Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Easy to choose operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

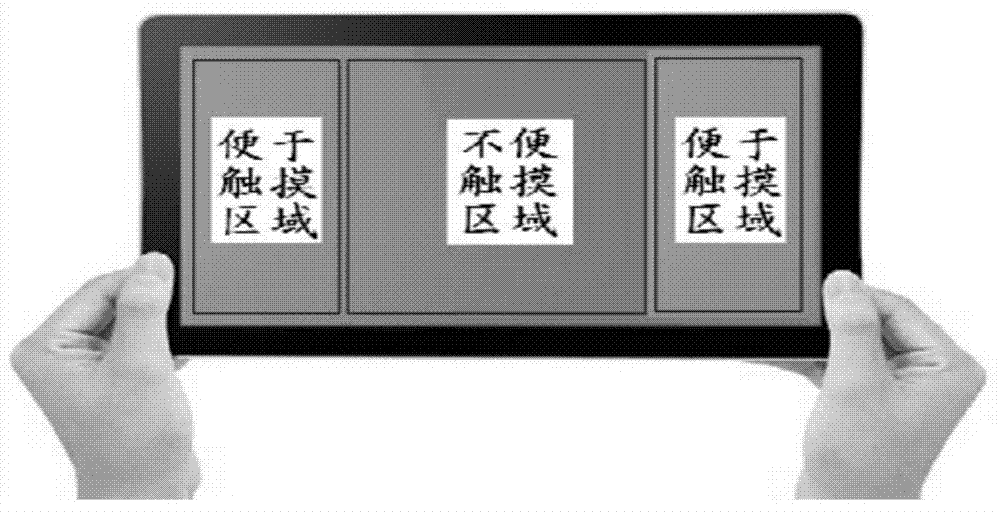

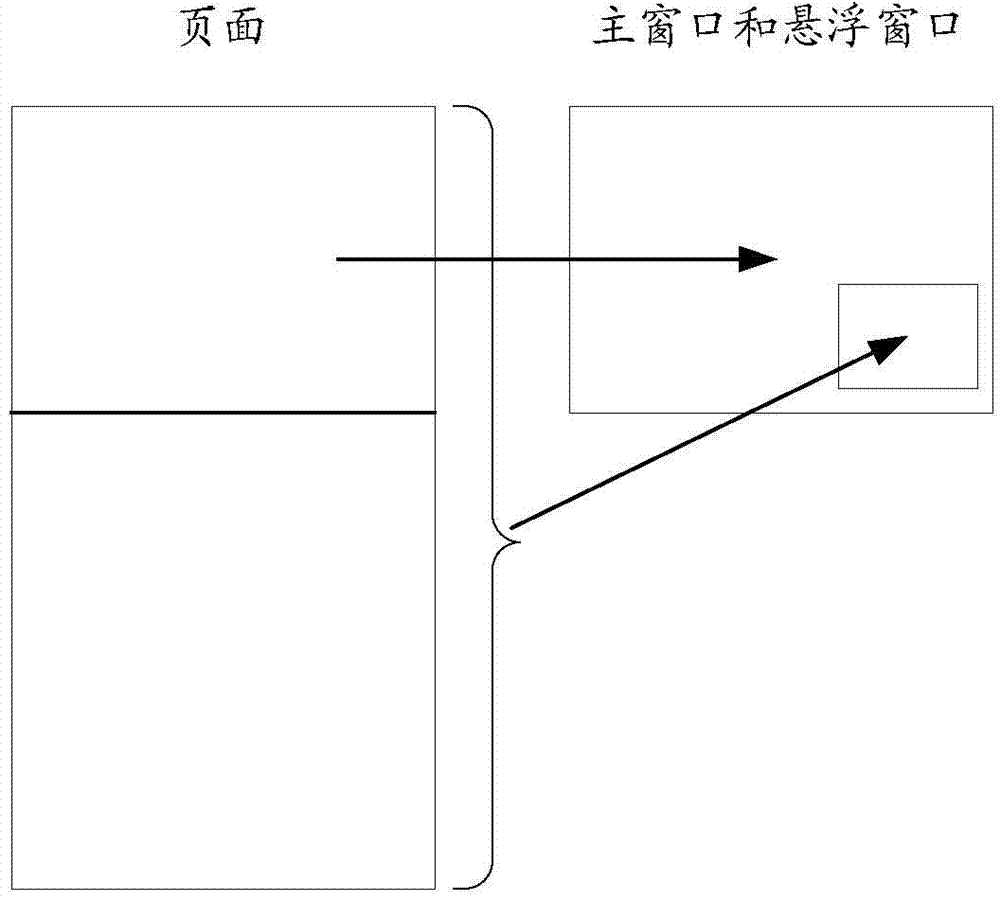

Method for rendering pages and device thereof

InactiveCN104267871AEasy to choose operationMove quicklySpecial data processing applicationsInput/output processes for data processingComputer graphics (images)Computer science

The purpose of the invention is to discloses a method for rendering pages and a device thereof. The method comprises the following steps of: rendering a main window and a suspension window, rendering one page in the main window, and rendering all or partial navigation information including the page in the suspension window. According to the solution, an user controls the navigation information in the suspension window such that the rendered page contents in the main window are quickly and precisely moved to object regions of the pages, if the rendered page contents in the main window are quickly moved from the upper area of the page to the lower region of the page; through the method, the user can conveniently select the navigation information from the suspension window, for example, outbound links or navigation links are selected to execute corresponding operations in the main window, thus the method is beneficial to the user when a great-size mobile phone is held by both hands.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

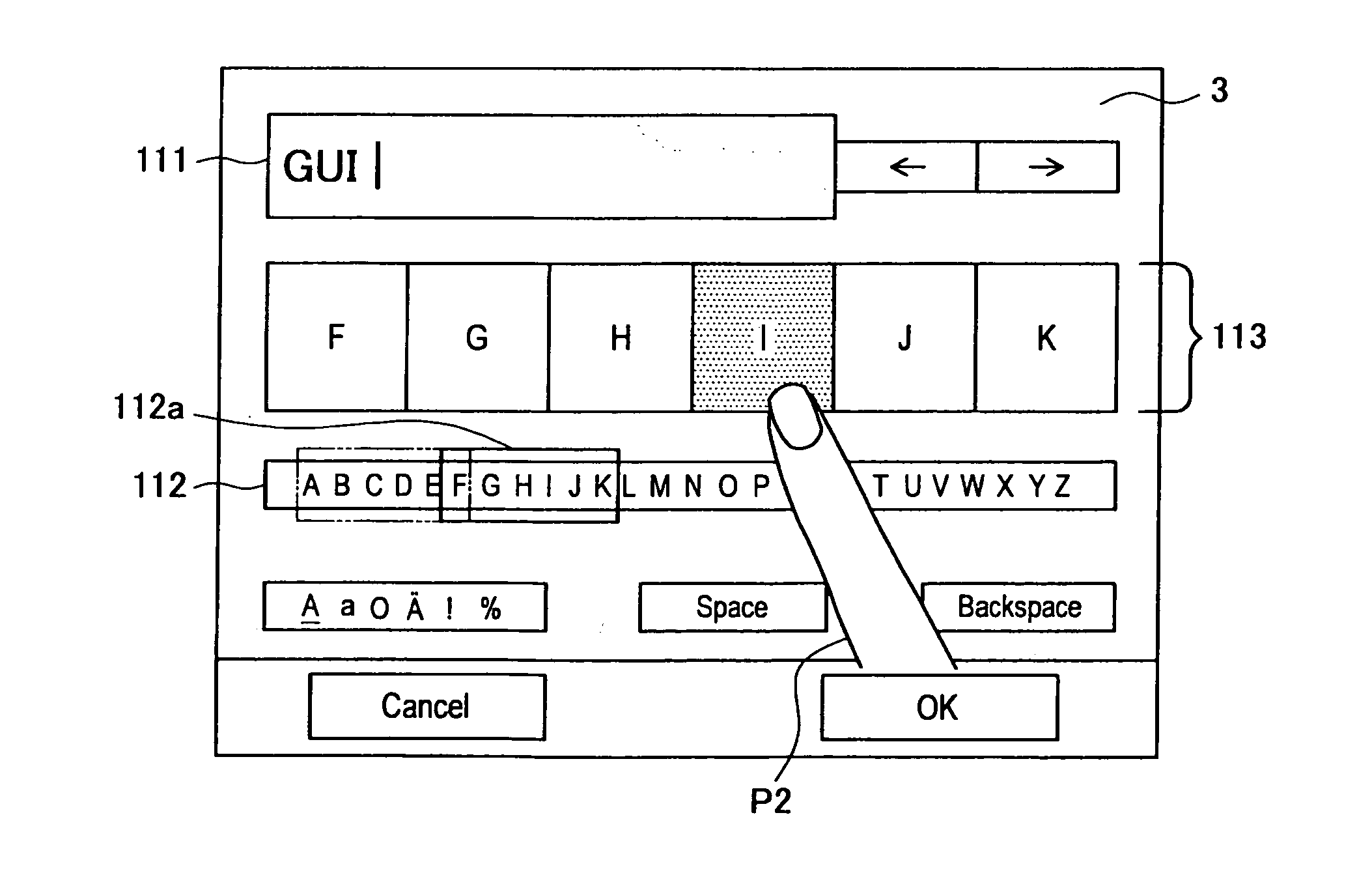

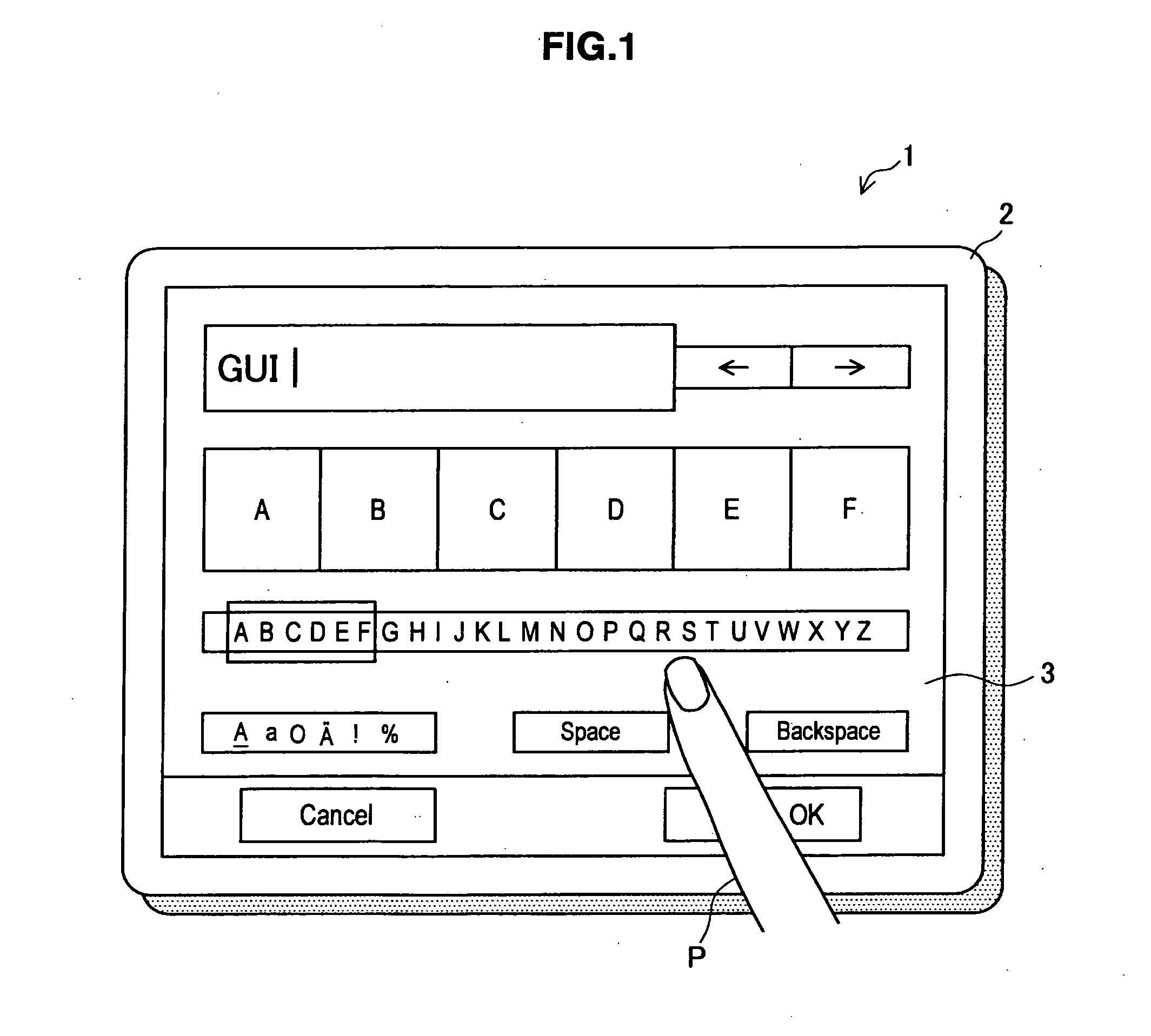

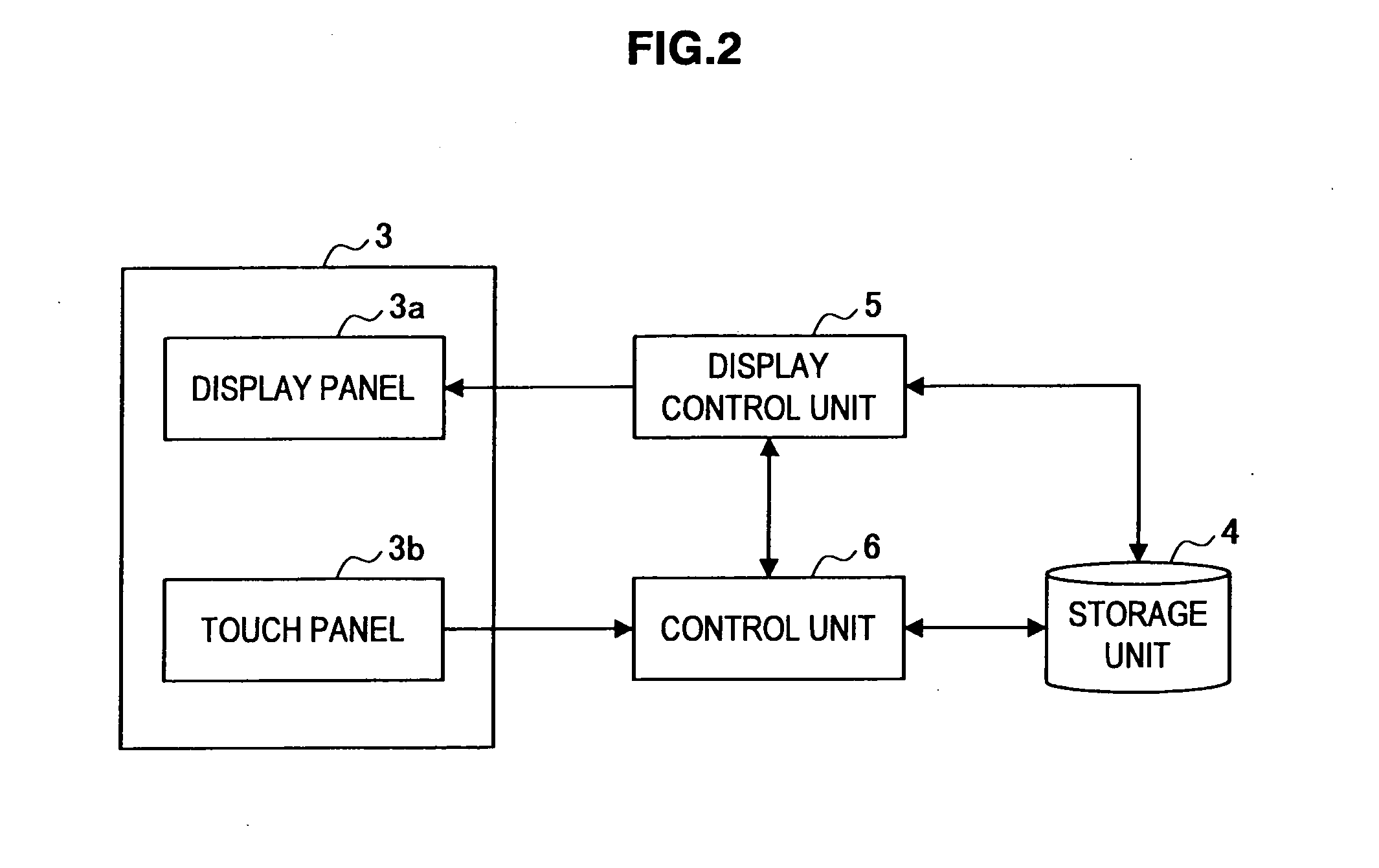

Information processing apparatus, information processing method, and program

ActiveUS20110302534A1Easy to operateEasy to choose operationInput/output processes for data processingInformation processingComputer science

There is provided an information processing apparatus including a display unit for arranging and displaying the plurality of items in a guide region, the display unit enlarging a series of items included in a specified range specified in the guide region to a size larger than a size of the items displayed in the guide region and displaying the series of items in one line in a selection region in the predetermined arrangement, a display control unit when a scroll gesture is given to scroll the series of items in the selection region, the display control unit controls the display unit to update display of the guide region so that the series of items displayed in the scrolled selection region is included in the specified range, and a control unit for determining selection of an item in accordance with a selection gesture given in the selection region.

Owner:SONY CORP

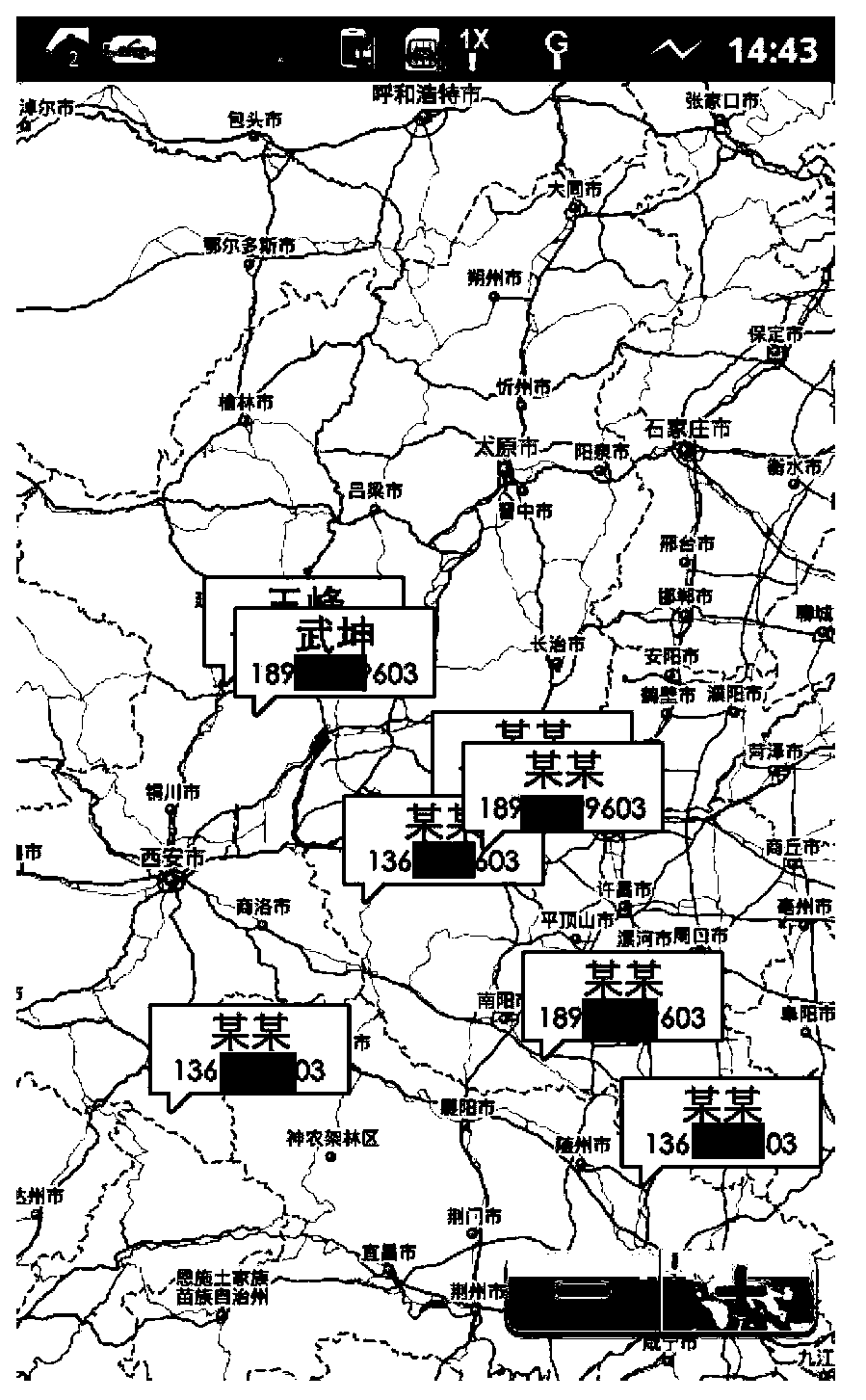

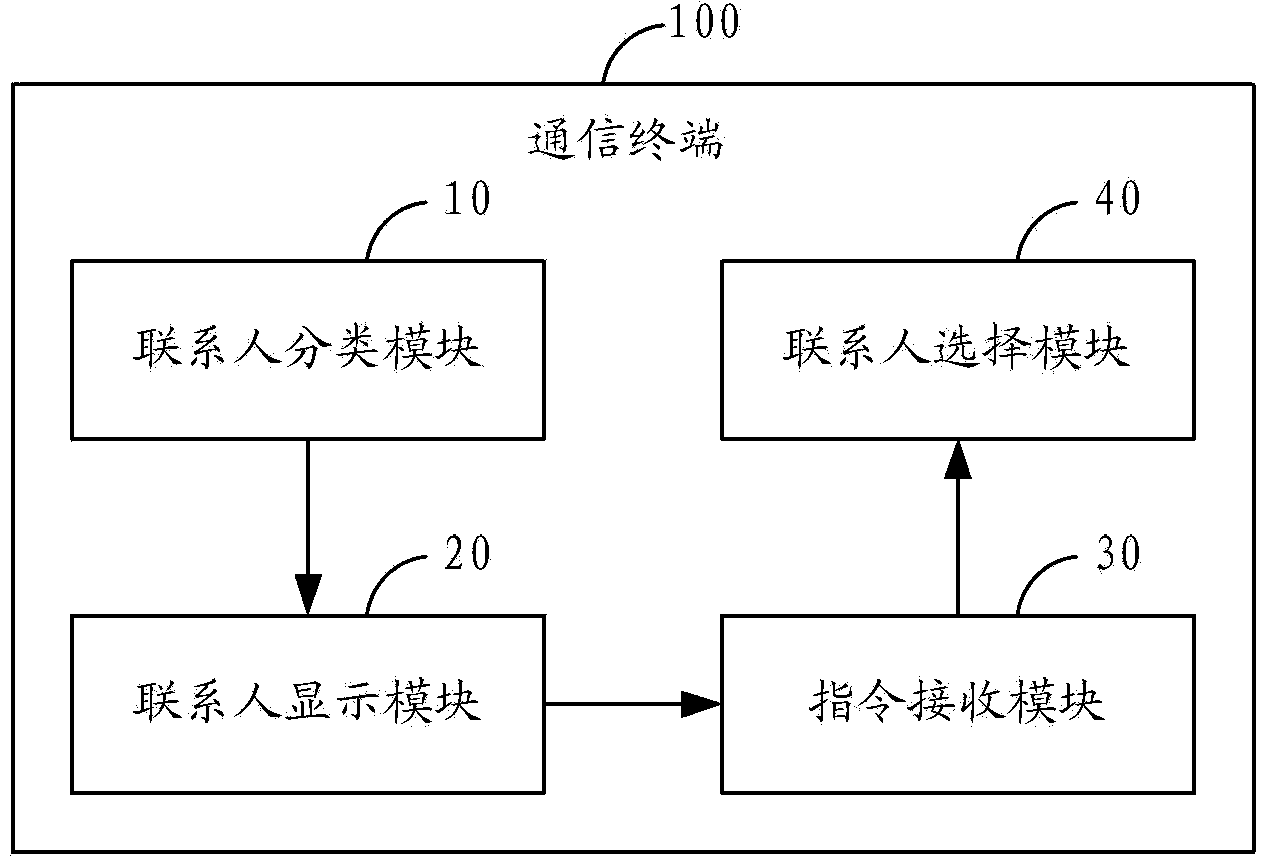

Contact selection method and communication terminal

ActiveCN103353825AEasy to choose operationIntuitive selectionInput/output processes for data processingComputer scienceSelection method

The invention is suitable for the field of communication technology, and provides a contact selection method which comprises the following steps: classifying contacts into different contact areas according to preset classification properties; displaying the contact areas; receiving customer selection instructions in the contact areas; confirming contacts corresponding to the selected contact area as selected contacts. Correspondingly, the invention further provides a communication terminal. Therefore, required contacts can be searched and selected fast according to the contact areas displayed on an interface, that is, the contact selection operation is more convenient, visual and fast.

