Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about "Packaging poultry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

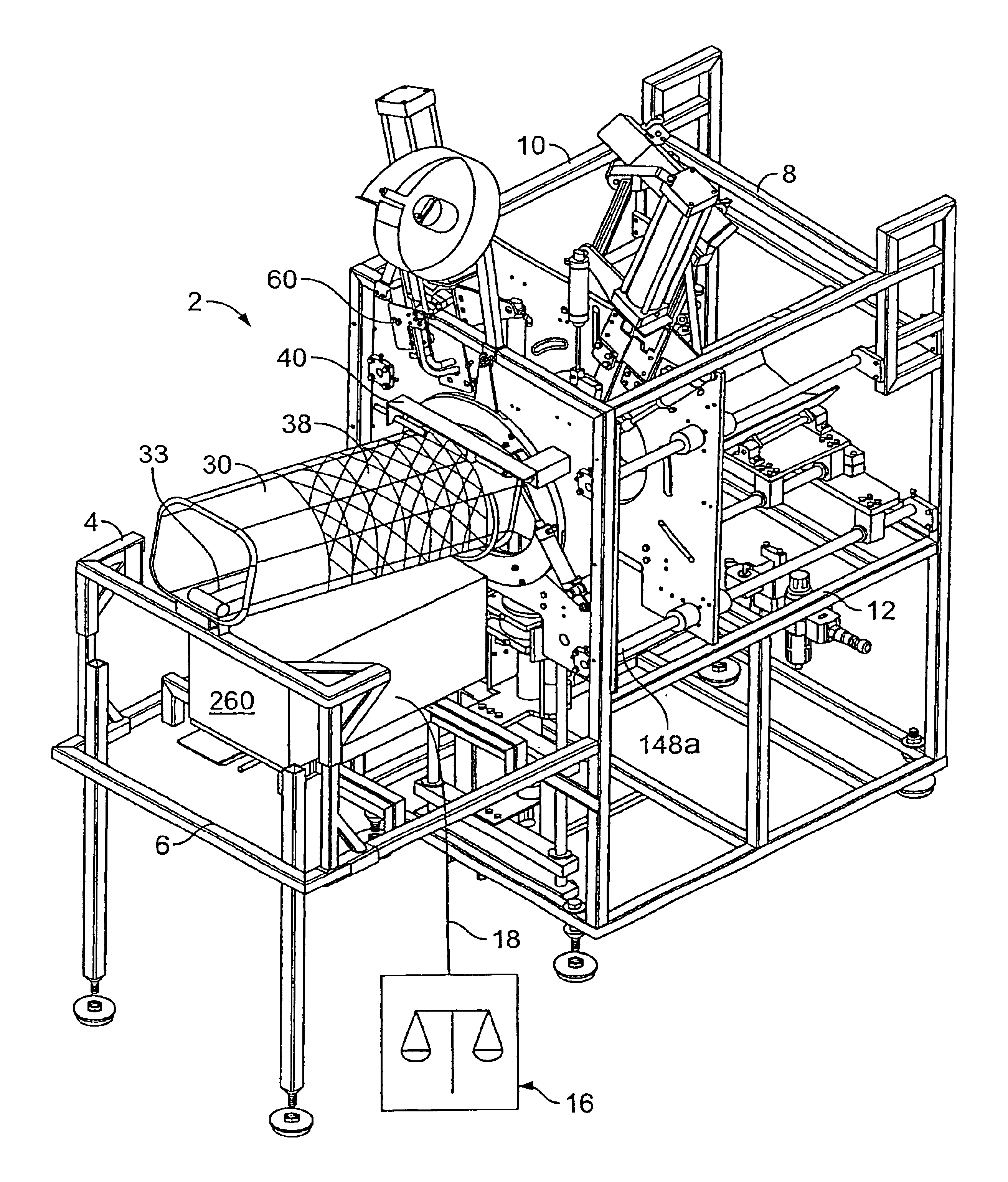

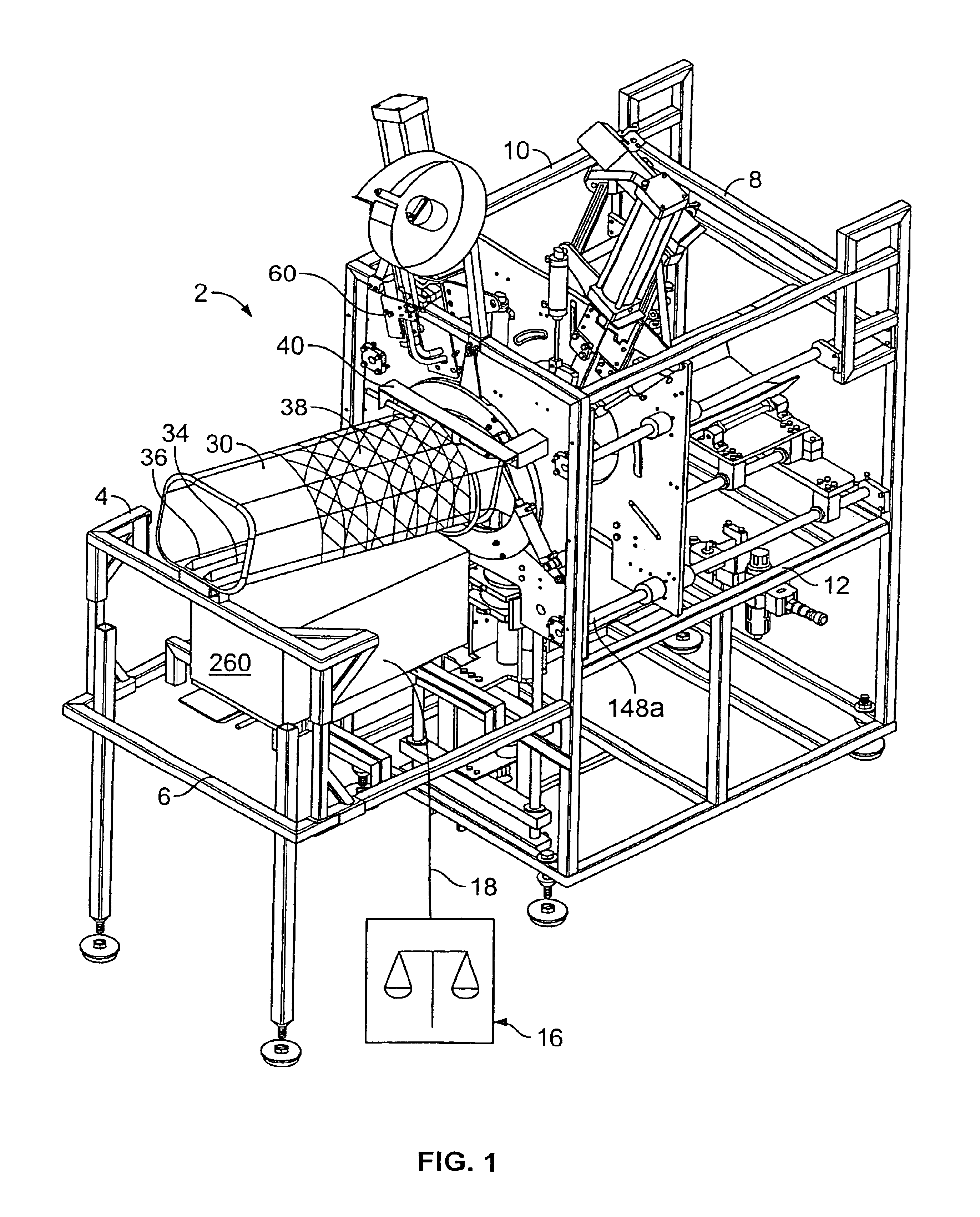

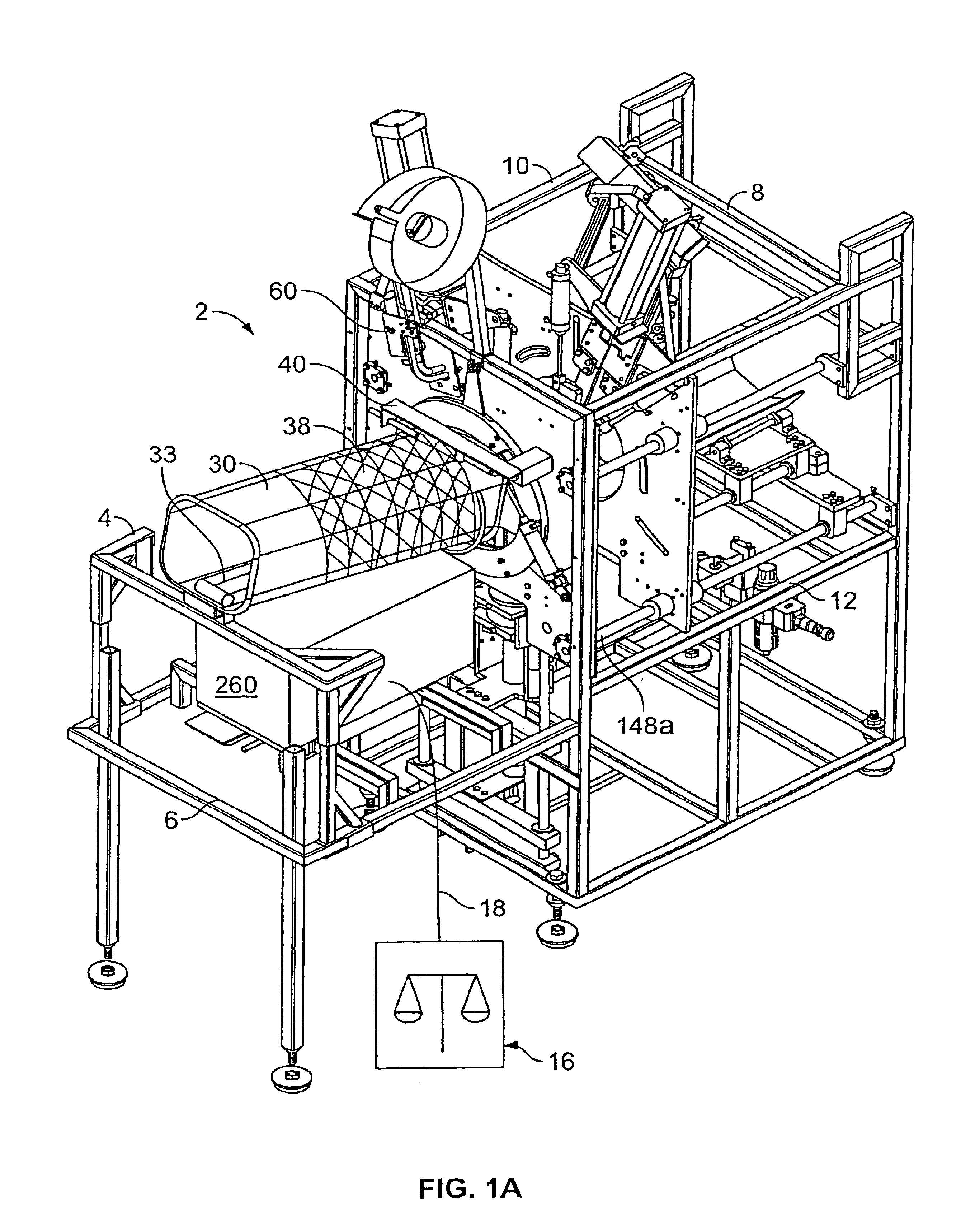

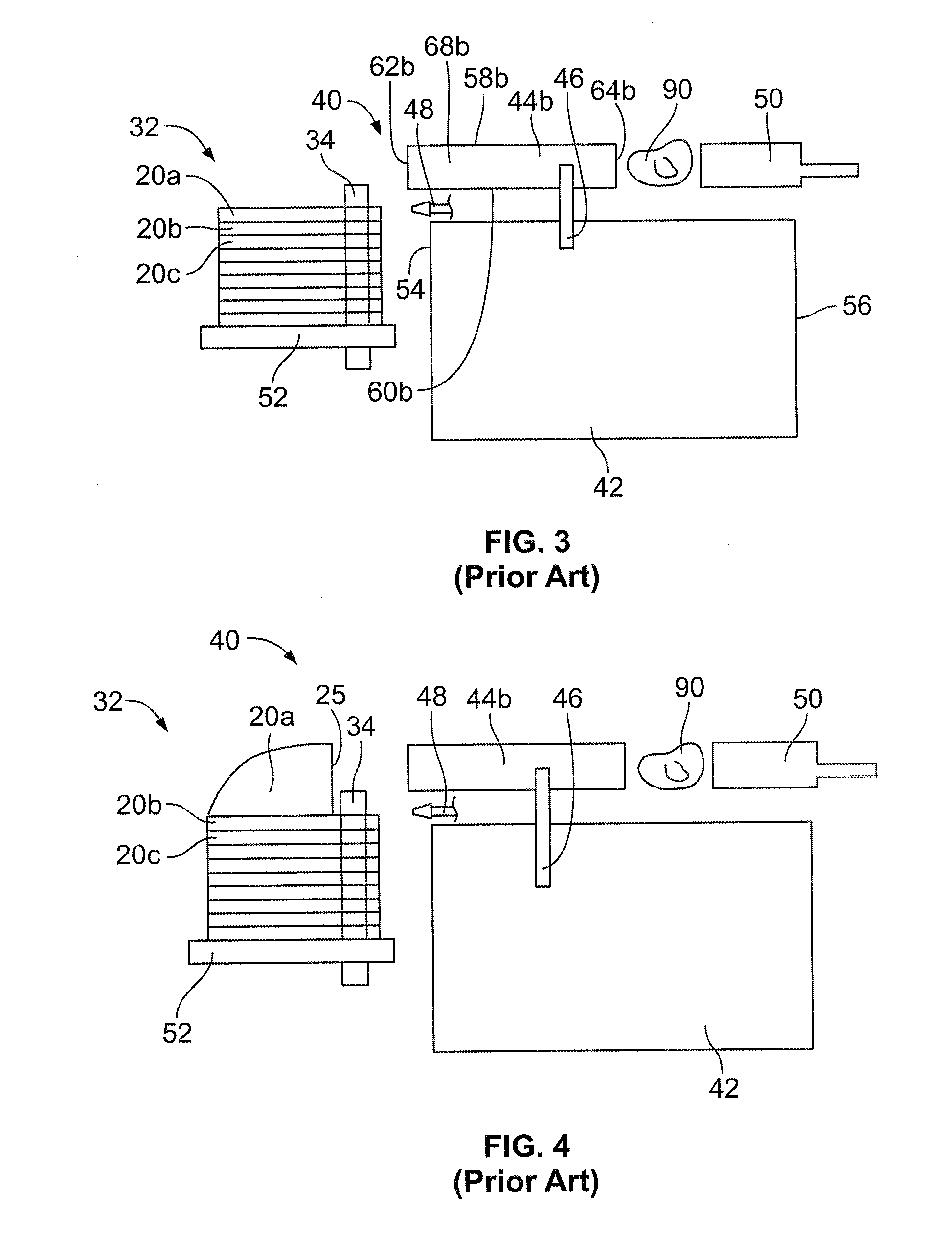

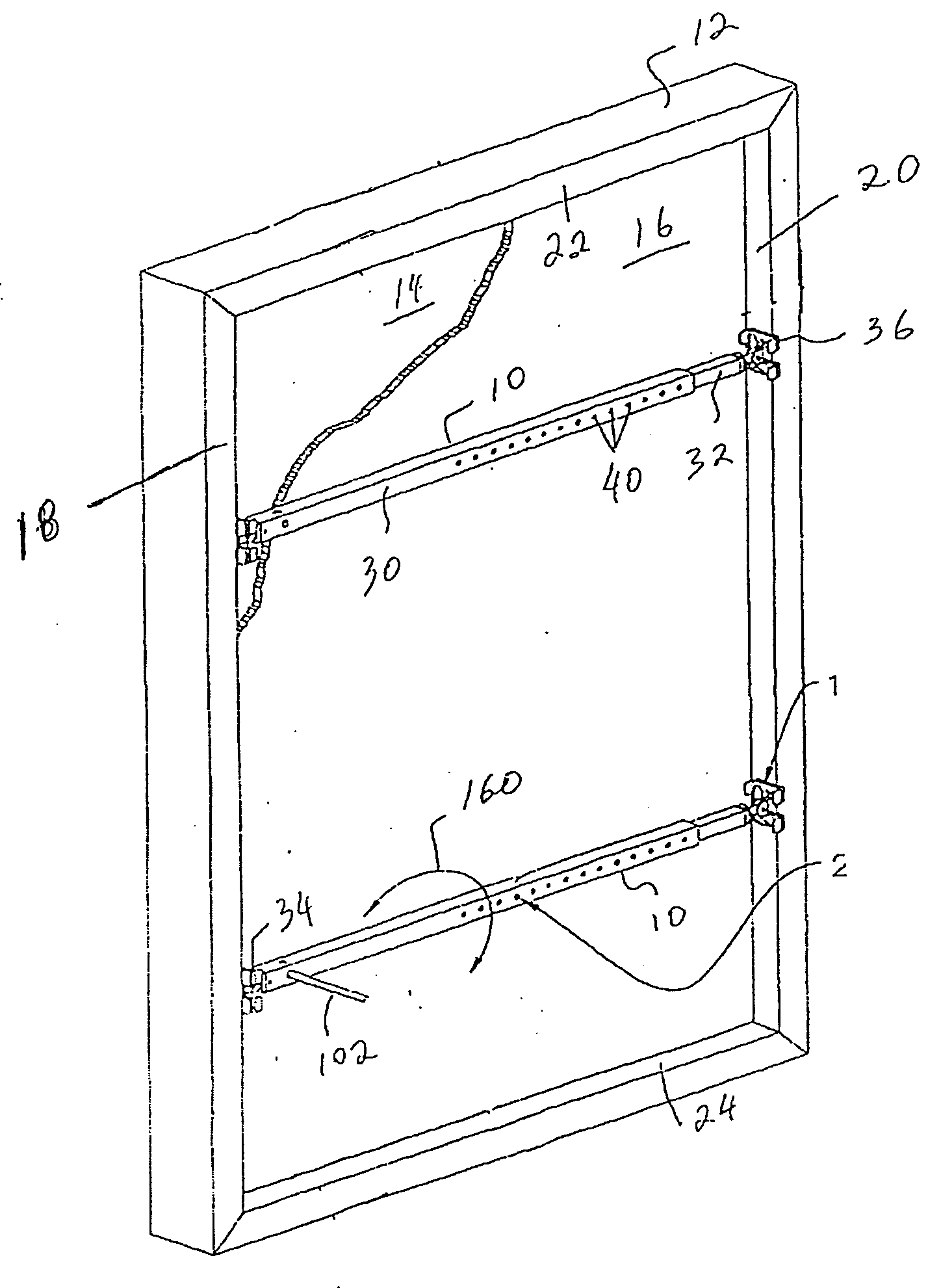

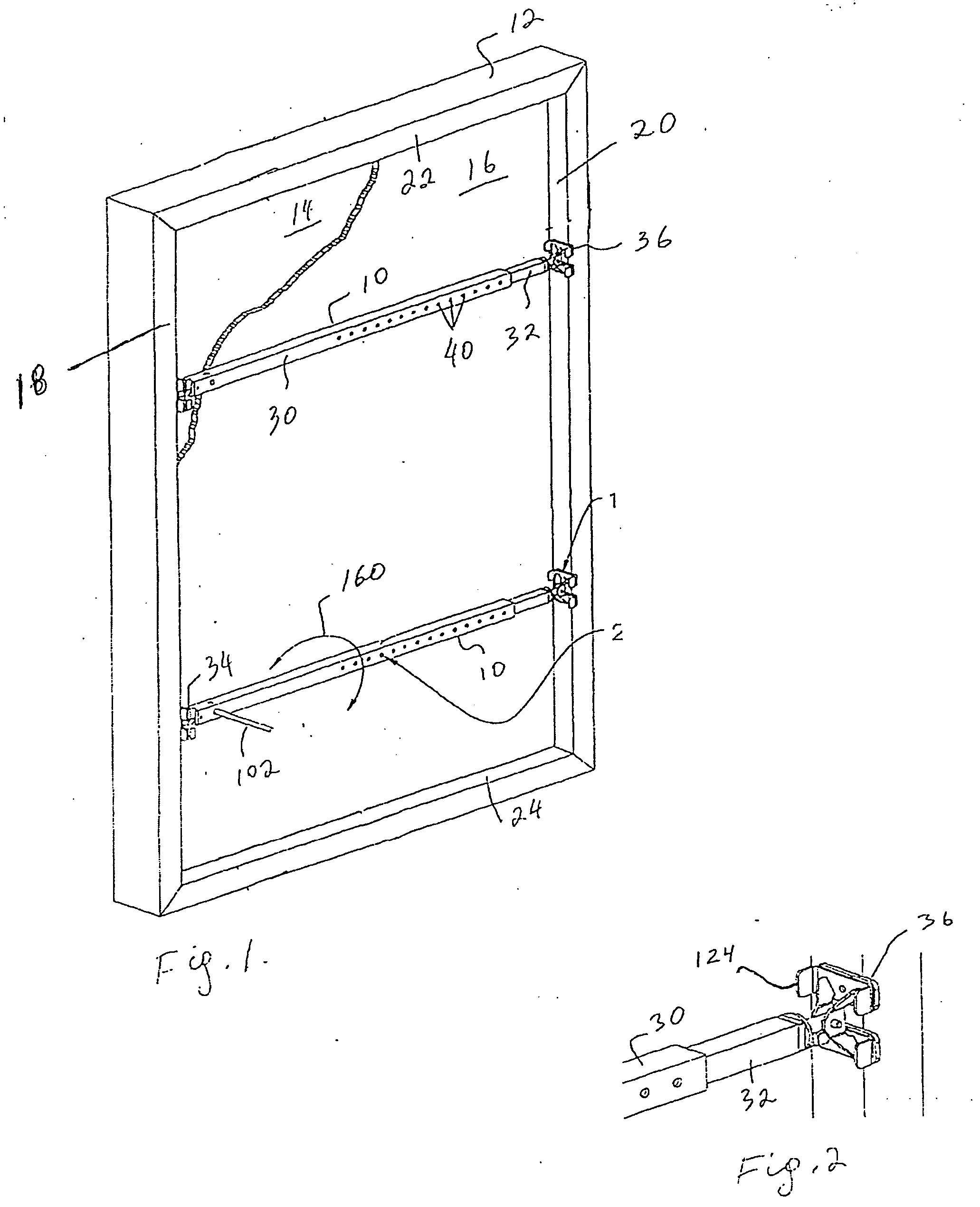

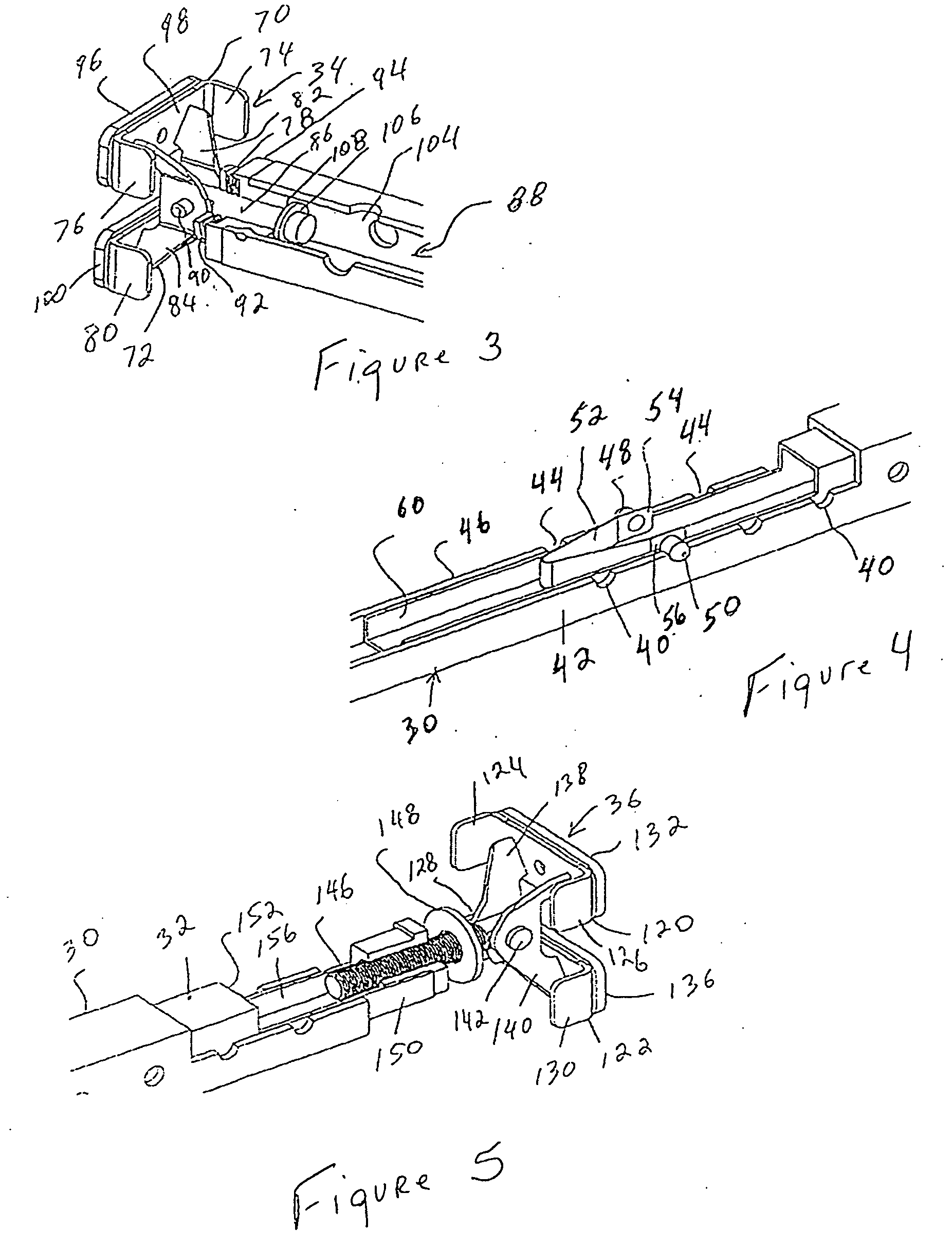

