Automatic screen printing device for mobile phone touch screen

A screen printing device and touch screen technology, applied in printing, printing machines, rotary printing machines, etc., can solve the problems of not being able to absorb pens, pick and place products, and silk screen ink damage, so as to avoid adverse effects, facilitate operation, and save time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with drawings and embodiments.

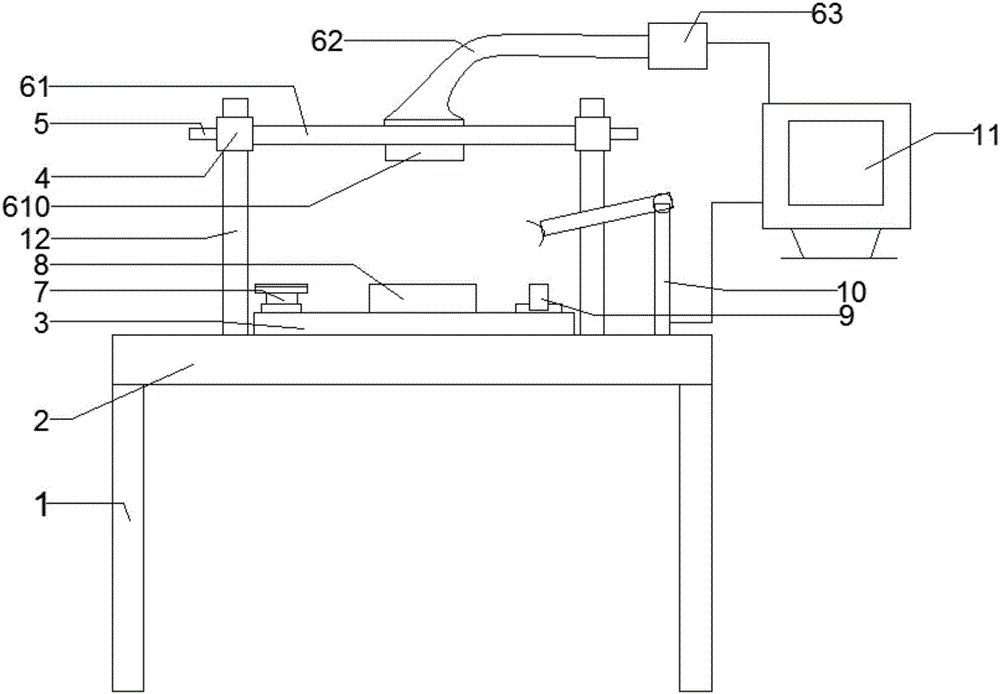

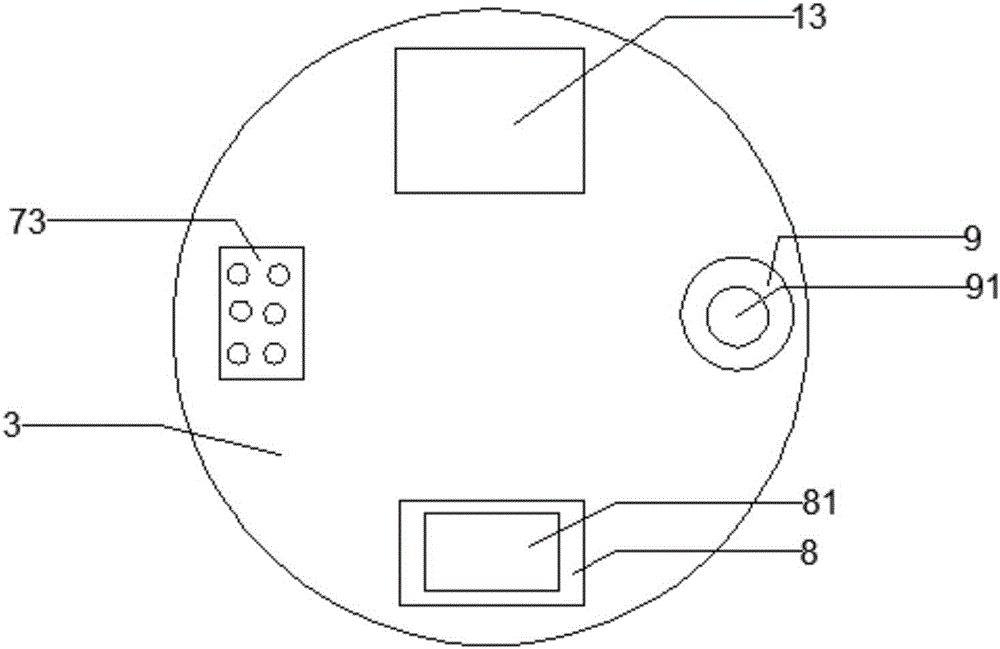

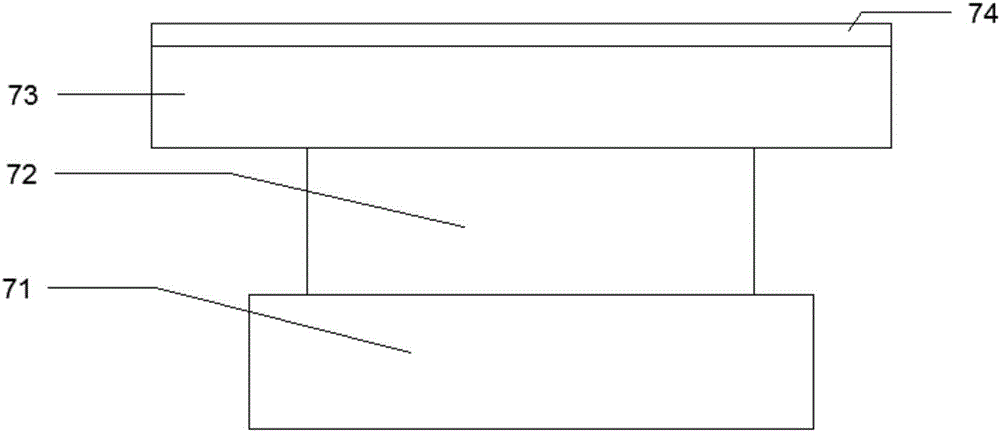

[0025] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the present embodiment includes a frame 1 positioned at one side of the production conveyor belt, a worktable 2 is arranged above the frame 1, and four equal-length support rods 12 are fixed vertically on the upper end of the worktable 2. The rods 12 are all equipped with linear slide rails, and the four support rods 12 are equipped with positioning sliders 4 that are compatible with the linear slide rails. A slider drive cylinder 5 is installed on the positioning sliders 4, and the four support rods A rotating disc 3 is installed on the upper end of the working table 2 in the space surrounded by 12, and the upper end of the rotating disc 3 is installed with a dust removal mechanism 7, a silk screen mechanism 13, a drying mechanism 9, a material receiving platform 8, and a dust removal mechanism 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com