Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Expand the scope of painting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

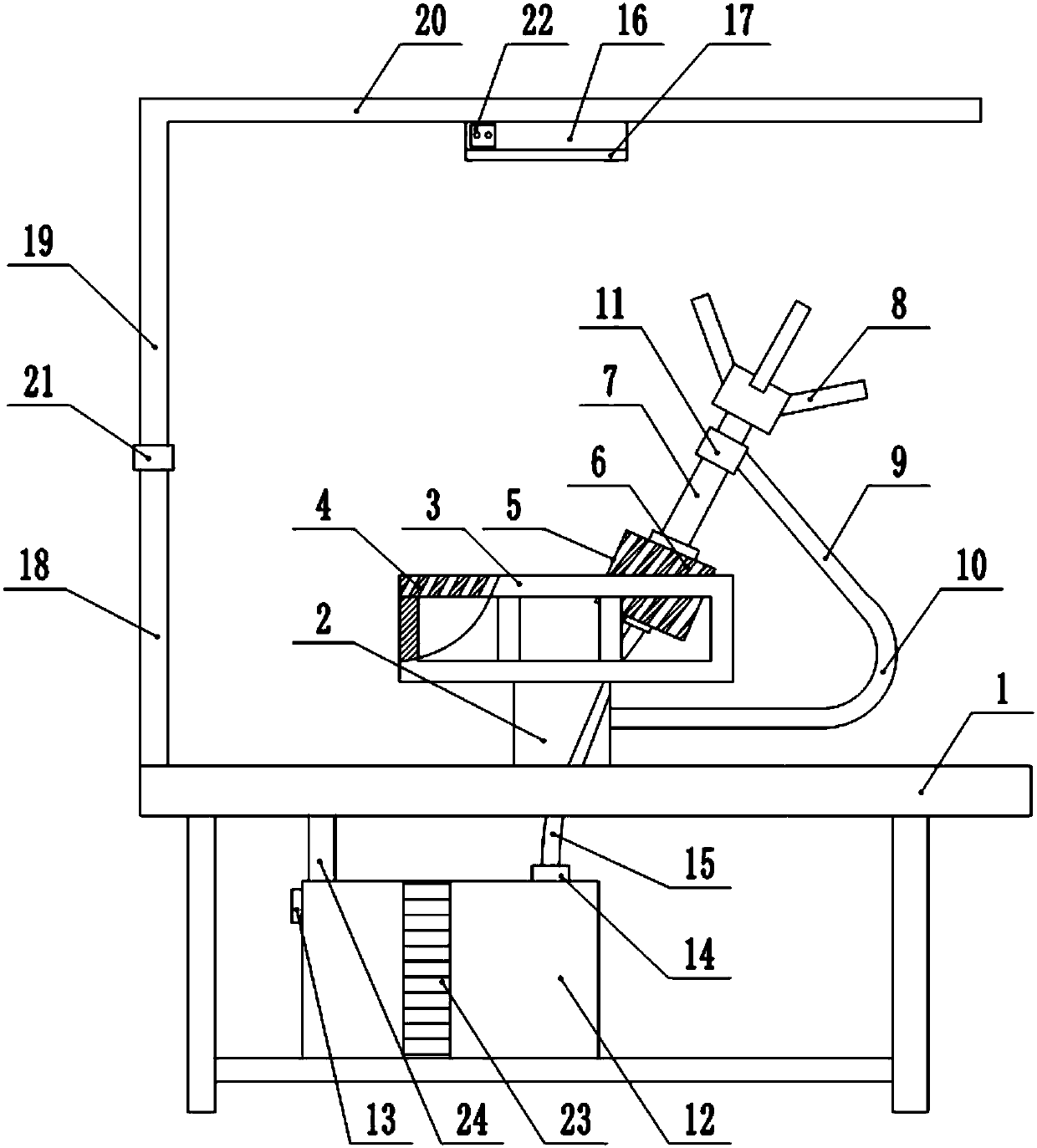

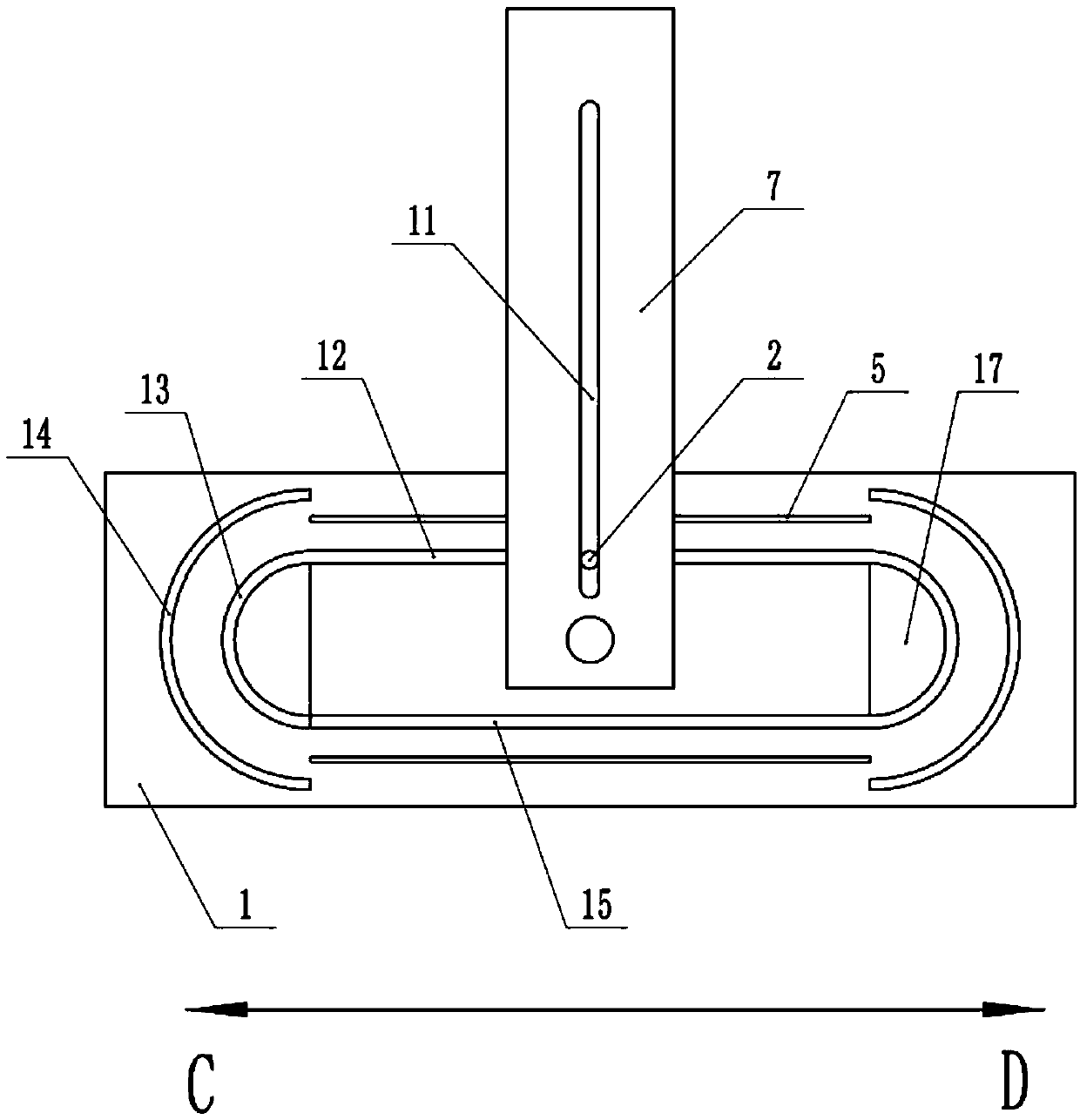

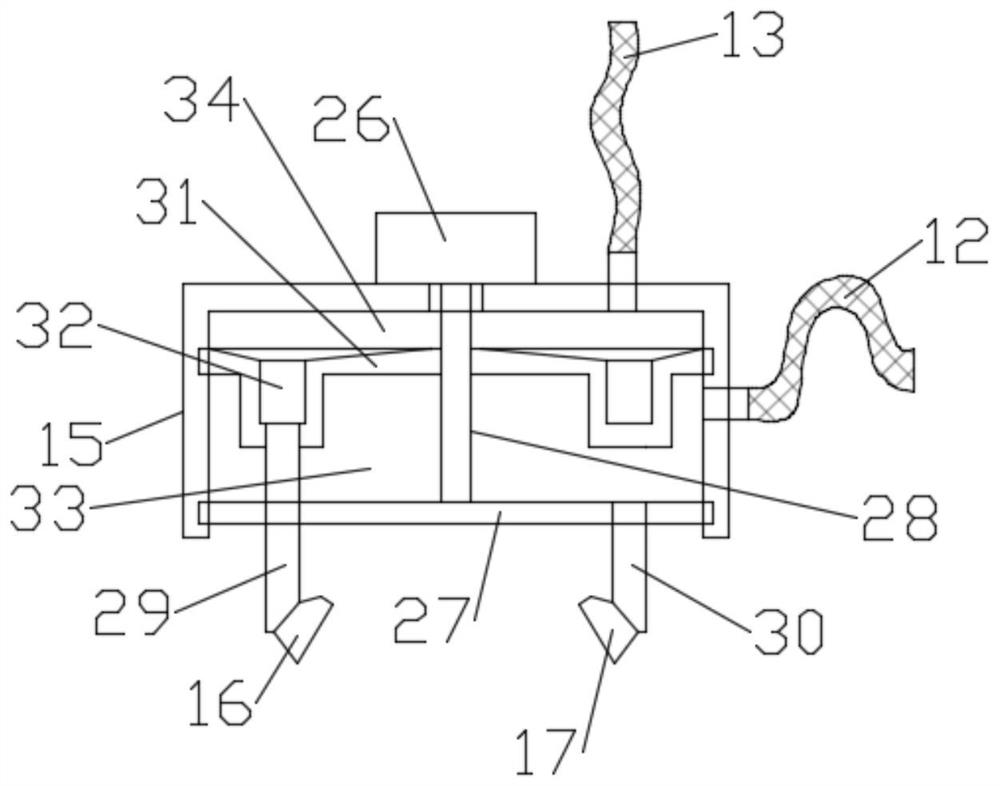

Multi-angle automatic paint spray equipment for machining mechanical part

ActiveCN110773365ADry evenlyGood effectPretreated surfacesLiquid spraying apparatusHot blastTelescopic cylinder

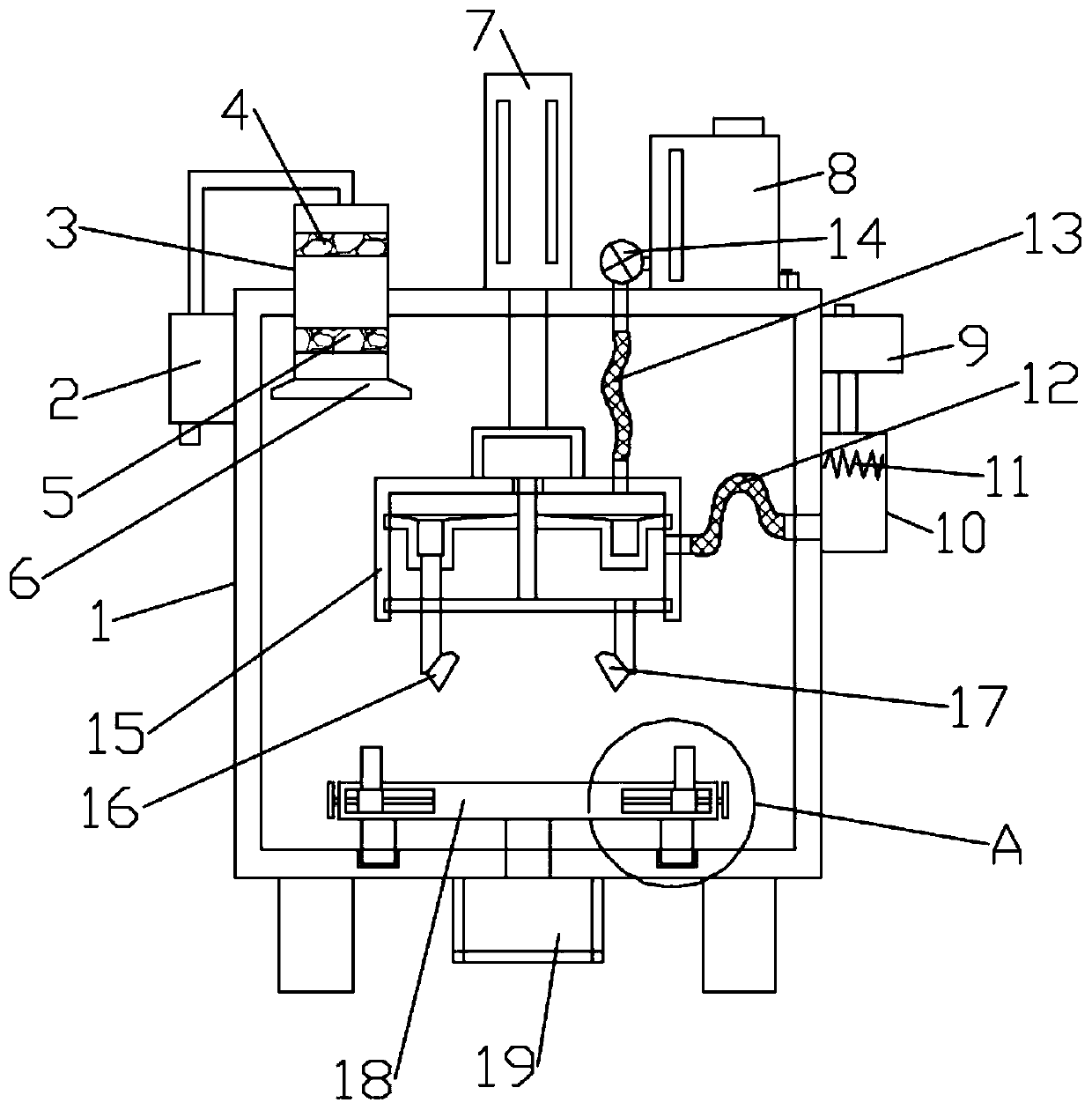

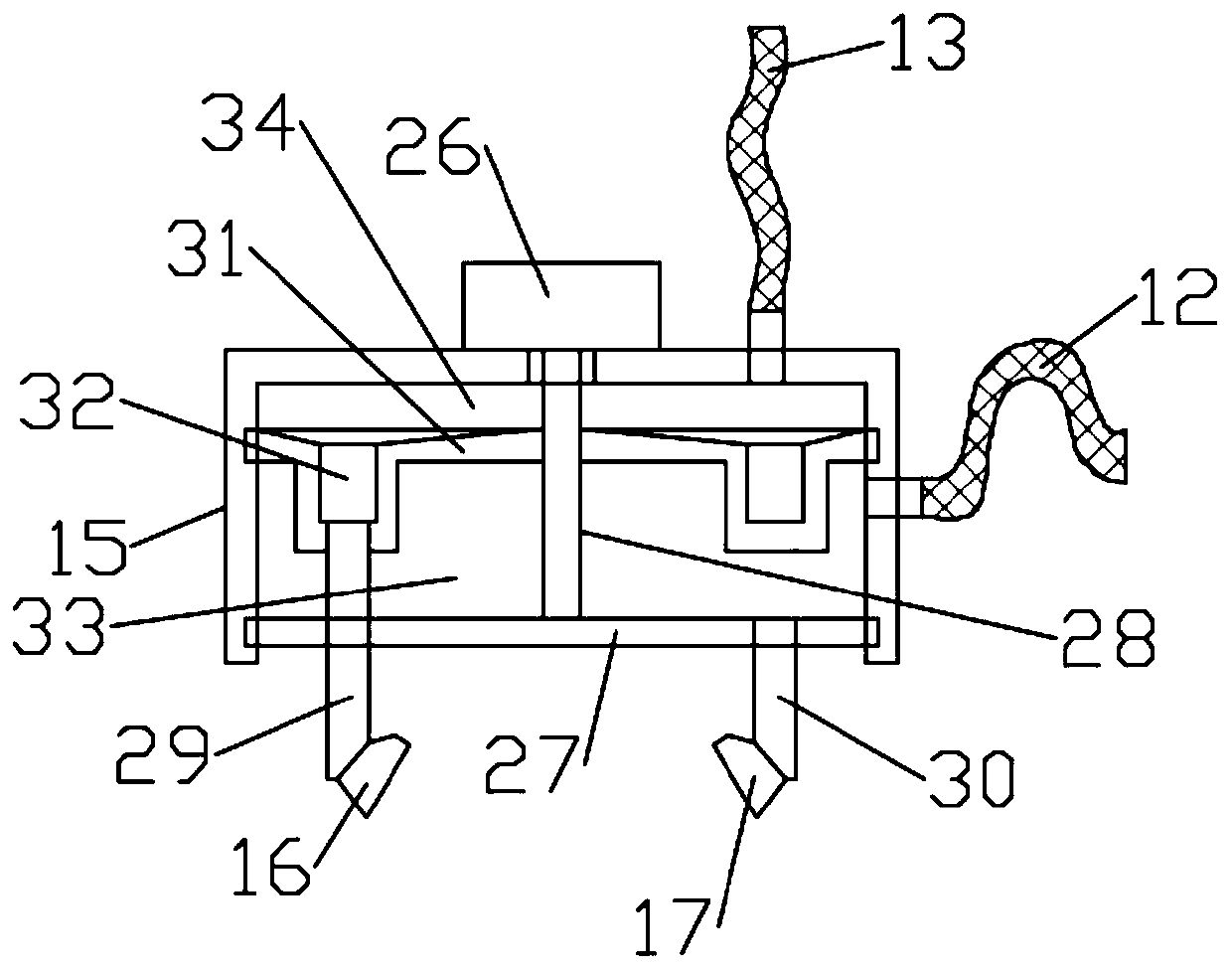

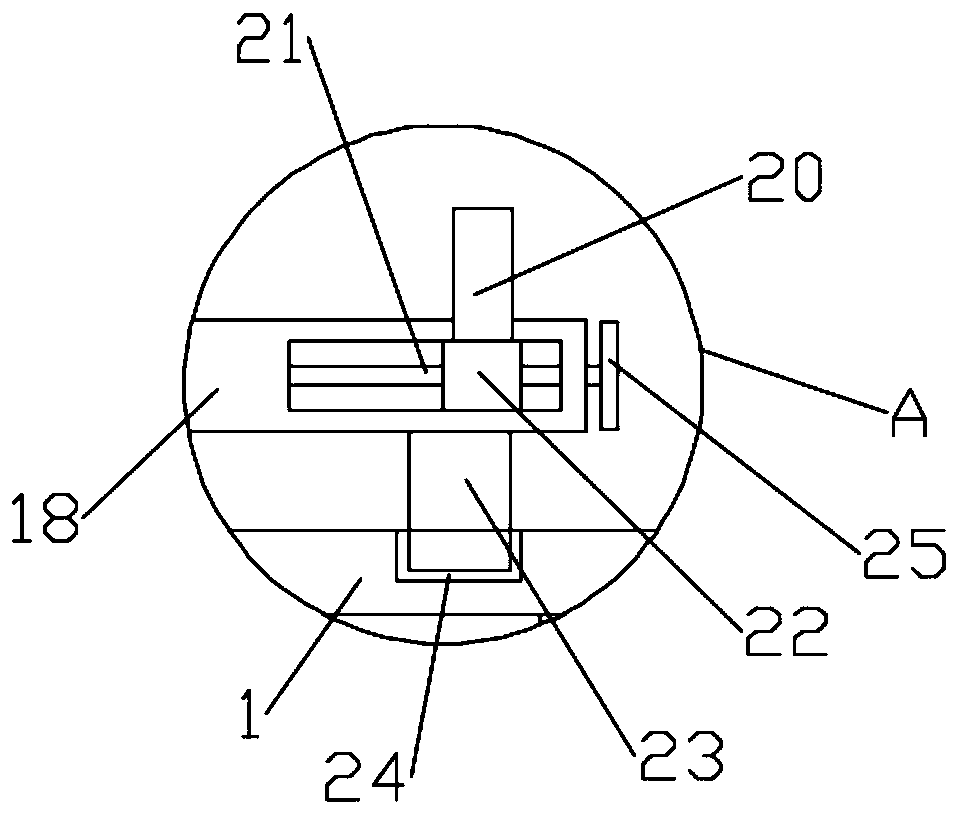

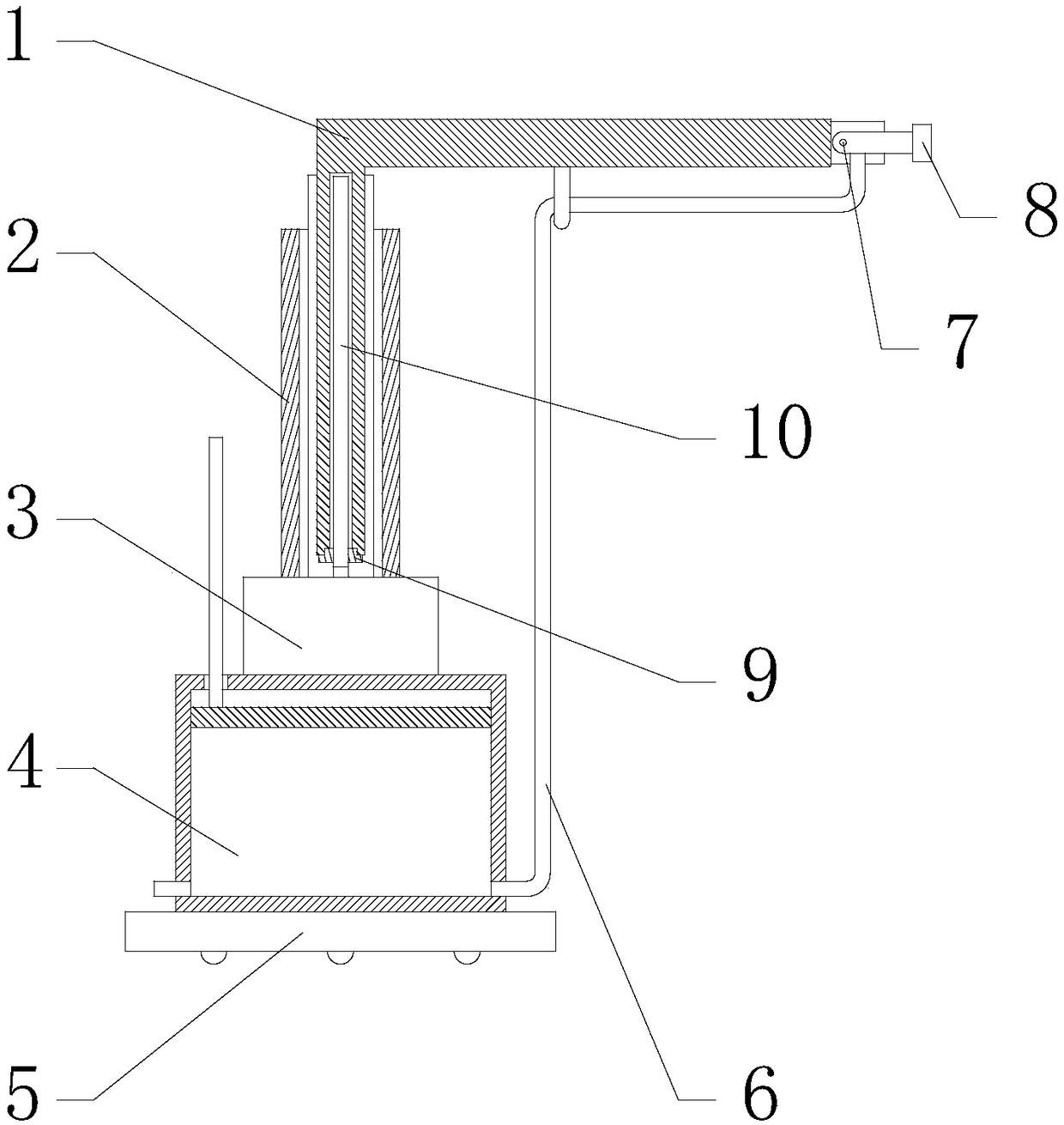

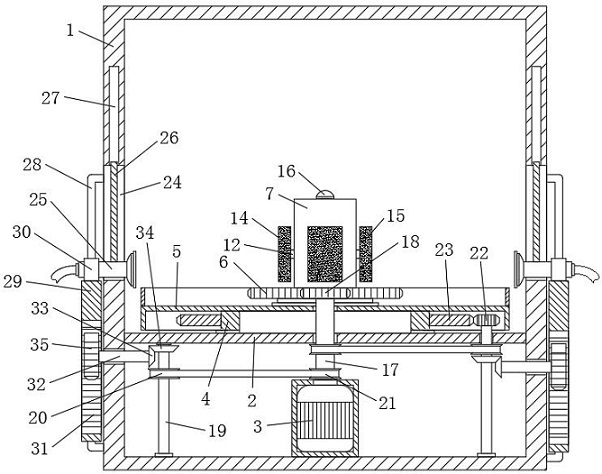

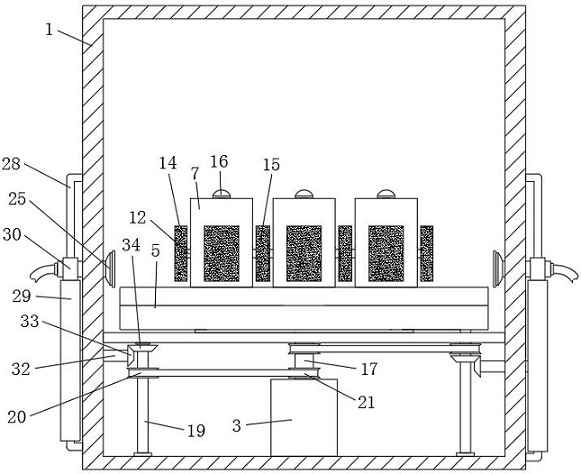

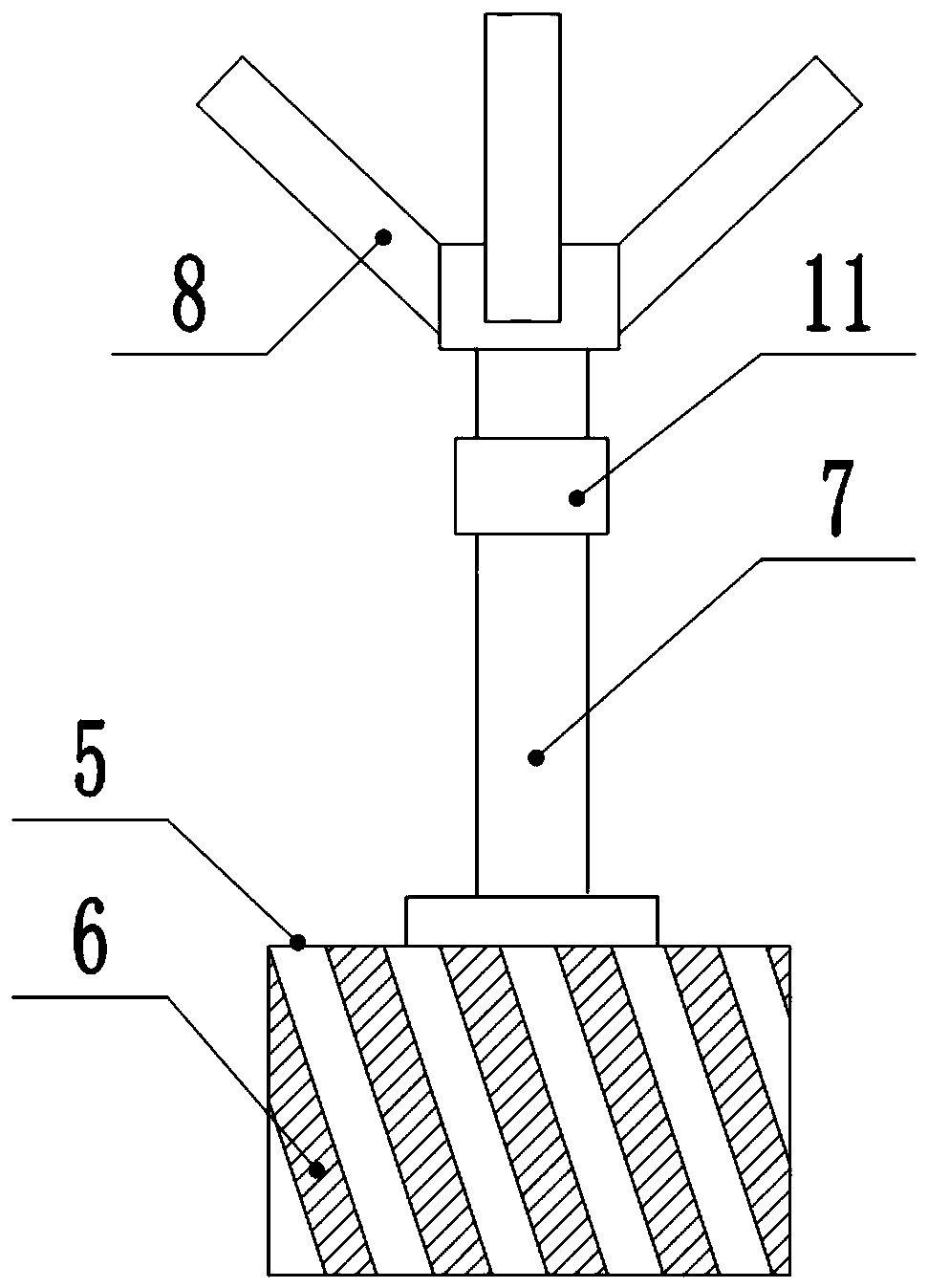

The invention relates to the field of automatic machining equipment and particularly discloses multi-angle automatic paint spray equipment for machining a mechanical part. The multi-angle automatic paint spray equipment comprises a box body; a supporting cylinder realizing height adjustment by virtue of a telescopic cylinder is arranged inside the box body; a rotating partition plate and a rotating plate are arranged in a synchronous rotation manner inside the supporting cylinder; an inner chamber of the supporting cylinder is divided into an upper chamber and a lower chamber, namely a paint liquid chamber and a hot air chamber by virtue of the rotating partition plate and the rotating plate; an air pipe used for exhausting hot air out of the hot air chamber is fixedly installed at one side of the rotating plate; a hot air nozzle is arranged at the bottom end of the air pipe; a paint liquid pipe used for discharging paint liquid inside the paint liquid chamber is fixedly installed at the other side of the rotating partition plate; and a paint mist sprayer used for atomizing the paint liquid is arranged at the bottom end of the paint liquid pipe which extends to a position below therotating plate. The multi-angle automatic paint spray equipment provided by the embodiment of the invention can effectively widen the paint spraying range, guarantees the uniformity of paint spraying, can also guarantee timely drying of the paint liquid at the surface of the part, and also realizes uniform drying and a good effect.

