Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

61results about "Paper-weights" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

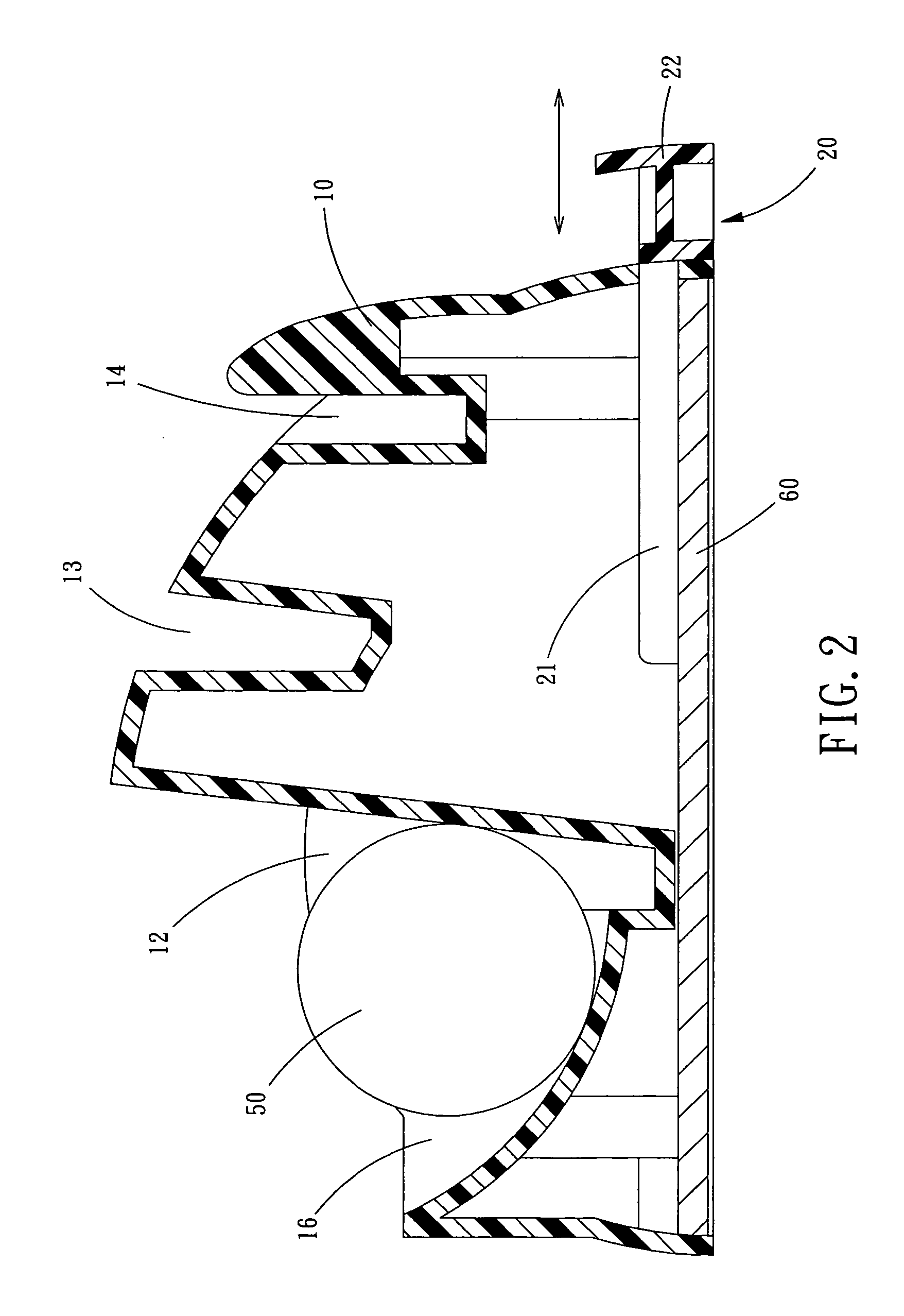

Method for positioning shooting documents by square of document shooting instrument

ActiveCN102137210AClear picture qualityNeat picture qualityTelevision system detailsColor television detailsProcess moduleImaging quality

The invention discloses a method for positioning shooting documents by a square of a document shooting instrument. The method is characterized in that three main functional parts, i.e., a shooting instrument, an image capturing and processing module built in the shooting instrument and a positioning piece which can be placed at will and identified by the image capturing and processing module, are utilized. The positioning piece is a square with two right-angle sides and has the thickness for positioning stacked files. With the adoption of the system, slope angle adjustment, clipping and magnification of the image can be accomplished, and then a plurality of documents can be shot once. The positioning square is not needed to be fixedly connected with the shooting instrument and can be placed at will. The required rotation angle is calculated after positioning by the positioning square, and tidy shot pictures with clear image quality are finally obtained through picture adjustments, clipping and magnification.

Owner:SHENZHEN KERUN VISUAL TECH CO LTD

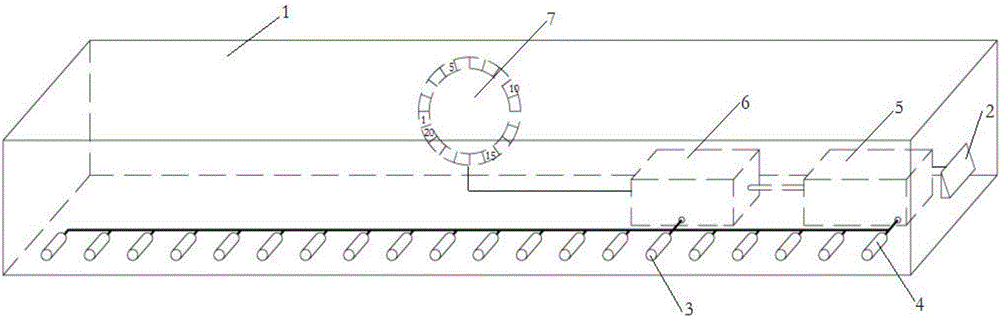

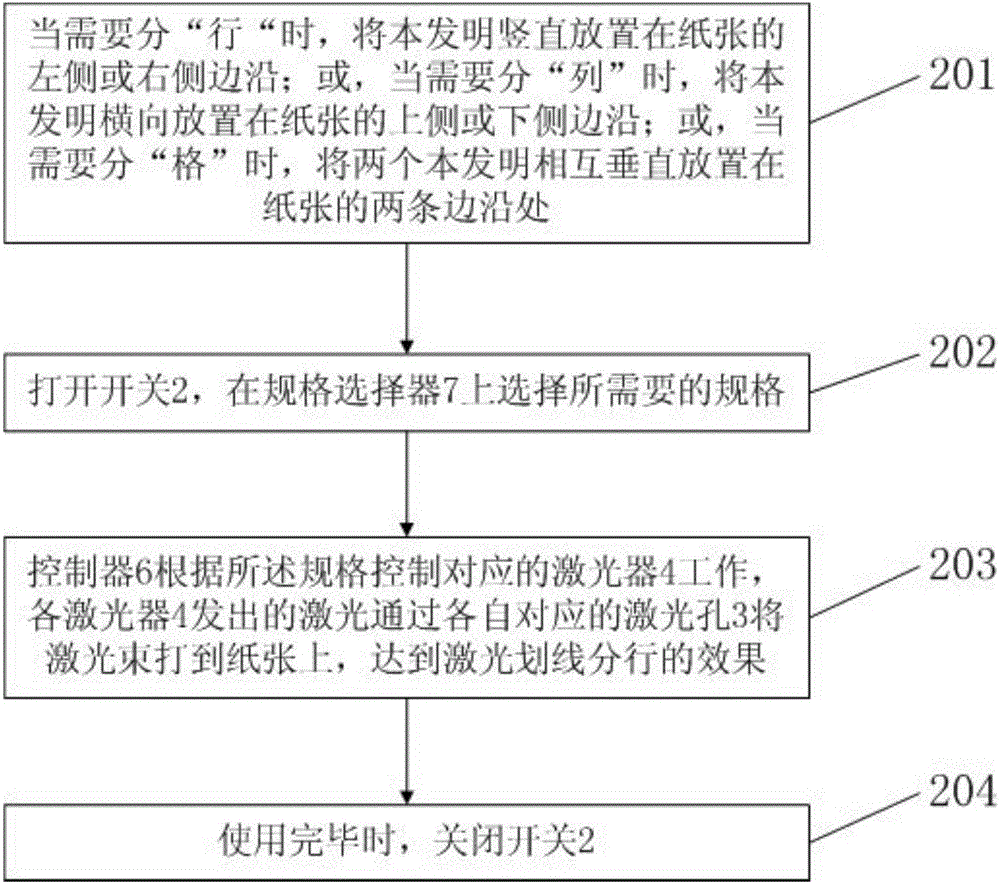

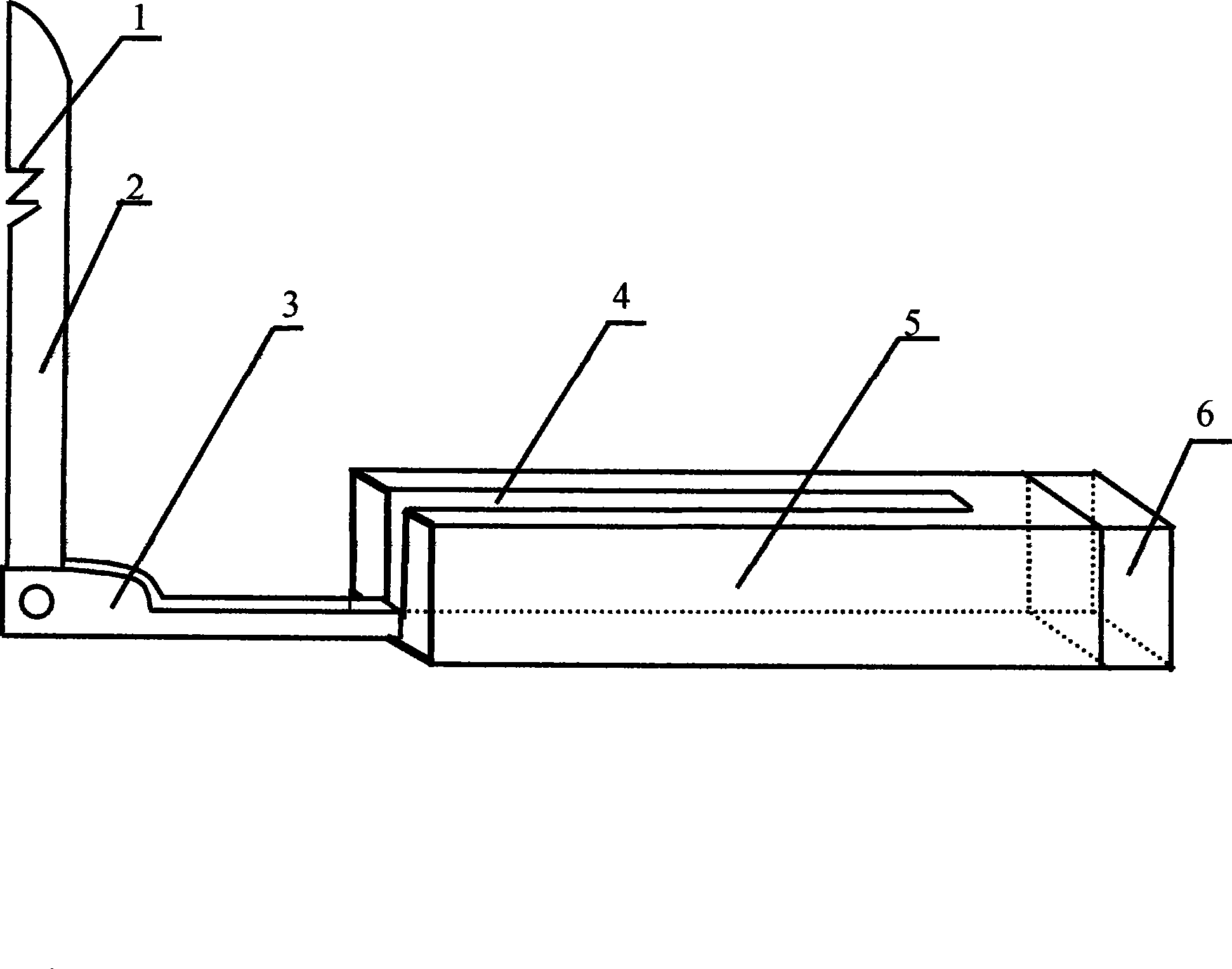

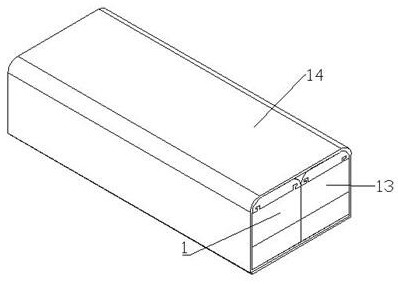

Multifunctional laser paperweight and usage method thereof

InactiveCN105835579AAvoid influenceEasy to createPaper-weightsTeaching apparatusEngineeringPaper sheet

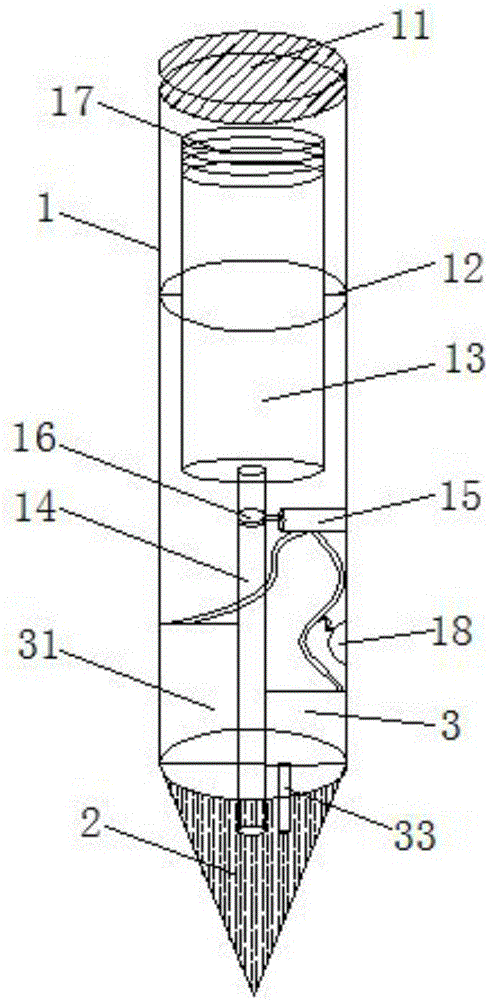

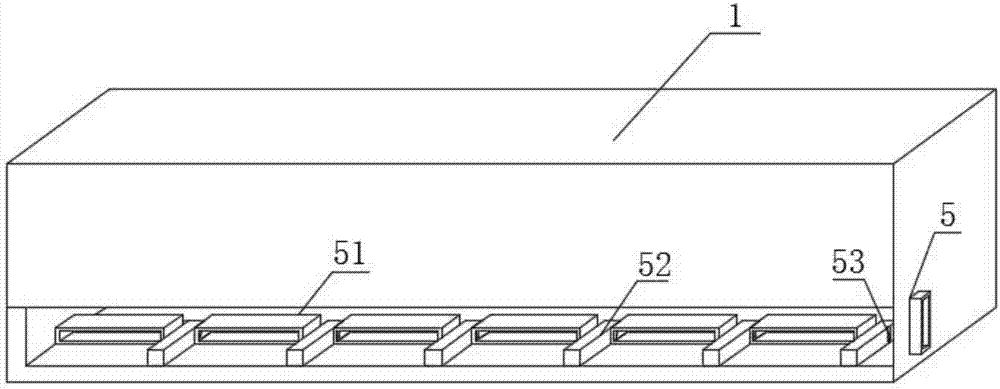

The invention discloses a multifunctional laser paperweight and a usage method thereof and relates to the field of calligraphy stationery. A plurality of lasers with high optical penetrability are adopted and distributed evenly, so that the multifunctional laser paperweight has both a paperweight function and a paper laser grid division function at the same time, and a plurality of grid division choices with different specifications are provided for a user. Therefore, usage is convenient, time and labor are saved, the influences of paper folding and creasing on calligraphy works are avoided, and thus the difficulty of the writing page layout is lowered greatly. According to the main points of the technical scheme, a switch is arranged on one side face of a cuboid-shaped paperweight body, a plurality of laser holes are distributed along the long lower edge of the paperweight body evenly and are in one-to-one correspondence with the lasers distributed in the paperweight body, and all the lasers are connected with a power source and a controller through wires; and a specification selector is arranged on the other side face of the paperweight body and connected with the controller, and the controller is connected with the power source. The multifunctional laser paperweight and the usage method thereof are mainly used for even paper division.

