Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Increased Design Possibilities" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

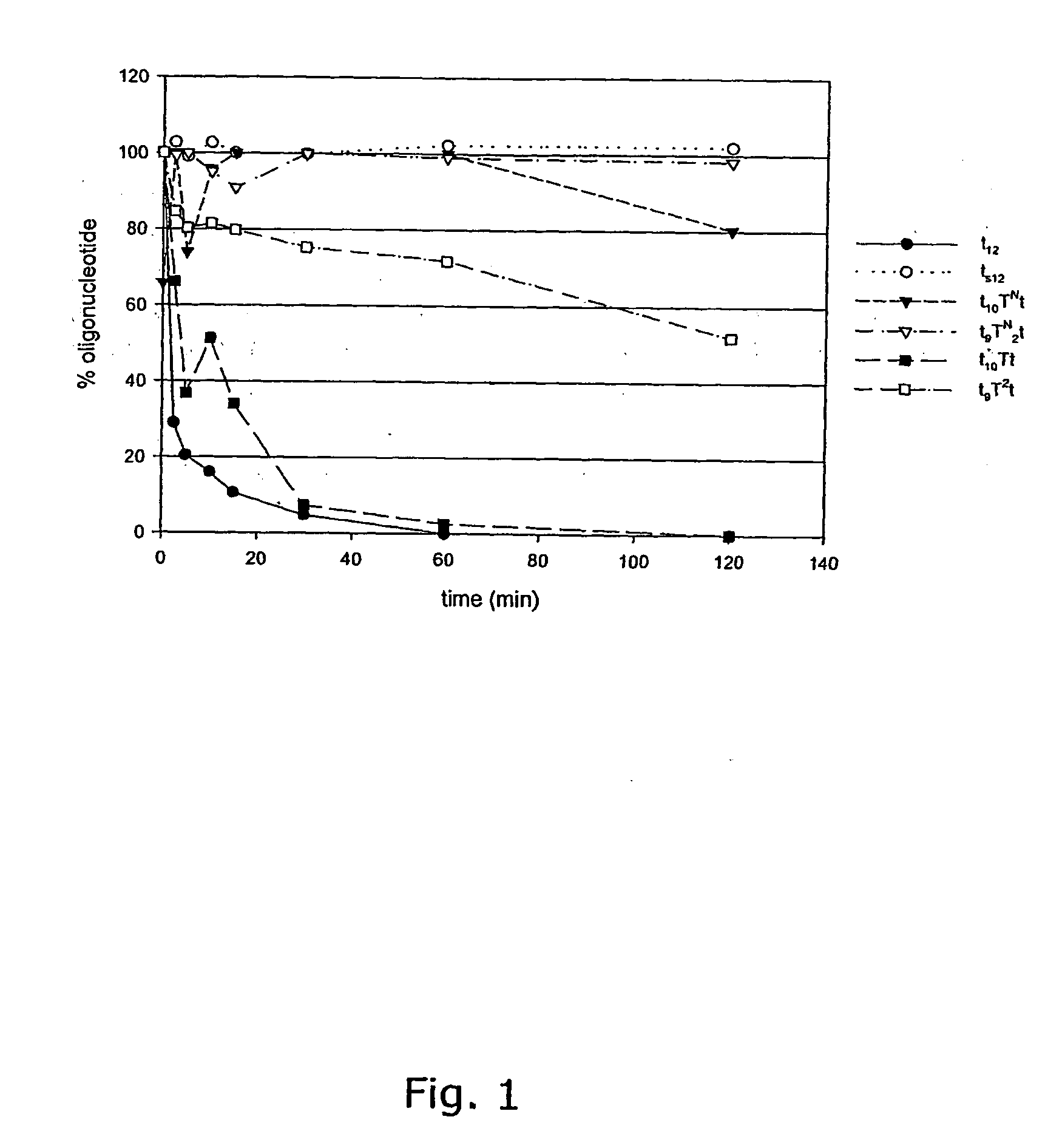

Oligonucleotides with alternating segments of locked and non-locked nucleotides

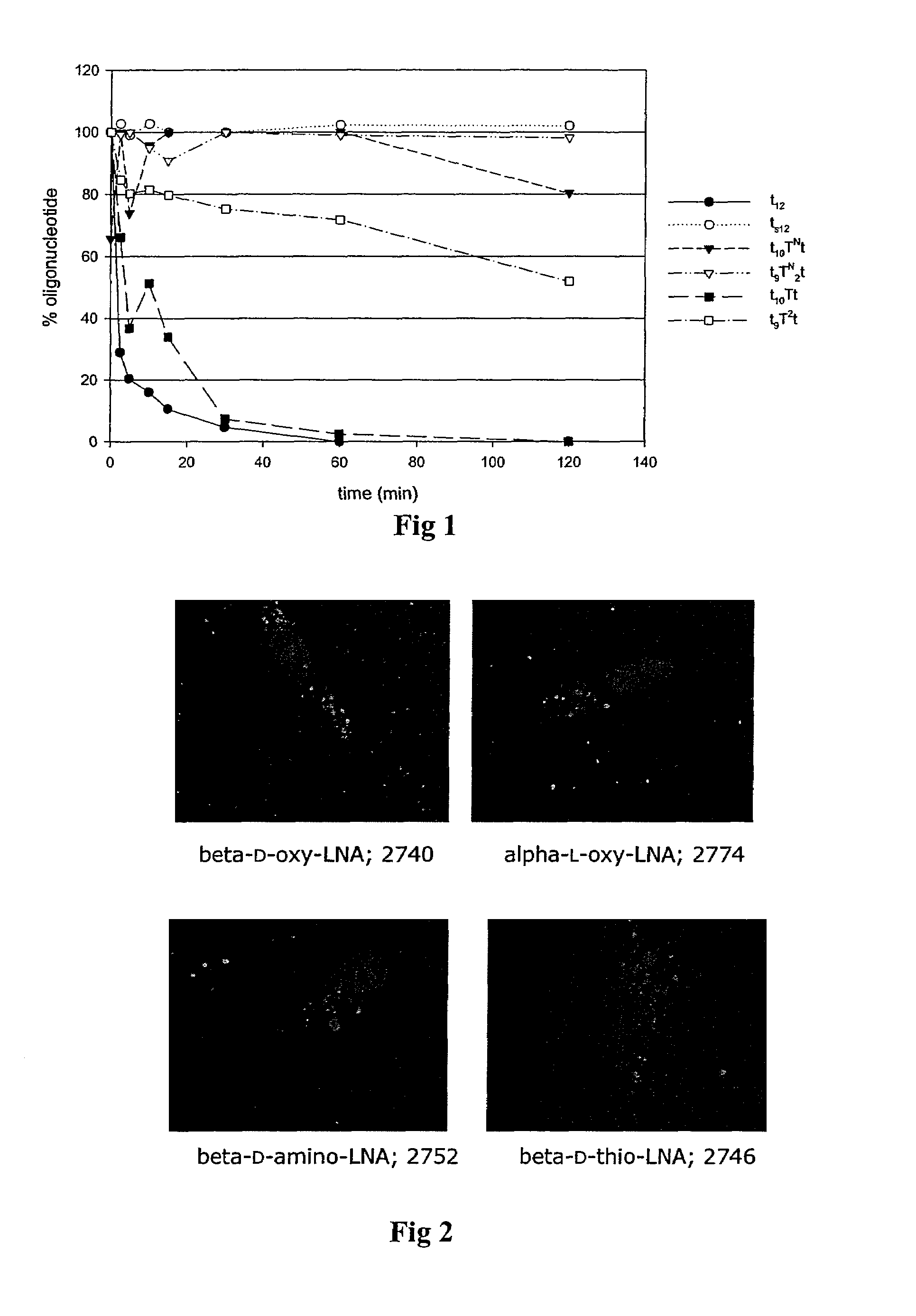

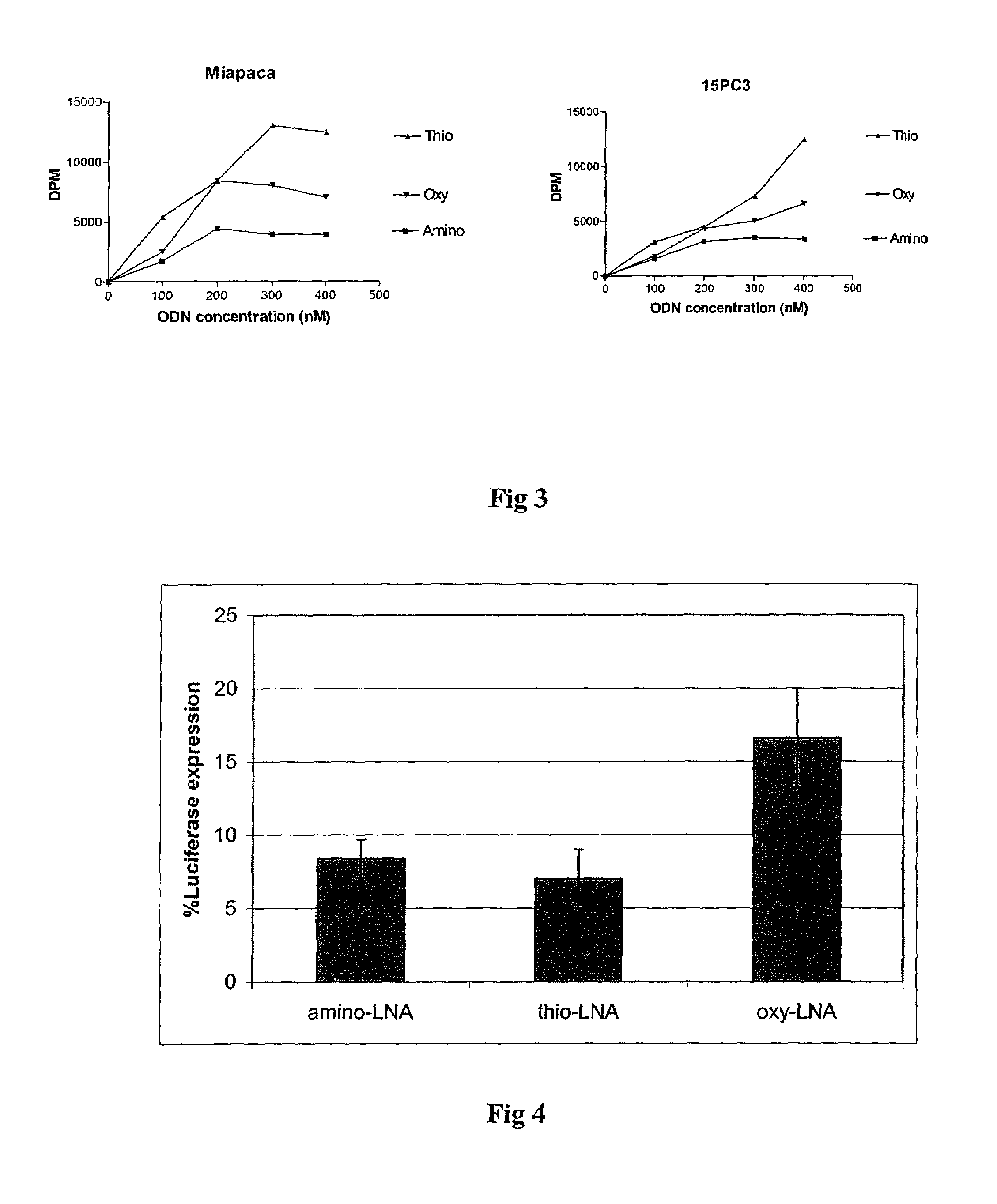

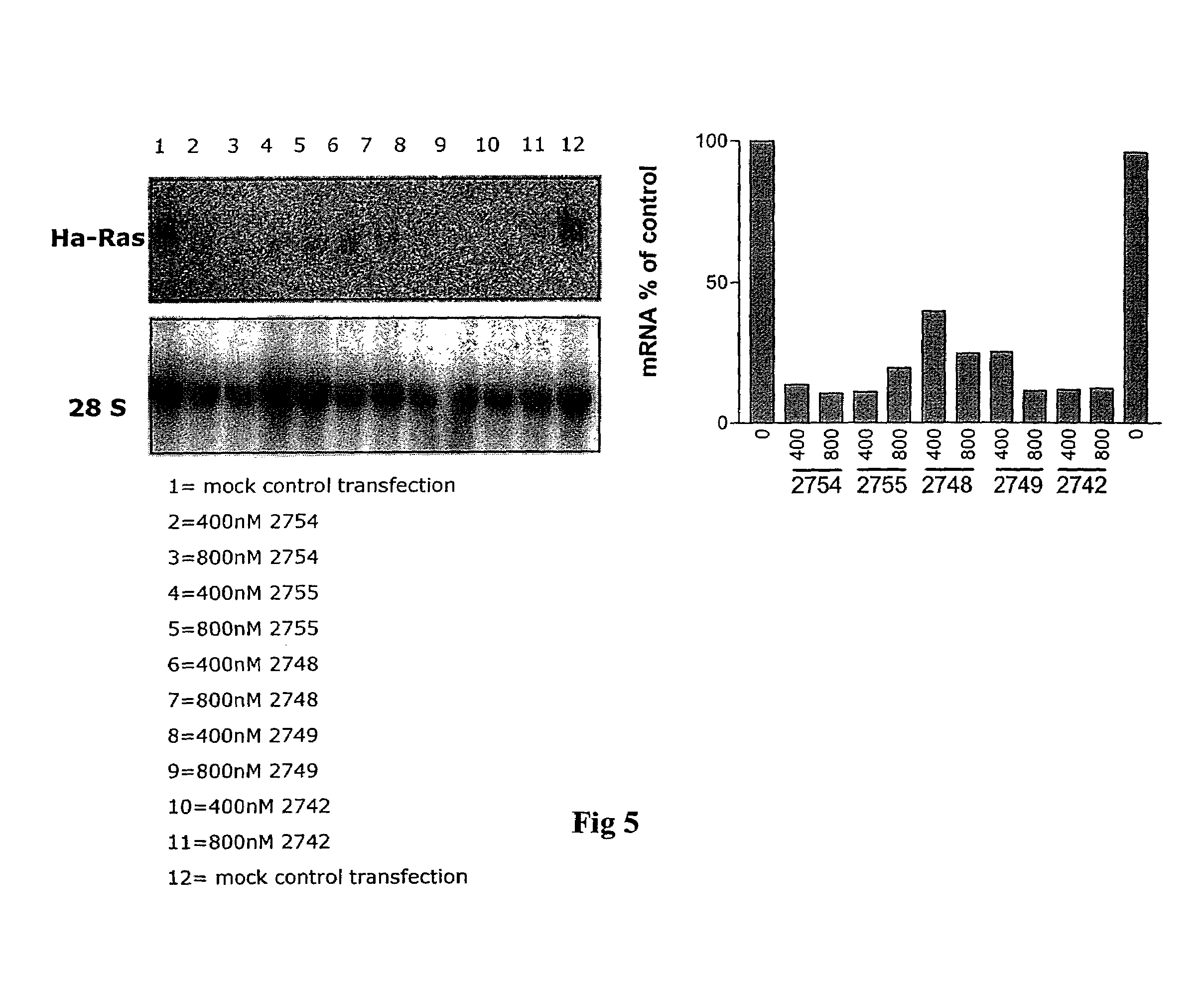

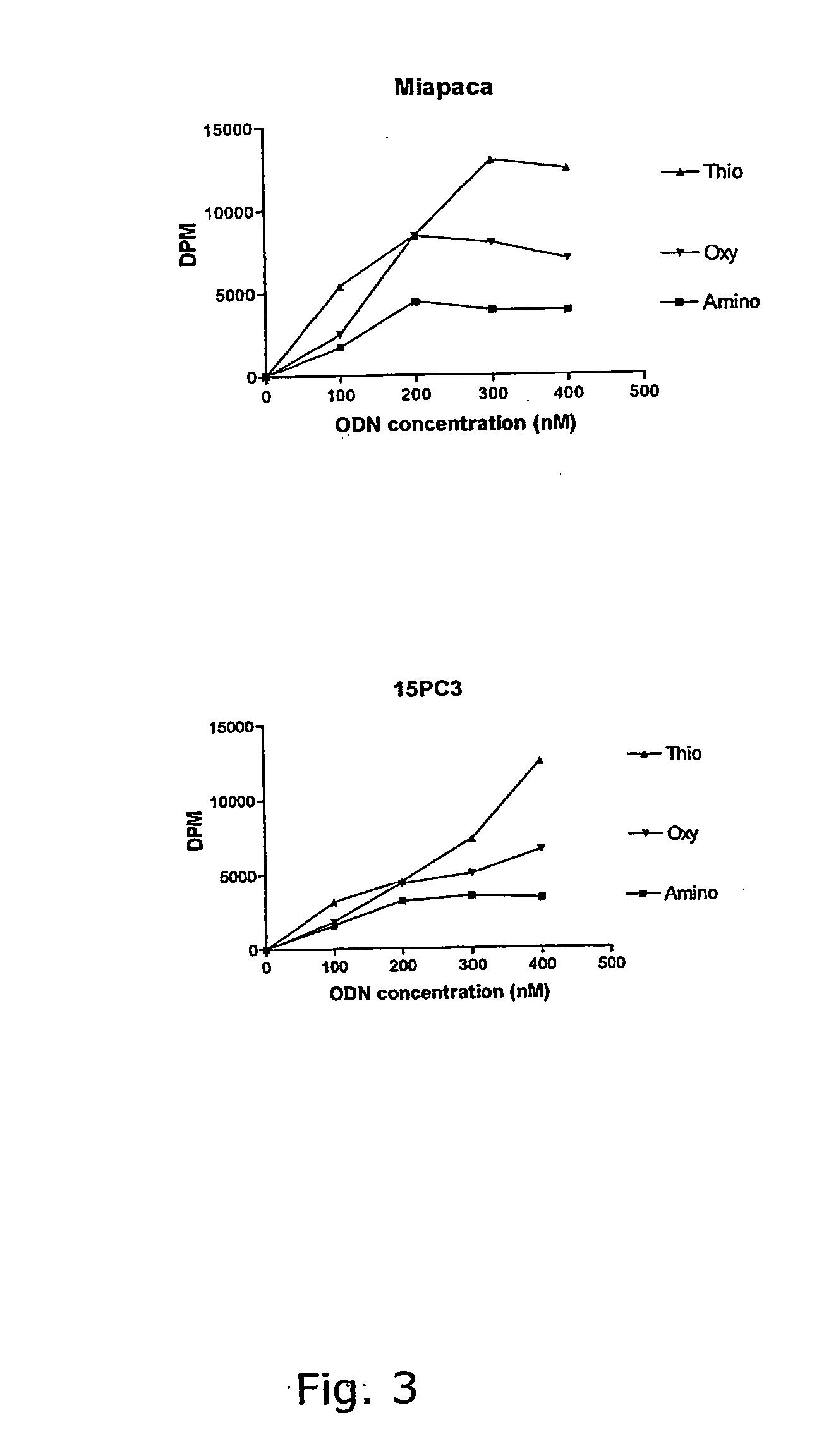

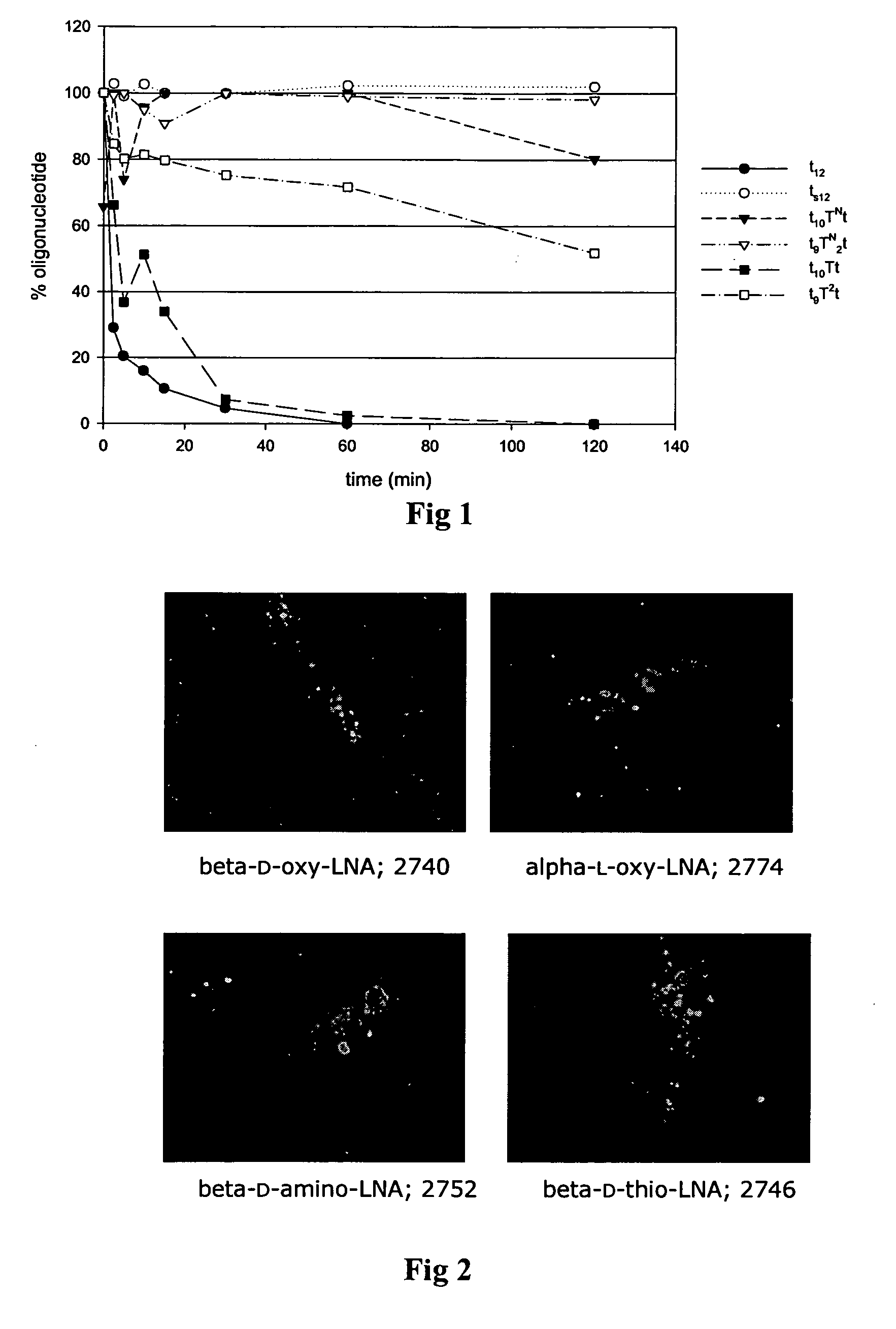

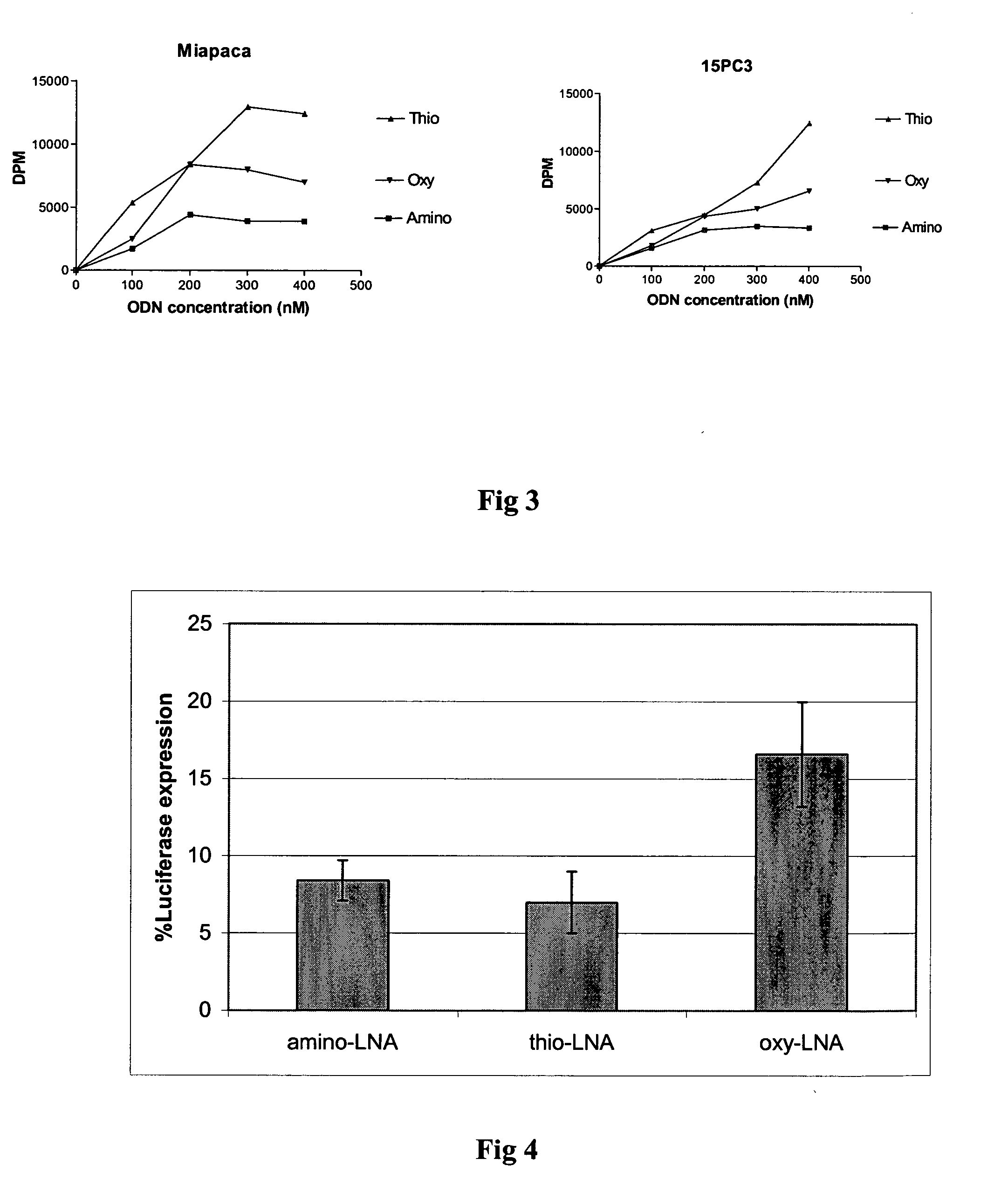

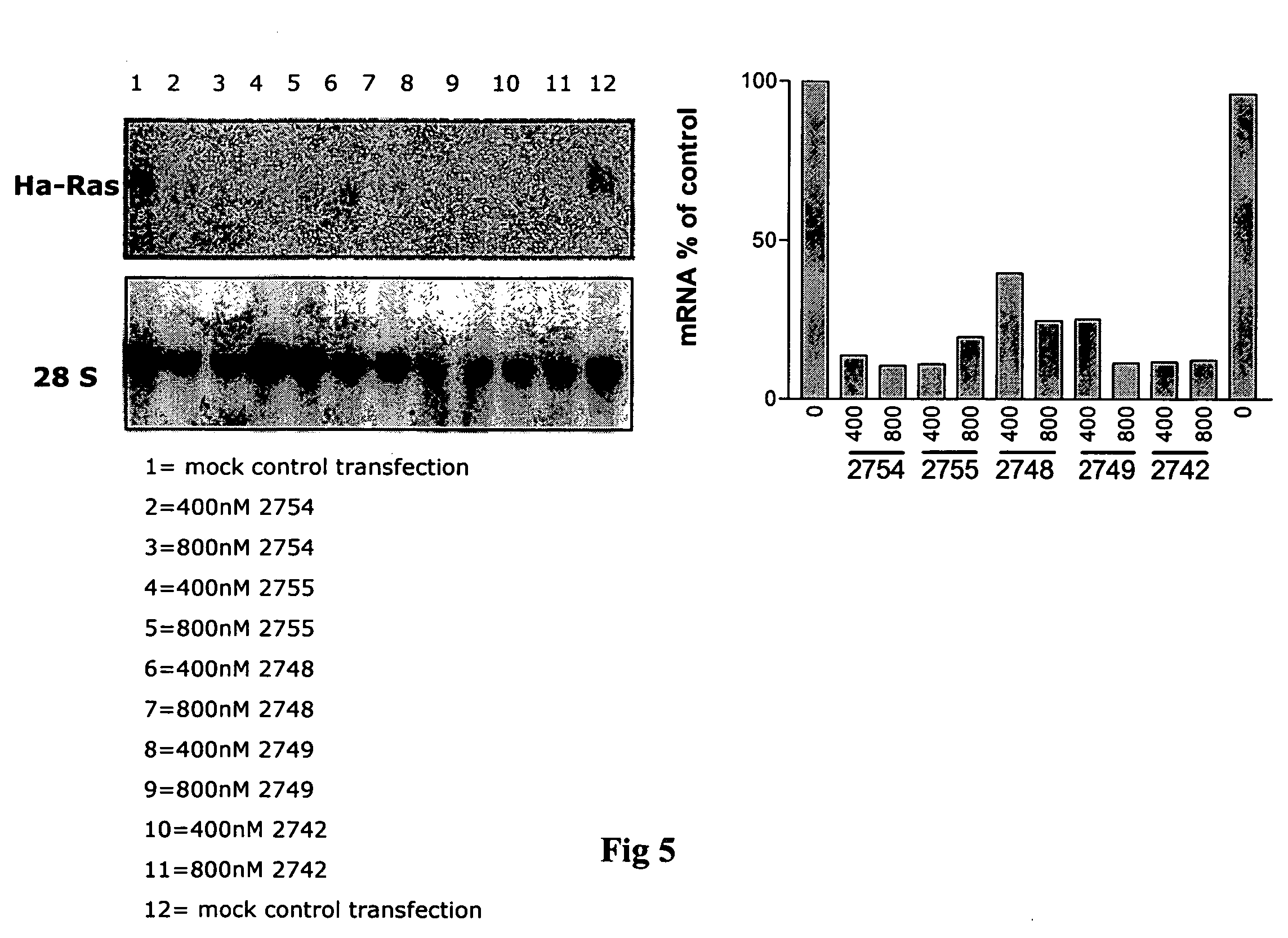

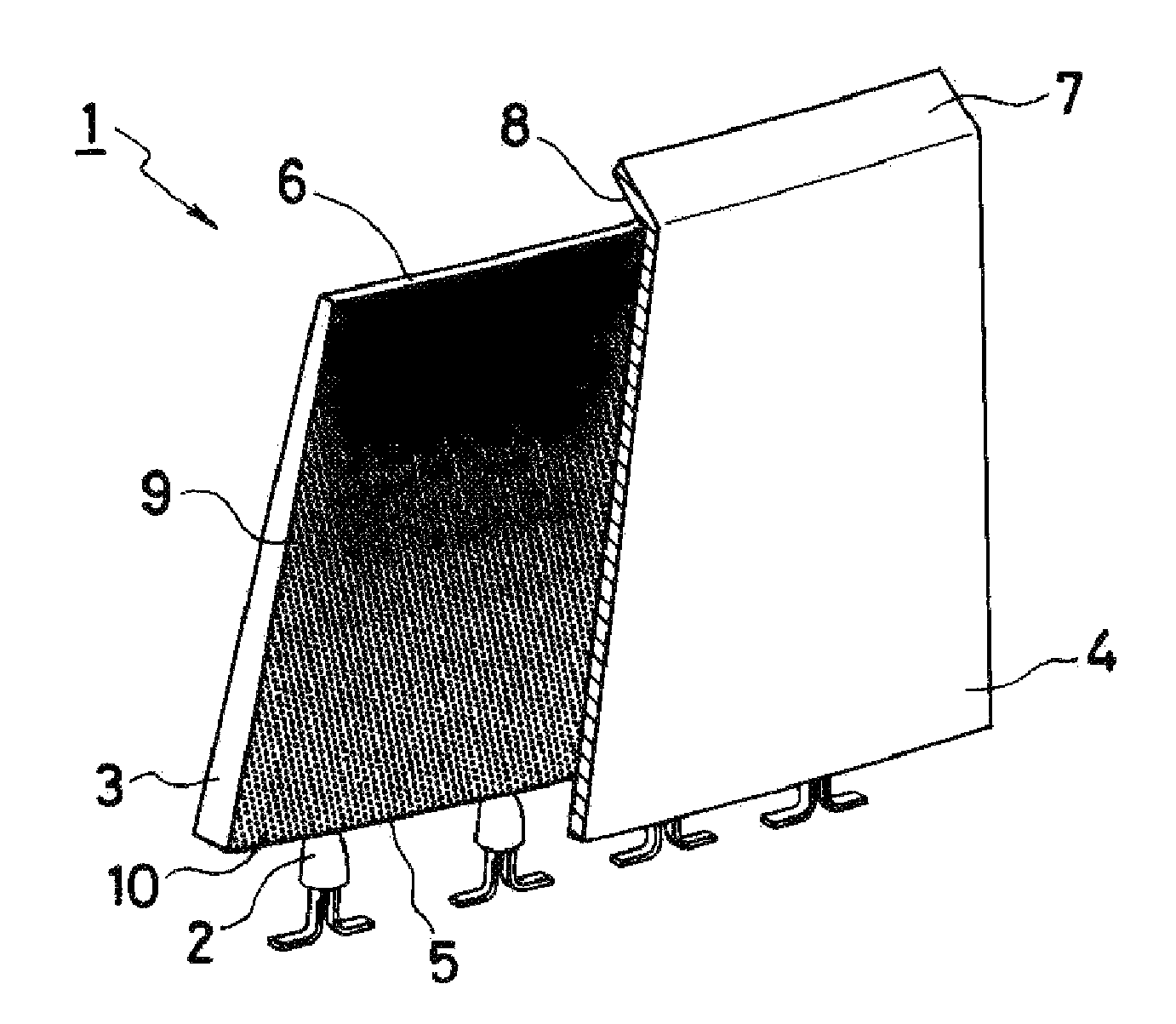

ActiveUS7687617B2Increased Design PossibilitiesEfficient substrateSugar derivativesActivity regulationNucleotideThio-

The present invention is directed to novel oligonucleotides with improved antisense properties. The novel oligonucleotides comprise at least one Locked Nucleic Acid (LNA) selected from beta-D-thio / amino-LNA or alpha-L-oxy / thio / amino-LNA. The oligonucleotides comprising LNA may also include DNA and / or RNA nucleotides. The present invention also provides a new class of pharmaceuticals which comprise antisense oligonucleotides and are useful in antisense therapy.

