Surface protection film and optical component attached with the film

A technology of surface protection film and surface resistivity, which is applied in the direction of optical components, optics, film/sheet adhesive, etc., can solve the problems of pollution and changes in the pollution of adherends, and achieve less pollution and no pollution. Produces the effect of aging deterioration and excellent anti-stripping static performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

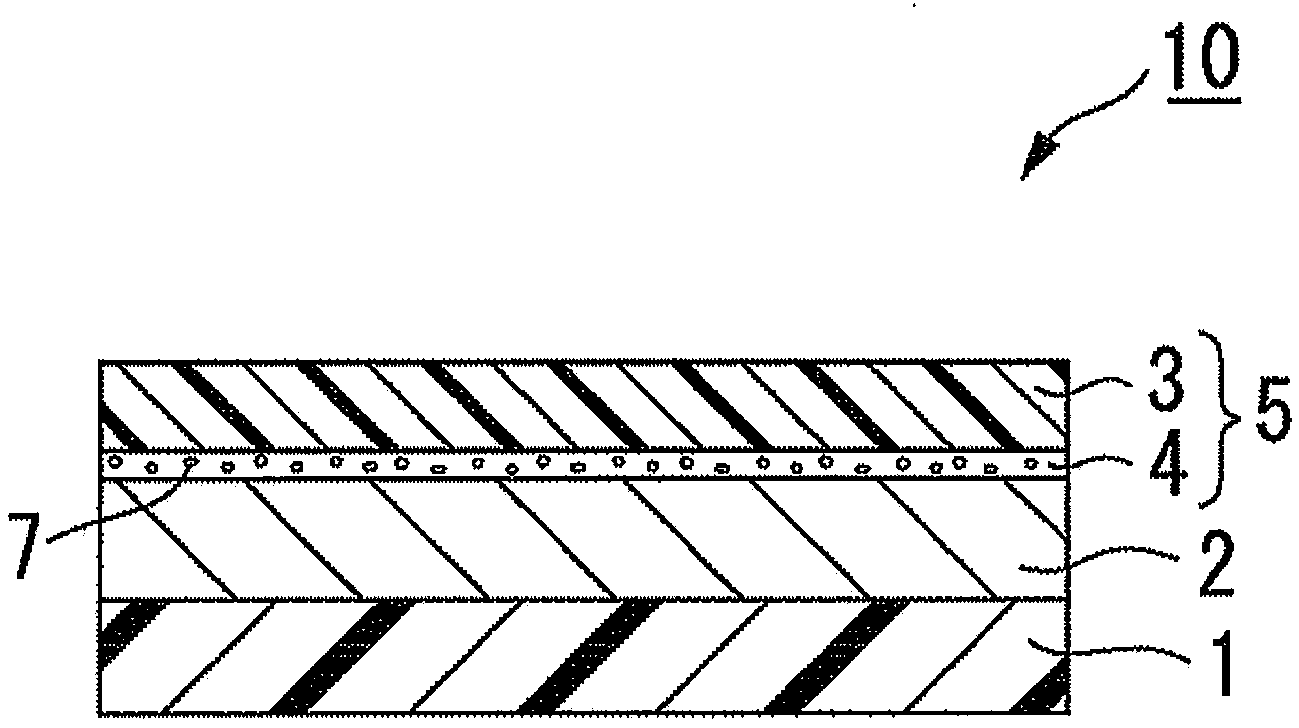

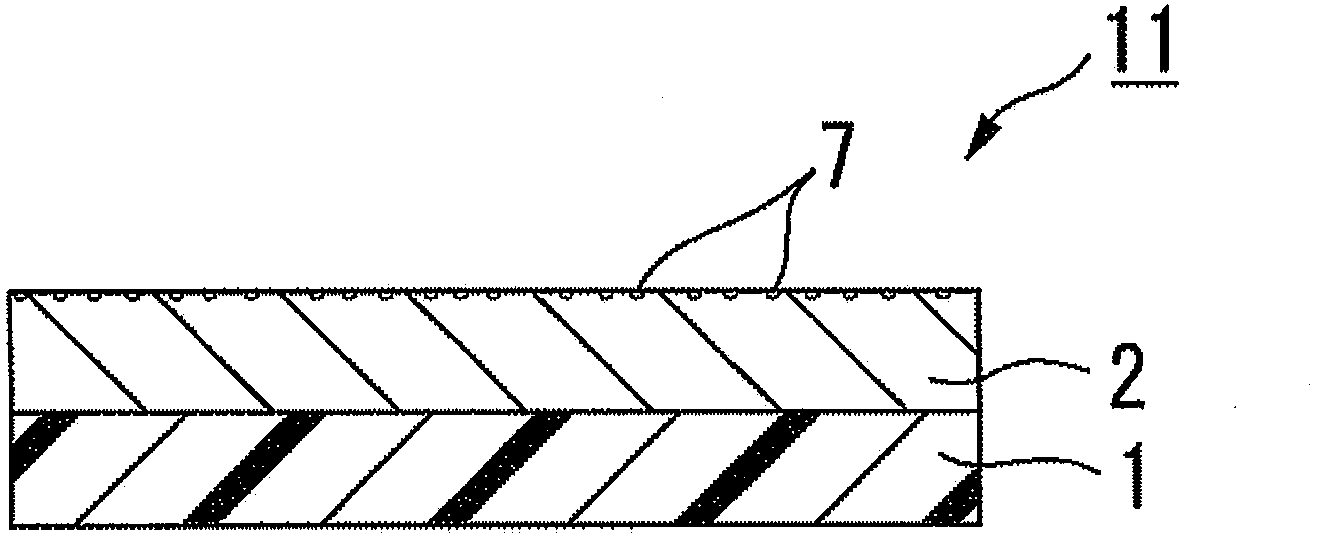

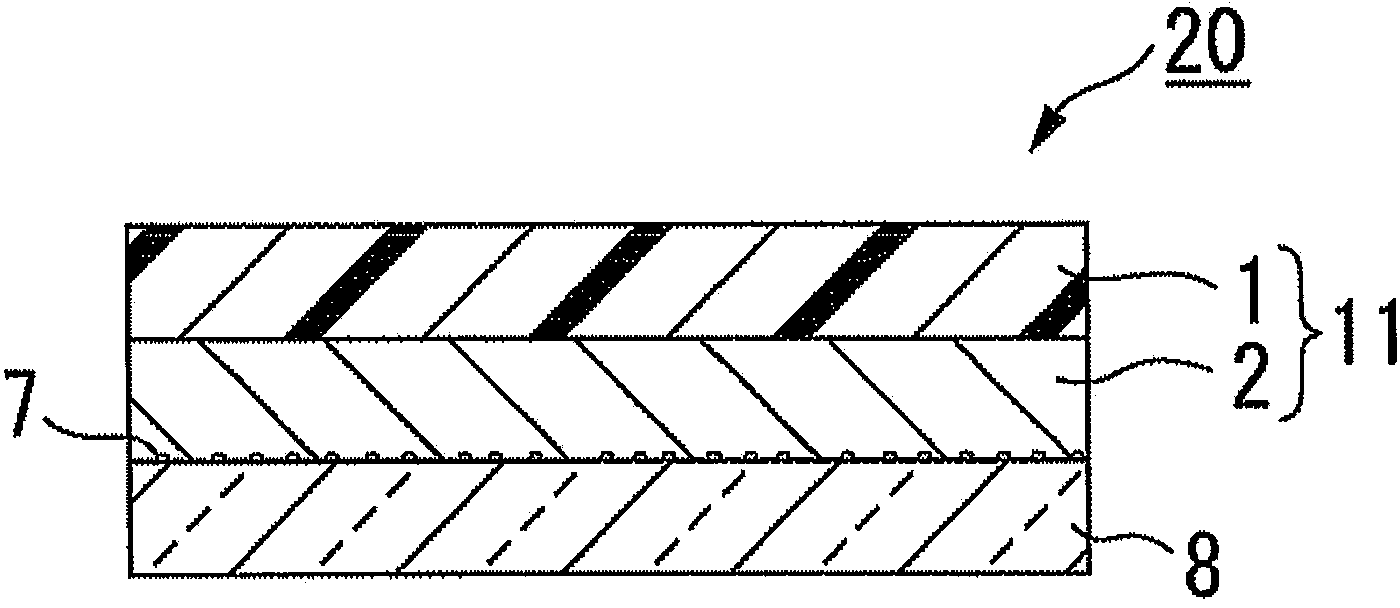

Image

Examples

Embodiment 1

[0088] Manufacture of Binder Compositions

[0089] Add 90 parts by weight of 2-ethylhexyl acrylate and 10 parts by weight of methoxypolyethylene glycol (400) monomethacrylate , 3 parts by weight of 2-hydroxyethyl acrylate, 0.2 parts by weight of 2,2'-azobisisobutyronitrile as a polymerization initiator, 154 parts by weight of ethyl acetate, stir the content while introducing nitrogen, and heat up to 65 ℃. Furthermore, a polymerization reaction was performed at a temperature of about 65° C. for 6 hours to obtain a polyoxyalkylene group-containing acrylic polymer. 100 parts by weight of the obtained polyoxyalkylene-containing acrylic polymer was stirred and mixed with 0.1 parts by weight of lithium perchlorate as an antistatic agent, thereby manufacturing the binder composition of Example 1 (solid content 40% ).

[0090] Manufacture of surface protection film

