Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Excellent anti-stripping static performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Antistatic surface protection film

ActiveCN104774569ASuppresses peeling static voltageLow agingLamination ancillary operationsNon-macromolecular adhesive additivesAntistatic agentKetone

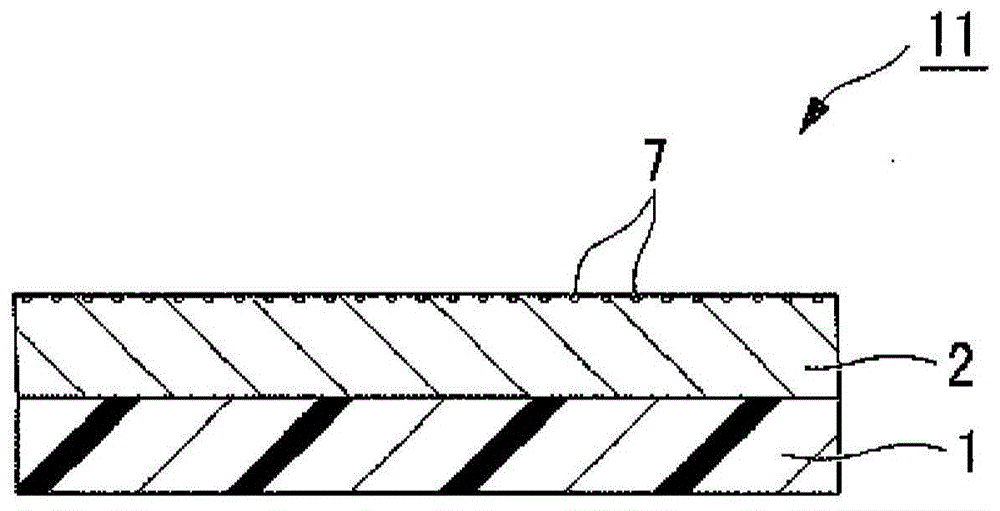

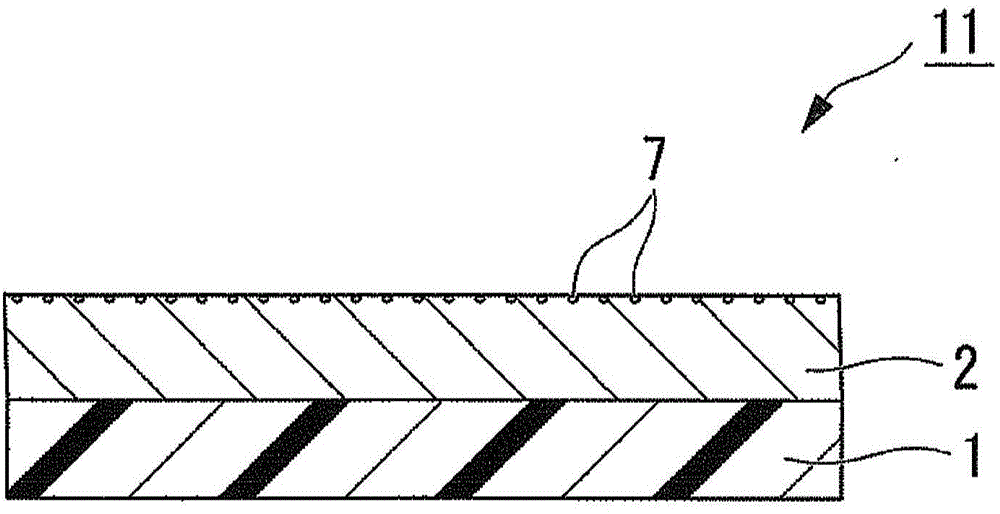

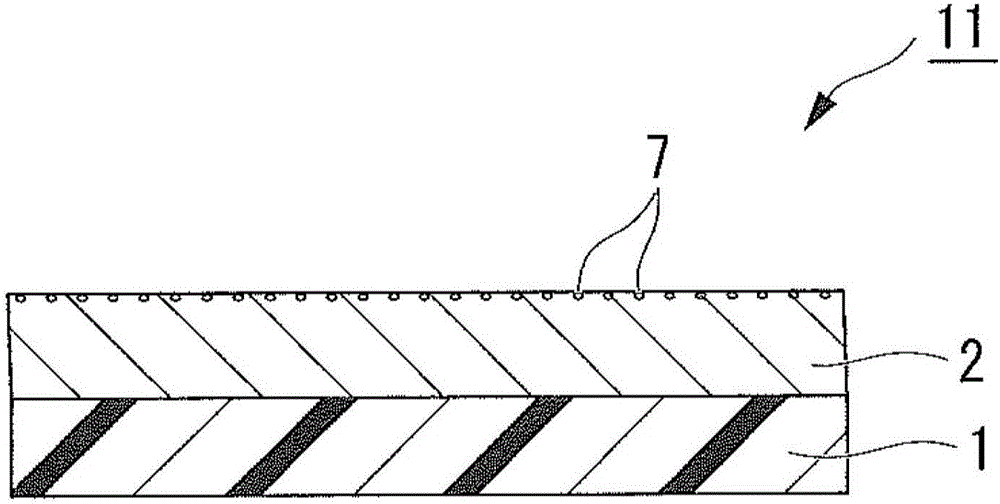

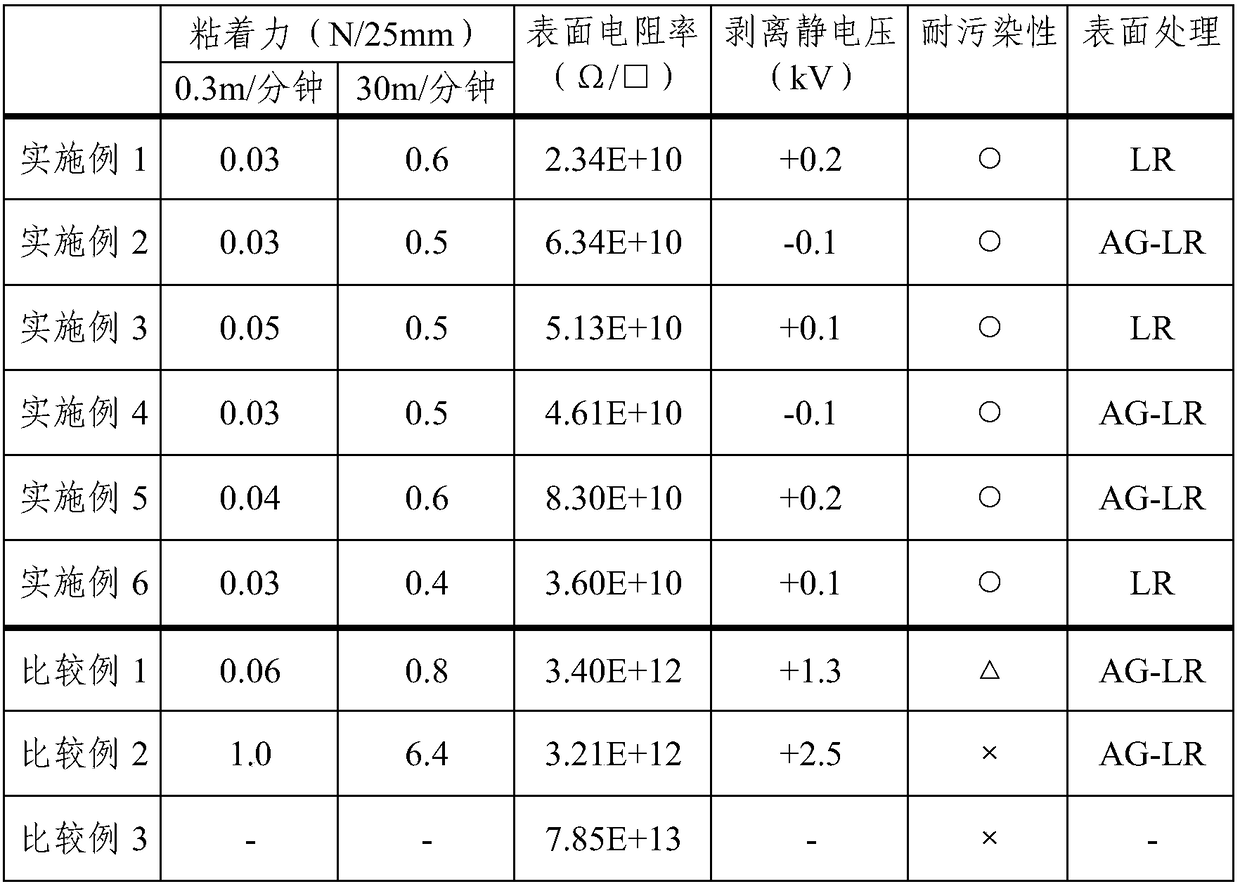

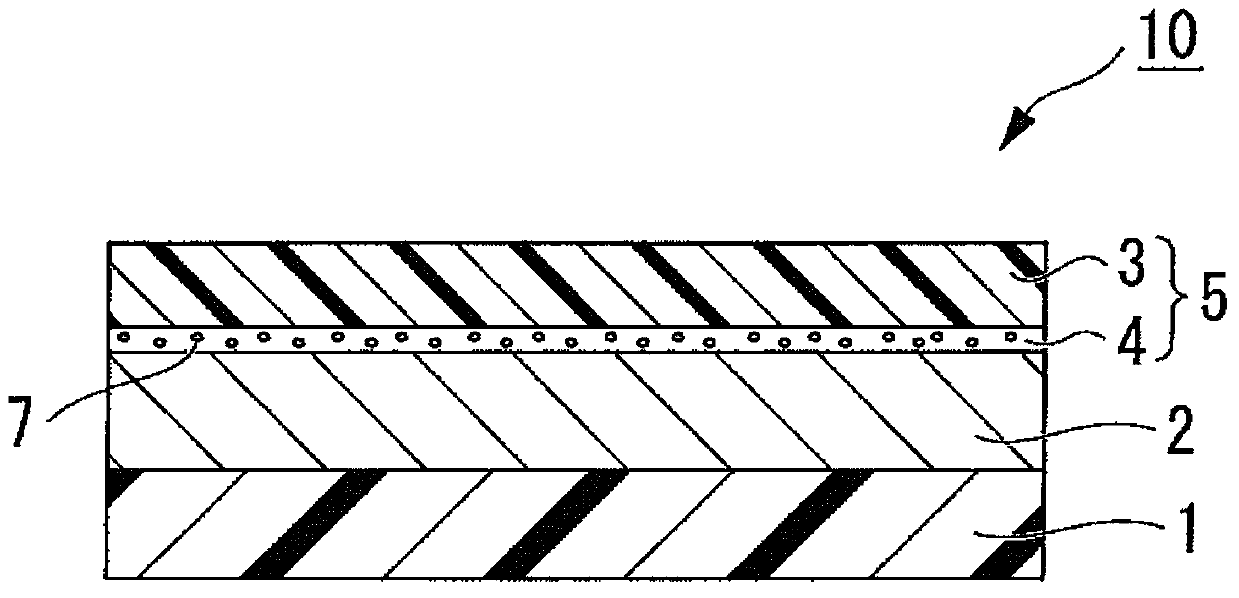

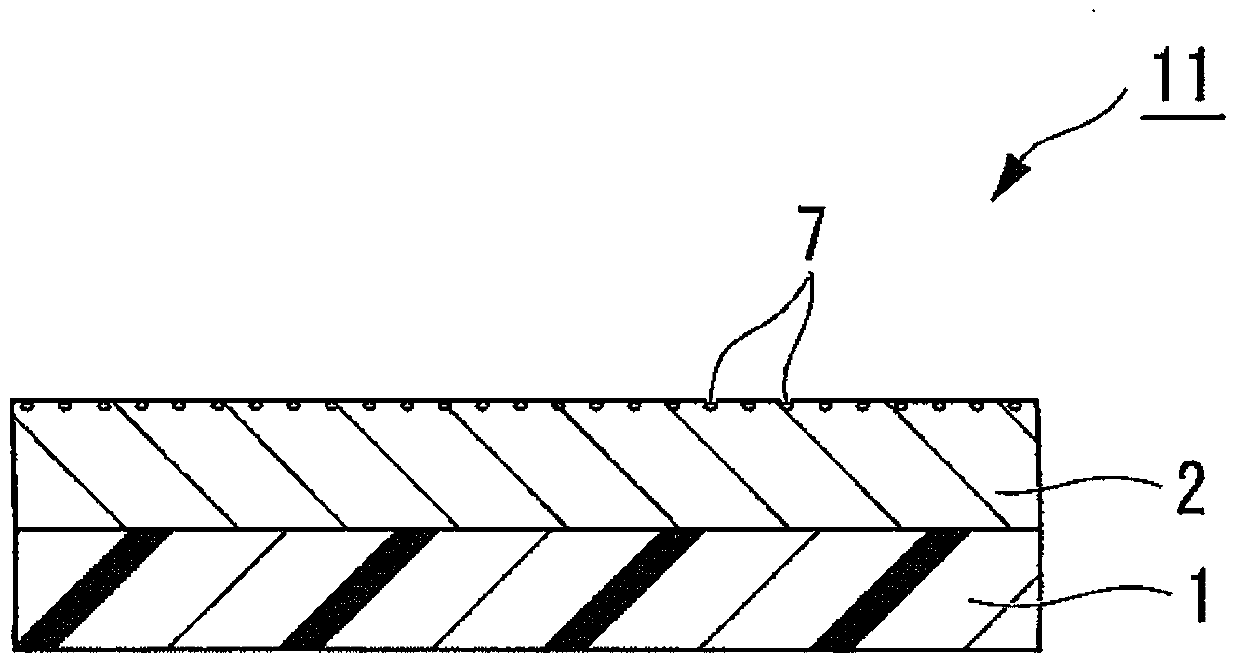

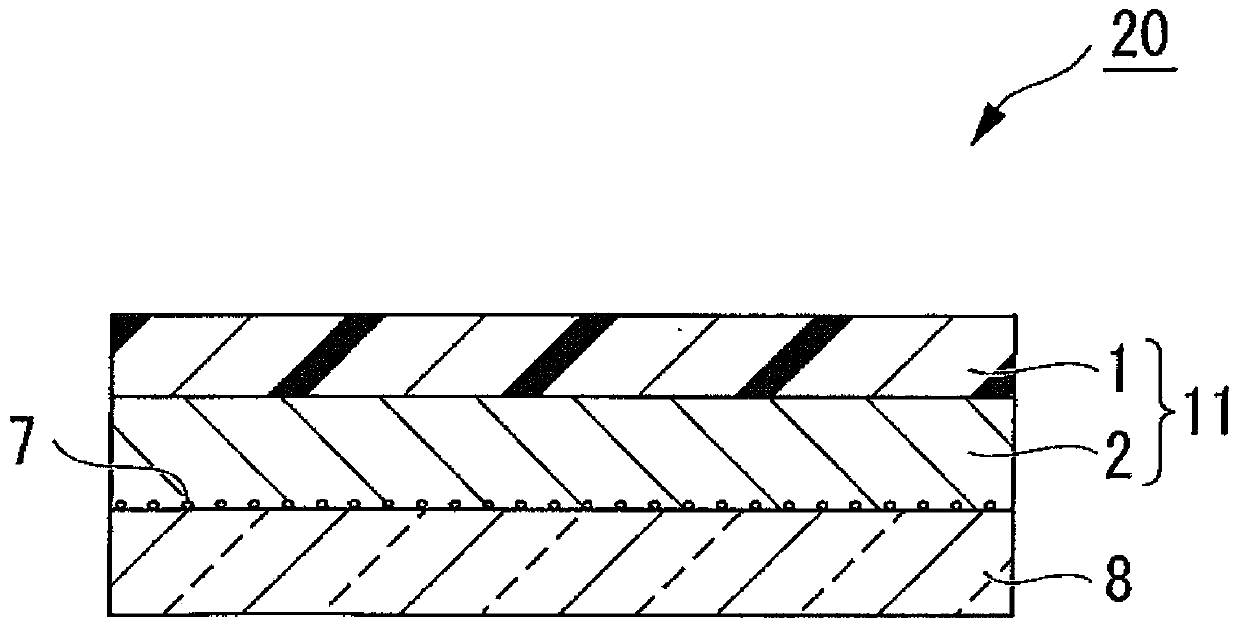

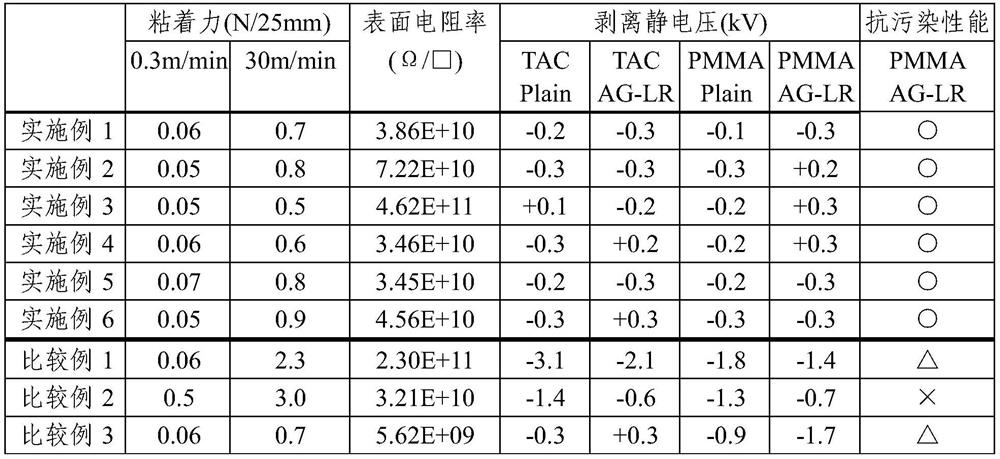

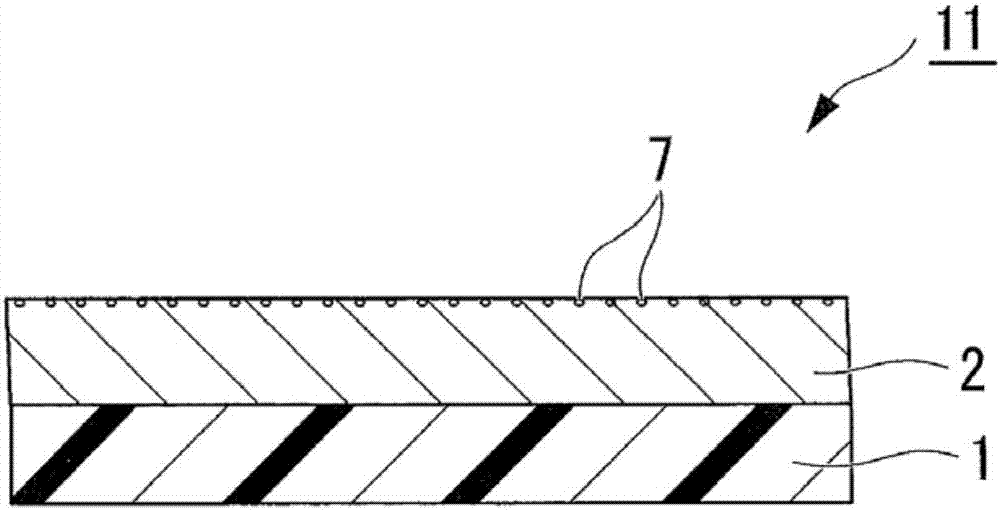

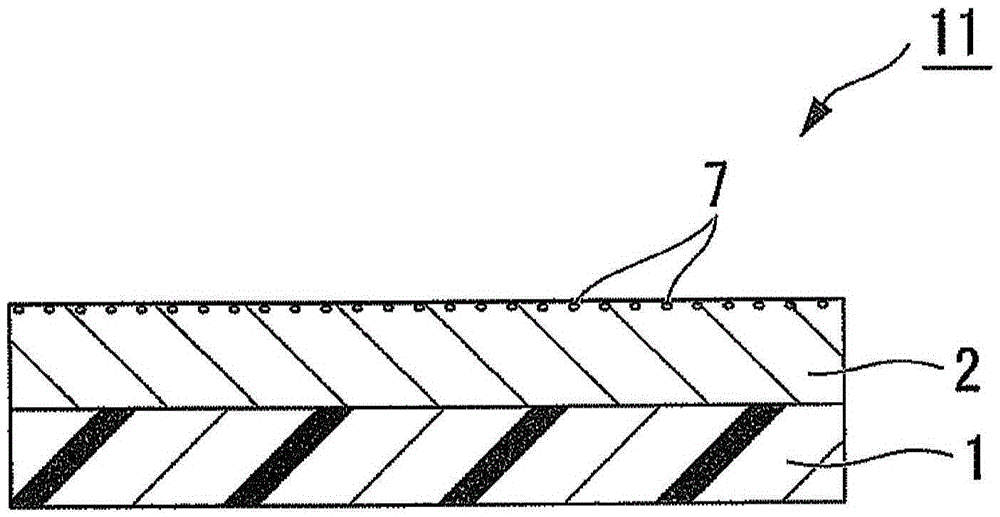

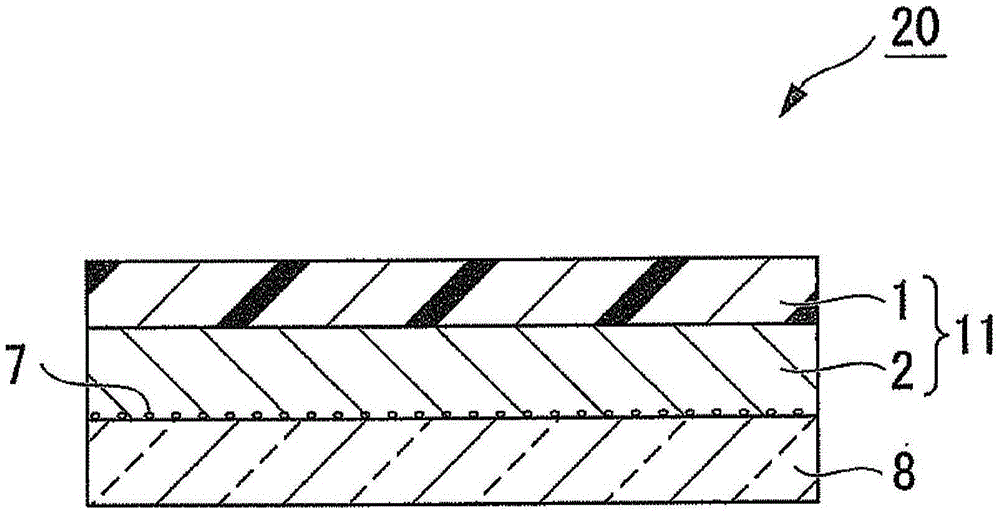

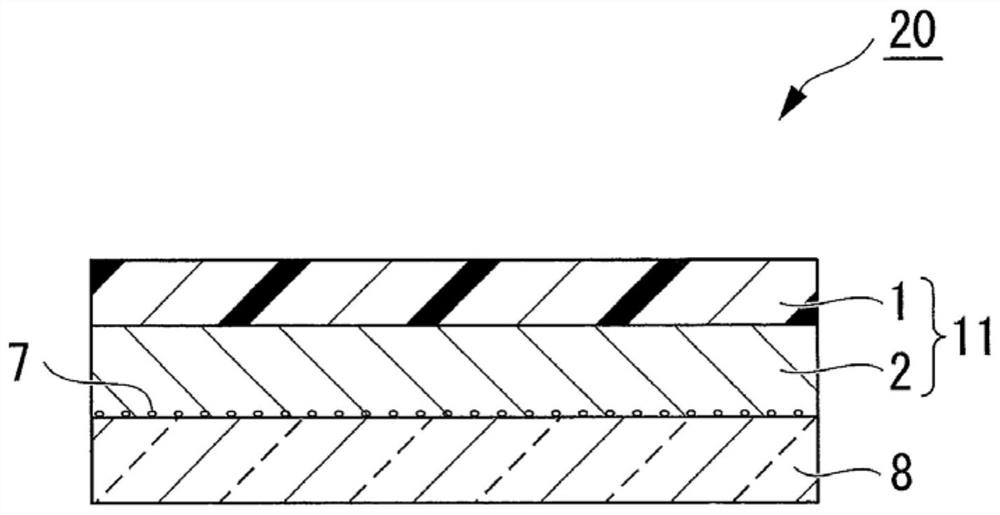

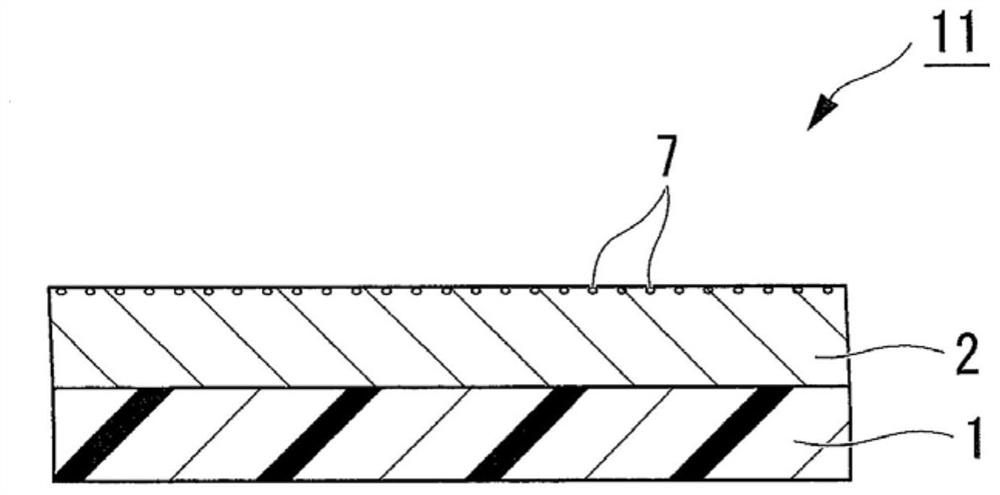

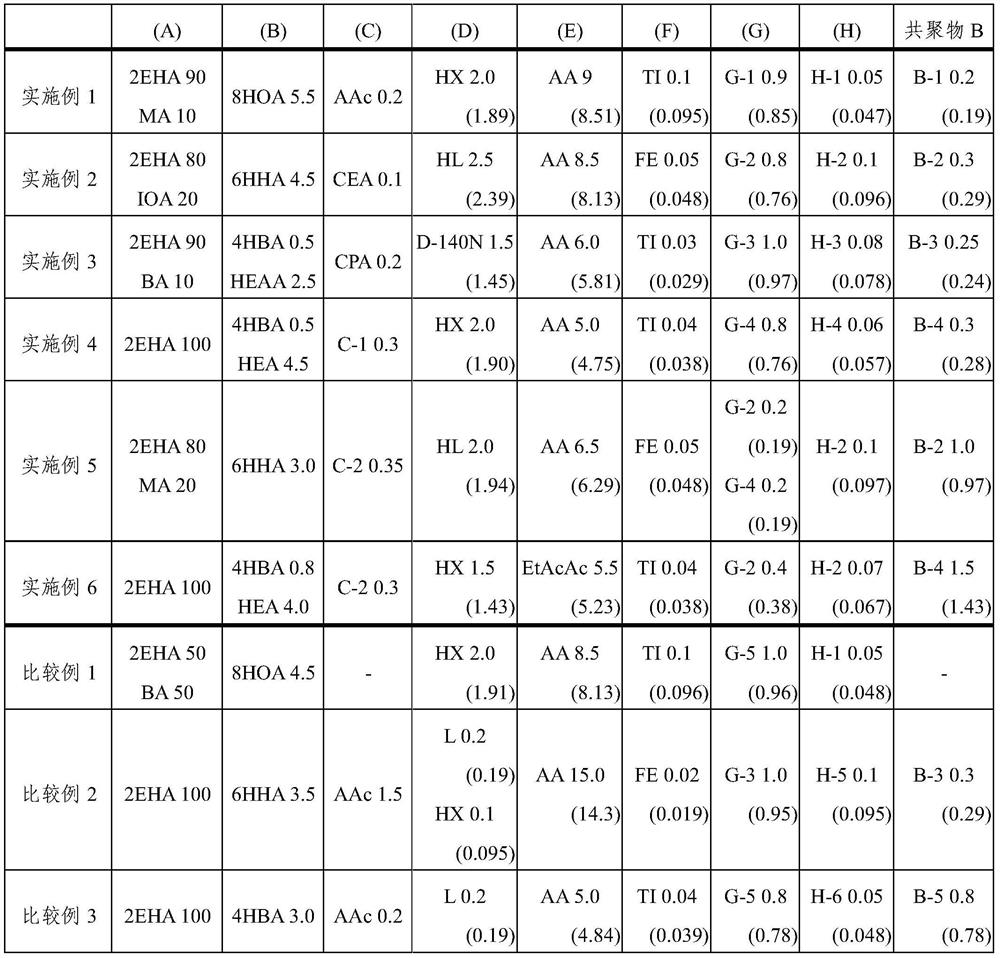

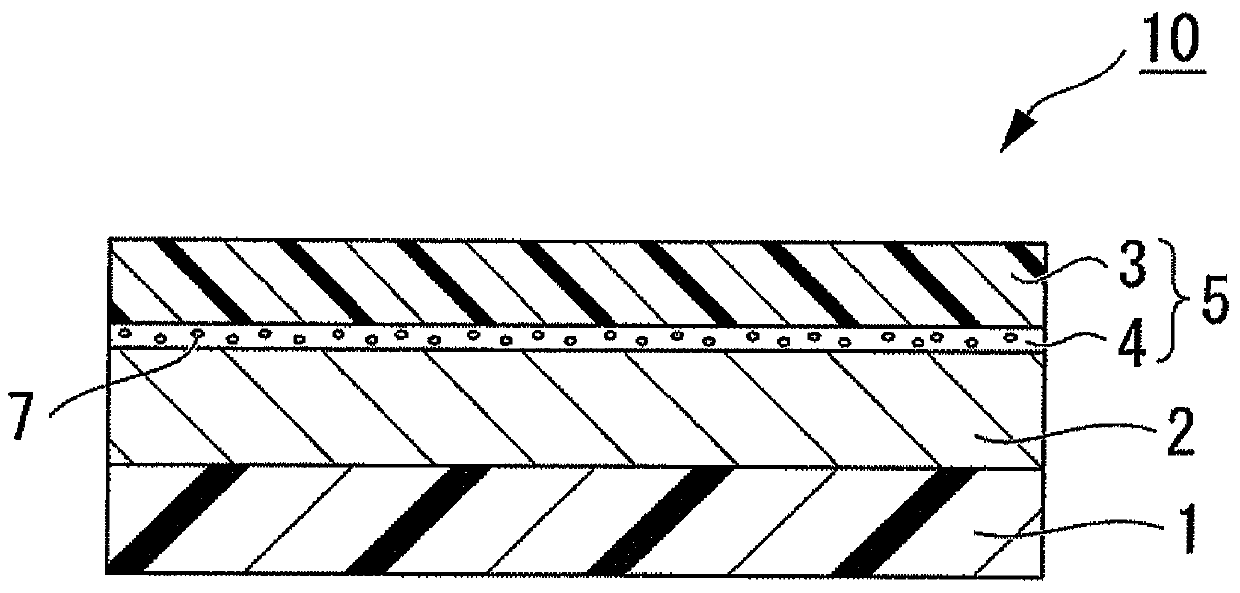

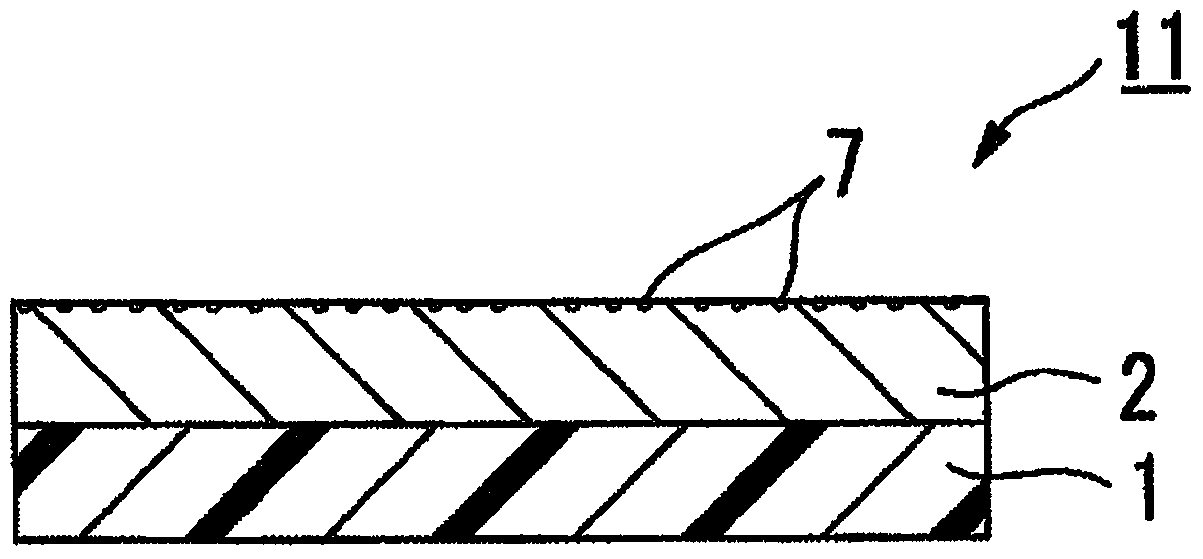

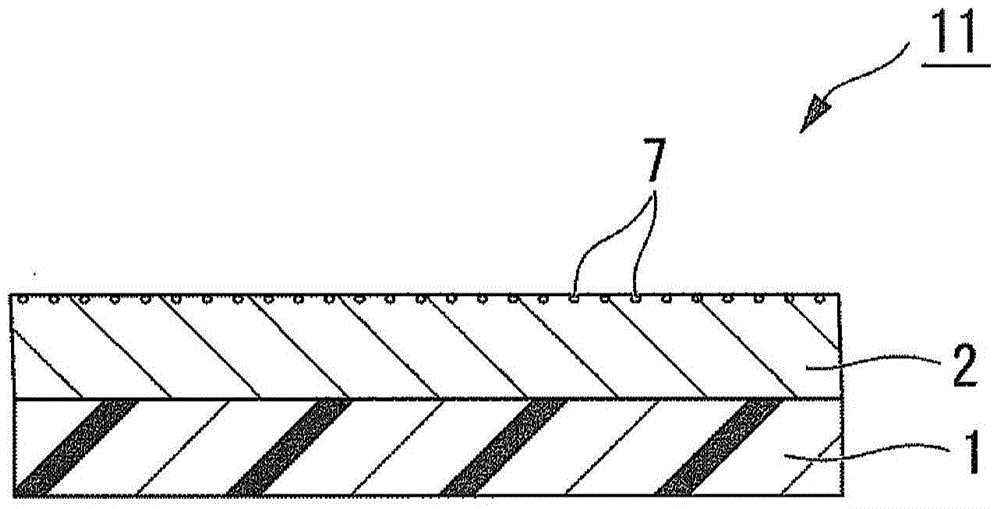

The invention provides an antistatic surface protection film, the pollution to a pasted body is light, and the antistatic surface protection film is provided with excellent anti-stripping electrostatic properties without time dependent degradation. The antistatic surface protection film is formed in a way that a binder layer (2) composed of a binder composition is formed on one side of a base film (1) formed by a transparent resin, the binder composition comprises an acrylate-based polymer containing copolymers, (F) an isocyanate compound containing more than two functional groups, (G) a crosslinking accelerator and (H) a ketone-enol tautomer compound, a stripping agent layer (4) containing an antistatic agent is laminated on one side of a resin film (3) to form a stripping film (5), and the stripping film (5) is attached to the surface of the binder layer (2) through the stripping agent layer (4). The stripping agent layer (4) is formed by a resin composition, and the resin composition comprises a stripping agent taking dimethyl polysiloxane as the key component, a polysiloxane compound which is liquid under 20 DEG C and an antistatic agent, and the stripping electrostatic pressure of the binder layer (2) is lower than + / -0.6kV.

Owner:FUJIMORI KOGYO CO LTD

Surface protection film and optical component attached with the film

ActiveCN103421436AExcellent anti-stripping static performanceReduce pollutionFilm/foil adhesivesSynthetic resin layered productsTectorial membraneAntistatic agent