Owner:SANTARIS PHARMA AS

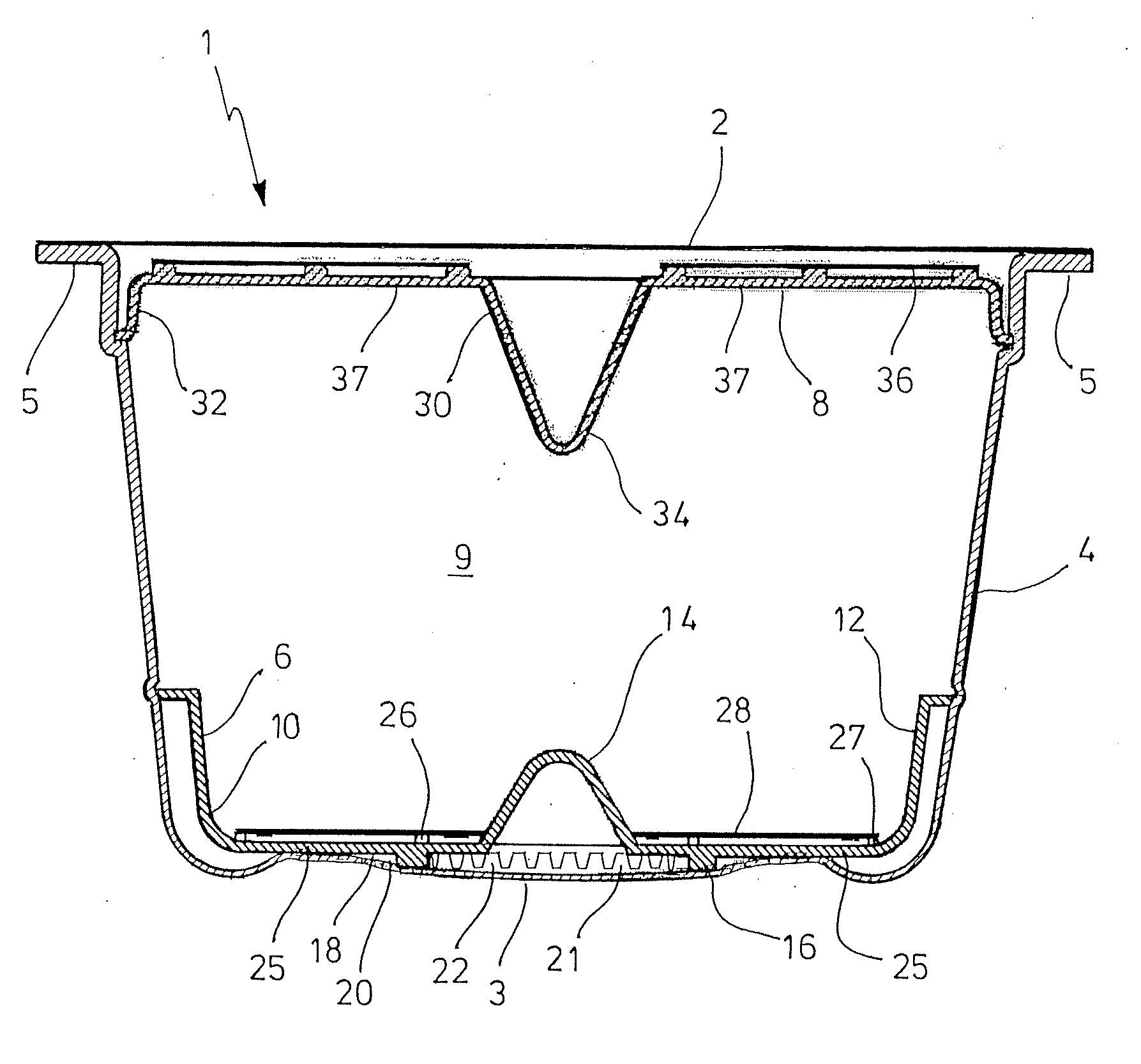

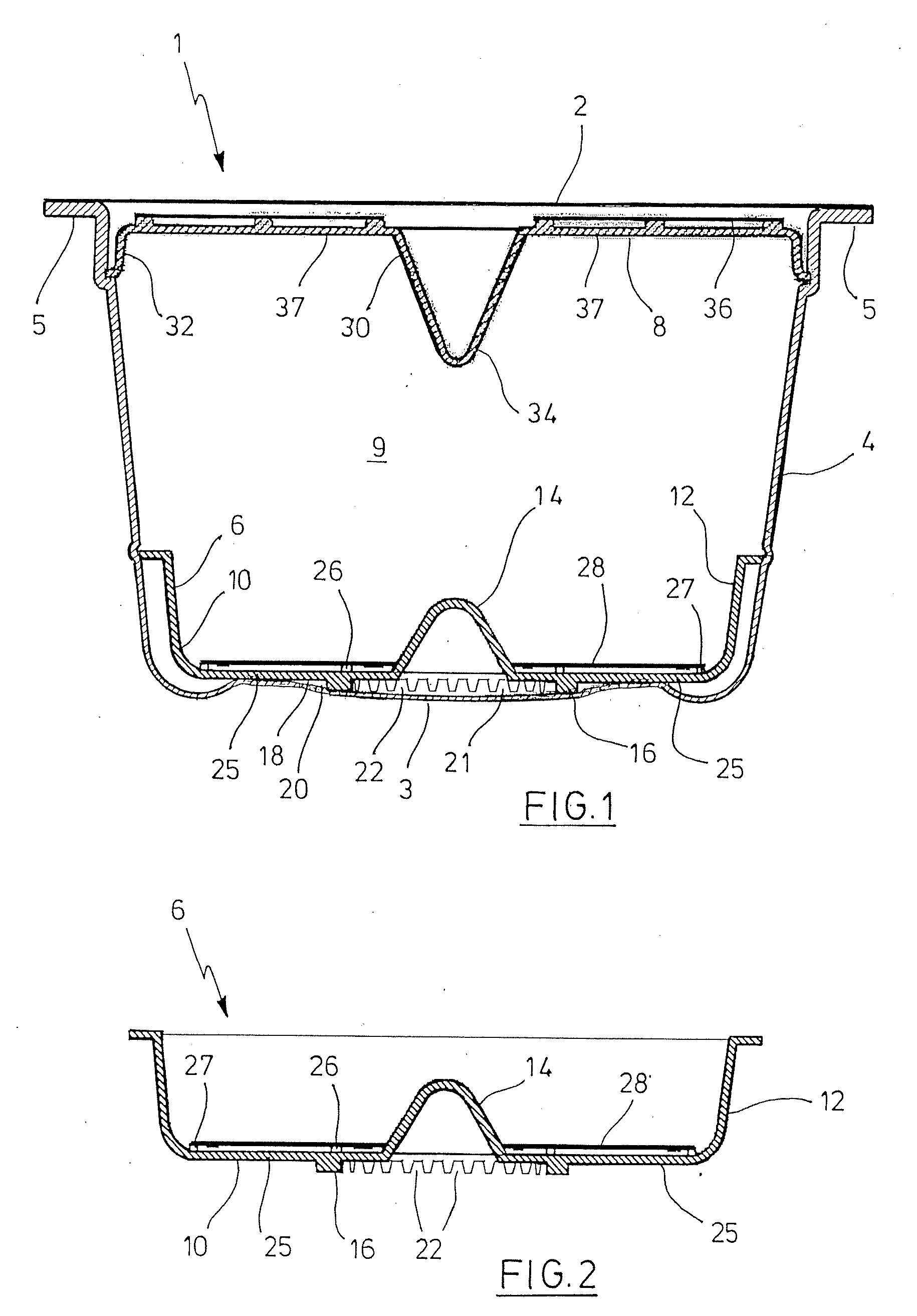

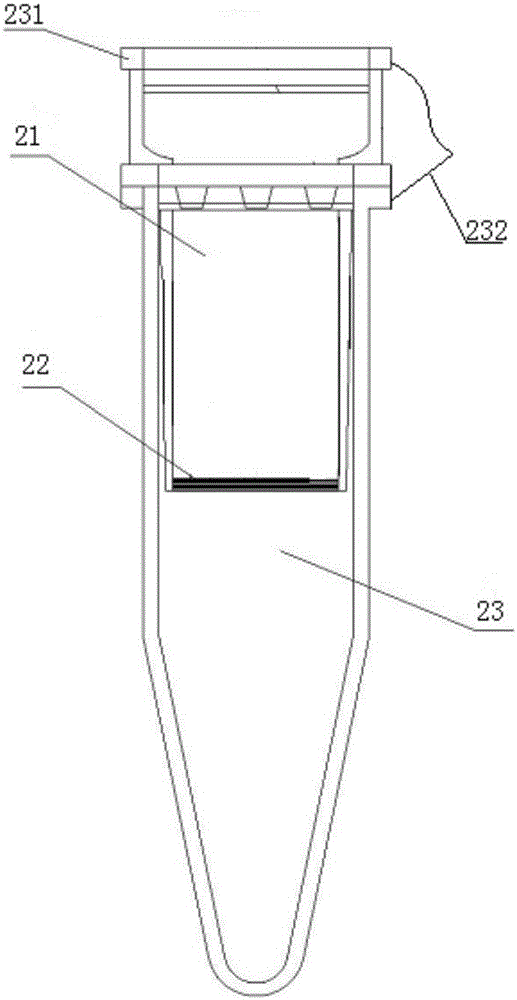

Portion capsule

InactiveUS20070148290A1Increased Design PossibilitiesEasy piercingTransportation and packagingConfectioneryParticulatesBiomedical engineering

A portion capsule, which is suitable in particular for brewing coffee, has a capsule cover and a capsule base and is closed on all sides in the state in which it is supplied. It contains a particulate beverage substance which can be extracted by water. A screening device is arranged between the beverage substance and the capsule base. The screening device is spaced apart from the capsule base, in the central region of the latter, by means of an annular structure which defines an outer region and an inner region in the interspace between the screening device and capsule base. The outer region is connected to the inner region via through-openings.

Owner:TCHIBO

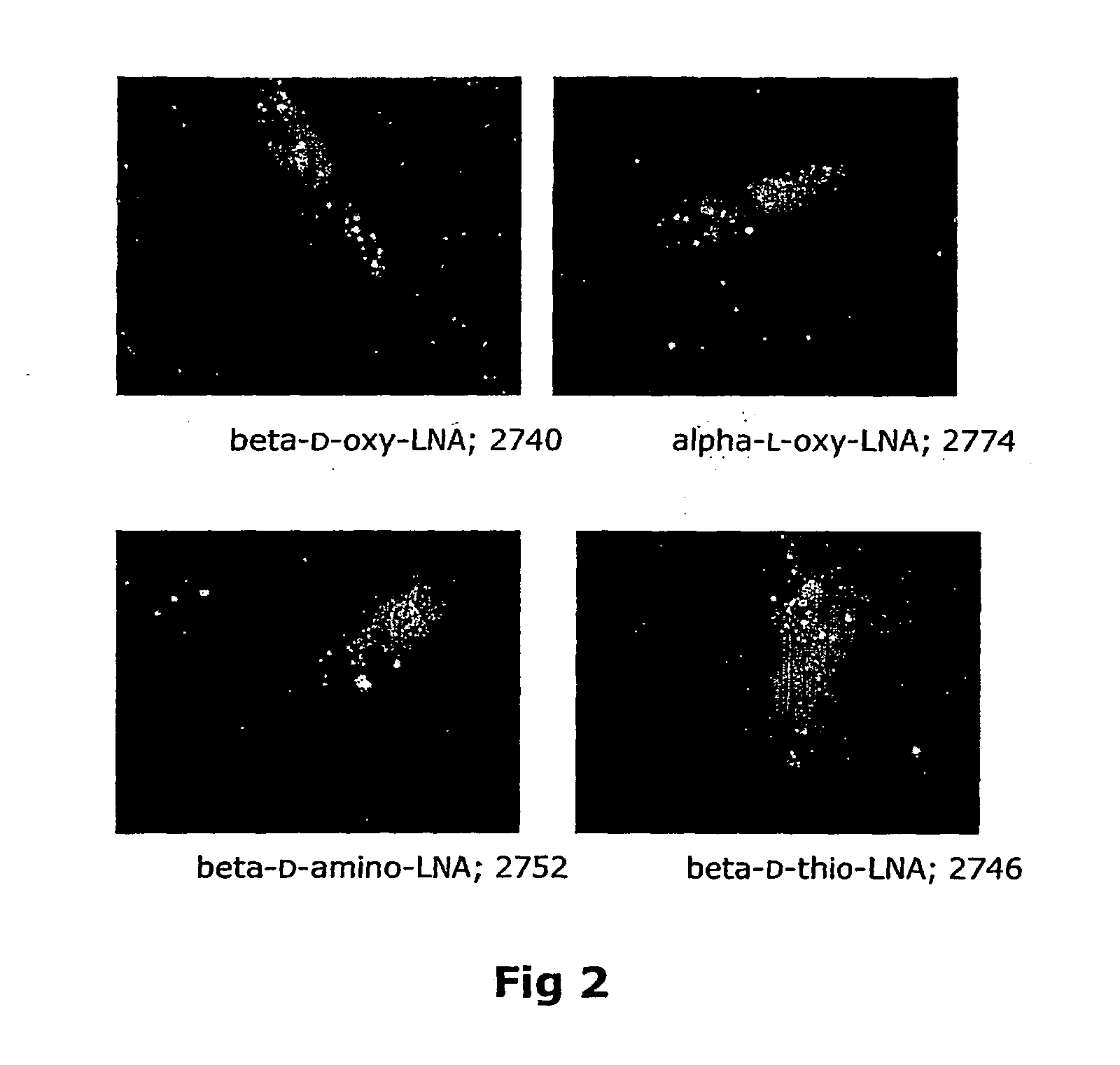

Antisense design

ActiveUS20060128646A1Efficient deliveryAiding diffusionOrganic active ingredientsPeptide/protein ingredientsThio-Locked nucleic acid

A novel class of pharmaceuticals which comprises a Locked Nucleic Acid (LNA) which can be used in antisense therapy. These novel oligonucleotides have improved antisense properties. The novel oligonucleotides are composed of at least one LNA selected from beta-D-thio / amino-LNA or alpha-L-oxy / thio / amino-LNA. The oligonucleotides comprising LNA may also include DNA and / or RNA nucleotides.

Owner:ROCHE INNOVATION CENT COPENHAGEN

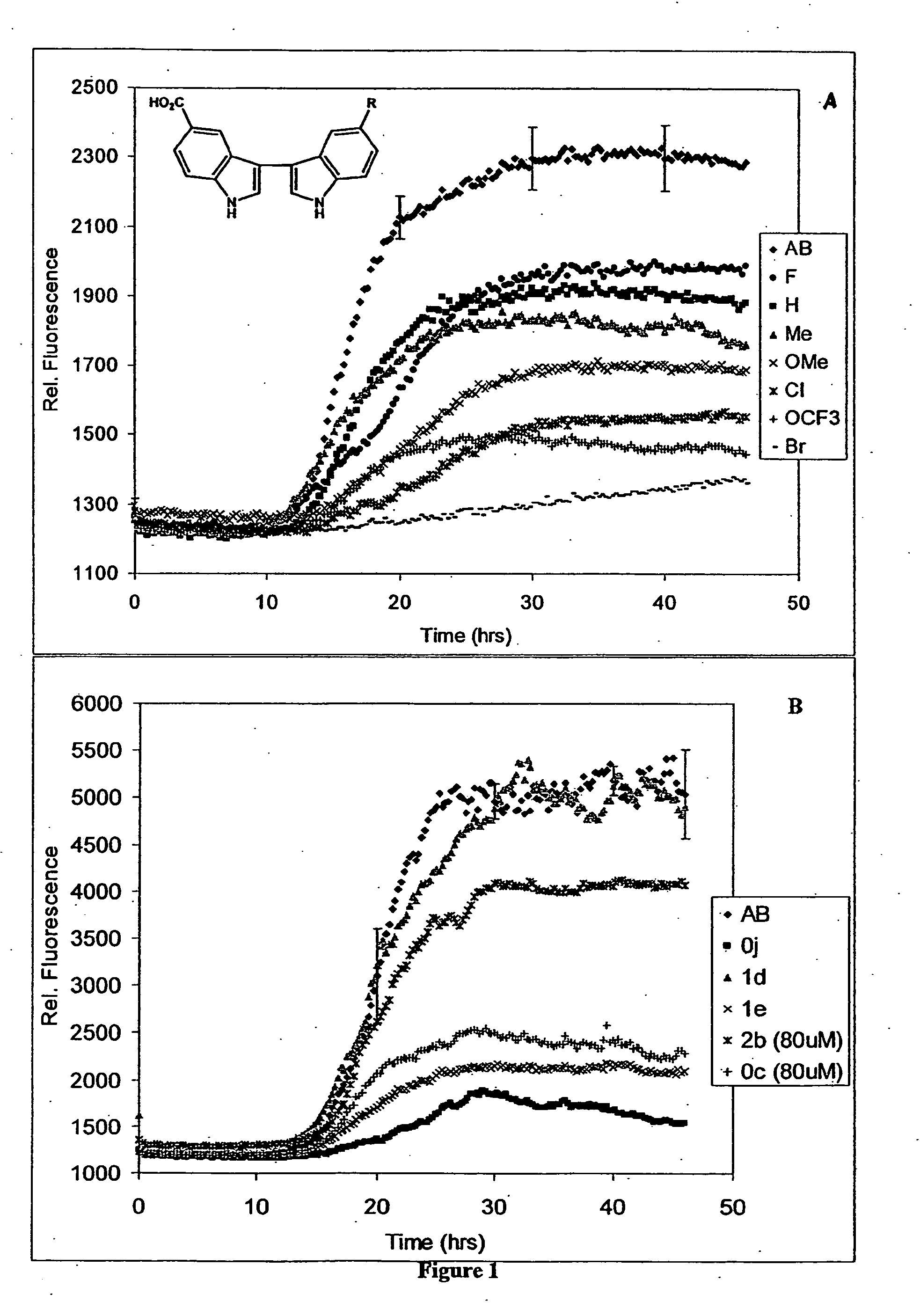

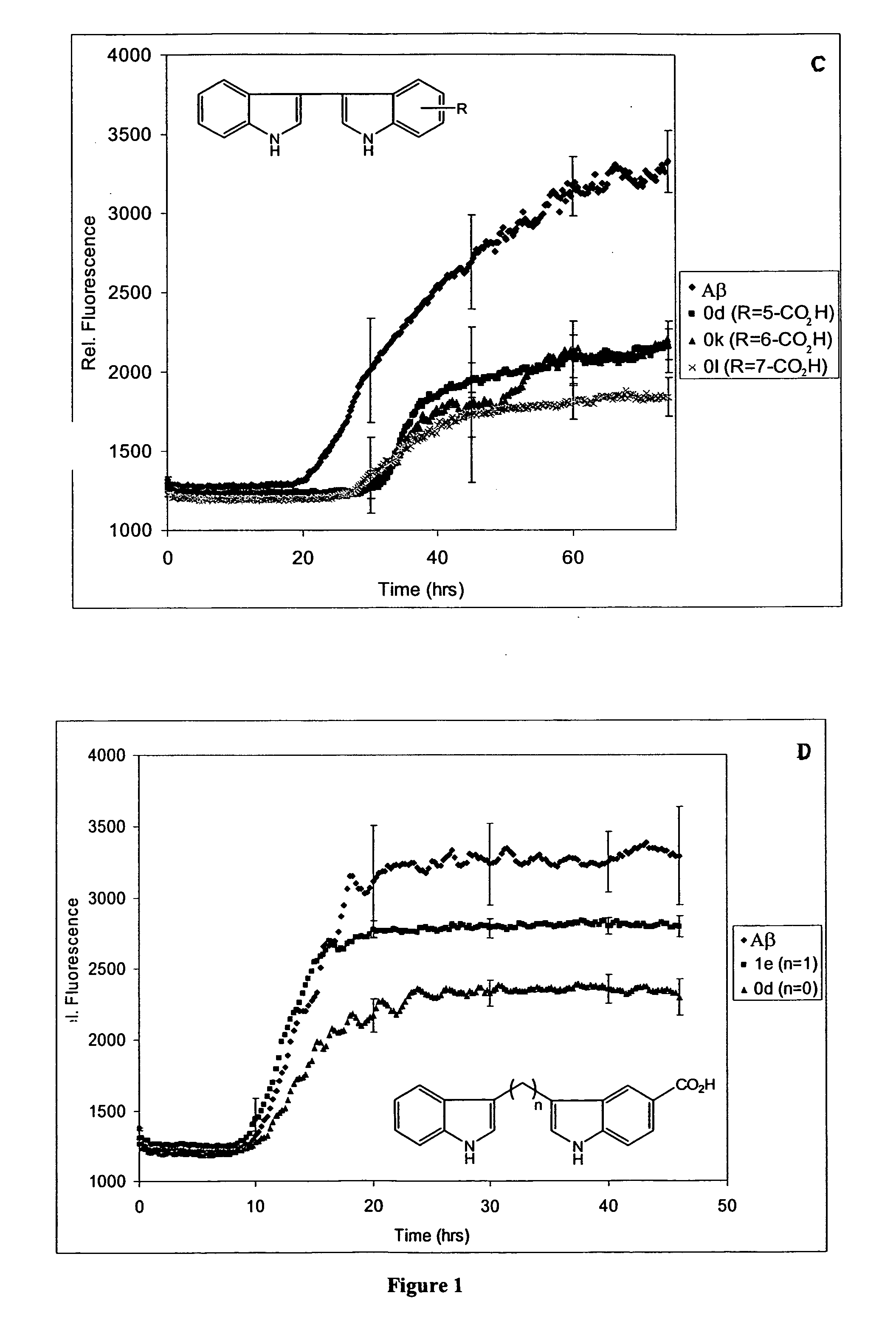

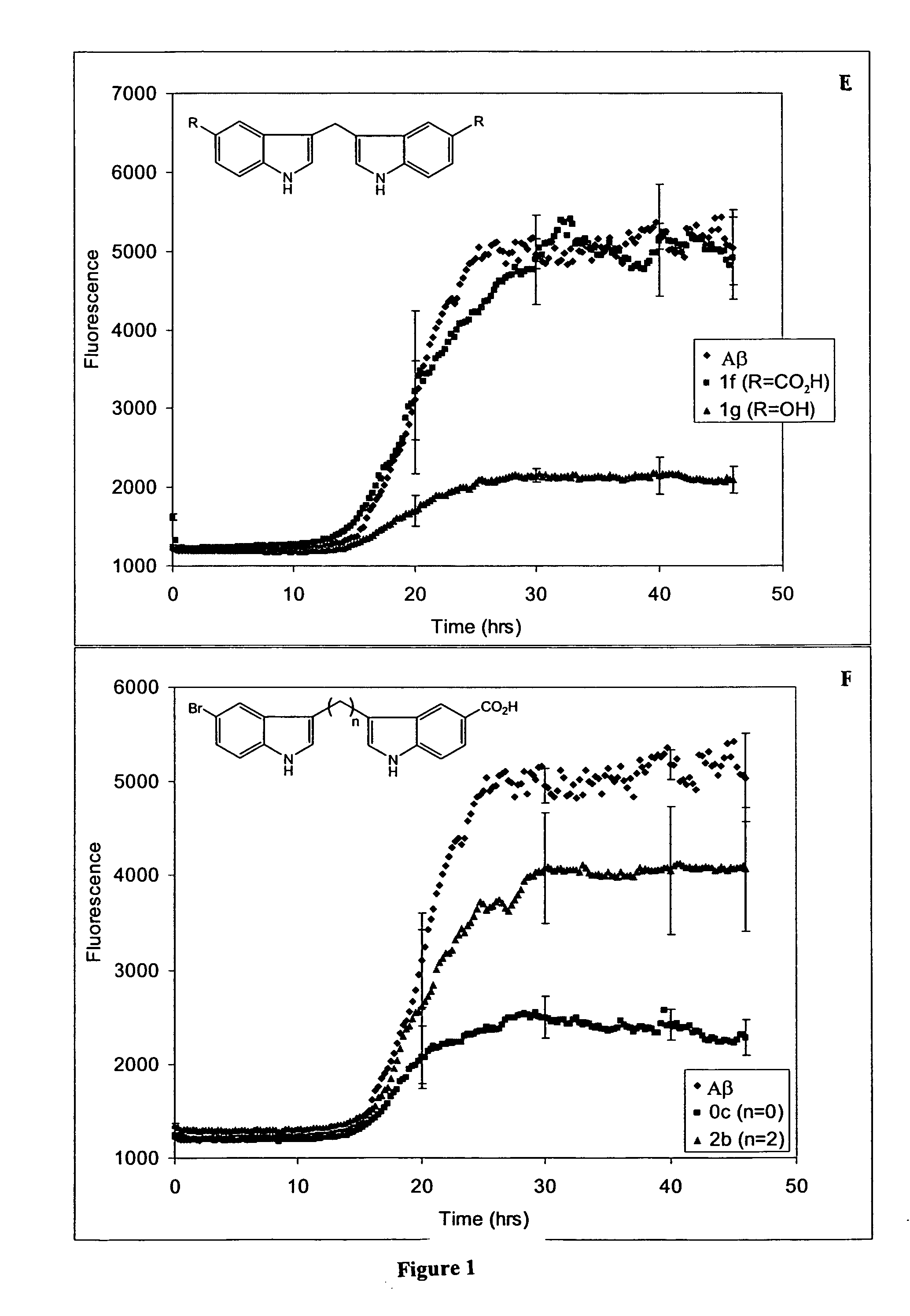

Treatment of protein folding disorders

InactiveUS20070015813A1Increased Design PossibilitiesBiocideNervous disorderMedicineCompound (substance)

In certain embodiments, the invention is directed to a method for treating a protein folding disorder comprising administering to a subject a compound of the formulas disclosed. In preferred embodiments, the compounds are bis-indole compounds.

Owner:TREVENTIS CORP

Oligonucleotides with alternating segments of locked and non-locked nucleotides

ActiveUS20090209748A1Increased Design PossibilitiesEfficient substrateOrganic active ingredientsSugar derivativesThio-Nucleotide

The present invention is directed to novel oligonucleotides with improved antisense properties. The novel oligonucleotides comprise at least one Locked Nucleic Acid (LNA) selected from beta-D-thio / amino-LNA or alpha-L-oxy / thio / amino-LNA. The oligonucleotides comprising LNA may also include DNA and / or RNA nucleotides. The present invention also provides a new class of pharmaceuticals which comprise antisense oligonucleotides and are useful in antisense therapy.

Owner:SANTARIS PHARMA AS

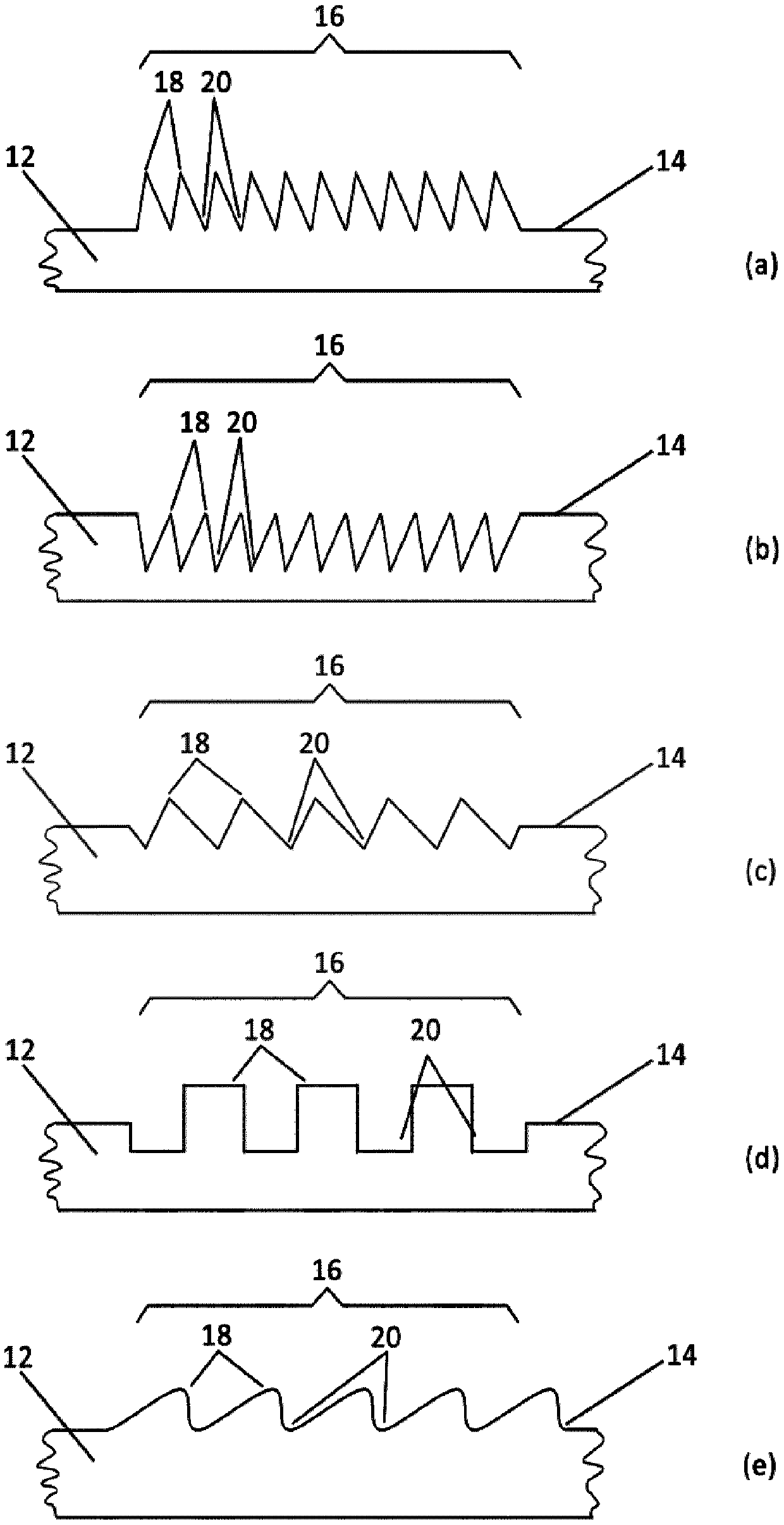

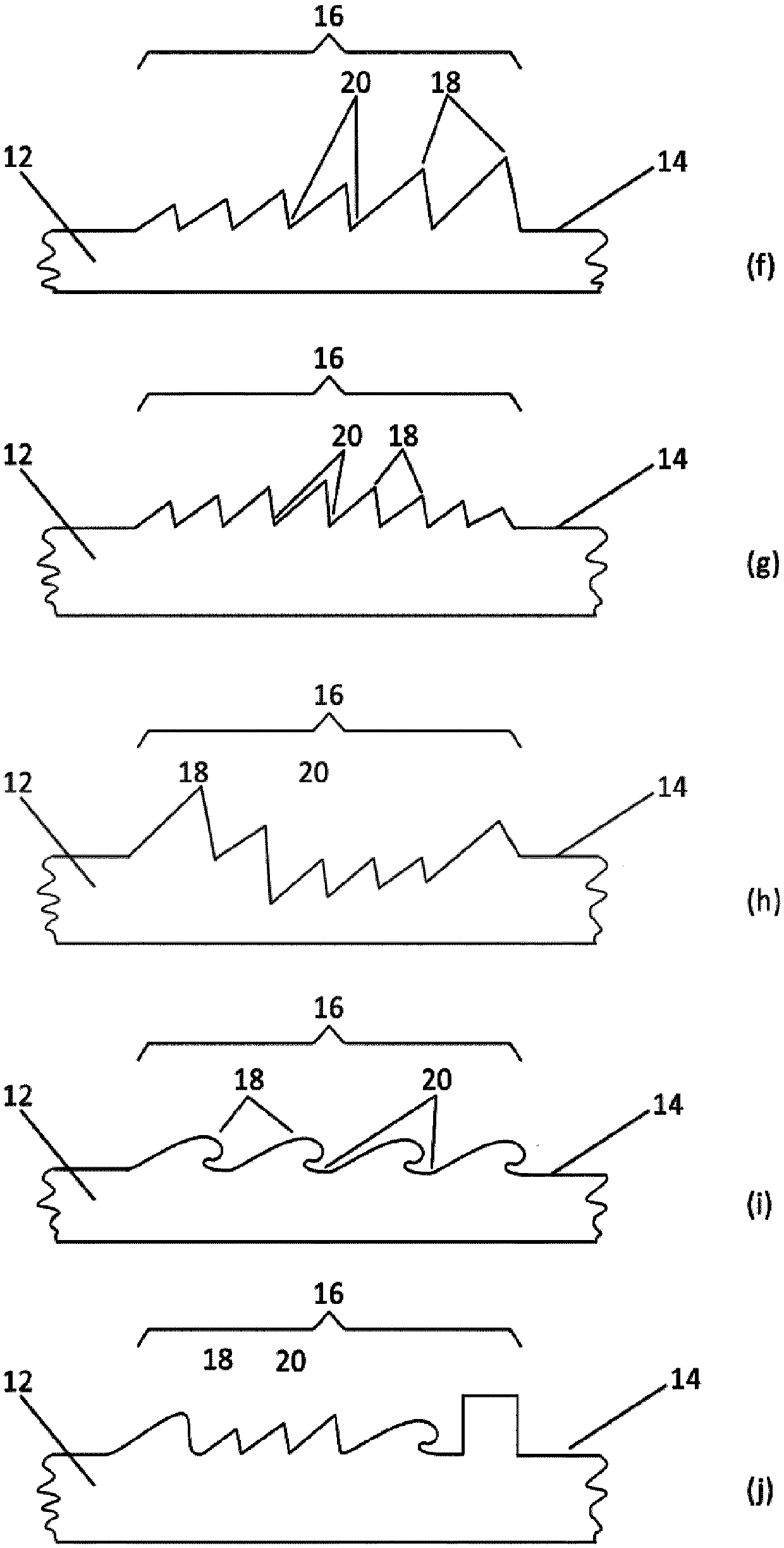

LED lighting unit and vehicle lamp

InactiveUS7654721B2Uniform light distributionImprove uniformityNon-electric lightingLighting support devicesOptical propertyLight guide

The disclosed subject matter includes an LED lighting unit that uses a light guide, and a thin vehicle lamp using the light guide and which can conform to light distribution standards for vehicle lamps. The LED lighting unit can include a light guide having one flat surface formed with many light diffusing patterns, a plurality of LEDs located along one end surface of the light guide, and a reflection board including a reflector located on a bend portion thereof. The reflection board can be located adjacent and extend along the one flat surface of the light guide. The one flat surface can form a large light distribution area with a uniform brightness. The reflector located at the bend portion of the reflection board can form a narrow light distribution having a maximum brightness at a central portion. Thus, the LED light unit can conform to optical characteristics for a vehicle lamp. A vehicle lamp using the above-described LED light unit can be relatively thin.

Owner:STANLEY ELECTRIC CO LTD

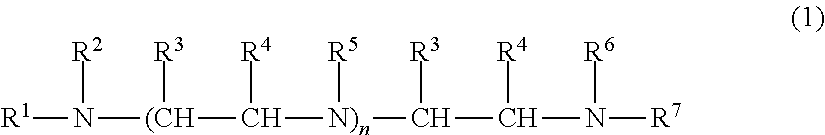

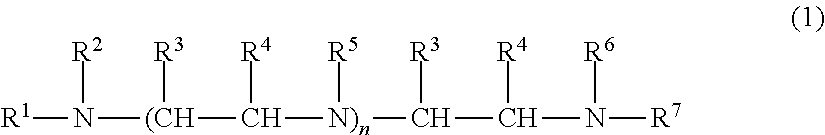

Defoamers for hydratable cementitious compositions

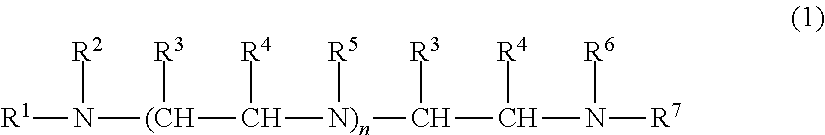

The present invention discloses additive compositions, cementitious compositions, and methods for controlling air in cementitious compositions, wherein a polyalkoxylated polyalkylene polyamine defoamer is deployed in combination with one or more air-entraining agents, such as higher alkanolamines, water-reducing agents including oxyalkylene-containing superplasticizers, or other air entraining agents.

