Temperature and humidity automatic control fermentation device in tea production process

A fermentation device and temperature and humidity technology are applied in the field of temperature and humidity automatic control fermentation devices, which can solve the problems of affecting the quality of black tea, unable to maintain quantitative and controllable temperature and humidity adjustment means, etc., and achieve good quality effects and stable process requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in detail below in conjunction with specific embodiments.

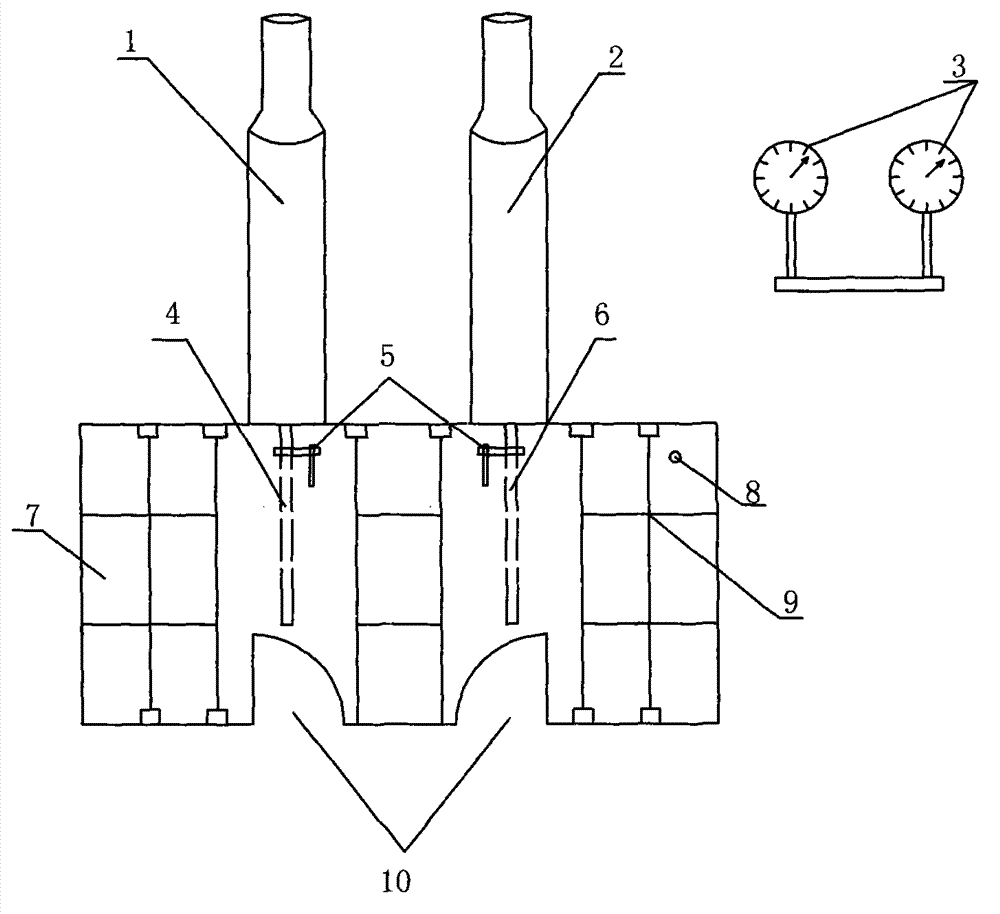

[0010] The invention discloses a temperature and humidity automatic control fermentation device in tea production. figure 1 , comprising a steam furnace 1, a hot gas furnace 2 and a fermentation chamber 7. The steam furnace 1 generates water vapor, which is transported into the fermentation chamber 7 through the porous steam pipe 4, and the hot air furnace 2 generates high-temperature air and is sent into the fermentation chamber 7 through the porous hot gas pipe 6. Fermentation A detection module 8 is set in the chamber 7 to detect the temperature and humidity in the fermentation chamber, the detected temperature and humidity are displayed on the instrument 3, and the switch module 5 controls the switch of the porous steam pipe 4 and the porous hot gas pipe 6 according to the temperature and humidity When the temperature is higher than the set temperature, the porous hot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com