Owner:SUZHOU ODIHUA ELECTRONIC CO LTD

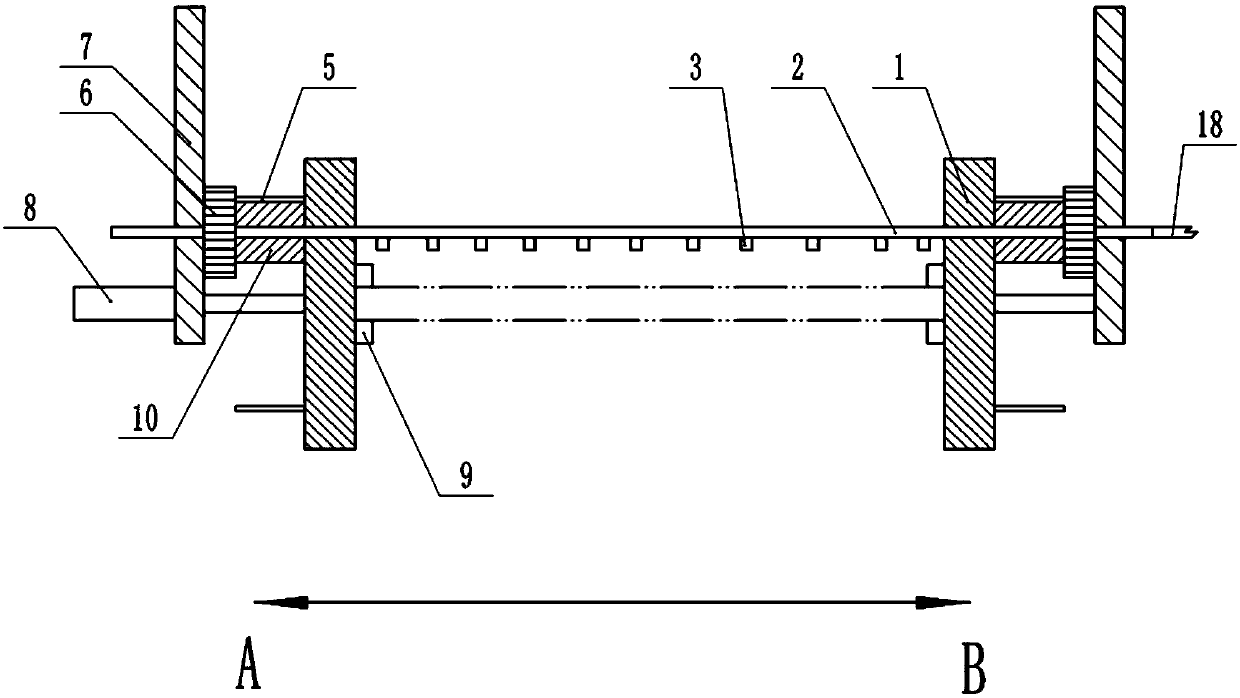

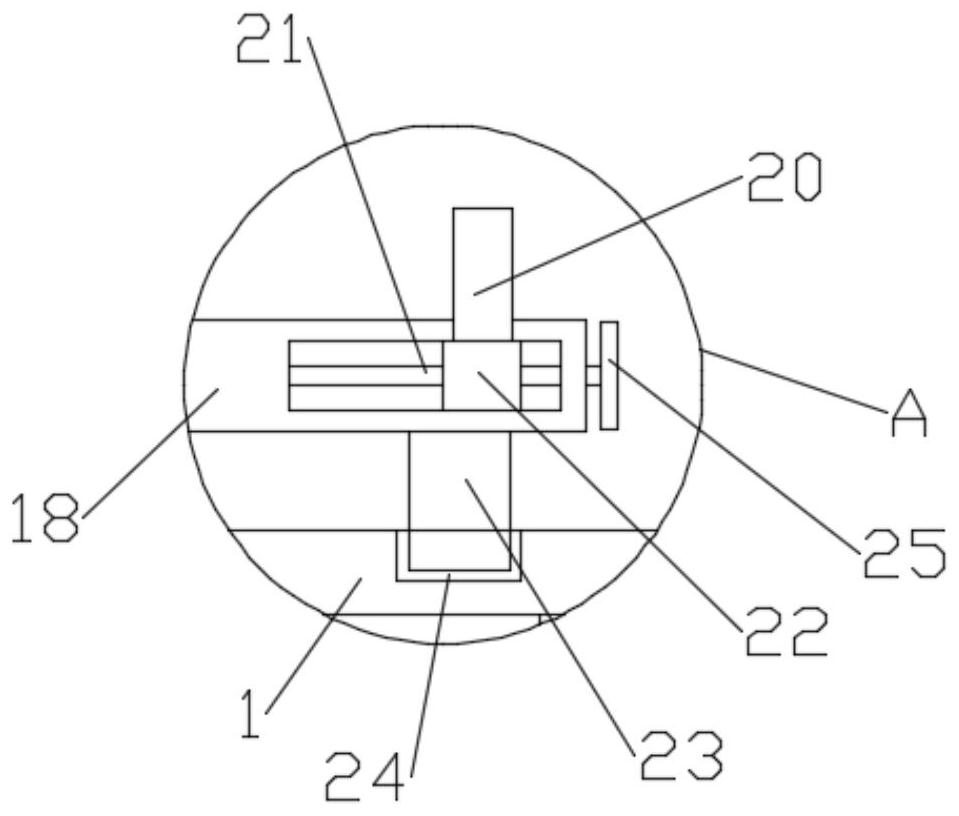

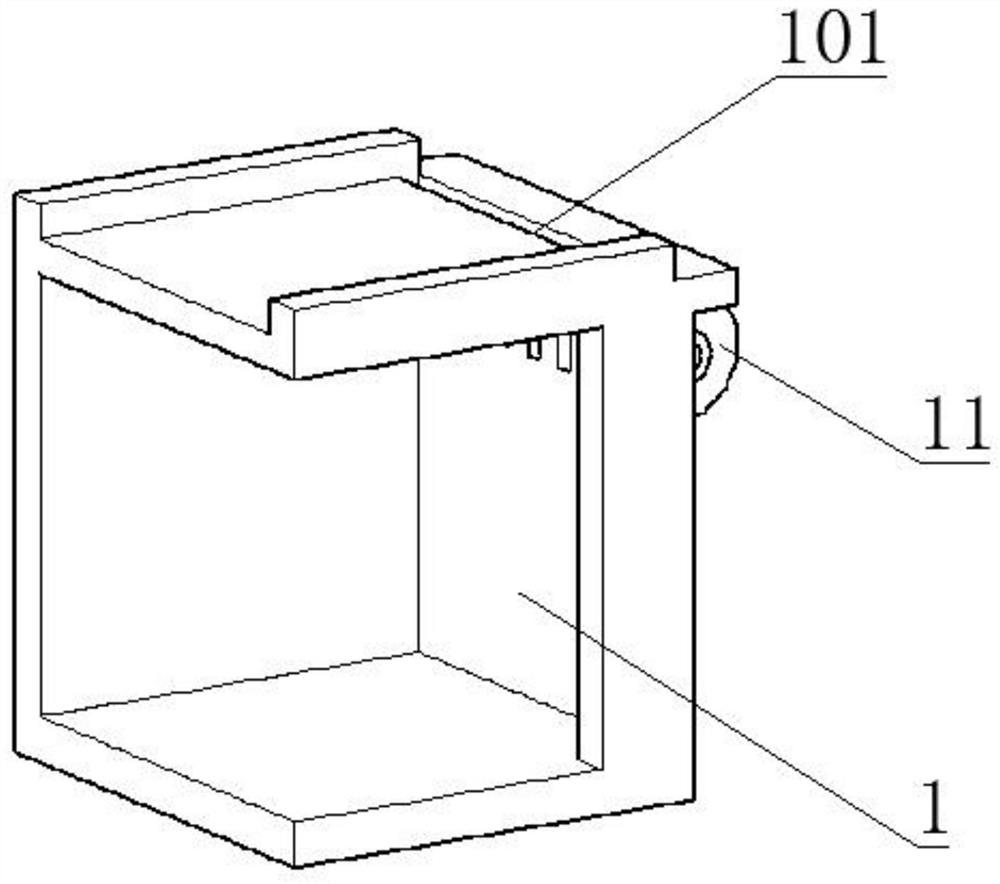

Paint spraying device for surface of machined steel plate

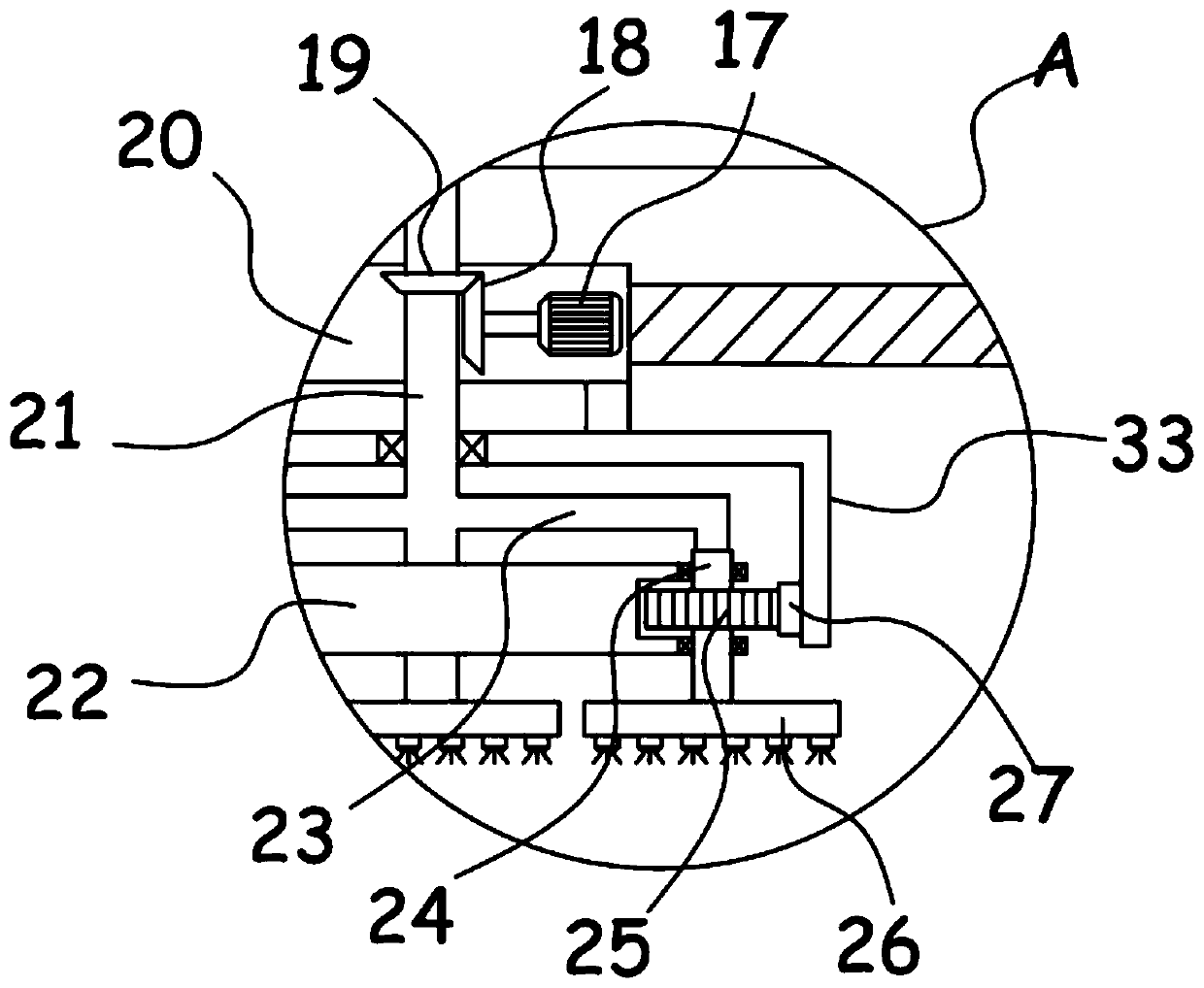

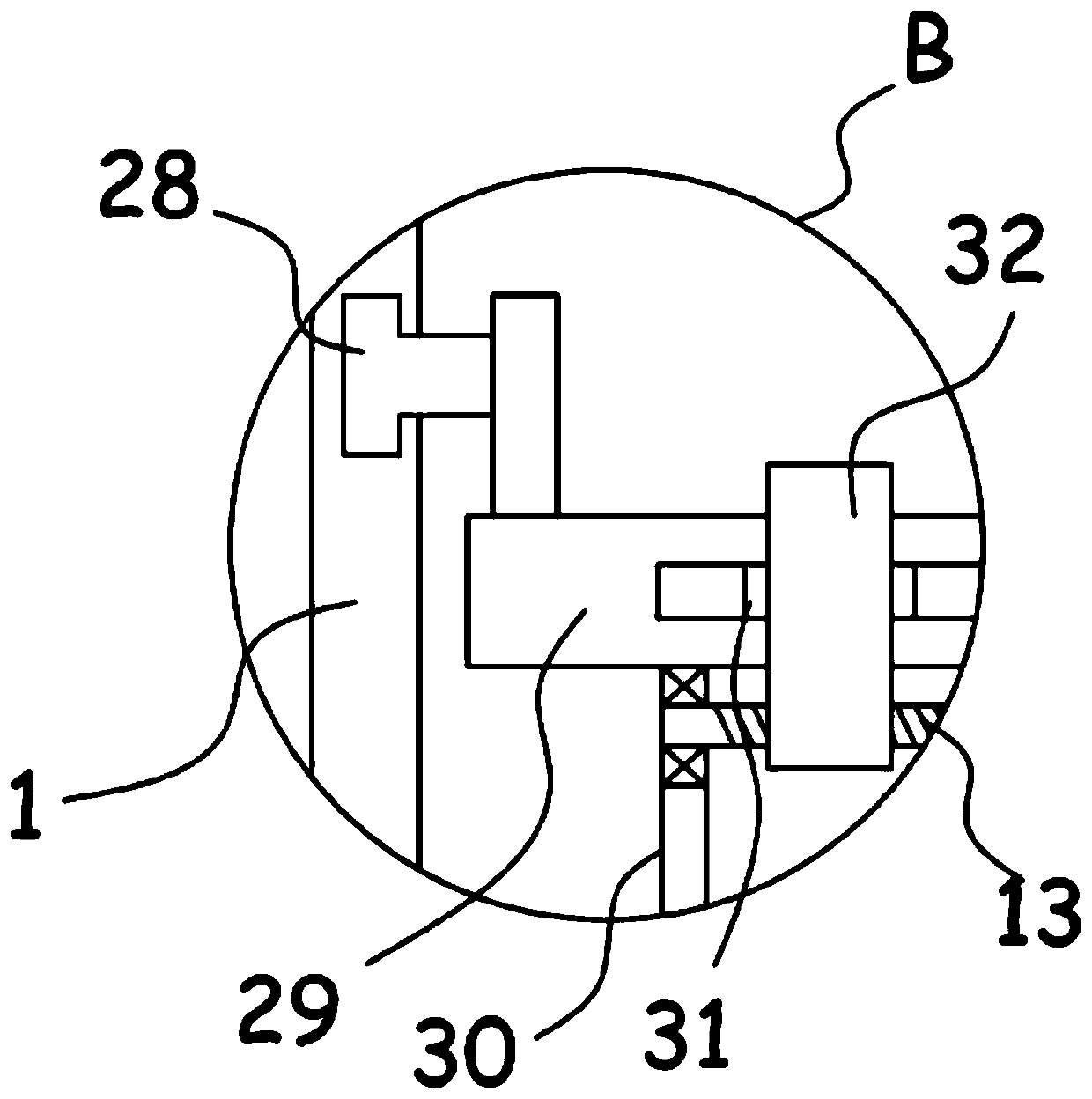

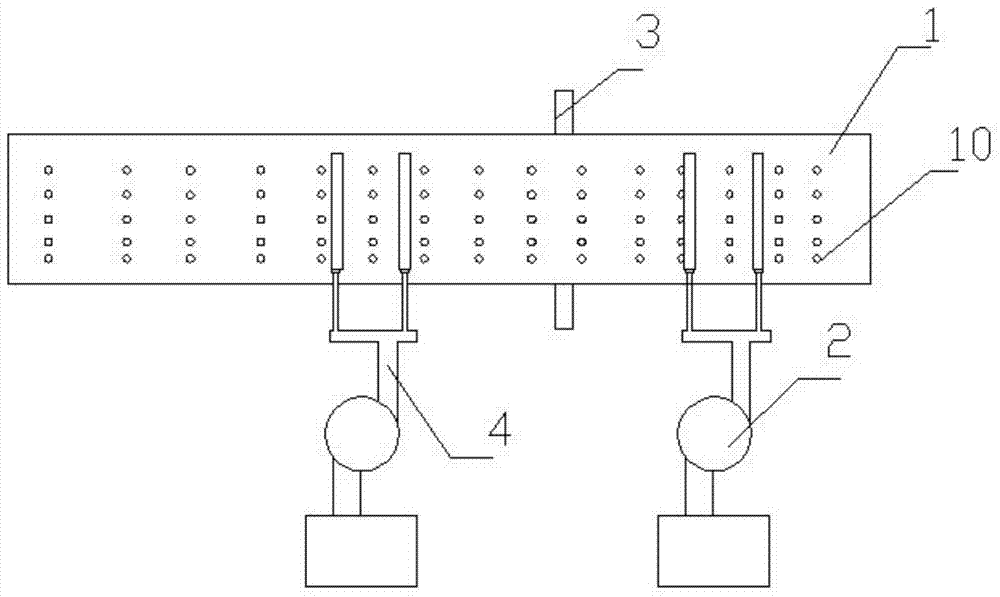

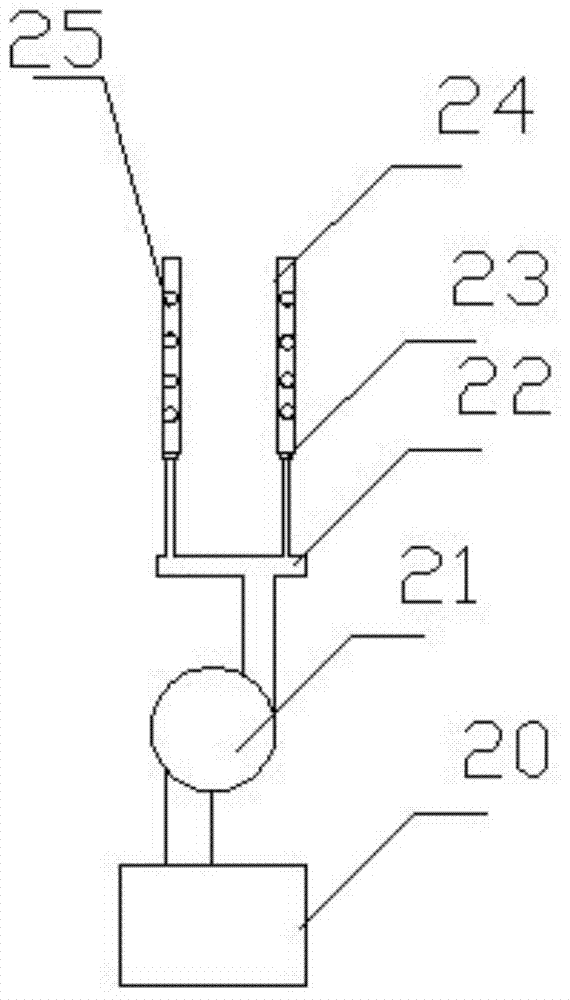

InactiveCN110976145AFully uniform and efficient painting effectFull and even paint effectSpraying apparatusReciprocating motionClassical mechanics