[0091] Addition-reactive silicone (manufactured by Dow Corning Toray Co., Ltd., trade name: SRX-345) 3 parts by wei...

Embodiment 2

[0093] Using 1.5 parts by weight of lithium bis(trifluoromethanesulfonyl)imide to replace 0.1 parts by weight of lithium perchlorate in the binder composition of Example 1, the binder composition of Example 2 (solid composition 40%).

[0094] Except having used the adhesive composition of Example 2 instead of the adhesive composition of Example 1, the surface protection film of Example 2 was obtained by the method similar to Example 1.

Embodiment 3

[0096]3 parts by weight of addition-reactive silicone (manufactured by Dow Corning Toray Co., Ltd., trade name: SRX-211), and 0.1 parts by weight of polyether-modified polysiloxane (manufactured by Shin-Etsu Chemical Co., Ltd., trade name: KF352A) 97 parts by weight of a 1:1 mixed solvent of toluene and ethyl acetate, and 0.03 parts by weight of a platinum catalyst (manufactured by Toray Dow Corning Co., Ltd., trade name: SRX-212) were stirred and mixed to form the compound of Example 3. Stripper layer of paint. On the surface of a polyethylene terephthalate film with a thickness of 38 μm, the coating material for the release agent layer of Example 3 is coated with a wire bar so that the thickness after drying becomes 0.1 μm, and then hot air at 120° C. is passed. The peeling film of Example 3 was obtained by drying in a circulating oven for 1 minute.

[0097] Except having used the release film of Example 3 instead of the release film of Example 1, the surface protection fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com