Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Improve screen printing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

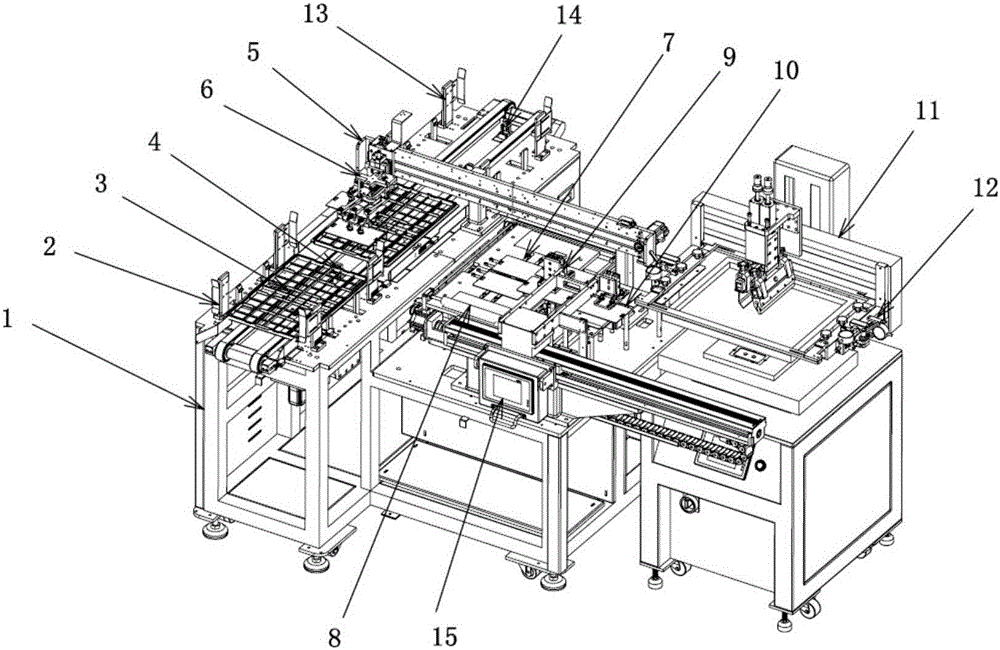

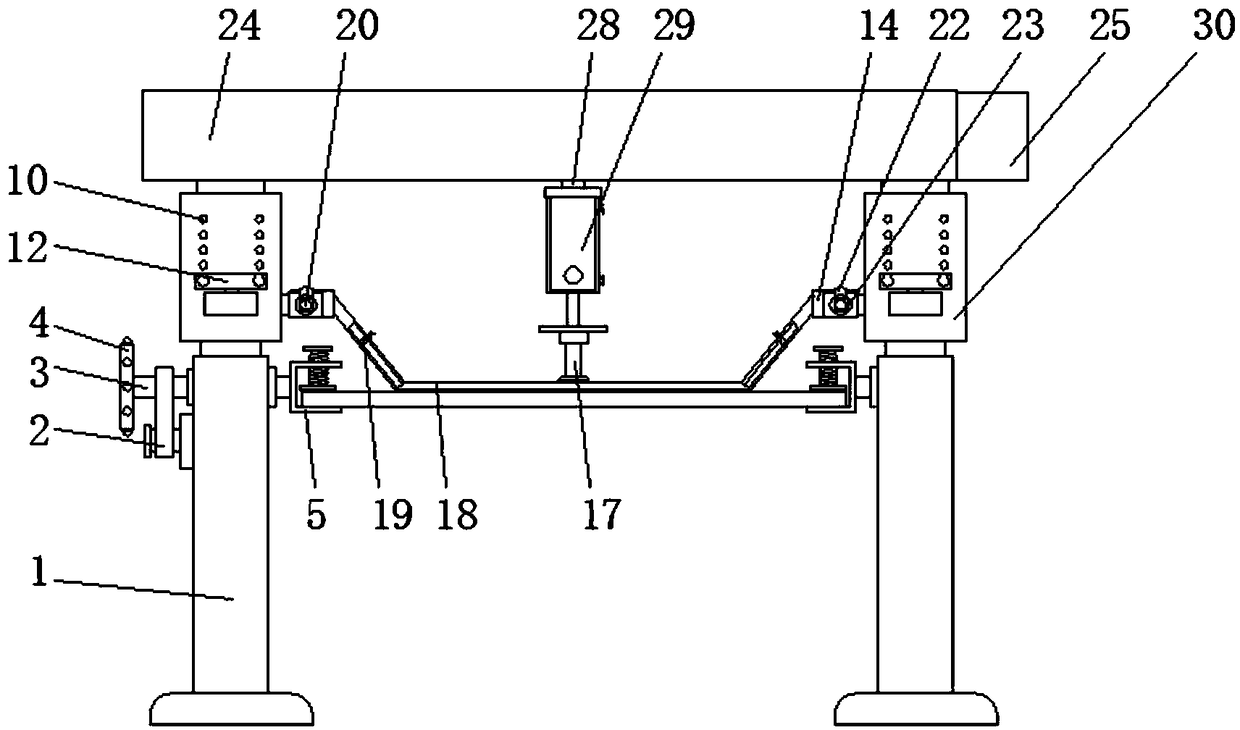

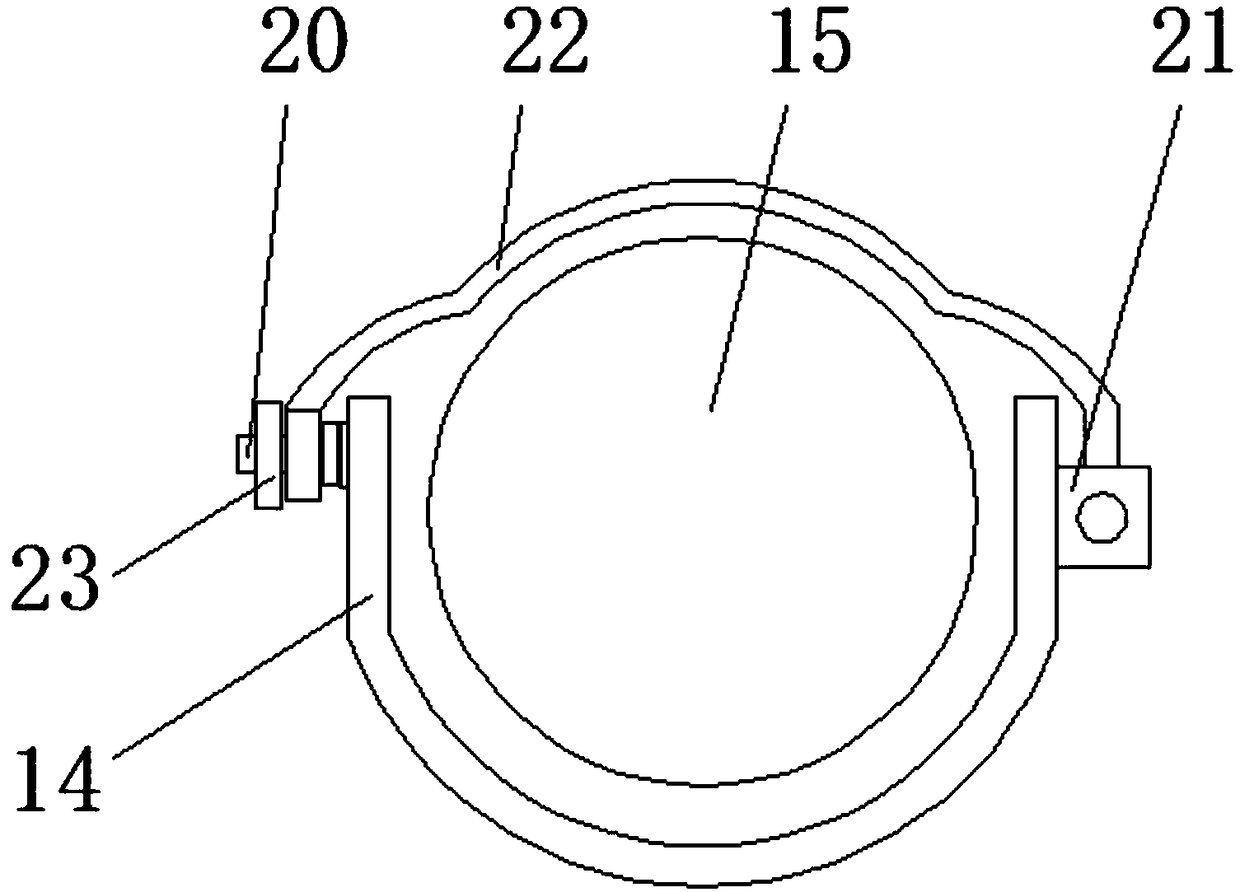

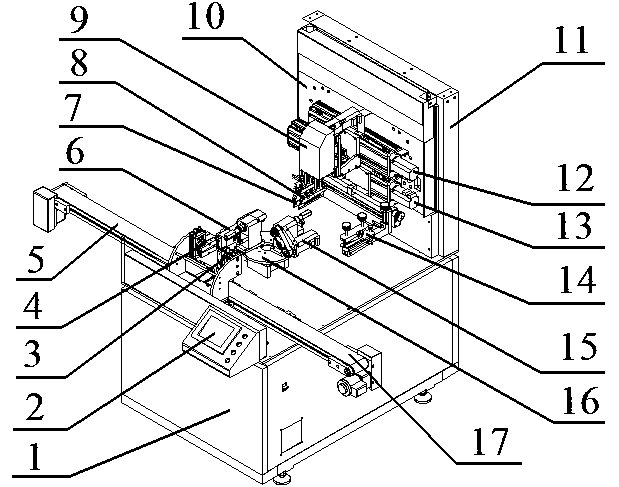

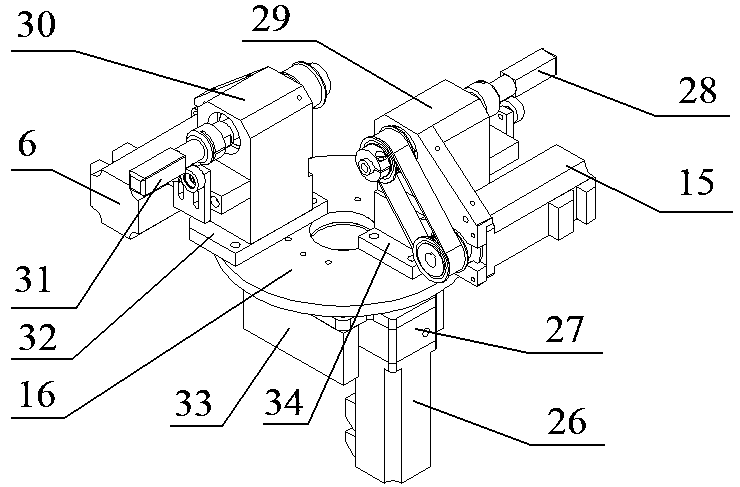

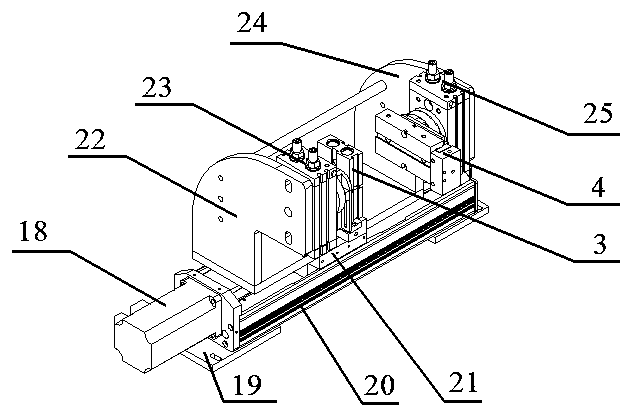

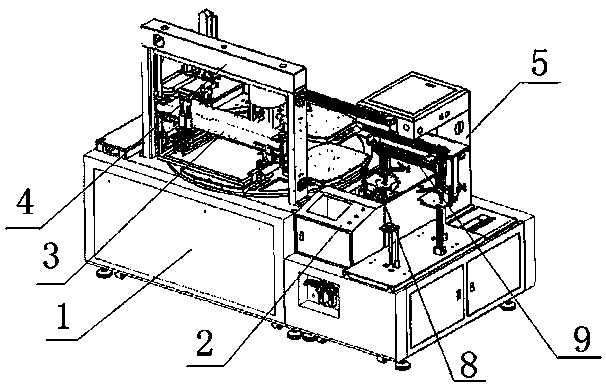

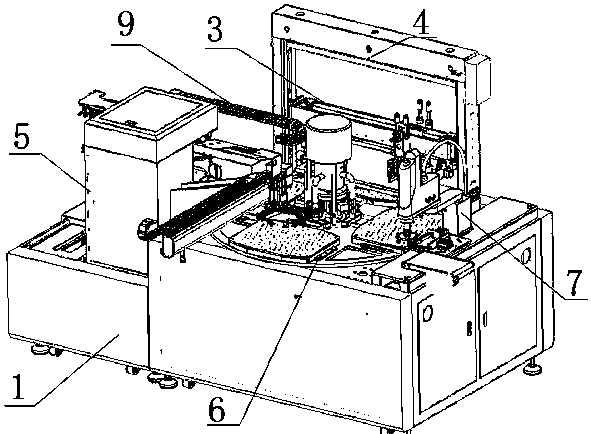

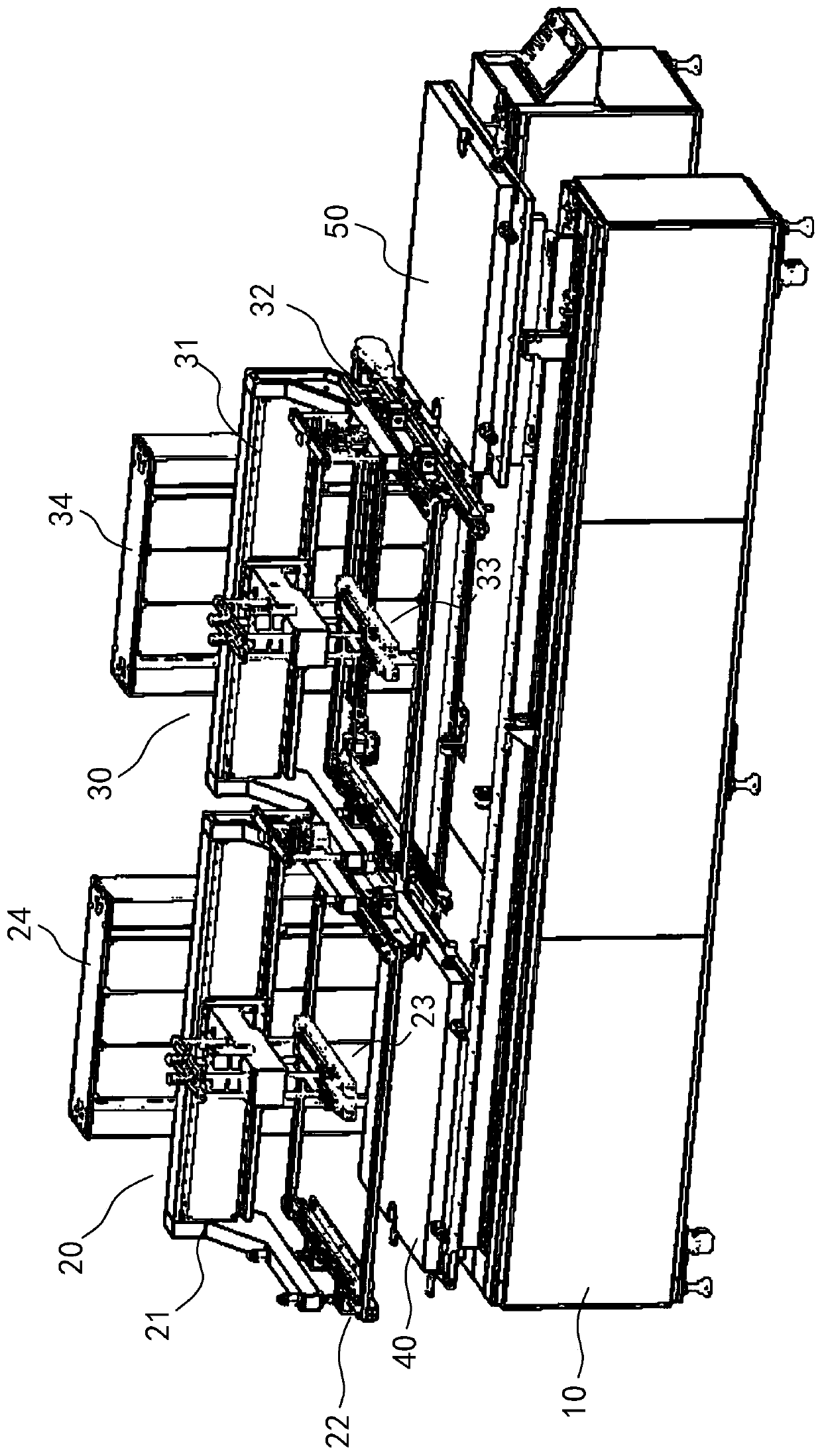

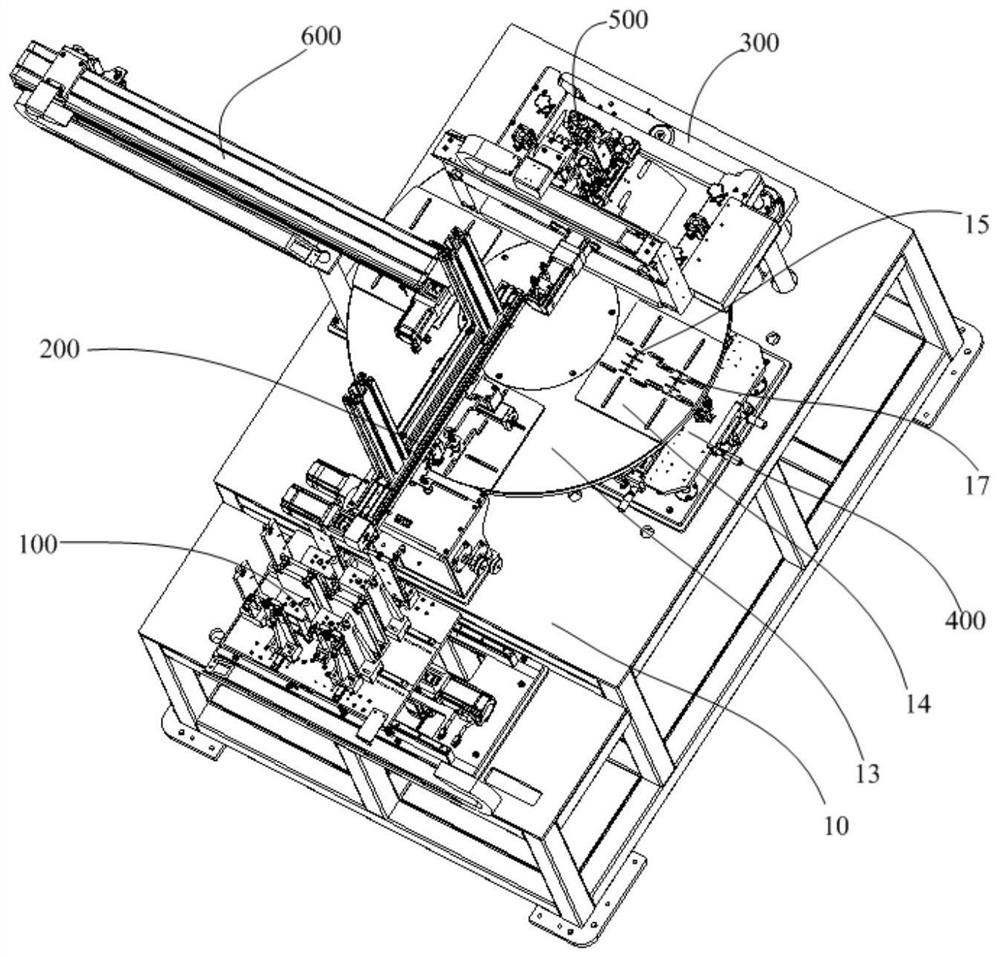

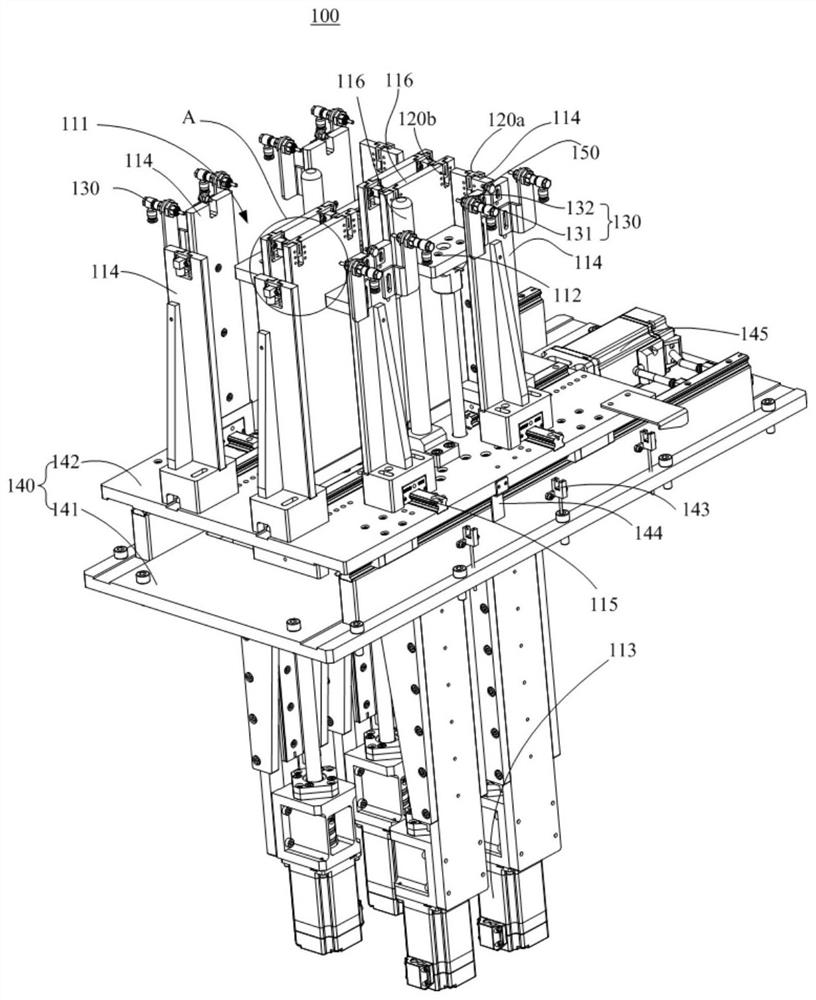

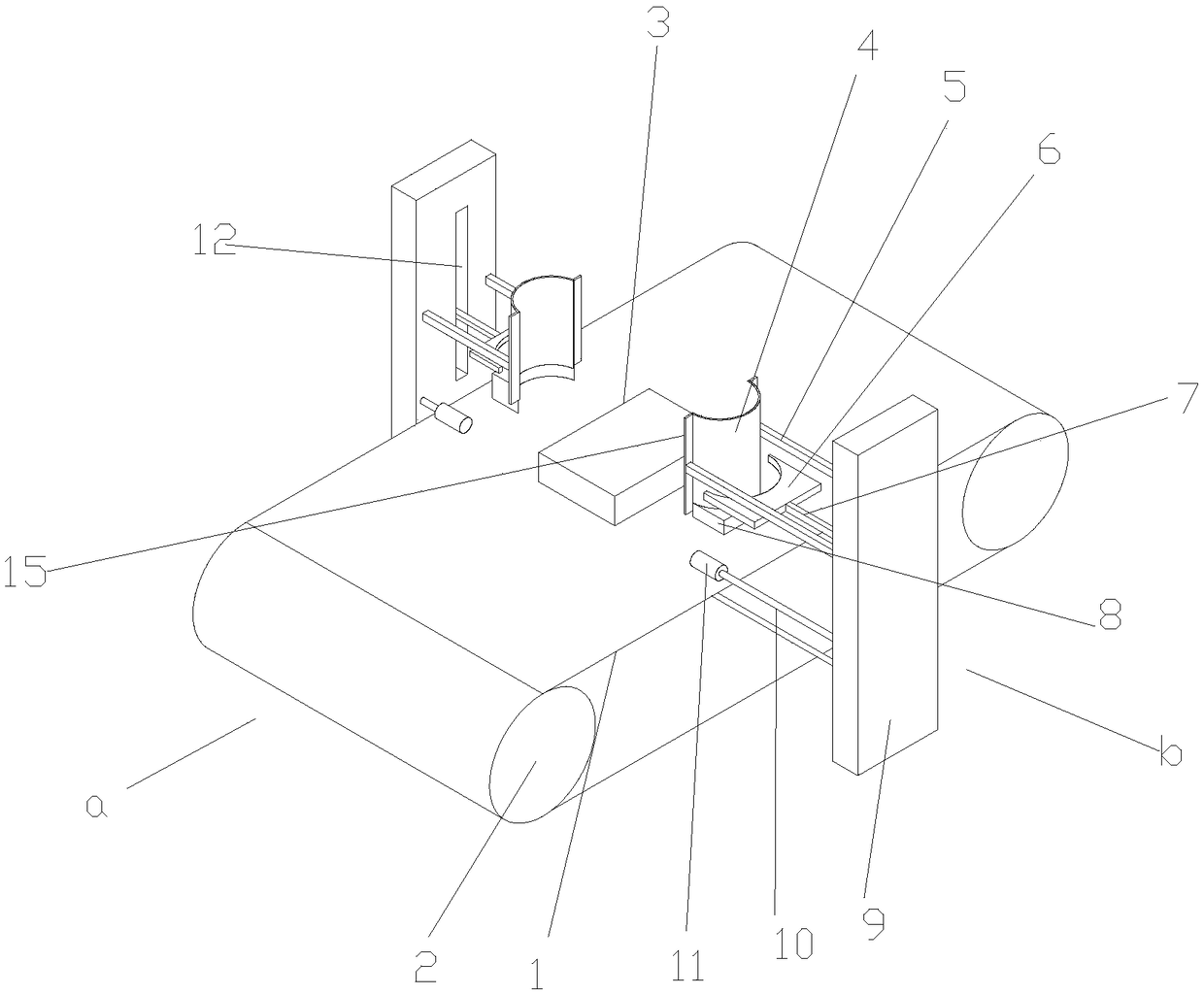

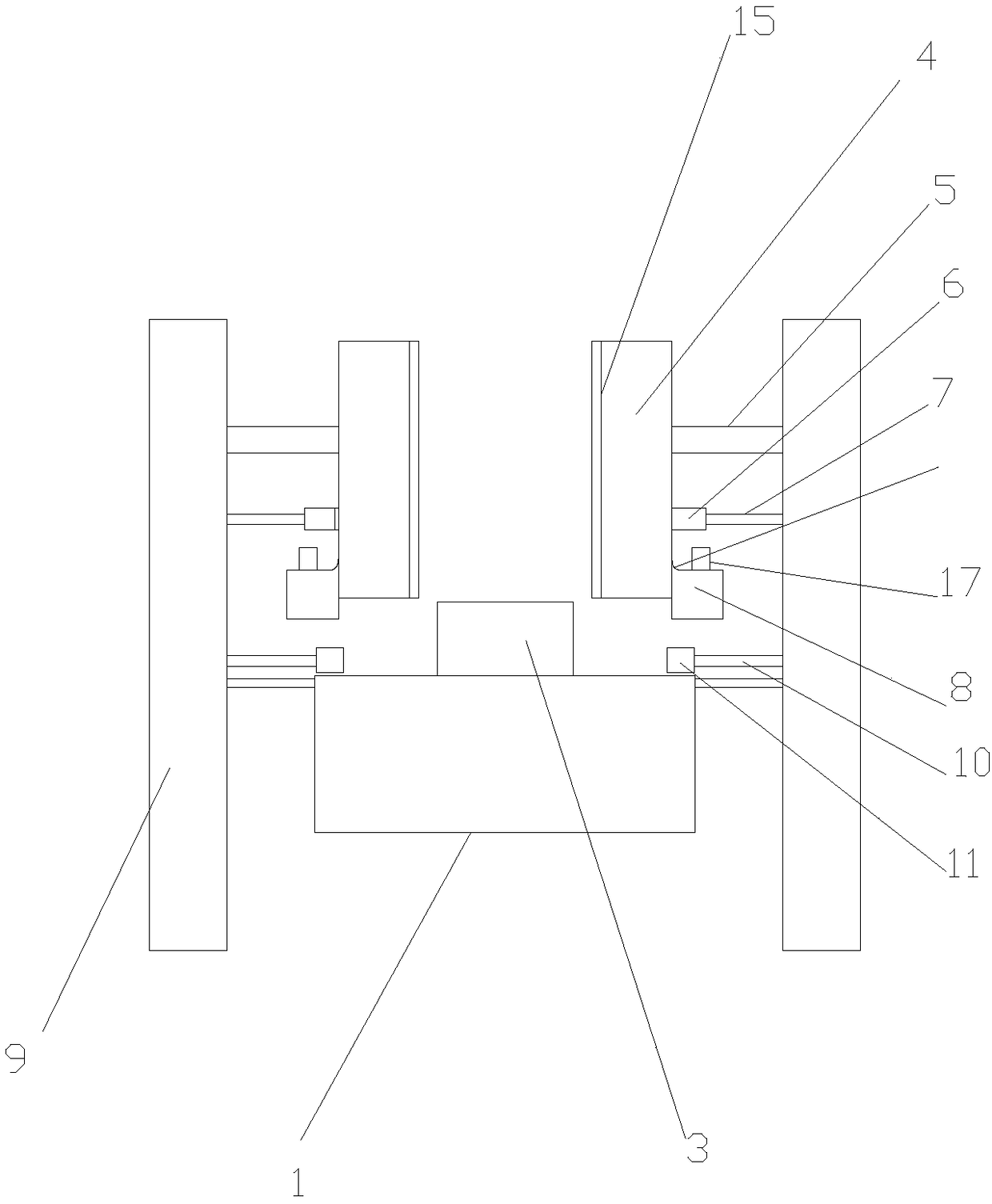

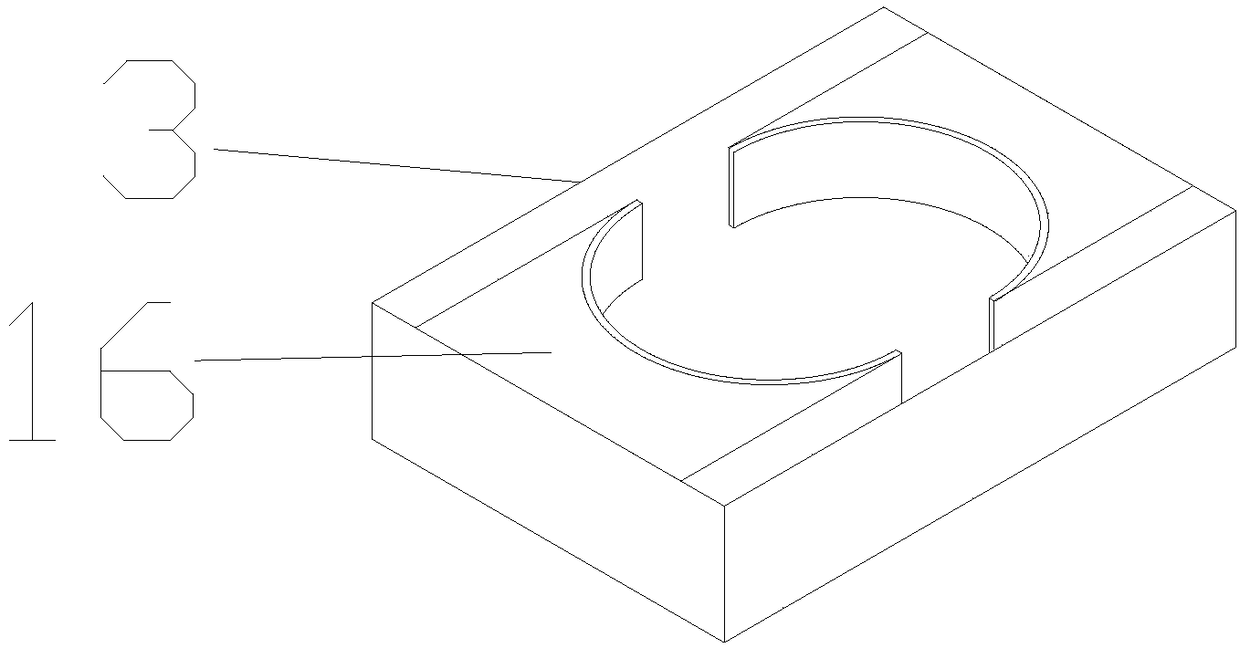

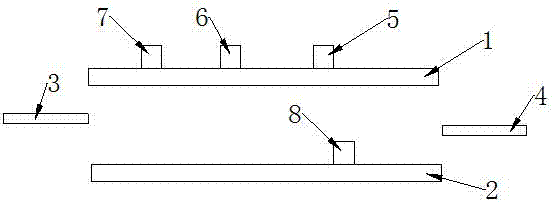

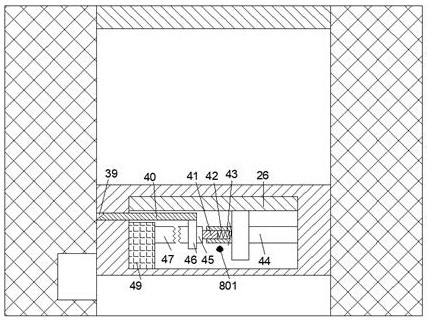

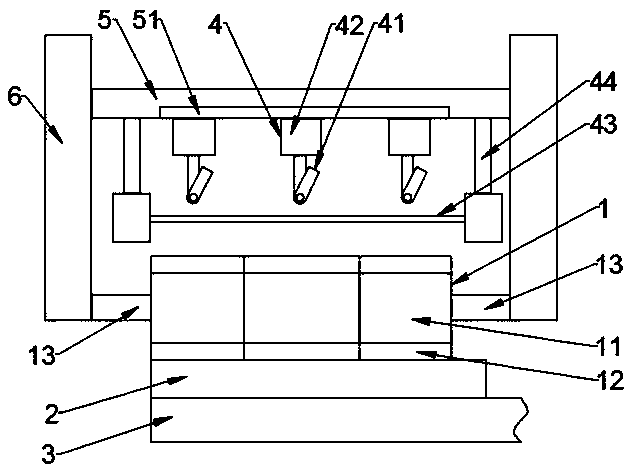

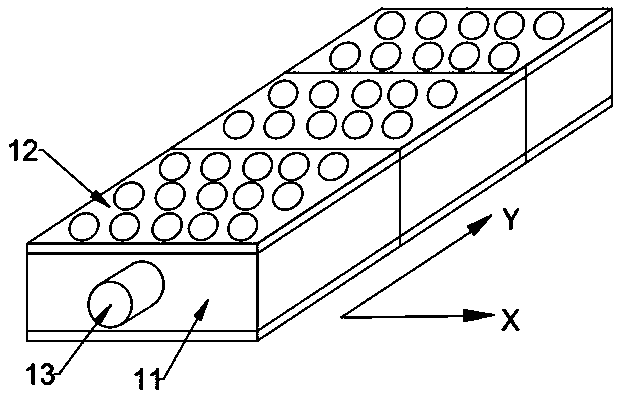

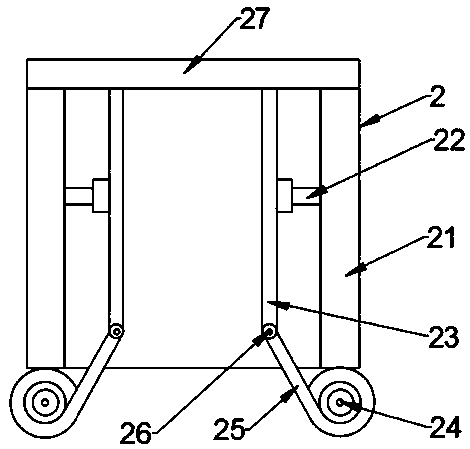

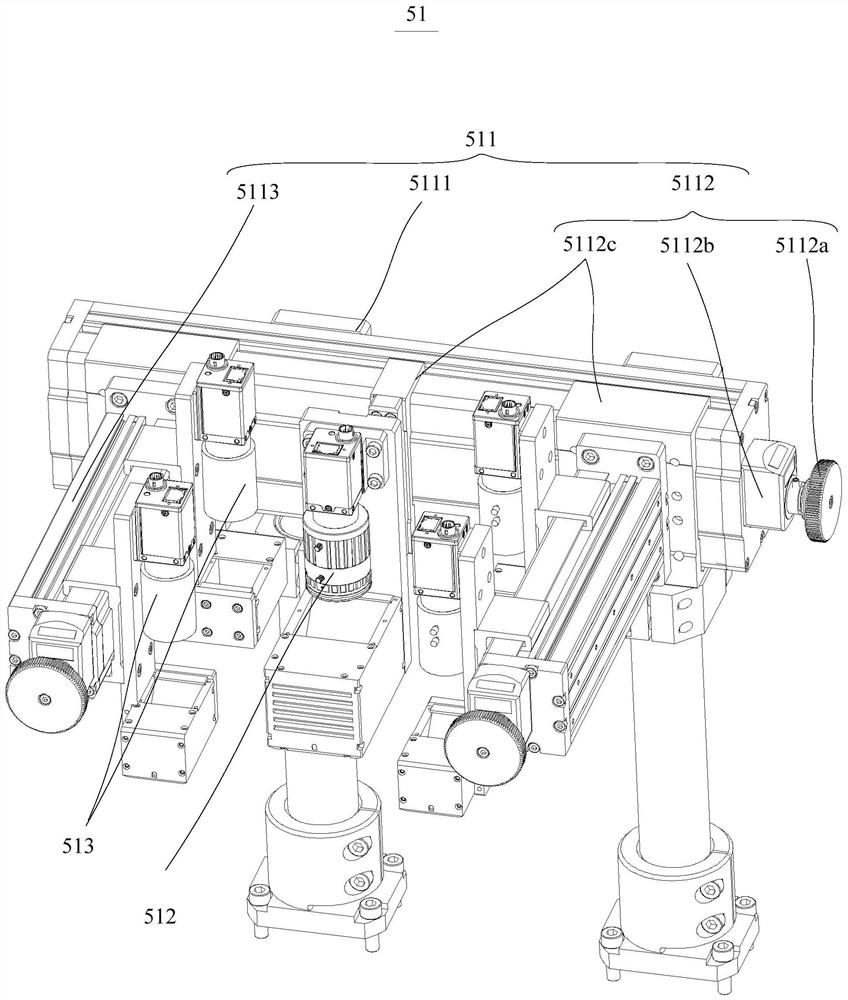

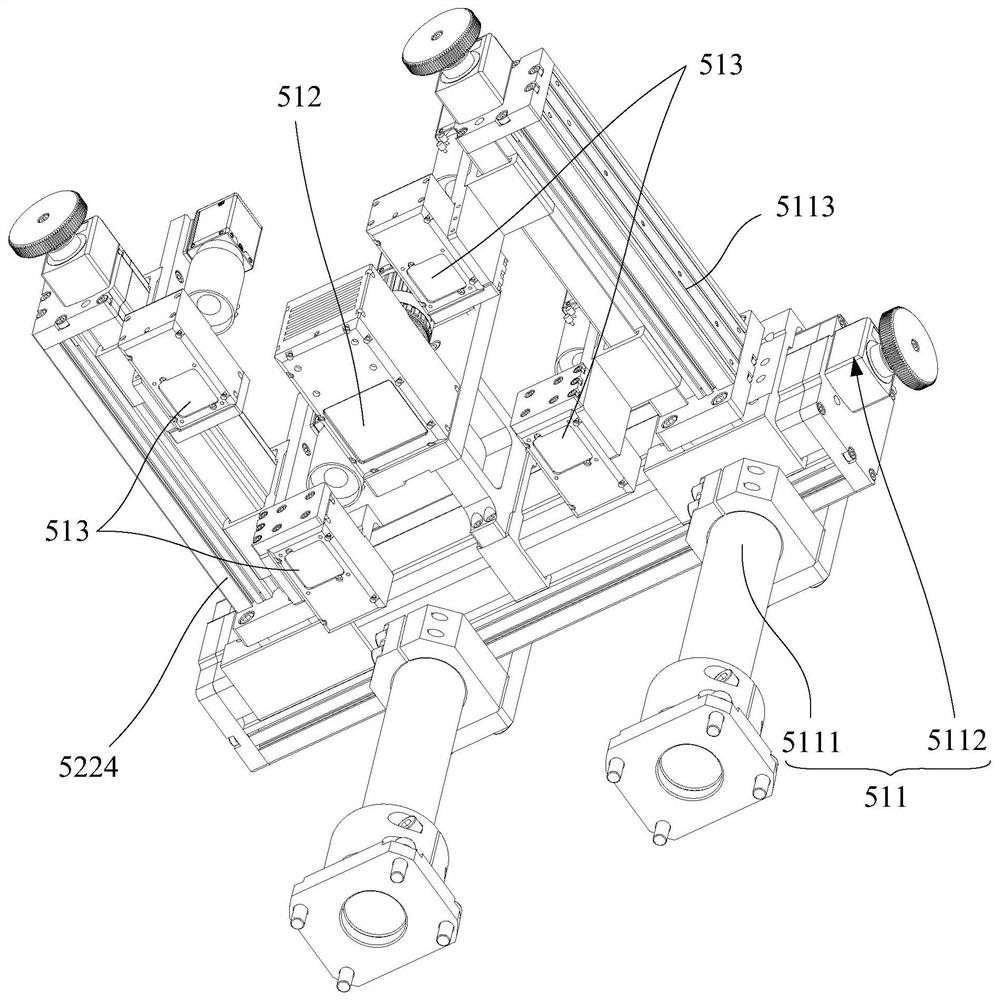

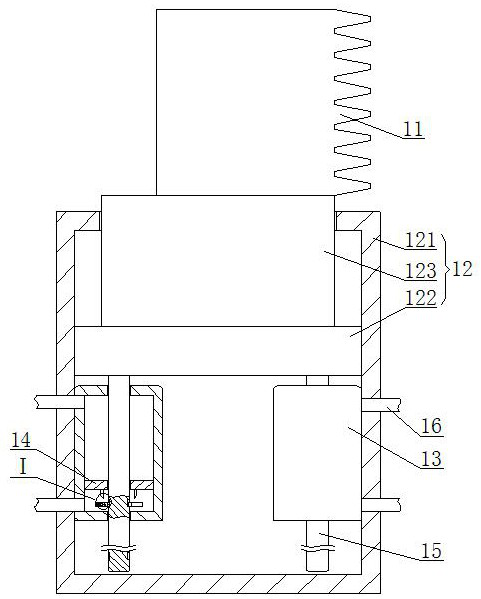

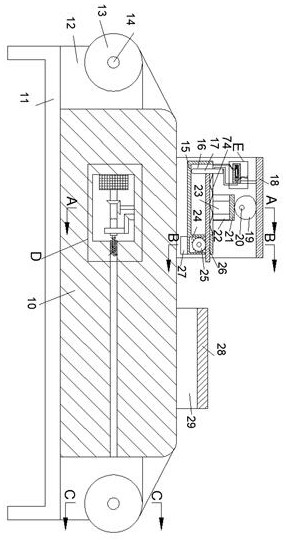

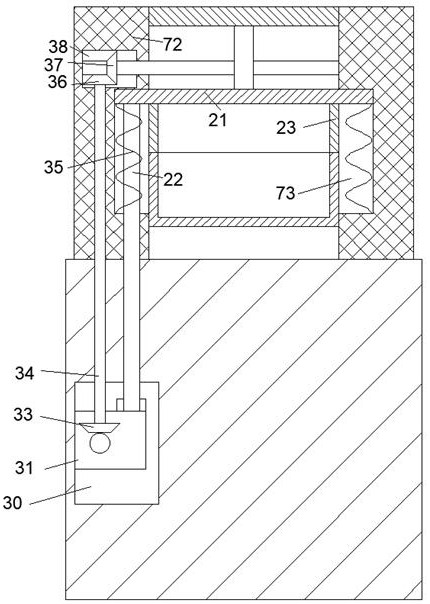

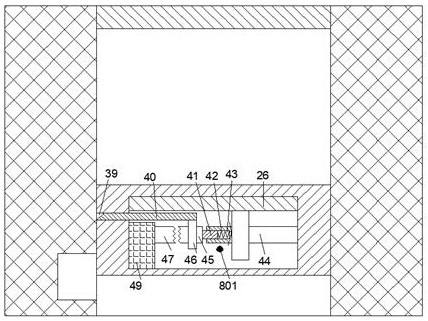

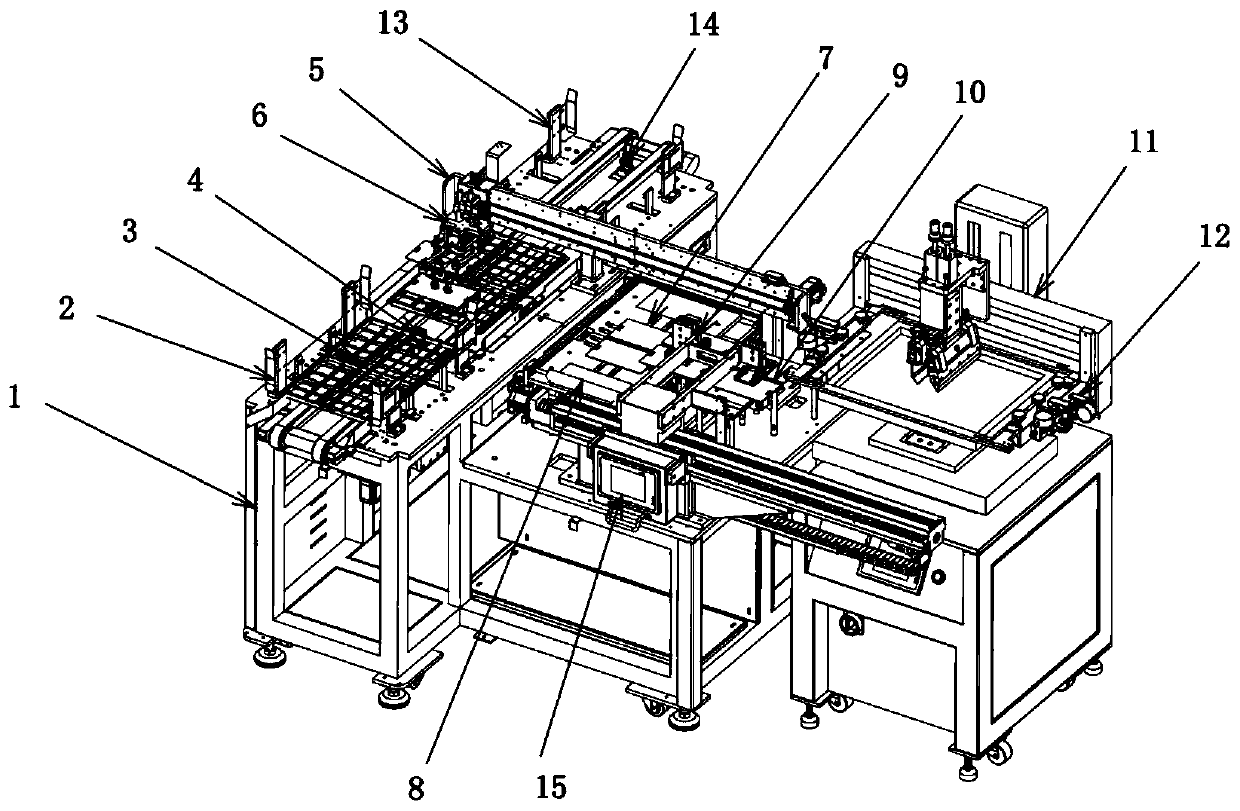

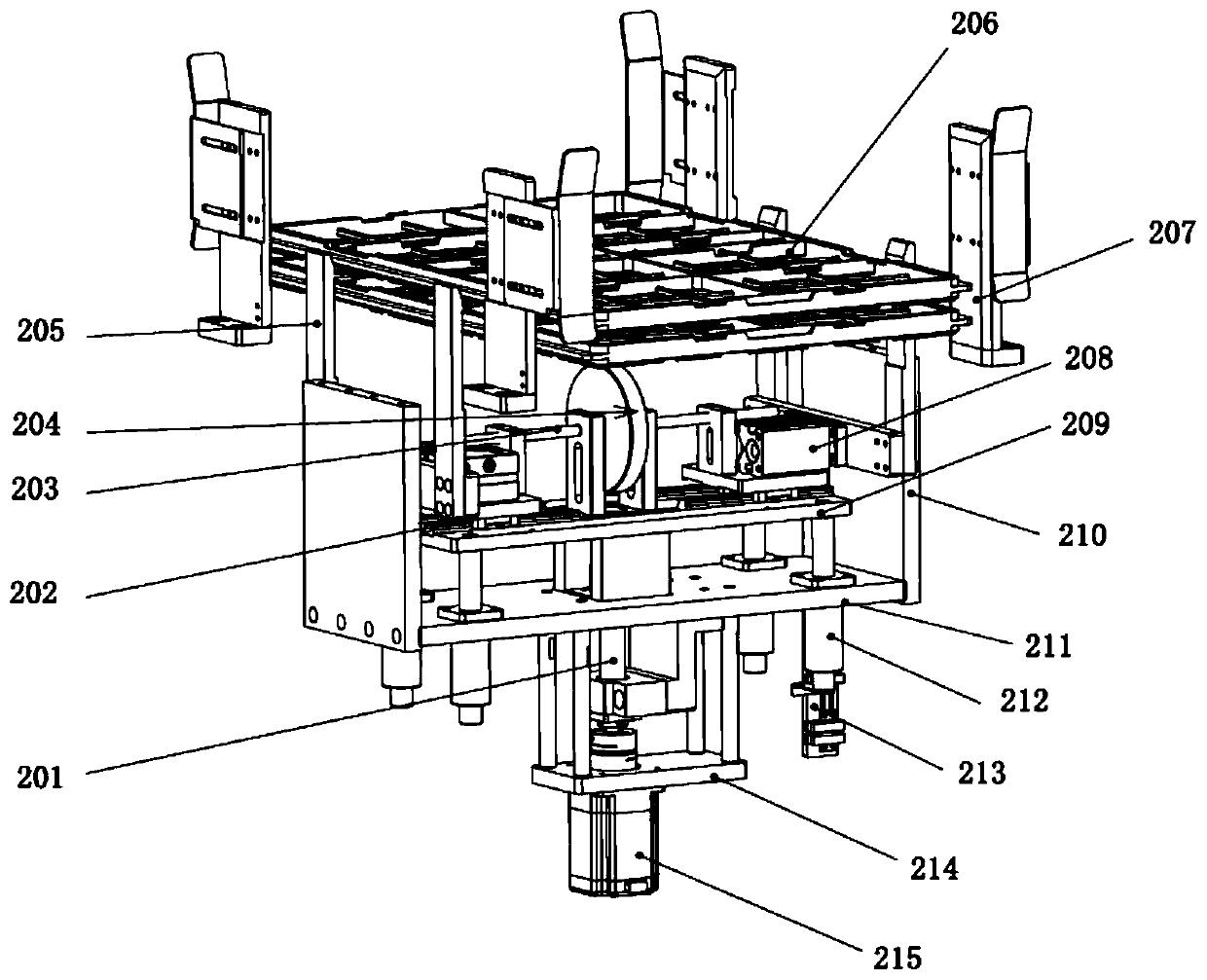