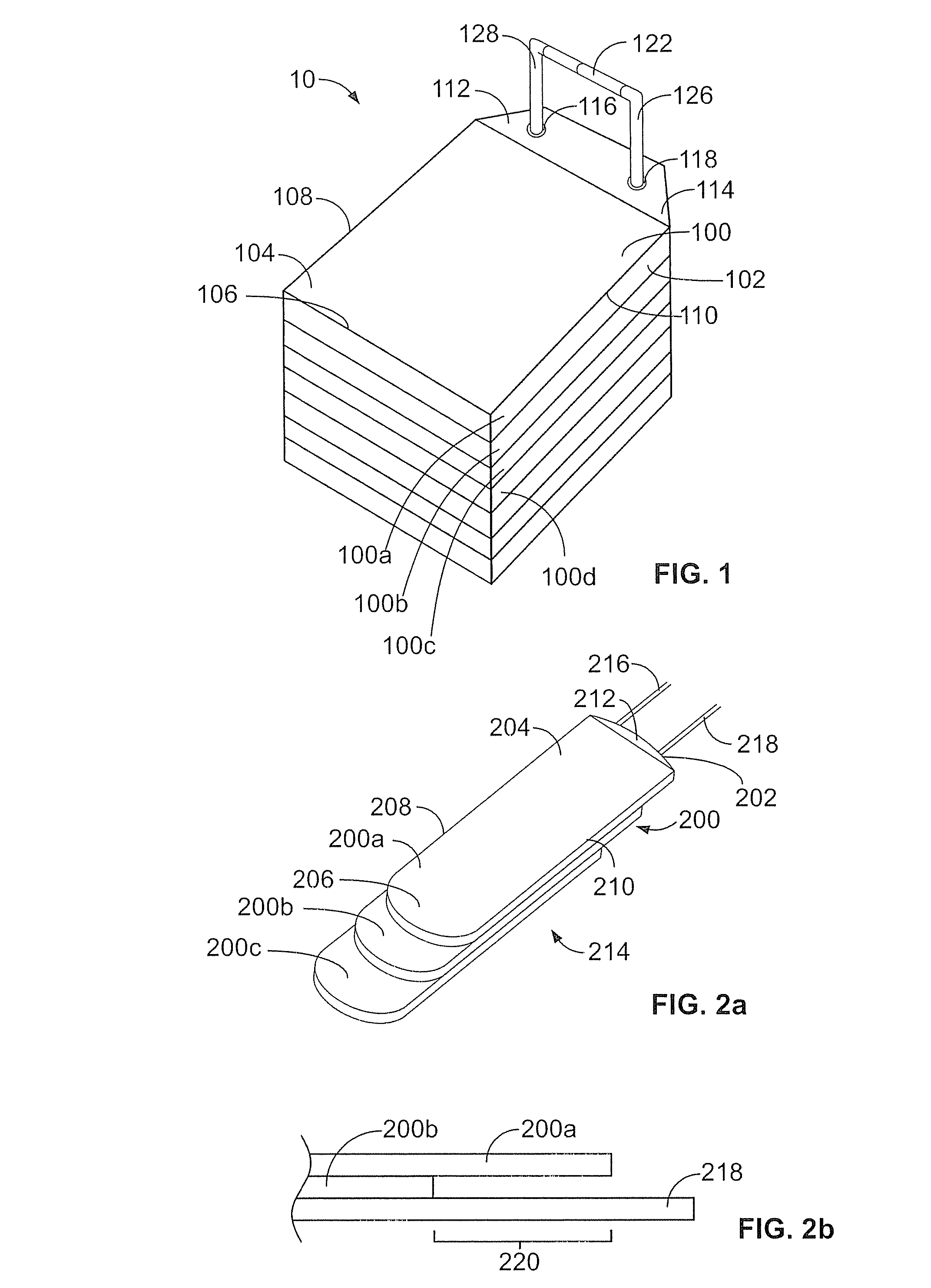

Apparatus for enclosing material in a net

InactiveUS6883297B2Uniform appearanceLighten the taskAffixing tagsSkinless sausage makingEngineeringMechanical engineering

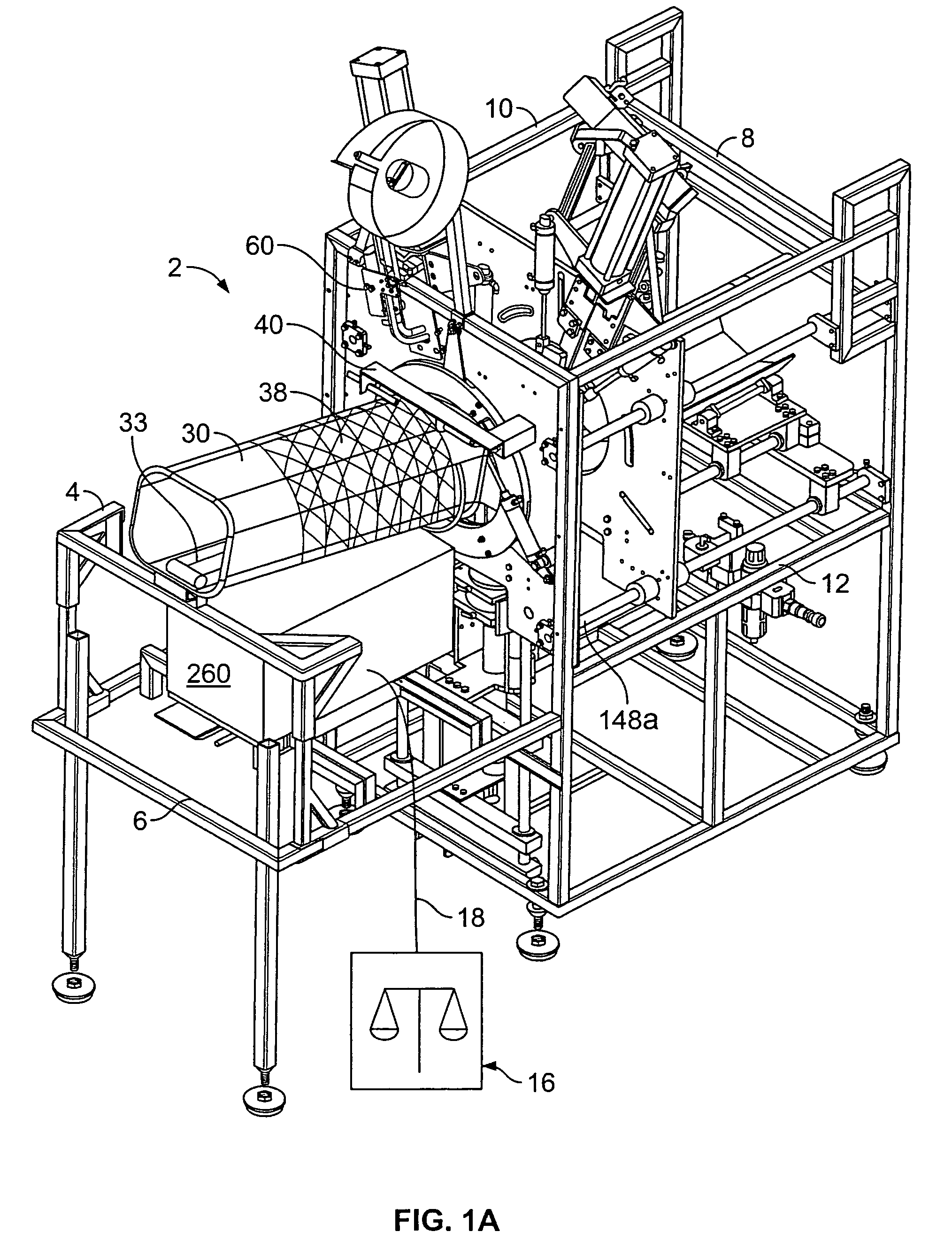

An apparatus and method of enclosing material in a net and supplying a handle for ease of carrying the netted material, comprising clippers, irises, and a handle maker. A conveyor carries the material to a pair of irises. The irises gather the netting around the material, the first clipper cuts and closes the netting, and the handle maker forms a loop out of the severed netting. The second clipper attaches the loop back to the netting to form a handle. A scale can be used to weigh the material and a printer can create a label, with the weight or whatever other information is desired, for attachment to the netting.

