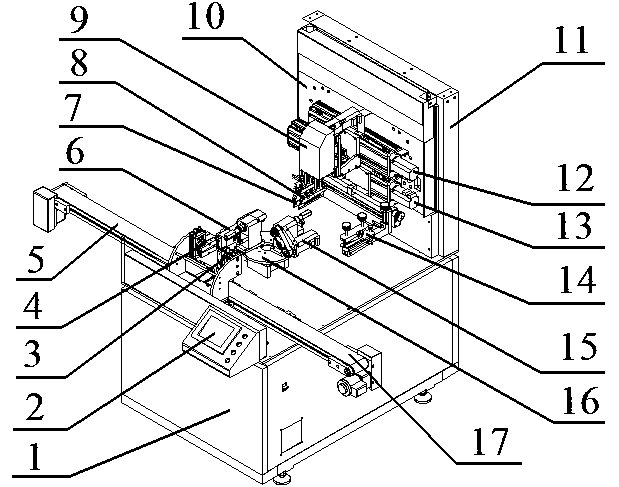

Full-servo drive control single-color double-station complex curved surface screen printing machine

A screen printing machine and complex curved surface technology, applied in screen printing machines, screen printing, printing machines, etc., can solve the problems of slow printing speed and unstable screen printing quality, and achieve convenient bottle replacement, good effect, and cycle time short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

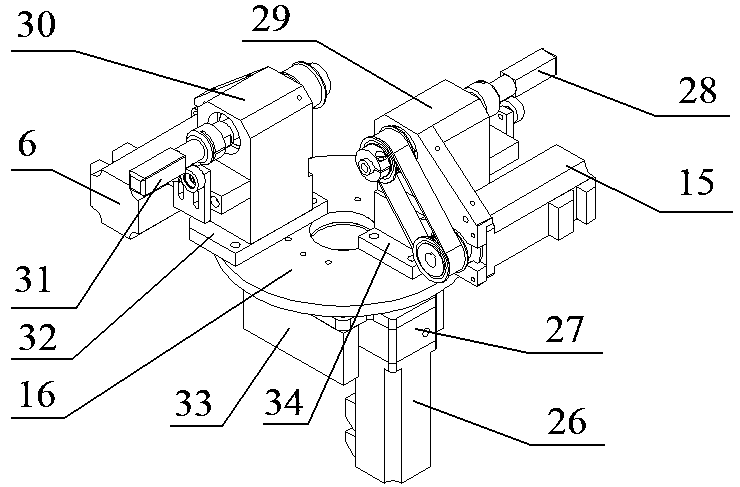

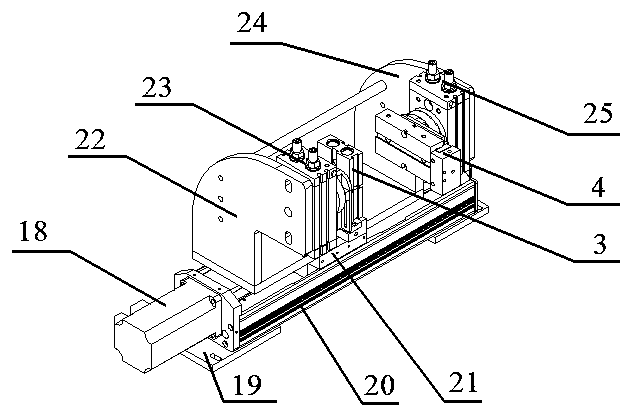

[0033] refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , Silk screen printing of elliptical bottle products: a full servo drive control single-color double-station complex curved surface screen printing machine. The screen printing action sequence is: first, the operator turns on the start button on the control panel, and the programmable controller starts running at the same time, and the operator Put the oval bottle product on the feeding conveyor belt 17, the feeding conveyor belt 17 will transport the oval bottle product to the clamping position of the feeding manipulator 3, the fifth servo motor 18 moves to the feeding position with the loading and unloading manipulator system, and then The programmable controller runs and starts to control the pneumatic control valve of the feeding manipulator 3 to open, and the feeding manipulator 3 sucks the oval bottle product tightly. After the first rotating cylinder 23 rotates 90 degrees counterclockwise with ...

Embodiment example 2

[0035] refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , Polygonal bottle product screen printing: a full servo drive control single-color double-station complex surface screen printing machine. The screen printing action sequence is as follows: first, the operator turns on the start button on the control panel, and the programmable controller starts running at the same time, and the operator Put the polygonal bottle product on the feeding conveyor belt 17, the feeding conveyor belt 17 will transport the polygonal bottle product to the clamping position of the feeding manipulator 3, the fifth servo motor 18 moves to the feeding position with the loading and unloading manipulator system, and then The programmable controller runs and starts to control the pneumatic control valve of the feeding manipulator 3 to open, and the feeding manipulator 3 sucks the polygonal bottle product tightly. After the first rotating cylinder 23 rotates 90 degrees counterclockw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com