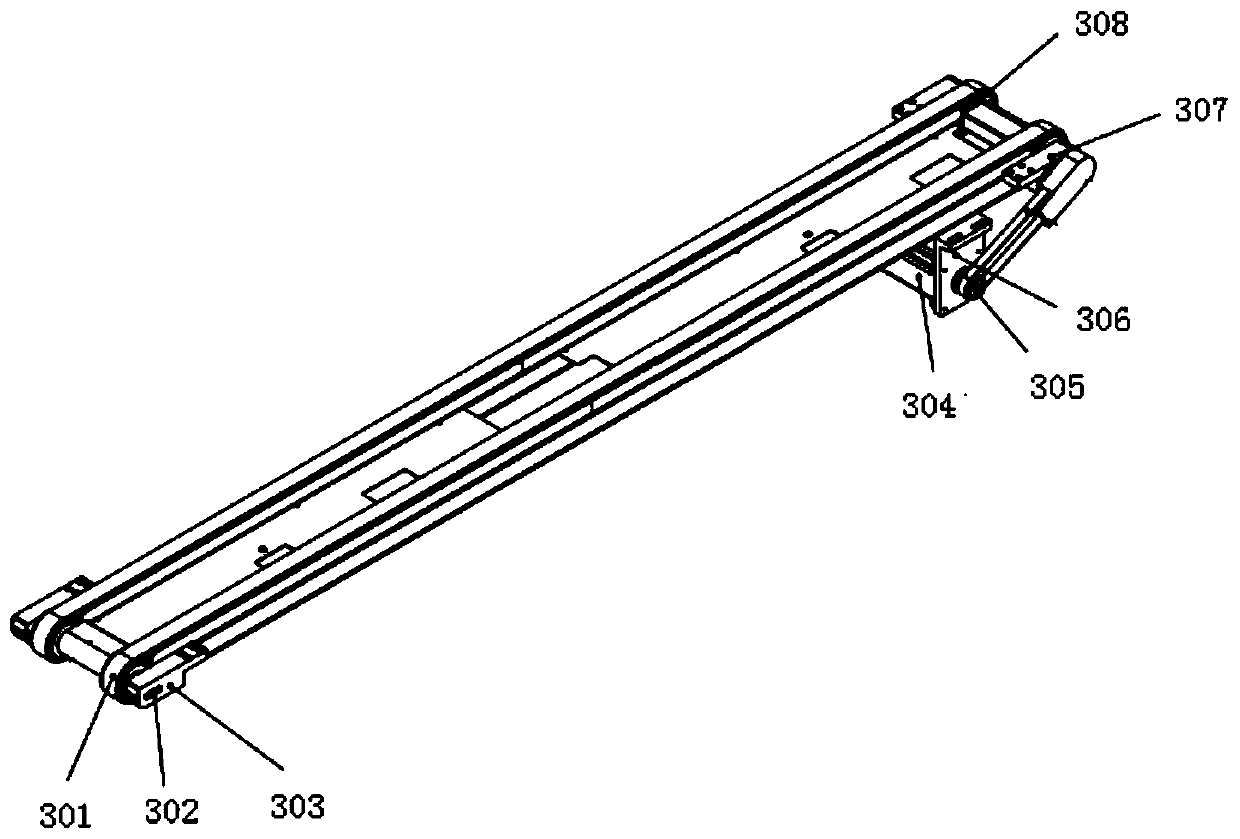

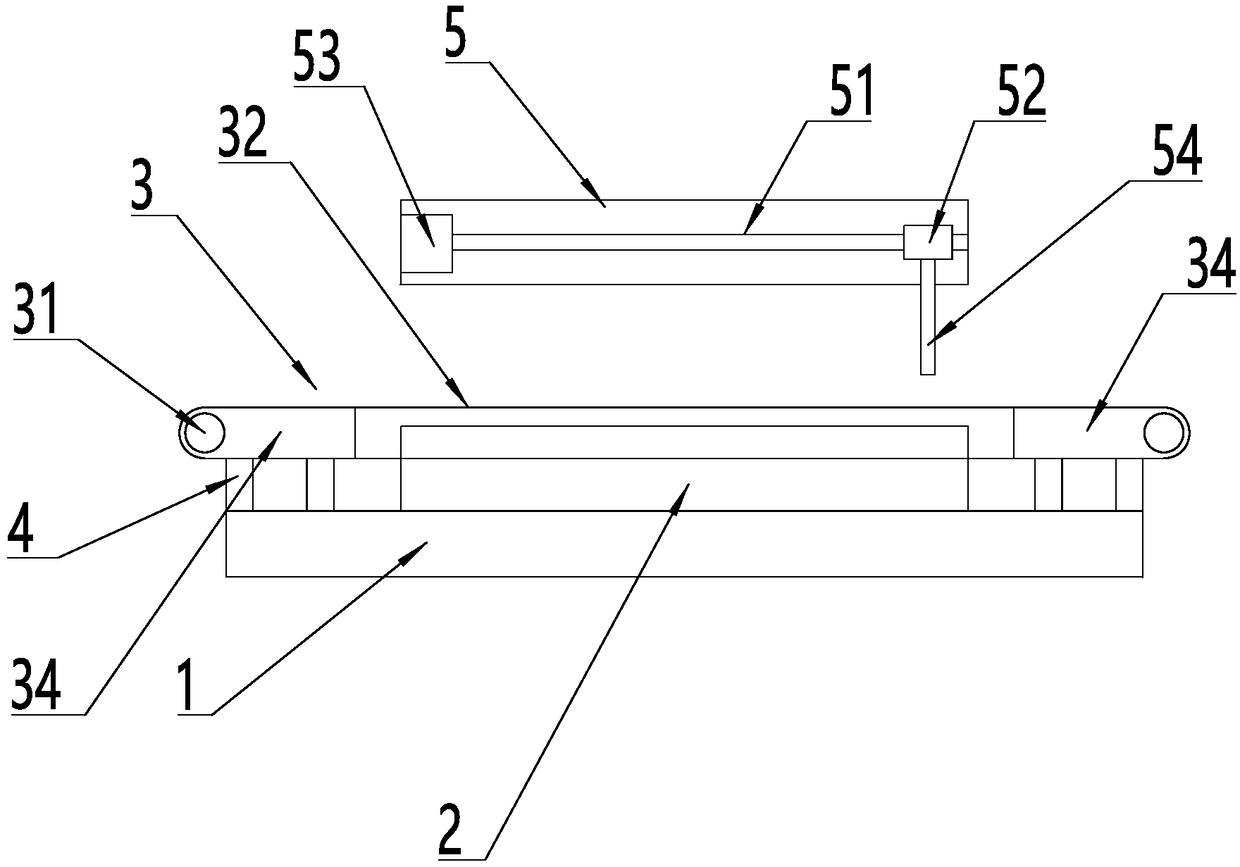

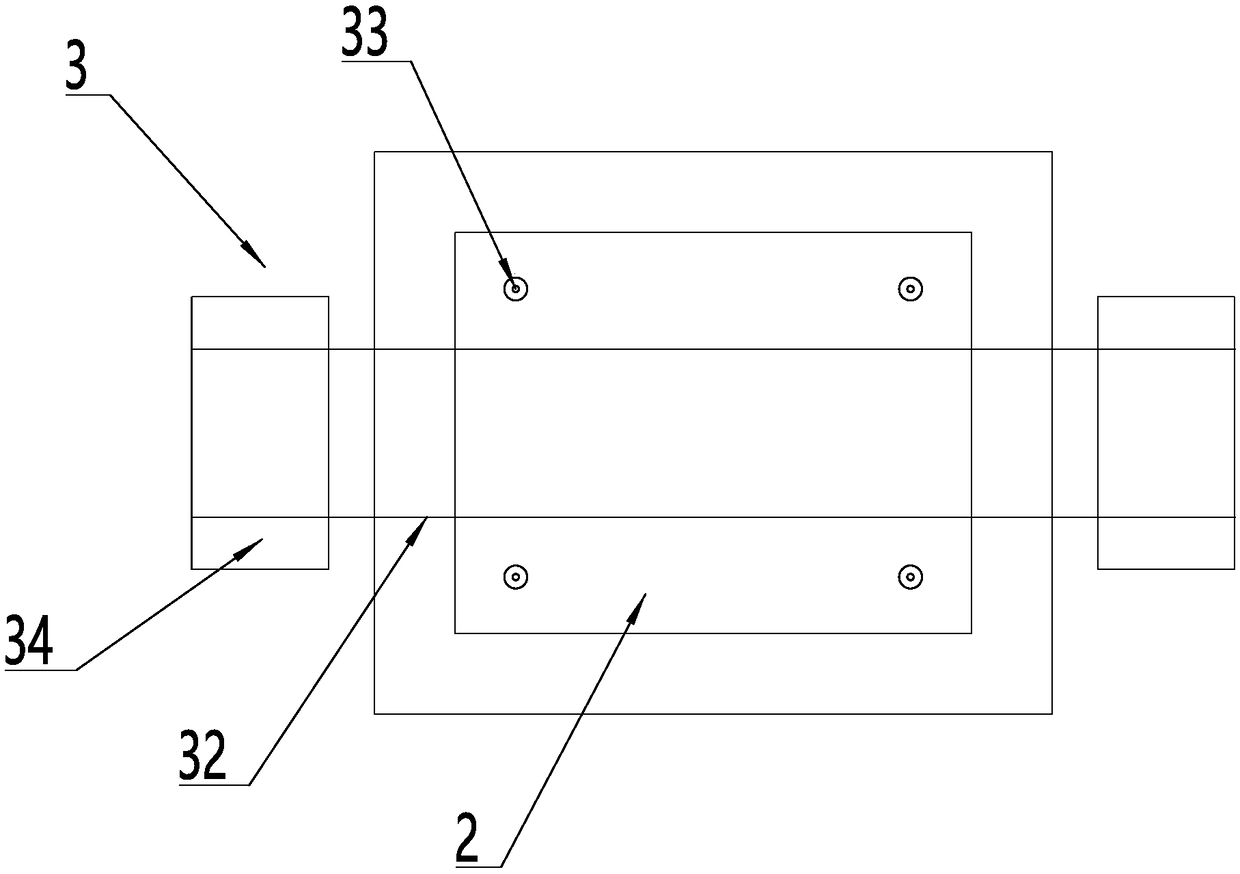

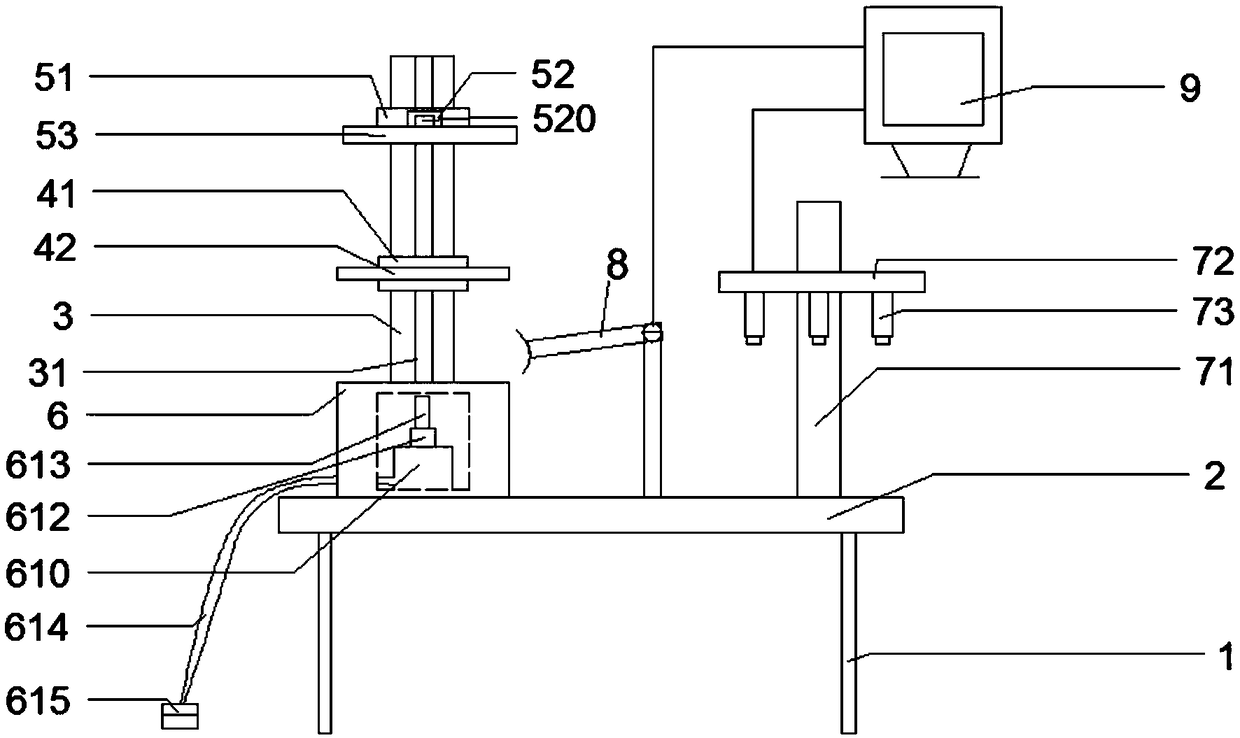

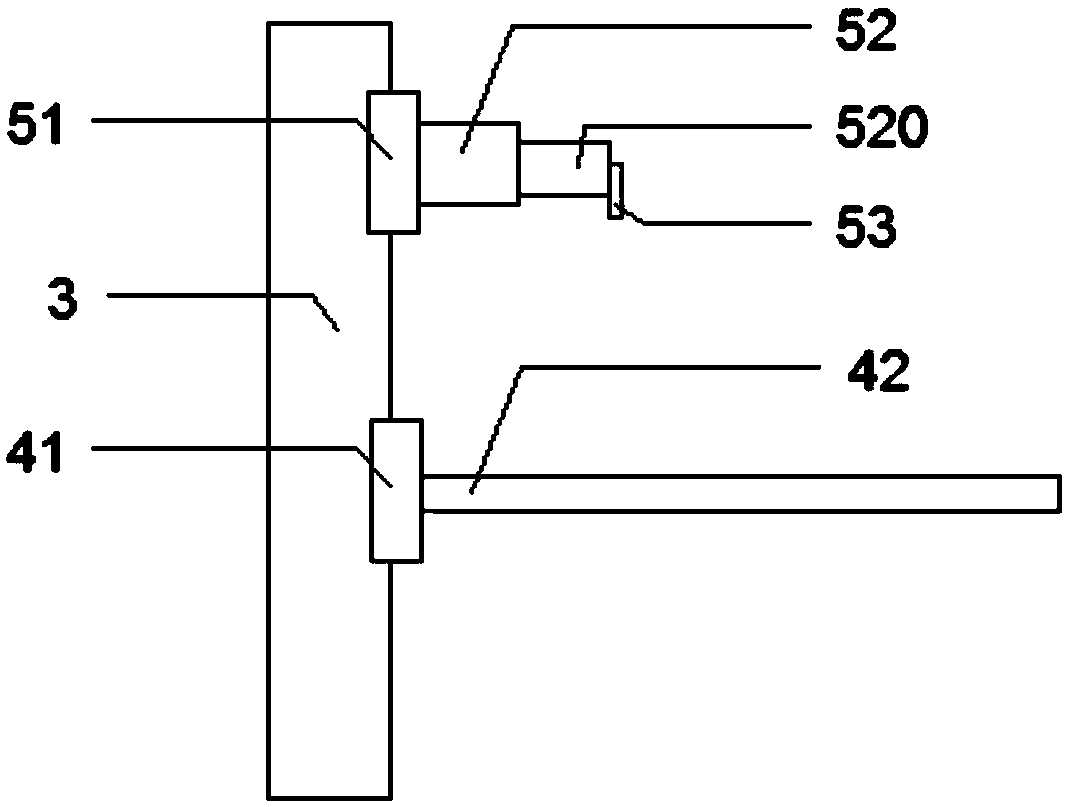

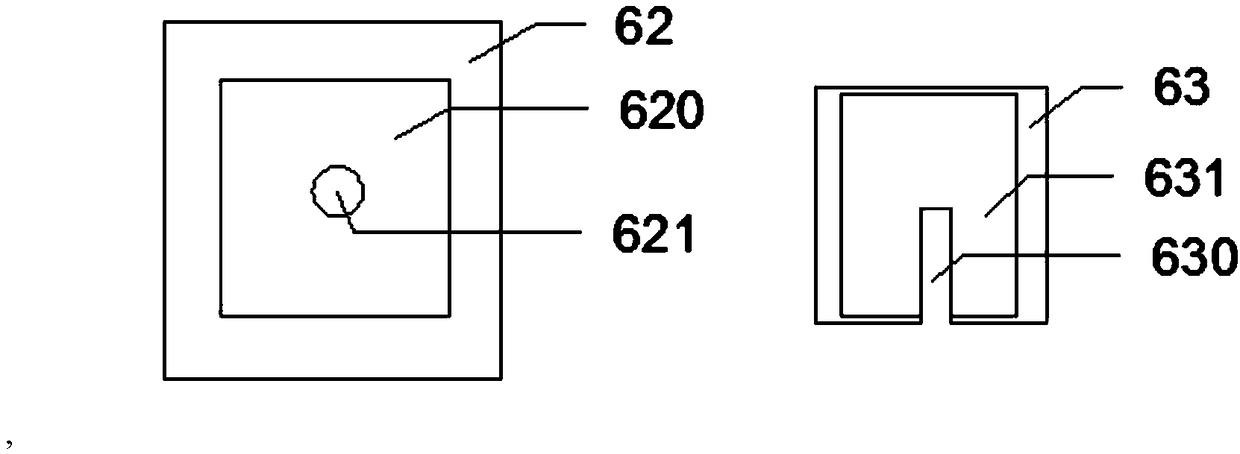

High-precision fully-automatic screen printing machine capable of printing double pieces in one process

InactiveCN106515201ADon't worry about the impactImprove printing accuracyScreen printersScreen printingScreen printingSemi automatic

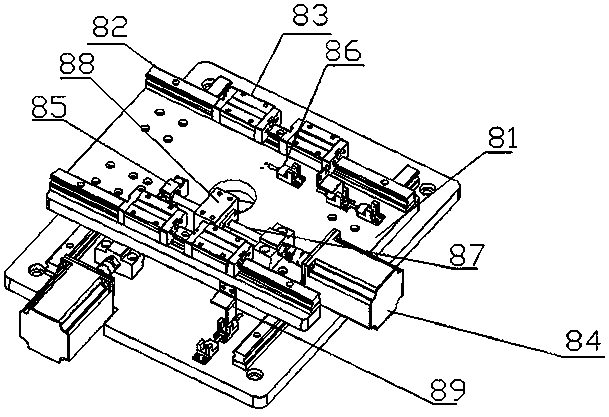

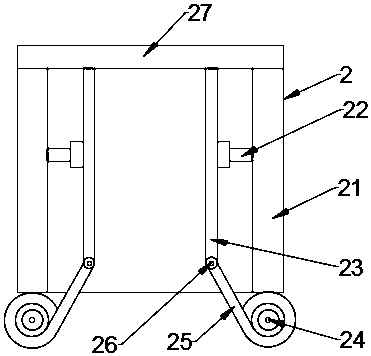

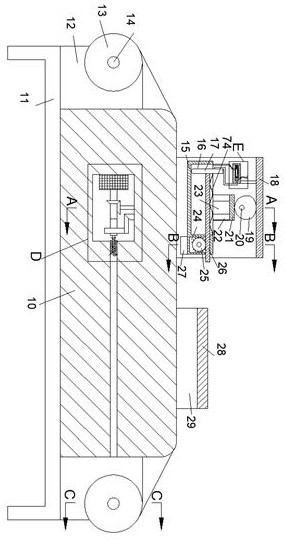

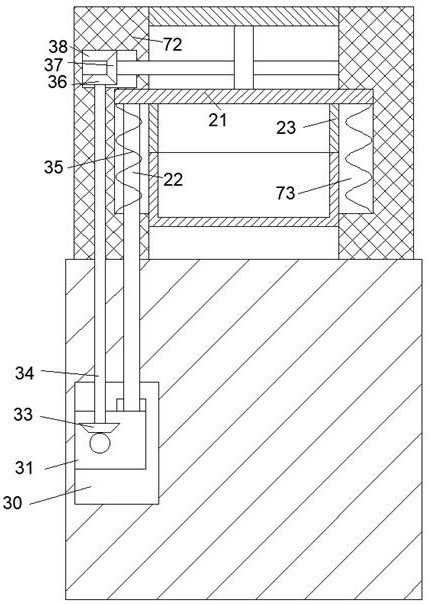

The invention relates to the technical field of screen printing. A high-precision fully-automatic screen printing machine capable of printing double pieces in one process abuts on a semi-automatic screen printing machine and comprises a rack, a conveying line assembly, a supplying-receiving disc assembly and feeding mechanisms, wherein the conveying line assembly is located on the rack; the supplying-receiving disc assembly is located on a transport surface of the conveying line assembly and capable of being driven to move by the conveying line assembly, and a plurality of printing stocks placed in pairs are arranged in