Owner:DONGGUAN YULONG COMM TECH +1

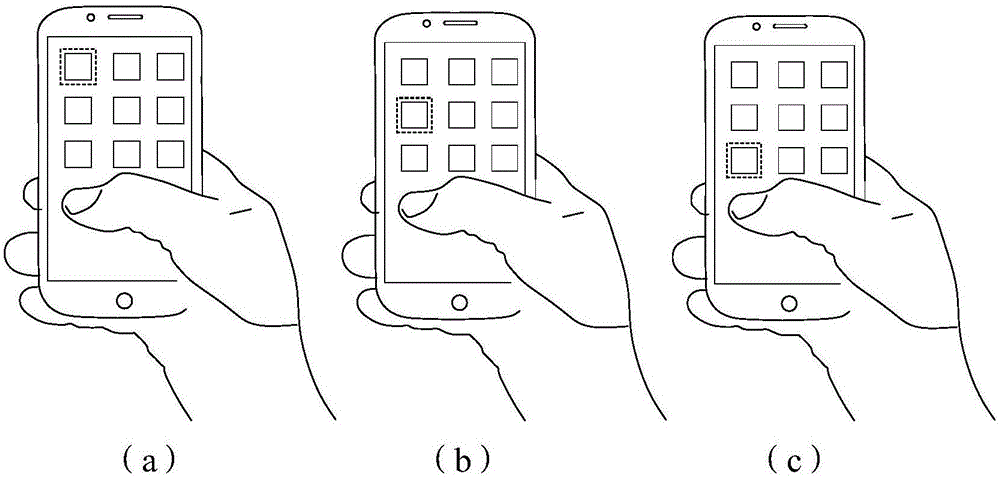

Mobile terminal and interactive method of mobile terminal

InactiveCN106843642AImprove experienceAdd funSubstation equipmentInput/output processes for data processingMobile data terminalComputer terminal

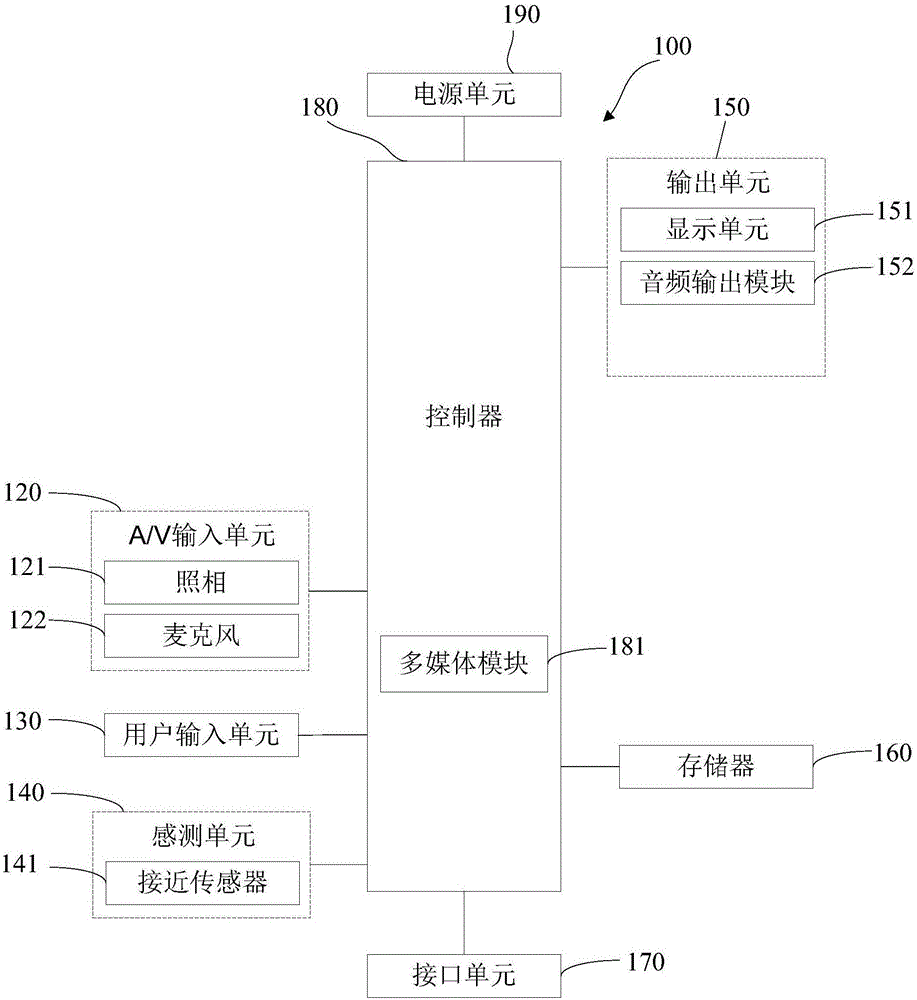

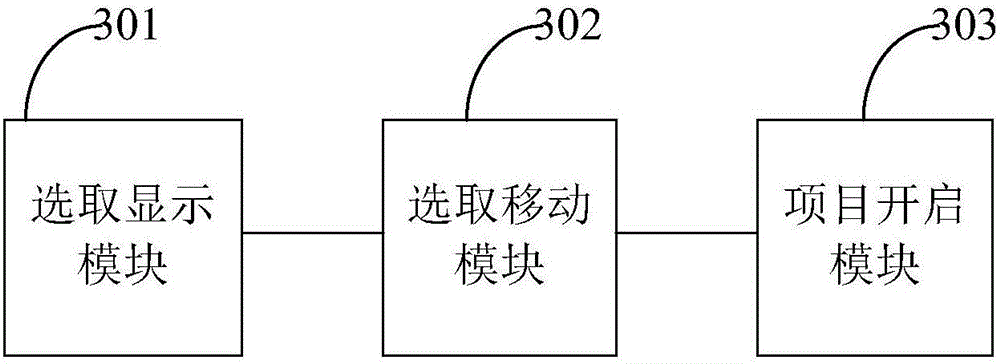

The invention provides a mobile terminal and an interactive method of the mobile terminal. The mobile terminal includes a selection and display module, a selection and movement module and an item starting module, wherein the selection and display module is used for displaying a selection mark on an item icon at a preset location in an item icon column under a preset one-hand operation mode when blank space of any one item icon column on an operation interface receives a selection and display command, the selection and movement module is used for moving the selection mark among all item icons in the item icon column on the basis of a selection and movement command when the blank space of the item icon column receives the selection and movement command, the item starting module is used for starting an item icon which corresponds to the selection mark at last when the blank space of the item icon column receives an item starting command. Under the conditions of not changing the arrangement order of the item icons on the operation interface, it is convenient for a user to conduct selection operation on various application programs or documents by single hand, and at the same time, the interestingness of the interaction process between the mobile terminal and human is improved.

Owner:NUBIA TECHNOLOGY CO LTD

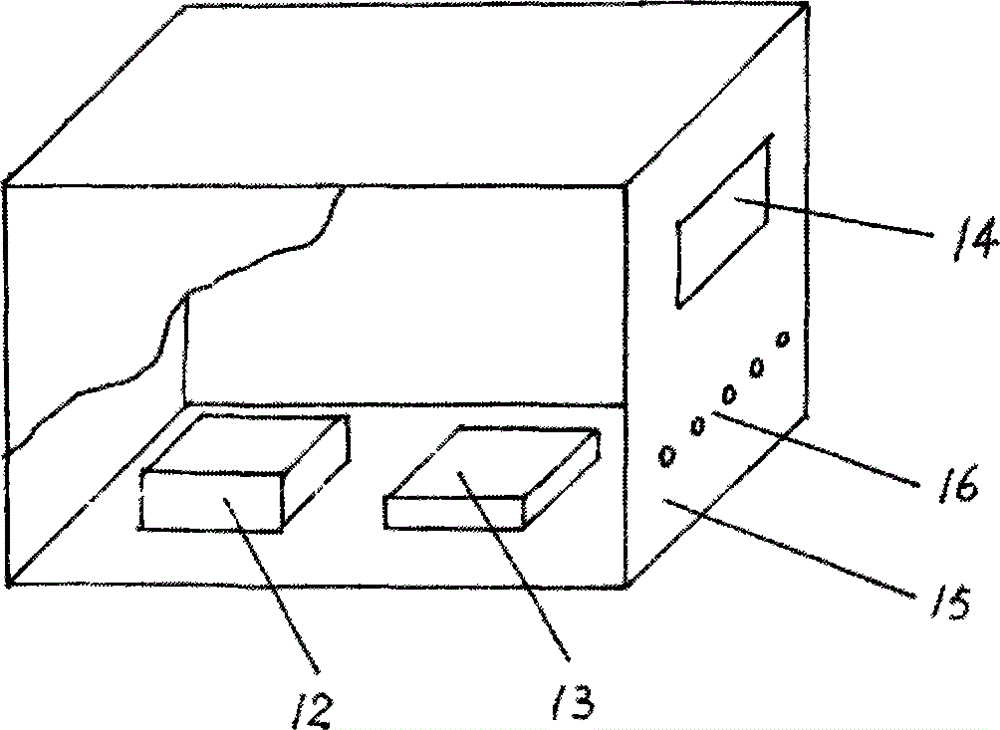

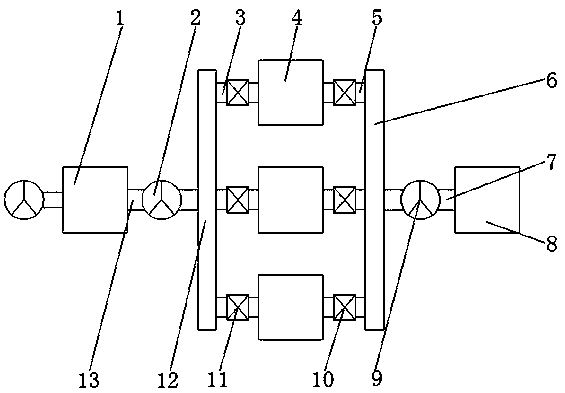

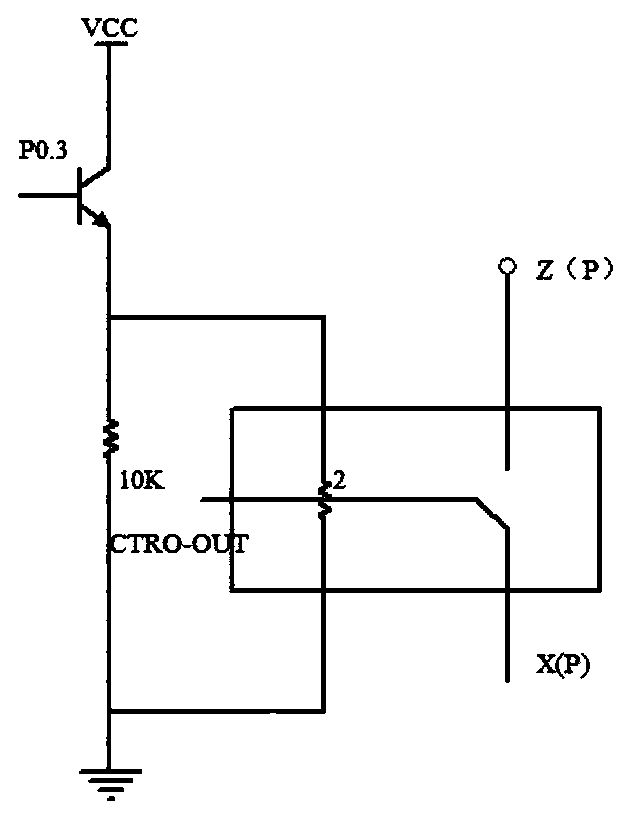

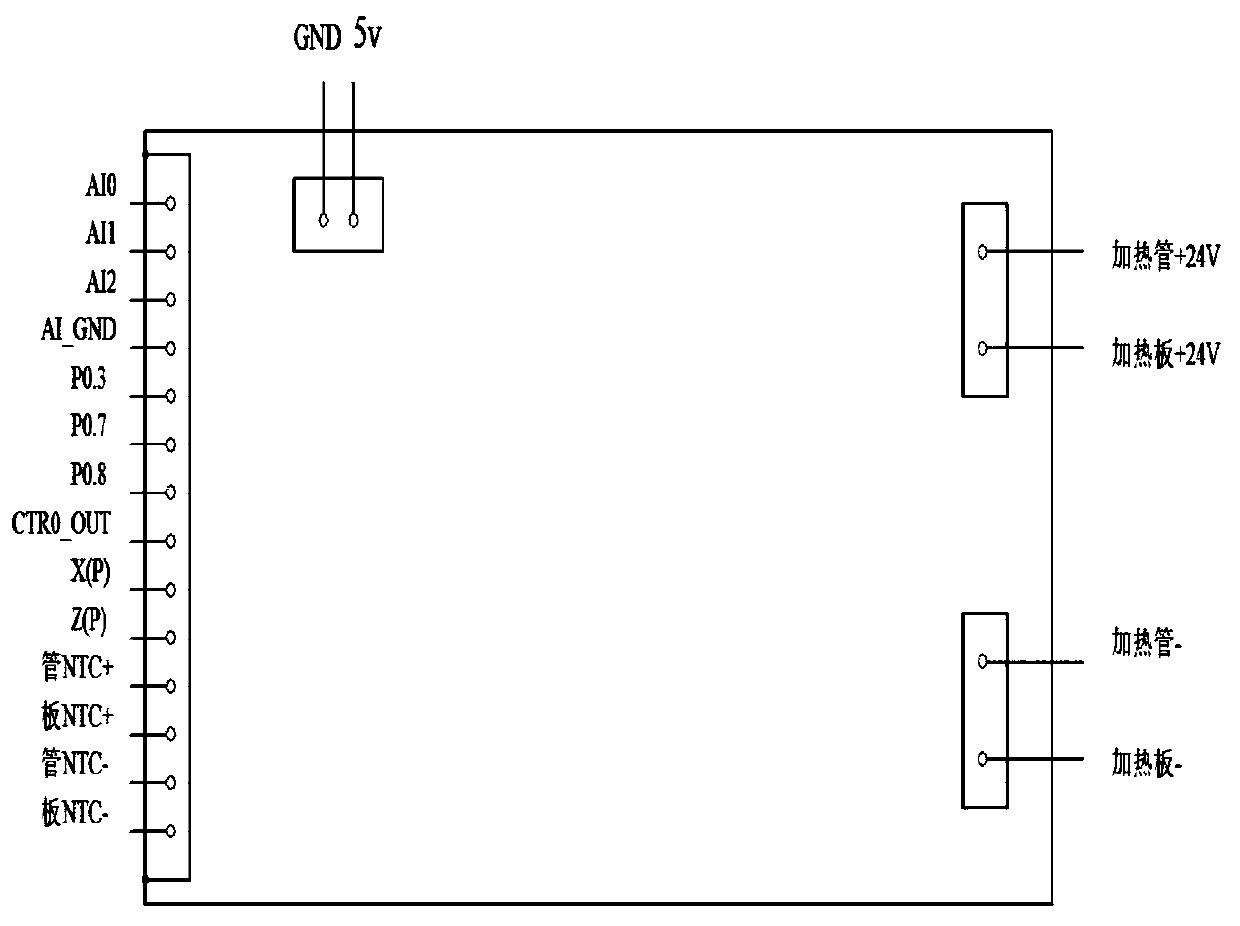

3D printing system based on virtual instrument

ActiveCN108608639ARun fastEasy to debugAdditive manufacturing apparatusAdditive manufacturing with liquidsSimulationInstrumentation

The invention discloses a 3D printing system based on a virtual instrument. An operation method for the 3D printing system comprises the following steps: initial operation: accomplishing the initial operation of the system by using a laminated sequential structure; parameter setting: controlling the upper and lower limits of the thermal resistance of a heating part by using a circulation embeddedcondition structure, setting an event structure in a waiting branch, and editing and modifying the thermal resistance of the heating part via the event structure so as to set upper and lower limit parameters; manual printing: pretreating the system, wherein the pretreatment includes preheating of the system and debugging and setting of the coordinates of a nozzle at the same time, and performing motor operation, extrusion motor operation and temperature control at the same time; and 3D printing: subjecting corresponding 3D object data to layering and slicing, contour optimization, lamellar data processing and other treatment so as to obtain corresponding coordinate information, and controlling a triaxial motor according to the coordinate information so as to realize fixed-point layer-by-layer printing and lamination so as to obtain a 3D object. The 3D printing system provided by the invention realizes 3D scanning and printing via LabVIEW, and is fast in the operation speed of programs,easily debuggable in visual programming and high in printing accuracy.

