Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about "Mechanical width measurements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

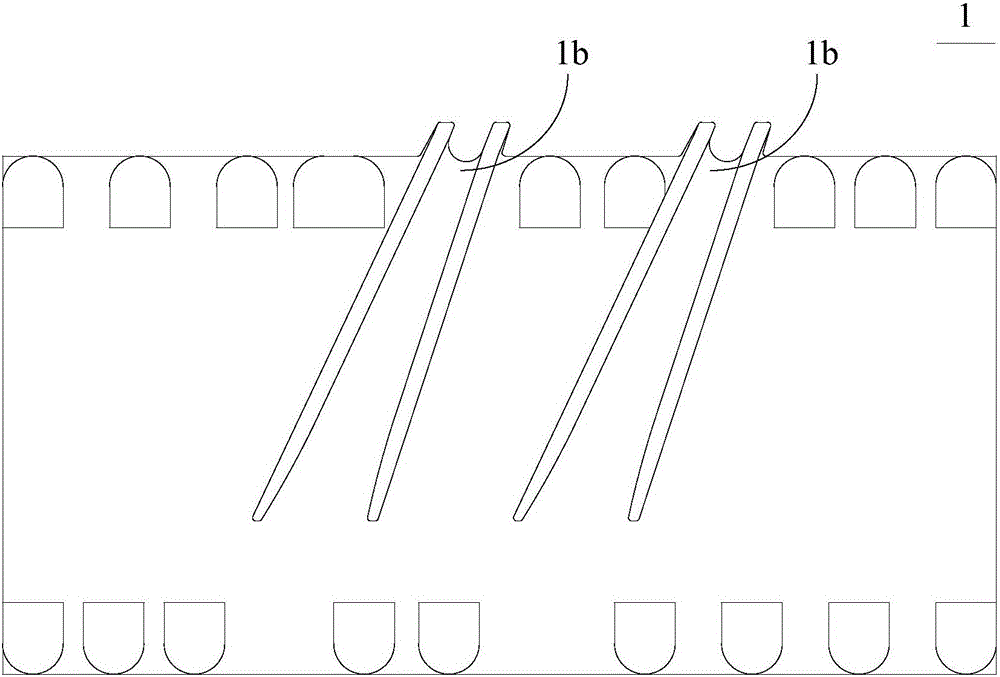

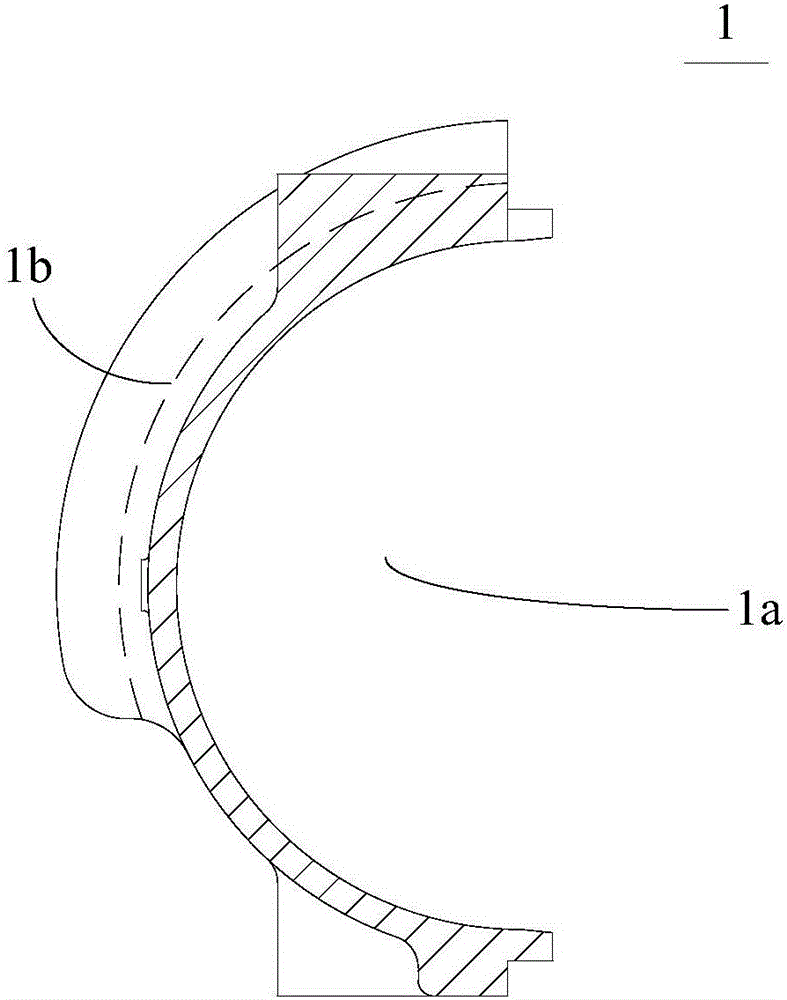

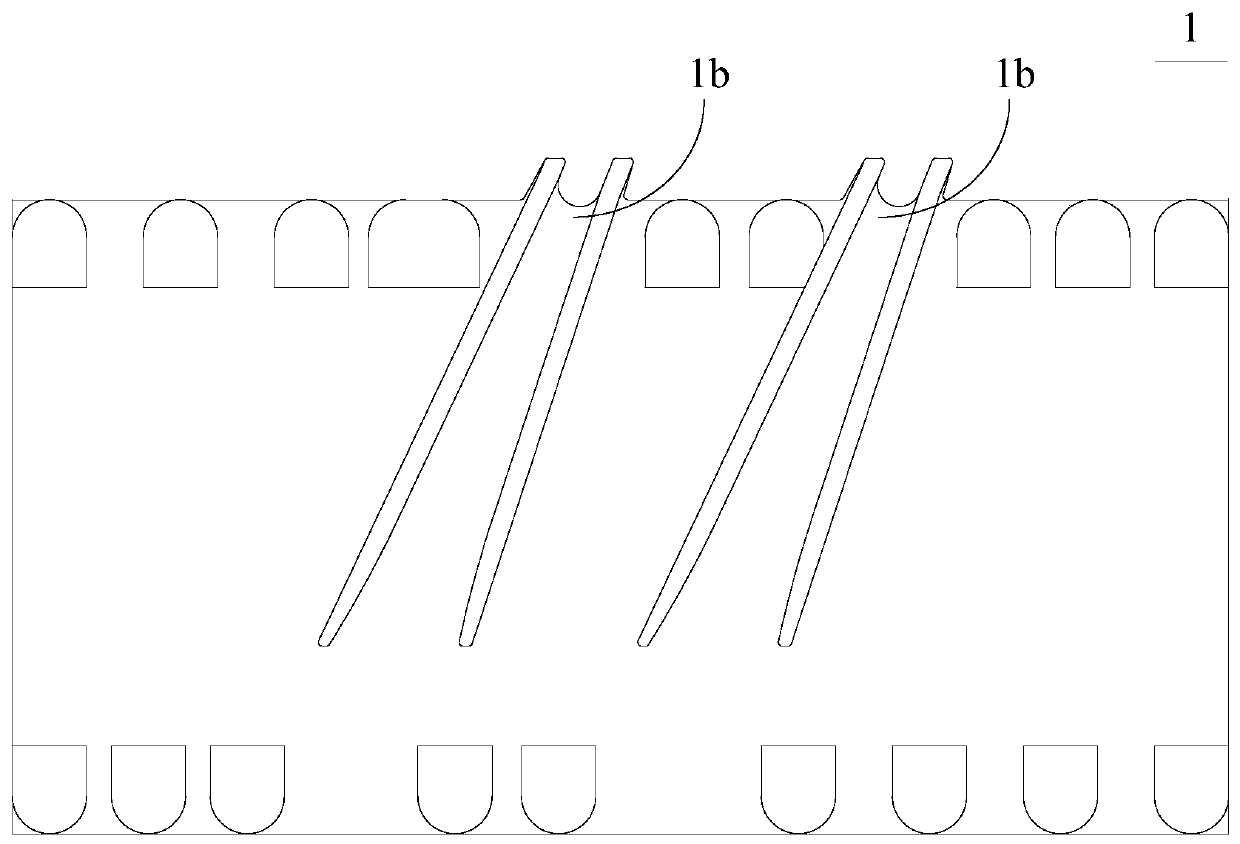

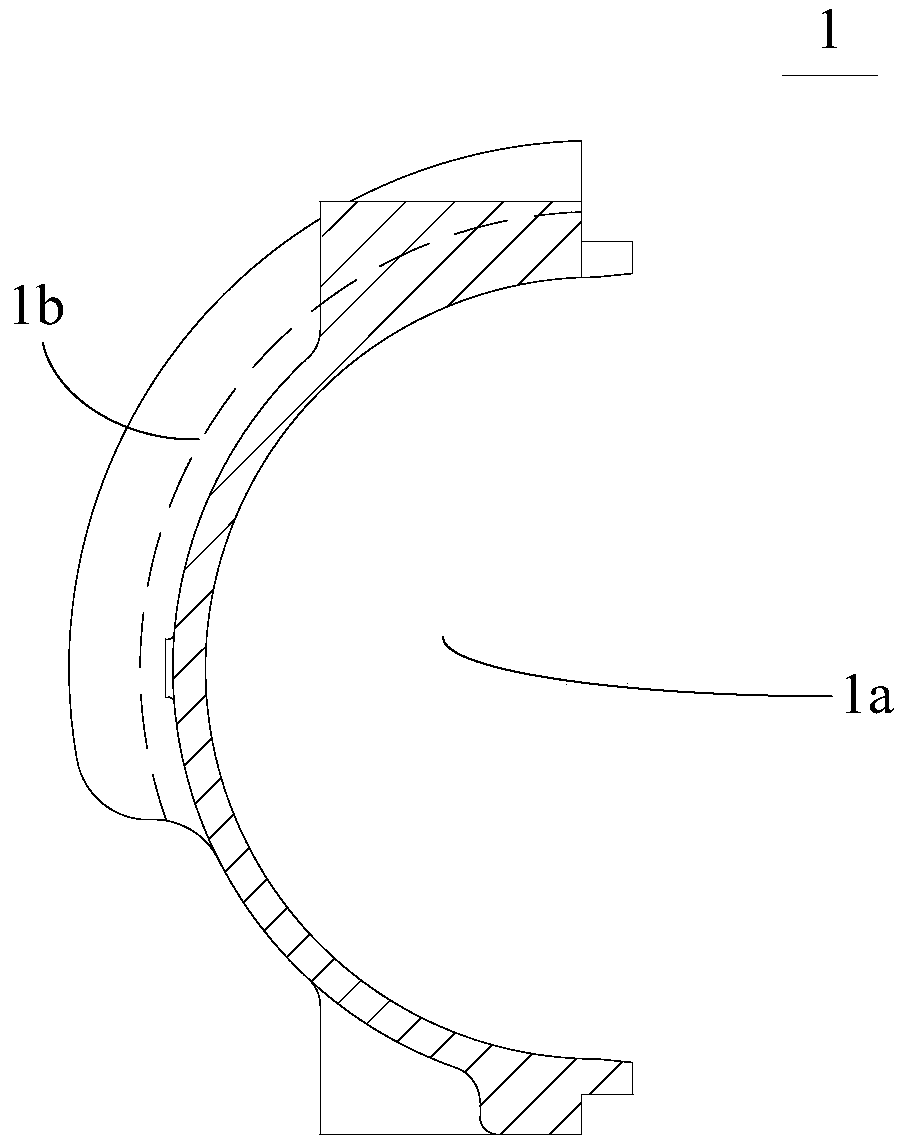

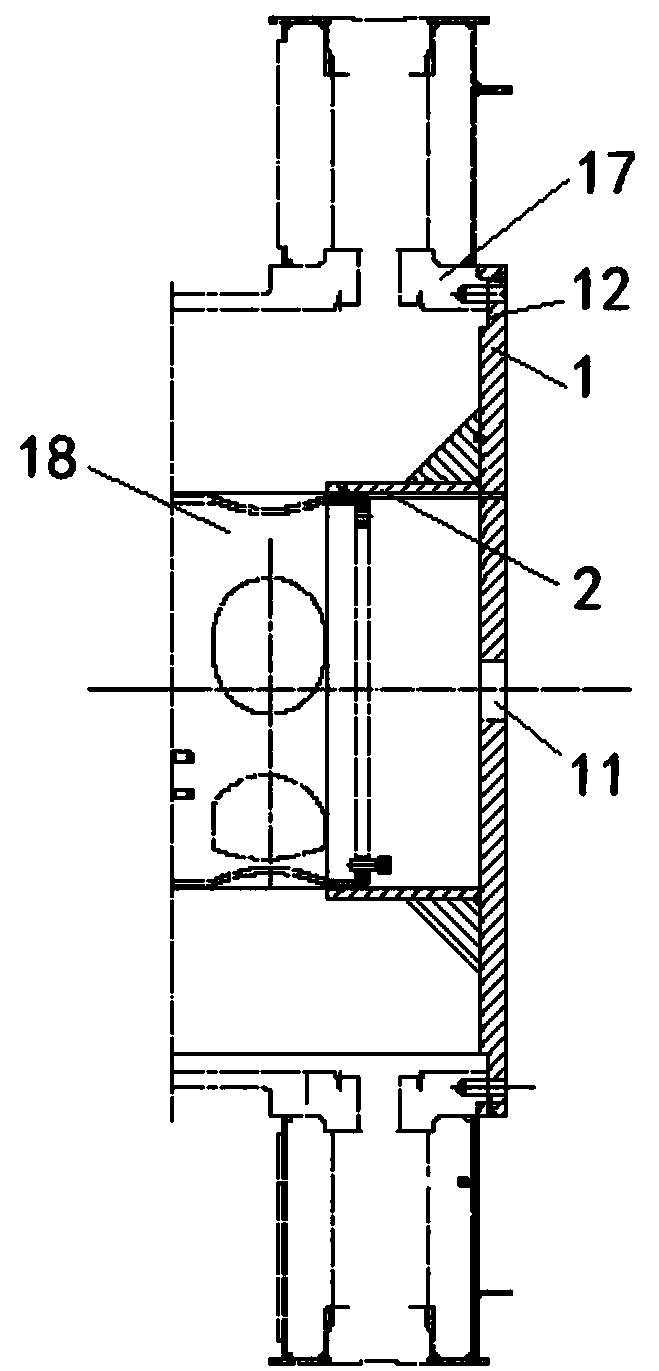

Automatic monitoring and controlling equipment for wire width of steel strand

ActiveCN111540539AThe detection method is simpleEasy to monitor in real timeMechanical width measurementsUsing optical meansWire widthEngineering