Owner:GCP APPL TECH INC

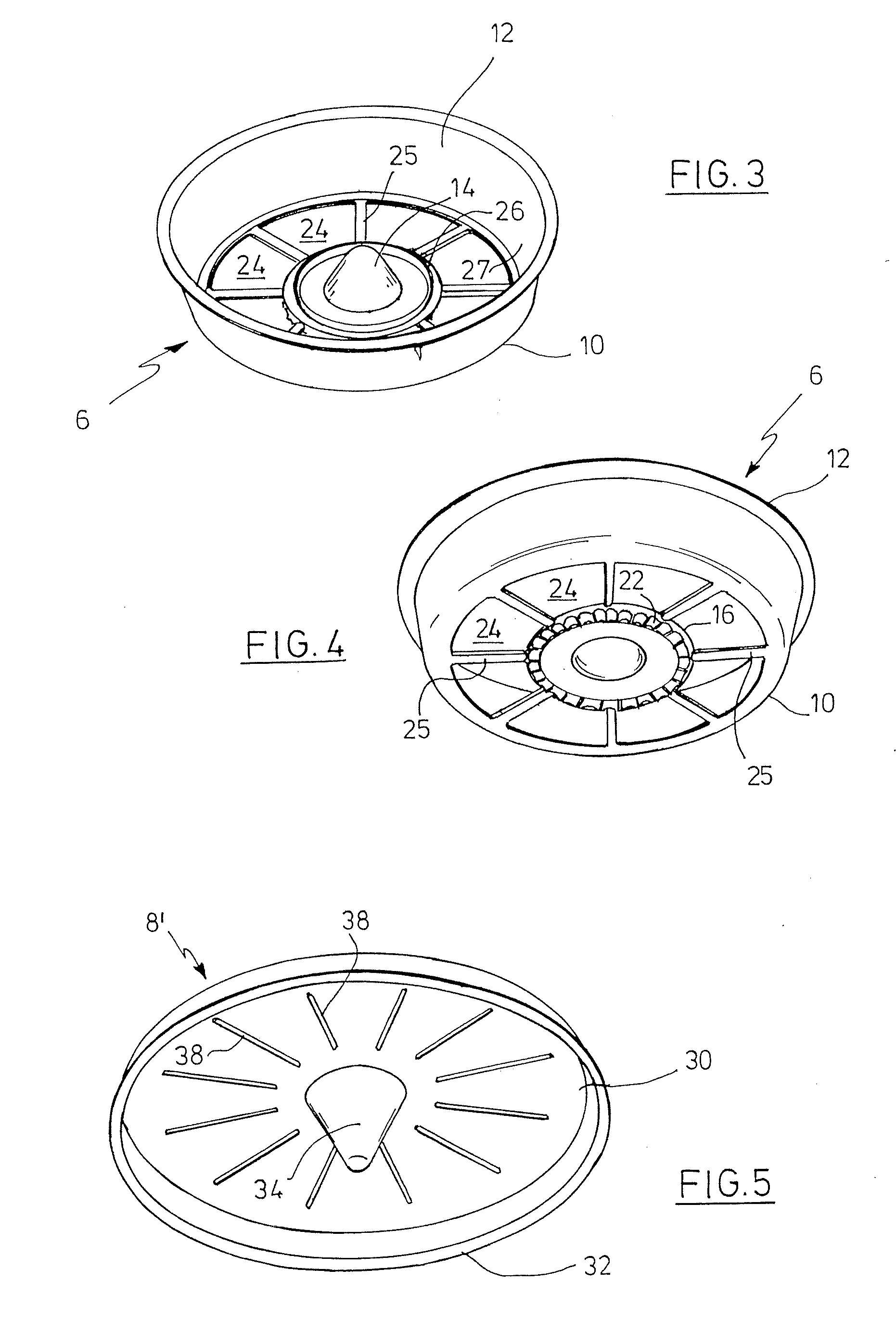

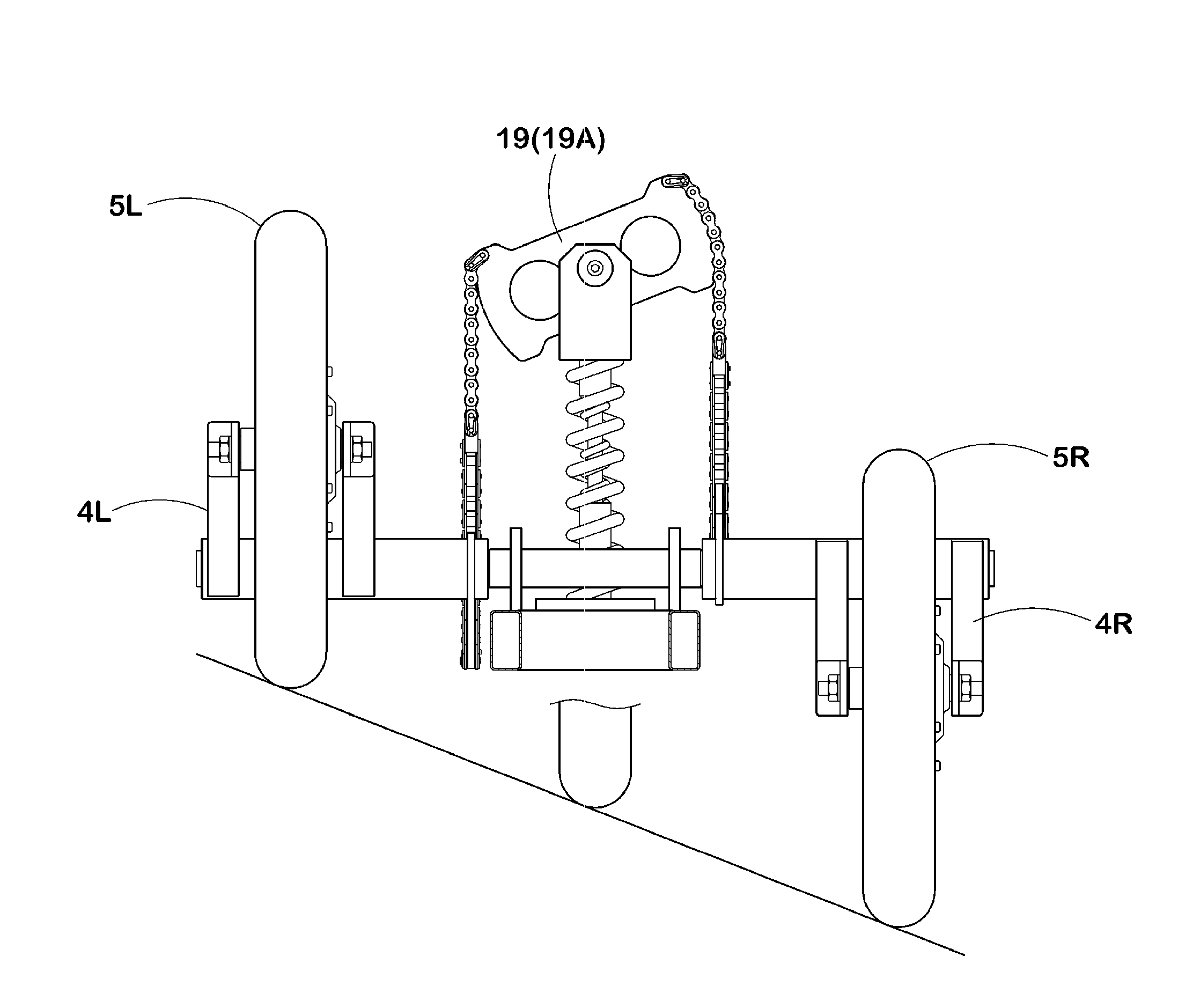

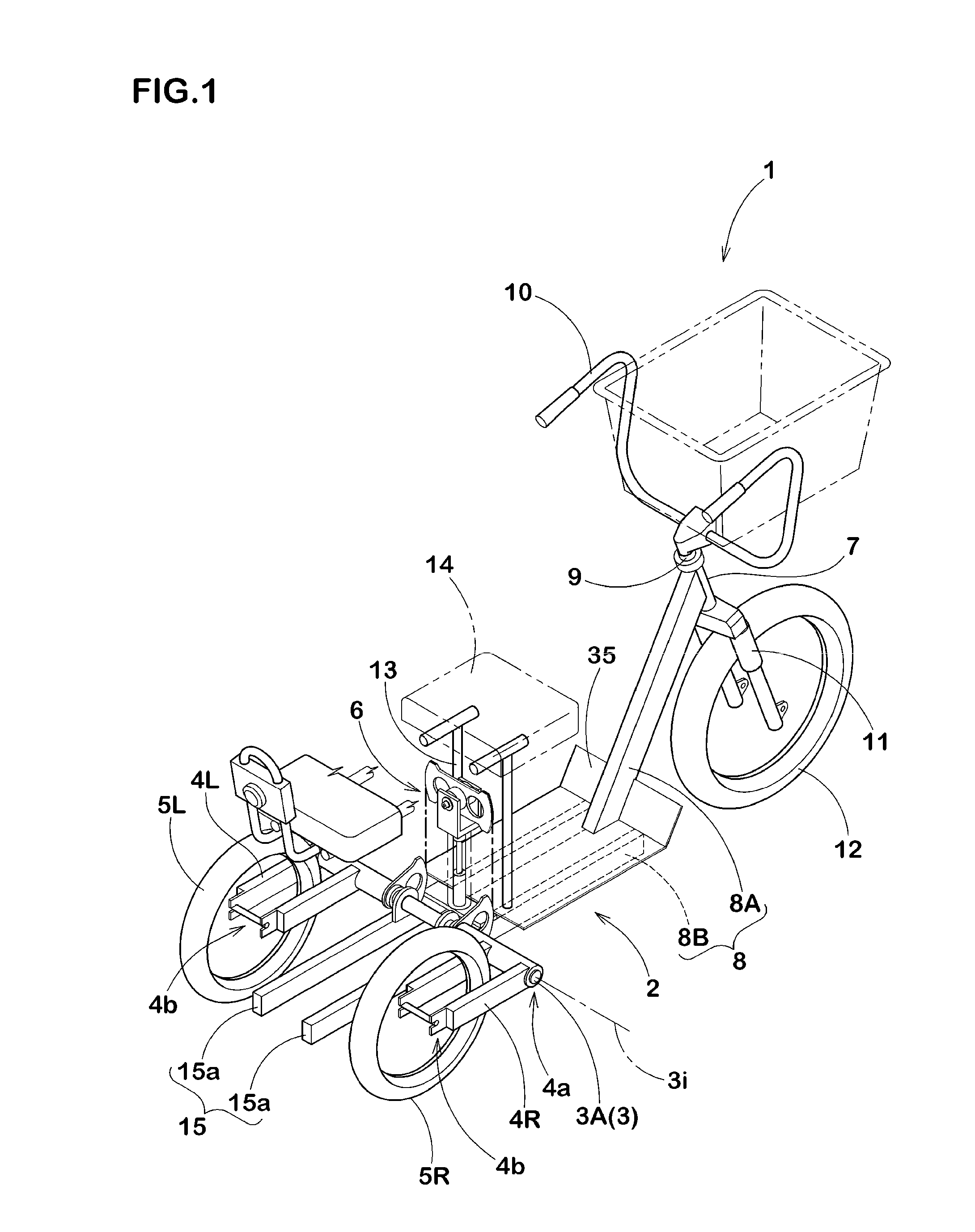

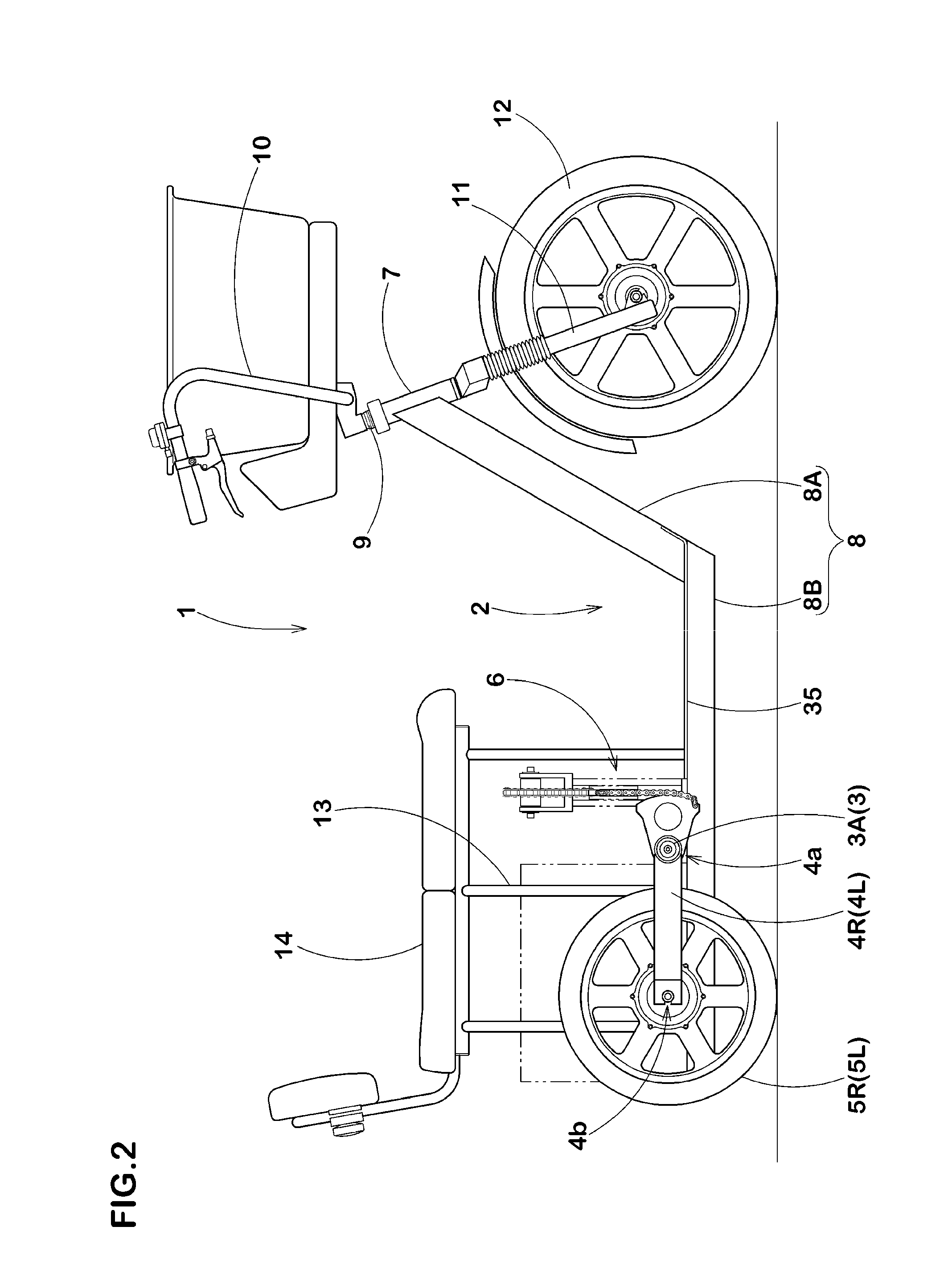

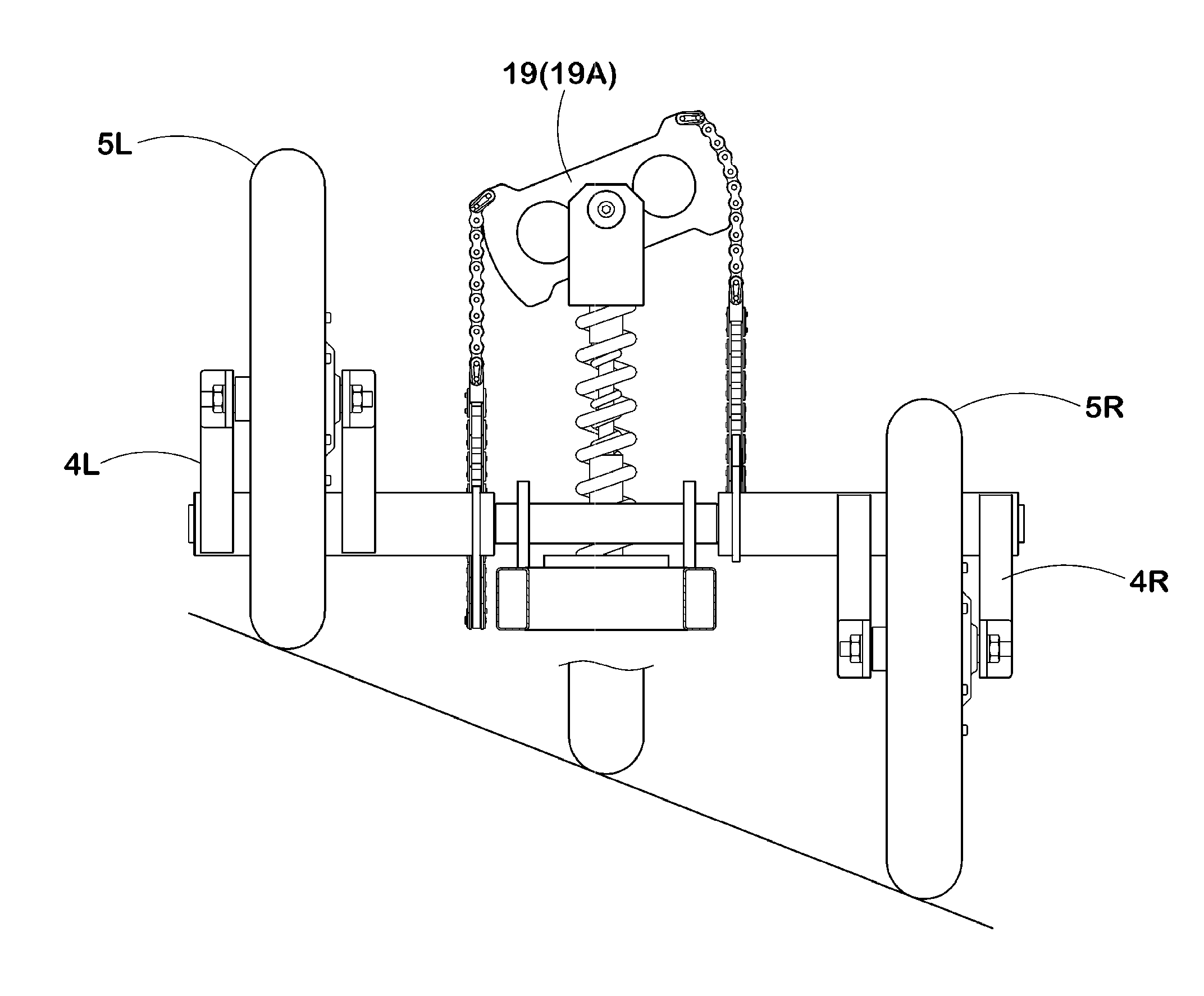

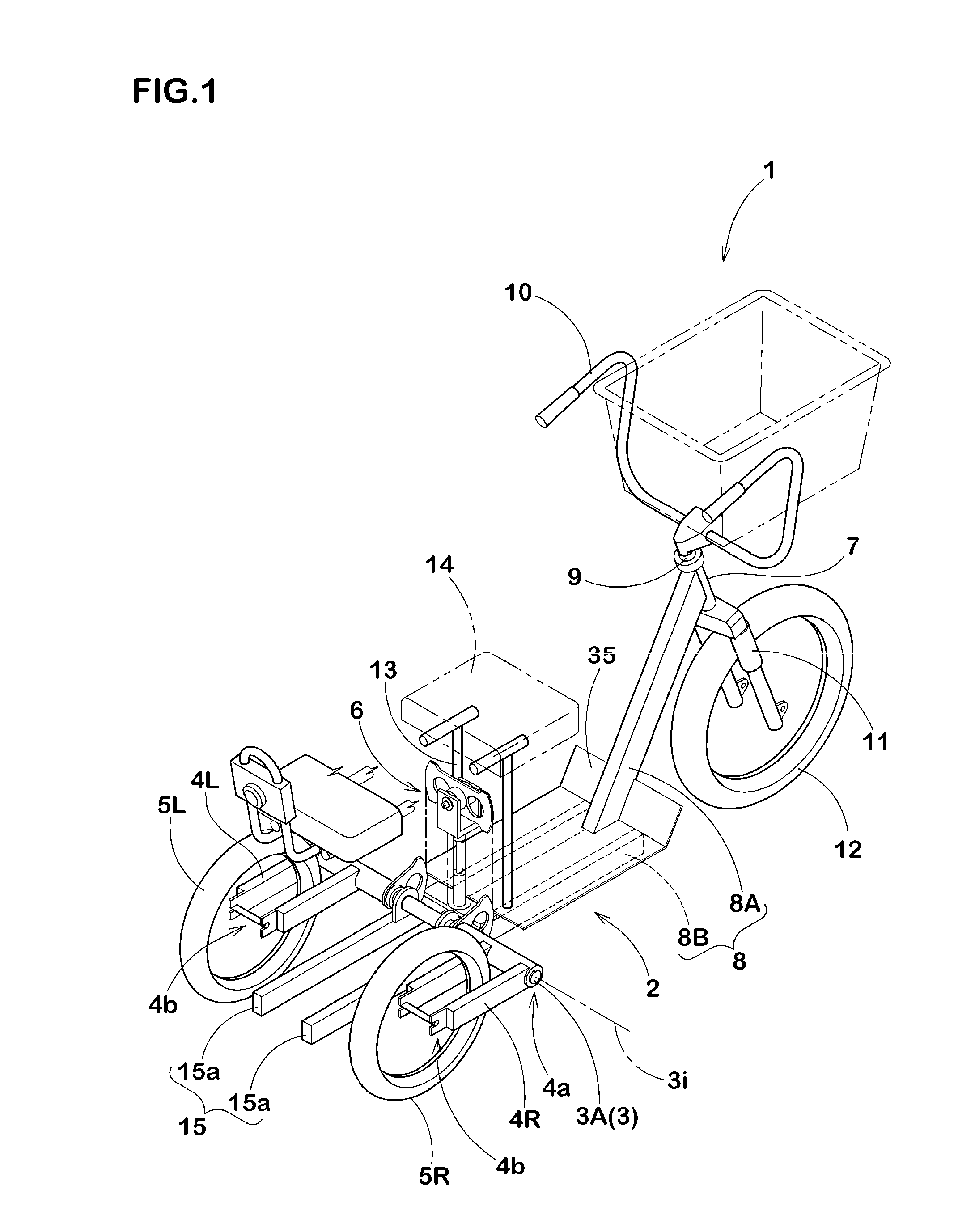

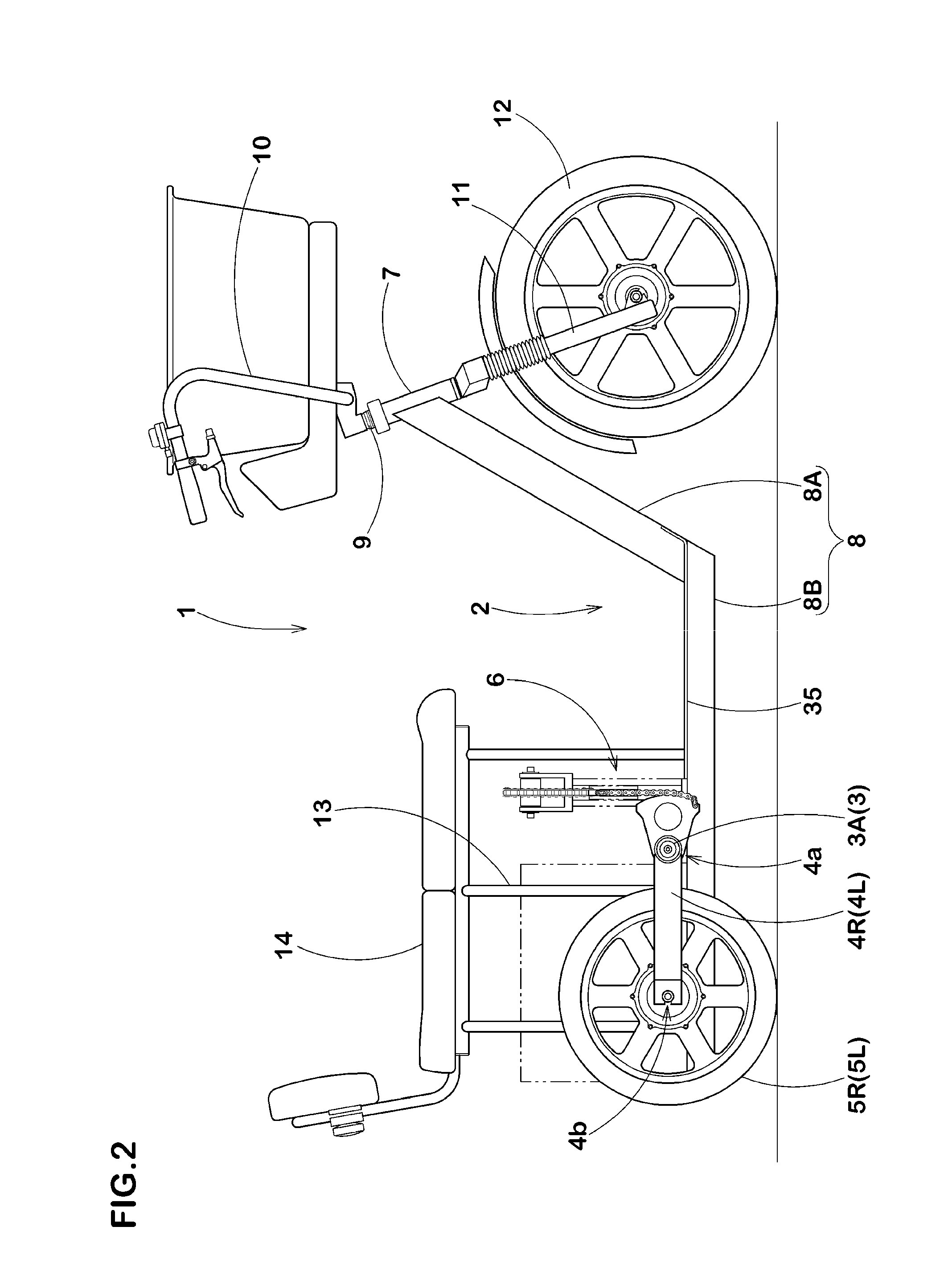

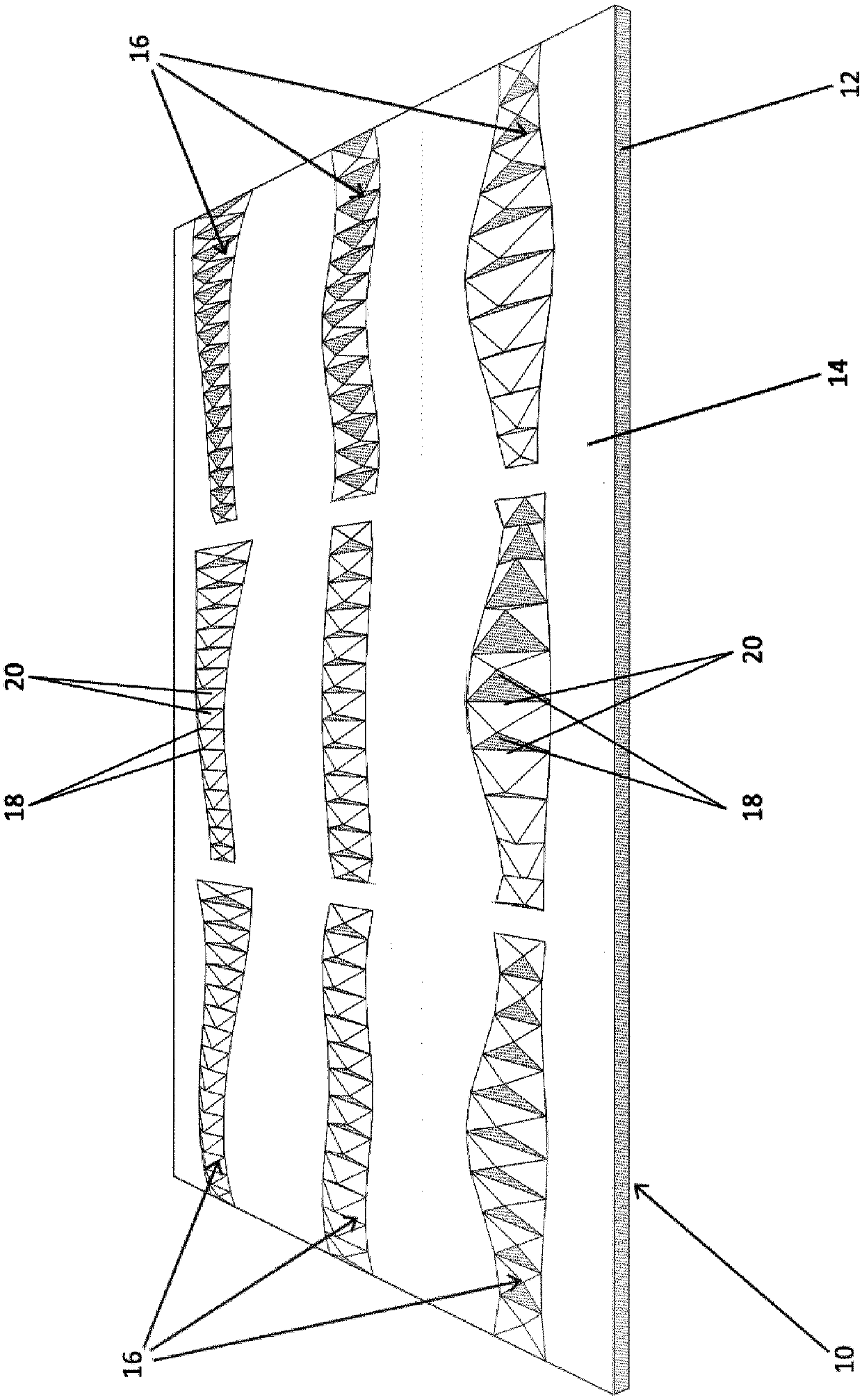

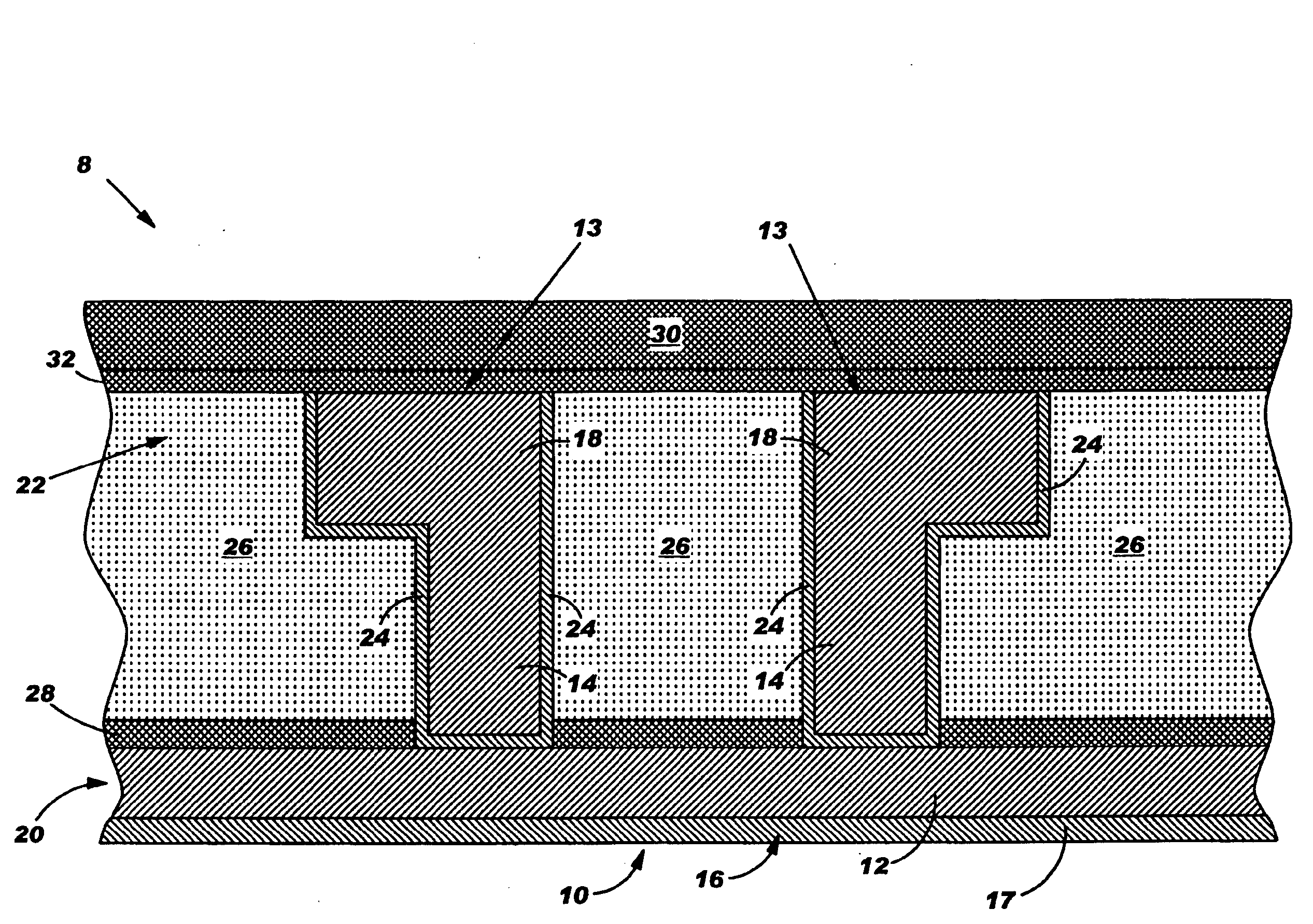

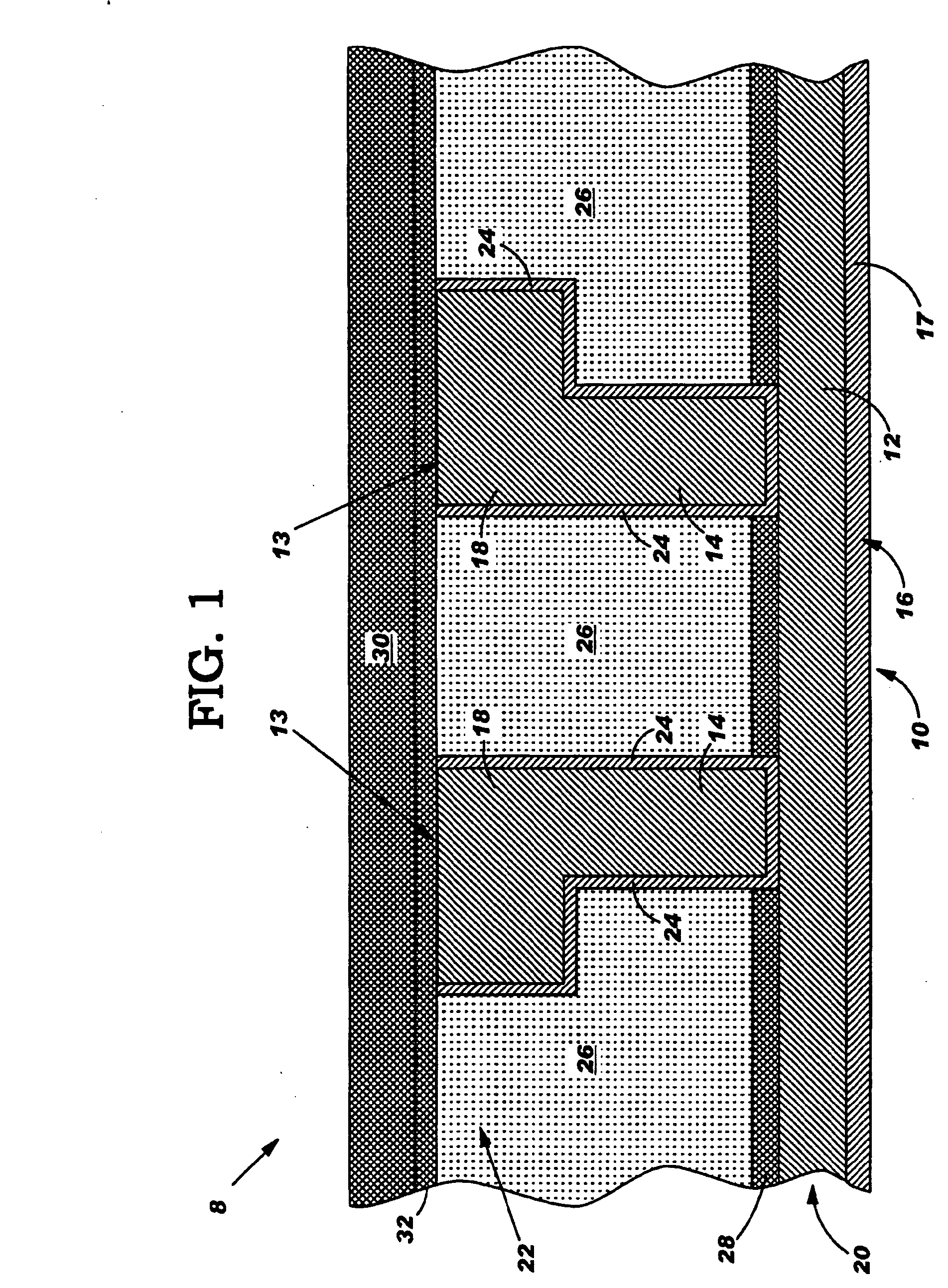

Multiple wheel vehicle

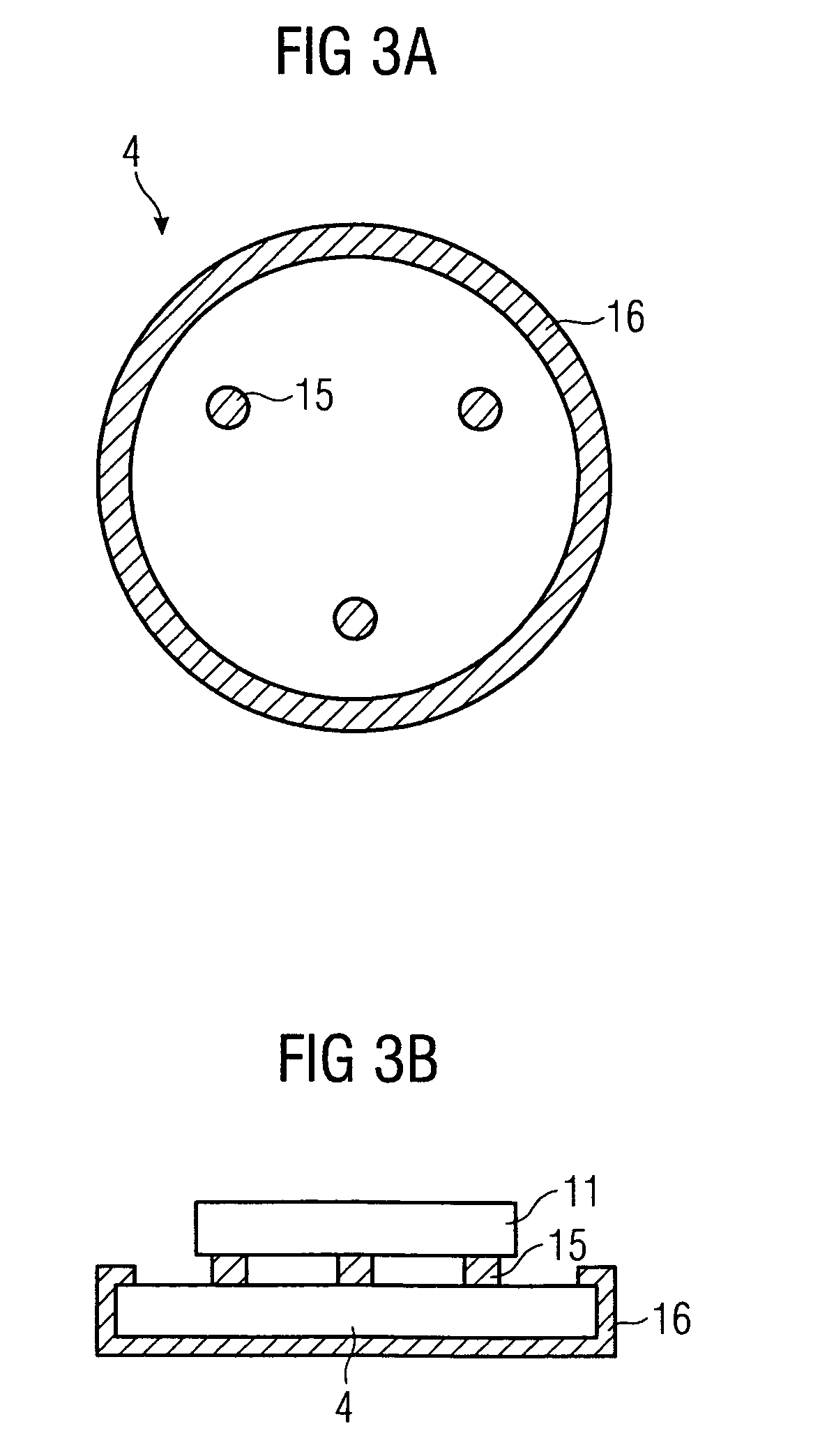

ActiveUS20110254238A1Improve camber thrustImprove cornering propertyCyclesCycle standsGround contactCircular surface

A multiple wheel vehicle according to the present invention enables to incline freely the two wheels together with the vehicle body while keeping the ground contacting pressures of the two wheels equal. The multiple wheel vehicle comprises a pair of swinging arms 4 each comprising one-side end portion supported pivotably with right and left support shaft portions 3A and an interlocking device 6 for interlocking them alternately up-and-down. The interlocking device 6 comprises a pair of tilted members 17, a divertible member 19, and a cord-like body 20 connecting them. Each of the tilted members 17 comprises a first circular surface part 21 that has a center of a circular arc as a shaft center 3i of the support shaft portion 3A, and tiltably supported integrally with the swinging arm 4. The above-mentioned divertible member 19 is provided on the right and left and on one-side and another-side with one-side and another-side second circular surface parts 26 which has a center of the circular arc as a second shaft center 18i which is in the direction perpendicular to each of the above-mentioned first shaft centers 3i, respectively. The above-mentioned cord-like body 20 comprises one-side cord-like part 20L connecting the first and second circular surface parts 21 on the one-side and other-side cord-like part 20R connecting the first and second circular surface parts 21 on the other-side.