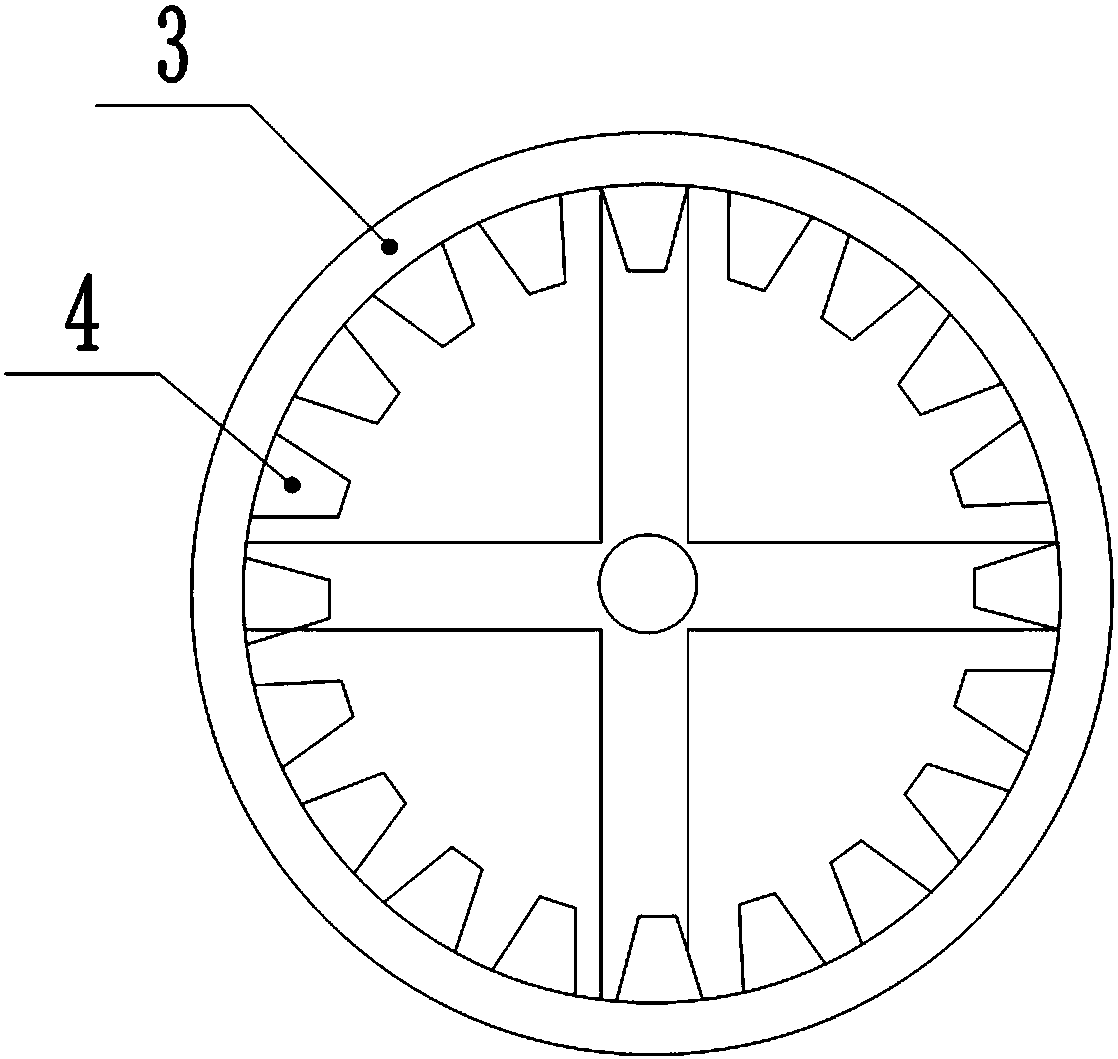

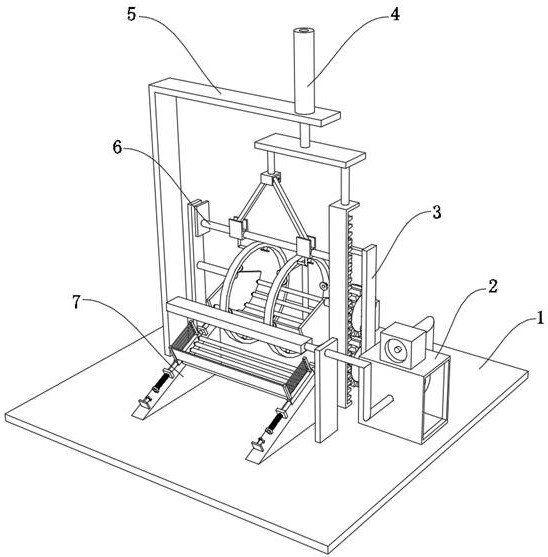

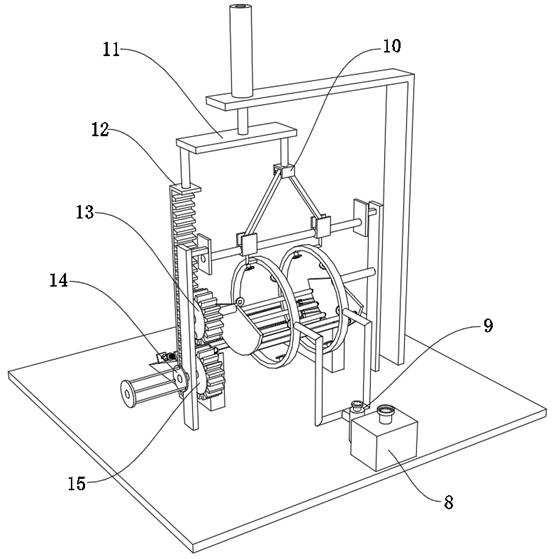

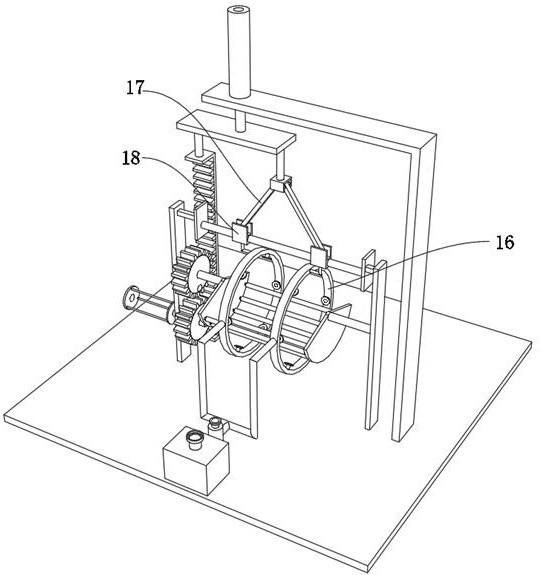

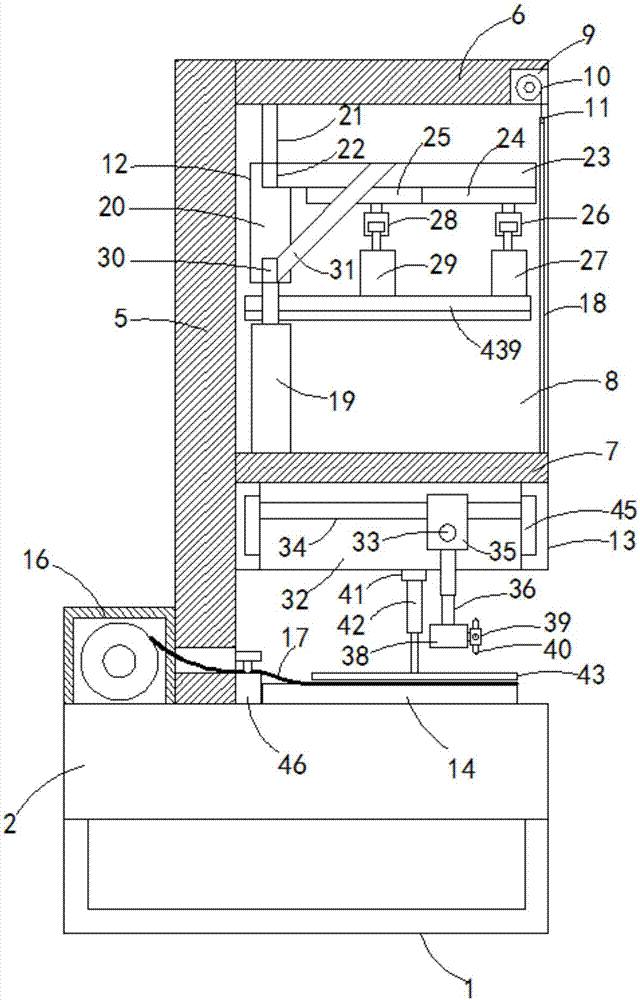

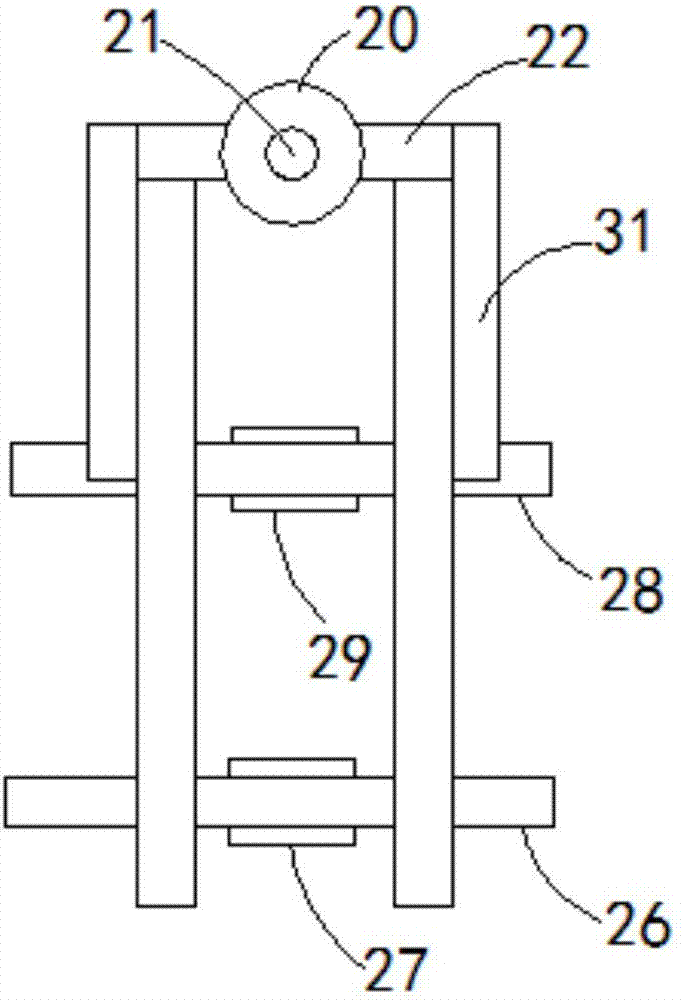

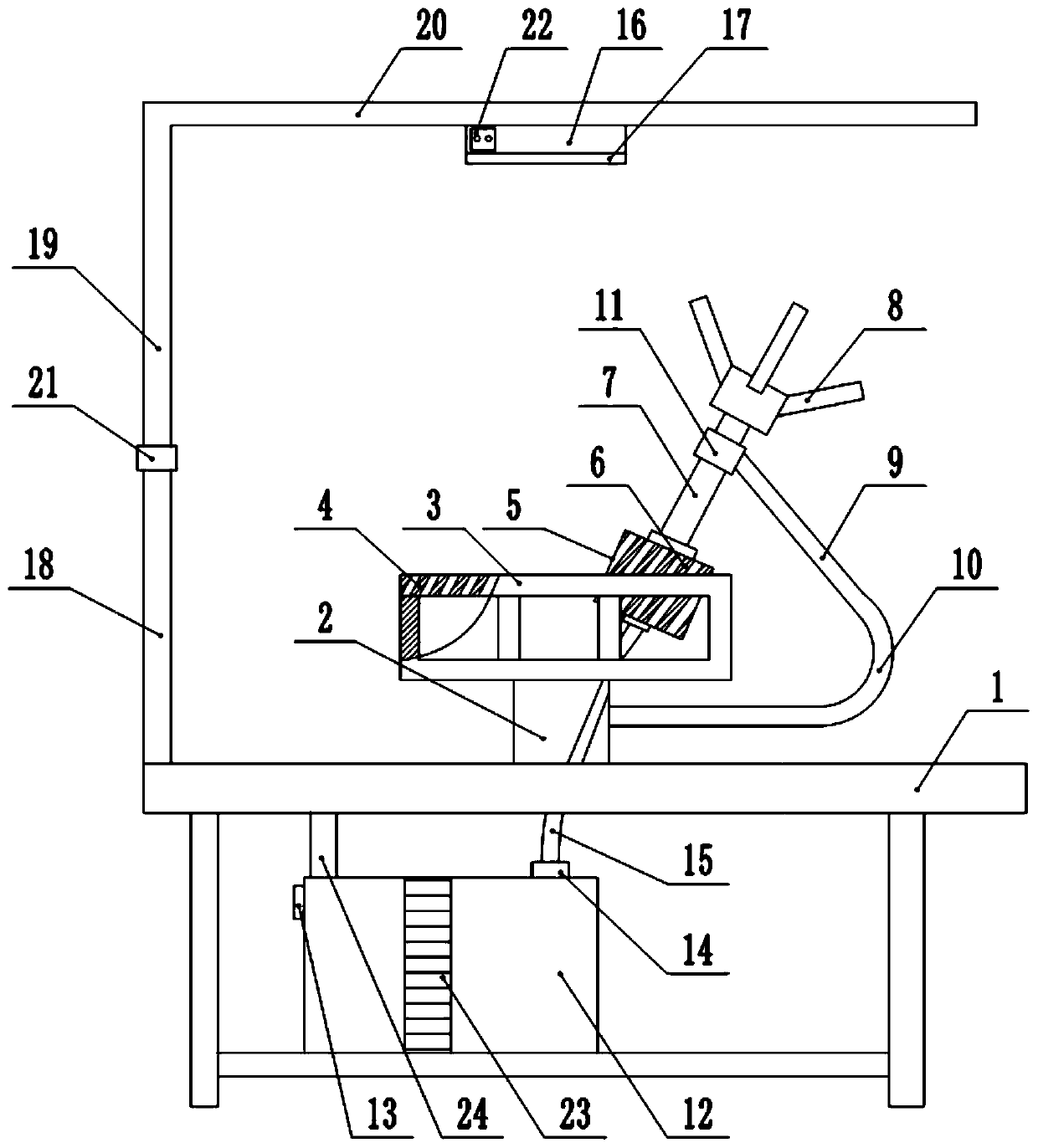

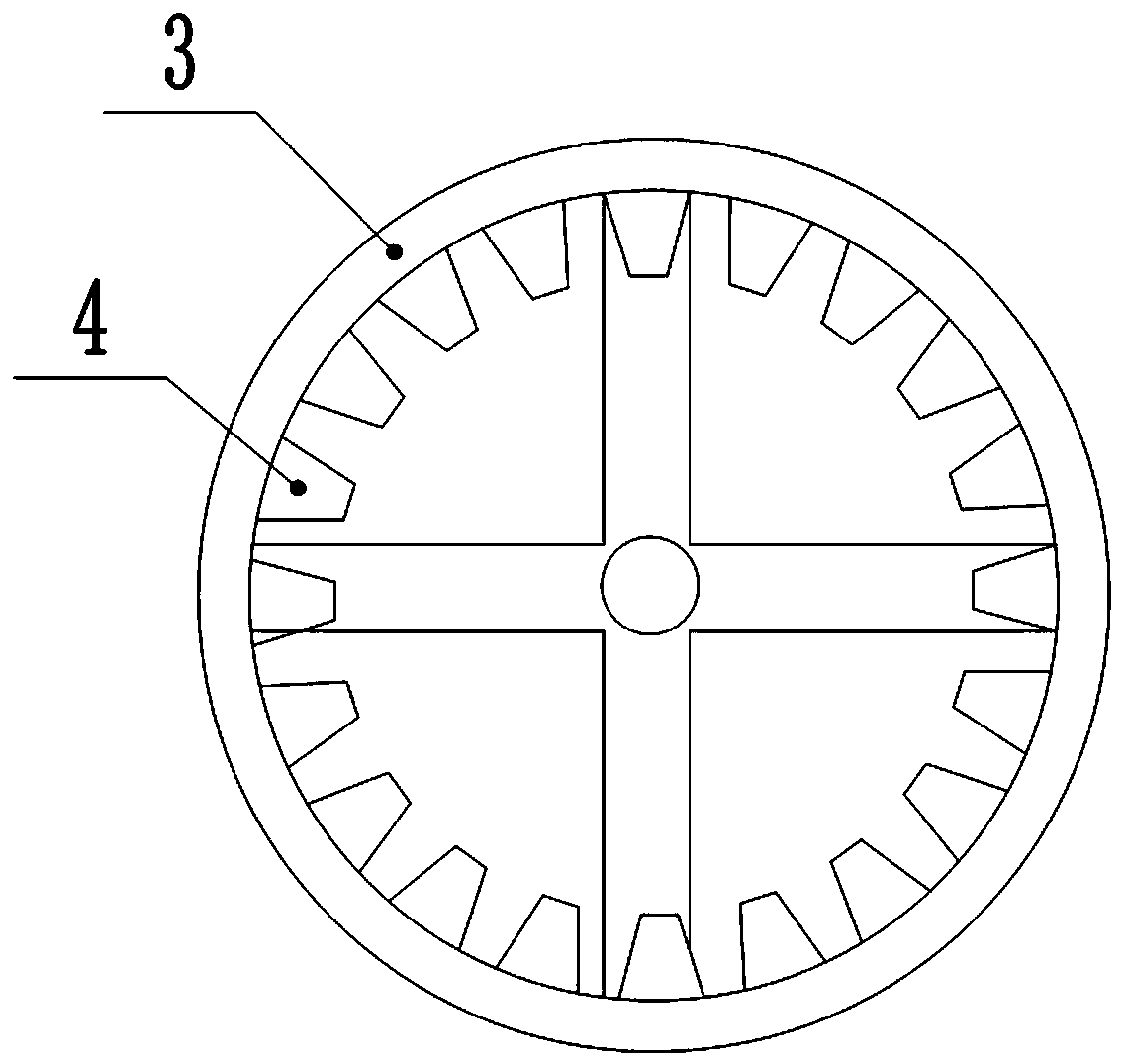

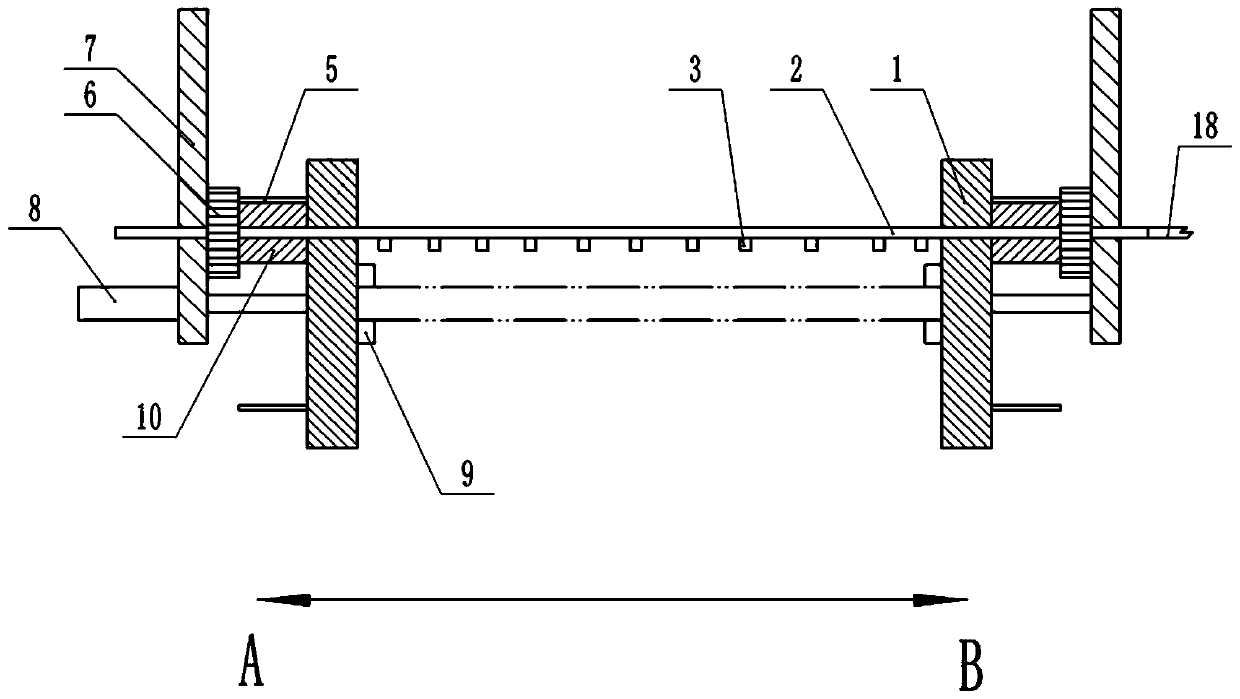

The invention discloses a paint spraying device for the surface of a machined steel plate, and relates to the technical field of paint spraying. The device comprises a fixing frame, a conveying pump and a paint box which are arranged in a communicating mode are fixed to the top of the fixing frame, a horizontally-arranged supporting frame is installed on the fixing frame in a sliding mode, a hanging bracket is rotatably installed in a threaded sleeve block, a rotary paint spraying mechanism communicating with the conveying pump is arranged on the hanging bracket, and a translation mechanism used for driving a rotating frame to transversely move is arranged on the fixing frame. Through the arranged rotary paint spraying mechanism, the paint spraying effect on the steel plate is achieved, inthe rotating process of the arranged rotating frame, an auxiliary gear is driven to be in engaged connection with an inner gear ring to achieve rotation, so that a hollow shaft II and a hollow shaftI simultaneously drive a paint spraying disc to rotate to spray paint to the surface of the steel plate; and moreover, an arranged reciprocating mechanism can drive the rotary paint spraying mechanismto do transverse reciprocating motion, and the arranged translation mechanism can flexibly adjust the position of the steel plate, so that the full, uniform and efficient paint spraying effect on thesurface of the steel plate is achieved.

Owner:武文家

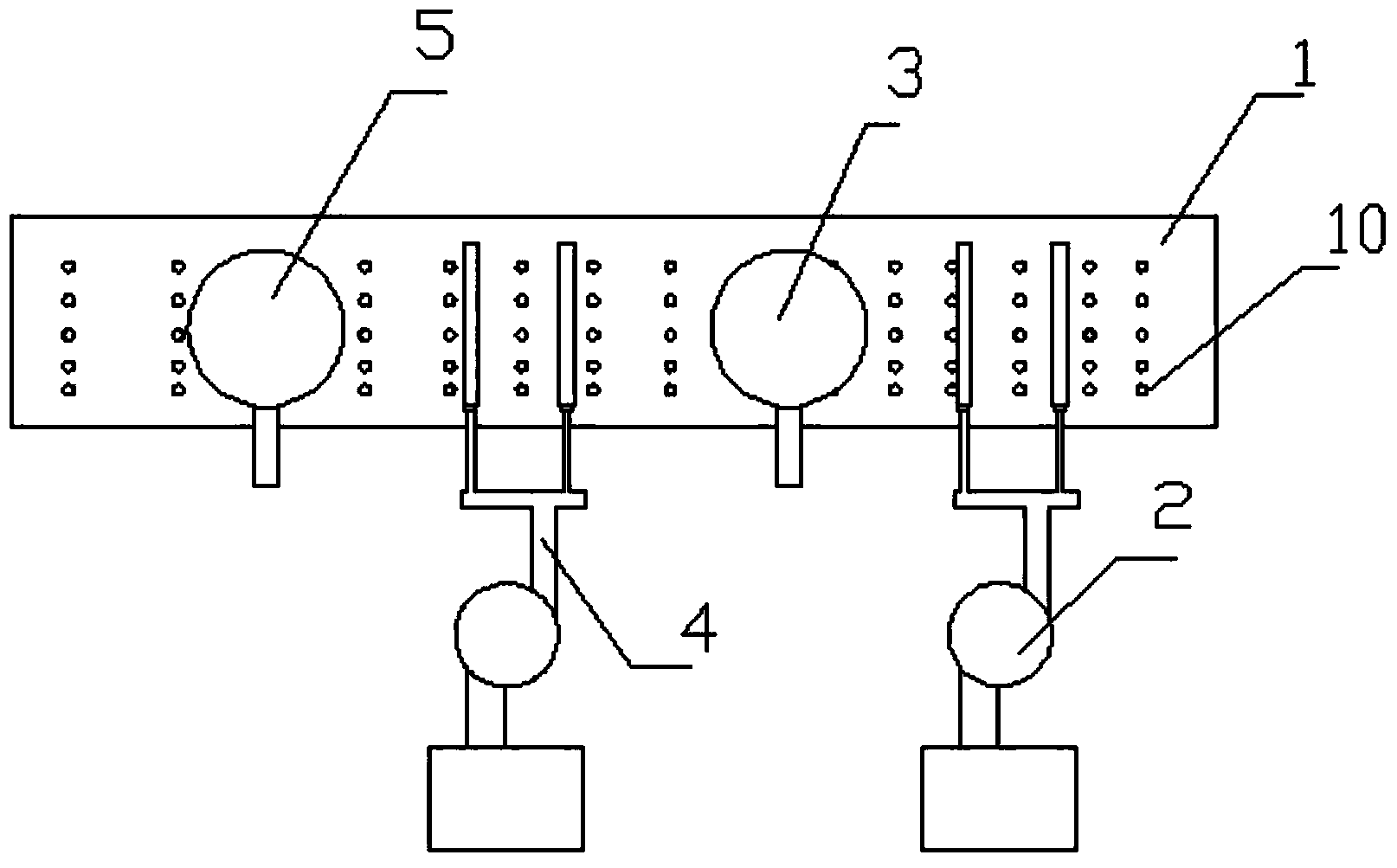

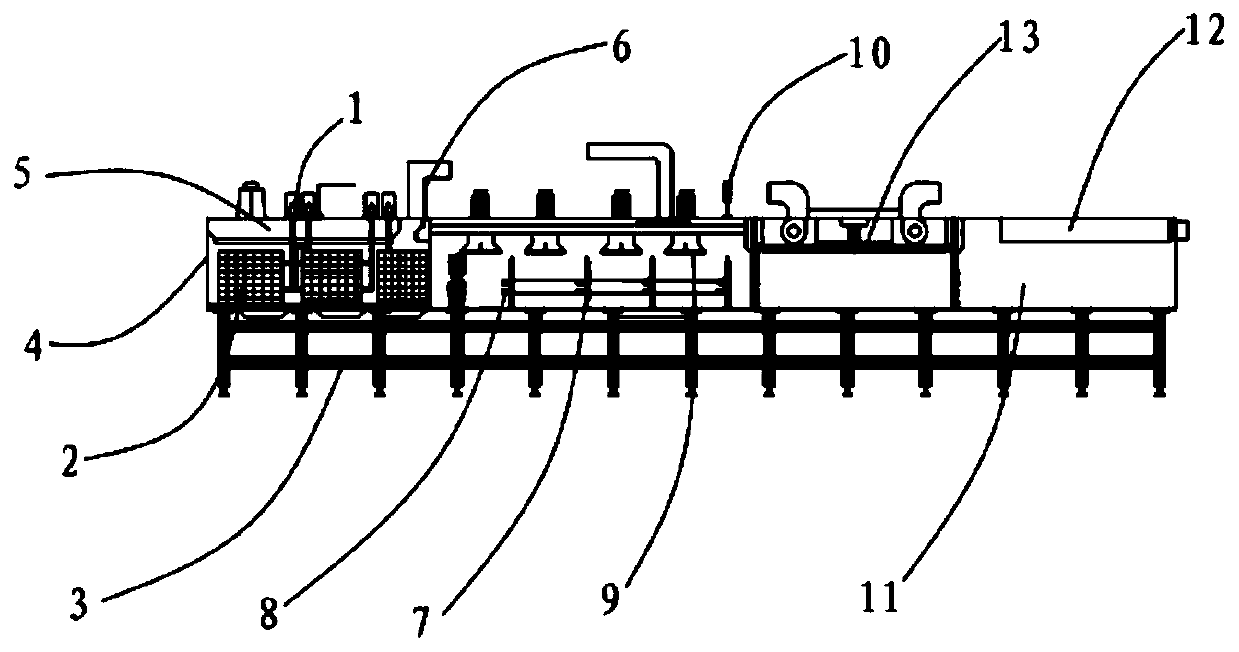

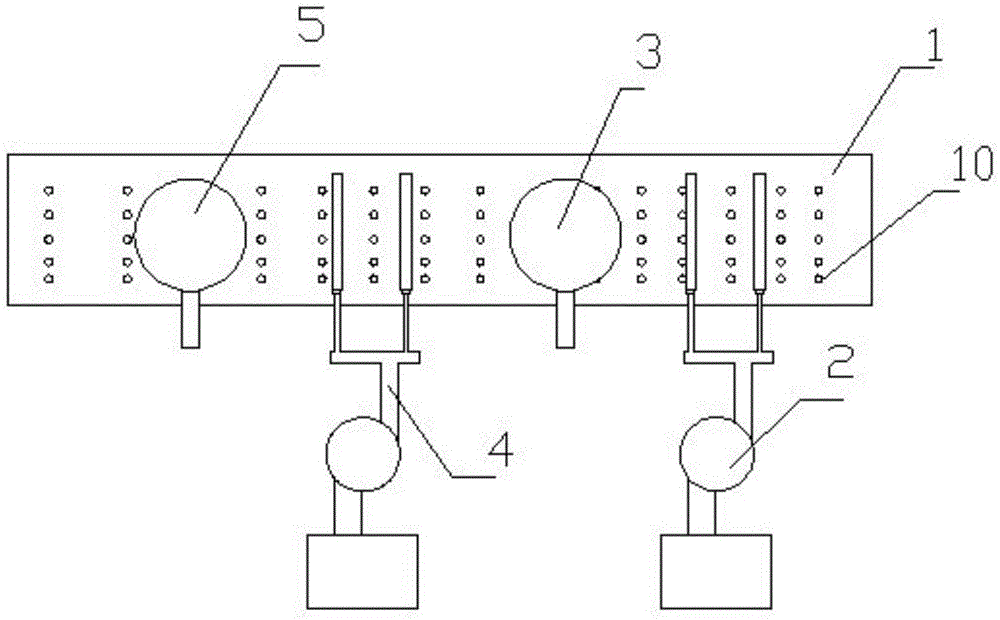

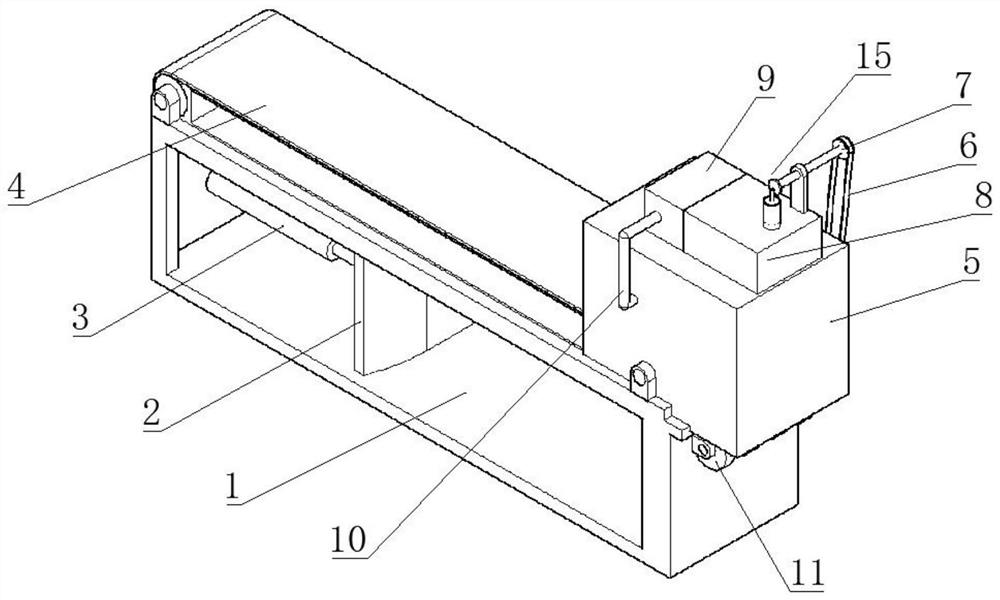

Paint spraying device for furniture

InactiveCN104117450AImprove painting efficiencyAchieve double-sided paintingSpraying apparatusEngineeringManipulator

The invention relates to a paint spraying device for furniture. The paint spraying device for furniture comprises a conveyor belt, a first paint spraying mechanism and a second paint spraying mechanism, the first paint spraying mechanism is located in front of the second paint spraying mechanism in the movement direction of the conveyor belt, and a manipulator is arranged between the first paint spraying mechanism and the second paint spraying mechanism. The paint spraying device for furniture can completely replace manpower to spray paints on the two sides of furniture, sprayed paint can evenly adhere to furniture planks, the paint spraying quality is high, and paint spraying efficiency is improved.