Owner:POLY CLIP SYST

Automatic packaging and discharging device

ActiveCN106976598AWeight increaseIncrease inertial forceSolid materialPackaging poultryImpellerEngineering

The invention relates to the technical field of packaging and discloses an automatic packaging and discharging device. The automatic packaging and discharging device comprises a feed hopper. A plurality of discharge plates are hinged to the feed hopper and define a discharge outlet. A pressing table is arranged below the discharge outlet. The outer side of the pressing table is provided with a first conveying mechanism. The outer side of the discharge outlet is provided with an annular pipe provided with an elastic layer. The discharge plates are all connected to the elastic layer. The pressing table is connected with a compressing column. The other end of the compressing column is provided with a piston. The outer side of the piston is provided with a pipeline in clearance fit with the piston. The pipeline communicates with the annular pipe. The outer side of the first conveying mechanism is provided with a bellows internally provided with an impeller. A rotary rod connected with the impeller is arranged outside the bellows. The upper end of the rotary rod is provided with a support rod provided with a hanging block. The support rod comprises an upper support rod body and a lower support rod body. A second conveying mechanism is further arranged on the outer side of the pressing table and comprises a second conveying belt. The upper end face of the second conveying belt and the lower support rod body are in the same horizontal plane. Through the automatic packaging and discharging device, the problem that a packaged product is liable to damage during automatic discharge stopping of an existing subpackaging device can be solved.

Owner:CHONGQING HAOJIE FOOD

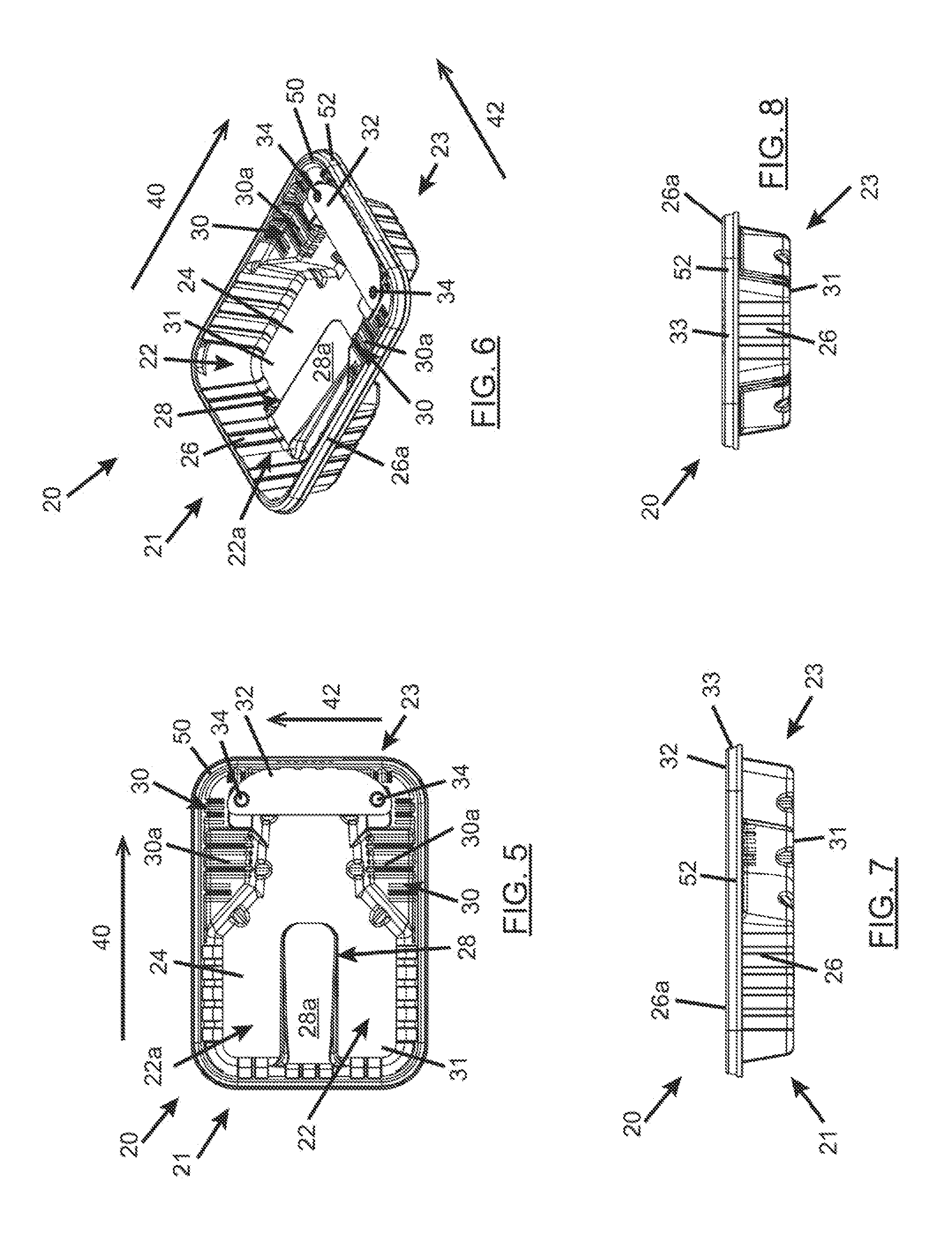

Two-in-one bagger

The invention comprises a system for encasing material in one of a stretchable bag and a shrinkable bag. The system comprises a pair of product horns rotatable in a plane from a first position to a second position; a stretchable-bag system comprising a bag carriage unit; a shrinkable-bag system, comprising a pair of pulling rollers mounted under said product horns and a collection roller mounted adjacent said pulling rollers, the collection roller configured to move a predetermined increment, a product ram configured to move material between the product horns and into one of a stretchable bag and a shrinkable bag, and an air jet for opening the bags.

Owner:POLY CLIP SYST

Automated loader with cone horn

An improved automated loader has a cone horn to prevent or minimize contact between the chicken and the bag. The loader has a loading tube and the tube has a cone horn comprising a plurality of plates configured to form a cone, each one of the plurality of plates attached to the proximal end of the loading tube by a spring-loaded hinge, each hinge biased radially inward.

Owner:PRETSITEK KORP

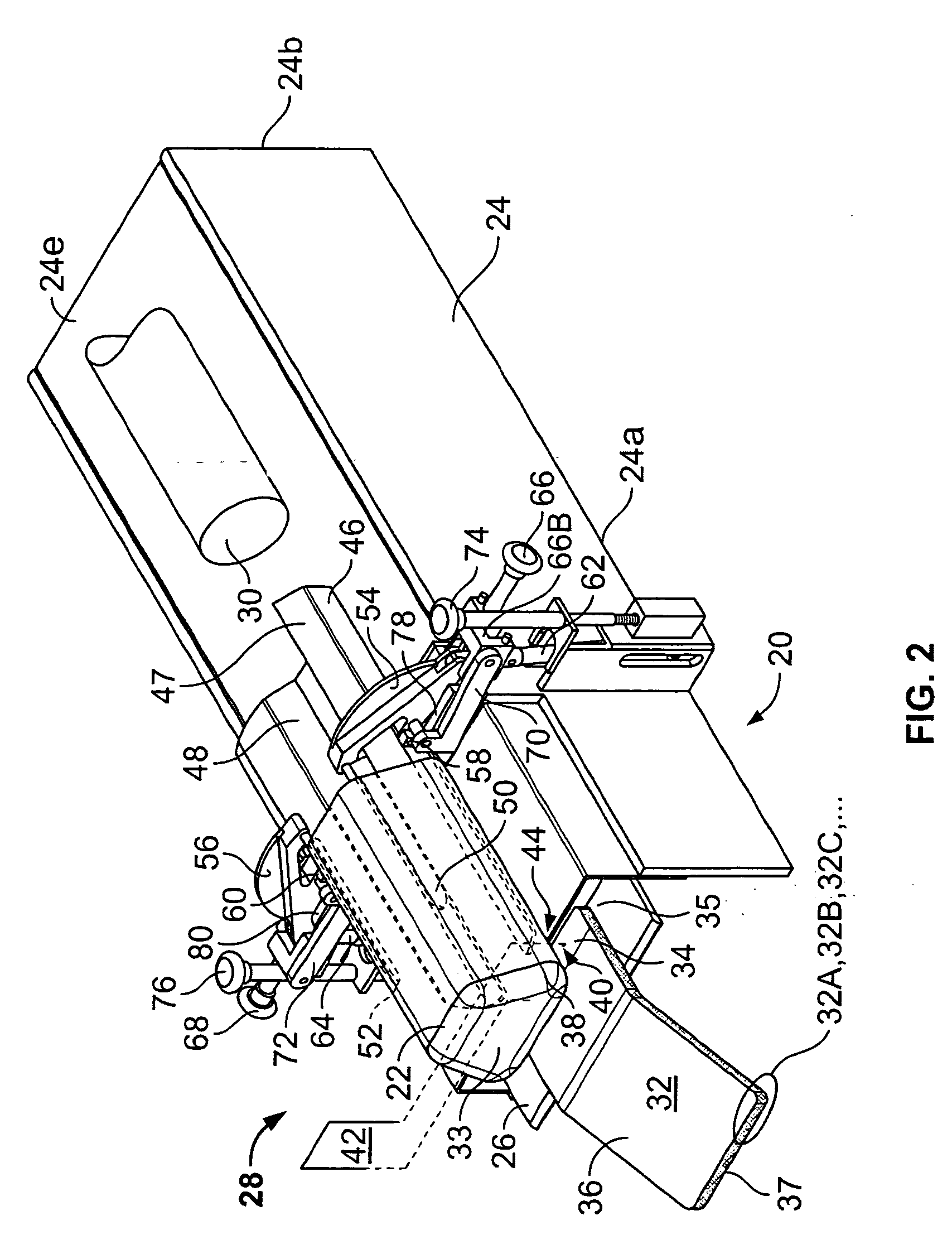

Poly-stretch bagger system

InactiveUS20020094924A1Good lookingQuantity minimizationIndividual articlesContainer making machineryDistortionPlastic bag

A bagger system for enclosing material very tightly in a plastic bag, to reduce packaging costs, present a pleasing appearance, decrease leaks, and minimize distortion of the printed information on the packaging. The system comprises a base guide to hold the material to be encased and stretching fingers to open a plastic bag. The rotational movement of the stretching fingers provides even stretching about the circumference of the bag and permits an approximation of the cross section of the material to be encased, allowing for use of a smaller bag. After the material is placed in the bag, the material and bag are ejected, whereupon the plastic bag retracts tightly around the material, presenting a pleasing appearance to consumers and minimizing distortion of any printed information on the bag.