the supplying-receiving disc assembly; and the feeding mechanisms are located between the conveying line assembly and the semi-automatic screen printing machine, grab the printing stocks in the supplying-receiving disc assembly in pairs, and transport the printing stocks to a printing surface of the automatic screen printing machine. According to the high-precision fully-automatic screen printing machine capable of printing double pieces in one process, which is disclosed by the invention, an ingenious double-piece taking mechanism, an accurate one-process double-piece location mechanism and a precise double-piece loading mechanism are designed, so that the printing accuracy can be increased, and the screen printing efficiency can be doubled on the basis of increasing a small amount of cost for a single-piece semi-automatic transformed screen printing machine.

Owner:SHENZHEN TINVICO TECH CO LTD

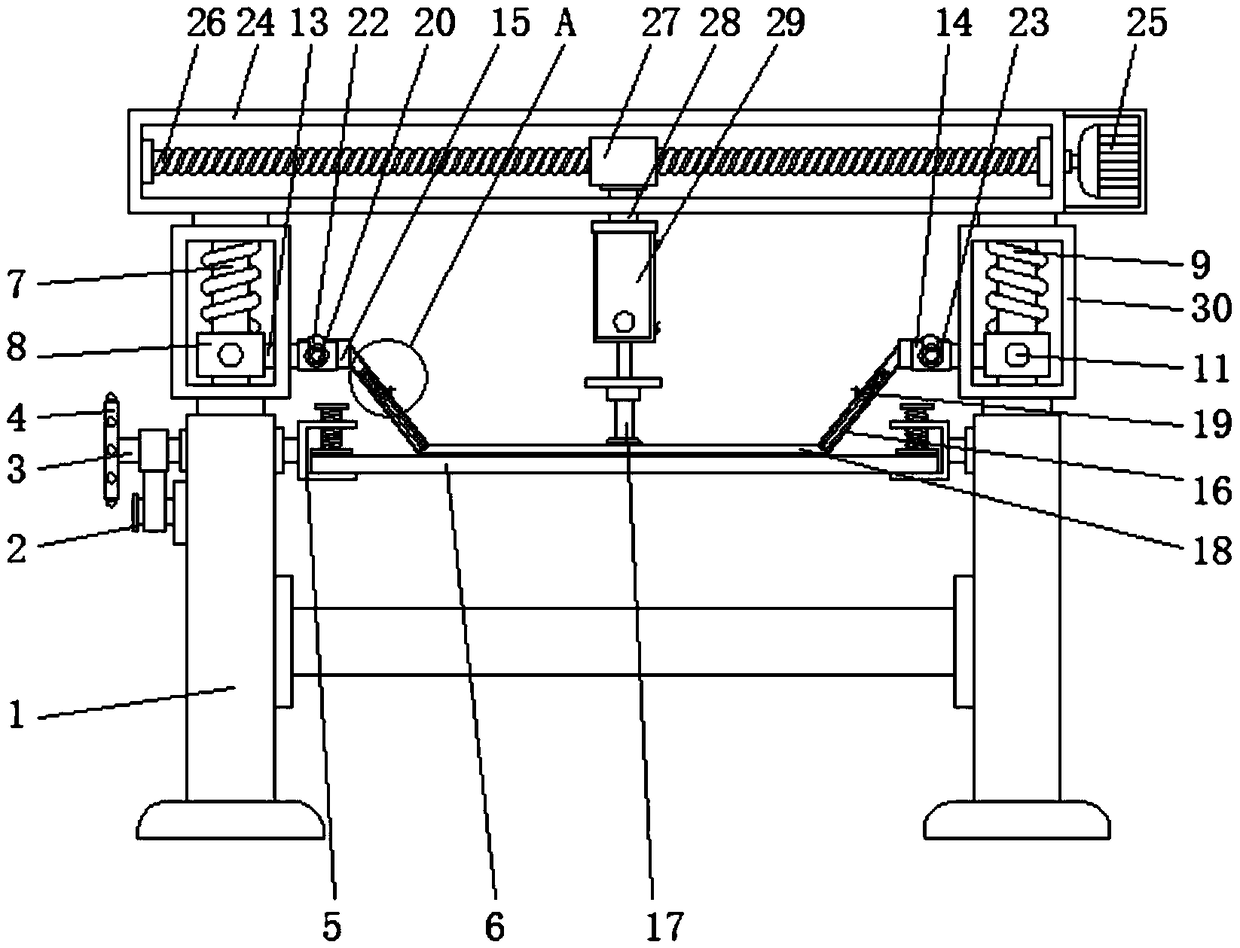

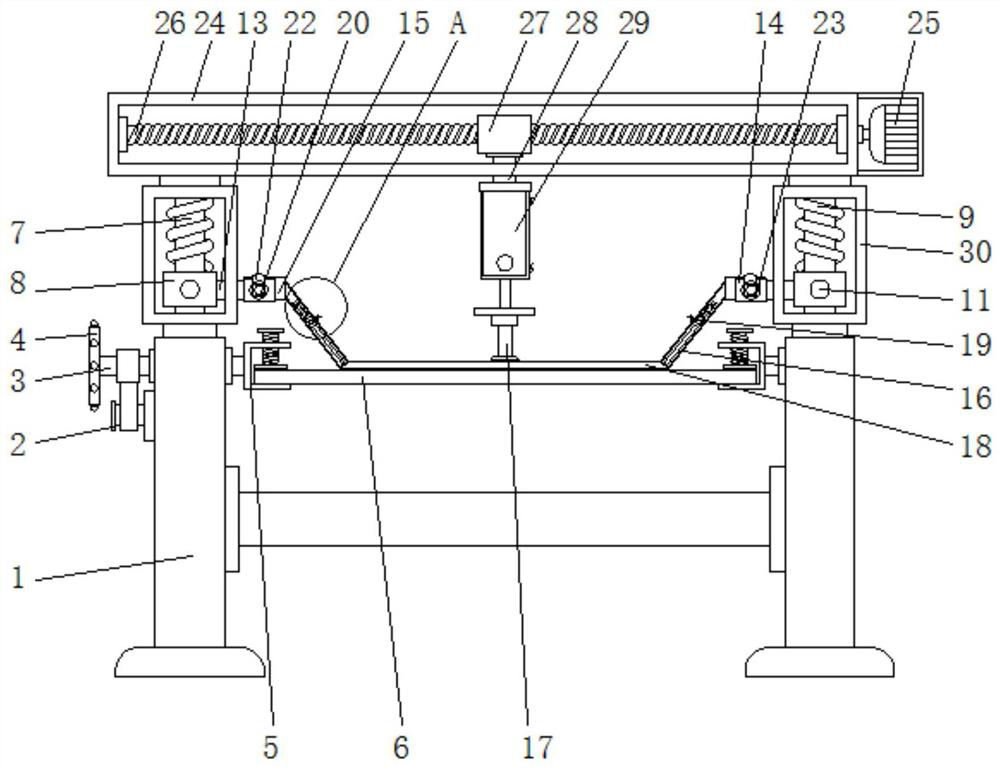

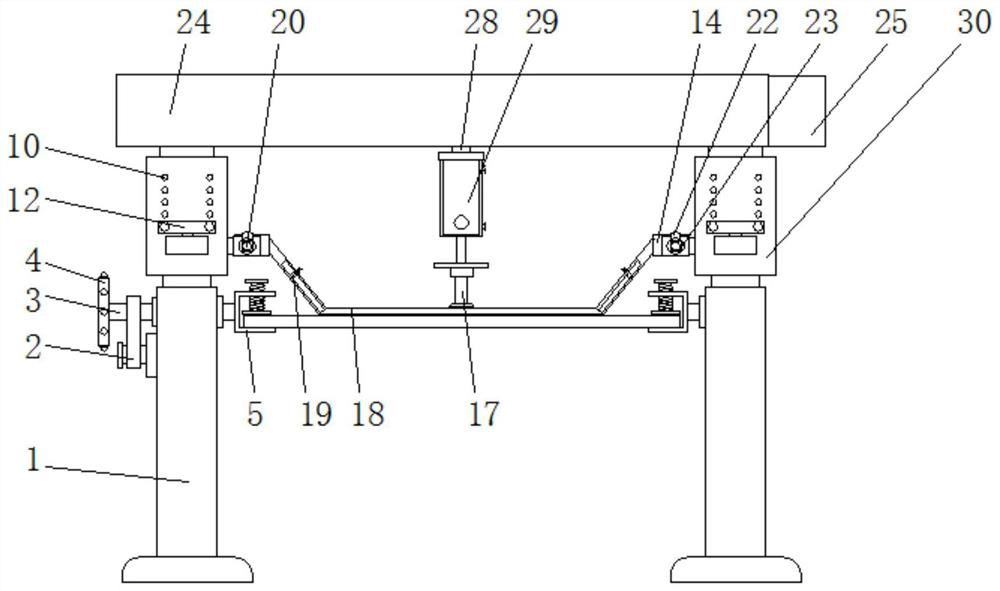

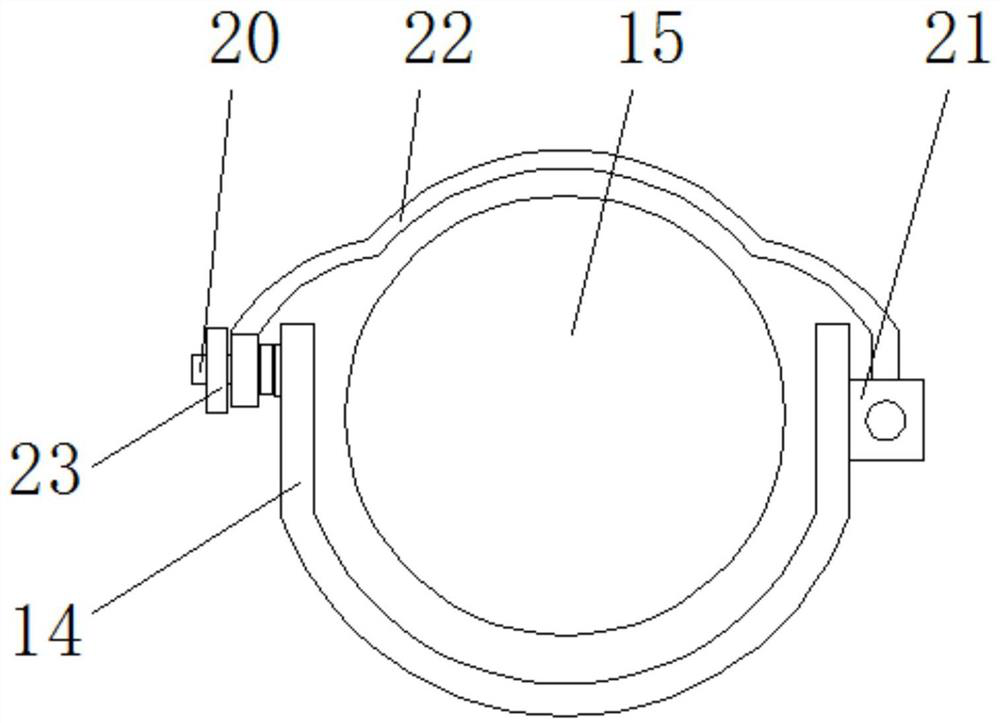

Large silk-screen printing equipment for wood plate

ActiveCN109435436AReduce labor intensityImprove screen printing efficiencyScreen printersPrinting press partsHydraulic cylinderScreen printing