Owner:GUANGZHOU YIYOUMING GLASS INDAL

Paint spraying apparatus for boards used for furniture

ActiveCN104107787AQuickly solidifies and dries upAvoid affecting the painting effectLiquid surface applicatorsCoatingsLacquerEngineering

The invention relates to a paint spraying apparatus for boards used for furniture. The paint spraying apparatus comprises a conveyer belt, a washing mechanism, a first drying mechanism, a paint spraying mechanism and a second drying mechanism, wherein the washing mechanism, the first drying mechanism, the paint spraying mechanism and the second drying mechanism are arranged at one side of the conveyer belt. In terms of the moving direction of the conveyer belt, the washing mechanism is located before the first drying mechanism, the paint spraying mechanism is located behind the first drying mechanism, and the second drying mechanism is located behind the paint spraying mechanism. The paint spraying apparatus can totally replace people in paint spraying, enables sprayed paint to be uniformly adhered on the boards of furniture and has high paint spraying quality.

Owner:GUANGDONG KNOYA HOME FURNISHING CO LTD

Paint spraying device

ActiveCN108097510AWide range of applicationsLarge range of motionSpraying apparatusPretreated surfacesLacquerMagnet

The invention relates to a paint spraying device. The paint spraying device comprises a supporting table; a driving shaft is connected to the supporting table in a rotating mode; a gear ring is arranged on the driving shaft; inclined first meshing teeth are uniformly distributed in the circumferential direction of the gear ring; a paint bucket is arranged in the gear ring in a meshing mode; secondmeshing teeth matched with the first meshing teeth are arranged on the outer wall of the paint barrel; a paint inlet is formed in the bottom of the paint bucket; a paint spraying rod is connected tothe top of the paint bucket; paint spraying blades are connected to the top end of the paint spraying rod; paint spraying openings are formed in the paint spraying blades; a connecting rod is fixedlyconnected to the driving shaft and is provided with a bending part; the other end of the connecting rod is fixedly connected to the paint spraying rod; a material storage box is arranged below the supporting table; a feed port and a discharge port are formed in the material storage box; the discharge port is connected with a discharging pipe; the other end of the discharging pipe communicates withthe paint inlet; a supporting mechanism is arranged on the supporting table; a rotating shaft is arranged on the supporting mechanism; a magnet is arranged on the rotating shaft; and the rotating shaft is located above the gear ring. The paint spraying device solves the problems that a traditional paint spraying device is small in spraying range, and the operation is inconvenient when paint spraying is carried out on other parts of accessories.

Owner:南通迪亚科开关科技有限公司

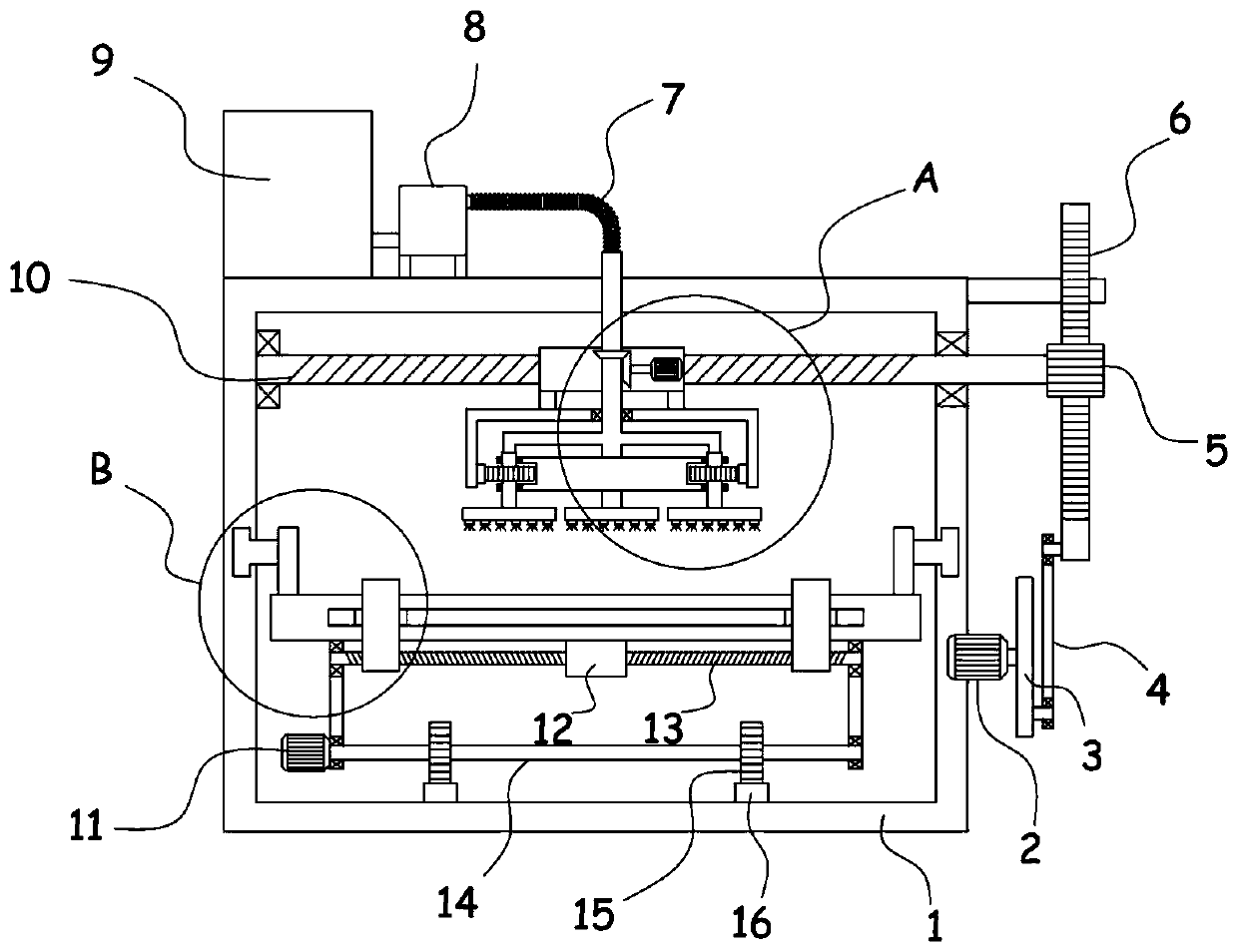

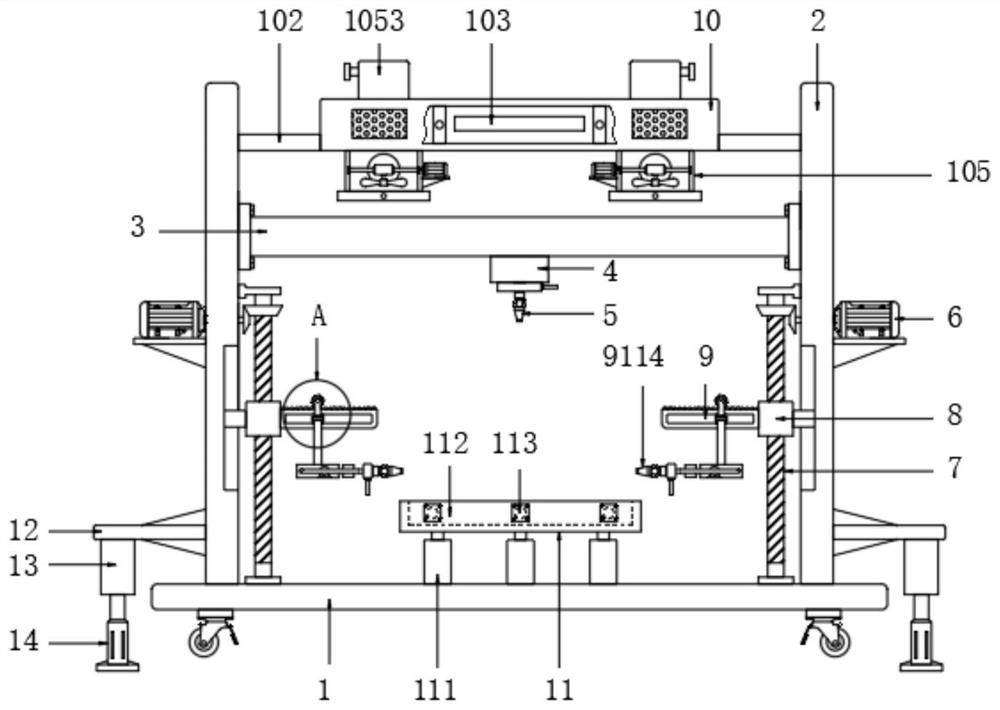

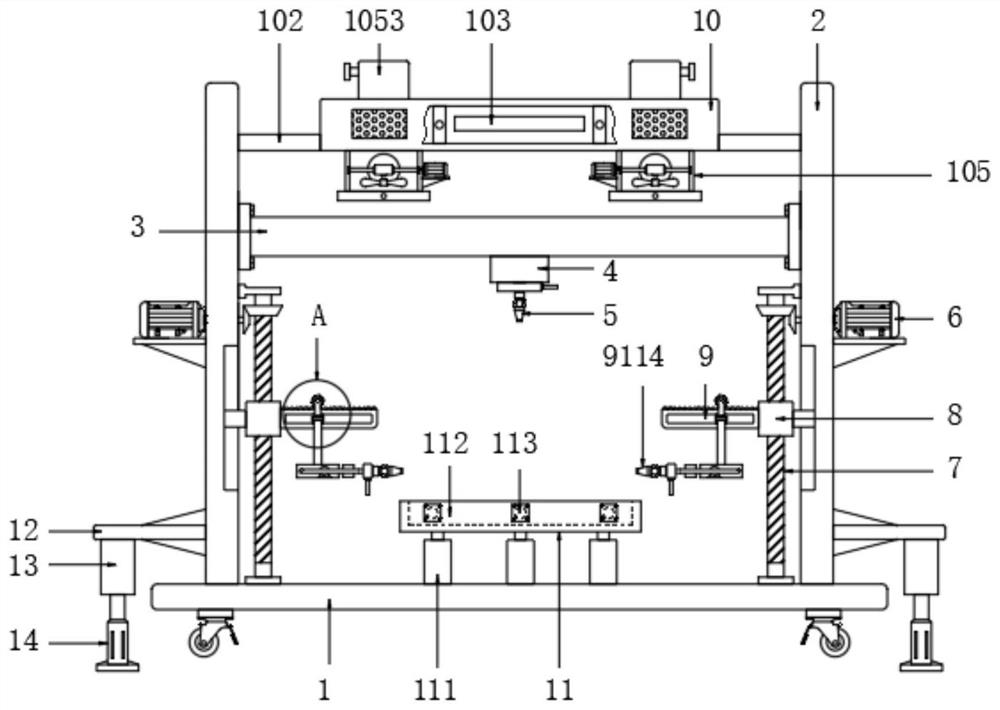

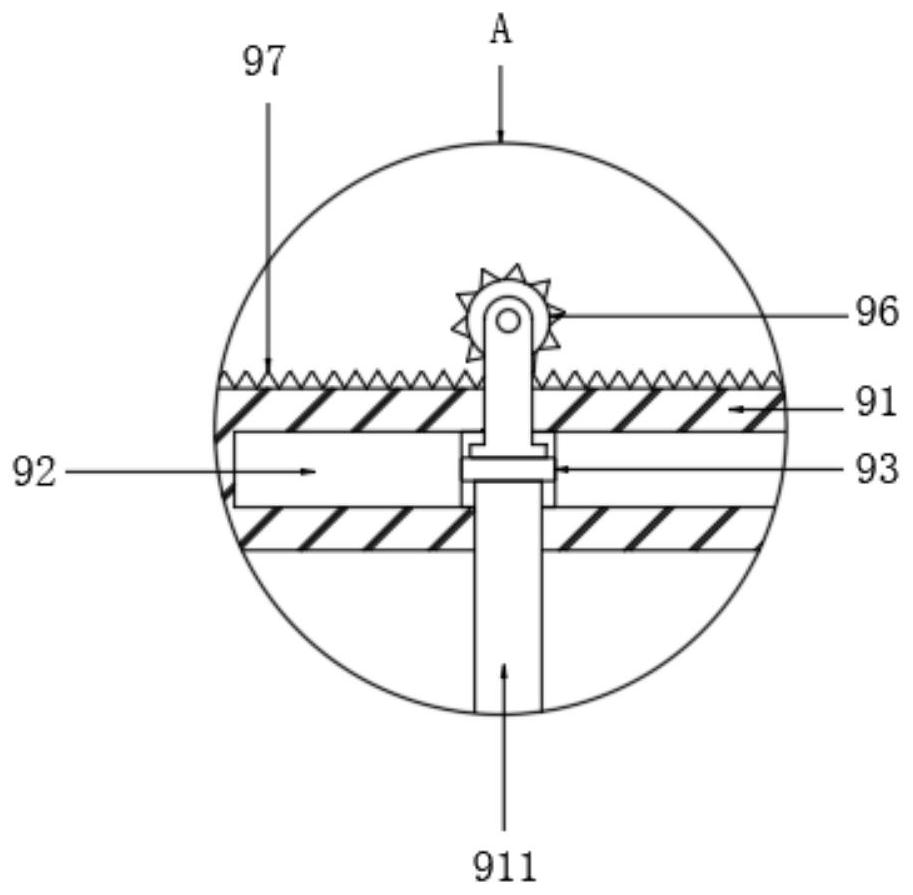

Surface treatment processing device and processing method of vehicle shell

ActiveCN111957488AExpand the scope of paintingImprove efficiency and effectivenessPretreated surfacesCoatingsDrive motorStructural engineering

The invention discloses a vehicle housing surface treatment and processing device and a processing method in the technical field of vehicle housing processing. The vehicle housing includes a base. Both sides of the top of the base are fixedly connected with vertical plates, and two sets of opposite sides of the vertical plates An electric guide rail is provided, a guide block is slidably connectedto the electric guide block, a first spray head is connected to the bottom of the guide block, and two groups of the vertical plates are fixedly connected with a driving motor on the sides away fromeach other. The driving bevel gear is connected to the power shaft through the vertical plate, and the driving bevel gear meshes with the driven bevel gear sleeved on the top of the screw rod, and therotating shaft is driven to rotate by the rotating motor, so that the fan can be aligned with the transmission tube or the fixed tube At the bottom, by changing the blowing direction of the fan, theintegrated design of purifying paint mist and air-dried paint of the device is realized, which greatly saves the production cost of the enterprise.

Owner:台州市森迪木业有限公司

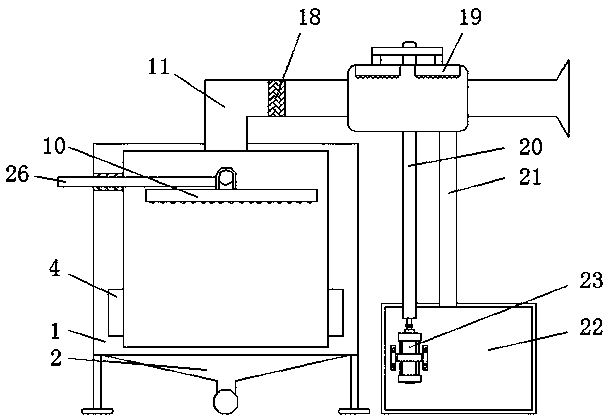

Multi-angle paint spraying device for production of wooden products

PendingCN109332068ACreate pollutionEasy to cleanLiquid spraying apparatusSpray boothsWastewaterEngineering

The invention discloses a multi-angle paint spraying device for production of wooden products. The multi-angle paint spraying device for production of the wooden products comprises a paint spraying booth and a door spindle; a discharge outlet is formed in the lower end of the paint spraying booth; a discharge pipe is arranged at the lower end of the discharge outlet; a heating pipe is inlaid at the lower end of the front side of the paint spraying booth; the lower end of the left side of the paint spraying booth is connected with a paint tank which is internally provided with a booster pump; apaint pipe is fixed to the upper end of the booster pump; a sliding track is arranged at the upper end of the interior of the paint spraying booth; a sliding block is arranged on the left side of thefront side of the sliding track; and a paint spraying valve is inlaid at the lower end of the sliding block. According to the multi-angle paint spraying device for production of the wooden products,the paint spraying booth is arranged, mesh holes are formed in the lower end of the paint spraying booth, waste paint generated in the paint spraying process can permeate through the mesh holes, wastewater can also permeate into the discharge pipe via the mesh holes when the interior is cleaned, and therefore, both the waste paint and the waste water can be discharged and treated in a unified way.

Owner:湖州南浔蚕乡原牧食品有限公司

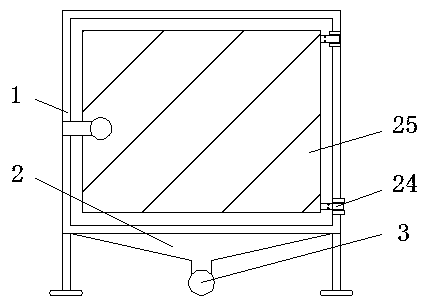

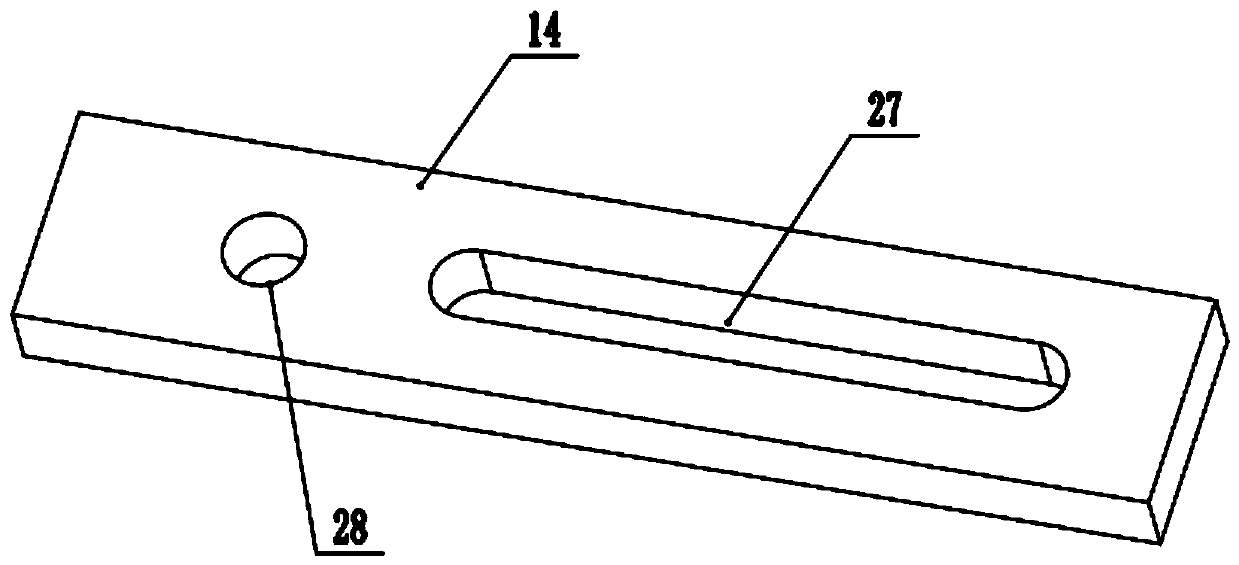

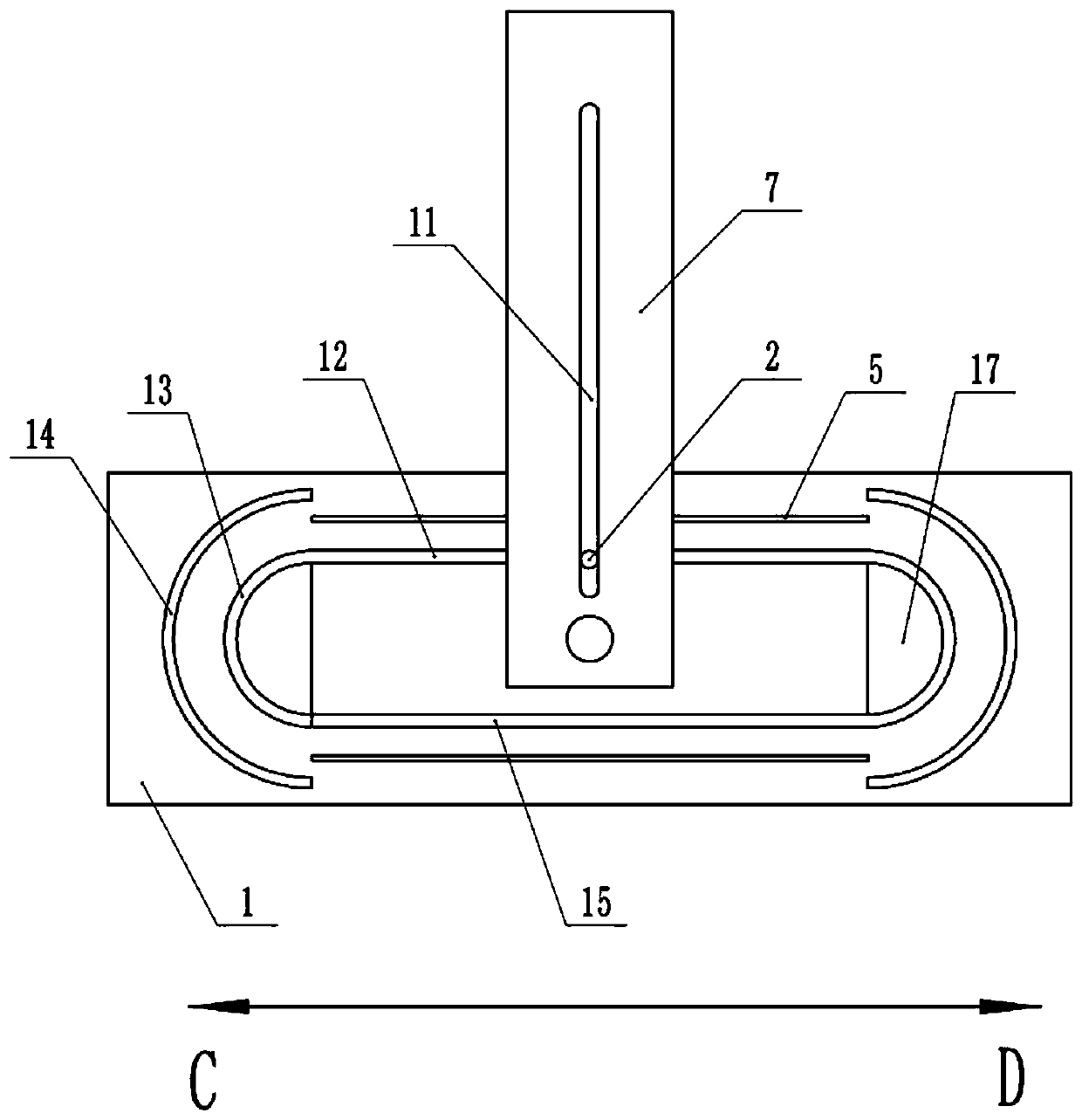

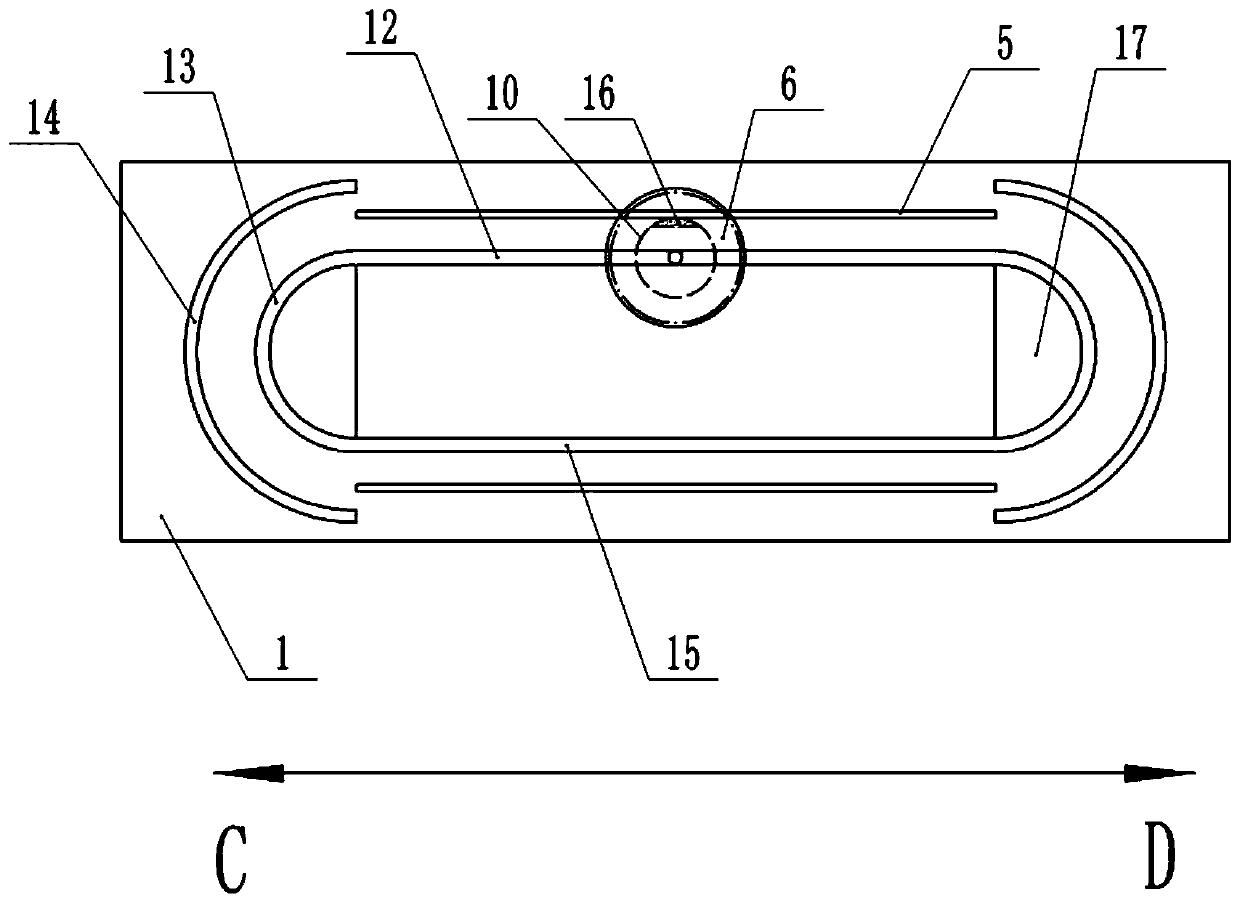

Double-sided paint spraying device for rectangular board

ActiveCN109622274AAchieve double-sided paintingHigh degree of automationSpraying apparatusEngineeringAutomation

The invention relates to the field of board paint-spraying, in particular to a double-sided paint spraying device for a rectangular board. The double-sided paint spraying device comprises a rack, wherein two clamping plates are fixedly connected on the rack; clamping parts are arranged on mutually opposite side surfaces of the two clamping plates; slide holes are formed in the two clamping plates;each slide hole comprises an upper strip-shaped hole, a lower strip-shaped hole and two arc-shaped holes, the upper strip-shaped hole is positioned above the lower strip-shaped hole, and the arc-shaped holes are connected between the end part of the lower strip-shaped hole and the end part of the lower strip-shaped hole; paint spraying tubes which are in sliding connection in slide holes are arranged between the two clamping plates; swing plates are arranged on the clamping plates; ends of the swing plates are rotatably connected onto the middle parts of the clamping plates; strip-shaped through holes are formed in the swing plates; the paint spraying tubes are in sliding connection in the strip-shaped through holes; two arc-shaped racks are arranged on the side surfaces of the two clamping plates; gears which are in intermittent engagement to the arc-shaped racks are fixedly connected on the paint spraying tubes; and a plurality of spray heads are arranged on the tube walls of the paint spraying tubes. According to the scheme adopted by the invention, the double-sided paint spraying device automatically realizes paint spraying for the two sides of the board, and improves automation degree of the paint spraying device.