Owner:苏州舜达易科信息技术有限公司

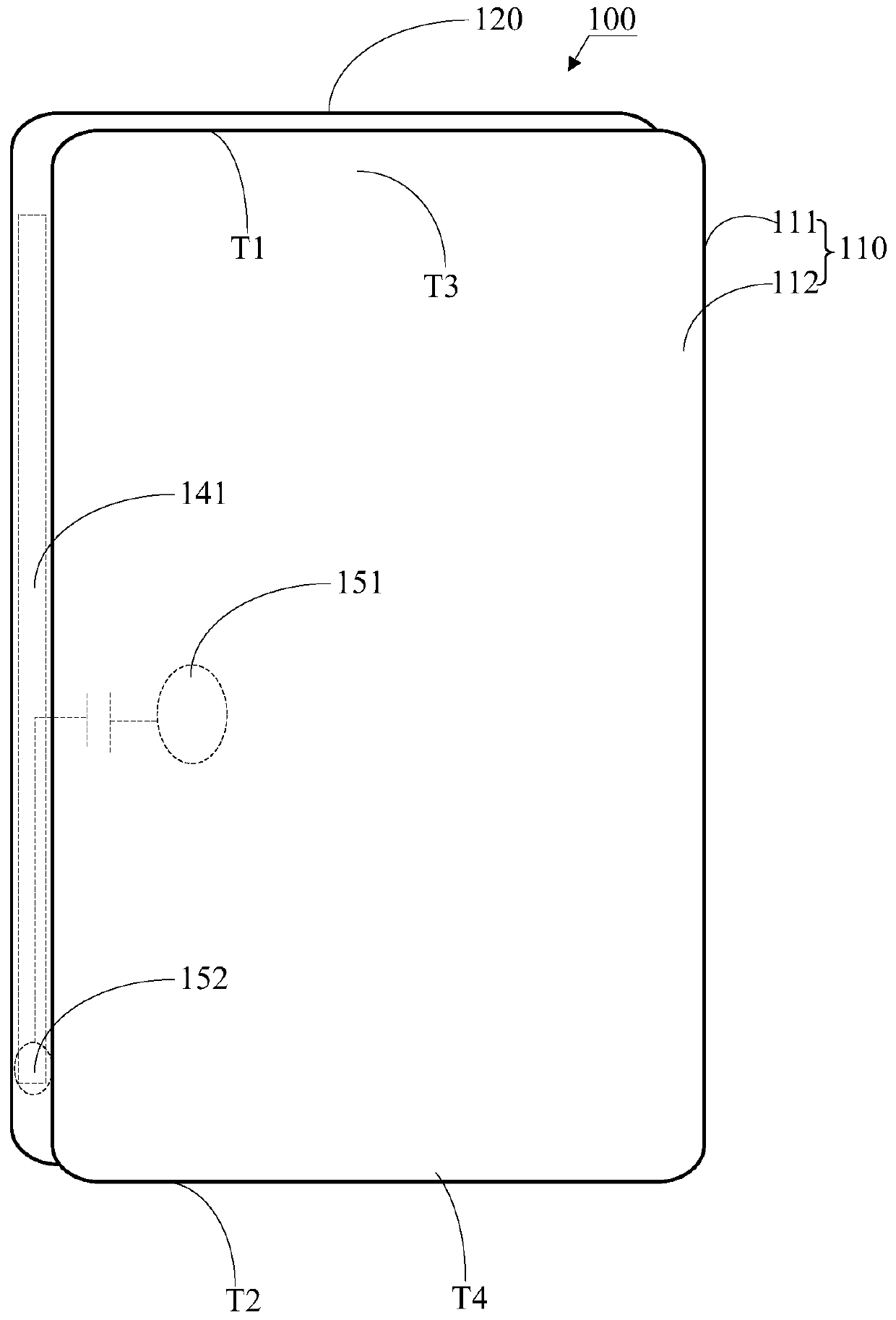

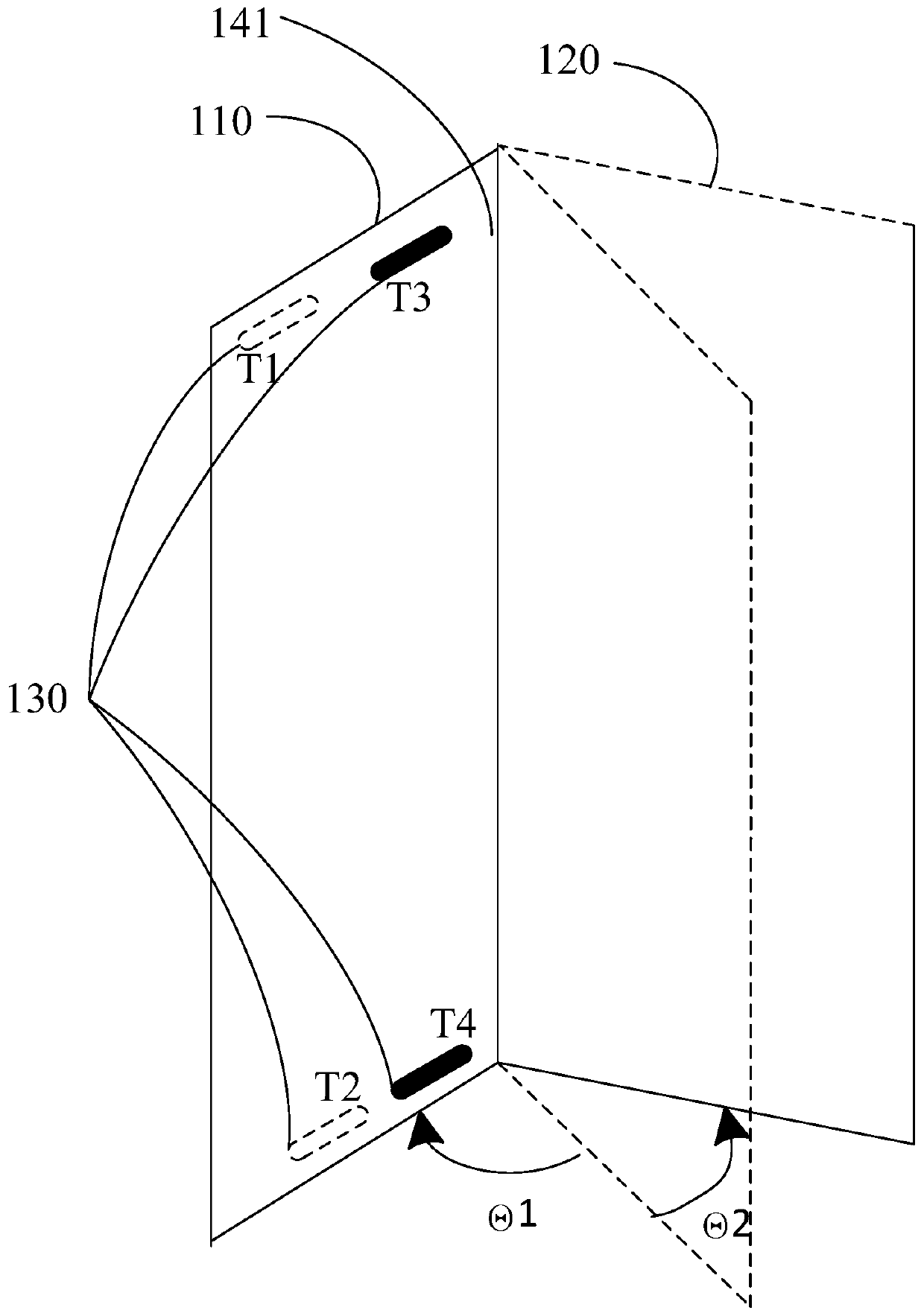

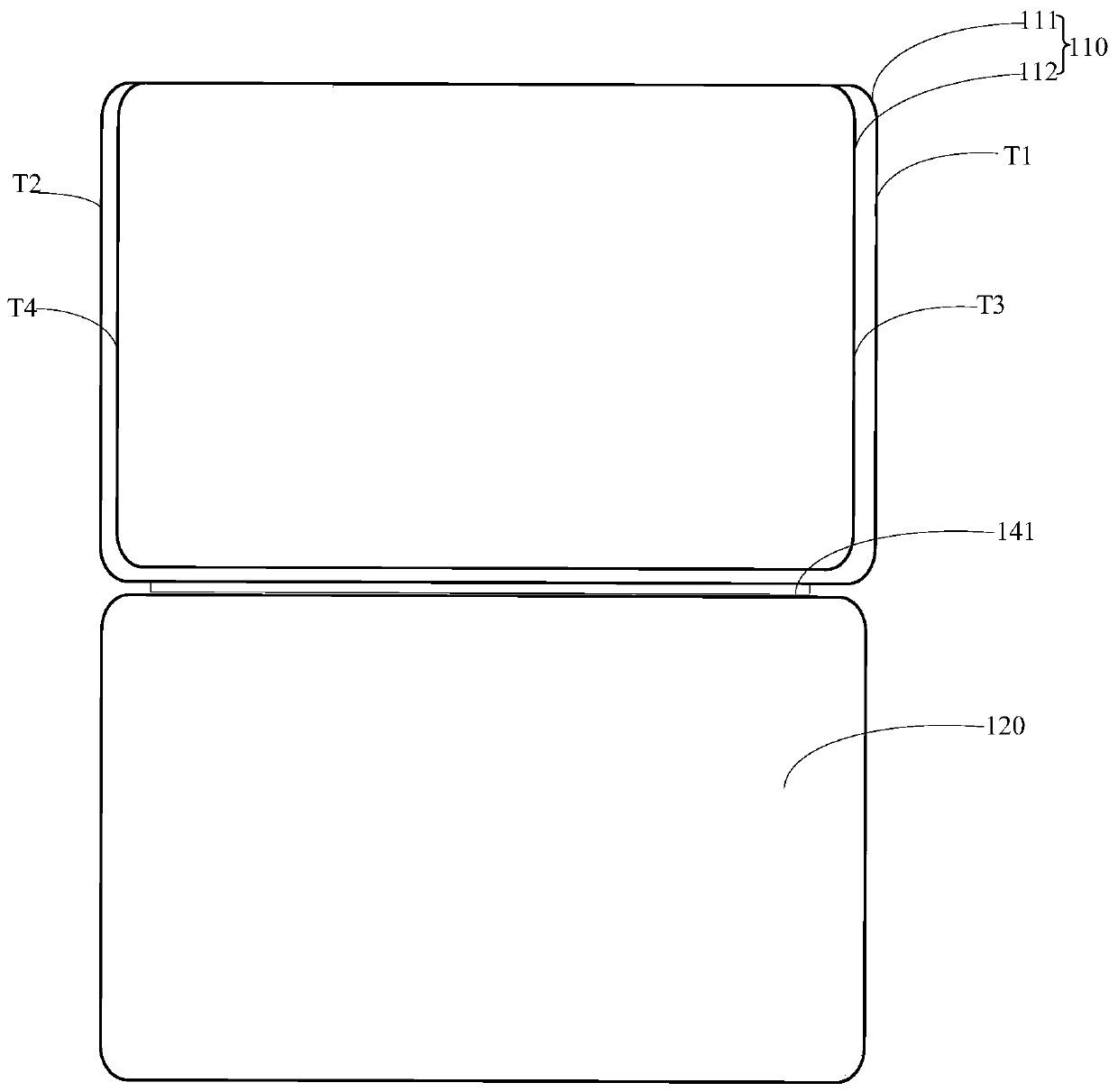

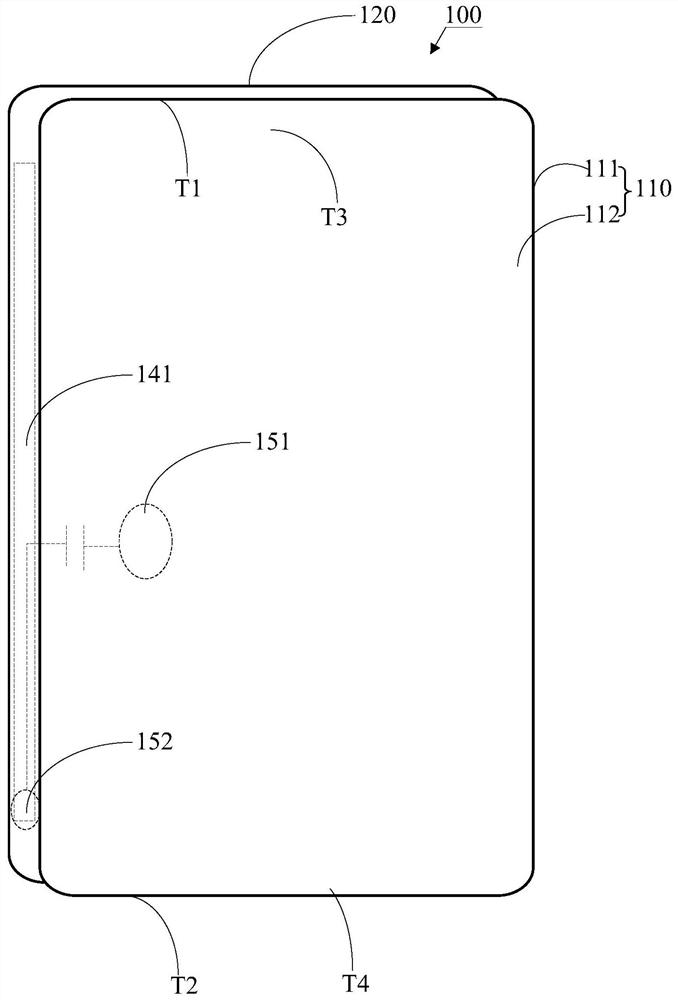

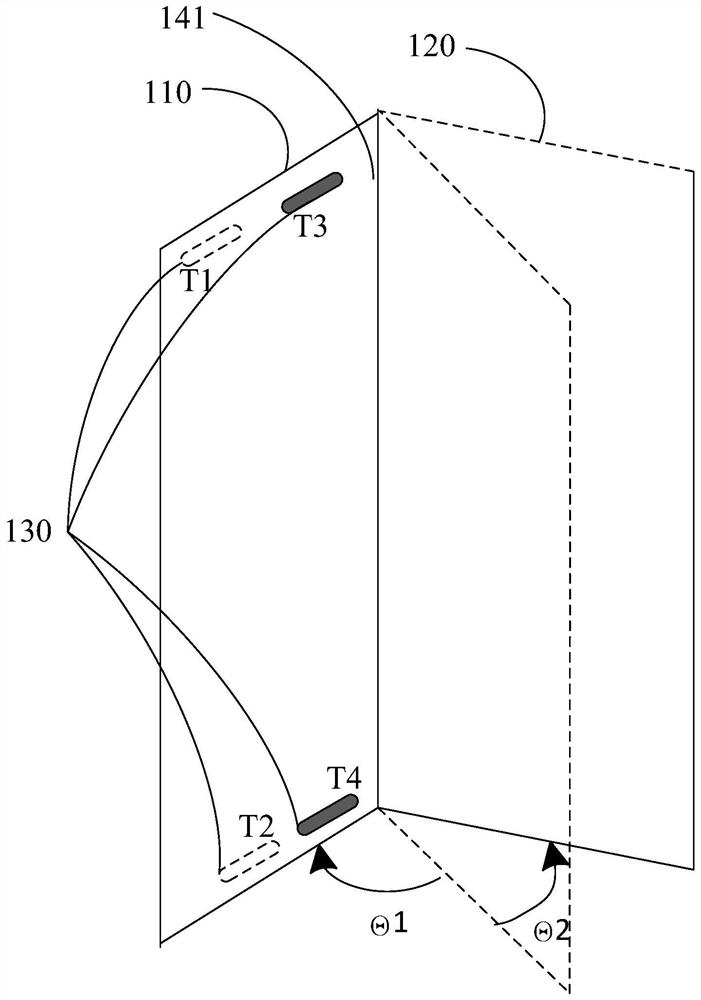

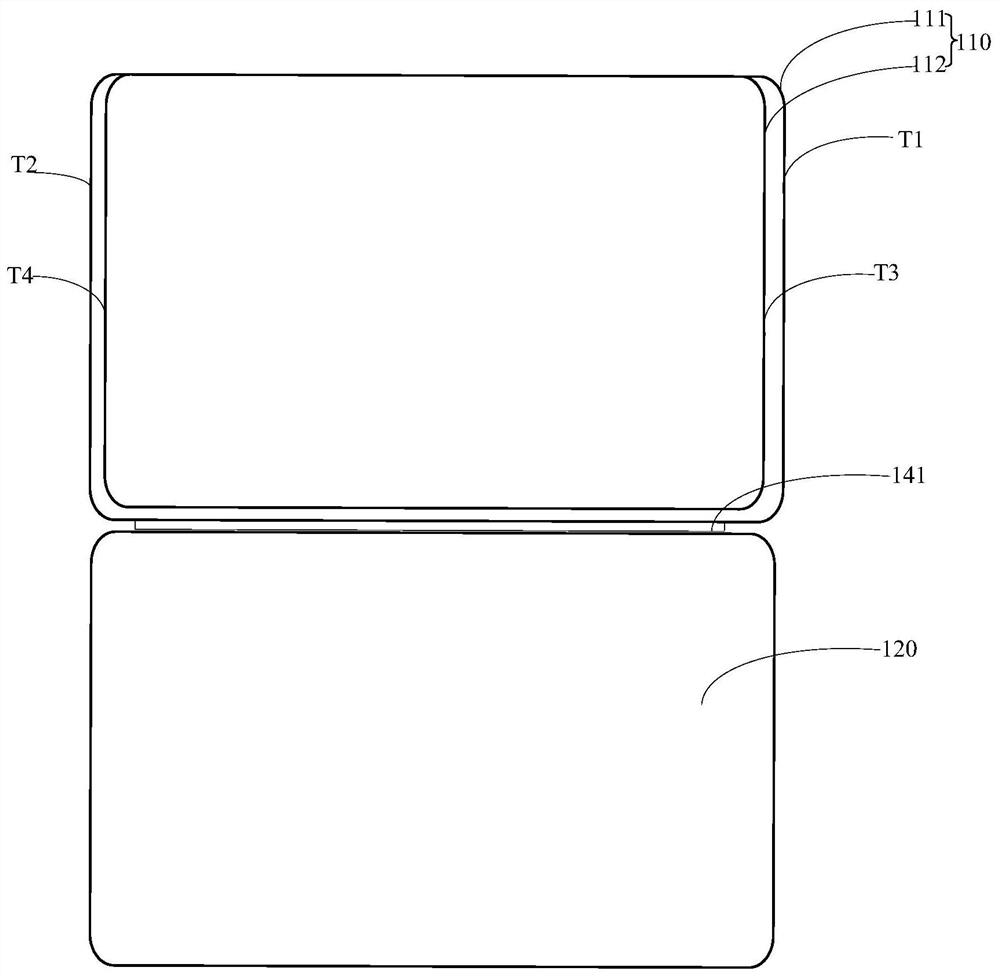

Terminal

ActiveCN109802223AEasy to choose operationSending and receiving function is goodAntenna supports/mountingsAntennas earthing switches associationElectricityEngineering

The present invention provides a terminal. The terminal is provided with at least two antennas and includes a first housing and a second housing. The first housing and the second housing are relatively moved by a motion mechanism to at least two states. The at least two antennas are distributed on the first housing and / or the second housing. Either the first housing or the second housing is provided with a feed point connected to a feed source. The other one of the first housing and the second housing is provided with at least two mutually insulated feeder line structures. Each of the feeder line structures is electrically connected to an antenna. In different states, the feed point is electrically connected to different feeder line structures to determine a working antenna in the at leasttwo antennas. In the embodiment, the feed source of the terminal is electrically connected to the working antenna in the state through the feed point. The terminal has a good signal transmission andreception function, avoids the interference caused by rotation, and greatly optimizes the antenna selection operation of the terminal.

Owner:VIVO MOBILE COMM CO LTD

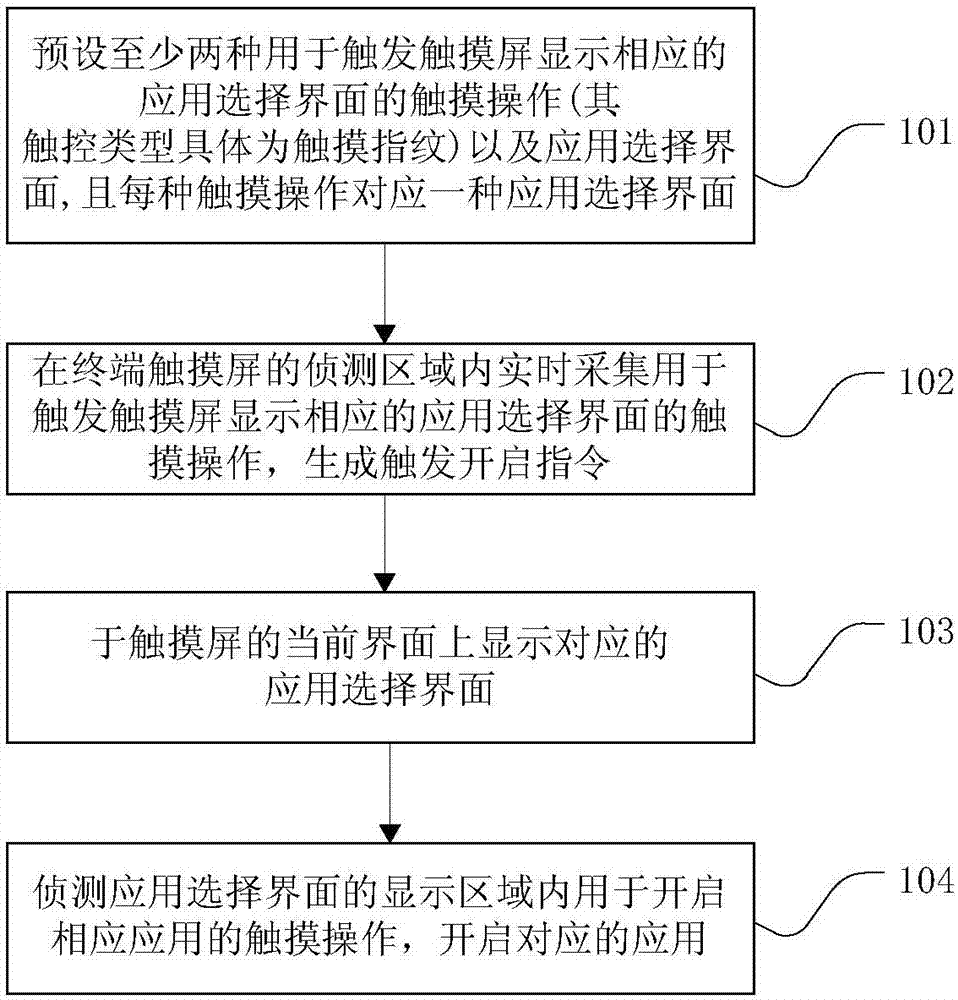

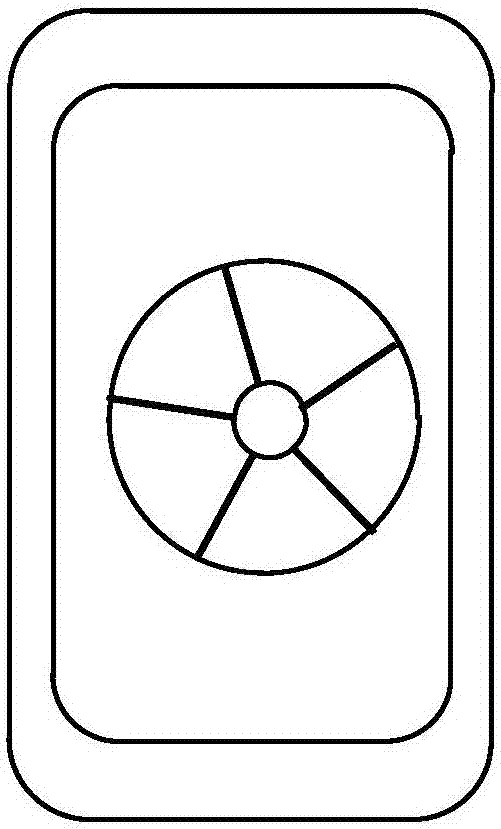

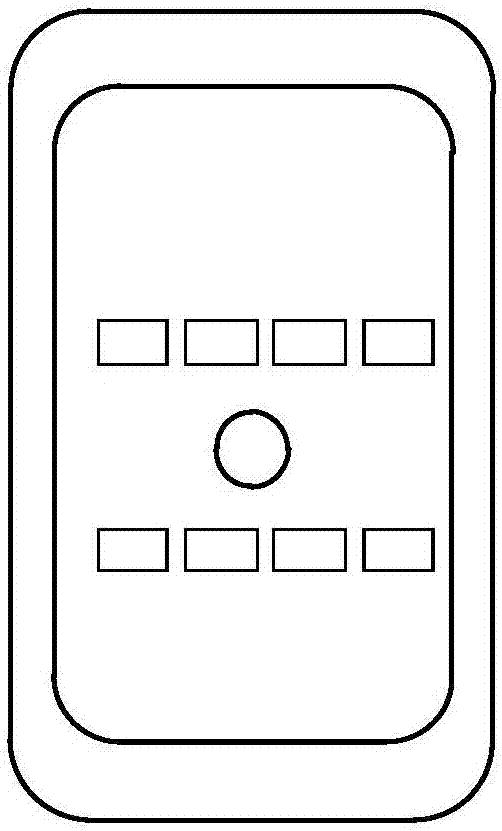

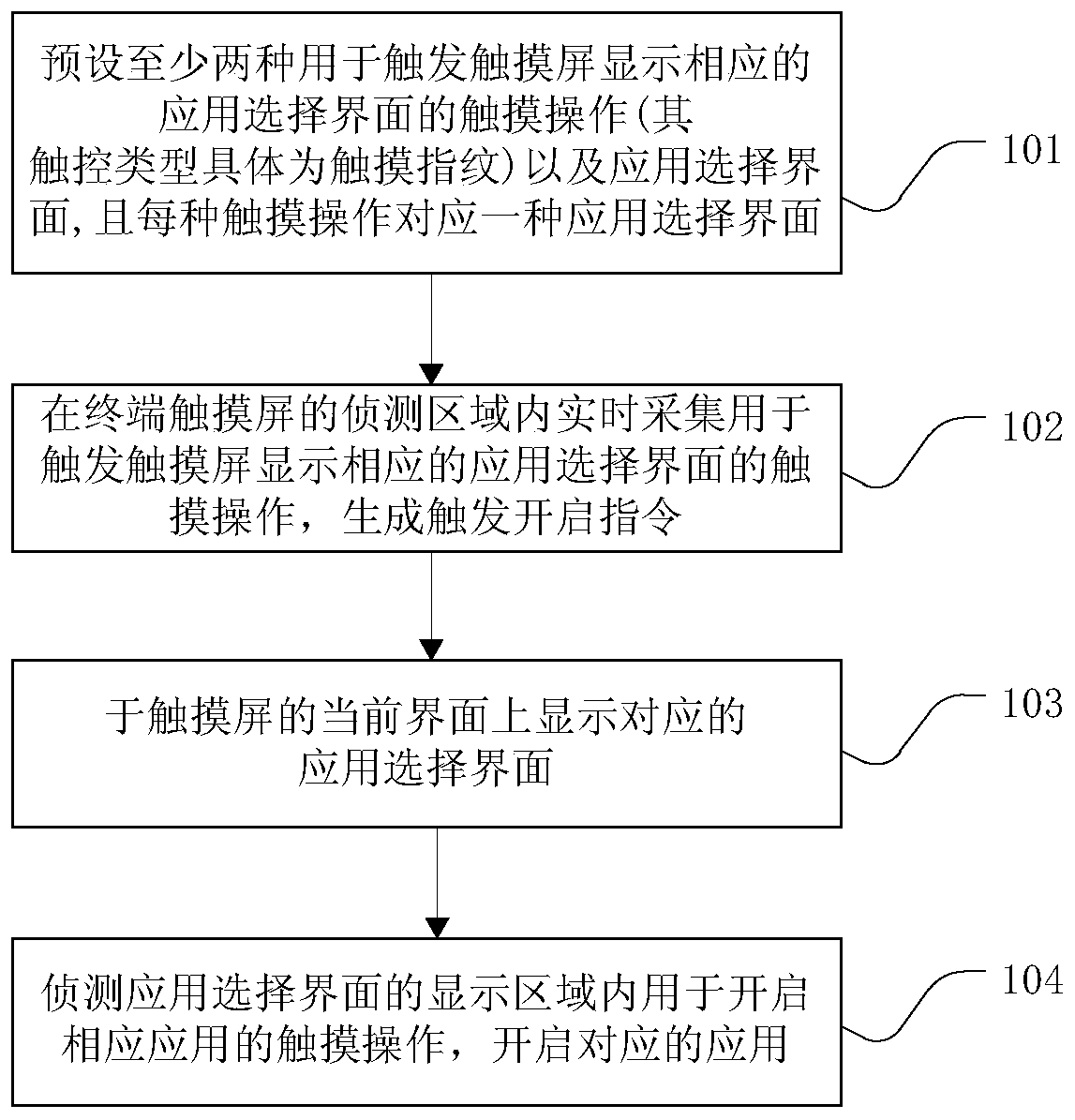

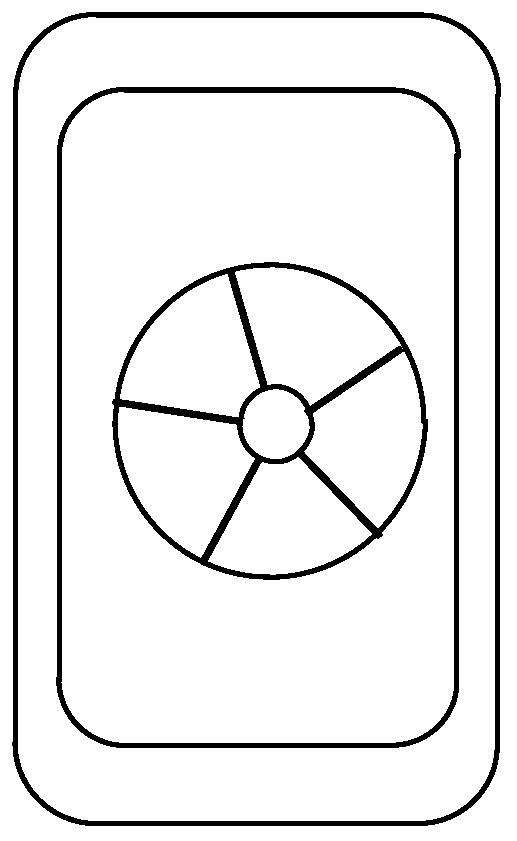

Application starting method and terminal

ActiveCN106933488AMeet the needs of personalized settingsImprove user experienceInput/output processes for data processingTouchscreenQuick start

The invention discloses an application starting method and a terminal. The method comprises the steps that touch operation on a touch screen is collected and recognized, and corresponding application selection interfaces are displayed on a current interface of the touch screen; and touch operation in display regions of the application selection interfaces is collected and recognized, and corresponding applications are started, wherein each of the touch operation triggering display of the corresponding application selection interfaces on the touch screen and the application selection interfaces is of two types, and the touch operation and the application selection interfaces are in one-to-one correspondence. By the application of the method, quick start of a designated application can be realized, and the method is suitable for a screen locking state and a screen unlocking state; different users can customize the application selection interfaces conforming to their own habits, and the same user can customize multiple different application selection interfaces; the application selection interfaces are set in multiple shapes, and display positions of the application selection interfaces can keep consistent with touch points, so that great convenience is brought to selection operation by the users; moreover, when interface display is incomplete, the application selection interfaces can be adjusted adaptively to guarantee an optimal visual effect.

