Multi-angle automatic paint spray equipment for machining mechanical part

A technology of mechanical parts and painting equipment, applied in the direction of painting room, spraying device, liquid spraying device, etc., can solve the problems of single function and unsatisfactory painting effect, and achieve the effect of uniform drying and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

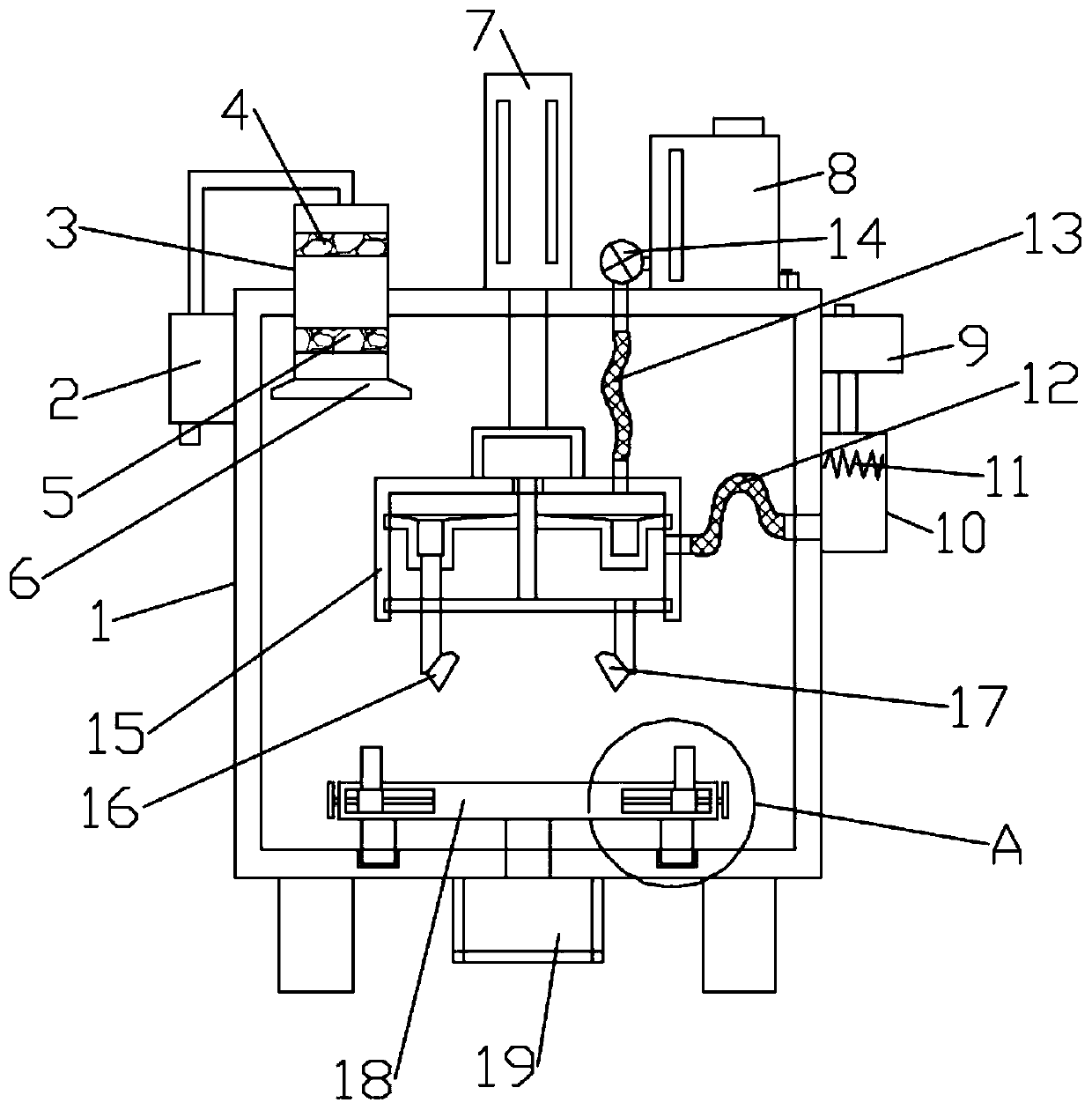

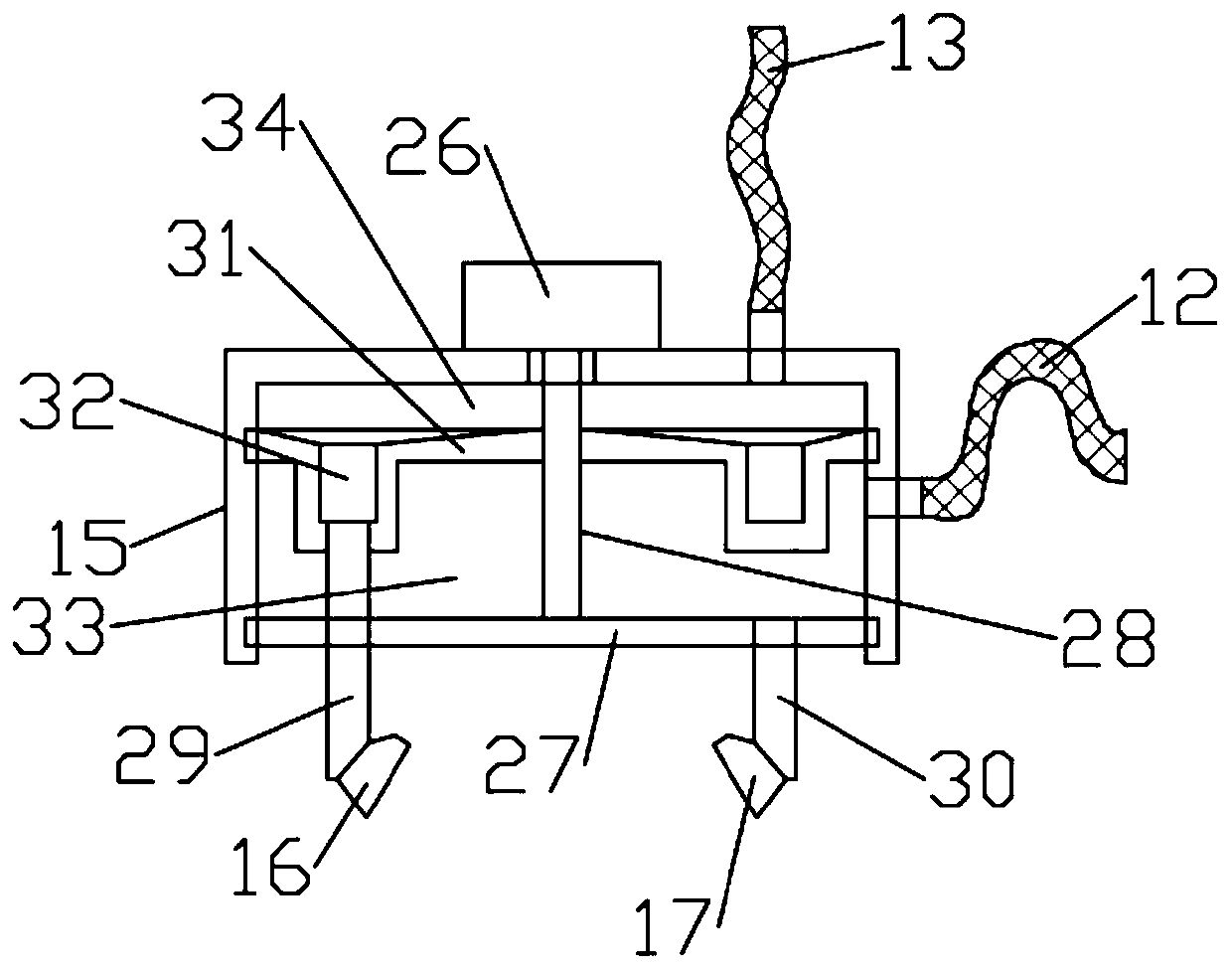

[0030] Such as Figure 1-3 As shown, in the embodiment provided by the present invention, a multi-angle automatic painting equipment for processing mechanical parts includes a box body 1, and the box body 1 is provided with a support cylinder 15 for height adjustment through a telescopic cylinder 7, A rotating partition 31 and a rotating disk 27 are provided for synchronous