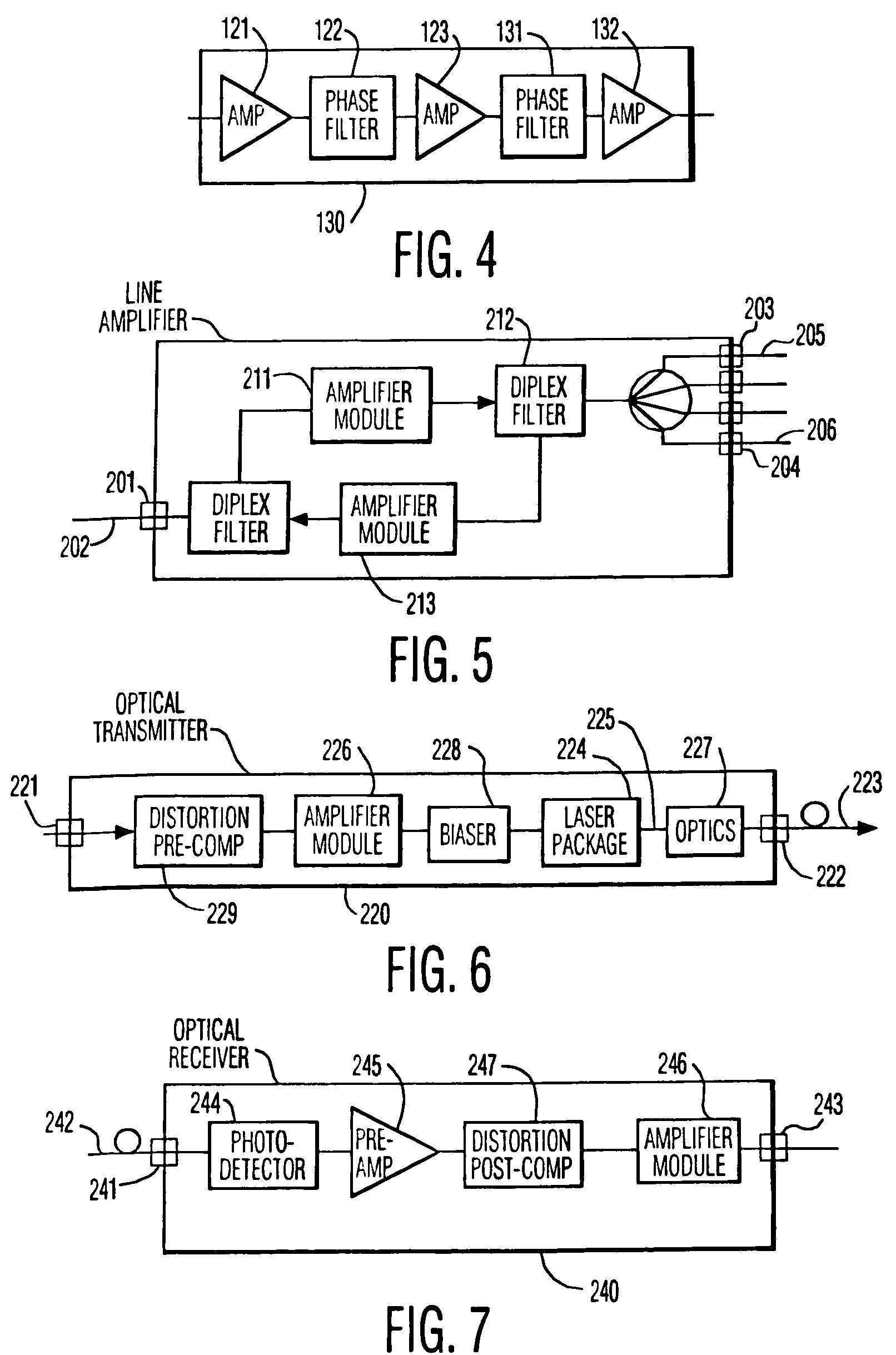

Amplifier composite triple beat (CTB) reduction by phase filtering

InactiveUS7474150B2Reduces accumulated amplitudeReduce distortion problemsAmplifier modifications to reduce non-linear distortionMultiple-port networksAudio power amplifierPhase filter

In a broadband communication system there are multi-stage power amplifier systems for amplifying the power of radio-frequency (RF) communication signals. Each stage of the amplifier system results in composite triple beat (CTB) distortion, and if the phase of the CTB distortions are approximately the same (i.e. are in-phase), then the amplitudes of the distortions are added (i.e. “20 dB” rule). The amplifier system of the invention includes one or more phase filters positioned in series between the power amplifier stages. The phase filters are adapted to shift the phase of the communication signals, so that the phase of CTB distortions, resulting from the amplification of the communication signals in the amplifier stages between the phase filters, are substantially different (i.e. are out-of-phase). Thus, only the power of the CTB distortions are added (i.e. “10 dB” rule).