Owner:GUANGDONG HONGQIN COMM TECH CO LTD

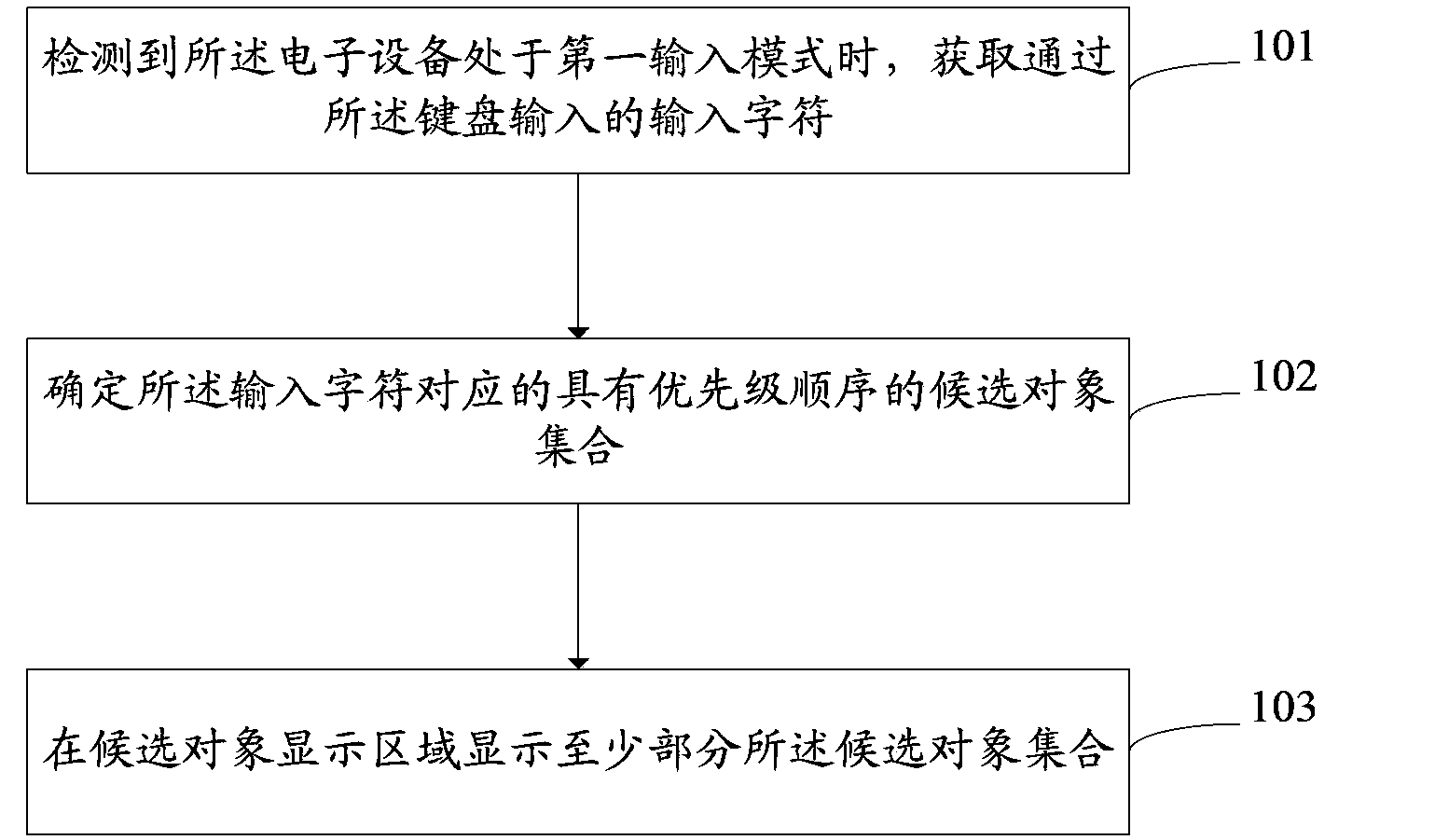

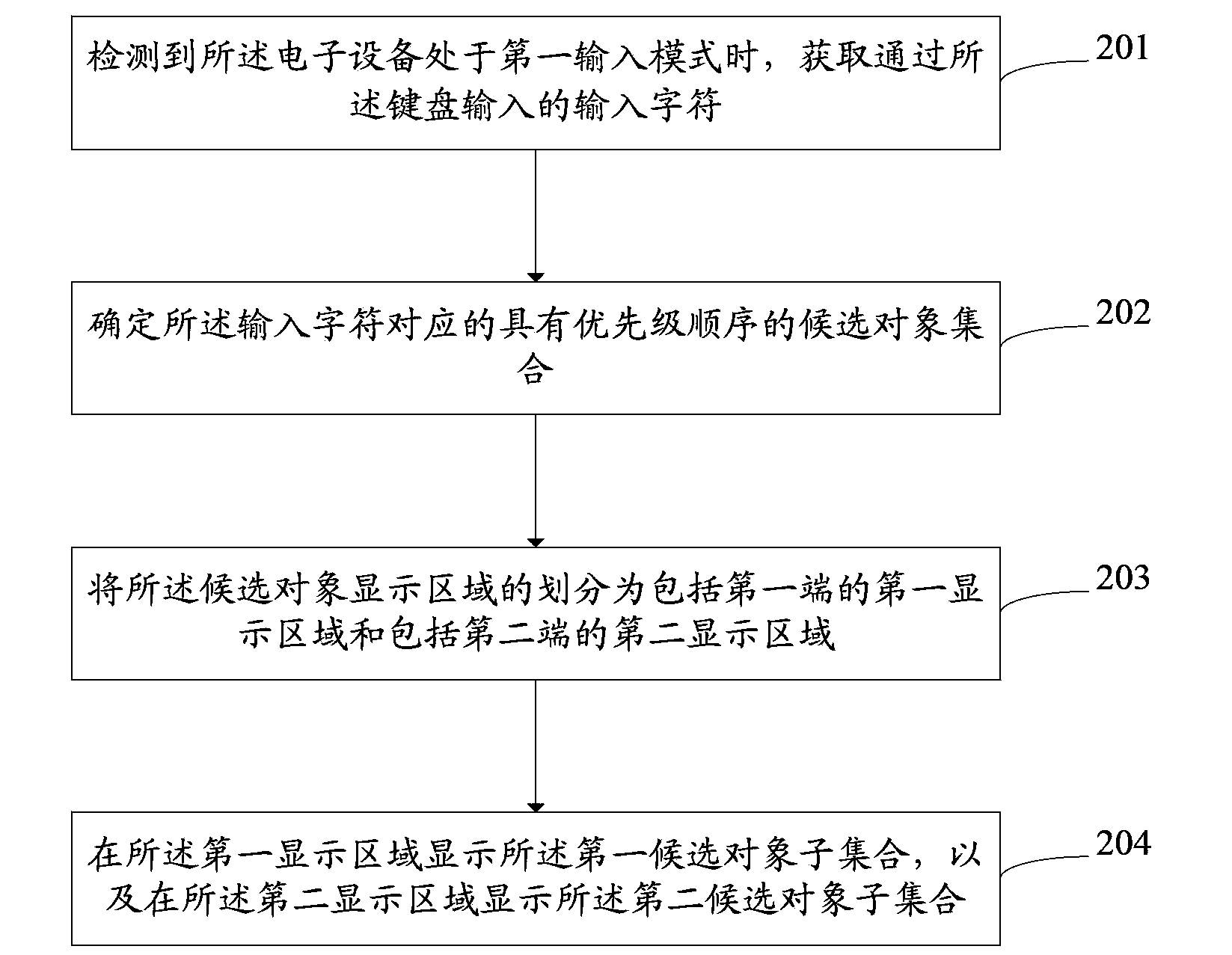

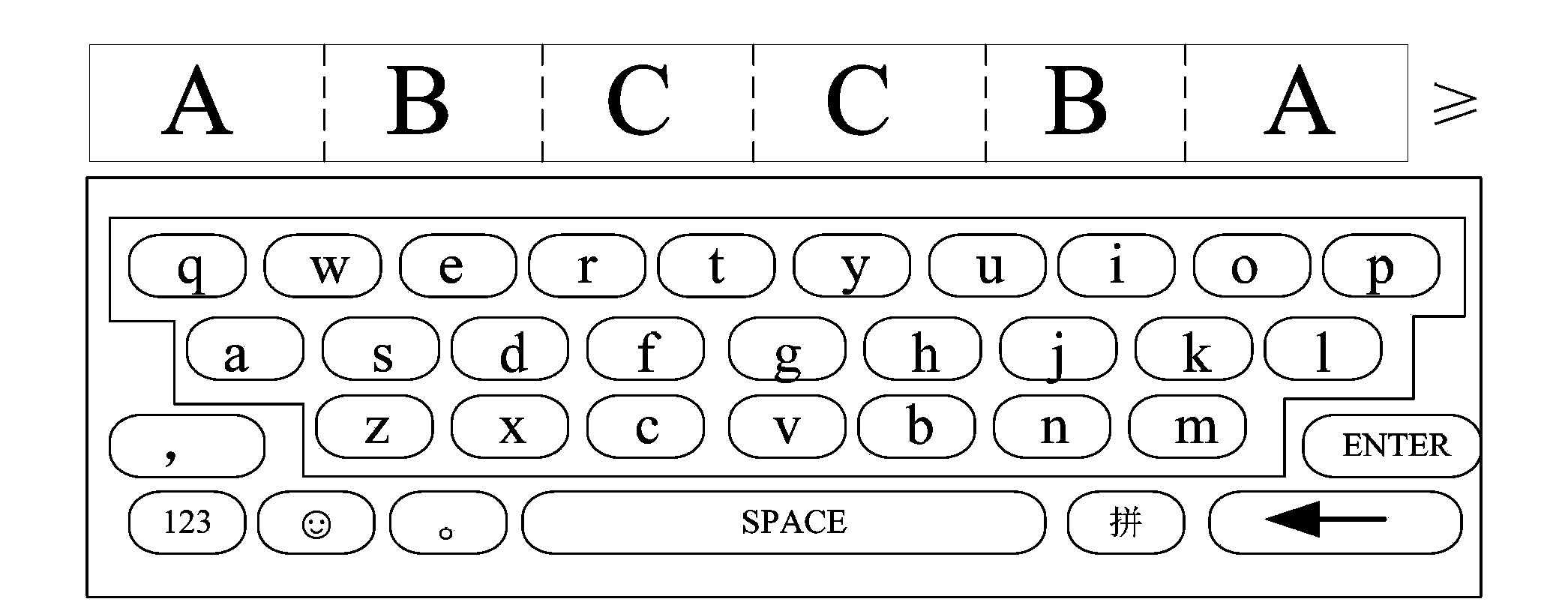

Candidate object display method and device

ActiveCN103677645AEasy to choose operationImprove selection efficiencyInput/output processes for data processingHuman–computer interactionElectronic equipment

Owner:LENOVO (BEIJING) LTD

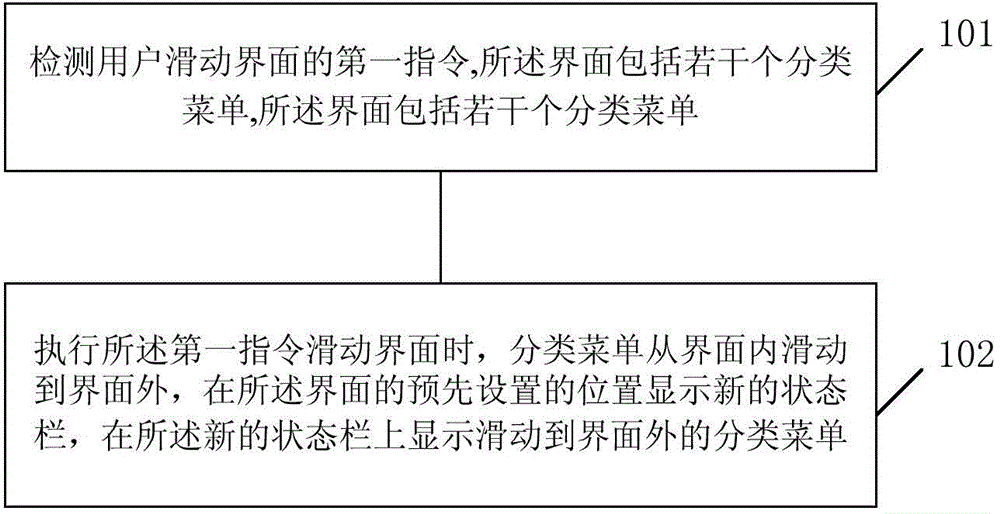

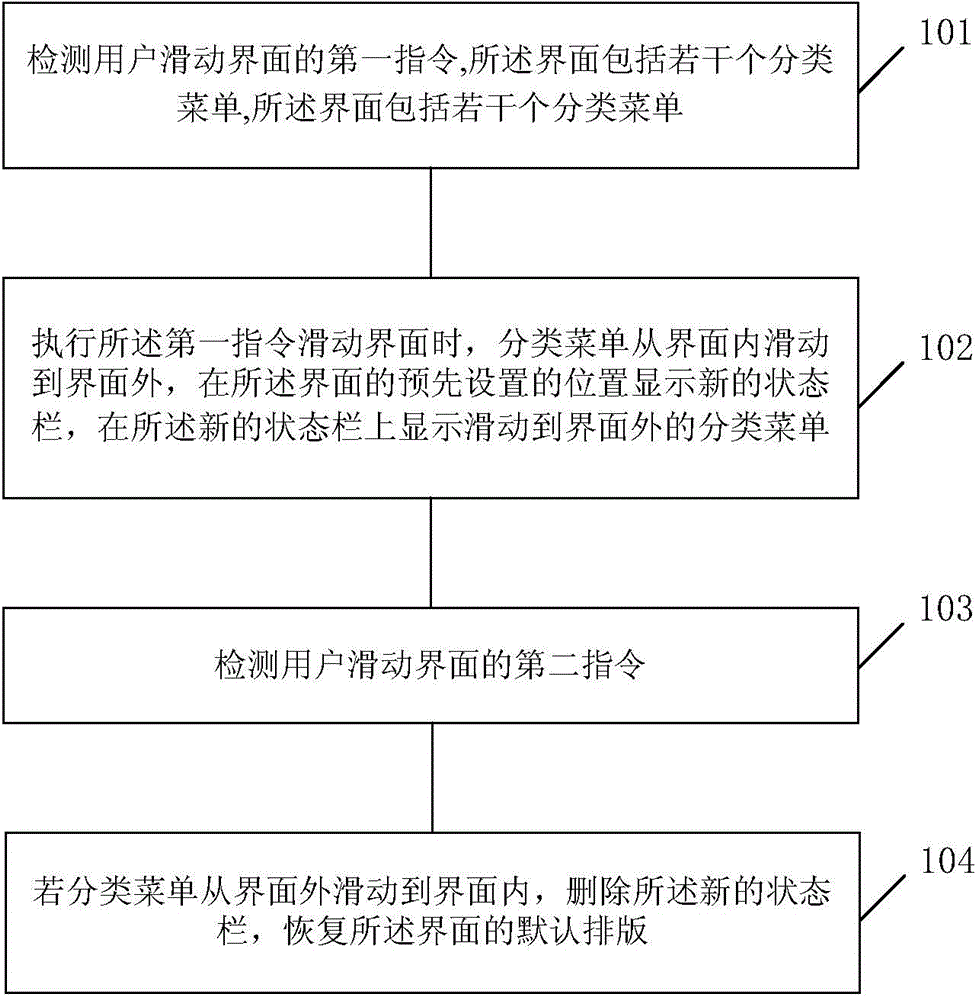

Interface display method and interface display device

InactiveCN104636032AEasy to choose operationImprove experienceInput/output processes for data processingDisplay deviceStatus bar

An embodiment of the invention discloses an interface display method and an interface display device. A first command of sliding an interface, including a plurality of classification menus, by a user is detected; the classification menus slide from the inside of the interface to the outside of the interface when the first command is executed to slide the interface; a new status bar is displayed at a preset position of the interface; the classification menus sliding to the outside of the interface are displayed on the new status bar; when the user slides the interface downwardly, classification menu items can be composed flexibly and automatically, concealing of the menus which the user wants to check constantly is avoided, and selection operation is facilitated for the user, so that user experience is improved.

Owner:SHANGHAI DROI TECH CO LTD

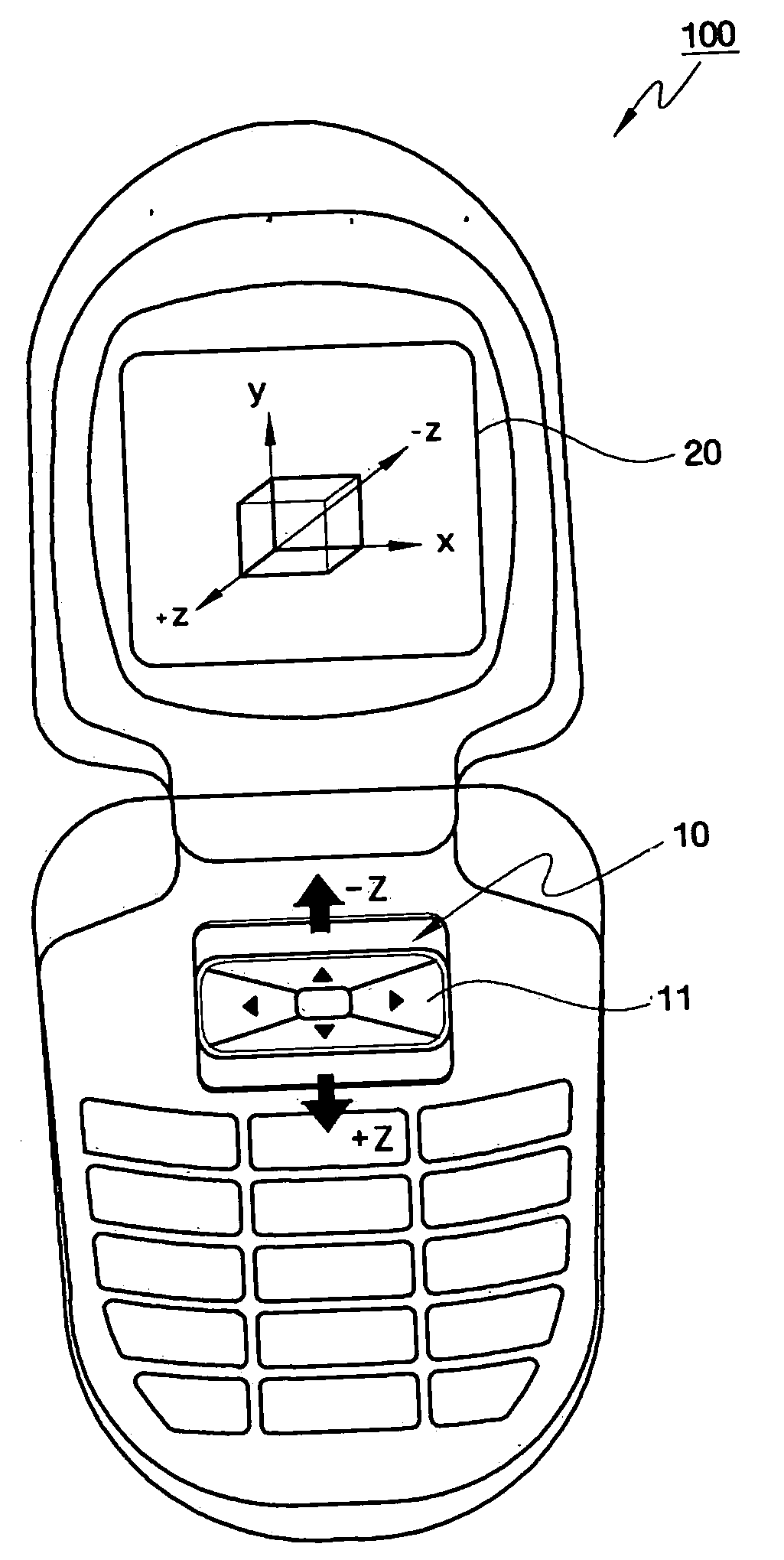

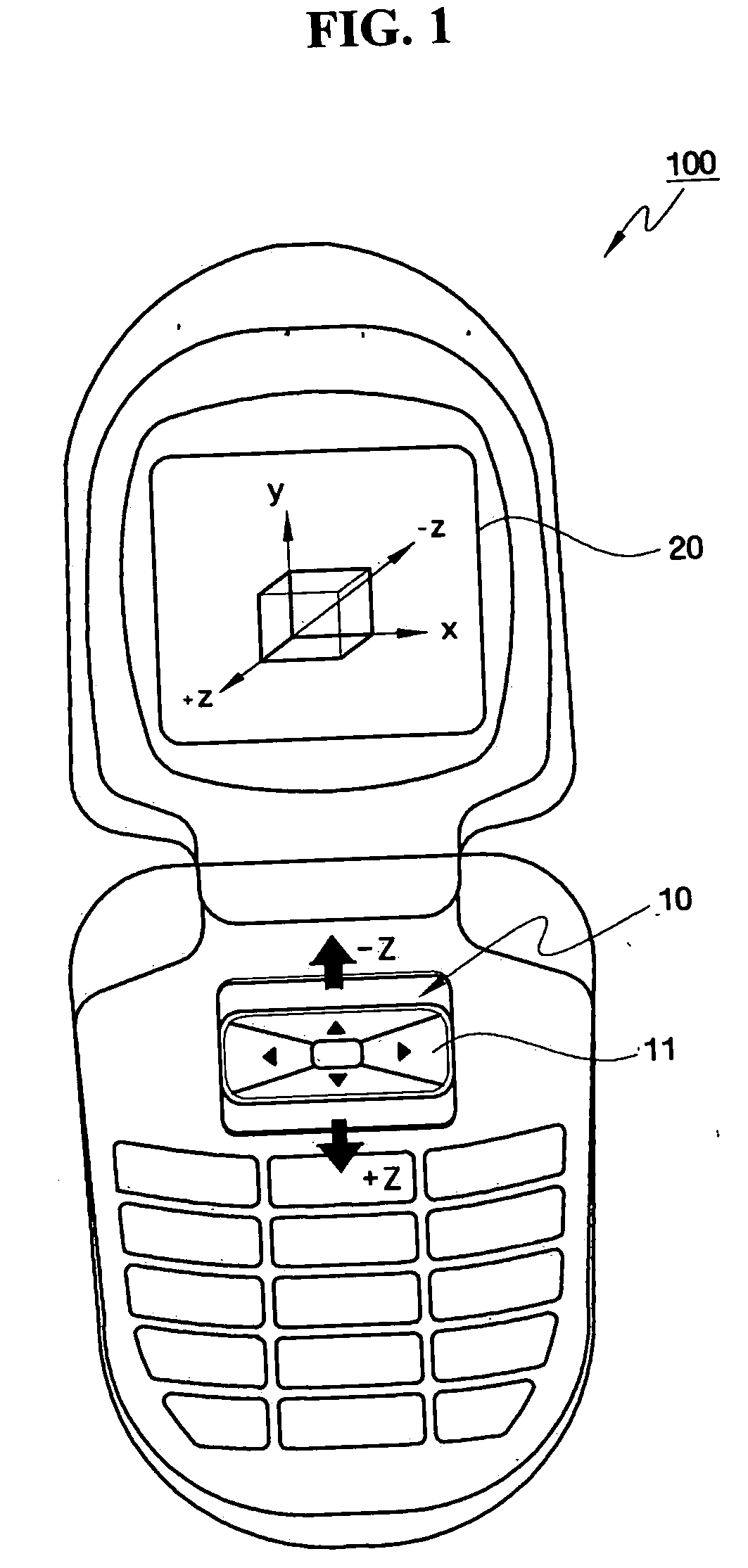

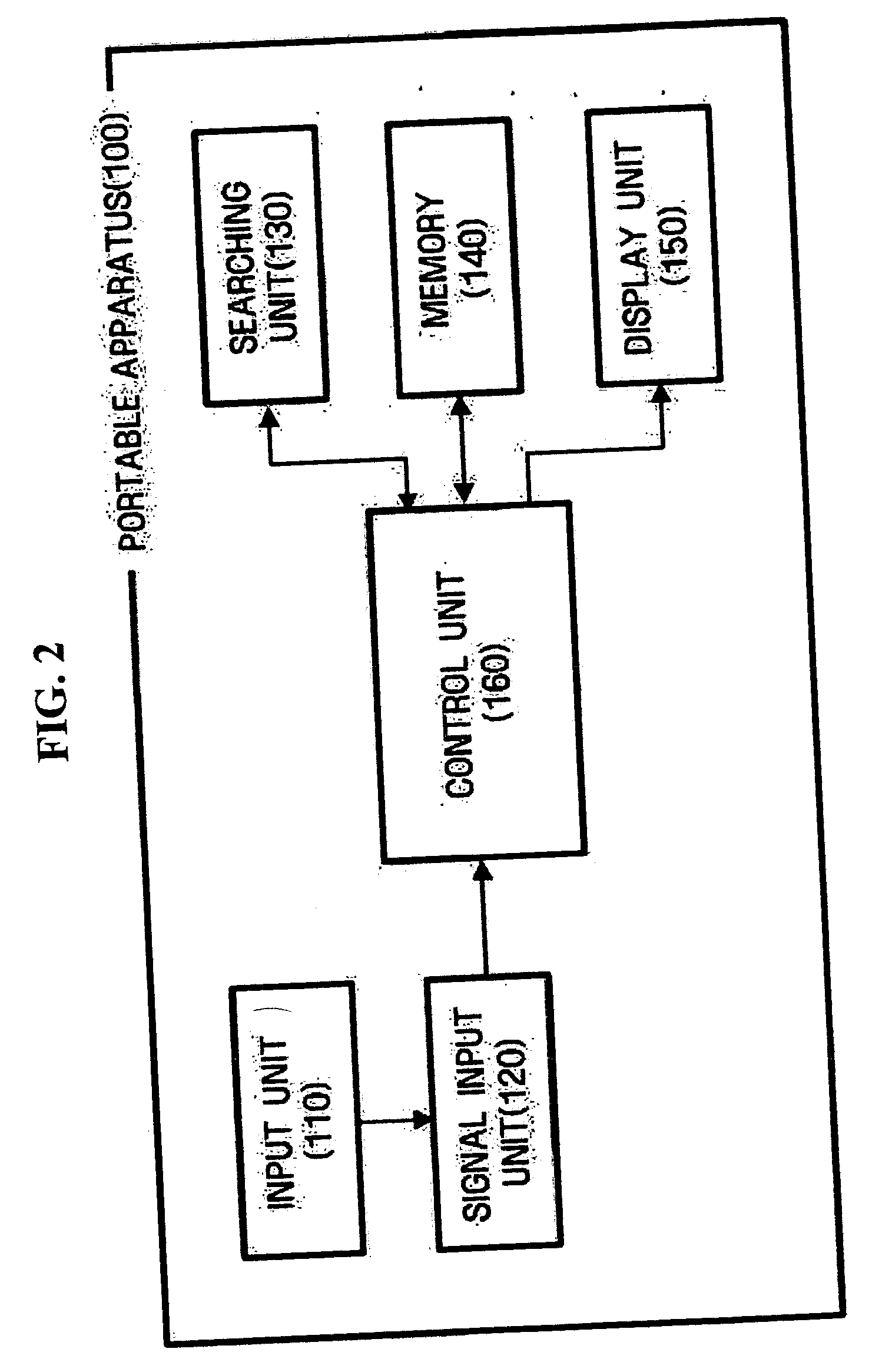

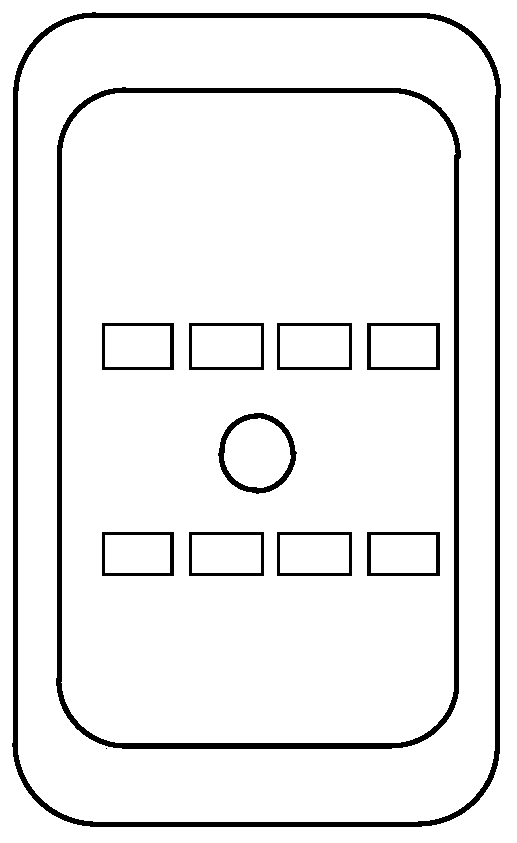

Slidable input device and portable apparatus including the same

InactiveUS20070035515A1Easy to operateEasy selectionInput/output for user-computer interactionEmergency actuatorsLeft directionControl unit

A slidable input device and a portable apparatus including the same, in which objects arranged in three-dimension or the size of a specific object can be easily manipulated and controlled. The portable apparatus includes an input unit for generating a key-selection signal corresponding to up, down, right or left directions selected by a user and a movement signal corresponding to a direction to which the input unit is moved by the user through an external force; a signal input unit for receiving the key selection signal and the movement signal generated by the input unit; a control unit for carrying out a predetermined operation indicated by the key selection signal and the movement signal inputted by the signal input unit; and a display unit for displaying the object according to the predetermined operation on a screen.