The invention relates to the technical field of wood plate machining equipment, and discloses large silk-screen printing equipment for a wood plate. The large silk-screen printing equipment for the wood plate comprises two support legs, wherein passive boxes are fixedly installed at the tops of the two support legs separately; a rotary shaft movably sleeves the top end of one support leg, and a fastening device located below the rotary shaft is fixedly installed on the outer side surface of the other support leg; a rotary wheel is fixedly connected to one end located at the left side of one support leg, of the rotary shaft; and a clamping device is fixedly connected to one end located at the right side of one support leg, of the rotary shaft. According to the large silk-screen printing equipment for the wood plate, a screw rod is driven to rotate through the running of a drive motor; by virtue of the cooperation between the screw rod and a moving block, the moving block is enabled to drive a hydraulic cylinder to move to left and right through a bottom rod; and then a scraping plate is driven by a hydraulic cylinder to repeatedly move to left and right to scrap a printing plate, sothat a workpiece to be machined is printed with a pattern, and therefore, the labor intensity of working personnel is lowered, and the silk-screen printing efficiency is increased.

Owner:诸暨市云傲机械配件厂

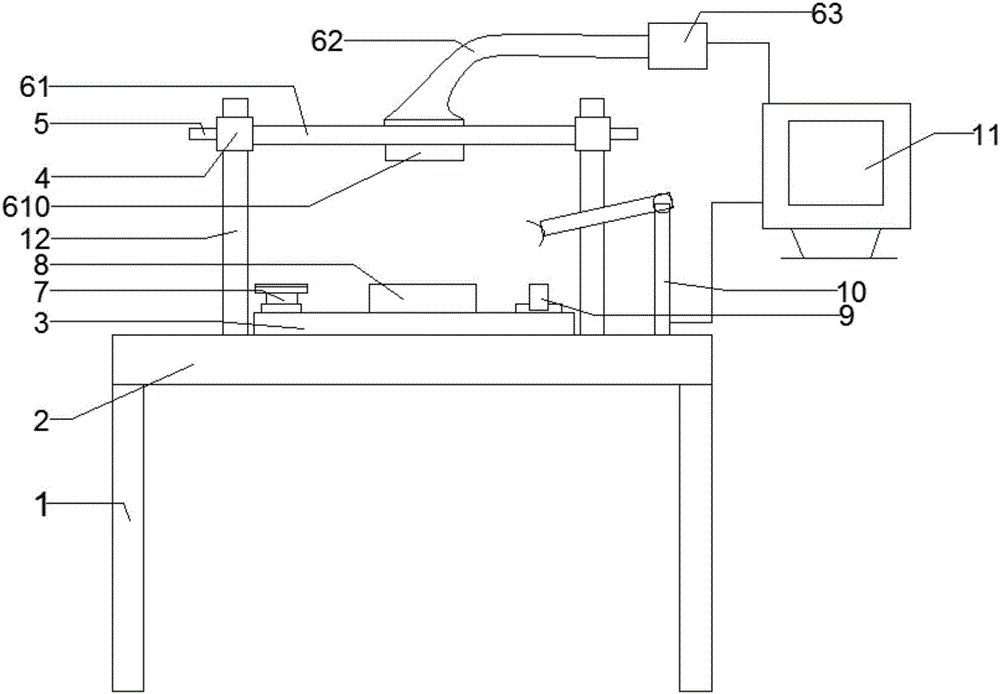

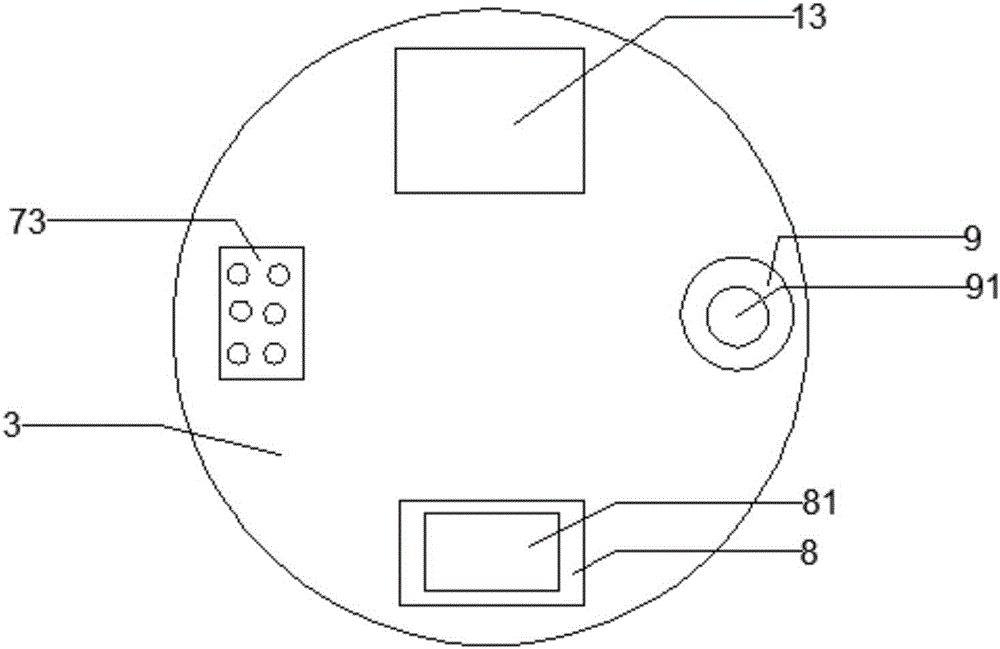

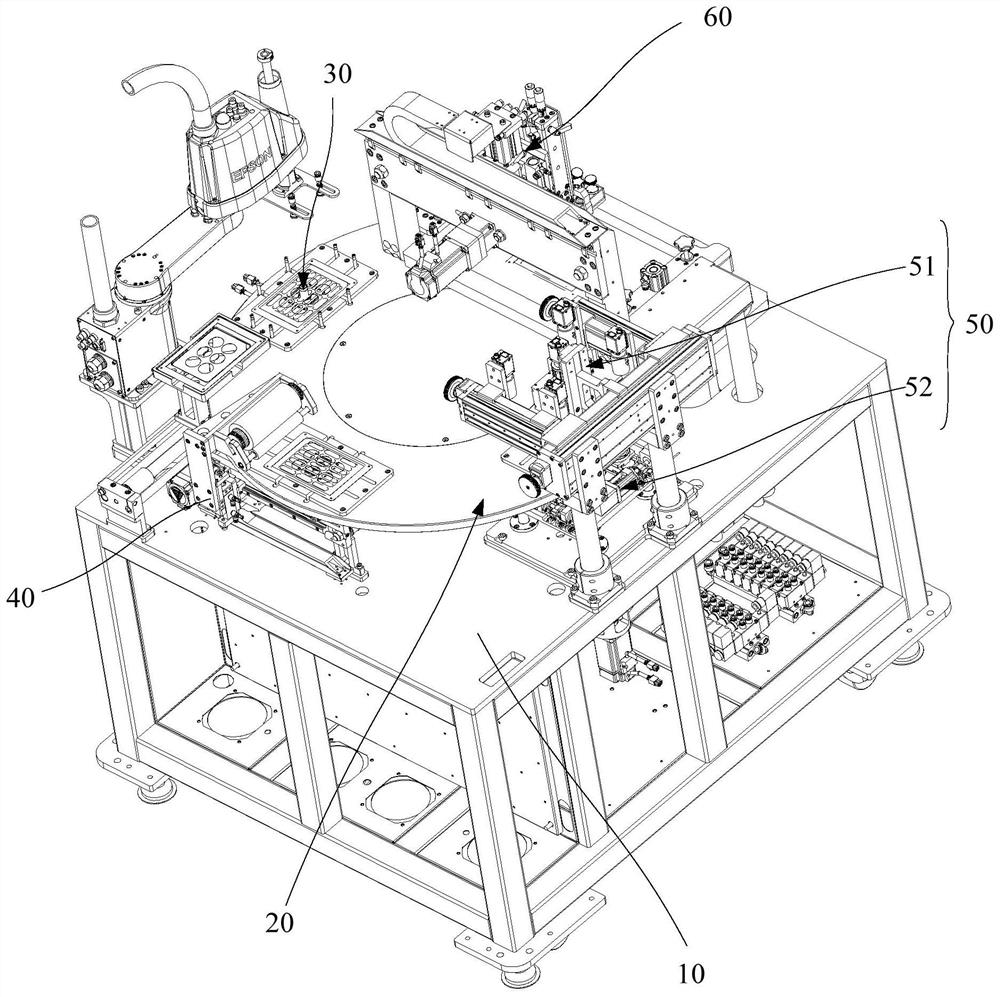

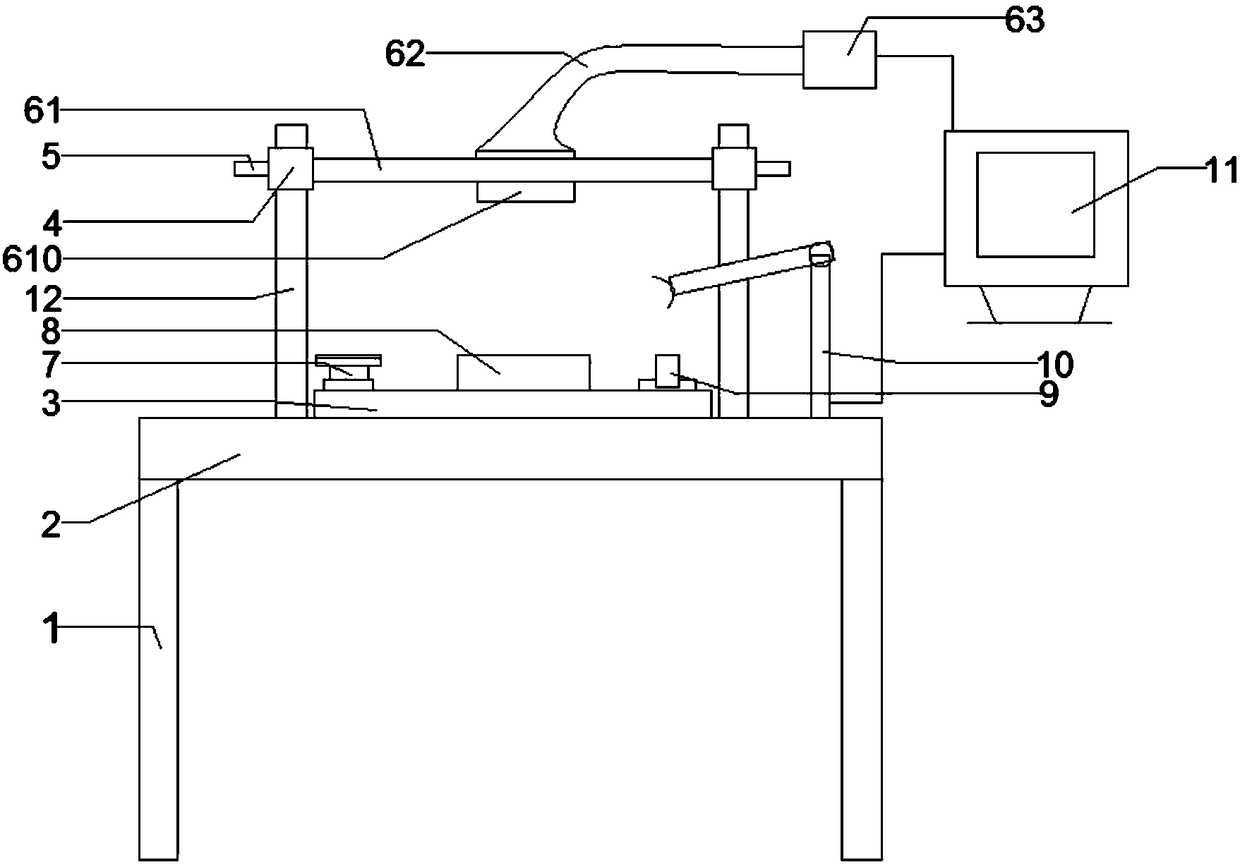

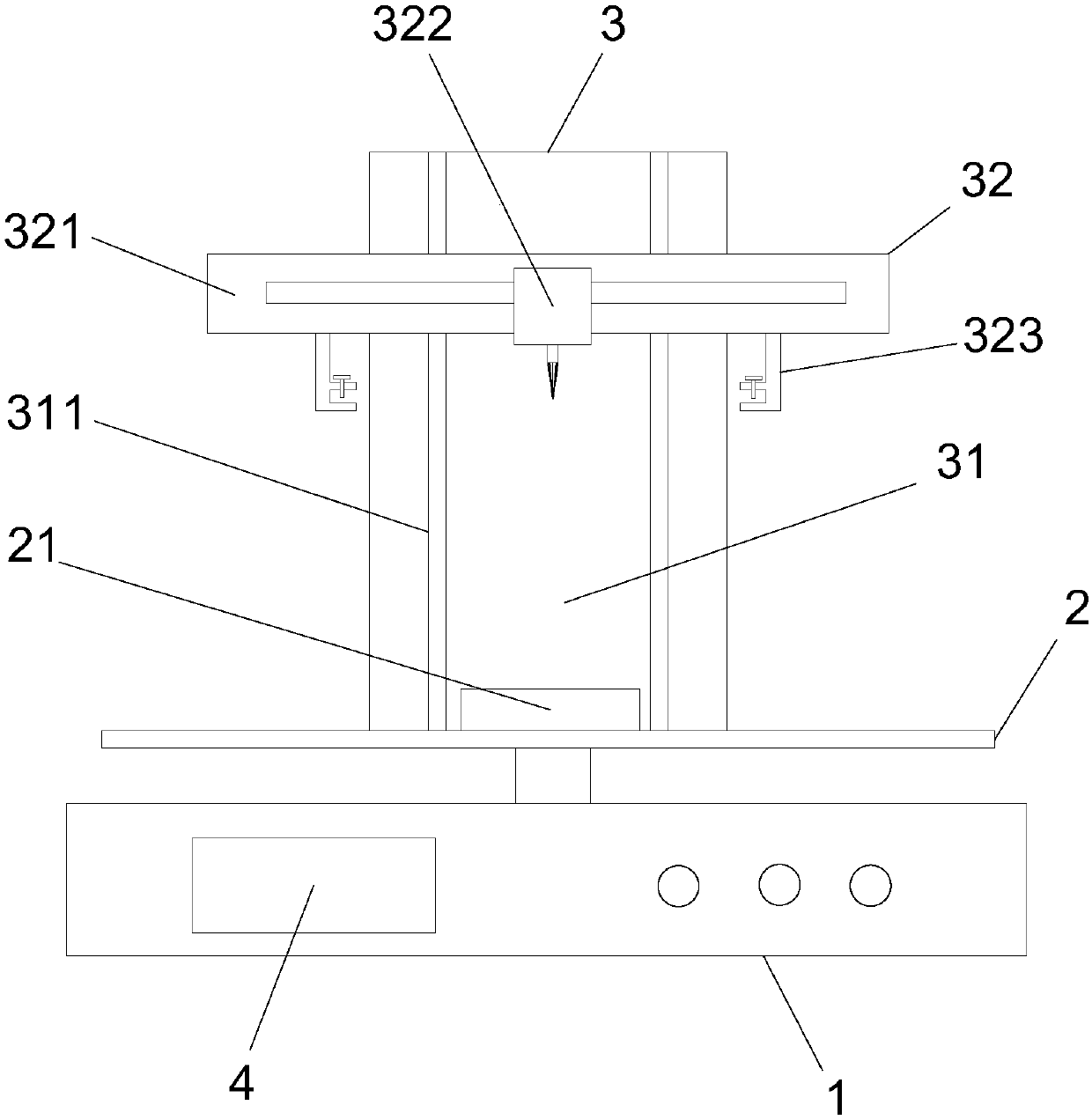

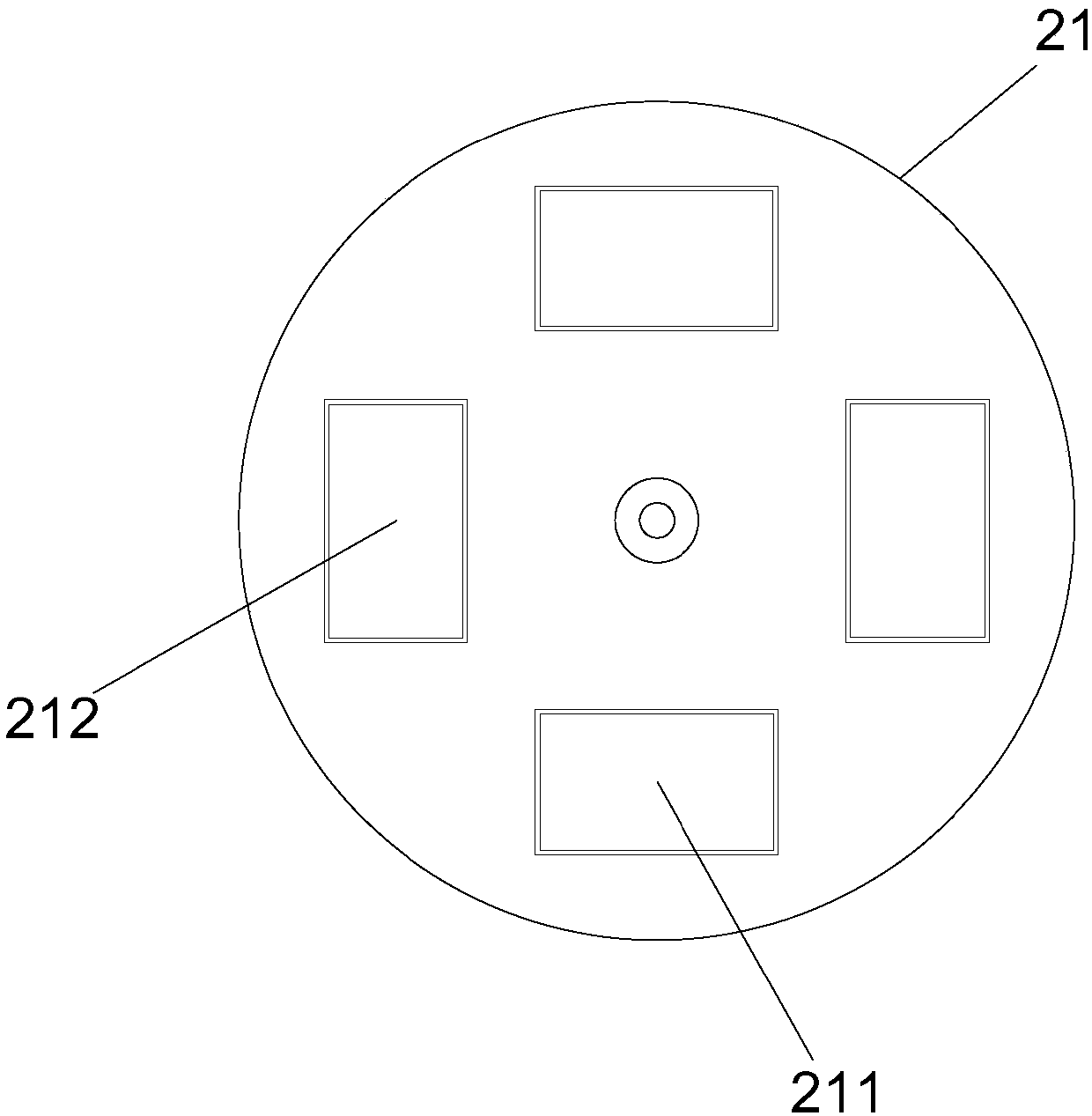

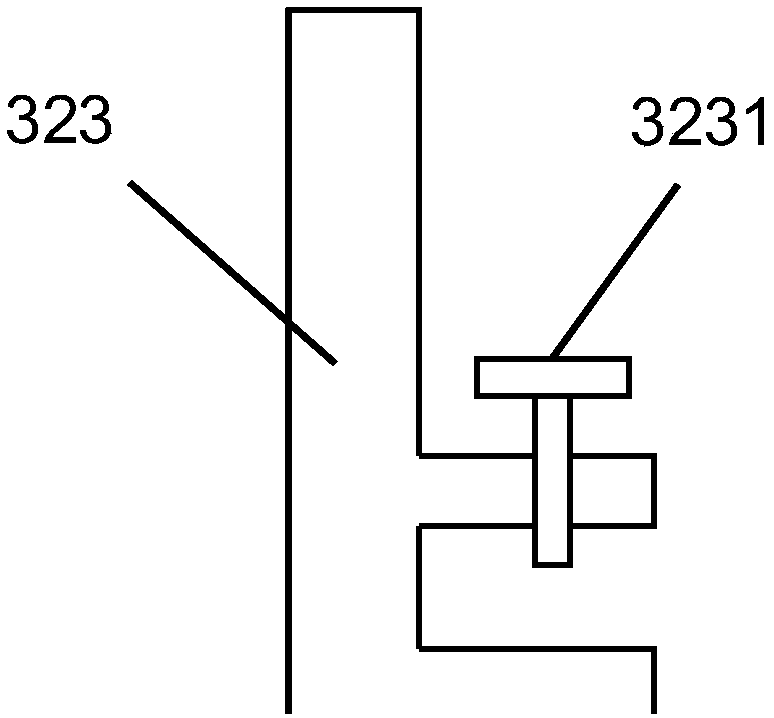

Automatic screen printing device for mobile phone touch screen

ActiveCN106626730AWon't breakImprove screen printing efficiencyScreen printersPrinting press partsScreen printingEngineering