Owner:KANOU KINYA

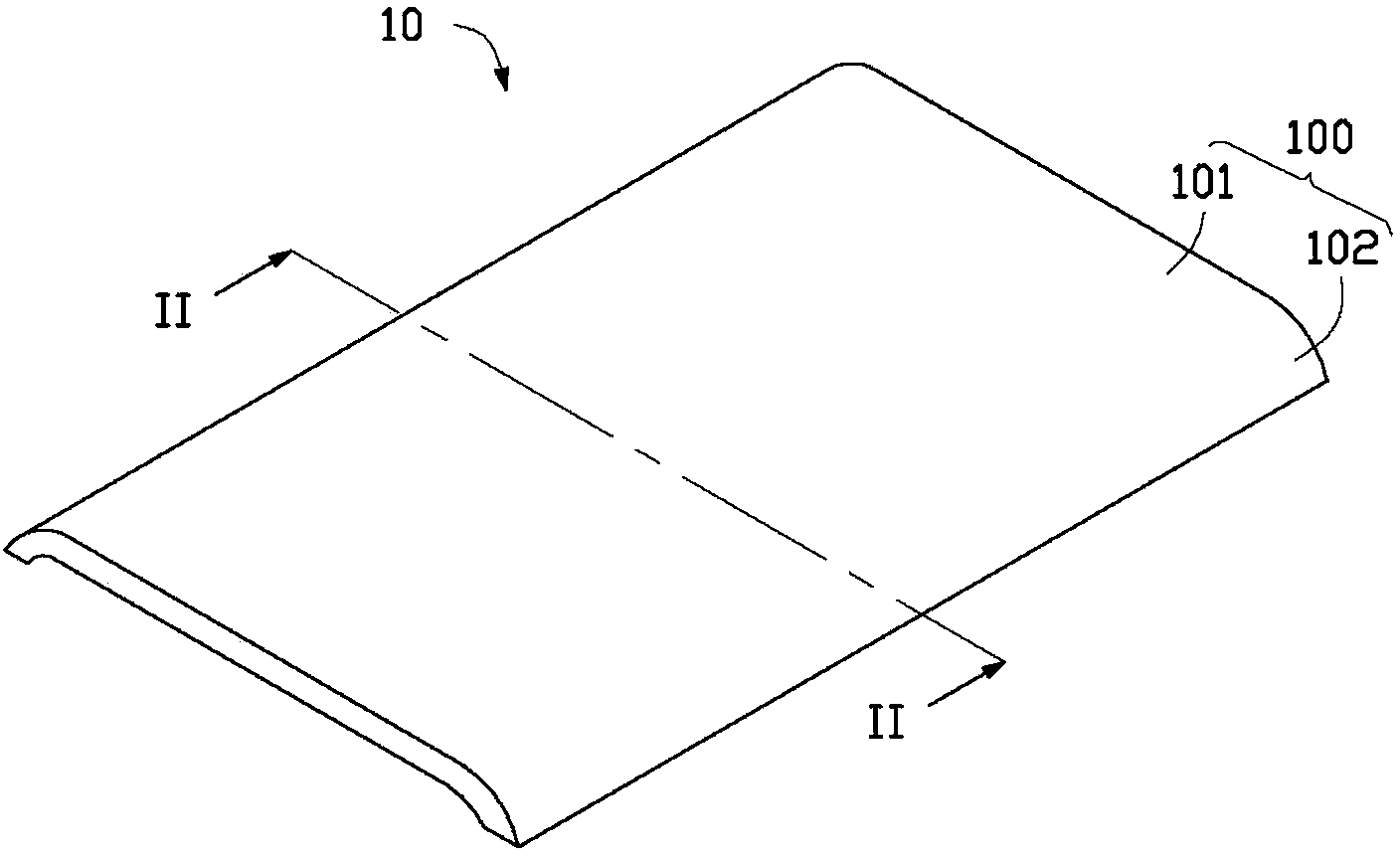

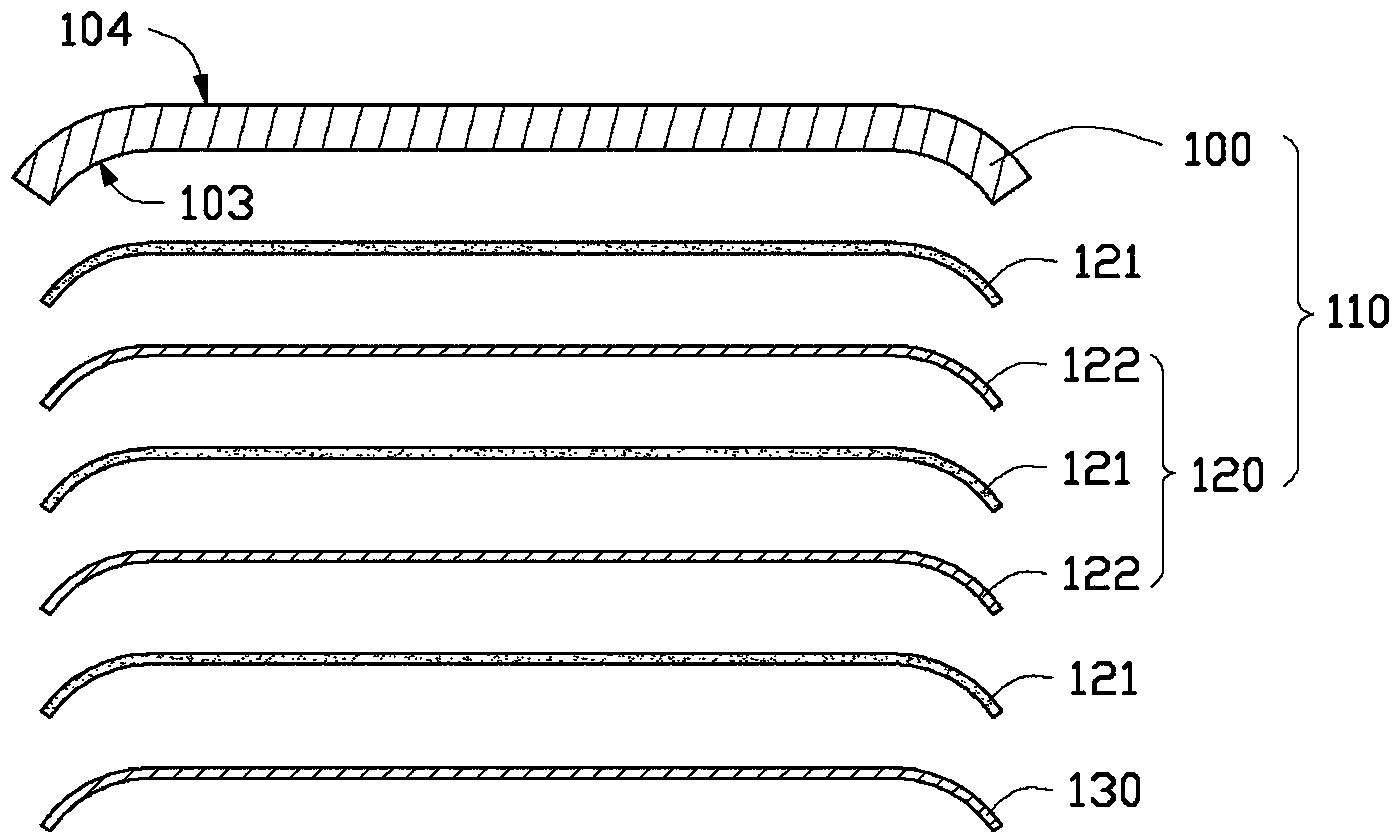

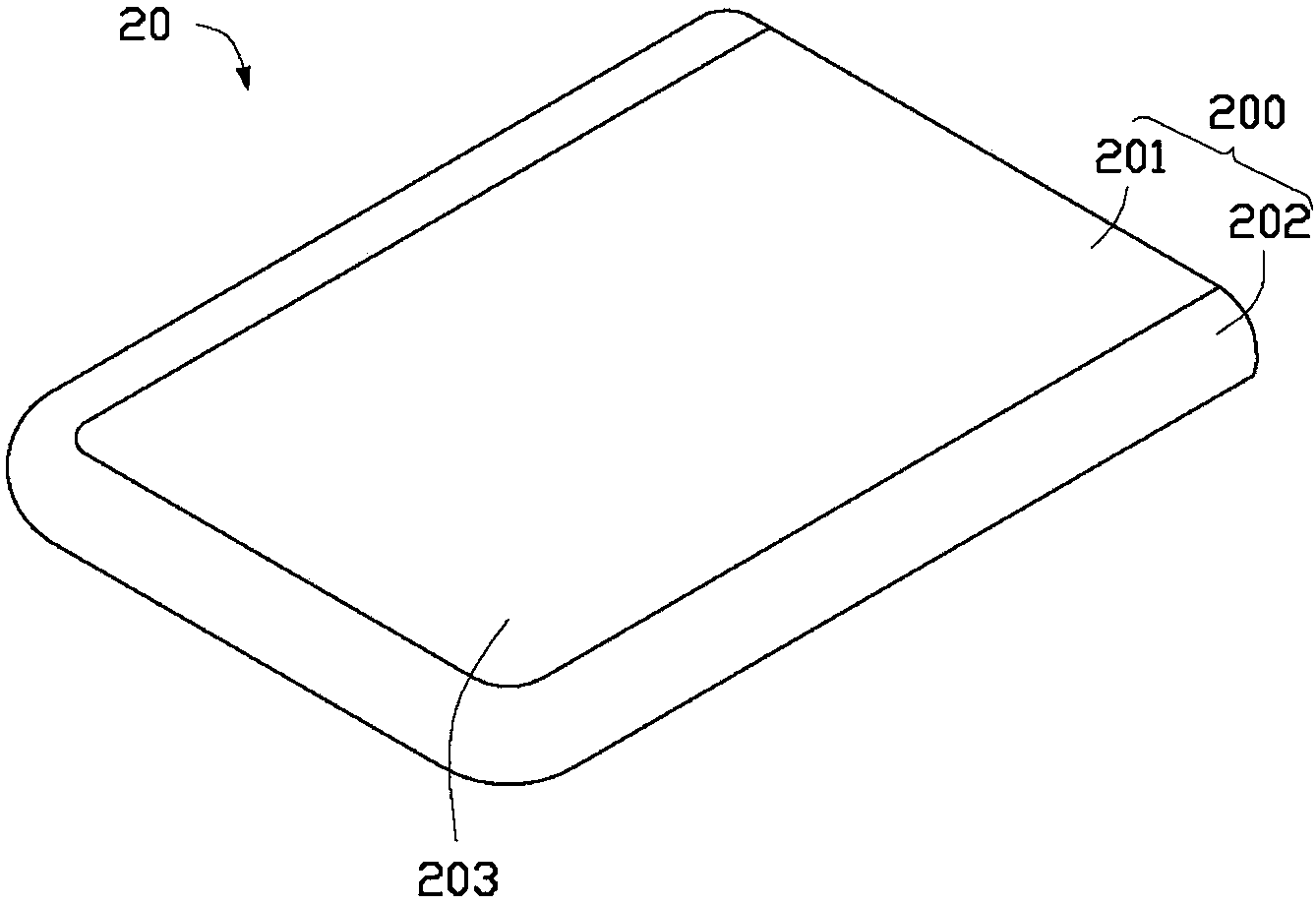

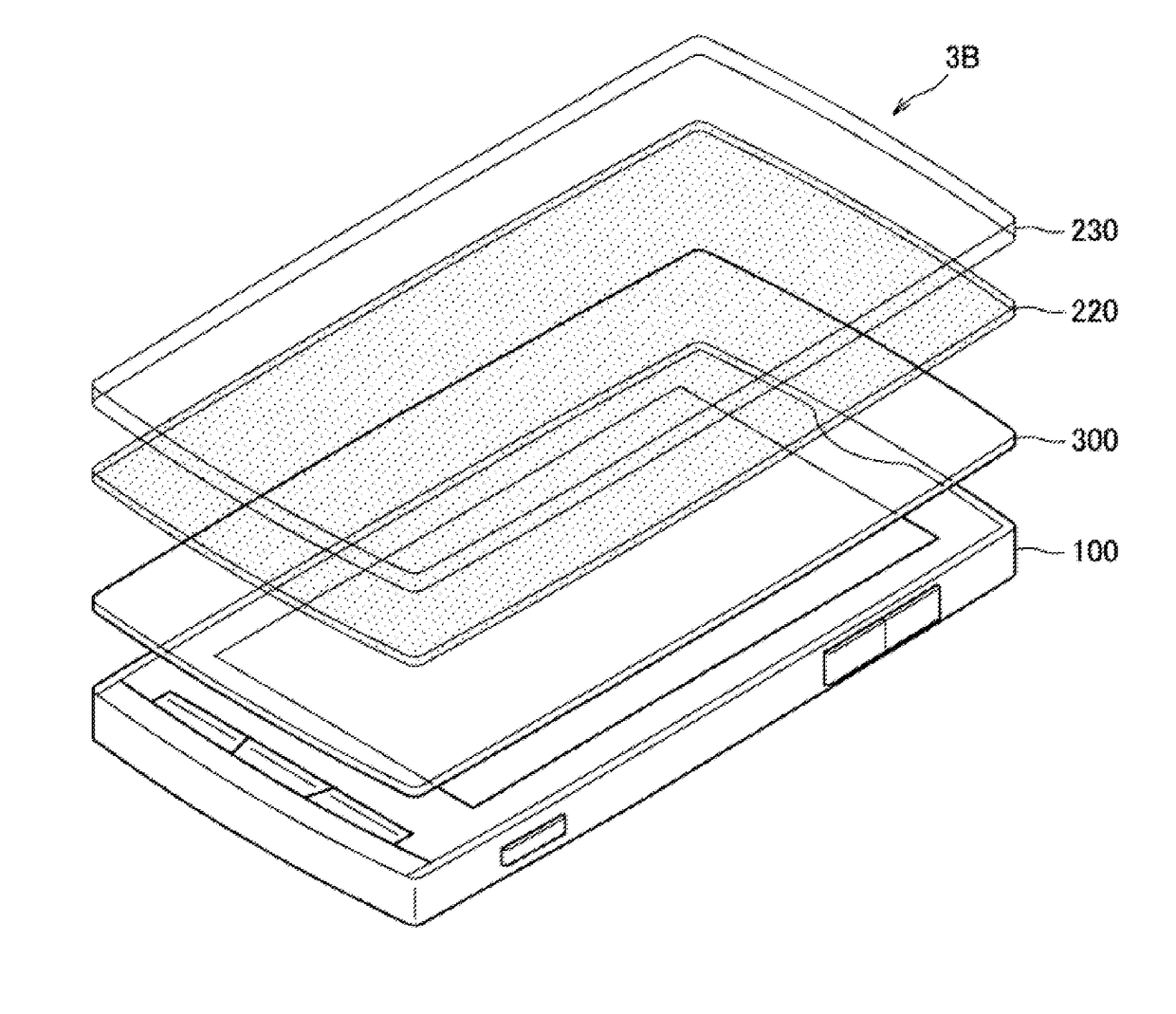

Touch control structure and electronic product provided with the same

InactiveCN103902089AEasy to attachIncreased Design PossibilitiesInput/output processes for data processingControl layerSenses touch

The invention provides a touch control structure comprises a substrate and a touch control layer for sensing touch and pressing actions. At least one part of the substrate is bended in shape and the touch control layer is provided with at least one shape corresponding the bended part of the substrate. The touch control layer is adhered to the substrate through a layer of adheresive agents. The invention also provides an electronic product with such a touch and control structure.

Owner:G TECH OPTOELECTRONICS CORP

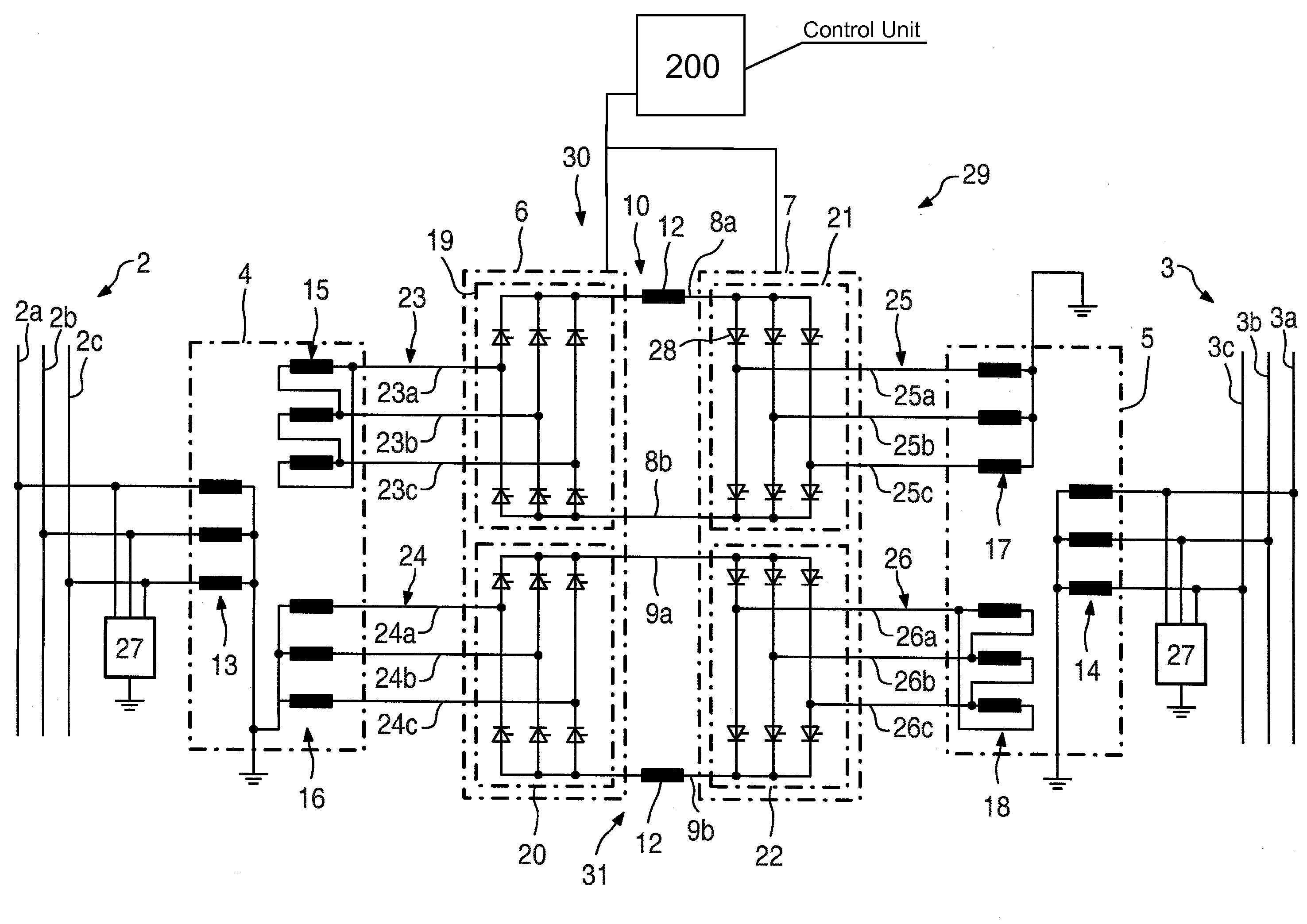

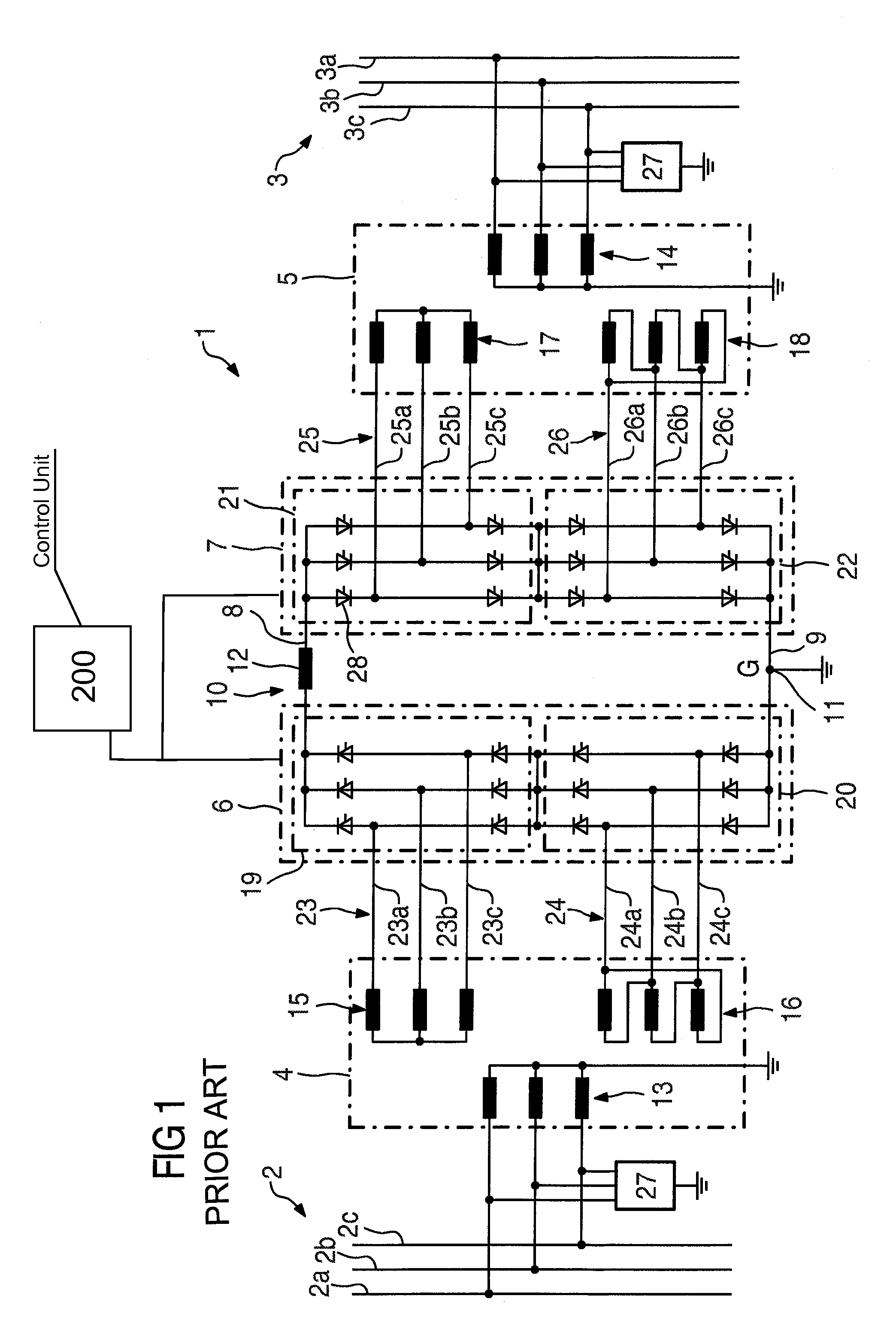

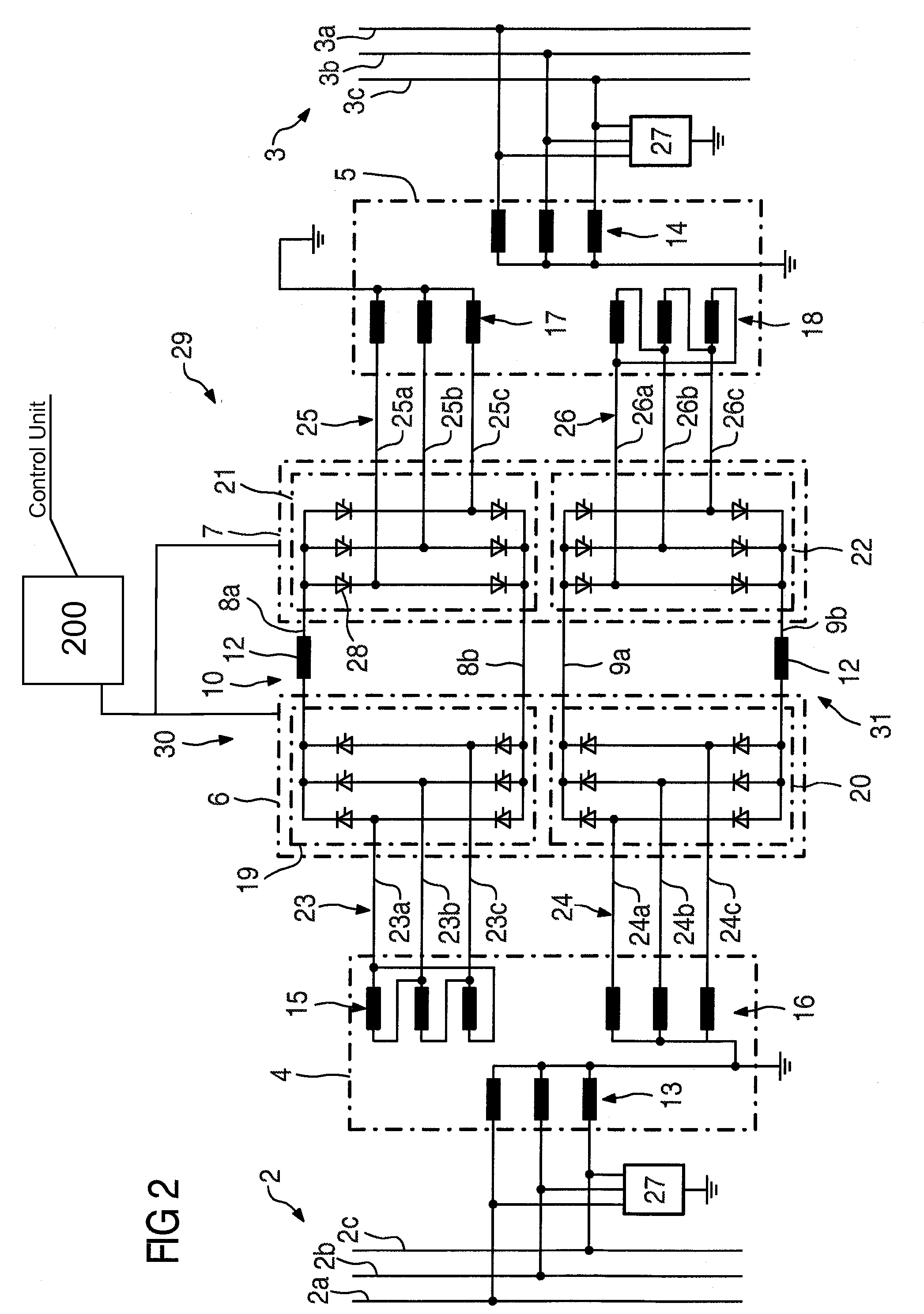

Twelve-pulse HVDC transmission

ActiveUS7881078B2Cost-effectiveMore cost-effectiveConversion with intermediate conversion to dcEmergency protective circuit arrangementsPhase shiftedInductance

A device for transmitting electric power between alternating voltage networks includes converters interconnected by direct current lines and provided each with several six-pulse conversion bridges. The six-pulse conversion bridges of one same converter are capable of being connected to an alternating voltage network associated with the converters via inductances differently phase-shifted. A control unit is provided to energize the valves of the six-pulse conversion bridges. The device is more economical and the converters are interconnected by a plurality of direct current circuits, each direct current circuit being galvanically separated from at least an alternating voltage network.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