Owner:宁波隆锐机械制造有限公司

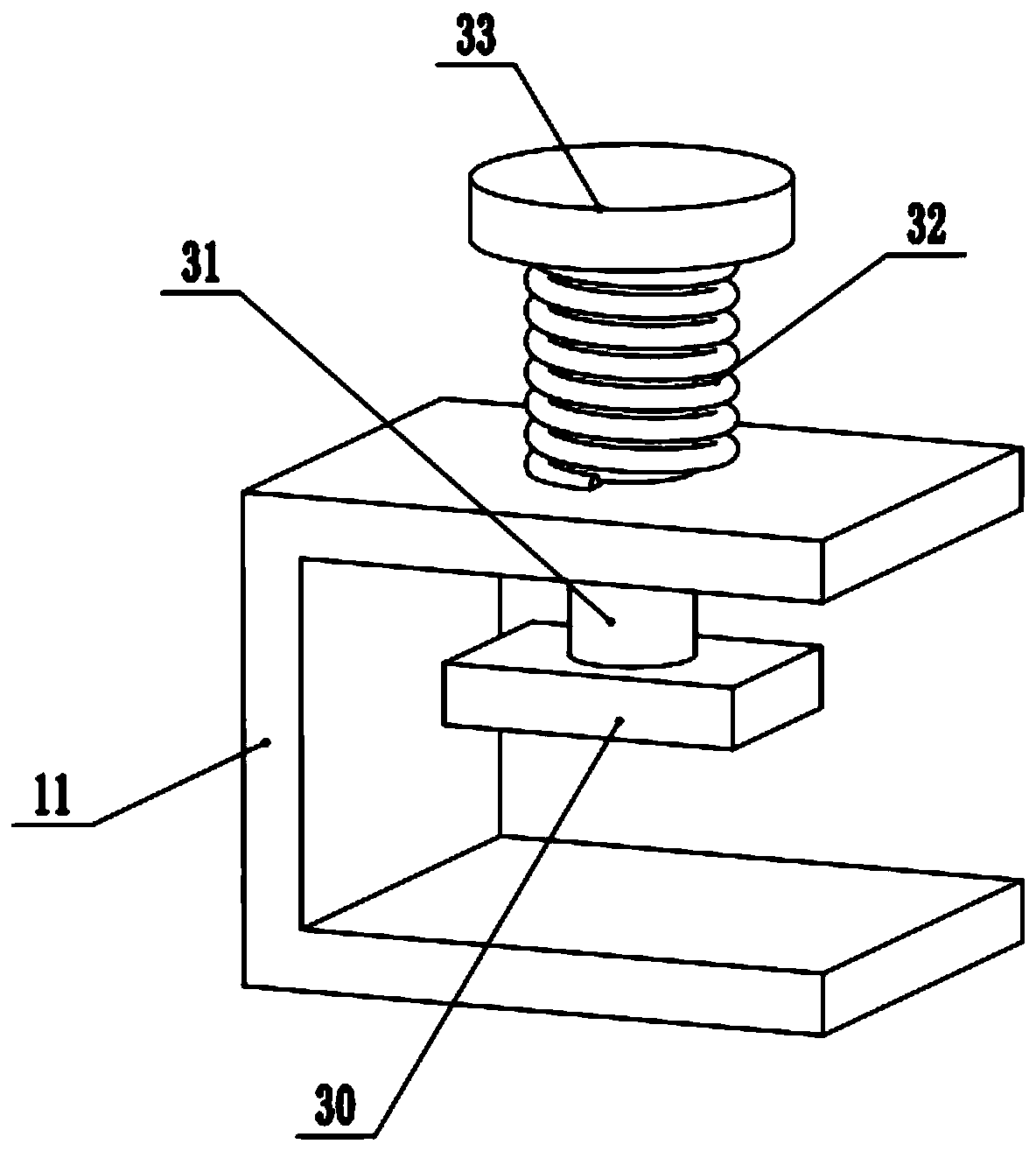

Paint spraying device for high-rise steel structure machining, and using method thereof

InactiveCN113289797AGuaranteed painting workReduce dead angleLiquid spraying apparatusSpray boothsMachiningSpray painting

The invention discloses a paint spraying device for high-rise steel structure machining, and a using method thereof, and relates to the technical field of paint spraying devices. In order to increase the paint spraying speed of a steel structure, the paint spraying device comprises a base, and an L-shaped frame is fixed to the outer wall of the top of the base by bolts; an air cylinder is fixed to the outer wall of the top of the L-shaped frame by bolts, and a pressing plate is fixed to the output end of the air cylinder by bolts; an adjusting frame is fixed to the outer wall of the bottom of the pressing plate by bolts, and two connecting rods are rotatably connected to the inner wall of the adjusting frame; and a mounting frame is fixed to the outer wall of the top of the base by bolts, and the same cross rod is fixed to the inner walls of the two sides of the mounting frame by bolts. The using method of the paint spraying device comprises the following steps that the steel structure is placed on the surfaces of two or more rotating columns I. According to the paint spraying device,through arrangement of the air cylinder, the adjusting frame can be driven to move up and down, and therefore two sliding seats are reversely slide along the circumferential outer wall of the cross rod under the adjusting action of the connecting rods.

Owner:武汉市达人联盟房地产投资发展有限公司

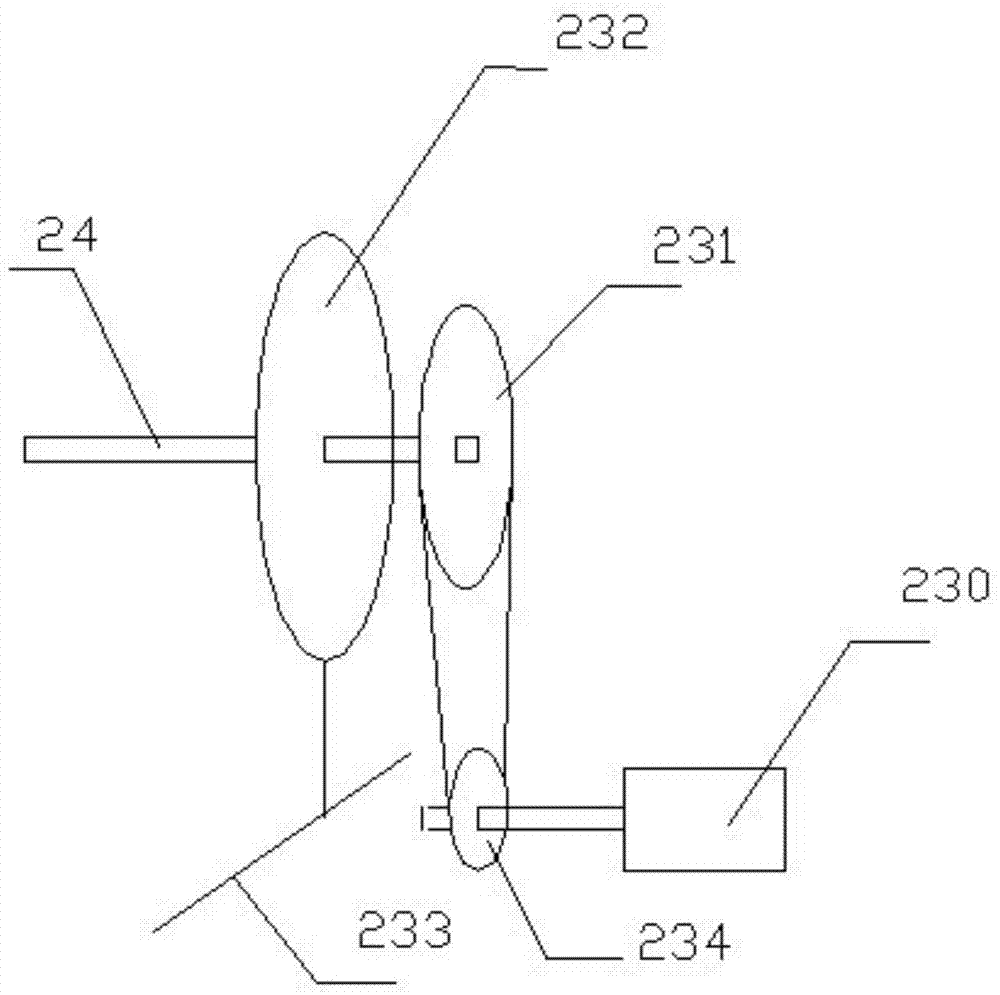

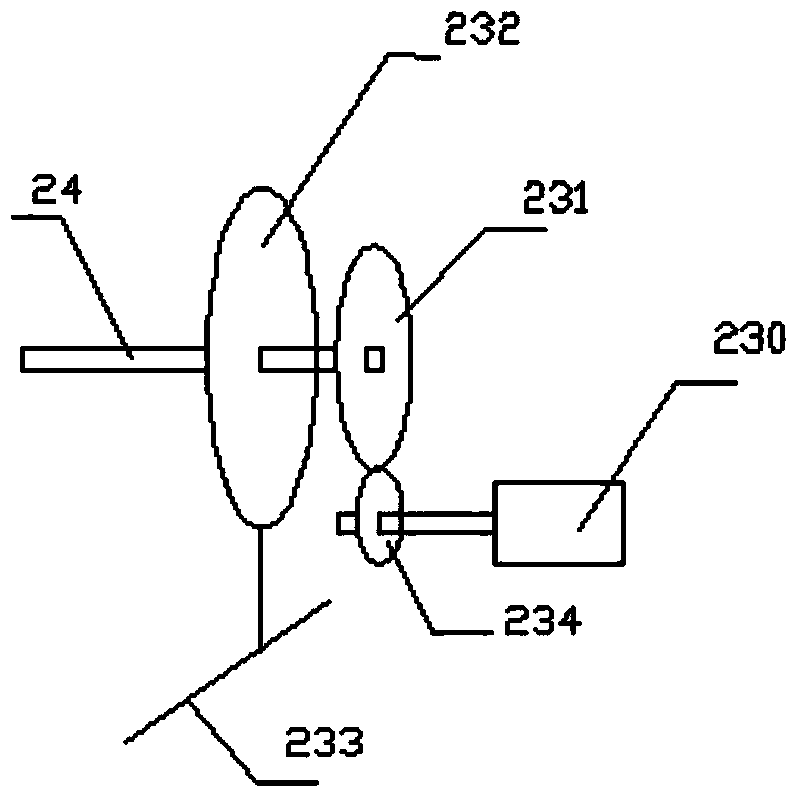

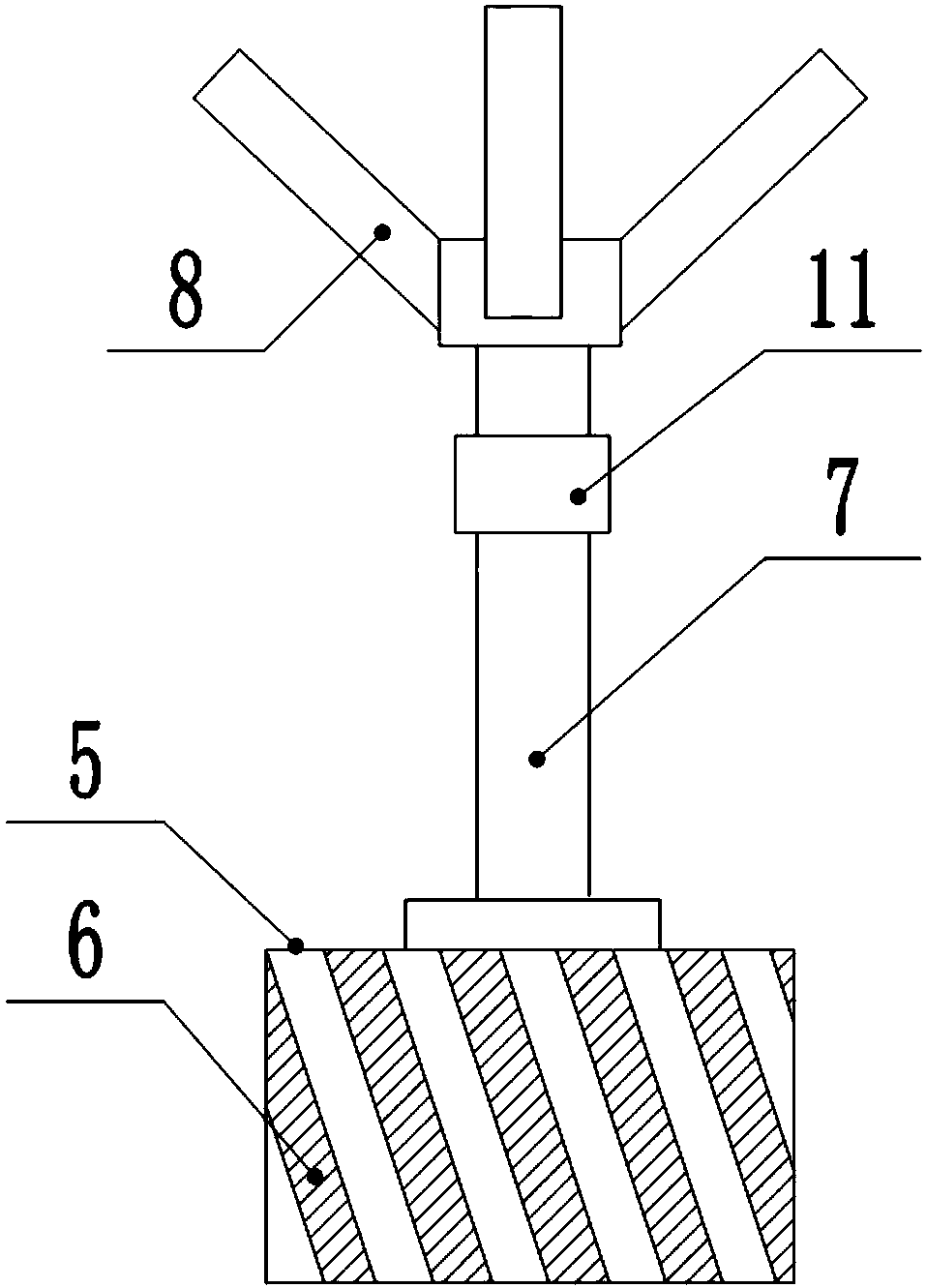

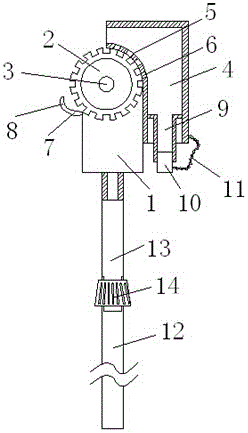

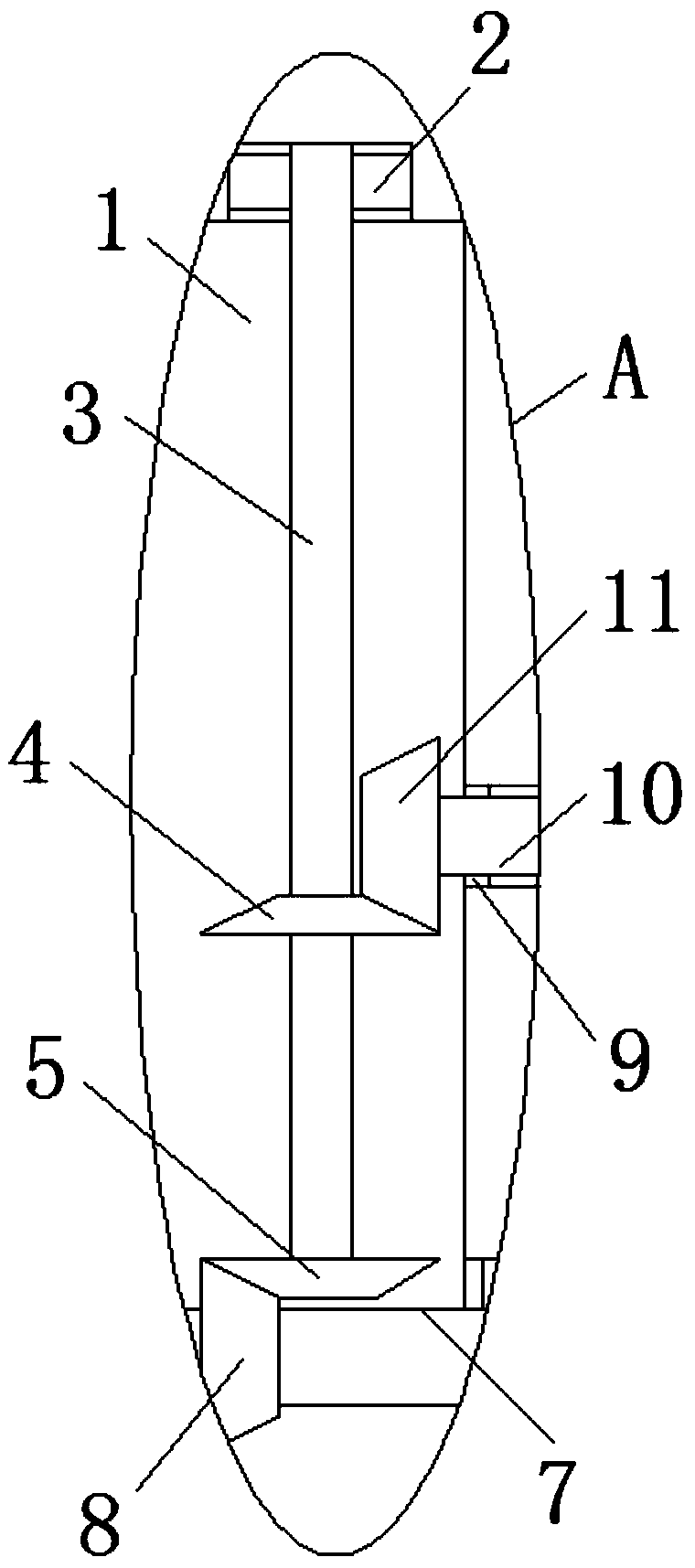

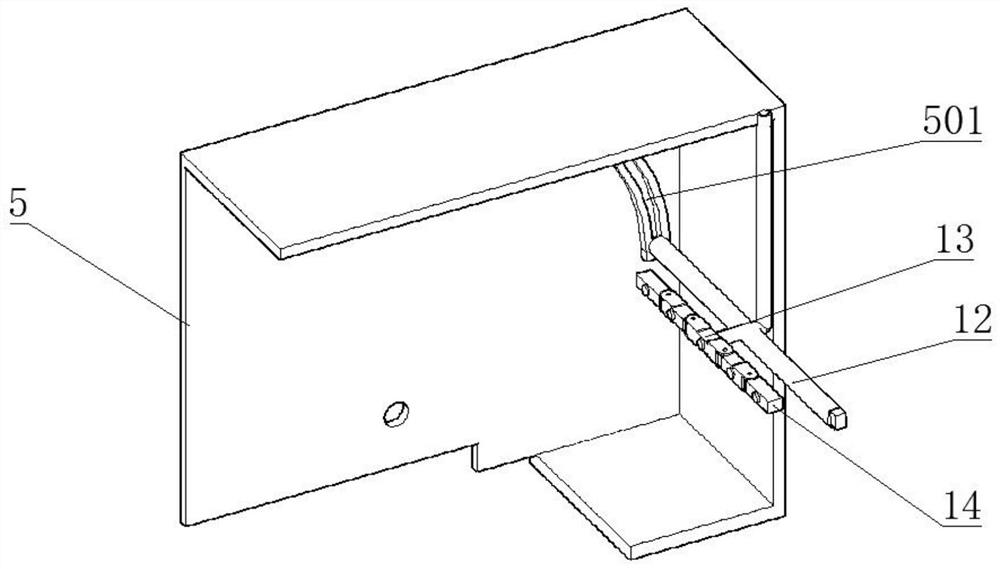

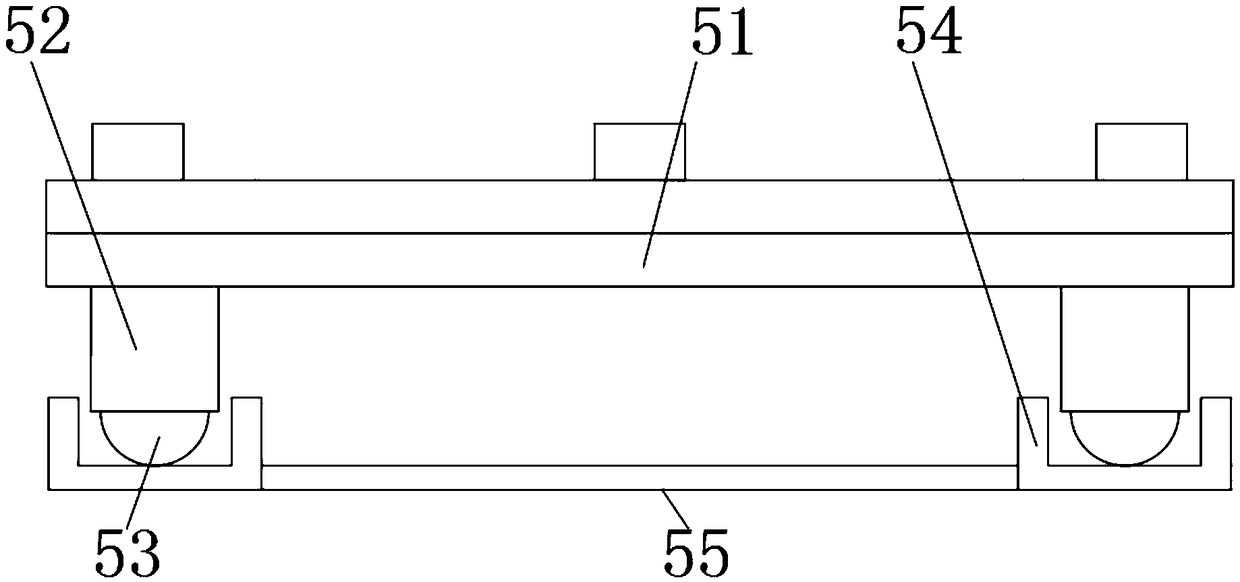

Rotation sprayer structure for paint spraying robot

InactiveCN108970871AExpand the scope of paintingEasy to placeSpraying apparatusEngineeringPaint robot

The invention provides a rotation sprayer structure for a paint spraying robot. The rotation sprayer structure comprises an L-shaped telescopic rod, a fixing pipe, a motor, a paint spraying tank, a connecting hose, a rotation rod, a sprayer, a nut base and a lead screw. The L-shaped telescopic rod is arranged on the upper end face of the fixing pipe in a sliding manner. The fixing pipe is fixed tothe upper end of the motor. The motor is fixed to the upper end face of the paint spraying tank through a flange plate. The connecting hose is connected to the lower right portion of the annular sideface of the paint spraying tank. The upper end of the connecting hose is connected to the lower end of the sprayer. The left end of the sprayer is connected with the L-shaped telescopic rod through the rotation rod. The lead screw is fixed to an output shaft on the upper side of the motor. The nut base is arranged on the annular side face of the lead screw through a ball nut pair, and the nut base is embedded in the lower end of the L-shaped telescopic rod. Through the design, the paint spraying range is enlarged. The rotation sprayer structure is convenient to use and operate, the paint spraying range is enlarged, and the lifting function is achieved.

