Full-automatic screen printer and screen printing control method for same

A screen printing machine, fully automatic technology, applied to screen printing machines, printing machines, screen printing, etc., can solve the problems of short clothing style update cycle, unqualified printing quality, heavy printing workload, etc., and achieve high screen printing efficiency , good printing quality and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

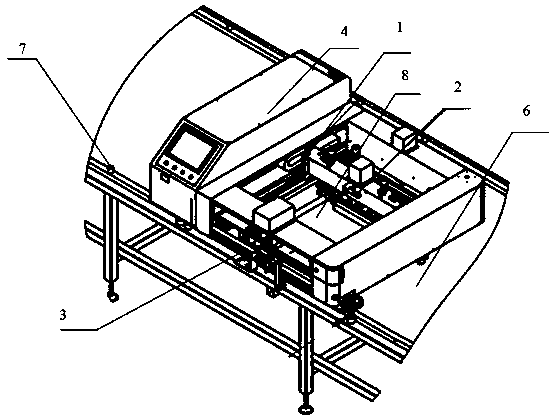

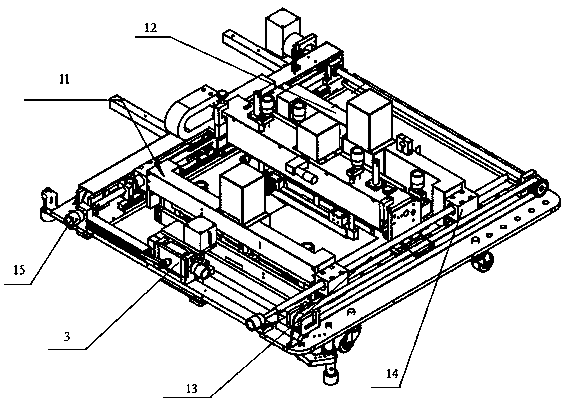

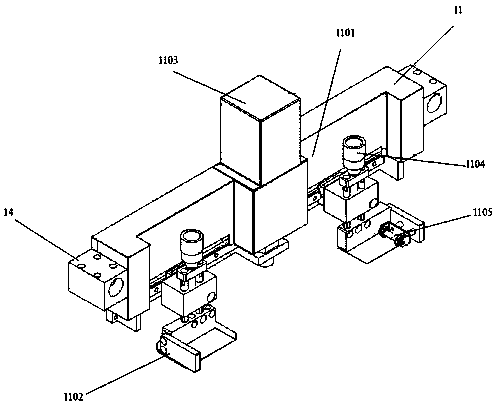

[0028] Such as Figure 1 to Figure 8 As shown, a fully automatic screen printing machine includes a screen installation device 1, a scraper device 2, a positioning assembly 3, a control device 4, and a travel drive device 5; the screen installation device 1 is fixed with a screen printing screen 8, and is equipped with A moving component that can move up and down the screen installation device 1; the scraper device 2 is installed above the screen printing screen 8 of the screen installation device 1, and is equipped with a left and right slide rail structure for scraping the screen printing screen 8 and ink return action; the control device 4 controls the walking drive device 5 to push the screen installation device 1 to walk on the screen printing platform 6, and performs the scraping of the scraper device 2 by positioning the positioning assembly 3 at the positioning code 7 of the screen printing platform 6 And back ink action.

[0029] The fully automatic screen printing m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com