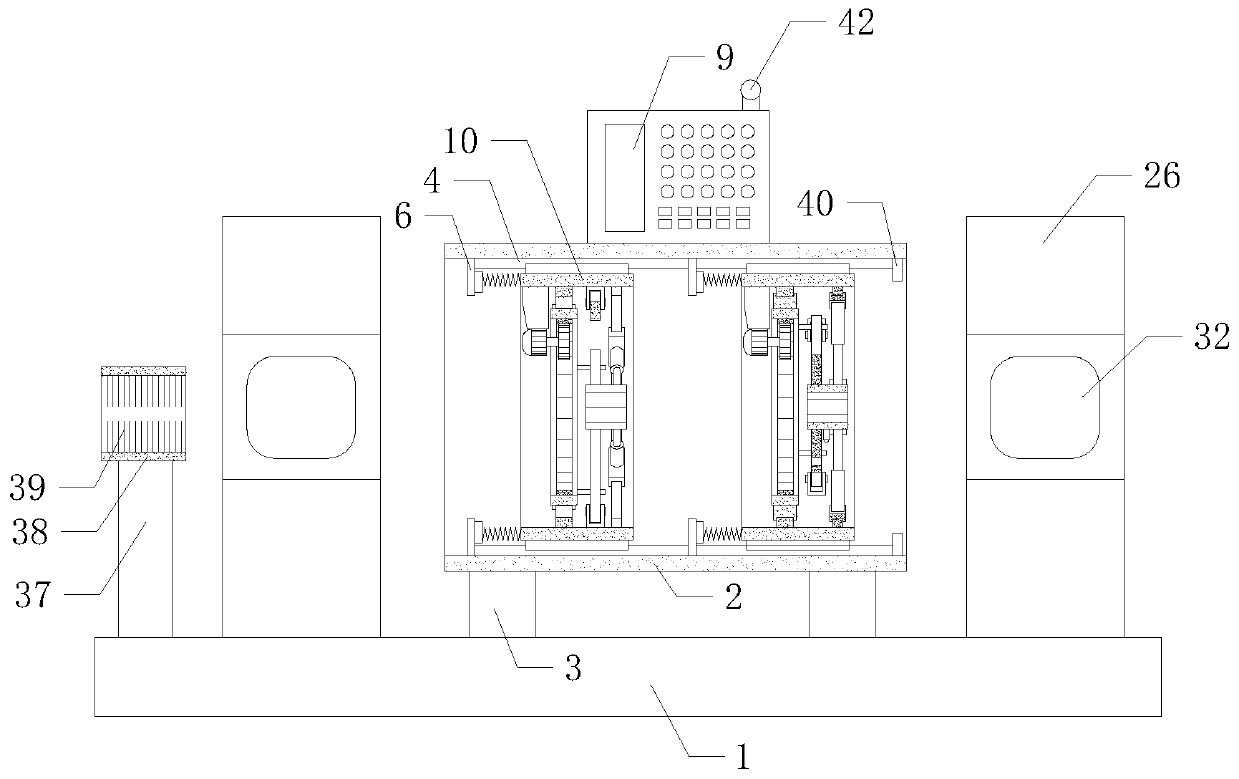

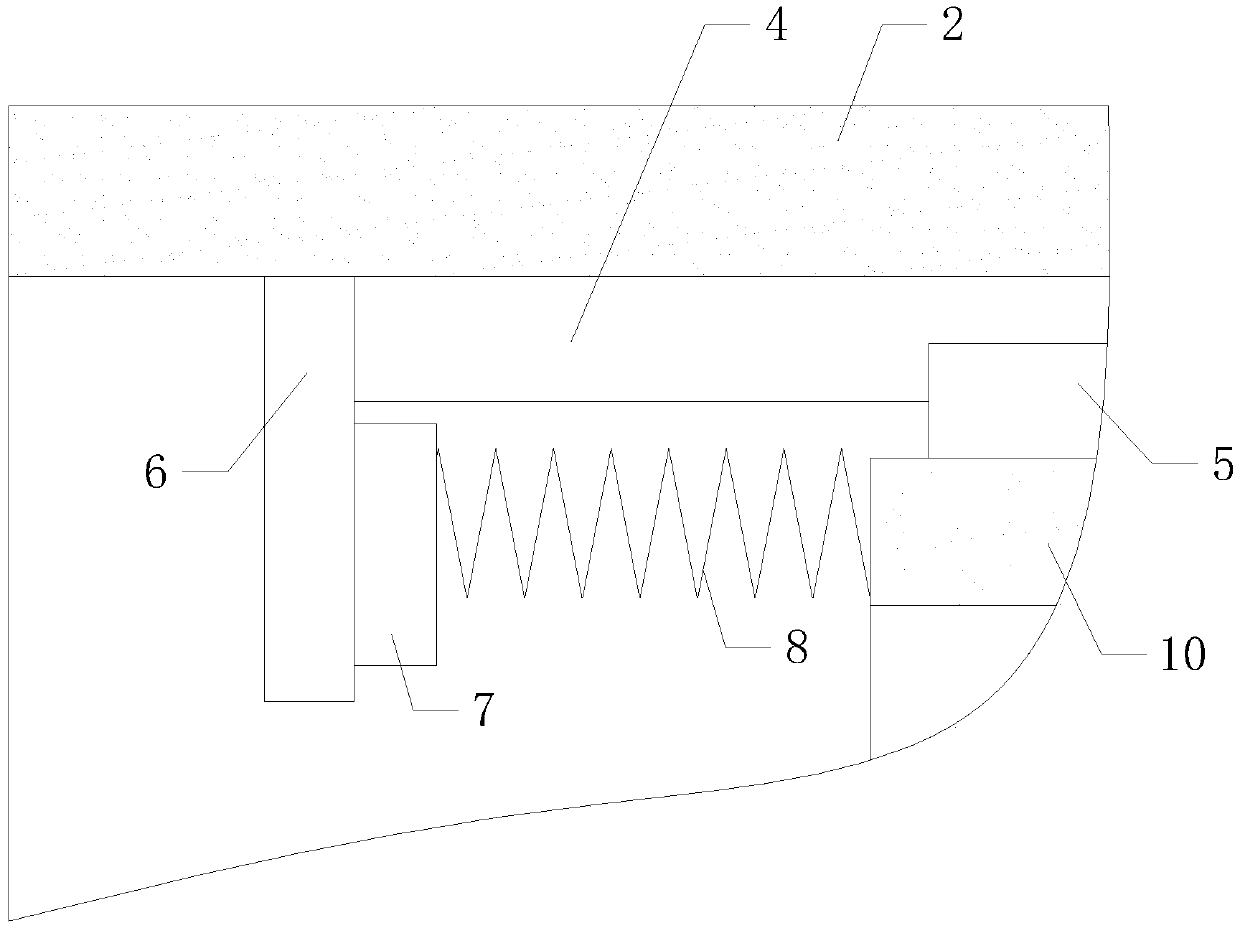

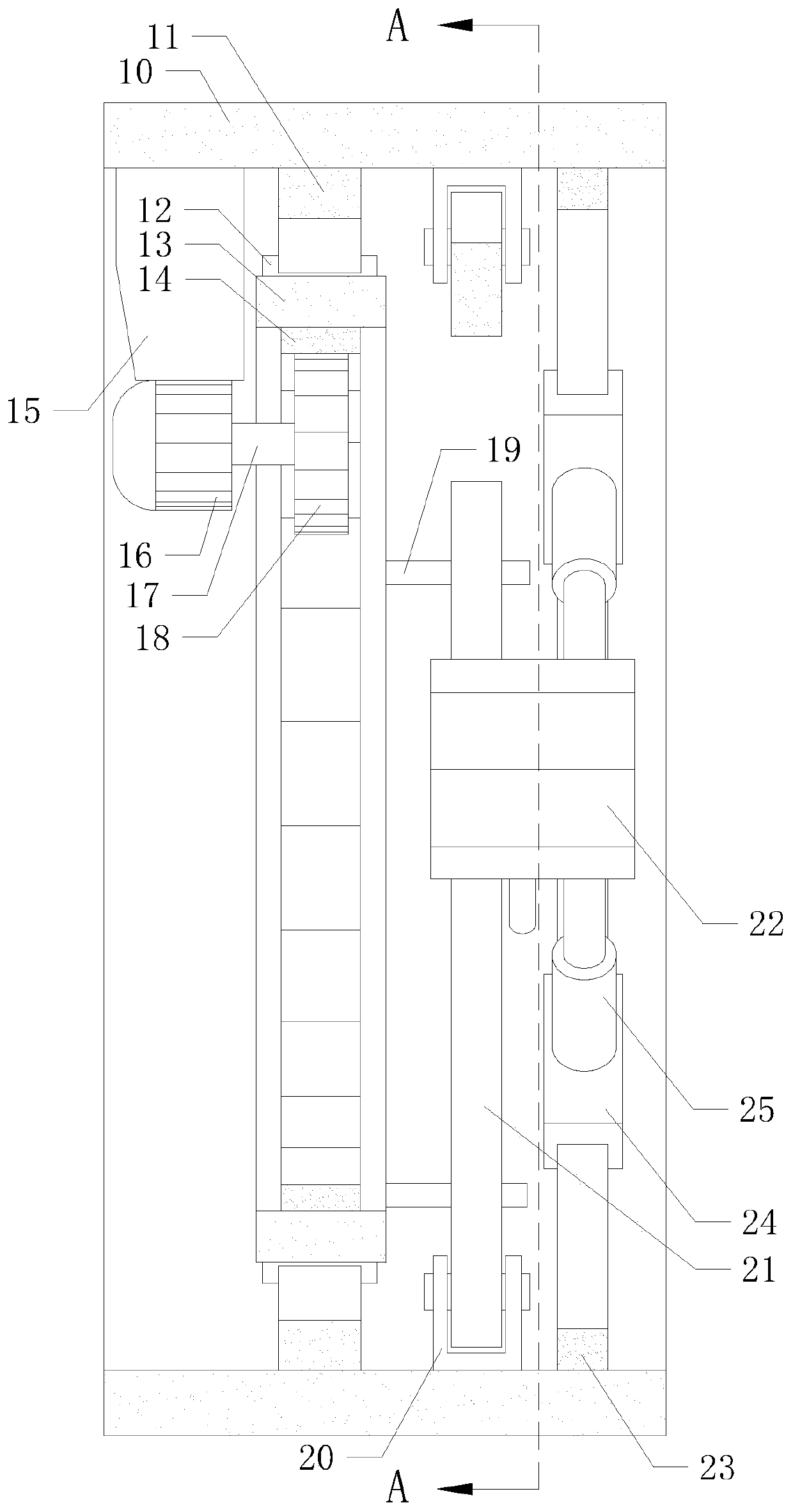

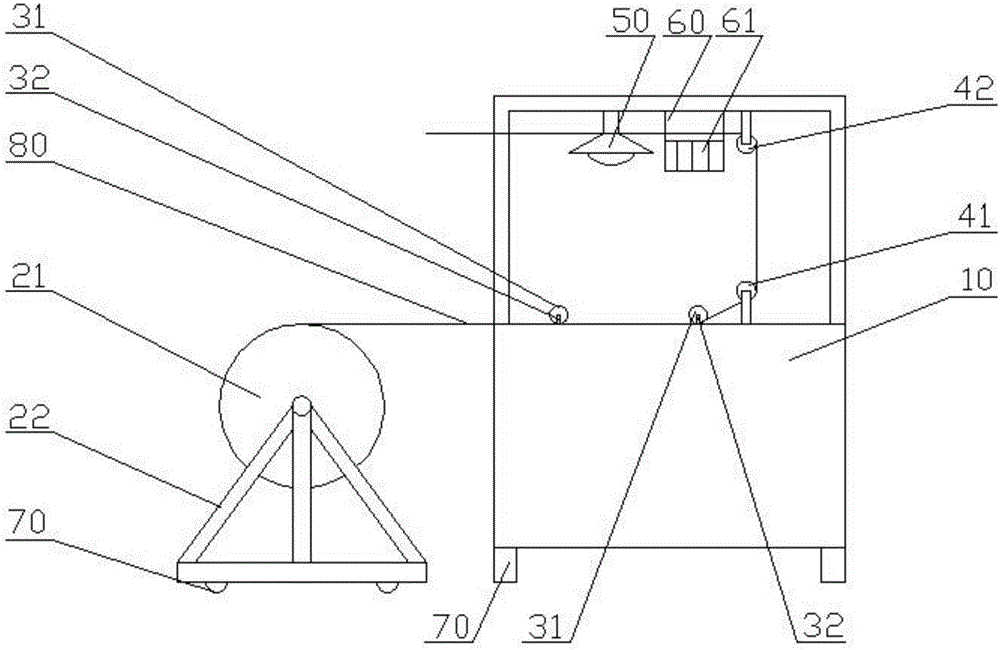

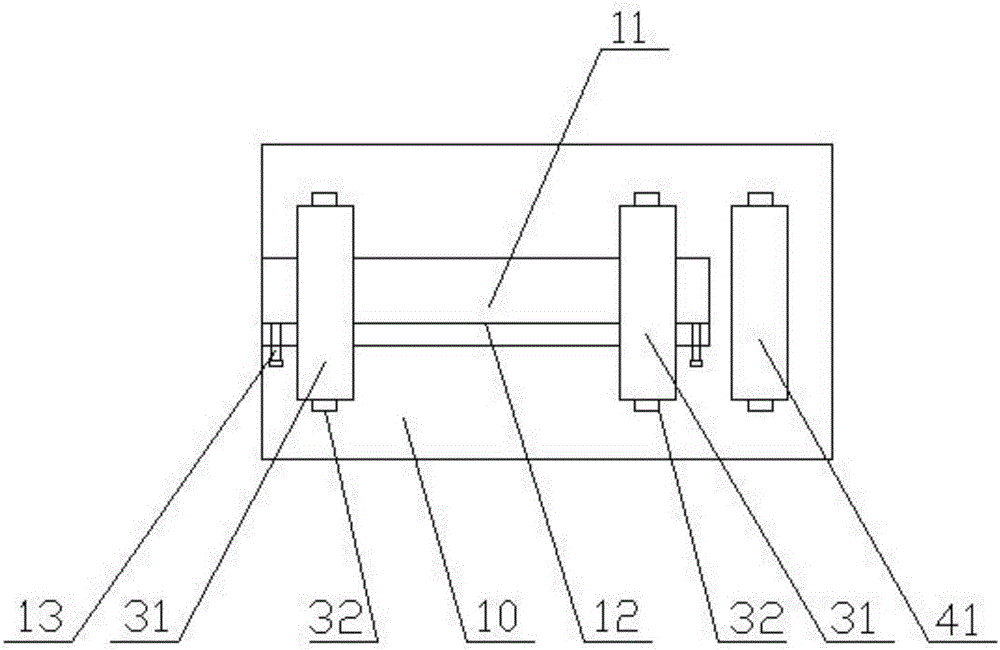

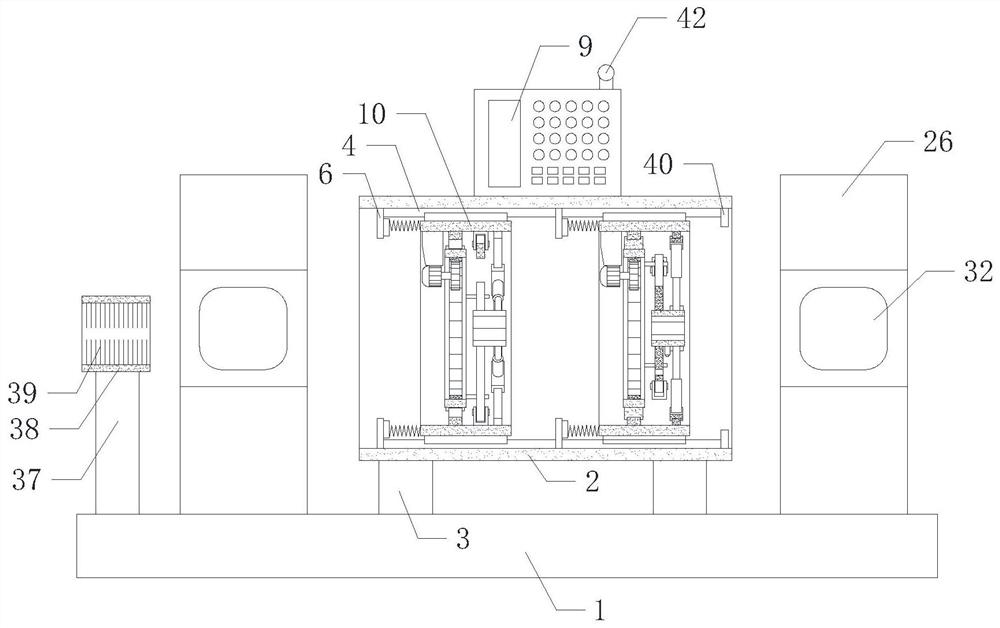

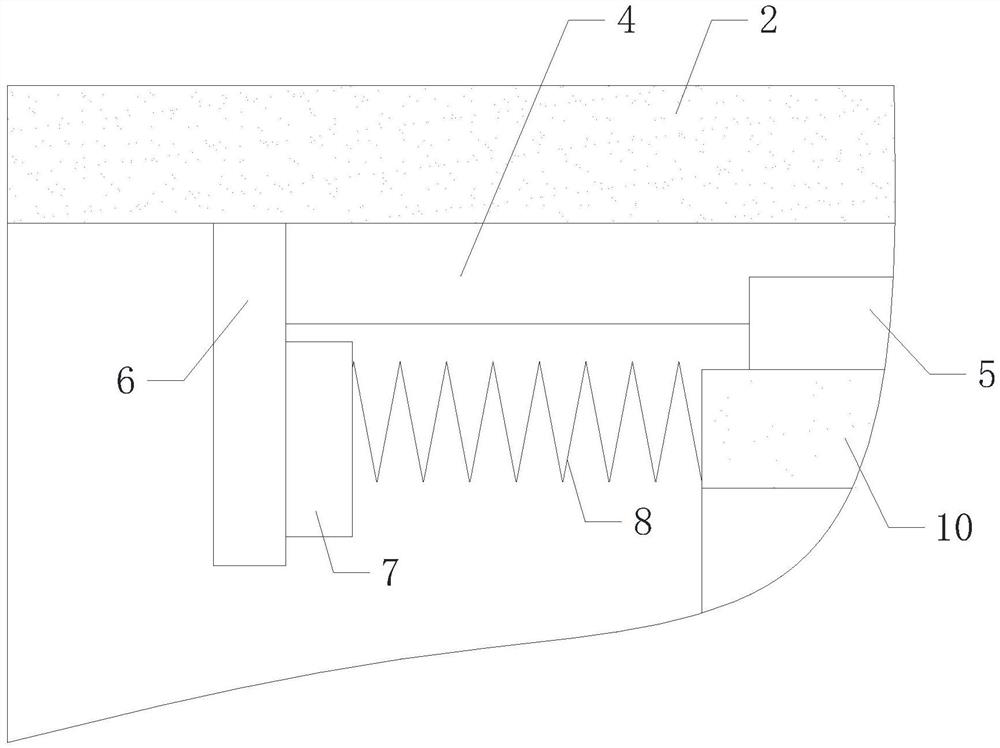

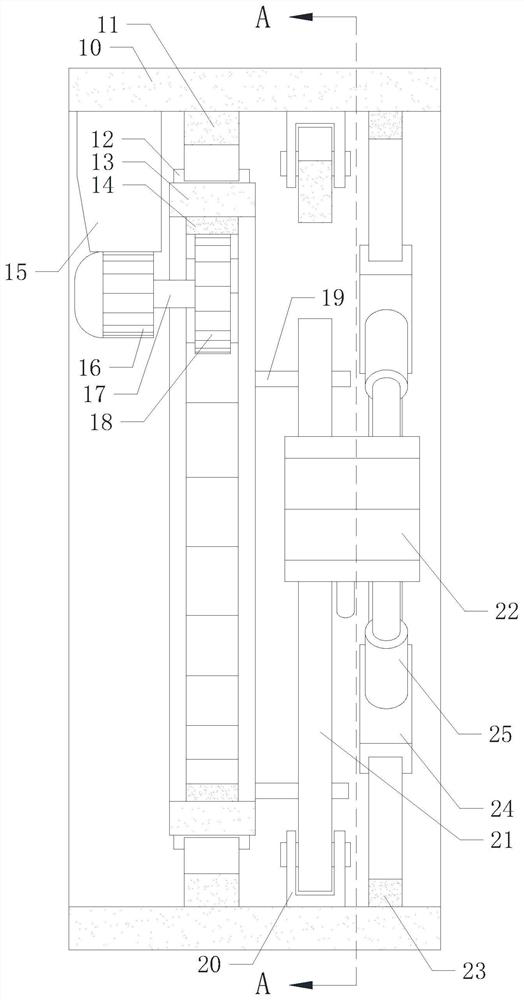

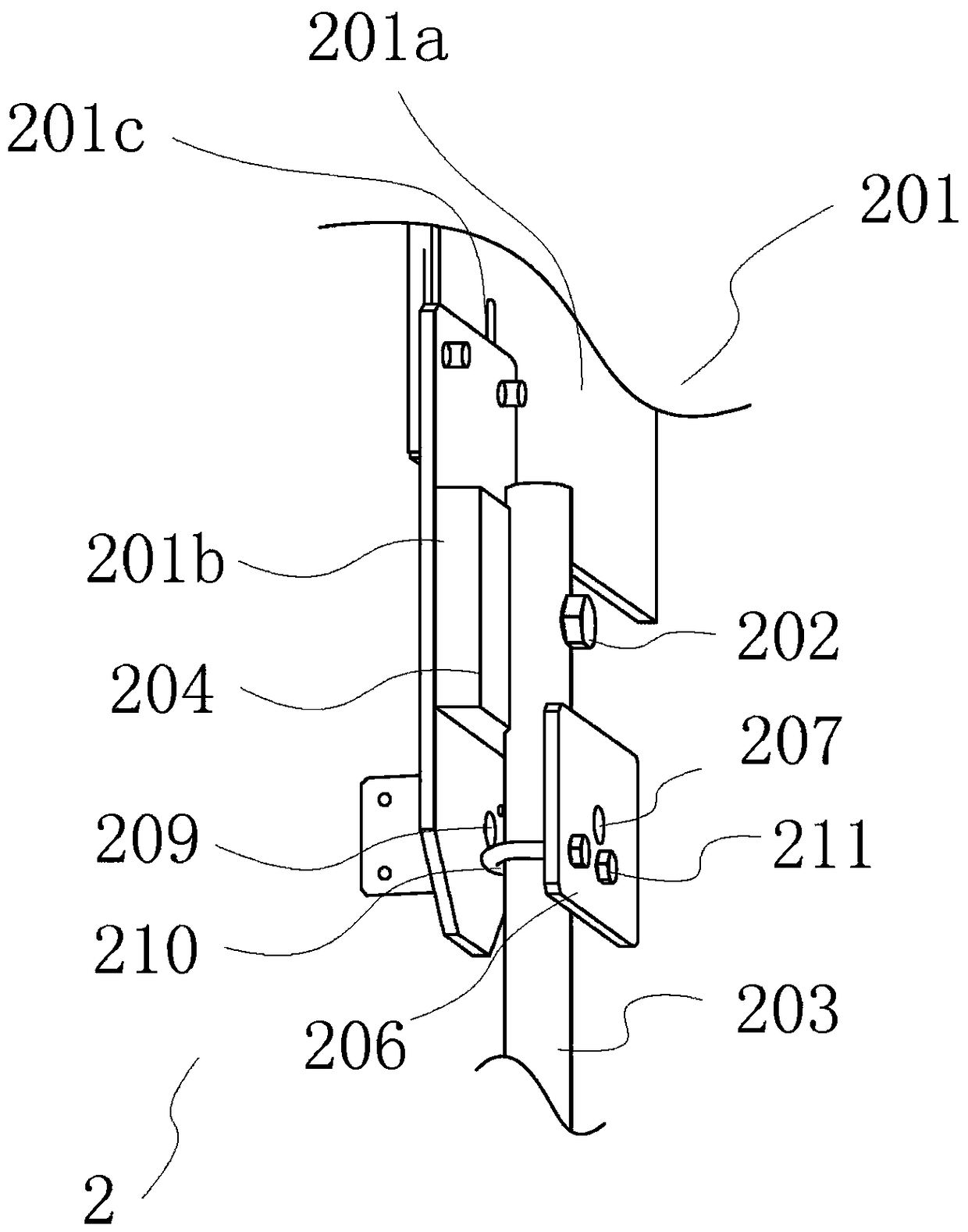

The invention relates to the technical field of detection equipment. The invention particularly relates to automatic monitoring and controlling equipment for the wire width of a steel strand, by automatically monitoring the wire width of a steel strand, the physical strength and time during manual detection can be effectively saved, the detection mode of the steel strand is simplified, the detection precision is effectively improved, the product quality is improved, and the practicability and reliability are improved. The equipment comprises a base, a threading sleeve, two groups of first supporting plates and two groups of linear guide rails, conveying devices are arranged on the left side and the right side of the base respectively, the two conveying devices correspond in height position, the threading sleeve is located between the two conveying devices and fixed to the base through two first supporting plates, and the two linear guide rails are transversely installed at the top andthe bottom of the inner wall of the threading sleeve respectively.

Owner:河北恒源线缆有限公司

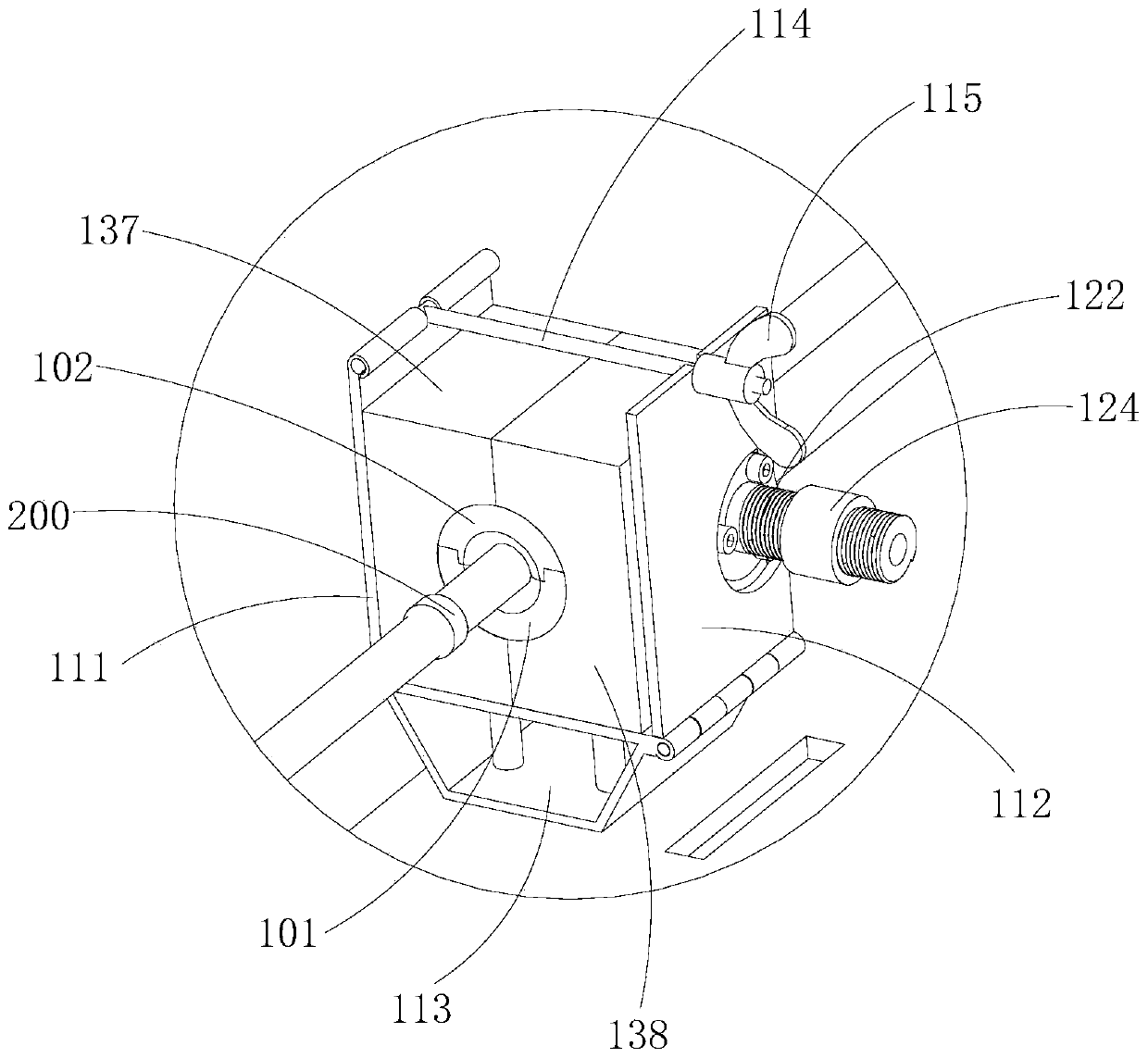

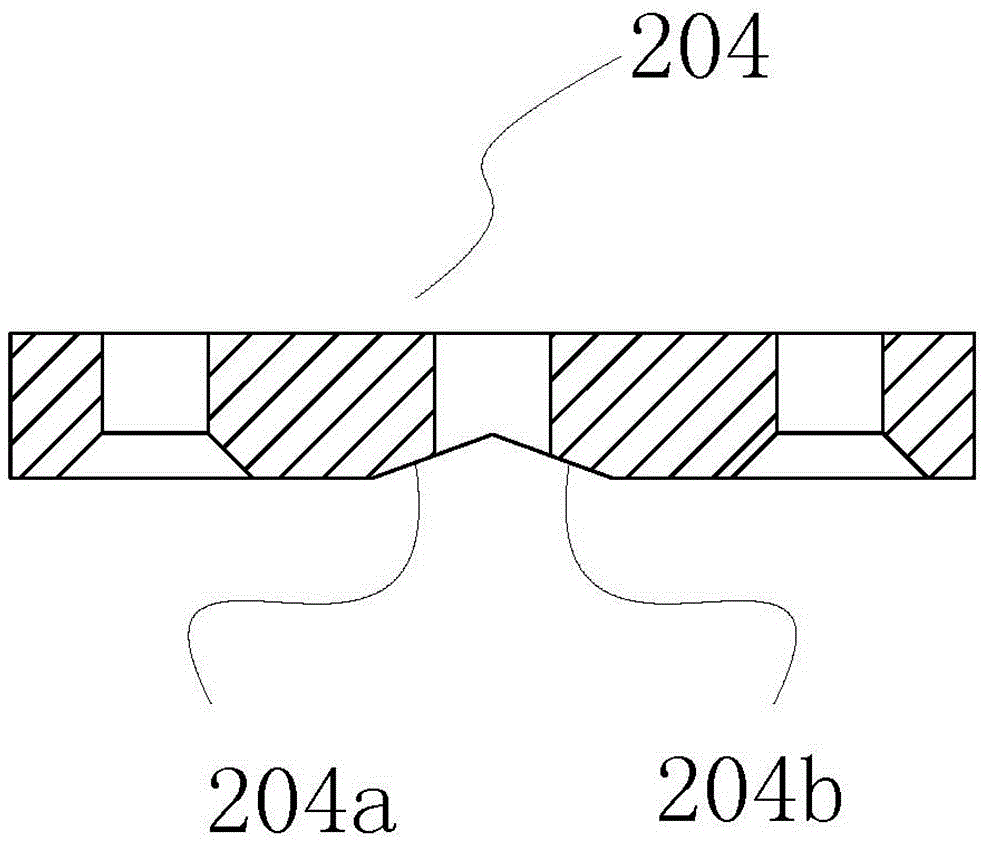

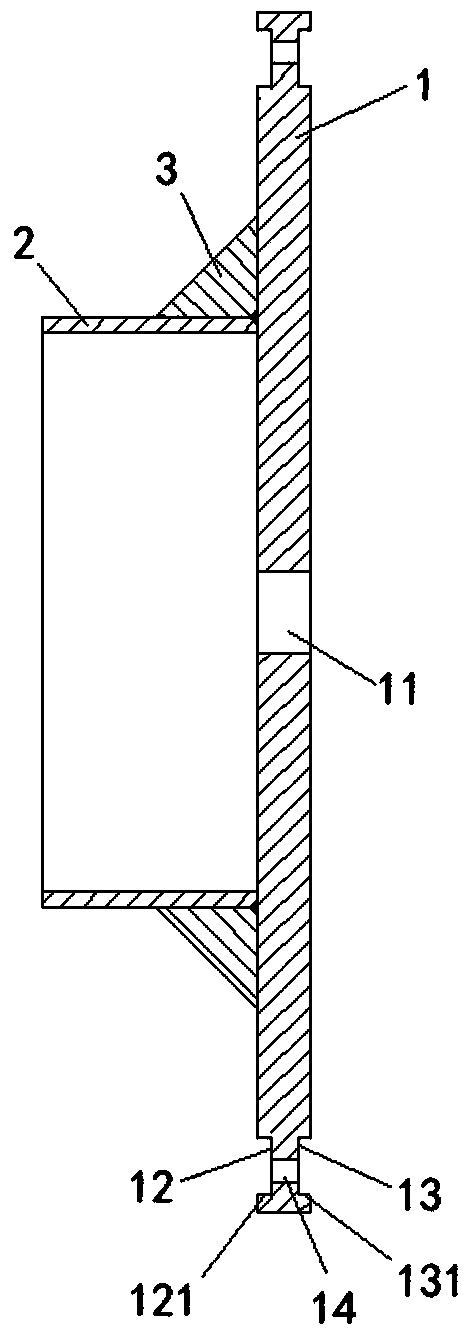

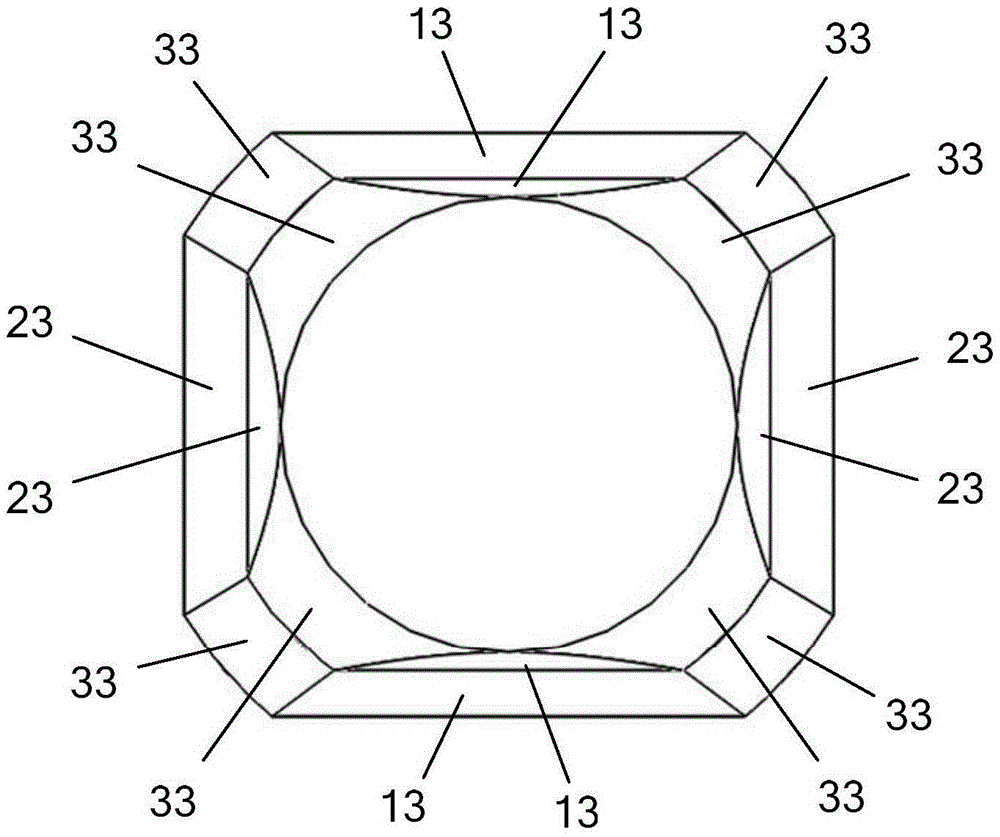

Cable block detection device

PendingCN110455144AQuick releaseMechanical diameter measurementsMechanical width measurementsEngineeringBlock detection

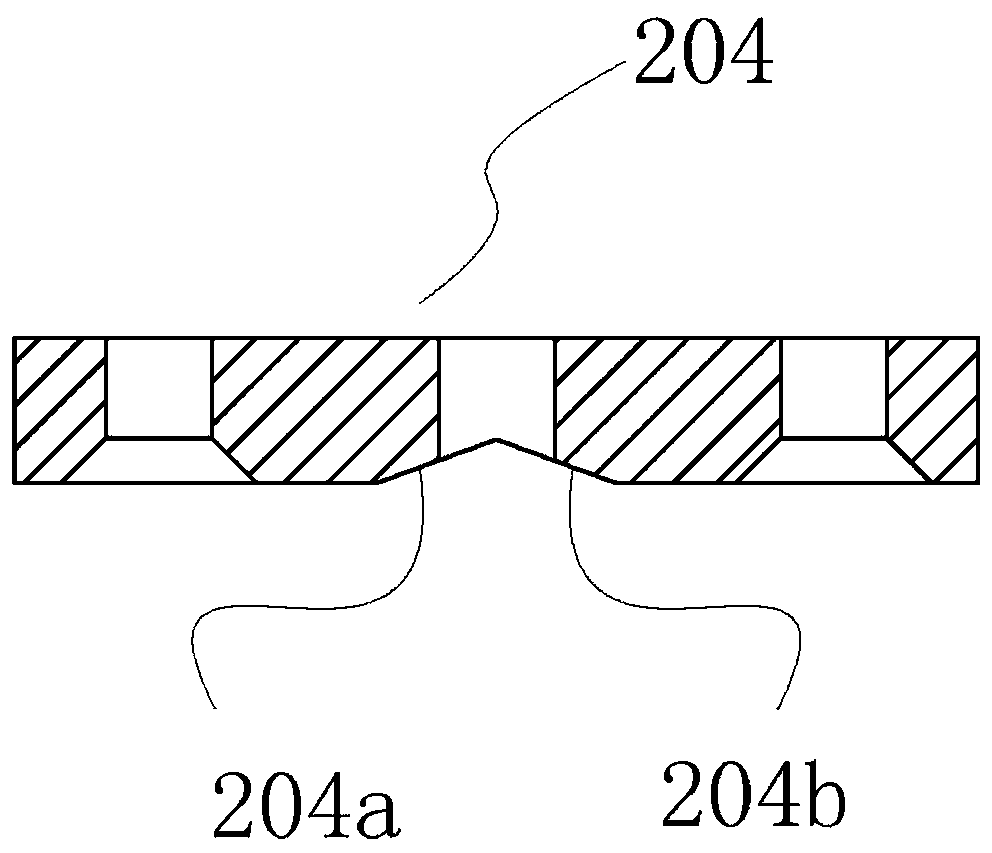

The invention relates to the technical field of cable production, in particular to cable block detection device. The cable block detection device comprises a fixing device and a cable passing die, wherein the fixing device is provided with a limit hole allowing placement of the cable passing die; the cable passing die comprises a first half die and a second half die, and the first half die and thesecond half die are placed in the limit hole and can be buckled to form a channel allowing a cable to pass through; when width of a block on the surface of the cable is larger than that of the channel, the block can be propped against the front end surfaces of the first half die and the second half die, the first half die and the second half die can be driven to move in the length direction of the limit hole, and therefore, the first half die and the second half die are broken away from the fixing device and are separated.According to the cable block detection device, the first half die and the second half die are placed in the fixing device, and can be immediately separated after being broken away from the fixing device, and the purpose of rapidly dismounting the cable penetrating die isachieved.