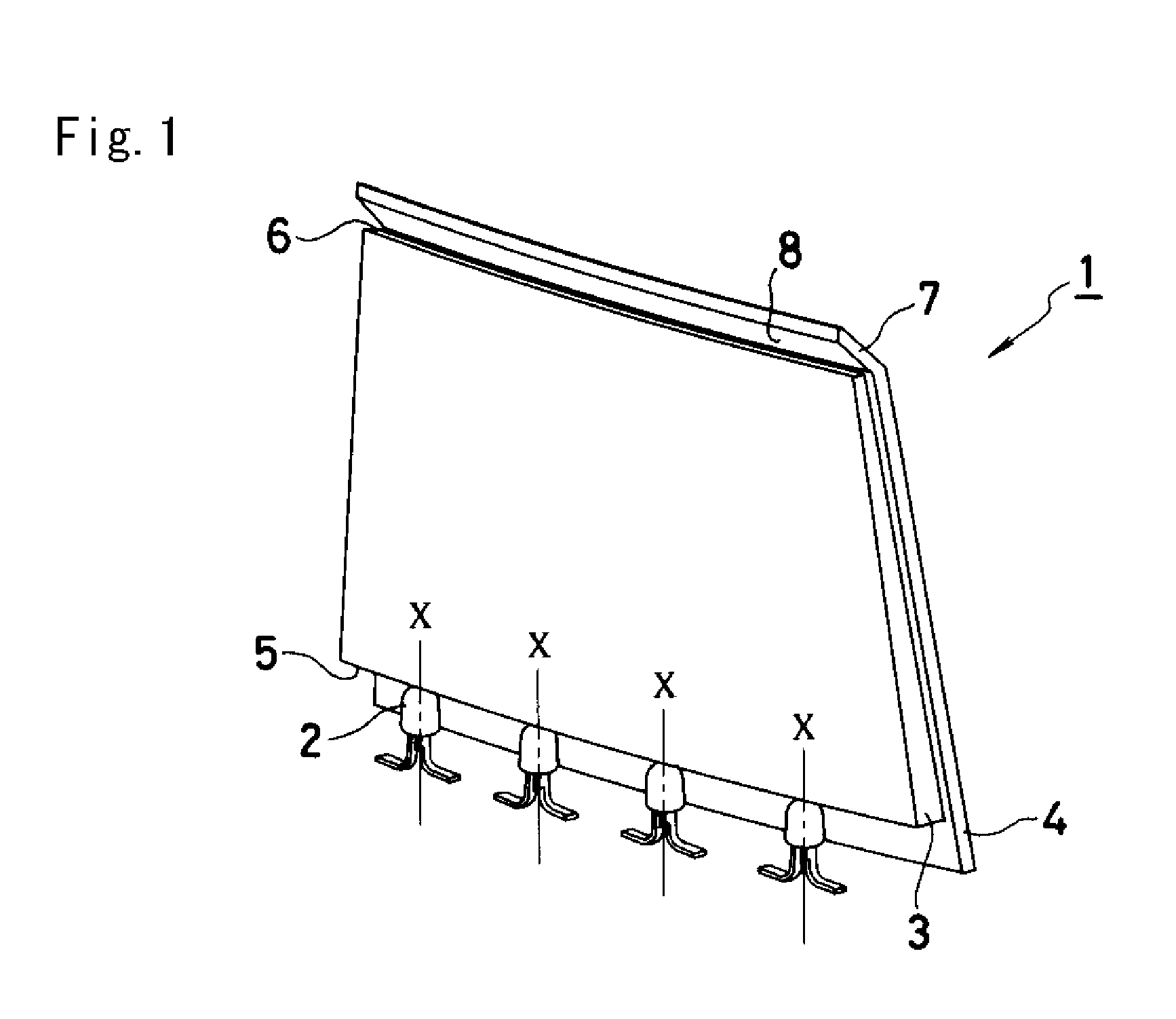

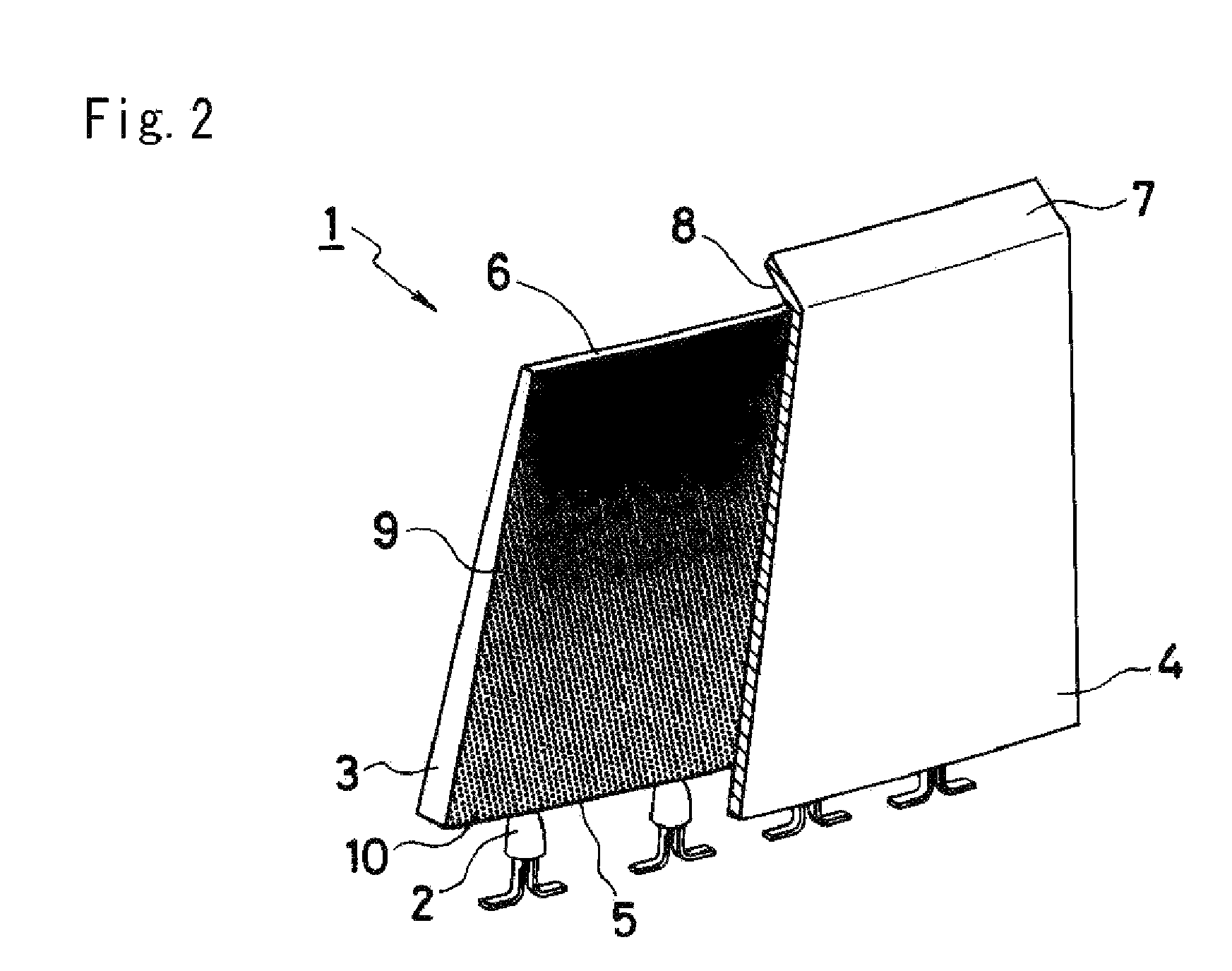

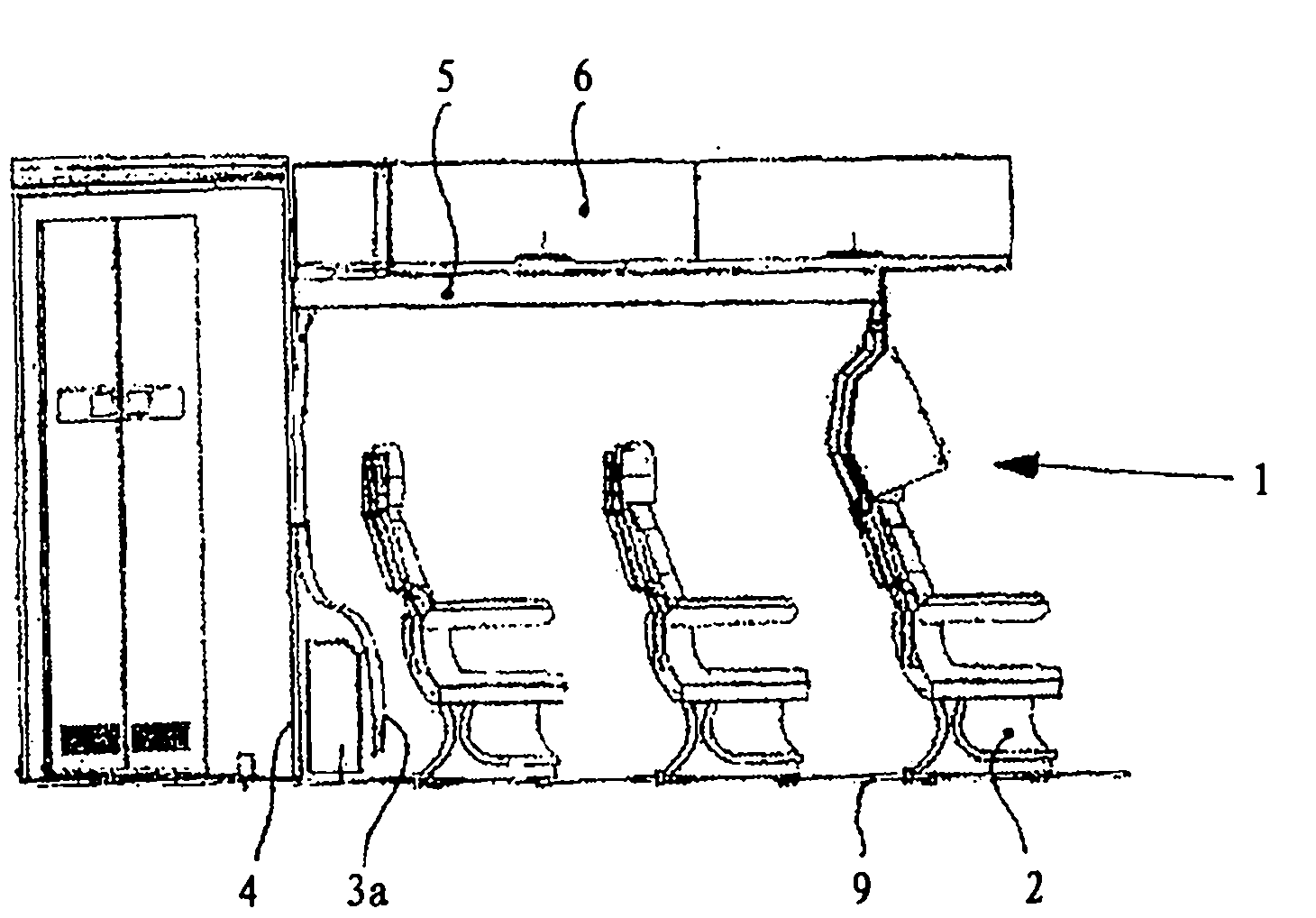

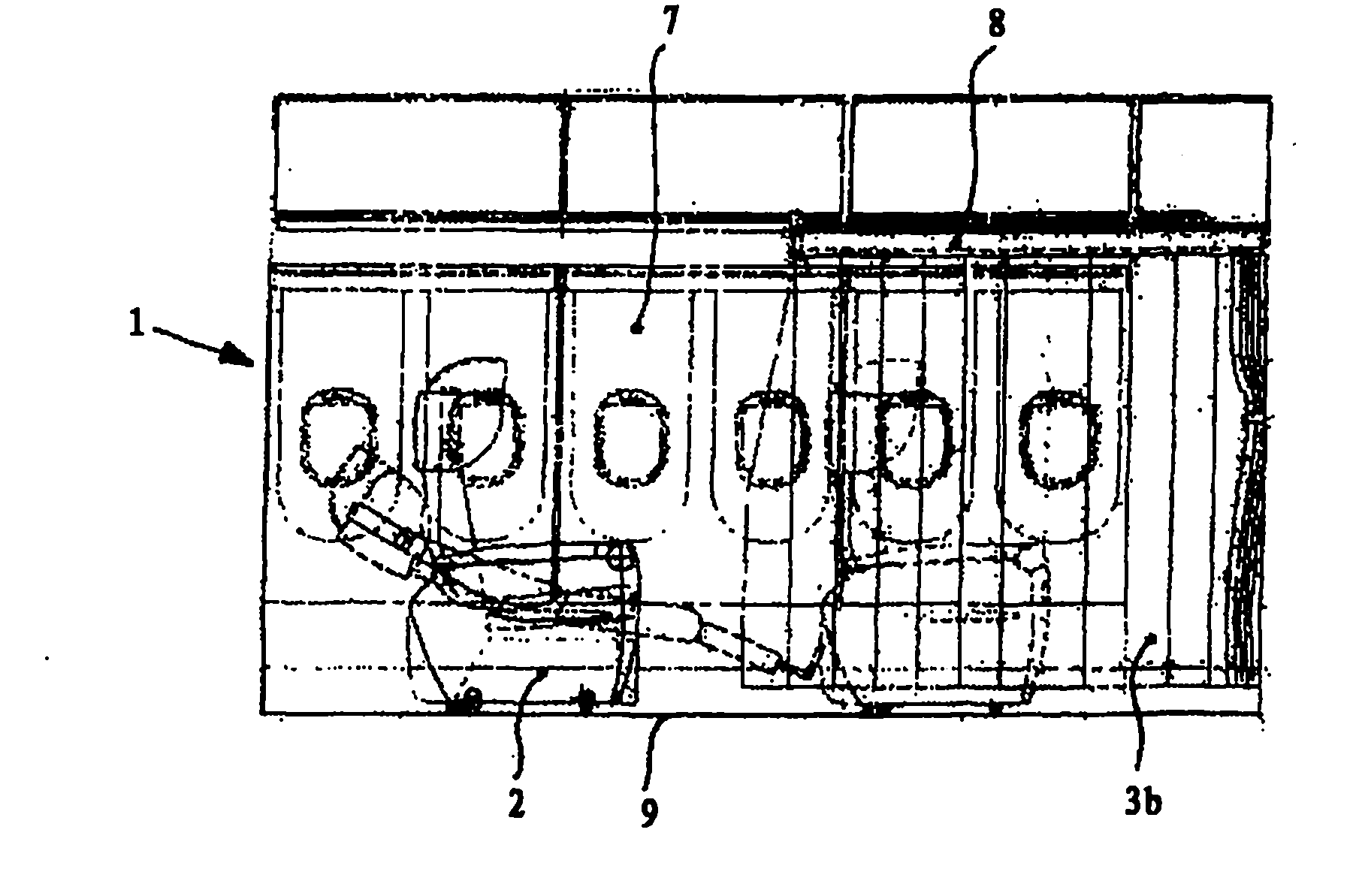

Screen for a passenger cabin

InactiveCN102317156AIncreased Design PossibilitiesPositive visual effectsSeating arrangementsFastener

Owner:AIRBUS OPERATIONS GMBH

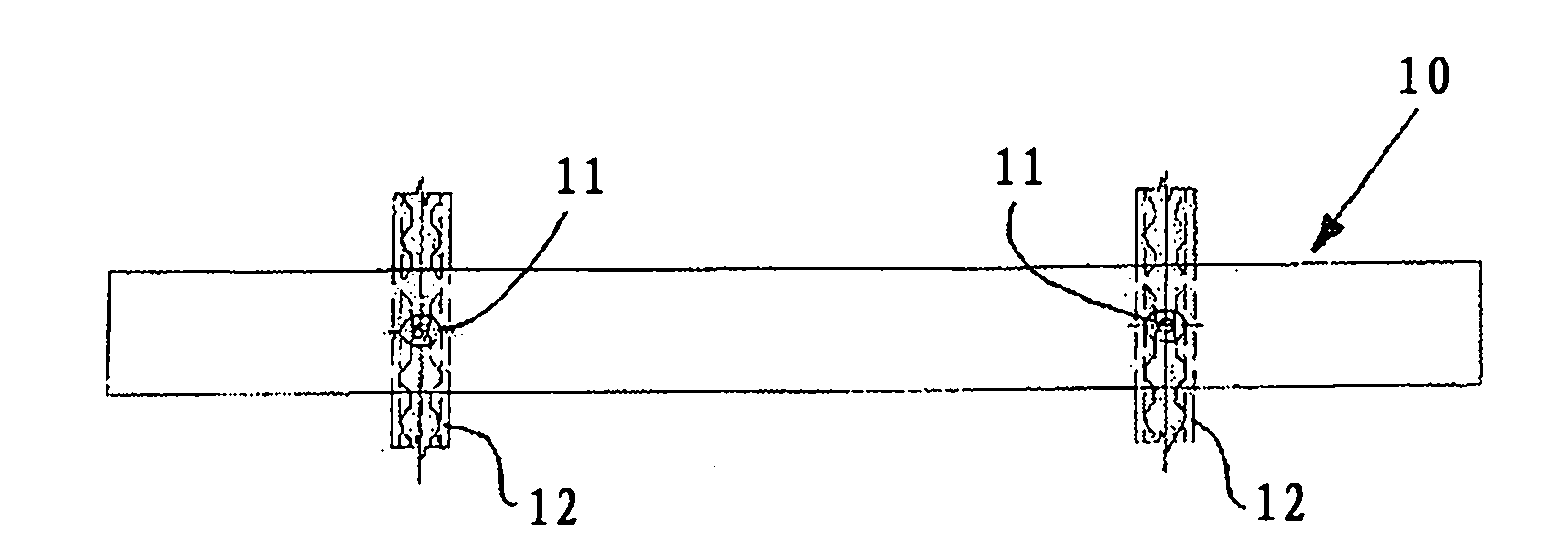

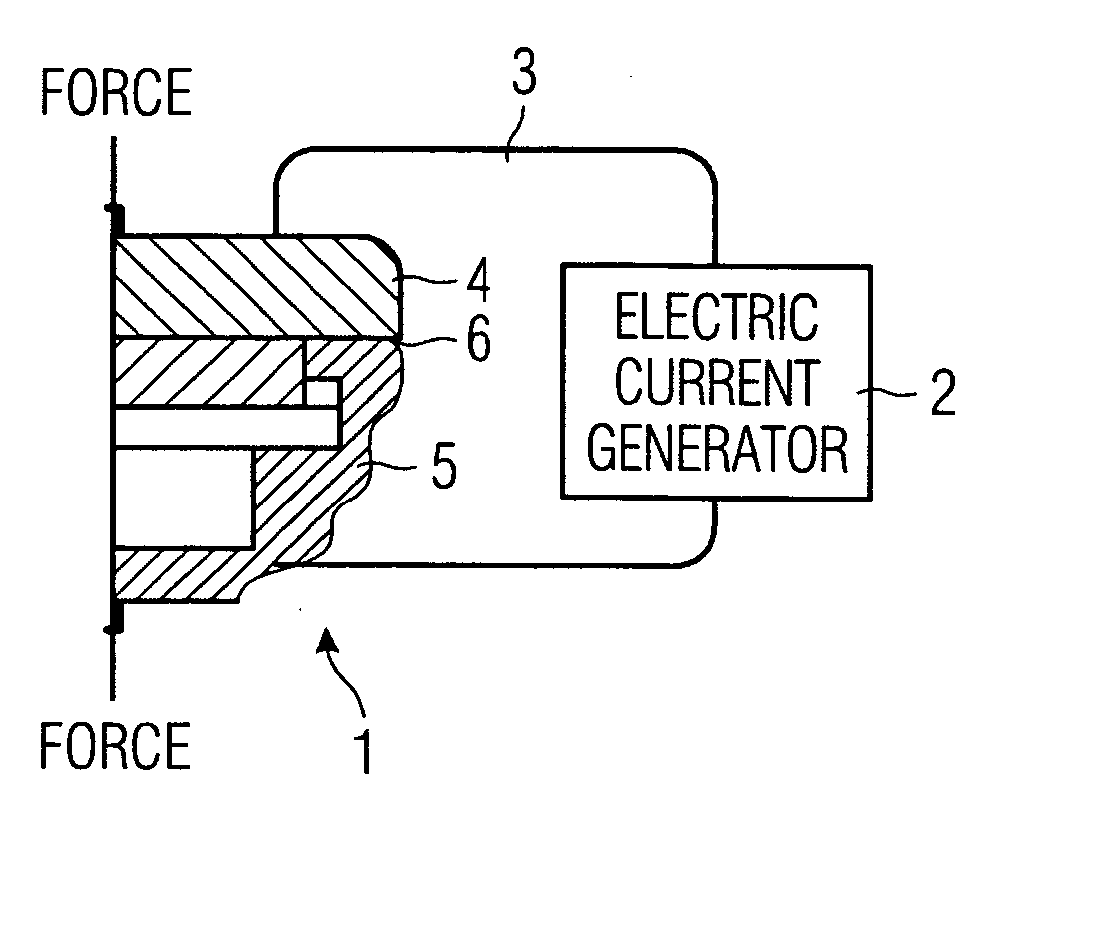

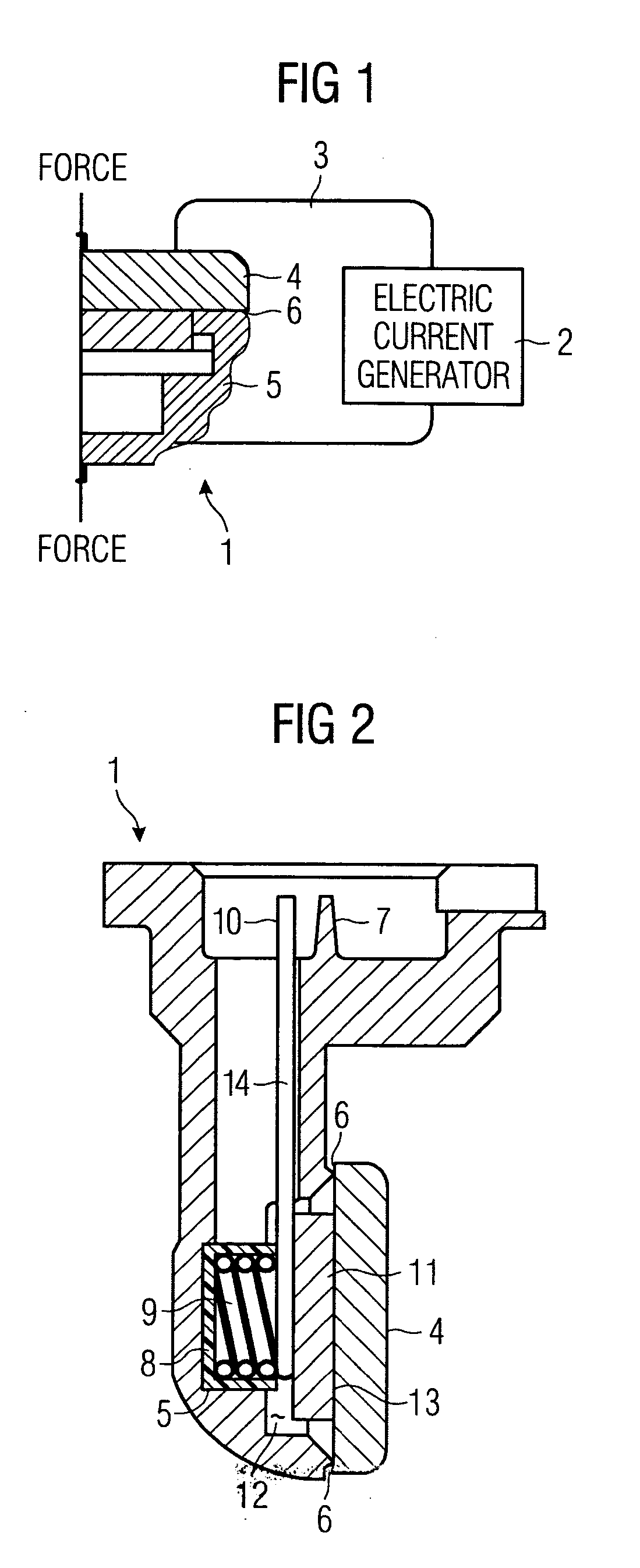

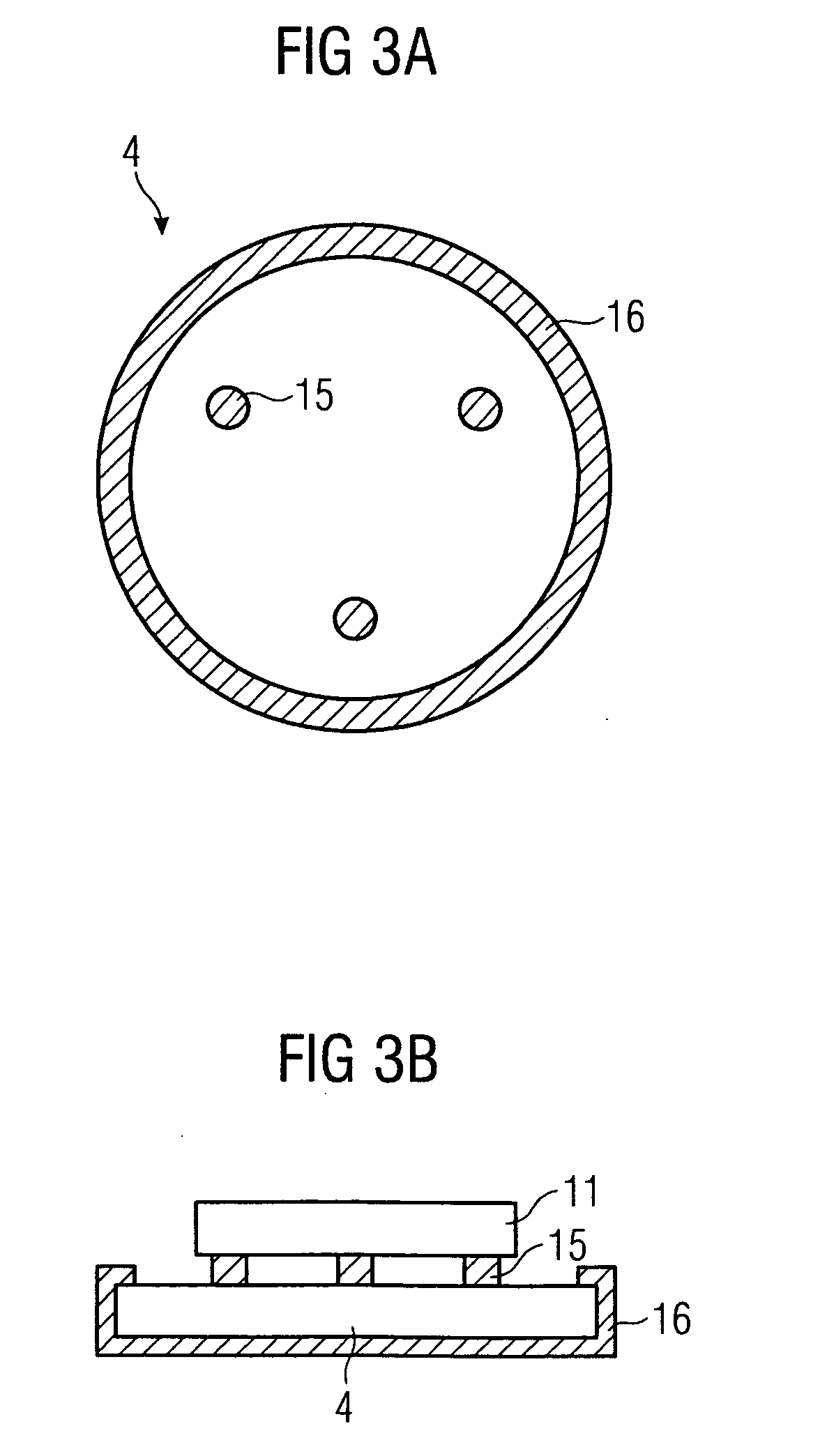

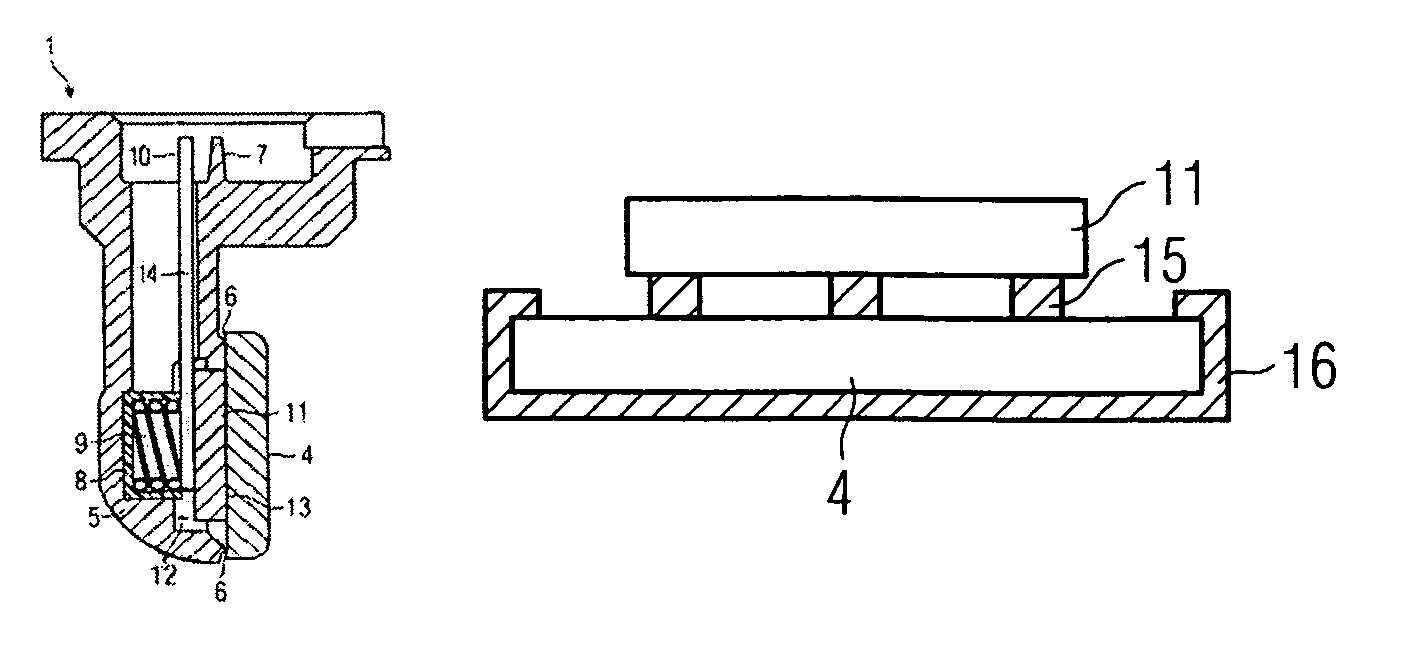

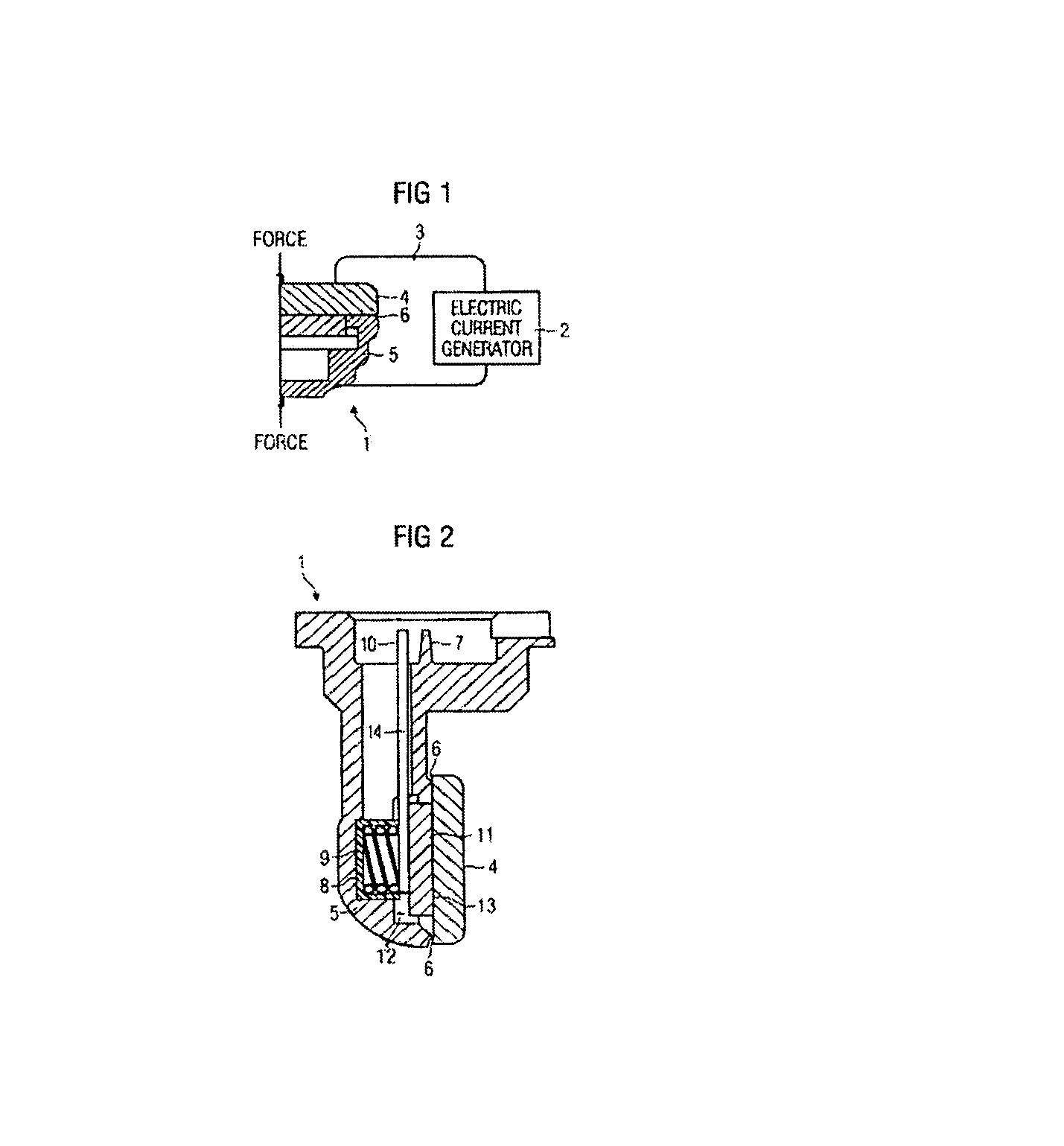

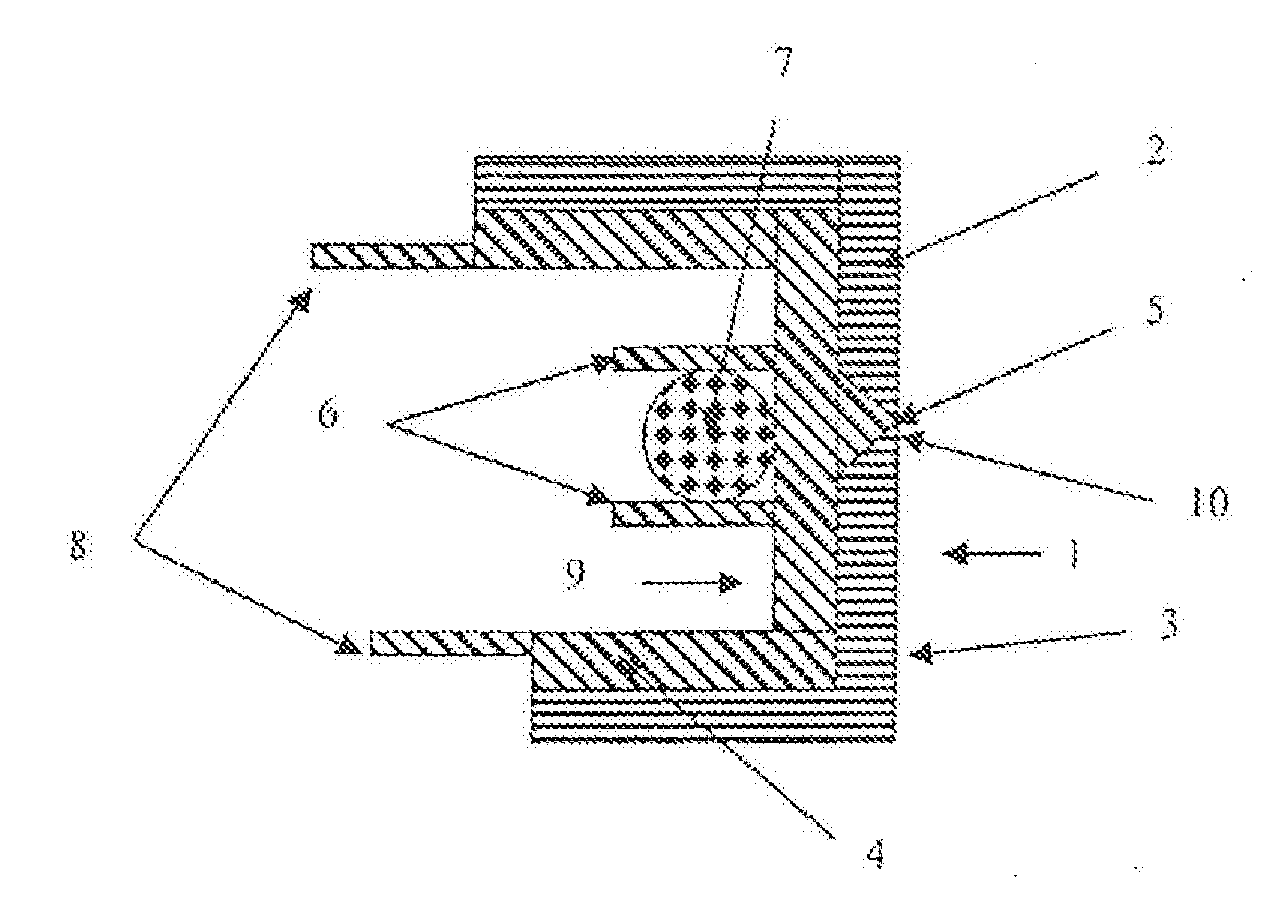

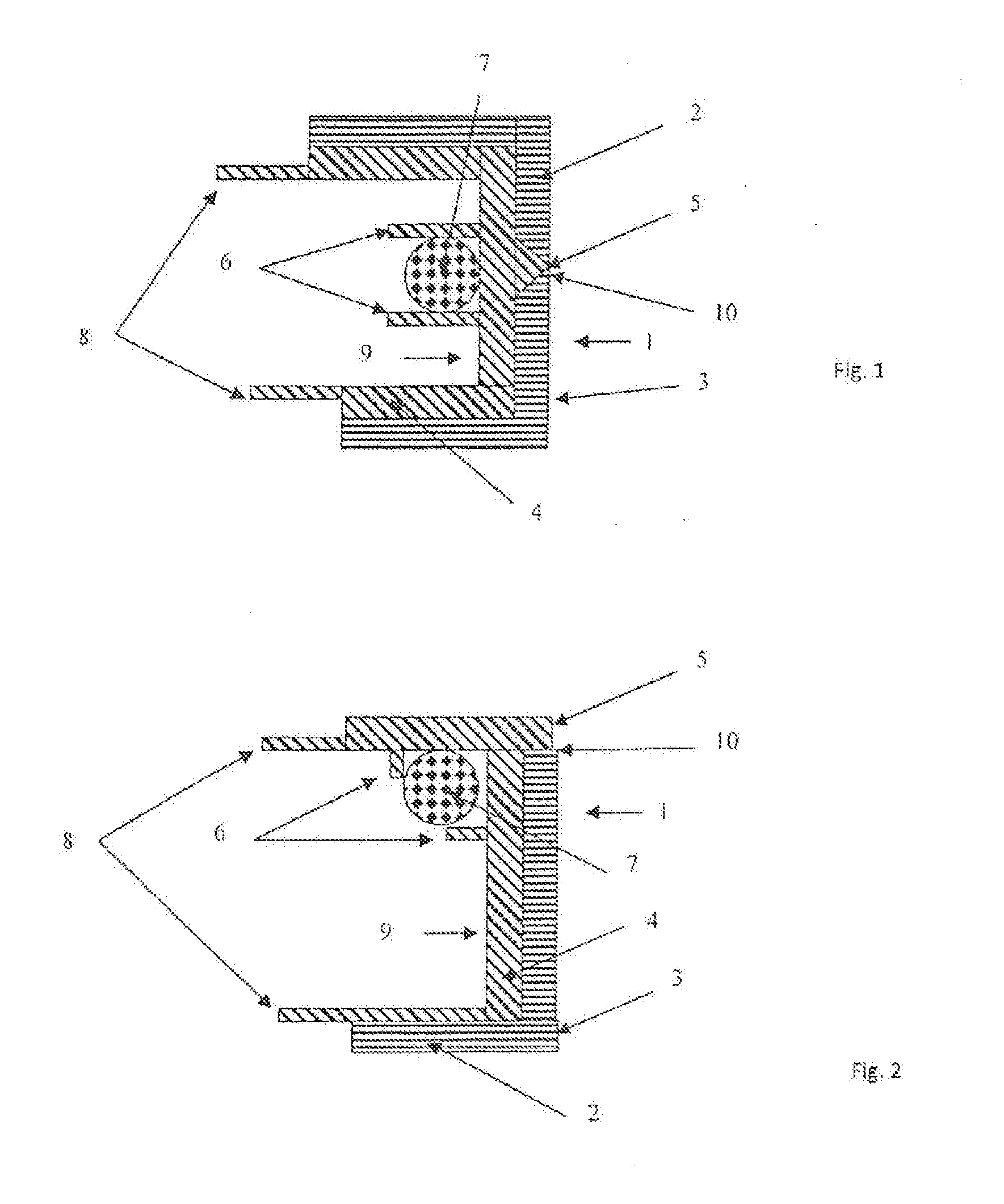

Ultrasonic transducer and method of joining an ultrasonic transducer

InactiveUS20050061084A1Low heat inputEasy to manufacturePiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive transducersUltrasonic sensorTransducer

The invention concerns an ultrasonic transducer, which is assembled from several parts. These parts are a protecting plate, a piezoelectric disc and a housing. Joining of the parts for transducers are normally done by means of TIG welding or laser welding, but these are relatively costly processes, which also has an impact on the transducer, especially the piezoelectric disc, due to the heat. In order to reduce the heat load and simultaneously simplify manufacturing an ultrasonic transducer is suggested, in which the protecting plate and the housing consists of electrically conducting materials of different kinds and where joining of housing and plate is done by using a mechanical force influence and an electrical current which flows through plate and housing. Also, a method for joining the parts of an ultrasonic transducer is described.