Owner:FUJIAN AGRI & FORESTRY UNIV

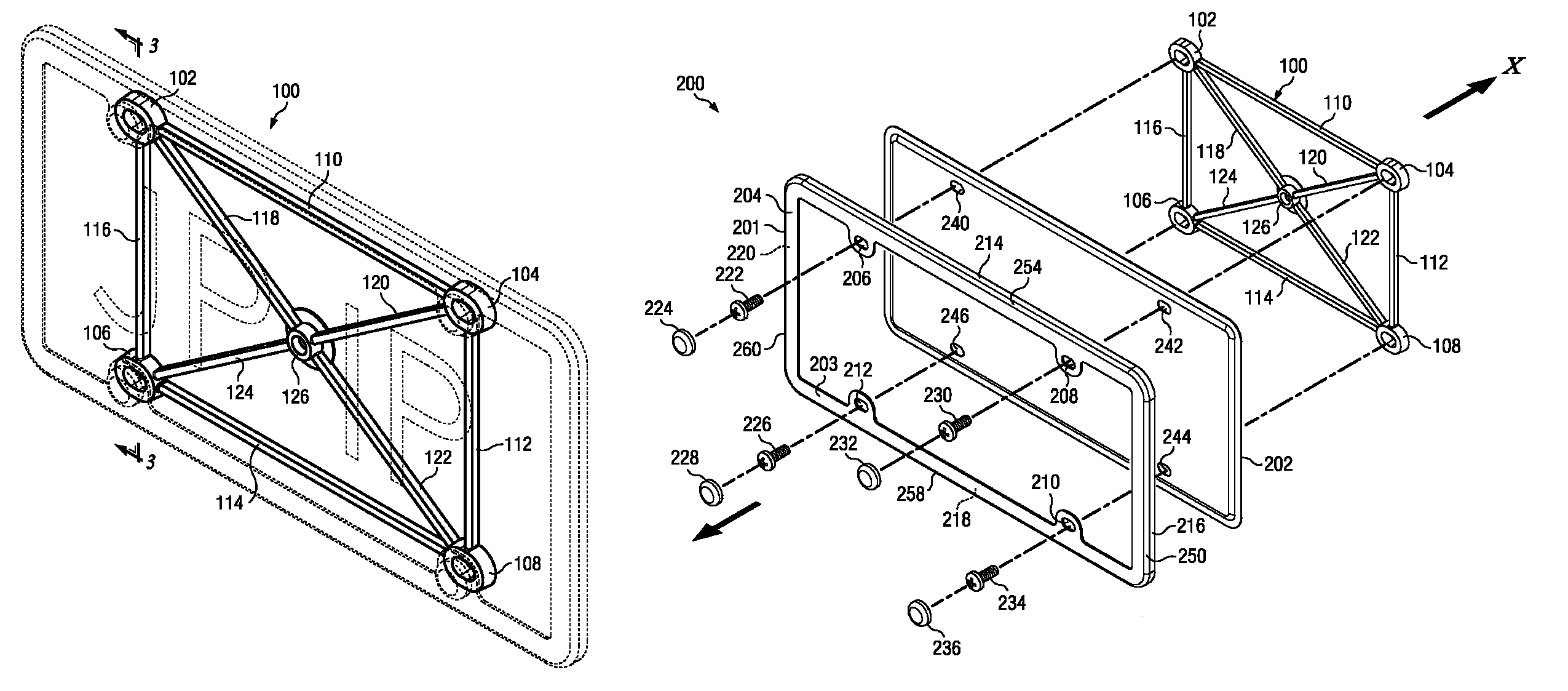

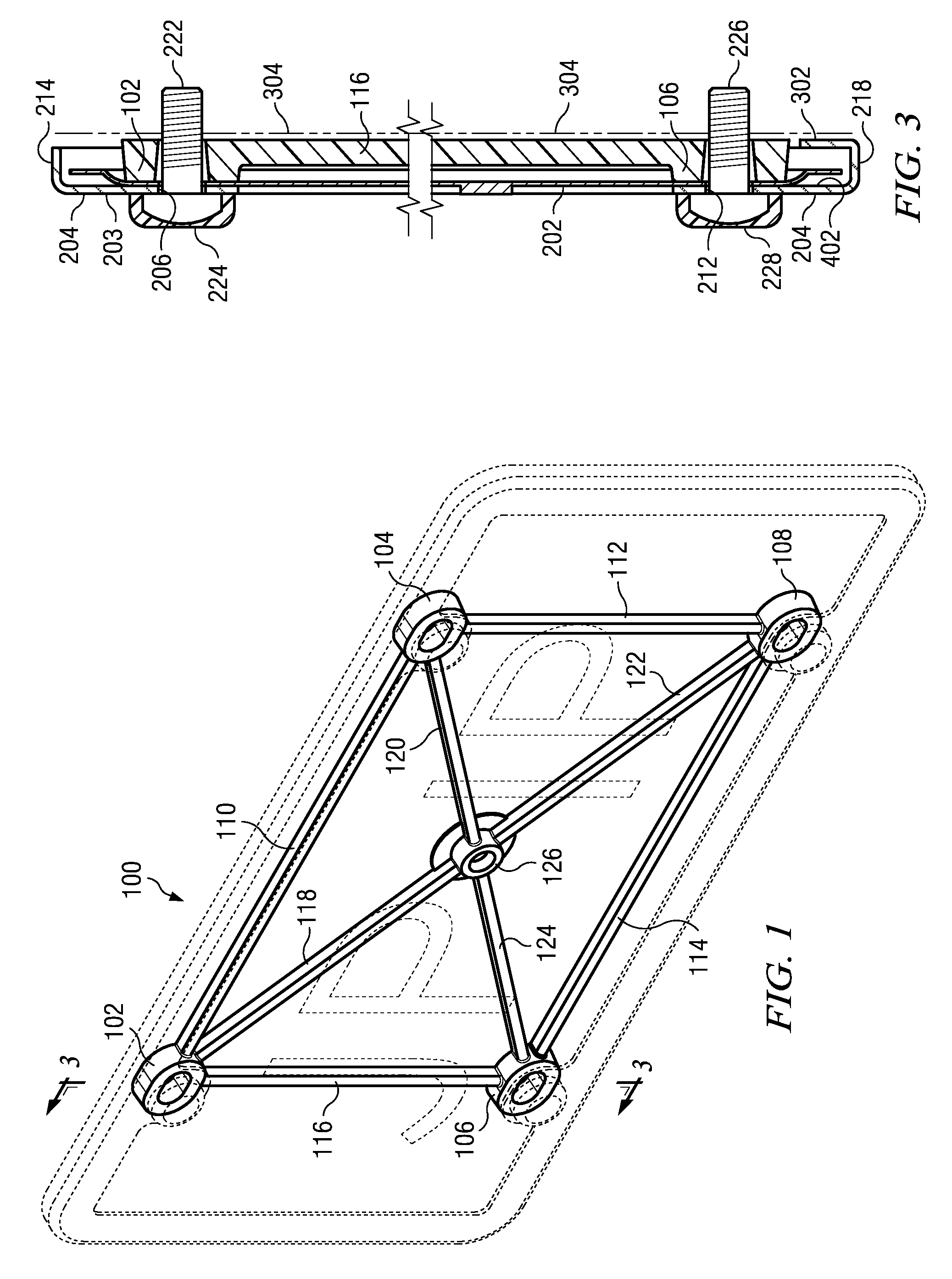

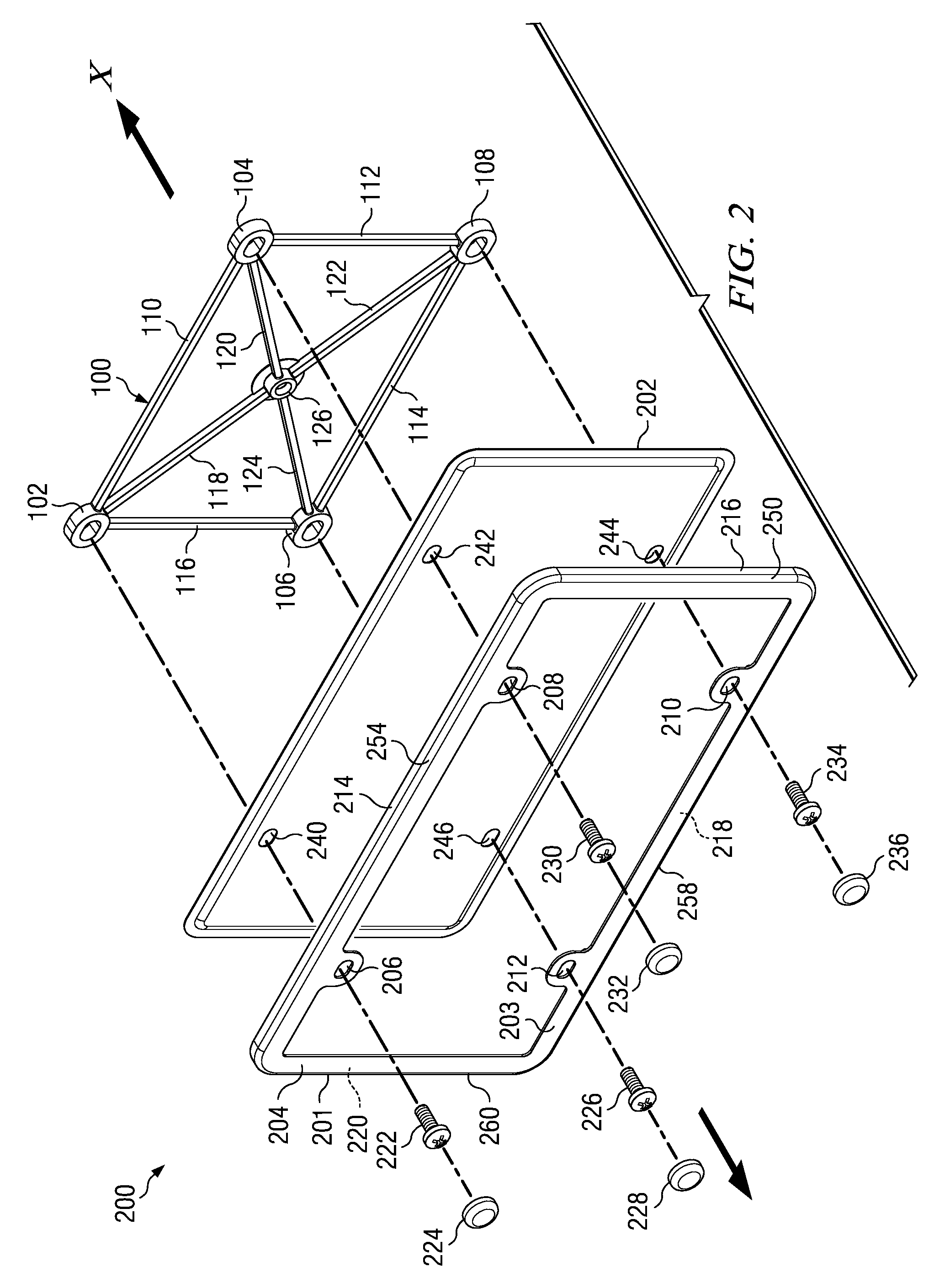

License plate frame spacer unit and system

ActiveUS8959809B2Easy to assembleEasy to installCurtain suspension devicesPaper-weightsEngineeringMechanical engineering

Owner:MACNEIL IP

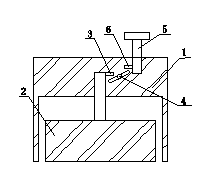

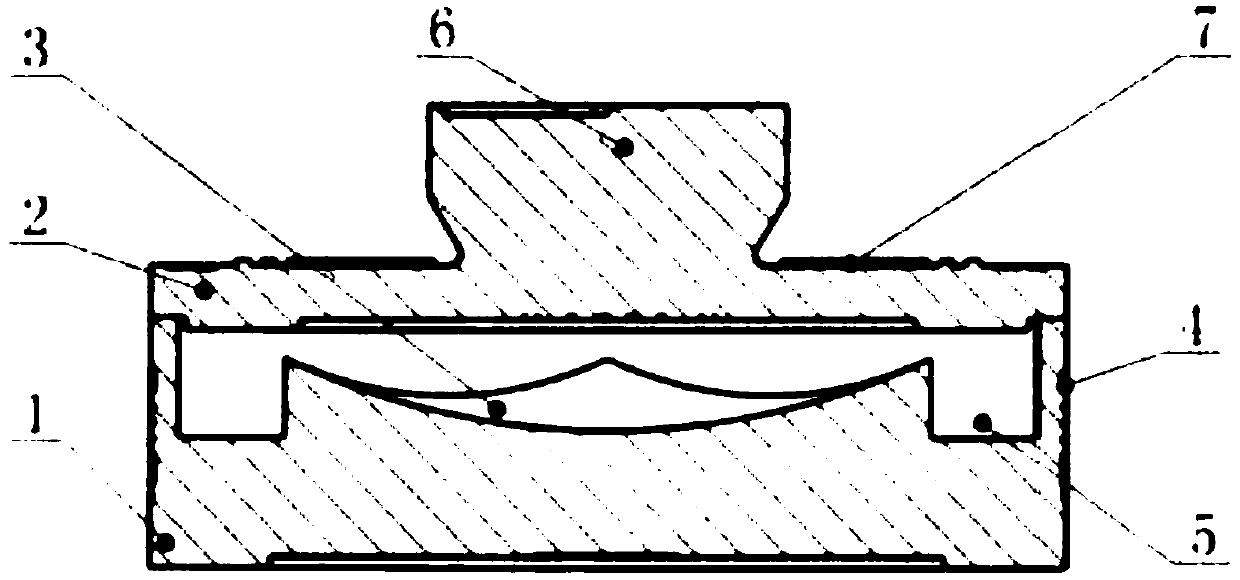

Paperweight for setting seal

The invention relates to a paperweight for setting a seal. The paperweight comprises a paperweight pressing plate, wherein a connecting groove is formed in the upper part of the paperweight pressing plate. The paperweight is characterized in that the connecting groove is connected with a seal box; a seal slot and an inkpad slot are formed in the seal box; a connecting strip connected with the connecting groove is arranged at the bottom of the seal box. The paperweight disclosed by the invention is simple in structure and convenient to use, and the space can be effectively saved.

Owner:方小玲

Intelligent Chinese calligraphy brush pen and paperweight suite

The invention discloses an intelligent Chinese calligraphy brush pen and paperweight suite. The intelligent Chinese calligraphy brush pen and paperweight suite comprises a penholder, a pen point, an integrated circuit board and a paperweight body. The lower end of the penholder is fixedly connected with the pen point. The integrated circuit board and a battery are fixed inside the penholder. The upper end of the penholder is sealed by a pen cap. A fixing support is arranged inside the penholder. An ink container is fixed on the fixing support. The lower end of the ink container is connected with the pen point through a conduit. The upper end of the ink container is sealed with a screw. A micro motor is fixed to the lower portion of the ink container. According to the intelligent Chinese calligraphy brush pen and paperweight suite, the flow rate of ink is intelligently controlled through a processor and a humidity sensor, the ink rate at the pen point is just right through precise control, and a user can write with facility; a multimedia device is integrated on a paperweight, a brush pen can be stored conveniently, and more joy is taken into writing; and the intelligent Chinese calligraphy brush pen and paperweight suite is multifunctional, people can realize the great charm of modern science and technology and traditional culture, more people can lean and love calligraphy, and thus the traditional culture of Chinese nation is developed and expanded.

Owner:新昌县厚道机械有限公司

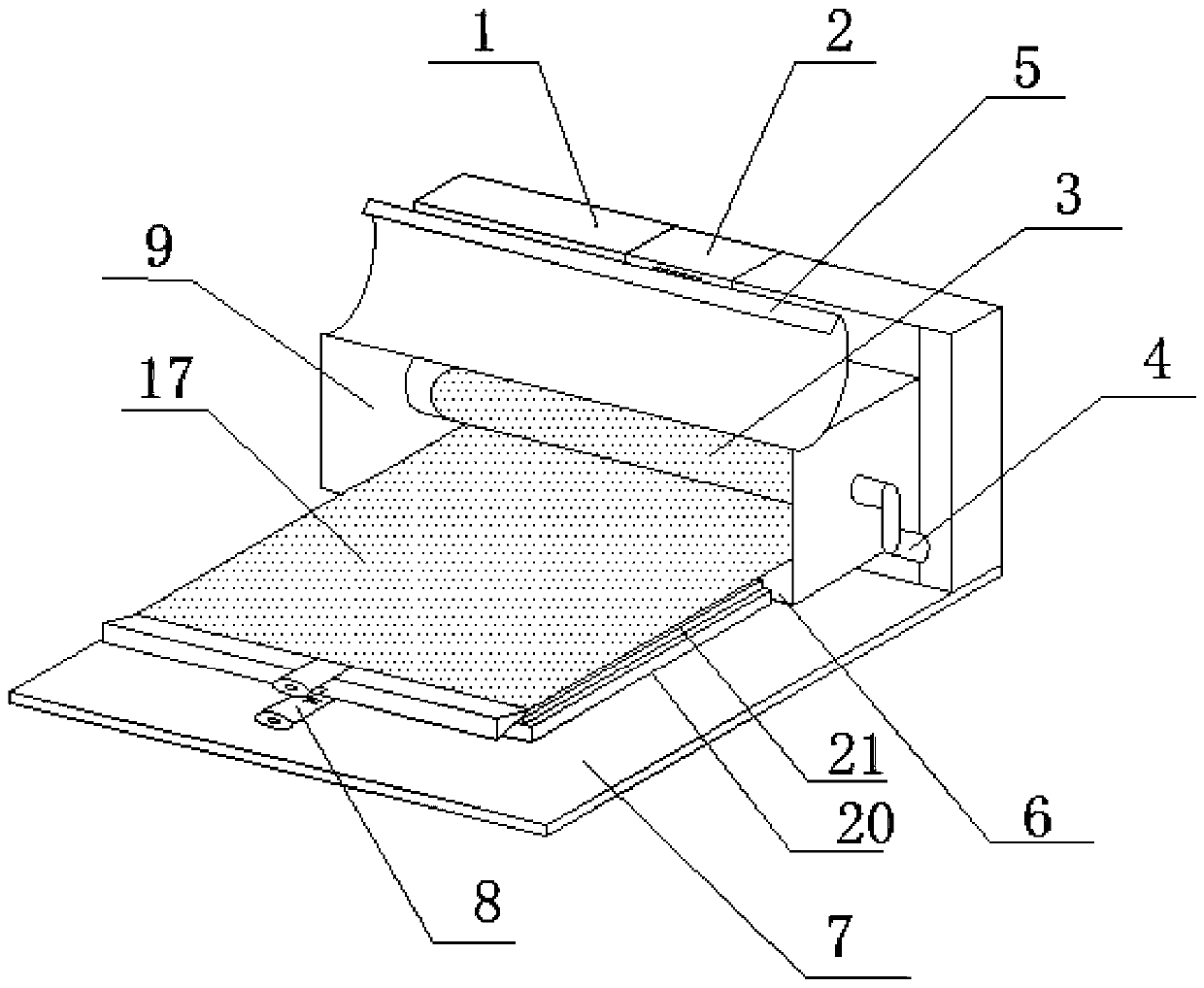

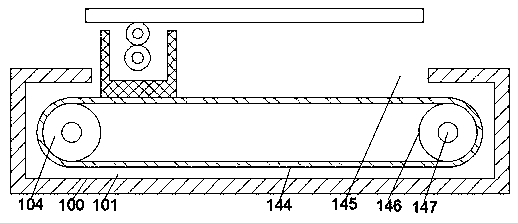

Convenient-to-expand winding and storage device for drawing paper

The invention discloses a convenient-to-expand winding and storage device for drawing paper. According to the convenient-to-expand winding and storage device for the drawing paper, a drawingcan be conveniently clamped and wound on a winding shaft and can further be tiled, absorbed and fixed during drawing, and modification and drawing of subsequent drawings are convenient; clamping of the windingend of the drawing can be realized without disturbing the roundness of the winding shaft, and the expansion end can conveniently make use of a tensioning component for tensioning operation; the jointaction of a rotating axis and a rocker can effectively realize expansion and contraction of drawing paper winding, and meanwhile, by arranging a rubber layer around a paper outlet, damage of the drawing paper in the process of expansion and contraction can be effectively reduced; and meanwhile, a paper cutter is further arranged to facilitate users to cut painted paper, a winding protective box isarranged on the exterior of drawing paper winding, the very good dustproof and waterproof effects can be played, and thus a drawing paper roll is protected.