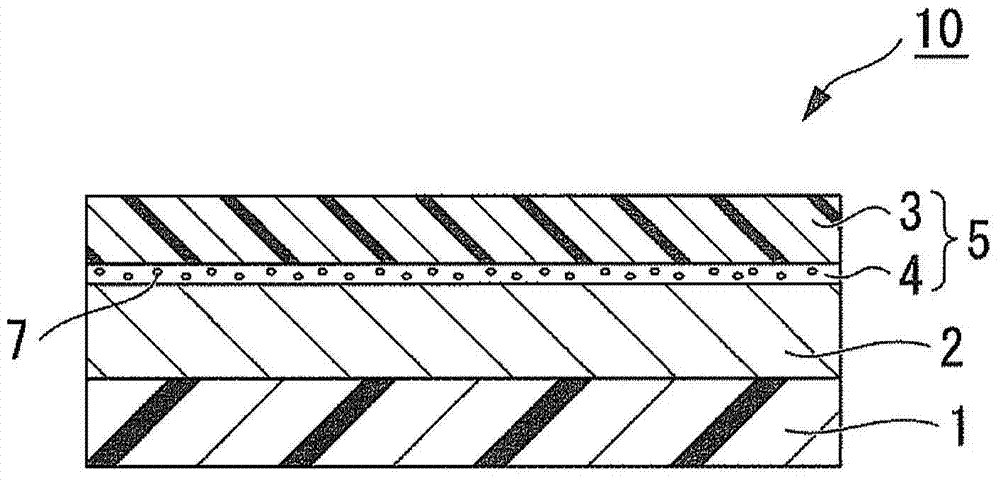

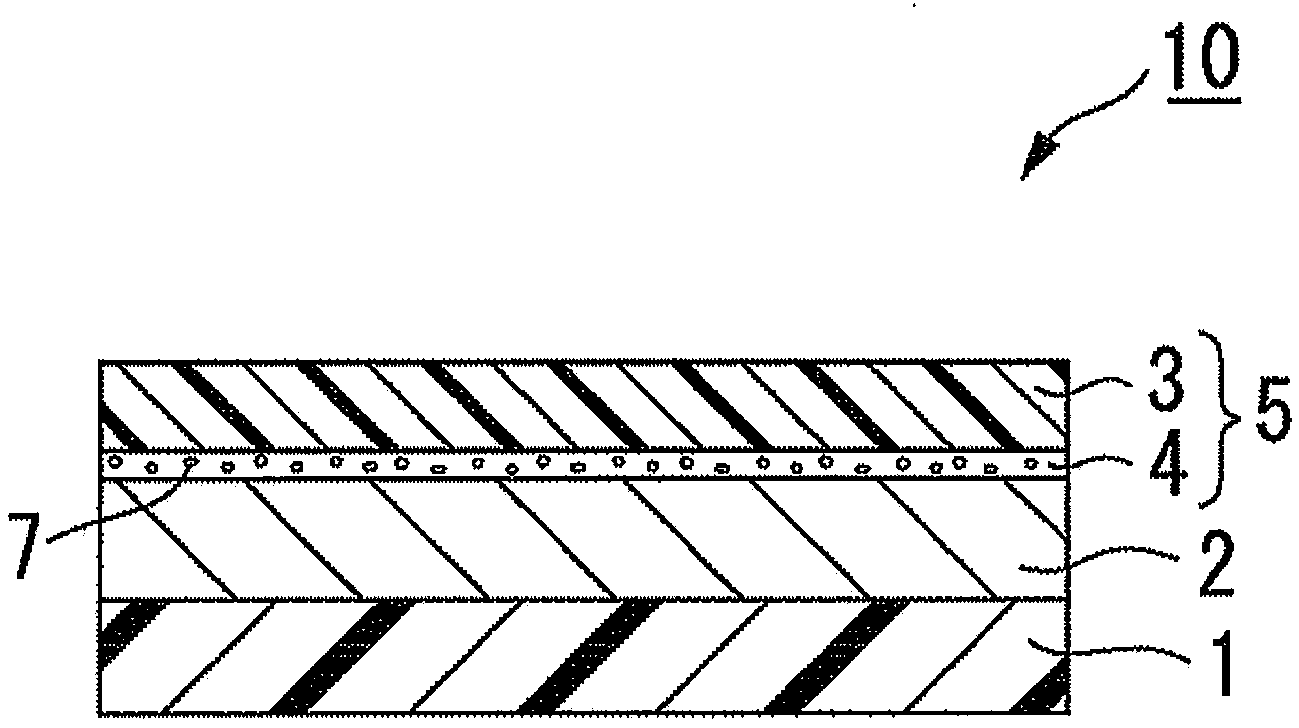

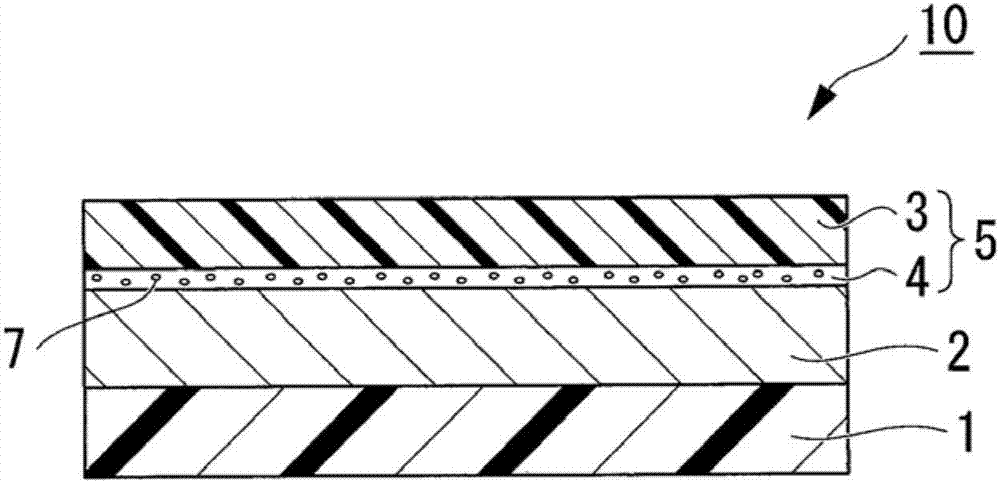

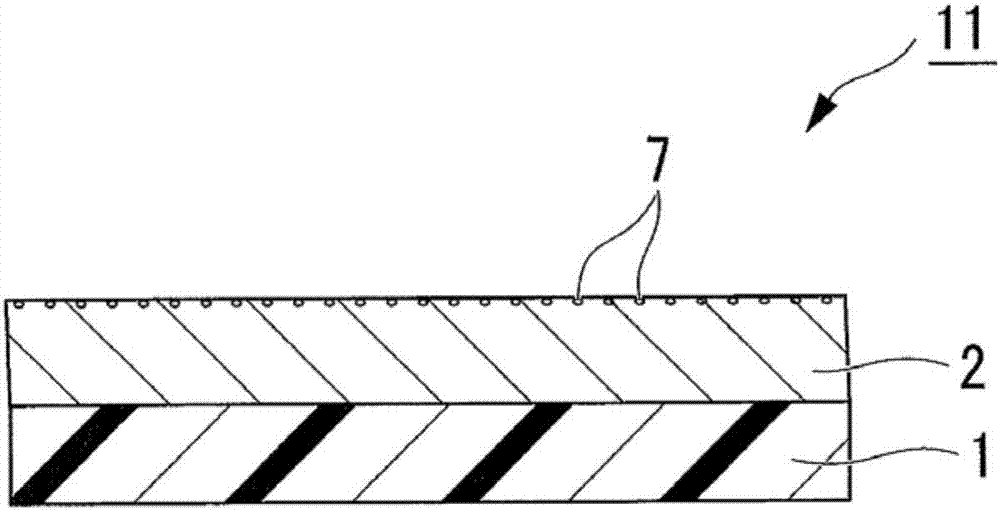

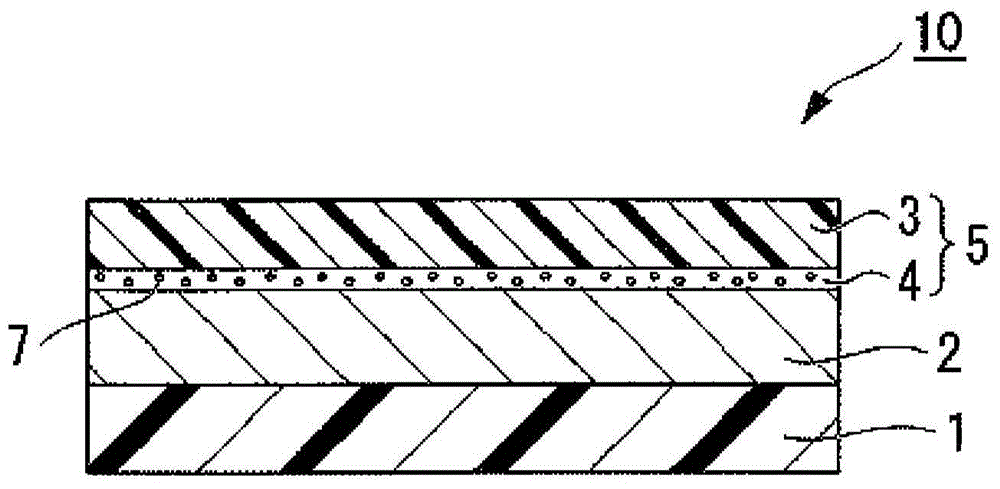

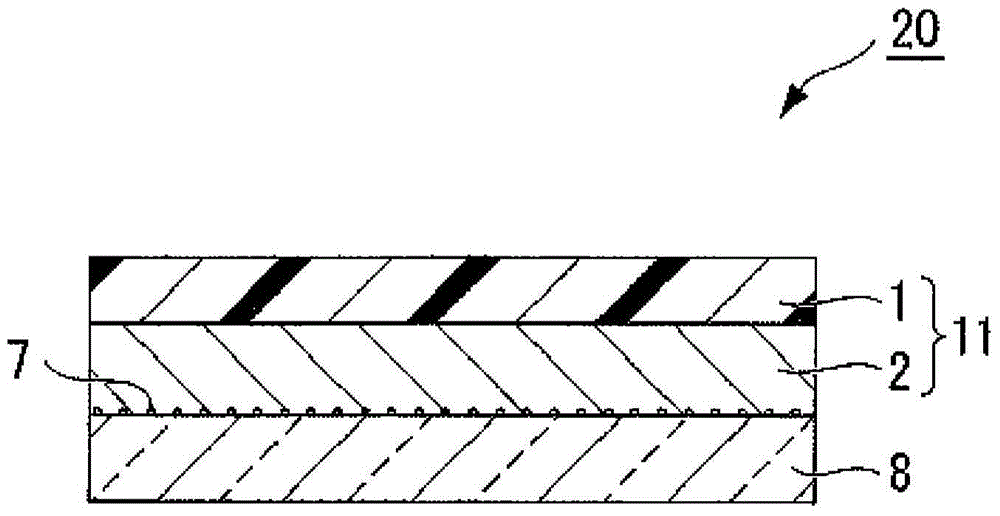

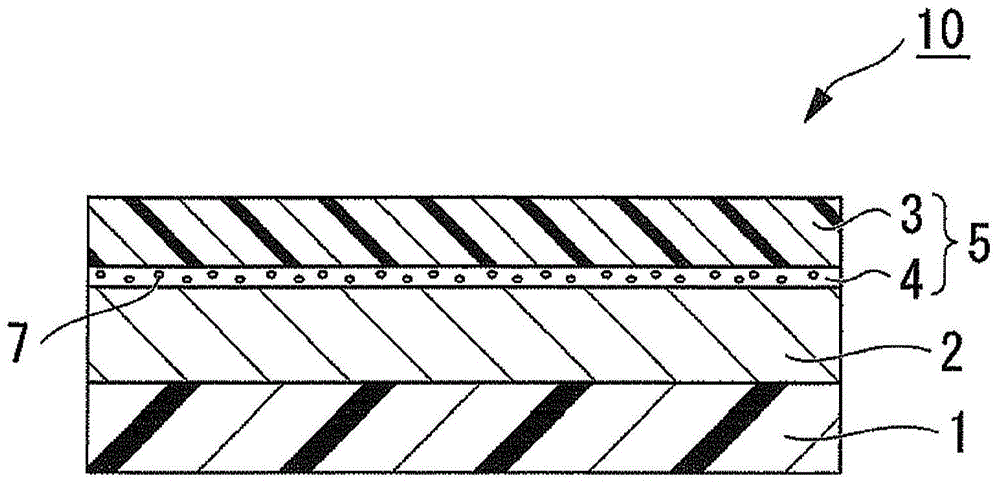

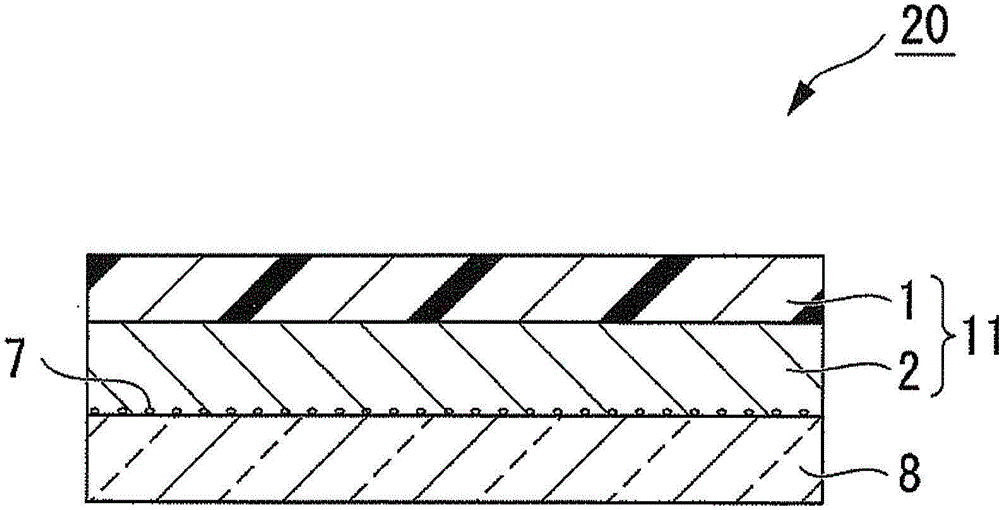

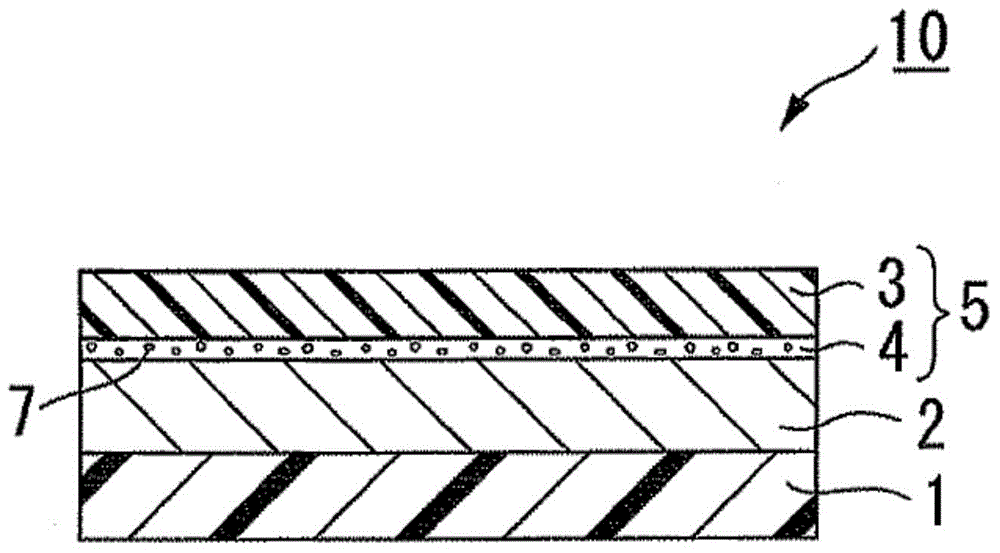

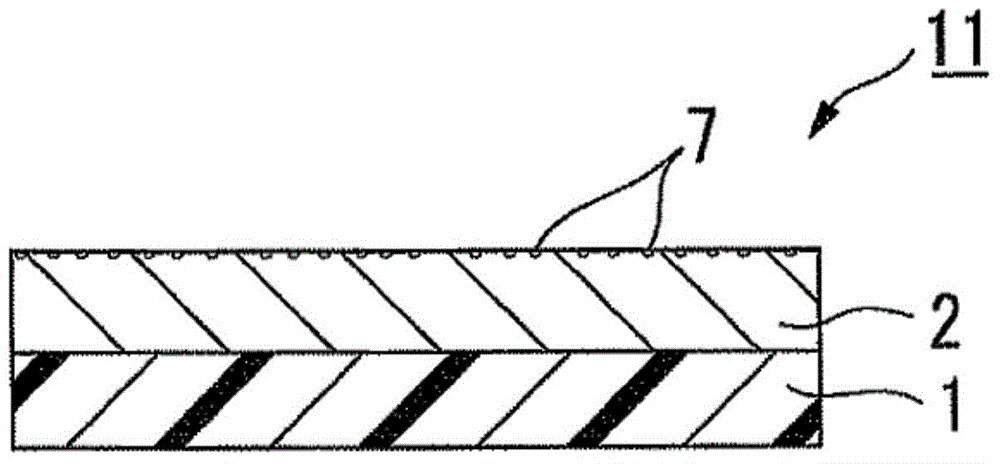

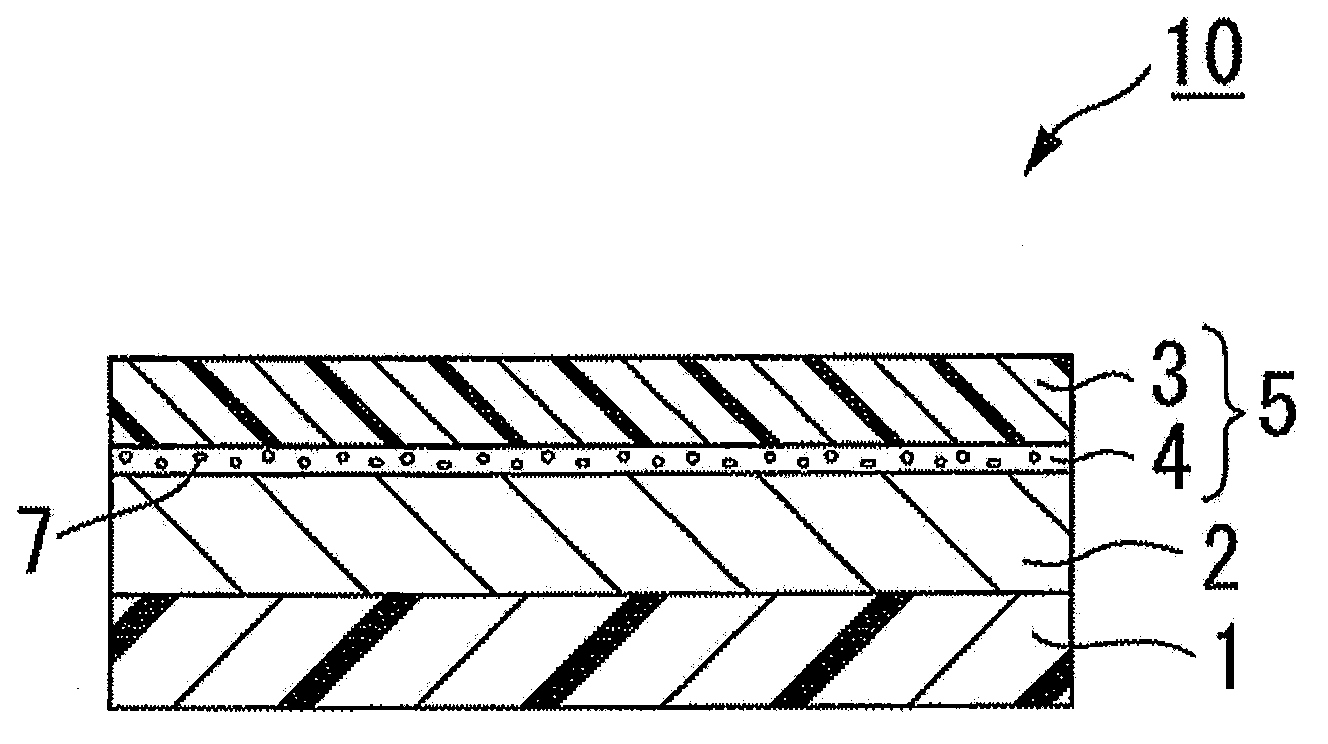

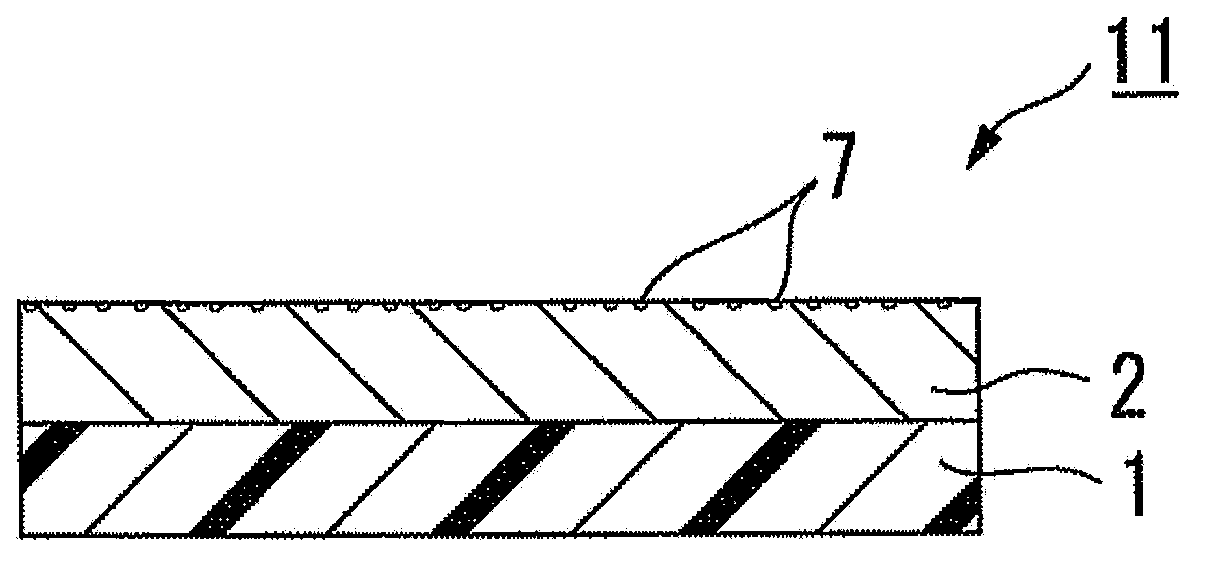

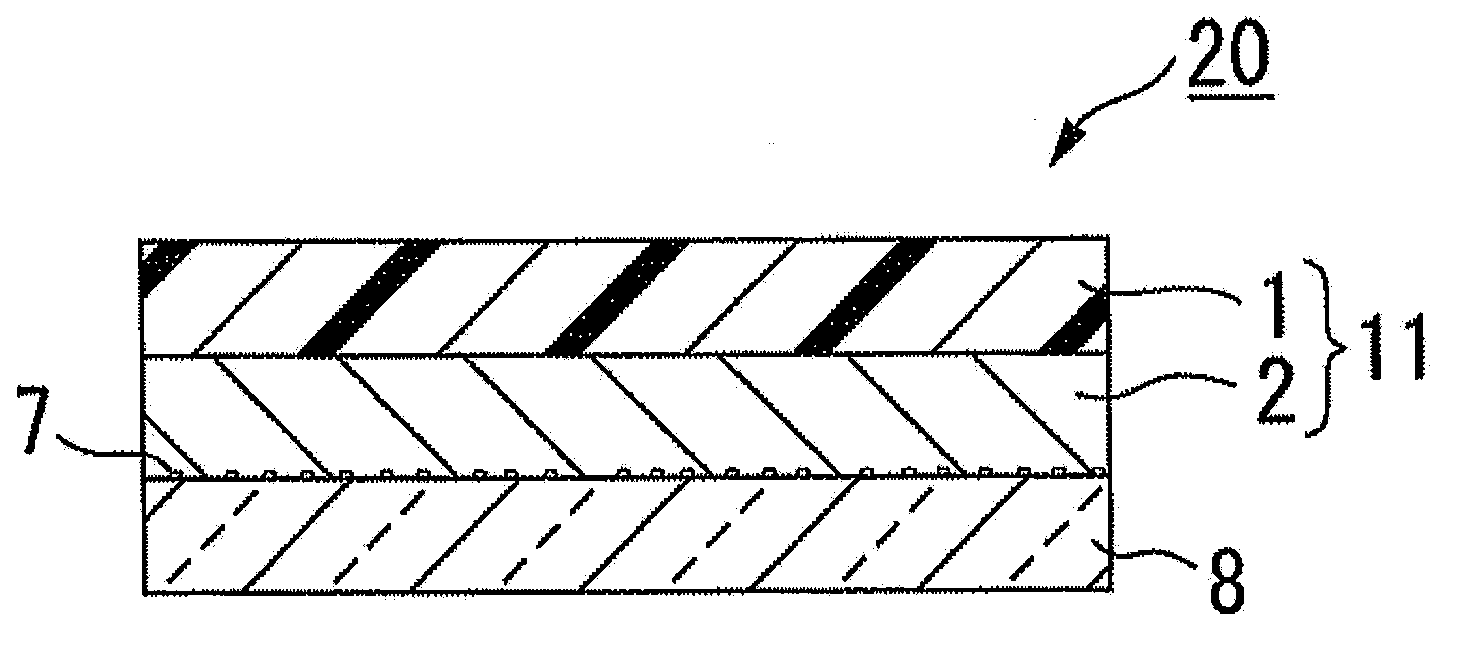

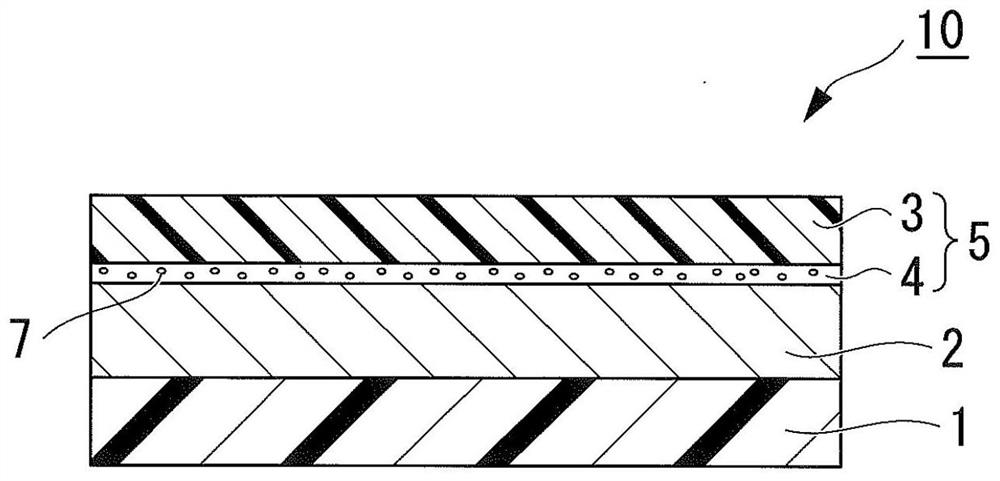

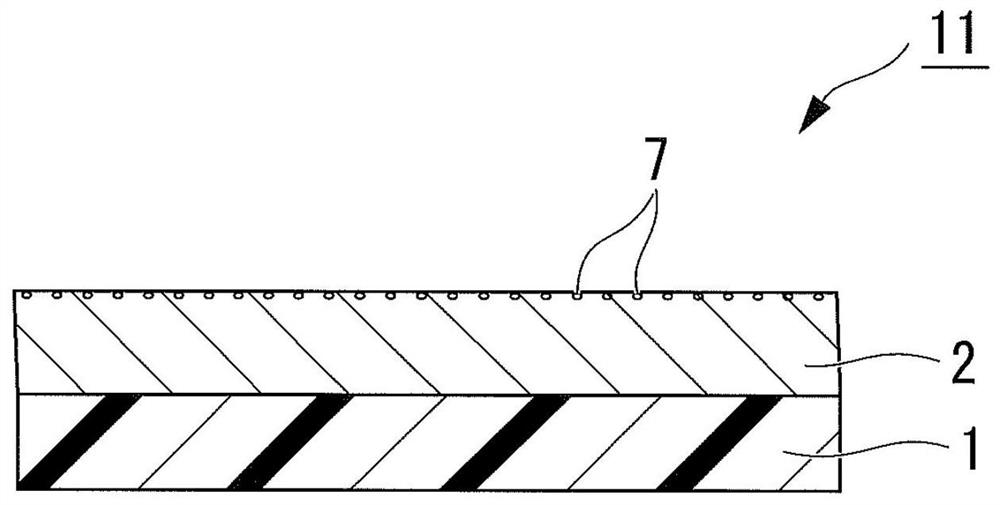

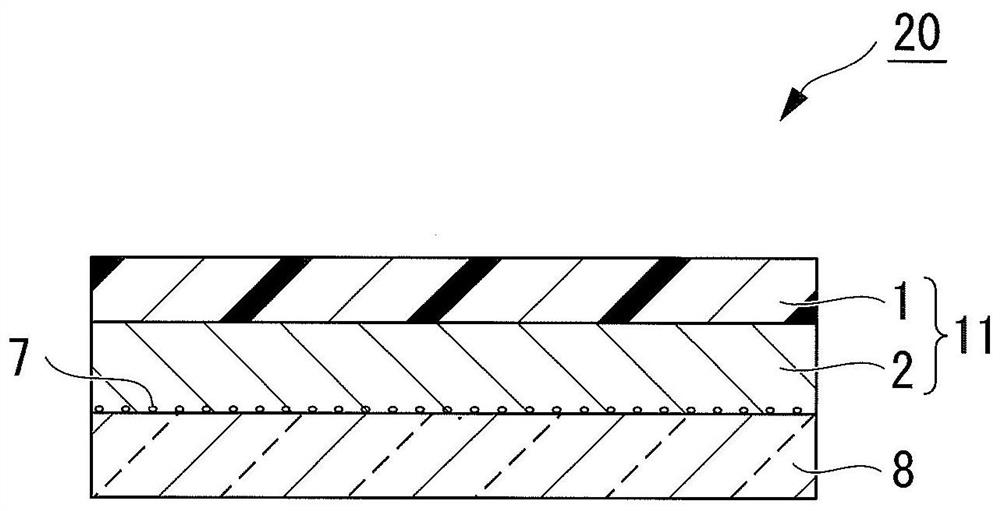

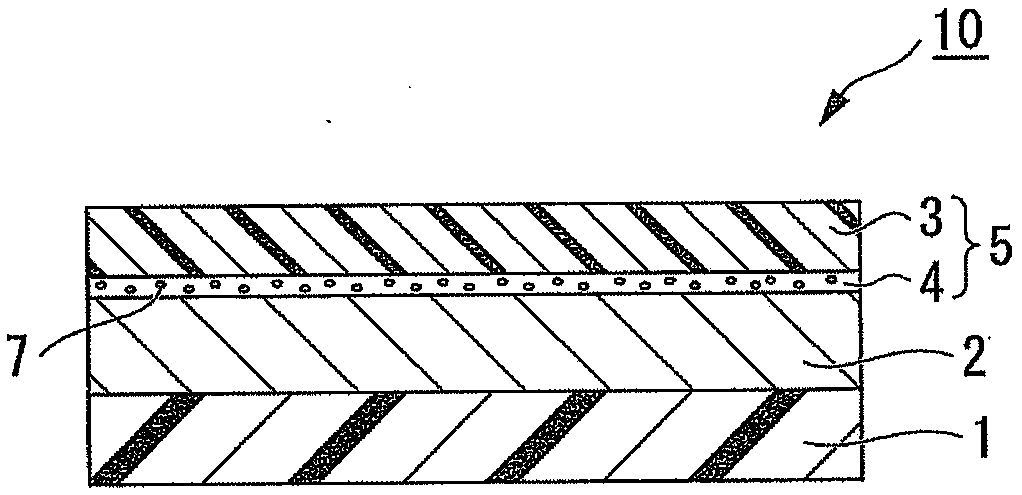

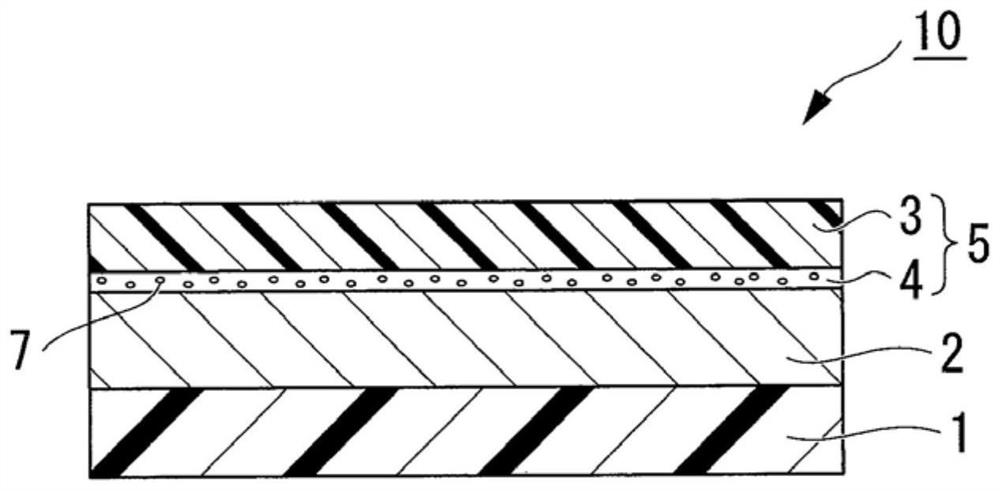