Owner:SHENYANG HENGTONG OPTICAL COMM CO LTD

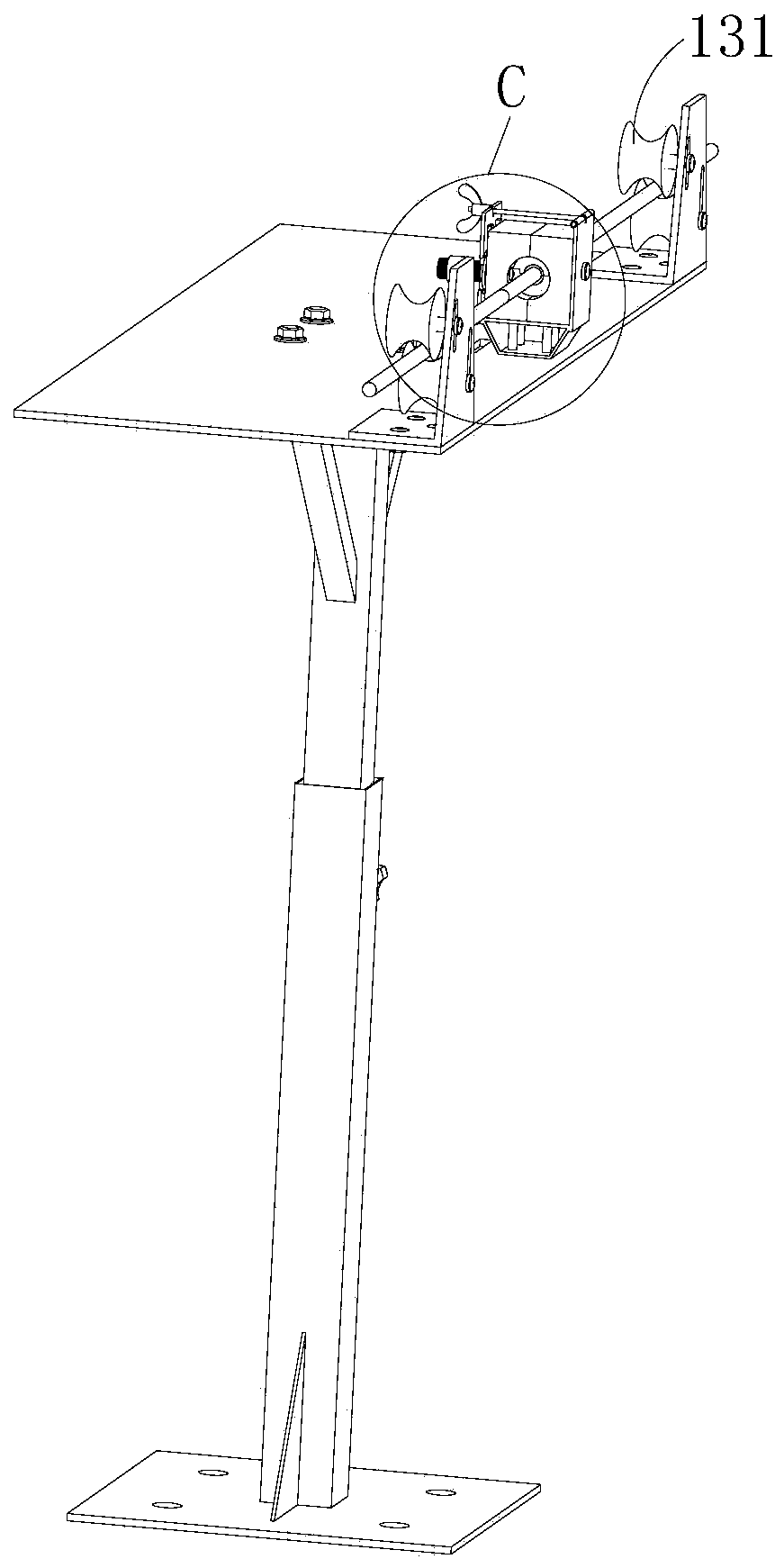

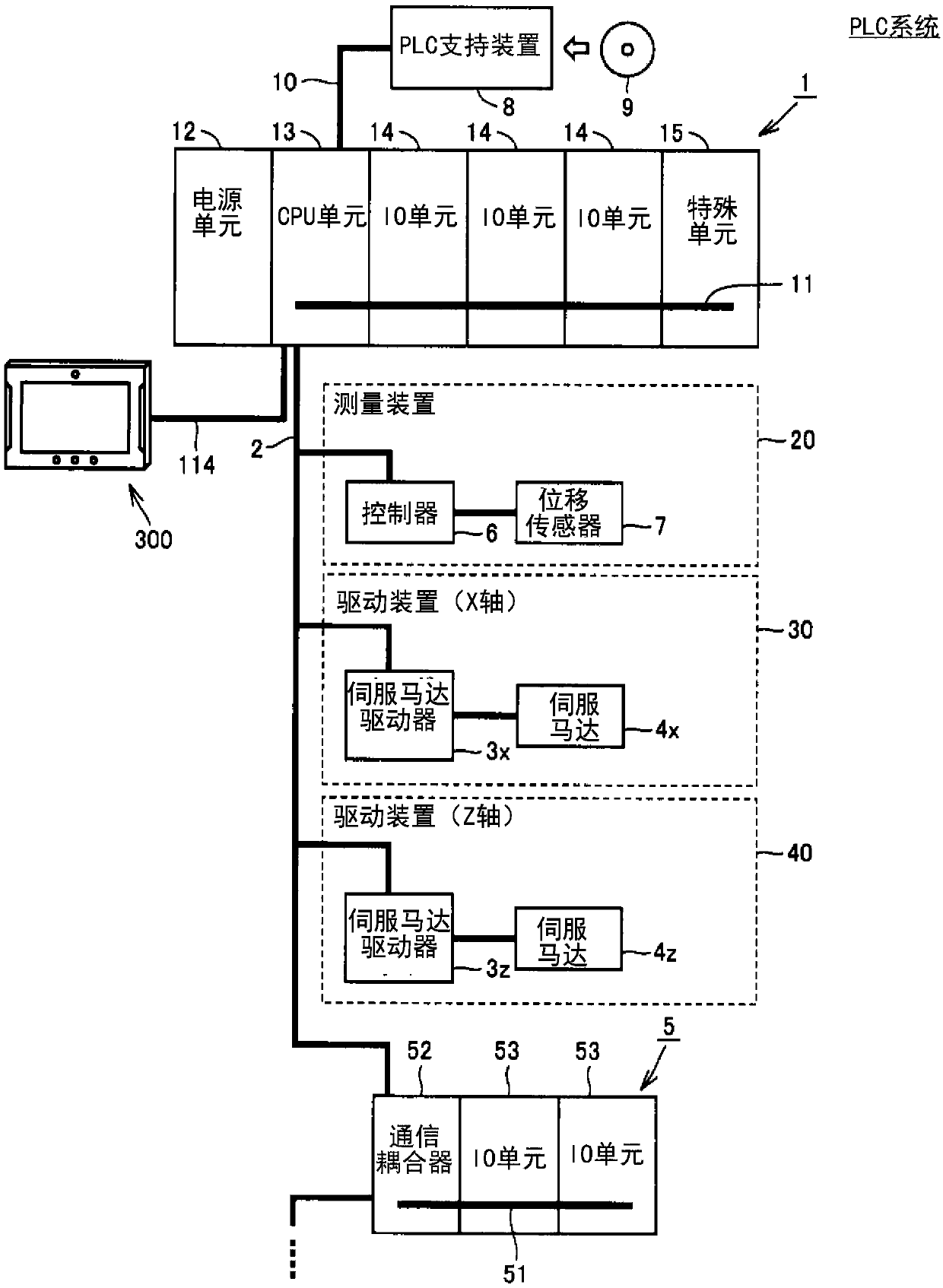

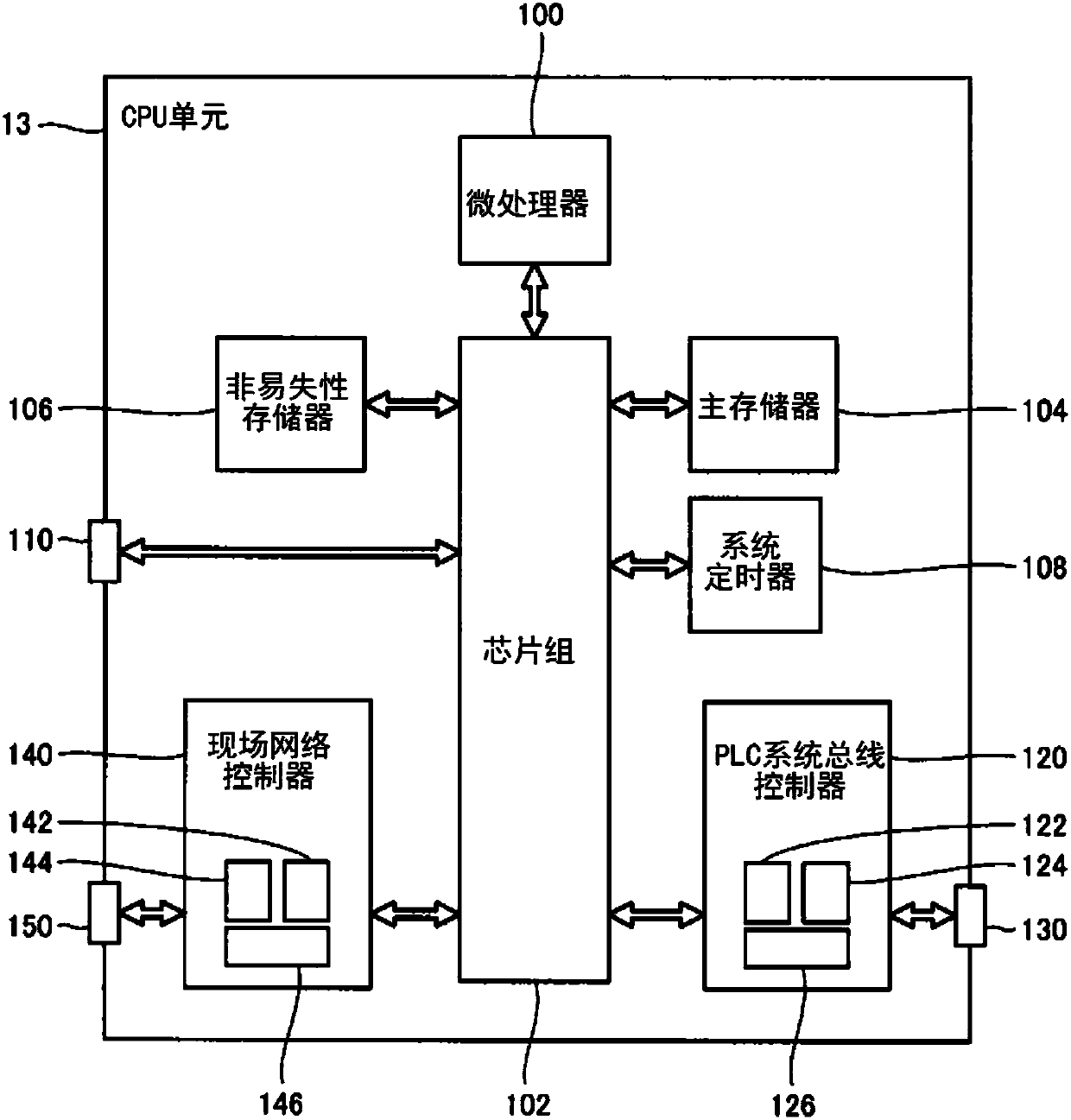

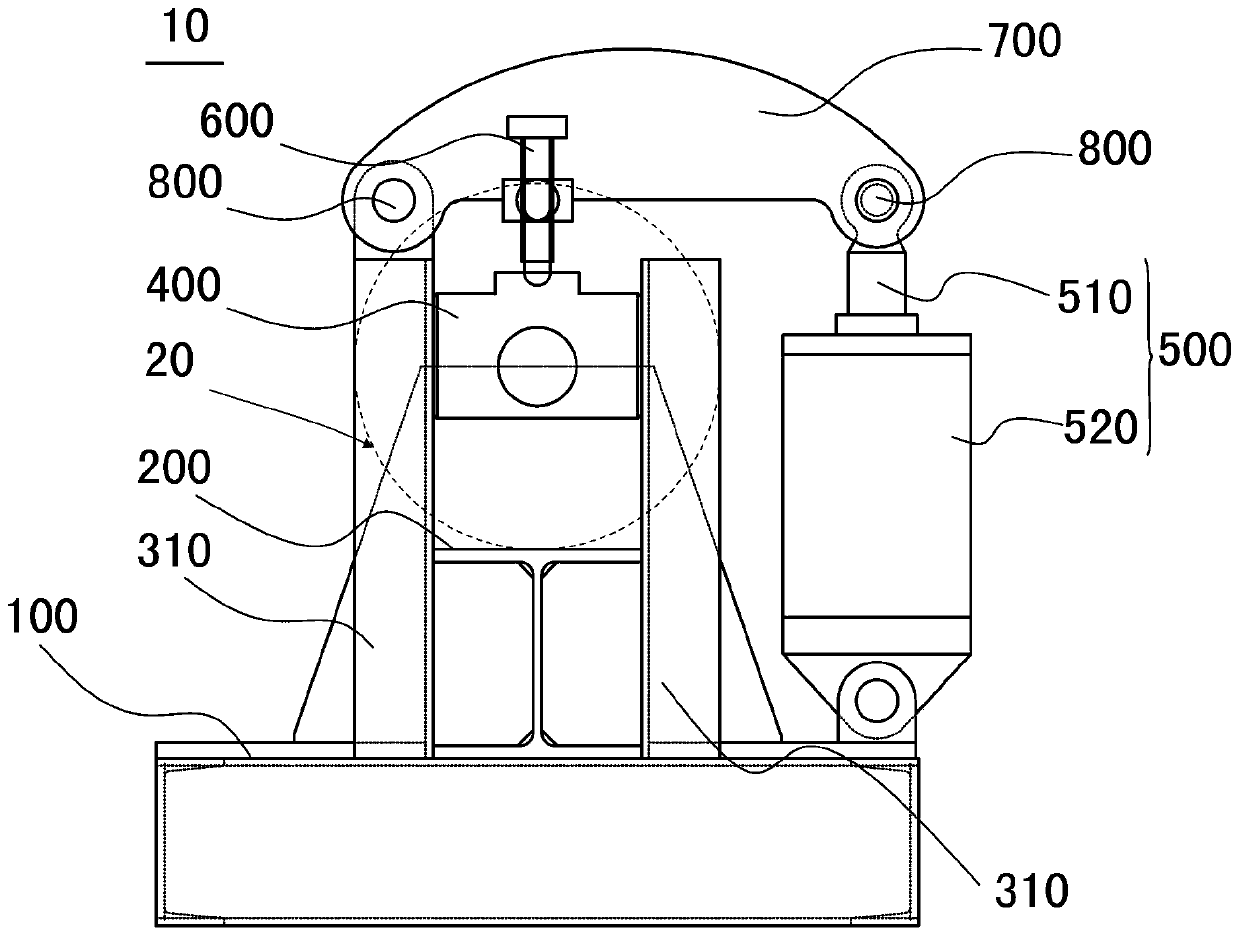

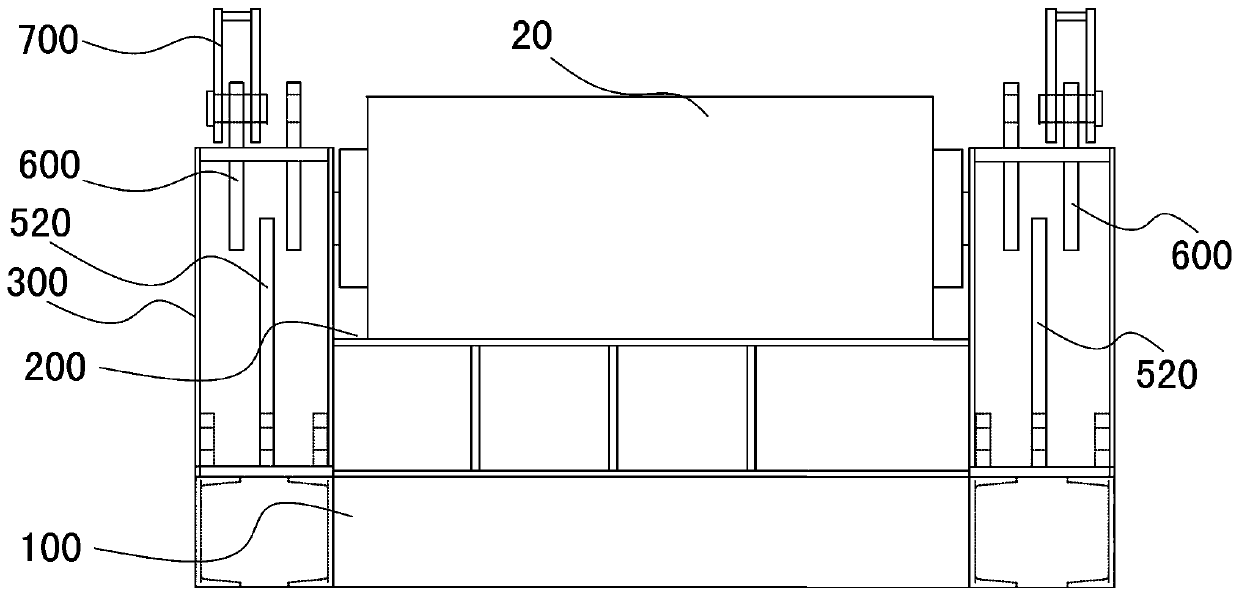

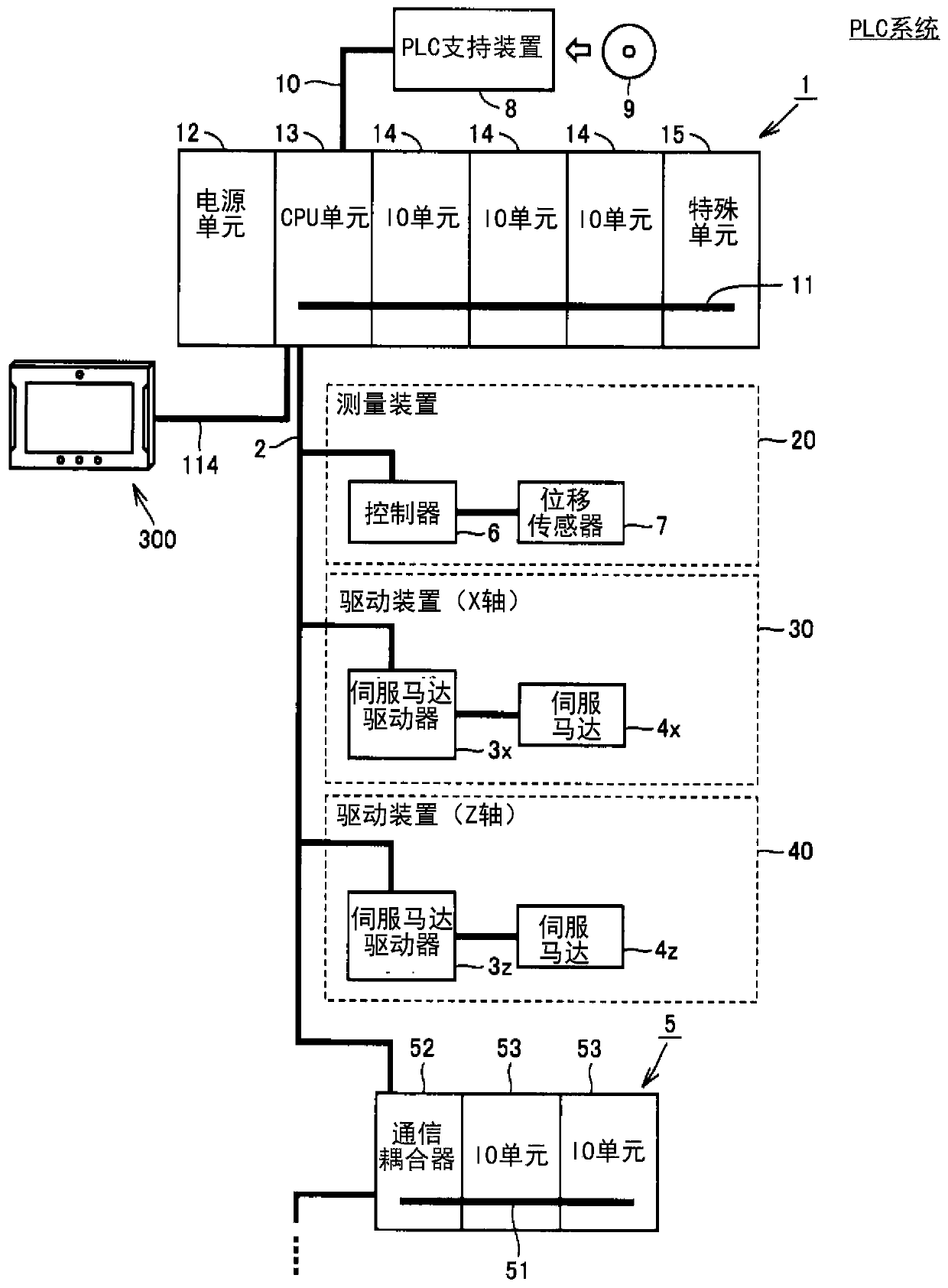

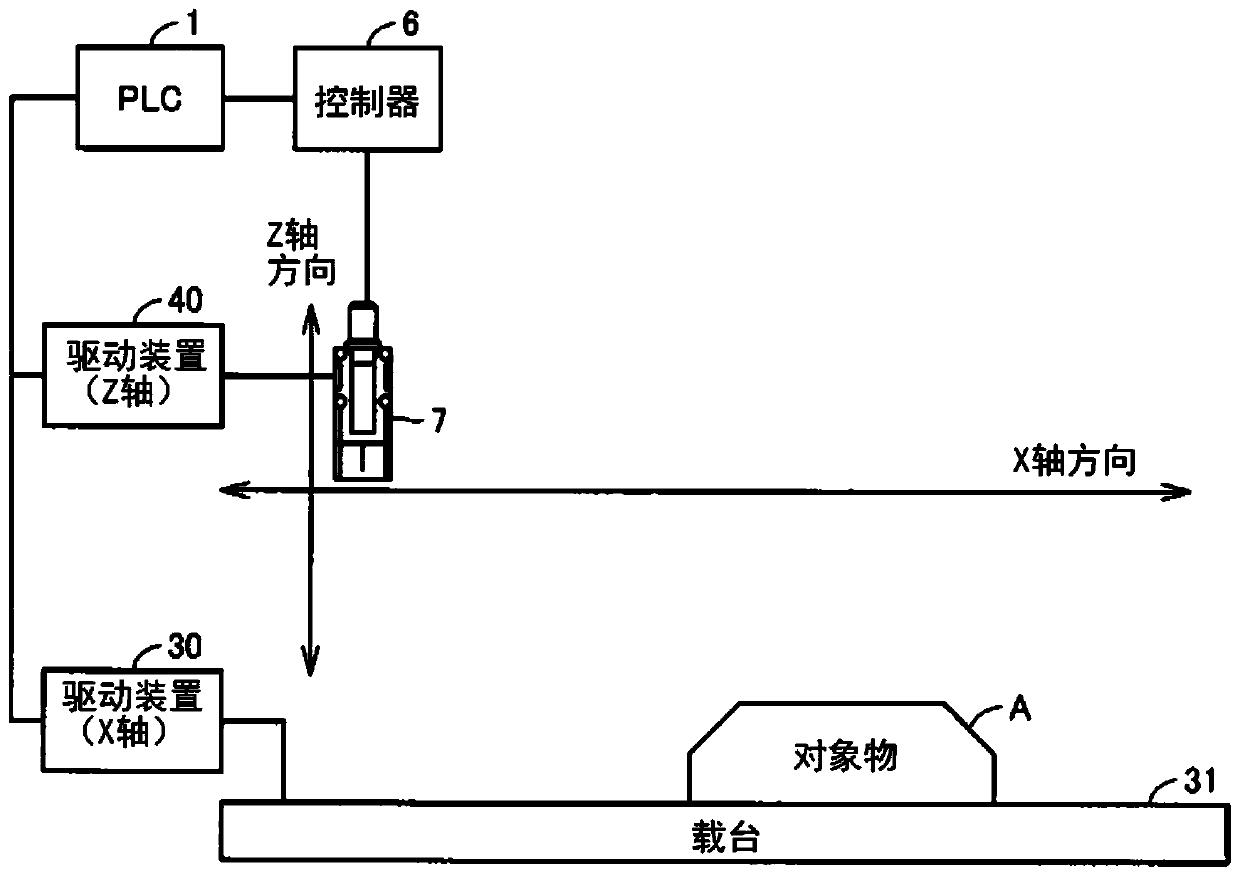

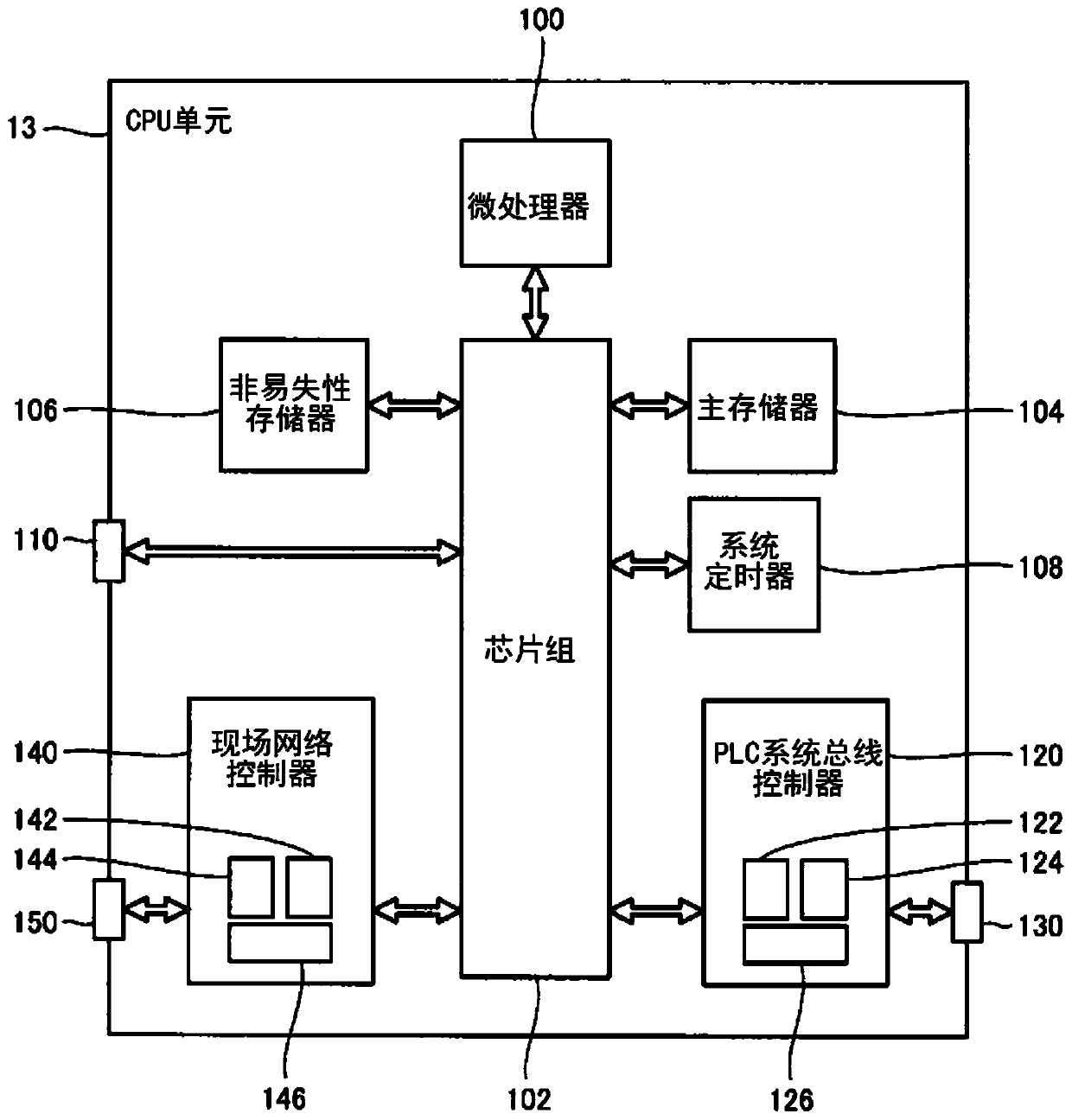

Control system, and control method and computer readable storage medium

ActiveCN108021089AReduce vibrationShorten takt timeAngles/taper measurementsMeasurement/indication equipmentsControl systemComputer science

A control system, a method, and a computer readable storage medium reduce oscillations in trace control and shorten the tact time in measurement. A PLC system (SYS) includes a displacement sensor (7),drives (30, 40), and a PLC (1). In the PLC system (SYS), the trace control unit (162) calculates a target position at which a distance between the displacement sensor (7) and the object (A) is constant based on measurement information (1D information) from which measurement noise (noise information) has been removed by the filter (162c) and positional information from the drives (30, 40).

Owner:ORMON CORP

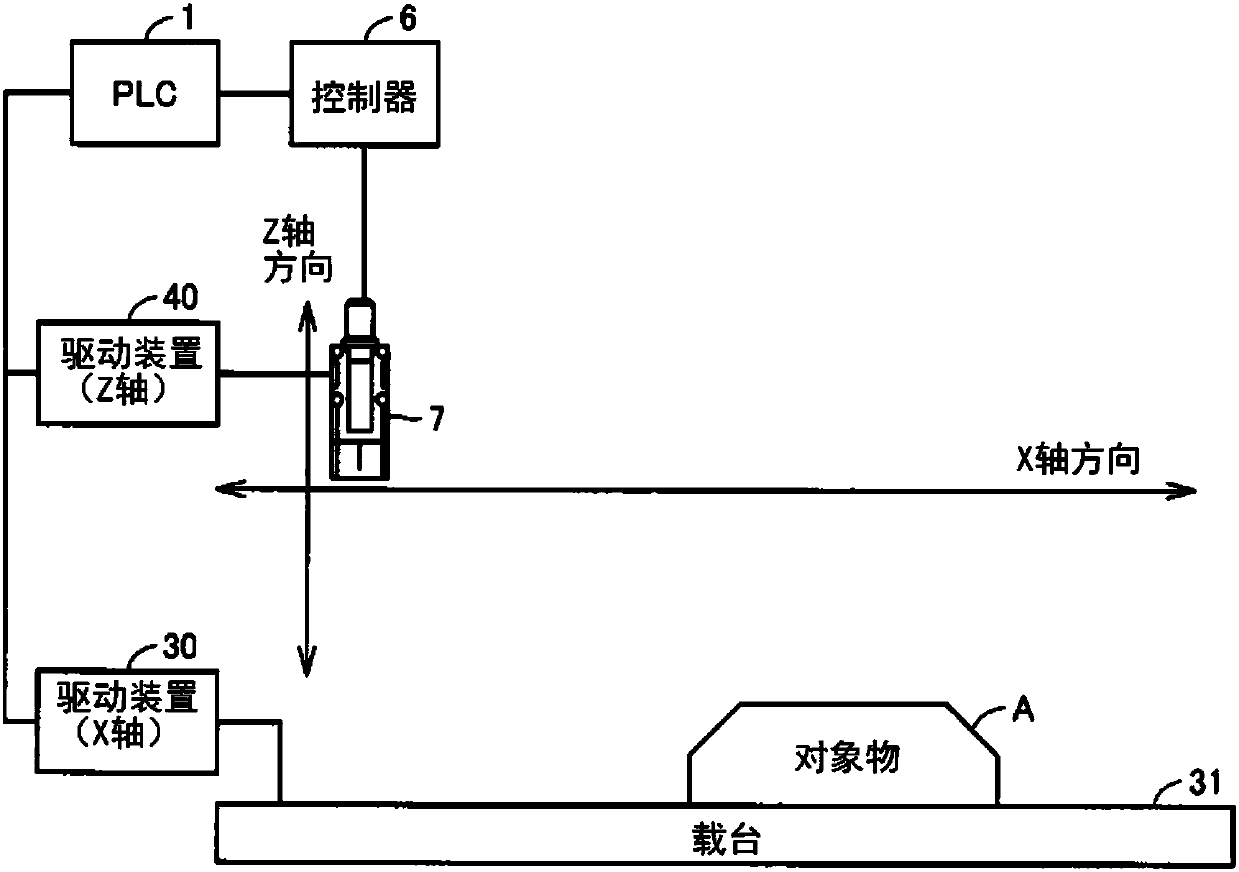

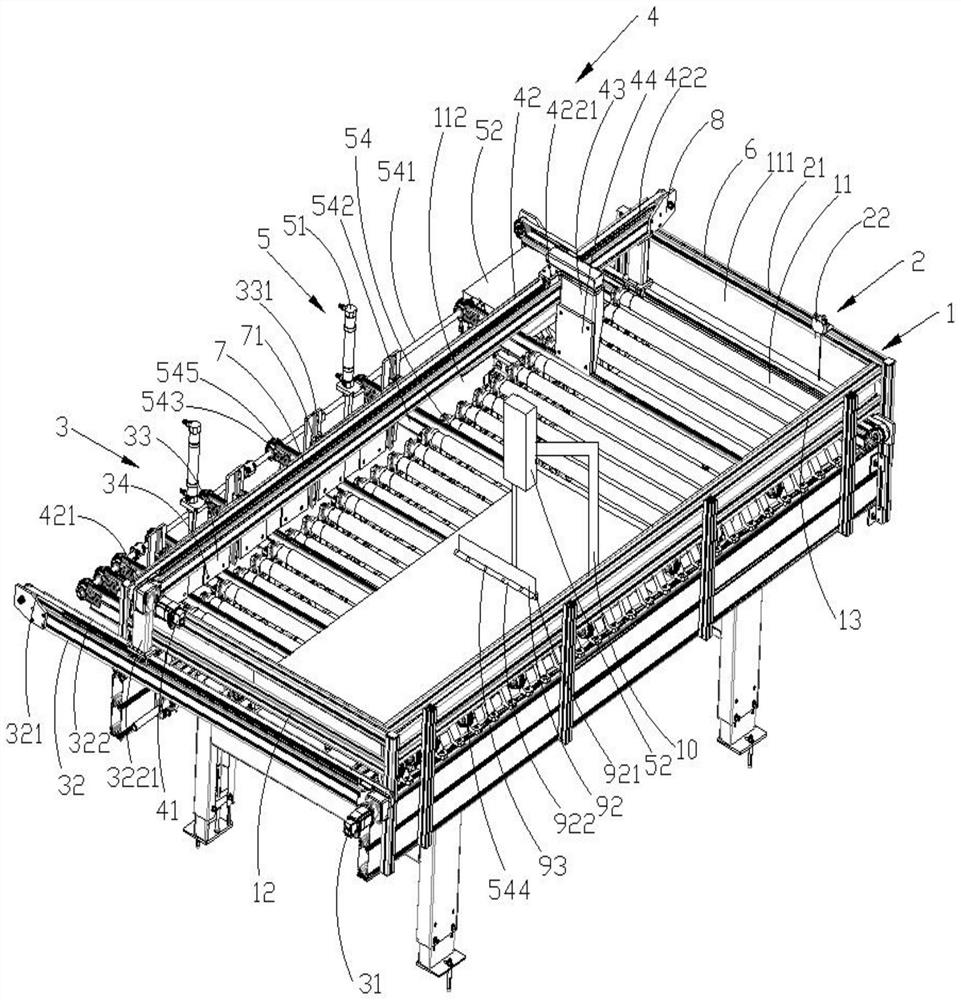

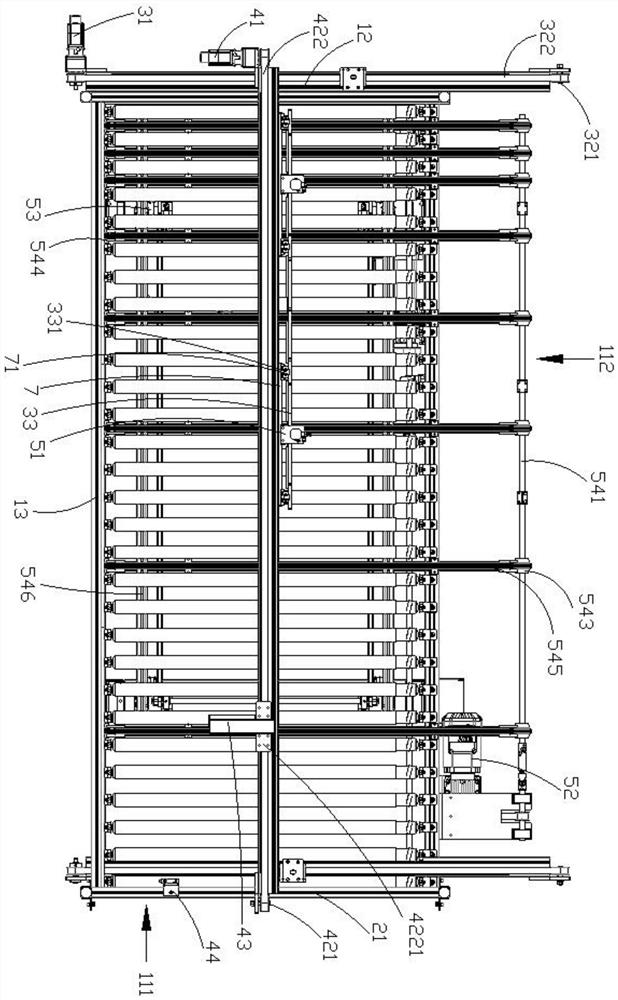

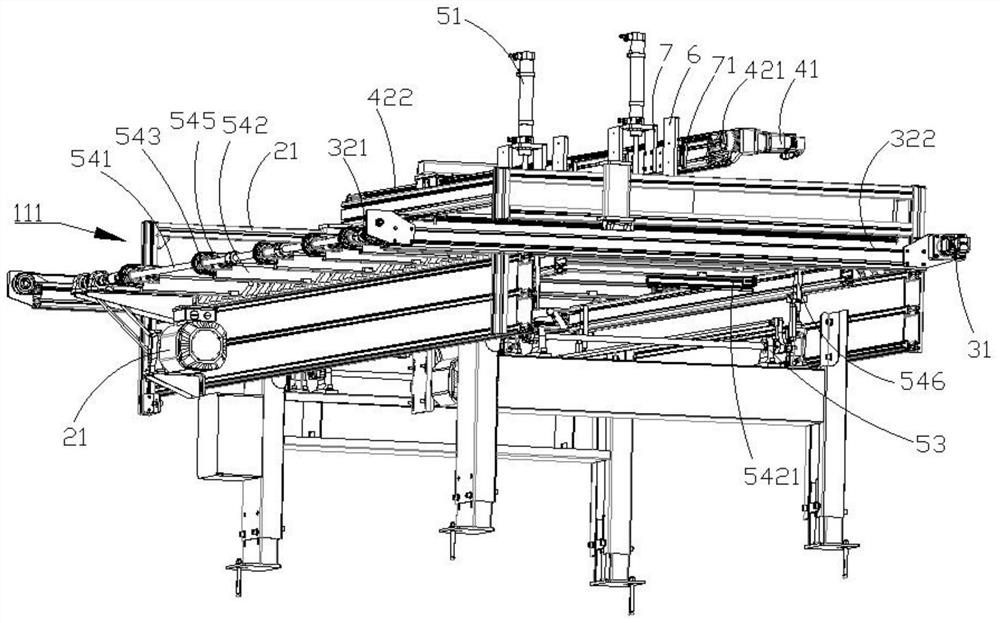

Automatic plate size measuring station and measuring method thereof

ActiveCN112729049ABeautiful packagingCompact structureControl devices for conveyorsMechanical width measurementsProcess engineeringMechanical engineering

The invention relates to the technical field of plate packaging, and in particular, relates to an automatic plate size measuring station and a measuring method thereof. The automatic plate size measuring station comprises a feeding mechanism, a thickness measuring mechanism, a width measuring mechanism, a length measuring mechanism and a discharging mechanism which are used for automatically measuring thickness data, width data and length data of plates respectively. According to the automatic plate size measuring station and the measuring method thereof, the length data, the width data and the thickness data of the plates are measured fully automatically and accurately, manpower is not needed, the labor cost is saved, the production efficiency is improved, the accuracy of the measured data is high, subsequent production of packaging paper of the corresponding size is facilitated, the plates are protected completely, resource waste is avoided, and the packaging appearance of the plates is more exquisite, the automatic plate size measuring station is capable of continuously measuring the plates of various sizes and high in practicability, and all operation in the measuring process is agile in cooperation and high in fluency.

Owner:湖北鑫光智能装备有限公司

Safety belt visual inspection device

The invention relates to a safety belt visual inspection device. The safety belt visual inspection device comprises a frame and a conveying mechanism used for conveying safety belts to the frame, wherein the frame is provided with a groove used for detecting width of the pass-by safety belts, a compaction mechanism used for limiting the safety belts in the groove for transmission, a transition mechanism used for turning over and conveying the safety belts coming out of the groove, an illumination lamp facing towards the groove, and a label box internally stored with labels used for being pasted on flaw positions of the safety belts, and one side wall of the groove is connected with an adjustment board capable of doing movement relative to the groove. According to the inspection device, through setting the transition mechanism, when the safety belts are conveyed to the transition mechanism, a first conveying roller and a second conveying roller are vertically arranged up and down, the safety belts pass through the first conveying roller and are then transmitted upwards to arrive the second conveying roller, the safety belts are horizontally transmitted by a second conveying guide pipe in a reverse direction relative to a transmission direction of the safety belts in the groove, the safety belts are turned over to the back surface, and the safety belts are transmitted with the back surface up.