Owner:SAMSUNG ELECTRONICS CO LTD

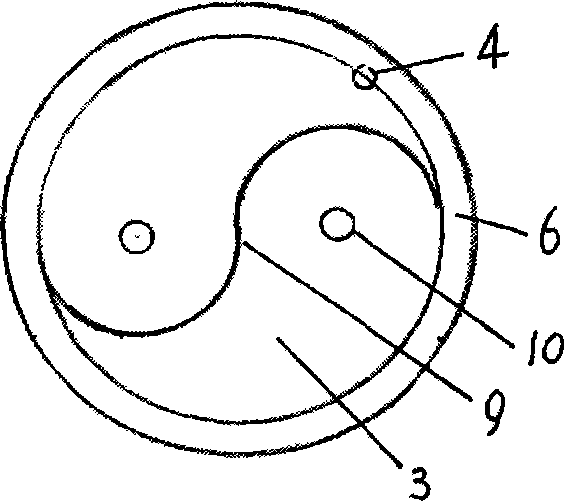

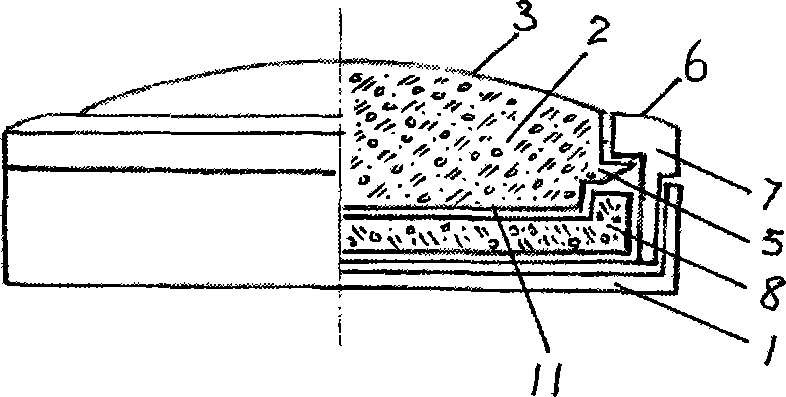

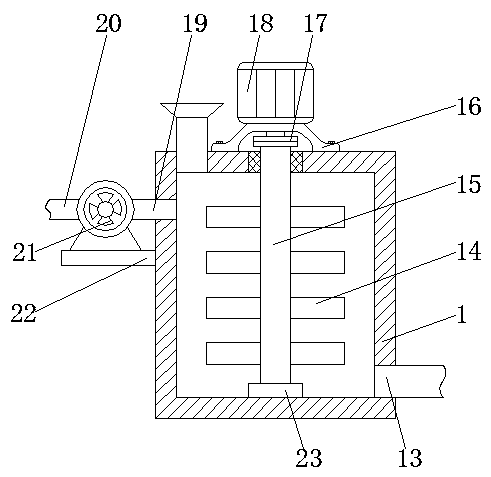

Three-color light thermal therapy head and three-color light thermal therapy instrument

InactiveCN105833432AReduce ambient temperatureReduce thicknessLight therapyTherapeutic coolingLight treatmentOptoelectronics

The invention discloses a three-color light thermal therapy head. A heating sheet 2 embedded with an electric heating body is arranged in a plastic shell 1. A circle of periphery of a heat radiating surface is tightly wrapped in a circle of a phototherapy radiating surface 6 of an LED light emitting ring, and the two circles are combined into the same radiation therapy surface. Of the heating sheet, the phototherapy radiating surface 6 of the LED light emitting ring on the radiation therapy surface, the middle S-shaped or reversed S-shaped Yin-Yang line and the fisheyes can emit red, yellow, blue and other optional LED light with enough treatment power when the heat radiating surface 3 emits heat and works. Through measures such as changing the relative positions of the LED light emitting ring and the heating sheet in the therapy head, transfer of heat treatment temperature to the LED light emitting ring is reduced, and the LED light emitting ring can work normally for a long time. A three-color light thermal therapy instrument provided by the invention is composed of a three-color light treatment signal generation and adjustment system and a treatment signal switching and output system. Disease treatment and heat preservation on the human body can be carried out once the three-color light thermal therapy head is plugged.

Owner:费健斌

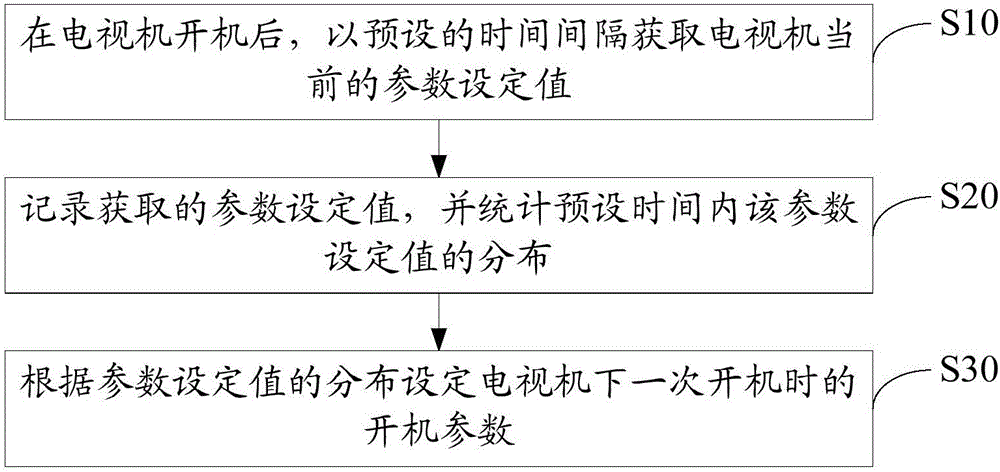

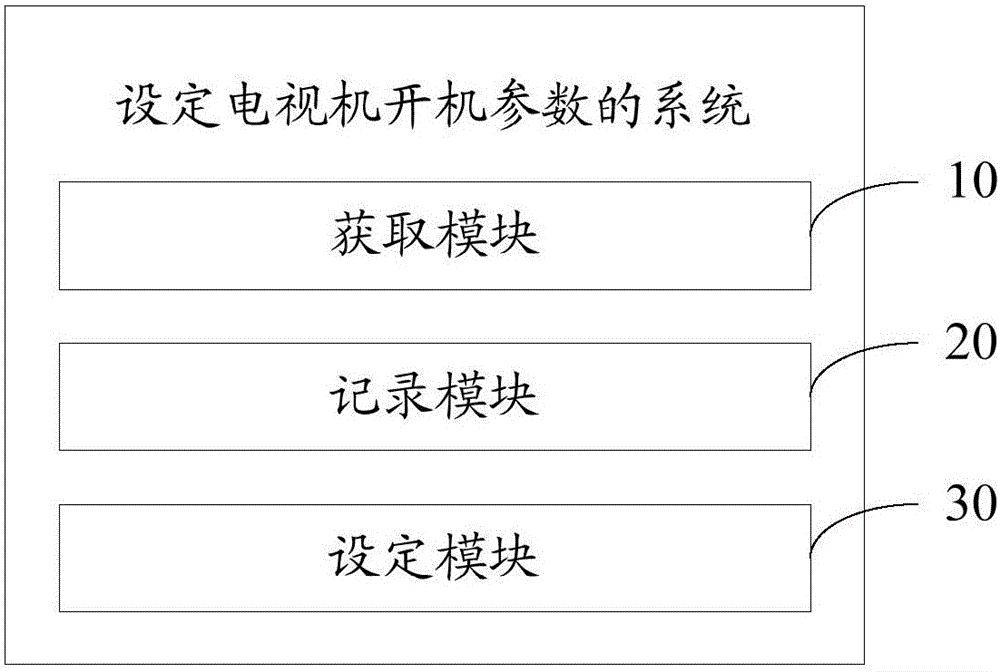

Method and system for setting television turn-on parameters

InactiveCN105681906AEasy to choose operationSimplify selection operationsSelective content distributionTelevision channelCable television

The invention discloses a method for setting television turn-on parameters. The method comprises the following steps: after turning on a television, acquiring current parameter set values of the television at a preset time interval; recording the parameter set value, and making a statistic of the distribution of the parameter set values within a preset time; and setting a turn-on parameter of the television of the next turn-on time according to the distribution of the parameter set values. The invention further discloses a system for setting the television turn-on parameters. The method and system for setting the television turn-on parameters provided by the invention can simplify a selection operation of television channels.

Owner:TCL OVERSEAS ELECTRONIC (HUIZHOU) CO LTD

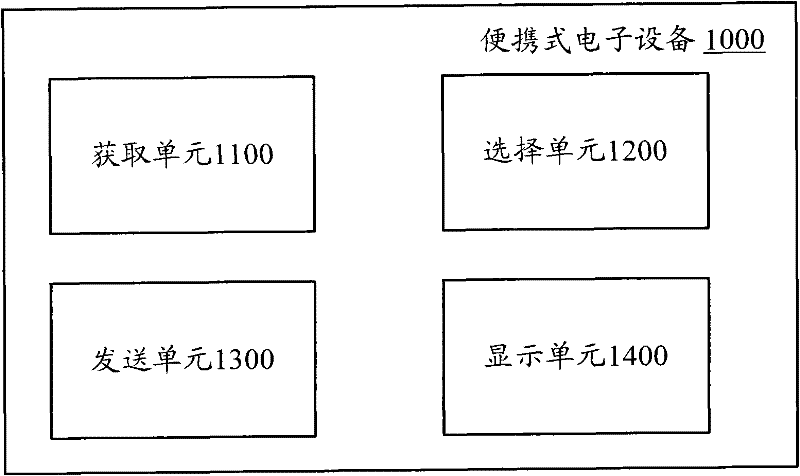

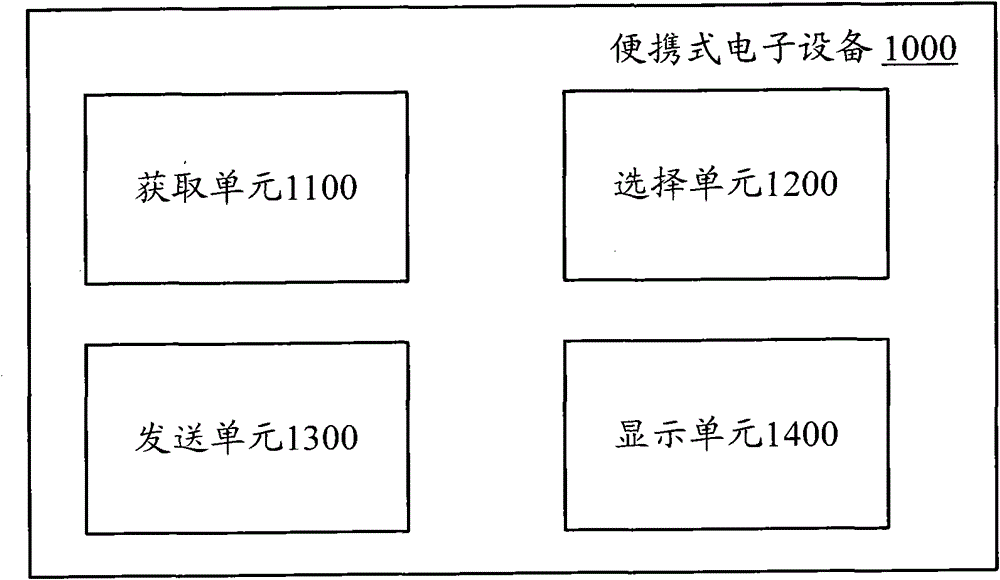

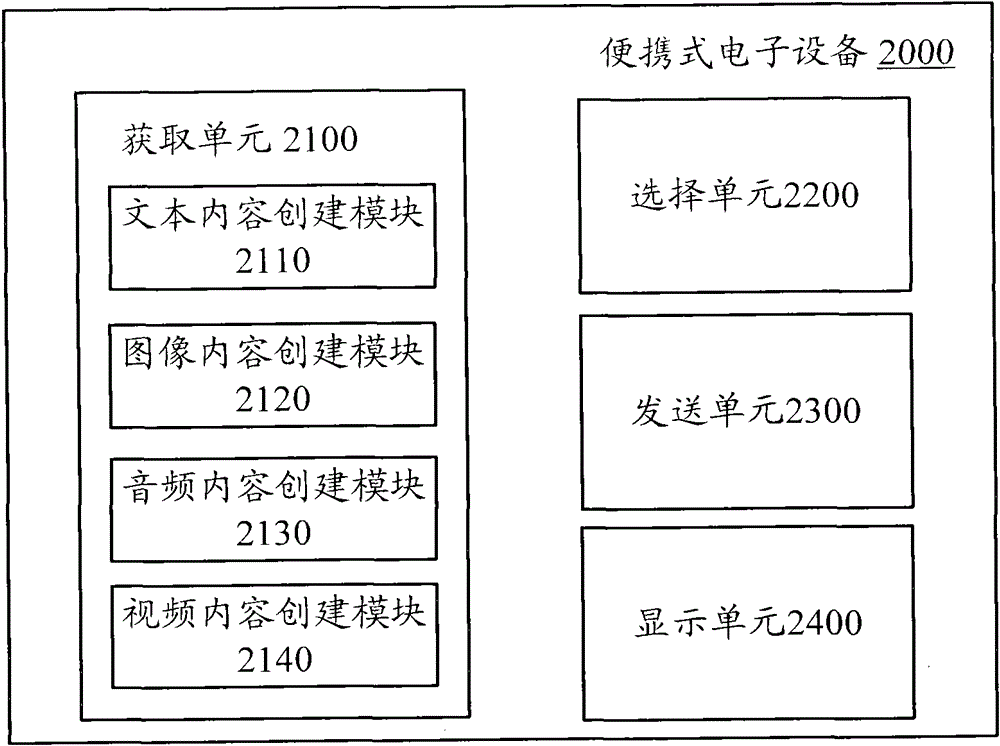

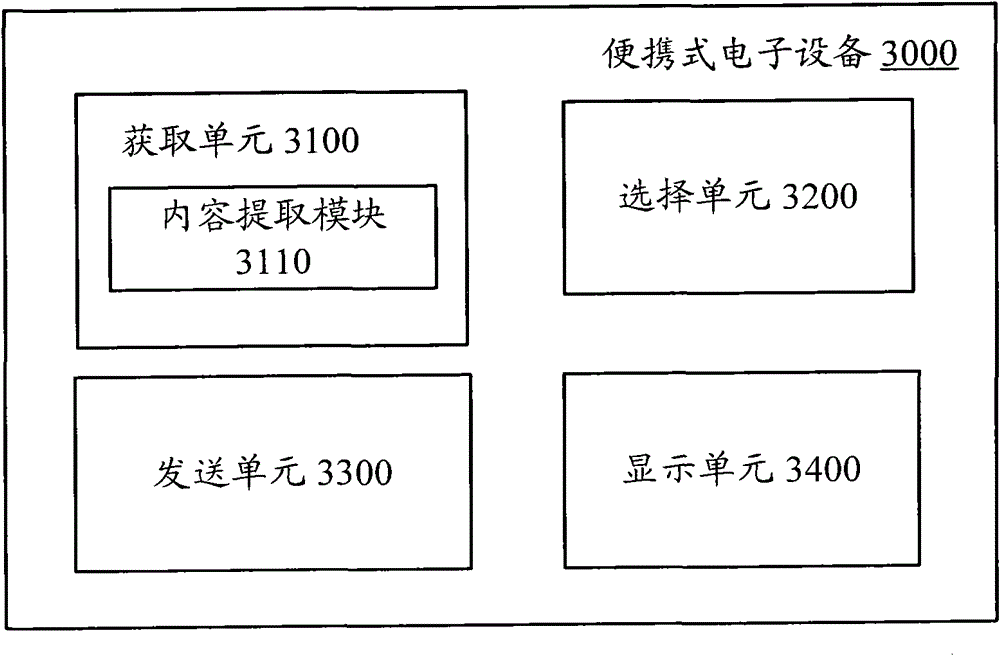

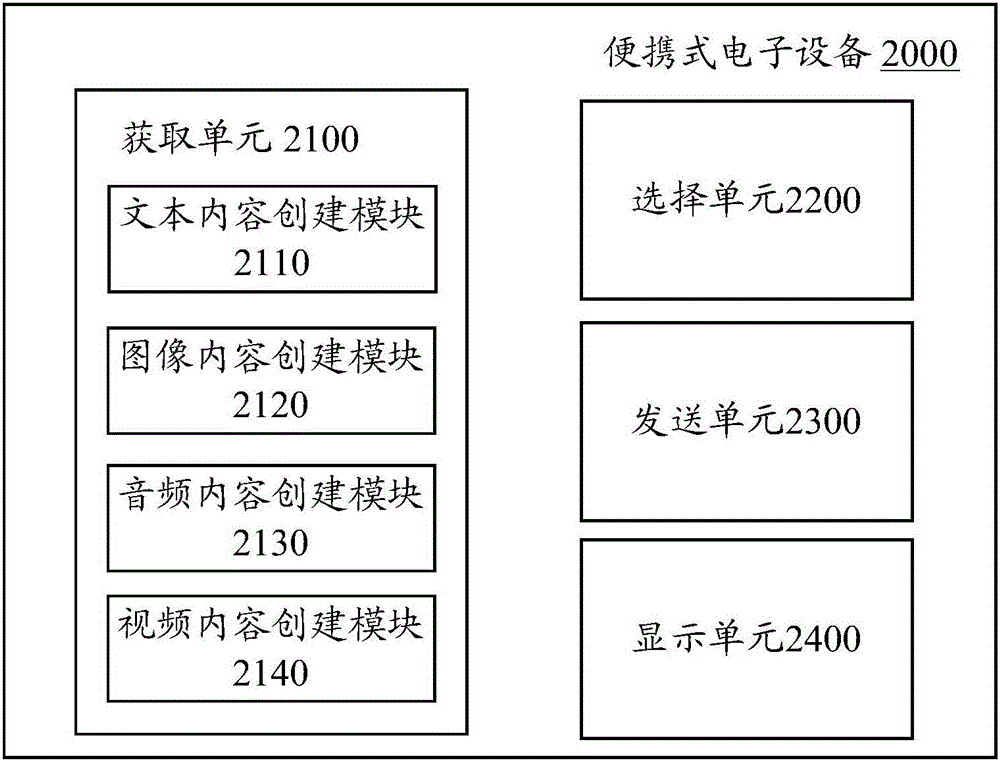

Portable electronic equipment and content publishing method for same

InactiveCN102447717AEasy to choose operationCreate quicklySubstation equipmentWebsite content managementComputer hardwareElectric equipment