Owner:INNER MONGOLIA FINANCE AND ECONOMICS UNIVERSITY

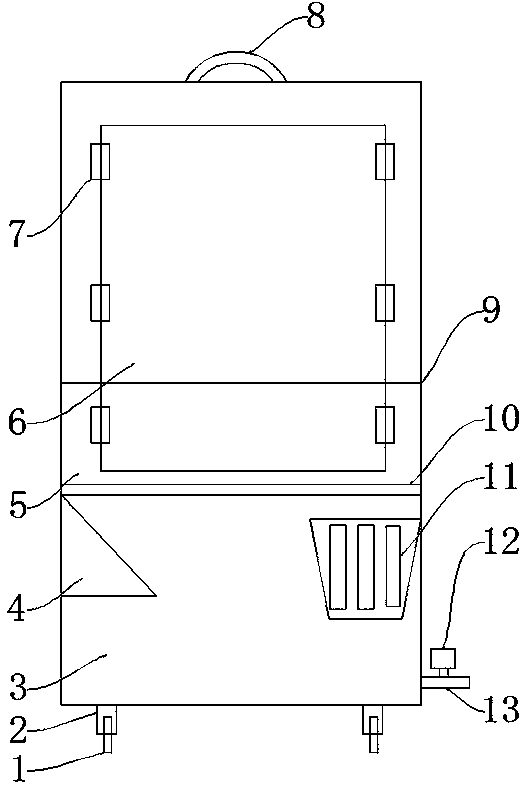

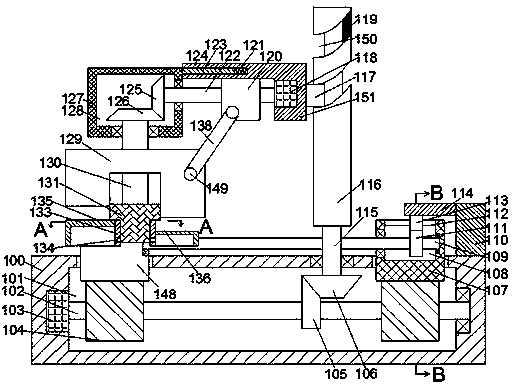

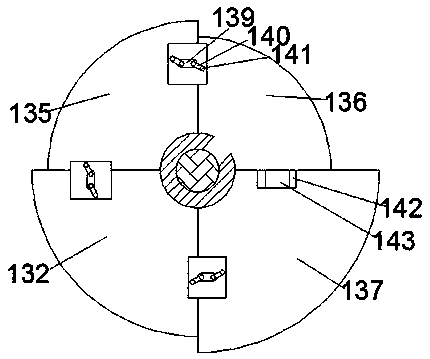

Paper pressing device

The invention discloses a paper pressing device. The paper pressing device comprises a machine body and a first cavity formed in the machine body; the upper end of the machine body is provided with first chutes in bilateral symmetry in a communicating mode; the inner wall of the top end of the first cavity is connected with a first transmission shaft located between the first chutes in a rotatingfit mode, and the first transmission shaft extends up and down; the tail end of the first transmission shaft is provided with a first bevel gear; the top end of the first transmission shaft is fixedlyconnected to a track barrel located on the upper end surface of the machine body; a track groove is formed in the track barrel circumferentially in a surrounding model; the upper end of the track groove is fixedly connected with a limiting block; the track groove is connected with a guide sliding block in an abutting mode; the other end of the guide sliding block is connected with an L-shaped power block; the left end surface of the L-shaped power block is provided with a second sliding chute with an opening facing leftwards; and an extension rod is slidably connected into the second slidingchute. The paper pressing device is high in linkage, a mechanical rod is used for simulating human hand smooth movement and is efficient and hygienic, and deviation is avoided through multi-directional pressing points.

Owner:陈亚利

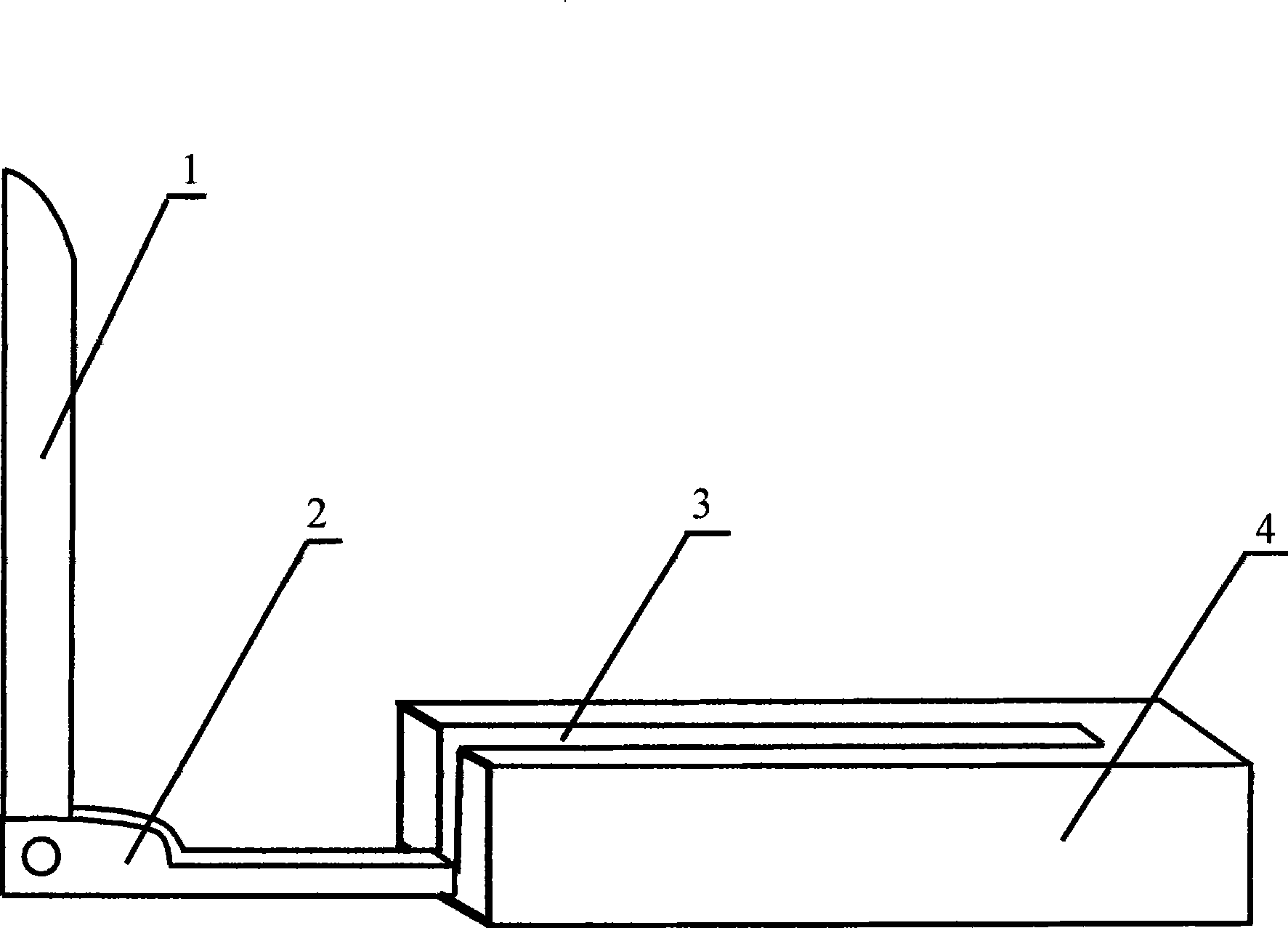

Paper-weight knife with lucky words stamp

InactiveCN101417429ASimple structureLow costPaper-weightsMetal working apparatusFlutePulp and paper industry

The invention discloses a paperweight knife with prints of lucky words, which consists of a blade, a cutting head, a flute and paperweight and is characterized in that the cutting head is arranged into the flute of the paperweight and connected with the blade; the angle between the cutting head and the blade is 90 degrees. When in use, the cutting head is pulled out of the paperweight flute and then the blade is pulled down in the angle of 90 degrees, and then the knife can be used for cutting the paper and the paper becomes paperweight after the recovery. The knife has the advantages of simpler structure, lower cost and stronger practicality.

Owner:卢心东

Magnet retainer

A magnet retainer comprising a box and a magnet is characterized in that the upper end of an extension of the magnet is provided with a projection first limit pin, the box is further provided with a control bar, the lower end of the control bar is provided with a projecting second limit pin, a rotating shaft is disposed inside the box and contacts with the two limit pins, and the two limit pins can be synchronously linked through the rotating shaft. Compared to the existing magnet retainers, the magnet retainer has the advantages that the magnet is controlled through mechanical linkage and accordingly the magnet retainer is more convenient to use.

Owner:周宇

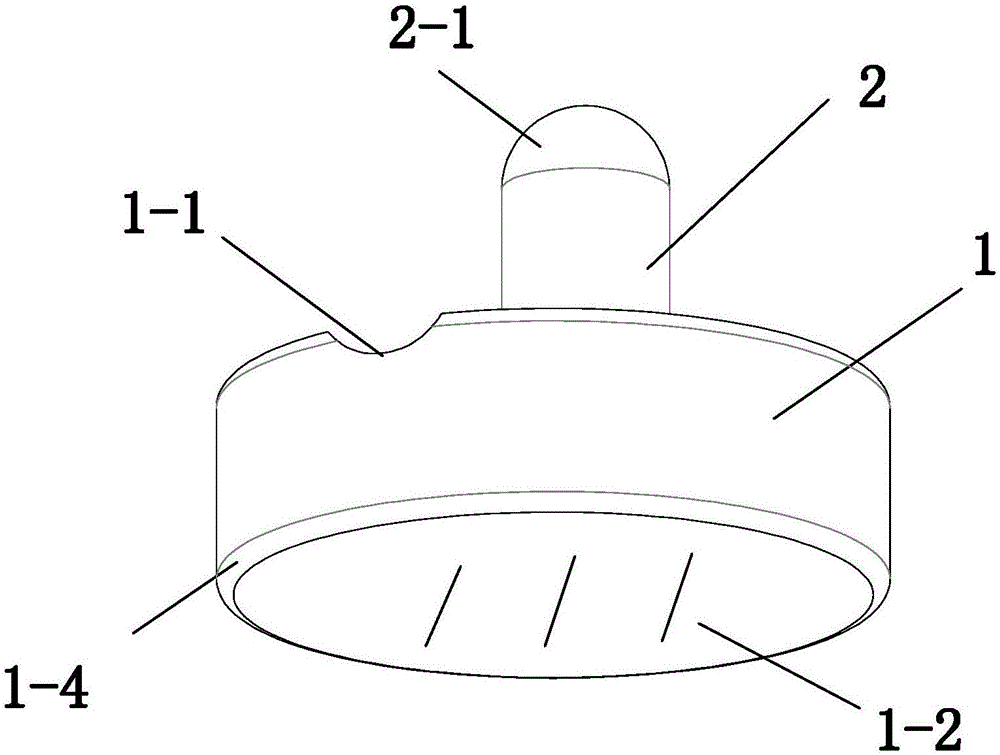

Paper pressing cake-shaped object

The invention discloses a pressed paper cake, which comprises a pressed cake and a handle, wherein the pressed cake is in the shape of a round cake; the handle is arranged in the middle of the pressed cake in a cylindrical shape. The invention has the beneficial effects of simple structure and convenient use.