Owner:WUHU CITY YUEZE ROBOT TECH CO LTD

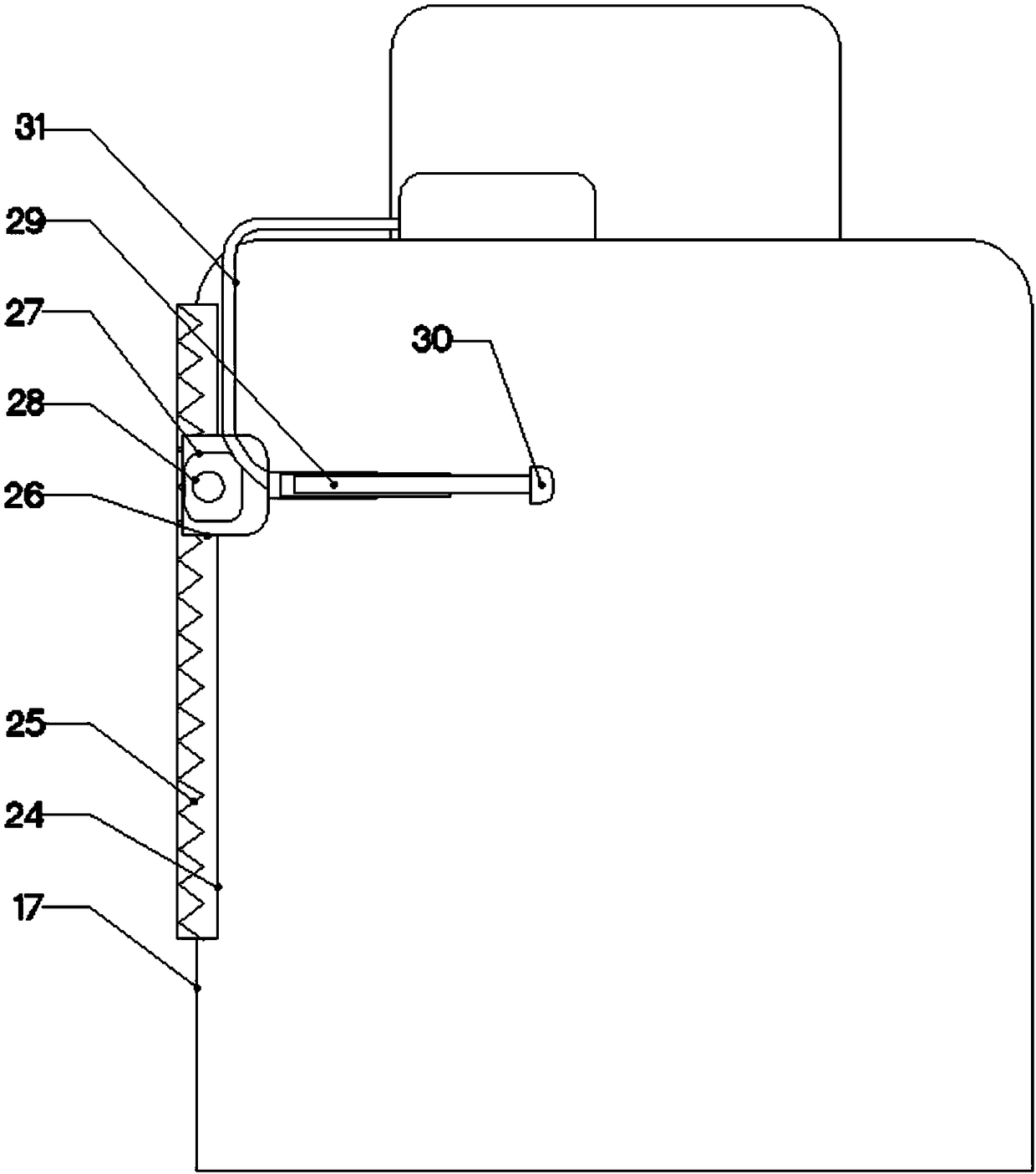

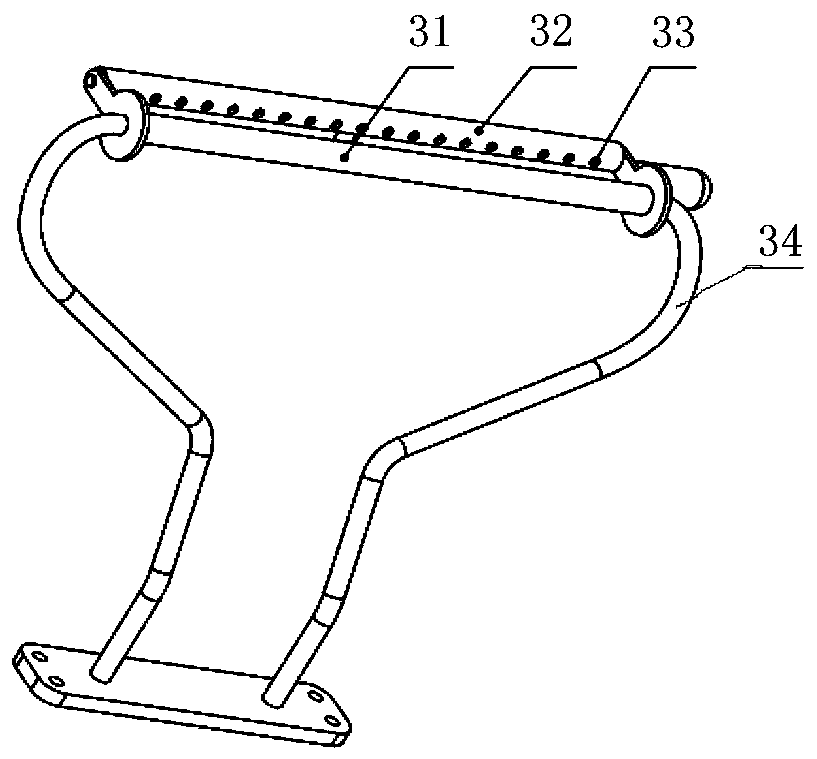

Paint brush preventing paint from falling

InactiveCN106111477AAvoid wastingAvoid getting dirtyLiquid surface applicatorsCoatingsEngineeringStorage tank

The invention relates to a paint brush preventing paint from falling. The paint brush preventing the paint from falling comprises a support body, a supporting rod and a paint brush body. The supporting rod is connected to the bottom of the support body. The paint brush body is connected to the inner side of the support body through a rotating shaft. A paint storage tank is connected to the back portion of the paint brush body. A curved face matched with the paint brush body in radian is arranged between the paint storage tank and the paint brush body and provided with paint passing holes. The outer end of the support body is provided with a paint collecting curved face layer extending to a lower arc face of the paint brush body. The front end of the paint collecting curved face layer is also connected with a capacity expanding layer. The paint brush preventing the paint from falling has the advantages that the paint collecting curved face layer is arranged outside the support body and extends to the lower portion of the paint brush body, paint dropping from the paint brush body can be collected and flow back to the paint brush body to be reutilized, paint waste is avoided, and clothes of working personnel are prevented from being dirty; and because of the capacity expanding layer arranged at the front end of the paint collecting curved face layer, the dropping paint collecting range can be further expanded.

Owner:JIANGSU WEIXU M&E CO LTD

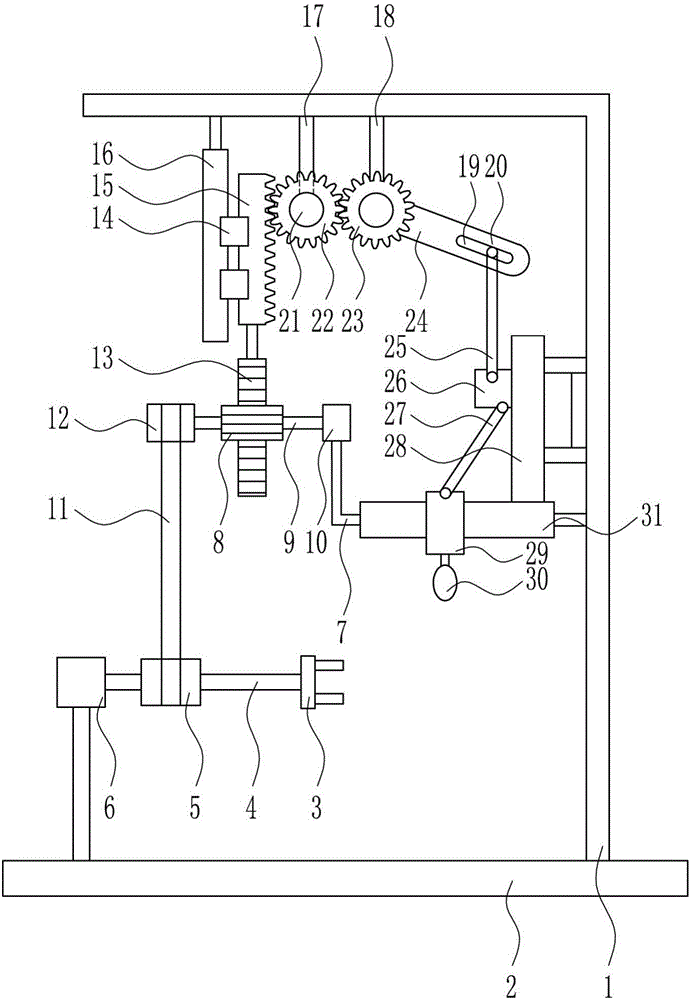

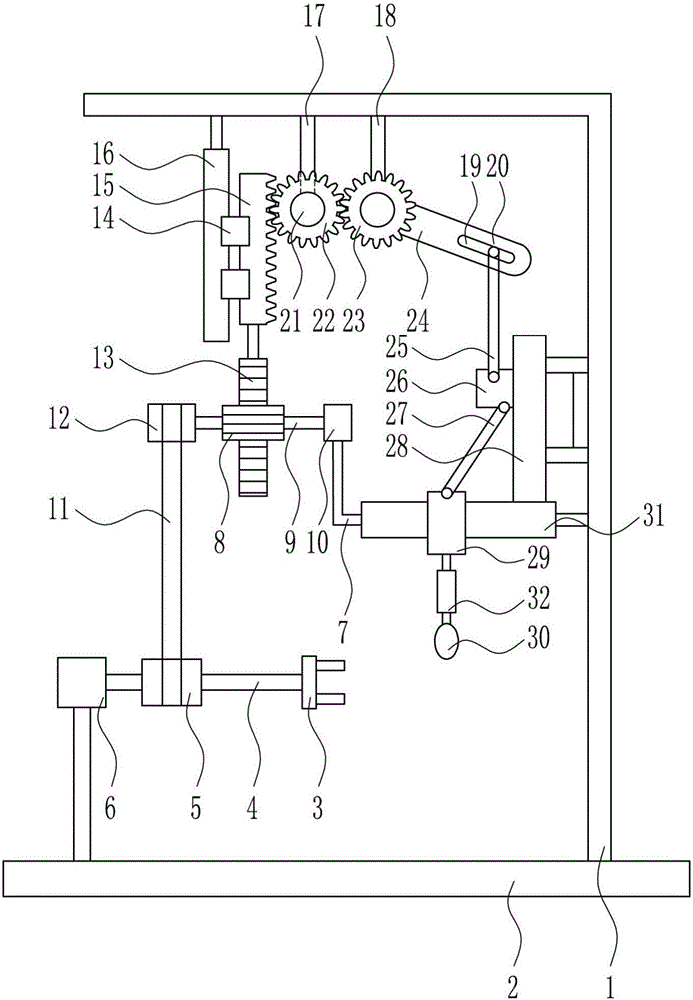

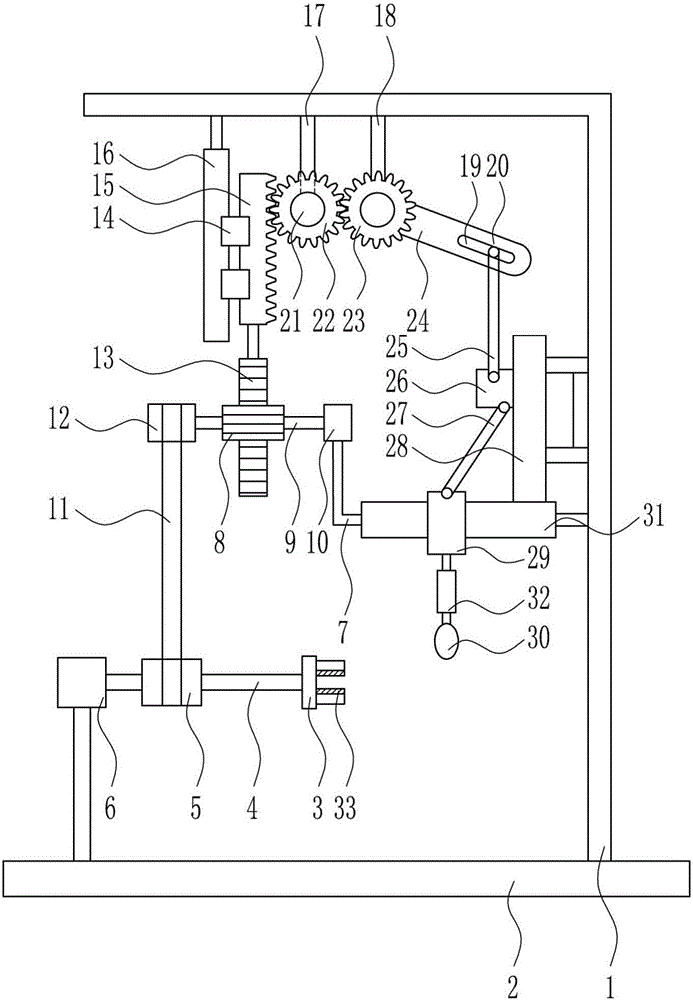

Paint spraying device for hardware mechanical part machining

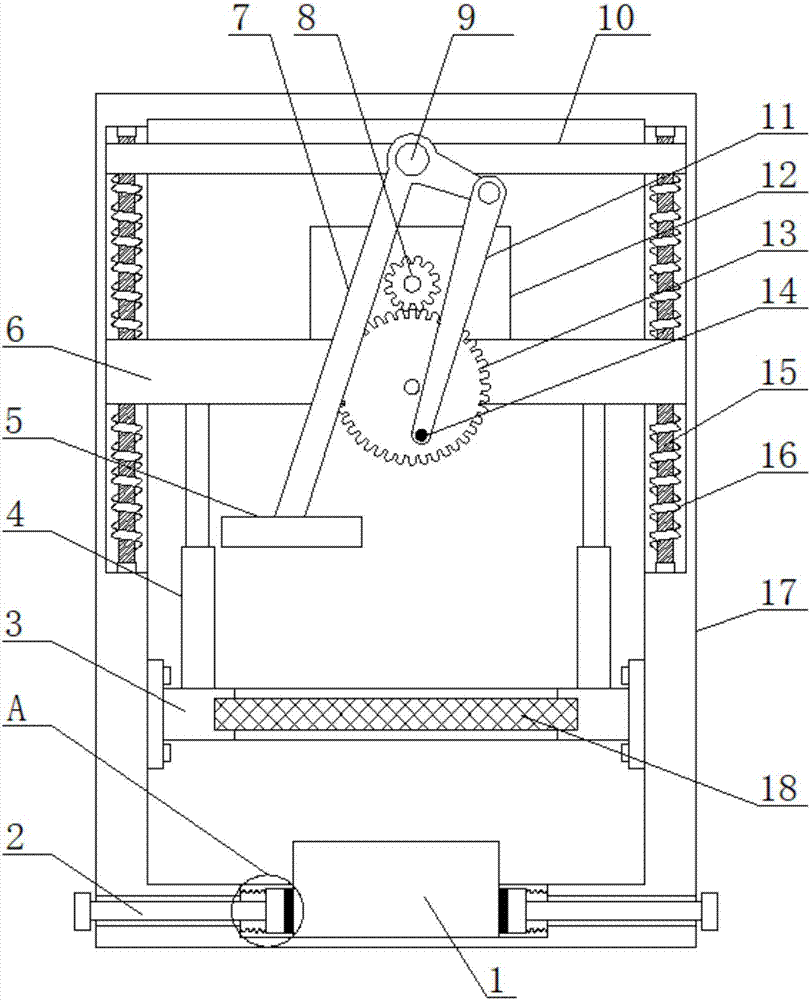

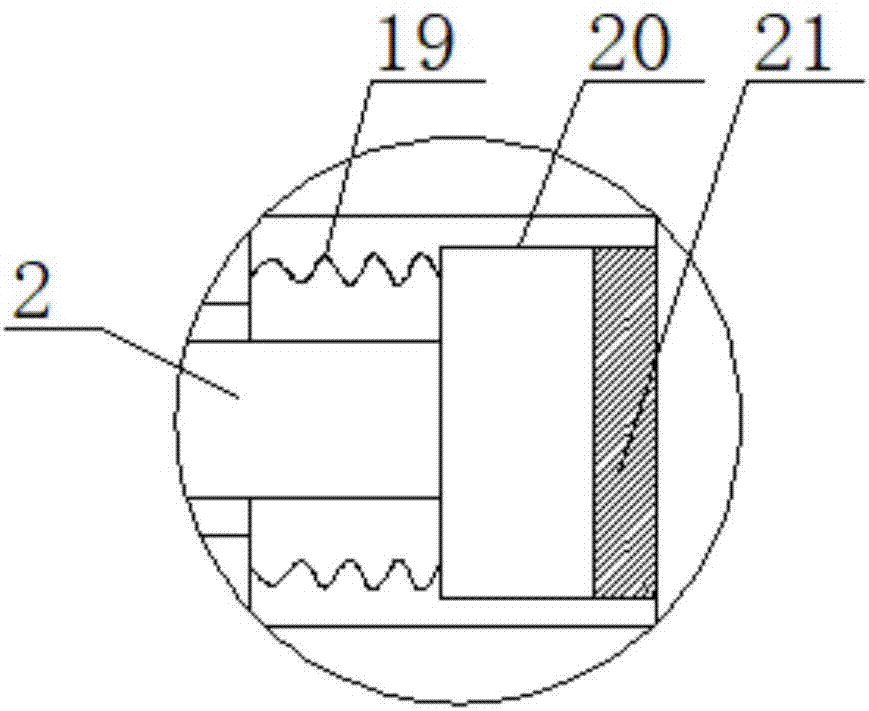

InactiveCN111111977AImprove the effect of spray paintReasonable structureSpraying apparatusRotational axisCrank

The invention relates to the technical field of hardware machining, and discloses a paint spraying device for hardware mechanical part machining. The device comprises a fixed base, supporting frames are mounted on the two sides of the upper end of the fixed base, the middle of the lower end of the supporting frame on the left side is provided with a driving shaft, the middle of the driving shaft is provided with a driving gear, the upper end of the driving gear is engaged with a driven gear, the upper end of the driven gear is provided with a rotating shaft, the middle of the upper end of therotating shaft is provided with an upper crank mechanism, the right end of the upper crank mechanism is connected with a paint guide rod, the right end of the paint guide rod is connected with a paintguide plate, the outer side of the paint guide plate is provided with a paint guide box, the middle of the lower end of the rotating shaft is provided with a lower crank mechanism, the right end of the lower crank mechanism is connected with a moving rod, the right end of the moving rod is hinged with a paint inlet box, and the middle of the paint inlet box is rotatably connected with a paint spraying shaft. The upper crank mechanism and the lower crank mechanism are matched, in the left and right moving process of the paint spraying disc, rotating paint spraying can be carried out, and the paint spraying effect on hardware mechanical parts can be increased.

Owner:裴学文

Environmentally-friendly automobile painting device

InactiveCN107511286AImprove painting efficiencyRealize the painting operationLiquid surface applicatorsSpraying apparatusEngineeringDrive motor

The invention discloses an environmentally-friendly automobile painting device. The device comprises a box body in which an empty chamber is formed, wherein sliding chutes in which sliding rods are arranged are formed in inner opposite sidewalls of the empty chamber; two ends of the sliding rods are fixedly connected to inner opposite sidewalls of the sliding chutes; a transverse rod, a moving platform and a positioning platform are sequentially arranged in the empty chamber from top to bottom; two ends of the transverse rod and the moving platform correspondingly sleeve the two sliding rods; a telescoping device is arranged between the moving platform and the positioning platform; a driving motor is arranged at the upper end of the moving platform; a gear is connected to the tail end of an output shaft of the driving motor; a turntable is rotatably connected to the outer sidewall of the moving platform; an annular rack which is engaged with the gear is arranged on the outer sidewall of the turntable; a convex rod is fixed to the side edge of the turntable. The environmentally-friendly automobile painting device is high in painting efficiency; the resource can be effectively saved; in additional, residual paint can be timely treated, so that the surrounding environment is protected.

Owner:肇庆高新区进化论科技有限公司

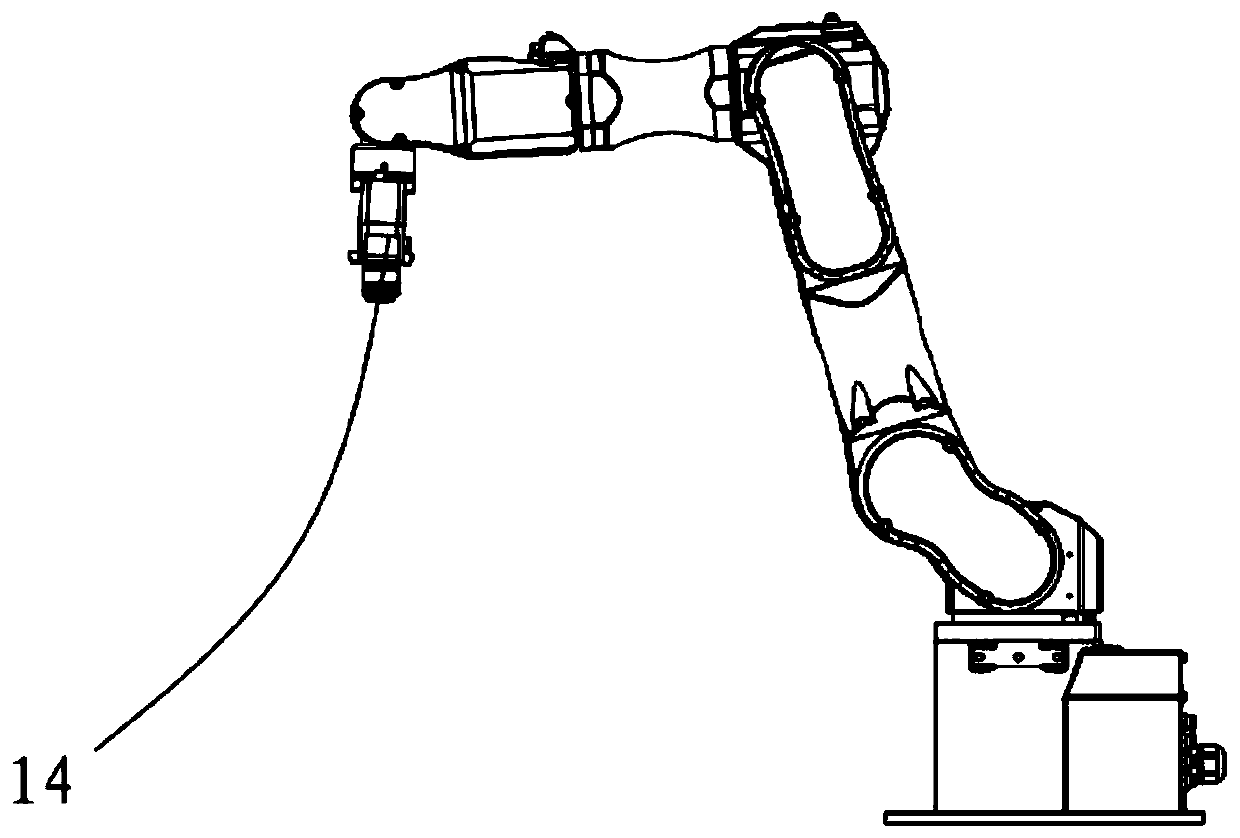

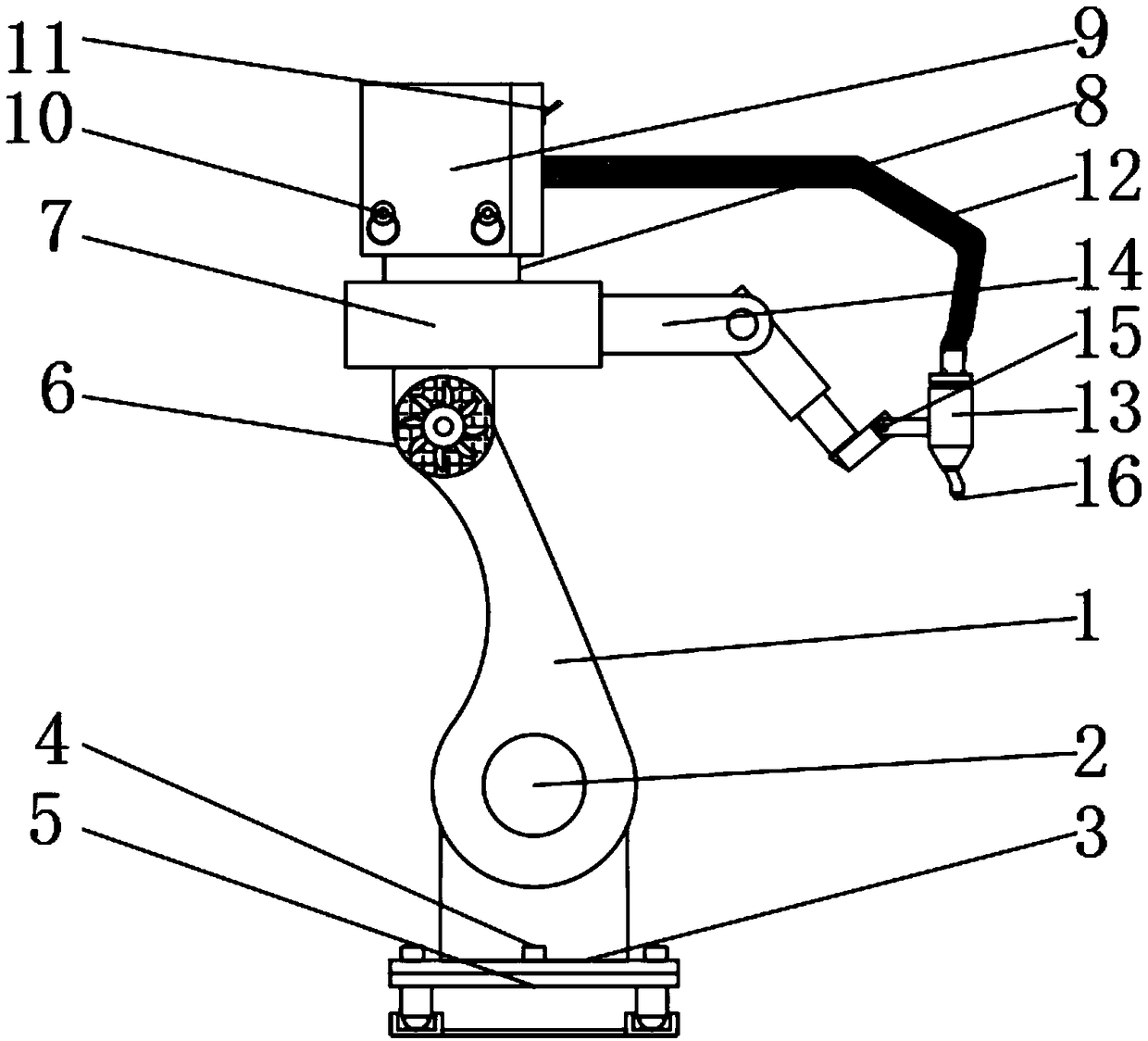

Automatic painting robot

InactiveCN107253423AExpand the scope ofExpand the scope of paintingOther artistic work equipmentsTransverse planeEngineering

The invention belongs to the technical field of robots, and particularly relates to an automatic painting robot. The automatic painting robot comprises an operation desk erected on a support frame, a control host and a monitor are arranged on the operation desk, a vertical plate is fixedly connected to the operation desk, a first transverse plate and a second transverse plate are connected to the front side of the vertical plate, the first transverse plate is located on the upper side of the second transverse plate, and side plates are connected between the left end and the right end of the first transverse plate and between the left end and the right end of the second transverse plate respectively; an image collecting mechanism is installed on the upper side of the first transverse plate, a drawing mechanism is installed on the lower side of the first transverse plate, a drawing desk is arranged on the portion, on the lower side of the drawing mechanism, of the operation desk, a paper fixing mechanism is arranged on the upper sides of the left end and the right end of the drawing desk, a paper cutter is arranged on the rear side of the drawing desk, an automatic unreeling machine is arranged on the side, far away from the paper cutter, of the vertical plate, and paper winds around an unreeling roller of the automatic unreeling machine. The automatic painting robot has the advantages that image collecting can be conducted on the spot, the drawing efficiency is high, and the application range is wide.