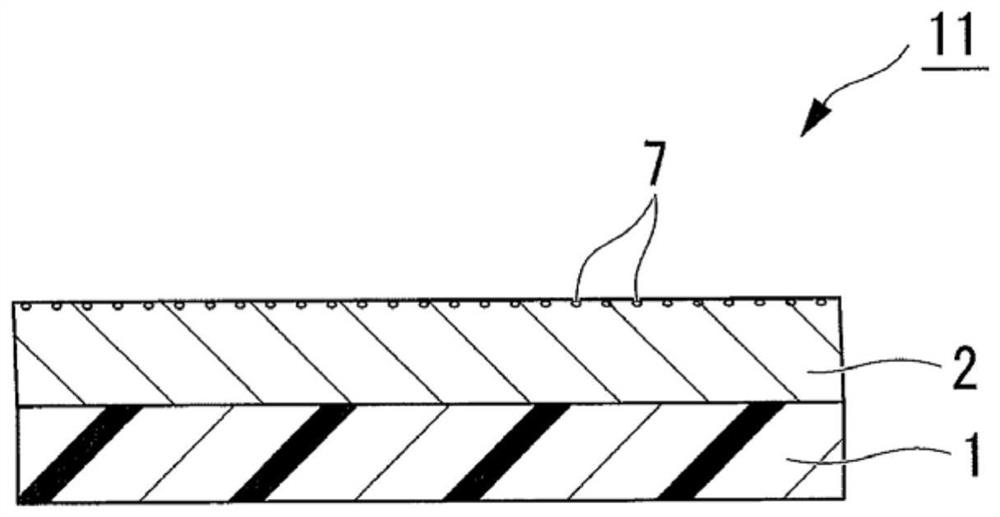

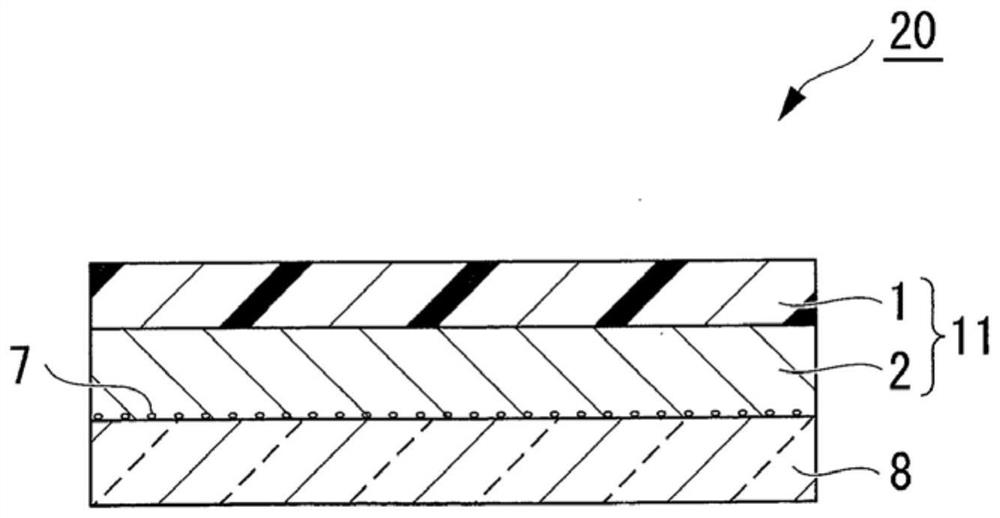

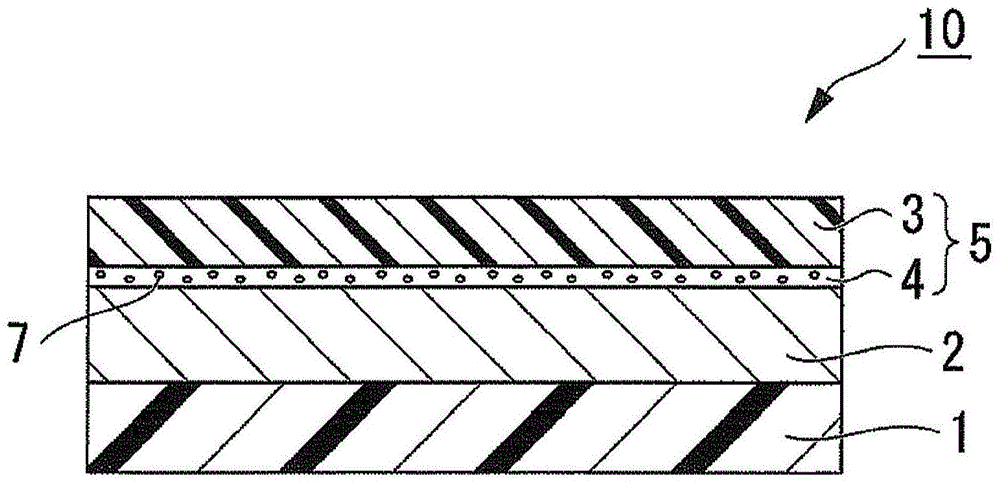

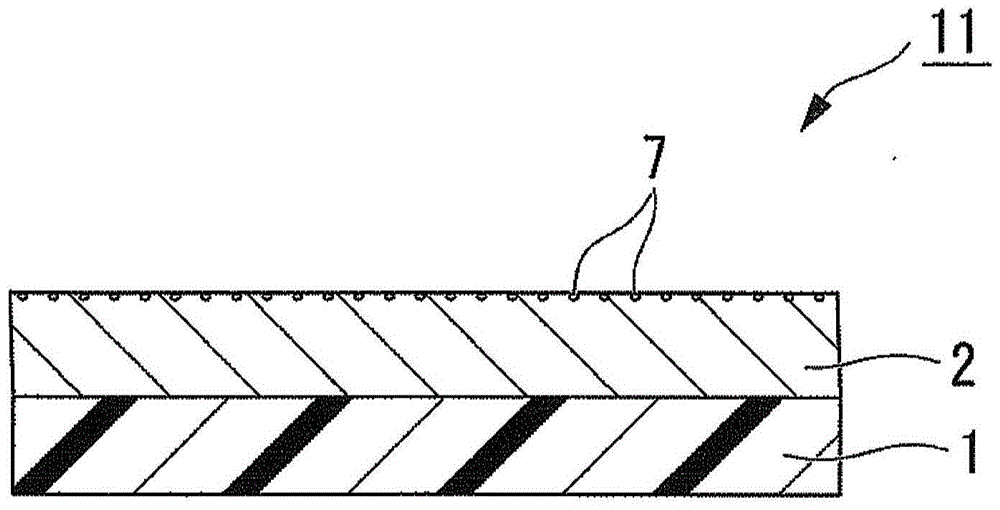

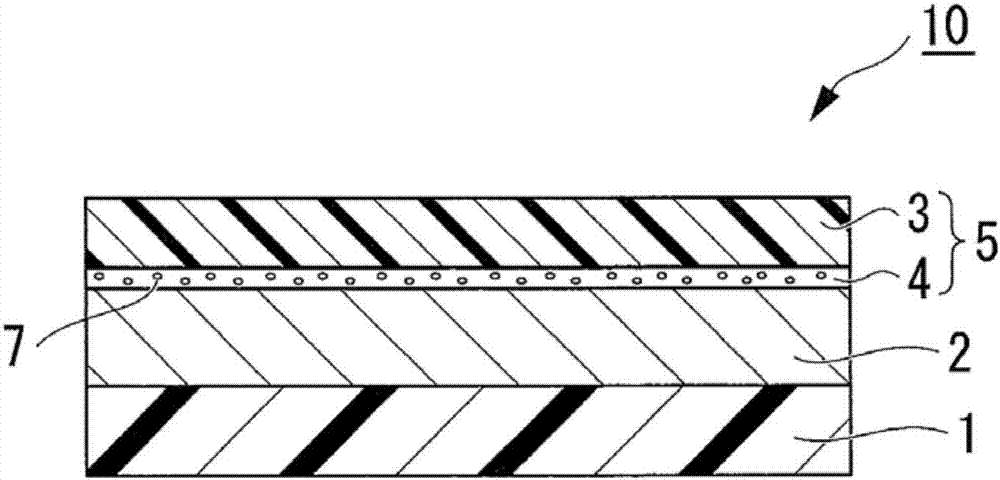

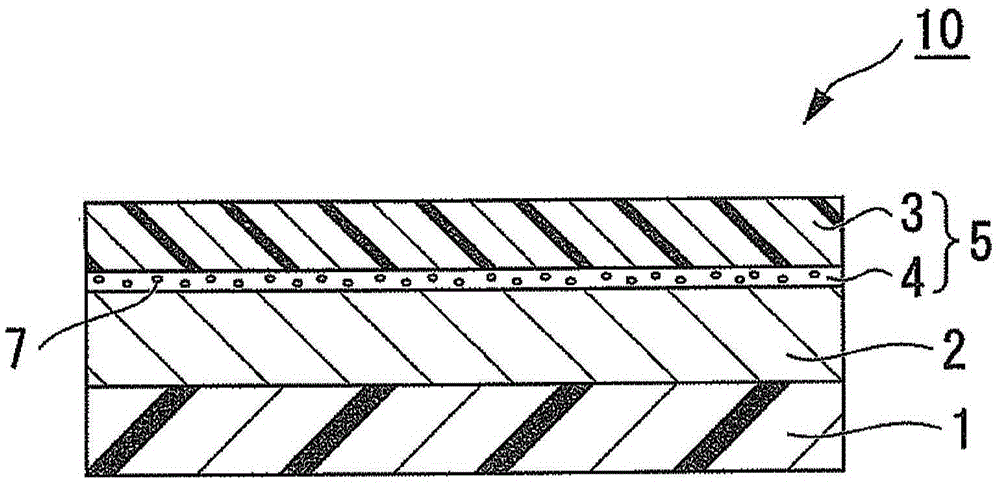

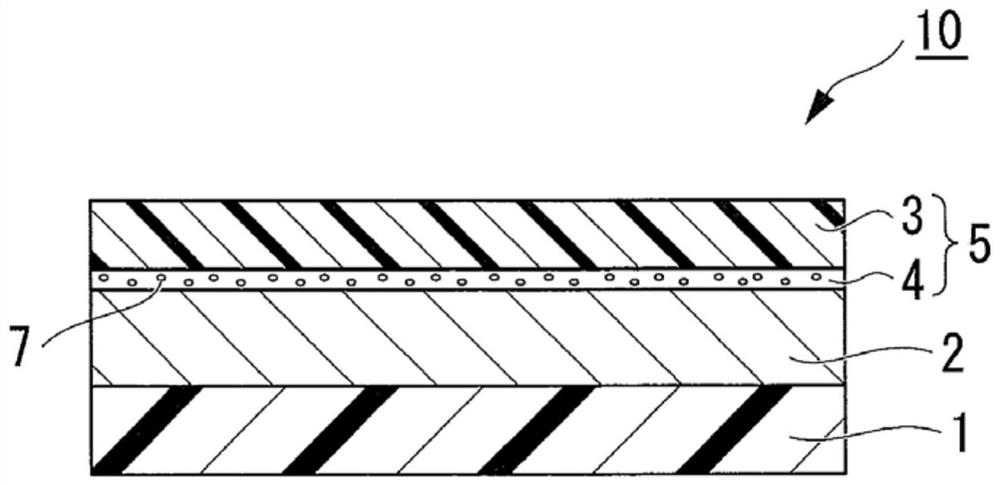

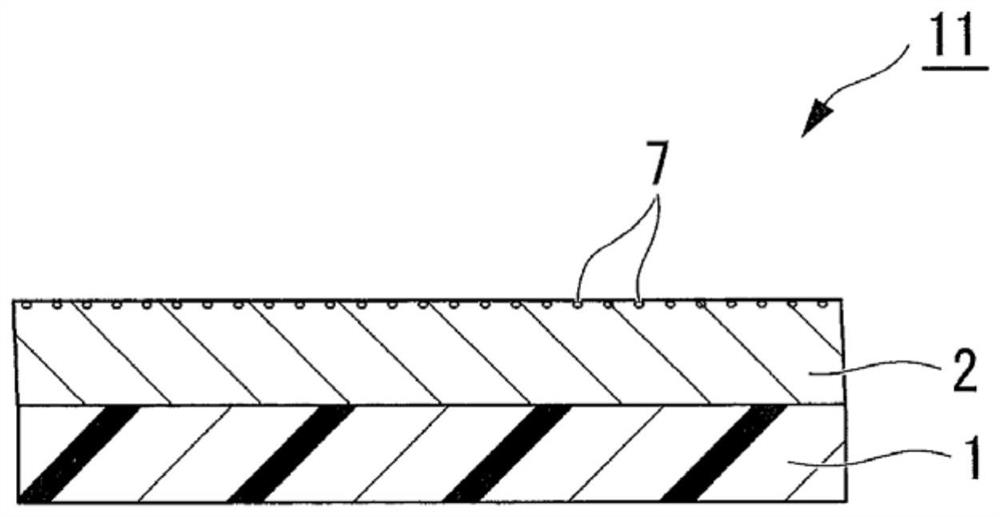

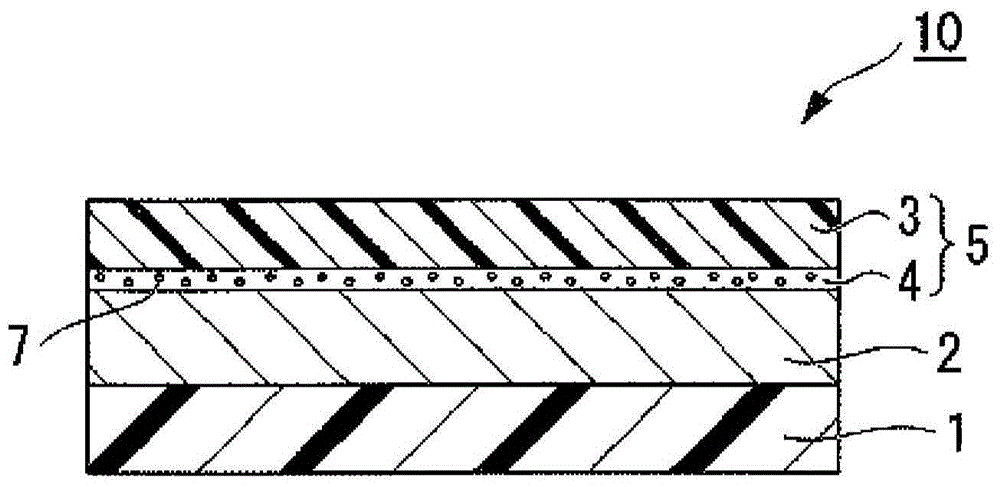

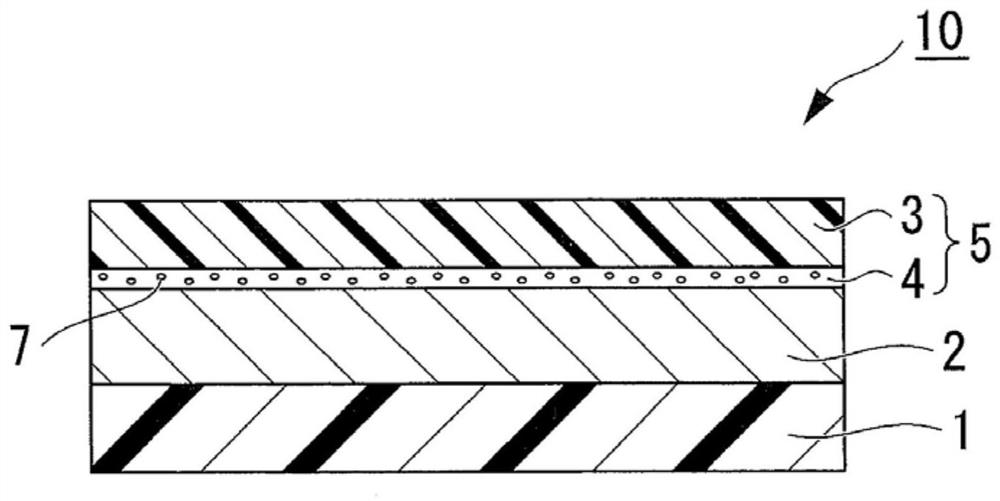

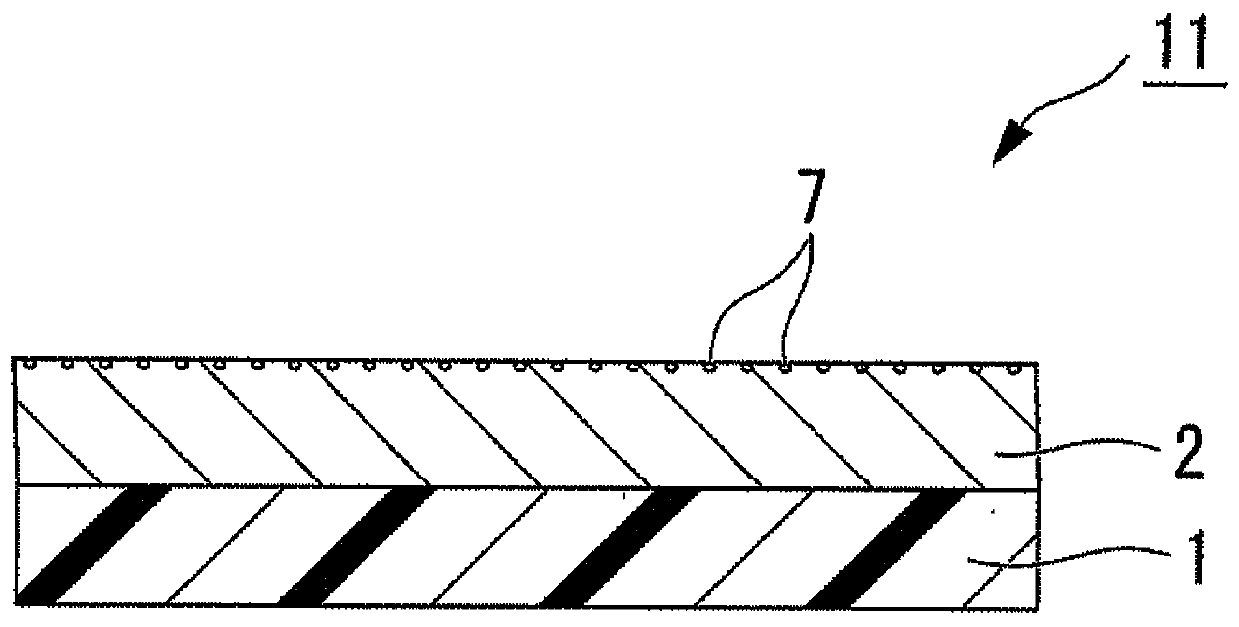

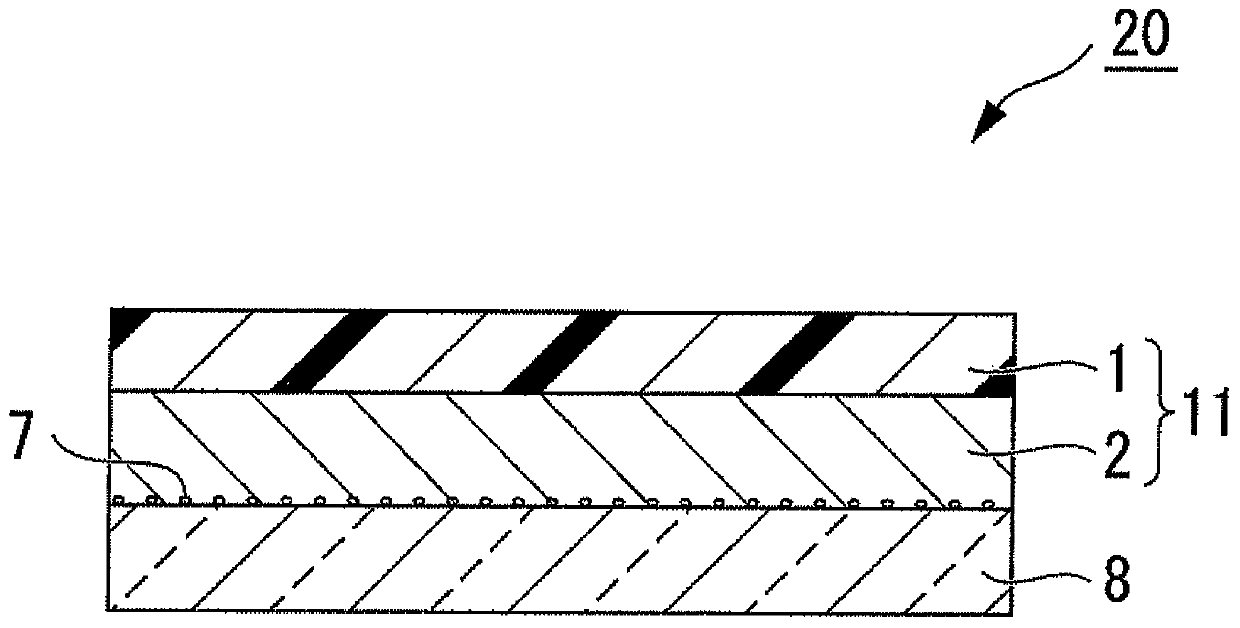

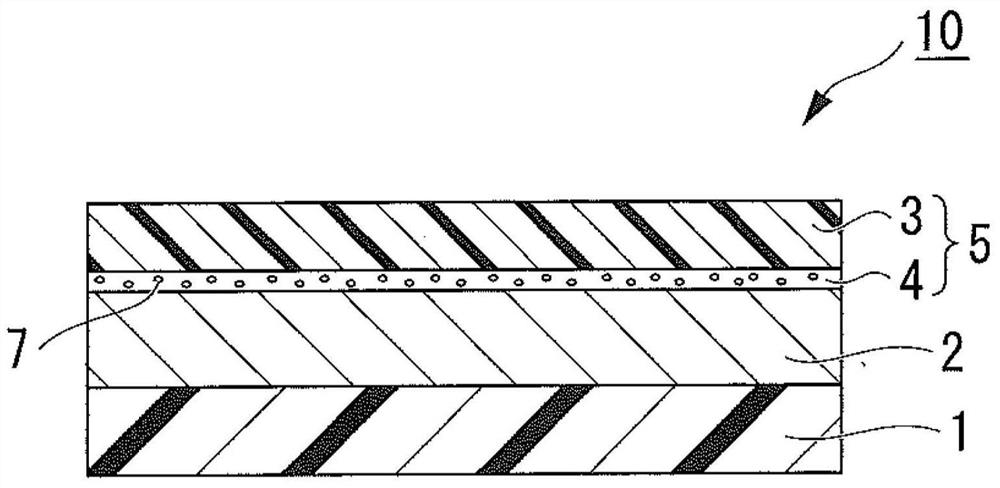

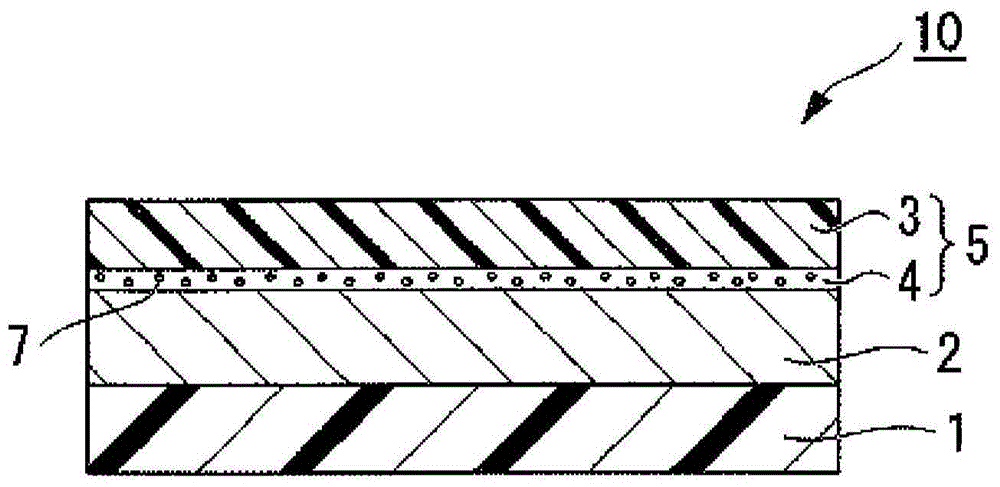

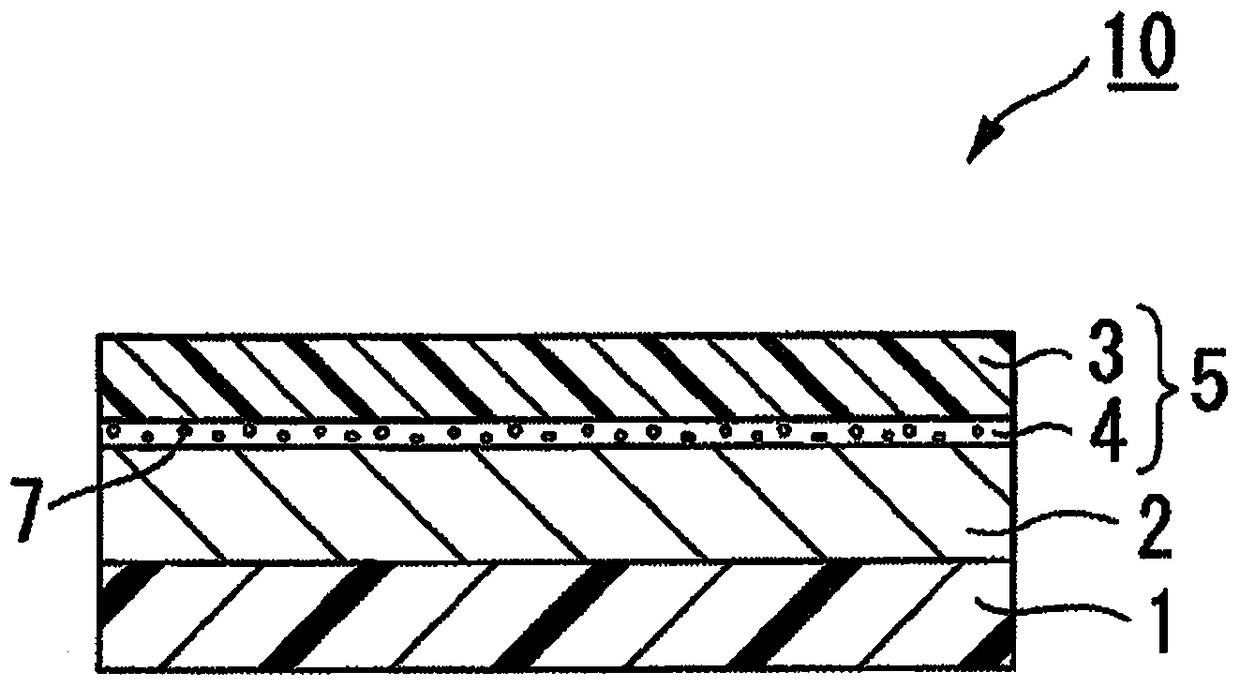

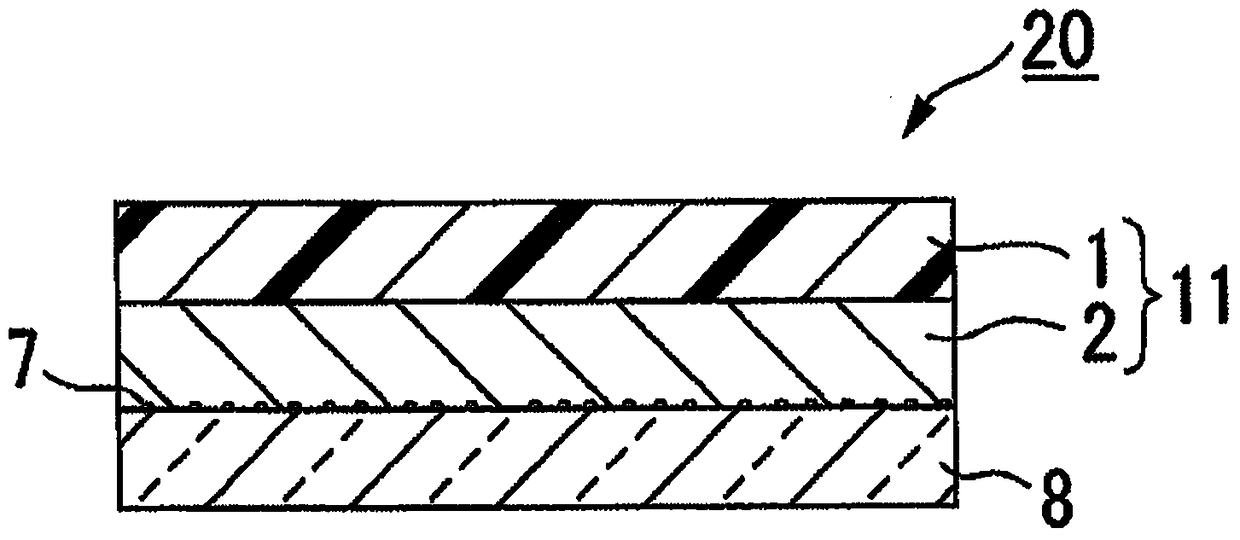

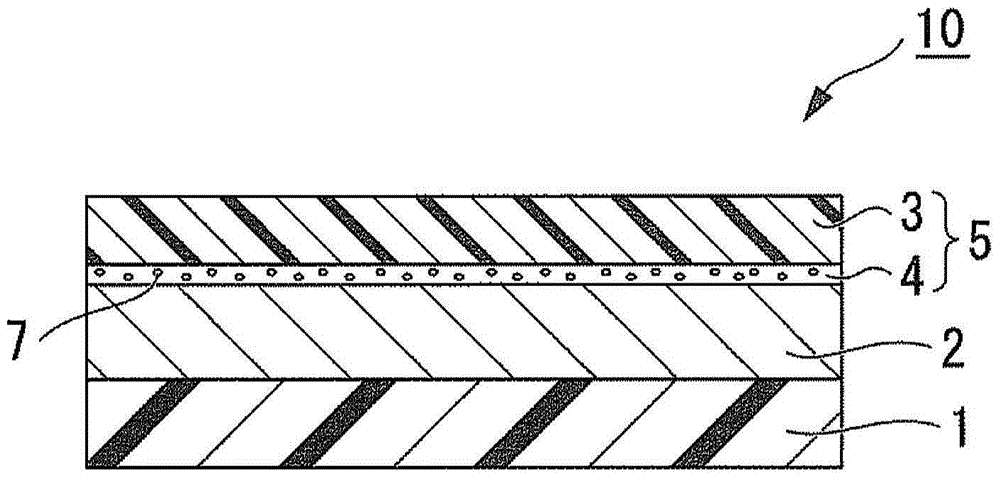

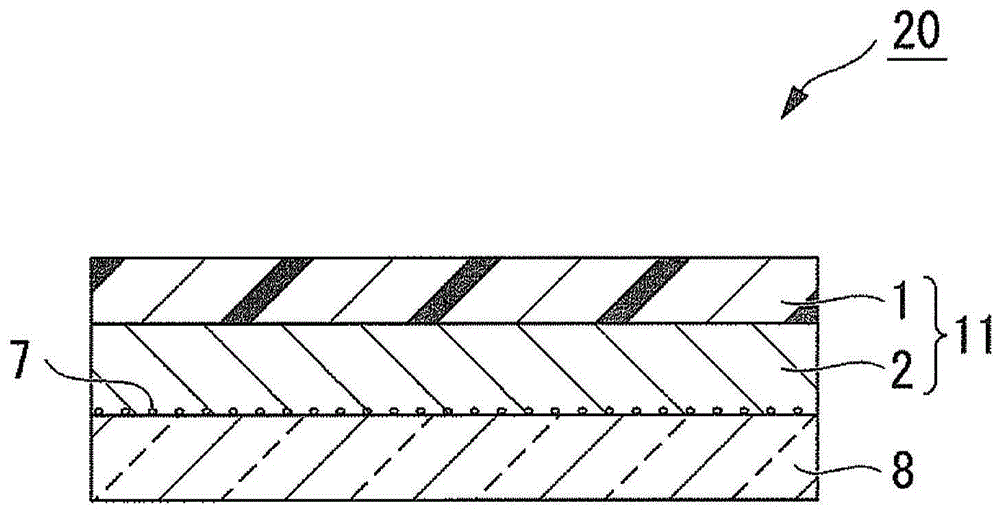