Owner:谢宇

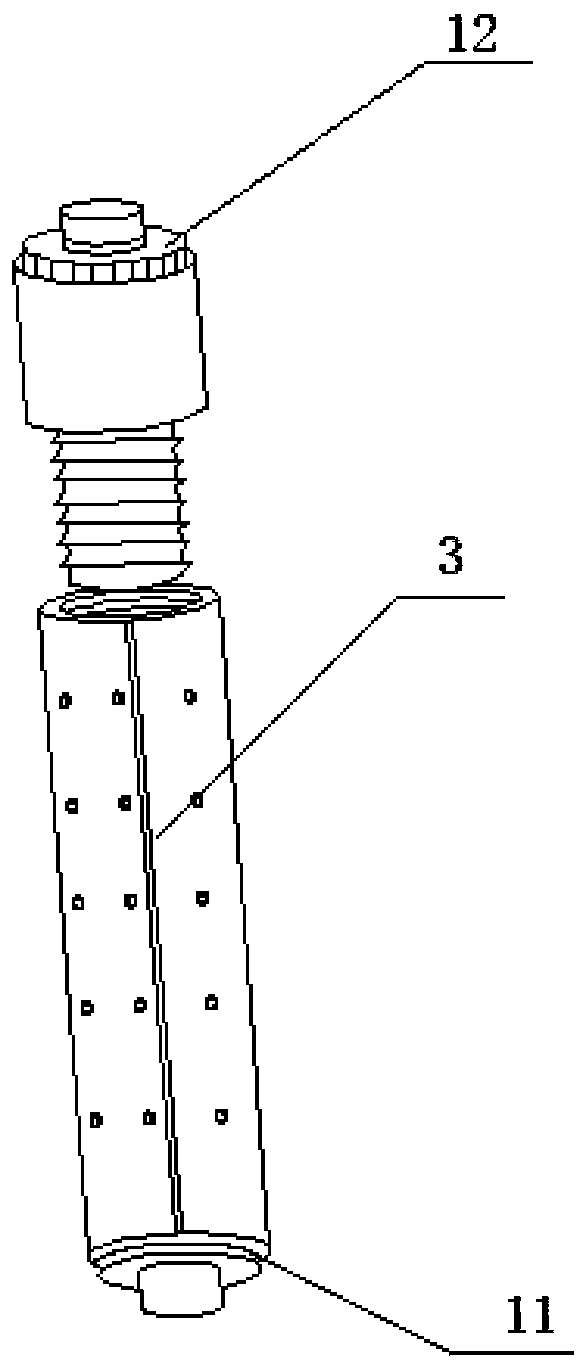

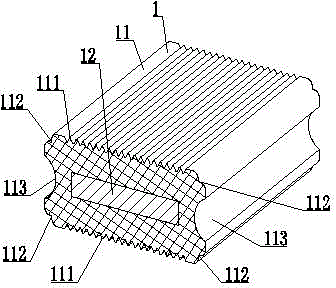

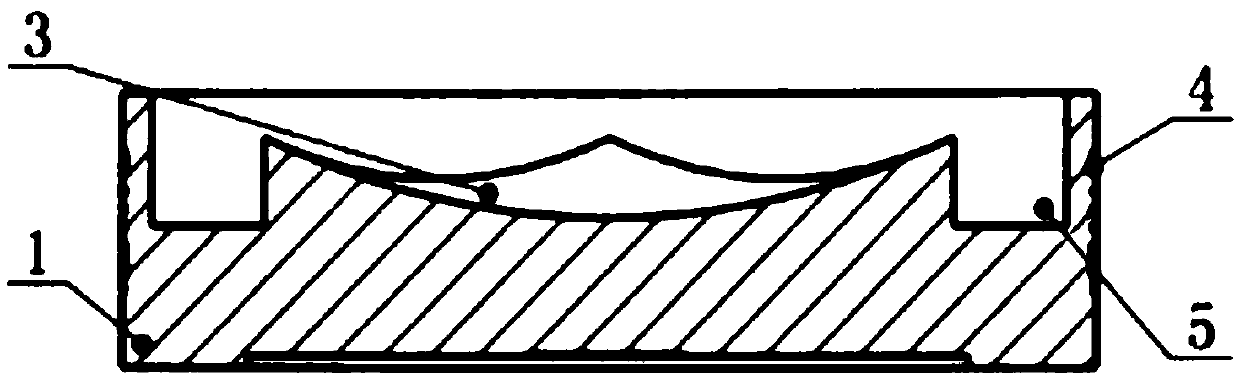

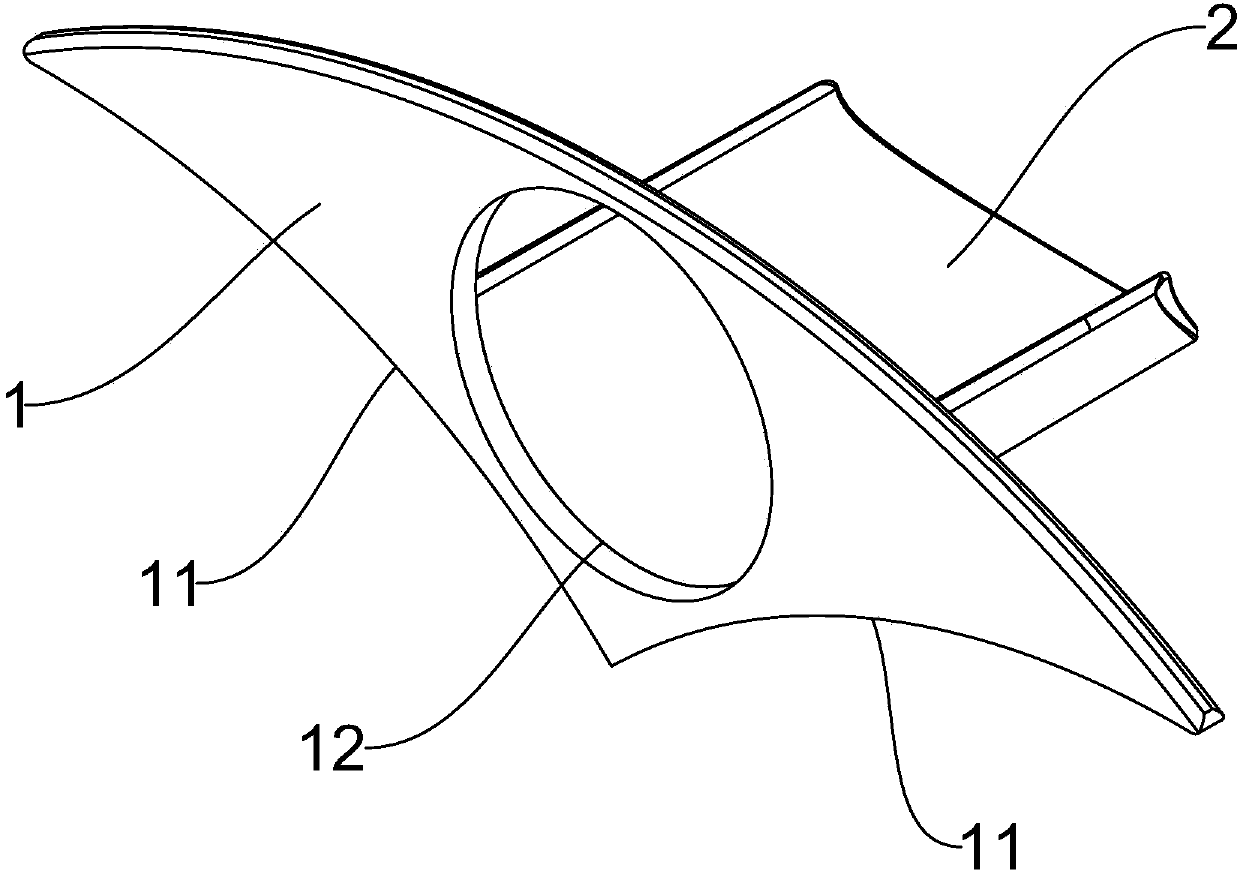

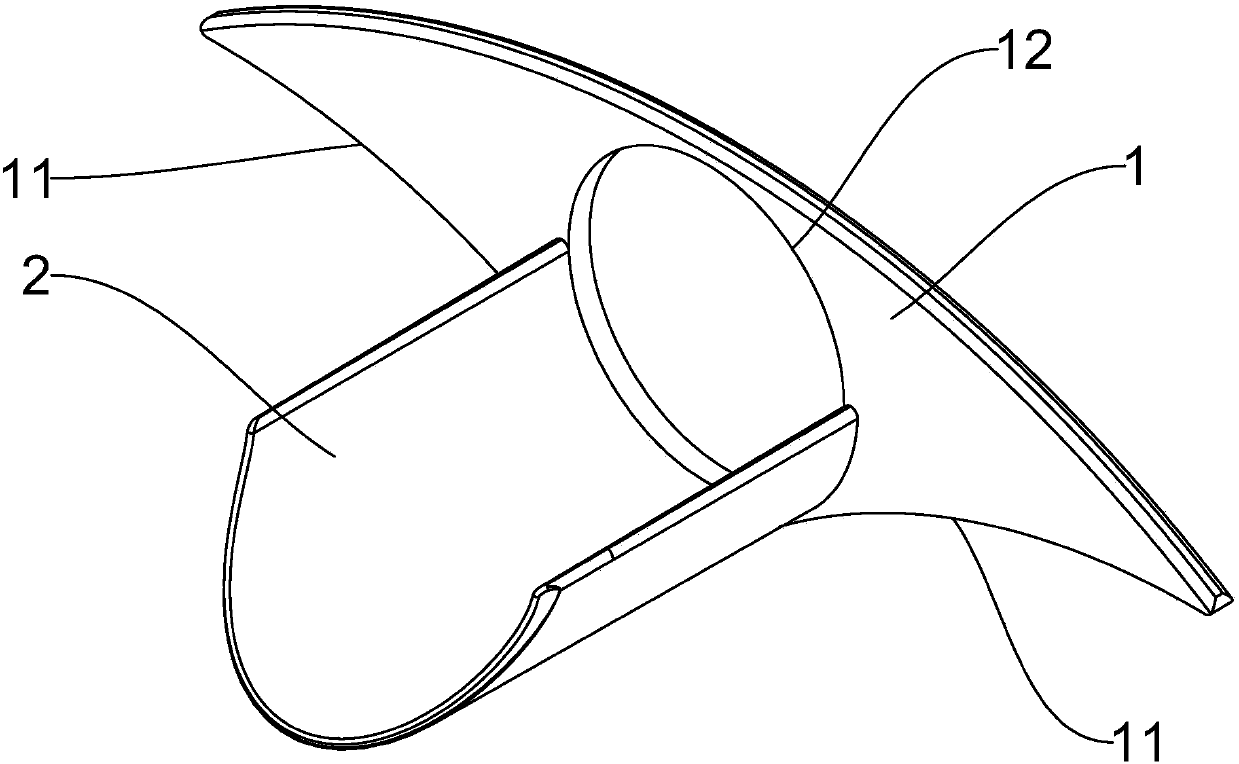

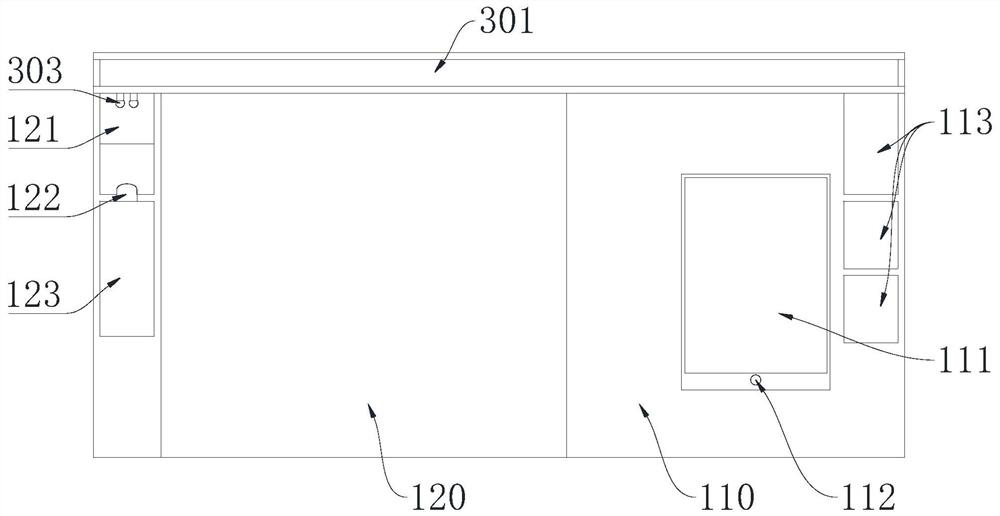

Wood-plastic paperweight provided with steel core

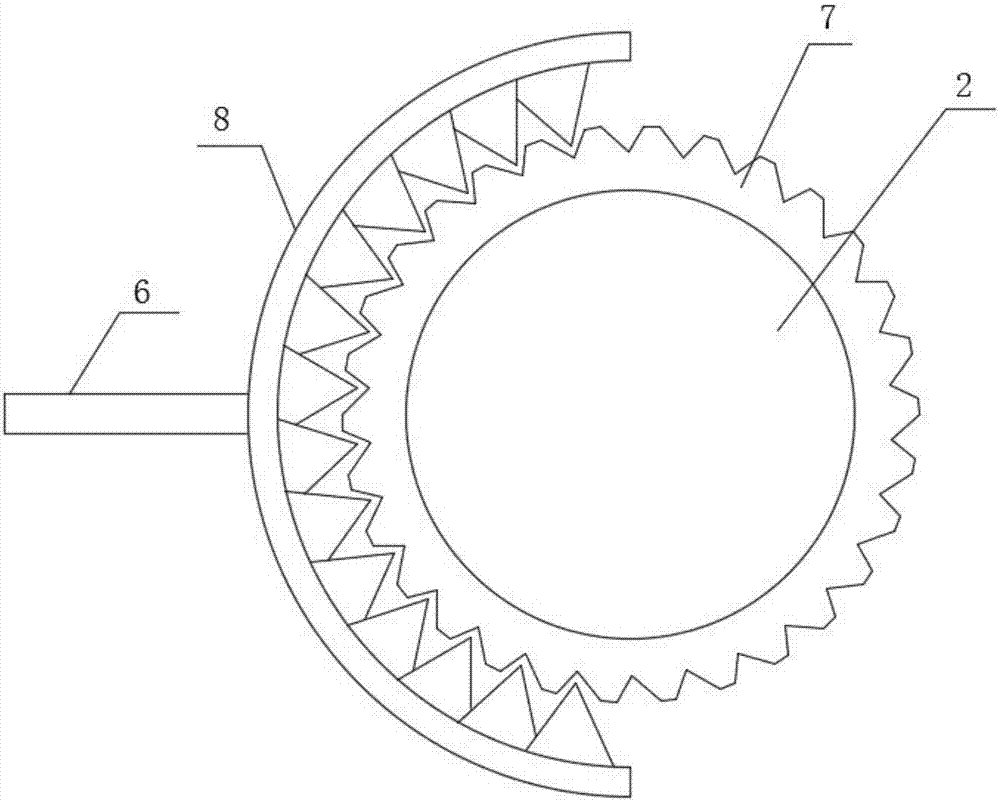

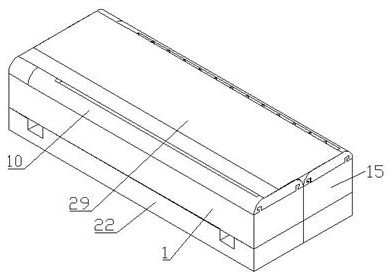

InactiveCN105398267AGood anti-corrosion and anti-shatter performanceEasy accessPaper-weightsPaper sheetSlip resistance

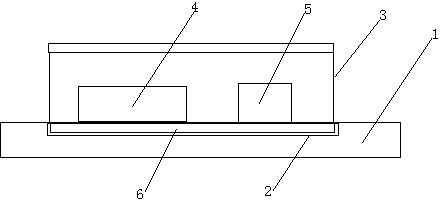

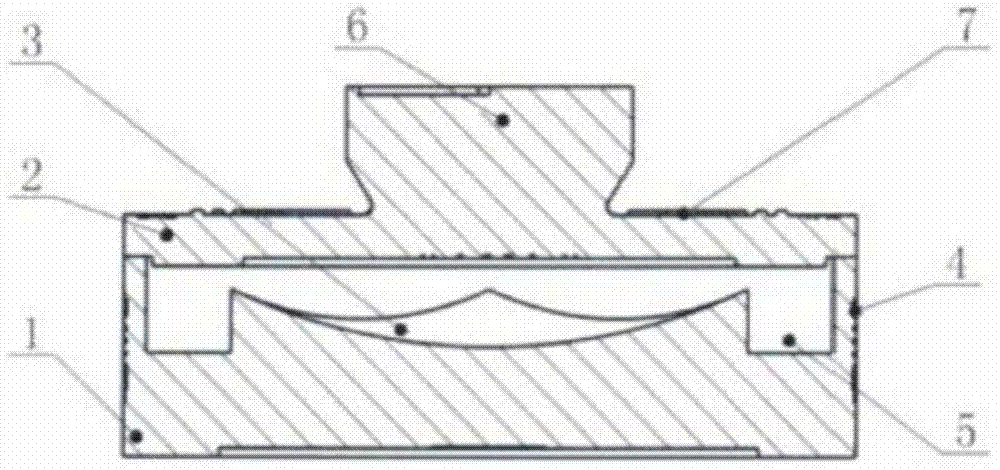

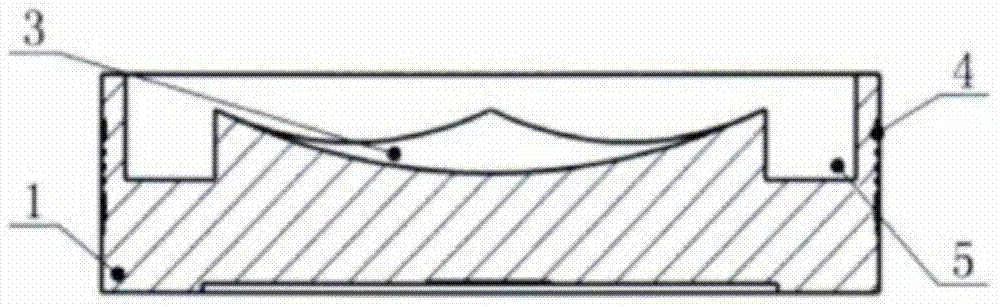

The invention discloses a wood-plastic paperweight provided with a steel core. The wood-plastic paperweight provided with the steel core comprises a pressing block (1). The wood-plastic paperweight provided with the steel core is characterized in that the pressing block (1) comprises the steel core (12) and a wood-plastic cladding layer (11) which is arranged on the outer surface of the co-extruded steel core (12); the upper surface and the lower surface of the pressing block (1) are each provided with a plurality of triangular teeth (111), grooves (112) are formed in the four corners of the pressing block (1) respectively, and arc-shaped grooves (113) are symmetrically formed in the left side face and the right side face of the pressing block (1); the steel core (12) can be flat steel or round steel or figured steel with a groove in the surface. The wood-plastic paperweight provided with the steel core is novel in structure, environmentally friendly, attractive, excellent in corrosion resistance, breakage resistance and slip resistance, low in cost and long in service life.

Owner:HUANGSHI ZHIYUN ELECTROMECHANICAL TECH INST

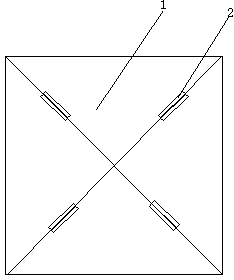

Split paperweight block

The invention relates to a split paperweight block which is characterized by consisting of four equilateral triangle bodies, wherein one connection magnet is arranged at each inner connection edge of each equilateral triangle body; the four equilateral triangle bodies are connected to form a rectangular body. The split paperweight block has the beneficial effects that the split paperweight block is firmly connected; the split paperweight block is firmly connected without being loosened when in use or not in use. Moreover, each sub connector is of a triangular shape and also can very stably press paper when in use singly.