Owner:重庆凌慧科技有限公司

Comprehensive high-coverage-rate furniture paint spraying device

InactiveCN108480111AExpand the scope of paintingLiquid spraying apparatusSpray boothsEngineeringMechanical engineering

The invention discloses a comprehensive high-coverage-rate furniture paint spraying device. A rectangular base is included; a moving device is arranged above the rectangular base, and is composed of arectangular rack, a first driving wheel, a second driving wheel, a first rotating motor, a second rotating motor, a rectangular bearing frame, a first fixed ring, a second fixed ring, a horizontal load bearing plate, a first hoisting ring, a second hoisting ring, a first annular groove, a second rectangular groove, a first telescopic motor, a second telescopic motor and a paint spraying device body jointly; the paint spraying device body is composed of a paint spraying chamber, a first rectangular opening, a first electronic roller shutter door, a second rectangular opening, a second electronic roller shutter door, a paint storage chamber, a sucking pump, a rectangular slide groove, a first rack, a first installing box, a third rotating motor, a first gear, an electronic telescopic pipe,a paint spraying head and a connection pipe; and a controller is arranged on one side of the paint spraying chamber, and is electrically connected with the sucking pump, the electronic telescopic pipe, the third rotating motor, the second rotating motor, the first rotating motor, the second electronic roller shutter door, the first electronic roller shutter door, the first telescopic motor and thesecond telescopic motor. The comprehensive high-coverage-rate furniture paint spraying device has the beneficial effects of being simple in structure and high in practicability.

Owner:吴生红

Paint spraying device for production and processing of furniture

InactiveCN108745744ASmooth rotationExpand the scope of paintingSpray boothsMechanical engineeringEngineering

The invention discloses a paint spraying device for production and processing of furniture. The paint spraying device comprises a paint spraying box, wherein the paint spraying box is of a hollow structure; two first rotating grooves are formed in the inner wall of the top of the paint spraying box; first rotating shafts are rotatably arranged in the two first rotating grooves; first conical gearsare arranged at the outer sides of the first rotating shafts in a fixing and sleeving manner; second conical gears are arranged at the bottoms of the first rotating shafts in a fixing and sleeving manner; second rotating grooves are formed in the inner walls of the two sides of the paint spraying box; rotating columns are rotatably arranged in the two second rotating grooves; and third conical gears are arranged at the outer sides of the rotating columns in a fixing and sleeving manner. The paint spraying device is simple in structure and convenient to operate; the body of the paint sprayingdevice can be rotated rapidly and conveniently and meanwhile can be adjusted angularly, so that the body of the paint spraying device has a relatively large paint spraying range on a door, the limitations of the body of the paint spraying device are reduced, and the working efficiency is improved; and the paint spraying device protects workers and reduces the influence on the health of paint spraying workers.

Owner:安吉木博家居有限公司

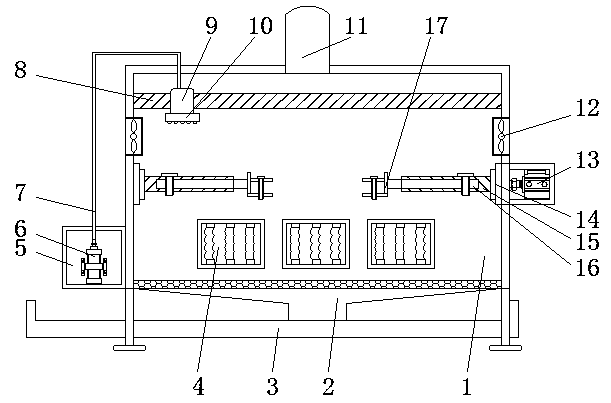

Intelligent paint spraying and coating production line

InactiveCN111185333ARealize painting workExpand the scope of paintingPretreated surfacesElectrostatic cleaningDust controlCooling chamber

The invention provides an intelligent paint spraying and coating production line which comprises a rack, supporting foot cups arranged below the rack, a dust removing chamber arranged on the rack, a paint spraying chamber arranged at an outlet of the dust removing chamber, a drying and solidifying chamber connected with the paint spraying chamber, a cooling chamber used for cooling and a conveyingcrawler used for conveying workpieces to be machined. Original dust removing, paint spraying, drying and cooling work procedures are combined, meanwhile, the spraying effect of paint spraying equipment is optimized, electronic detection is utilized, safety and explosion prevention are paid attention to, the intelligent automation is better compared with a traditional production line, and the safety performance is better.

Owner:江苏剑桥涂装工程股份有限公司

Hammer rust-prevention treatment device for hardware manufacturing

The invention relates to a rust-prevention treatment device, in particular to a hammer rust-prevention treatment device for hardware manufacturing. In order to solve the technical problems, the invention provides the hammer rust-prevention treatment device for hardware manufacturing. The hammer rust-prevention treatment device for hardware manufacturing comprises a bracket, a bottom plate, a thumb air cylinder, a second rotary shaft, a big belt pulley, a second bearing base, an L-shaped connecting rod, a second gear, a first rotary shaft, a first bearing base, a flat belt, a small belt wheel, a second rack, a third slide block, a first rack, a third slide rail, a first supporting rod, a second supporting rod, a slide shaft, a rotary motor and the like; and the second bearing base and the bracket are arranged on the top of the bottom plate. According to the hammer rust-prevention treatment device, the rotary motor rotates to drive a paint sprayer to move rightwards or leftwards to drive the thumb air cylinder to rotate anticlockwise or clockwise, so that uniform paint spraying is carried out on the surface of the hammer, and obvious rust-prevention effect is achieved.

Owner:NANTONG GAOXIN ANTIWEAR MATERIALS TECH CO LTD

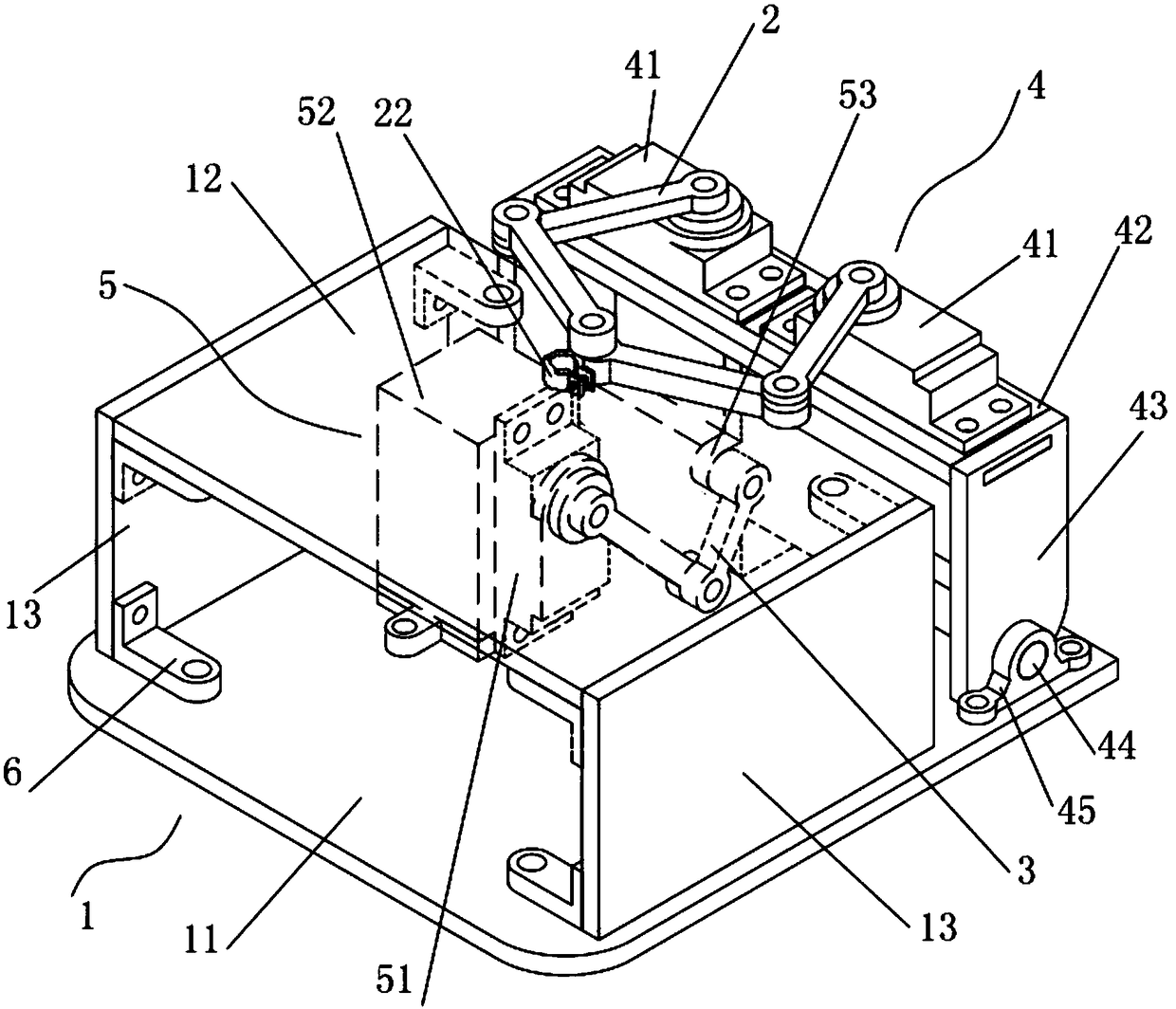

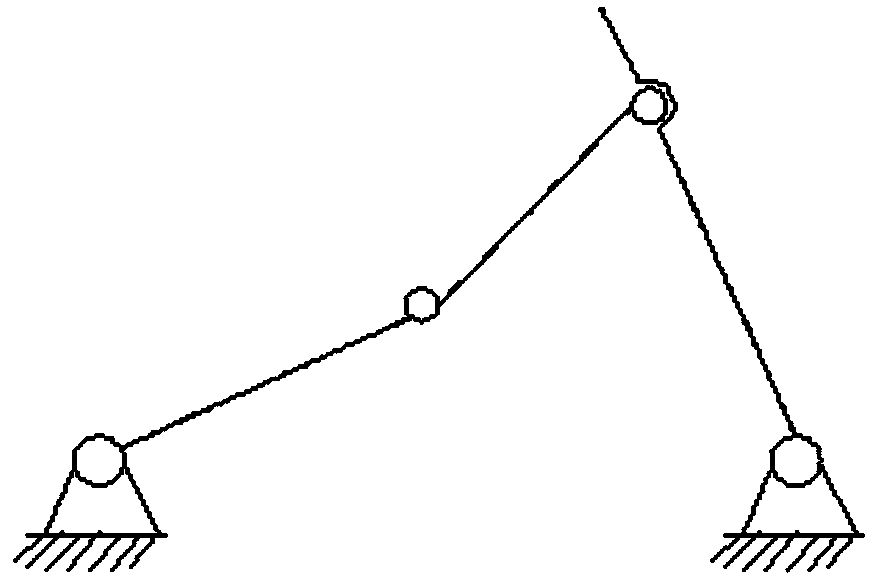

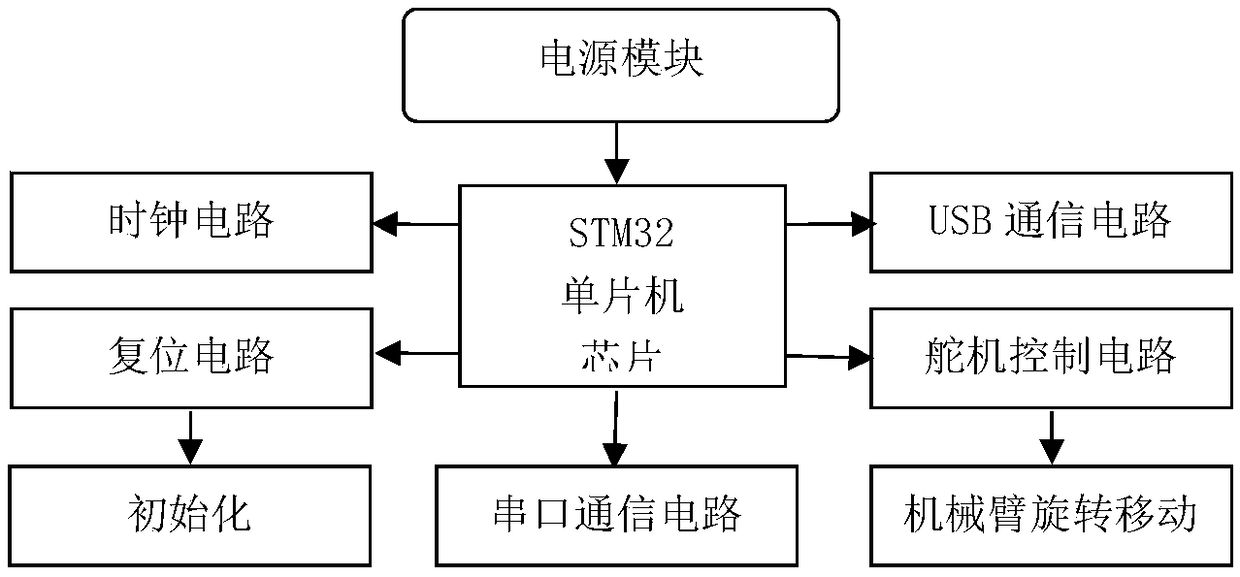

Drawing robot

PendingCN109278055AImprove operating speedImprove controllabilityJointsOther artistic work equipmentsStructural errorEngineering

The invention relates to a drawing robot which comprises a support device, an actuating mechanism, and a control mechanism in communication with an upper computer. The actuating mechanism comprises afive-connecting-rod manipulator and a four-connecting-rod mechanical arm, and is used for utilizing the five-connecting-rod manipulator for moving a paintbrush to the specific position for drawing according to a received operating path control command and a drawing command; the four-connecting-rod mechanical arm is used for driving the five-connecting-rod manipulator to rotate so as to lift a penor put the pen; a first drive mechanism is rotatably connected with the five-connecting-rod manipulator and is used for controlling and driving the movement direction of the five-connecting-rod manipulator; a second drive mechanism is rotatably connected with the four-connecting-rod mechanical arm and is used for controlling and driving the movement direction of the four-connecting-rod mechanicalarm; and the control mechanism is used for converting a code sent by the upper computer into coordinates and sending the coordinates to the first drive mechanism and the second drive mechanism so as to drive the actuating mechanism to rotate or move to the specific position for drawing. According to the drawing robot provided by the invention, the structural error of the four-rod mechanism is compensated, the high-accuracy movement output is realized, the complicated movement locus capable of being drawn by the four-rod mechanism can be drawn, and the drawing range is expanded.

Owner:深圳当然智能科技有限公司

Environment-friendly spraying device for door and window aluminum profile machining

PendingCN112657723AExpand the scope of paintingPromote environmental protectionSpraying apparatusMachiningSpray painting

The invention discloses an environment-friendly spraying device for door and window aluminum profile machining, which comprises a spraying box shell; a first stress support is connected to the interior of the spraying box shell; a waste liquid collecting basin is connected to the interior of the spraying box shell; a rotary clamping device is connected to a second stress support; a sliding groove is connected to the surface of a third stress support; the surface of the sliding groove is connected with a spraying device; and the upper side of the spraying device is connected with a second sliding groove. The invention relates to a spraying device. According to the environment-friendly spraying device for the door and window aluminum profile machining provided by the invention, the paint spraying range of the spraying device in the paint spraying process can be greatly enlarged, the use rate of paint spraying liquid is greatly increased, use of spraying liquid is reduced, and therefore the environment friendliness of the spraying device is effectively improved, and the spraying device can rotate around the axis in the spraying process, so that an aluminum profile is painted and turned over in the painting process, so that the coverage rate of the painted surface of the aluminum profile is wider, and the painting efficiency is greatly improved.

Owner:芜湖科捷铝业科技有限公司

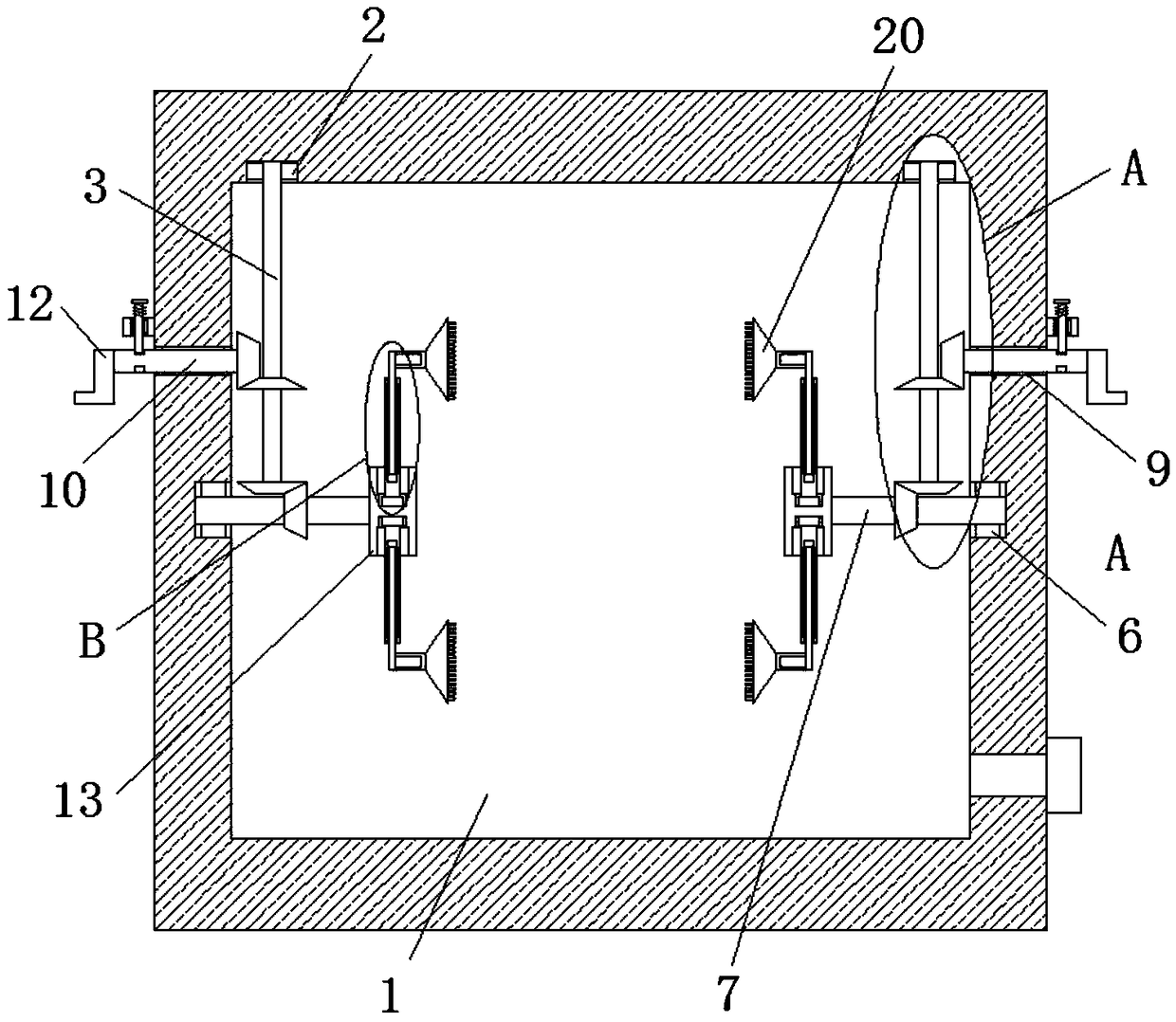

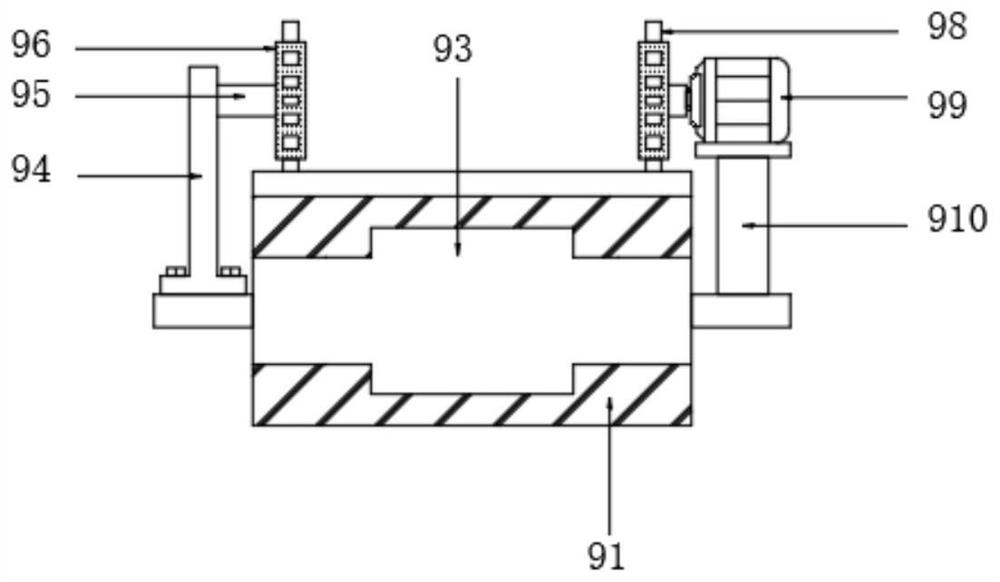

Anti-splashing device for paint spraying of aluminum alloy motor shell

InactiveCN114029182AImprove painting efficiencyImprove uniformitySpray boothsElectric machineryEngineering

The invention discloses an anti-splashing device for paint spraying of an aluminum alloy motor shell. The device comprises a cabinet body, a fixing plate is fixedly connected in the cabinet body, and a shell fixing device is arranged above the fixing plate; the shell fixing device is connected with the fixing plate through a shell rotating mechanism, paint spraying devices are arranged at the two sides of the cabinet body respectively, a motor is installed at the bottom of the inner wall of the cabinet body, and a spray head linkage mechanism is arranged between the motor and the paint spraying devices. Through the arrangement of the multiple shell fixing devices, the multiple aluminum alloy shells can be limited and fixed at a time, paint spraying operation of the multiple motor shells can be conducted at a time, and the paint spraying efficiency of the device can be effectively improved; and by arranging the shell rotating structure, the multiple motor shells can be driven to rotate with a rotating shaft as the center and the center point of a fluted disc as the center in the paint spraying process, and the paint spraying uniformity of the device can be improved while the paint spraying efficiency of the device can be guaranteed.