Owner:LENOVO (BEIJING) CO LTD

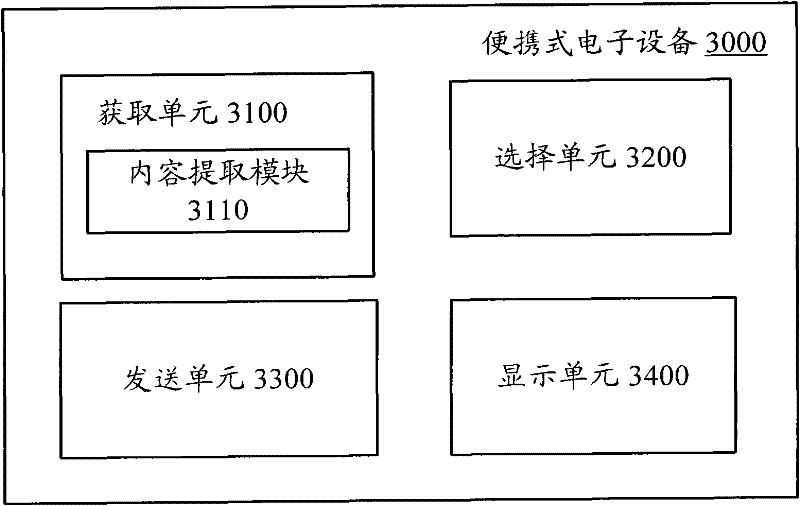

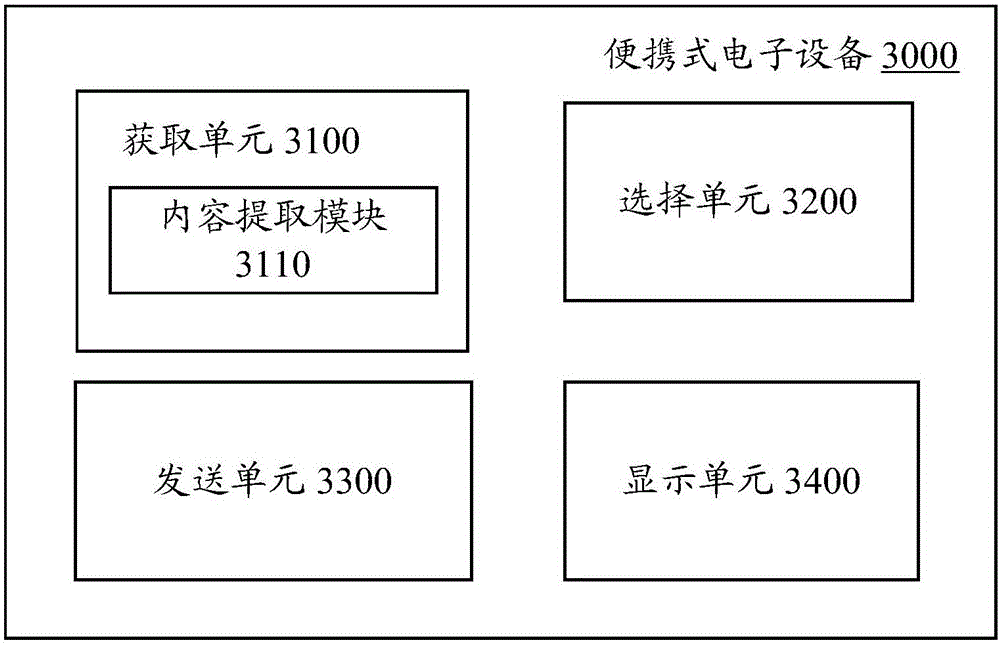

Portable electronic device and prompt method for content selection

Owner:LENOVO (BEIJING) LTD

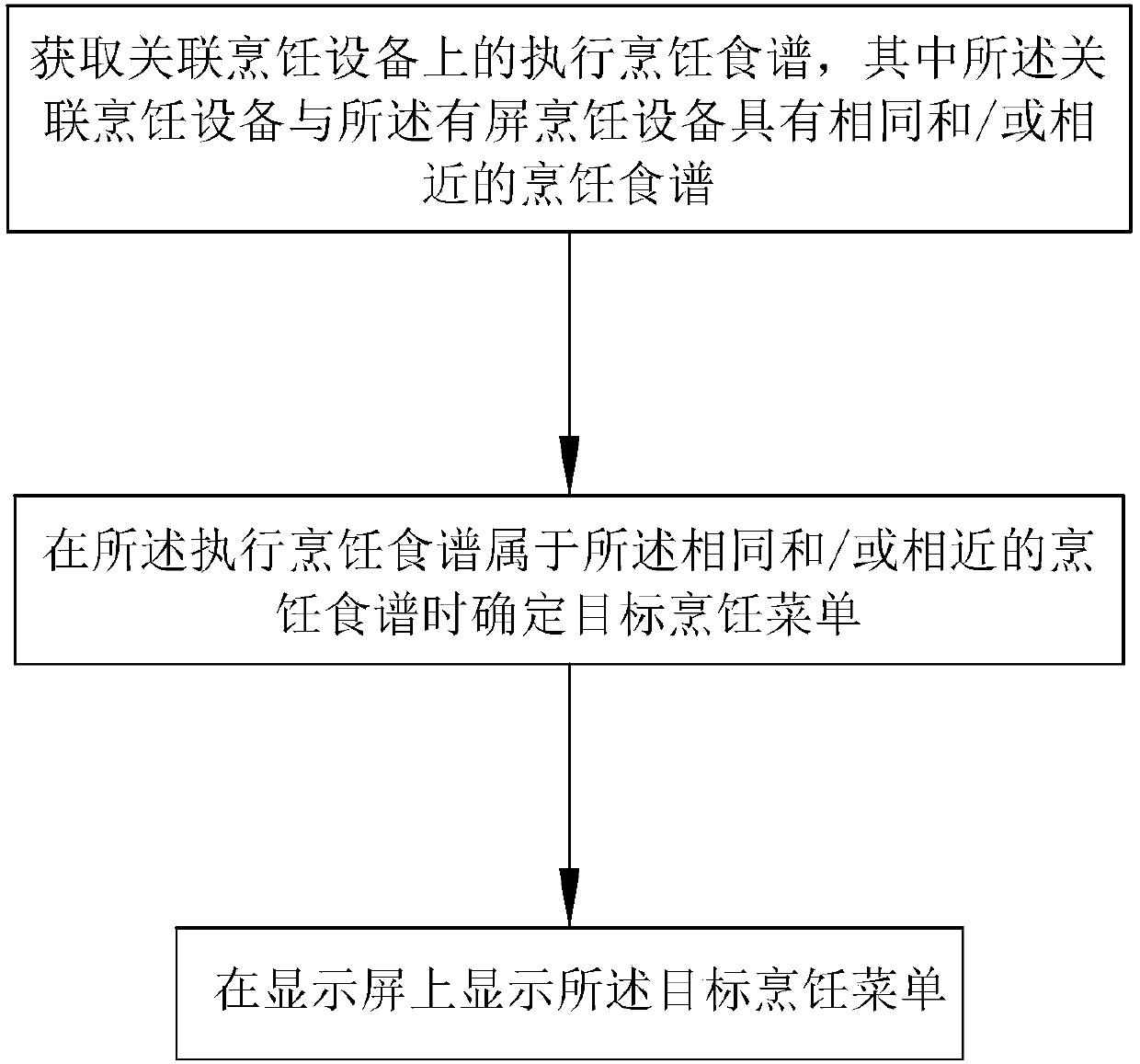

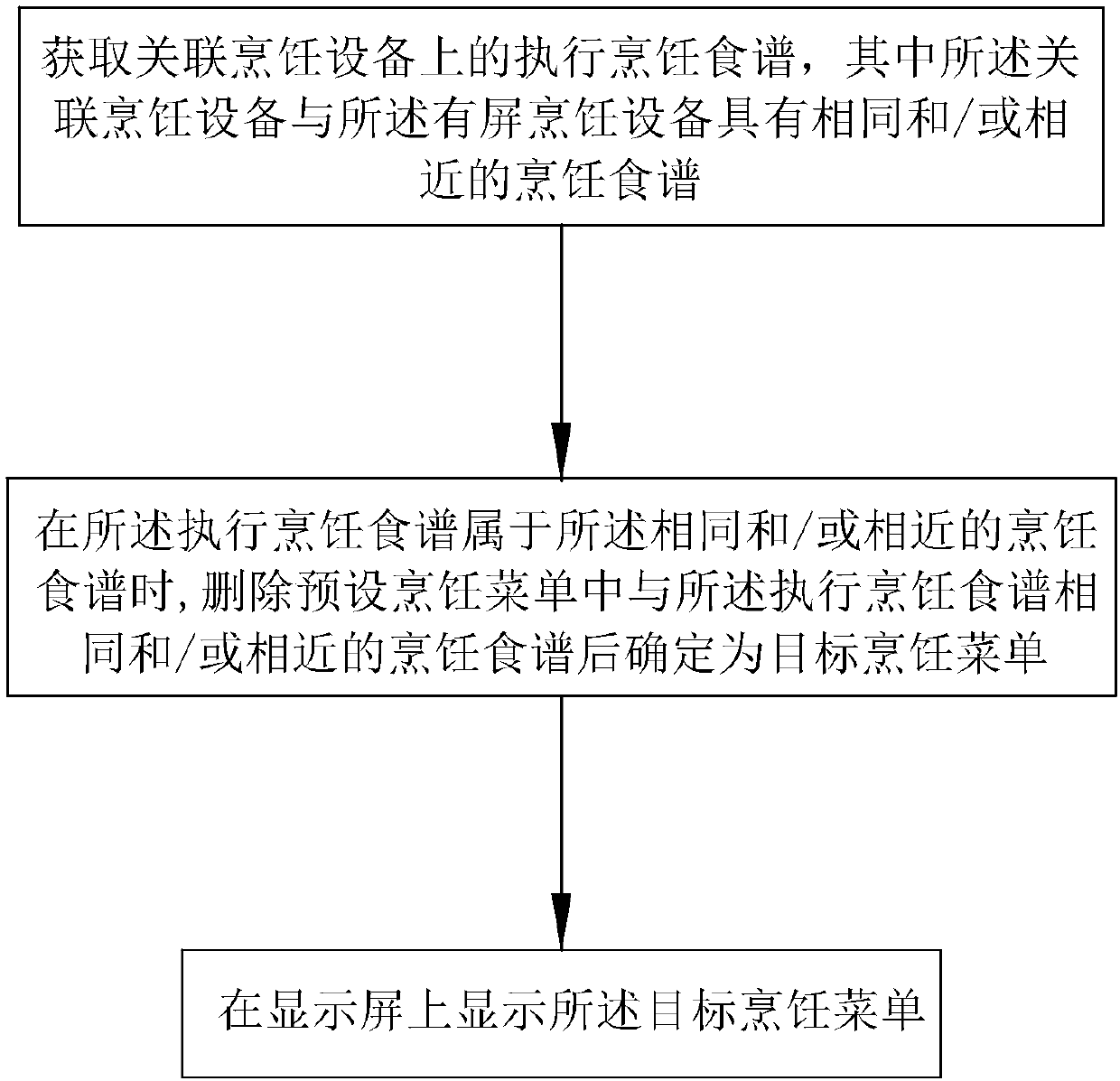

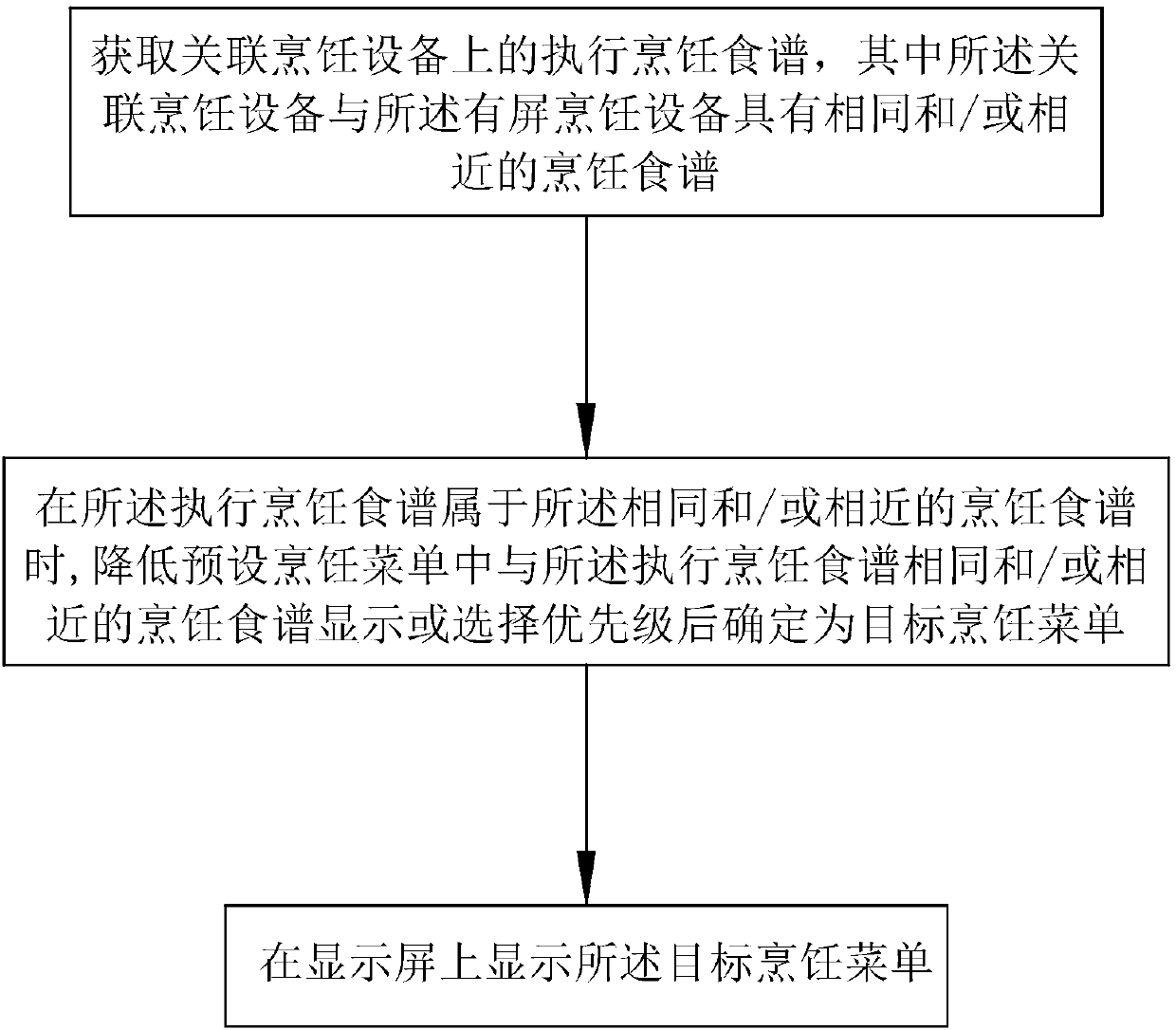

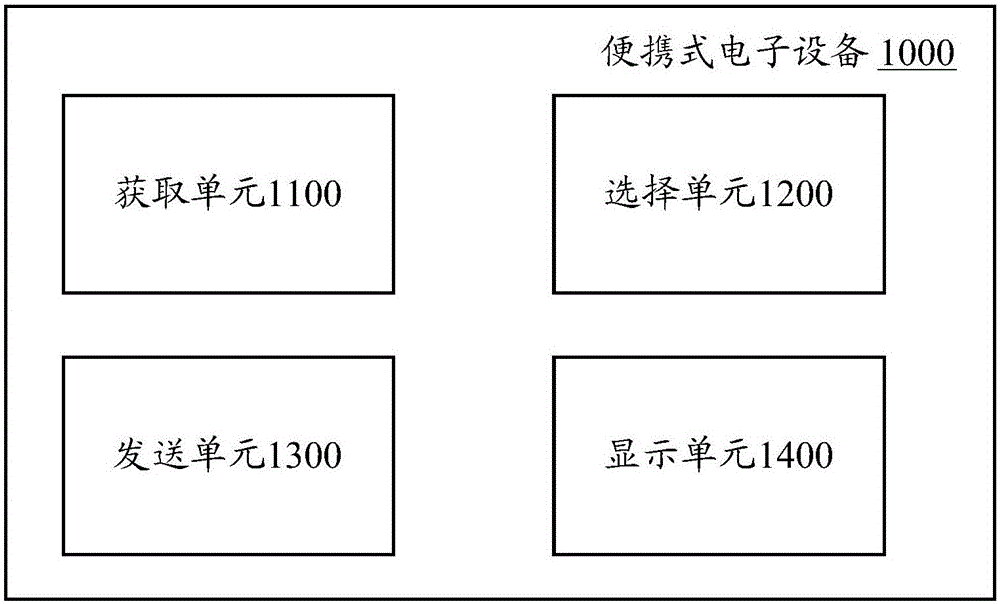

Cooking recipe providing method and system based on screen cooking device

PendingCN109917678AImprove user experienceQuick selectionProgramme control in sequence/logic controllersProcess engineeringRecipe

The invention relates to a cooking recipe providing method based on a screen cooking device. The method comprises the steps: obtaining an execution cooking recipe on an associated cooking device, wherein the associated cooking device and the screen cooking device have the same and / or similar cooking recipe; determining a target cooking menu when the execution cooking recipe belongs to the same and / or similar cooking recipe; and displaying the target cooking menu on a display screen. In addition, the invention further provides a cooking recipe providing system based on the screen cooking device. By adopting the technical scheme, a user can be prevented from repeatedly browsing the same and / or similar cooking recipes on the screen cooking device to influence the efficiency of selecting the recipes, so that the user can quickly and accurately select the desired cooking recipes, and the use experience of the user is improved.

Owner:JOYOUNG CO LTD

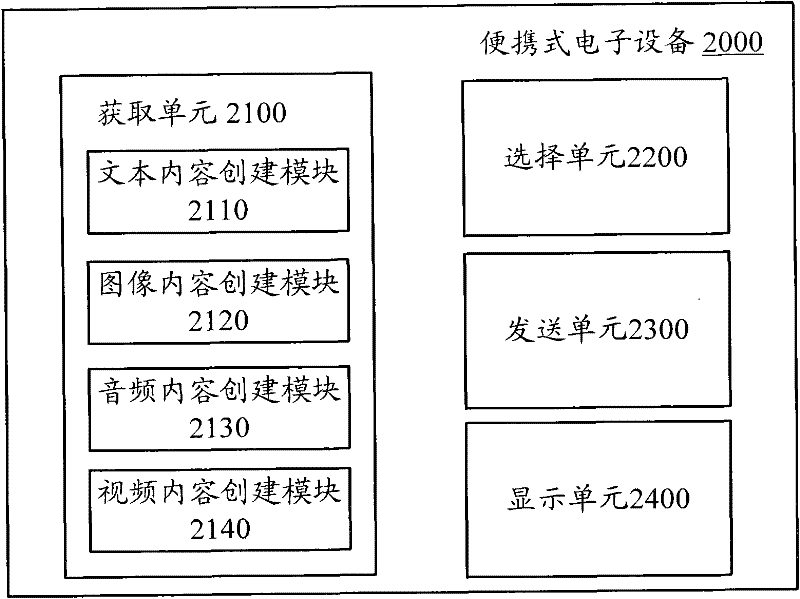

Portable electronic device and content release method for portable electronic device

InactiveCN106027383ACreate quicklyQuick extractionSubstation equipmentWebsite content managementWorld Wide WebRelease methods

Owner:LENOVO (BEIJING) LTD

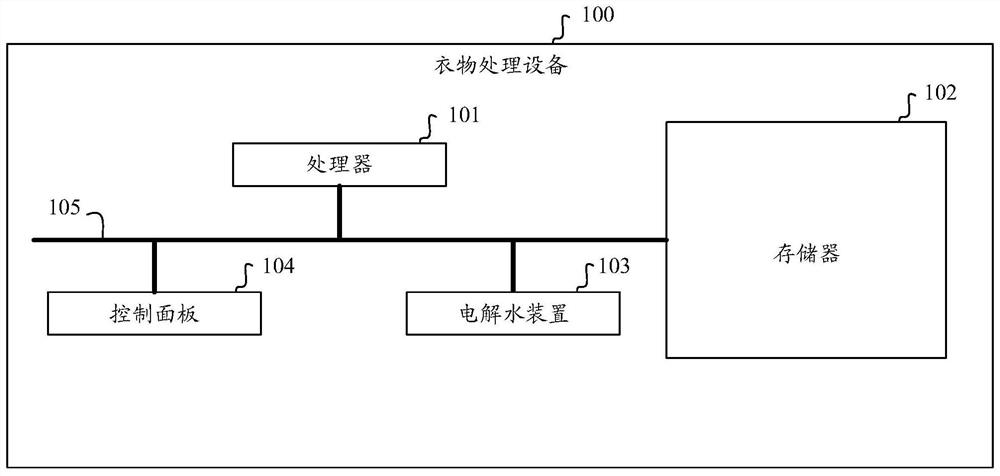

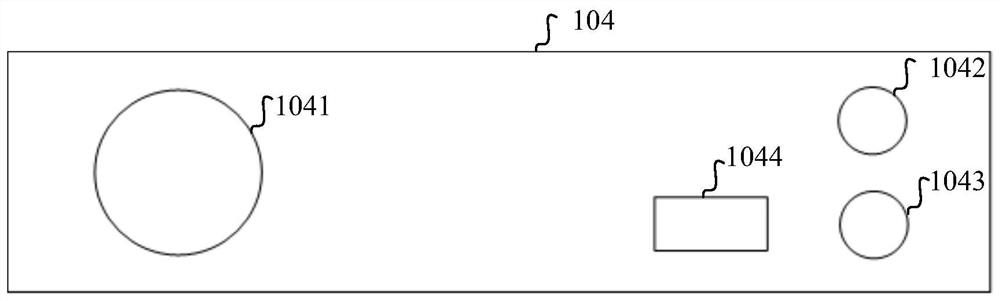

Clothes treating equipment

PendingCN113914068AEasy to choose operationHigh degree of intelligenceOther washing machinesControl devices for washing apparatusProcess engineeringManufacturing engineering

The application discloses clothes treating equipment. The clothes treating equipment comprises a control device in which a first treatment program and a second treatment program are stored, and a water electrolysis device which is associated with the first treatment program and is started along with starting of the first treatment program. Thus, for the water electrolysis device, the trouble of independent selection can be omitted, and especially when a user omits selection of a water electrolysis function due to operation negligence, a washing machine often needs to be turned off and then restarted for selection, so that operation is tedious; and by the embodiment of the invention, the selection operation can be simplified, and the intelligent degree of the clothes treating equipment can be improved.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

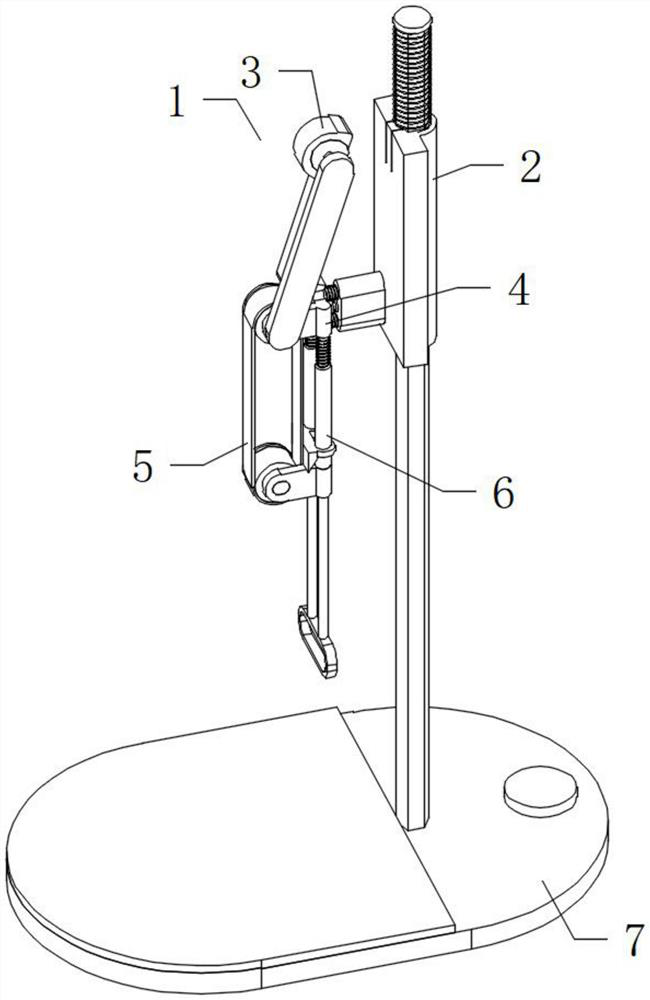

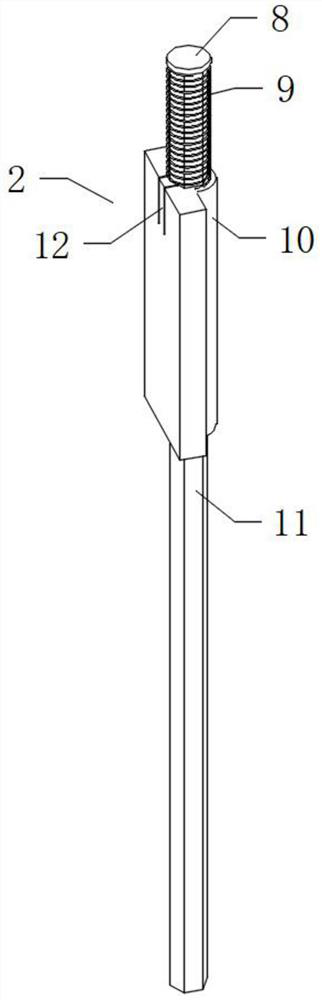

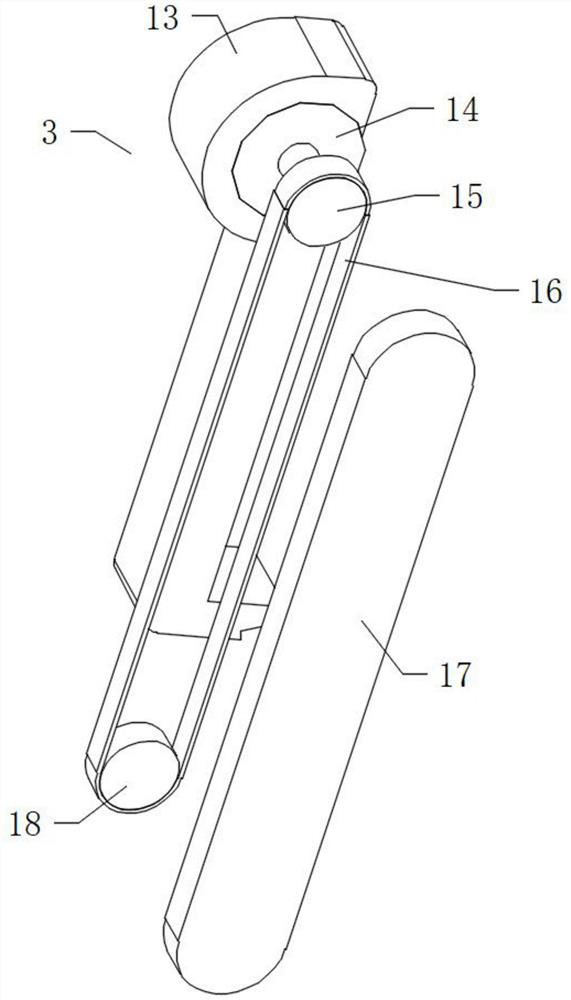

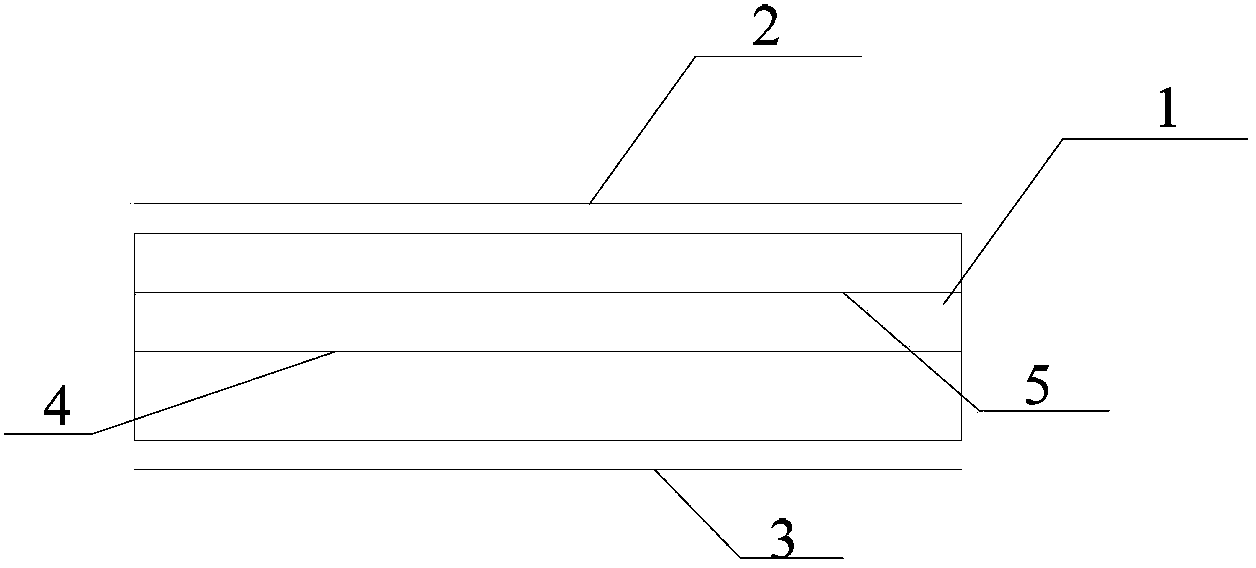

Auxiliary bathing device for disabled people

InactiveCN113180522AEasy to operateOvercoming elasticityBathroom accessoriesElectric machineryElectrical and Electronics engineering

The invention discloses an auxiliary bathing device for disabled people. The device comprises a scrubbing and washing mechanism, the scrubbing and washing mechanism comprises a waterproof gear motor, a waterproof switch and a waterproof touch switch, and the waterproof gear motor is electrically connected with an external power source in series through the waterproof switch and the waterproof gear motor; The scrubbing and washing mechanism further comprises a supporting main body, a power main body, a control main body, a scrubbing main body, a cleaning main body and a fixing base, the lower end of the supporting main body is fixedly installed at the upper end of the fixing base, the lower end of the power main body is fixedly installed at the upper end of the scrubbing main body, and the control main body and the supporting main body are fixedly installed together; and the upper end of the scrubbing main body and the control main body are fixedly installed together, and the cleaning main body is installed at the outer end of the rear portion of the scrubbing main body in a sliding mode. The invention relates to the technical field of articles for disabled people. The auxiliary bathing device can be conveniently used by disabled people with inconvenient hands, and can better meet the use requirements.

Owner:HANGZHOU VOCATIONAL & TECHN COLLEGE

System data processing method and device and storage medium

ActiveCN110673868AEasy to choose operationImprove experienceFile access structuresRedundant operation error correctionPathPingEngineering

The invention discloses a system data processing method and device and a storage medium. The system data processing method comprises the following steps: in a terminal system recovery operation mode,performing preset format file scanning on a file storage path related to terminal system recovery operation, and filtering out a directory which does not contain preset format files and / or invalid preset format files in the file storage path to obtain a filtered to-be-displayed file list; and displaying the filtered to-be-displayed file list so as to select a corresponding file from the displayedfile list to perform recovery related operation on the terminal system. According to the system data processing method, invalid directories and invalid files can be filtered, and the operation is convenient, and the user experience is improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

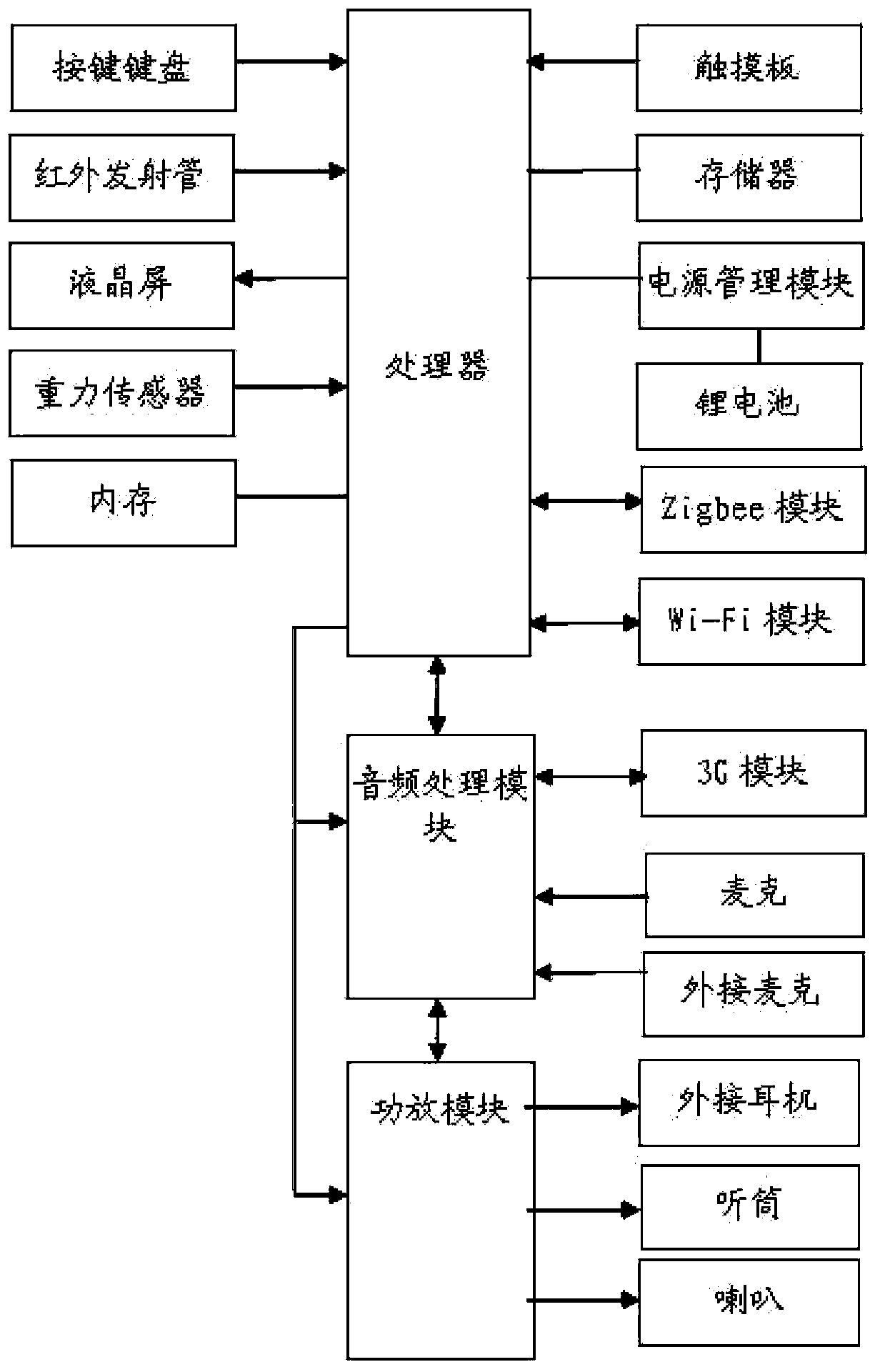

Input switching method of touch pad and double-side remote controller

InactiveCN103065447BAdd input modeEasy to choose operationInput/output for user-computer interactionNon-electrical signal transmission systemsKey pressingHandwriting

The invention provides an input switching method of a touch pad and a double-side remote controller, belonging to the filed of remote controllers. The remote controller comprises a gravity sensor and a circuit board; a processor and an LED (Light Emitting Diode) lamp are arranged on the circuit board; a keystroke panel is arranged on one face of a remote controller body, and the touch pad is arranged on the other face of the remote controller body; and the processor is used for judging that the keystroke panel or the touch pad is effective input face according to the detection signal of the gravity sensor and controlling the LED lamp on the circuit board to work through signals received by the touch pad according to the effective input face and the processor, so that the touch pad of the remote controller has the functions of keystroke, mouse and handwriting input. Moreover, the remote controller further comprises an infrared emitter, a WiFi module and a Zigbee module, and can control various different types of devices of infrared controllable devices and controllable devices in Internet of things. The double-side remote controller has call function simultaneously, and can adopt various different manners such as WiFi, Zigbee and 3G (3 Generation) to realize calls.