Owner:PINTO ROBERT +1

Poly-stretch bagger system with hocking pusher

InactiveUS20050155330A1Good lookingQuantity minimizationWrappers shrinkageSolid materialDistortionPlastic bag

A bagger system for enclosing poultry very tightly in a plastic bag, to reduce material costs, present a pleasing appearance, decrease leaks, and minimize distortion of the printed information on the bag. A grabber assembly is described, to grasp the legs of the poultry and guide the poultry into a bag in proper hocking position.

Owner:POLY CLIP SYST

Loader

A horn system for an automated loader has horns with upstanding and bottom walls. The horns move from a first, adjacent position in which the bottom walk of the horns completely or almost completely overlap to a second, remote position in which the bottom walls of the horns just barely overlap or do not overlap.

Owner:PRETSITEK KORP

Vacuum skin packaging

Disclosed are packages and methods for packaging perishable foods such as meat, fish, poultry, vegetables or other food products. The packaging comprises a vacuum skin package comprising a film having specific package gas permeability requirements and a framing element within which the packaged goods are held.

Owner:EI DU PONT DE NEMOURS & CO

Poultry loader with alignment mechanism

An improved loader is described. The loader includes a frame having an upper surface, a pair of horns adjustably connected to the upper surface, each horn comprising an upper shoulder, a lower shoulder, and an air duct between the upper shoulder and the lower shoulder, a pair of air hoses connecting each air duet to a controller, the controller being connected to a pressurized air supply, and an alignment mechanism mounted, the alignment mechanism including an axle mounted to the frame, a first arm connected to a first panel, the first arm rotatably connected to the axle, a second arm connected to a second panel, the second arm rotatably connected to the axle, a gear mechanism connected to the axle and to the first arm and the second arm, the gear mechanism configured to rotate the second arm in a direction opposite to a direction of rotation of the first arm, and a dual-action cylinder connected to at least one of the first arm and the second arm.

Owner:PRETSITEK KORP

Netting knife cutter

ActiveUS7216469B2Uniform appearanceCompletely severWrapper twisting/gatheringSolid materialEngineeringMechanical engineering

An apparatus and method of enclosing material in a netting and supplying a handle for ease of carrying the netted material, comprising clippers, irises, and a handle maker. A novel scissors assembly for severing the netting is disclosed. A conveyor carries the material to a pair of irises. The irises gather the netting around the material, the first clipper closes and severs the netting, and the handle maker forms a loop out of the severed netting. The second clipper attaches the loop back to the netting to form a handle. A scale can be used to weigh the material and a printer can create a label, with the weight or whatever other information is desired, for attachment to the netting.

Owner:POLY CLIP SYST

Poly-stretch bagger system with hocking pusher

InactiveUS7178310B2Good lookingQuantity minimizationWrappers shrinkageSolid materialDistortionPlastic bag

A bagger system for enclosing poultry very tightly in a plastic bag, to reduce material costs, present a pleasing appearance, decrease leaks, and minimize distortion of the printed information on the bag. A grabber assembly is described, to grasp the legs of the poultry and guide the poultry into a bag in proper hocking position.

Owner:POLY CLIP SYST

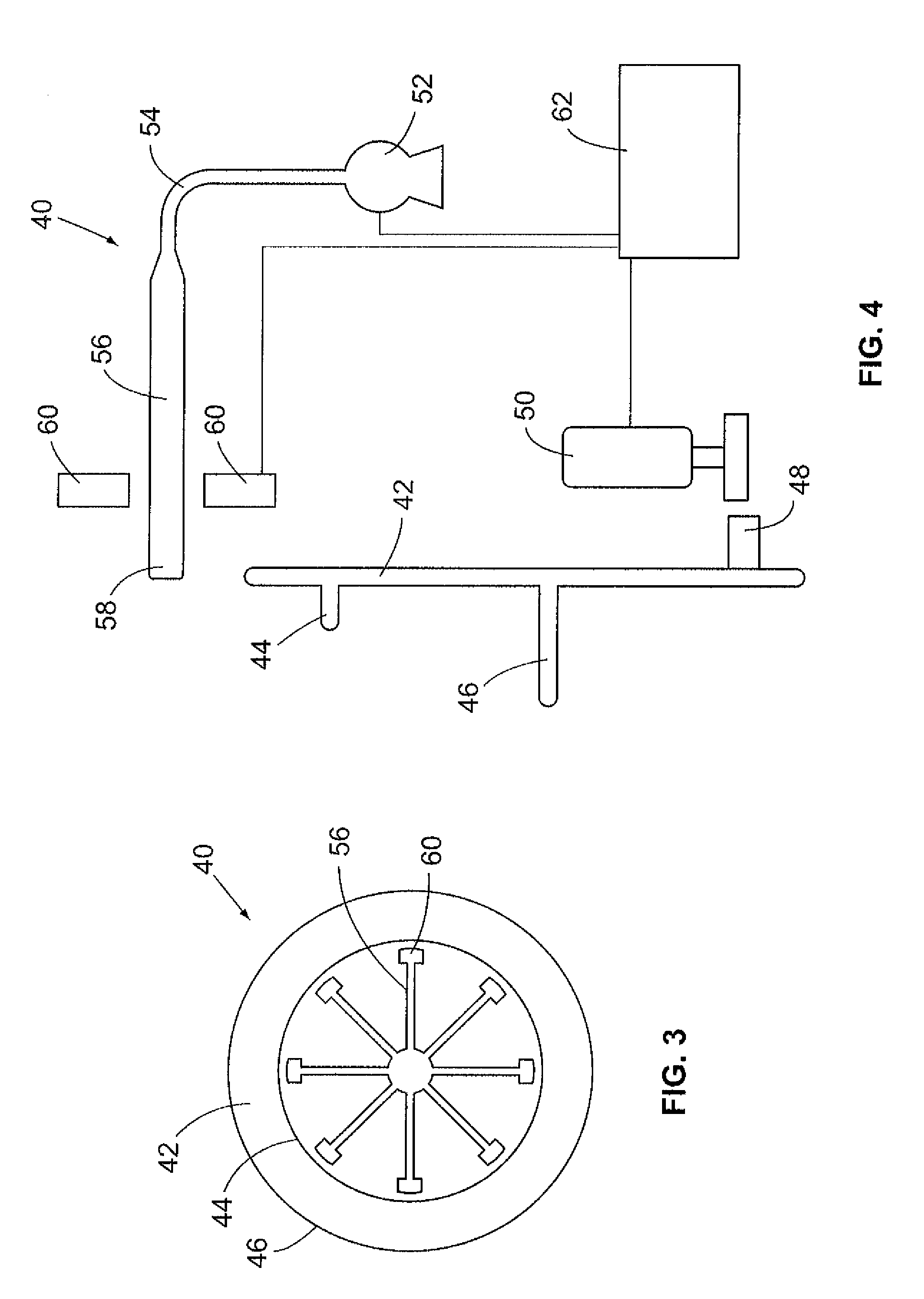

Dual mode bagger

InactiveUS20090044488A1Packaging by pressurising/gasifyingWrapper twisting/gatheringDual modeAcute angle

An apparatus for sealing a bag of encased material is described. A plurality of nozzles radiate from a central vacuum system, each nozzle associated with a clamping means. A framework rotates about the central vacuum system. A holding tray and an elevating device are removably attachable to the framework. The holding tray is attachable below a one of the plurality of nozzles and comprises an upright section and a projecting section. The upright section is supported by the framework at an acute angle from vertical, a top end of the upright section being adjacent to the framework and a bottom end of the upright section being remote from the framework. The projecting section is removably attachable to the bottom end of the upright section and projects approximately normal to the upright section. The elevating device is removably attachable to the framework below a one of the plurality of nozzles. The elevating device comprises an upright section, a lower strut, and an upper strut, the upright section supported by the framework at an acute angle from vertical, a top end of the upright section being adjacent to the framework and a bottom end of the upright section being remote from the framework. The lower strut has a first end and a second end, the first end of the lower strut being attached to a first end of the upper strut and the second end of the lower strut being releasably attached to the bottom end of the upright section. A second end of the upper strut is releasably attachable to the top end of the upright section.

Owner:POLY CLIP SYST

Vacuum skin packaging

Disclosed are packages and methods for packaging perishable foods such as meat, fish, poultry, vegetables or other food products. The packaging comprises a vacuum skin package comprising a film having specific package gas permeability requirements and a framing element within which the packaged goods are held.

Owner:EI DU PONT DE NEMOURS & CO

Poultry tray and method of packaging poultry using same

A poultry tray for shipping and displaying a dressed poultry. The poultry tray comprises a receptacle including a bottom wall and a peripheral wall having an upper end defining a receptacle opening. The poultry tray also comprises a flap pivotally connected to the receptacle at a rear end thereof. The flap is pivotable between an open configuration wherein the flap extends outwardly from the receptacle opening and a closed configuration wherein the flap covers a section of the receptacle opening and has a distal end detachably secured to the receptacle.

Owner:CASCADES CANADA INC

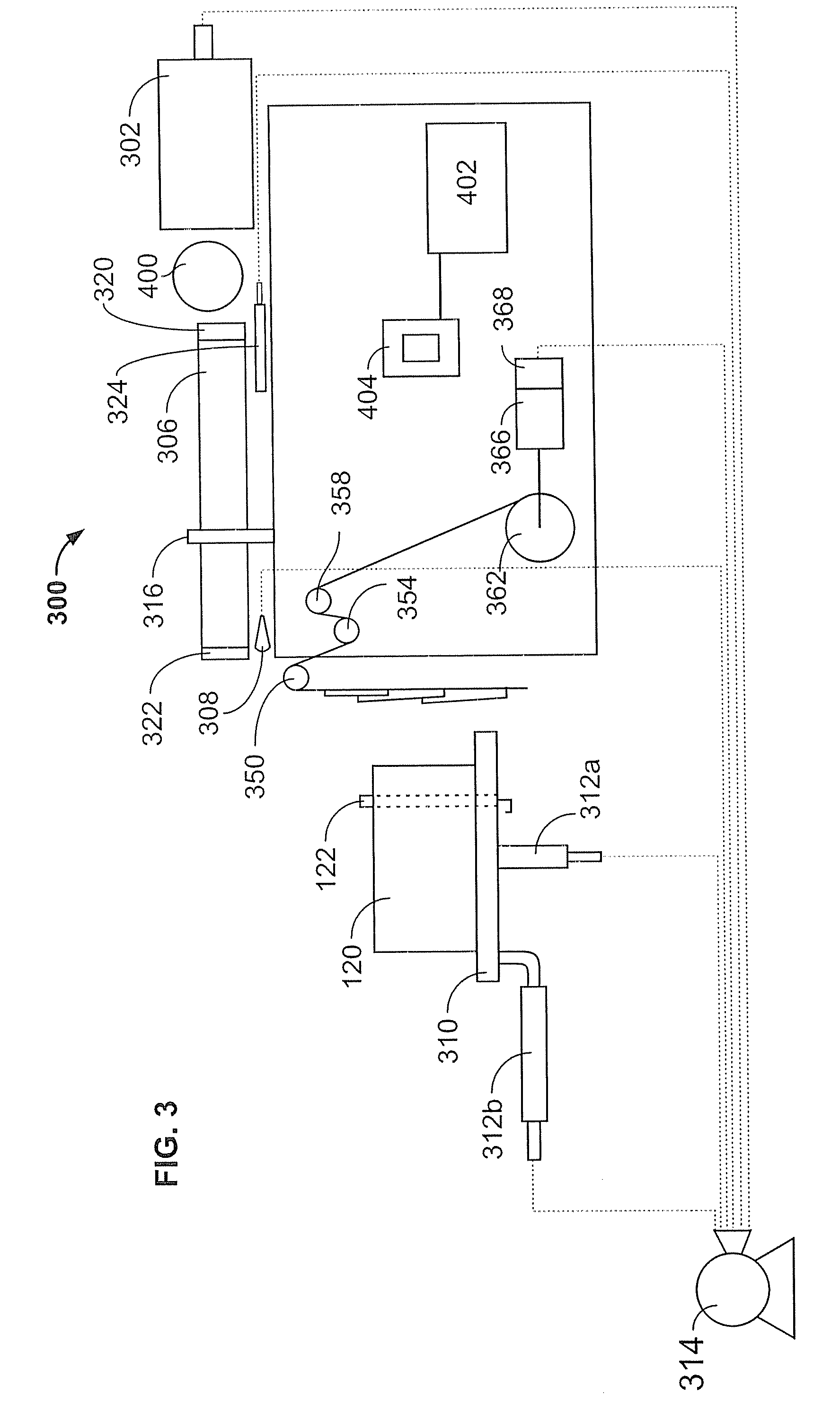

Method and system for bagging material

InactiveUS20110107726A1Multiple wrapper applicationPackaging by pressurising/gasifyingSpray nozzleEngineering