Owner:方小玲

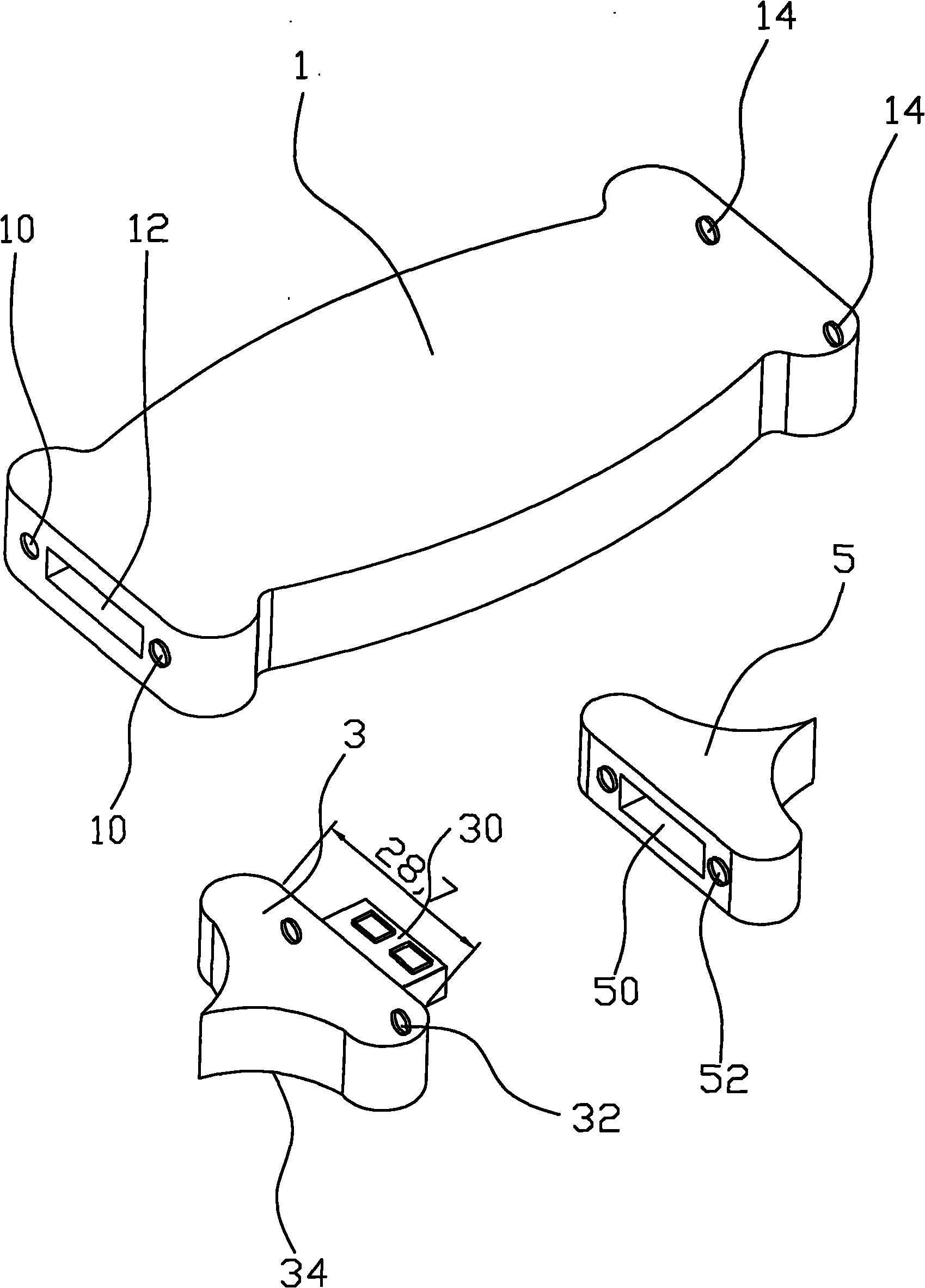

Multifunctional paperweight

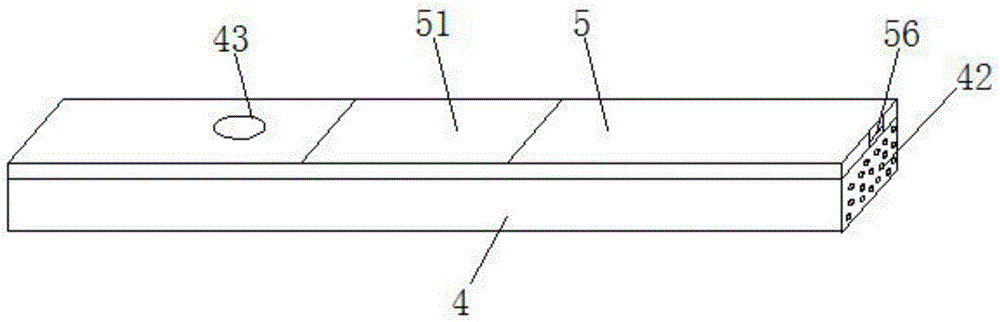

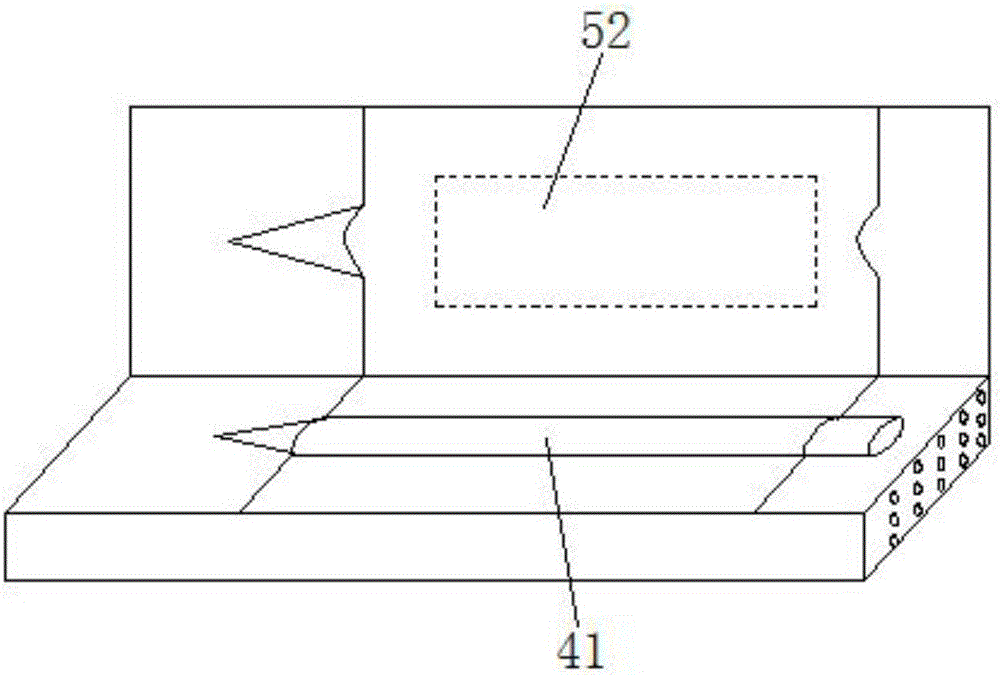

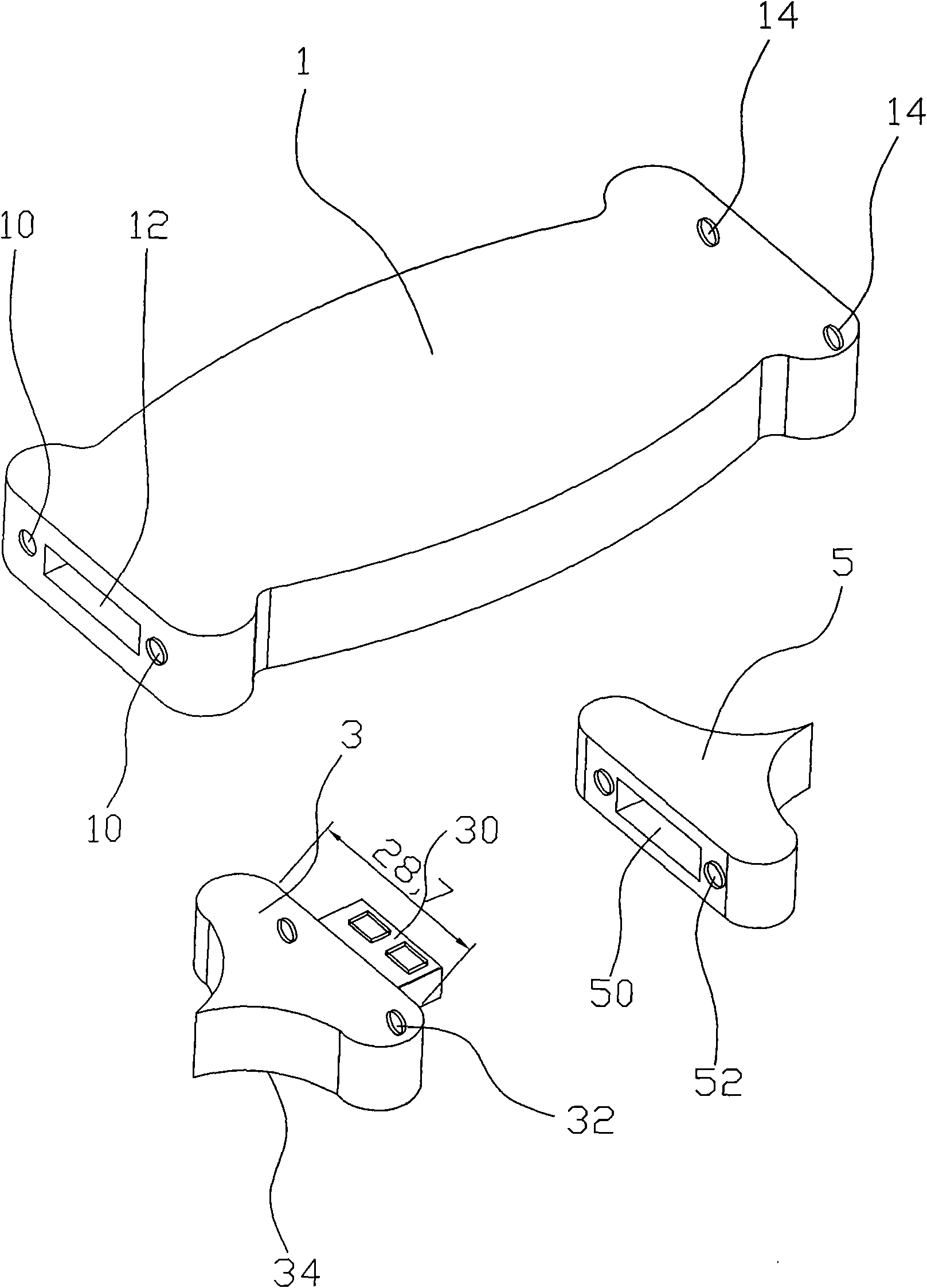

The invention discloses a multifunctional paperweight, which comprises a paperweight body. Two first magnetic blocks are arranged at the left end of the paperweight body; a first concave hole is formed on the paperweight body; a left paperweight head is arranged on the left side of the paperweight body and is provided with second magnetic blocks; the second magnetic blocks and the first magnetic blocks are arranged in a mode that opposites attract; a universal serial bus (USB) connector is arranged at the left paperweight head corresponding to the first concave hole; the USB connector is connected with a USB flash disk; the USB flash disk is arranged in the left paperweight head; third magnetic blocks 14 are arranged at the right end of the paperweight body; a right paperweight body is arranged on the right side of the paperweight body; fourth magnetic blocks are arranged on the right paperweight head; the fourth magnetic blocks and the third magnetic blocks are arranged in a mode that opposites attract; and a second concave hole is formed on the right paperweight head. The multifunctional paperweight is unique in style, the left and right paperweight heads at two ends of the paperweight body can be detached from the paperweight body, the USB flash disk on the left paperweight head can store electronic files, and the detached left and right paperweight heads can be combined to form a small paperweight.

Owner:李洁

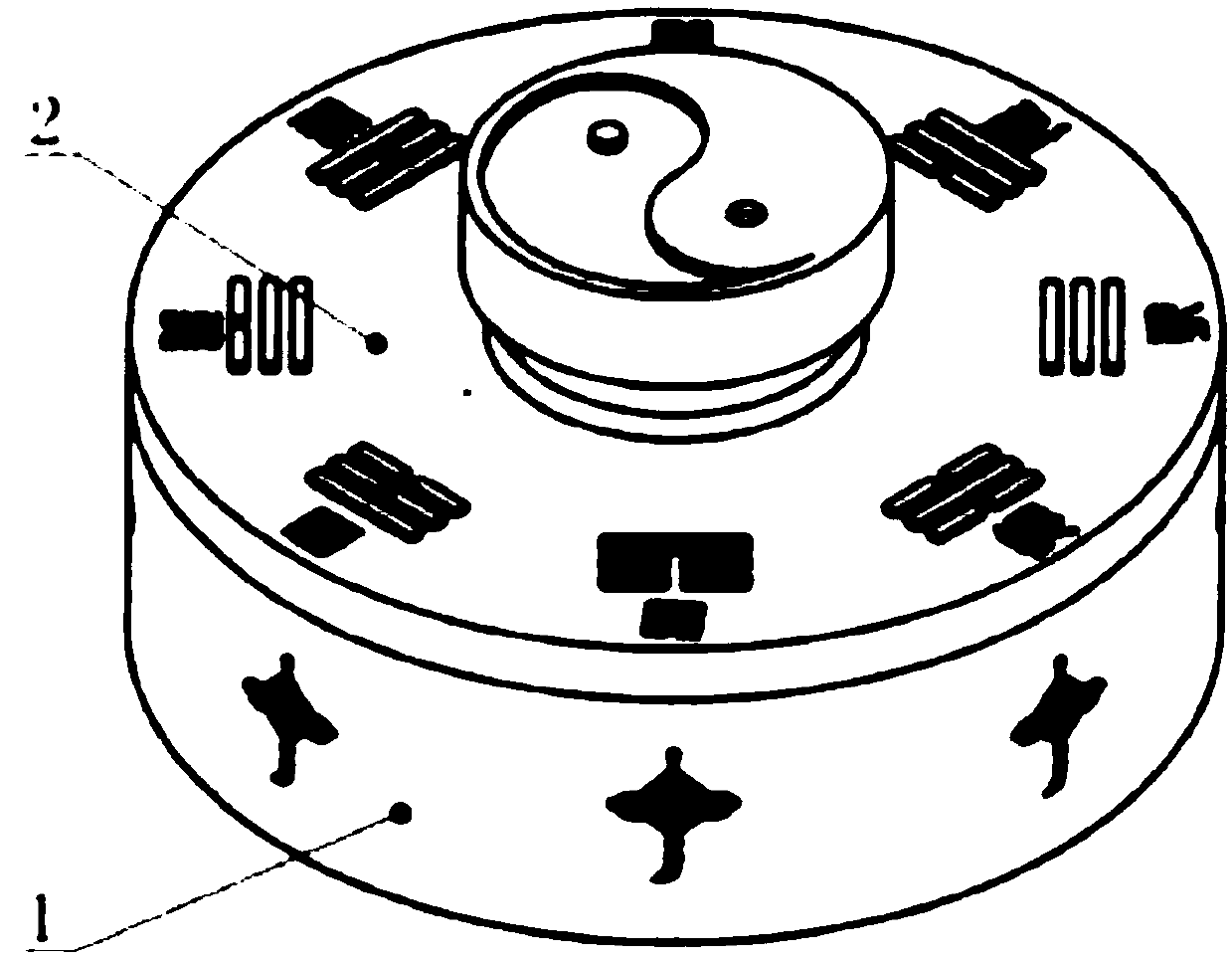

Ink slab

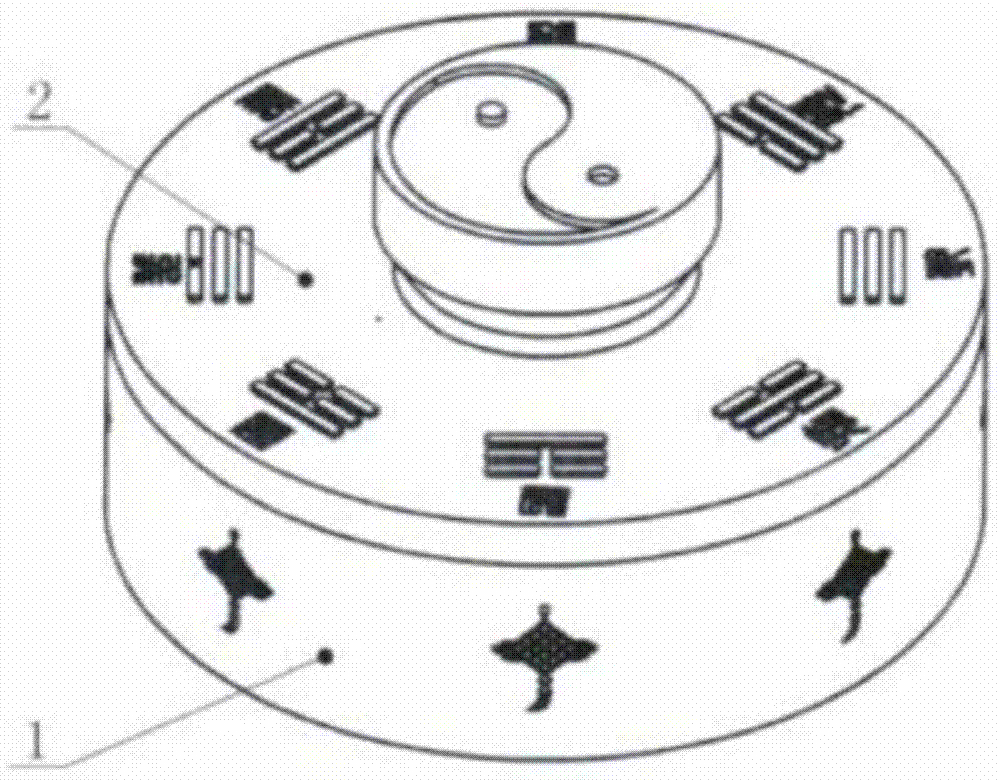

The invention discloses an ink slab. The ink slab comprises an ink slab body and an ink slab cover, wherein the ink slab body and the ink slab cover are made of ink stones; the ink slab body is cylindrical; an ink grinding space is defined in the middle of the ink slab body and in a square shape; the upper part of the ink grinding space is formed by enabling a spherical surface to be sunk downwards; a concave writing-brush washing groove is formed between the ink slab body wall and the ink grinding space; patterns are carved on the outer side of the ink slab body wall; the ink slab cover is an inverted T shape; patterns are carved at an ink slab cover handle and the top surface of an ink slab cover plate. In the using process, a user can fetch water, wet a writing brush, grind ink, accommodate the ink, dip in the ink, write, wash the writing brush, dip the writing brush in ink and the like within a certain range during the writing process in the ink slab disclosed by the invention; the whole process is coherent and smooth from beginning to end without stopping; the ink slab can provide good writing conditions for writers and creators to the largest extent; the inner-square and outer-circle structure of the ink slab reflects the essence of culture in China and enriches the traditional culture connotation of the ink slab.

Owner:宁波昱骁文化创意有限公司

Paper-weight knife

InactiveCN101417430ASimple structureLow costPaper-weightsMetal working apparatusFlutePulp and paper industry

The invention discloses a paperweight knife, which consists of a blade, a cutting head, a flute and paperweight and is characterized in that the cutting head is arranged into the flute of the paperweight and connected with the blade; the angle between the cutting head and the blade is 90 degrees. When in use, the cutting head is pulled out of the paperweight flute and then the blade is pulled down in the angle of 90 degrees, and then the knife can be used for cutting the paper and the paper becomes paperweight after the recovery. The knife has the advantages of simpler structure, lower cost and stronger practicality.

Owner:卢心东

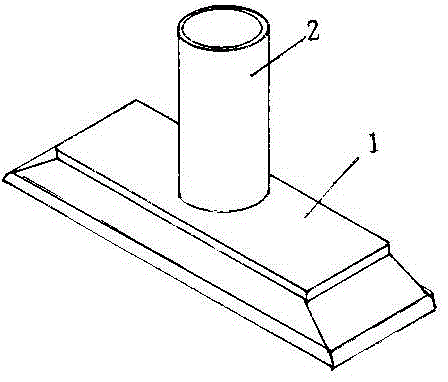

Paperweight provided with pen holding pipe

The invention provides a paperweight provided with a pen holding pipe. The pen holding pipe is arranged on a paperweight bock body for paperweight using. During study and work, when pages need to be pressed by a paperweight block so as to be prevented from being blown by wind or being naturally folded, a required pen can be inserted in a pen holder; by combining the pen holder and the paperweight block into a whole, a product can be beautified, and the use functions of the paperweight block are enriched.

Owner:XIANGYANG CITY XIANGZHOU DISTRICT NO 4 HIGH SCHOOL

Seat of a compound draft-paper rack

InactiveUS20070181512A1Save spaceStable supportCard-filingWriting connectorsPaper documentDocument preparation

Owner:TING SHAO CHIEH

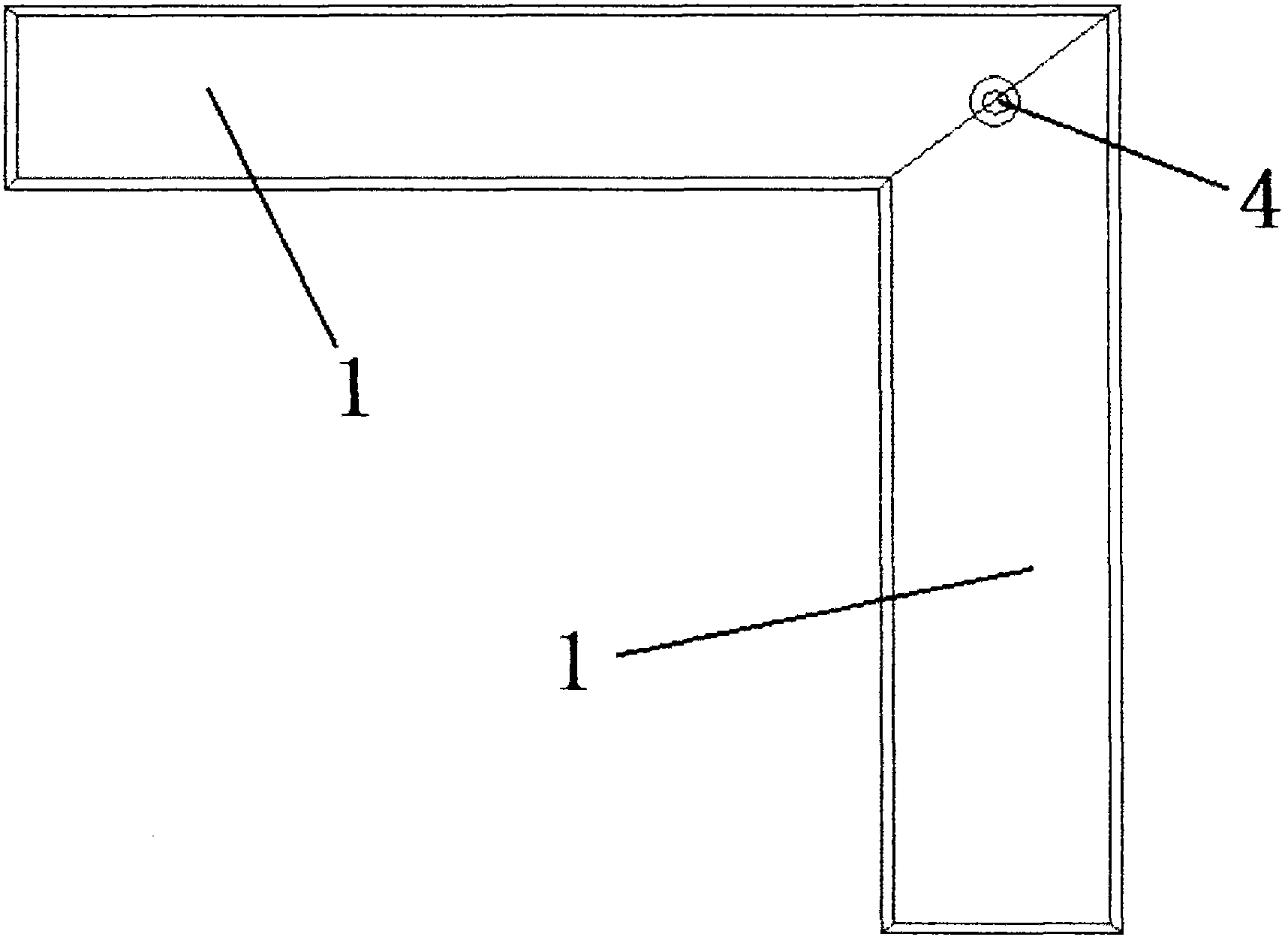

Folding paperweight

The invention provides a folding paperweight which comprises a first paperweight body, a second paperweight body and a connecting device arranged between the first paperweight body and the second paperweight body. The folding paperweight is characterized in that the connecting device is an arc-shaped connecting block; two ends of the connecting blocks are respectively articulated at the lower end of the first paperweight body and the upper end of the second paperweight body; in order to ensure the connection steadiness, the connecting block is further arranged on the other sides of the first paperweight body and the second paperweight body. The folding paperweight has the beneficial effects that the paperweight can be folded and unfolded freely so as to adapt to a writing paperweight function of a large-area painting and calligraphy book or a small-area painting and calligraphy book, and does not occupy a painting and calligraphy place.

Owner:左颖

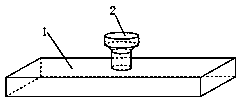

Paperweight with handle

The invention discloses a paperweight with a handle. The paperweight comprises a paperweight body and the handle. The paperweight body is rectangular. The handle is arranged in the middle of the paperweight body. The paperweight has the beneficial effects of being simple in structure and convenient and comfortable to use.

