Double-sided paint spraying device for rectangular board

A board and double-sided technology, which is applied in the field of double-sided painting devices for rectangular boards, can solve the problems of low automation of automatic painting devices, inability to realize double-sided painting of nozzles, and low painting efficiency, so as to prevent waste, reduce work intensity, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following is further described in detail through specific implementation methods:

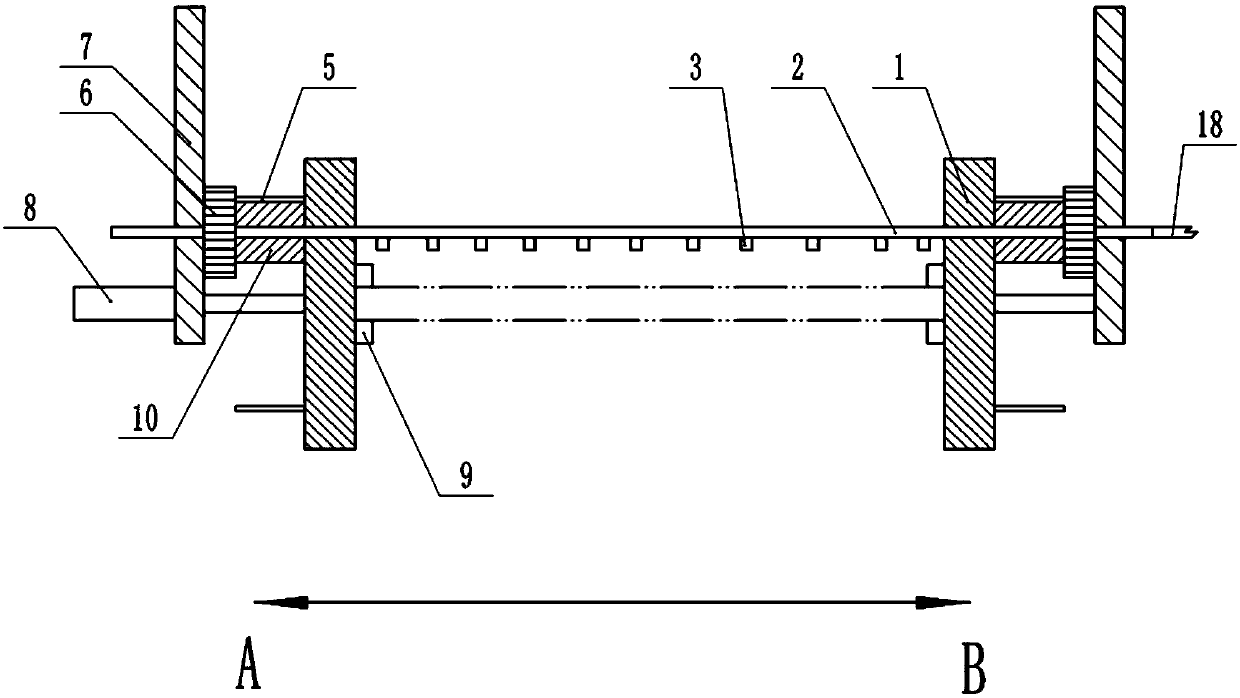

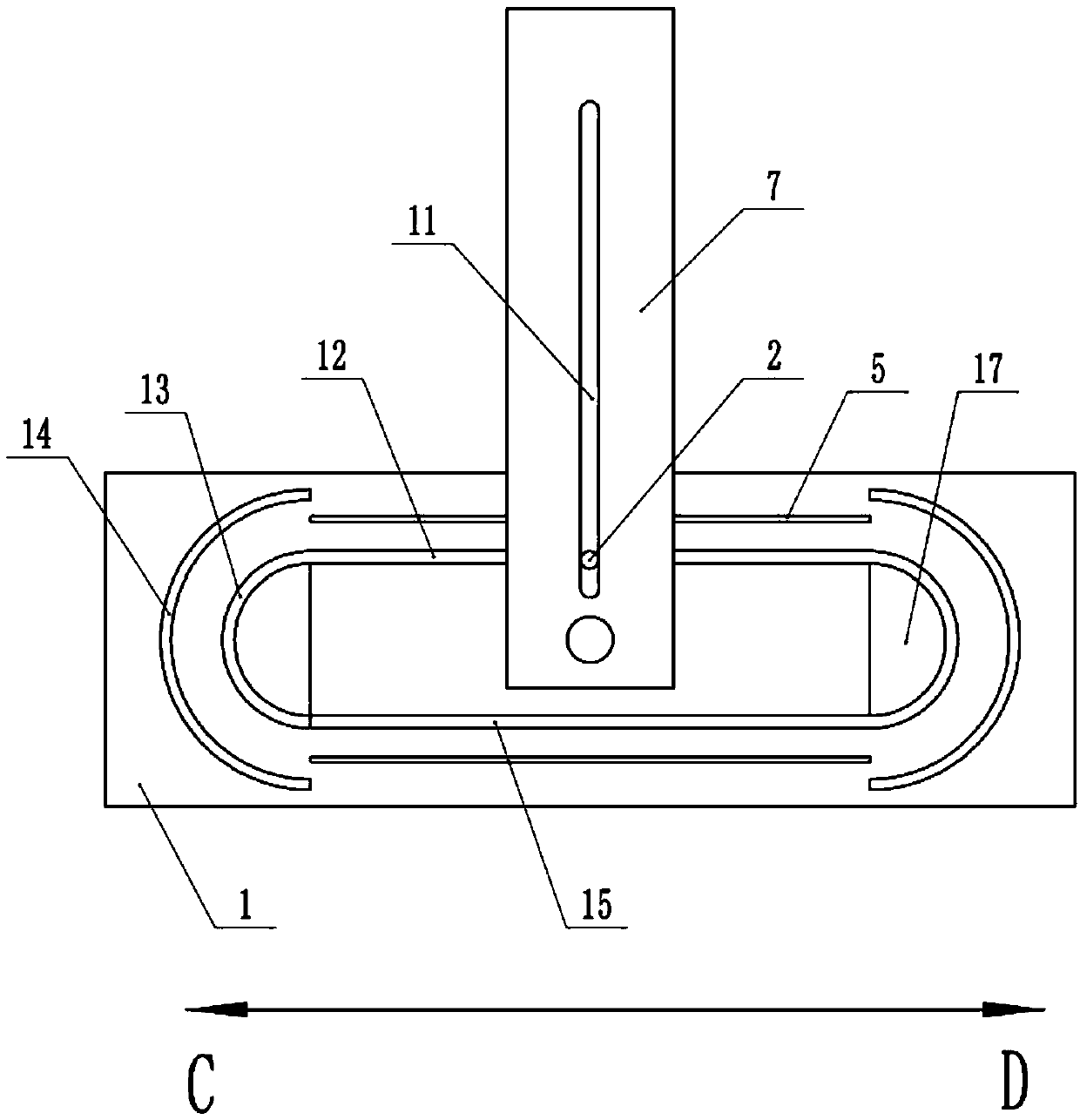

[0020] The reference signs in the accompanying drawings of the specification include: splint 1, paint spray pipe 2, spray head 3, upper platen 5, gear 6, swing plate 7, drive shaft 8, clamping block 9, sliding block 10, strip-shaped through hole 11, upper Bar-shaped hole 12, arc-shaped hole 13, arc-shaped tooth bar 14, lower bar-shaped hole 15, magnet 16, air chamber 17, flexible pipe 18.

[0021] The embodiment is basically as attached Figure 1-Figure 3 As shown, the direction A in this embodiment indicates that the direction is left, the direction B indicates that the direction is right, the direction C indicates that the direction is front, and the direction D indicates that the direction is rear.

[0022] A double-sided paint spraying device for a rectangular plate, comprising a frame on which two vertical splints 1 are welded. The clamping piece in this embodiment is the clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com