Release film for adhesive film, and adhesive film using the release film for adhesive film

一种粘结膜、粘结剂层的技术,应用在薄膜/薄片状的粘合剂、胶粘剂、粘合剂类型等方向,能够解决被粘附体污染性变化、污染等问题,达到优异防剥离静电性能、污染少的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

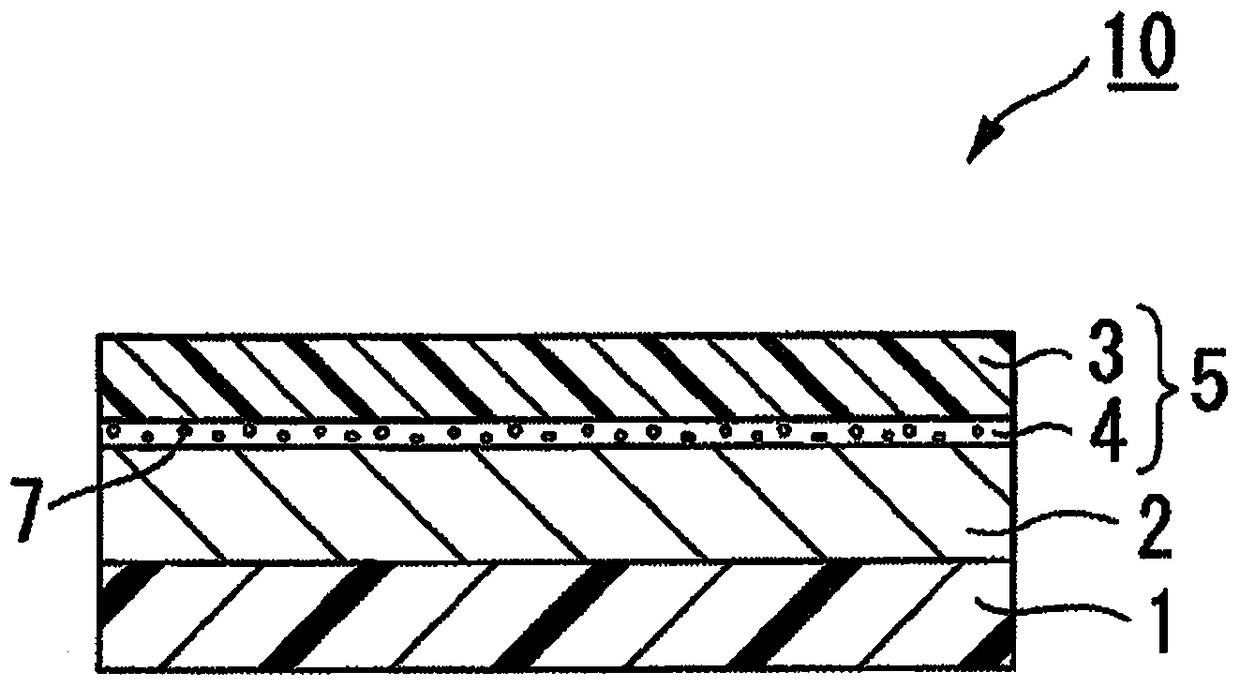

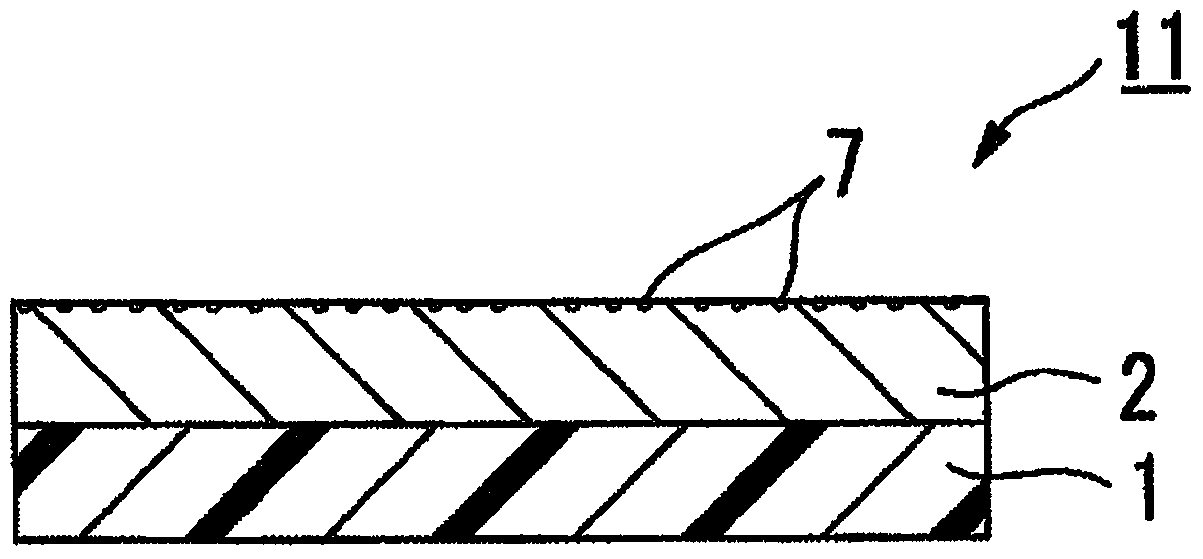

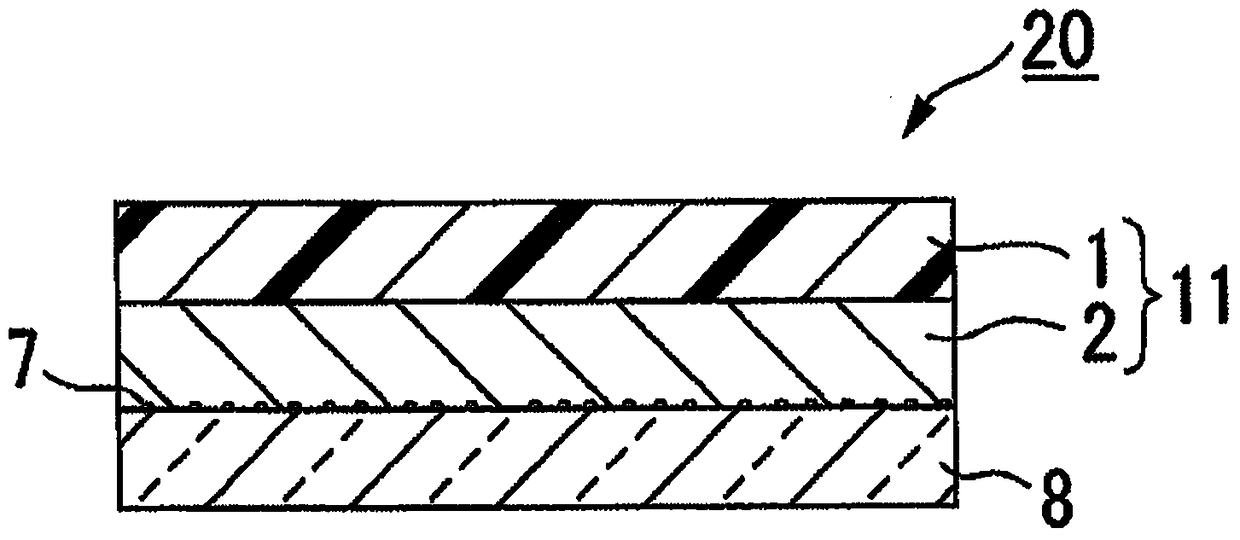

[0088] Manufacture of release film for adhesive film

[0089] 3 parts by weight of addition reaction silicone (manufactured by Dow Corning Toray Co., Ltd., trade name: SRX-345), 0.1 parts by weight of polyether-modified polysiloxane (manufactured by Dow Corning Toray Co., Ltd., trade name: SH8400) parts, 97 parts by weight of a 1:1 mixed solvent of toluene and ethyl acetate, and 0.03 parts by weight of a platinum catalyst (manufactured by Dow Corning Toray Co., Ltd., trade name: SRX-212) were stirred and mixed to prepare the Stripper layer of paint. On the surface of polyethylene terephthalate with a thickness of 38 μm, the coating material for the release agent layer of Example 1 was coated with a wire bar so that the thickness after drying was 0.1 μm, and hot air at 120° C. was used. The peeling film for adhesive films of Example 1 was obtained by drying in a circulating oven for 1 minute.

[0090] Manufacture of Binder Compositions

[0091] In a four-necked flask with a ...

Embodiment 2

[0095]100 parts by weight of the binder composition of Example 1 and 0.1 part by weight of lithium perchlorate as an antistatic agent were stirred and mixed to prepare the binder composition of Example 2 containing an antistatic agent. Except for using the adhesive composition of Example 2 instead of the adhesive composition of Example 1, by the same method as Example 1, the adhesive film bonded with the release film for the adhesive film of Example 2 was obtained. Adhesive film.

Embodiment 3

[0097] 100 parts by weight of the adhesive composition of Example 1 was stirred and mixed with 1.5 parts by weight of bis(trifluoromethanesulfonyl)imide lithium as an antistatic agent to produce the adhesive composition of Example 3 with an antistatic agent. agent composition. Except for using the adhesive composition of Example 3 instead of the adhesive composition of Example 1, by the same method as Example 1, the adhesive film bonded with the release film for the adhesive film of Example 3 was obtained. Adhesive film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| surface potential | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com