Owner:SUZHOU ICOOLMACH EQUIP MFG

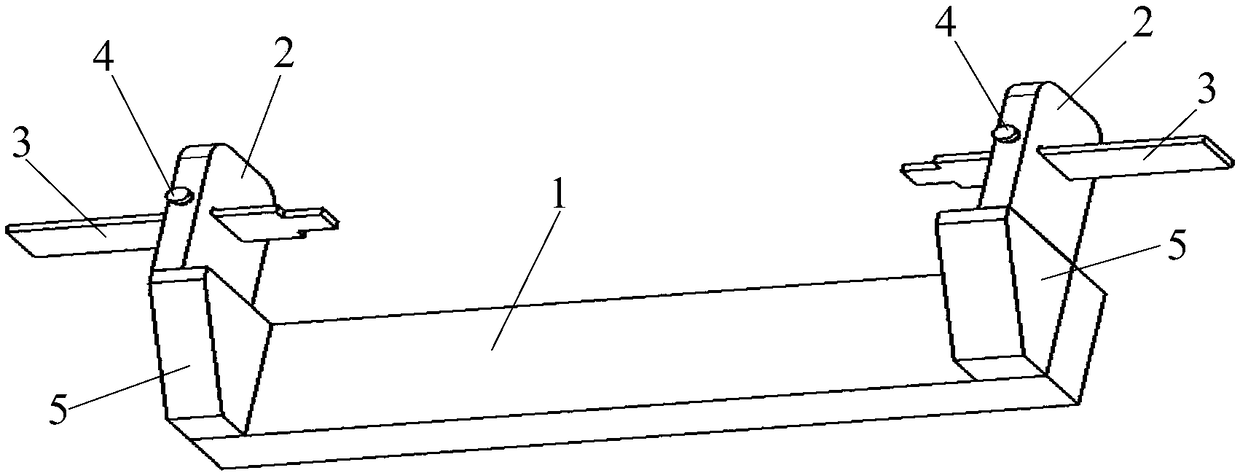

Detection tool for detecting hot-rolling forklift beam type steel size

InactiveCN109238089AReduced measurement timeImprove measurement efficiencyMechanical width measurementsMechanical thickness measurementsFast measurementEngineering

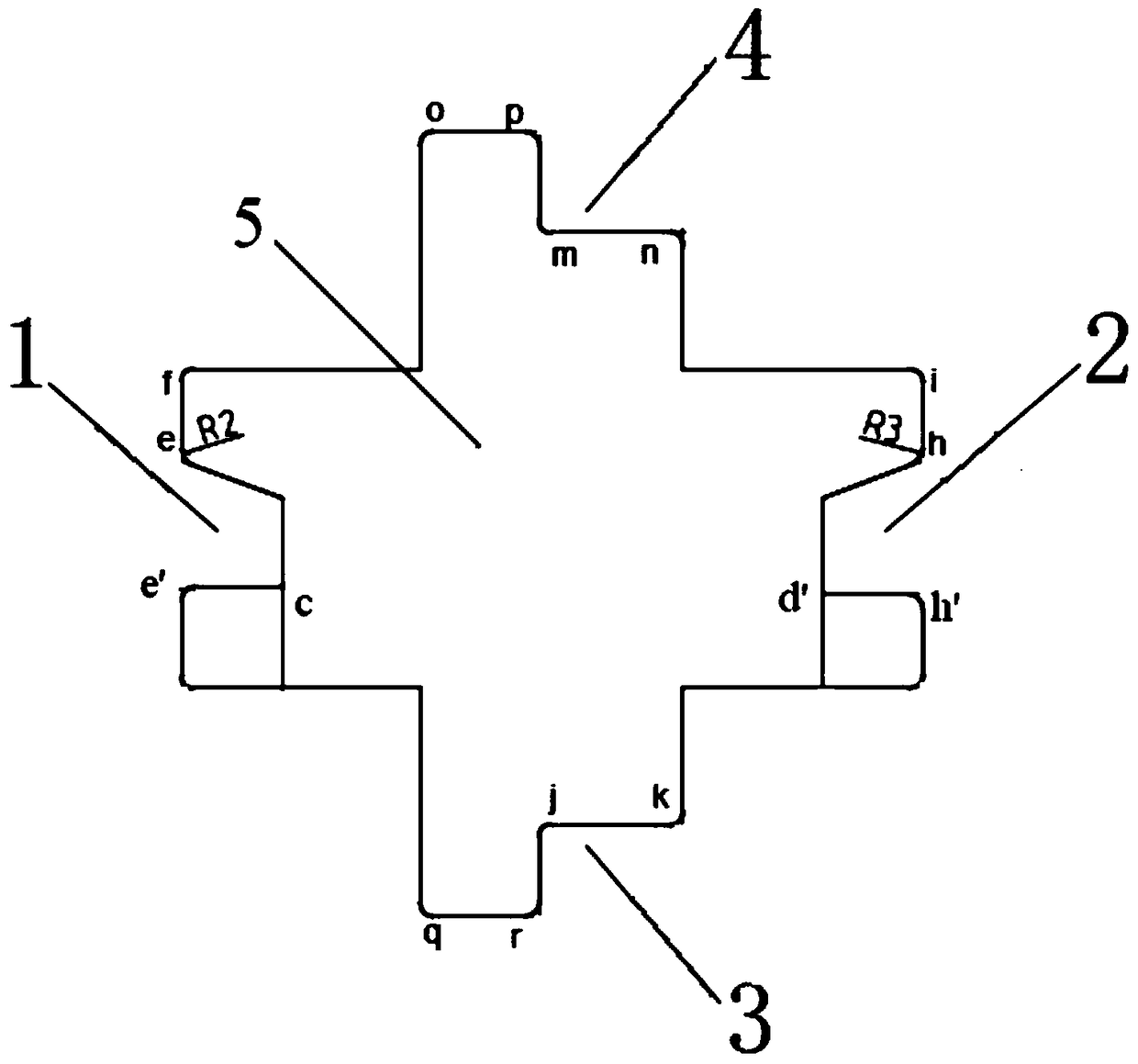

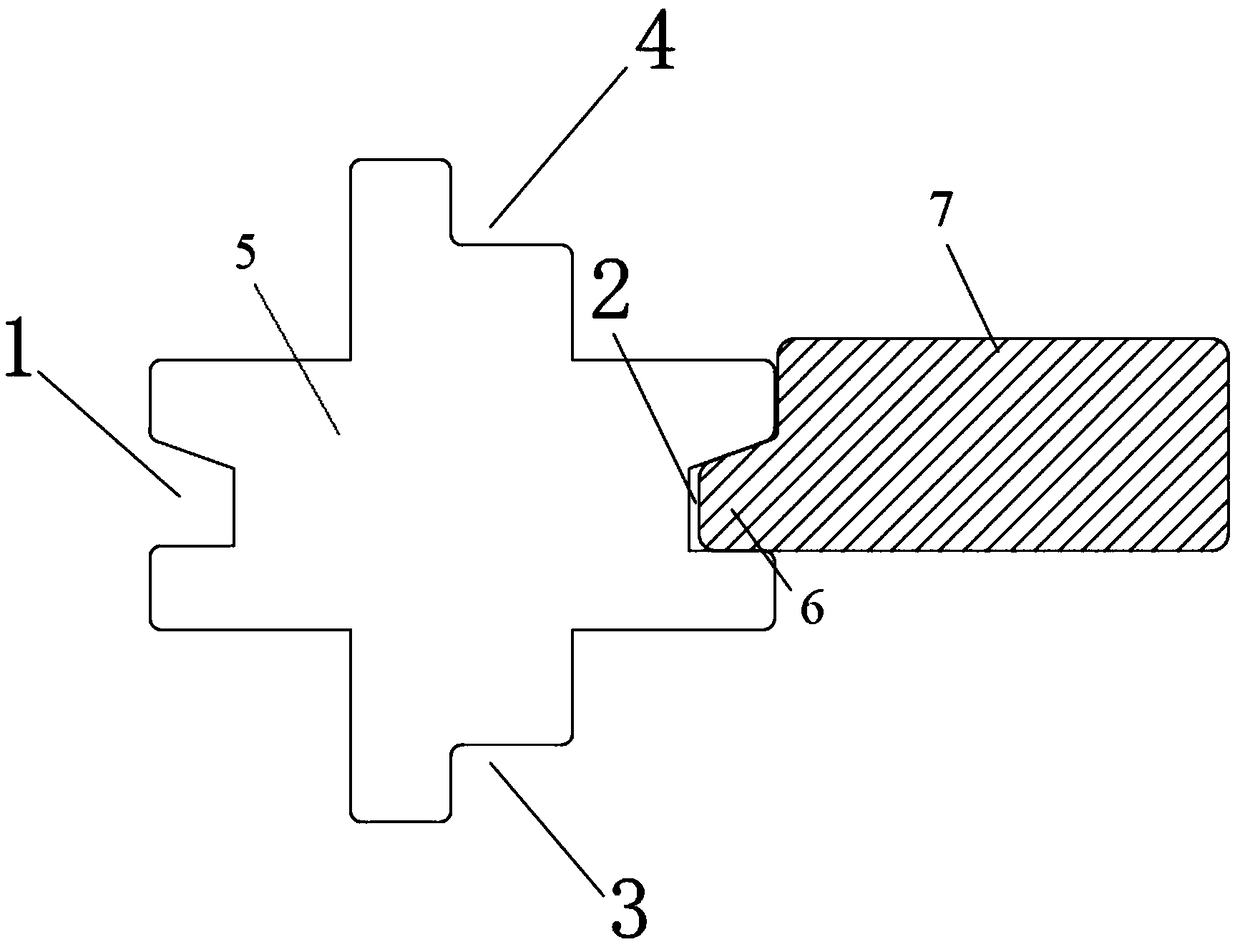

The invention discloses a detection tool for detecting hot-rolling forklift beam type steel size. The detection tool comprises a measurement body (5) which is of a cross structure; a first neck (1), asecond neck (2), a third neck (3) and a fourth neck (4) are arranged at four end parts of the measurement body (5) and used for measuring boss bottom width and box height of the hot-rolling forkliftbeam type steel; the first neck (1) and the second neck (2) are of a symmetric structure, and the third neck (3) and the fourth neck (4) are of the symmetric structure; the detection tool can quicklymeasure whether the boss width and height of the hot-rolling forklift beam type steel are in a tolerance range, and the production efficiency is improved.

Owner:SHANDONG IRON & STEEL CO LTD

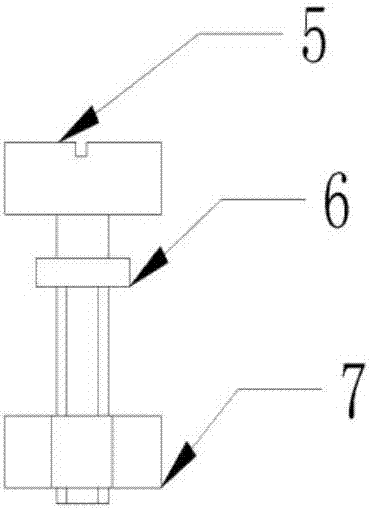

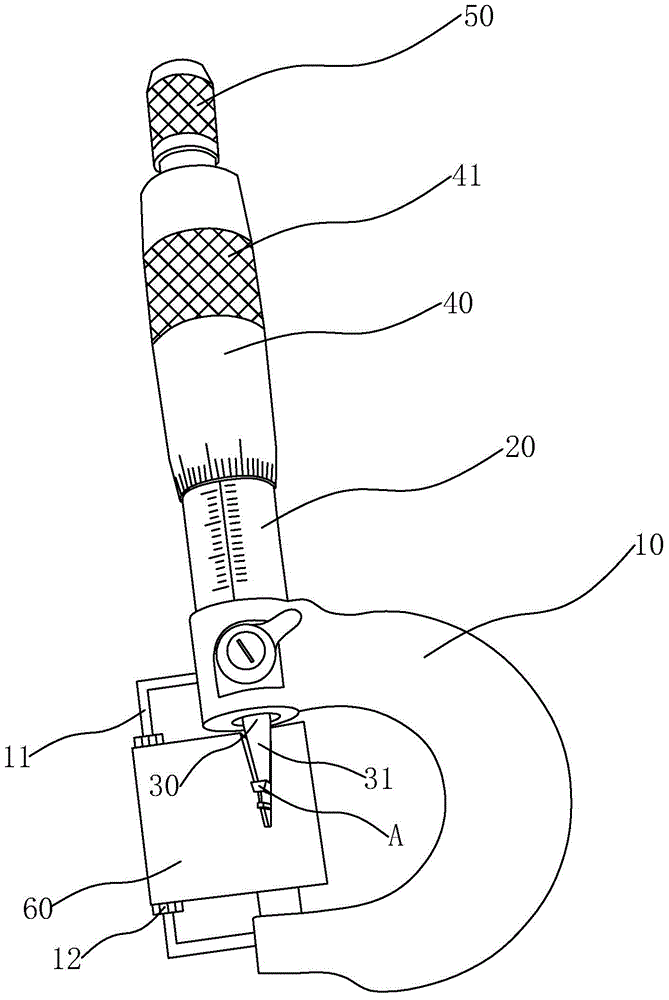

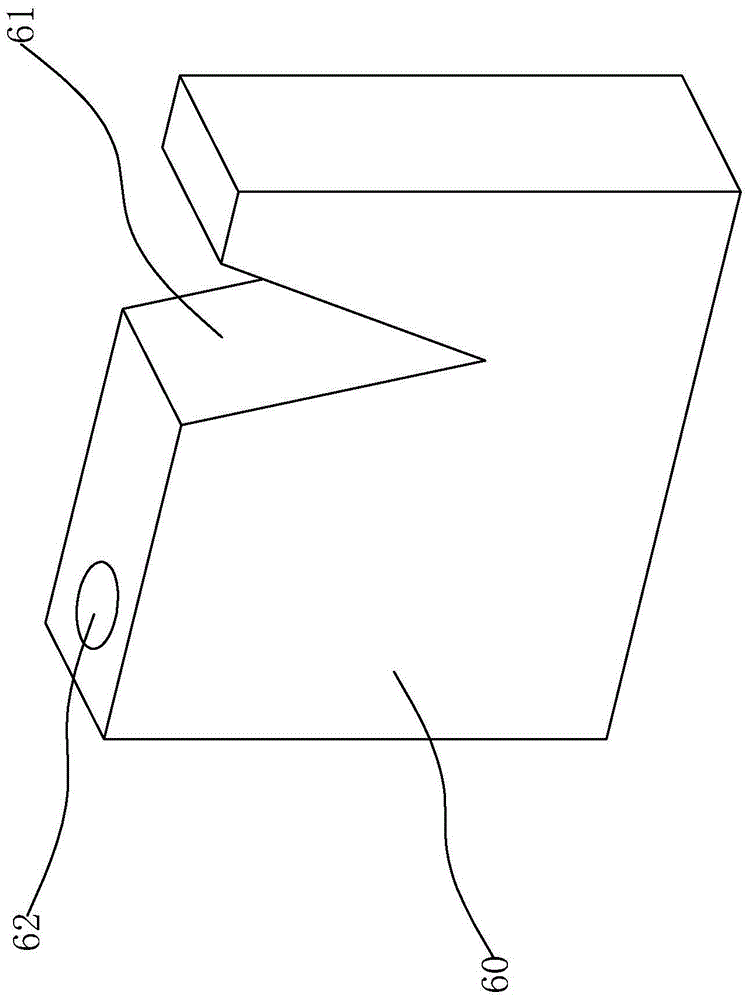

Tungsten steel and commutator contact chip measuring device applying same

ActiveCN104593658AChange distribution statusImprove wettabilityAngles/taper measurementsMechanical counters/curvatures measurementsLow speedWire cutting

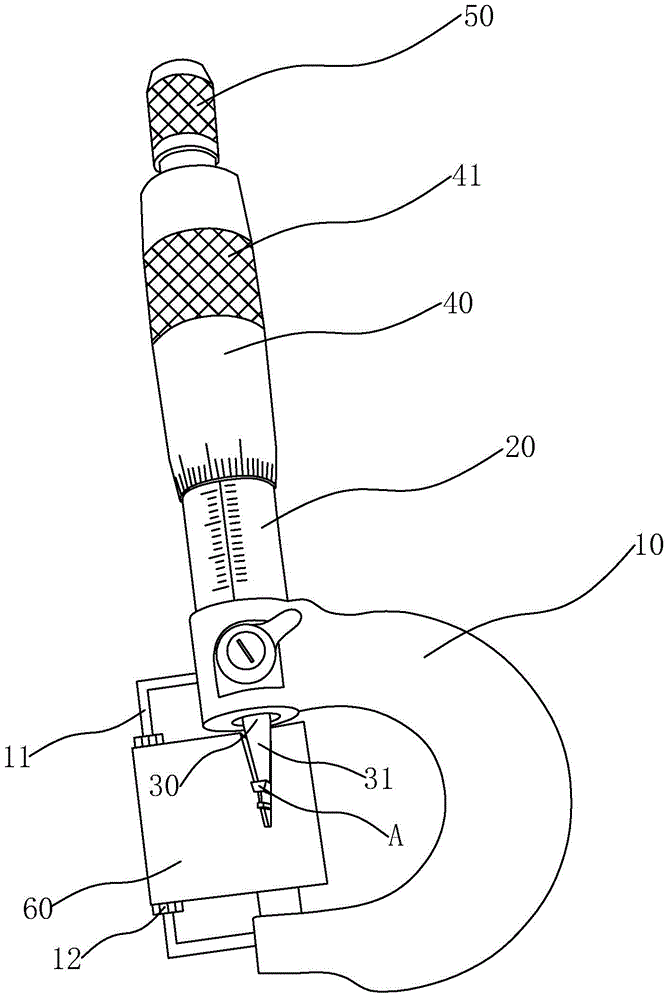

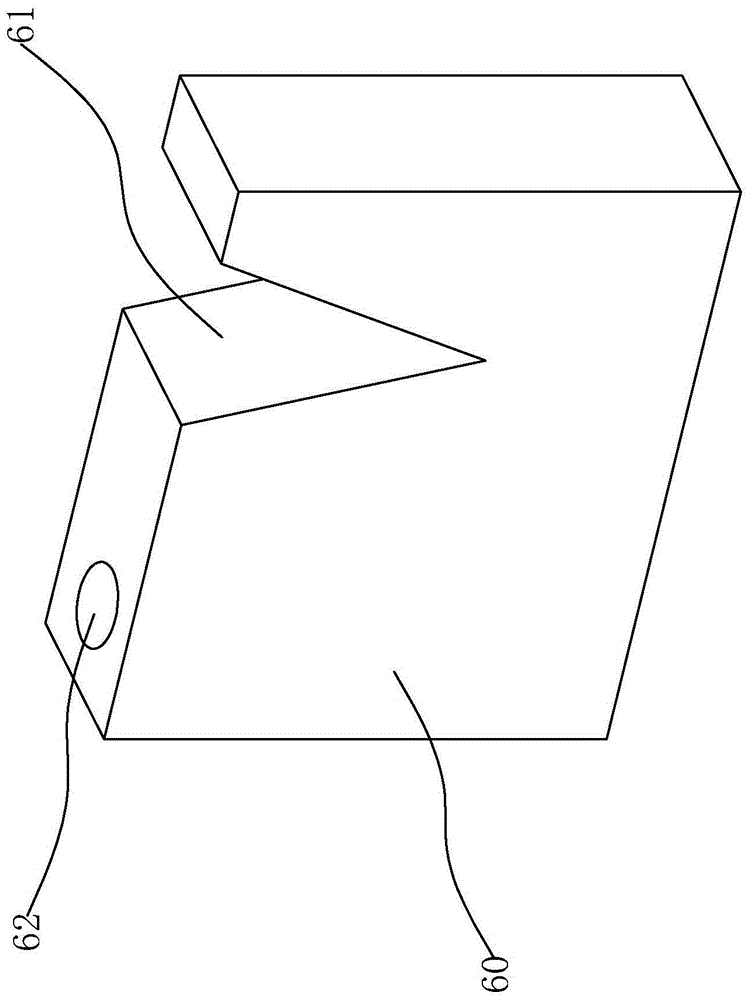

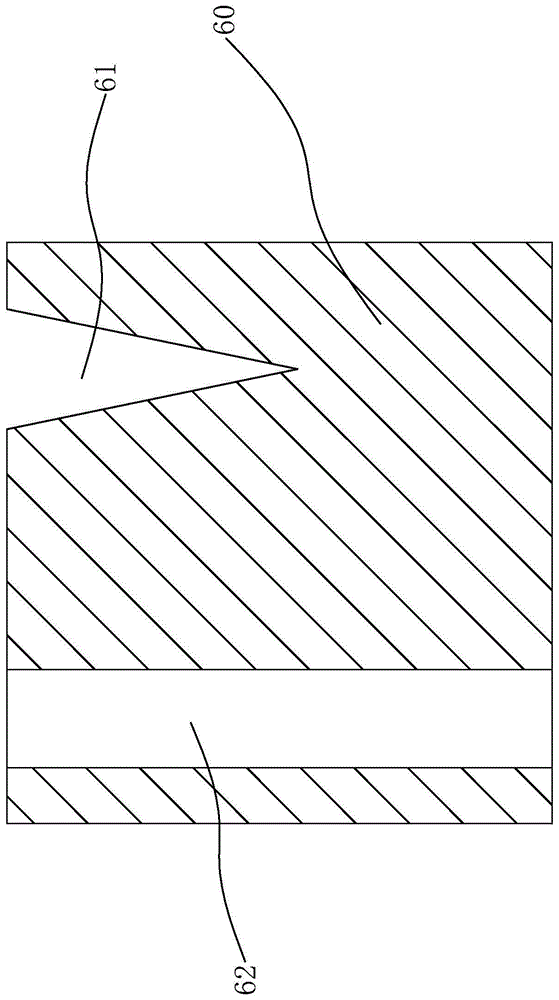

The invention relates to tungsten steel mainly comprising the raw materials: 10-20% of a bonding metal, 0.05-0.5% of a rare earth metal, 0.3-1% of an inhibitor, and the balance tungsten carbide, wherein the crystal particle size of the tungsten steel is in a range of 0.1-1 [mu]m. With adopting of a low speed wire cutting technology, the tungsten steel is made into a measuring block applied in a commutator contact chip measuring device; the measuring device includes a ruler frame, a fixed sleeve, a movable measuring rod and a microdrum; the movable measuring rod is arranged in the fixed sleeve; the fixed sleeve is fixedly connected with the ruler frame; the movable measuring rod passes through the ruler frame; the microdrum is arranged on the fixed sleeve; the measuring block is arranged between two ends of the ruler frame and is provided with a conical notch; an included angle of two side edges of a contact chip is equal to an included angle of the conical notch; the front end of the movable measuring rod is provided with a conical measuring head corresponding to the conical notch. The tungsten steel with excellent performance of hardness, strength, wear resistance and the like is made into the measuring block applied to the commutator contact chip measuring device, and the measurement precision is high.

Owner:HUARUI ELECTRICAL APPLIANCE

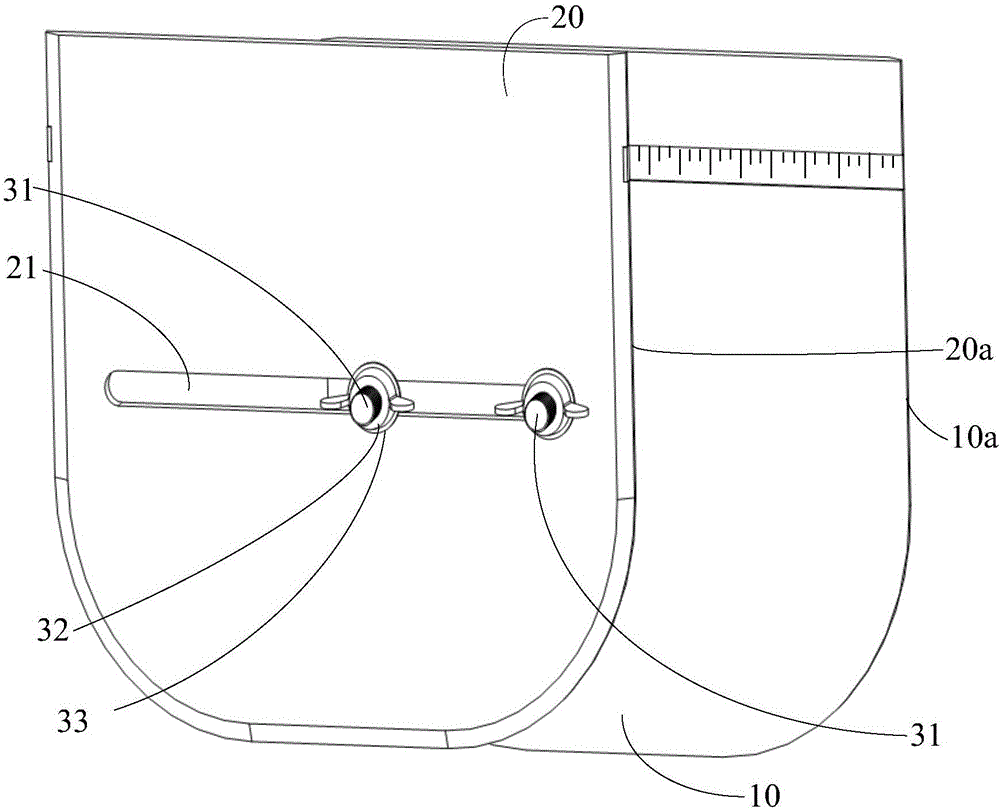

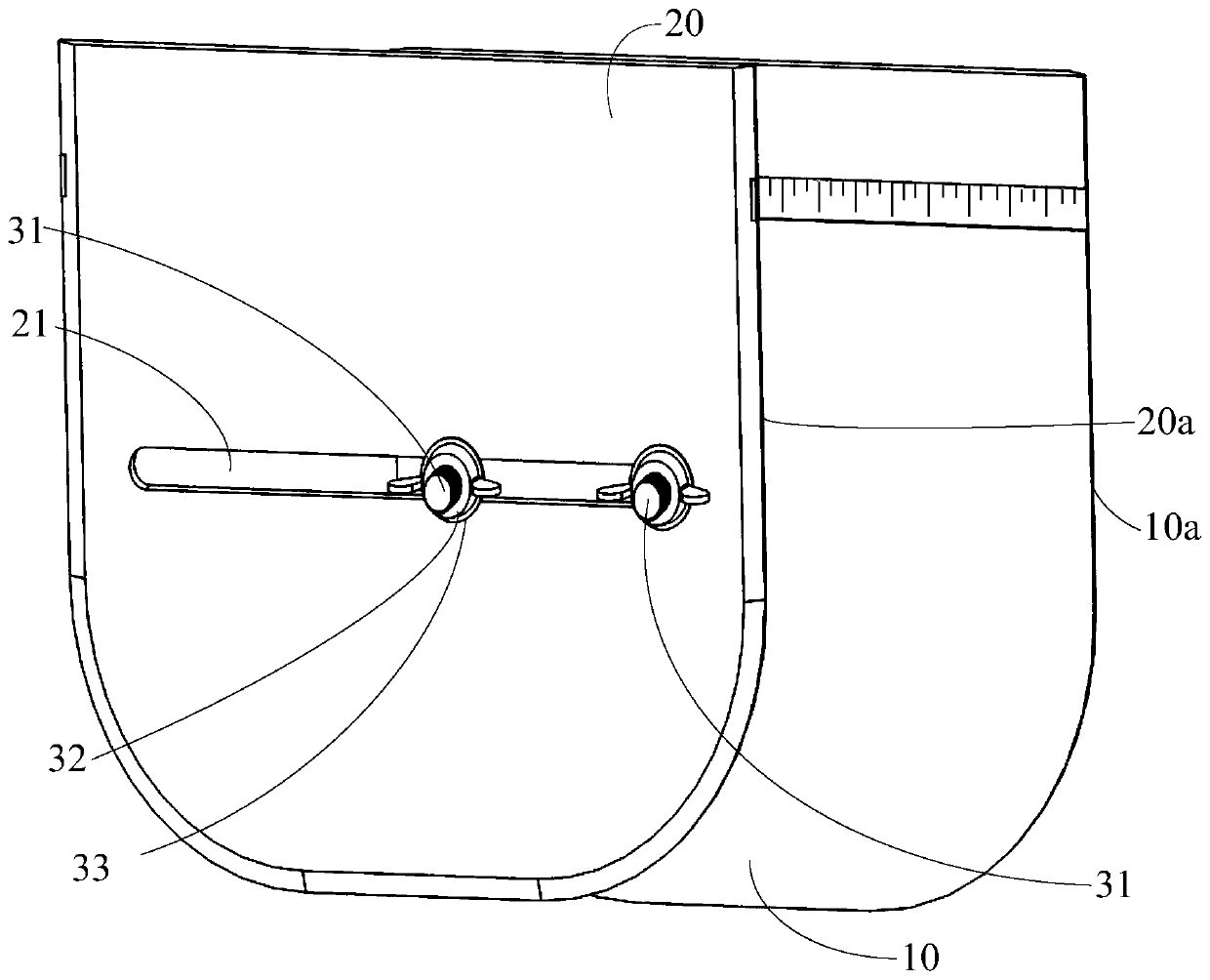

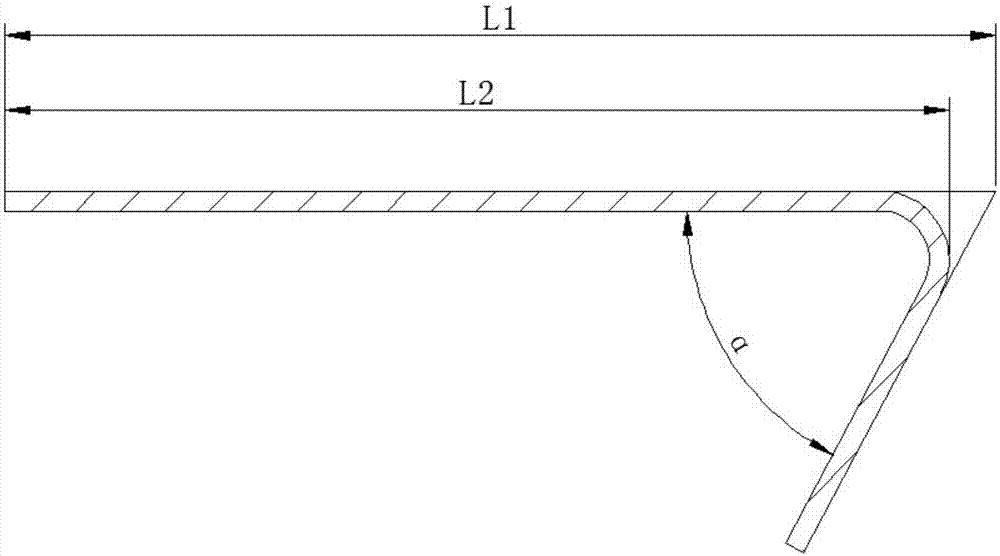

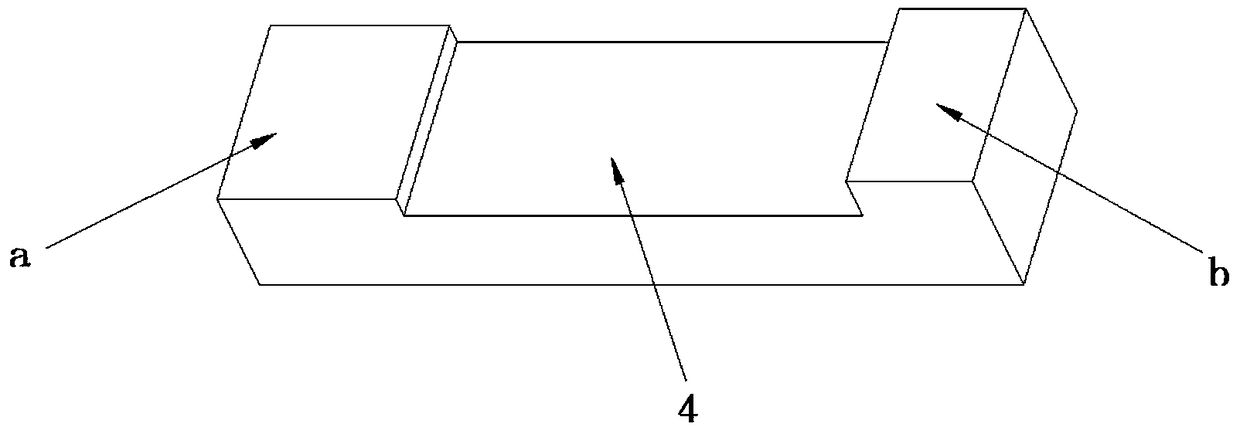

Measuring tool for cable bearing groove of suspension bridge cable clamp

The present invention discloses a measuring tool for the cable bearing groove of a suspension bridge cable clamp and belongs to the bridge manufacturing engineering technical field. The measuring tool includes a first measuring plate and a second measuring plate; the second measuring plate is slidably stacked on the plate surface of the first measuring plate; the second measuring plate slides linearly between a first position and a second position; one surface of the first measuring plate, which is opposite to the second measuring plate, is provided with scale marks; and the scale marks are distributed along the direction of the linear slide of the second measuring plate. When the measuring tool is applied to measurement, when the second measuring plate is located at the first position, and the first side edge of the first measuring plate can abut against one side wall of the cable bearing groove; the sliding of the second measuring plate is adjusted, so that the second side edge of the second measuring plate can abut against the other side wall of the cable bearing groove; and therefore, the width of the cable bearing groove can be measured on the basis of an exposed scale mark. The position of the measuring tool in the cable bearing groove can be adjusted, and the second measuring plate is made to slide, and then, the width of the different cross-sections of the cable bearing groove can be measured quickly and accurately.