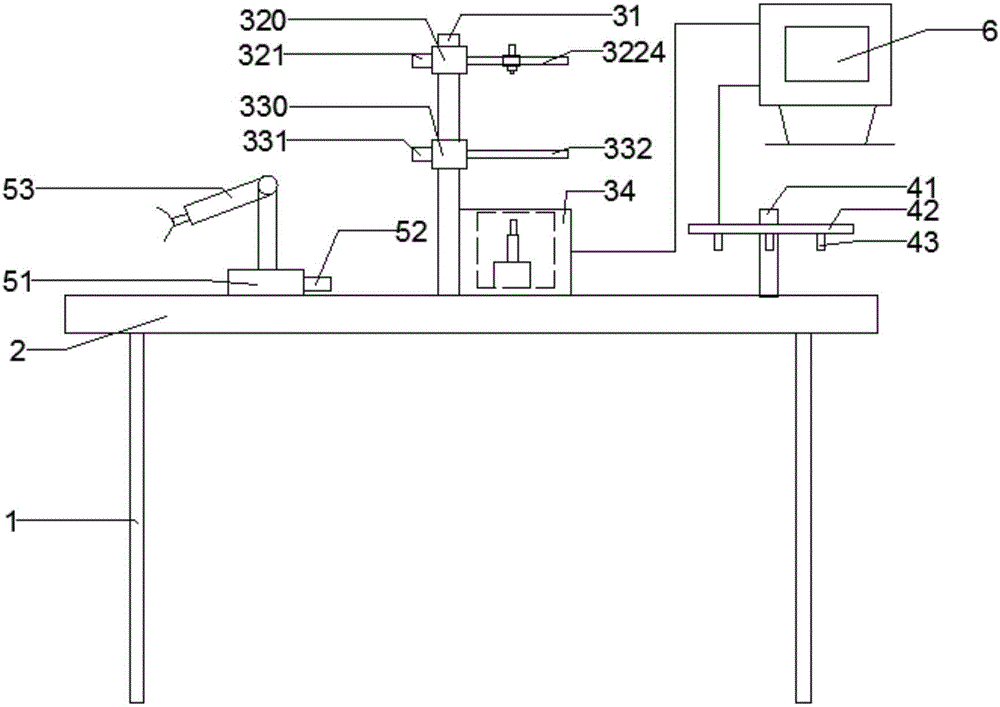

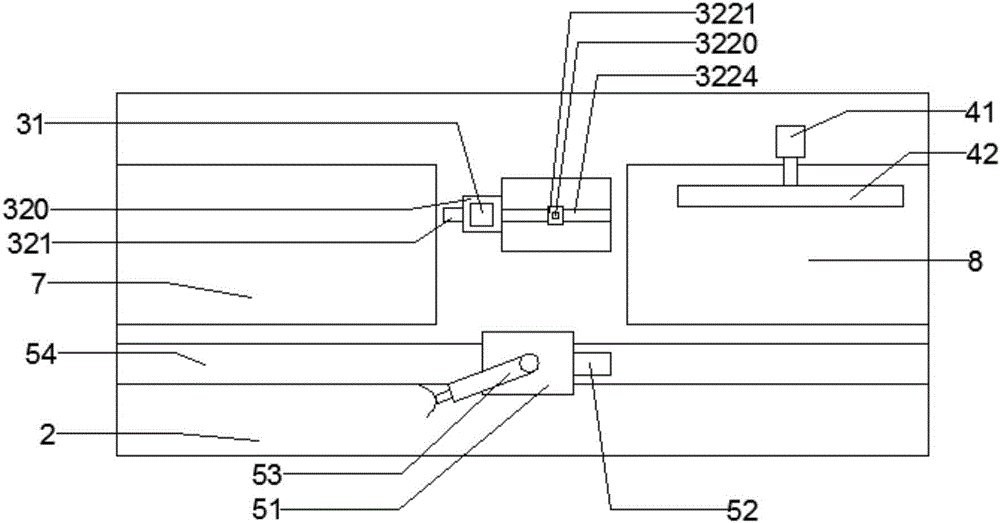

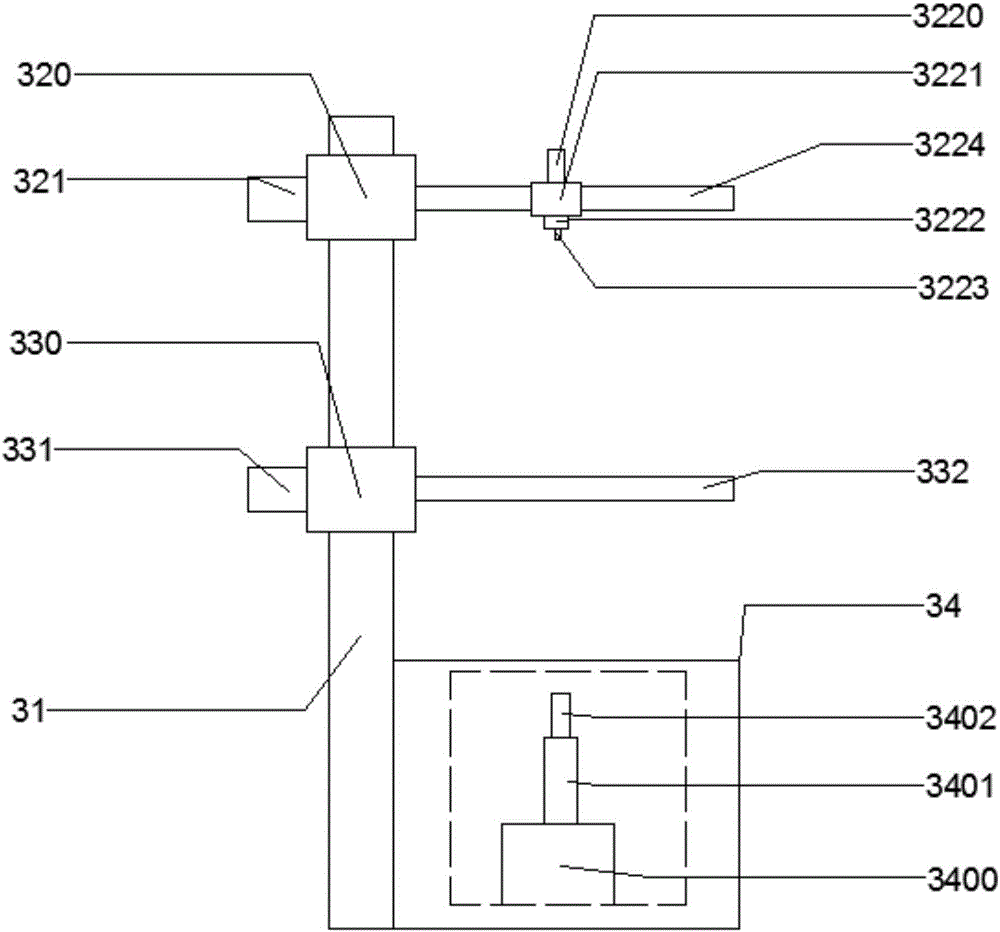

The invention discloses an automatic screen printing device for a mobile phone touch screen. The automatic screen printing device comprises a rack, a screen printing base, a dedusting mechanism, a screen printing mechanism, a drying mechanism, a receiving platform, a manipulator and a programmable controller. A work table surface is arranged on the upper portion of the rack. The upper end face of the work table surface is fixedly connected with four equal-length support rods. The screen printing base is slidably mounted on the support rods. A rotary disc is mounted on the portion, in a space defined by the four support rods, of the upper end face of the work table surface. The rotary disc is located under the screen printing base. The dedusting mechanism, the screen printing mechanism, the drying mechanism and the receiving platform are sequentially arranged on the rotary disc in the circumferential direction. The manipulator is mounted on the upper end face of the work table surface. The manipulator can be controlled by the programmable controller to complete the process of automatic taking and placing of products; and the automatic screen printing device is high in automation degree, simple in structure and convenient to operate, the situation that a screen print product is stained when being held by hand is avoided, sampling can be fast, and the production efficiency is greatly improved.

