Comfortable jaw clutch

A clutch and claw technology, applied in the field of comfortable claw clutches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

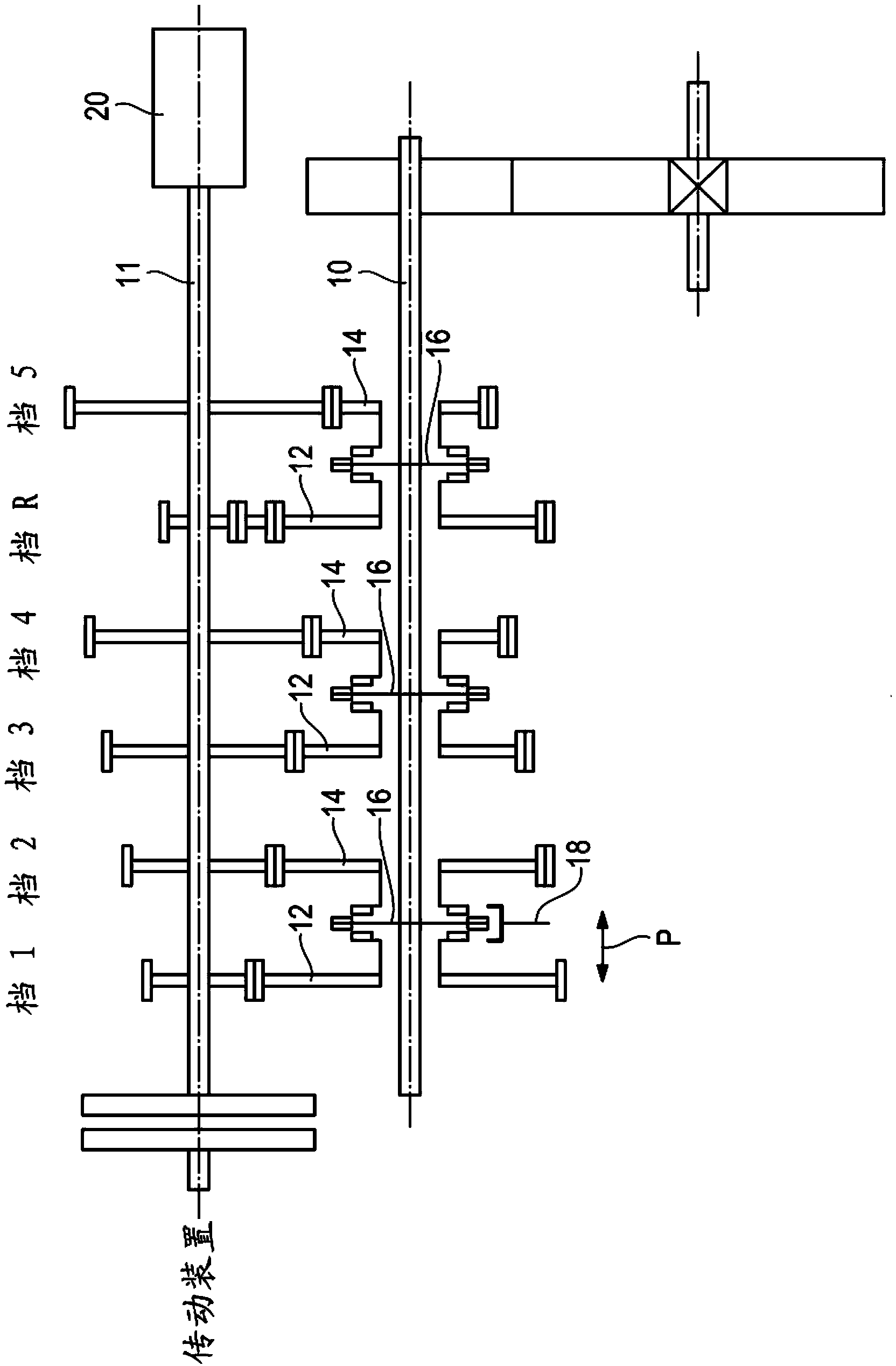

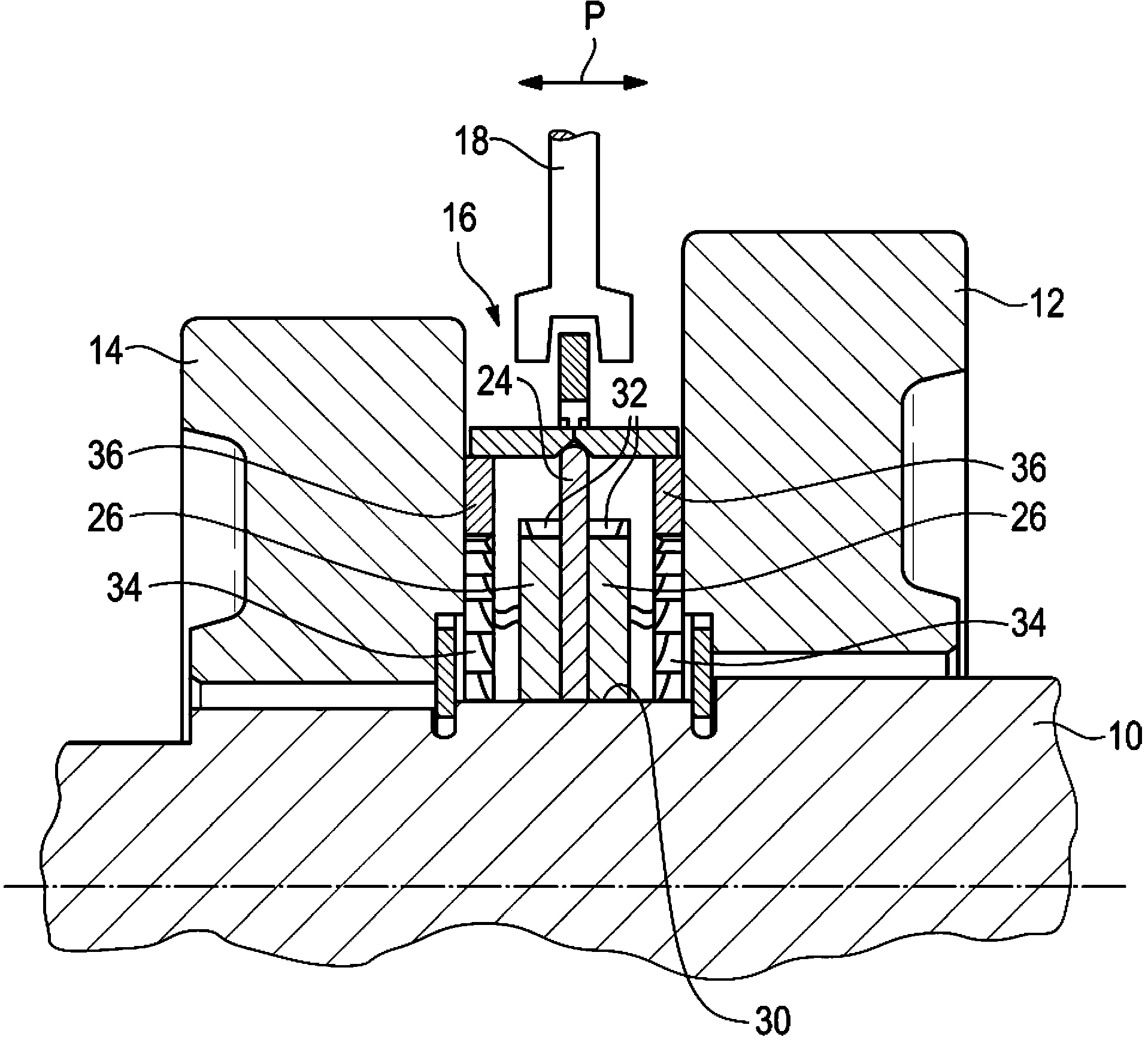

[0028] exist figure 1 A transmission shaft 10 of the transmission is shown in , on which two output wheels 12 , 14 are arranged. The driven wheels 12 , 14 are mounted rotatably in the circumferential direction on the transmission shaft 10 . The other driven wheels meshing with the driven wheels 12 , 14 , which are arranged on the second transmission shaft, are shown here for the sake of clarity as few as the other driven wheel pairs and the rest of the gearbox.

[0029] Between the two driven wheels 12 , 14 is arranged a transmitter 16 which can be shifted in one or the other direction (see arrow P) by means of a shift fork 18 in order to make the two driven wheels One or the other of 12 , 14 is coupled to the transmission shaft 10 in a torque-proof manner.

[0030] In addition, in figure 1 Also shown schematically is an electric motor 20 with which the rotational speed of the second transmission shaft 11 can be brought to a defined value. On the second transmission shaft,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com