Owner:WUHAN MARINE MACHINERY PLANT

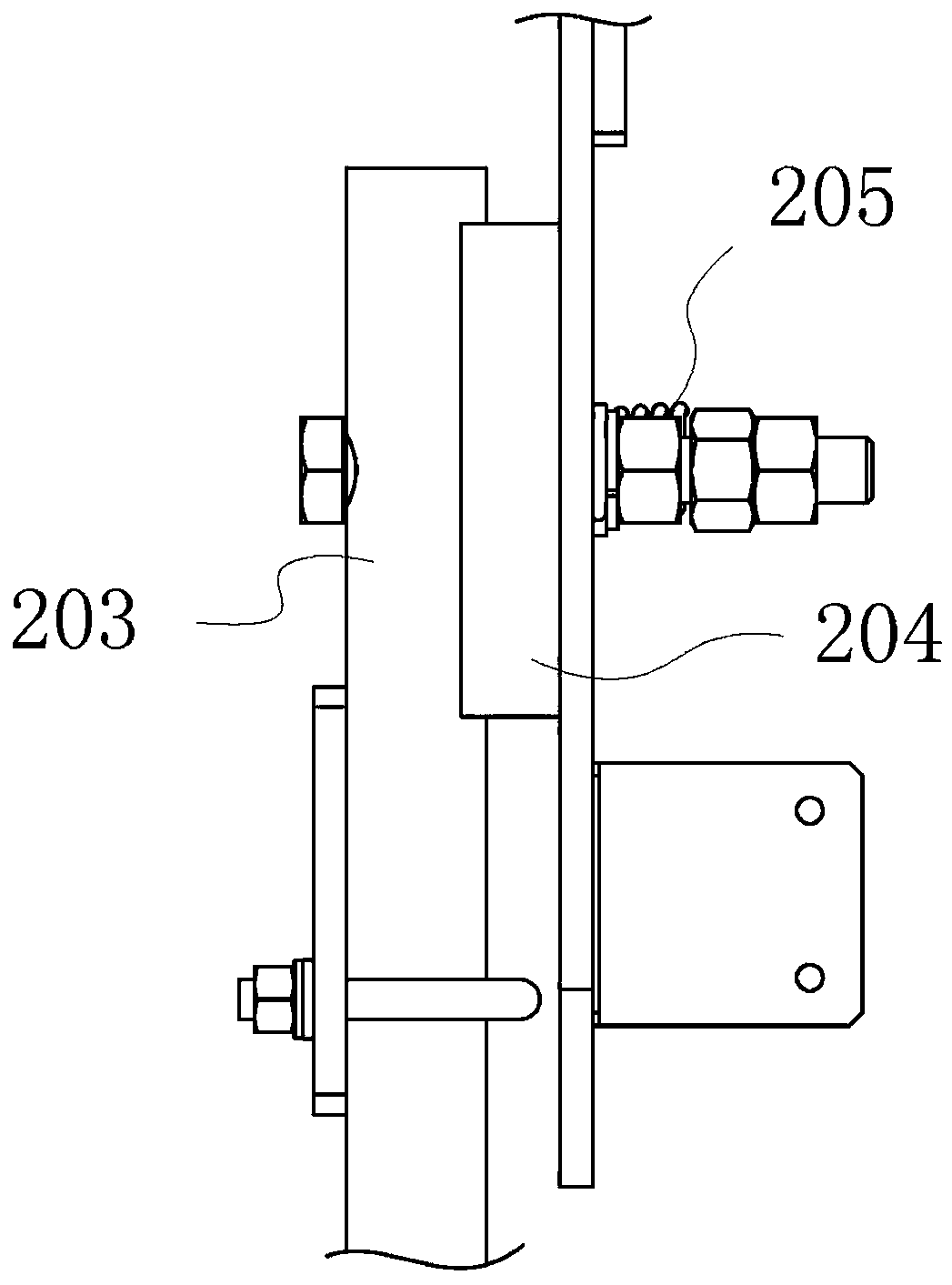

Mechanical width detection unit and appearance detector

ActiveCN105606010AEasy to operateLow costMechanical width measurementsMechanical thickness measurementsEngineeringLight hole

The invention disclose a mechanical width detection unit. The detection unit comprises a basic installation part, a detection collision rod hinged to the basic installation part, a limiting part limiting rotation of the collision rod, an elastic force part which acts a radial elastic force on the collision rod and a light shield which is arranged on the collision rod and includes a light hole. The mechanical width detector and the appearance detector are characterized by low cost and simple operation.

Owner:ZHEJIANG DAMON TECH CO LTD

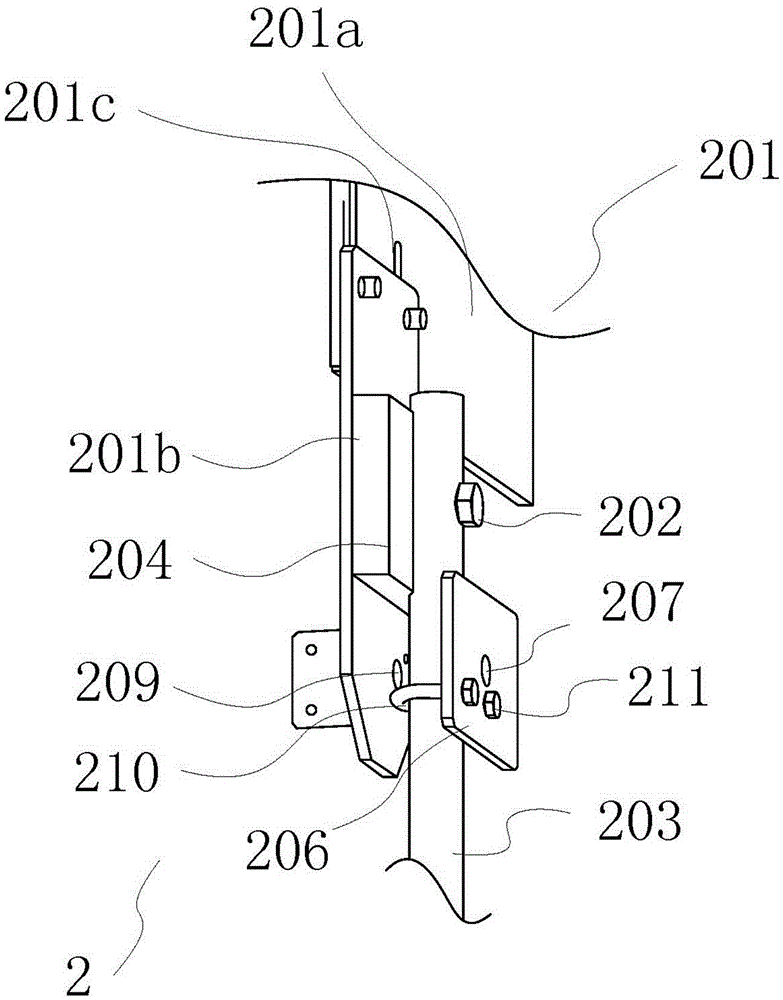

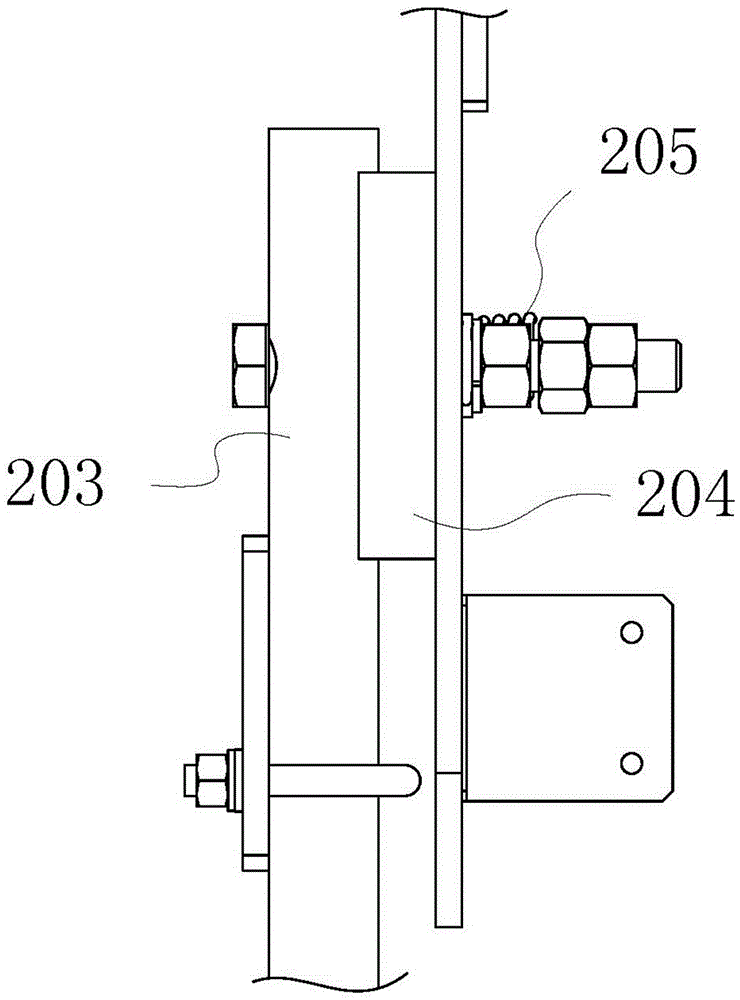

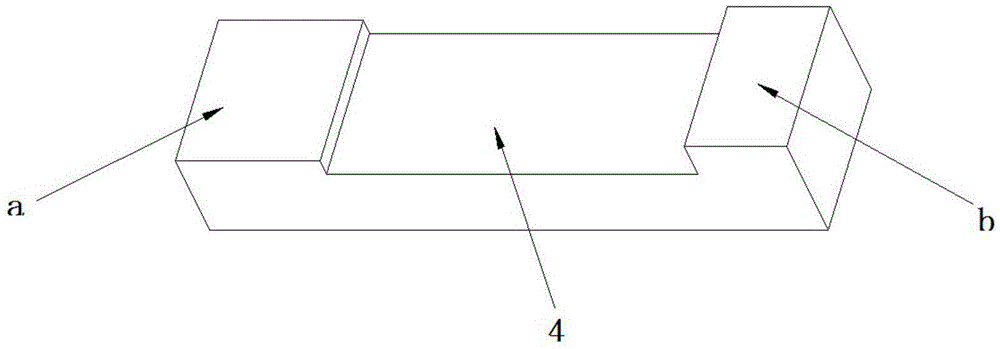

A measuring tool for the cable groove of a suspension bridge cable clamp

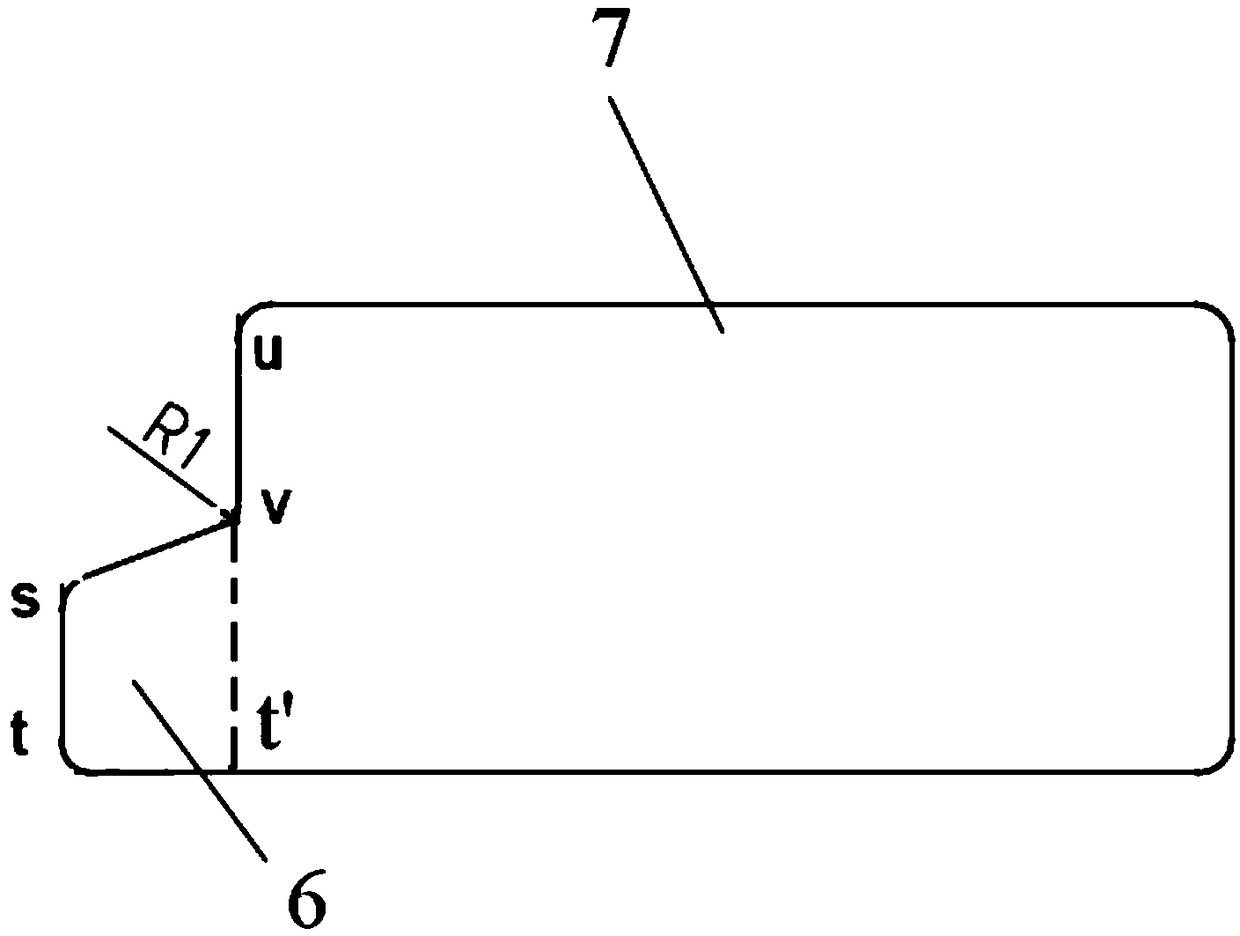

ActiveCN106643407BAccurate measurementMechanical width measurementsCable carrierGeotechnical engineering

The present invention discloses a measuring tool for the cable bearing groove of a suspension bridge cable clamp and belongs to the bridge manufacturing engineering technical field. The measuring tool includes a first measuring plate and a second measuring plate; the second measuring plate is slidably stacked on the plate surface of the first measuring plate; the second measuring plate slides linearly between a first position and a second position; one surface of the first measuring plate, which is opposite to the second measuring plate, is provided with scale marks; and the scale marks are distributed along the direction of the linear slide of the second measuring plate. When the measuring tool is applied to measurement, when the second measuring plate is located at the first position, and the first side edge of the first measuring plate can abut against one side wall of the cable bearing groove; the sliding of the second measuring plate is adjusted, so that the second side edge of the second measuring plate can abut against the other side wall of the cable bearing groove; and therefore, the width of the cable bearing groove can be measured on the basis of an exposed scale mark. The position of the measuring tool in the cable bearing groove can be adjusted, and the second measuring plate is made to slide, and then, the width of the different cross-sections of the cable bearing groove can be measured quickly and accurately.

Owner:WUHAN MARINE MACHINERY PLANT

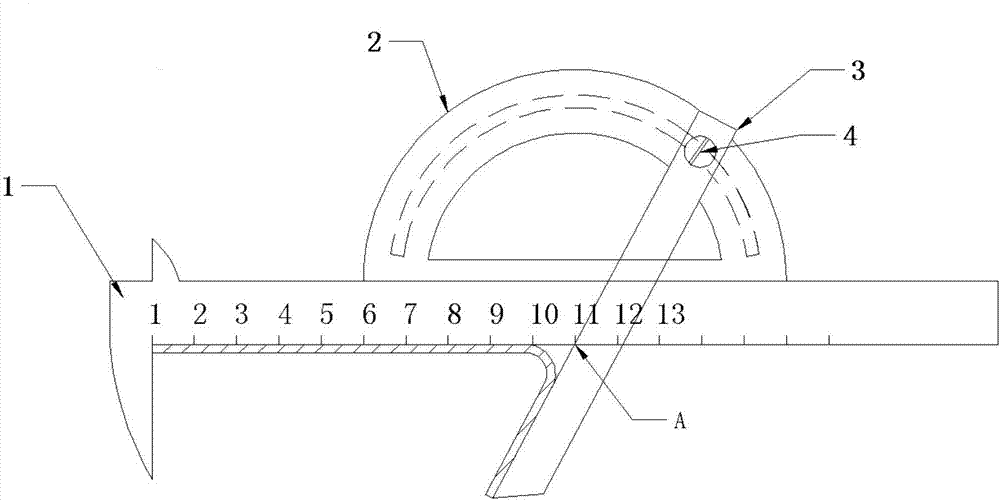

Metal plate part size measurement tool

InactiveCN107388918ASimple structureReduce manufacturing costMechanical width measurementsSize measurementEngineering

The invention relates to a metal plate part size measurement tool. The tool comprises a caliper (1) with scales, a slide block (2), a fixing device (4) and a positioning rule (3). The slide block (2) can slide left and right on the caliper (1). The positioning rule (3) can be rotatably installed on the slide block (2) through the fixing device (4). The metal plate part size measurement tool can be designed into multiple specifications. The structure is simple, manufacturing cost is low, wide versatility is possessed, measuring efficiency is high and accuracy is high too.

Owner:CHANGHE AIRCRAFT INDUSTRIES CORPORATION

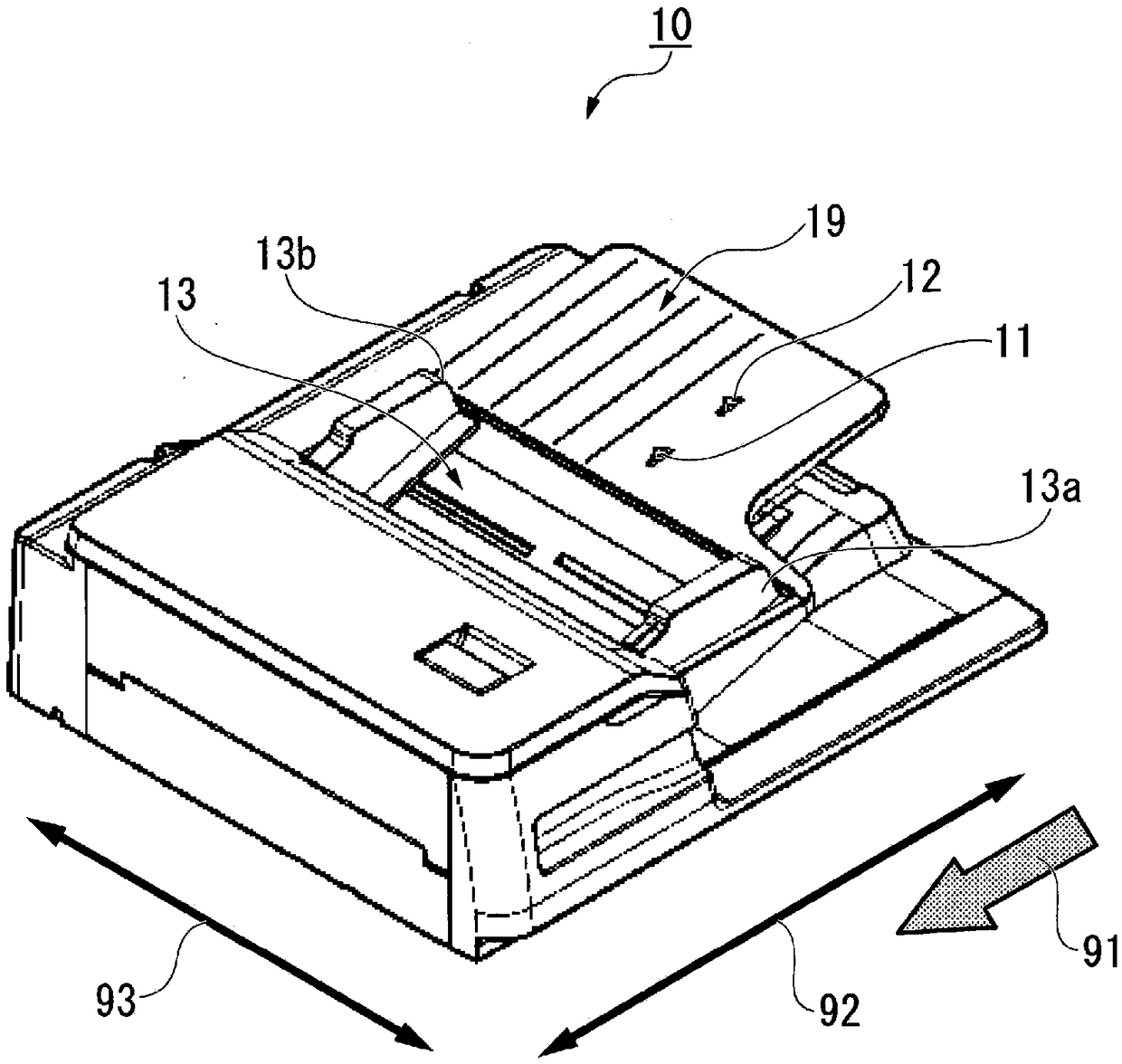

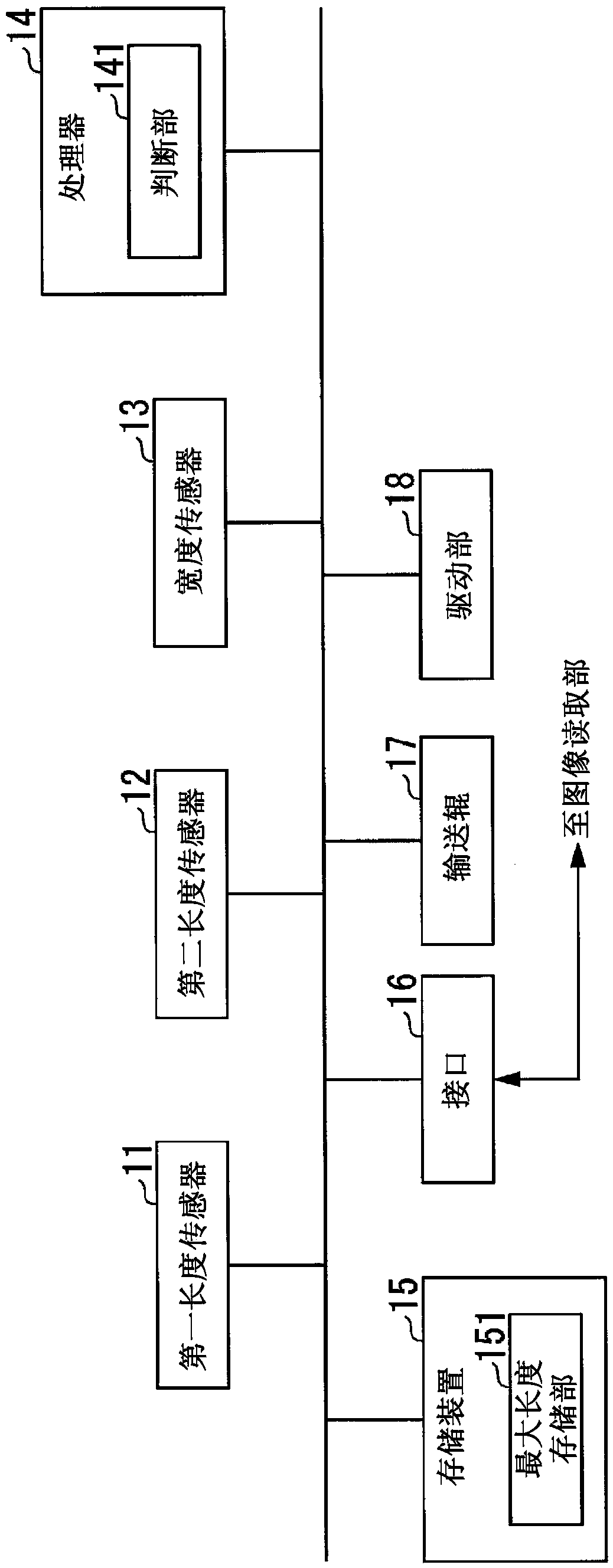

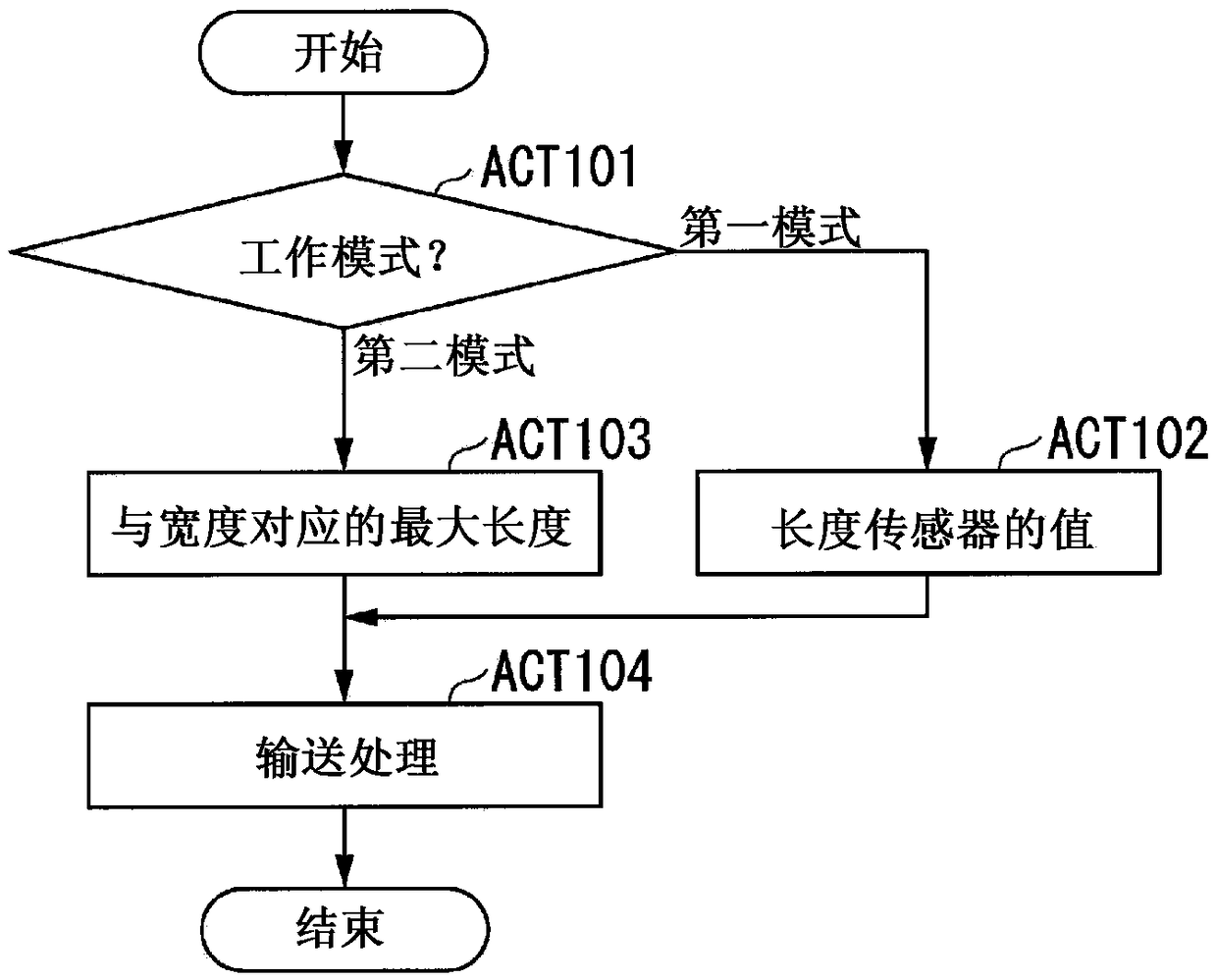

Sheet conveying device and image reading device

InactiveCN109426108AReduce bad influenceMechanical width measurementsUsing optical meansEngineeringShort length

The invention provides a sheet conveying device and an image reading device, capable of reducing a bad influence in subsequent processing due to erroneous detection of the sheet length. A sheet conveying device includes a length sensor configured to detect a length of a sheet to be conveyed, and a processor configured to determine the length of the sheet while operating in a first mode and while operating in a second mode. While operating in the first mode, the processor determines the length detected by the length sensor as the length of the sheet. While operating in the second mode, the processor determines a predefined length as the length of the sheet, wherein the predefined length is greater than a shortest length detectable by the length sensor.