A method and an apparatus for enclosing material in a bag is described for a bag comprising a stretchable material and having a first dimension and a second dimension. The method comprises stretching the bag in the first dimension, placing material in the bag, releasing the bag in the first dimension, stretching the bag in a second dimension, evacuating the bag, and sealing the bag. The apparatus comprises a bagger configured to stretch the bag in a first dimension, to receive the material, and to release the bag in the first dimension, and a packaging apparatus comprising a nozzle coupled to a vacuum system, a grasping means, and a clipper means, the grasping means configured to hold a neck of the bag to the nozzle and to stretch the bag in the second dimension.

Owner:PRETSITEK KORP

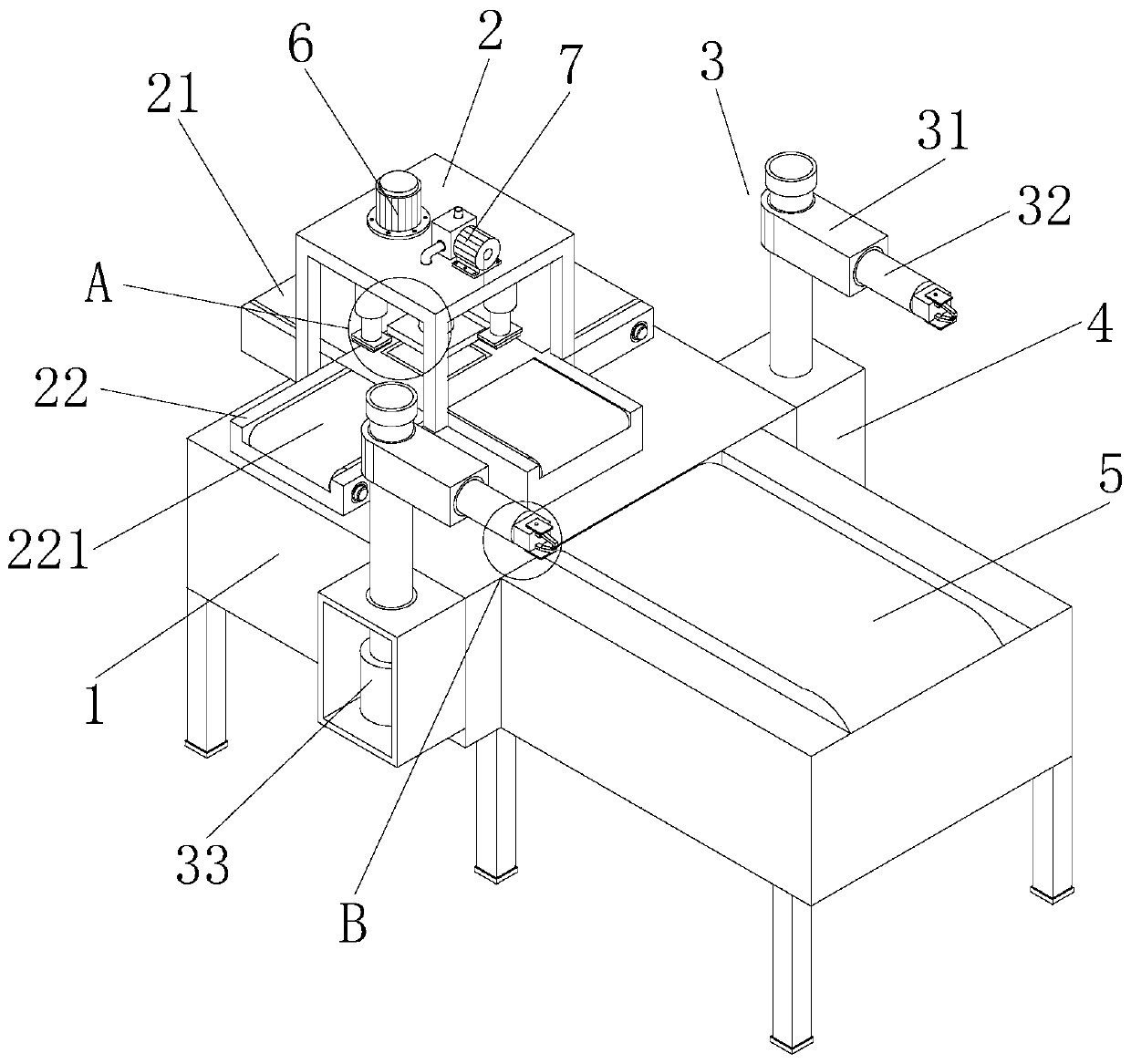

Multi-station brine duck vacuum packaging machine

InactiveCN110816944AImprove efficiencyNo manual feedingPackaging by pressurising/gasifyingWrapper twisting/gatheringGear wheelElectric machinery

The invention provides a multi-station brine duck vacuum packaging machine. The multi-station brine duck vacuum packaging machine comprises a working platform, wherein a driving motor is arranged on an inner bottom plate of the working platform, an output end of the driving motor is rotationally connected with a rotating shaft, a straight tooth bevel gear is arranged at one end of the rotating shaft, a straight gear is arranged on one side of the straight tooth bevel gear, a rotating rod is arranged at the top end of the straight gear, a multi-station rotating platform is arranged at one end of the rotating rod, three working positions are arranged on the outer periphery of a lower bottom plate of the multi-station rotating platform, a mounting groove is formed in the top end of the lowerbottom plate of the multi-station rotating platform, a fixed plate is arranged on an inner bottom plate of the mounting groove, a first hydraulic telescopic rod is arranged at the bottom end of an upper bottom plate of the multi-station rotating platform, and a moving plate is arranged at the bottom end of the first hydraulic telescopic rod. According to the multi-station brine duck vacuum packaging machine, through rotation of the fixed plate, the first hydraulic telescopic rod, the moving plate, the working positions and the multi-station rotating platform, simultaneous packaging of a plurality of brine ducks is achieved, and the vacuum packaging efficiency is improved.

Owner:衡阳县湘衡食品有限公司

Vacuum-assisted poultry loader

InactiveUS20130269292A1Wrapping material feeding apparatusWrapper twisting/gatheringVacuum assistedDistal portion

An improved loader is described, The loader includes a frame, a pair of horns adjustably connected to the frame, each horn comprising an upper shoulder, a lower shoulder, a proximal portion, a distal portion, and an air duct between the upper shoulder and the lower shoulder, a pair of air hoses connecting each air duct to a first controller, the first controller being connected to a pressurized air supply, and a pair of vacuum hoses connecting each air duct to a second controller, the second controller being connected to a vacuum supply.

Owner:PRETSITEK KORP

Chicken and duck meat bagged finished product and frozen raw material separated feeding device

The invention discloses a chicken and duck meat bagged finished product and frozen raw material separated feeding device comprising a slide. Movable baffles are arranged on the slide. Torsion springs are arranged between the movable baffles and flanges of the slide, so that when one material passes, the movable baffles rebound, and then the purpose of separating the materials to be mutually independent is achieved. Meanwhile, a conveyer belt mechanism is arranged on the upper side of the slide, helps the materials to pass by the movable baffles and prevents the materials from being accumulated, and then the materials sequentially slide downwards one by one. A V-shaped groove is formed in the lower end of the slide, so that falling points of the materials are concentrated on one point, and therefore a container on the lower side can control the position to catch the materials. According to the scheme, the chicken and duck meat bagged finished product and frozen raw material separated feeding device has the beneficial effects of being simple in structure and reasonable in design, freeing manpower, achieving the purpose that the chicken and duck meat bagged finished products and the frozen raw materials are fed one by one continuously and improving work efficiency and work quality.