Owner:ARRIS ENTERPRISES LLC

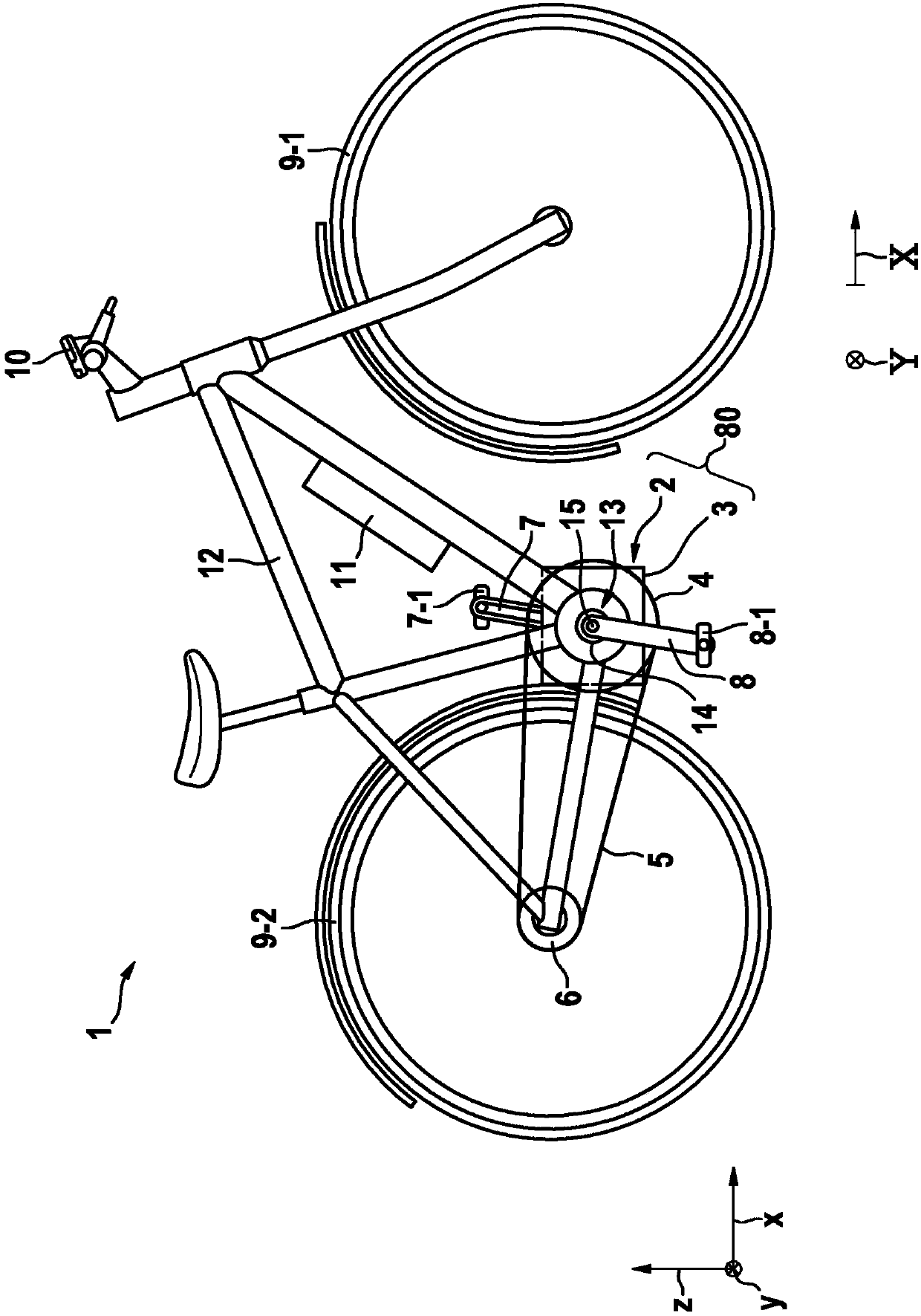

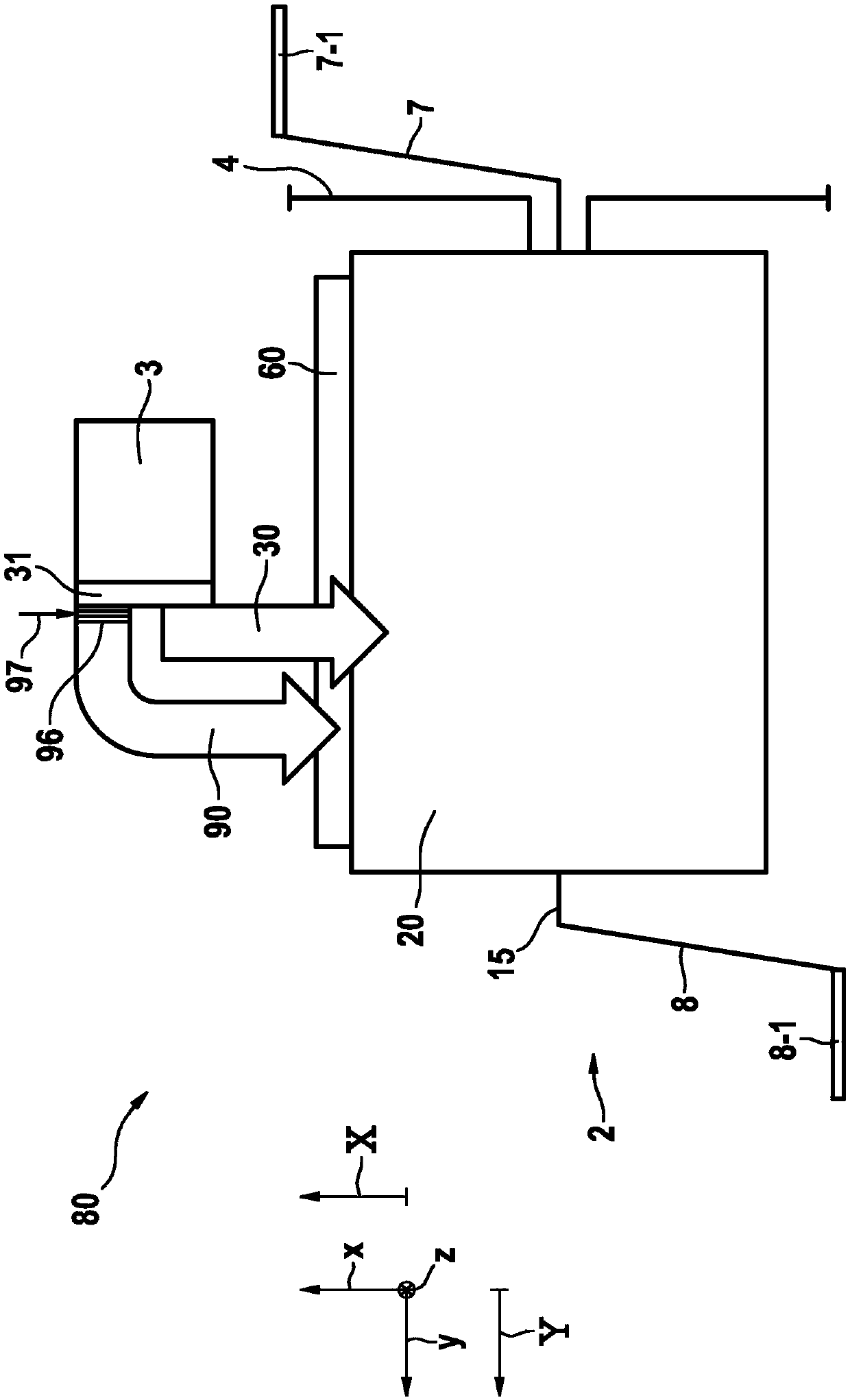

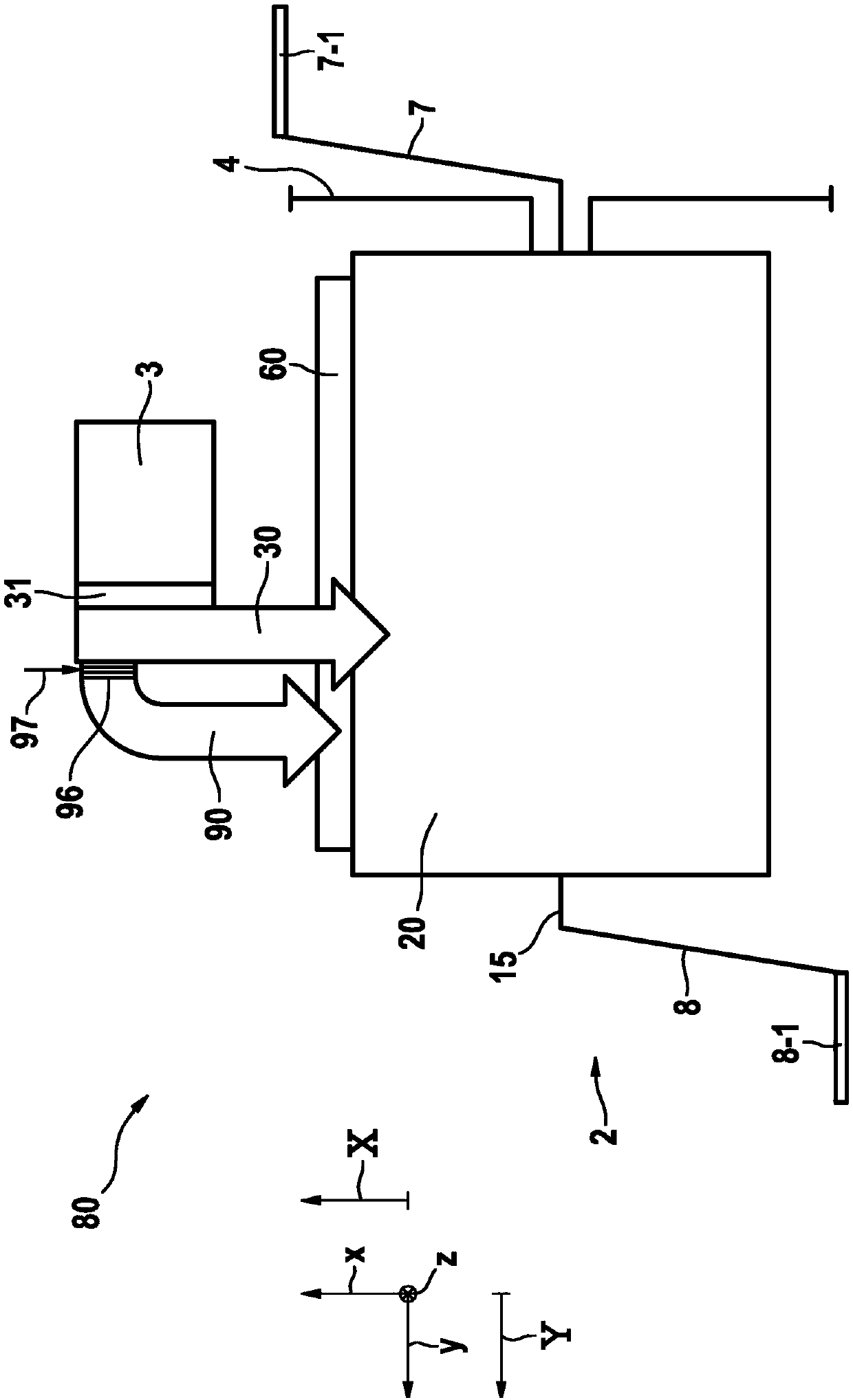

Drive assembly and vehicle

ActiveCN109689491AChange gear ratioReduce necessityWheel based transmissionRider propulsionDrive wheelElectric drive

The present invention provides a drive assembly (80) for a vehicle (1) which can be driven with engine power and in particular additionally with muscle power, an electric bicycle, eBike or pedelec, the drive assembly has an electric drive (3) for generating an engine torque, a crankshaft (15) rotatable around an axis of rotation (Y) for receiving at least the engine torque, a transmission device (20) designed to transmit a torque from the crankshaft (15) to a driven element (4) that can be coupled to a drive wheel (9-2) of the vehicle (1), the transmission device being designed to create a shiftable variable transmission ratio, and an adjusting device (60) which is coupled to the transmission device (20) and via the actuation of which the transmission ratio of the transmission device (20)can be adjusted, wherein the electric drive (3) is designed to actuate the adjusting device (60) and can be coupled to the adjusting device (60), in particular to transmit at least some of the enginetorque.