Owner:SIEMENS AG +1

Multiple wheel vehicle

ActiveUS8376372B2Improve propertiesImprove stabilityCyclesCycle standsGround contactCircular surface

A multiple wheel vehicle according to the present invention enables to incline freely the two wheels together with the vehicle body while keeping the ground contacting pressures of the two wheels equal. The multiple wheel vehicle comprises a pair of swinging arms 4 each comprising one-side end portion supported pivotably with right and left support shaft portions 3A and an interlocking device 6 for interlocking them alternately up-and-down. The interlocking device 6 comprises a pair of tilted members 17, a divertible member 19, and a cord-like body 20 connecting them. Each of the tilted members 17 comprises a first circular surface part 21 that has a center of a circular arc as a shaft center 3i of the support shaft portion 3A, and tiltably supported integrally with the swinging arm 4. The above-mentioned divertible member 19 is provided on the right and left and on one-side and another-side with one-side and another-side second circular surface parts 26 which has a center of the circular arc as a second shaft center 18i which is in the direction perpendicular to each of the above-mentioned first shaft centers 3i, respectively. The above-mentioned cord-like body 20 comprises one-side cord-like part 20L connecting the first and second circular surface parts 21 on the one-side and other-side cord-like part 20R connecting the first and second circular surface parts 21 on the other-side.

Owner:KANOU KINYA

Sensor device and method

ActiveCN107710129ASimple and cheap to manufactureImprove experienceElectronic switchingInput/output processes for data processingElectrical connectionConductive materials

Owner:TOUCH ZERO CO LTD

Ultrasonic transducer and method of joining an ultrasonic transducer

InactiveUS7161280B2Low heat inputEasy to manufacturePiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive transducersSonificationUltrasonic sensor

Owner:SIEMENS AG +1

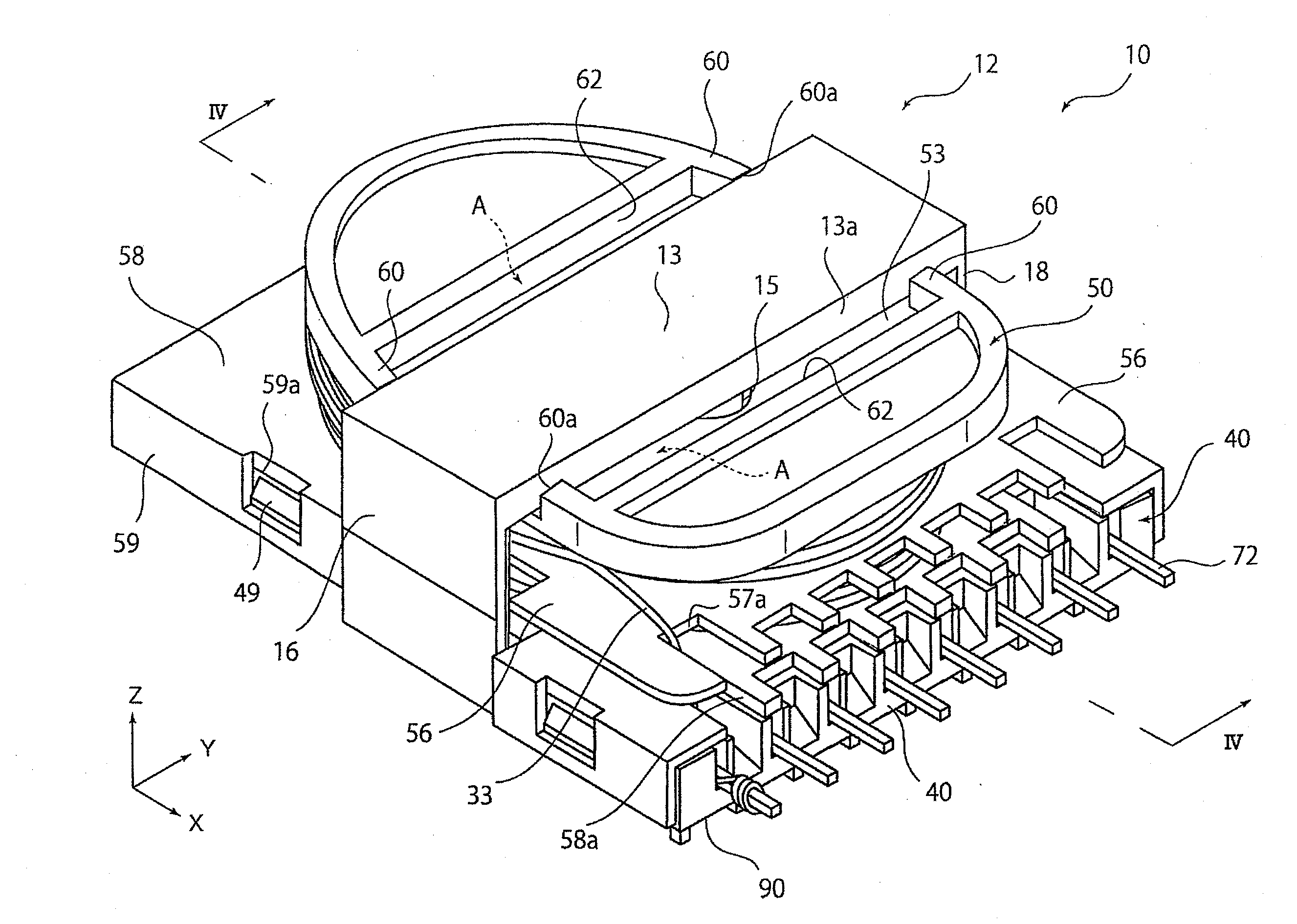

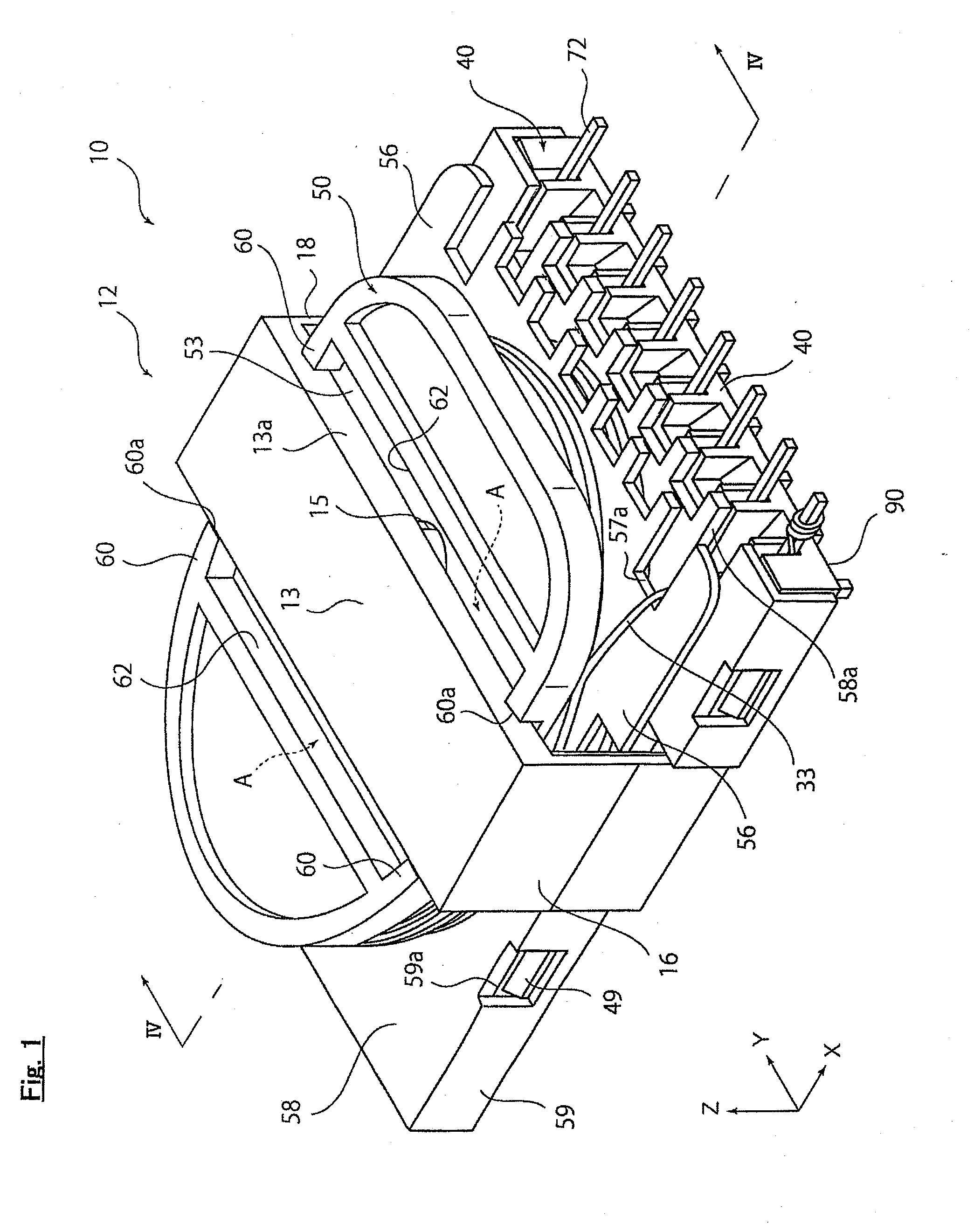

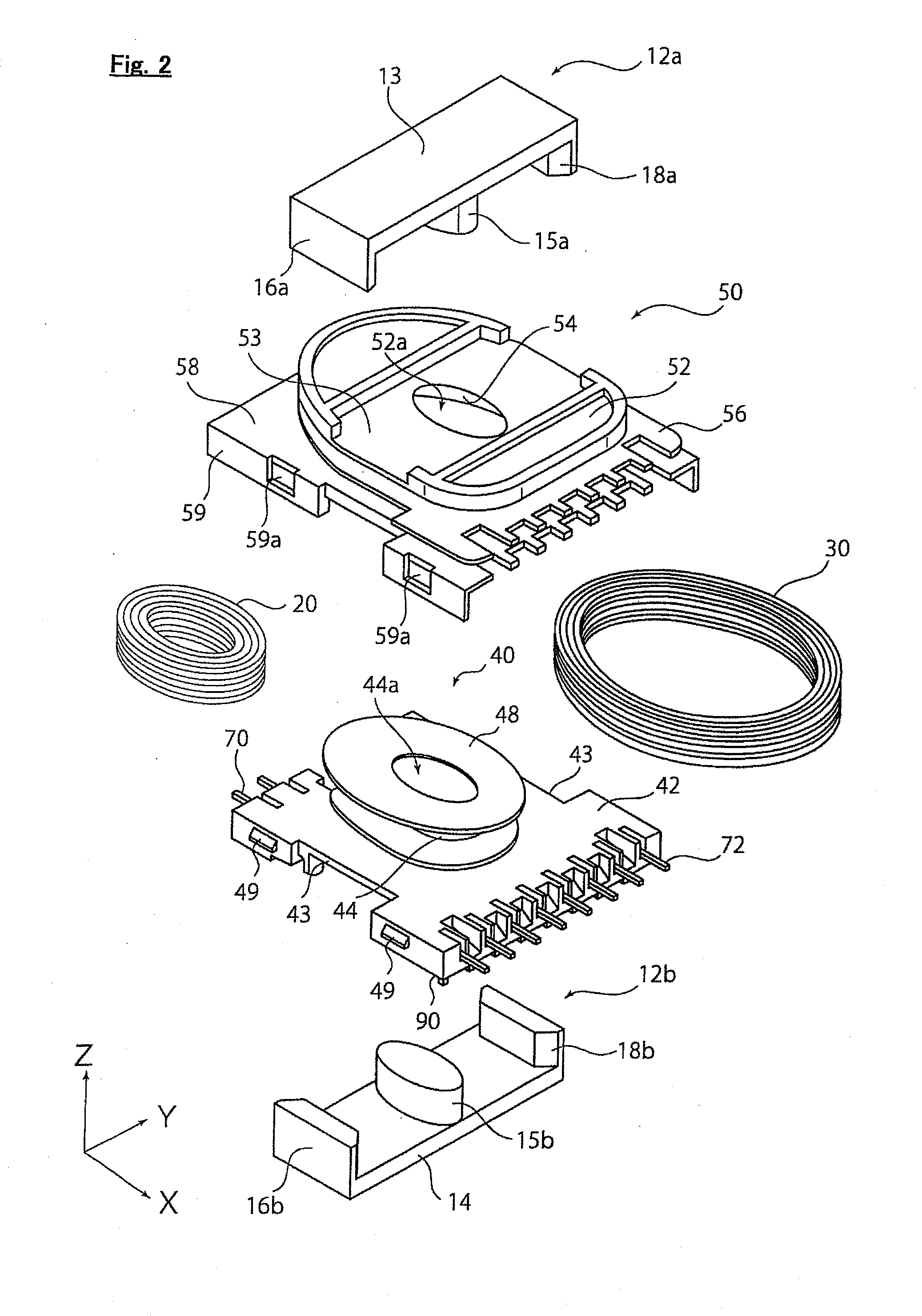

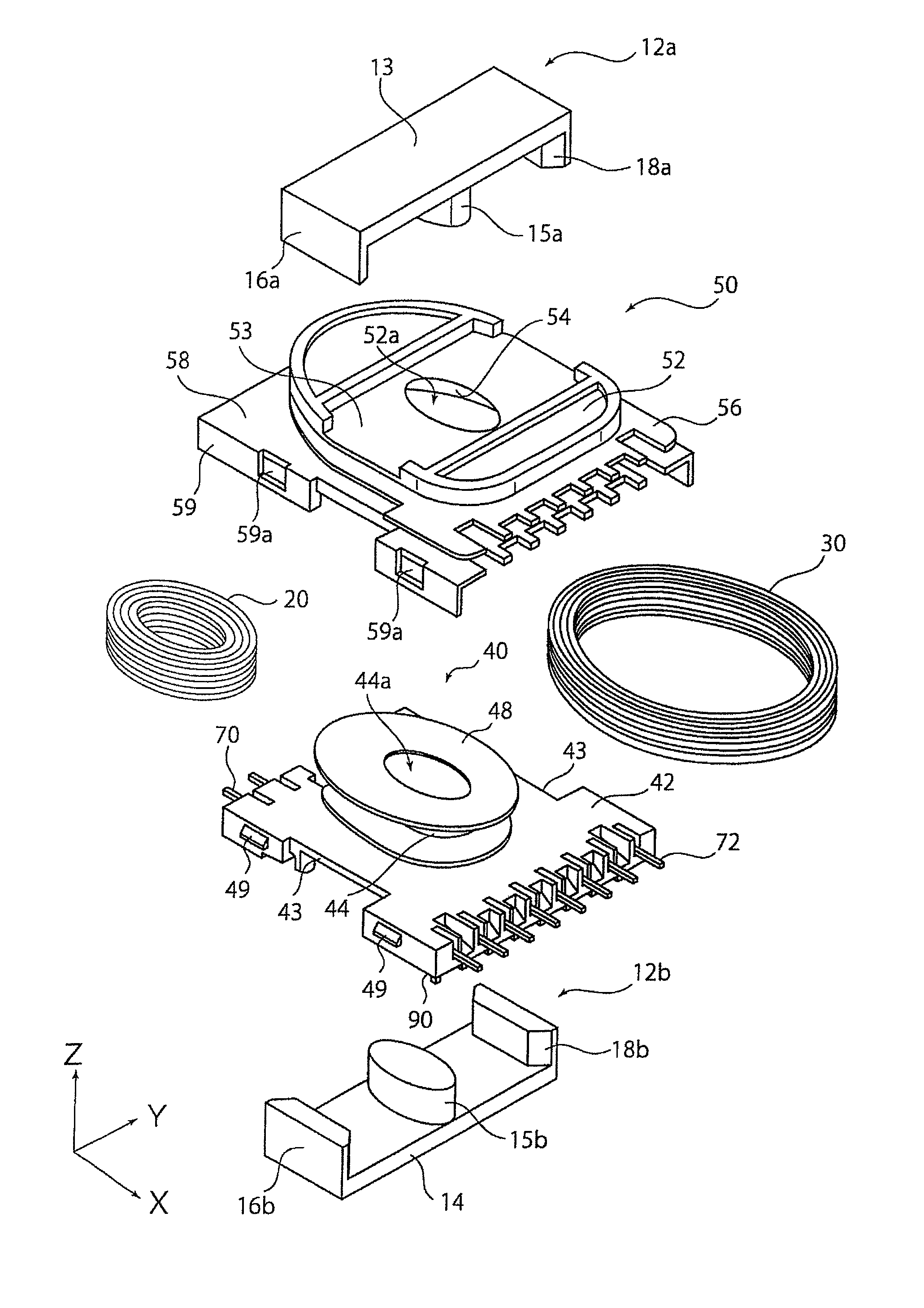

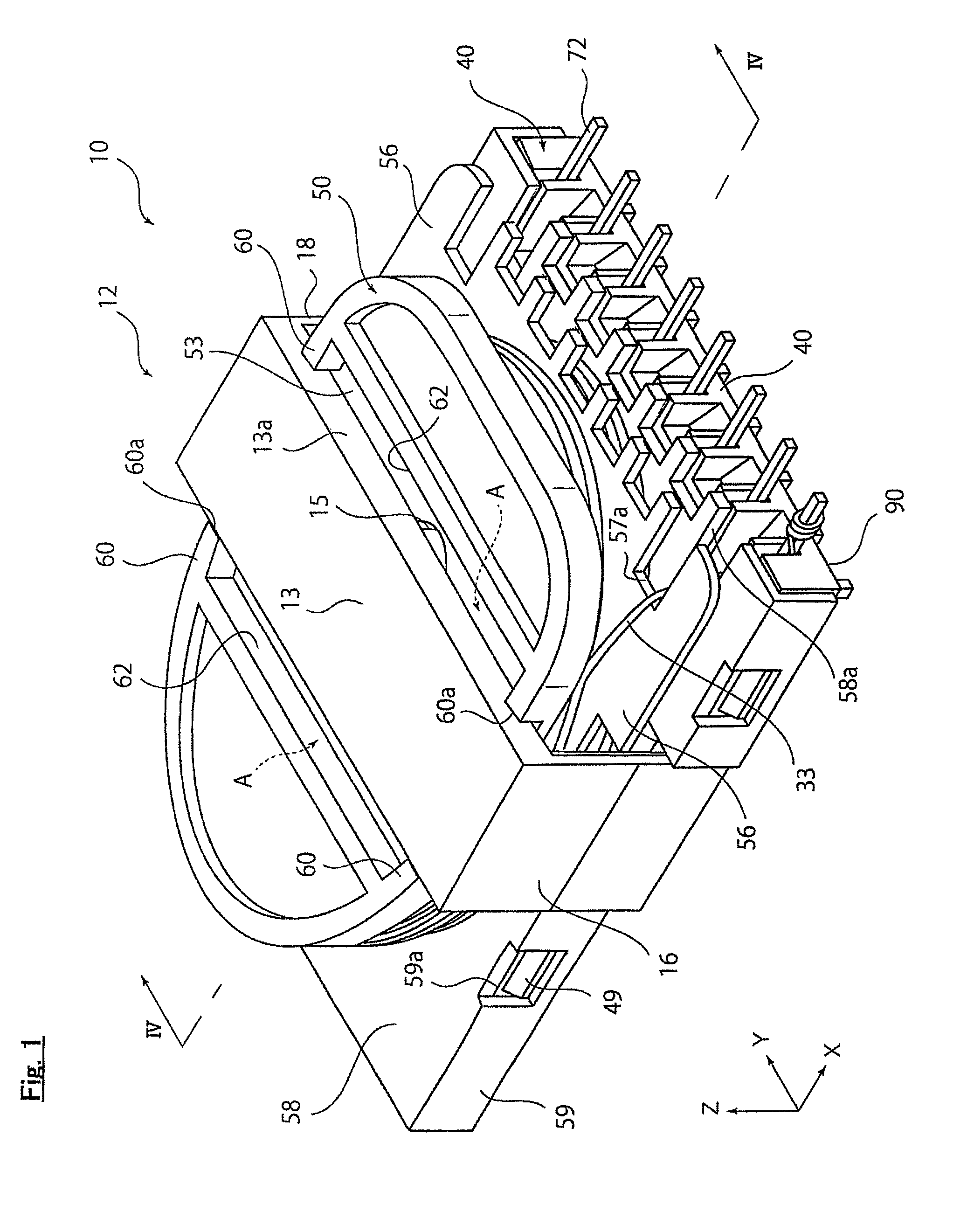

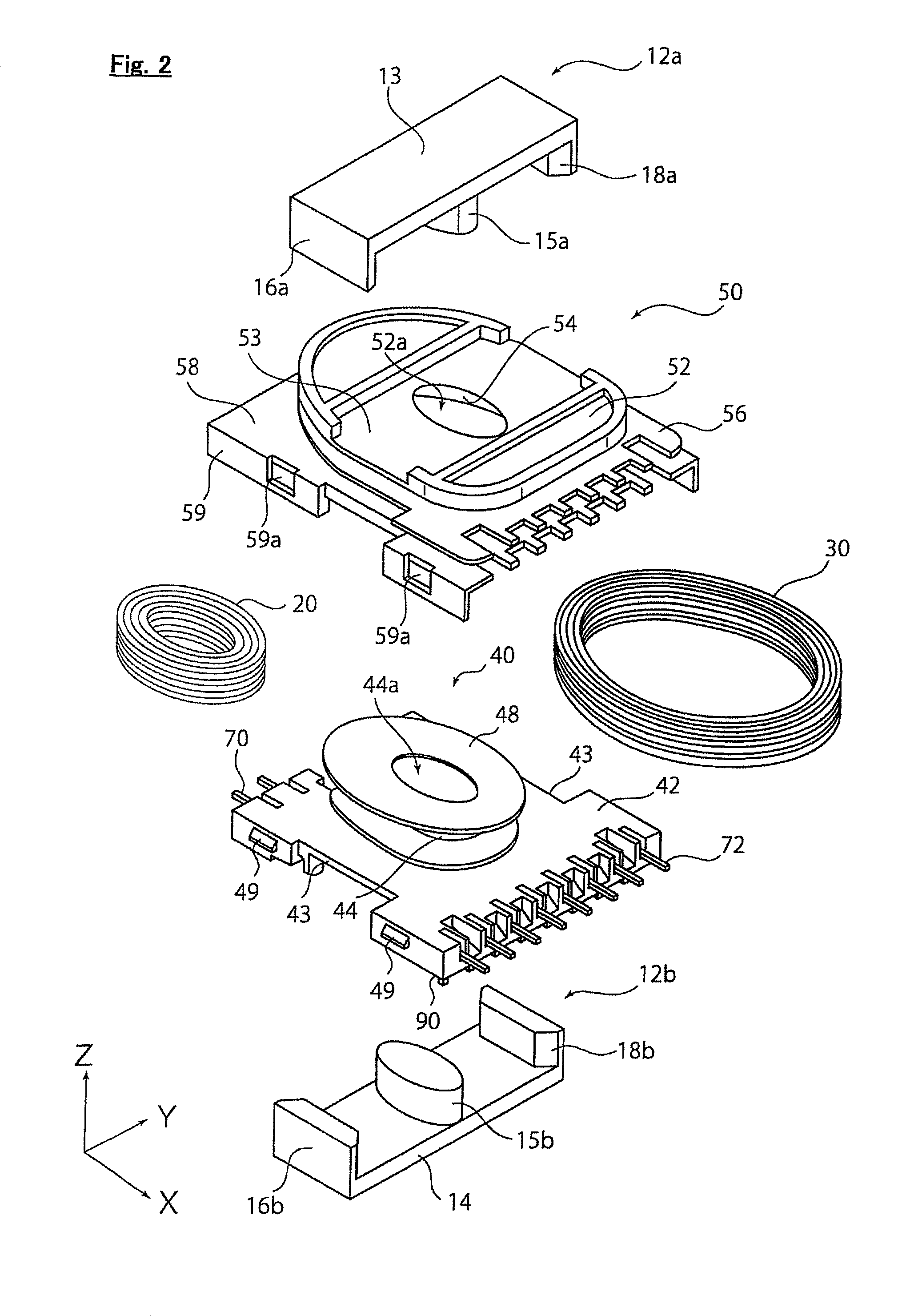

Vertical transformer

ActiveUS20130141204A1Increased durabilitySuperior silenceTransformers/inductances coils/windings/connectionsCores/yokesBobbinOn board

A vertical transformer comprising a core provided with a middle leg installing a first and a second coils, a side leg, a first connection part connecting an end of the middle leg and that of the side leg, and a second connection part connecting the other end of the middle leg and that of the side leg, a first bobbin provided with a first hollow cylinder where at least either the first or the second coil is wound, and a core on-board face connected to an end of the first hollow cylinder, and an adhesive hardened part connecting a connection side face, and the core on-board face, and formed by hardening an adhesion, wherein the core on-board face is provided with a positioning part positioning the connection side face, and a positioning projection, is formed on both sides of the first connection part.

Owner:TDK CORPARATION

Defoamers for hydratable cementitious compositions

The present invention discloses additive compositions, cementitious compositions, and methods for controlling air in cementitious compositions, wherein a polyalkoxylated polyalkylene polyamine defoamer is deployed in combination with one or more air-entraining agents, such as higher alkanolamines, water-reducing agents including oxyalkylene-containing superplasticizers, or other air entraining agents.

Owner:GCP APPL TECH INC

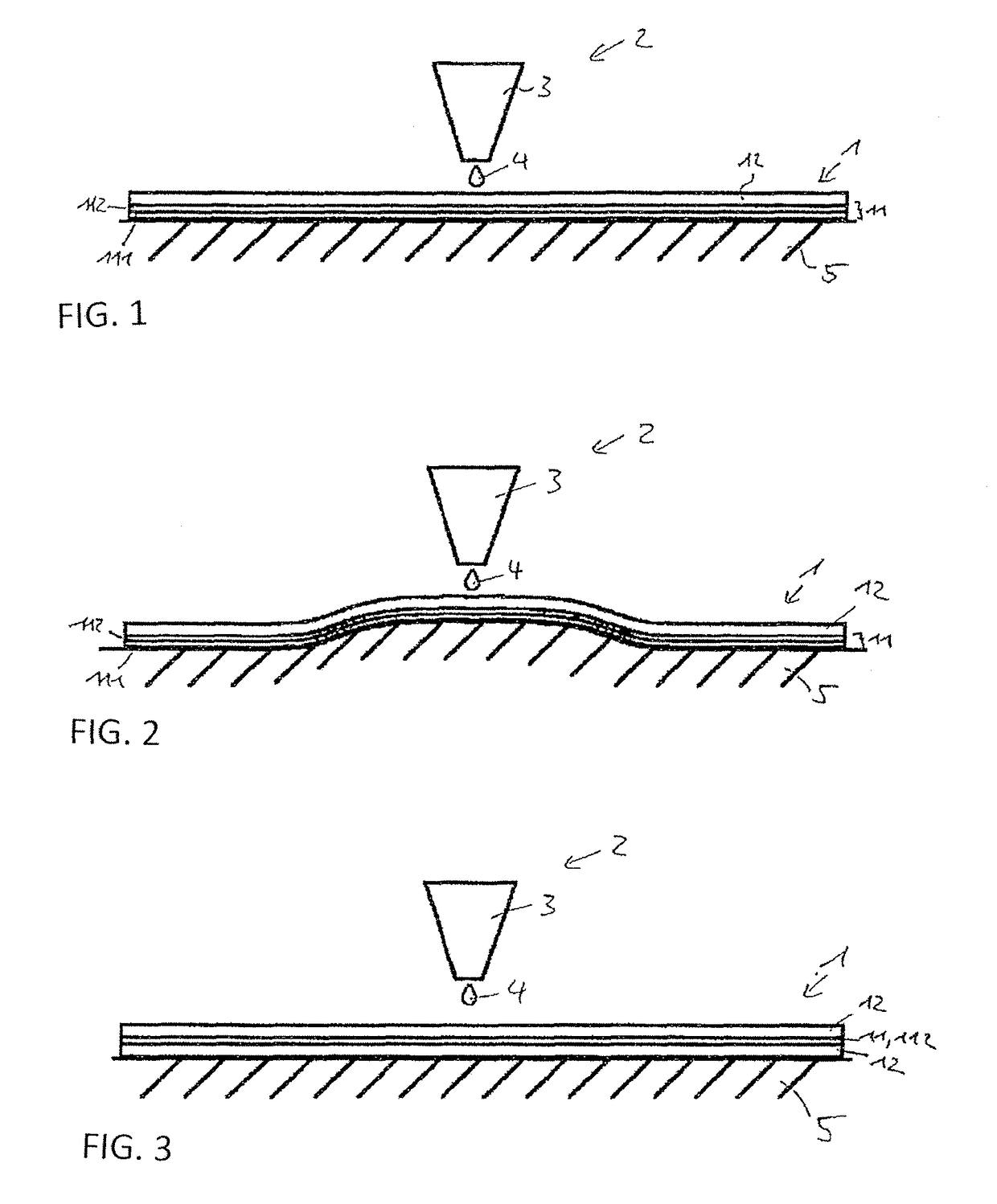

Method of 3D printing plastic molding compound on foil ply

ActiveUS9815241B2Increases counterfeiting securityIncreased Design PossibilitiesAdditive manufacturing apparatusOrnamental structuresThree dimensional shapePlastic molding

A method for producing a molded body having the following steps: a) providing a foil ply; b) applying a plastic molding compound in a predefined three-dimensional shape onto the foil ply by means of a three-dimensional printing method.