Owner:冯先菊

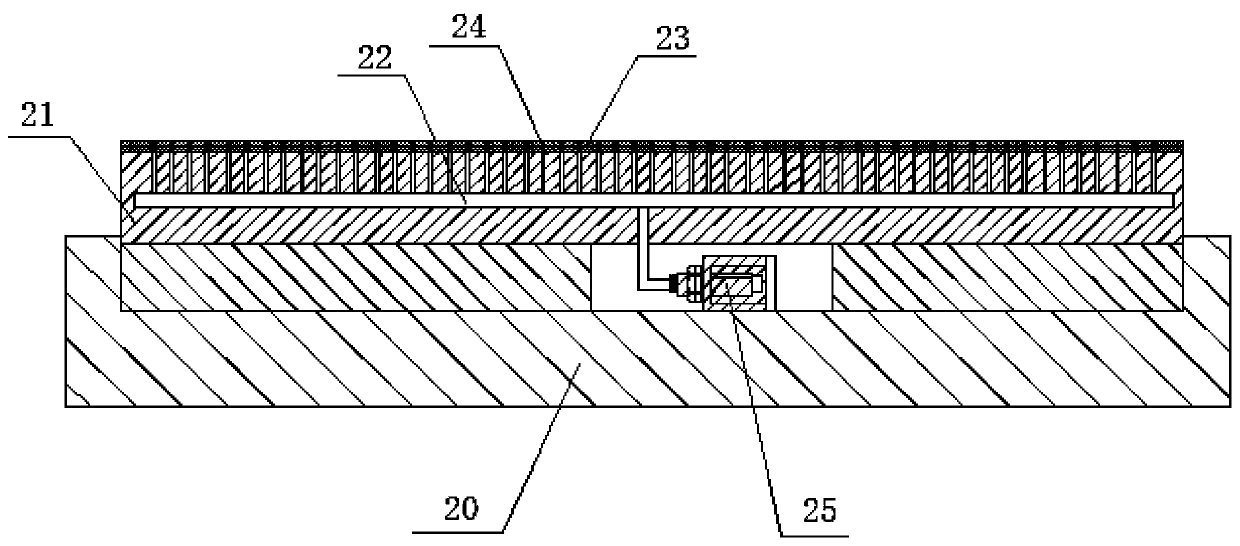

Paperweight with eye-protection panel light

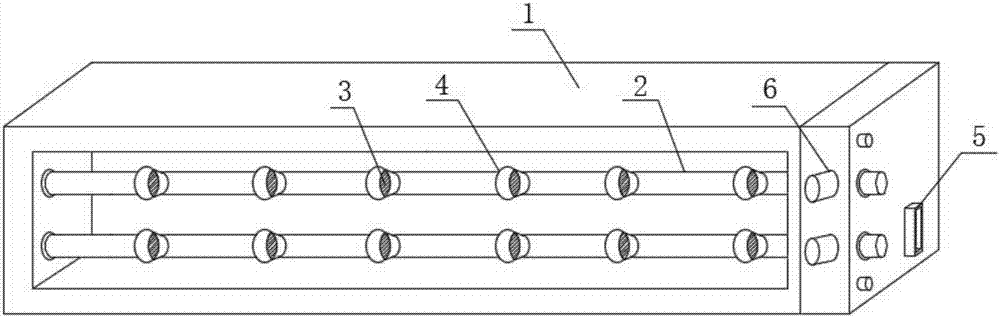

PendingCN106945441APrevent creative influenceBroad market shareLighting support devicesElectric circuit arrangementsProtecting eyeEffect light

The invention discloses a paperweight with an eye-protection panel light. The paperweight comprises a paperweight body, mounting rods and LED lamp caps. One side of the interior of the paperweight body is of a hollow structure. One ends of the mounting rods penetrate through the side wall of one end of the paperweight body and are connected with the inner side wall of the other end of the paperweight body. Clamping sleeves are fixedly connected to the mounting rods in a sleeving mode. Clamping ports are formed in the outer sides of the clamping sleeves. Clamping blocks matched with the clamping ports re arranged on the other sides of positioning plates. The vertical section of each positioning plate is in a semicircle shape. The clamping blocks are inserted and connected into the clamping ports. The demand of creation for lights can be met, the situation that lights are too strong and stimulate eyes of users, and consequently creation is influenced can be prevented, and the number of the turned-on LED lamp caps can be chosen according to the actual surrounding conditions; and an AA battery is used for providing electricity, repeated charging and using can be achieved, energy is saved, the environment is protected, and the paperweight has a high market share.