Owner:深圳市松录科技有限公司

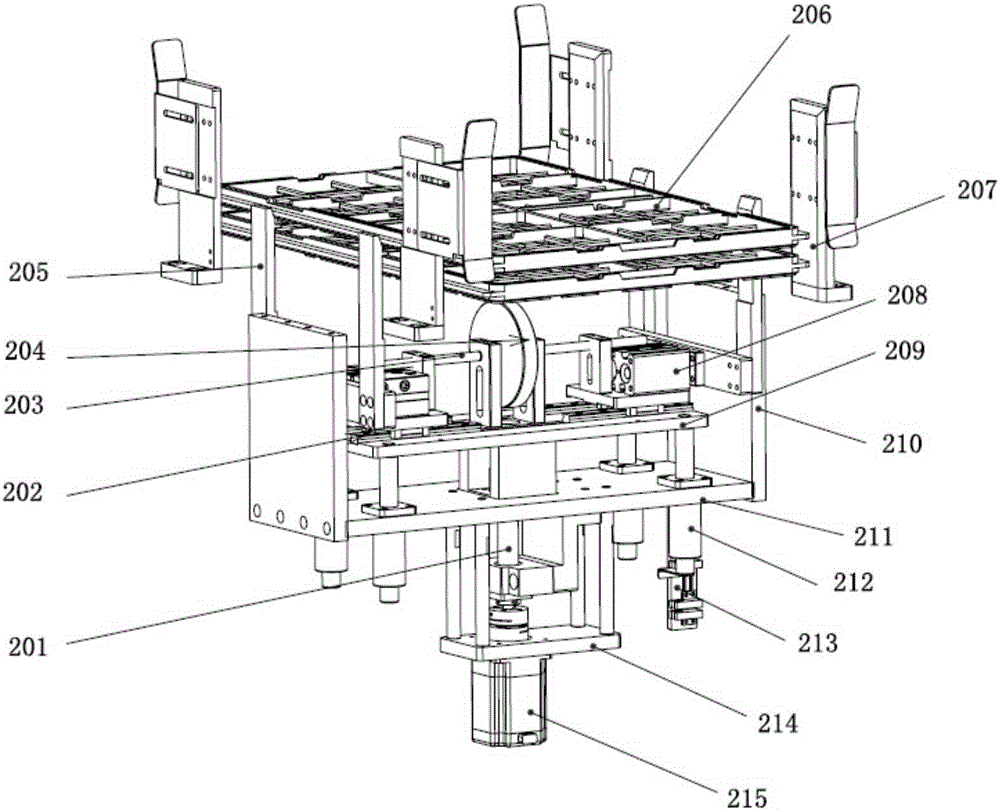

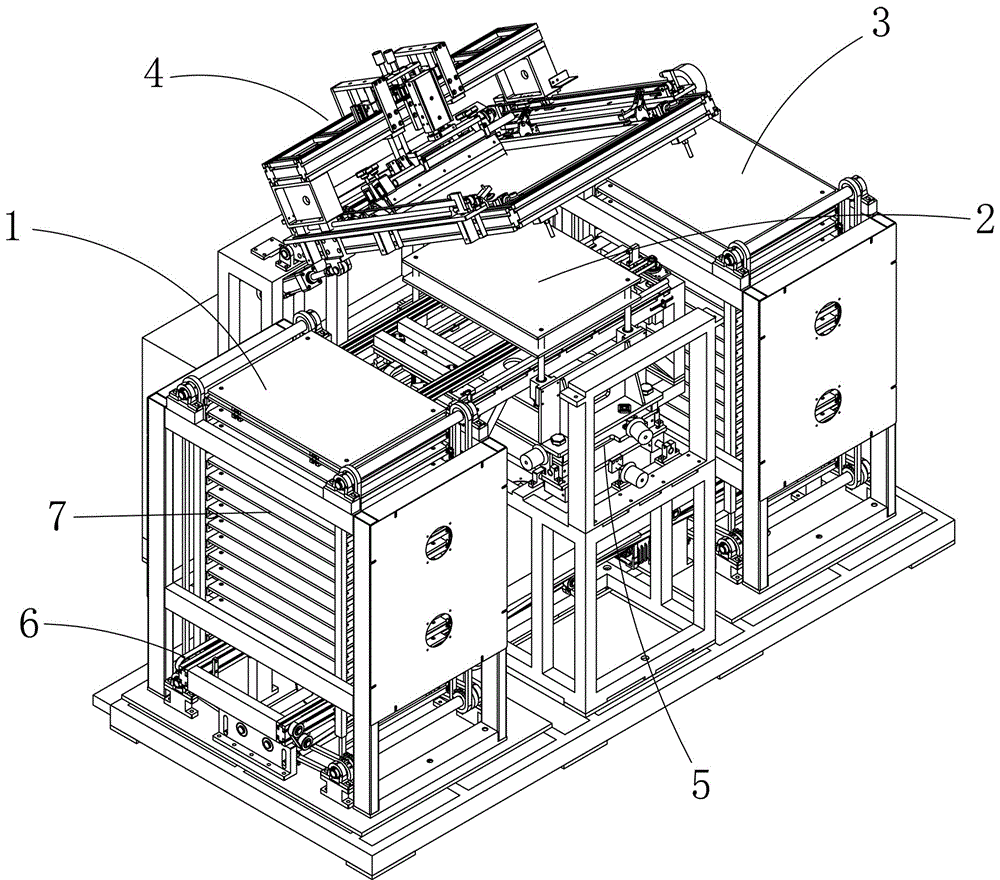

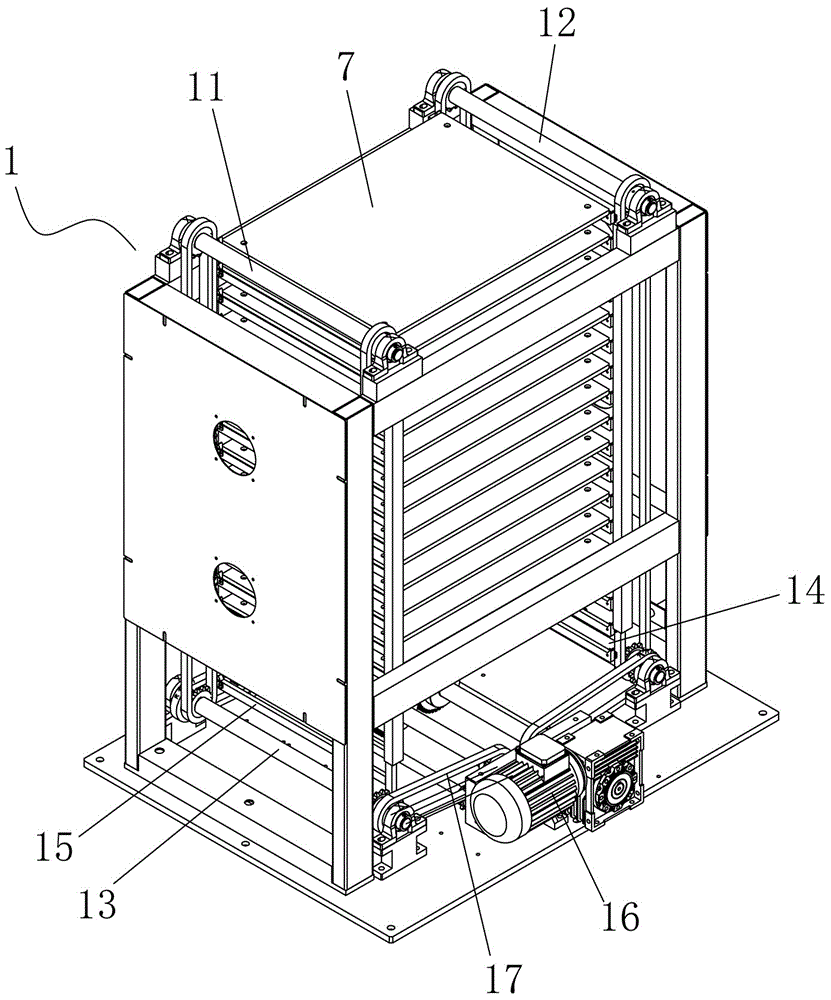

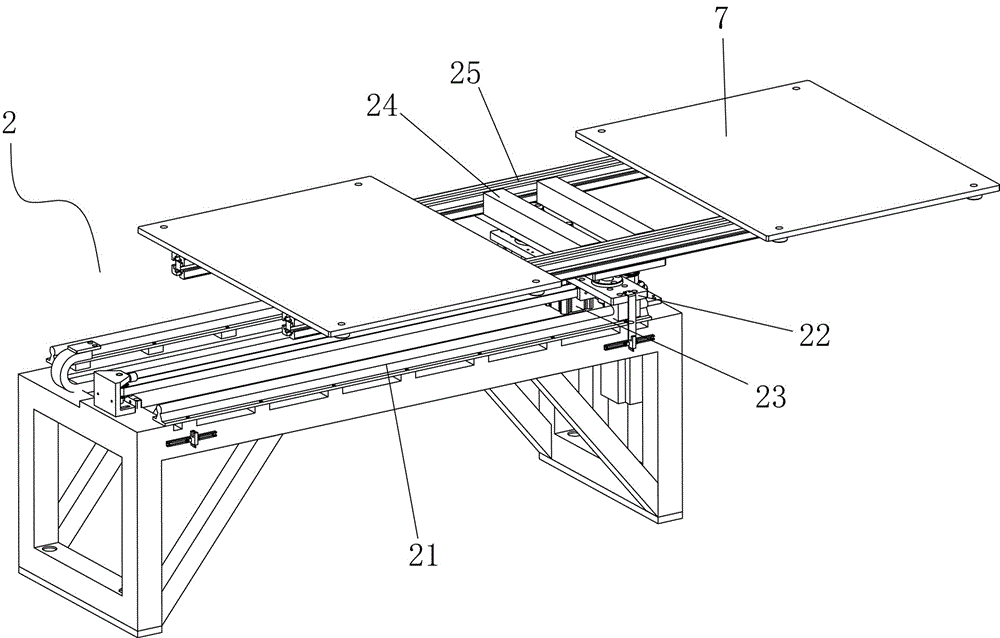

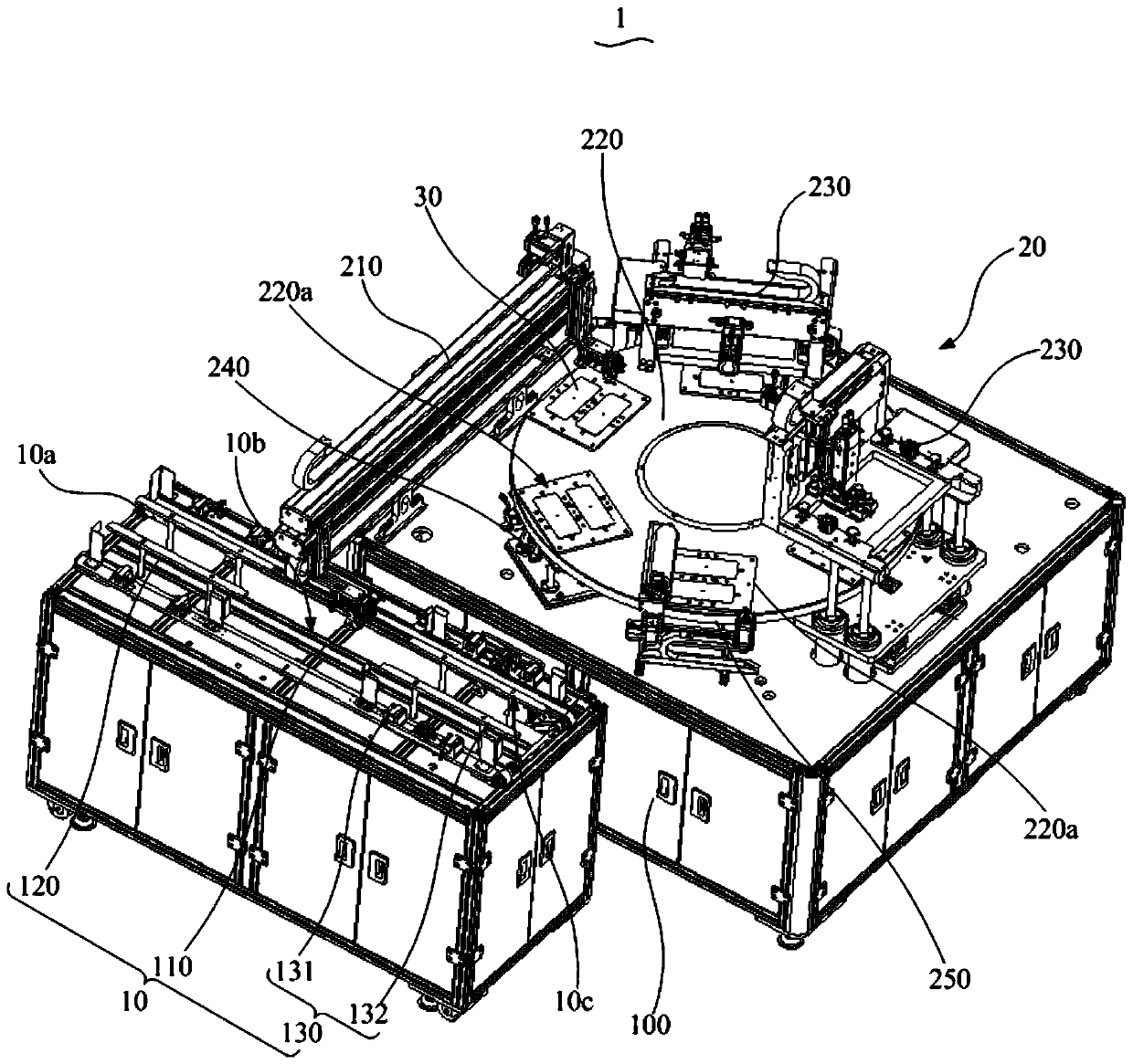

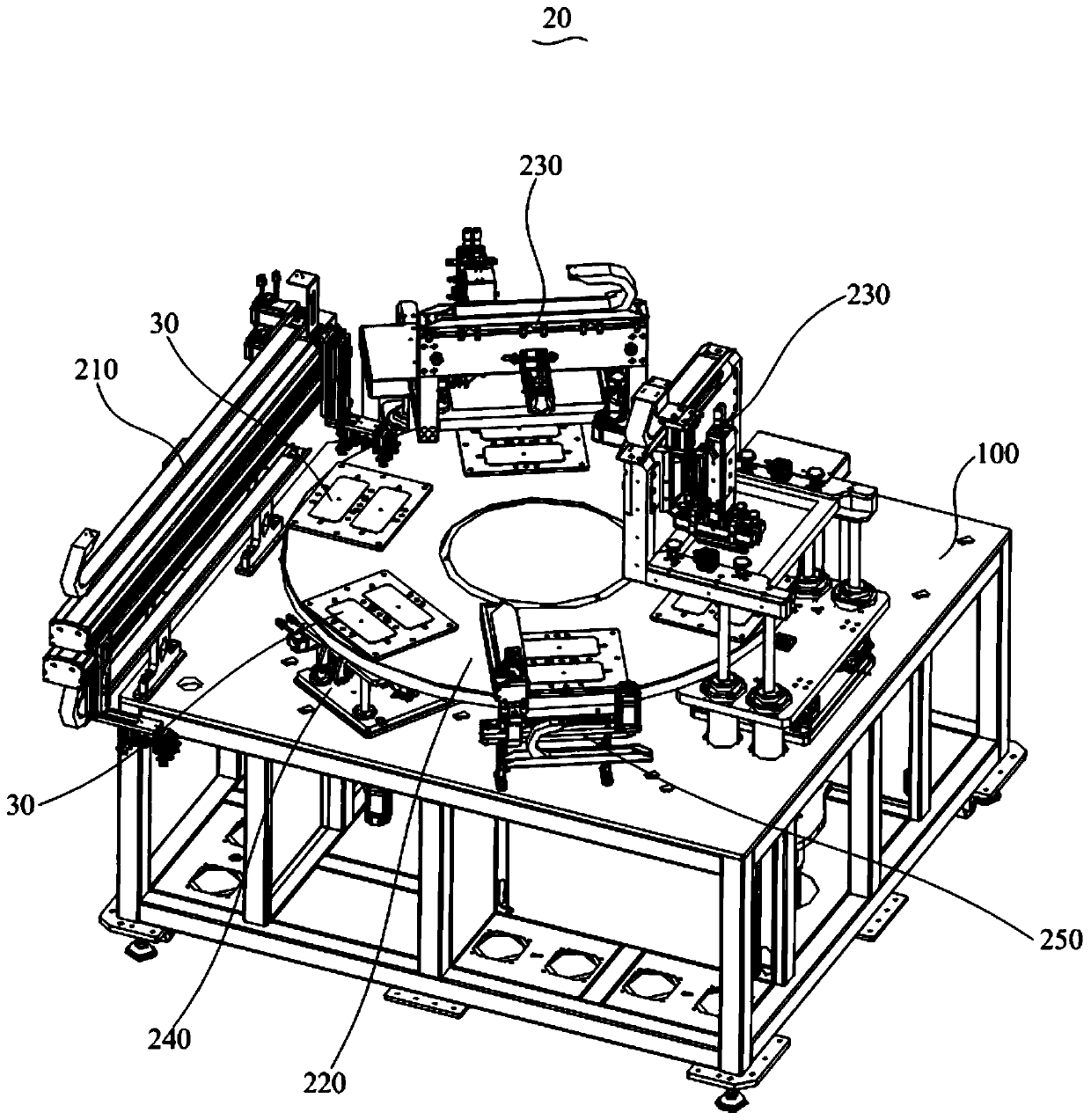

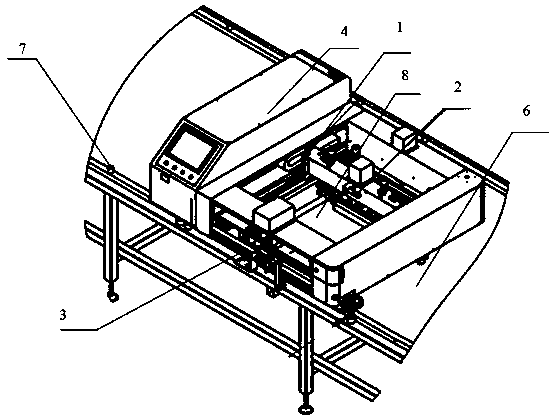

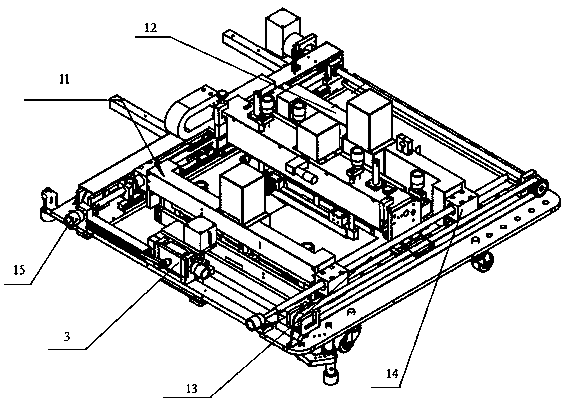

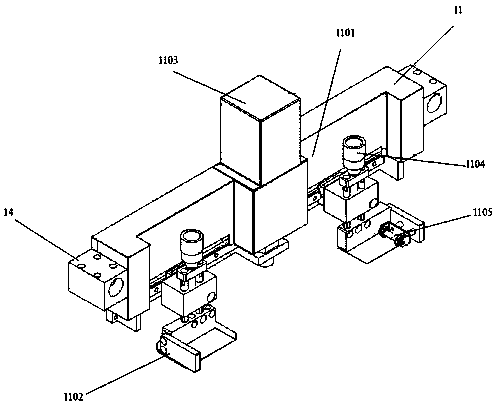

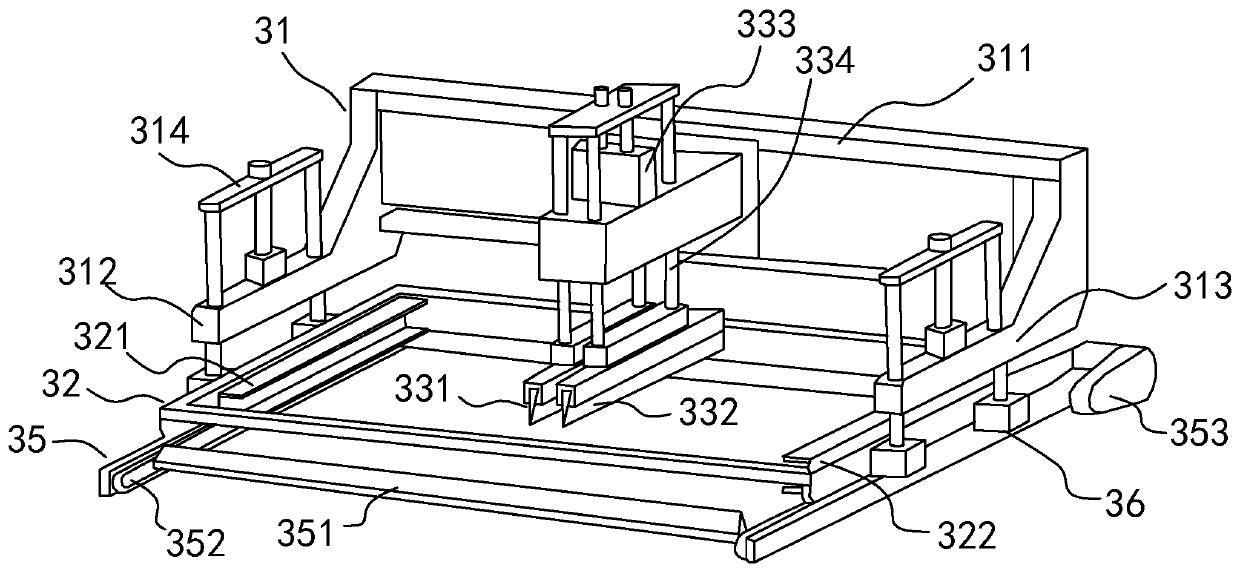

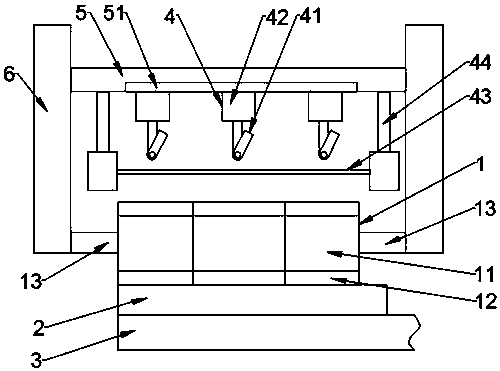

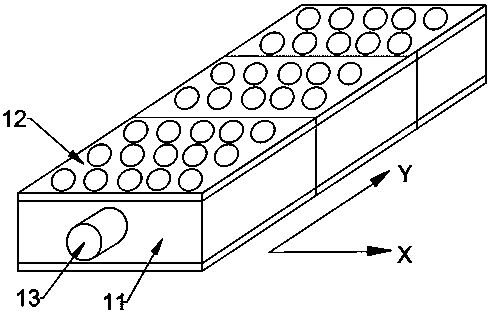

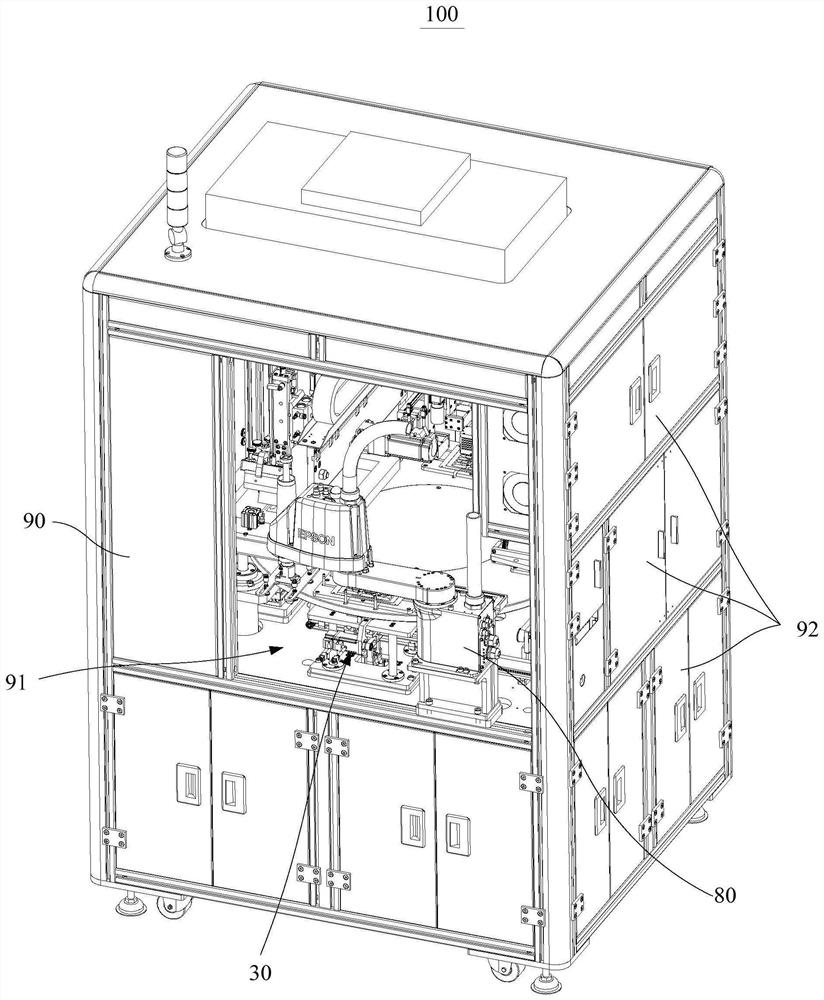

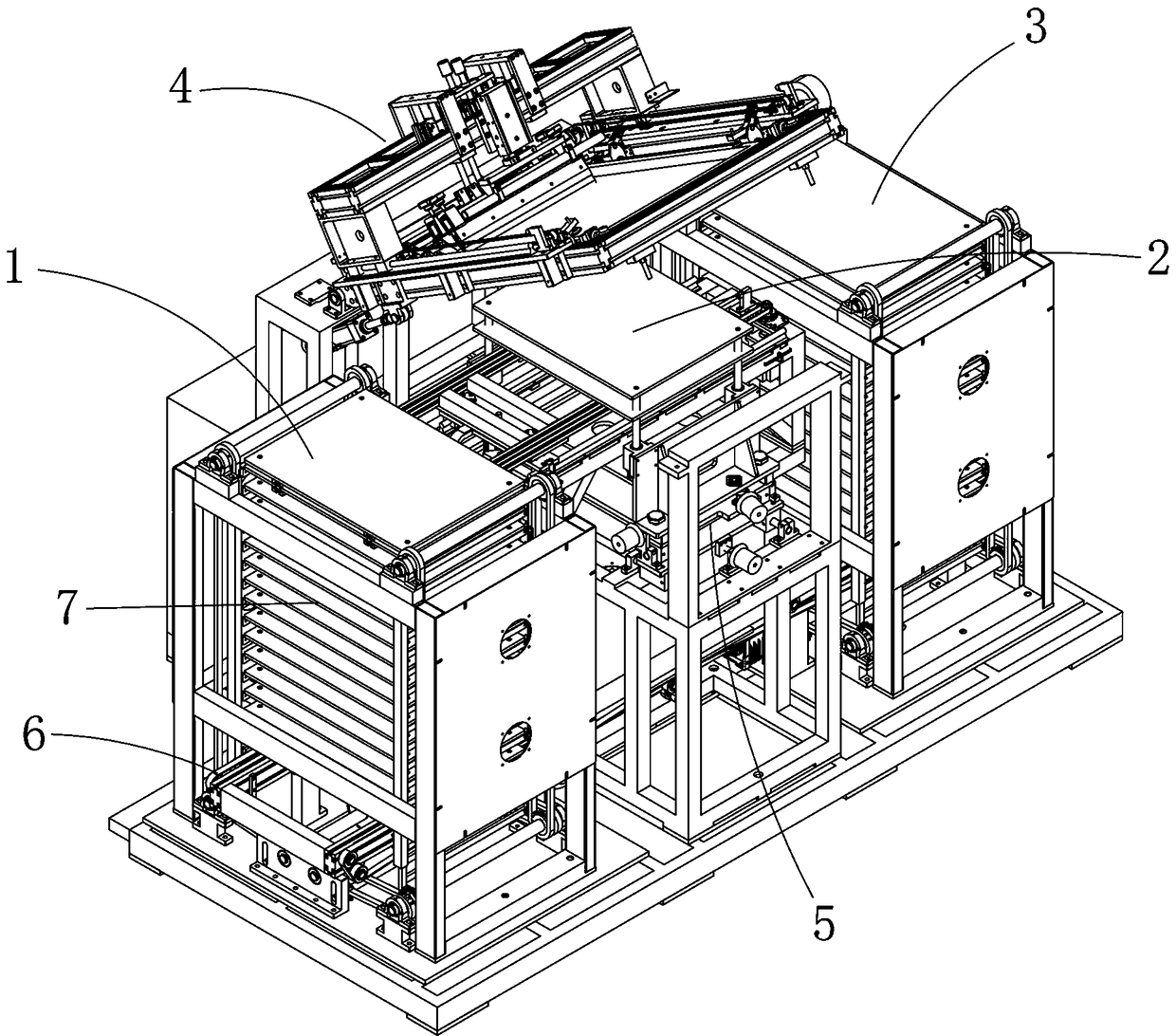

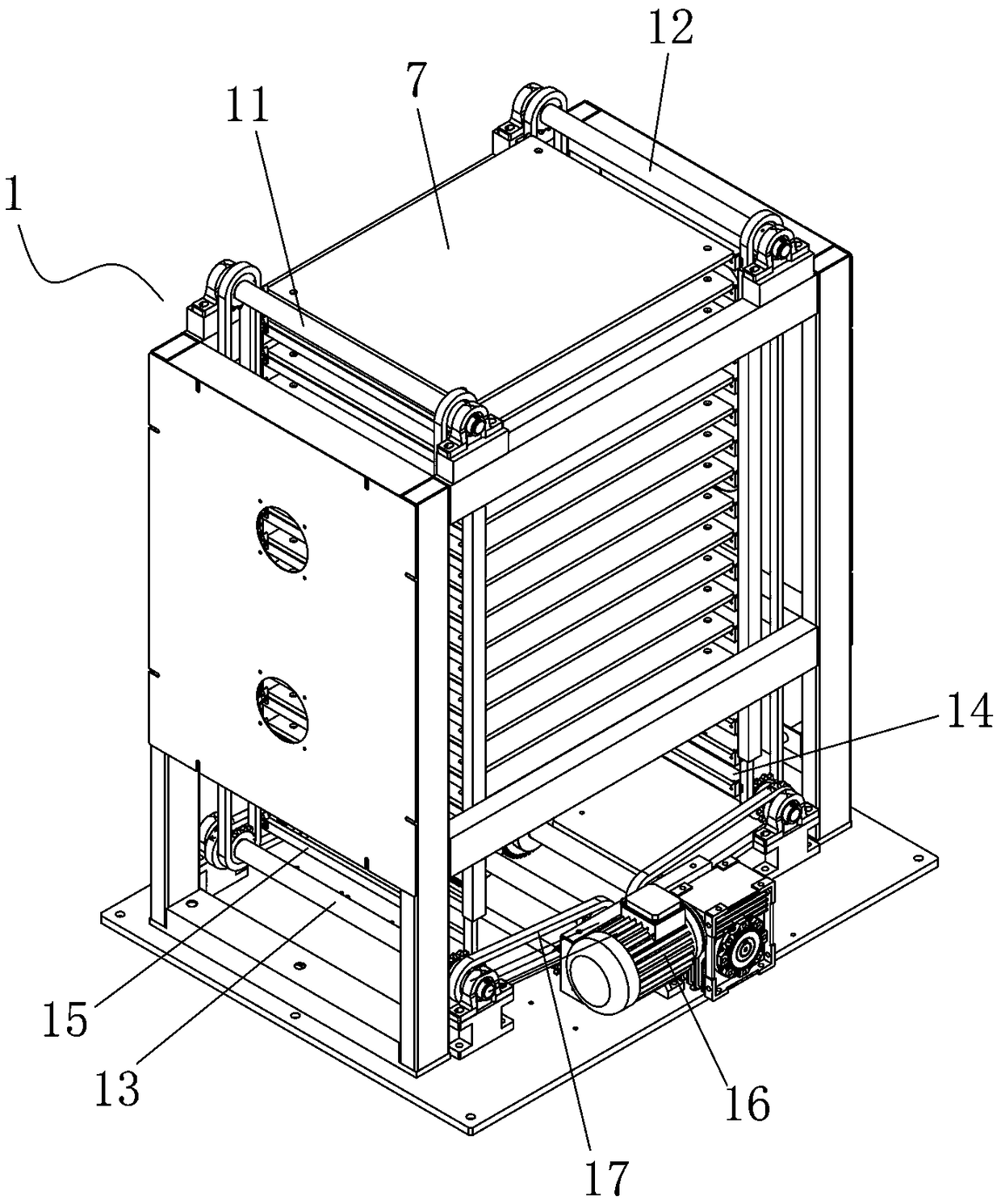

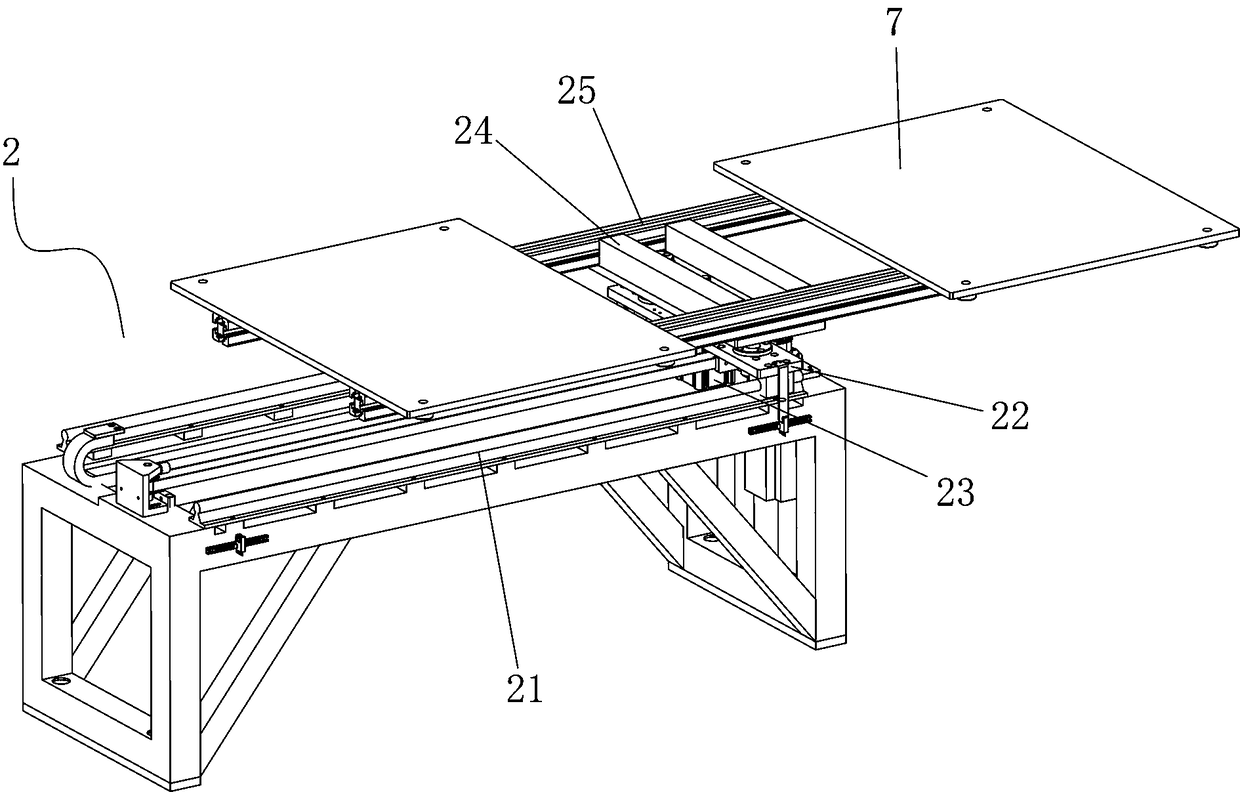

Full-automatic screen printing machine and production line thereof

ActiveCN106364143AQuality improvementImprove the three-dimensional effectScreen printersScreen printingScreen printingProduction line

The invention discloses a full-automatic screen printing machine which comprises a feeding device, a material sending device and a discharging device. A screen printing device is arranged above the material sending device. A jacking device is arranged below the material sending device. A conveying device is arranged below the feeding device and the discharging device. Jigs carrying materials are stacked on the feeding device. The material sending device is used for carrying the top-layer jigs stacked on the feeding device to the position below the screen printing device and above the jacking device; the jacking device ascends to position the jigs and jacks the jigs into a screen printing station of the screen printing device; after the screen printing device completes screen printing, the jacking device descends to put the jigs onto the material sending device, and the jigs are sent into the discharging device through the material sending device to serve as the top-layer jigs to be stacked; the discharging device conveys the bottom-layer jigs to the bottom layer of the feeding device through the conveying device; and operation is conducted cyclically in this way, and therefore the jigs are subjected to repeated screen printing. The invention further discloses a production line for combining the full-automatic screen printing machine, and the screen printing quality and efficiency are greatly improved.

Owner:DONGGUAN EID NC TECH CO LTD

Full-servo drive control single-color double-station complex curved surface screen printing machine

PendingCN109435438AGood quality and effectEasy to change bottlesScreen printersPrinting press partsTouchscreenPrinting press

The invention discloses a full-servo drive control single-color double-station complex curved surface screen printing machine. The full-servo drive control single-color double-station complex curved surface screen printing machine is composed of a touch screen mounted on a rack, a feeding and discharging manipulator system, a screen printing device, a product station conversion device and a servodrive control cabinet. The full-servo drive control single-color double-station complex curved surface screen printing machine can conduct screen printing on products of round bottles, double sides ofelliptical bottles, square bottles and multilateral bottles, a screen printing head can get close to or away from the surfaces of the products for screen printing through vertical and horizontal motion of the screen printing head and rotation motion of the printed products, and the printing machine is good in printing effect, bottle replacing is convenient, the cycle is short, and the efficiencyis high.

Owner:广州市申发机电有限公司

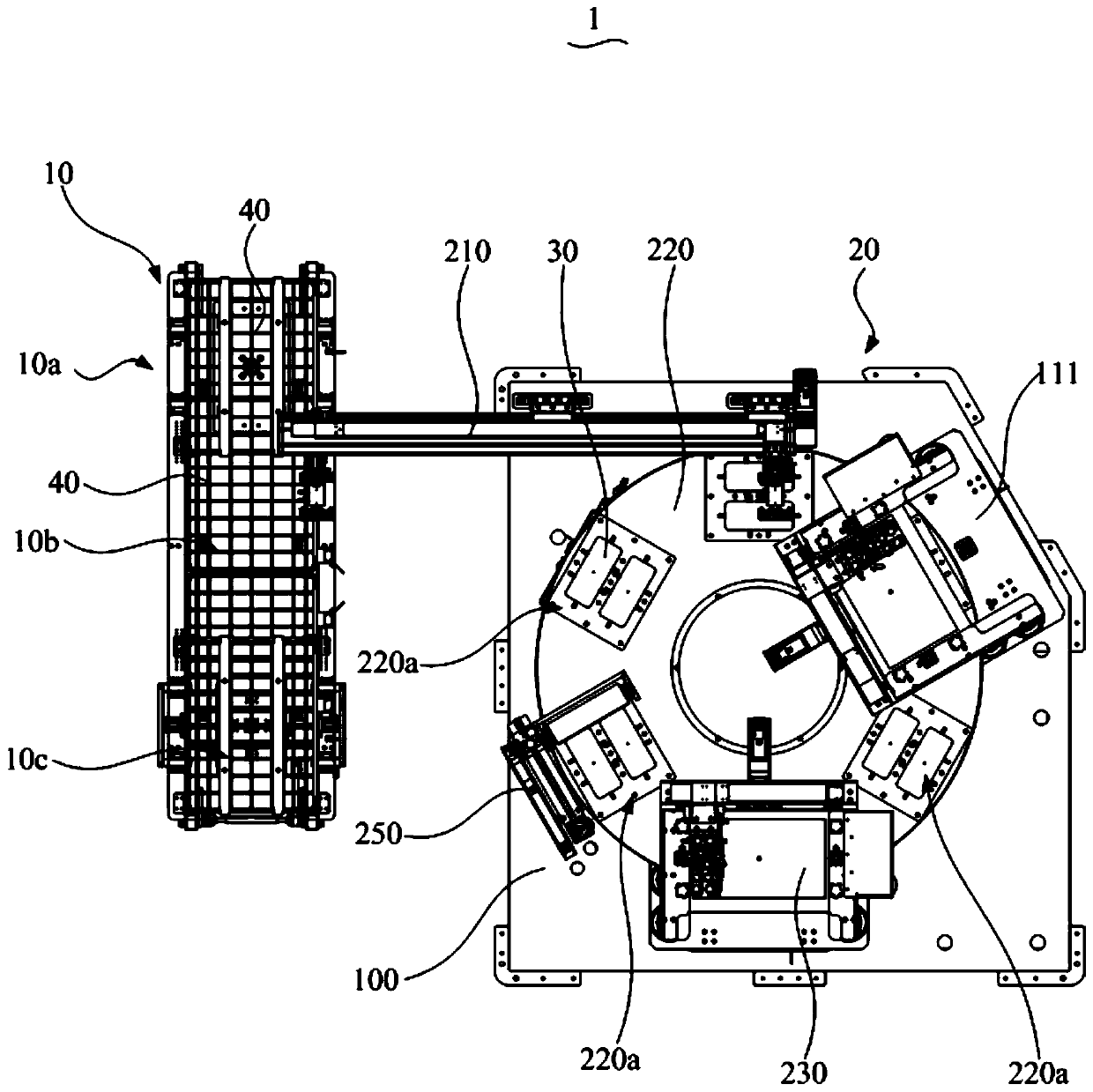

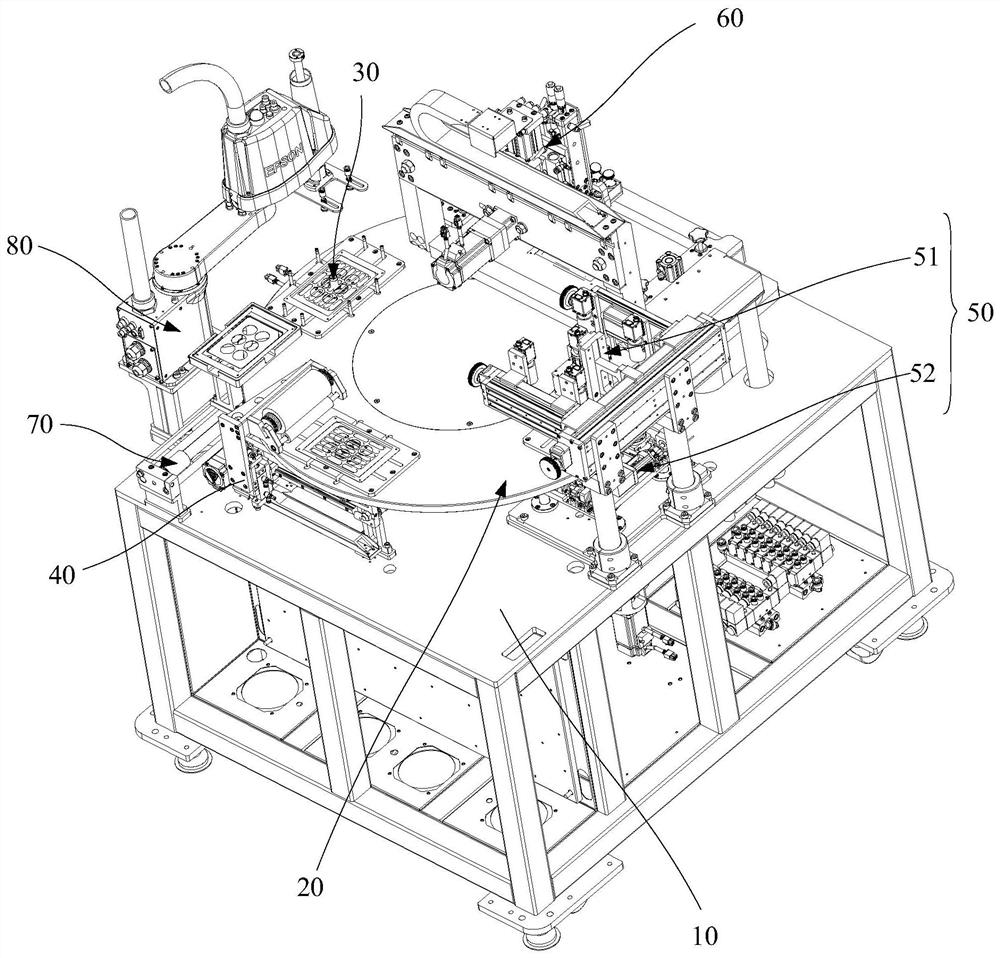

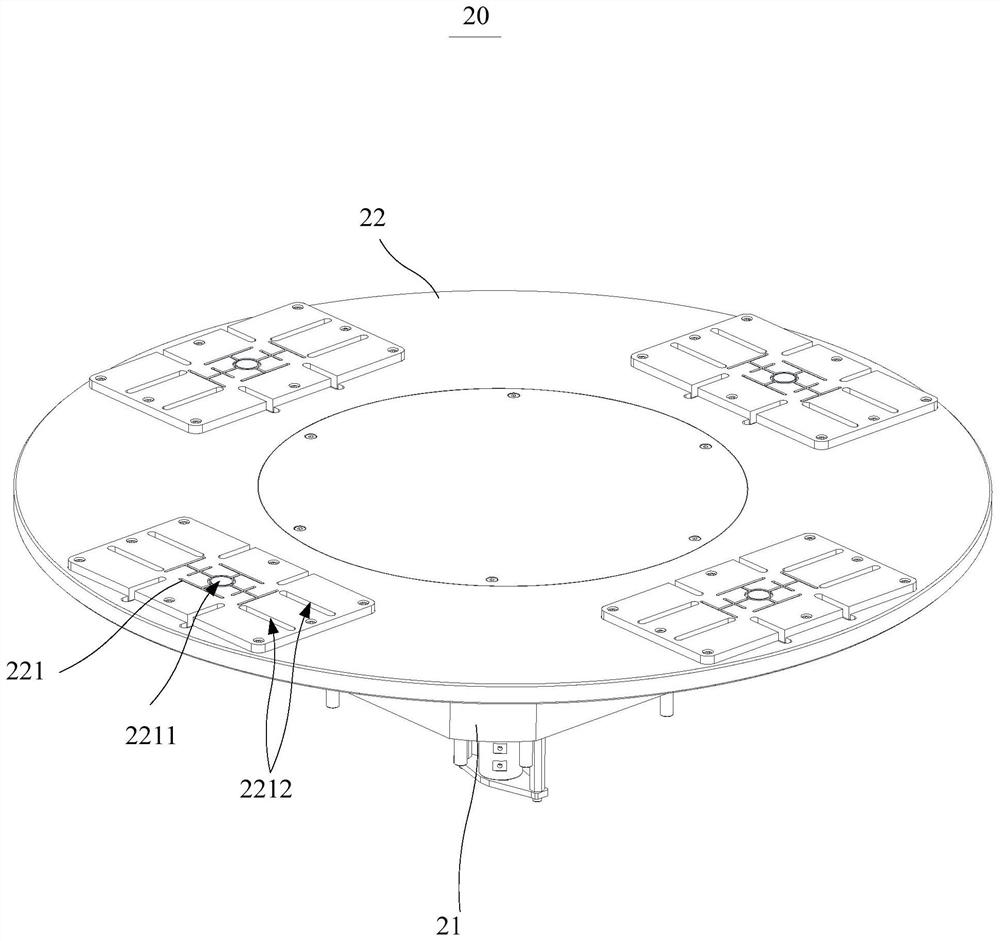

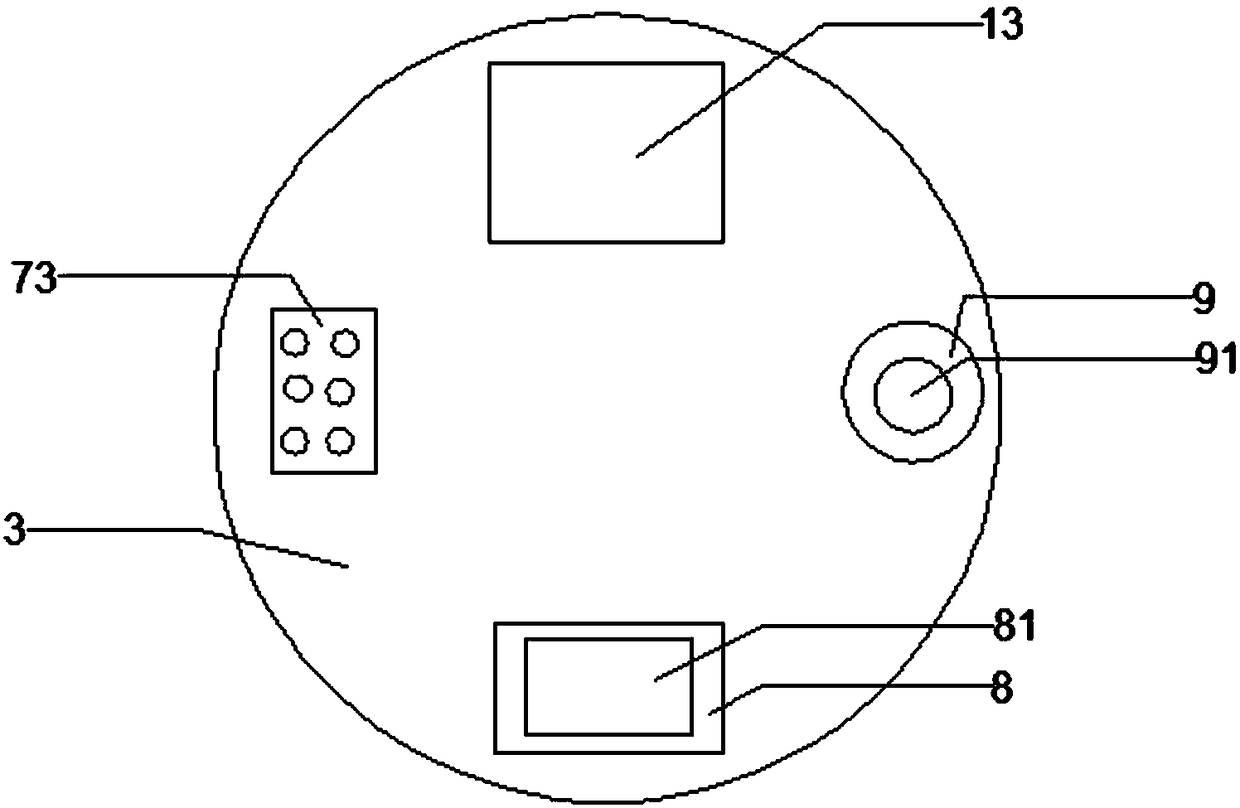

Screen printing equipment

PendingCN111204116AReduce labor intensityReduce manufacturing costScreen printersCharge manipulationScreen printingGlass cover

