Cutting-grinding integrated machine

An all-in-one machine, cutting machine technology, applied in other manufacturing equipment/tools, manufacturing tools and other directions, can solve the problems of single function, few composite products, high cutting efficiency, achieve good quality effect, compact structure design, cutting and grinding Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

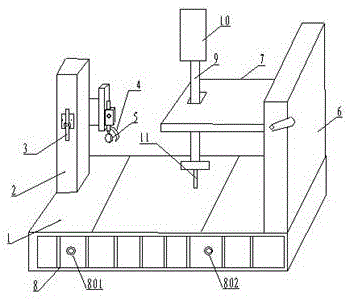

[0014] see figure 1 , the embodiment of the present invention includes:

[0015] The cutting and grinding integrated machine includes a base, the base adopts a cuboid structure, the material is cast iron, and a support pad is provided at the lower end of the base to make the base more stable. At the same time, a hollow cooling pipe is provided in the base , the cooling pipeline is connected with a water inlet hole and a water outlet hole, and the water circulation is realized through the connection of the water pipe, so that the workpiece can be cooled rapidly during the cutting process.

[0016] A working table is set on the base, and the worki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com