rotation in the supporting cylinder 15, and the inner cavity of the supporting cylinder 15 is divided into two chambers, the paint liquid chamber 34 and the hot air chamber 33, by the rotating partition 31 and the rotating disk 27. One side of the rotating disc 27 is fixedly installed with an air pipe 30 for discharging the hot air in the hot air chamber 33. The bottom end of the air pipe 30 has a hot air nozzle 17. When spraying paint, the opening of the hot air nozzle 17 faces to the Paint spraying parts; the other side of the rotating partition 31 is fixedly installed with a paint liquid pipe 29 for disc...

Embodiment 2

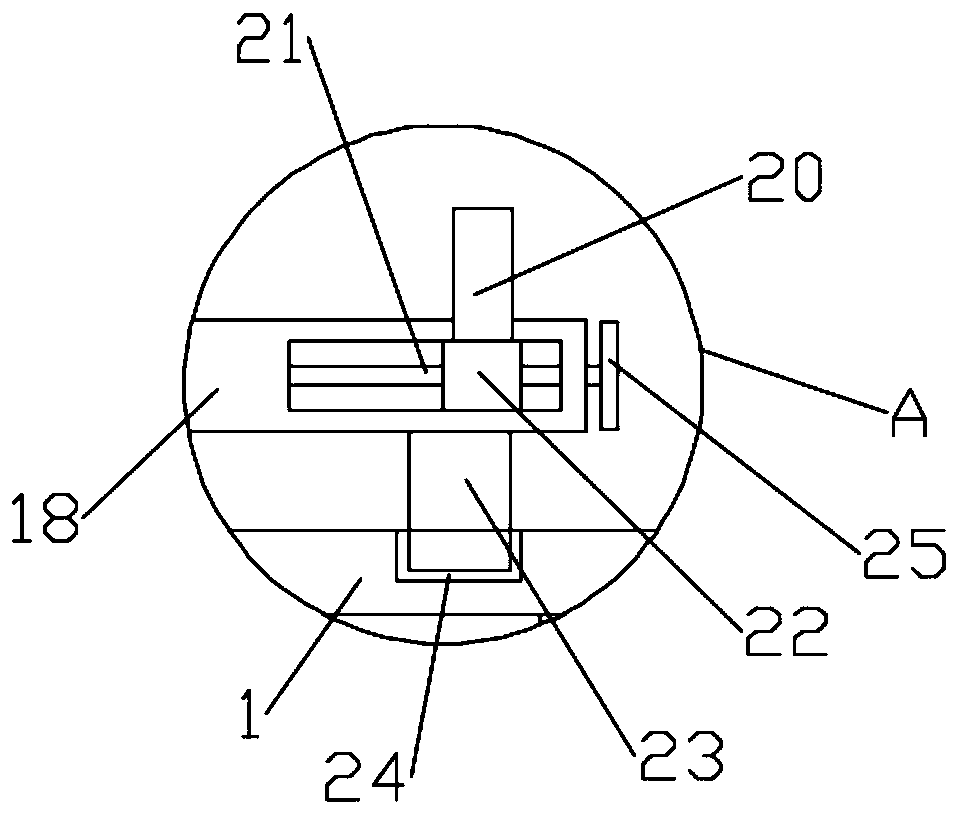

[0037] Such as Figure 1-3 As shown, different from Embodiment 1, in the embodiment provided by the present invention, the turret in the box 1 is provided with a support platform 18 directly below the support cylinder 15, and the mechanical parts to be painted are placed On the supporting platform 18, the clamping assembly for clamping and fixing the mechanical parts is also arranged on the supporting platform 18, and the clamping assembly includes a supporting wire that is rotated in the inner cavity at the end of the supporting platform 18. The rod 21 is horizontally slidable and the adjusting screw sleeve 22 arranged in the end cavity of the support platform 18 is sleeved on the support screw rod 21 through threaded connection, and the outer end of the support screw rod 21 is also fixedly installed with an adjusting The handle 25 drives the supporting screw rod 21 to rotate by operating the adjusting handle 25, so as to achieve the effect of adjusting the position of the ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com