The invention discloses screen printing equipment which comprises a material supply device and a screen printing device, wherein the material supply device is arranged on a rack, and provided with a material supply area, a material loading area and a material receiving area; a plurality of material trays for carrying glass cover plates are stacked in the material supply area, conveyed to one sideof the material receiving area through the material loading area, and then stacked in the material receiving area; the screen printing device comprises a material loading component, a material conveying rotary plate and at least two screen printing components; the material conveying rotary plate is rotationally connected to the rack and used for conveying the glass cover plates; a plurality of screen printing stations are arranged in a spacing manner in the circumferential direction of the material conveying rotary plate; and the multiple glass cover plates are placed on each screen printing station. According to the technical scheme of the screen printing equipment, the material supply device is adopted for providing the glass cover plates and the screen printing device is adopted for thescreen printing of the glass cover plates, so that the glass cover plate screen-printing efficiency can be improved to a relatively great extent.

Owner:深圳市和力泰智能科技有限公司

Multi-station rotary-table screen printing machine

PendingCN109109442AAvoid bondingImprove screen printing efficiencyScreen printersEngineeringMechanical engineering

The invention relates to a multi-station rotary-table screen printing machine. A three-axis adjusting and feeding device, a multi-station rotary table, a screen printing device and a box embryo placement device are arranged on a rack; the three-axis adjusting and feeding device enables a printed material to move in the XYR directions, adjusts the position of the printed material and feeds the printed material into the multi-station rotary table; the multi-station rotary table is sequentially divided into a loading station, a screen printing station, a box embryo placement station and an unloading station along the feeding direction; the screen printing device is arranged on one side of the screen printing station; the printed material subjected to screen-printing through the screen printing device is fed into the box embryo placement station; and the box embryo placement device is arranged on one side of the box embryo placement station. According to the multi-station rotary-table screen printing machine provided by the invention, during the screen printing process, the printed material can be prevented from adhering onto a screen printing mesh frame, so that the screen printing efficiency is improved; the multi-station rotary-table screen printing machine is safe to operate, and the work on the various stations can be recognized and controlled, so that the various stations works orderly; and through one-time precise localization, the printed material is accurately placed at the appropriate position on the tray so as to be free from being re-adjusted when being placed in the later period, so that the time is saved, and the working efficiency is improved.

Owner:XUCHANG YUTO PRINTING & PACKING

Screen printing ink and manufacturing process thereof

The invention discloses screen printing ink and an application process thereof. The screen printing ink consists of printing color ink and a curing agent, wherein the printing color ink is 100 parts by volume and the curing agent is 3-10 parts by volume; the curing agent consists of the following components by in parts by volume: 100 parts of acrylic baking paint, 40 parts of isophorone, 20 partsof cyclohexanone and 25 parts of butyl acetate; and the application process of the screen printing ink comprises the steps of configuration of the curing agent, configuration of the screen printing ink, screen printing, drying and curing, etc. The process is simple and the screen printing efficiency is high. The screen printing ink provided by the invention is added with a curing agent for improving adhesion and wear resistance, and the main composition of the curing agent is a mixture of acrylic baking paint, isophorone, cyclohexanone, butyl acetate and the like, and the acrylic baking painthas good adhesion, wear resistance and gloss retention, so that the adhesion and wear resistance of the whole screen printing ink are greatly improved, a printed pattern is very stable, cannot fall off, has strong wear resistance, and the product quality is greatly improved.

Owner:佛山市敏博电子有限公司

Full-automatic screen printer and screen printing control method for same

PendingCN110065296ASimple designLow costScreen printersPrinting press partsScreen printingComputer engineering

The invention discloses a full-automatic screen printer which comprises a screen installation device, a scraper device, a positioning assembly, a control device and a walking drive device, wherein thea movable front screen-printing screen support and a movable rear screen-printing screen support (the front screen support is equipped with left and right supporting plates or a top plate which can be slid) are installed fixedly on the screen installation device, and a driving structure which can execute up-down actions of the screen installation device is disposed; the scraper device can be disposed above a screen on the screen installation device through back-forth sliding; and the control device controls the walking drive device to push the screen installation device to walk on a screen printing platform, and scrapping printing of the scraper device and ink returning are realized through positioning of the positioning assembly at a positioning code of the screening platform. A full-automatic printing structure disclosed by the invention has the beneficial effects that design is simple; equipment cost is low; cost for production and rebuilding is low; equipment running is stable; printing quality is high; screen printing efficiency is high; production cost of screen printing enterprises is greatly reduced; and with multiple adjustable structures, operations are simple, replacement and adjustment are quick, and applicability is extensive.

Owner:深圳市跃凡智能装备技术有限公司

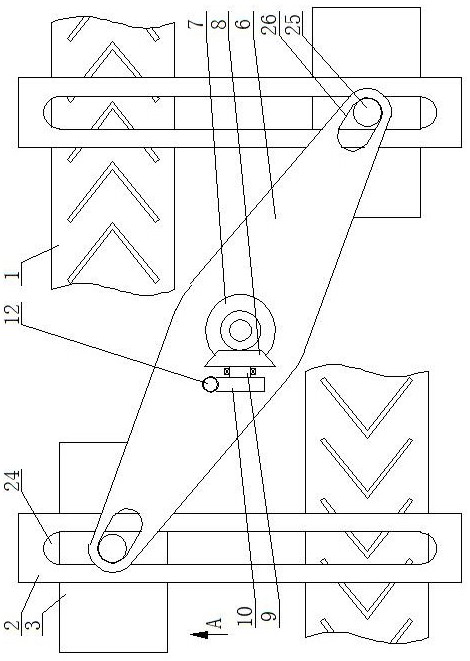

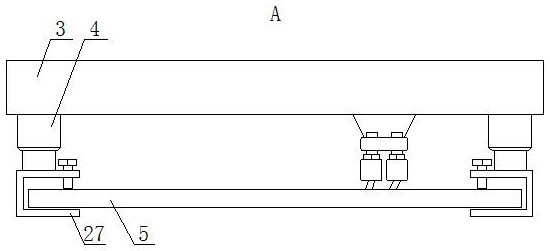

Silk screen printing machine and silk screen printing technology

PendingCN110154505AIncrease productivityPractical and reliable structureScreen printersOther printing apparatusResistPrinting ink

The invention discloses a silk screen printing machine and a silk screen printing technology. The silk screen printing machine comprises a first silk screen printing station, a second silk screen printing station, a first moving table, a second moving table, a driving device and a feeding device; the first silk screen printing station and the second silk screen printing station are adopted to respectively carry out hole plugging silk screen printing and solder resist board face silk screen printing on a PCB, the PCB is borne by the first moving table to be subjected to the hole plugging silk screen printing and silk screen printing of one board face sequentially through the first silk screen printing station and the second silk screen printing station, the PCB is borne by the second movingtable to be subjected to silk screen printing on the other board face through the second silk screen printing station, and the driving device can drive the first moving table and the second moving table to move at the same time so as to complete corresponding operation; and the hole plugging silk screen printing and the solder resist board face silk screen printing can be completed on one printing machine, the silk screen printing is more efficient, and the structure is practical and reliable; and when the two silk screen printing stations work, the feeding device automatically supplies printing ink to a first silk screen printing mesh and a second silk screen printing mesh, manual operation is not needed, more time and labor are saved, and the production efficiency is higher.

Owner:鹤山市泰利诺电子有限公司

Screen printing machine

InactiveCN112848646AImprove screen printing efficiencyScreen printersCharge manipulationScreen printingSoftware engineering

The invention discloses a screen printing machine which comprises a rack, a rotary table, a feeding mechanism, a material taking mechanism and a screen printing positioning mechanism. The rotary table is provided with a first processing station and a second processing station. The feeding mechanism is used for storing materials. The material taking mechanism reciprocates between the feeding mechanism and the rotary table so as to gradually transfer materials in the feeding mechanism to an objective table. The screen printing positioning mechanism comprises a screen printing device and a positioning device, and the screen printing device is provided with a first screen printing station and a second screen printing station which are arranged at an interval. The positioning device positions the two materials to the first processing station and the second processing station respectively, so that the first screen printing station and the second screen printing station are aligned to the first processing station and the second processing station respectively. By means of the screen printing machine, the purpose of simultaneous screen printing of the two materials can be achieved, and the screen printing efficiency is improved.

Owner:深圳市和力泰智能科技有限公司

Screen printing device and screening printing method thereof

ActiveCN108248204AImprove screen printing efficiencySimplify complexityScreen printersOther printing apparatusTelescopic cylinderComputer engineering

The invention provides a screen printing device and a screening printing method thereof. The screen printing device comprises a supporting plate, a guide structure, a conveyor belt, scraping knife components, a cross beam and lifting arms. The supporting plate comprises a rotating plate, adsorption layers and lifting rods, wherein the adsorption layers are arranged on the upper surface and the lower surface of the rotating plate and are uniformly provided with suction holes; the lifting rods are arranged at the two ends of the rotating plate; the rotating plate is internally provided with a rotating motor and can rotate with the lifting rods as the axis. When the screen printing device conducts screen printing, the top end of the guide structure is flush with the lower surface of the adsorption layer on the lower portion. The conveyor belt is arranged on the lower portion of the guide structure. The scraping knife components are arranged above the supporting plate. The lower portion ofthe cross beam is provided with a slide rail. The slide rail is matched with telescopic cylinders. A screen plate is connected with the cross beam through connecting rods. The lifting arms are arranged on the two sides of the supporting plate and the cross beam. The lifting rods and the cross beam are connected with the lifting arms. The screening printing device can adsorb a plurality of printedscreens through the adsorption layers of the supporting plate simultaneously, the screen printing efficiency is greatly improved, and the screen printing cost is reduced.

Owner:JIANGXI HOLITECH TECH

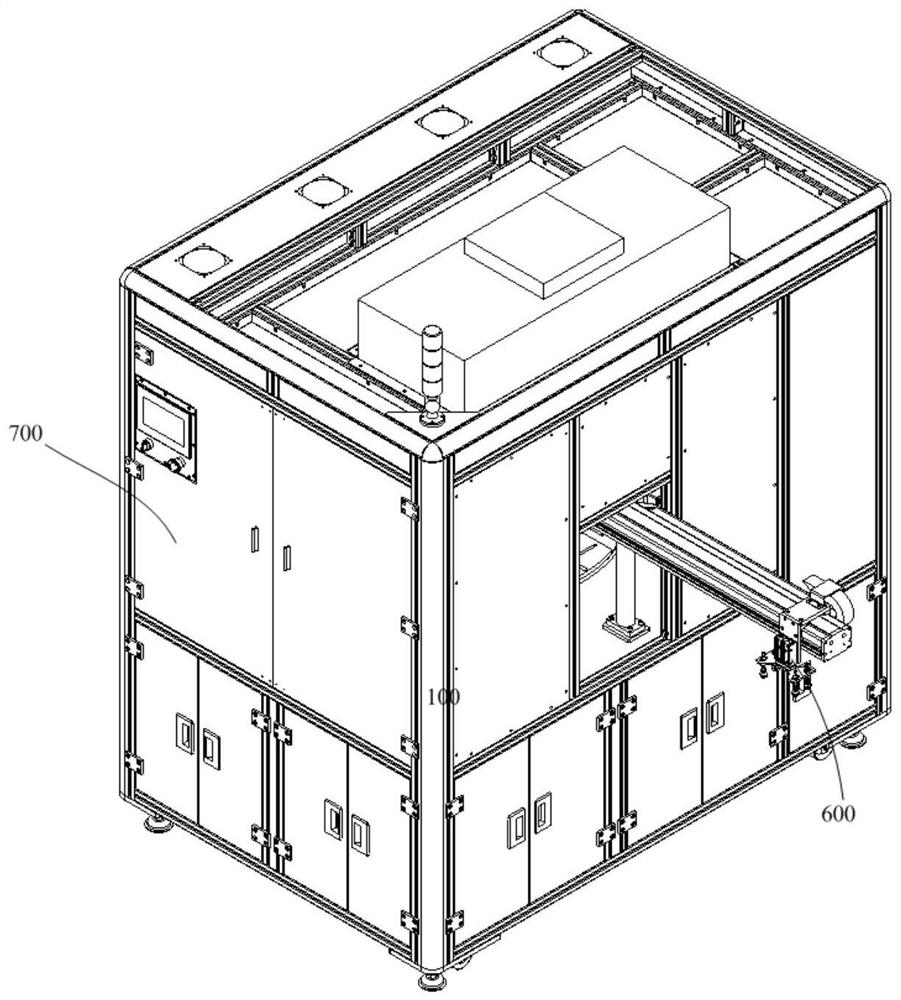

Automatic screen printing machine with mobile phone touch screen

ActiveCN106494070AImprove screen printing efficiencyHigh degree of automationScreen printersScreen printingComputer terminal

The invention discloses an automatic screen printing machine with a mobile phone touch screen. The automatic screen printing machine comprises a rack, an automatic feeding conveying belt, a screen printing device, an automatic discharging conveying belt, a drying device, an automatic sampling device and a control terminal, wherein a working table is arranged above the rack, the screen printing device is mounted on the working table, the automatic feeding conveying belt is mounted on the working table and on one side of the screen printing device, the automatic discharging conveying belt is mounted on the working table and on the other side of the screen printing device, the upper end face of the automatic feeding conveying belt and the upper end face of the automatic discharging conveying belt are flush with the working table, the drying device is mounted on the working table and right above the automatic discharging conveying belt, and the automatic sampling device is slidingly mounted on the working table. According to the automatic screen printing machine disclosed by the invention, the control terminal is used for controlling a mechanical arm to suck a product and place the product at a designated spot of the screen printing device in the whole process, and after screen printing is completed, the product is sucked and placed on the automatic discharging conveying belt by the mechanical arm and is dried. The device has high degree of automation, high screen printing efficiency and stable quality.

Owner:深圳市松录科技有限公司

Silk printing device for wine bottle production line

InactiveCN108608723AImprove screen printing efficiencySmall color deviationScreen printersScreen printingProduction lineWine bottle

The invention discloses a silk printing device for a wine bottle production line, and relates to the technical field of wine bottle processing. The silk printing device comprises a conveying device and a silk printing device body; the conveying device comprises a conveying belt and a conveying wheel, and the conveying belt is provided with a fixing clamping seat; and the silk printing device bodycomprises silk printing screen plates, scraping plates and supports, the supports are arranged on the two sides of the conveying belt, the silk printing screen plates are connected with the supports through first telescopic rods, the scraping plates are connected with the supports through second telescopic rods, the second telescopic rods are connected with the supports through sliding grooves, the silk printing screen plates are arc-shaped, the scraping plates are arc-shaped corresponding to the silk printing screen plates, ink boxes are arranged on the silk printing screen plates, and ink outlet grooves are formed in the oil ink box. According to the silk printing device, the arc-shaped silk printing screen plates and the arc-shaped scraping plates can be adapted to different bottle bodies, the silk printing efficiency is high, the color deviation is small, the structure is simple, the design is reasonable, and the device can be well used on the wine bottle production line.

Owner:ANHUI YICAI GLASSWARE

Glass cover plate silk-screen printing device

ActiveCN111634111AImprove efficiencyImprove silk screen effectScreen printersPrinting press partsScreen printingGlass cover

The invention discloses a glass cover plate silk-screen printing device which comprises a rack, a material conveying mechanism, a dust removing mechanism, a CCD positioning mechanism and a silk-screenprinting mechanism. The material conveying mechanism is rotationally connected to the rack and used for bearing and conveying a glass cover plate; the dust removal mechanism is arranged on the rack,and the roughly positioned glass cover plate borne by the material conveying mechanism is conveyed to the dust removing mechanism for dust removal; the CCD positioning mechanism is arranged on the rack, and the dedusted glass cover plate carried by the material conveying mechanism is conveyed to the CCD positioning mechanism for fine positioning; and the silk-screen printing mechanism is arrangedon the rack, and the precisely-positioned glass cover plate borne by the material conveying mechanism is conveyed to the silk-screen printing mechanism to be subjected to silk-screen printing. According to the technical scheme, the screen printing efficiency and the screen printing effect of the glass cover plate are improved.

Owner:深圳市和力泰智能科技有限公司

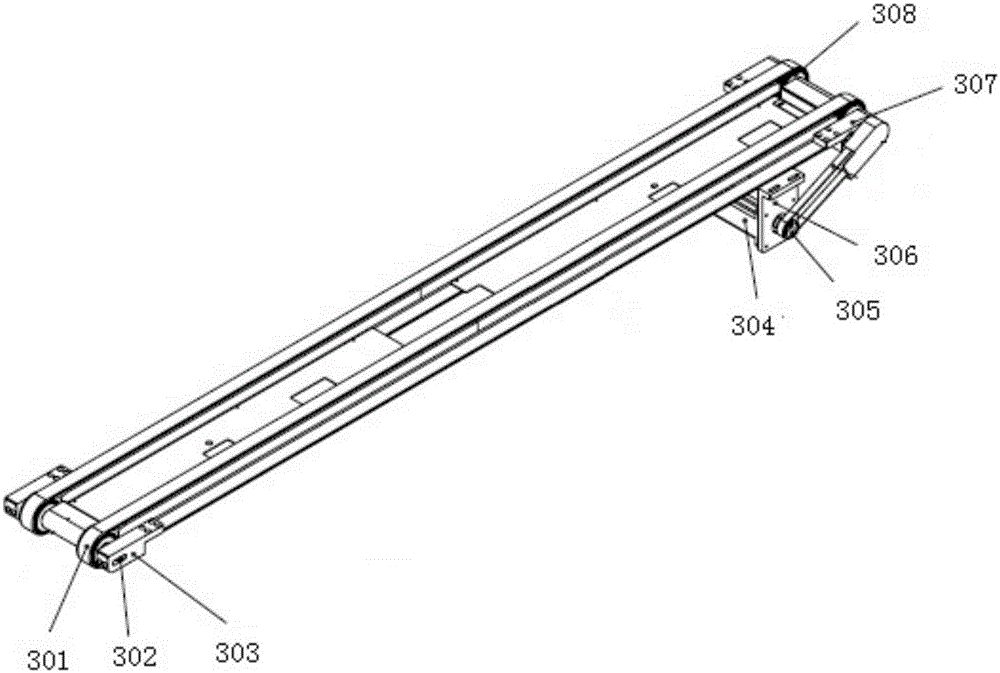

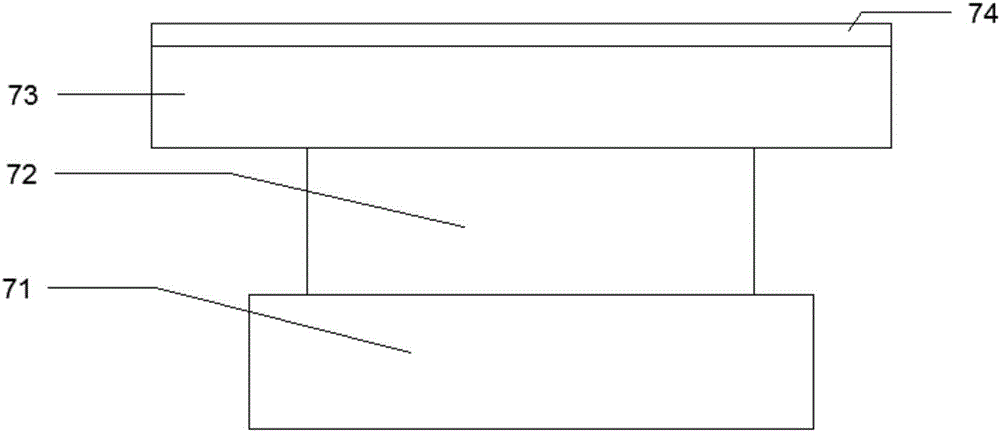

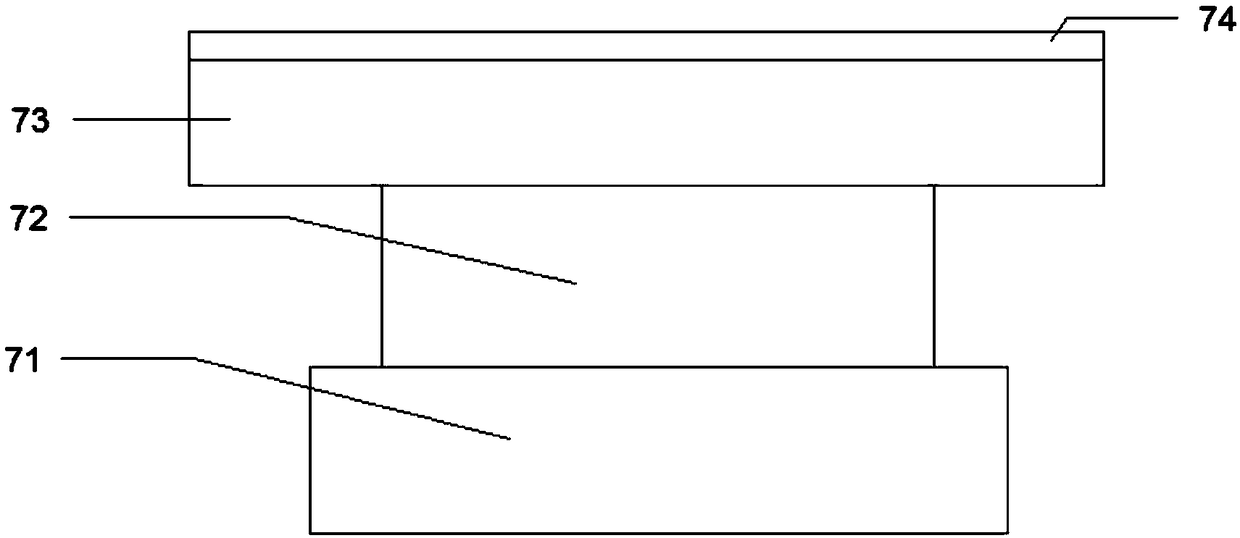

Tray circulating conveying device of plane screen printing machine

PendingCN107416431AImprove transmission efficiencyReasonable structureConveyorsScreen printingEngineering

The invention discloses a tray circulating conveying device of a plane screen printing machine. The tray circulating conveying device comprises a horizontal conveying mechanism, wherein the horizontal conveying mechanism comprises an upper conveying belt and a lower conveying belt of which the conveying directions are opposite; a first rack is arranged on the tail end of the upper conveying belt, a first lifting conveying belt is installed on the first rack, and a first feeding inductive switch, a first putting inductive switch, a first butting inductive switch and a first discharging inductive switch are matched with the first lifting conveying belt; and a second rack is arranged on the tail end of the lower conveying belt, a second lifting conveying belt is installed on the second rack, and a second feeding inductive switch, a second putting inductive switch, a second butting inductive switch and a second discharging inductive switch are matched with the second lifting conveying belt. The tray circulating conveying device of the plane screen printing machine has the advantages of reasonable structure and high conveying efficiency, and circulating conveying of a plurality of trays can be performed at the same time, so that the screen printing efficiency is improved.