Owner:中山市德润名高信息技术有限公司

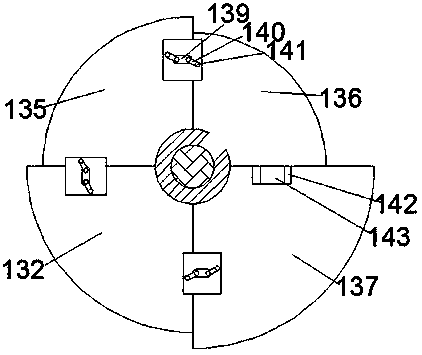

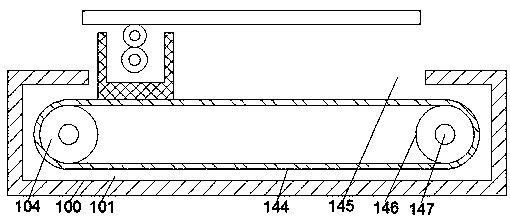

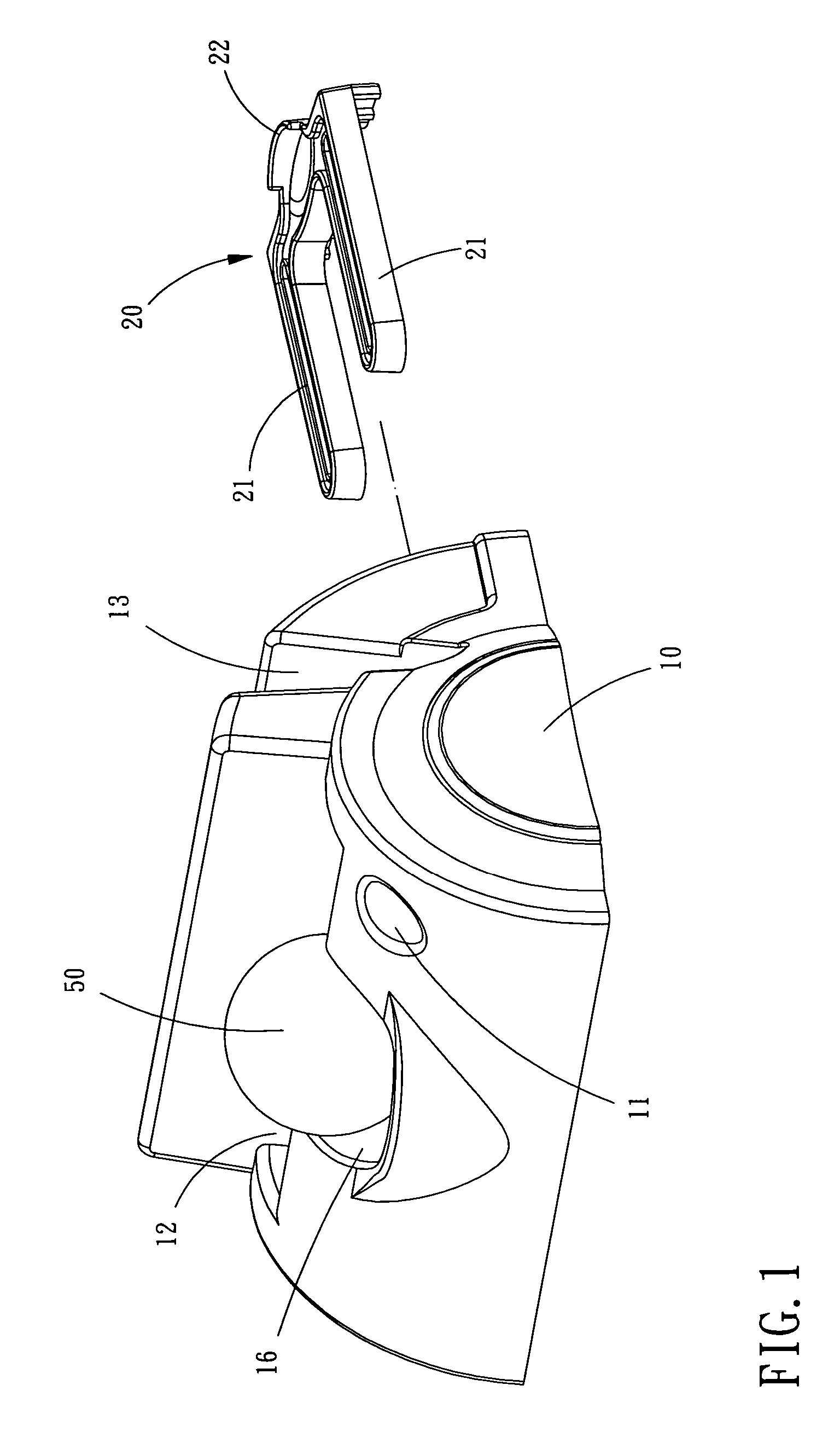

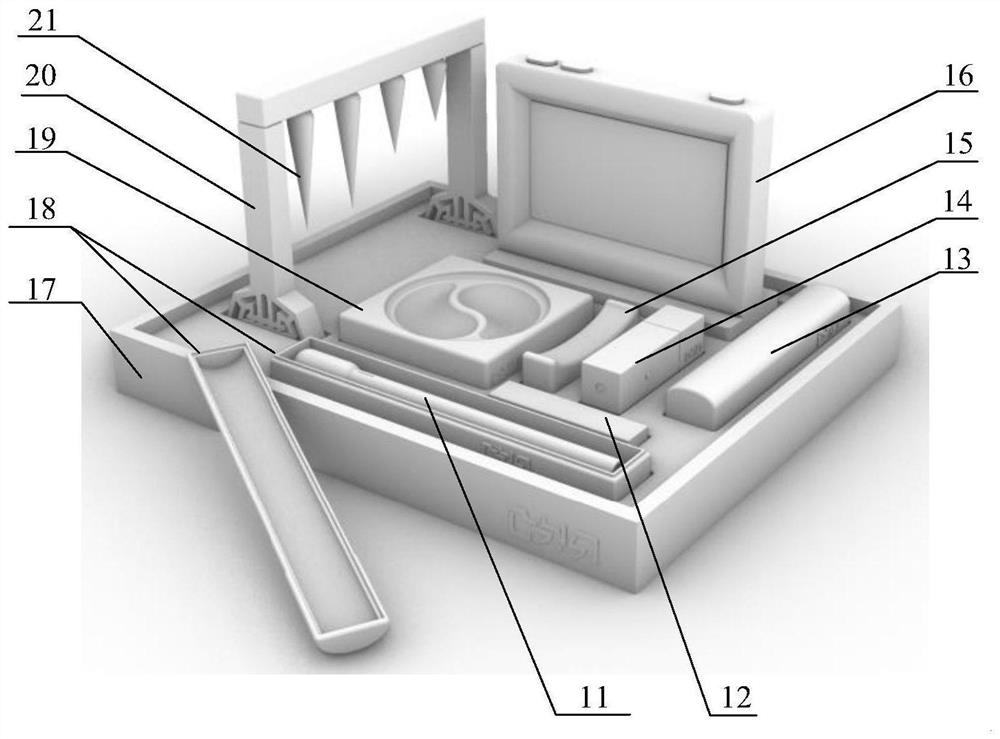

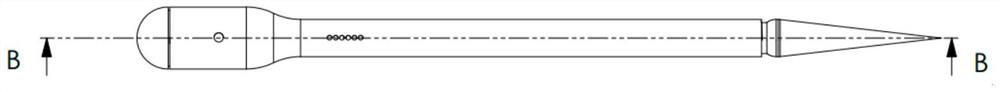

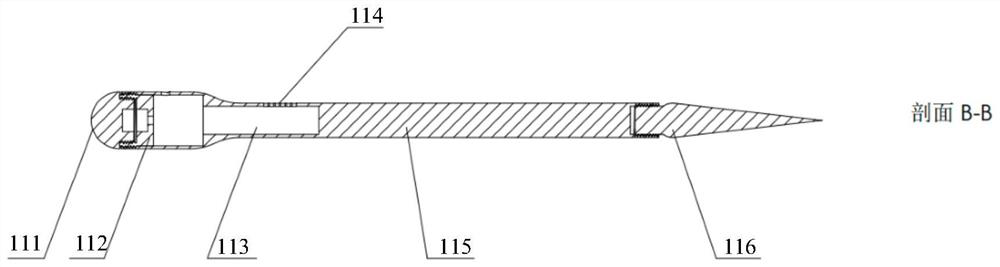

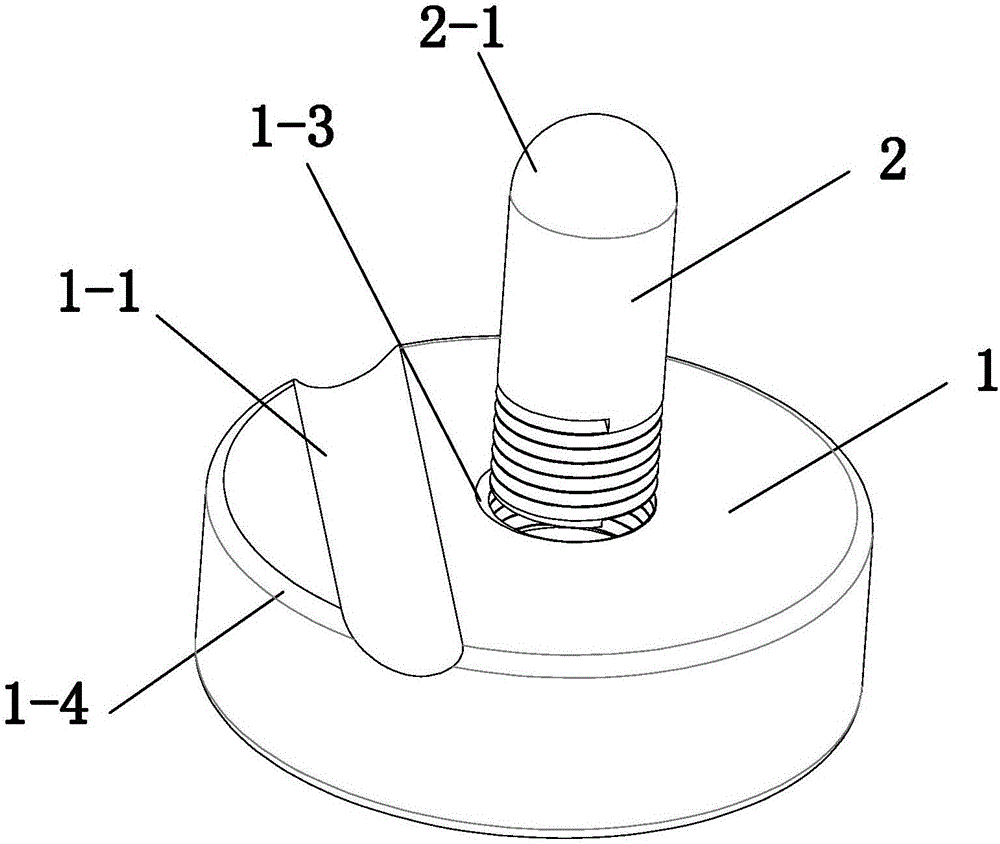

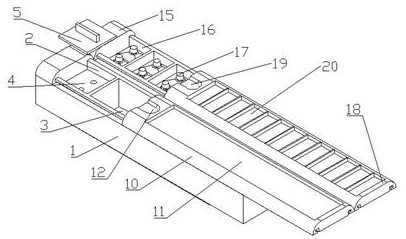

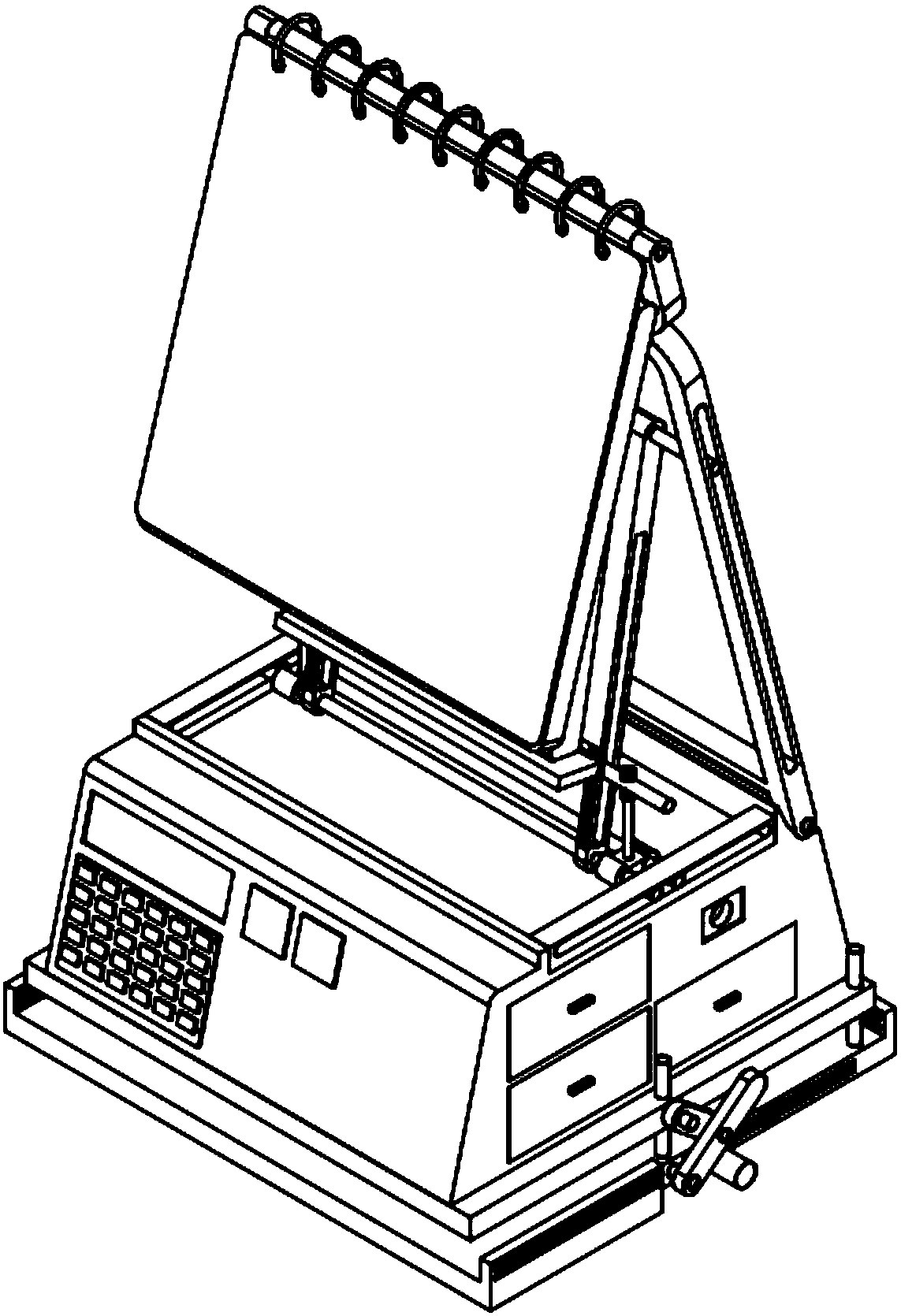

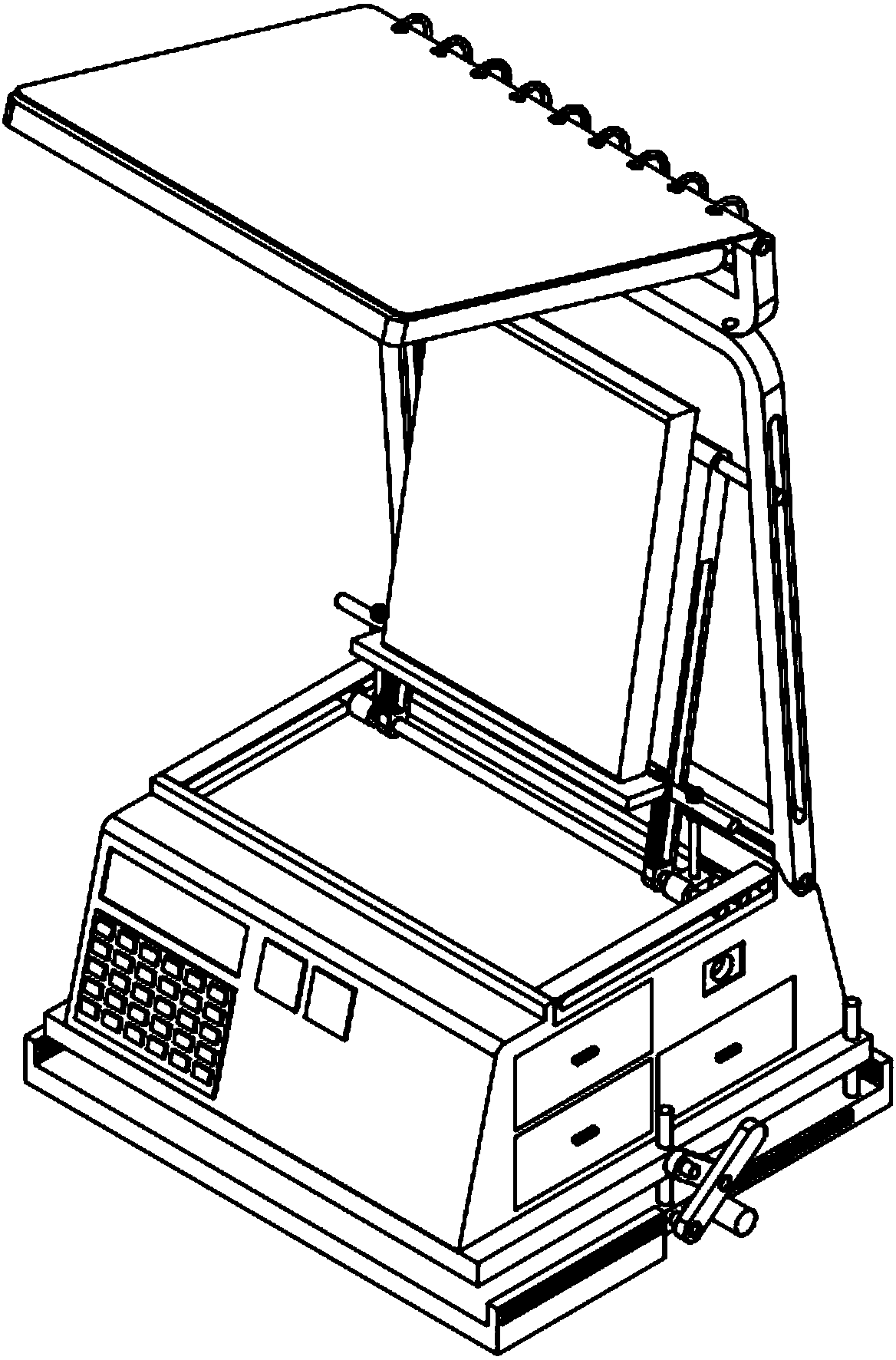

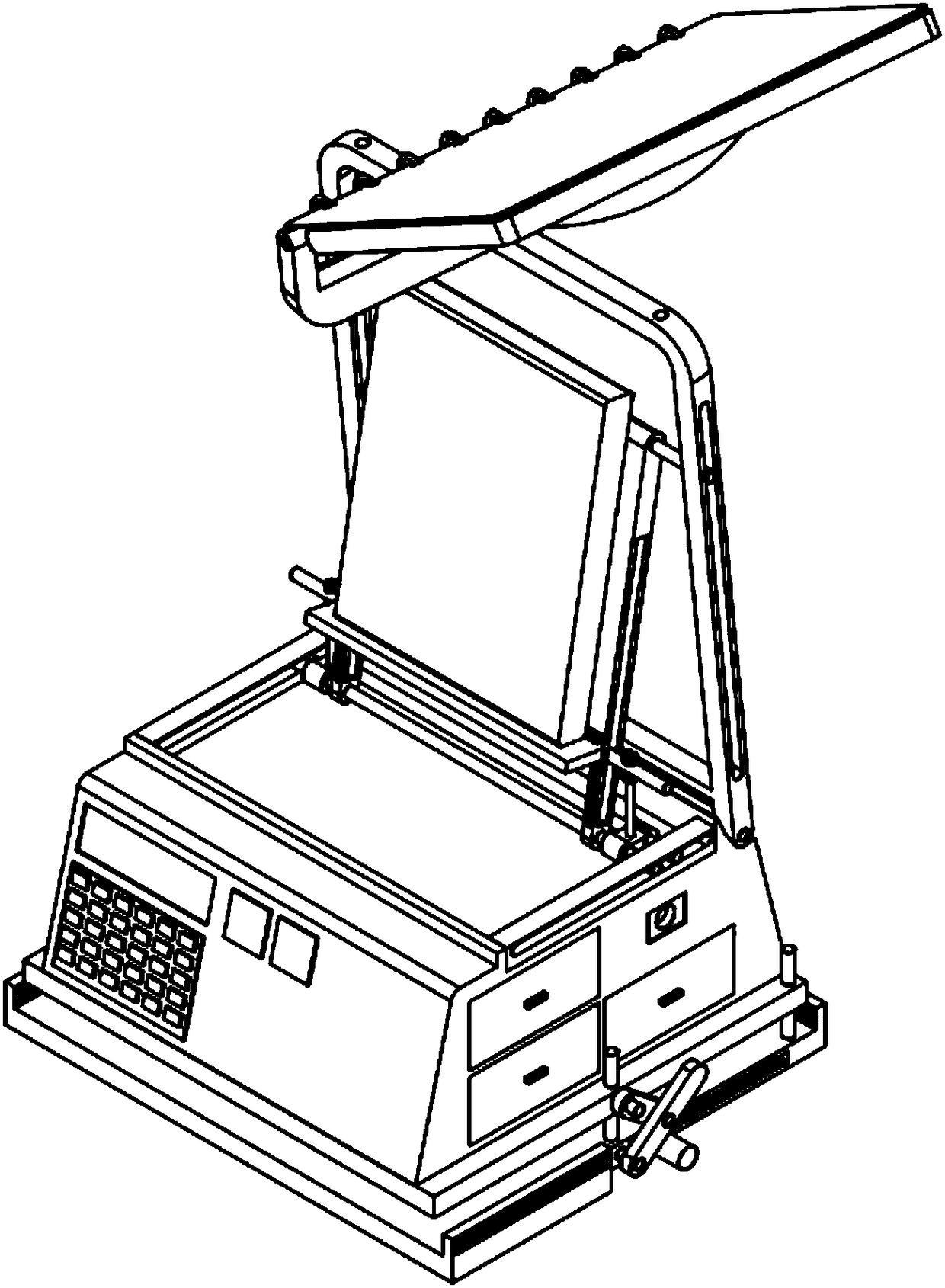

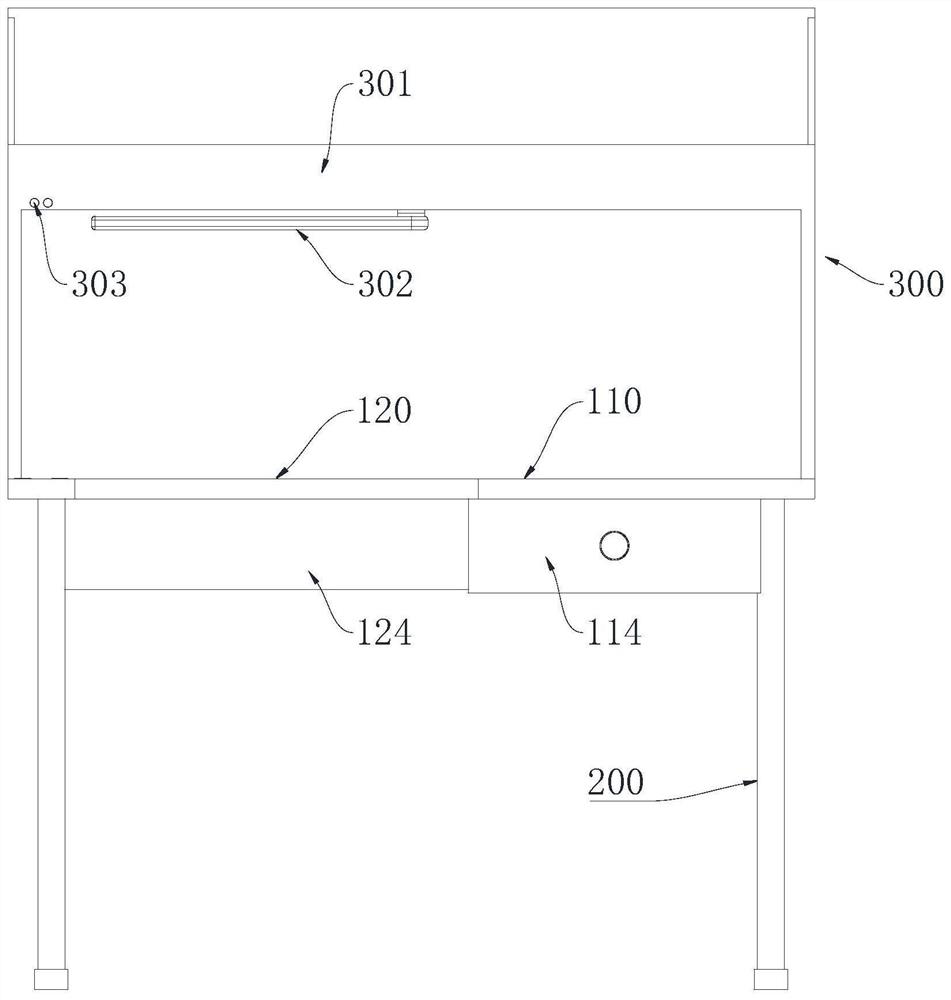

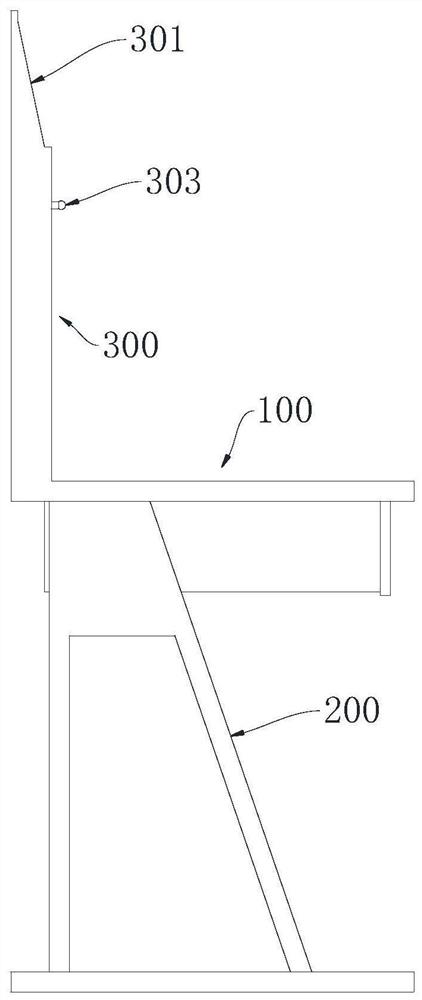

Intelligent writing brush writing and evaluation system and application method

PendingCN114801552AFind and correct problems with incorrect pen holding postureAdd funWriting implementsPaper-weightsEvaluation resultEngineering

The invention discloses an intelligent writing brush writing and evaluation system and an application method.The intelligent writing brush writing and evaluation system comprises an intelligent writing device, an intelligent writing brush subsystem and a writing evaluation system, and the intelligent writing device can detect the pen holding posture of a beginner and conduct visual prompt according to the detection result by installing a posture detection module; the writing evaluation system uses a visual method to carry out stroke comparison on the picture contours of the standard fonts and the fonts of the beginner, and gives out the writing stroke evaluation of the beginner according to the comparison result. By means of the intelligent writing brush, the problem that the writing brush holding posture is not correct can be found and corrected in time, meanwhile, through the paperweight system and the writing evaluation display system, the font and the stroke of the written font can be compared with the standard font, and the evaluation result is displayed. And the interestingness of the calligraphy beginner on calligraphy practice is improved.

Owner:JIANGSU UNIV

Multifunctional paperweight

The invention provides a multifunctional paperweight. The multifunctional paperweight comprises a paperweight body of a cylindrical structure. An object holding groove is formed in the top of the paperweight body, and a mirror surface capable of conducting imaging serves as the bottom surface of the paperweight body. A smooth chamfer is arranged on the outline edge of the paperweight body. The object holding groove is arranged close to the edge of the paperweight body, a fixing hole is formed in the other side, and a supporting rod used for fixing an object inside the object holding groove is placed inside the fixing hole. According to the paperweight body, the functions of a storage rack, a hand playing piece, a mirror and the like are added to a common paperweight, and the multifunctionality and practicality of the paperweight can be effectively improved. The multifunctional paperweight is made from large-density and high-hardness metal materials, achieves line coherence, is small and exquisite and has certain ornamental and collection value.

Owner:GUILIN LYUYUAN TECH CO LTD

Inkstone

The invention discloses an inkstone. The inkstone comprises an inkstone body and an inkstone cover; the inkstone body and the inkstone cover are made of inkstone; the inkstone body is a cylindrical; an inkstone hall is arranged at the middle part of the inkstone body; the inkstone hall is square; the upper part of the inkstone hall is concave with a spherical surface; a concave pen washing grooveis formed between the wall of the inkstone body and the inkstone hall; patterns are carved on the outer side of the wall of the inkstone body; the inkstone cover is inverted T-shaped; and patterns arecarved on the top surface of an inkstone cover handle and an inkstone cover plate. In a writing process, action links such as fetching water, moistening a pen, grinding ink, filling ink, dipping ink,writing, washing the pen and pulling the pen are completed within a certain range, the whole process is coherent, smooth and integrated, and good writing conditions are provided for a writer and a creator to the greatest extent, and meanwhile, an inner-square and outer-circular interior structure of the inkstone body embodies the essence of Chinese culture and enriches the traditional cultural connotation of the inkstone.

Owner:SHAOXING JINCHEN BIOLOGICAL TECH CO LTD

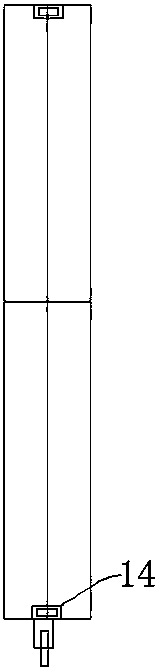

Multifunctional paper weight for art painting

InactiveCN112519462AMeet diversityEasy to carryWriting implementsPaper-weightsMechanical engineeringIndustrial engineering

The invention discloses a multifunctional paper weight for art painting. The multifunctional paper weight comprises a first paper weight, a first storage bin, a second storage bin, an ink block, a handle, a first writing brush holder, a second writing brush holder, a writing brush head, a suspension lug, a first upper cover, a grinding groove, a first push-pull groove, a second paper weight part and an auxiliary part, the vertical first storage bin and the vertical second storage bin are arranged in the first paper weight, the vertical ink block is arranged in the first storage bin, and the vertical handle is connected to the top end of the ink block in an inserted mode. An original paper pressing function is innovated and modified, the multifunctional paper pressing device can be used ona flat plane, a flat plane can be provided by itself, and therefore the requirement for diversity of the sketching environment can be met, the multifunctional paper pressing device has the storage function, writing brushes, pigments, ink blocks and other stationery can be stored, and meanwhile the multifunctional paper pressing device is convenient to use and high in practicability. and meanwhilecarrying of an user is facilitated, and immediate creation during sketching of the user is more convenient.

Owner:王龙龙

Multifunctional table lamp

ActiveCN108458271AAchieve strong and weak changesSpatial adjustmentLighting support devicesElectric circuit arrangementsLight flashesEngineering

The invention discloses a multifunctional table lamp. The lamp comprises a lamp base seat system, a bottom plate lifting system and a bookshelf system. The multifunctional table lamp has the advantages that the bookshelf system is used for connecting an axis C and an axis D with a track A through a connecting piece, and screw rods and nuts are arranged on the connecting piece; the screw rods and the nuts can control the height of an axis B so as to control the inclination angle of a bookshelf, the connecting piece can be kept in a horizontal position due to combined action of the axis C and the axis D on the connecting piece, so that the connecting piece can be kept stable when the connecting piece works, and a user can adjust the state of the connecting piece to the most appropriate stateconveniently; a bottom plate lifting system drives connecting rods to rotate by adjusting the position of a gear part, so that the distance between an upper bottom plate and a lower bottom plate is adjusted, the function of paperweight can be achieved, and meanwhile, the overall height of the table lamp can be adjusted; and the lamp base seat system comprises a light flash alarm clock button, thealarm clock function can be set, the light function of the table lamp is combined, so that the intensity of light can be changed, a user can be reminded, and the disturbance cannot be caused.

Owner:浙江龙腾电工器材有限公司

Portable paperweight

The invention discloses a portable paperweight. The portable paperweight includes a triangular plate which is of an isosceles triangle structure of which the vertex is arranged downwards; the portablepaperweight further includes a balancing weight; the two waists of the isosceles triangle structure of the triangular plate are arcs bent inwards, and the balancing weight is connected with one sideface of the triangular plate. The portable paperweight has the advantages of being small and exquisite in appearance and size, relatively low in dead weight, relatively low in production cost and suitable for being taken along.