Owner:TOSHIBA TEC KK

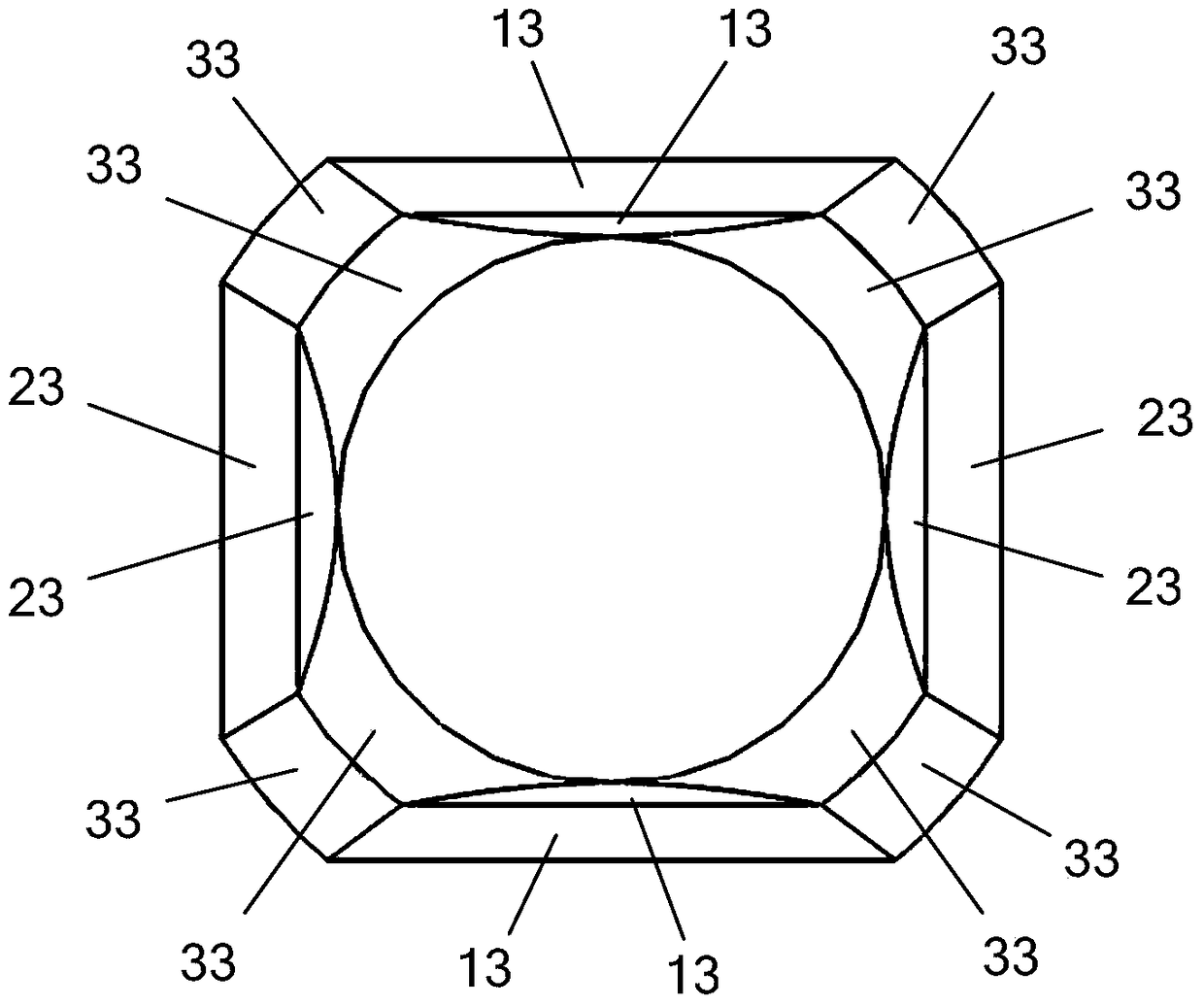

Go-no-go rule

InactiveCN105627877BLow costSave materialMechanical diameter measurementsMechanical width measurementsEngineeringMechanical engineering

Owner:SHAANXI TECHN INST OF DEFENSE IND

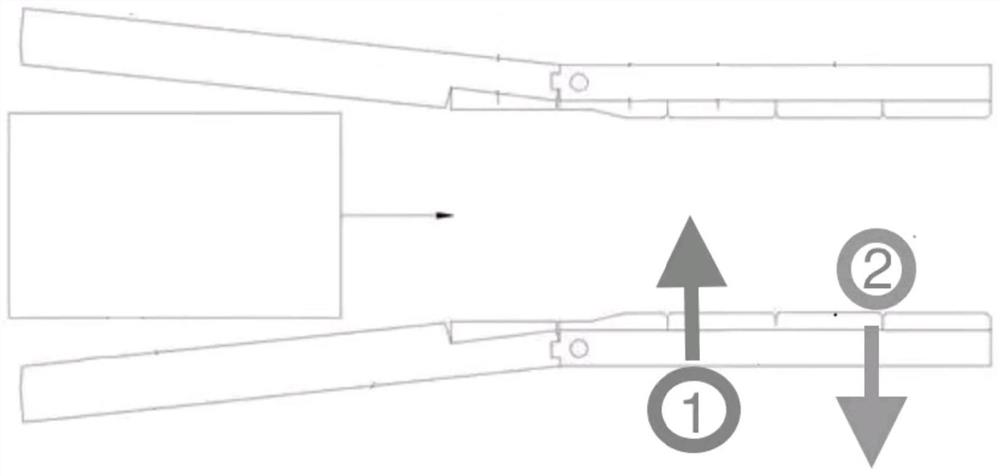

Hot rolling coiler side guide plate control method capable of improving coiling quality

PendingCN114535355AImprove control methodAvoid harmMechanical width measurementsEngineeringStrip steel

The invention relates to the technical field of hot coiling, in particular to a hot rolling coiler side guide plate control method capable of improving coiling quality, which comprises the following steps: carrying out primary short stroke when the head of strip steel reaches the middle position of the parallel section of a side guide plate, and carrying out secondary short stroke when a pinch roll bites steel; when the coiling block bites steel, the side guide plate carries out position allowance, the side guide plate with the remaining pressure allowance carries out strip steel clamping on the two sides, when the pressure reaches P% of the second-stage set pressure, one side of the side guide plate is fixed and is changed into position control, and the other side of the side guide plate carries out pressure control to clamp the strip steel; when the clamping is stable, the side guide plate is changed into position control. The problems of over-clamping, under-clamping, staggered-layer rolling and the like of the side guide plate during hot rolling are solved, and meanwhile, equipment damage caused by abnormal width of strip steel can be avoided.