Owner:INJELIC PRECISION MOLD & PLASTICS

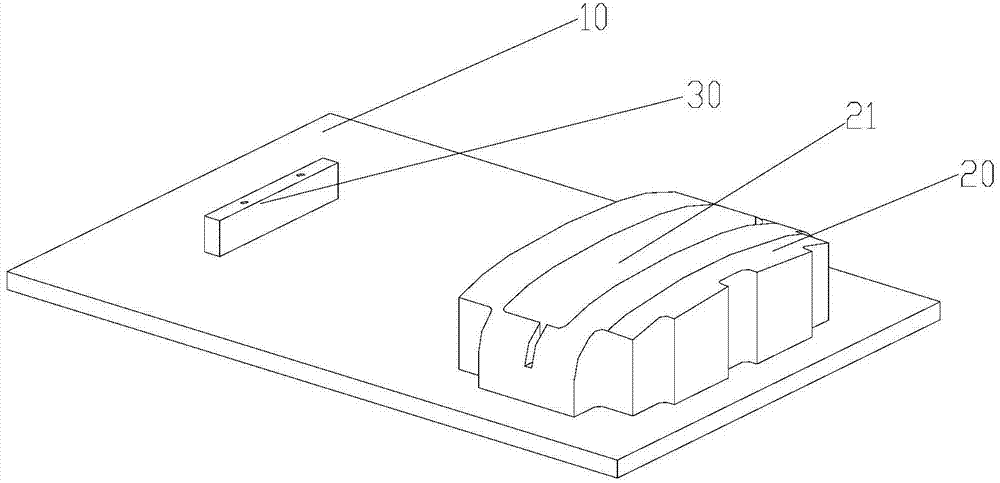

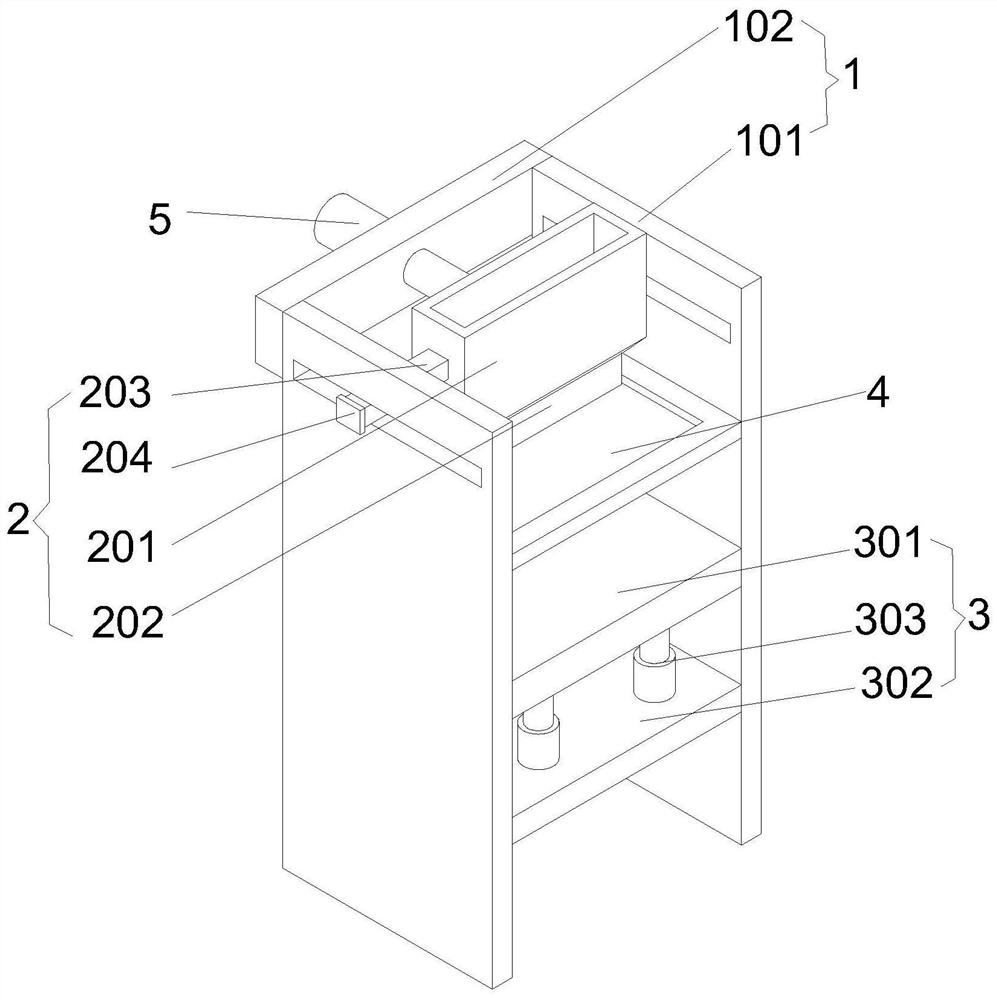

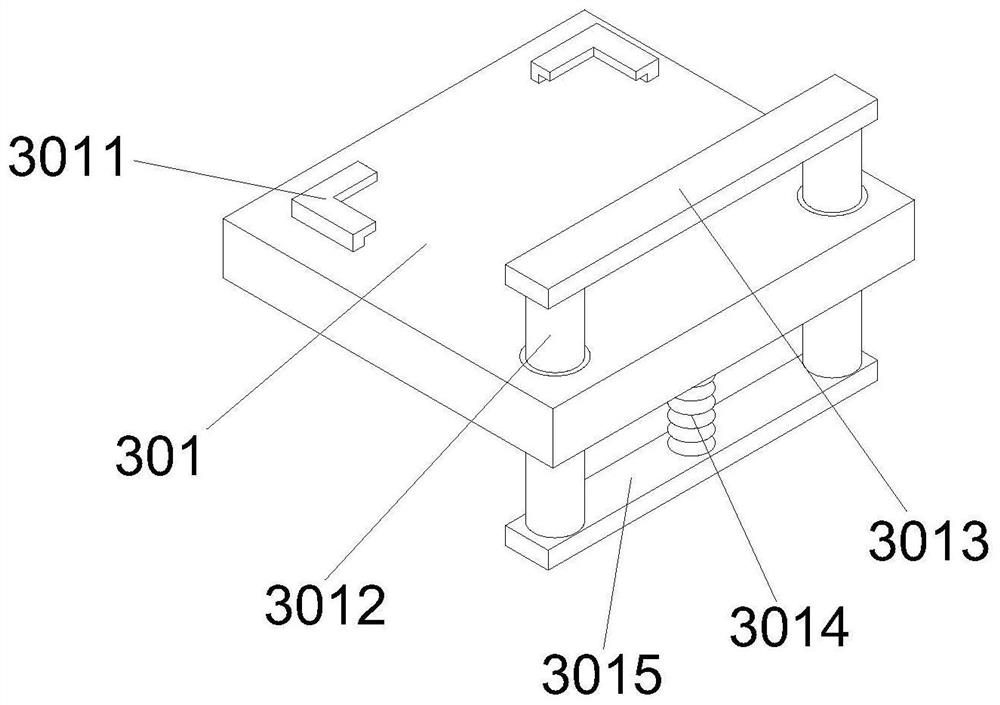

Water dispenser front shell silk printing fixing device

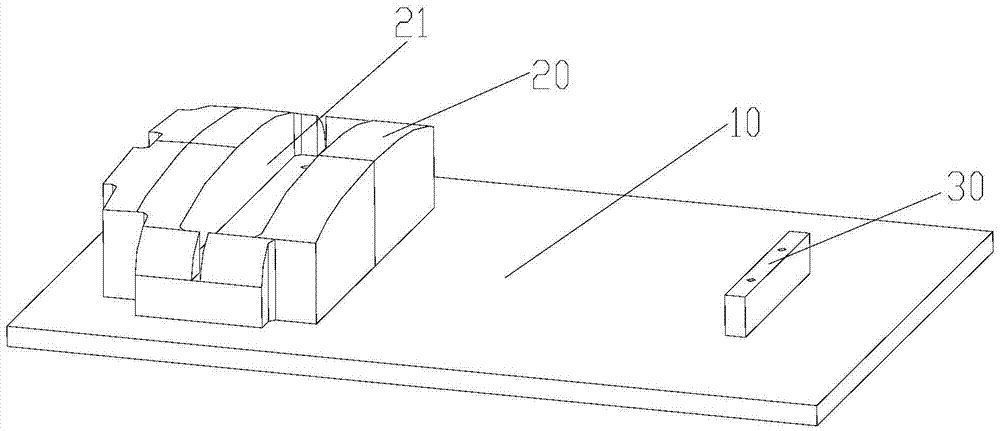

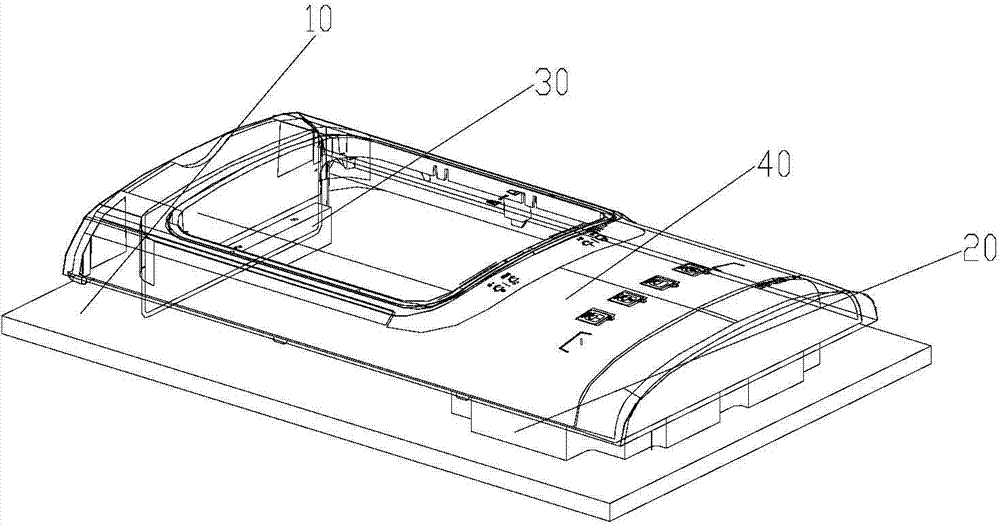

ActiveCN104490273AAchieve fixationImprove screen printing efficiencyBeverage vesselsEngineeringMechanical engineering

The invention provides a water dispenser front shell silk printing fixing device which comprises a base, a front end positioning block and a rear end positioning block. The front end positioning block is arranged on the base and matched with the front end of a back-side recessed portion of a water dispenser front shell, and the rear end positioning block is arranged on the base and matched with the rear end of the recessed portion. The water dispenser front shell silk printing fixing device can avoid a water dispenser front shell fixing device scratching the outer surface of the water dispenser front shell, so that silk printing efficiency of the water dispenser front shell is improved; the front end positioning block and the rear end positioning block are arranged on the back side of the water dispenser front shell, so that the water dispenser front shell silk printing fixing device can be prevented from interfering a silk printing tool, so that convenience is brought to the process of silk printing.

Owner:GREE ELECTRIC APPLIANCES ZHONGSHAN SMALL HOUSEHOLD APPLIANCES MFG +1

Full-automatic cloth screen-printing device

ActiveCN111890788AImprove screen printing efficiencyReduce labor intensityScreen printersScreen printingEngineeringElectrical and Electronics engineering

The invention discloses a full-automatic cloth screen-printing device. The device comprises a base. The base is fixedly provided with a machine body. The two sides of the machine body are fixedly connected with side plates with the front positions and the rear positions symmetrical. First rotating shafts are connected between the side plates in a rotating mode. The first rotating shafts are fixedly connected with rotating drums used for winding cloth. The upper surface of the machine body is fixedly connected with supporting plates with the front positions and the rear positions symmetrical. Atop plate is fixedly connected between the supporting plates. The lower side of the top plate is provided with a second rotating shaft connected between the lateral walls, opposite each other, of thesupporting plates in a rotating mode. The second rotating shaft is fixedly connected with a cam. The device realizes full-automatic screen-printing operation on the cloth with high screen-printing effect and low labor intensity. The cloth is always in a straight state when fed, so no drape of the cloth appears. At the same time, a brush board repeatedly brushes the bottom of a screen-printing chamber, so that a pattern can be more solid and the quality of the screen printing is better.

Owner:佛山市顺德区琪发纺织有限公司

A kind of silk screen printing device and silk screen printing method thereof

ActiveCN108248204BImprove screen printing efficiencyImprove practicalityScreen printersOther printing apparatusScreen printingComputer engineering

The invention provides a screen printing device and a screening printing method thereof. The screen printing device comprises a supporting plate, a guide structure, a conveyor belt, scraping knife components, a cross beam and lifting arms. The supporting plate comprises a rotating plate, adsorption layers and lifting rods, wherein the adsorption layers are arranged on the upper surface and the lower surface of the rotating plate and are uniformly provided with suction holes; the lifting rods are arranged at the two ends of the rotating plate; the rotating plate is internally provided with a rotating motor and can rotate with the lifting rods as the axis. When the screen printing device conducts screen printing, the top end of the guide structure is flush with the lower surface of the adsorption layer on the lower portion. The conveyor belt is arranged on the lower portion of the guide structure. The scraping knife components are arranged above the supporting plate. The lower portion ofthe cross beam is provided with a slide rail. The slide rail is matched with telescopic cylinders. A screen plate is connected with the cross beam through connecting rods. The lifting arms are arranged on the two sides of the supporting plate and the cross beam. The lifting rods and the cross beam are connected with the lifting arms. The screening printing device can adsorb a plurality of printedscreens through the adsorption layers of the supporting plate simultaneously, the screen printing efficiency is greatly improved, and the screen printing cost is reduced.

Owner:JIANGXI HOLITECH TECH

A fully automatic screen printing machine and its production line

ActiveCN106364143BQuality improvementImprove the three-dimensional effectScreen printersScreen printingScreen printingProduction line

The invention discloses a full-automatic screen printing machine which comprises a feeding device, a material sending device and a discharging device. A screen printing device is arranged above the material sending device. A jacking device is arranged below the material sending device. A conveying device is arranged below the feeding device and the discharging device. Jigs carrying materials are stacked on the feeding device. The material sending device is used for carrying the top-layer jigs stacked on the feeding device to the position below the screen printing device and above the jacking device; the jacking device ascends to position the jigs and jacks the jigs into a screen printing station of the screen printing device; after the screen printing device completes screen printing, the jacking device descends to put the jigs onto the material sending device, and the jigs are sent into the discharging device through the material sending device to serve as the top-layer jigs to be stacked; the discharging device conveys the bottom-layer jigs to the bottom layer of the feeding device through the conveying device; and operation is conducted cyclically in this way, and therefore the jigs are subjected to repeated screen printing. The invention further discloses a production line for combining the full-automatic screen printing machine, and the screen printing quality and efficiency are greatly improved.

Owner:DONGGUAN EID NC TECH CO LTD

Glass cover plate silk-screen printing device

InactiveCN111792326AQuality assuranceHigh precisionScreen printersConveyor partsScreen printingGlass cover

The invention discloses a glass cover plate silk-screen printing device which comprises a rack, a material conveying mechanism and a CCD positioning mechanism, wherein the rack is provided with a positioning station and a silk-screen printing station; the material conveying mechanism is connected to the rack and used for bearing a glass cover plate and conveying the glass cover plate to the silk-screen printing station from the positioning station for silk-screen printing. The CCD positioning mechanism comprises a lens assembly which is connected to the rack and located above a material conveying rotary disc so as to shoot the glass cover plate located at the positioning station; and an adjusting assembly which is connected to the rack and located below the material conveying rotary disc,is electrically connected with the lens assembly, and is used for receiving an image of the lens assembly and adjusting and positioning the glass cover plate located at the positioning station. According to the technical scheme, the screen printing precision and the silk-screen printing effect of the glass cover plate are improved.

Owner:深圳市和力泰智能科技有限公司

Bidirectional feeding type metal shell silk-screen printing device

ActiveCN114132055AReduce investmentScreen printing efficiency will not decreaseScreen printersOther printing apparatusScreen printingProduction line

A two-way feeding type metal shell silk-screen printing device comprises two parallel conveying belts, the two conveying belts penetrate through two parallel guide supports, a movable plate parallel to the conveying belts is arranged in each guide support, the two movable plates are arranged in a staggered mode, ink scraping plates are movably installed on the faces, facing the conveying belts, of the movable plates, and the ink scraping plates are arranged on the conveying belts. The two sides of the movable plates are provided with the screen plate frame through first oil cylinders, the two movable plates are connected through a swing arm, the middle of the swing arm is fixedly provided with a first bevel gear, the first bevel gear is meshed with a second bevel gear, the second bevel gear is connected with the gear through a connecting shaft, and the second bevel gear, the connecting shaft and the gear are coaxially arranged. Compared with two continuous silk-screen procedures, the silk-screen efficiency cannot be reduced, but in the subsequent drying procedure, each of the two conveying belts corresponds to one drying device, the drying efficiency can be doubled, and compared with two independent silk-screen production lines, the investment of the two silk-screen devices can be reduced.

Owner:凯瑞电子诸城有限公司

A mobile phone touch screen automatic screen printing device

ActiveCN106626730BWon't breakImprove screen printing efficiencyScreen printersPrinting press partsScreen printingTouchscreen

The invention discloses an automatic screen printing device for a mobile phone touch screen. The automatic screen printing device comprises a rack, a screen printing base, a dedusting mechanism, a screen printing mechanism, a drying mechanism, a receiving platform, a manipulator and a programmable controller. A work table surface is arranged on the upper portion of the rack. The upper end face of the work table surface is fixedly connected with four equal-length support rods. The screen printing base is slidably mounted on the support rods. A rotary disc is mounted on the portion, in a space defined by the four support rods, of the upper end face of the work table surface. The rotary disc is located under the screen printing base. The dedusting mechanism, the screen printing mechanism, the drying mechanism and the receiving platform are sequentially arranged on the rotary disc in the circumferential direction. The manipulator is mounted on the upper end face of the work table surface. The manipulator can be controlled by the programmable controller to complete the process of automatic taking and placing of products; and the automatic screen printing device is high in automation degree, simple in structure and convenient to operate, the situation that a screen print product is stained when being held by hand is avoided, sampling can be fast, and the production efficiency is greatly improved.

Owner:深圳市松录科技有限公司

A large wood screen printing equipment

ActiveCN109435436BReduce labor intensityImprove screen printing efficiencyScreen printersPrinting press partsScreen printingHydraulic cylinder

The invention relates to the technical field of wood plate machining equipment, and discloses large silk-screen printing equipment for a wood plate. The large silk-screen printing equipment for the wood plate comprises two support legs, wherein passive boxes are fixedly installed at the tops of the two support legs separately; a rotary shaft movably sleeves the top end of one support leg, and a fastening device located below the rotary shaft is fixedly installed on the outer side surface of the other support leg; a rotary wheel is fixedly connected to one end located at the left side of one support leg, of the rotary shaft; and a clamping device is fixedly connected to one end located at the right side of one support leg, of the rotary shaft. According to the large silk-screen printing equipment for the wood plate, a screw rod is driven to rotate through the running of a drive motor; by virtue of the cooperation between the screw rod and a moving block, the moving block is enabled to drive a hydraulic cylinder to move to left and right through a bottom rod; and then a scraping plate is driven by a hydraulic cylinder to repeatedly move to left and right to scrap a printing plate, sothat a workpiece to be machined is printed with a pattern, and therefore, the labor intensity of working personnel is lowered, and the silk-screen printing efficiency is increased.

Owner:诸暨市云傲机械配件厂

A fully automatic cloth screen printing device

ActiveCN111890788BRealize silk screen operationNo creasesScreen printersScreen printingScreen printingEngineering

The invention discloses a fully automatic cloth screen printing device, which comprises a base, on which a machine body is fixed, two sides of the machine body are fixedly connected with front and rear symmetrical side plates, and the side plates are rotatably connected with a first A rotating shaft, the first rotating shaft is fixedly connected with a drum for winding cloth, the upper surface of the body is fixedly connected with support plates with symmetrical front and rear positions, and a top plate is fixedly connected between the support plates, and the top plate The lower side is provided with a second rotating shaft rotatably connected between the opposite side walls of the support plate, and a cam is fixedly connected to the second rotating shaft, which realizes the silk screen operation of the cloth fully automatically, with high screen printing efficiency and low labor intensity. Low; the fabric is always in a straightened state during feeding, so there will be no fabric wrinkles, and at the same time, the brush board will repeatedly brush the bottom of the silk screen cavity, so that the pattern can be more solidified. The quality of silk screen printing is better.

Owner:佛山市顺德区琪发纺织有限公司

Screen printing device for LED lamp lampshade

InactiveCN111605295AImprove screen printing efficiencyExcellent screen printing performanceScreen printersScreen printingEngineering

The invention discloses a screen printing device for an LED lamp lampshade. The device comprises a bracket mechanism, a scraping mechanism and a positioning mechanism. The scraping mechanism and the positioning mechanism are both connected with the bracket mechanism. A screen printing screen is arranged between the scraping mechanism and the positioning mechanism. The screen printing screen is fixedly connected to the bracket mechanism. The scraping mechanism is slidably connected to the bracket mechanism, the lampshade positioned and fixed by the positioning mechanism is subjected to screen printing through the screen printing screen, the mechanized operation is achieved, the screen printing efficiency is high, the screen printing effect is good, in the screen printing process of the scraping mechanism, the force is uniform, the appearance of chromatic aberration is reduced, and at the same time, the screen printing device has a simple structure and a small floor area, and is convenient to use and suitable for various workshops.

Owner:ANHUI SHILIN LIGHTING

Multifunctional printing machine

InactiveCN108016124AImprove screen printing efficiencyNo manualScreen printersScreen printingScreen printingEngineering

The invention relates to a multifunctional printing machine. The multifunctional printing machine comprises a base, a rotary table and a screen printing device. Four working positions are arranged onthe rotary table. The four working positions include one feeding position and one discharging position. The rotary table is arranged on the base. The rotary table is driven to rotate by a driving device in the base. The screen printing device is used for printing a product to be printed fixed to the working positions. According to the printing machine provided by the invention, the feeding position and the discharging position are separated, so that the screen printing efficiency is improved; moreover, the screen printing device can automatically move downwards and brush ink and achieves automatic screen printing, and manpower is saved.

Owner:SUZHOU TEMING PRECISION TECH

High-precision single-pass double-sheet automatic screen printing machine

InactiveCN106515201BDon't worry about the impactImprove printing accuracyScreen printersScreen printingScreen printingSemi automatic

Owner:SHENZHEN TINVICO TECH CO LTD

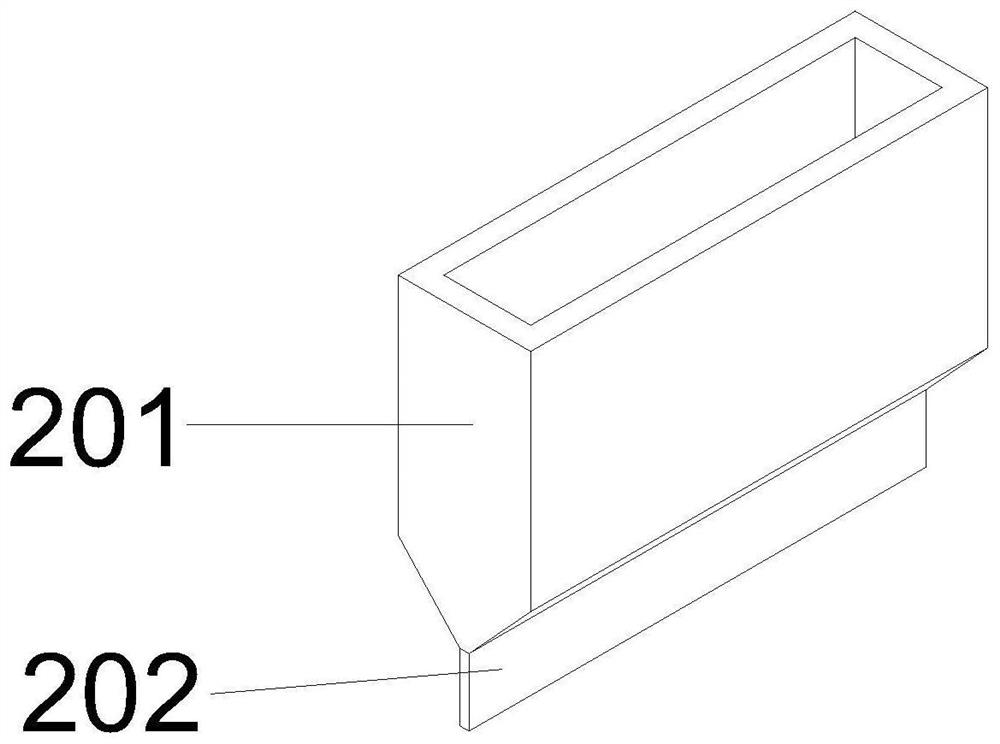

Silk-screen anti-adhesion PCB nail bed template

The invention discloses a silk-screen anti-adhesion PCB nail bed template which comprises a base. A silk-screen platform and conveying devices arranged on the two sides of the silk-screen platform andused for workpiece feeding are mounted on the base. The conveying devices comprise a lifting mechanism and a conveying belt mechanism mounted on the lifting mechanism. The conveying belt mechanism comprises drive wheels arranged on the two sides of the silk-screen platform correspondingly and a conveying belt annularly arranged on the two drive wheels in a sleeving manner. An empty groove used for allowing the conveying belt to pass is formed in the silk-screen platform, and protrusions used for bearing workpieces are evenly distributed on the silk-screen platform. The workpieces are transported to the silk-screen platform through the conveying device capable of ascending and descending and are located on the protrusions, gaps are kept between the workpieces and the silk-screen platform by means of bearing of the protrusions, the workpieces can be turned over to achieve silk-screen printing of the other faces after silk-screen printing of one faces of the workpieces is completed, andthe silk-screen printing is improved.

Owner:鹤山市泰利诺电子有限公司

A mobile phone touch screen screen printing device for easy sampling

ActiveCN106739440BImprove screen printing efficiencyWon't breakScreen printersPrinting press partsScreen printingTouchscreen

The invention discloses a mobile phone touch screen silk printing device facilitating sampling. The mobile phone touch screen silk printing device facilitating sampling comprises a rack, a silk printing base, a silk printing mechanism, a drying mechanism and a programmable controller. A work tabletop is arranged above the rack. The silk printing base is installed on the worktable top. A first stand column provided with a linear sliding rail is fixedly connected to the worktable top. The silk printing mechanism can be installed on the first stand column in a sliding manner and is located over the silk printing base. The drying mechanism is installed on the worktable top and is located on one side of the silk printing base. A mechanical hand is installed on the worktable top, and the mechanical hand, the silk printing mechanism and the drying mechanism can conduct data interaction with the programmable controller. According to the device, an air control mechanism is used for jacking up a product, the programmable controller controls the mechanical hand to complete the process of automatically taking and putting products, the device is high in automation degree, simple in structure and convenient to operate, stain caused by taking the silk printing products by hands is avoided, fast sampling can be conducted, and the production efficiency is greatly improved.

Owner:深圳市松录科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com