The invention provides a surface protective film which has low pollution on an adhered object , will not be degradated over time and has an excellent release static prevention property, and a optical component attached with the surface protection film. A binder layer (2) is formed on a single surface of a transparent substrate film, the surface protection film (10) with a release film is attached on the binder layer (2), the binder film (2) contains an antistatic agent, the release film (5) is formed by stacking a release agent layer (4) on the single surface layer of a resin film (3), and the release agent layer (4) contains a release agent using dimethyl polysiloxane as a main component, and a silicon compound which is a liquid under 20 DEG C. The binder layer (2) is formed by a (methyl) acrylic copolymer copolymerized with a compound with a polyoxyalkene group, or is formed by the (methyl) acrylic copolymer mixed with the compound with the polyoxyalkene group.

Owner:FUJIMORI KOGYO CO LTD

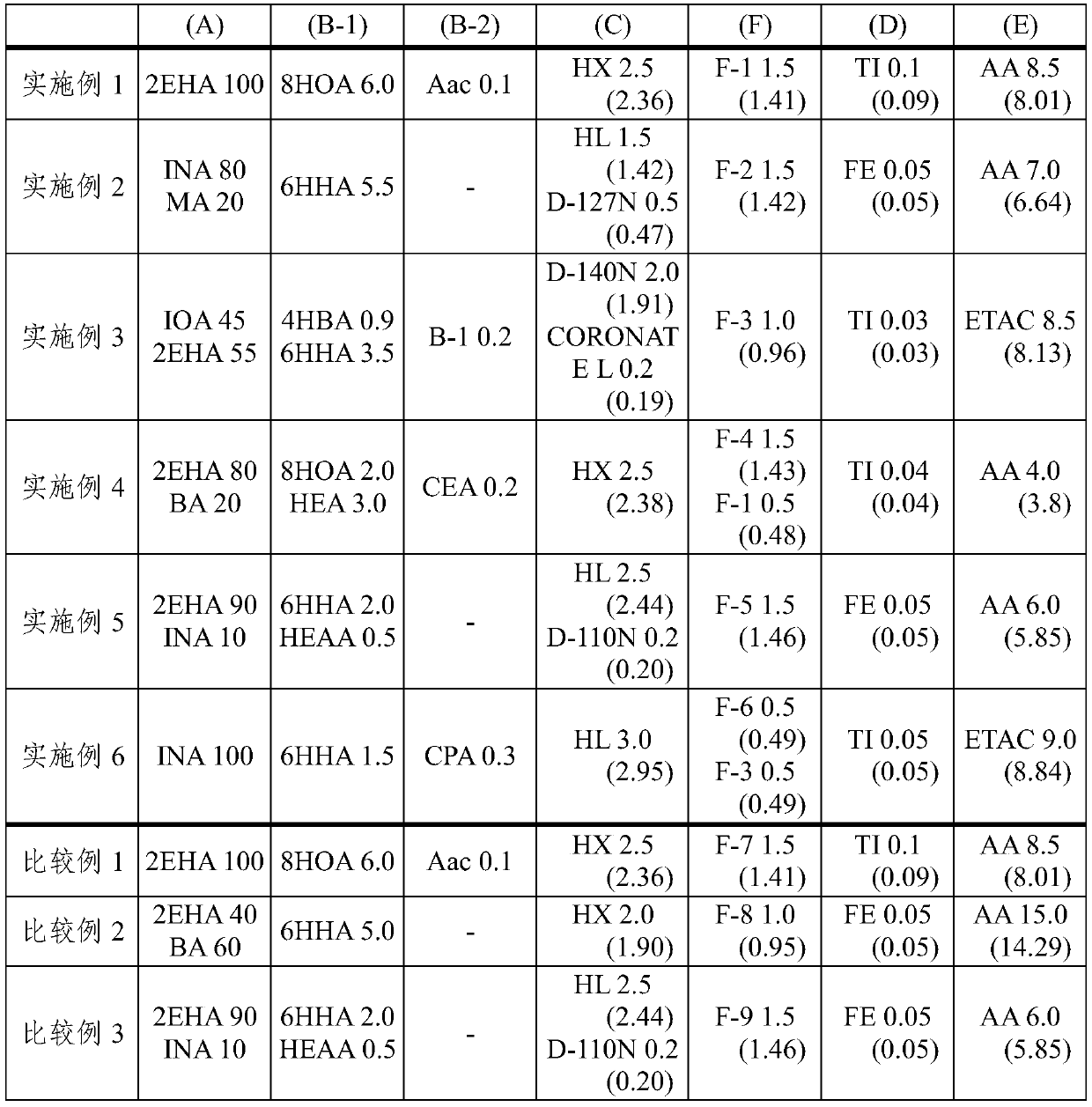

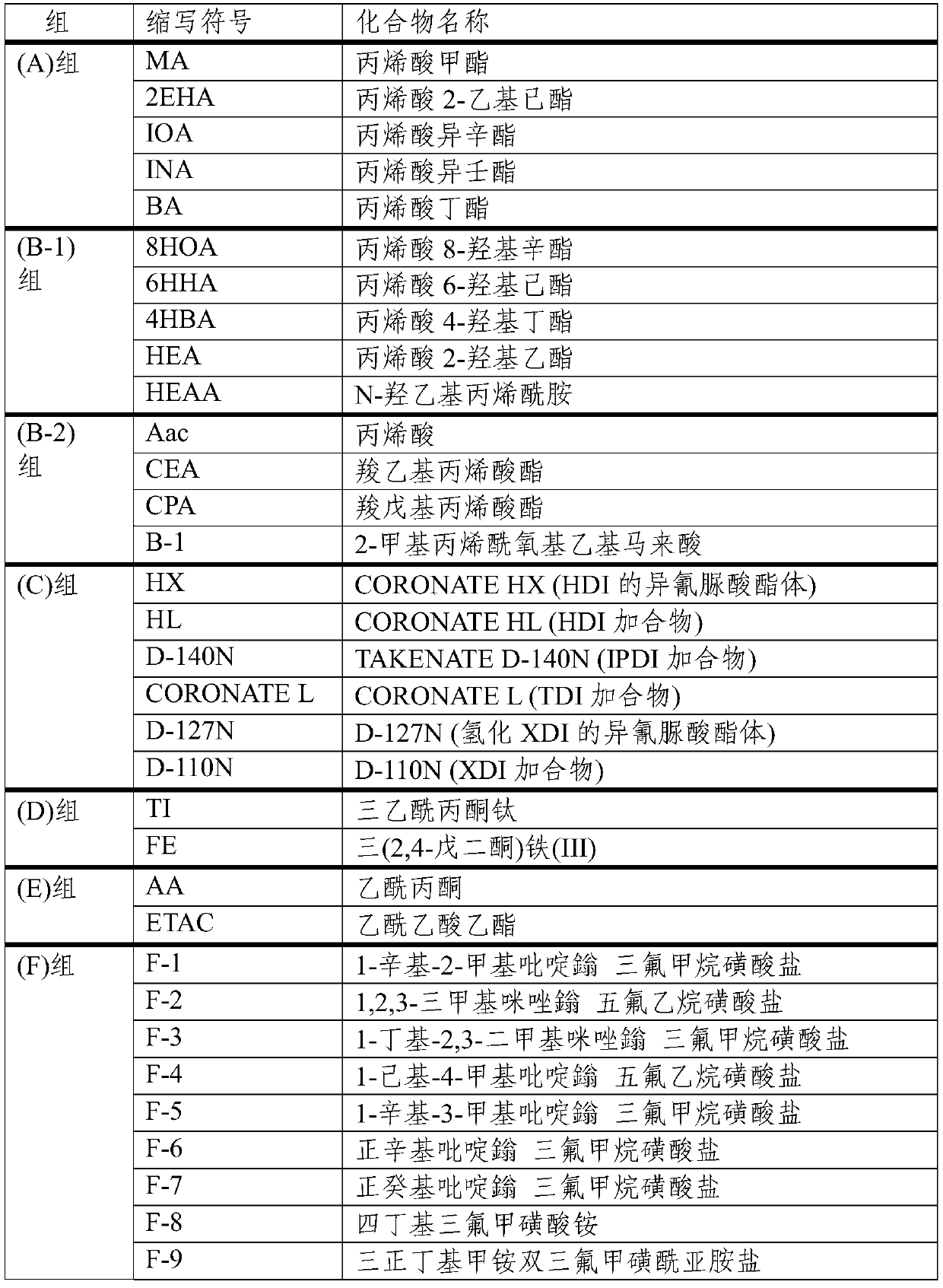

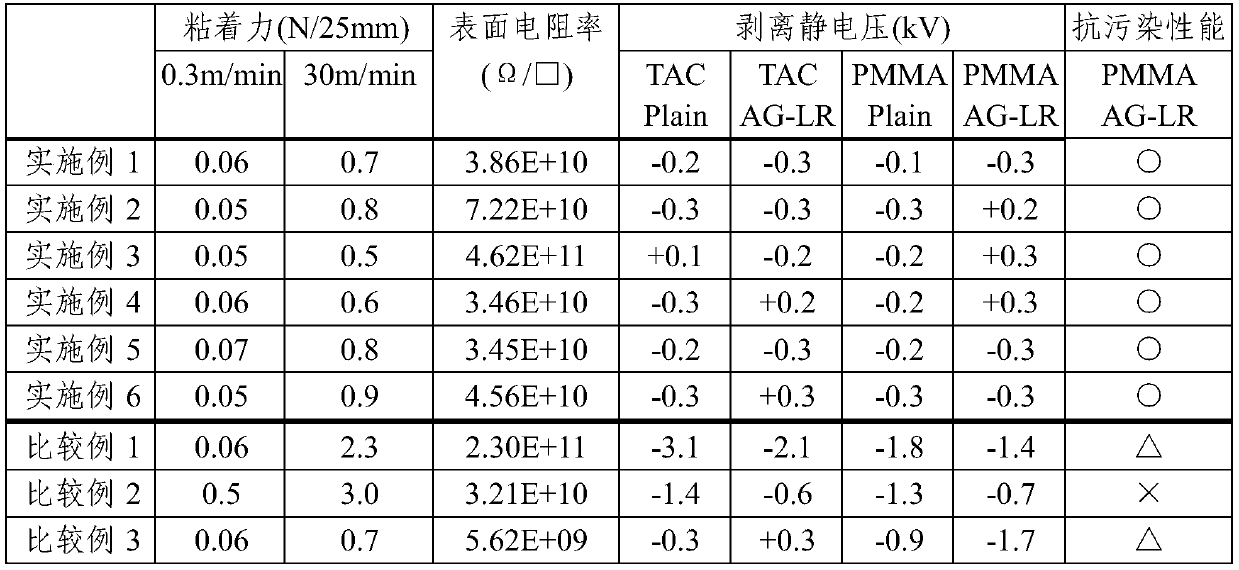

Method for producing antistatic surface-protective film and antistatic surface-protective film

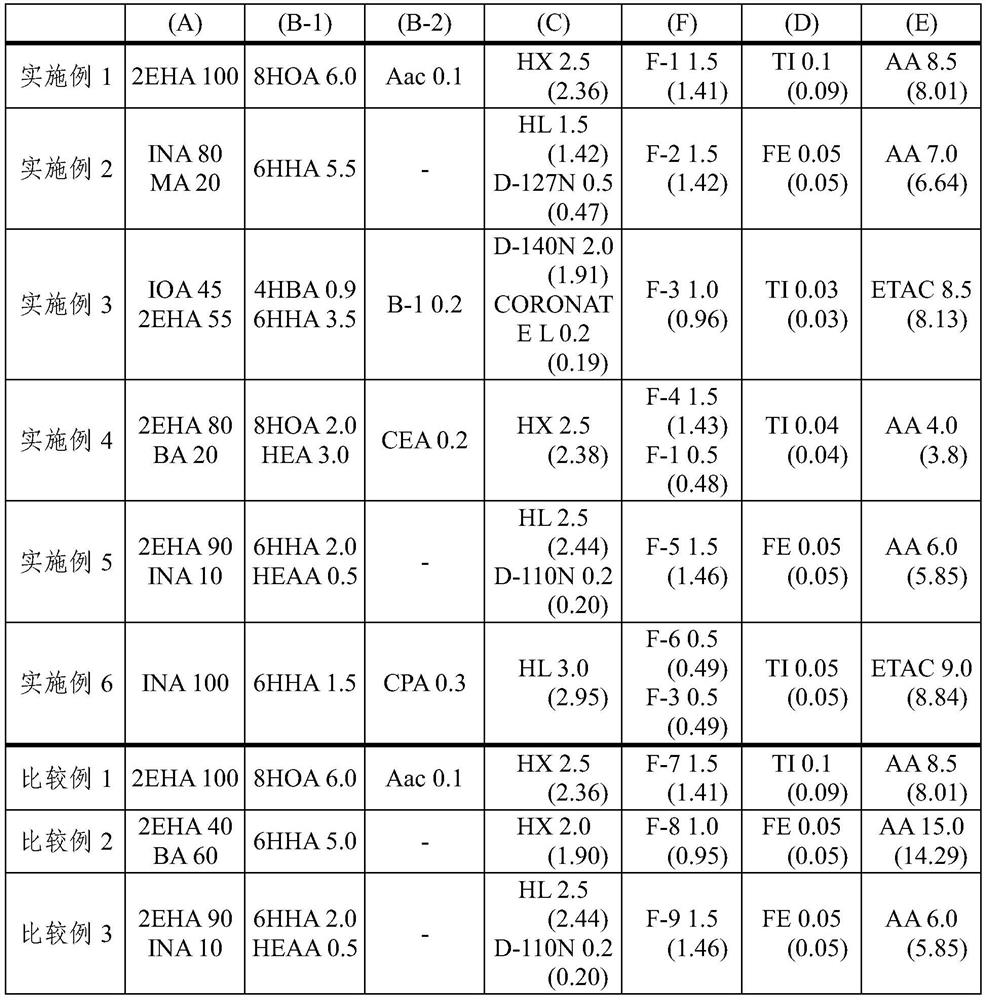

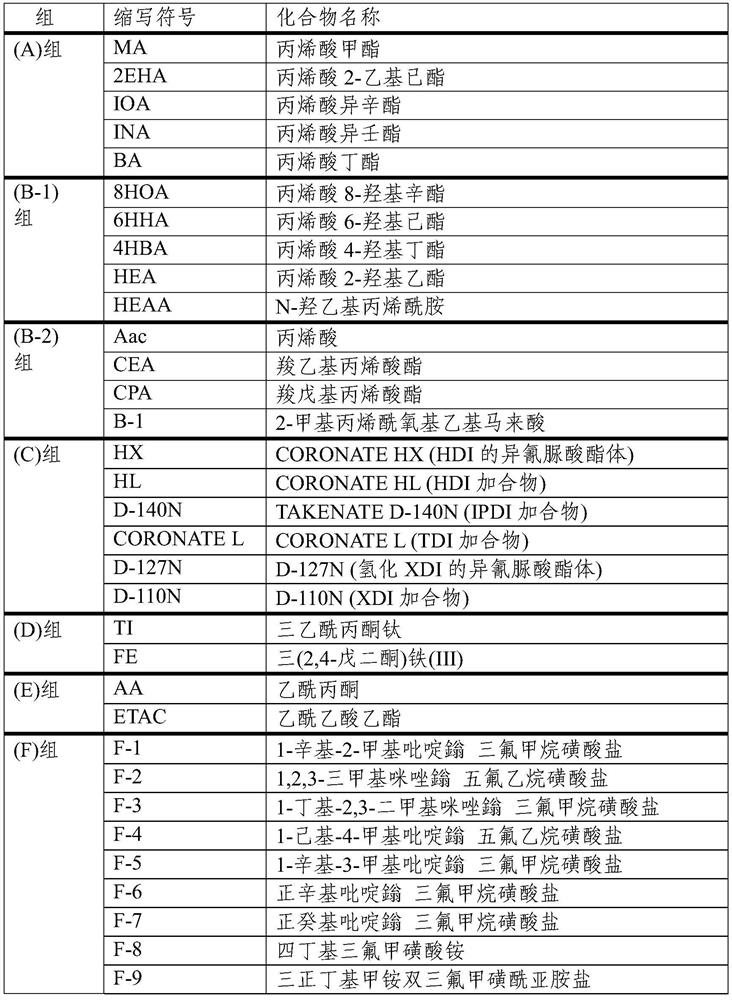

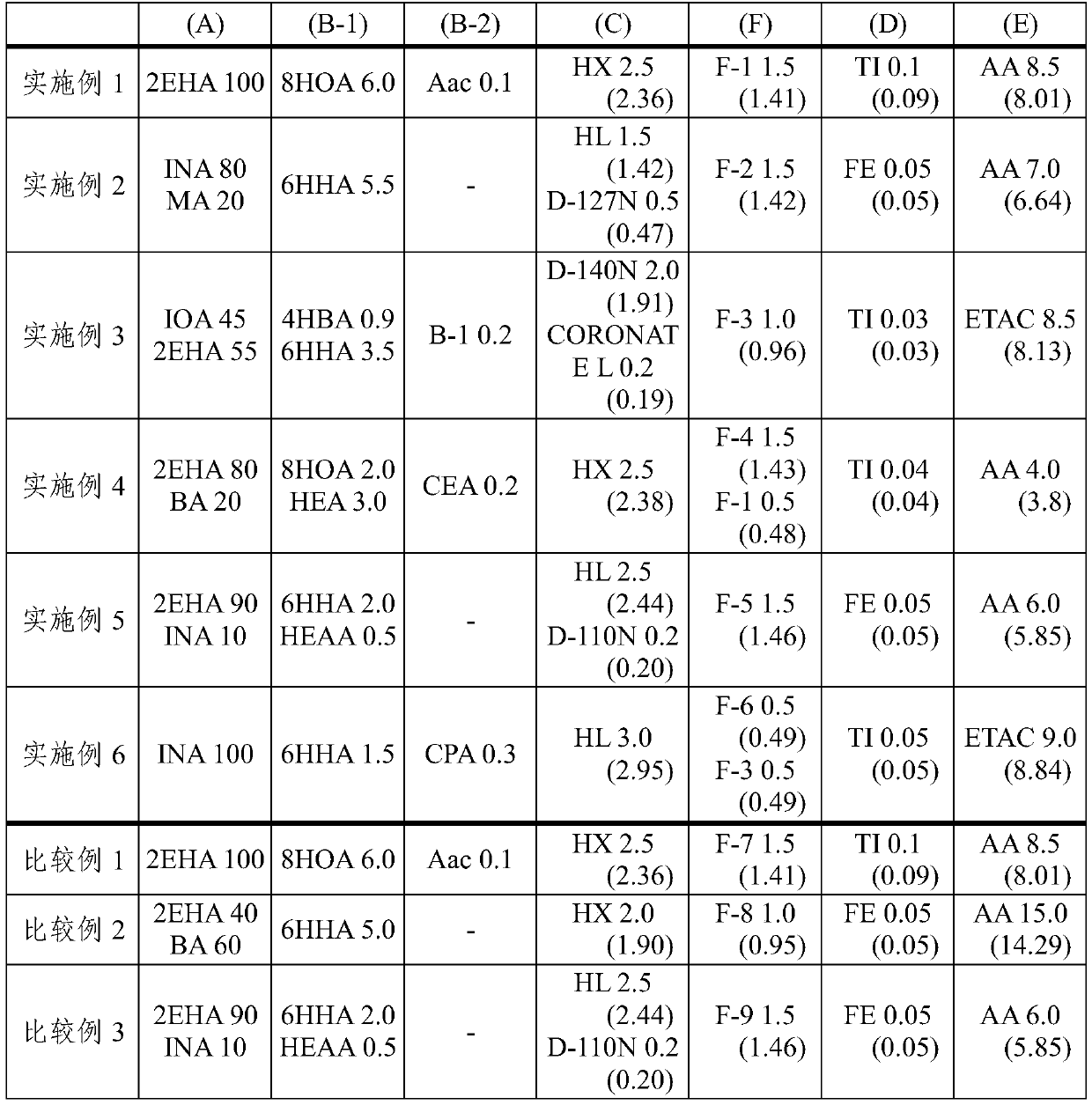

ActiveCN107129766AGood pollution effectReduce pollutionNon-macromolecular adhesive additivesFilm/foil adhesivesCarbon numberPolymer science