Owner:SD STEEL RIZHAO CO LTD

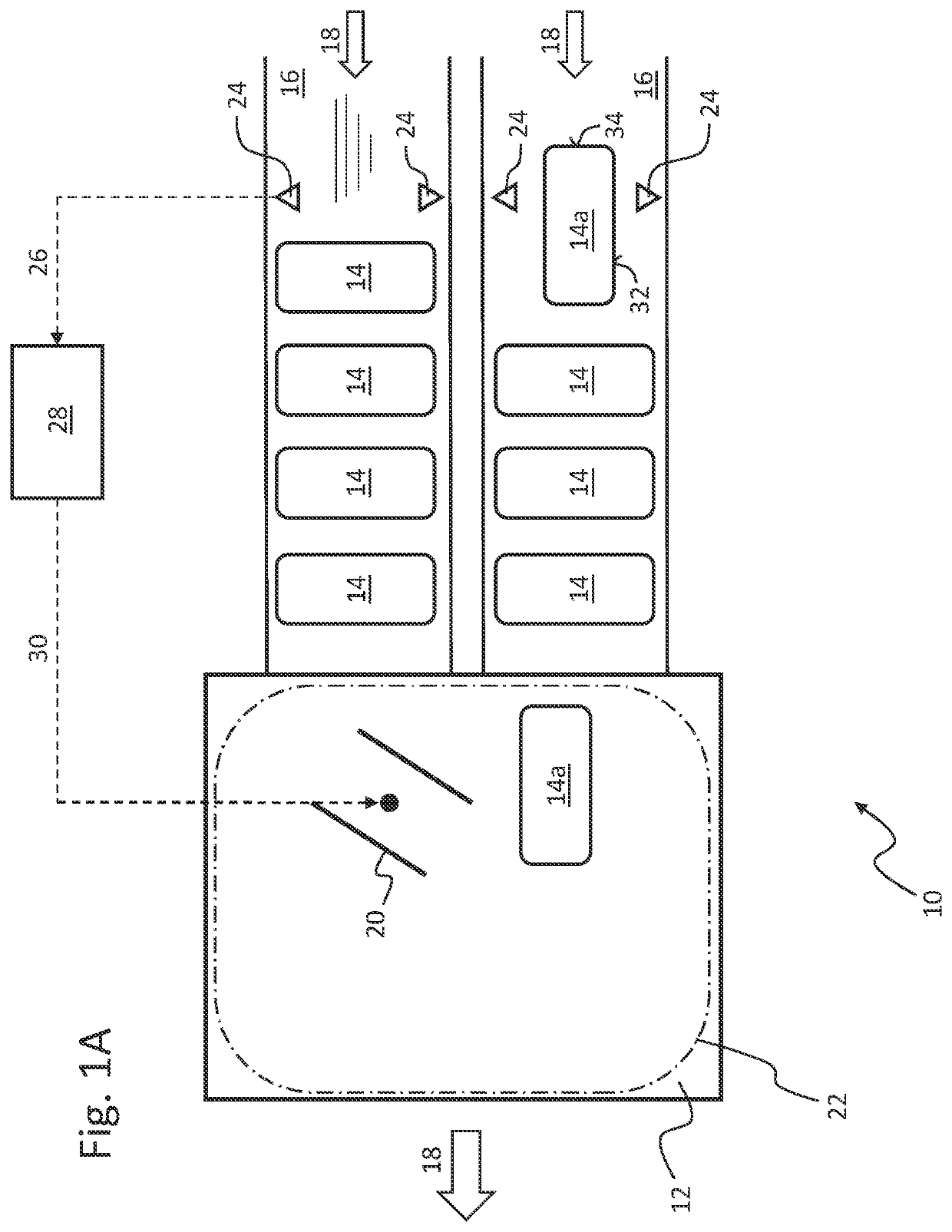

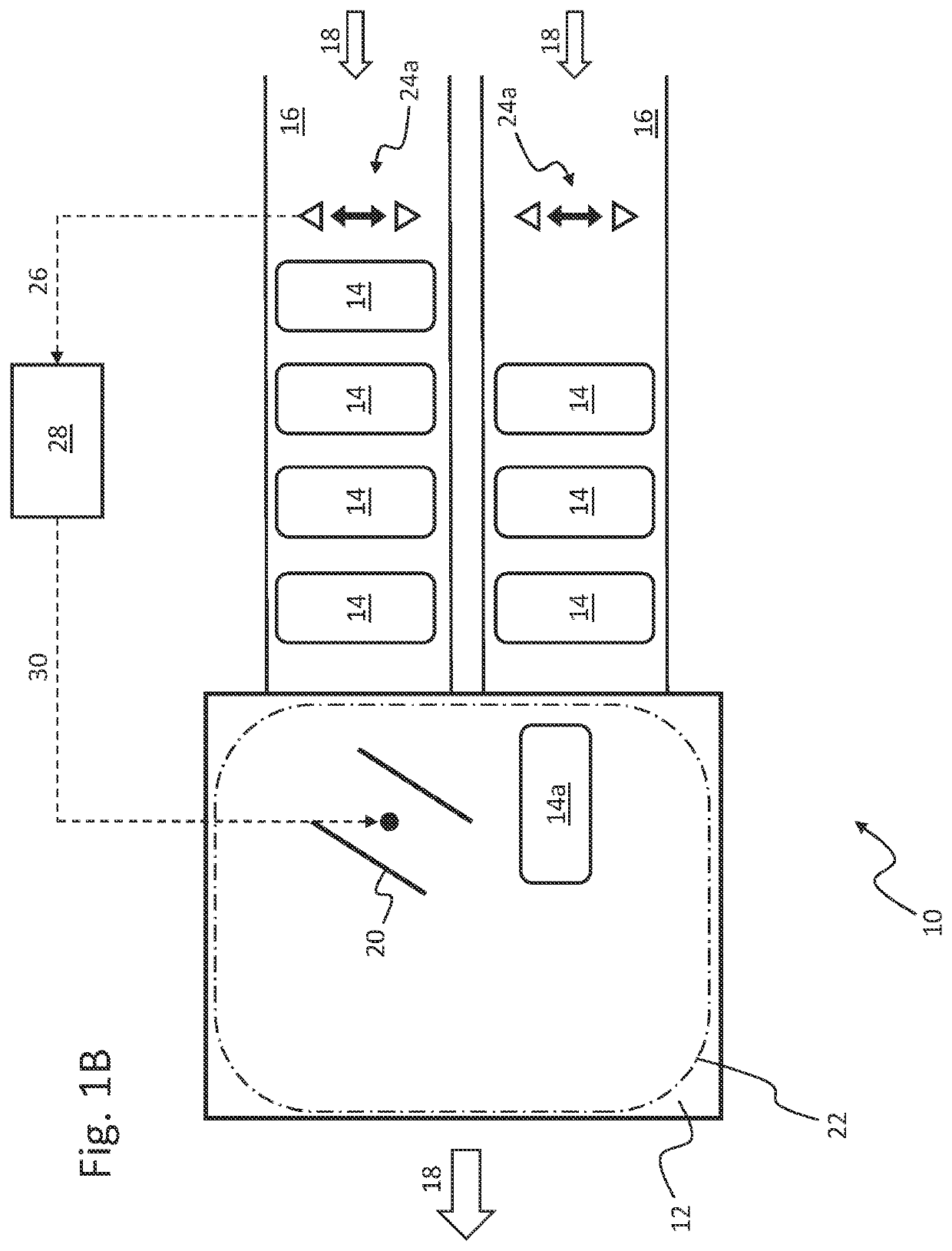

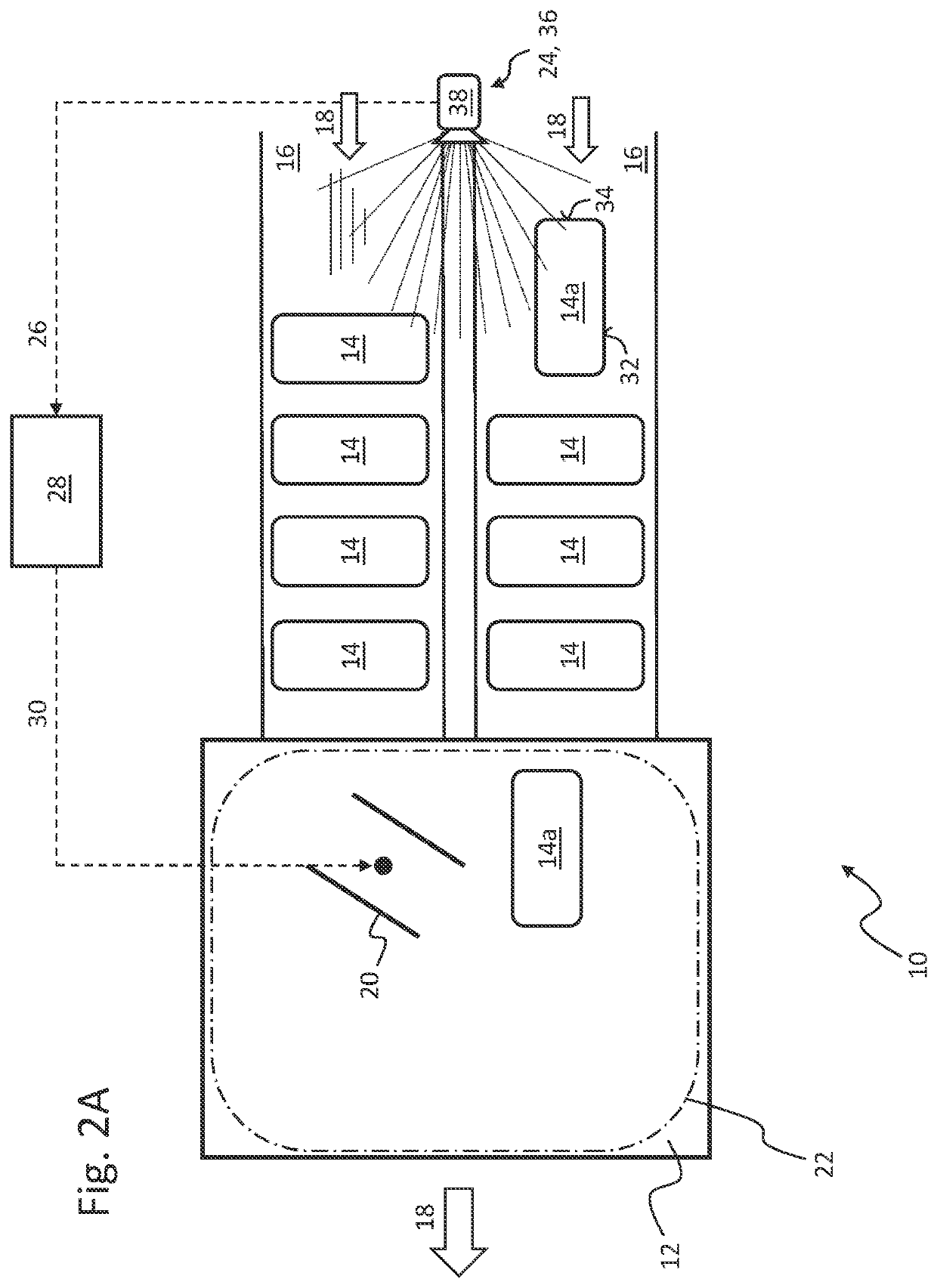

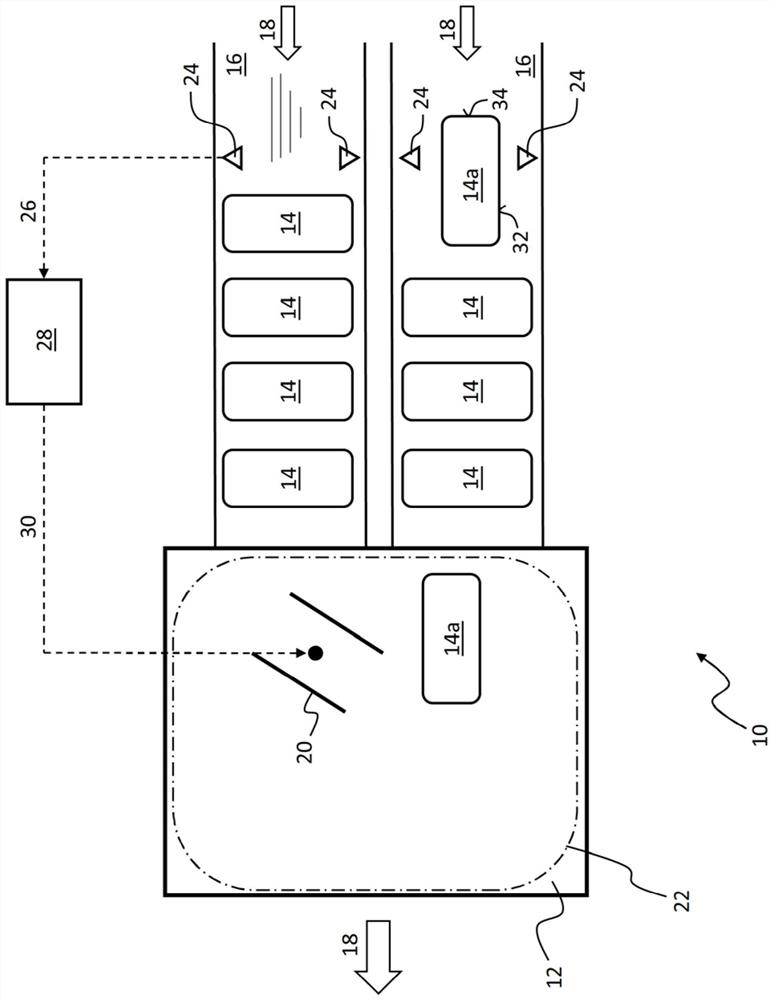

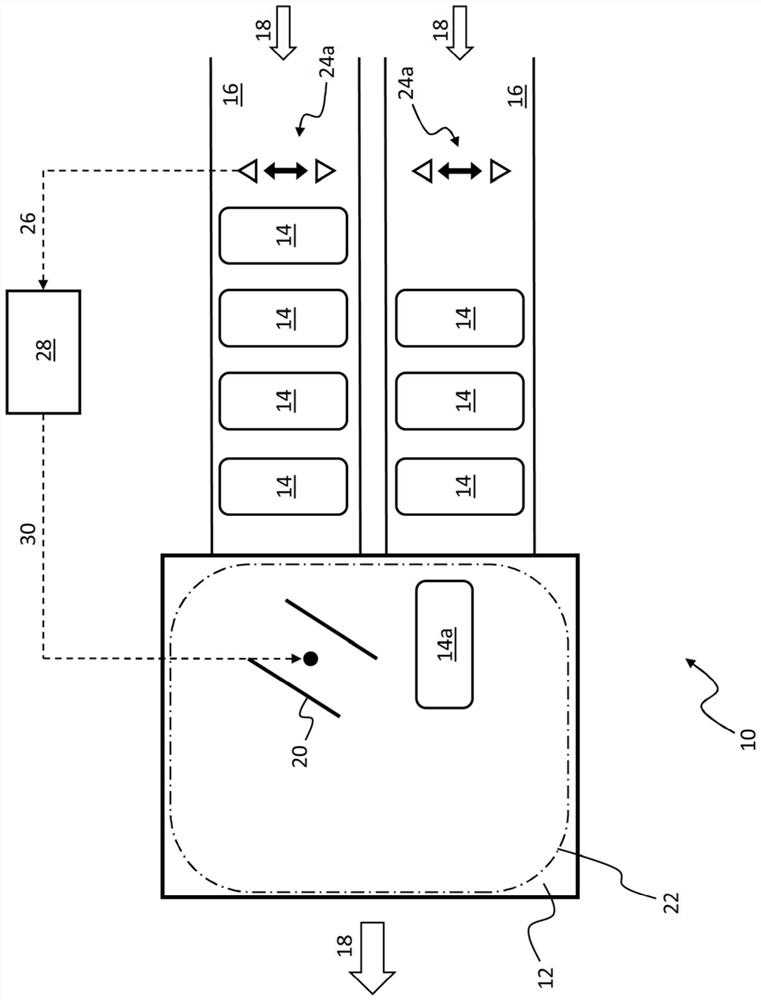

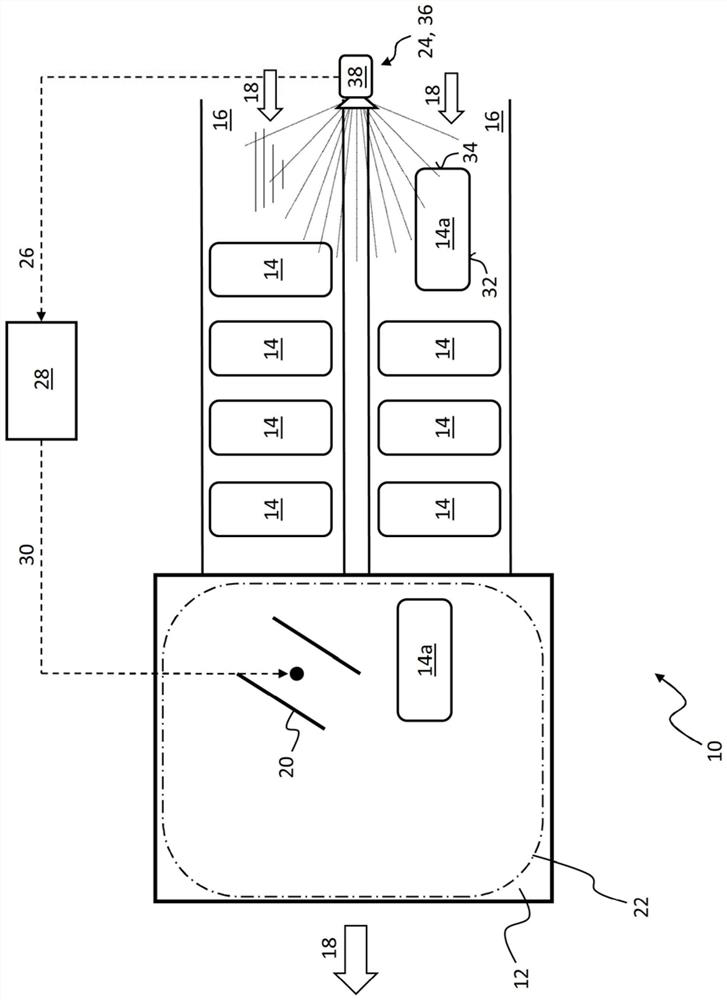

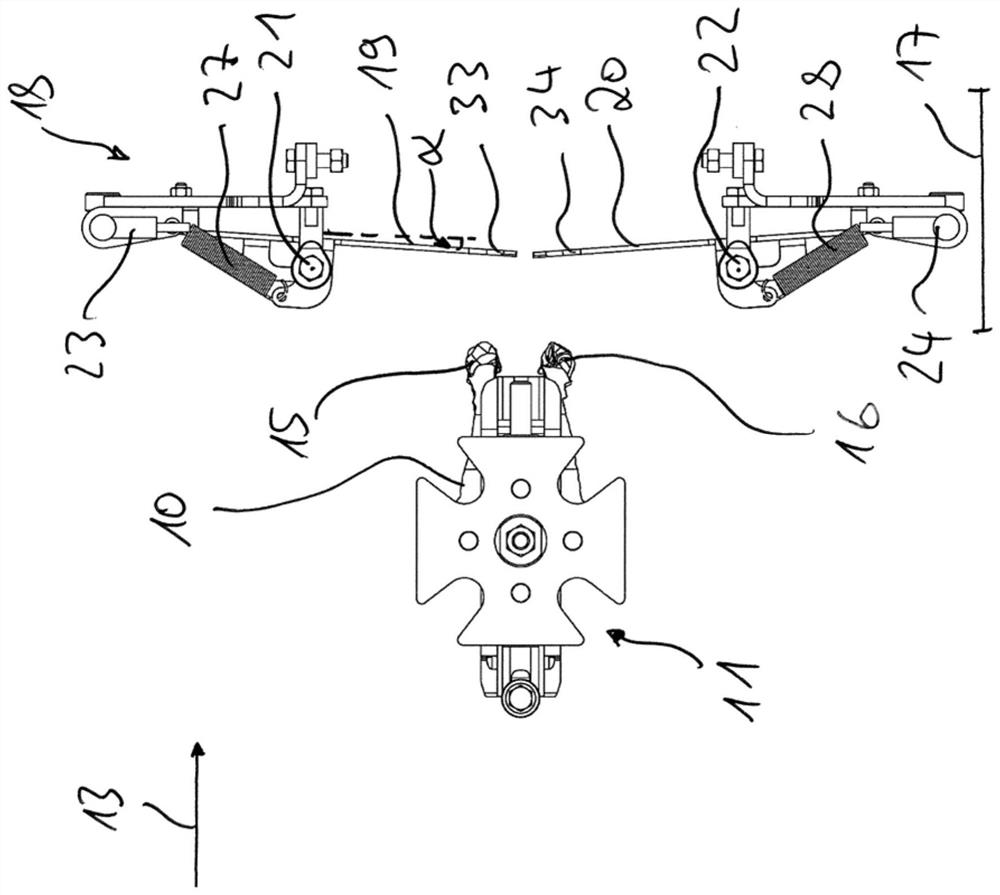

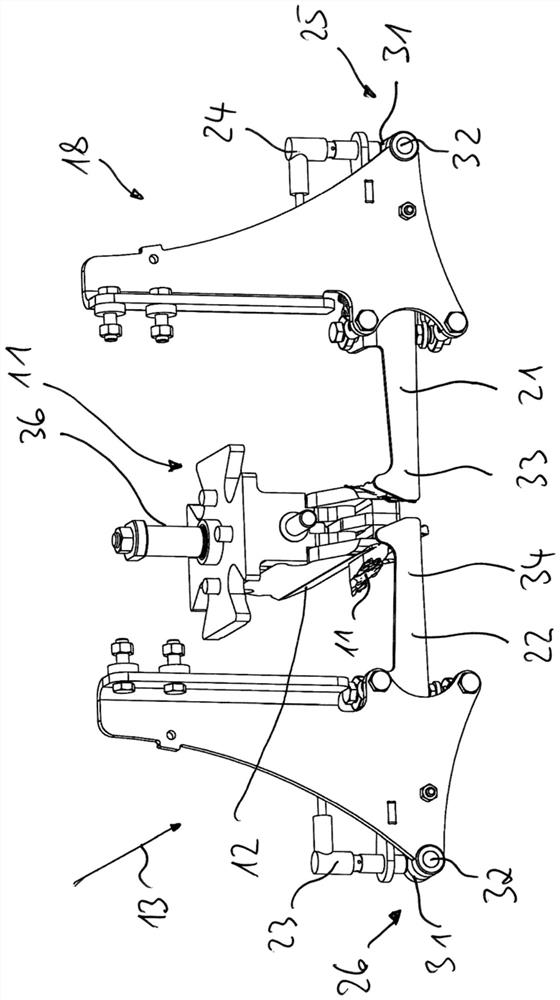

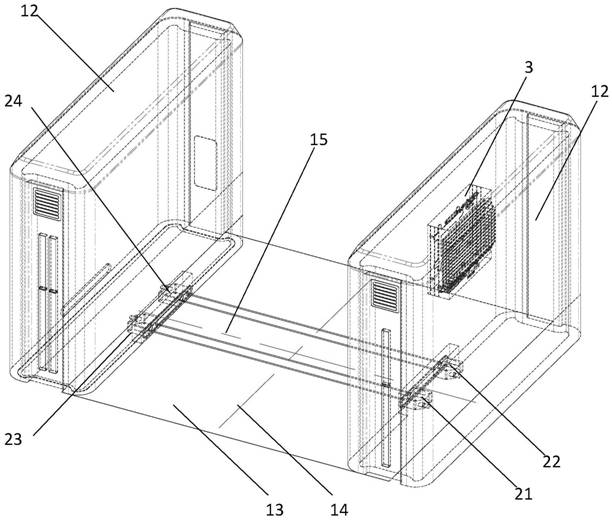

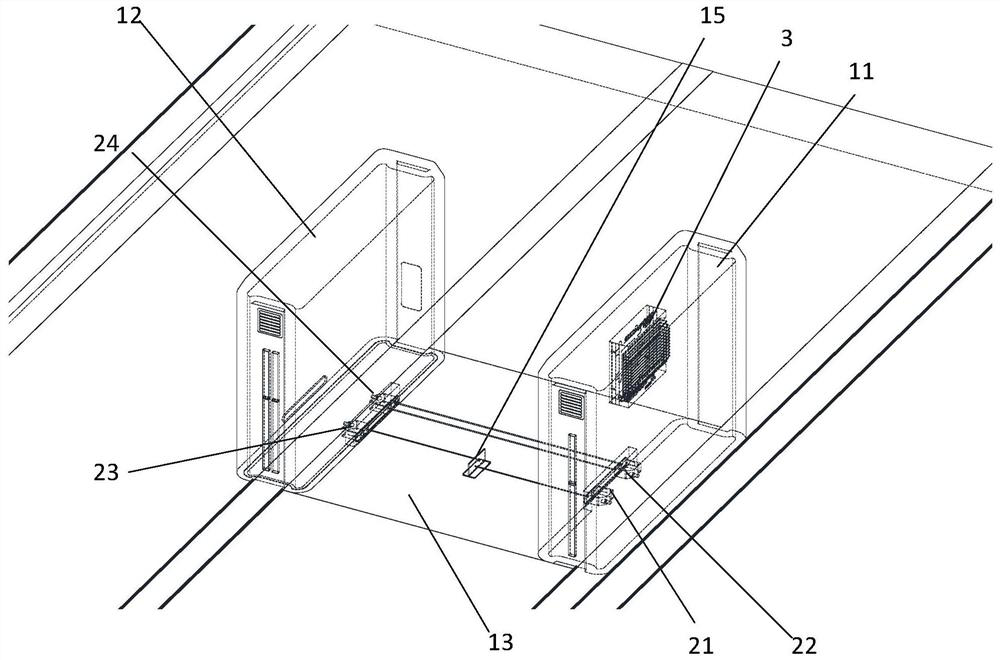

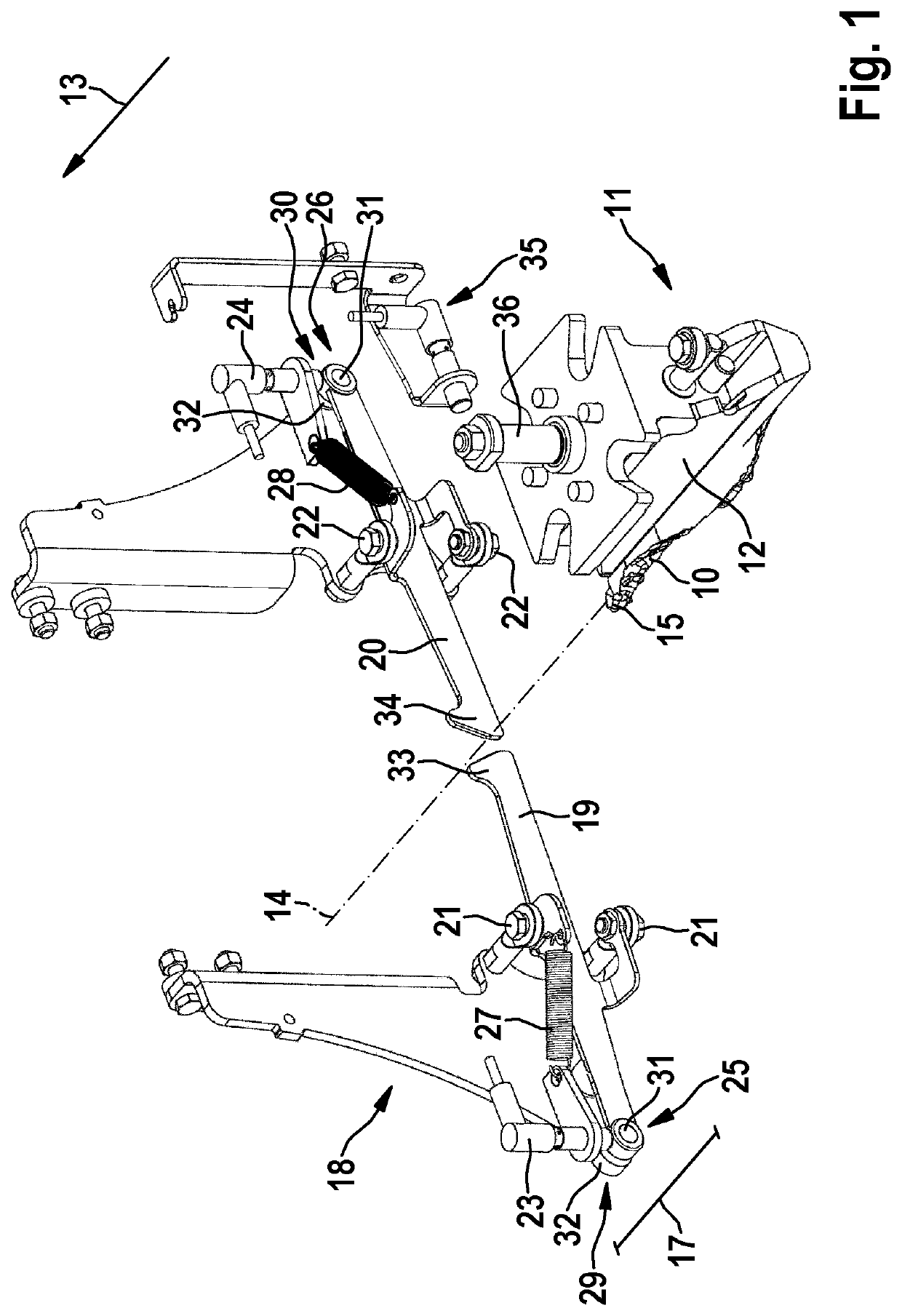

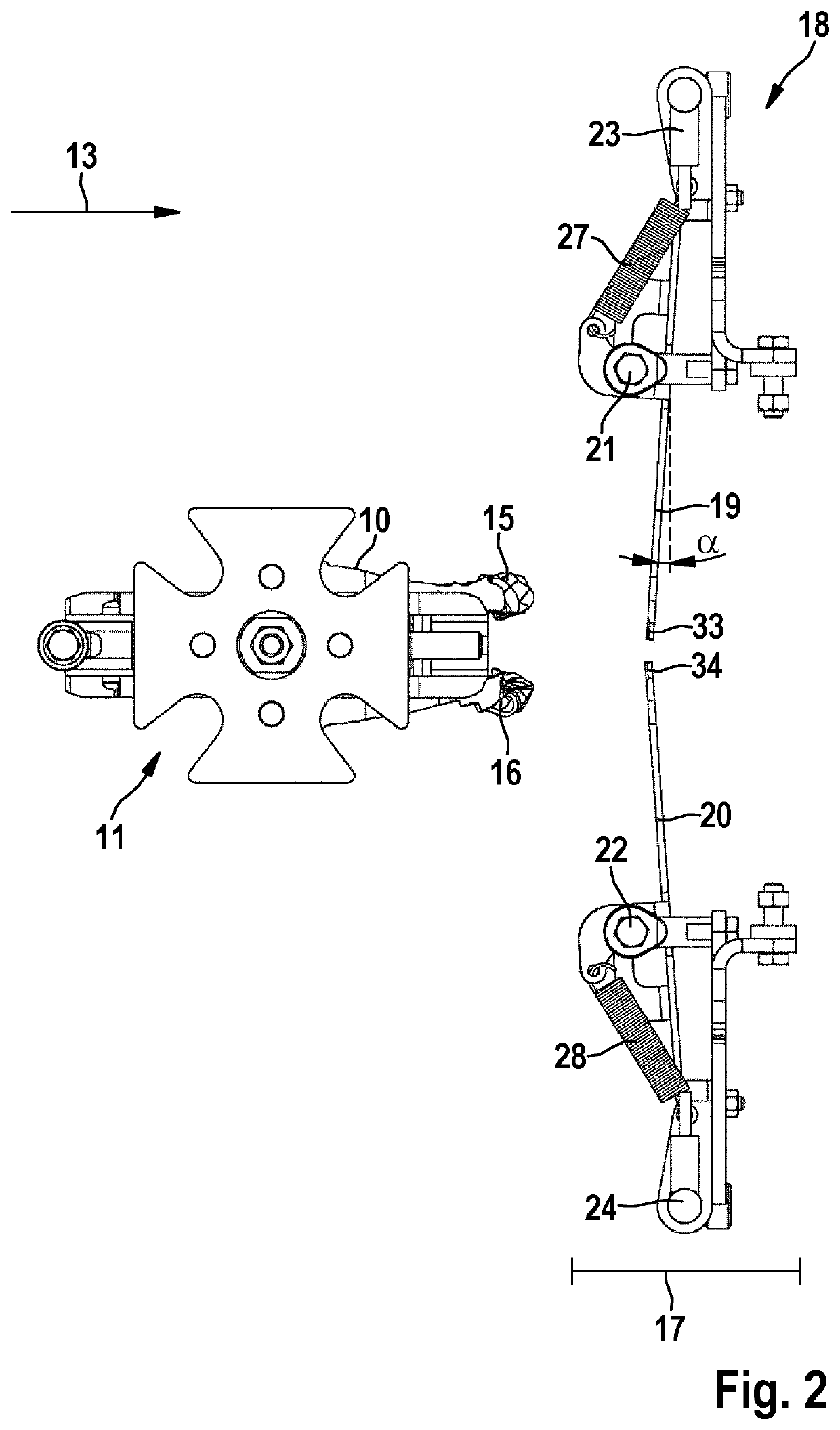

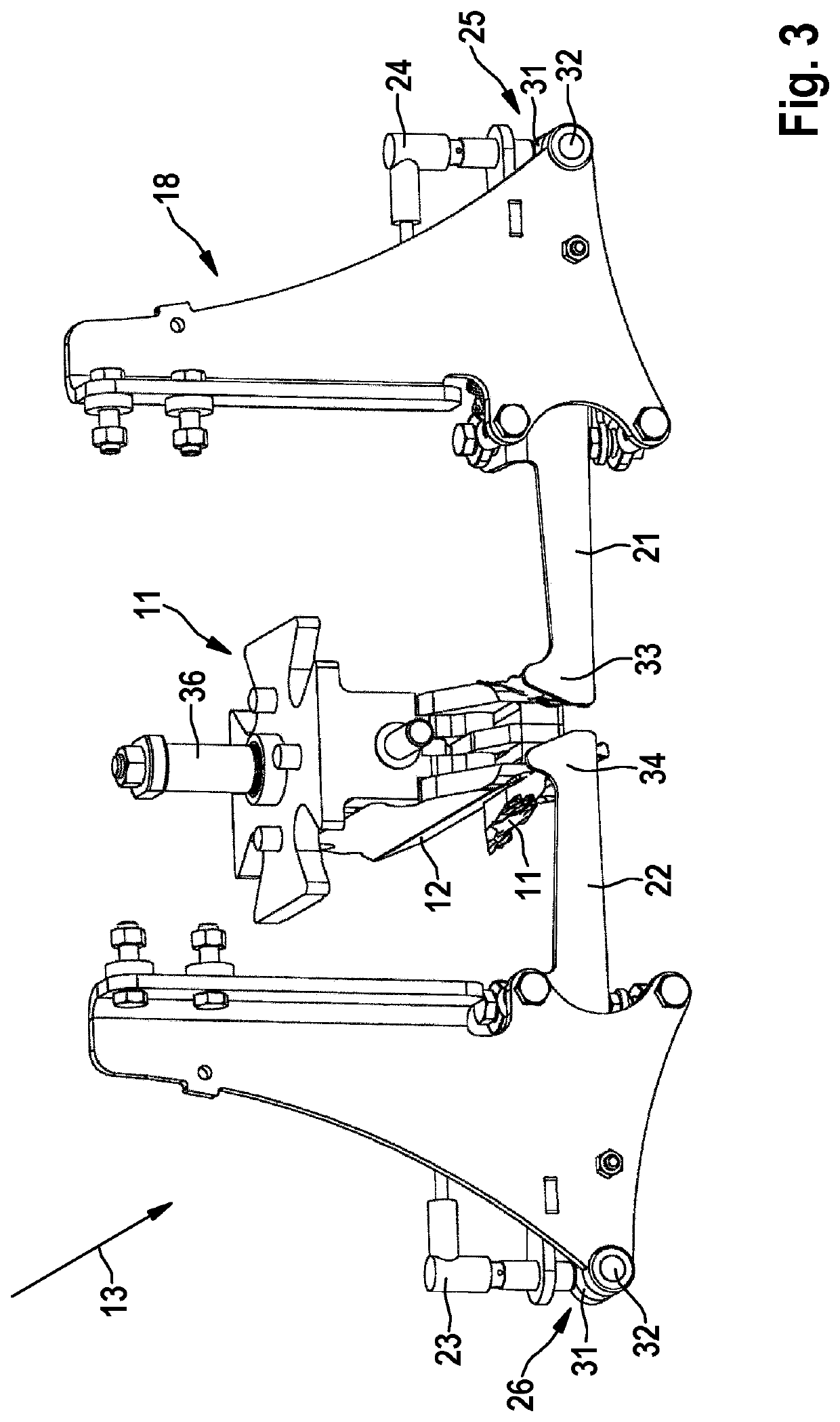

Device and method for the treatment and/or handling of piece goods moved in at least one row

PendingUS20220315350A1Enough timeQuick evaluationConveyorsControl devices for conveyorsWork cycleEngineering

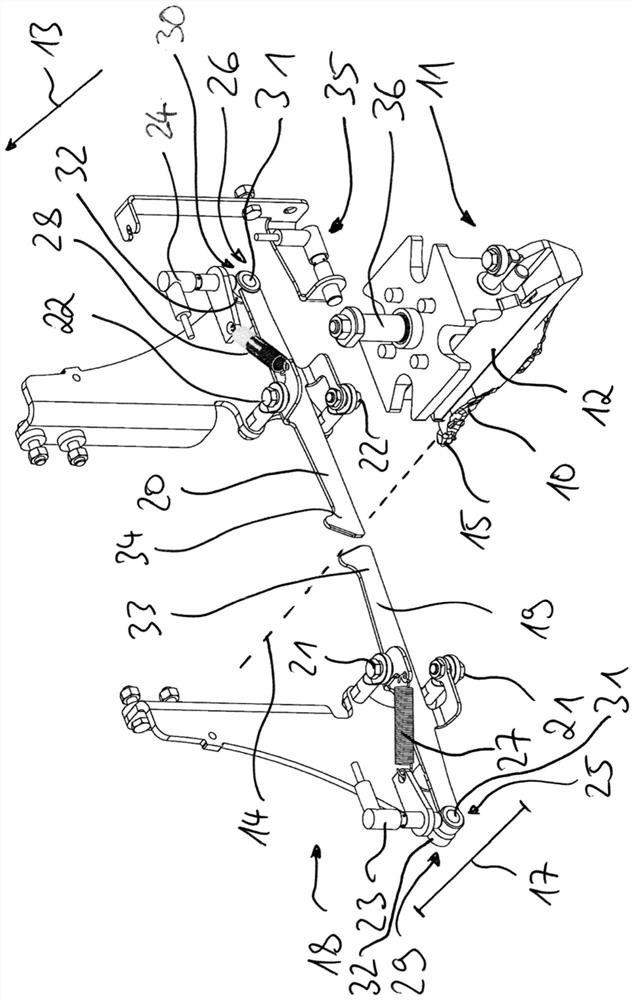

The invention relates to a handling device and / or layer forming device (10) and a method for forming piece good layers. Piece goods (14, 14a) are conveyed on a horizontal conveying device (16) to a grouping station and / or layer forming station (12) comprising a manipulator (20). In a work cycle the manipulator (20) seizes at least one piece good (14, 14a) and moves it into a defined relative target position and / or target alignment, in particular with regard to a piece good layer to be formed.The horizontal conveying device (16), which is arranged upstream of the grouping station and / or layer forming station (12) in the transport direction (18) of the piece goods (14, 14a), comprises at least one sensor device (24) for obtaining positional data and / or dimensional data and / or alignment data of the transported piece goods (14, 14a). Electronic output signals (26) are generated from the obtained data, which processed in a control device (28). The control device (28) controls the movements of the manipulator (20) within the movement range (22) for the purpose of the layer formation.

Owner:KRONES AG

A tungsten steel and a commutator contact piece measuring device using the tungsten steel

ActiveCN104593658BStrength balanceHardness balanceAngles/taper measurementsMechanical counters/curvatures measurementsLow speedRare earth

The invention relates to tungsten steel mainly comprising the raw materials: 10-20% of a bonding metal, 0.05-0.5% of a rare earth metal, 0.3-1% of an inhibitor, and the balance tungsten carbide, wherein the crystal particle size of the tungsten steel is in a range of 0.1-1 [mu]m. With adopting of a low speed wire cutting technology, the tungsten steel is made into a measuring block applied in a commutator contact chip measuring device; the measuring device includes a ruler frame, a fixed sleeve, a movable measuring rod and a microdrum; the movable measuring rod is arranged in the fixed sleeve; the fixed sleeve is fixedly connected with the ruler frame; the movable measuring rod passes through the ruler frame; the microdrum is arranged on the fixed sleeve; the measuring block is arranged between two ends of the ruler frame and is provided with a conical notch; an included angle of two side edges of a contact chip is equal to an included angle of the conical notch; the front end of the movable measuring rod is provided with a conical measuring head corresponding to the conical notch. The tungsten steel with excellent performance of hardness, strength, wear resistance and the like is made into the measuring block applied to the commutator contact chip measuring device, and the measurement precision is high.

Owner:HUARUI ELECTRICAL APPLIANCE

Apparatus and method for handling piece goods moving in at least one row

The invention relates to a handling and / or layering apparatus (10) and to a method for forming layers of piece goods. Piece goods (14, 14a) are conveyed on a horizontal conveyor (16) to a grouping and / or layering station (12) having a manipulator (20). In one working cycle, the manipulator (20) picks up at least one piece of piece goods (14, 14a) and moves same into a defined relative target position and / or target orientation, in particular with respect to a layer of piece goods to be formed. The horizontal conveyor (16) upstream of the grouping and / or layering station (12) in the transport direction (18) of the piece goods (14, 14a) has at least one sensor device (24) for obtaining position data and / or dimension data and / or orientation data of the transported piece goods (14, 14a). From the obtained data, electronic output signals (26) are generated, which are processed in a controller (28). The controller (28) controls the movements of the manipulator (20) within the movement space (22) for the purposes of layering.

Owner:KRONES AG

An automatic monitoring and control device for steel strand wire width

ActiveCN111540539BThe detection method is simpleEasy to monitor in real timeMechanical width measurementsUsing optical meansWire widthEngineering

The invention relates to the technical field of detection equipment, in particular to an automatic monitoring and control device for the wire width of a steel strand, which can effectively save physical strength and time during manual detection by automatically monitoring the wire width of the steel strand, and simplify The line detection method can effectively improve the detection accuracy, improve product quality, and improve practicability and reliability; it includes the base, the threading sleeve, two sets of first support plates and two sets of linear guide rails, and the left and right sides of the base are equipped with Conveying device, two sets of conveying devices have corresponding height positions, the threading sleeve is located between the two groups of conveying devices and fixed on the base through two sets of first support plates, and two sets of linear guide rails are installed horizontally on the top and bottom of the inner wall of the threading sleeve respectively.

Owner:河北九天科技有限公司

Device for measuring shoulder joint position of plurality of poultry carcasses conveyed continuously, device for slicing poultry carcasses, and corresponding method

The invention relates to a device for measuring the shoulder joint position of a plurality of poultry bodies conveyed continuously, having a measuring station arranged along a conveying line, which measuring station is adapted to detect the shoulder joint position. The invention also relates to a device for slicing poultry bodies, comprising such a device for measuring, and to a corresponding method.

Owner:NORDISCHER MASCHINENBAU RUD BAADER GMBH CO KG

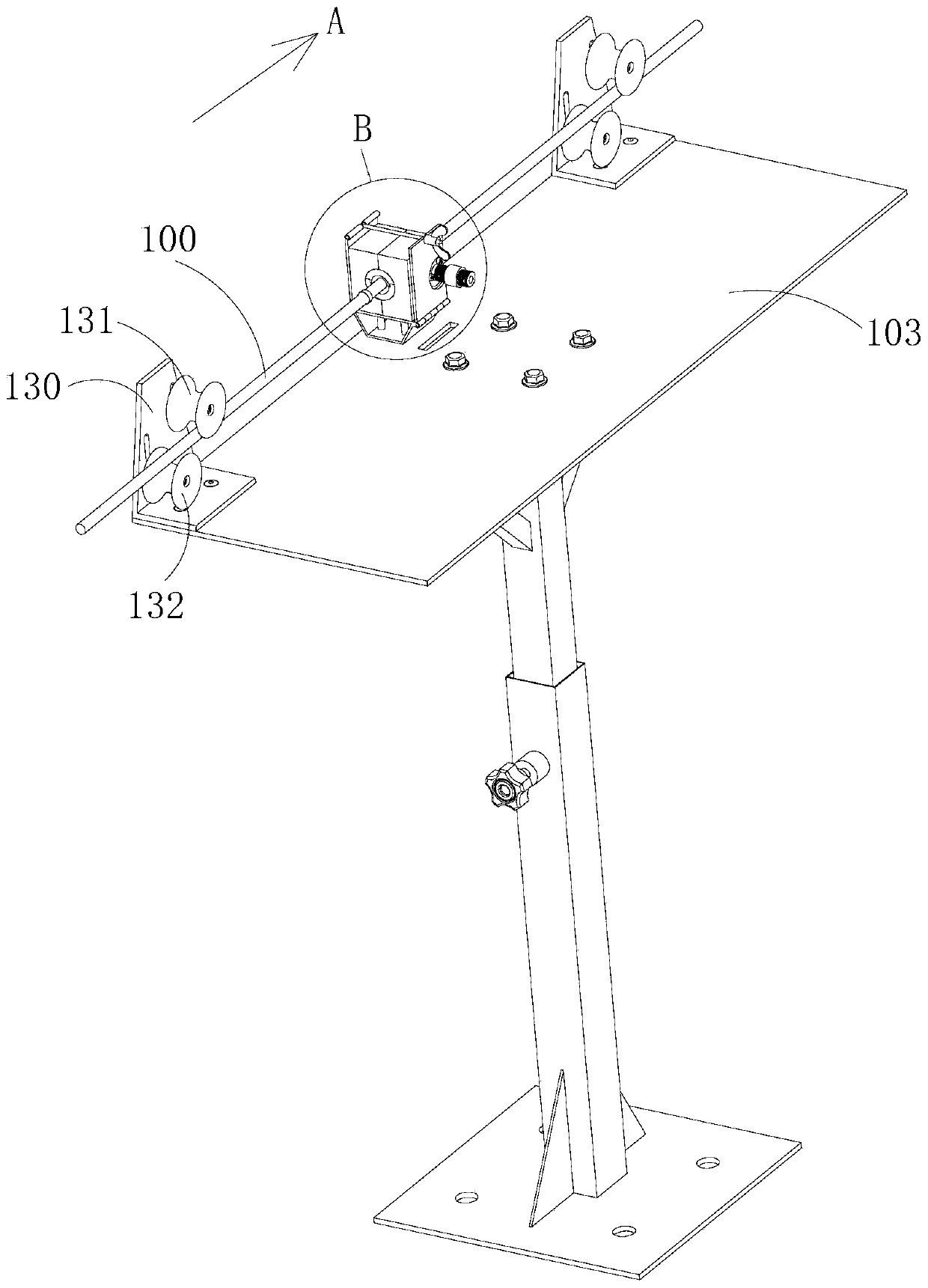

Device and method for non-contact rapid measurement of bicycle tire width

ActiveCN112595207BGuarantee the right of wayEasy to implementMechanical width measurementsFast measurementCarriageway

The invention discloses a non-contact type rapid measurement device and method for bicycle tire width, comprising: a structural shell, a laser range finder group and a control host, the laser range finder group is used for measuring distance information data, and feeding back a trigger signal to the control host. The invention has the advantages of simple implementation, installed on both sides of the entrance of the special bicycle lane, and can measure the front and rear tire widths of bicycles, electric vehicles, motorcycles, scooters and other vehicles passing through the passage, and send the measurement results to the control system. The main engine is used for identification, which is used to guarantee the right of way of bicycles in the bicycle-only lanes established for green travel in cities, to avoid non-bicycles from occupying bicycle-only lanes, and to provide solutions for low-carbon and environmentally friendly urban travel. The feature of the present invention is that the tire width of vehicles such as bicycles passing through can be measured when riding fast without stopping and pushing, and the vehicle can deviate from the center line in the lane without being affected by the deviation amount.

Owner:BEIJING INST OF RADIO METROLOGY & MEASUREMENT

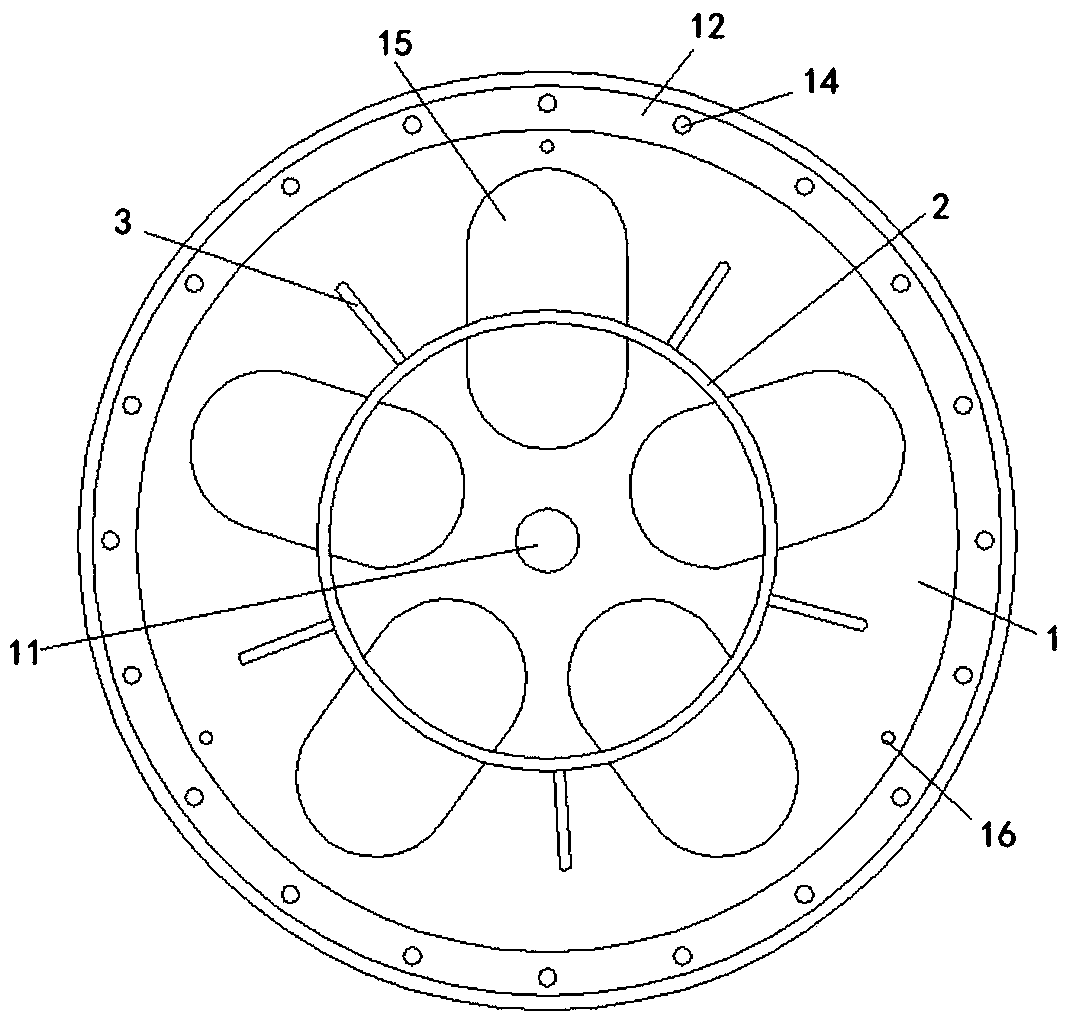

Coaxiality measurement tool and measurement method

ActiveCN109238108AGuaranteed assembly accuracyAssembly position influenceMechanical clearance measurementsMechanical width measurementsEngineering

The invention discloses a coaxiality measurement tool and a measurement method, and relates to the technical field of the measurement tool. The coaxiality measurement between a guide shaft and a wheelhub in a rotor of a wind tunnel compressor is realized, thereby guaranteeing assembling precision between the guide shaft and the wheel hub. The main technical scheme of the invention is as follows:the coaxiality measurement tool comprises a body, and a measurement barrel; the body is disciform, and a round first through hole coaxial with the body is arranged on the body, an inner diameter of the first through hole is greater than an outer diameter of the guide shaft, and a connecting part for performing coaxial connection on the body and the wheel hub is arranged on the body; and the measurement barrel is arranged on a surface of the body, the measurement barrel is coaxial with the body, and the inner diameter of the measurement barrel is greater than the outer diameter of an adjustingbarrel in a rotor. The measurement tool disclosed by the invention is mainly used for measuring the coaxiality.

Owner:SHENYANG TURBO MASCH CORP

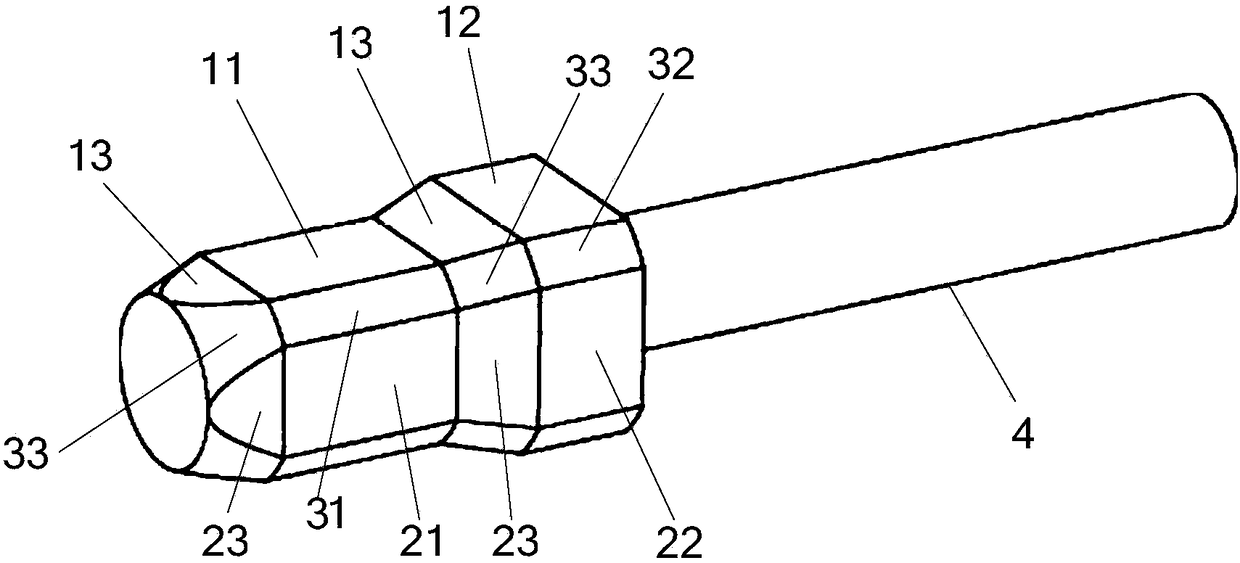

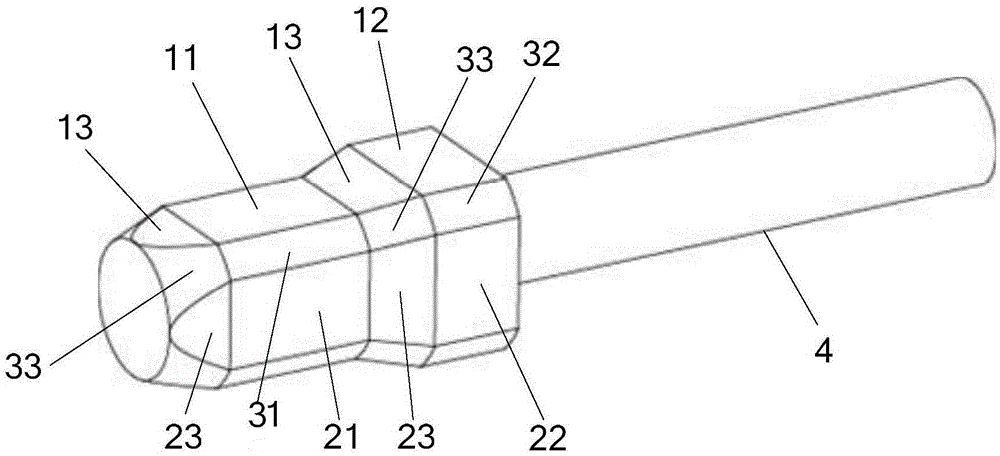

Go-no go gauge

InactiveCN105627877ALow costSave materialMechanical diameter measurementsMechanical width measurementsEngineeringMechanical engineering

The invention, which relates to the testing fixture field, provides a go-no go gauge comprising a cylindrical section bar body. A first groove go end, a first groove no-go end, and a handle are formed successively from one end to the other end of the section bar body relative to a first radial direction of the section bar body; and a second groove go end and a second groove no-go end are formed successively at the A first groove go end and the first groove no-go end relative to a second radial direction of the section bar body. The two opposite side surfaces of the first groove go end and the two opposite side surfaces of the second groove go end are connected by an arc surface to form a circular hole go end; and the two opposite side surfaces of the first groove no-go end and the two opposite side surfaces of the second groove no-go end are connected by an arc surface form a circular hole no-go end. Therefore, an effect of one gauge with three purposes is realized and the go-no go gauge can be used conveniently. When the go-no go gauge is used for checking, head turning is avoided; the operation becomes convenient; the time is saved; the cost of the cylindrical section bar material is low and processing becomes convenient.

