Paint spraying device for hardware mechanical part machining

A mechanical and hardware technology, which is applied in the field of painting devices for hardware and mechanical parts processing, can solve the problem of uneven painting, poor painting effect, hooks are arranged around the metal parts placing frame, and a support plate is fixedly connected under the upper seat, and A base is fixedly connected under the support plate, a servo motor is arranged on the upper end of the base, and a screw rod is fixedly connected to the upper end of the servo motor, a moving block is spirally connected to the outside of the screw rod, and a nozzle placement frame is fixedly connected to the right side of the moving block, The front end of the spray head rack is fixedly connected with a spray head, and the front end of the spray head is fixedly connected with a nozzle, and the upper end of the base is set, etc., so as to achieve the effects of large spraying range, increased spraying effect, and novel design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

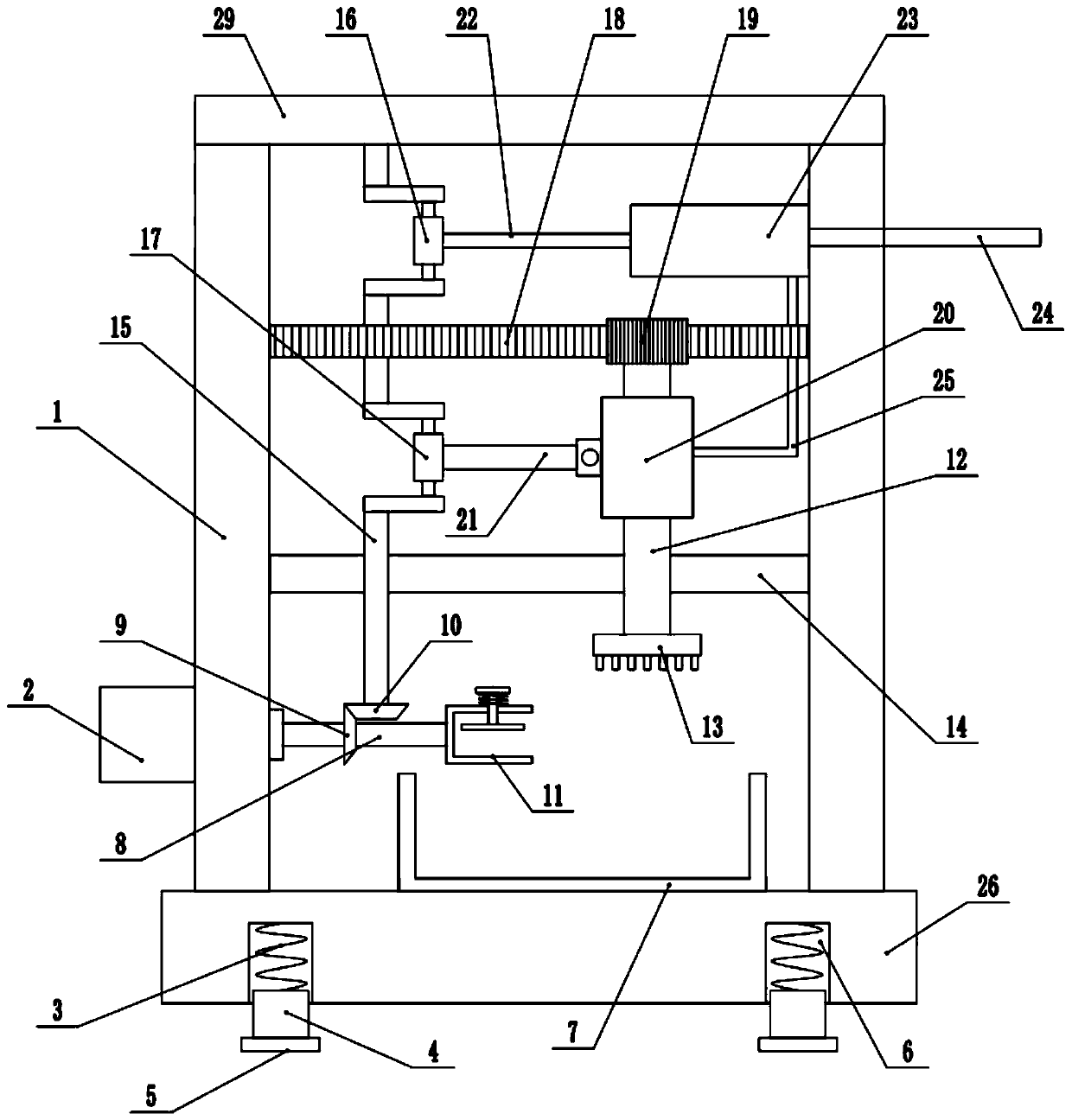

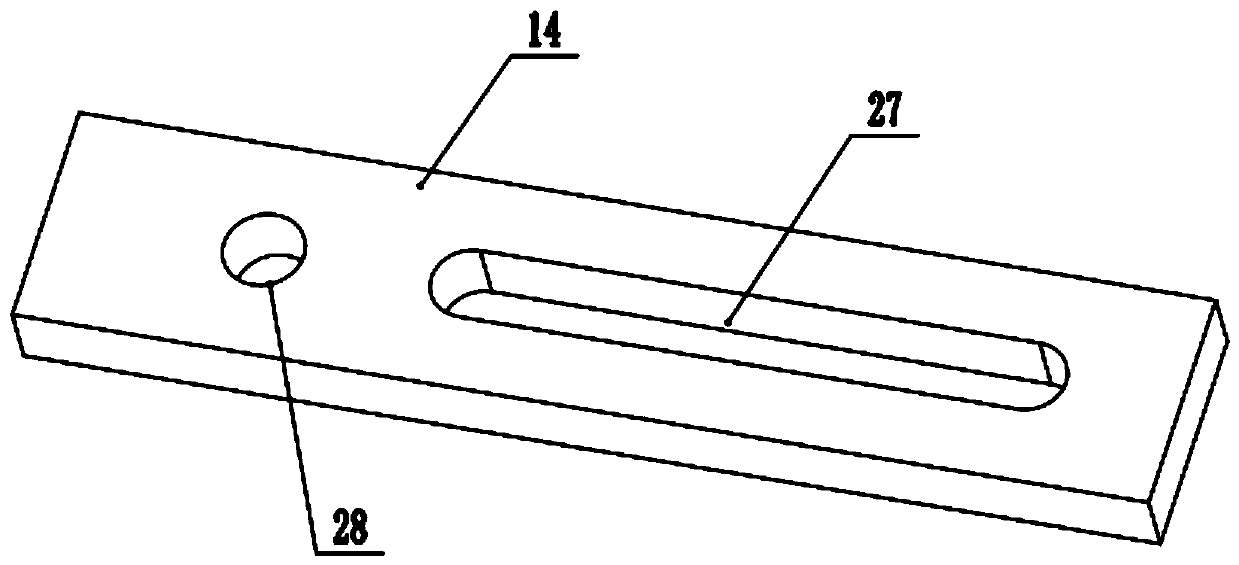

[0028] refer to Figure 1~3 , in an embodiment of the present invention, a paint spraying device for processing hardware and mechanical parts, including a fixed base 26, a collection chamber 7 is installed in the middle of the upper end of the fixed base 26, and is used to collect the residual paint generated in the paint spraying process 1, so that it can carry out For recycling, spring grooves 6 are arranged on both sides of the lower end of the fixed base 26, buffer columns 4 are installed at the bottom of the inner walls of the spring grooves 6, buffer plates 5 are installed at the bottom of the buffer columns 4, and support frames 1 are installed on both sides of the upper end of the fixed base 26. , the guide plate 14 is installed between the lower ends of the support frame 1, the left middle part of the guide plate 14 is provided with a rotating hole 28 that cooperates with the rotating shaft 15, and the right middle part is provided with a waist-shaped hole 27 that coop...