Owner:SHANDONG NEW HOPE LIUHE GROUP +1

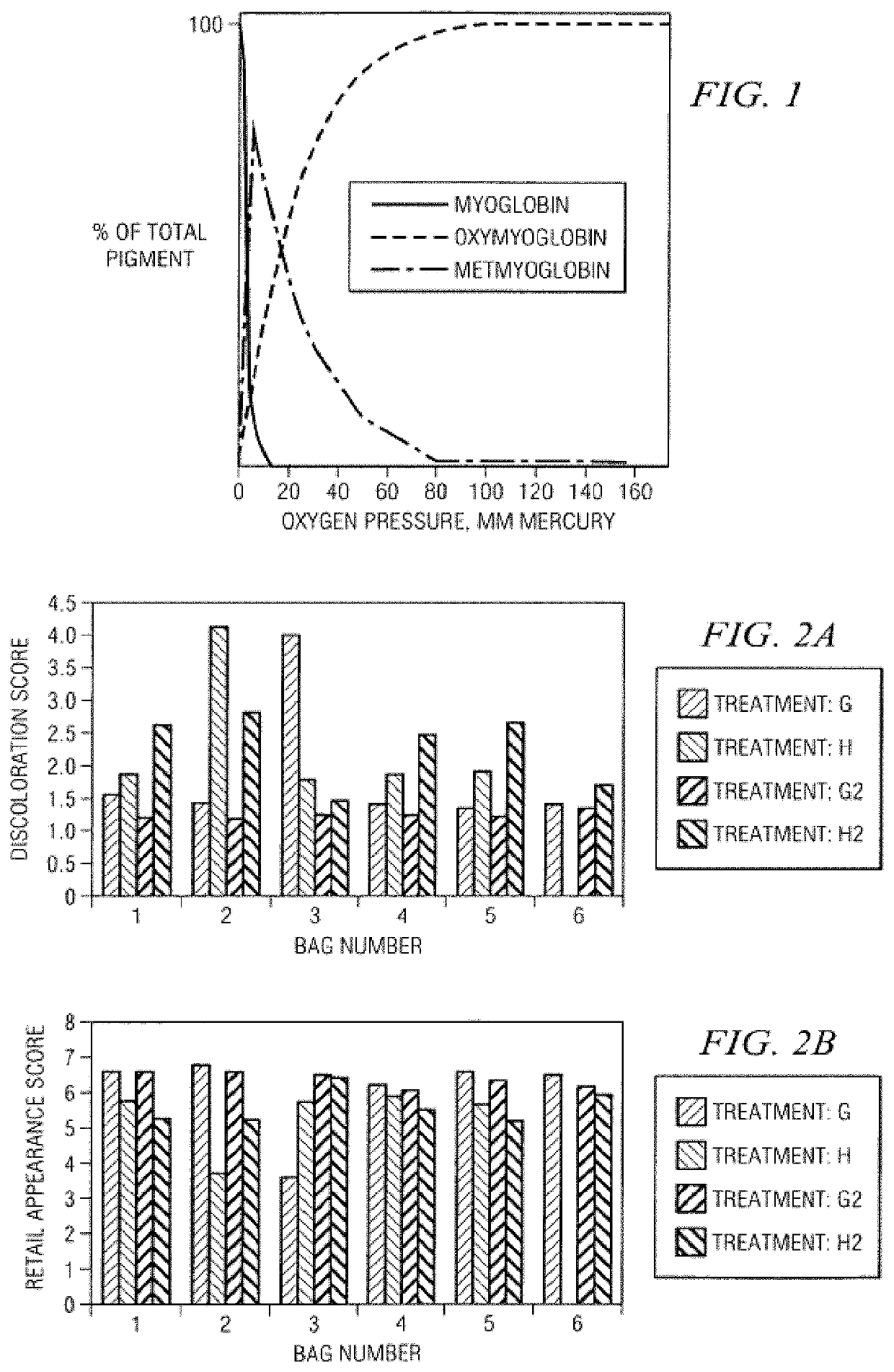

Method and apparatus for extending shelf-life of meat & poultry

PendingUS20200315220A1Reduce fluctuationReduce handlingWrappers shrinkageGas treatmentBiotechnologyPacking procedure

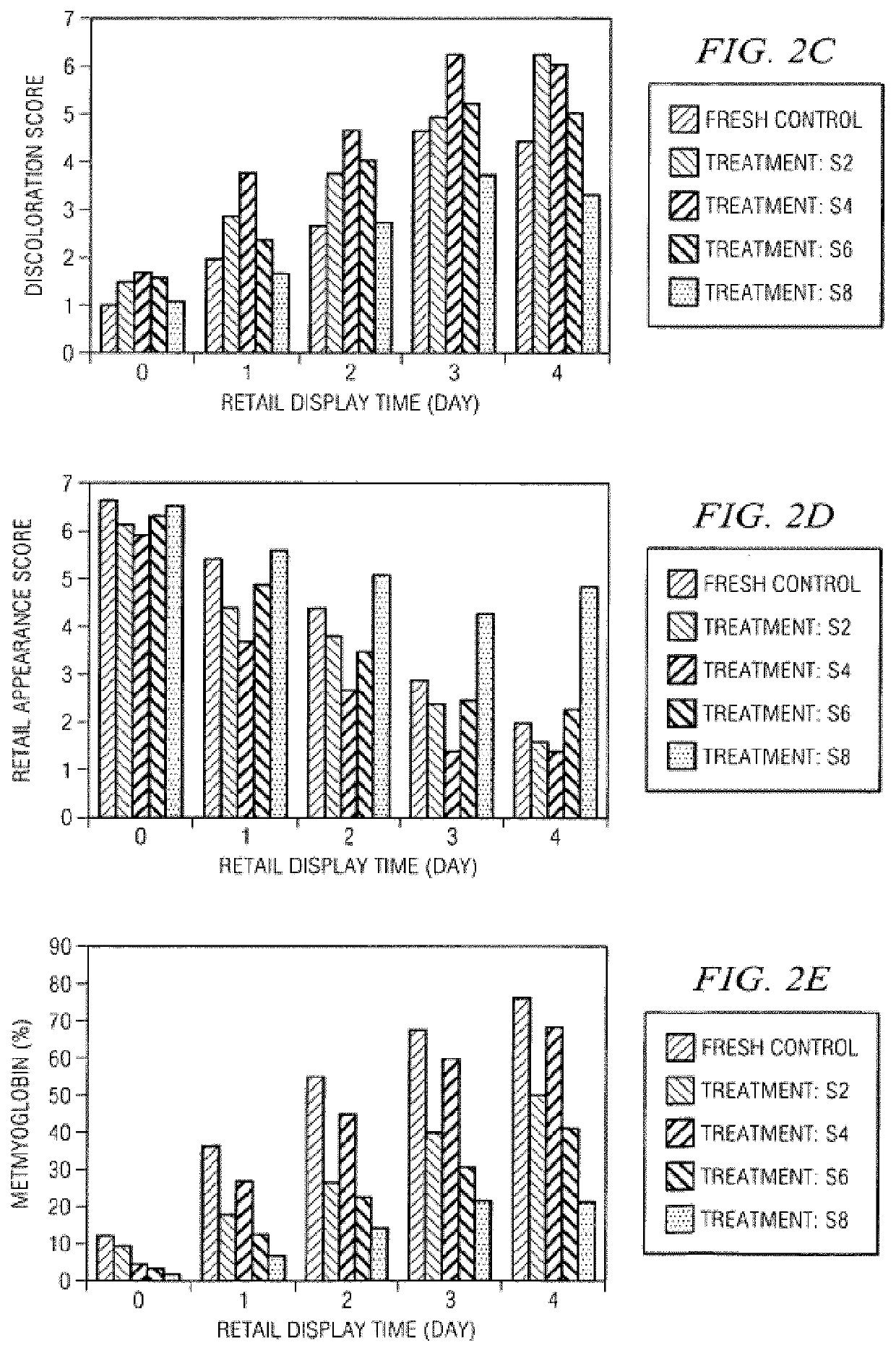

The current invention covers an improved meat-packaging procedure and machine for packaging meat cuts for long-term storage at temperatures of between 28° and 42° F. The process includes sealing meat cuts or full poultry birds or bird pieces within a master bag containing (i) oxygen scavenger materials capable of reducing the residual oxygen content of the atmosphere within the bag to 0 ppm within 96 hours of sealing, and (ii) a CO2 generator capable to generate CO2 in the amount of at least 100 mL per pound of meat or poultry within 7 days of sealing. Gas is injected into the master bag to form a CO2-rich storage environment of at least 50% CO2. Depending upon the gas-volume and oxygen scavengers design in the master-bag to maintain diffusion, the CO2 generators may not be needed in the master-bag. The over-wrap of the meat or poultry trays, if meat or poultry are packed in trays, can be perforated so that gas exchange occurs within the master bag between the interior and exterior of the meat tray to absorb the residual oxygen inside the meat trays. For meat trays containing meat with poor color stability, oxygen scavengers are preferably placed within the meat trays. For cuts with good color stability, the oxygen scavengers may be placed outside the meat trays. Meat can be stored by this system for up to 10 weeks and up to twelve days of retail display life. Poultry can be stored for 28+ days by this system. Poultry can be treated with PAA or without PAA and can either be air-chilled or water-chilled with or without PAA: in both instances substantial shelf-life extension is obtained. PAA treated poultry tend to show high microbial growth when compared with non-PAA treated poultry.