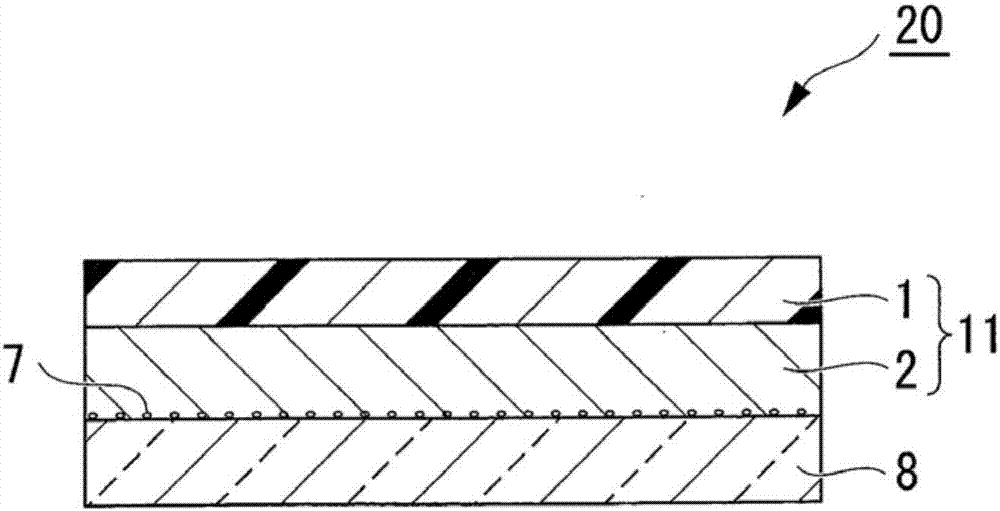

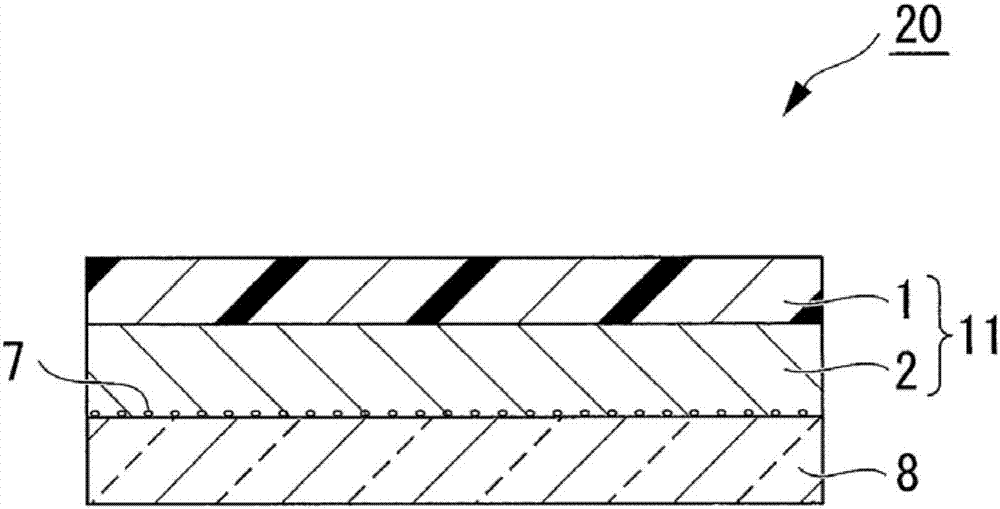

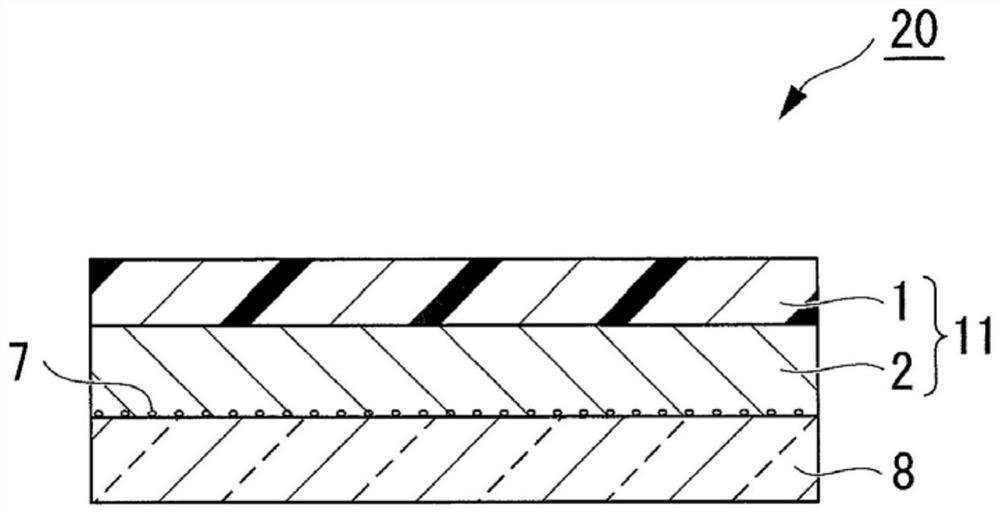

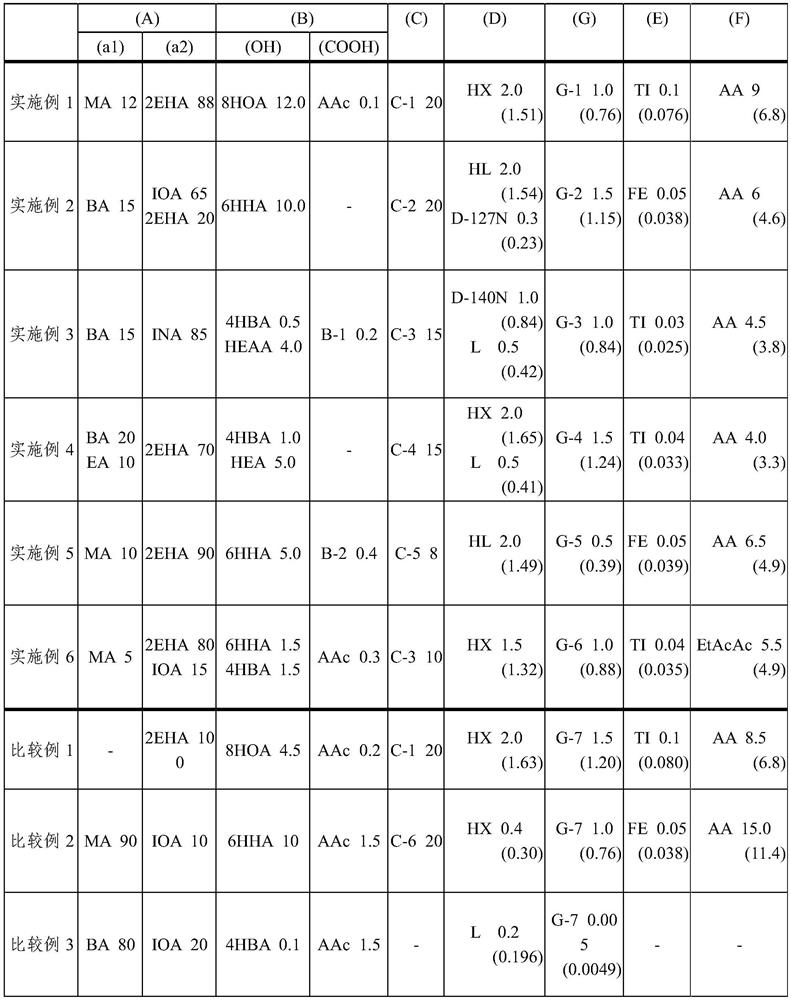

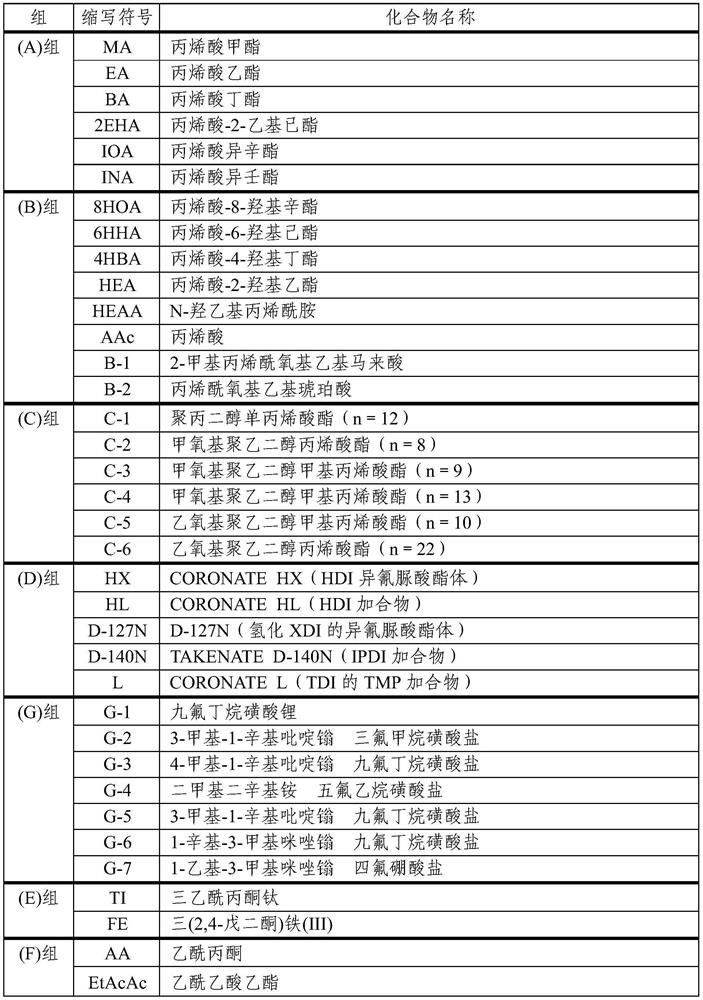

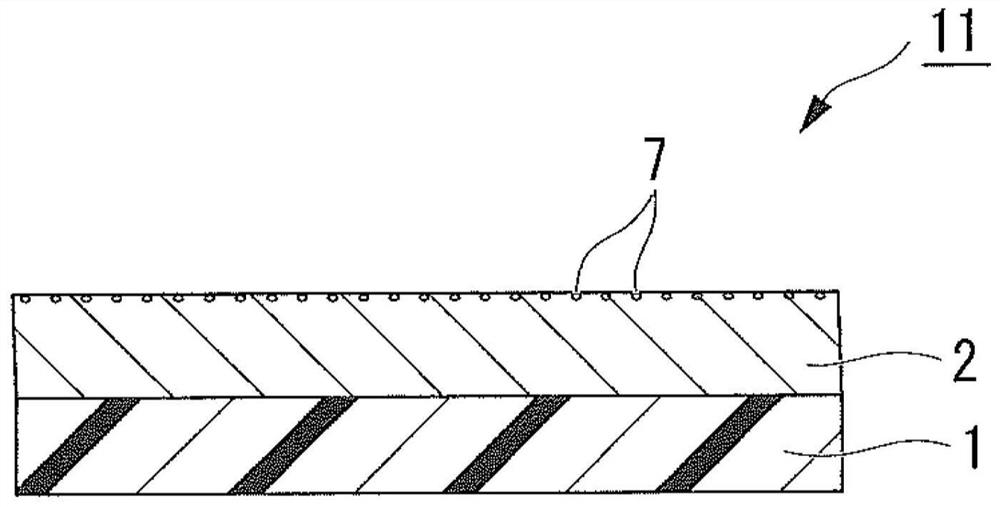

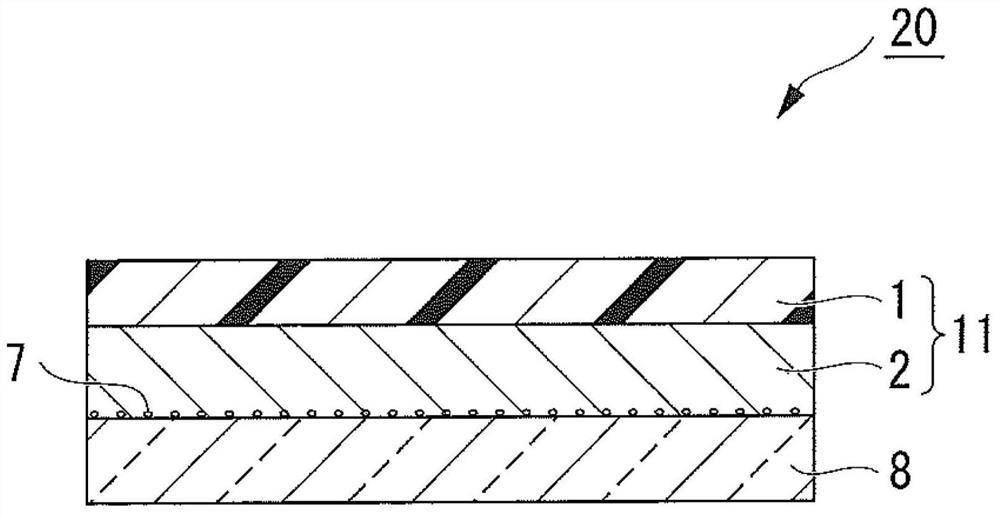

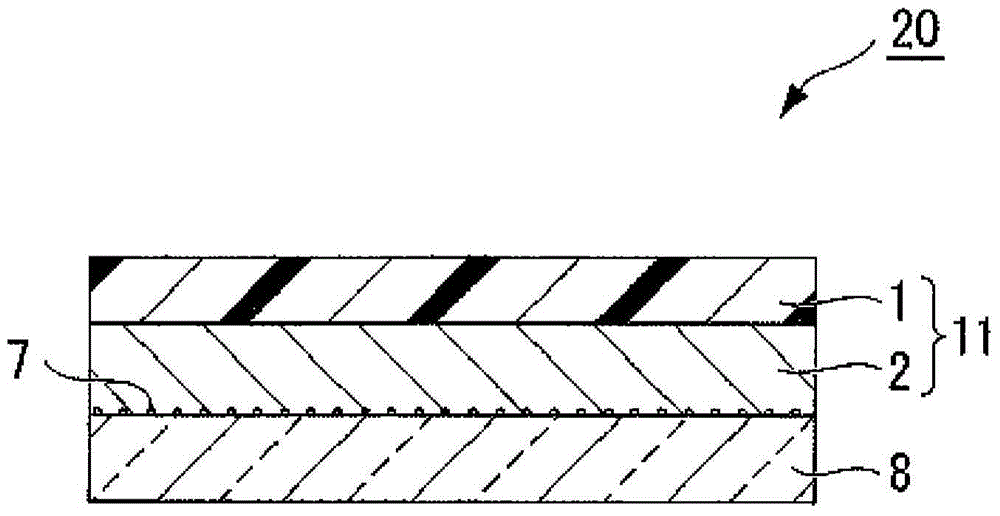

The present invention provides an antistatic surface-protective film having excellent peeling and electrostatic resistance properties without polluting an adherent and without being deteriorated over time. An adhesive layer (2) formed from an adhesive composition is formed on one surface of a base film (1), and a release film (5) on which a release agent layer (4) is laminated, wherein an antistatic agent of the release agent layer (4 ) is transferred onto the surface of the adhesive layer (2), and the adhesive composition contains acrylic polymer, and further comprises: (C) an isocyanate compound having two or more degrees of functionality, (D) a crosslinking accelerator and (E) a ketone-enol tautomer. The acrylic polymer is made from 1-30 by weight part of (a1), 70-99 by weight part of (a2), and 0.1-12 by weight part of (B) through copolymerization, wherein (a1) is a (methyl) acrylate monomer having alkyl group with a C1 to C4 carbon number, (a2) is a (methyl) acrylate monomer having alkyl group with a C5 to C18 carbon number, and (B) is a hydroxyl group-containing copolymerizable monomer.

Owner:FUJIMORI KOGYO CO LTD

Surface protection film and optical component attached with the same

ActiveCN104371581AExcellent anti-stripping static performanceReduce pollutionFilm/foil adhesivesSynthetic resin layered productsTectorial membraneAntistatic agent

The invention provides a surface protection film and an optical component attached with the same. The surface protection film is available for an optical film with a concave-convex surface, less pollutes a to-be-adhered body, will not degrades the low ability to contaminate the to-be-adhered body and is provided with excellent anti-stripping static performance. A binder layer (2) is formed on a single face of a base material film (1) formed by transparent resin. A stripping film (5) with a stripping agent layer (4) is attached to the binder layer (2). The stripping agent layer (4) is laminated on the single face of a resin film (3), so the stripping film (5) is formed. The stripping agent layer (4) contains the stripping agent with dimethyl polysiloxane being as the main component, and anti-static agent which will not react with the stripping agent. When the anti-static agent component shifts from the stripping film (5) towards the binder layer (2), stripping static voltage can be reduced when the above binder layer (2) is stripped from the to-be-adhered body.

Owner:FUJIMORI KOGYO CO LTD

Surface protection film and optical component attached with the film

ActiveCN104342044AReduce pollutionSuppresses peeling static voltageOther chemical processesFilm/foil adhesivesTectorial membraneStatic performance

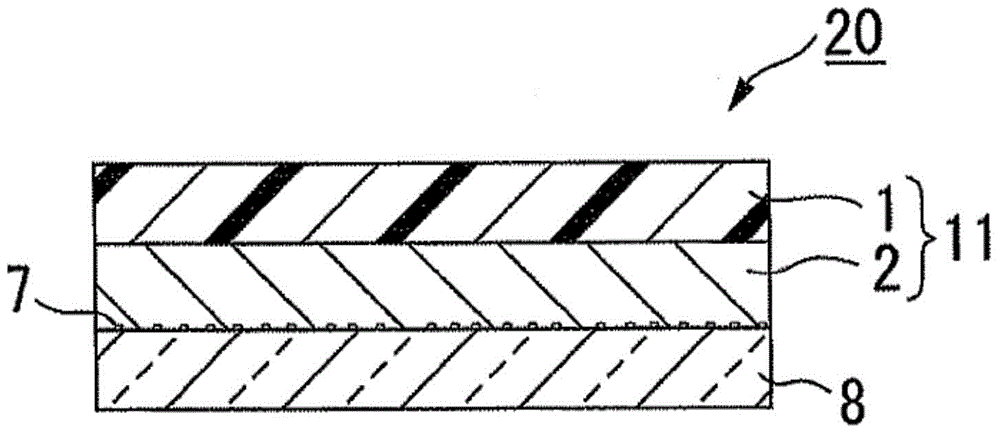

The invention provides a surface protection film having little pollution to an adhered object, low pollution unchanged along with the time, and good anti-stripping static performance without degradation, and an optical component attached with the surface protection film. The surface protection film (10) is provided with an adhesive layer (2) on a single surface of a substrate film (1) formed by transparent resin, and a stripping film (5) adhered with a stripping agent layer (4) is adhered to the adhesive layer (2), wherein the stripping film (5) is formed by forming the stripping agent layer (4) on the single surface of a resin film (3). The stripping agent layer (4) comprises the stripping agent adopting dimethyl polysiloxane as the main component, a polysiloxane compound that is liquid below 20 DEG C and a resin composition of an ionic compound having a melting point of 30-80 DEG C. The adhesive layer (2) is an acrylic acid type adhesive layer.

Owner:FUJIMORI KOGYO CO LTD

Release film for adhesive film, and adhesive film using the same

ActiveCN104962209AExcellent anti-stripping static performanceEffective protectionFilm/foil adhesivesEster polymer adhesivesMethyl polysiloxaneChemistry

Owner:FUJIMORI KOGYO CO LTD

Antistatic surface-protective film

ActiveCN106189895ASuppresses peeling static voltageLow agingFilm/foil adhesivesOrganic non-macromolecular adhesiveCross-linkMeth-

The present invention provides an antistatic surface-protective film that has little contamination of an adherend and that has excellent peeling antistatic performance which does not deteriorate over time. In accordance with the present invention, on one surface of a base film 1 including a transparent resin, is formed an adhesive layer 2 including an adhesive composition, which includes an acrylic-based polymer of a copolymer including (A) a least one (meth)acrylic acid ester monomer having a C4 to C18 alkyl group and (B) at least one hydroxyl group-containing copolymerizable monomer, but not including a carboxyl group-containing copolymerizable monomer, and which further contains (C) a bifunctional or higher isocyanate compound, (D) a cross-linking promoting agent, and (E) a keto-enol tautomer compound; and a peeling film 5, which has a release agent layer 4 laminated, is attached on a surface thereof, wherein the release agent layer 4 includes a release agent having dimethylpolysiloxane as the main component and an antistatic agent.