Owner:南通方正机电制造有限公司

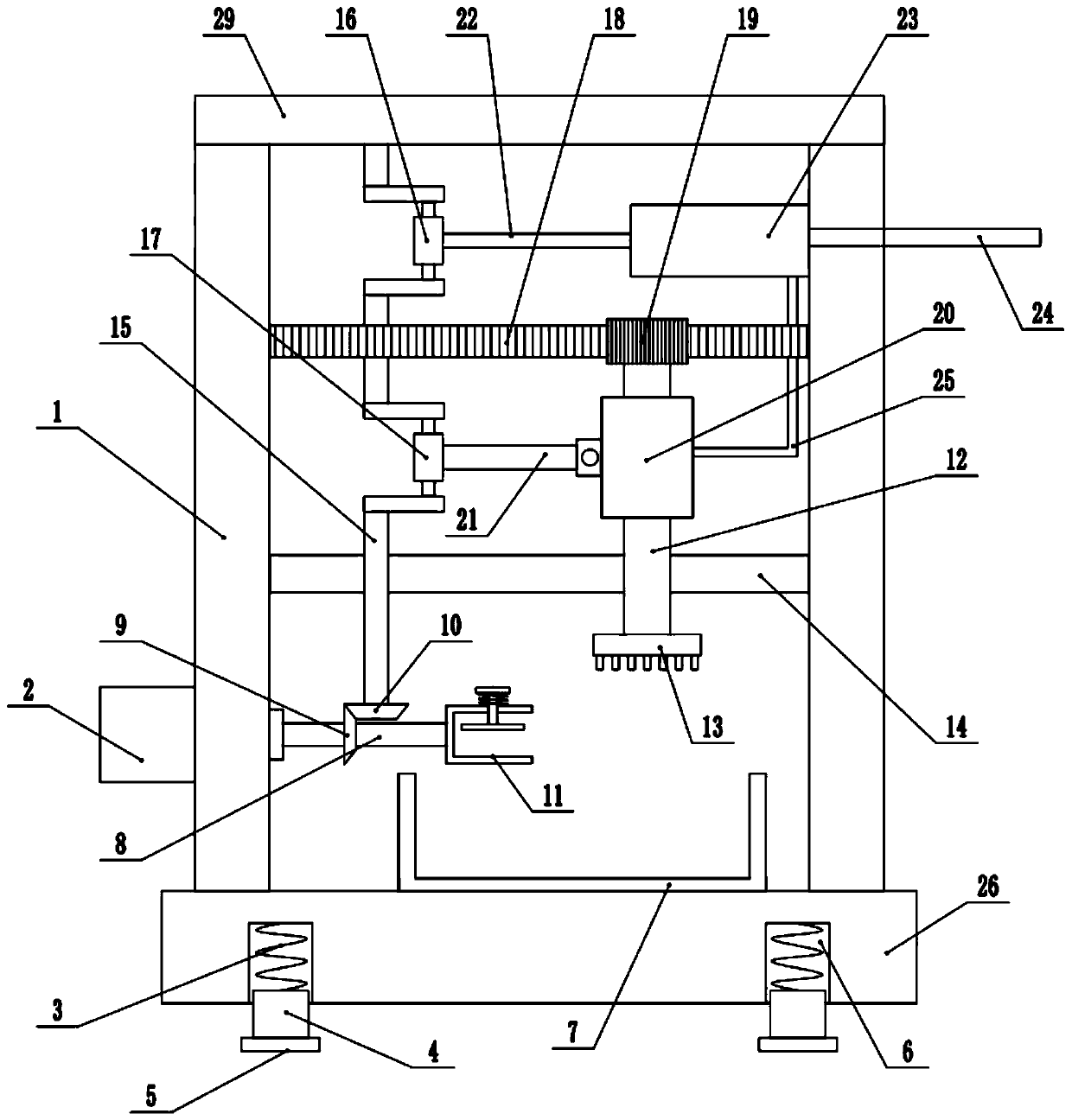

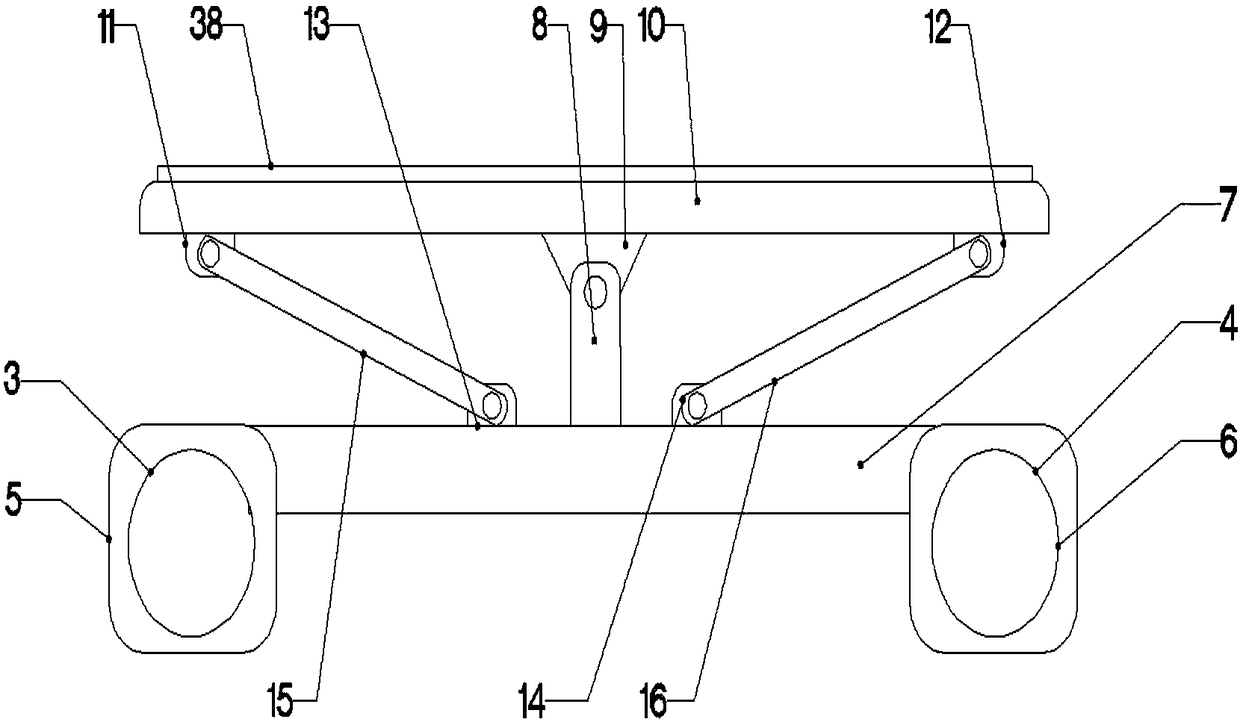

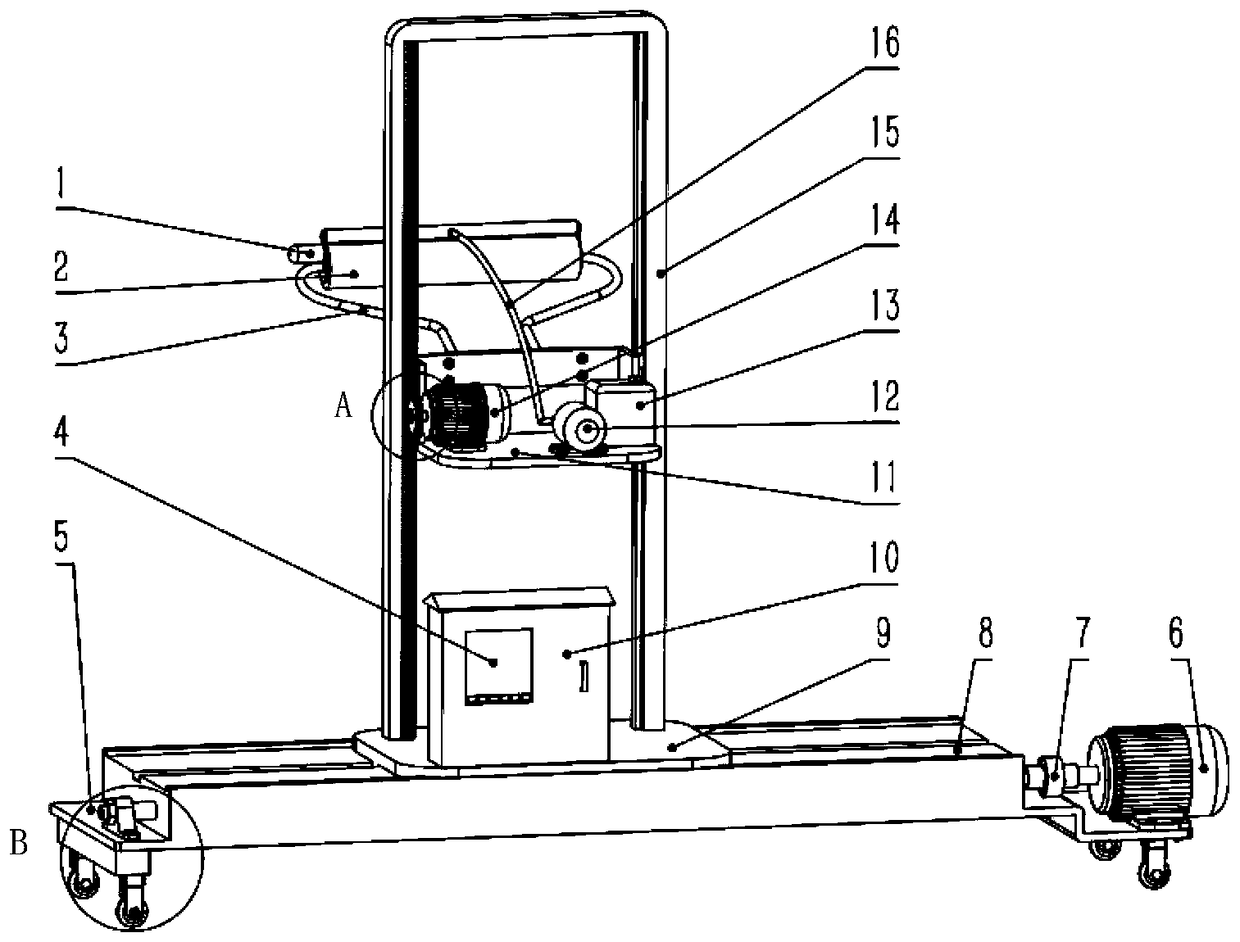

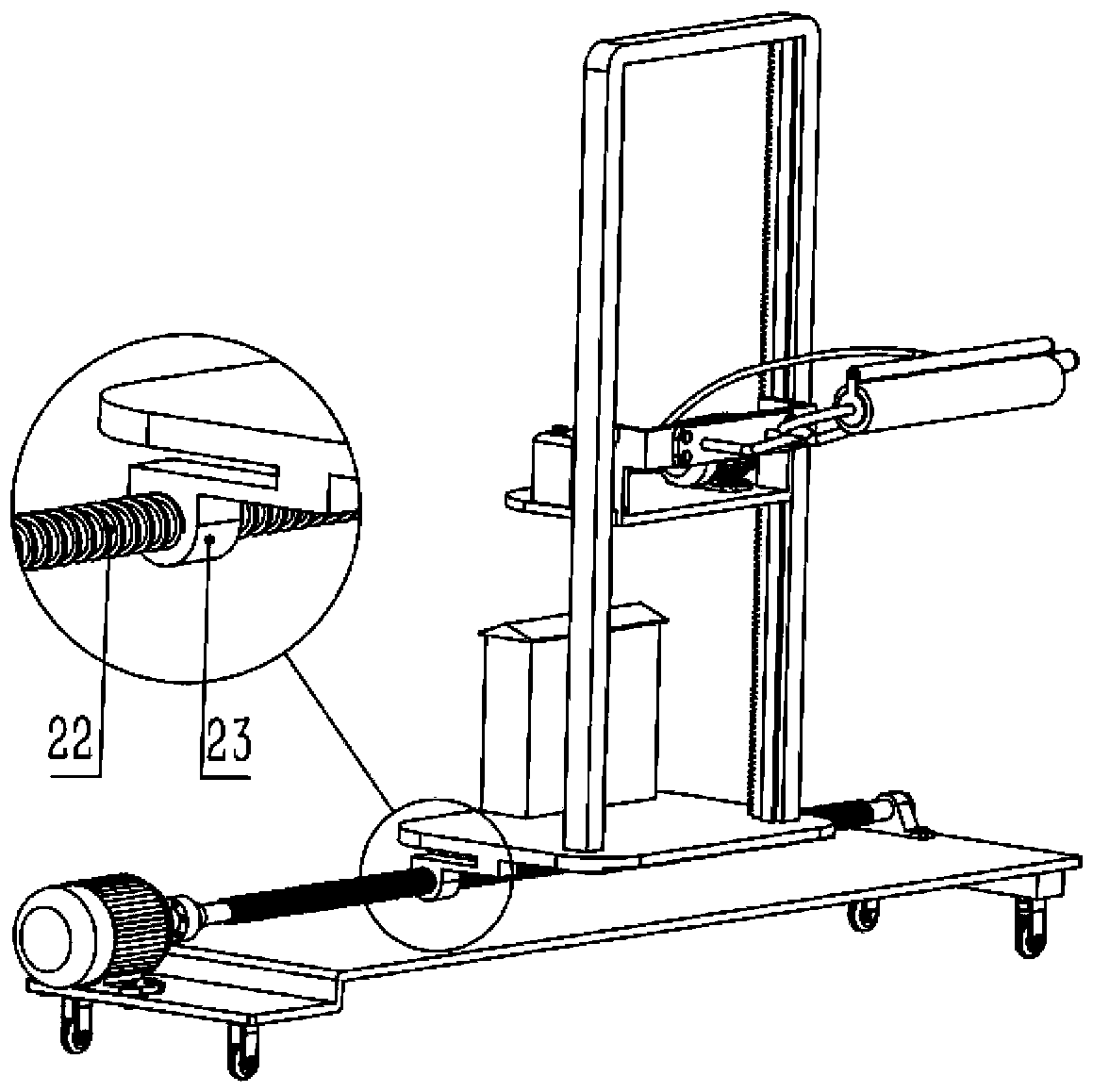

Vertical and horizontal mobile wall brushing machine

The invention belongs to the technical field of wall brushing machinery and equipment, and in particular relates to a vertically and horizontally moving wall brushing machine, which is characterized in that it includes a horizontal moving mechanism, a vertical moving mechanism vertically arranged on the horizontal moving mechanism, and a vertical moving mechanism arranged on the vertical moving mechanism The wall brushing mechanism is provided with a feedback control system on the longitudinal movement mechanism. The present invention has simple structure, strong practicability, high degree of automation, and greatly replaces manual wall painting. The main structure of the present invention is composed of a longitudinal movement mechanism and a transverse movement mechanism. The vertical and horizontal movement of the machine expands the painting range and improves the painting efficiency.

Owner:UNIV OF SCI & TECH LIAONING

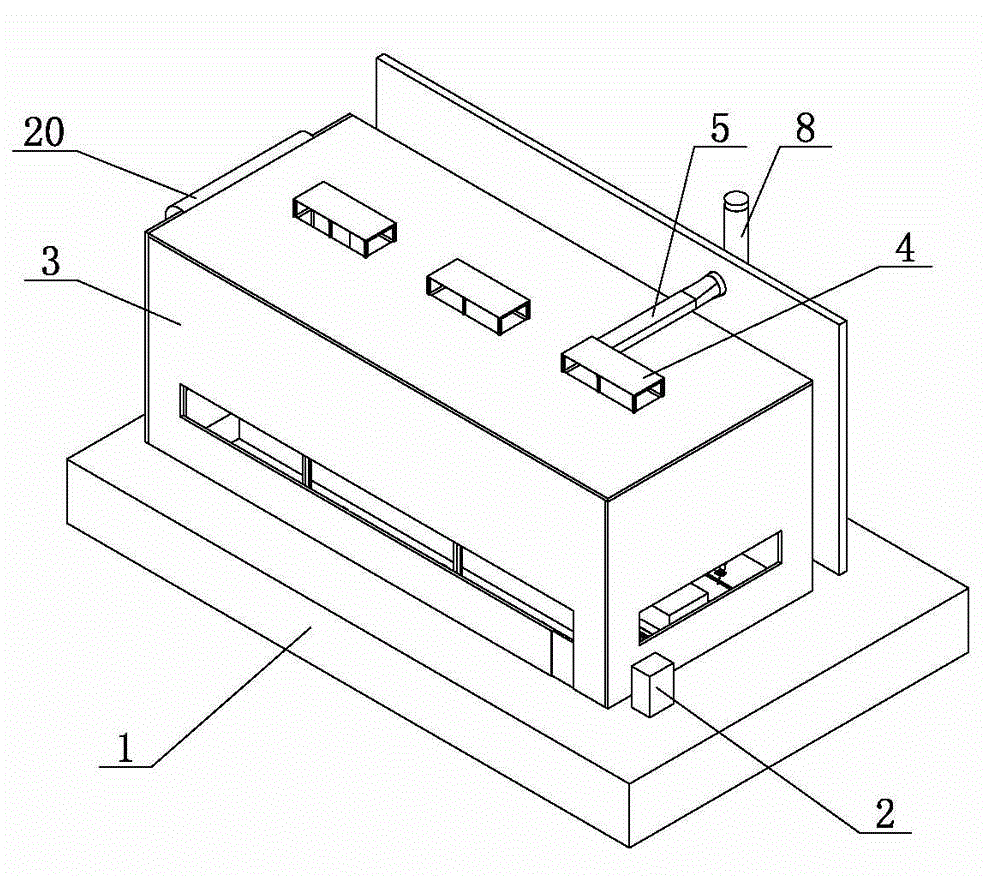

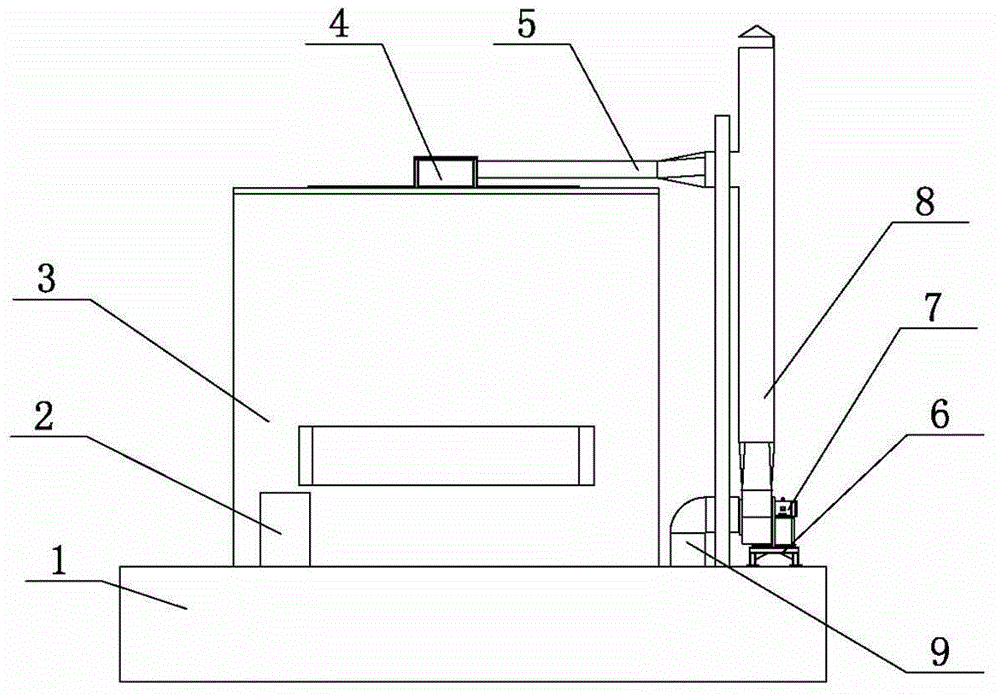

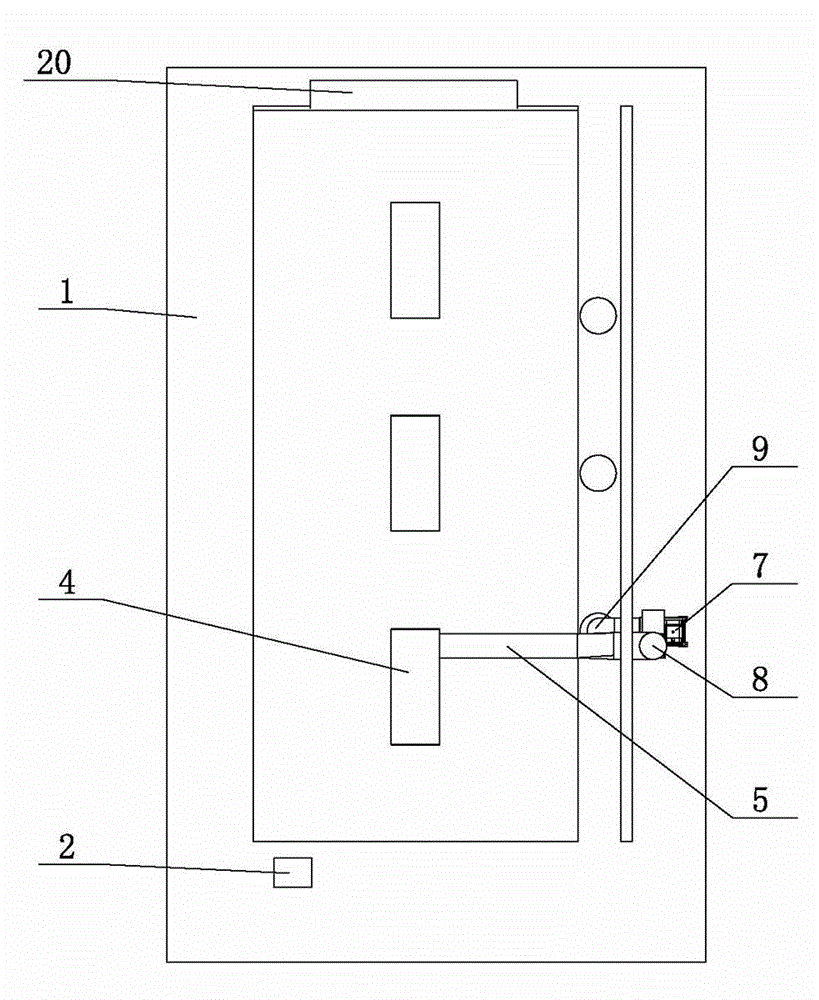

paint house

ActiveCN103008163BExpand the scope of paintingEnsure that there are no dead ends when sprayingLiquid surface applicatorsSpraying apparatusEngineeringHead moving

The invention discloses a paint spray booth which comprises a paint spray booth main body. A door is formed in the paint spray booth main body; a foundation is arranged at the bottom of the paint spray booth main body; a machine head moving mechanism is mounted in the paint spray booth main body; a lifting mechanism is mounted on the machine head moving mechanism; a machine head is mounted at the lower end of the lifting mechanism; the machine head comprises a paint cylinder and a connecting sleeve; the paint cylinder is connected with the connecting sleeve; a servo motor is mounted in the connecting sleeve; a connecting supporting piece is mounted on an output shaft of the servo motor; a suspending mechanism is mounted on the connecting supporting piece; a locating sleeve is mounted on the suspending mechanism; a third motor is horizontally mounted on the locating sleeve; a spray gun is mounted on an output shaft of the third motor; a camera device is mounted on the spray gun; and the spray gun is connected with the paint cylinder through a pipeline. The machine head moving mechanism capable of driving the machine head to flexibly move is mounted on the paint spray booth, so that the machine head can randomly move within the whole horizontal plane in the paint spray booth main body. The spray gun on the machine head can rotate in both horizontal direction and vertical direction, so that the paint spray range of the machine head can be further enlarged.

Owner:SHANDONG SHUIBO WELDING & CUTTING EQUIP MFG CO LTD

a paint spraying device

ActiveCN108097510BImplement Tilt RotationLarge range of motionSpraying apparatusPretreated surfacesDrive shaftStructural engineering

The invention relates to a paint spraying device. The paint spraying device comprises a supporting table; a driving shaft is connected to the supporting table in a rotating mode; a gear ring is arranged on the driving shaft; inclined first meshing teeth are uniformly distributed in the circumferential direction of the gear ring; a paint bucket is arranged in the gear ring in a meshing mode; secondmeshing teeth matched with the first meshing teeth are arranged on the outer wall of the paint barrel; a paint inlet is formed in the bottom of the paint bucket; a paint spraying rod is connected tothe top of the paint bucket; paint spraying blades are connected to the top end of the paint spraying rod; paint spraying openings are formed in the paint spraying blades; a connecting rod is fixedlyconnected to the driving shaft and is provided with a bending part; the other end of the connecting rod is fixedly connected to the paint spraying rod; a material storage box is arranged below the supporting table; a feed port and a discharge port are formed in the material storage box; the discharge port is connected with a discharging pipe; the other end of the discharging pipe communicates withthe paint inlet; a supporting mechanism is arranged on the supporting table; a rotating shaft is arranged on the supporting mechanism; a magnet is arranged on the rotating shaft; and the rotating shaft is located above the gear ring. The paint spraying device solves the problems that a traditional paint spraying device is small in spraying range, and the operation is inconvenient when paint spraying is carried out on other parts of accessories.

Owner:南通迪亚科开关科技有限公司

A double-sided paint spraying device for rectangular plates

ActiveCN109622274BAchieve double-sided paintingHigh degree of automationSpraying apparatusClassical mechanicsEngineering

The present invention relates to the field of plate painting, in particular to a double-sided paint spraying device for a rectangular plate, which includes a frame on which two splints are fixedly connected. Sliding holes are provided on the splints. The sliding holes include an upper bar hole, a lower bar hole and two arc holes. The upper bar hole is located above the lower bar hole, and the arc hole is connected to the end of the upper bar hole. Between the bottom and the end of the lower strip hole; between the two splints, there is a paint spraying tube that is slidably connected in the sliding hole, and a swing plate is provided on each splint, and one end of the swing plate is connected to the middle of the splint by rotation, swinging There is a strip-shaped through hole on the board, and the paint spray pipe is slidably connected in the strip-shaped through hole; two arc-shaped racks are arranged on the sides of the two splints, and the paint spray pipe is fixedly connected with the arc-shaped tooth rack. Gears; several nozzles are arranged on the pipe wall of the paint spraying pipe. The scheme realizes automatic painting on both sides of the plate, and improves the automation degree of the painting device.

Owner:宁波隆锐机械制造有限公司

Surface treatment and processing device and processing method for vehicle shell

ActiveCN111957488BGood effectImprove efficiencyPretreated surfacesCoatingsElectric machineStructural engineering

Owner:台州市森迪木业有限公司

A multi-angle automatic painting equipment for processing mechanical parts

ActiveCN110773365BGuaranteed uniformityExpand the scope of paintingPretreated surfacesLiquid spraying apparatusMechanical componentsLacquer

Owner:SUZHOU ODIHUA ELECTRONIC CO LTD

A device for painting wooden panels for furniture

ActiveCN104107787BQuickly solidifies and dries upAvoid affecting the painting effectLiquid surface applicatorsCoatingsEngineeringConveyor belt

The invention relates to a device for spraying paint on wooden boards for furniture, which includes a conveyor belt, a water washing mechanism, a first drying mechanism, a painting mechanism and a second drying mechanism, the water washing mechanism, the first drying mechanism, the painting mechanism and the second drying mechanism The second drying mechanism is arranged on one side of the conveyor belt. According to the moving direction of the conveyor belt, the washing mechanism is located in front of the first drying mechanism, the painting mechanism is located behind the first drying mechanism, and the second drying mechanism is located behind the painting mechanism. The invention can completely replace manual painting, and the sprayed paint can evenly adhere to the furniture board, and the painting quality is high.

Owner:GUANGDONG KNOYA HOME FURNISHING CO LTD

Continuous production equipment for organic silicon resin paint film and continuous production method

ActiveCN113318883AImprove paint uniformityAdjust the spray angleLiquid spraying apparatusMaterials scienceOrganosilicon

The invention provides continuous production equipment for an for organic silicon resin paint film and a continuous production method of the continuous production equipment, and relates to the field of organic silicon resin paint. The continuous production equipment comprises a plate conveying mechanism, a spraying mechanism is connected to the side face of the plate conveying mechanism, the spraying mechanism communicates with a material box, the plate conveying mechanism comprises a plate material groove, and a plate outlet groove is formed in the side face of the plate material groove. A plate feeding wheel is rotatably connected to the side face of the plate material groove, a conveying belt is connected to the top of the plate material groove, a pressing mechanism is arranged on the side face of the plate material groove, and the plate feeding wheel is in transmission connection with the pneumatic mechanism at the top of the material box. In the continuous production equipment and the continuous production method, the plate feeding wheel and the pneumatic mechanism at the top of the material box are in transmission connection, the feeding speed and the inflating speed in the materials are made to be at a certain proportion, and when a certain amount of resin paint is sprayed out of the material box, proper pressure is supplemented, so that the paint spraying speed of a spray head is in direct proportion to the plate moving speed, the paint spraying uniformity can be improved, and then the accuracy of paint film index detection can be improved.

Owner:宿迁市同创化工科技股份有限公司

Paint spraying robot

ActiveCN108970869AExpand the scope of paintingSmooth traverseLiquid spraying apparatusPaint robotEngineering

The invention relates to the technical field of functional robots and discloses a paint spraying robot. The paint spraying robot comprises a supporting column. The lower end of the supporting column is provided with a first rotary shaft. A base is arranged under the first rotary shaft. Fixing bolts penetrate through the inner side of the base. A moving component is arranged on the outer surfaces of the lower ends of the fixing bolts. A heat dissipation device is arranged on the upper portion of the outer surface of the front end of the supporting column. The upper end of the heat dissipation device is provided with a telescopic outer rod. The outer surface of the upper end of the telescopic outer rod is provided with a fixed plate. The upper end of the fixed plate is provided with a paintbox. The lower portion of the outer surface of the front end of the paint box is provided with pull rings. The paint spraying robot drives a rotary disk and cooling fan blades to rotate to generate air flow through rotation of a power shaft of the heat dissipation device and guide out heat, protects the working state of components and protects movable components against damage, and the paint spraying range of the robot can be expanded through the moving component.

Owner:蒋世豪

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com