Embodiment 2

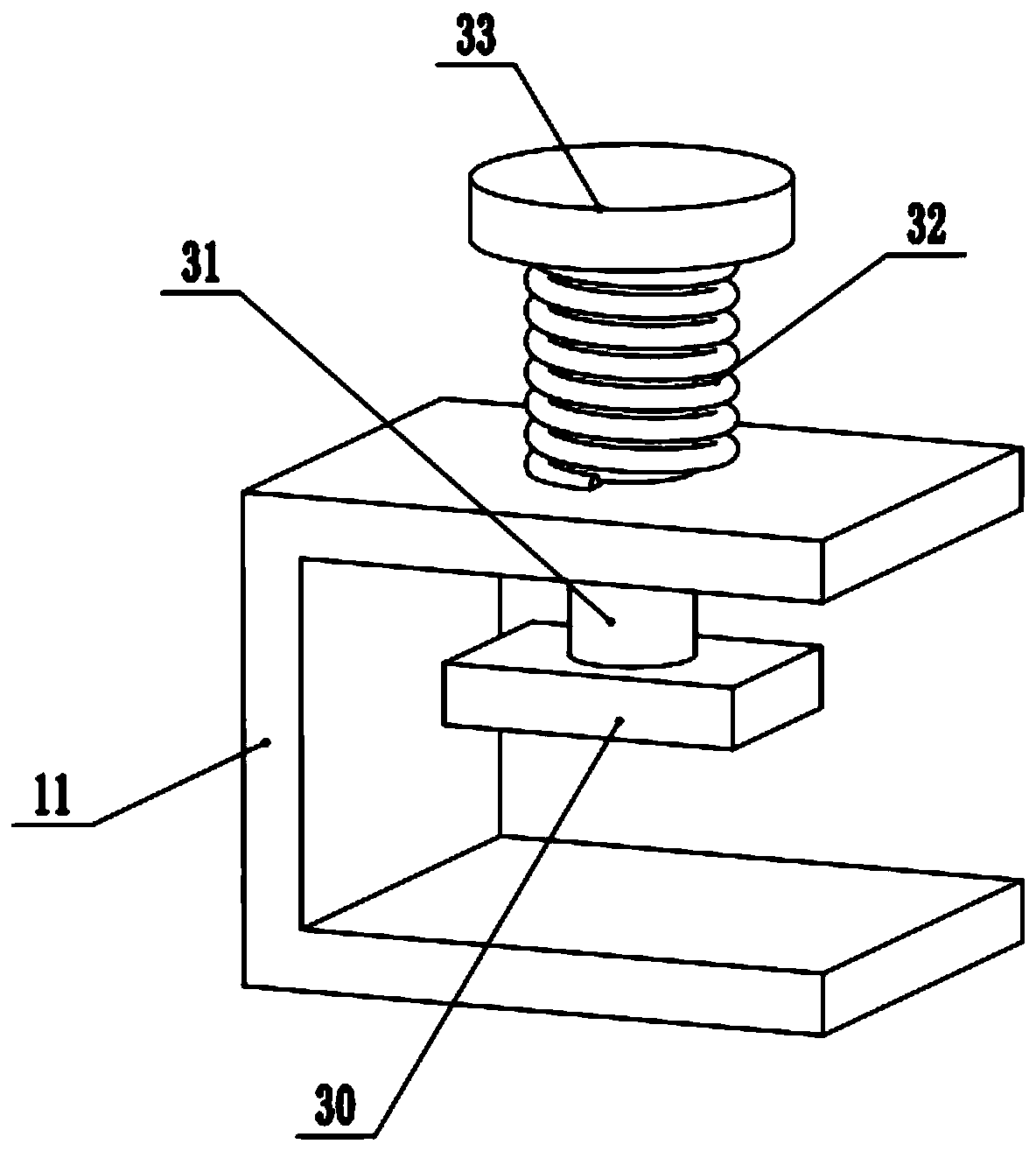

[0030] In another embodiment of the present invention, the difference between this embodiment and the above-mentioned embodiment is that an adjustment spring 32 is sheathed on the outer side of the adjustment rod 31 between the lower end of the adjustment knob 33 and the clamping frame 11, and an adjustment spring 32 is set. The spring 32 increases the rotational friction between the adjusting rod 31 and the clamping frame 11 .

[0031]In the present invention, when working, the hardware and mechanical parts that need to be painted are placed on the clamping mechanism, and then the driving motor 2 is started, and the driving motor 2 drives the hardware and mechanical parts to rotate through the driving shaft 8, and at the same time, the driving gear 9 and the driven gear The cooperation between 10 makes the rotating shaft 15 rotate, and the rotating shaft 15 drives the upper crank mechanism 16 and the lower crank mechanism 17 to rotate. On the one hand, the paint drawing box 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com