Adhesive composition

A composition and adhesive technology, applied in the directions of adhesives, adhesive types, ester copolymer adhesives, etc., can solve the problems of undocumented, residual and other problems, and achieve high utilization value, excellent adhesion performance, and antistatic performance. Effect with anti-pollution properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0105] Nitrogen gas was introduced into a reaction device equipped with a stirrer, a thermometer, a reflux condenser, and a nitrogen gas introduction tube to replace the air in the reaction device with nitrogen gas. Then, 100 parts by weight of 2-ethylhexyl acrylate, 6.0 parts by weight of 8-hydroxyoctyl acrylate, 0.1 parts by weight of acrylic acid, and a solvent (ethyl acetate) were simultaneously added to the reaction device. Then, 0.1 parts by weight of azobisisobutyronitrile as a polymerization initiator was dropped over 2 hours, and reacted at 65° C. for 6 hours to obtain an acrylic polymer used in Example 1.

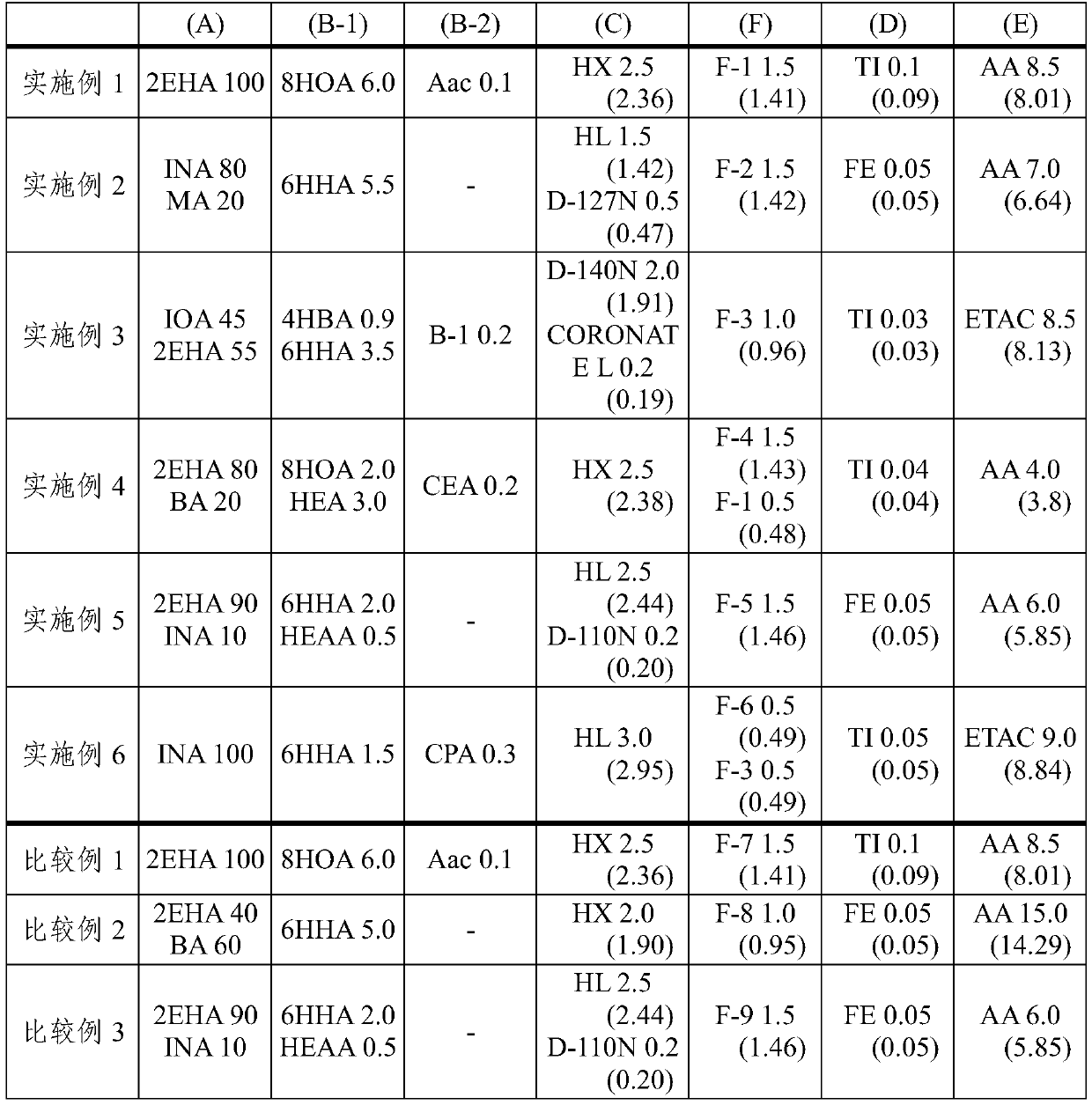

Embodiment 2~6 and comparative example 1~3

