Center wheel fixed single-wheeled direct drive multi-speed full-automatic transmission

A center wheel, fully automatic technology, used in one-way clutches, vehicle gearboxes, gear transmissions, etc., can solve problems such as inability to achieve automatic shifting, difficult to maintain transmission, and achieve compact structure, reduced requirements, and easy riding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

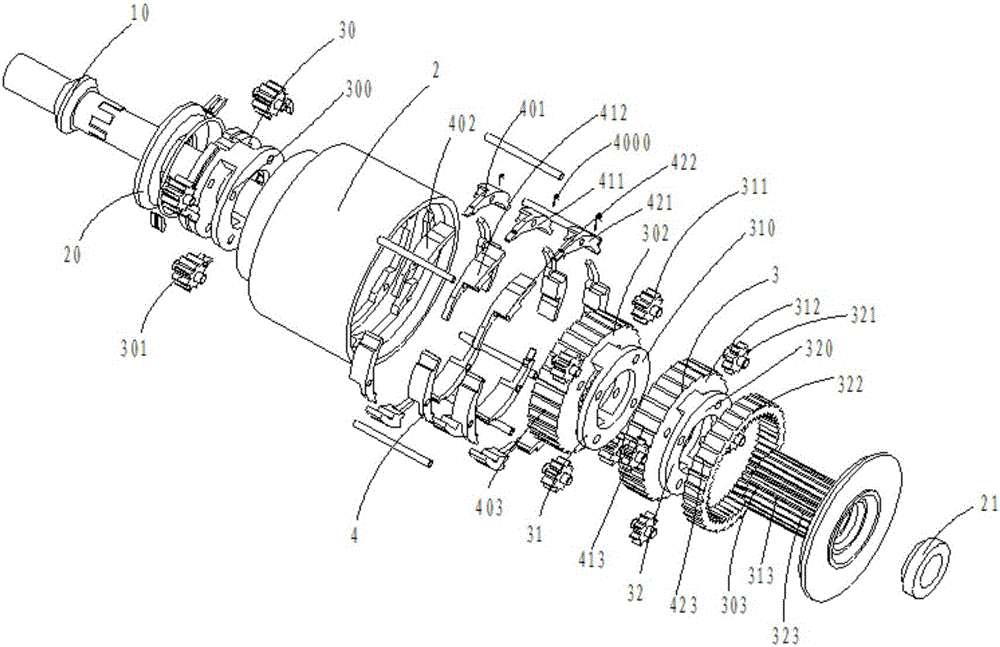

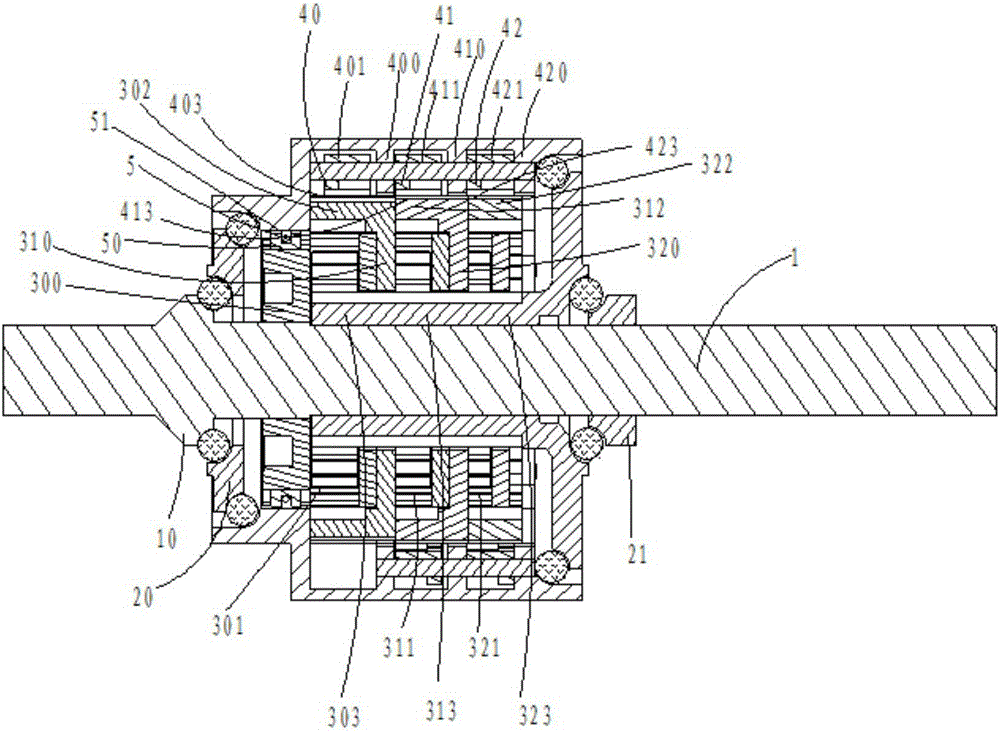

[0027] ginseng Figure 1 to Figure 4 As shown, a center-wheel fixed single-wheel direct-drive multi-speed automatic transmission includes: a central shaft 1, a hub 2 and a speed change mechanism arranged between the central shaft 1 and the hub 2, and the central shaft 1 is a power input member , the hub 2 is a power output member, and the speed change mechanism includes at least two sets of planetary transmissions and at least one set of automatic centrifugal shift mechanism. One set of planetary transmissions 3 and three sets of automatic centrifugal shifting mechanisms 4, of course, in other embodiments, the number of planetary transmissions and automatic centrifugal shifting mechanisms can be determined according to specific requirements.

[0028] The planetary transmission 3 comprises: a first planetary transmission 30, a second planetary transmission 31 and a third planetary transmission 32 arranged side by side, and the first planetary transmission 30 comprises: a first ...

Embodiment 2

[0034] ginseng Figure 5 As shown, compared with the center-wheel fixed single-wheel direct-drive multi-speed automatic transmission in this embodiment, compared with the center-wheel fixed single-wheel direct-drive multi-speed automatic transmission in Embodiment 1, the rest of the structure is the same, the difference is that : In Embodiment 1, three sets of automatic centrifugal shifting mechanisms are included, and the overrunning clutch is arranged between the wheel hub 2 and the first planet carrier 300, and in the present embodiment, two sets of automatic centrifugal shifting mechanisms are included , the overrunning clutch is arranged between the first assembly and the hub 2, that is, compared with the embodiment 1, the embodiment 2 removes the first automatic centrifugal shift mechanism 40, and will be originally arranged between the first planet carrier 300 and the The overrunning clutch 5 between the hubs 2 is placed at the position where the first automatic centrif...

Embodiment 3

[0037] ginseng Image 6 As shown, compared with the center-wheel fixed single-wheel direct-drive multi-speed automatic transmission in this embodiment and the center-wheel fixed single-wheel direct-drive multi-speed automatic transmission in Embodiment 2, the rest of the structure is the same, the difference is : in embodiment 2, comprise two sets of automatic centrifugal shifting mechanisms and three sets of planetary transmissions altogether, and in the present embodiment, comprise altogether a set of automatic centrifugal shifting mechanisms and two sets of planetary transmissions, promptly compared to embodiment 2. The single-wheel direct-drive multi-speed fully automatic transmission in this embodiment removes the second planetary transmission 31 and the second automatic centrifugal shift mechanism 41 in Embodiment 2.

[0038] The working principle of the center wheel fixed single-wheel direct-drive multi-speed automatic transmission in this embodiment is: the pawl 50 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com