Owner:FUJIMORI KOGYO CO LTD

Adhesive composition and surface-protective film

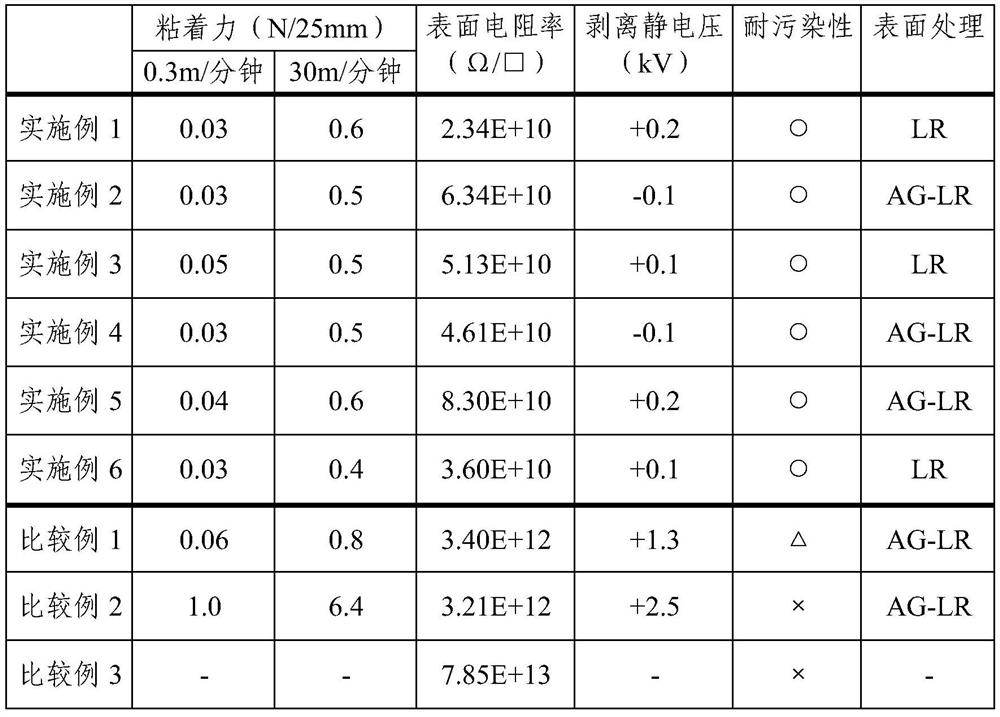

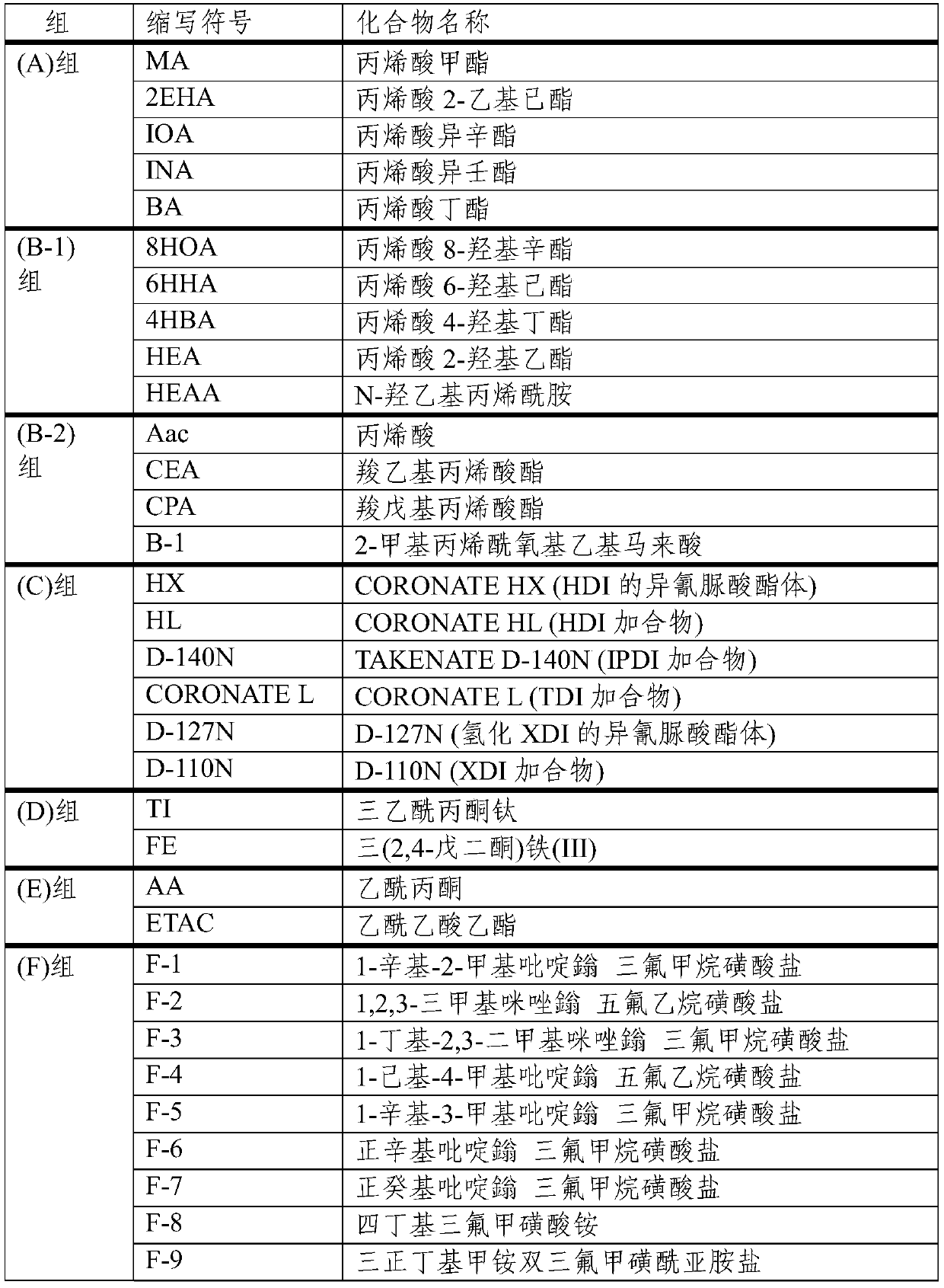

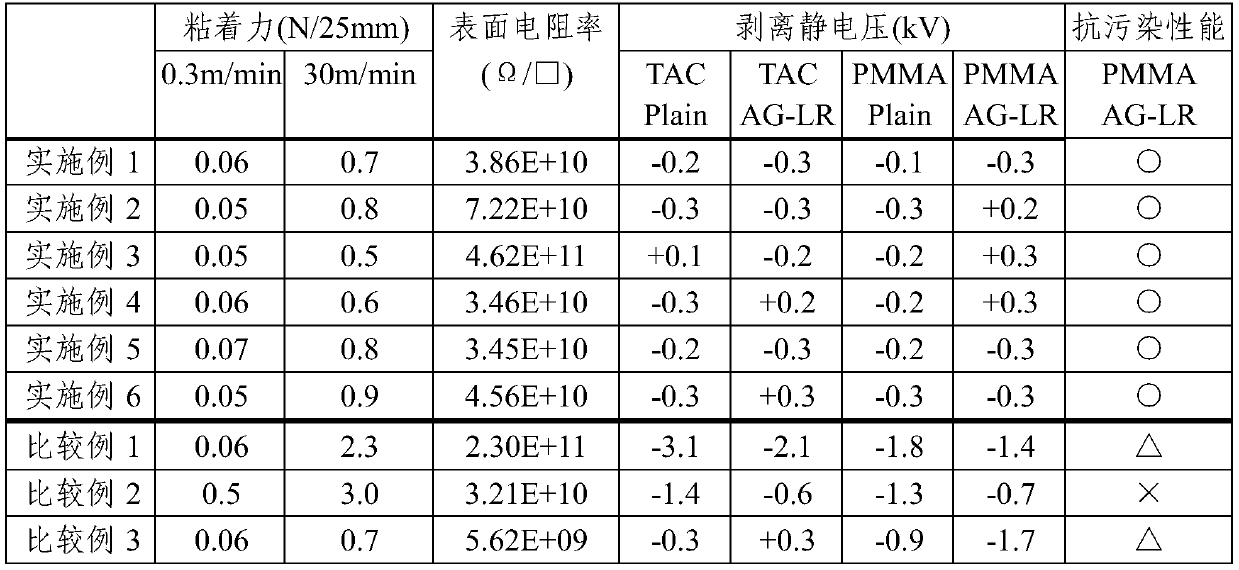

ActiveCN108865017AExcellent adhesionExcellent anti-stripping staticNon-macromolecular adhesive additivesFilm/foil adhesivesCarbon numberPolymer science

The present invention provides an adhesive composition and a surface protective film. The excellent balance of adhesion is ensured at low-speed peeling speed and high-speed peeling speed. The film hasstain resistance and excellent antistatic property and excellent deterioration resistance without deterioration. The adhesive composition contains a (meth) acrylate monomer having (C) an alkyl grouphaving a C1 to C18 carbon number, (B) a hydroxyl group-containing copolymerizable monomer, and (C) a carboxyl group-containing copolymerizable group. An acrylic polymer obtained by copolymerization ofa monomer has an acid value of 0.1 to 1.0, and 100 parts by weight of (A) alkyl group having a C1-C18 (meth)acrylic group. The ester monomer contains acrylic acid ethyl hexyl acrylate in a ratio of 70 parts by weight or more. The crosslinking agent is (D) a trifunctional or higher isocyanate compound; and the antistatic agent is an anion having a fluorine atom number of F7 or more. An ionic compound has a melting point from 25 to 50 DEG C.

Owner:FUJIMORI KOGYO CO LTD

Release film for adhesive film, and adhesive film using the same

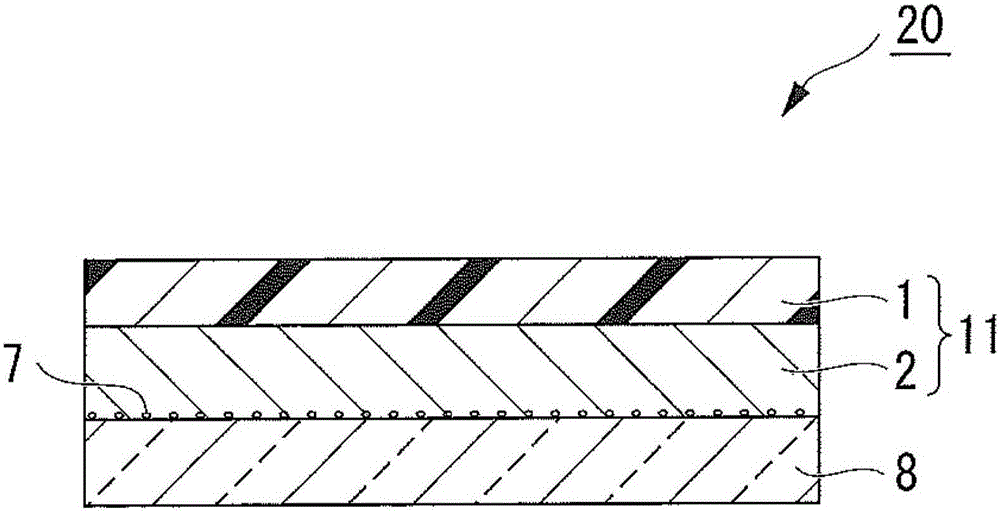

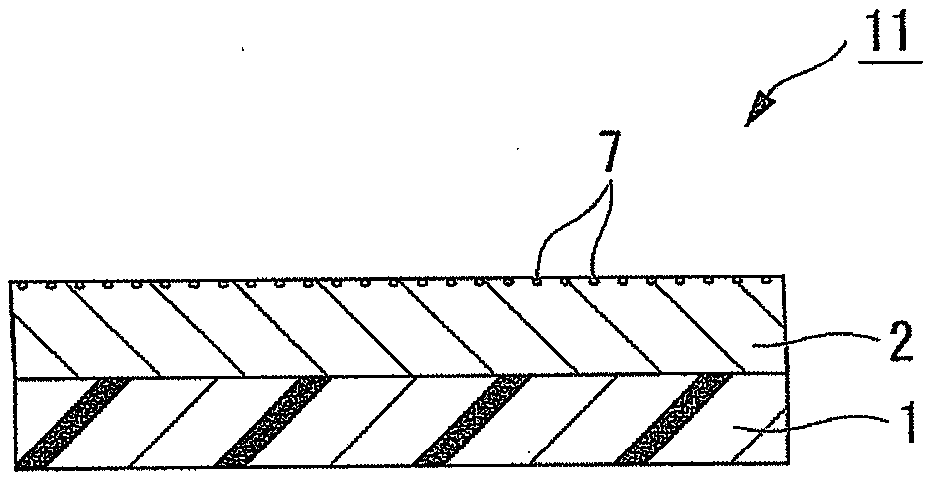

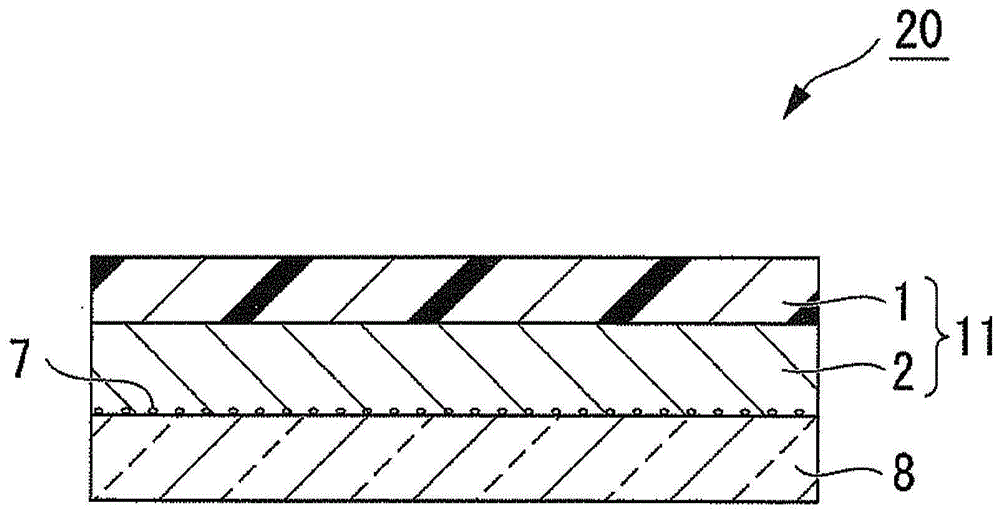

InactiveCN103421438AReduce pollutionExcellent anti-stripping static performanceFilm/foil adhesivesSynthetic resin layered productsChemistrySurface layer

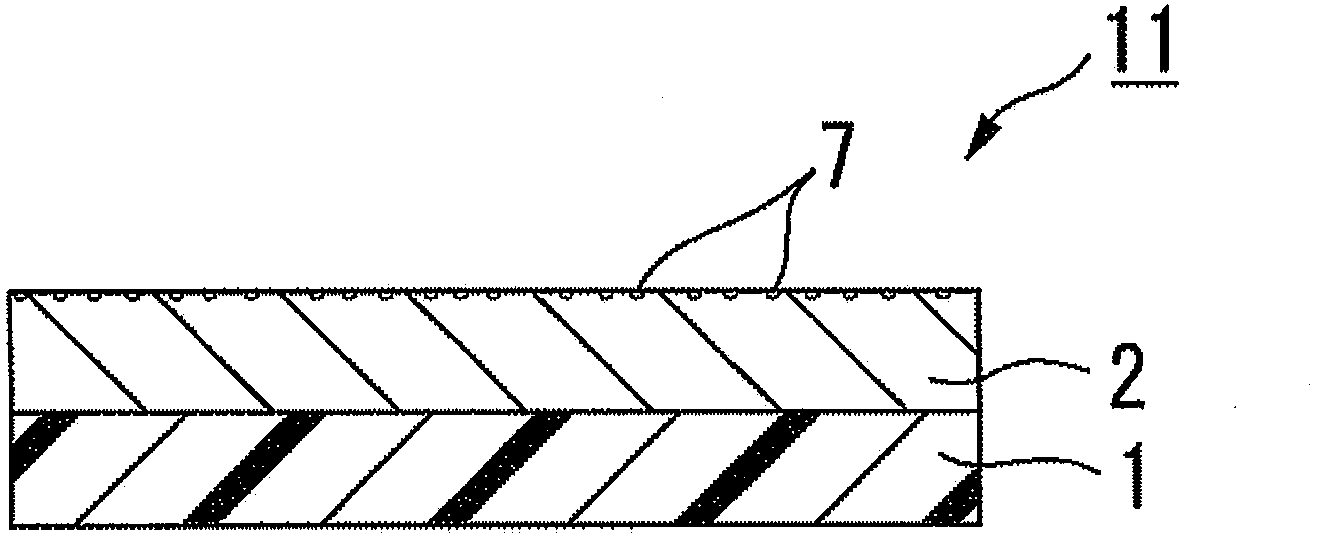

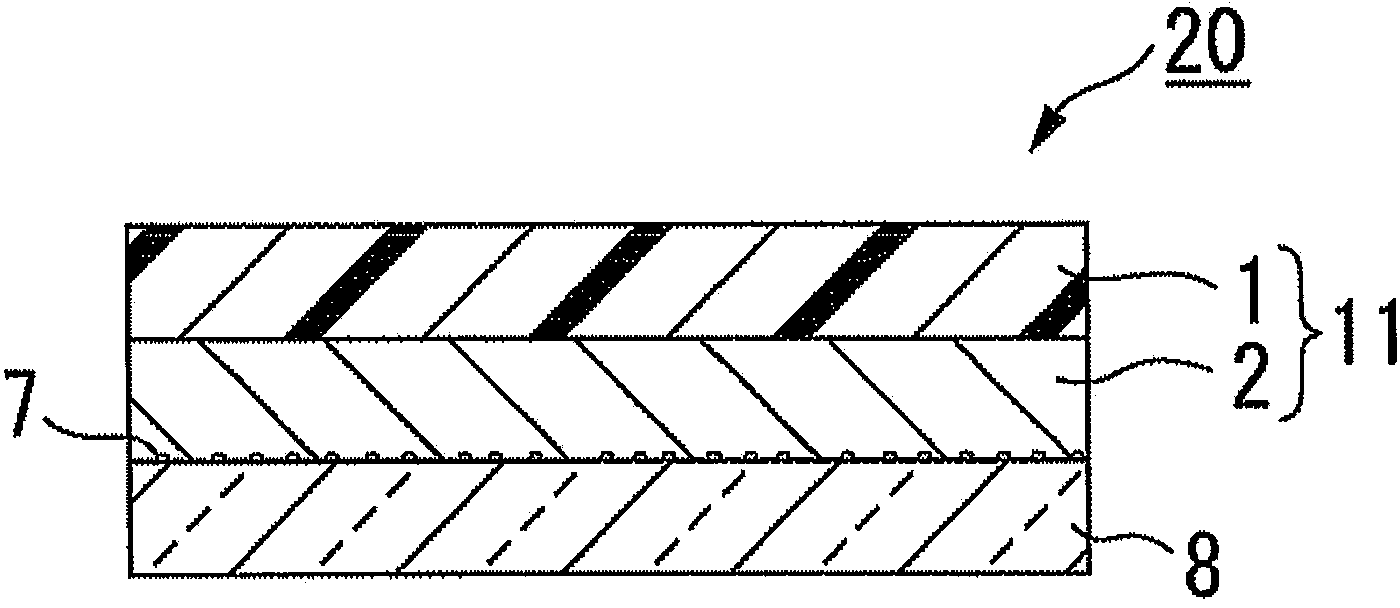

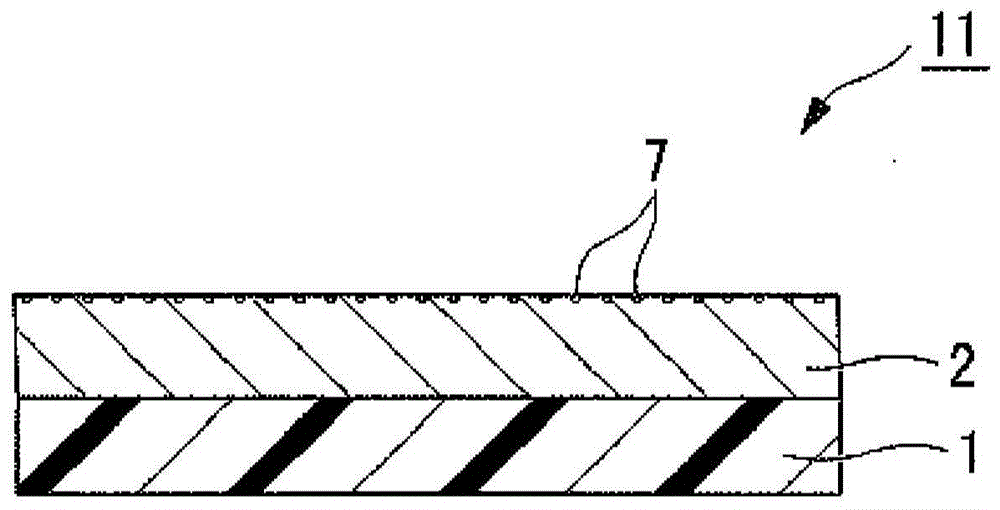

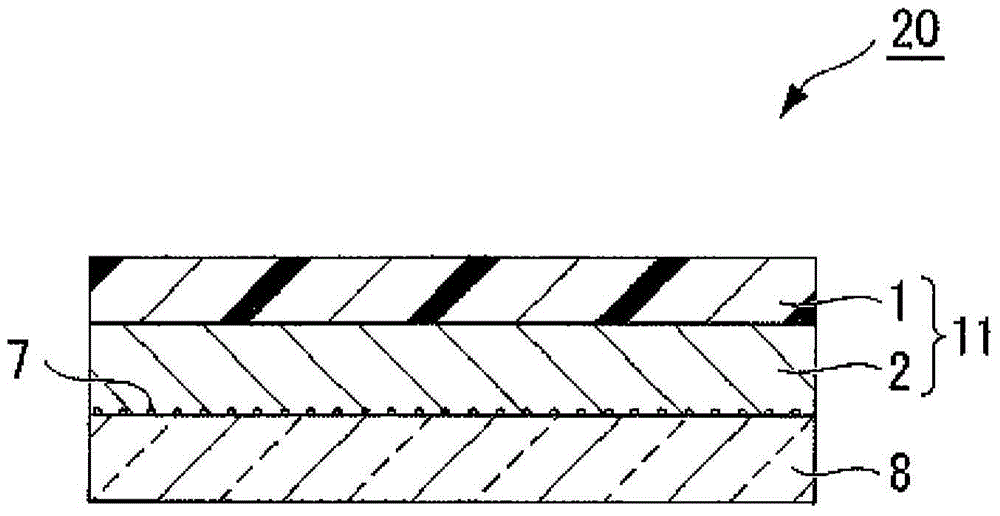

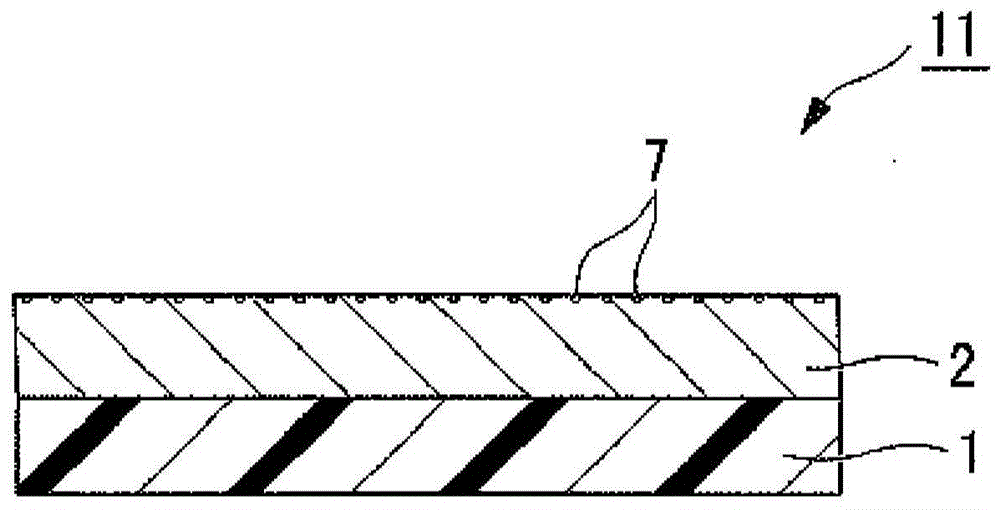

The invention provides release film for forming an adhesive film with low pollution on an article to be adhered, further provides a release film for forming adhesive film with an excellent release static prevention property, and the adhesive film using the release film. The release film (5) for the adhesive film can protect the binder layer (2) of the adhesive film with the binder layer (2) at least stacked on a single layer of the substrate film (1), and can be released, wherein the release film is formed by stacking a release agent layer (4) at least on a single surface layer of a resin film (3), and is adhered on the surface of the binder layer (2) by the release agent layer (4), and the release agent layer (4) contains a release agent using dimethyl polysiloxane as a main component, and a silicon compound which is a liquid under 20 DEG C.