Owner:中感兴实业有限公司

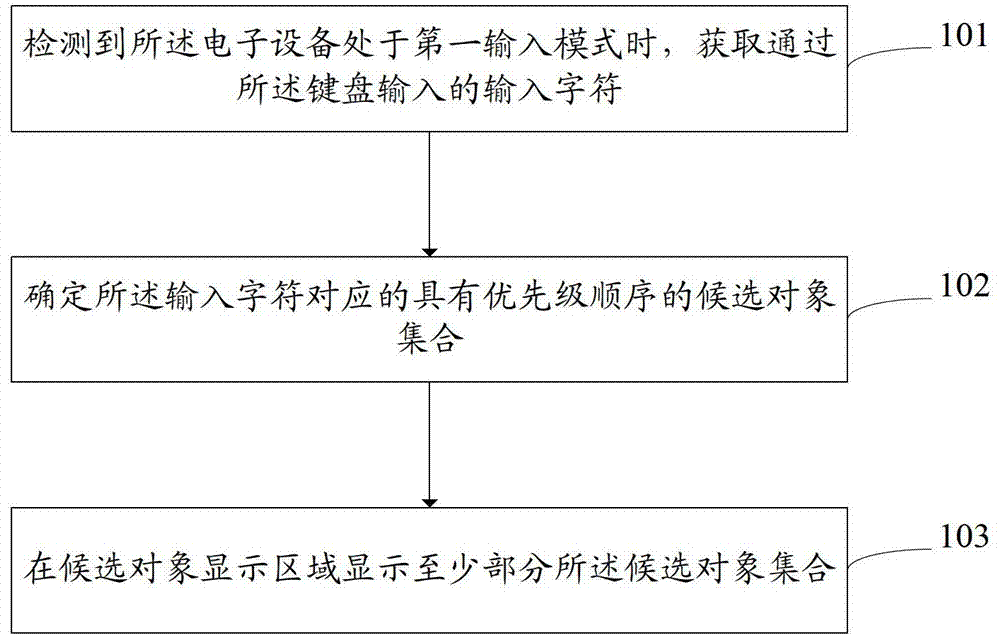

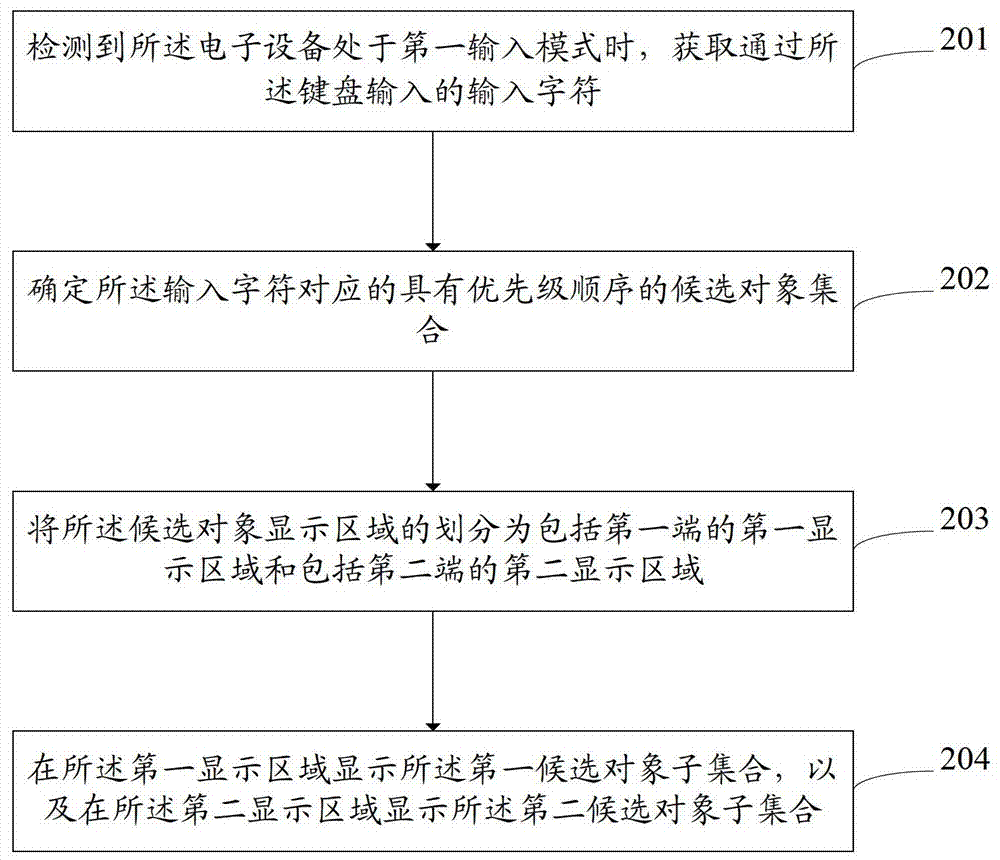

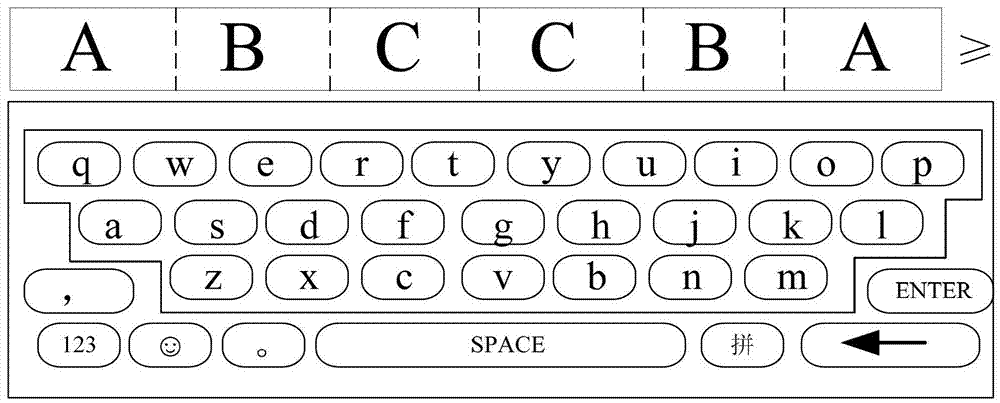

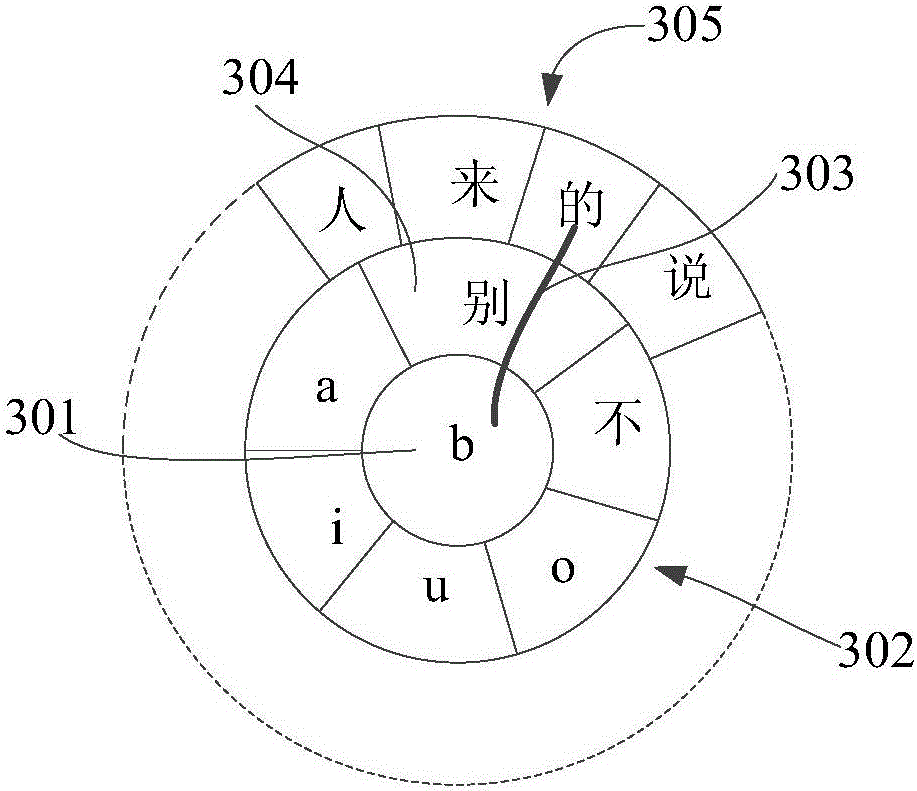

Method and device for displaying candidate objects

ActiveCN103677645BEasy to choose operationImprove selection efficiencyInput/output processes for data processingComputer graphics (images)Computer vision

The present invention provides a method and device for displaying candidate objects, which are applied to electronic equipment. The electronic equipment has a keyboard and a display unit, and the display unit includes a display area. When the electronic equipment is in the first input mode, the acquisition Through the input characters input by the keyboard, and determine its corresponding set of candidate objects with priority order; display at least part of the set of candidate objects in the candidate object display area; wherein, the displayed set of candidate objects includes The first candidate object subset at the first end of the candidate object display area and the second candidate object subset at the second end, the priority of the first candidate object in the first candidate object subset is the highest in its set, The second candidate object in the second candidate object subset has the highest priority in the set, and the embodiment of the present invention improves the convenience and selection efficiency of candidate objects.

Owner:LENOVO (BEIJING) LTD

a terminal

ActiveCN109802223BEasy to choose operationSending and receiving function is goodAntenna supports/mountingsAntennas earthing switches associationElectrical connectionFeed line

The present disclosure provides a terminal having at least two antennas and comprising a first housing and a second housing. The first housing and the second housing can be relatively moved to at least two states by means of a motion mechanism. The at least two antennas are distributed at the first housing and / or the second housing. A feed point connected to a feed source is disposed at one of the first housing and the second housing. At least two mutually insulated feed line structures are disposed at the other one of the first housing and the second housing, and each feed line structure is electrically connected to one of the antennas. The feed point, when in different states, is electrically connected to different feed line structures, such that the antenna at operation can be determined from the at least two antennas.

Owner:VIVO MOBILE COMM CO LTD

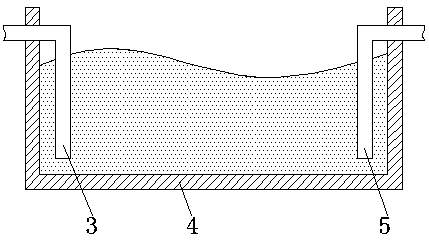

Integrated sewage treatment device and method

InactiveCN110950465AHigh degree of rationalizationPhenomena that affect useTreatment involving filtrationMultistage water/sewage treatmentElectric machinerySewage

The invention discloses an integrated sewage treatment device and method. The device comprises a reaction bin, a driving motor is arranged at the top of the reaction bin, the output end of the drivingmotor is fixedly connected with a coupler, the bottom of the coupler is fixedly connected with a rotating rod, the bottom of the rotating rod penetrates through the reaction bin and is movably connected with a bearing, and the bottom of the bearing is fixedly connected with the joint of the reaction bin. Through arrangement of the reaction bin, a first water pump, a sedimentation tank, a filtering bin, a second water pump, a first electromagnetic valve, a second electromagnetic valve, a stirring plate, a rotating rod, a driving motor and a third water pump, the device can achieve the functionof the high device use rationalization degree, and solves the problems that the existing sewage treatment operation continuity is not strong, the device utilization rate is different, the device input amount is large, the cost is increased, and the treatment efficiency cannot meet the use requirements because the operation time of each stage of the sewage is difficult to coordinate and the operation time of each process is different.

Owner:无锡开迪环保科技有限公司

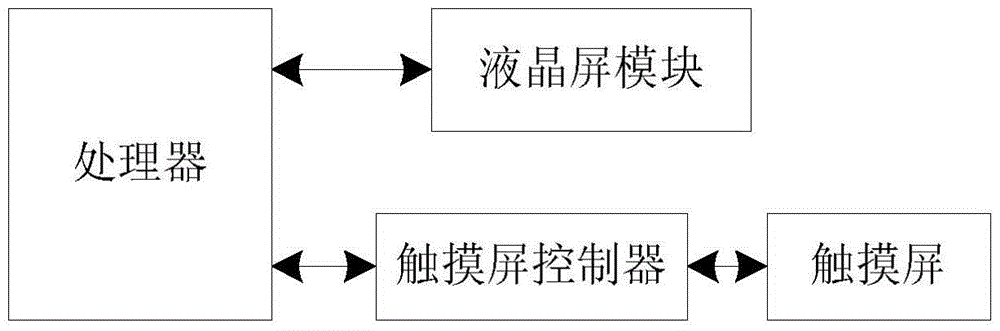

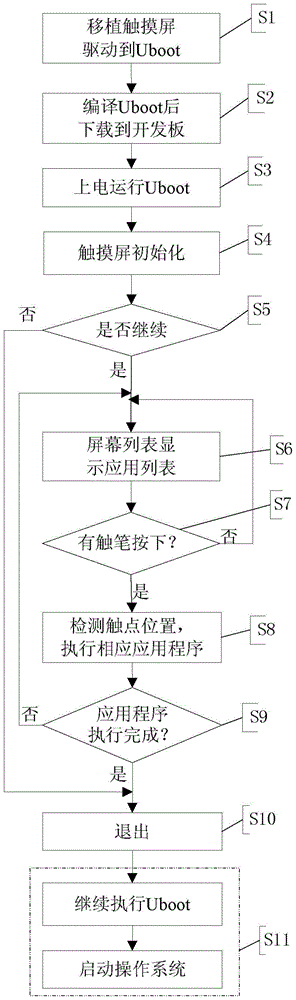

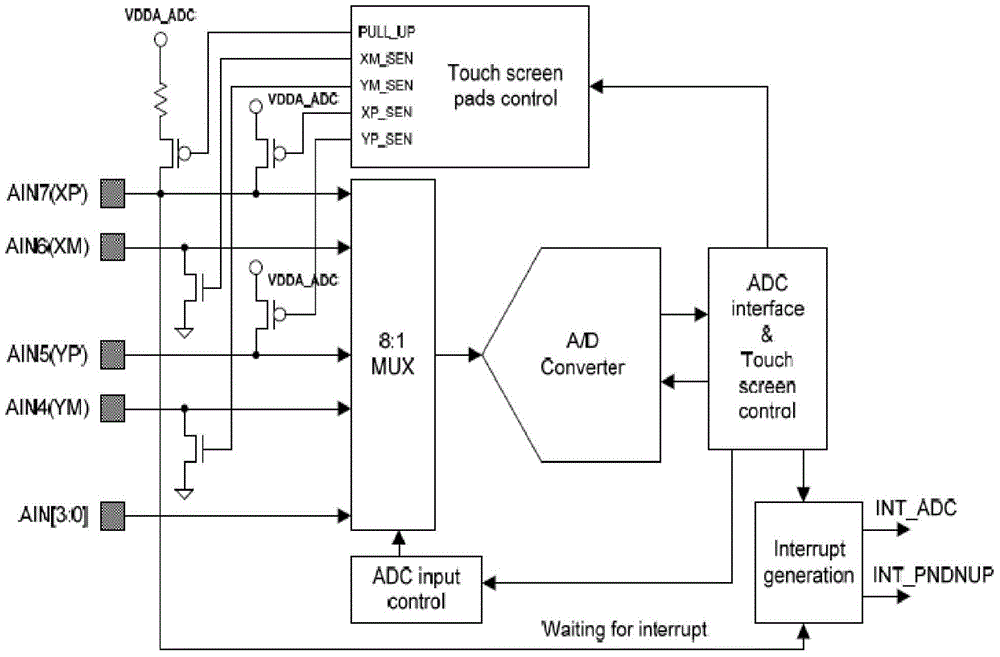

A method of implementing touch screen driver in uboot

InactiveCN103853383BEasy to useImplementation supportSpecific program execution arrangementsInput/output processes for data processingApplication softwareTouchscreen

The invention discloses a method of realizing a touch screen driver in Uboot (Universal Bootloader Loader). The method comprises the steps of modifying and cutting the touch screen driver in an operating system nucleus, transplanting the touch screen driver in the Uboot, compiling the Uboot after transplantation, transplant the compiled Uboot into a development board, operating the Uboot after the development board is powered on and starts, and initializing a touch screen. If a user operates the touch screen during the operation of the Uboot, the user continues the operation, the touch screen can show the application programs available to the user in a list, the user clicks the screen and selects the needed application program, the application program jumps to the corresponding program entry and executes after the coordinate of the touching point is detected and the mapping relation between the application program and the coordinate range of the touching point is compared, the operation to the touch screen exits after execution, Uboot code continues to execute and the operating system is started. If the user does not operate the touch screen during the operation of the Uboot, the operation to the touch screen exits, the Uboot code continues to execute and the operating system is started. The method of realizing the touch screen driver in the Uboot solves the problem that the touch screen can only be used after the operating system is started.

Owner:CENT SOUTH UNIV

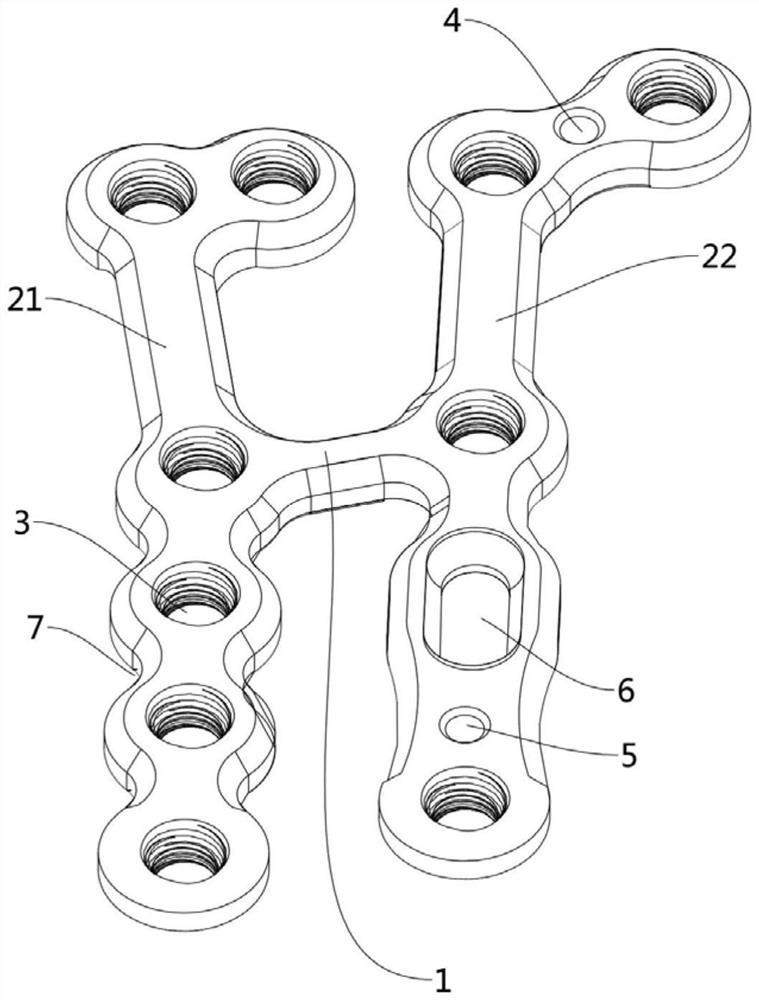

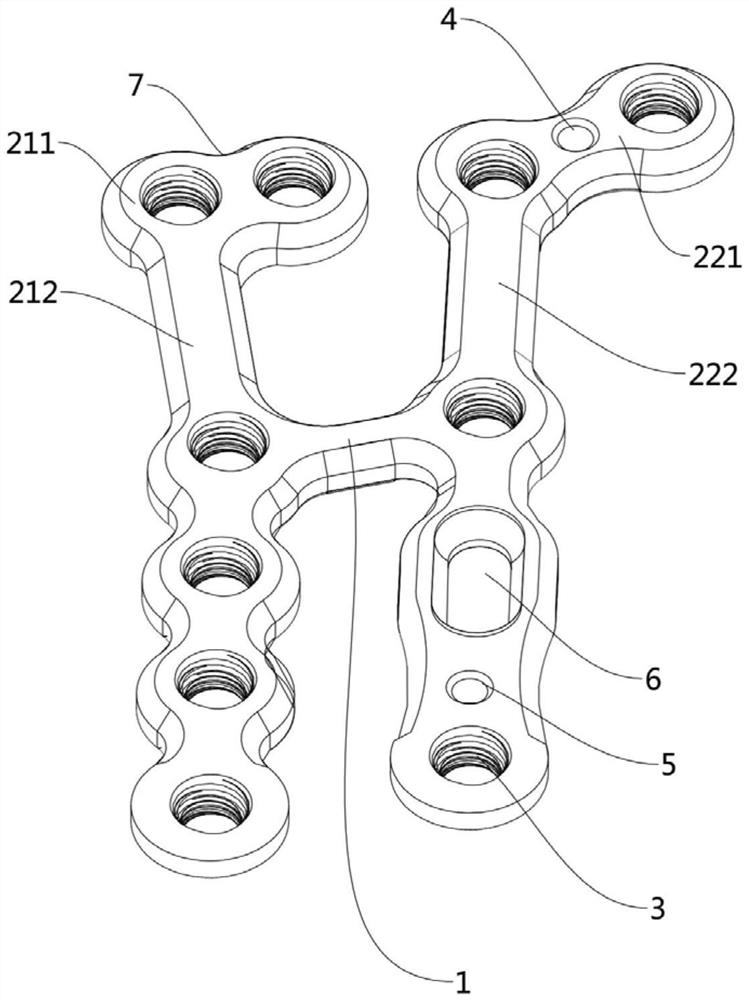

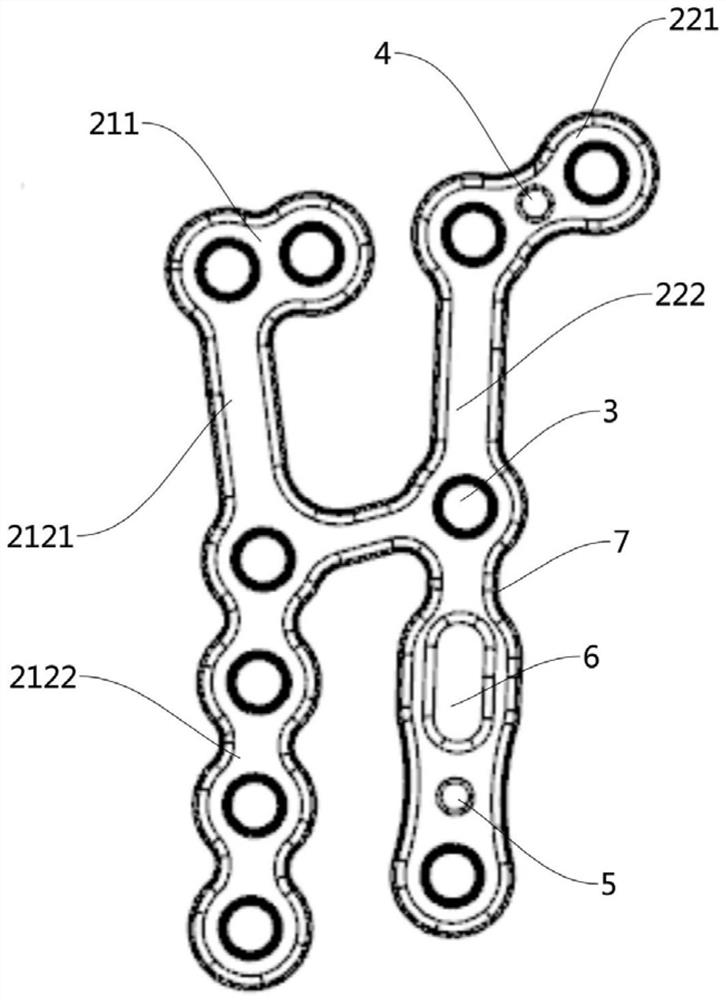

Wrist locking plate and osteosynthesis device

ActiveCN109288576BEasy to choose operationEasy to useBone platesPhysical medicine and rehabilitationOrthopedic department

The invention discloses a wrist joint locking plate and a bone-synthesizing device, which relate to the technical field of orthopedic medical devices and aims to solve the technical problem of poor adaptability and inability to adapt to most situations in the treatment of wrist joints in the prior art. The wrist joint locking plate of the present invention comprises a connecting plate and two fixing plates spaced apart from each other, and the two ends of the connecting plate are respectively connected with the middle parts of the two fixing plates to form an "H" shape structure; At least one threaded hole is opened on each of the fixing plates. The invention has the characteristics of convenient operation and use, free shaping, strong adaptability, etc., and can solve various fracture problems.