Owner:LEONHARD KURZ GMBH & CO KG

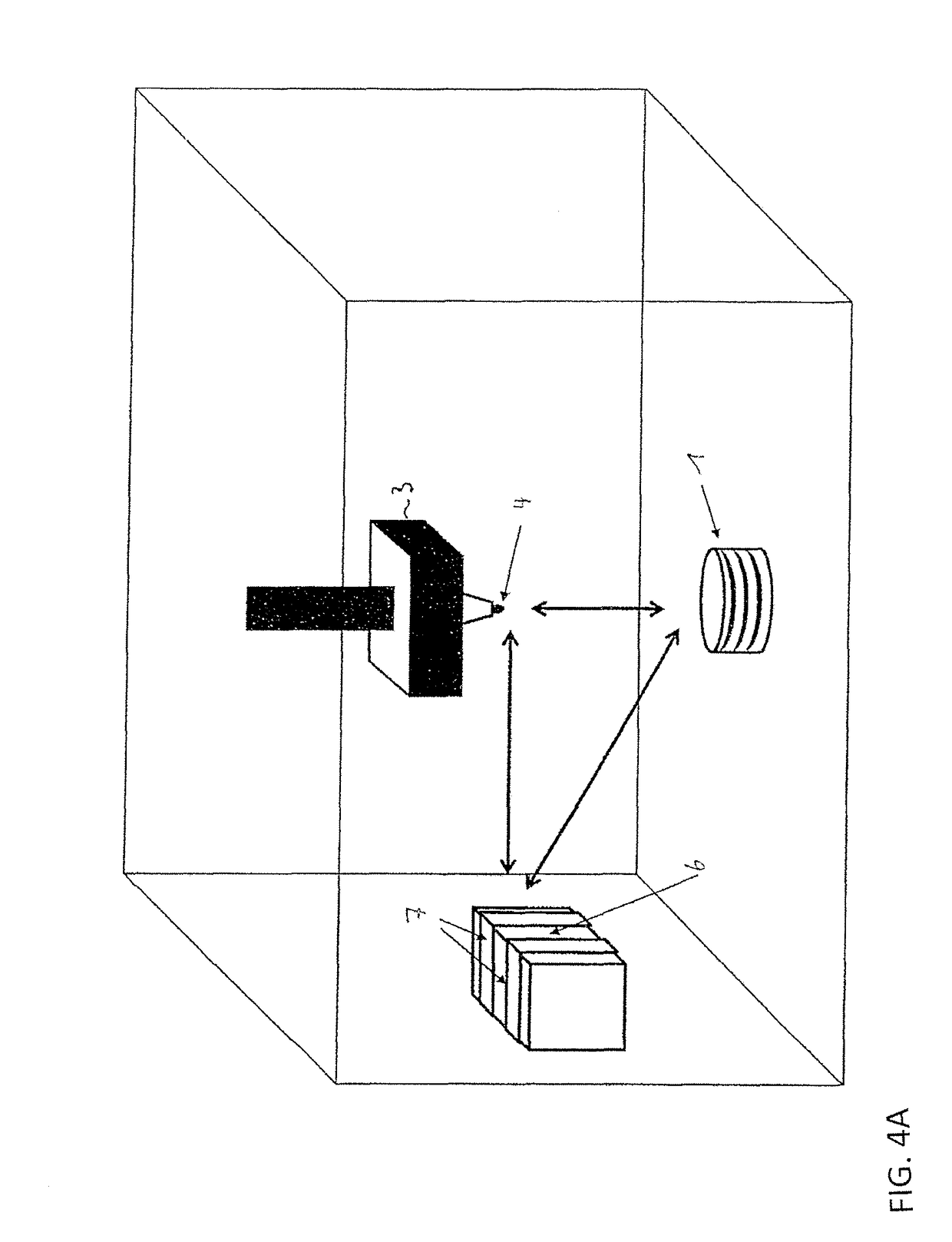

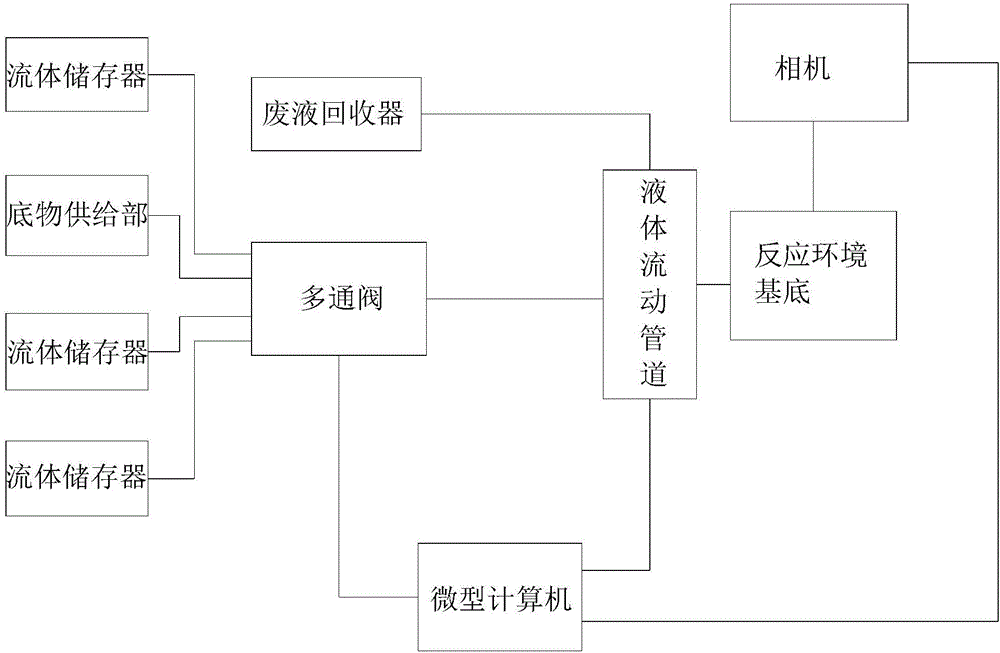

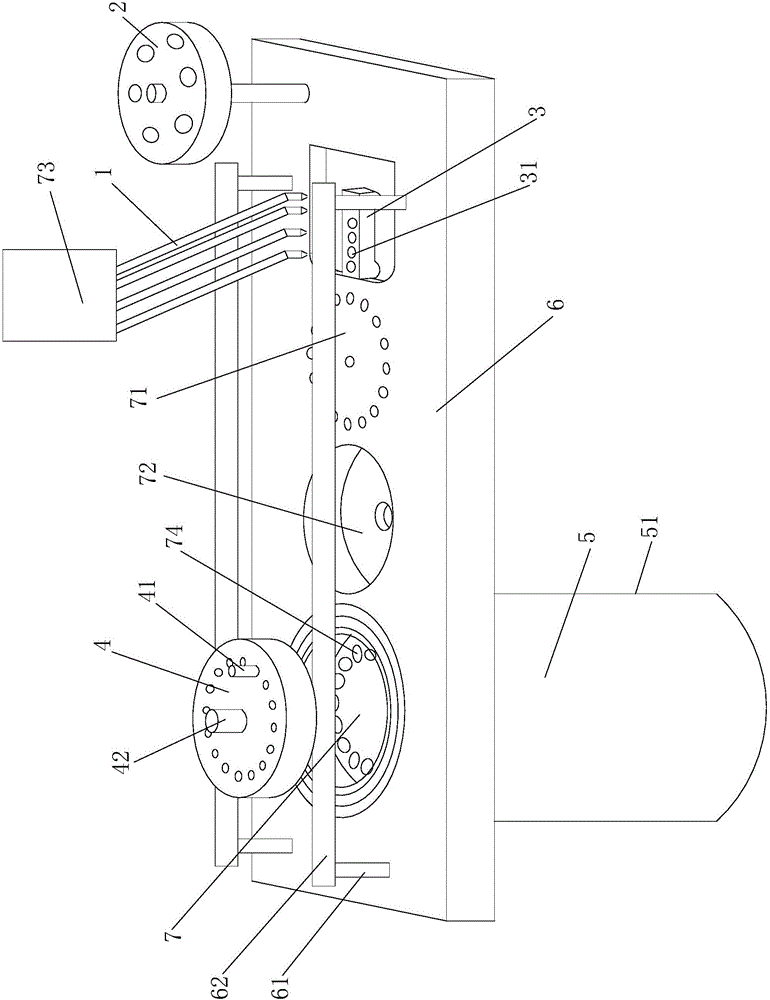

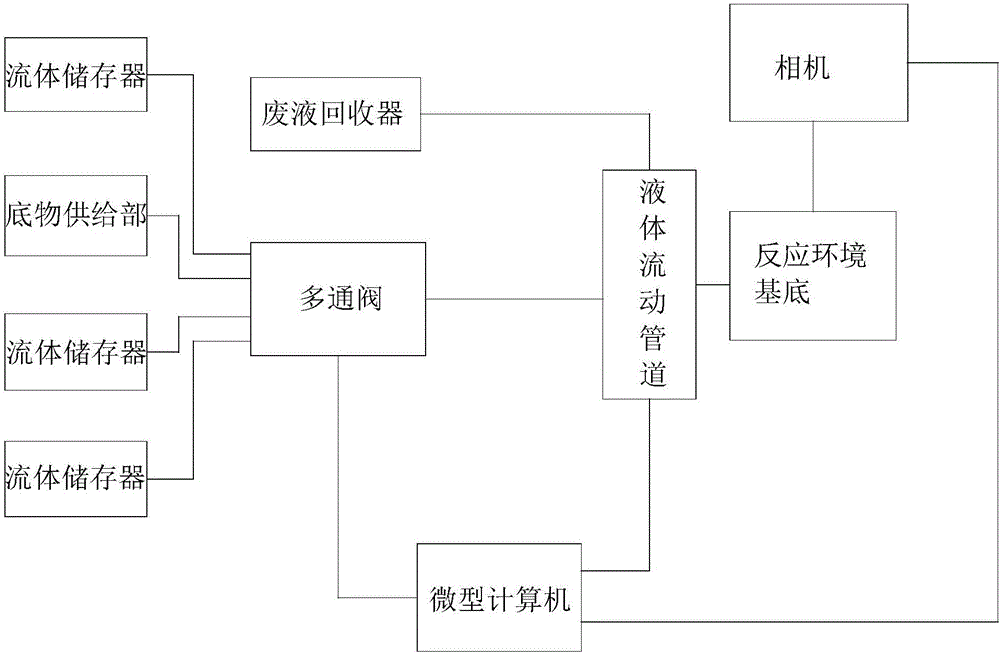

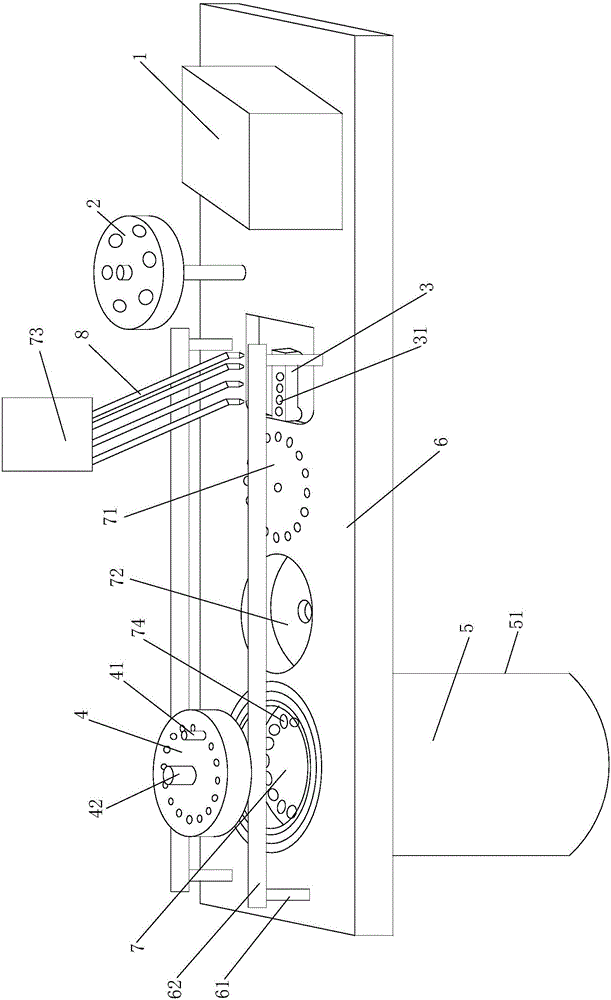

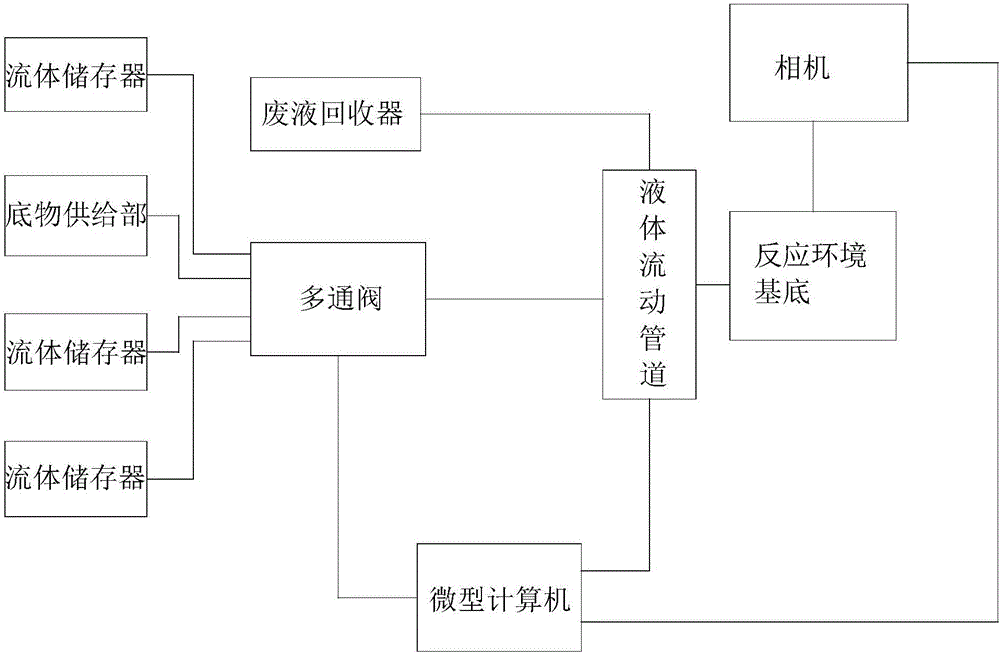

DNA sequencing device and system based on pyrosequencing

ActiveCN106754343AEasy to separateIncrease the use of occasionsBioreactor/fermenter combinationsBiological substance pretreatmentsControl areaBiology

The invention provides a DNA sequencing system based on pyrosequencing. The DNA sequencing system comprises a sample area, a reaction area, a detection area and a control area, wherein the sample area comprises a rotatable separating plate; the separating plate comprises at least one DNA separating area; the separating area comprises a hollow filtering column in which a filtering film is arranged; a DNA single chain which is connected with an affine connector and the DNA single chain which is not connected with the affine connector are filtered by the filtering film and then are separated; the reaction area comprises a sampling part and a sample slot; the sampling part comprises a dNTP reagent slot, a sampling needle frame and a plurality of sampling needles arranged on the sampling needle frame; the sampling needle frame is located on the sample slot; a plurality of slot positions are formed on the sample slot; the detection area comprises a bioluminescence detection device; the slot positions are connected with the bioluminescence detection device; the sample area, the reaction area and the detection area are monitored and controlled through the control area. The DNA sequencing system and device based on pyrosequencing, provided by the invention, have the advantages of simple and convenient operation and quick detection.

Owner:武汉菲思特生物科技有限公司

Freezer Cabinet

ActiveUS20170027338A1Easy to operateReliable functionShow cabinetsDomestic cooling apparatusEngineeringMechanical engineering

The invention relates to a freezer cabinet in which foods are stored frozen for sale in a shop, with a freezer space surrounded by solid walls at the front, at the rear, at the sides and at the bottom, which freezer space, at its upper end, is accessible via a housing opening from a user-side front edge, which opening, in the closed state, is covered by a cover unit with a cover part, adjoining the use-side edge and movable in a forwards / backwards direction, and a stationary rear cover part located away from the user-side edge. An advantageous embodiment is one in which, in order to open it, the front cover part is arranged in front of the rear cover part in the closed state or the central cover part can be pushed at least partially over the rear cover part.