Owner:ROBERT BOSCH GMBH

Continuously variable transmission device

ActiveUS9353835B2Sufficient forceSufficient transmission torqueGear lubrication/coolingGearing controlCamMechanical engineering

A continuously variable transmission device includes an input shaft, an output shaft, an input roller, an output ring, a transmission ring, a plurality of planetary rollers including a first conical portion externally contacted to the input roller and internally contacted to the output ring and a second conical portion internally contacted to the transmission ring, a movable holder which holds the plurality of planetary rollers to be capable of rotating about each rotating axis line and revolving about the center axis line, and a loading cam mechanism (CM1, CM2) which generates a thrust load. The input roller, the output ring, and the transmission ring are formed so that each face being contacted to the planetary roller is formed to have a convex curved face. The planetary rollers are supported by the movable holder so that an inclination angle of a rotation axis line against the center axis line is variable.

Owner:MIKUNI CORP

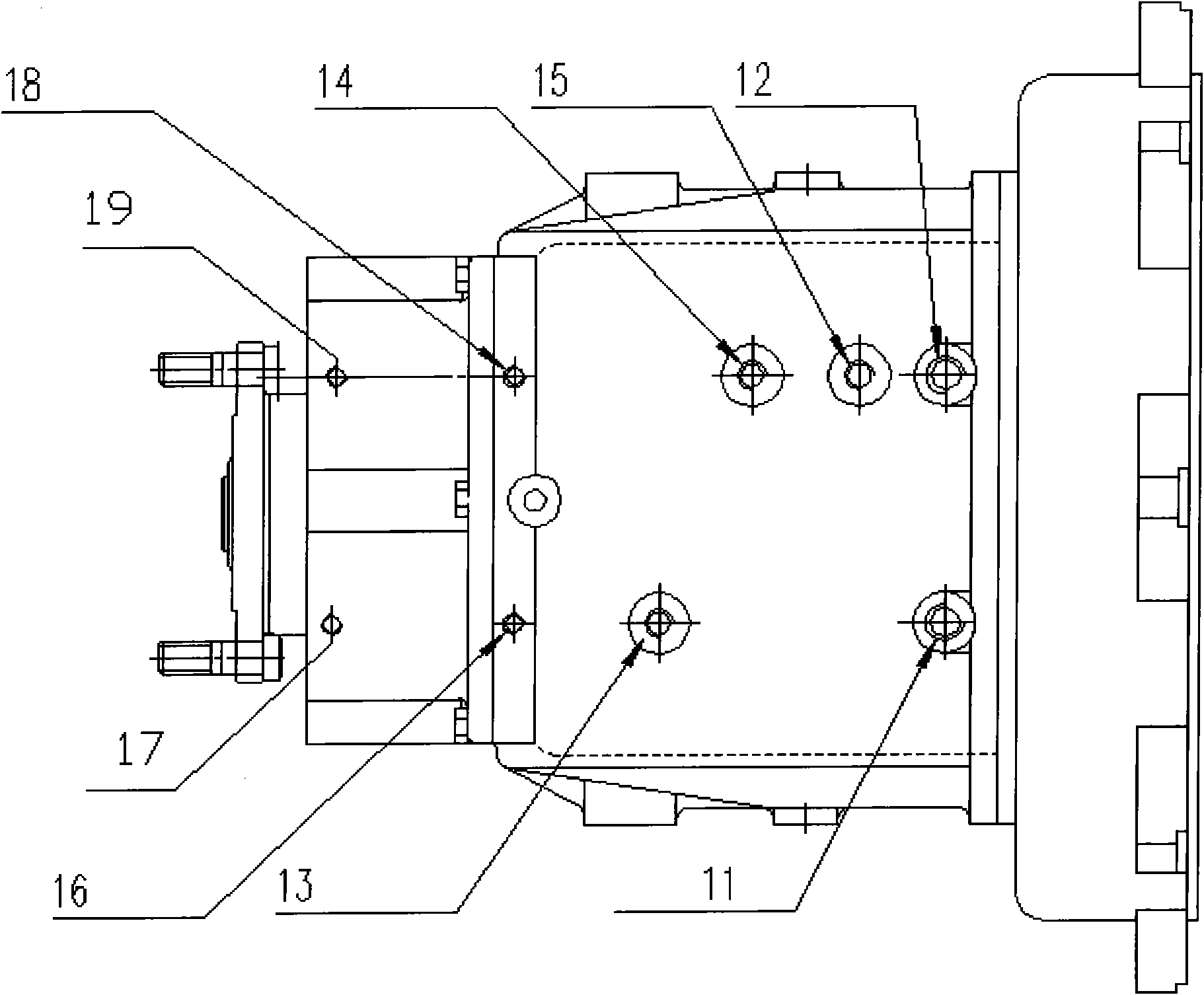

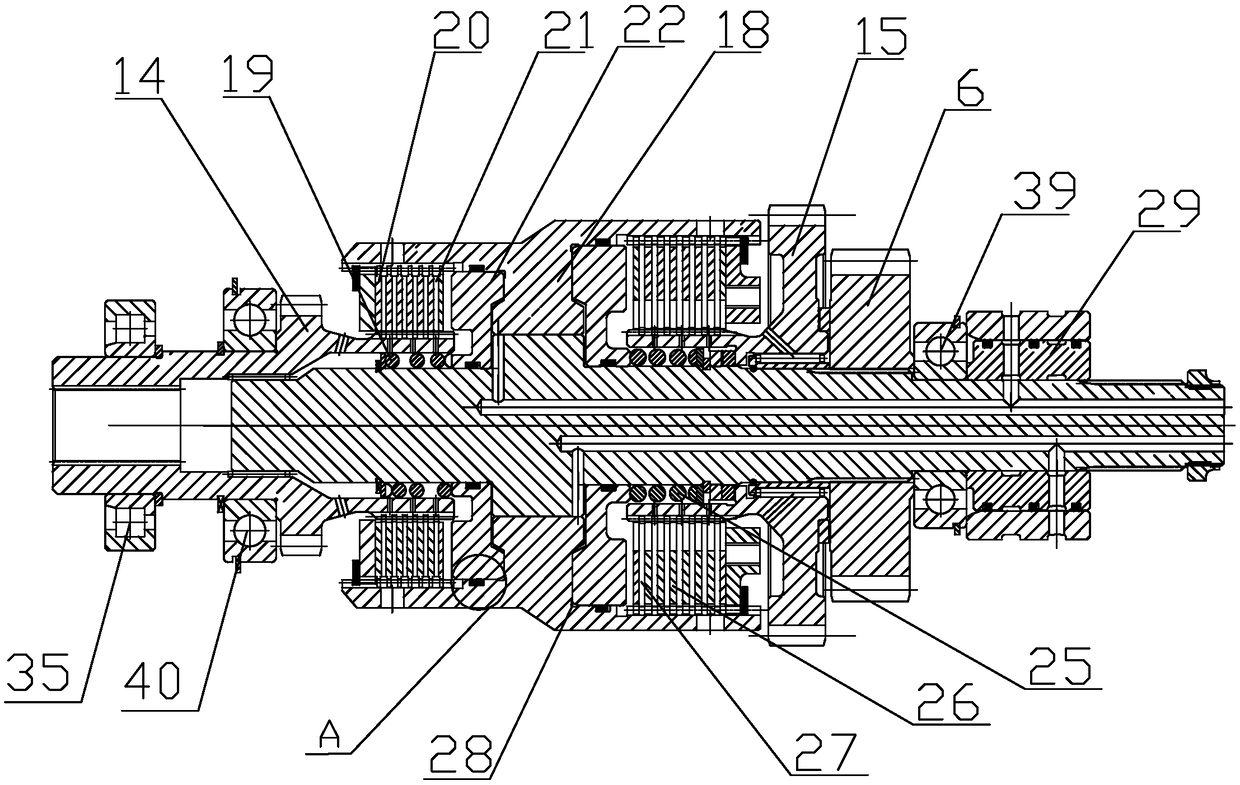

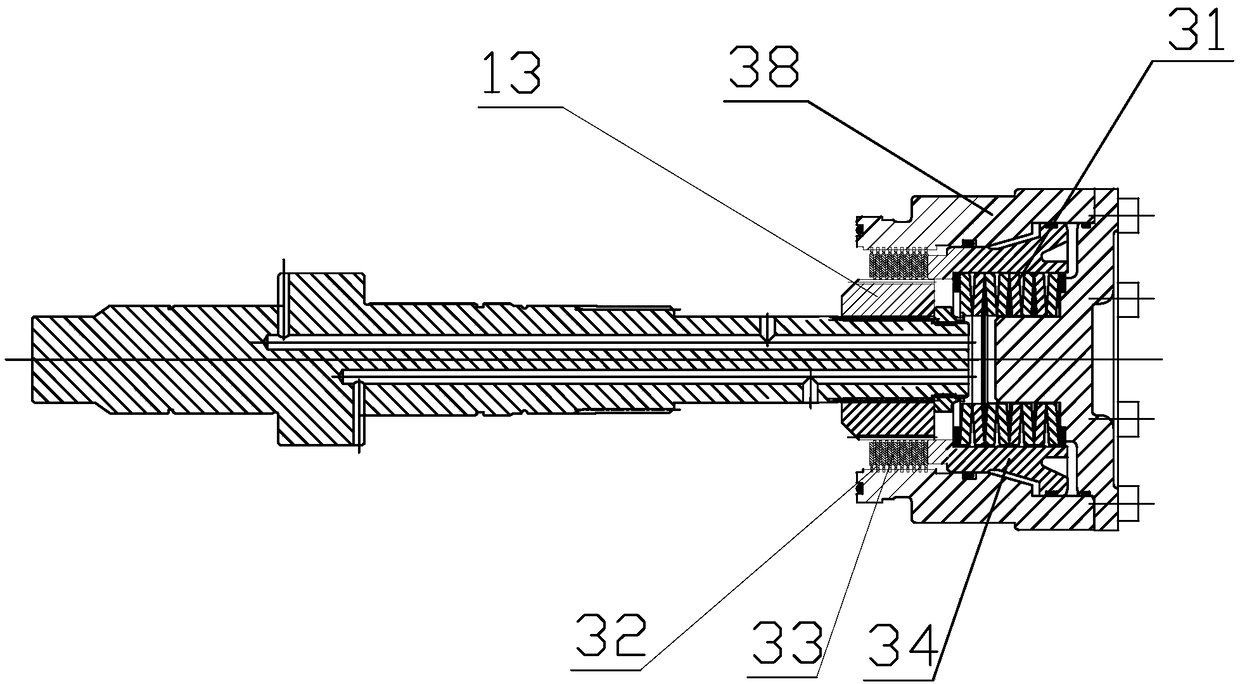

Power gear shift gearbox for wheel excavator

PendingCN109340324AEasy to assembleEasy to repair and replaceGearboxesGear lubrication/coolingNeedle roller bearingGear wheel

The invention relates to the technical field of power devices of engineering machinery, in particular to a power gear shift gearbox for a wheel excavator. The power gear shift gearbox comprises a boxbody, and the interior of the box body is connected with an input shaft and an output shaft; a first needle bearing, a clutch and an input gear are fixed to the input shaft, a first spline sleeve is connected to the first needle bearing, one end of the first spline sleeve is provided with a first-position gear connected with the clutch, a second-position gear connected with the clutch is arrangedbetween the clutch and the input gear, and a second needle bearing is connected between the second-position gear and the input shaft; and a third needle bearing, a fourth needle bearing and an outputgear engaged with the input gear are fixed to the output shaft, the third needle bearing is provided with a first transmission gear engaged with the first-position gear, and the fourth needle bearingis provided with a second transmission gear engaged with the second-position gear. The power gear shift gearbox has the advantages that engagement of the two pairs of gears is controlled through the clutch, gear shifting is achieved, and output of different speed ratios is achieved; and the interior structure is compact, and the space of the whole gearbox is greatly utilized.

Owner:SHAOXING ADVANCE GEARBOX CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com