Owner:JIANGSU GUOLI MEDICAL EQUIP

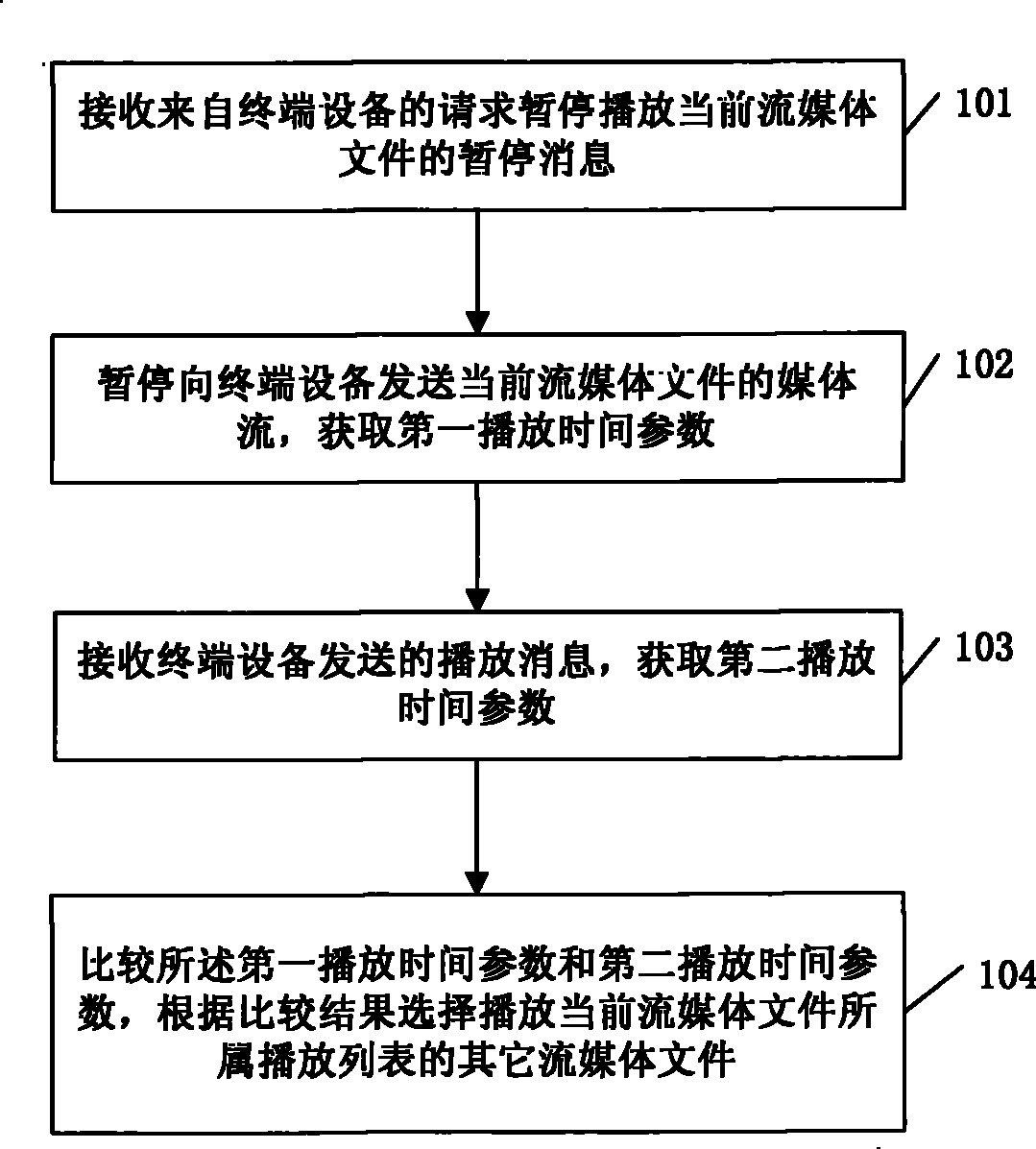

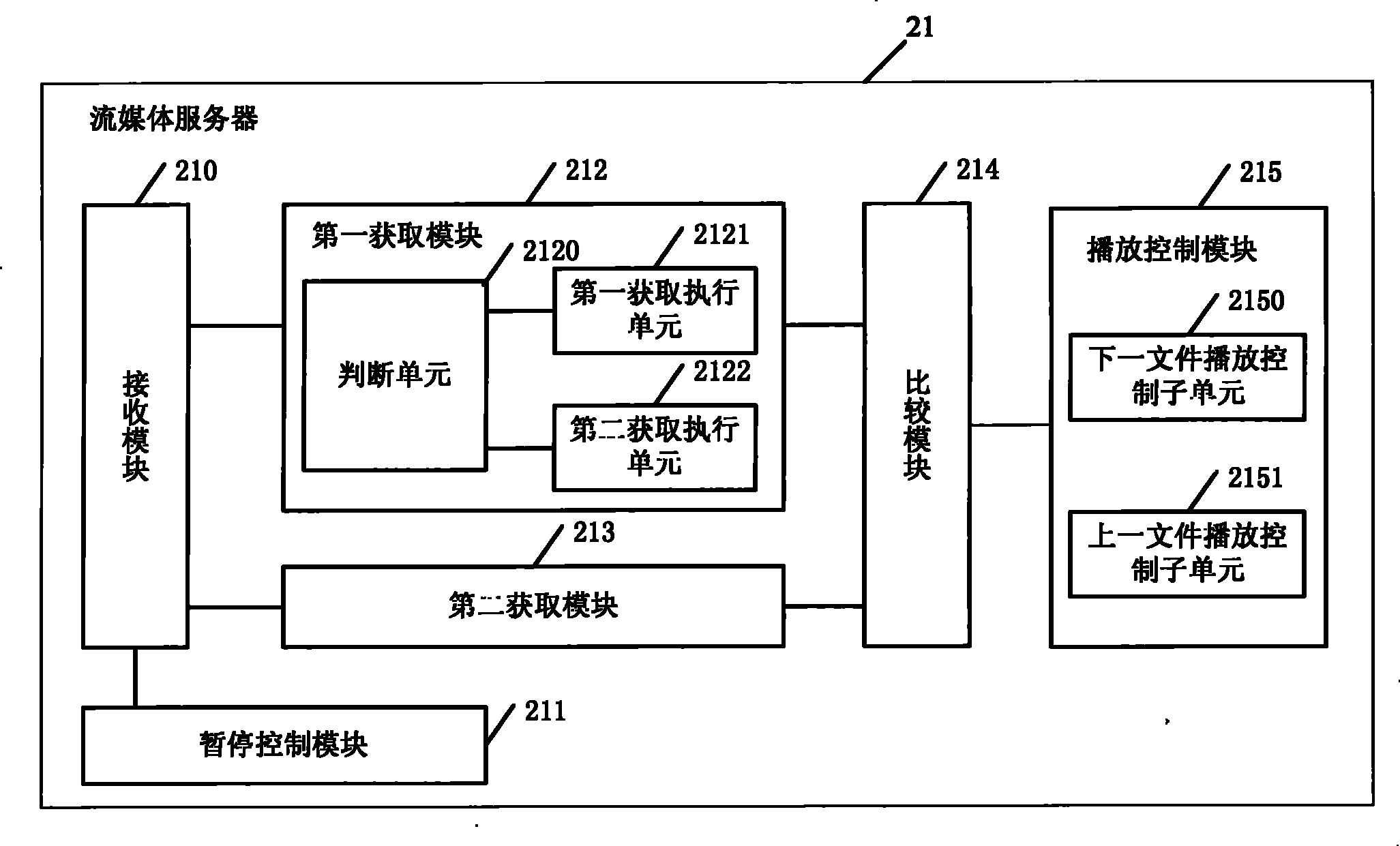

Method, equipment and system for stream media playing control

ActiveCN101459976BEasy to choose operationImprove experienceWireless network protocolsTransmissionTerminal equipmentComputer terminal

The invention discloses a method for playing and controlling streaming media, which comprises: receiving pause message of asking for stopping playing a current streaming media file from a terminal device, stopping sending streaming media of the current streaming media file to the terminal device, obtaining a first playing time parameter when the current streaming media file is stopped, receiving a playing message sent by the terminal device, carrying a second playing time parameter for positioning the playing position of the streaming media file in the message, comparing the first playing time parameter with the second playing time parameter, and selecting other streaming media files of a playing list of the current streaming media file according to the comparison results. Correspondingly, the invention also discloses a device and a system for playing and controlling the streaming media, the device and the system realize that other streaming media files in the playing list of the current streaming media file can be selectively played in the playing process of the streaming media files, which is convenient for users to select the streaming media files, and the user experience feeling is increased.

Owner:HUAWEI CLOUD COMPUTING TECH CO LTD

A method and terminal for starting an application

ActiveCN106933488BMeet the needs of personalized settingsImprove user experienceInput/output processes for data processingTouchscreenQuick start

Owner:GUANGDONG HONGQIN COMM TECH CO LTD

3D printing system based on virtual instrument

ActiveCN108608639BRun fastEasy to debugAdditive manufacturing apparatusAdditive manufacturing with liquidsTemperature controlElectric machinery

The invention discloses a 3D printing system based on a virtual instrument. An operation method for the 3D printing system comprises the following steps: initial operation: accomplishing the initial operation of the system by using a laminated sequential structure; parameter setting: controlling the upper and lower limits of the thermal resistance of a heating part by using a circulation embeddedcondition structure, setting an event structure in a waiting branch, and editing and modifying the thermal resistance of the heating part via the event structure so as to set upper and lower limit parameters; manual printing: pretreating the system, wherein the pretreatment includes preheating of the system and debugging and setting of the coordinates of a nozzle at the same time, and performing motor operation, extrusion motor operation and temperature control at the same time; and 3D printing: subjecting corresponding 3D object data to layering and slicing, contour optimization, lamellar data processing and other treatment so as to obtain corresponding coordinate information, and controlling a triaxial motor according to the coordinate information so as to realize fixed-point layer-by-layer printing and lamination so as to obtain a 3D object. The 3D printing system provided by the invention realizes 3D scanning and printing via LabVIEW, and is fast in the operation speed of programs,easily debuggable in visual programming and high in printing accuracy.

Owner:苏州舜达易科信息技术有限公司

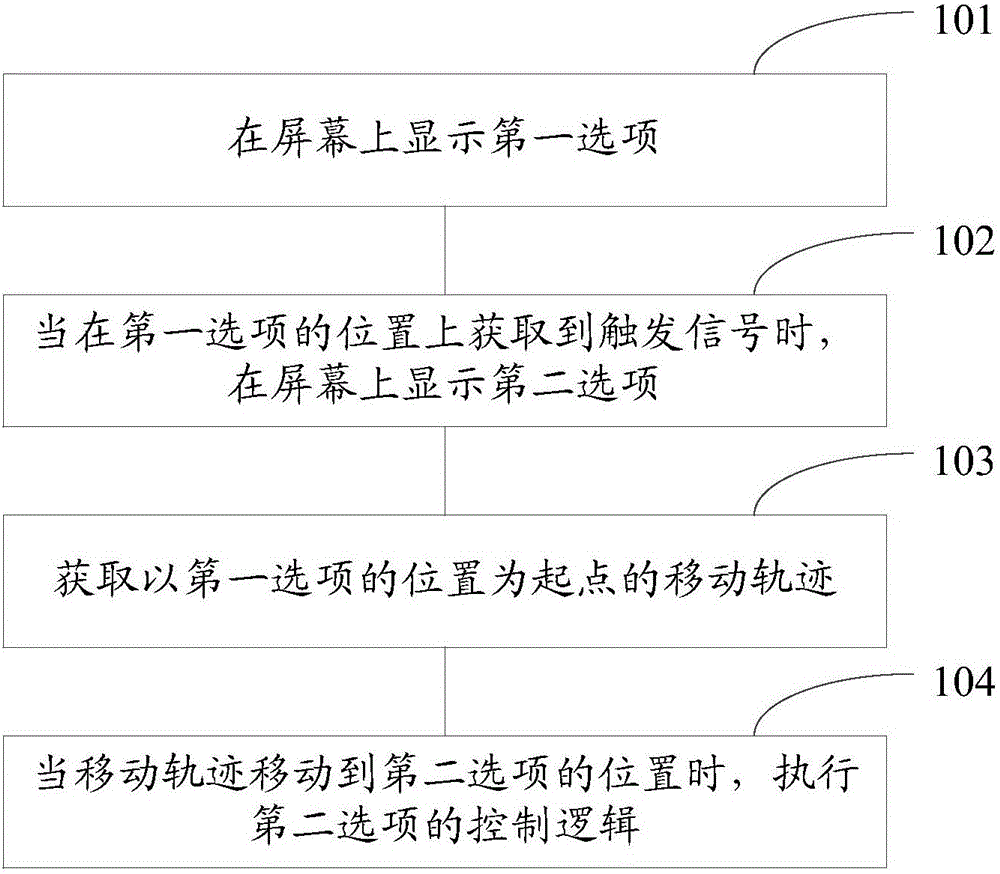

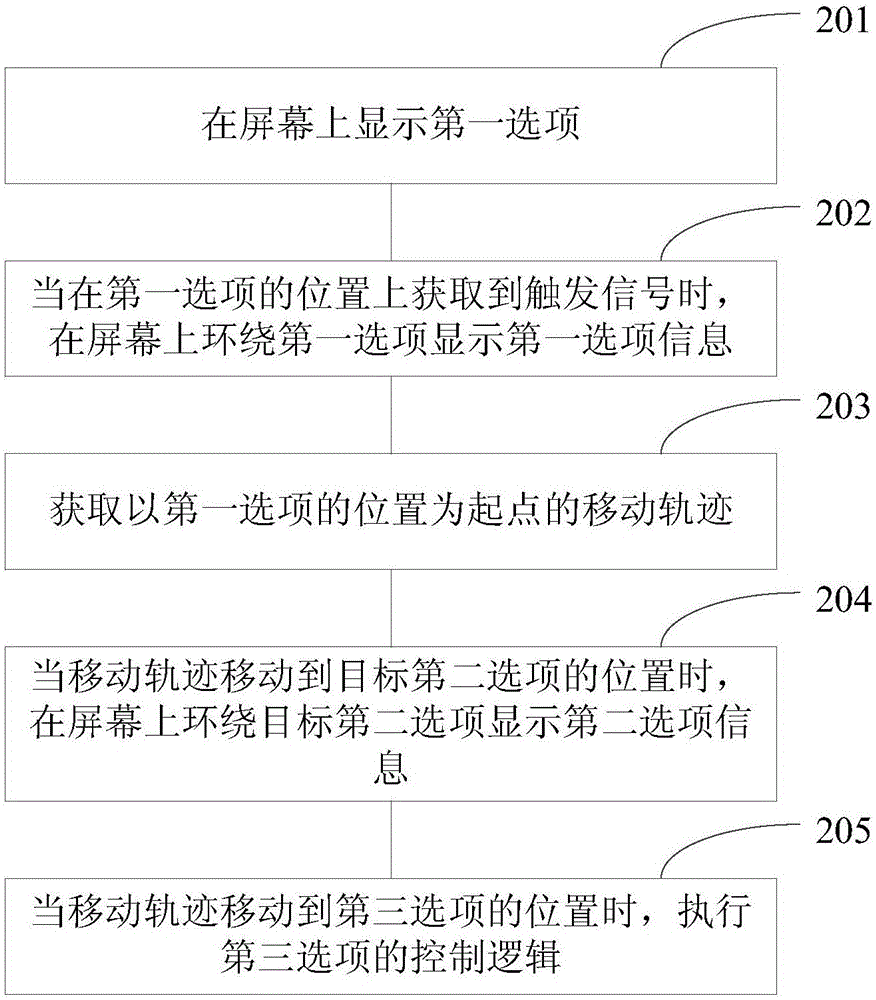

An operating method and device for options

InactiveCN106406669AEasy to choose operationReduce occupancyInput/output processes for data processingOperating systemSystems engineering

The embodiments of the invention provide an operating method and device for options, which facilitate option selecting operations of users. The method comprises the steps of displaying a first option on a screen; when a trigger signal is obtained at the position of the first option, displaying a second option on the screen; acquiring a moving path with the position of the first option as the starting point, and, when the moving path moves to the position of the second option, executing the control logic of the second option. Thus, users can select continuous options rapidly only through slide operations on a screen, so that the selection operations of users are facilitated; a second option is not displayed until a first option is triggered, so that the screen occupation of options is reduced and the space on a screen is fully utilized.

Owner:MEIZU TECH CO LTD

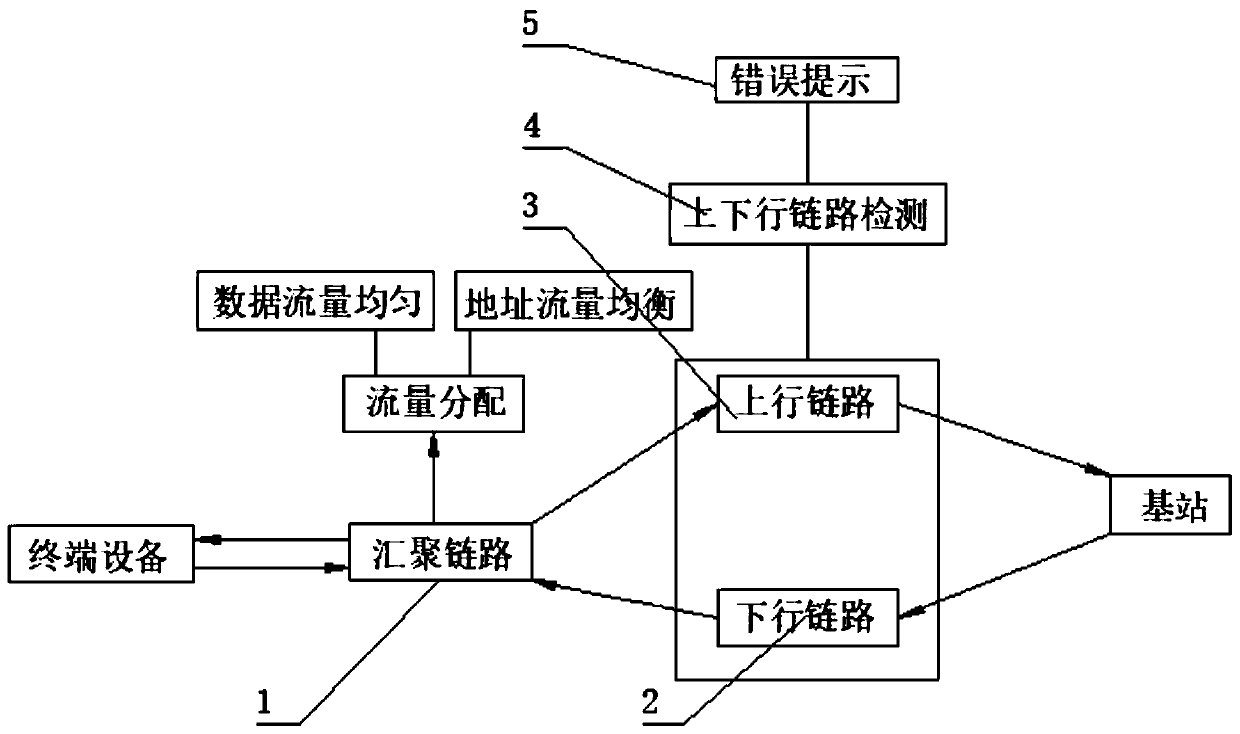

Multi-processor system based on topological structure formed by four pairs of bidirectional communication links

InactiveCN111200835APerfect Link Topology SystemPerfect topology systemNetwork traffic/resource managementConnection managementLine cardPluribus

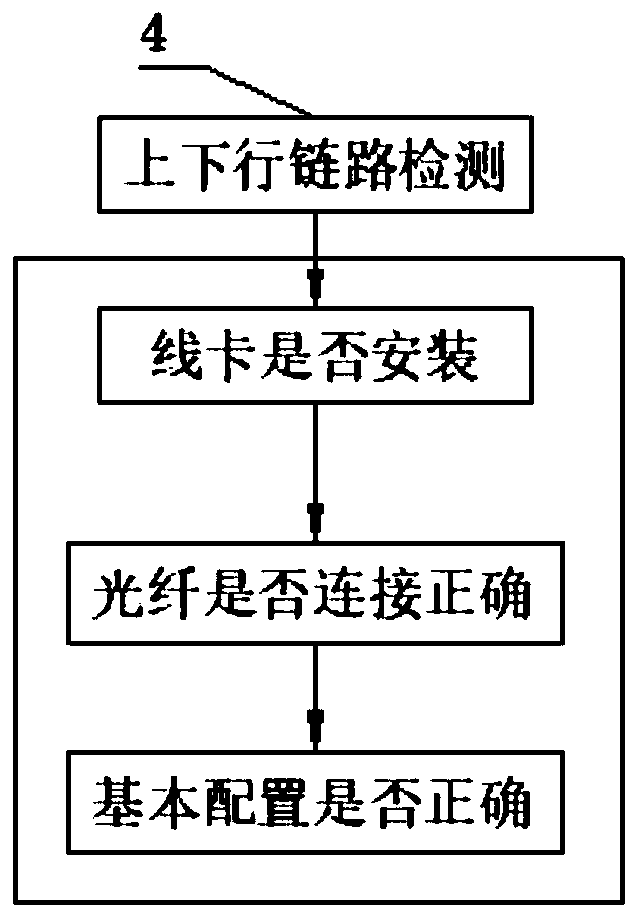

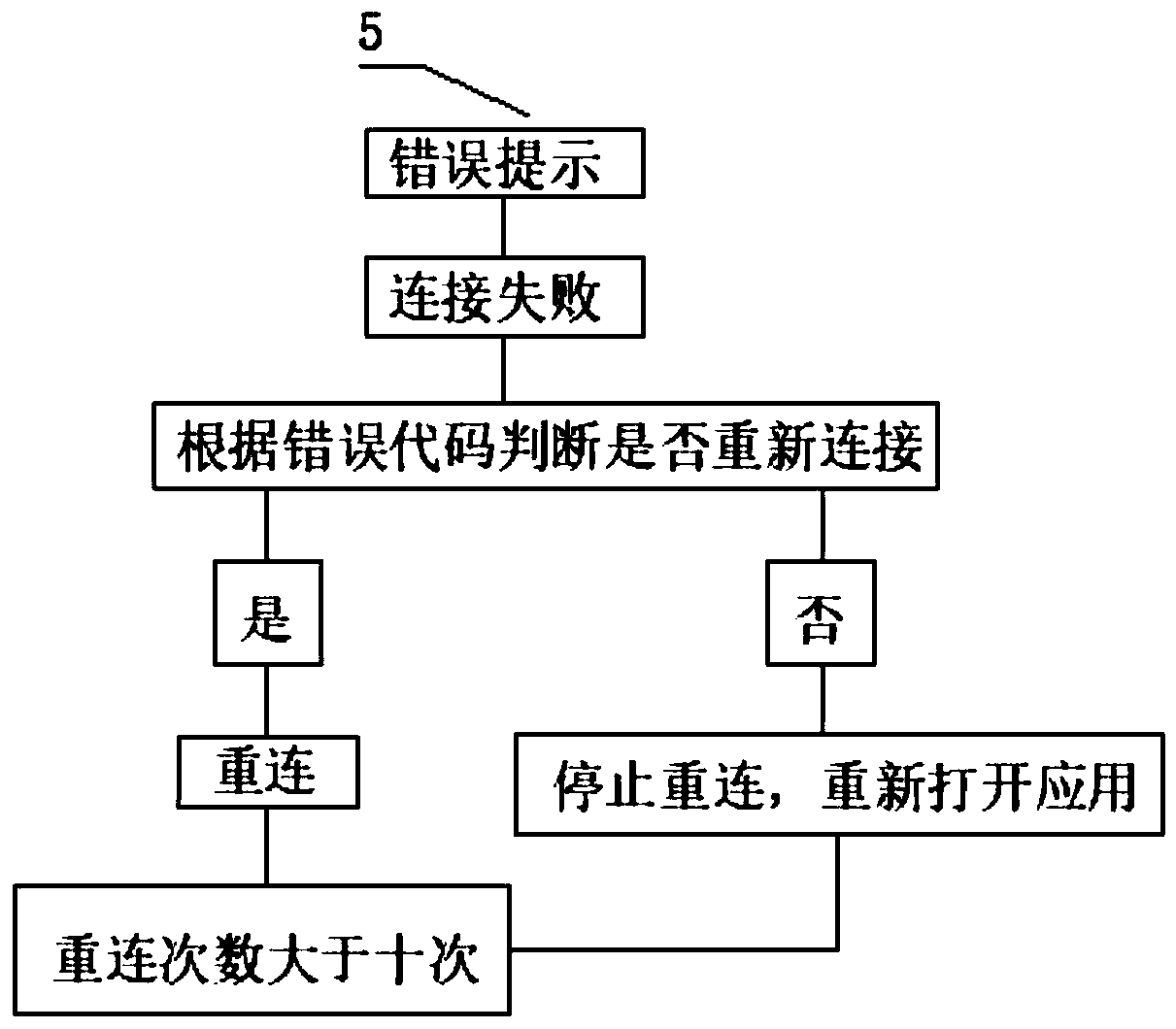

The invention discloses a multi-processor system based on a topological structure formed by four pairs of bidirectional communication links. The system comprises a convergence link. The convergence link receives a signal sent by mobile equipment and then transmits the signal to a base station through an uplink; the base station sends the signal back to the mobile equipment through a downlink; uplink and downlink detection is carried out when receiving and sending faults of the uplink and the downlink occur; a user is reminded through error prompt after connection failure of the mobile equipment; reconnection or reopening can be analyzed according to the error prompt when connection failure occurs by perfecting uplink and downlink fault detection; and a link topology system is perfected. By perfecting detection during uplink and downlink faults and analyzing reconnection or reopening according to the error prompt during connection failure, the link topology system is perfected. Uplinkand downlink detection comprises detection of whether a line card is installed, whether optical fibers are connected correctly and whether basic configuration is correct, and detection analysis can beperformed during connection failure.

Owner:山东公链信息科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com