Owner:AHT COOLING SYSTEMS GMBH

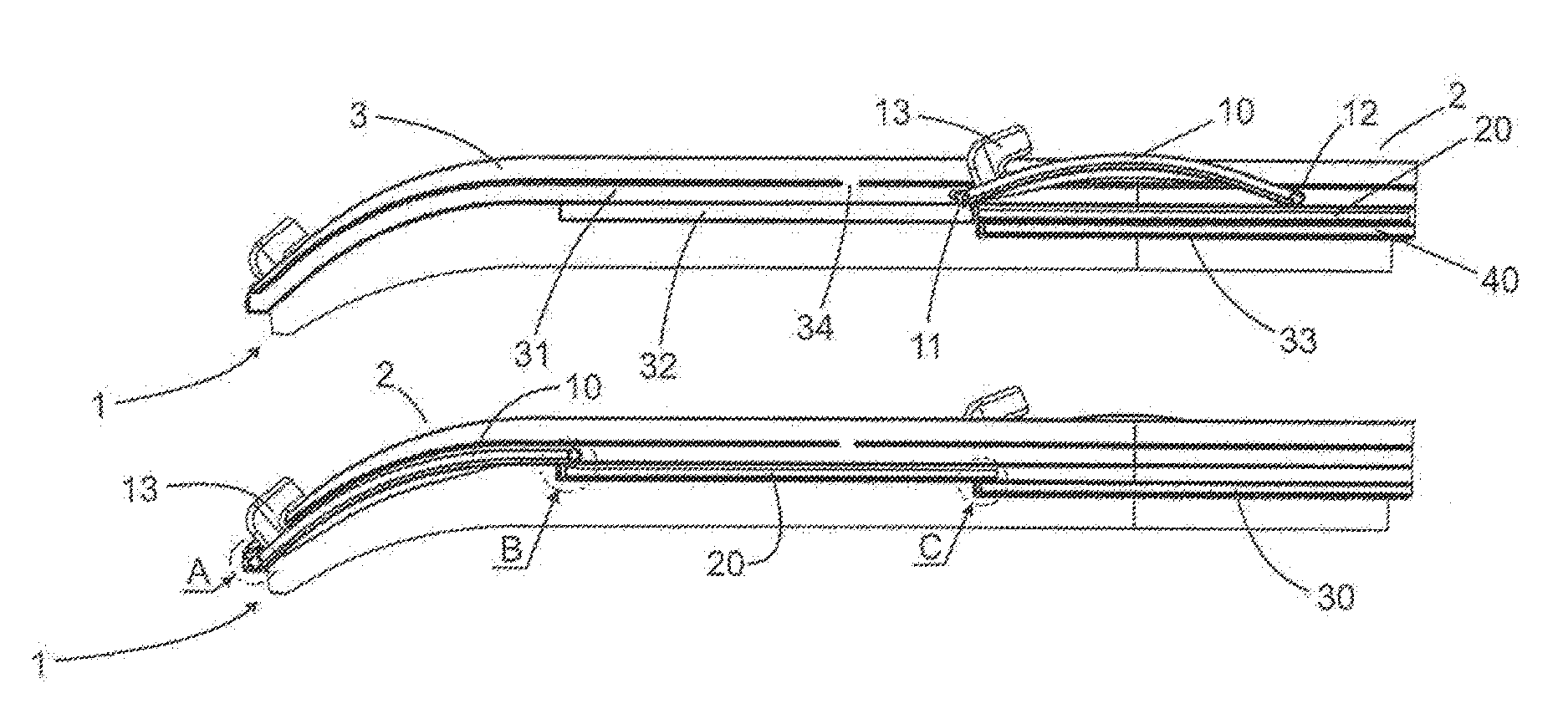

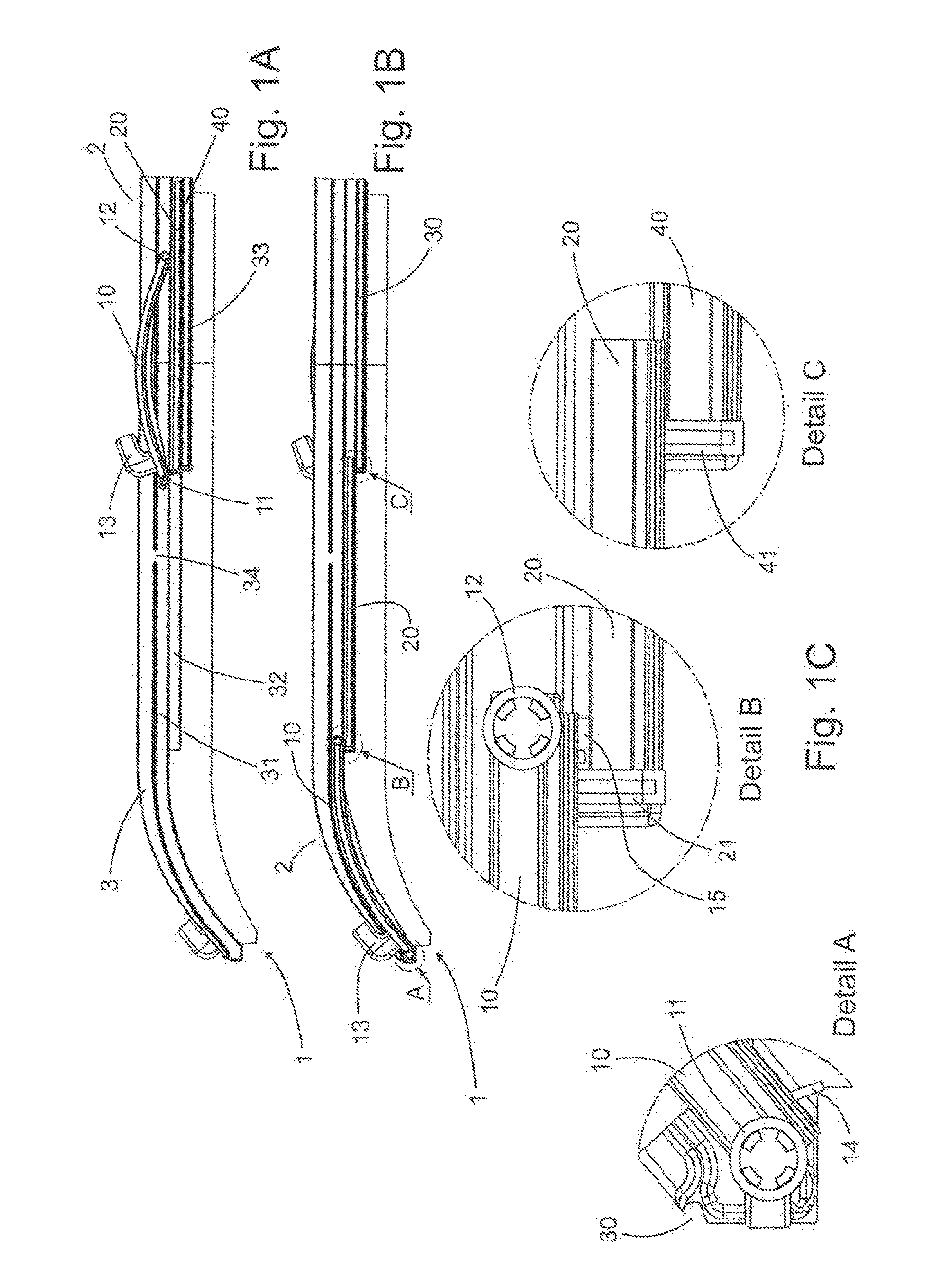

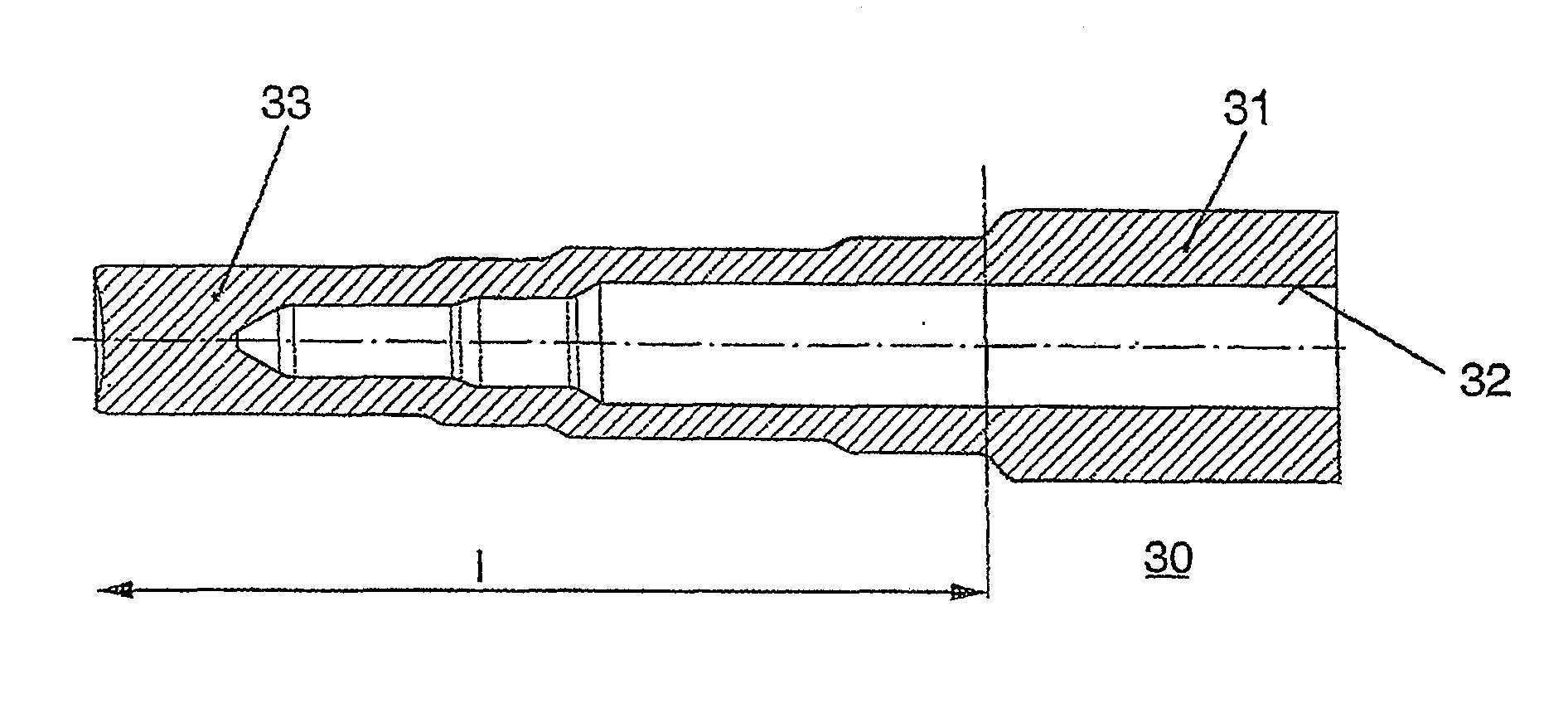

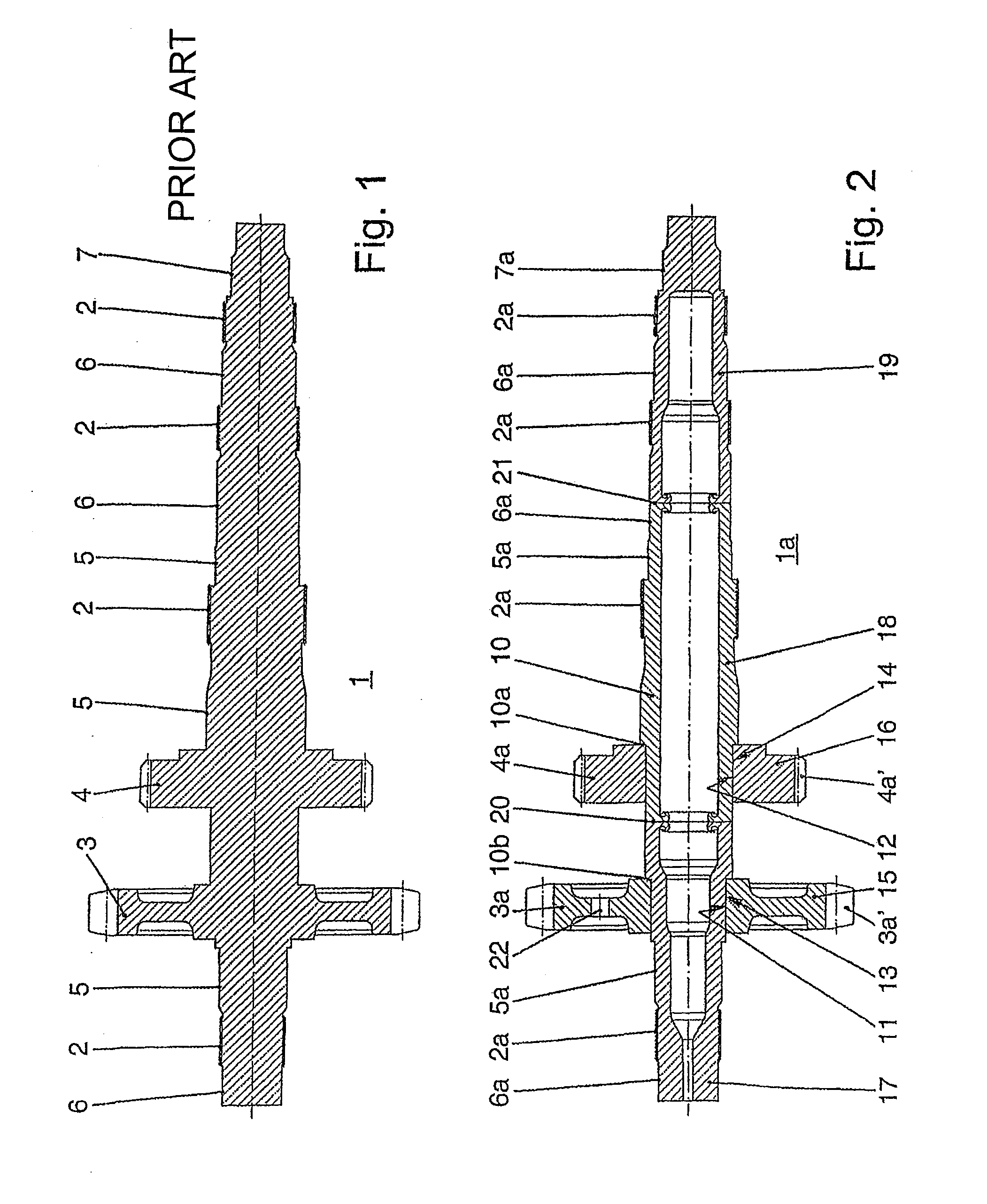

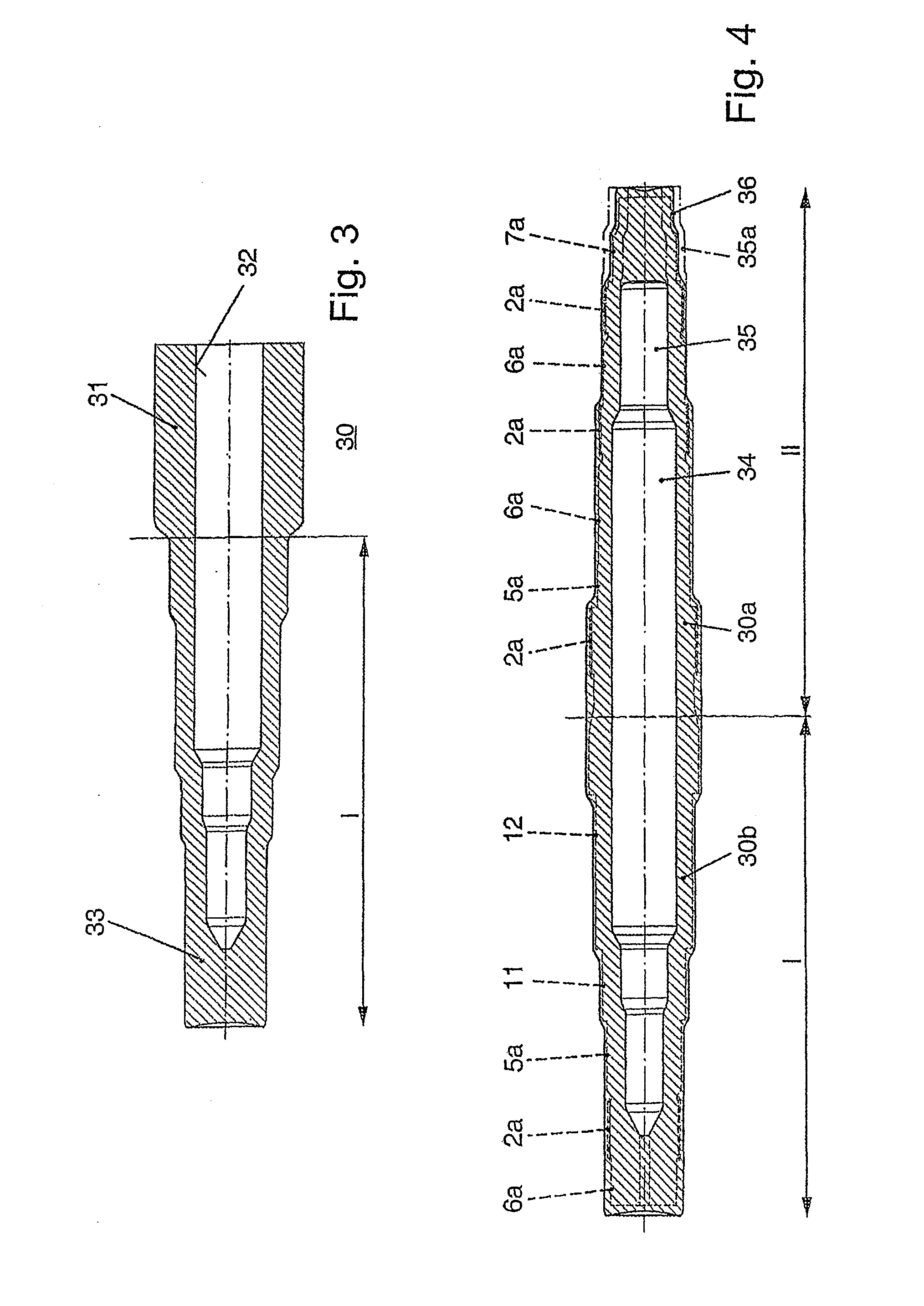

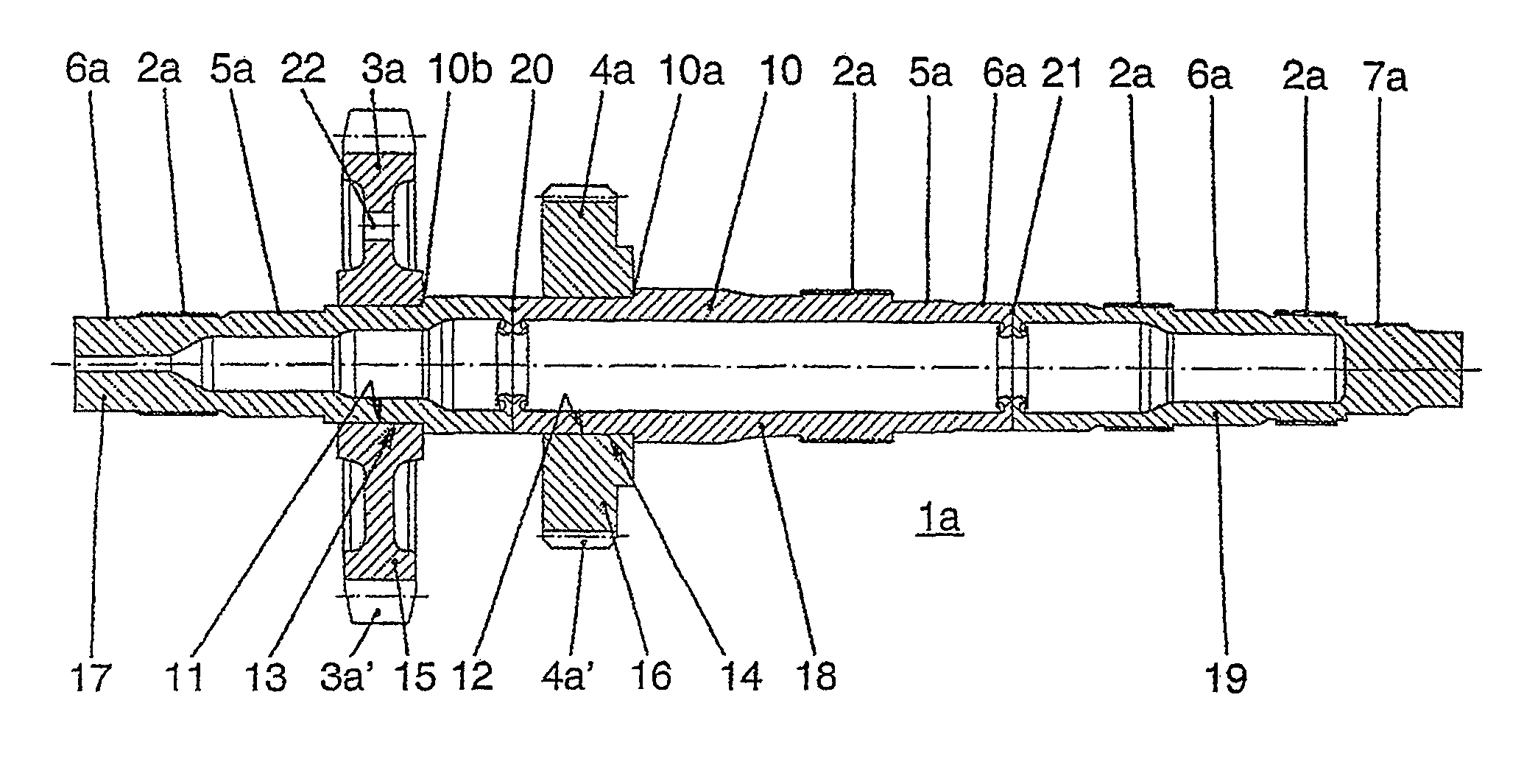

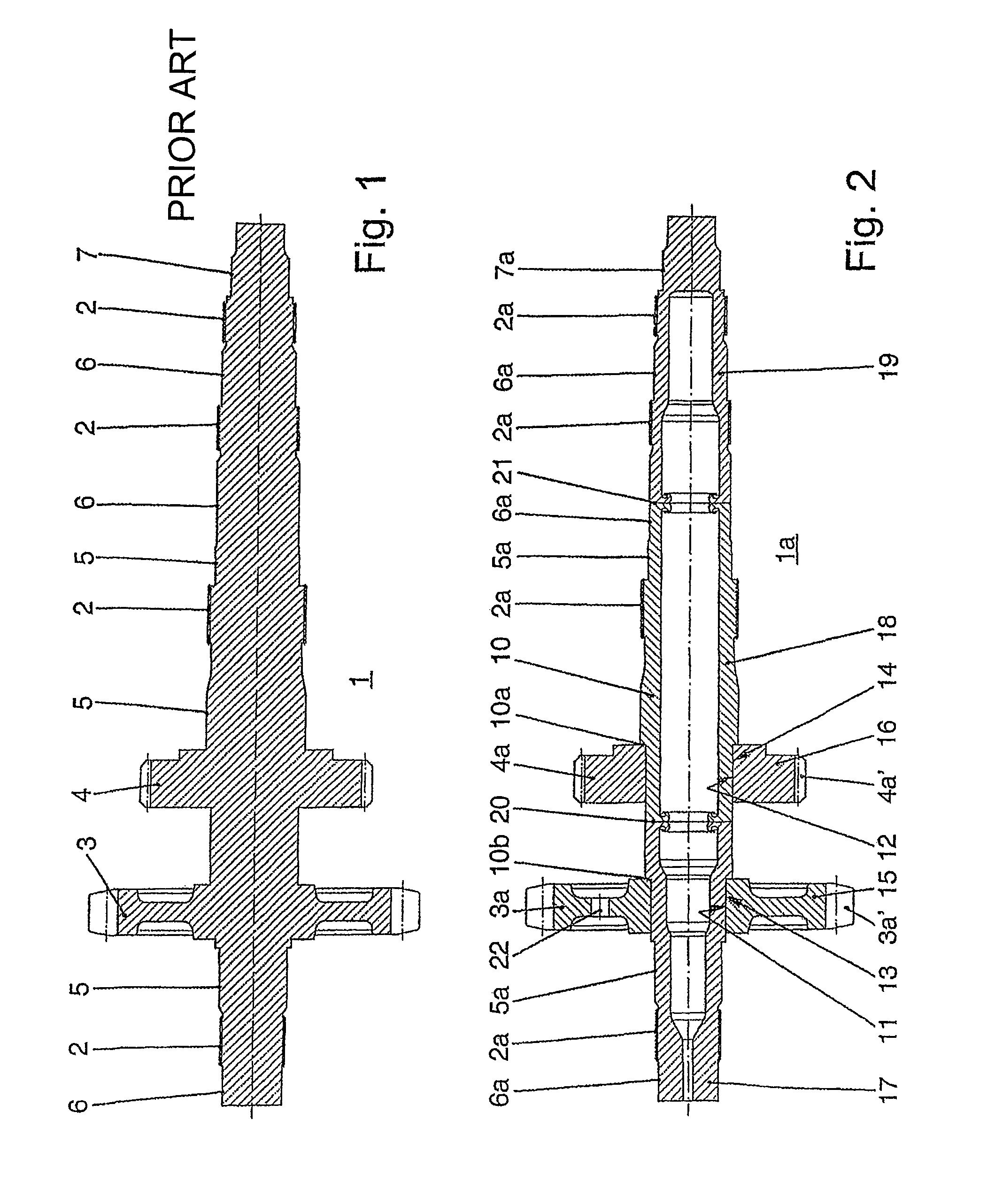

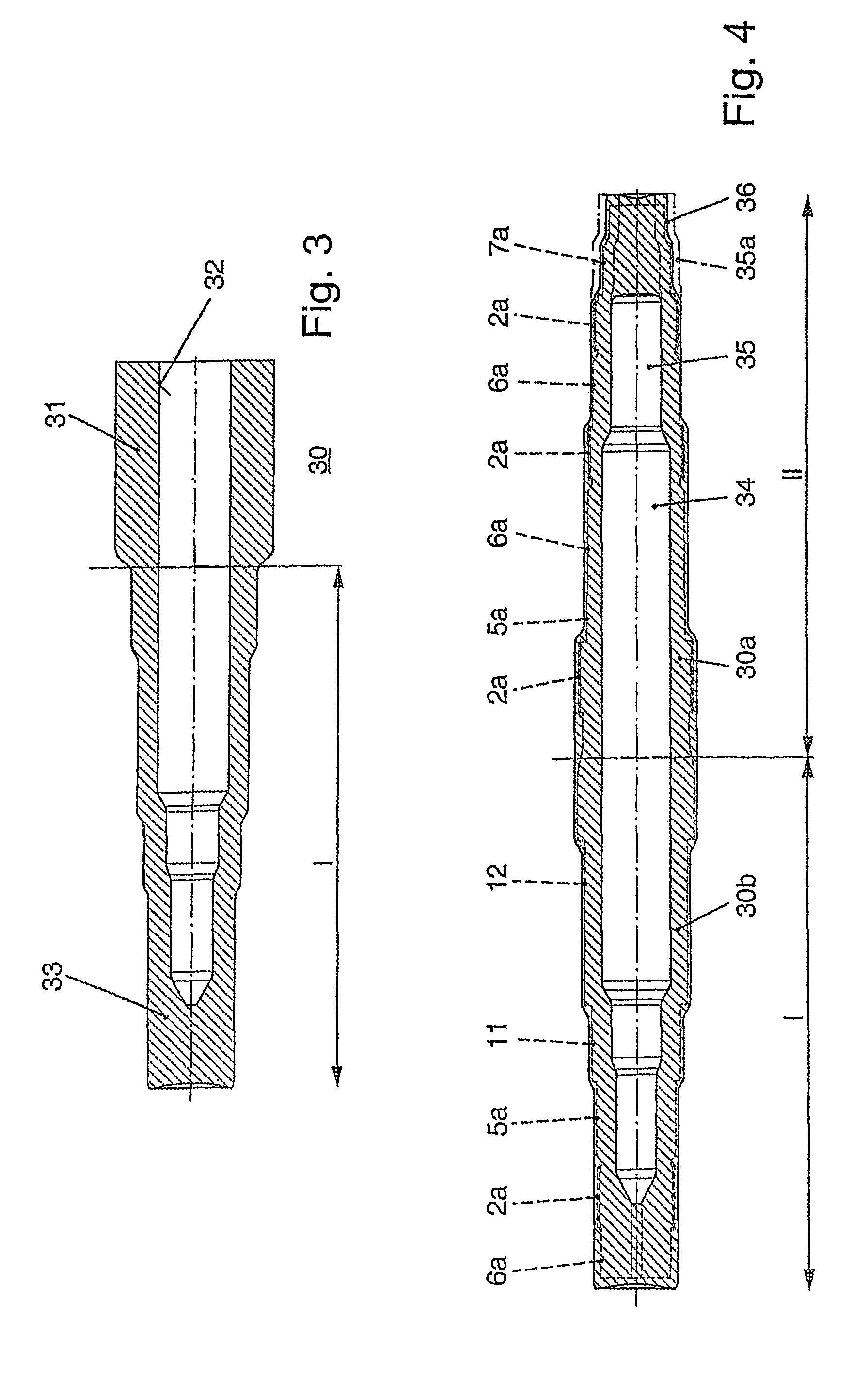

Transmission suitable for a motor vehicle, shafts therefor and method of producing such shafts

ActiveUS20100218583A1Easy to manufactureSave weight and thus costValve arrangementsCouplings for rigid shaftsMobile vehicleTorque transmission

Owner:NEUMAYER TEKFOR ENG GMBH

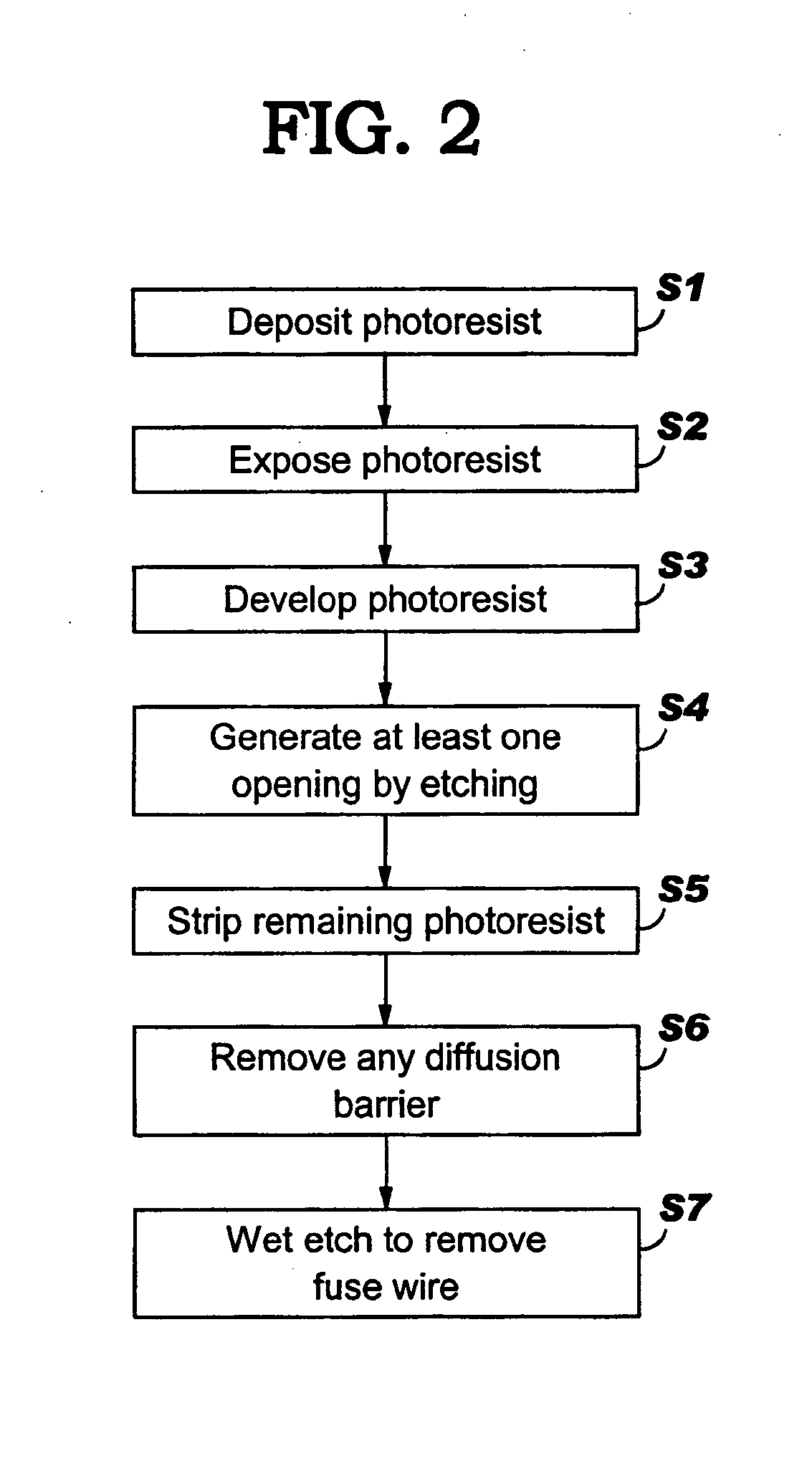

Integrated circuit fuse

InactiveUS20080179709A1Increased Design PossibilitiesRadiation applicationsSemiconductor/solid-state device detailsMetalIntegrated circuit design

An integrated circuit and a fuse therefore are disclosed. The integrated circuit fuses includes a plurality of terminals coupled by a fuse element, wherein the fuse element is located in a non-last metal layer and / or wherein each terminal is fully-landed on an upper surface of a wire of the fuse element. As a result, there is no explosion that causes damage to surrounding material. In addition, use of the wet etchant allows positioning of a fuse in any metal layer including any non-last metal layer, thus increasing design possibilities.

Owner:META PLATFORMS INC

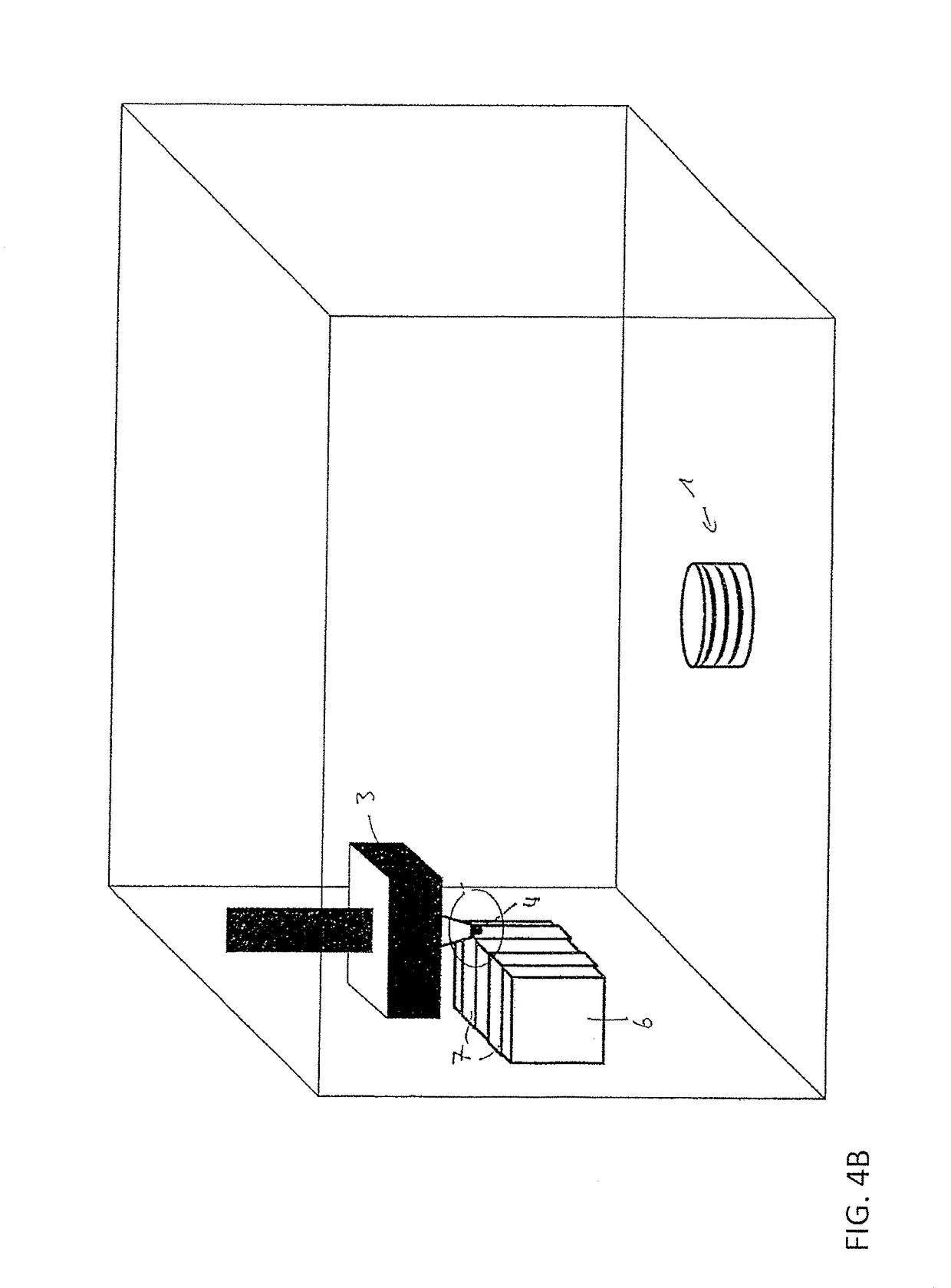

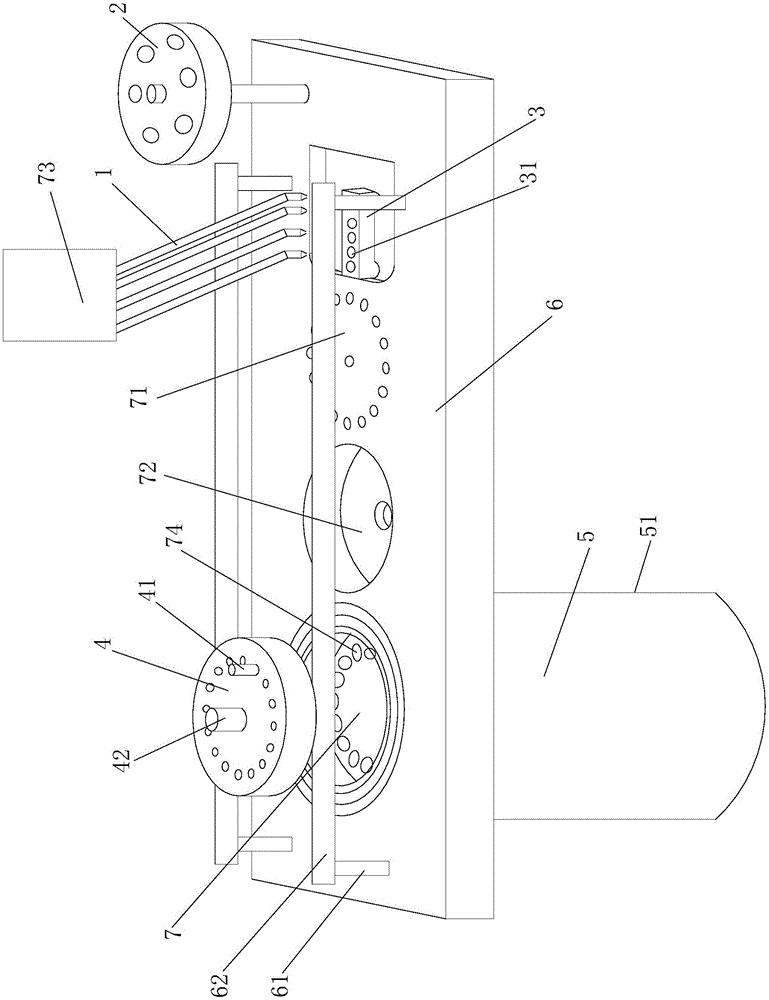

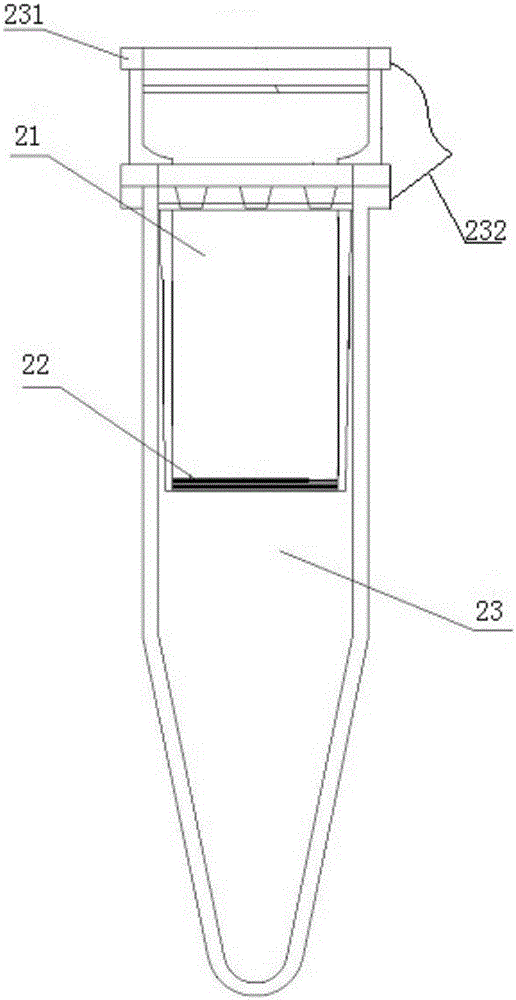

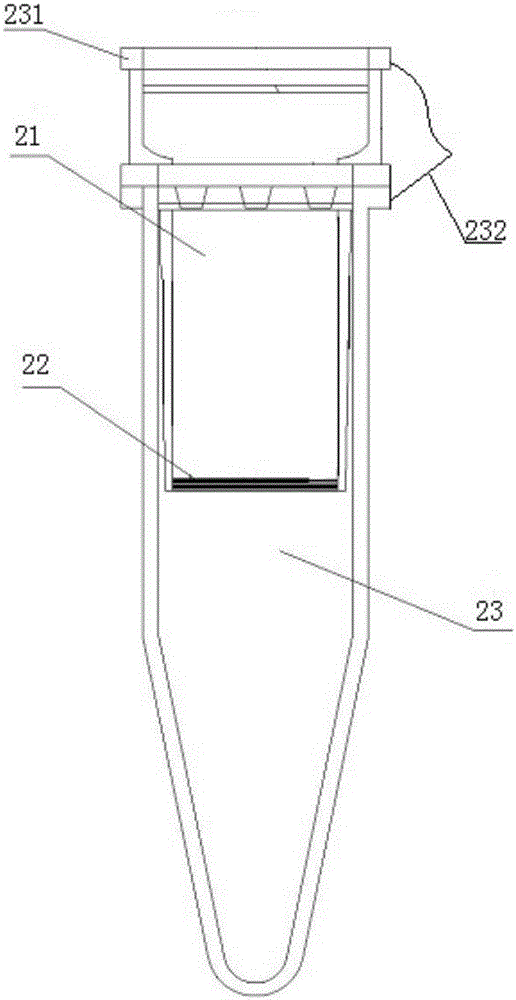

Sample adding device for pyrosequencing

ActiveCN106591107AEasy to separateIncrease the use of occasionsBioreactor/fermenter combinationsBiological substance pretreatmentsDNAReagent

The invention provides a sample adding device for pyrosequencing. The sample adding device comprises a sample area and a reaction area; the sample area comprises a rotational separating disc, the separating disc comprises at least one DNA separating area, the separating area comprises a hollow filtering column with the inside provided with a filtering film, and DNA single chains connected with compatible connecting bodies and DNA single chains unconnected with compatible connecting bodies are filtered through the filtering film to be separated; the reaction area comprises a sample adding part and a sample trough, and the sample adding part comprises a dNTP reagent trough, a sample adding needle frame and a plurality of sample adding needles installed on the sample adding part; the sample adding needle frame is located on the sample trough; a plurality of trough positions are arranged on the sample trough. The sample adding device and system for pyrosequencing have the advantages of being easy and convenient to operate and rapid in detection.

Owner:菲思特(上海)生物科技有限公司

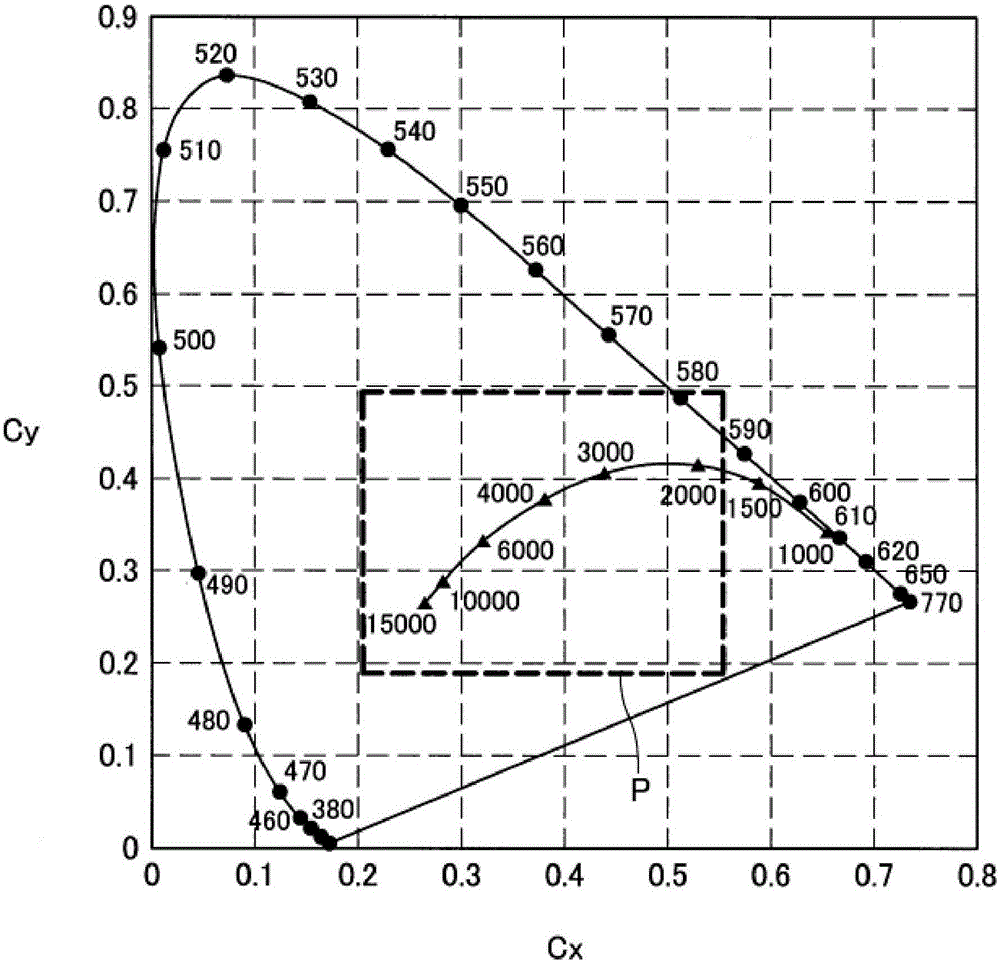

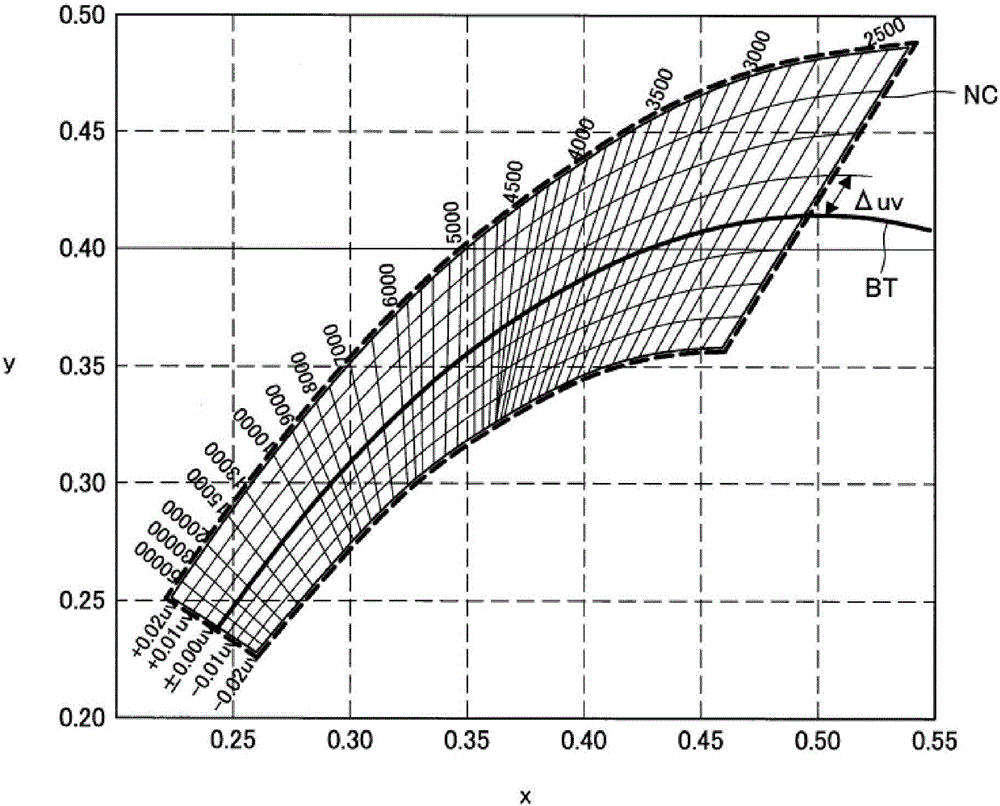

Electronic device

ActiveCN106233370AIncreased Design PossibilitiesTelevision system detailsColor signal processing circuitsComputer graphics (images)Display device

Provided is an electronic device which is provided with a display device, and which has improved designability. The electronic device is provided with: a display device; and a coloured layer disposed on the display surface of the display device. The display device corrects the display image on the basis of the transmission properties of the coloured layer such that achromatic colours in the display image transmitted through the coloured layer are included in the white region of a colour coordinate system.

Owner:SONY CORP

Nucleic acid sequencing device and system

InactiveCN106754313AEasy to separateIncrease the use of occasionsBioreactor/fermenter combinationsBiological substance pretreatmentsElectrophoresisA-DNA

The invention provides a nucleic acid sequencing method and a device. The device comprises a sample area, a reaction area, a detection area and a control area, wherein the sample area comprises an electrophoresis apparatus and a rotatable separating plate; the separating plate comprises at least one DNA separating area; the separating area comprises hollow filtering columns in which a filtering film is arranged; a DNA single chain which is connected with an affine connector and a DNA single chain which is not connected with the affine connector are filtered by the filtering film and then are separated; the reaction area comprises a sampling part and a sample slot; the sampling part comprises a dNTP reagent slot, a sampling needle frame and a plurality of sampling needles arranged on the sampling needle frame; the sampling needle frame is located on the sample slot; a plurality of slot positions are formed on the sample slot; the detection area comprises a bioluminescence detection device; the slot positions are connected with the bioluminescence detection device; the sample area, the reaction area and the detection area are monitored and controlled through the control area. The nucleic acid sequencing device provided by the invention has the advantages of simple and convenient operation and quick detection.

Owner:武汉菲思特生物科技有限公司

Method of producing shafts

ActiveUS8108996B2Easy to manufactureSave weight and thus costValve arrangementsCouplings for rigid shaftsControl theory

Owner:NEUMAYER TEKFOR ENG GMBH

Galvanically decorated decorative element with contour light

ActiveUS20160312974A1Improve adhesionDelicate transilluminable contourPoint-like light sourceLight effect designsEngineeringInert

A galvanically decorated decorative element with contour light is produced from at least two plastic components in a material-fit composite, wherein a first plastic component is galvanigable and forms the decorative element. At least one second plastic component is galvano-inert. Consequently, it is uncoated and passes through the electroplating process unchanged. It represents a transilluminable contour light region.

Owner:GERHARDI KUNST

Electronic apparatus

InactiveUS20170178377A1Increased Design PossibilitiesStatic indicating devicesTexturing/coloringElectric devicesWhite area

[Object] To provide an electronic apparatus having a display device and improved appearance design possibility.[Solution] An electronic apparatus includes a display device, and a colored layer above a display surface of the display device. The display device corrects a display image on the basis of a transparent characteristic of the colored layer in a manner that a white region in a color coordinate includes an achromatic color of the display image through the colored layer.

Owner:SONY CORP

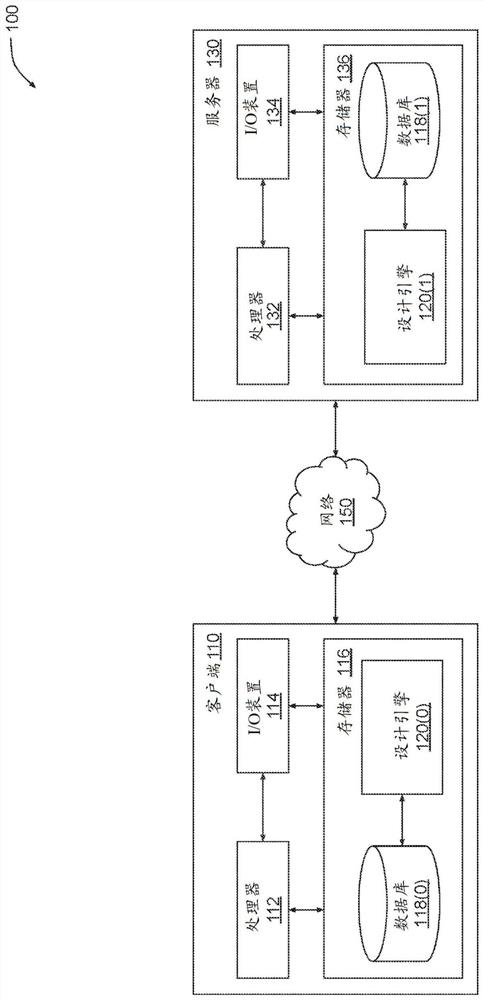

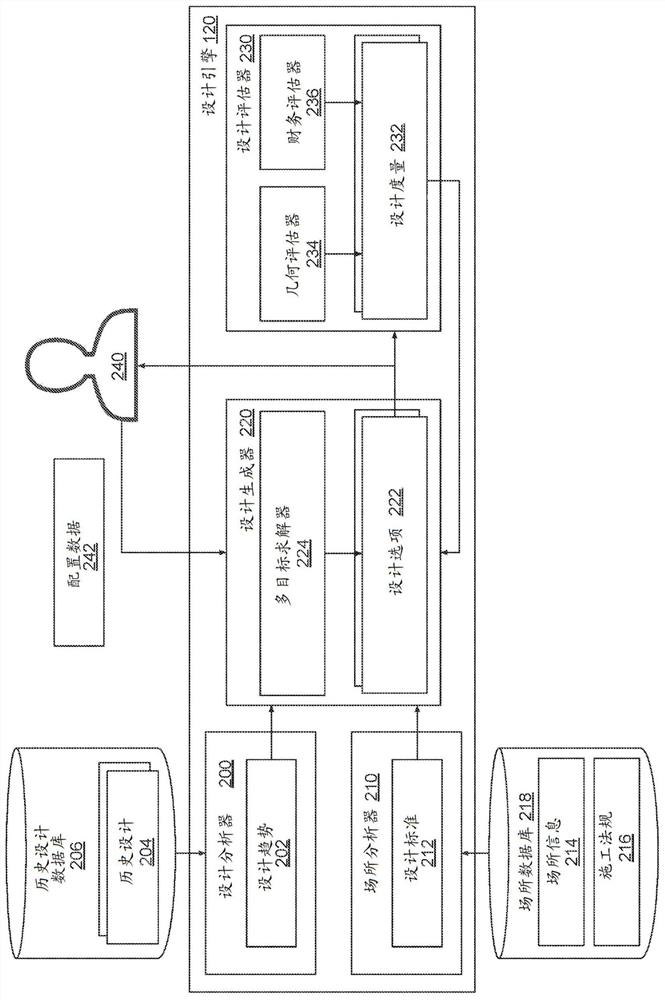

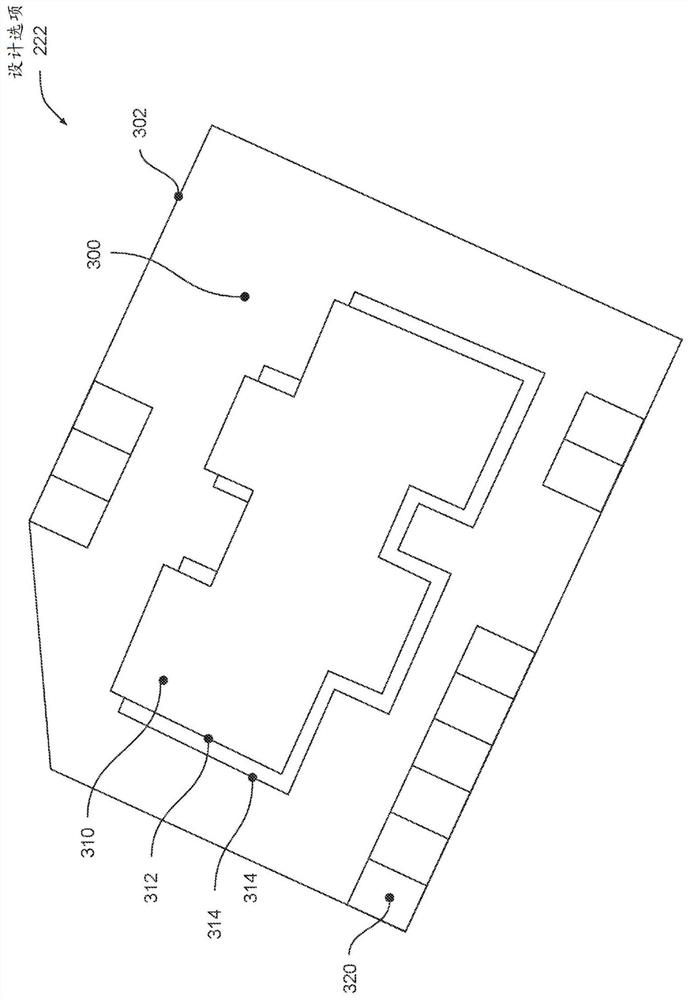

Generative design technology for multi-household residence project

PendingCN114730401AIncreased Design PossibilitiesRaise the possibilityGeometric CADCAD network environmentResidenceGenerative Design

A design engine automatically generates a design of a multi-household residence project that simultaneously meets local construction regulations, while also meeting specific financial goals. The design engine includes a design analyzer, a venue analyzer, a design generator, and a design evaluator. A design analyzer generates design trends based on a historical database of designs. A site analyzer generates design criteria based on related construction regulations. A design generator generates design options reflecting design trends while also complying with the construction regulations. The design evaluator then analyzes the design options and generates various design metrics. Based on the design metrics, the design generator generates additional design options that better meet the design criteria.

Owner:AUTODESK INC

Vertical transformer

ActiveUS8665051B2Suppress soundImprove silent qualityTransformers/inductances coils/windings/connectionsCores/yokesBobbinOn board

A vertical transformer comprising a core provided with a middle leg installing a first and a second coils, a side leg, a first connection part connecting an end of the middle leg and that of the side leg, and a second connection part connecting the other end of the middle leg and that of the side leg, a first bobbin provided with a first hollow cylinder where at least either the first or the second coil is wound, and a core on-board face connected to an end of the first hollow cylinder, and an adhesive hardened part connecting a connection side face, and the core on-board face, and formed by hardening an adhesion, wherein the core on-board face is provided with a positioning part positioning the connection side face, and a positioning projection, is formed on both sides of the first connection part.

Owner:TDK CORPARATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com