Owner:FUJIMORI KOGYO CO LTD

Method for producing antistatic surface protective film, and antistatic surface protective film

PendingCN112126372AExcellent anti-stripping static performanceReduce pollutionNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceMeth-

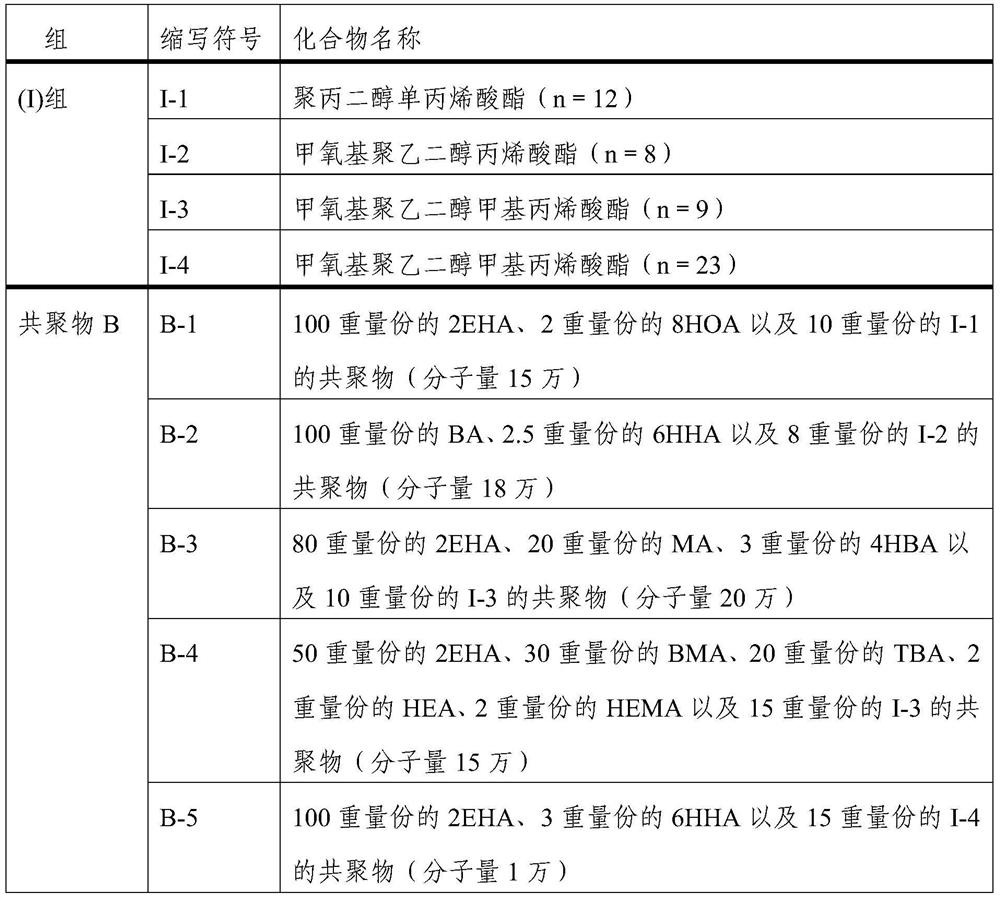

The invention provides an antistatic surface-protective film which has balanced adhesive force at a low peeling speed and a high peeling speed and can achieve both antistatic property and anti-foulingproperty. As a solution, a release film (5) on which a release agent layer (4) containing an antistatic agent is laminated is bonded to the surface of an adhesive layer (2) formed by crosslinking anadhesive composition via the release agent layer (4), and the antistatic agent of the release agent layer (4) is transferred to the surface of the adhesive layer (2). The adhesive composition comprises: (A) an acrylic polymer which is obtained by polymerizing an acrylic polymer and a (meth)acrylic acid ester having at least two or more alkyl groups having C1-C10 carbon atoms in a total of 100 parts by weight of the acrylic polymer; 2-Ethylhexyl acrylate is contained in an amount of 50 parts by weight or more, and one or more monofunctional methacrylate monomers having a homopolymer Tg of 0 DEGC or more are contained in an amount of 5-40 parts by weight in total; (C) an isocyanate compound having a trifunctionality or higher; (D) a crosslinking retarder; (E) a crosslinking accelerator other than a stannide.

Owner:FUJIMORI KOGYO CO LTD

Antistatic surface protective film

ActiveCN108864974ALow agingNo agingNon-macromolecular adhesive additivesSynthetic resin layered productsCross-linkAntistatic agent

The invention provides an antistatic surface protection film that has little contamination of an adherend and that has superior peeling antistatic performance which does not deteriorate over time. Theantistatic surface protection film is made by, in order: a step of forming, on one surface of a base film (1) including a transparent resin, an adhesive layer (2) including an adhesive composition, which includes an acrylic-based polymer of a copolymer, and which further contains (D) a bifunctional or higher isocyanate compound, (E) a cross-linking promoting agent, (F) a keto-enol tautomer compound; a step of attaching a peeling film (5), which has a release agent layer (4) containing an antistatic agent laminated on one surface of a resin film (3), on a surface of the adhesive layer (2) viathe release agent layer (4), wherein the release agent layer (4) is formed by a resin composition including: a release agent having dimethylpolysiloxane as the main component; a polysiloxane compoundthat is a liquid at 20 DEG C; and an antistatic agent, wherein the peeling charge pressure of the adhesive layer (2) is + / -0.6 kV or less.

Owner:FUJIMORI KOGYO CO LTD

Adhesive composition and surface-protective film

ActiveCN108795348AImproves stain resistanceExcellent anti-stripping static performanceNon-macromolecular adhesive additivesFilm/foil adhesivesSulfonatePolymer science

The present invention provides an adhesive composition and a surface protective film which can simultaneously achieve excellent antistatic properties and stain resistance. The adhesive composition contains an acrylic polymer, an antistatic agent, and a crosslinking agent; the acrylic polymer has a glass transition temperature of 0 deg c or lower, and the crosslinking agent is a trifunctional or higher isocyanate compound. The antistatic agent is an ionic compound having a melting point of 25 deg c or above and formed by a cation and an anion; the anion is selected from the group consisting ofa trifluoromethane sulfonate anion, a pentafluoroethane sulfonate anion, a heptafluoropropane sulfonate anion, and a nonafluoro butane sulfonate. The antistatic agent is contained as an essential component in an amount of 0.01 to 10 parts by weight based on 100 parts by weight of the acrylic polymer.

Owner:FUJIMORI KOGYO CO LTD

Adhesive composition

ActiveCN110951421AExcellent adhesionExcellent anti-stripping static performanceNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceMeth-

The invention provides an adhesive composition, an adhesive film using the adhesive composition, and a surface protective film using the adhesive composition. The adhesive composition has excellent adhesive performance such as balanced adhesive force at a low peeling speed and a high peeling speed, and can achieve both antistatic performance and anti-fouling performance. In the adhesive composition, the antistatic agent (F) is an ionic compound with a melting point of 25-80 DEG C as shown in a general formula K<+>.A<->, wherein K<+> is one cation selected from the group consisting of pyridiniums, imidazolium, phosphonium, sulfonium, pyrrolidinium, guanidinium, ammonium, isouronium, thioureaonium, piperidinium, pyrazolium, methyl carbocation, and morpholinium; A<-> is one anion selected from the group consisting of imido group-free, trifluoromethane sulfonate, pentafluoroethane sulfonate, and the ionic compound is contained in an amount of 0.01-10 parts by weight per 100 parts by weightof the acrylic polymer.

Owner:FUJIMORI KOGYO CO LTD

Surface protection film and optical part bonded with the surface protection film

ActiveCN105331296BExcellent anti-stripping static performanceReduce pollutionPolyureas/polyurethane adhesivesSynthetic resin layered productsForeign matterPolymer science

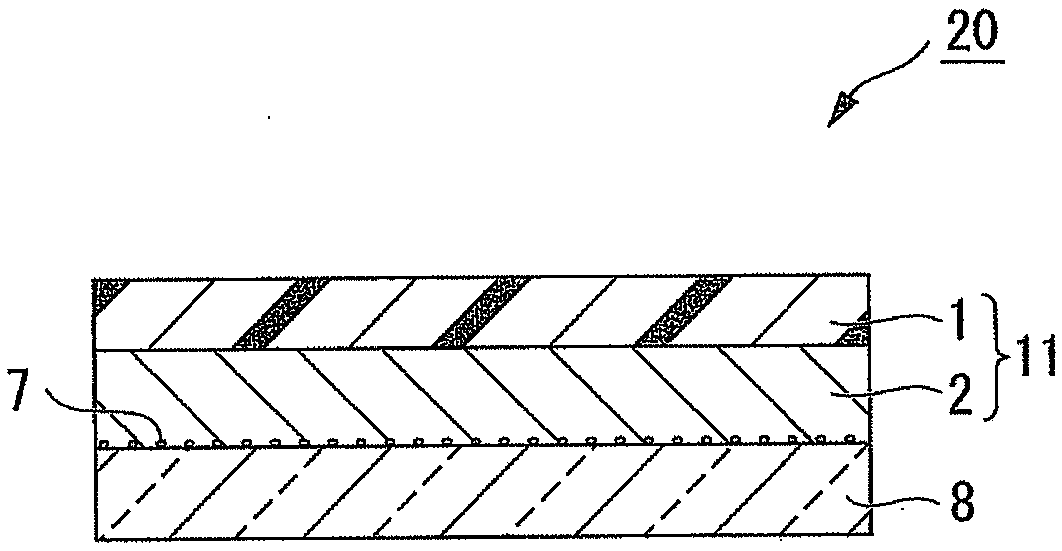

The present invention provides a surface protective film having excellent peeling antistatic performance without degradation with time, which hardly produces foreign substances (adhesive lumps) caused by an adhesive even during cutting, has good affinity (wettability) for an optical film having irregularities on the surface thereof, has low contamination on an adherend, and provides low contamination on the adherend, which does not change even if the time elapses, and an optical component to which the surface protective film is bonded. In a surface protective film (10) in which a polyurethane adhesive layer (2) is formed on one surface of a base film (1) made of a transparent resin and a release film (5) having a release agent layer (4) is laminated on the adhesive layer (2), the release film (5) is formed by laminating the release agent layer (4) including a release agent and an antistatic agent, which does not react with the release agent, on one surface of a resin film (3), a component of the antistatic agent is transferred from the release film to the surface of the adhesive layer (2), and a peeling antistatic voltage when the adhesive layer (2) is peeled off from an adherend is reduced.

Owner:FUJIMORI KOGYO CO LTD

adhesive composition

ActiveCN110951421BExcellent adhesionExcellent anti-stripping static performanceNon-macromolecular adhesive additivesFilm/foil adhesivesPyridiniumMeth-

The present invention provides an excellent adhesive performance such as a bonding performance that can be balanced at low -speed peeling speed and high -speed peeling speed. At the same timeThe adhesive film and surface protective film of the adhesive composition.In the composition of the adhesive, (F) the antistatic agent is a general K + · A ‑ The melting point shown is a ionic compound of 25-80 ° C. Among them, K + In order to choose a group composed of groups of free pyridine, pyrimazole, pyrodis, pyrine, pyrodermine, ammonium, ammonia, albumin, pyrine, pyrazole, nail carbon positive ion, morpholine ion, and morpholine ionOne of the cations, A ‑ In order to choose a group of anion in a group composed of a group composed of ionic ions composed of a toto fluorine, sulfons, and pentraromythane sulfonate, compared to the 1001 to 10 weights compared to the 1001 to 10 portion compared to 100 weights of acrylic polymersThe proportion contains ionic compounds.

Owner:FUJIMORI KOGYO CO LTD

Preparation method of antistatic surface protective film, and antistatic surface protective film

ActiveCN107129766BReduce pollutionDoes not change over timeNon-macromolecular adhesive additivesFilm/foil adhesivesMethacrylateCarbon number

The present invention provides an antistatic surface protection film which has excellent anti-peeling static performance, which causes little contamination to an adherend, does not deteriorate over time, and has excellent anti-peeling static properties. An adhesive layer (2) formed of an adhesive composition is formed on one side of the base film (1), and a release film (5) with a release agent layer (4) laminated on the surface is bonded, and the release agent layer (4) ) is transferred to the surface of the adhesive layer (2), and the adhesive composition contains an acrylic polymer, and further contains: (C) an isocyanate compound with a functionality of more than two, (D) a crosslinking accelerator , and (E) keto-enol tautomeric compounds, the acrylic polymer is 1 to 30 parts by weight of (a1), 70 to 99 parts by weight of (a2), and 0.1 to 12 parts by weight (B) is an acrylic polymer of a copolymer obtained by copolymerization, wherein (a1) is a (meth)acrylate monomer having C1-C4 carbon atoms in the alkyl group, and (a2) is a carbon A (meth)acrylate monomer with an atomic number of C5-C18, (B) is a copolymerizable monomer containing a hydroxyl group.

Owner:FUJIMORI KOGYO CO LTD

Surface protection film and optical part bonded with the surface protection film

ActiveCN104342044BReduce pollutionSuppresses peeling static voltageOther chemical processesFilm/foil adhesivesTectorial membraneAcrylic adhesive

PROBLEM TO BE SOLVED: To provide a surface protective film that gives little contamination to an adherend and shows no change in low contamination property to an adherend with lapse of time, and that has excellent peeling antistatic performance without degradation with time, and to provide an optical component using the surface protective film.SOLUTION: A surface protective film 10 includes an adhesive layer 2 formed on one surface of a base film 1 comprising a resin having transparency, and a release film 5 having a release agent layer 4 laminated on the adhesive layer 2. The release film 5 includes the release agent layer 4 formed of a resin composition containing a release agent essentially comprising dimethyl polysiloxane, a silicone compound that is liquid at 20°C, and an ionic compound having a melting point of 30 to 80°C, on one surface of a resin film 3. The adhesive layer 2 is an acrylic adhesive layer.

Owner:FUJIMORI KOGYO CO LTD

Surface-protective film and optical component attached with the same

ActiveCN107083198AExcellent anti-stripping static performanceReduce pollutionFilm/foil adhesivesPolarising elementsChemistryEther

The present invention provides a surface-protective film and an optical component attached with the same. The surface-protective film has a good affinity (wettability) toward an optical film with irregular surface, makes little pollution to an adhered body, and has excellent antistatic properties during peeling without deterioration over time. The surface-protective film (10) is formed through attaching a stripping film (5) comprising a stripping layer (4) on an adhesive agent layer (2), the stripping film (5) is formed through laminating stripping agent layer (4) on a resin film, the stripping agent layer (4) contains a stripping agent containing polydimethylsiloxane as a main component, an antistatic agent which do not act with the stripping agent and an ester plasticizer containing more than one ether bonds, the components of the antistatic agent are anionic compounds with melting point of 30-80 DEG C, the components of the antistatic agent layer and the ester plasticizer transfer from the stripping layer (4) of the stripping film (5) to the surface of the adhesive agent layer, decreasing the peel voltage during peeling the adhesive agent layer from the adhered body.

Owner:FUJIMORI KOGYO CO LTD

Production method of antistatic surface protection film and antistatic surface protection film

ActiveCN104293222BReduce pollutionLow pollution, no change over timeFilm/foil adhesivesSynthetic resin layered productsAntistatic agentStatic performance

Owner:FUJIMORI KOGYO CO LTD

Surface protection film and optical part bonded with the surface protection film

ActiveCN107083198BExcellent anti-stripping static performanceReduce pollutionFilm/foil adhesivesPolarising elementsPolymer sciencePlasticizer

The present invention provides an optical film having irregularities on the surface which can also be used, has less contamination to adherends, has low contamination to adherends that does not change over time, and has excellent anti-peeling static electricity that does not deteriorate over time Performance surface protection film and optical components using the same. A surface protective film (10) is formed by laminating a release film (5) having a release agent layer (4) on an adhesive layer (2), and the release film (5) is formed by laminating one side of a resin film (3) A release agent layer (4) comprising a release agent mainly composed of polydimethylsiloxane, an antistatic agent that does not react with the release agent, and an ester containing at least one ether bond plasticizer, the antistatic agent component is an ionic compound with a melting point of 30 to 80°C, and the antistatic agent component and the ester plasticizer are transferred from the release agent layer (4) of the release film (5) to the adhesive layer ( 2) On the surface, the peeling electrostatic voltage when peeling the adhesive layer (2) from the adherend is reduced.

Owner:FUJIMORI KOGYO CO LTD

Surface protection film and optical component bonded with the surface protection film

ActiveCN104371581BExcellent anti-stripping static performanceReduce pollutionFilm/foil adhesivesSynthetic resin layered productsRough surfaceTectorial membrane

Owner:FUJIMORI KOGYO CO LTD

Surface protection film and optical part bonded with the surface protection film

ActiveCN107083197BExcellent anti-stripping static performanceReduce pollutionLayered productsEster polymer adhesivesPolymer sciencePlasticizer

The present invention provides a surface that can be used even for optical films having irregularities on the surface, has less contamination to adherends, does not change over time in low contamination of adherends, and has excellent anti-peeling electrostatic properties that do not deteriorate over time Protective films and optical parts using them. A surface protection film (10), which is formed by bonding a release film (5) with a release agent layer (4) on the adhesive layer (2), and the release film (5) is formed on one side of the resin film (3) The release agent layer (4) is laminated on top, and the release agent layer (4) contains a release agent mainly composed of polydimethylsiloxane, an antistatic agent that does not react with the release agent, and contains at least one ether bond. The ester plasticizer, the antistatic agent component is an ionic compound with a melting point of less than 30°C, the antistatic agent component and the ester plasticizer are transferred from the release agent layer (4) of the release film (5) to the adhesive layer The surface of (2) reduces the peeling static voltage when peeling the adhesive layer (2) from the adherend.

Owner:FUJIMORI KOGYO CO LTD

Adhesive composition and surface protection film

ActiveCN108795348BImprove antistatic performanceImprove pollutionNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceCross linker

Owner:FUJIMORI KOGYO CO LTD

Adhesive composition

ActiveCN110951420AGood adhesionBoth antistatic performance and anti-pollution performanceNon-macromolecular adhesive additivesPolarising elementsAcrylic polymerImide

The invention provides an adhesive composition, an adhesive film using the adhesive composition, and a surface protective film using the adhesive composition. The adhesive composition has excellent adhesive performance such as balanced adhesive force at a low peeling speed and a high peeling speed, and can achieve both antistatic performance and anti-fouling performance. In the adhesive composition, the antistatic agent (F) is an ionic compound having a melting point of 25-80 DEG C and represented by general formula (1) K<+>.A<->, wherein K<+> is a cation, A<-> is one anion selected from the group consisting of imido group-free, trifluoromethane sulfonate ions, pentafluoroethane sulfonate ions; the acrylic polymer is an acrylic polymer having a glass transition temperature of 0 DEG C or less, and the acrylic polymer contains an ionic compound as an essential component in an amount of 0.01-10 parts by weight per 100 parts by weight of the acrylic polymer.

Owner:FUJIMORI KOGYO CO LTD

Adhesive composition and surface protection film

ActiveCN108865017BExcellent adhesionExcellent anti-stripping static performanceNon-macromolecular adhesive additivesFilm/foil adhesivesMethacrylateCarbon number

The present invention provides an adhesive composition that has an excellent balance of adhesive force at low and high peeling speeds, has stain resistance, excellent adhesive performance, and excellent antistatic performance that does not deteriorate over time. and surface protection film. The adhesive composition contains (A) a (meth)acrylate monomer with an alkyl group having carbon atoms of C1 to C18, (B) a copolymerizable monomer containing a hydroxyl group, and (C) a copolymerizable monomer containing a carboxyl group. An acrylic polymer of a copolymer with an acid value of 0.1 to 1.0 formed by copolymerization of monomers, in 100 parts by weight of (A) (meth)acrylate monomers with alkyl groups having carbon atoms of C1 to C18 , containing 2-ethylhexyl acrylate in a ratio of more than 70 parts by weight; the crosslinking agent is (D) an isocyanate compound with more than three functions; Ionic compounds at ~50°C.

Owner:FUJIMORI KOGYO CO LTD

Surface protection film and optical part bonded with the surface protection film

ActiveCN105385370BLow agingNo agingFilm/foil adhesivesSynthetic resin layered productsChemistryRelease agent

The present invention provides a surface protection film that can be used for an optical film having irregularities on the surface, has little contamination to an adherend, and has no time-dependent change in the low-contamination property of the adherend, and has no time-dependent deterioration A surface protection film with excellent anti-stripping static properties, and an optical component using the surface protection film. In this surface protection film, an adhesive layer (2) is formed on one side of a base film (1) made of a transparent resin, and a release agent layer (4) is bonded on the adhesive layer (2). ), wherein the release film (5) is formed by laminating a release agent layer (4) on one side of the resin film (3), and the release agent layer (4) contains a resin containing a long-chain alkyl group The release agent as the main component and the antistatic agent that does not react with the release agent, the antistatic agent component is transferred from the release film (5) to the surface of the adhesive layer (2), reducing the amount of adhesive layer (2) The peeling static voltage when peeling off from the adherend.

Owner:FUJIMORI KOGYO CO LTD

Antistatic surface protection film

ActiveCN106189895BSuppresses peeling static voltageLow agingFilm/foil adhesivesOrganic non-macromolecular adhesiveMethacrylatePolymer science

The present invention provides an antistatic surface protection film that has less contamination to an adherend, does not deteriorate over time, and has excellent anti-peeling static performance. In this antistatic surface protection film, an adhesive layer (2) composed of an adhesive composition is formed on one side of a base film (1) composed of a transparent resin, and the surface thereof is bonded. A release agent film (5) laminated with a release agent layer (4), the release agent layer (4) containing a release agent and an antistatic agent mainly composed of dimethyl polysiloxane, the adhesive composition comprising : at least one of (A) alkyl-containing (meth)acrylate monomers with carbon atoms of C4 to C18 and (B) hydroxyl-containing copolymerizable monomers excluding carboxyl-containing copolymerizable monomers an acrylic polymer of at least one copolymer in the body, and also includes (C) a difunctional or higher isocyanate compound, (D) a crosslinking accelerator, and (E) a keto-enol tautomer compound.

Owner:FUJIMORI KOGYO CO LTD

Surface protection film and optical part bonded with the surface protection film

ActiveCN104342045BNo agingExcellent anti-stripping static performanceFilm/foil adhesivesSynthetic resin layered productsTectorial membraneAntistatic agent

PROBLEM TO BE SOLVED: To provide a surface protective film that can be used even for an optical film having a rugged surface, gives little contamination to an adherend and shows no change in low contamination property to an adherend with lapse of time, and that has excellent peeling antistatic performance without degradation with time, and to provide an optical component using the surface protective film.SOLUTION: A surface protective film 10 includes an adhesive layer 2 formed on one surface of a base film 1 comprising a resin having transparency, and a release film 5 having a release agent layer 4 laminated on the adhesive layer 2. The release film 5 includes the release agent layer 4 containing a release agent essentially comprising dimethyl polysiloxane and an antistatic agent that does not react with the release agent, layered on one surface of a resin film 3. As a component of the antistatic agent is transferred from the release film 5 to the surface of the adhesive layer 2, a peeling electrification voltage when the adhesive layer 2 is peeled from an adherend is reduced.

Owner:FUJIMORI KOGYO CO LTD

Release film for adhesive film, and adhesive film using the release film for adhesive film

ActiveCN104962209BExcellent anti-stripping static performanceEffective protectionEster polymer adhesivesCoatingsSurface layerSilicon

The present invention provides a release film for an adhesive film for forming an adhesive film with less contamination to an adherend, and further provides a release film for an adhesive film for forming an adhesive film having excellent anti-peeling static performance , and an adhesive film using the release film for an adhesive film. The release film (5) for an adhesive film of the present invention can protect the adhesive layer (2) of the adhesive film in which the adhesive layer (2) is laminated on at least one side of the base film (1), and can Peeling, wherein at least one side of the resin film (3) is laminated with a release agent layer (4), and the release agent layer (4) is attached to the surface of the adhesive layer (2). Layer (4) contains a release agent mainly composed of dimethylpolysiloxane and a silicon compound that is liquid at a temperature of 20°C.

Owner:FUJIMORI KOGYO CO LTD

Antistatic surface protection film

ActiveCN104774569BSuppresses peeling static voltageLow agingLamination ancillary operationsNon-macromolecular adhesive additivesAntistatic agentAdhesive

The present invention provides an antistatic surface protection film that has less contamination to an adherend, does not deteriorate over time, and has excellent anti-peeling static electricity performance, which is sequentially passed through: on one side of a base film (1) made of a transparent resin Formation of an adhesive combination consisting of an acrylic polymer containing a copolymer, further containing (F) a difunctional or higher isocyanate compound, (G) a crosslinking accelerator, and (H) a keto-enol tautomer compound The process of the adhesive layer (2) composed of material; the release film (5) formed by laminating the release agent layer (4) containing an antistatic agent on one side of the resin film (3) is passed through the release agent layer (4) ) is bonded to the surface of the adhesive layer (2), and the release agent layer (4) contains a release agent mainly composed of dimethyl polysiloxane, which is a liquid polysiloxane at 20°C. Formed from a resin composition of a compound and an antistatic agent, the peeling static voltage of the adhesive layer (2) is ±0.6kV or less.

Owner:FUJIMORI KOGYO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com