[0107] In the same manner as the acrylic polymer solution used in Example 1, Acrylic polymer solutions used in Examples 2-6 and Comparative Examples 1-3 were obtained.

[0108]

[0109] [Example 1]

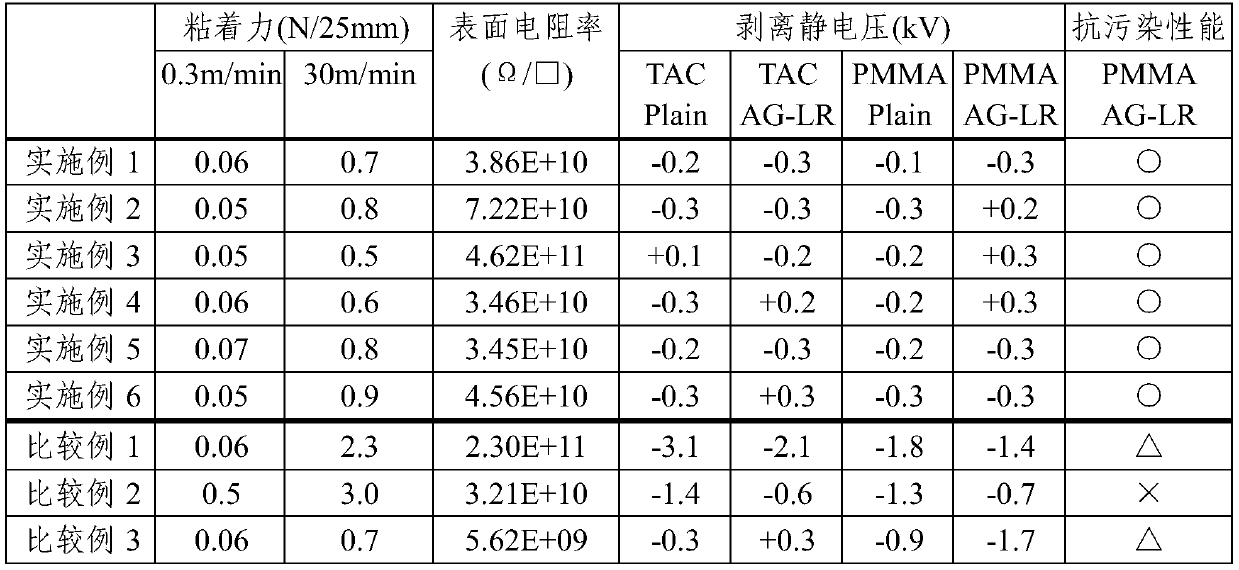

[0110] To the acrylic polymer solution of Example 1 prepared as described above, 2.5 parts by weight of a crosslinking agent (CORONATE HX), 1.5 parts by weight of an antistatic agent (1-octyl-2-methylpyridinium trifluoro methanesulfonate), 0.1 parts by weight of a crosslinking catalyst (titanium triacetylacetonate) and 8.5 parts by weight of acetylacetone were stirred and mixed to obtain the adhesive composition of Example 1. After coating this adhesive composition on a release film (a PET film coated with a silicone resin), the solvent was removed by drying at 90° C. to obtain an adhesive layer with a thickness of 20 μm. Then, the adhesive layer with the release film is transferred to the surface of the substrate film (PET film with antistatic and antifouling treatment on one...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com