Owner:TEWARI GAURAV

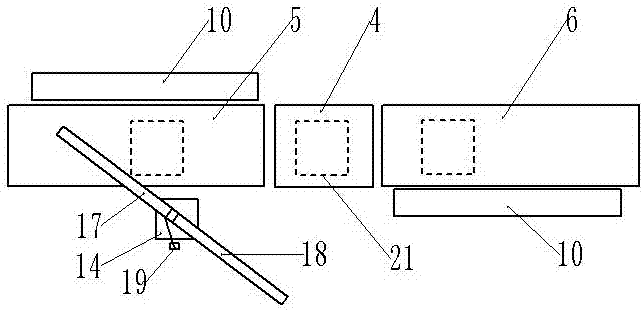

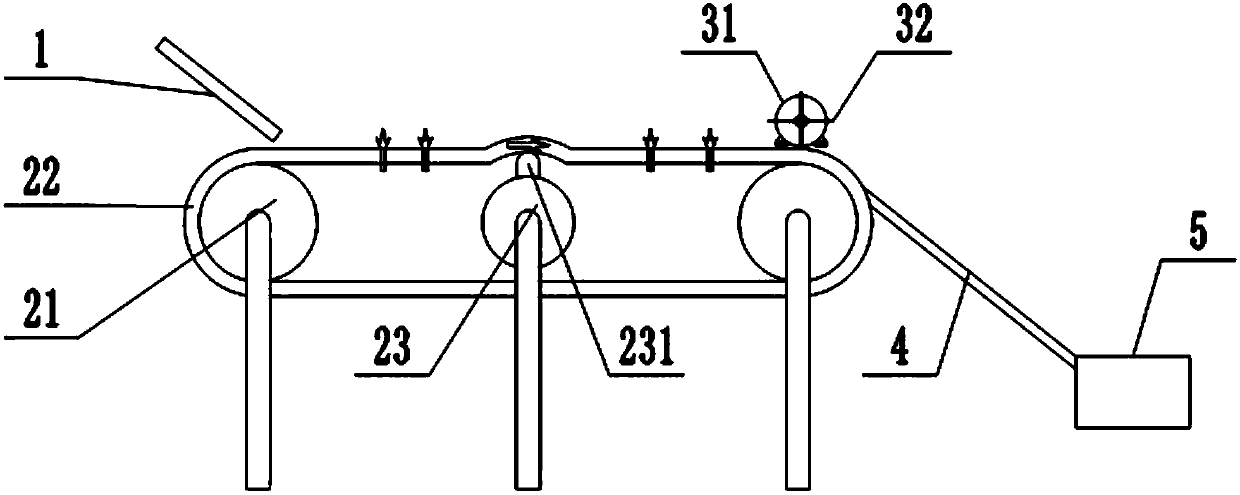

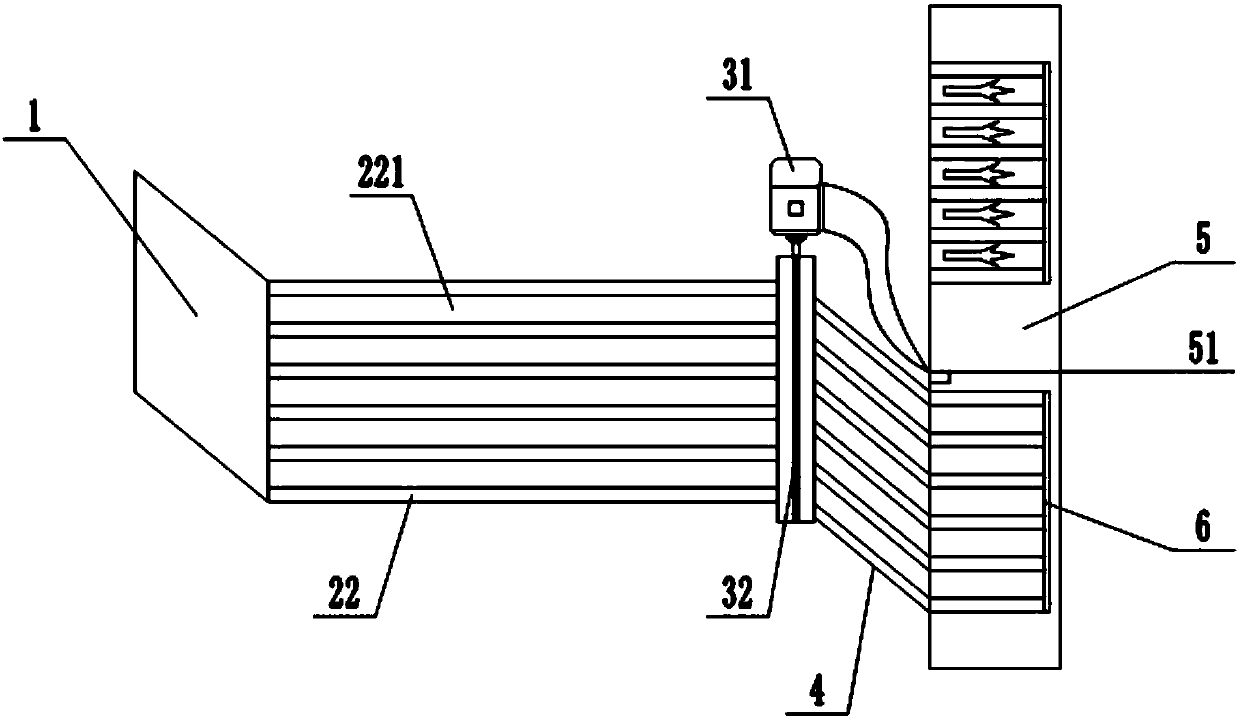

Device for packing frozen chicken feet

The invention relates to the field of processing of frozen goods, and specifically relates to a device for packing frozen chicken feet. The deice comprises a feeding plate, a conveying mechanism and apacking conveyor belt, wherein the conveying mechanism comprises two transmission rollers and alignment conveyor belts; a supporting roller is arranged between the two transmission rollers; vibrationbumps which are in contact with the alignment conveyor belts are arranged on the supporting roller; alignment grooves which are formed in the conveyor belt direction are formed in the conveyor belts;discharging chutes are connected to the end parts of the conveyor belts; a cross shifting plate is arranged at a part where the alignment conveyor belts are connected to the discharging chutes; a motor is connected to the cross shifting plate; a pressure sensor is arranged on the shifting plate; an infrared sensor is arranged at the upper end of the contacting surface between the discharging chutes and the packing conveyor belt. According to the device, the chicken feet are aligned through the alignment conveyor belts; the motor is controlled to accurately rotate the chicken feet through thepressure sensor on the cross shifting plate and the infrared sensor on the packing conveyor belt, so that the chicken feet can accurately enter packing boxes.

Owner:象山县远洋冻品有限公司

Poly-stretch bagger system

InactiveUS20030202402A1Good lookingQuantity minimizationDigital storageIndividual articlesEngineeringDistortion

A bagger system for enclosing material very tightly in a plastic bag, to reduce packaging costs, present a pleasing appearance, decrease leaks, and minimize distortion of the printed information on the packaging. The system comprises a base guide to hold the material to be encased and stretching fingers to open a plastic bag. The rotational movement of the stretching fingers provides even stretching about the circumference of the bag and permits an approximation of the cross section of the material to be encased, allowing for use of a smaller bag. After the material is placed in the bag, the material and bag are ejected, whereupon the plastic bag retracts tightly around the material, presenting a pleasing appearance to consumers and minimizing distortion of any printed information on the bag.

Owner:POLY CLIP SYST

A gripper device

ActiveUS20210068406A1Beautiful appearancePrevents food products from fallingGripping headsMeat packaging/handling/transportingStructural engineeringMechanical engineering

A gripper device is configured to pick up a pliable food product having a tail-like part from a pick-up area and releasing it at a releasing area, where a support is provided. A pair of jaws is mounted to the support for movement of distal ends thereof towards each other defining a closing position of the pair of jaws and away from each other defining an open position of the pair of jaws. A tail bender device is attached to the support and adjacent to one end of the pair of jaws. The tail bender device is moveable in relation to the pair of jaws and is configured to bend the tail-like part while transferring the food product from the pick-up area until releasing it at the releasing area.

Owner:MAREL HF

Novel packaging method of marinated and roasted chicken feet

PendingCN111317102ACortex tightGood tenacityPackaging by pressurising/gasifyingWrapper twisting/gatheringBiotechnologyRoast chicken

The invention relates to a novel packaging method of marinated and roasted chicken feet, and mainly solves the problems of short storage time and poor eating taste in chicken foot packaging in the prior art. The novel packaging method comprises the following steps: 1) placing fresh chicken feet into a cooking pot, and placing seasoners for seasoning; 2) fishing out and naturally air-drying the cooked chicken feet; 3) carrying out dee frying; 4) placing the chicken feet in an oven for press roasting; 5) weighing and sub-packaging the processed chicken feet, and placing the chicken feet in packaging bags; 6) placing the packaging bags containing food in a mold cavity of a sealing machine, vacuumizing the mold cavity and filling the mold cavity with nitrogen; 7) performing radiation sterilization on the chicken feet with cobalt 60, and finally, sealing the packaging bags; and 8) placing the packaging bags packaging the chicken feet in packaging boxes, placing the packaging boxes togetherwith the packaging bags in a mold cavity of a press-fit mold for laminating plastic film covers, vacuumizing the mold cavity, filling the mold cavity with nitrogen, and finally, laminating the plasticfilm covers on the opening of the packaging boxes.

Owner:南安市洪濑黑果食品有限公司

Dual mode bagger

InactiveUS7770367B2Packaging by pressurising/gasifyingWrapper twisting/gatheringAcute angleDual mode

An apparatus for sealing a bag of encased material is described. A plurality of nozzles radiate from a central vacuum system, each nozzle associated with a clamping means. A framework rotates about the central vacuum system. A holding tray and an elevating device are removably attachable to the framework. The holding tray is attachable below a one of the plurality of nozzles and comprises an upright section and a projecting section. The upright section is supported by the framework at an acute angle from vertical, a top end of the upright section being adjacent to the framework and a bottom end of the upright section being remote from the framework. The projecting section is removably attachable to the bottom end of the upright section and projects approximately normal to the upright section. The elevating device is removably attachable to the framework below a one of the plurality of nozzles.

Owner:POLY CLIP SYST

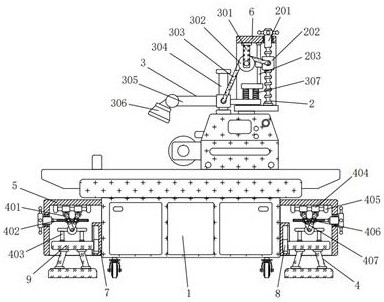

Instant duck meat product packaging equipment

ActiveCN114194456AFully automatedOvercome the shortcomings of manual operationPackaging by pressurising/gasifyingWrapper twisting/gatheringMicrocomputerProcess engineering

The invention discloses instant duck meat product packaging equipment. The instant duck meat product packaging equipment comprises a bagging device and a bag sealing device; the bagging device and the bag sealing device are connected through a conveying belt and electrically connected through a microcomputer. The bagging device is used for automatically opening and bagging duck meat products, and then the bag sealing device is used for automatically vacuumizing and packaging, so that full automation of instant duck meat product packaging is realized.

Owner:SHUNHUA DUCK INDAL DEVMET LINWU COUNTY HUNAN

Meat product processing and packaging device

InactiveCN112124674AEasy to moveEasy to cutPackaging meatPackage sterilisationBiotechnologyEngineering

The invention relates to the technical field of meat product processing equipment, and discloses a meat product processing and packaging device. The meat product processing and packaging device comprises a base, a first moving part, a cutting part, a second moving part, a disinfecting part, a packaging part and a sealing part, wherein the first moving part, the cutting part, the second moving partand the disinfecting part are arranged above the base; the first moving part is fixedly arranged at one end of the base; the cutting part is positioned at one side of the first moving part; the second moving part is positioned at one side of the cutting part; the disinfecting part is fixedly arranged on the base; the disinfecting part is positioned above the second moving part; the packaging partis fixedly arranged at one side of the base; the sealing part is arranged below the packaging part; and the sealing part corresponds to a working end of the packaging part. Through cooperation of theparts, the problems that manual meat product processing is low in speed and efficiency are solved, and the problems that manual meat product packaging is low in speed and efficiency are solved.

Owner:张玉玲

Full-automatic modified atmosphere fresh-keeping packaging machine for poultry meat

InactiveCN113734532AHeight adjustableAchieve sterilizationPackage sterilisationPackaging poultryBiotechnologyUltraviolet lights

The invention discloses a full-automatic modified atmosphere fresh-keeping packaging machine for poultry meat, which comprises a second shell; a packaging machine body is fixedly arranged at the bottom of the second shell; a moving structure is arranged on the inner side of the packaging machine body; the moving structure comprises a threaded rod, a transverse block and a first sliding rod; the upper portion of the outer wall of the threaded rod is rotationally connected with the inner wall of the top of the second shell through a bearing; and the outer wall of the threaded rod is in threaded connection with the transverse block. According to the full-automatic modified atmosphere fresh-keeping packaging machine for the poultry meat, through cooperation of the packaging machine body, a first shell, the second shell, a groove plate, a sliding block, a base, the moving structure and a sliding structure, the threaded rod is rotated; the threaded rod drives the transverse block to move up and down; the transverse block winds and unwinds a steel wire rope; the steel wire rope drives a straight rod to move upwards; a spring drives the straight rod to move downwards; then the straight rod drives an ultraviolet lamp to move up and down, so that a worker can conveniently adjust the height of the ultraviolet lamp; sterilization during meat packaging is achieved; and bacteria and meat are prevented from entering a packaging box together.

Owner:徐金胜

Two-in-one bagger

ActiveUS8938935B2Wrapping material feeding apparatusOral administration deviceEngineeringMechanical engineering

The invention comprises a system for encasing material in one of a stretchable bag and a shrinkable bag. The system comprises a pair of product horns rotatable in a plane from a first position to a second position; a stretchable-bag system comprising a bag carriage unit; a shrinkable-bag system, comprising a pair of pulling rollers mounted under the product horns and a collection roller mounted adjacent the pulling rollers, the collection roller configured to move a predetermined increment, a product ram configured to move material between the product horns and into one of a stretchable bag and a shrinkable bag, and an air jet for opening the bags.

Owner:POLY CLIP SYST

Netting knife cutter

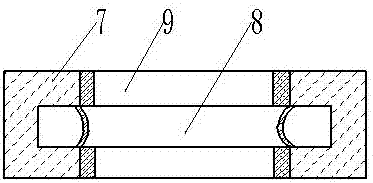

An apparatus for packaging material in netting is described. The apparatus in a first embodiment is a netter for enclosing material in netting and a scissors assembly for severing the netting. The scissors assembly comprises a pair of blade elements pivotally connected by a pin affixed to the netter and each of the pair of blade elements comprises a knife section extending in a first direction from the pin and a lever section extending in a second direction from the pin. The scissors assembly further comprises a pair of link arms each connecting one of the lever sections of the pair of blade elements to a piston, the piston extendable in a first direction to pivot the knife sections of the blade elements toward each other and extendable in a second direction to pivot the knife sections of the blade elements away from each other. In another embodiment, the piston comprises an air-actuated cylinder.

Owner:POLY CLIP SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com