Owner:丁茂明

Multifunctional student desk

PendingCN113729395AAvoid contaminationAvoid pollutionBed-tablesPaper-weightsSoftware engineeringLiquid crystal

The invention discloses a multifunctional student desk which comprises a desk top, a supporting part used for supporting the desk top is arranged below the desk top, a bookshelf is arranged above the desk top, the desk top is divided into a fixed desk top and a turnover desk plate, and one wide face of the turnover desk plate is arranged to be a felt surface. A liquid crystal writing board, a sunken stationery storage grid and a sunken inkstone are embedded in the fixed desktop; a pen rack is arranged on the bookshelf, and the pen rack is positioned right above the inkstone. The desk top is divided into the fixed desk top and the turnover desk plate, and the turnover desk plate comprises the felt surface, so that quick conversion between a calligraphy writing scene and a hard-tipped writing scene is facilitated. Common tools for writing brush practice are ingeniously integrated into the desk, so that space is saved, desktop management is facilitated, and the desktop can be kept clean and tidy. Through the sinking type design and the embedded type design, the desktop is flat, transparent and free of blocking, and no obstacle is caused to students in the reading or homework process.

Owner:杨岑瑀

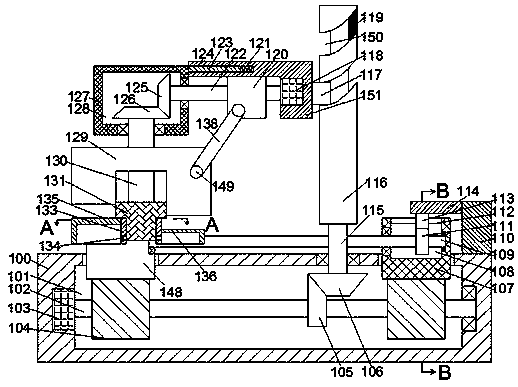

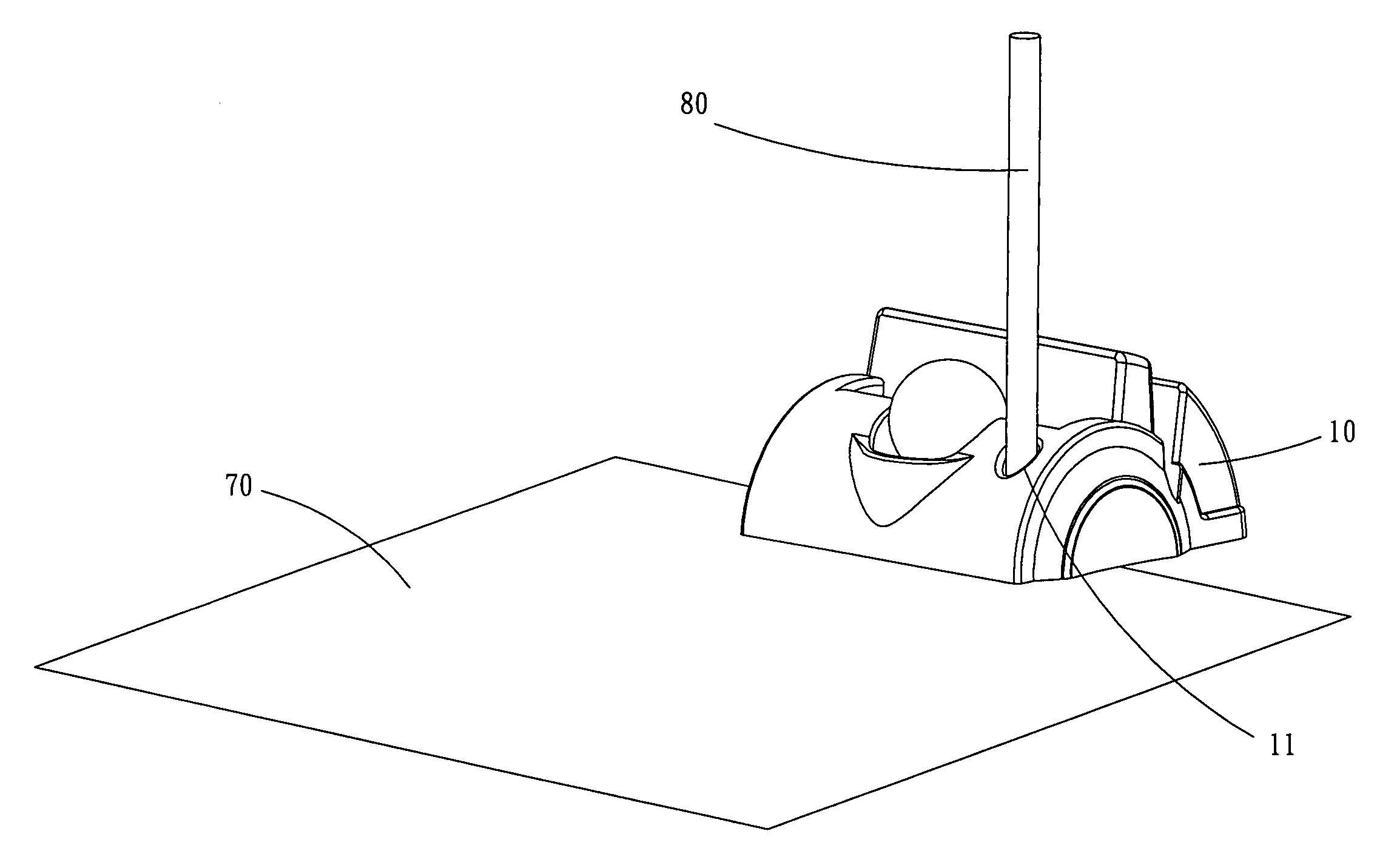

Multifunctional device for Chinese characters calligraphy

InactiveCN109703253AFixed issues that are not well resolvedMeet the use requirementsPaper-weightsInk standsChinese charactersEngineering

The invention discloses a multifunctional device for Chinese characters calligraphy. The multifunctional device for Chinese characters calligraphy comprises bottom moving rollers, a pen point dippingtable, a device moving handle and an ink discharging valve, wherein roller fixing supports are arranged above the bottom moving rollers; the device moving handle is connected above fixed magnet blocks; a device folding port is formed under the device moving handle; a paper placement tank is arranged under the device folding port; a brush pen drying device communicates to the lower part of the paper placement tank; the ink discharging valve is arranged above the brush pen drying device; an ink discharging pipe is arranged under the ink discharging valve; foldable fixed fasteners are arranged onthe back part of a device body; and a hand-pushing handrail is arranged under the foldable fixed fasteners. The multifunctional device for Chinese characters calligraphy has the beneficial effects that paper is fixed by adopting magnets, so that the problem that the paper is too big to fix is solved; and meanwhile, the device can be folded, so that the transportation volume of the device is reduced, and the use requirement of a calligraphy enthusiast is met.

Owner:惠州市惠阳翠意文化传播有限公司

Anti-microbial plastic composition and washing machine comprising the parts manufactured by using the same

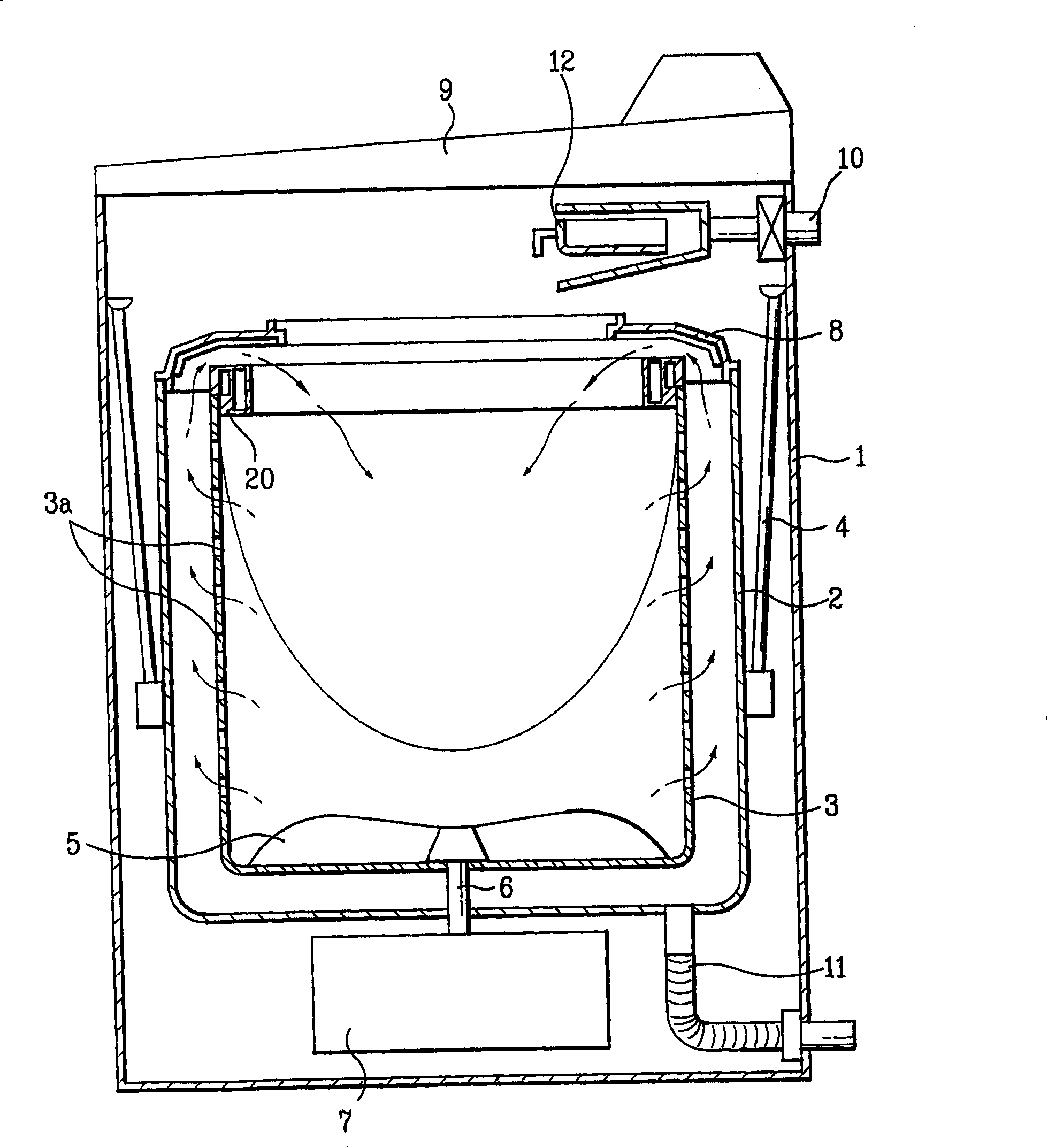

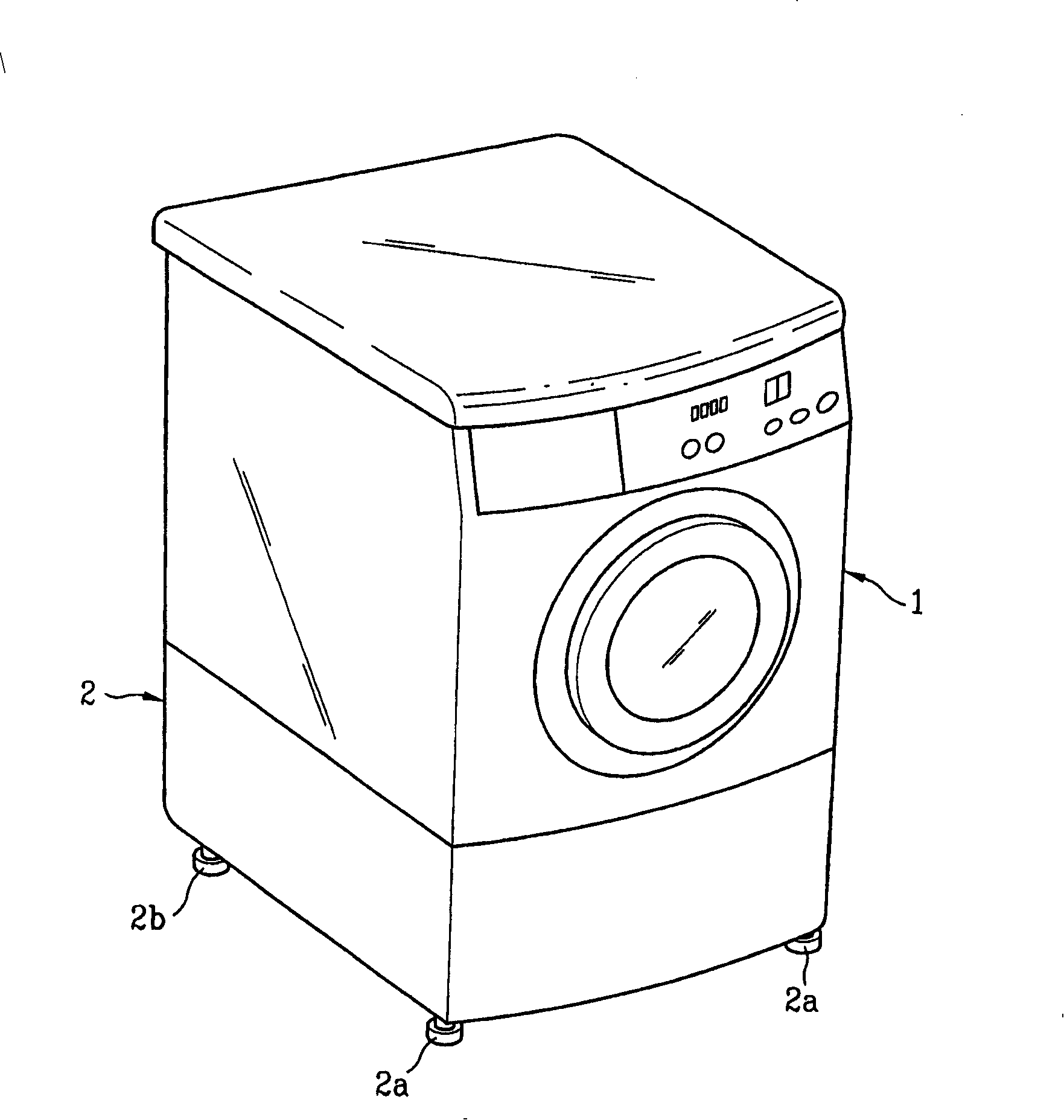

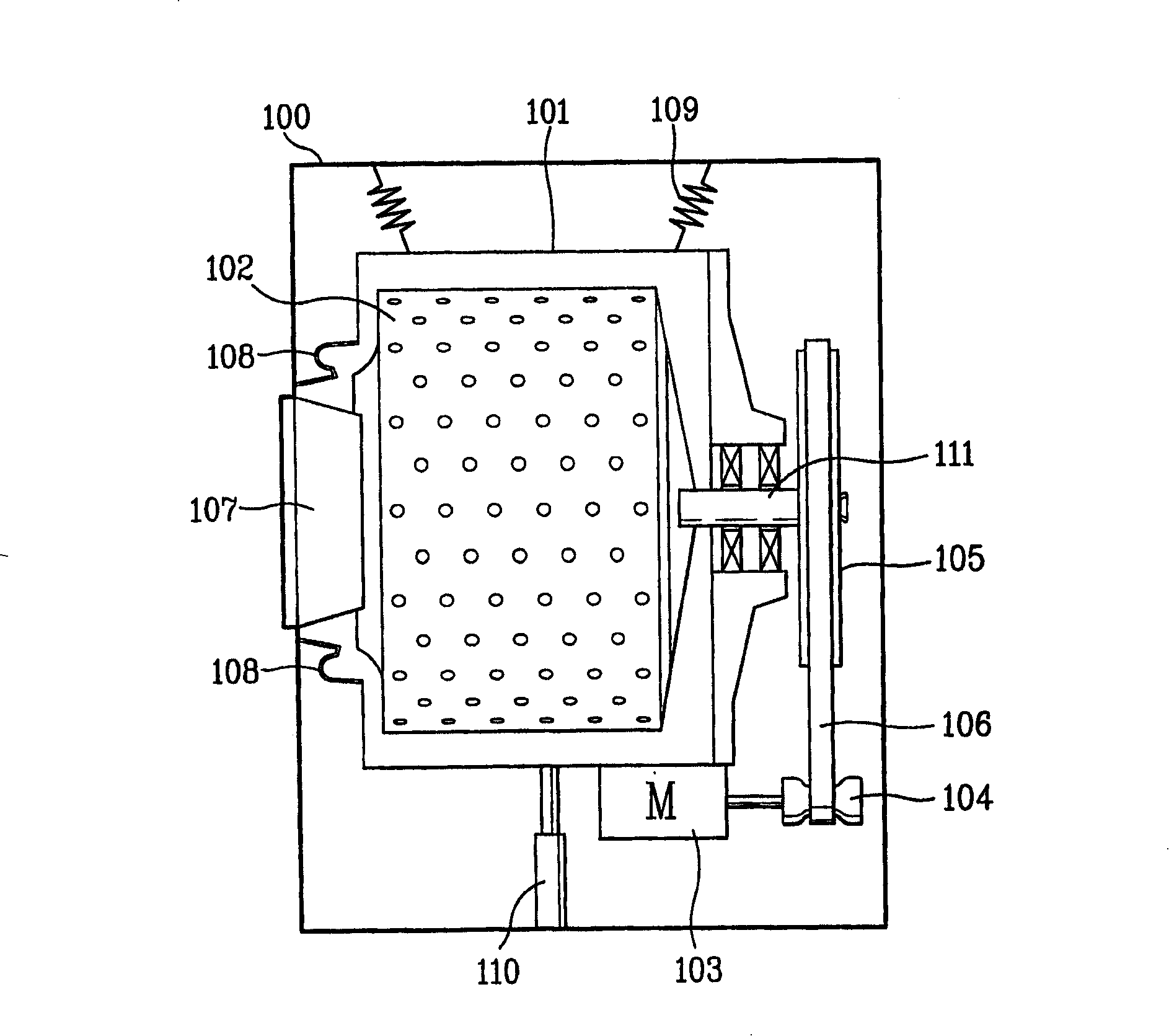

InactiveCN100404607CAvoid it happening againAvoid pollutionBiocideSpecial ornamental structuresInorganic compoundEngineering

Owner:LG ELECTRONICS INC

Paper pressing device

The invention discloses a paper pressing device. The paper pressing device comprises a machine body and a first cavity formed in the machine body, wherein left-right symmetrical first sliding groovesare formed in the upper end of the machine body in a communicating mode; a first transmission shaft positioned between the first sliding grooves and extending up and down is rotatably and cooperatively connected to the inner wall of the top end of the first cavity; a first bevel gear is arranged at the tail end of the bottom end of the first transmission shaft; and a track barrel positioned on theupper end face of the machine body is fixedly connected to the top end of the first transmission shaft; the track barrel is circumferentially provided with a track groove in a surrounding mode, a limiting block is fixedly connected to the tail end of the upper end of the track groove, and a guide slide block is connected to the track groove in an abutting mode; and an L-shaped power block is fixedly connected to the other end of the guide slide block, a second sliding groove with an opening to the left is formed in the left end face of the L-shaped power block, and an extension rod is connected in the second sliding groove in a sliding fit mode. According to the paper pressing device, the linkage is high, the manual leveling action simulated by a mechanical rod is efficient and sanitary,and multi-directional pressing points ensures that offset does not occur.

Owner:福州安辛达环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com