Owner:SHAANXI TECHN INST OF DEFENSE IND

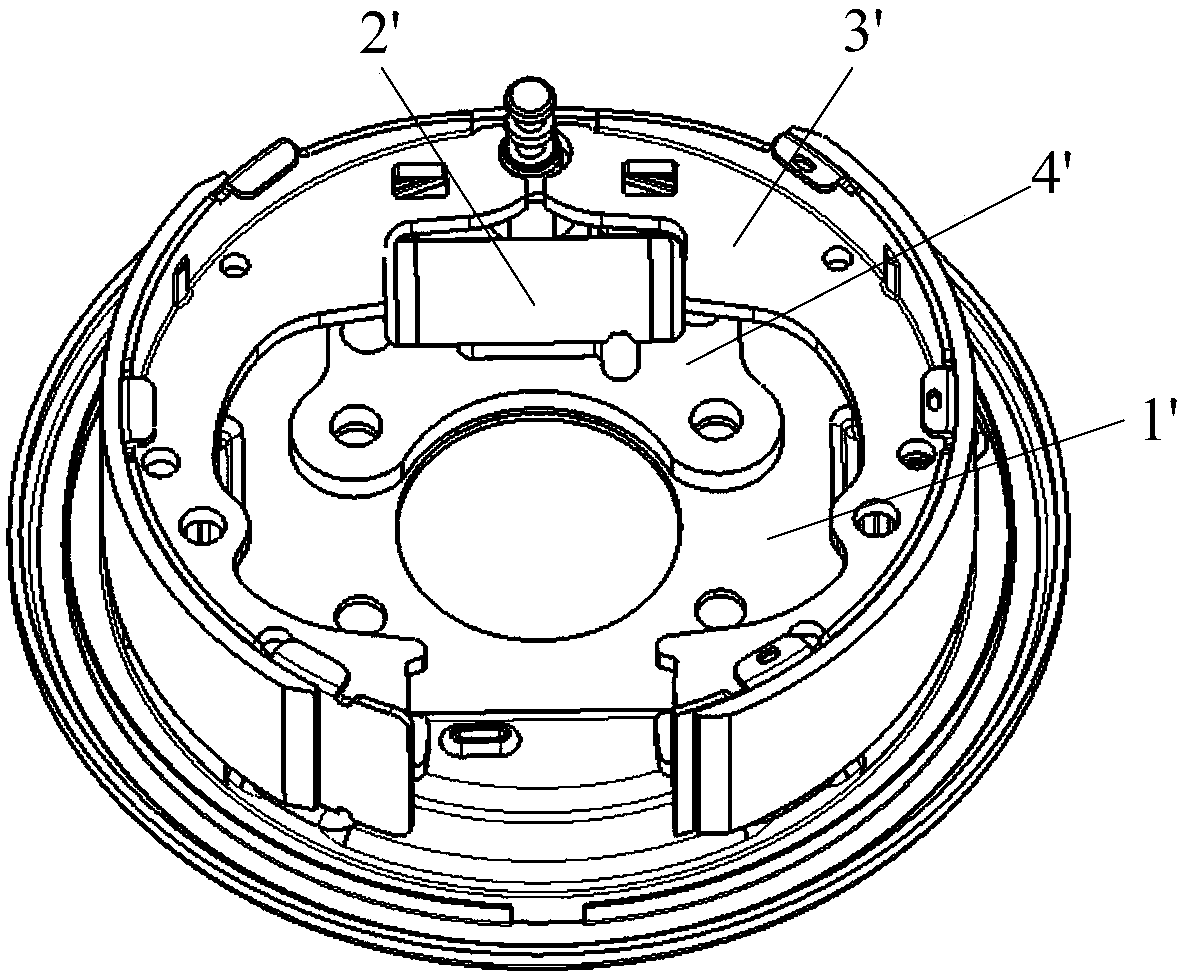

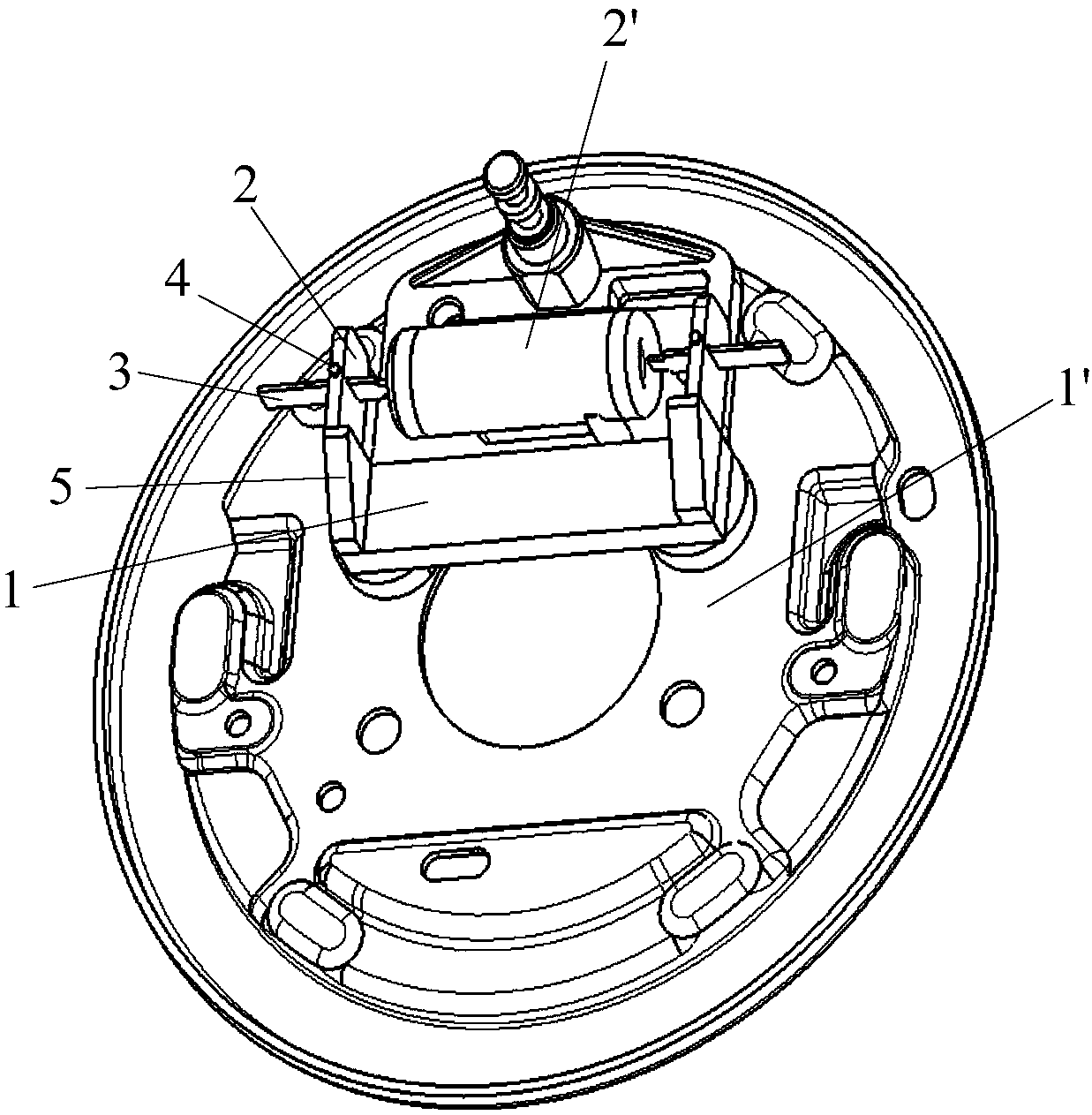

Brake wheel cylinder stroke detecting device

InactiveCN108426509AHigh-precision detectionMechanical clearance measurementsMechanical width measurementsDrum brakeAgricultural engineering

The invention discloses a brake wheel cylinder stroke detecting device which comprises a base, two side plates and two detecting calipers. The two side plates are arranged on the same side of the basein parallel and each provided with a detecting hole. The two detecting calipers slidingly penetrate through the two detecting holes respectively. The brake wheel cylinder stroke detecting device canconveniently detect the stroke of a drum type brake wheel cylinder.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Roller indentation width detection device and method

PendingCN110823058ASimple structureLow costMechanical width measurementsEngineeringStructural engineering

The invention discloses a roller indentation width detection device and method. The roller indentation width detection device comprises a detection base, a detection platform, two supporting components, a movable pressing seat and a power component, wherein the detection platform is arranged on the detection base, a horizontal detection plane is arranged on the upper surface of the detection platform, the detection plane is used for laying detection paper, the detection base is provided with the two supporting components which are oppositely arranged at the two sides of the detection platform,the movable pressing seat is movably connected to the supporting components and can move along the supporting components in the vertical direction, the movable pressing seat is used for fixed connection with a to-be-detected roller, the power component is arranged on the detection base and is connected with the movable pressing seat, and the power component is used for driving the movable pressing seat to move so as to apply pressure to the to-be-detected roller. The roller indentation width detection device can quickly detect whether the circumferential surface of the rubber roller is flat or not.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

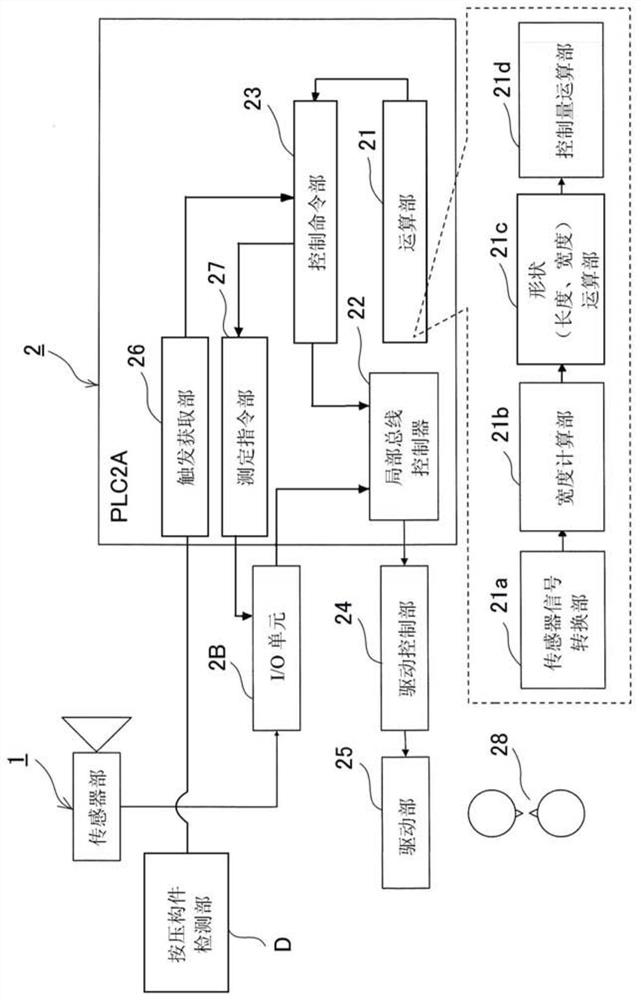

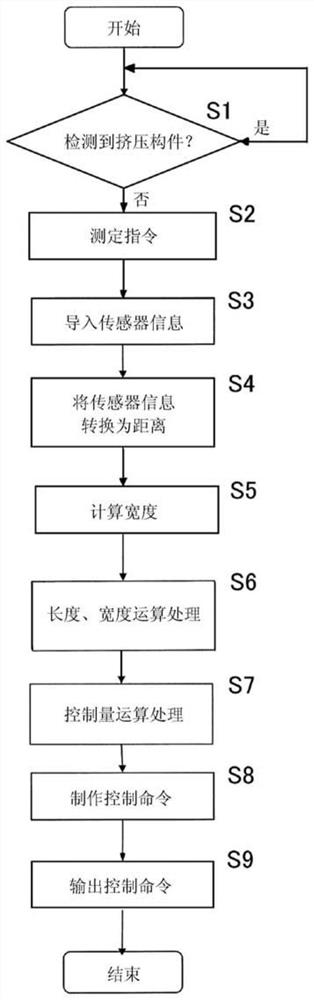

Control system and control method thereof, computer readable storage medium

ActiveCN108021089BReduce vibrationShorten takt timeAngles/taper measurementsMeasurement/indication equipmentsControl systemControl engineering

The present invention provides a control system, a control method thereof, and a computer-readable storage medium capable of shortening the tact time of measurement while suppressing vibration in profiling control. The present invention is a PLC system (SYS) having a displacement sensor (7), a driving device (30, 40) and a PLC (1). In the PLC system (SYS), the profiling control unit (162) of the PLC (1) is based on the measurement information (one-dimensional information) of the displacement sensor (7) from which measurement noise (noise information) has been removed by the filter unit (162c) and From the position information of the driving device (30, 40), the target position where the distance between the displacement sensor (7) and the object A becomes constant is calculated.

Owner:ORMON CORP

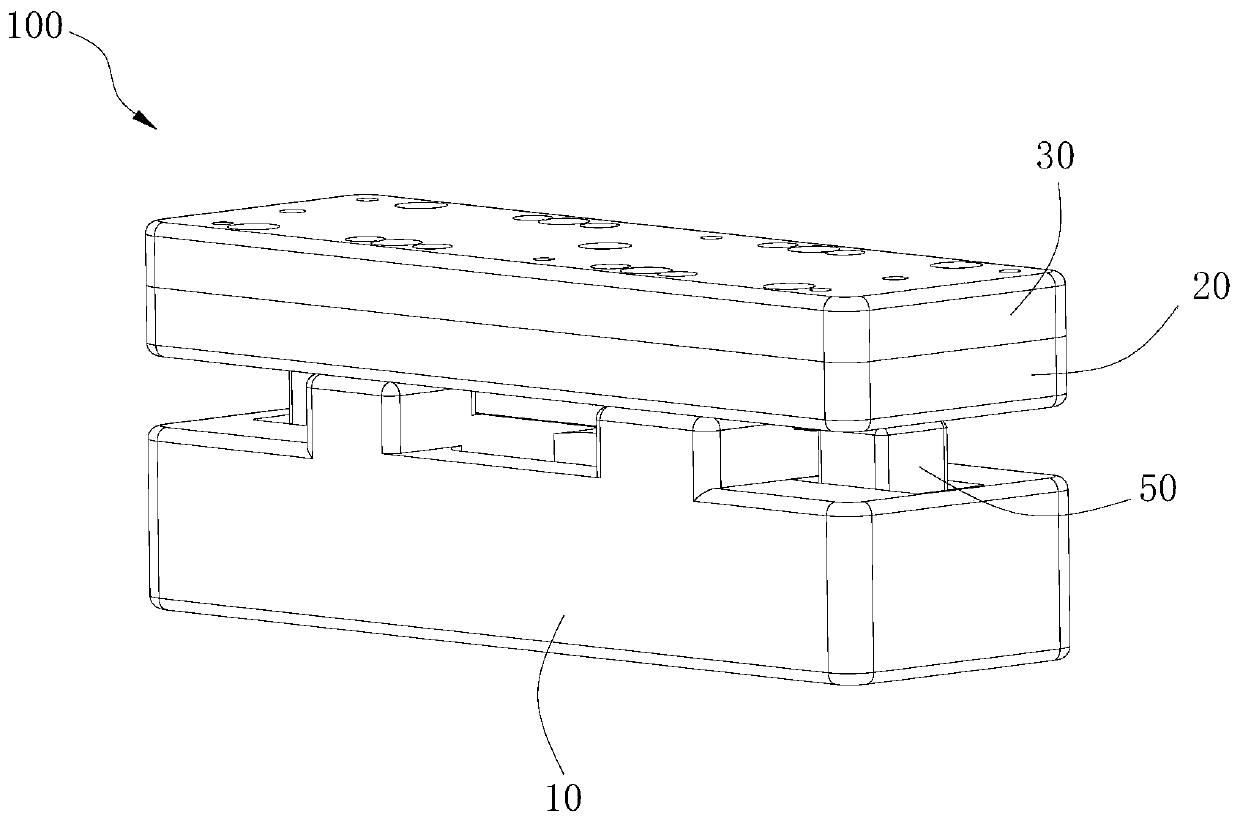

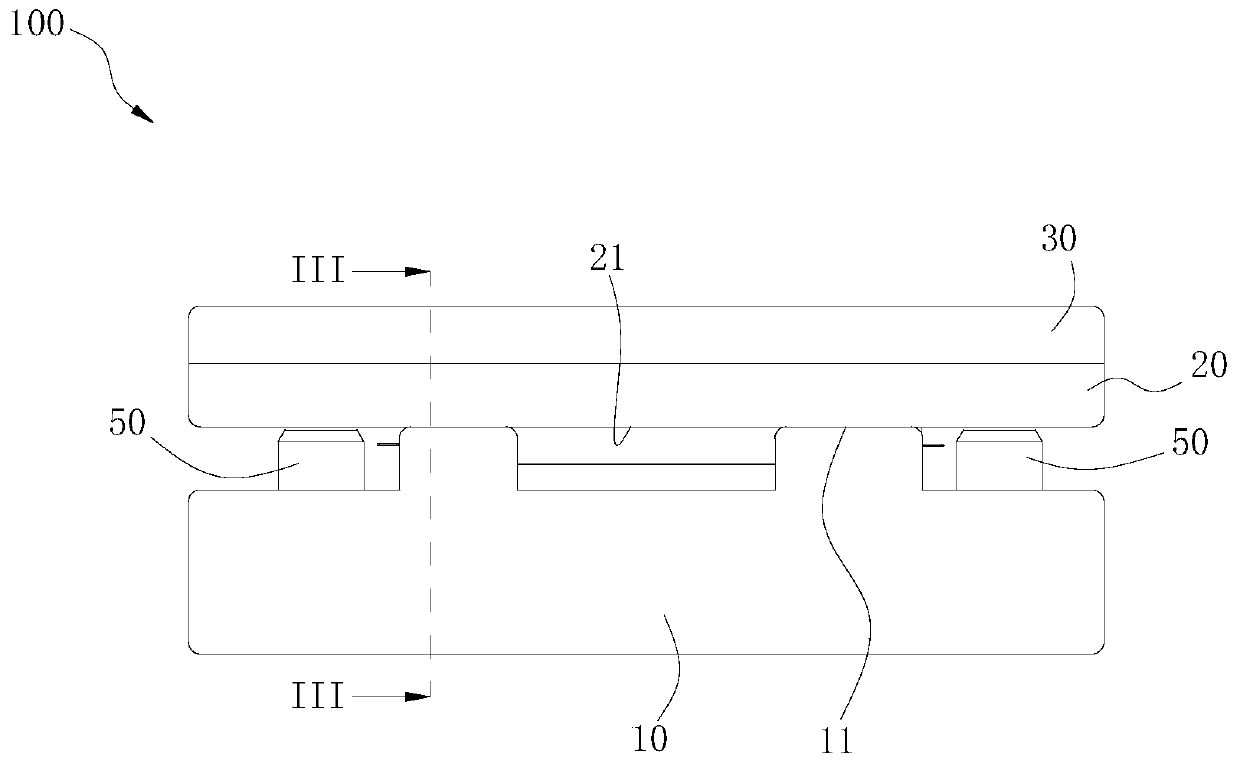

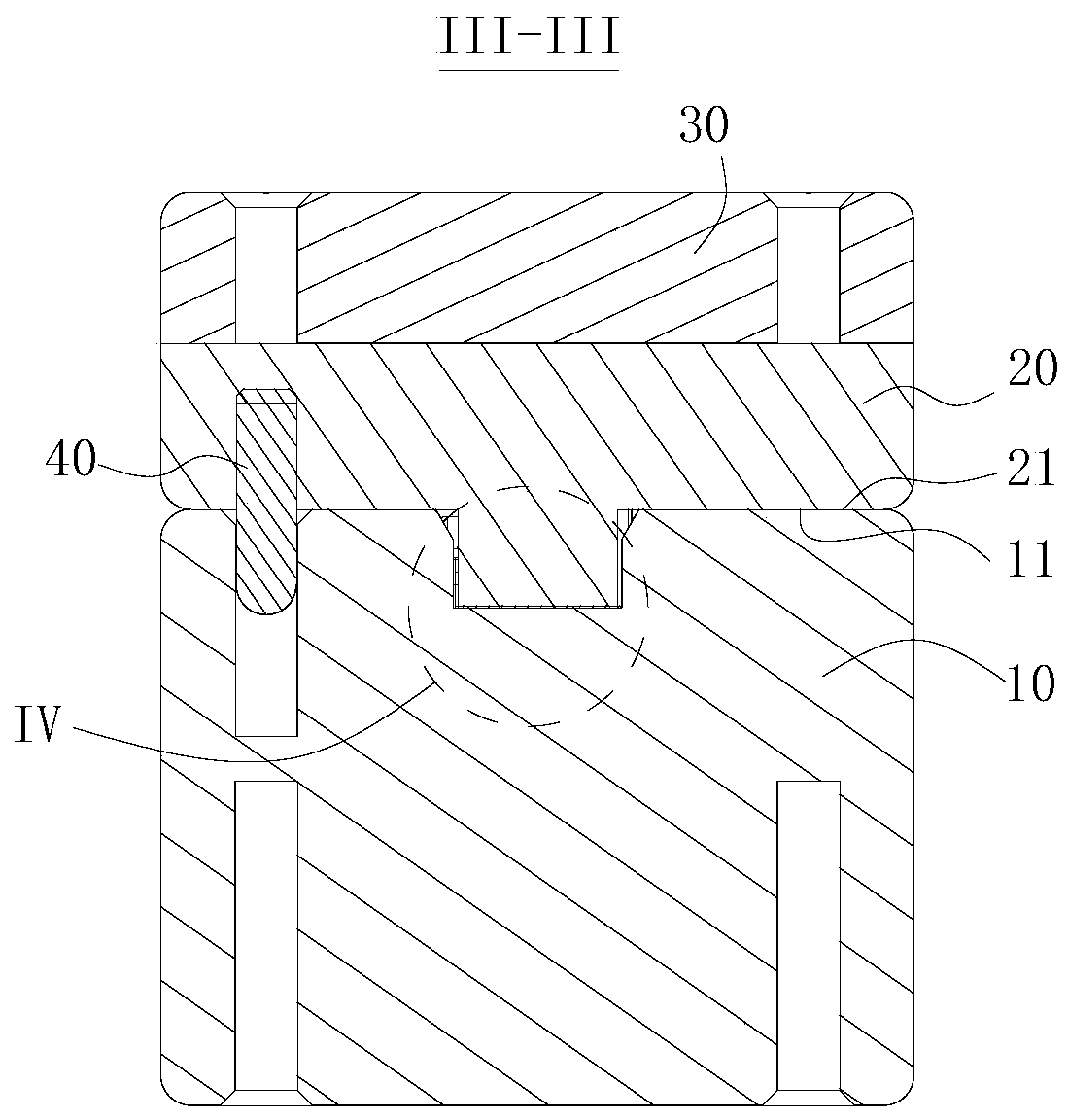

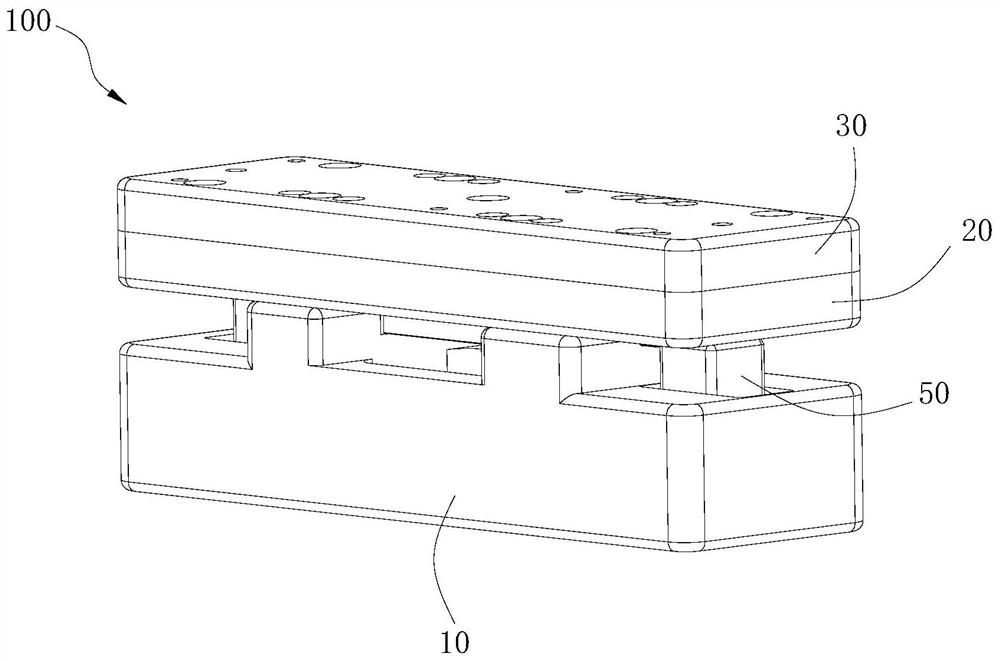

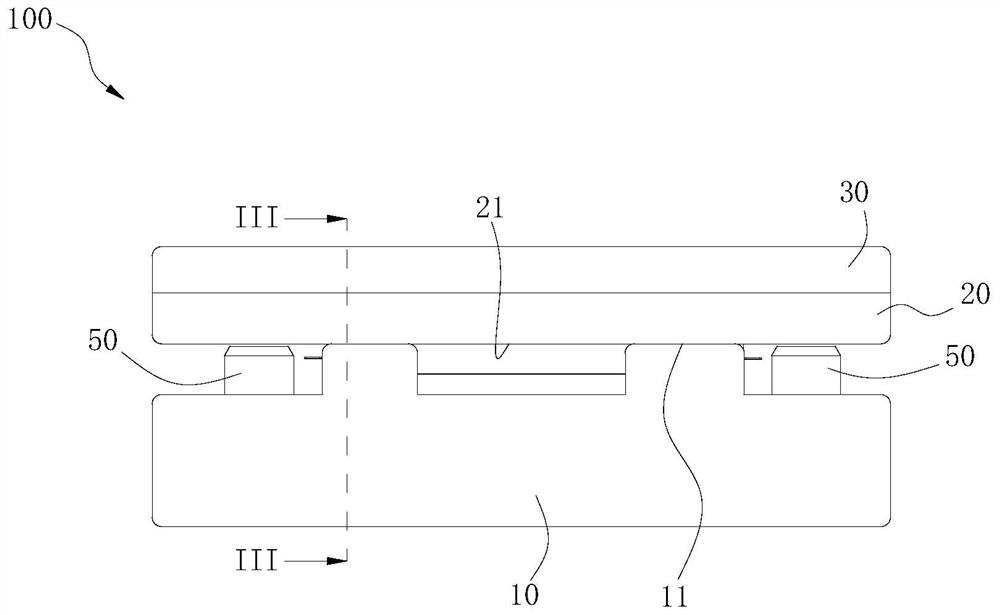

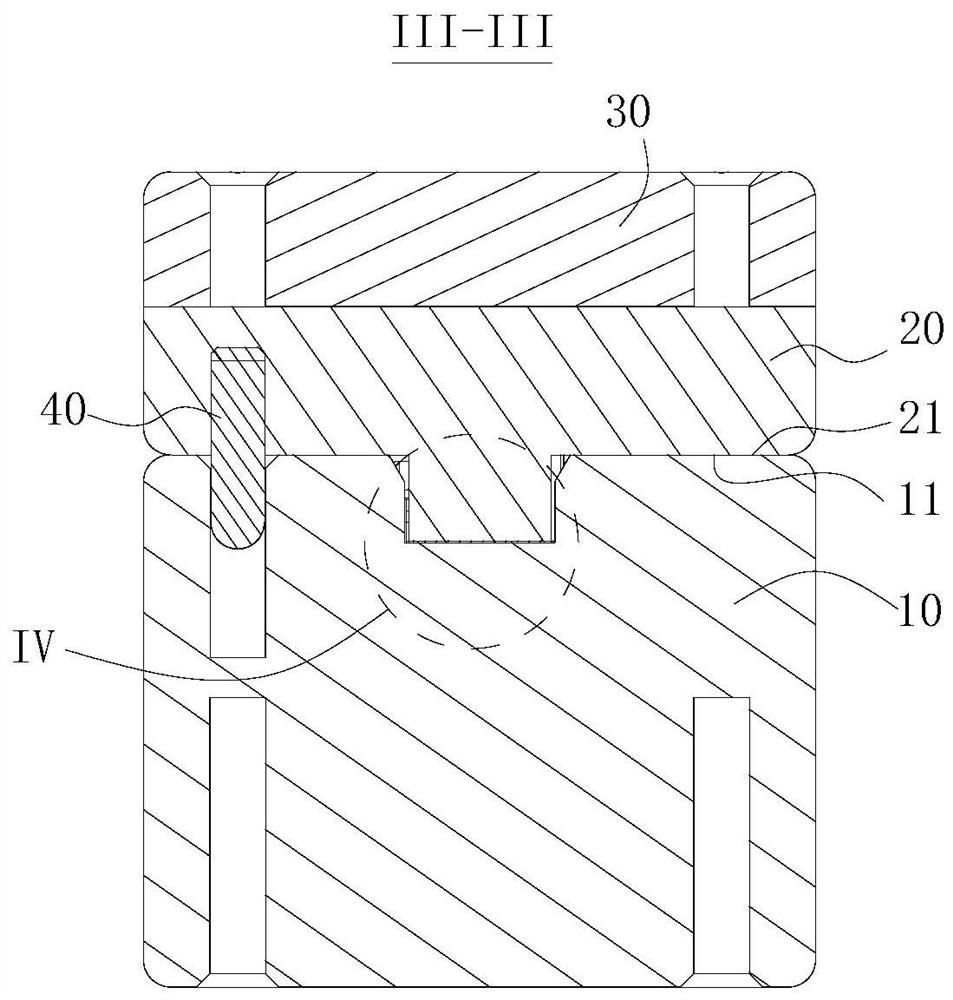

Detection device and detection method

ActiveCN111504157AImprove detection efficiencyMechanical width measurementsMechanical thickness measurementsFlexible circuitsStructural engineering

The invention discloses a detection device and a detection method. The detection device is used for detecting the flexible circuit board, and comprises a lower module, the lower module comprises an upward first butt joint surface, and a mounting groove is formed in the first butt joint surface and used for placing the flexible circuit board; the detection device also comprises an upper module which is arranged on the lower module, the upper module comprises a downward second butt joint surface, the first butt joint surface is in contact with the second butt joint surface, the upper module comprises a convex block matched with the mounting groove, the convex block comprises a lower surface facing the bottom surface of the mounting groove, a gap is formed between the lower surface and the bottom surface of the mounting groove, and the gap is used for accommodating the flexible circuit board. Thus, the detection device can detect two sizes of the flexible circuit board at one time, and the detection efficiency is improved.

Owner:OPPO CHONGQING INTELLIGENT TECH CO LTD

Detection device and detection method

ActiveCN111504157BMechanical width measurementsMechanical thickness measurementsFlexible circuitsMechanical engineering

Owner:OPPO CHONGQING INTELLIGENT TECH CO LTD

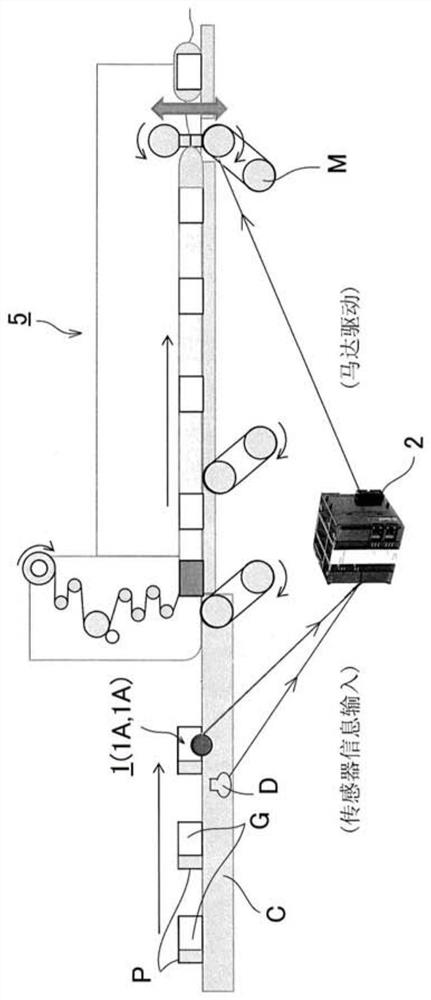

Measurement control device, packaging device equipped with said measurement control device, and measurement control method

ActiveCN112533835AControl devices for conveyorsMechanical width measurementsAgricultural engineeringHorizontal orientation

The purpose of the present invention is to provide a measurement control device which, even for packaging devices of the type equipped with a pressing member P, and even in the case of packaging agricultural products, bread, and other articles that each have a different size and shape, can optimally perform optimal film packaging and, without wasting film, can perform film packaging with a good appearance. A sensor unit 1 arranged at least in the horizontal direction perpendicular to the direction of travel in which the article being packaged G is conveyed, and a pressing member detection unitD for detecting a packaged article conveyance pressing member P mounted on the packaging device are connected to the measurement control device main body 2, and the measurement control device is provided with an acquisition signal stopping unit which stops acquisition of signals from the sensor unit 1 when the pressing member detection unit D detects the pressing member P, and a signal acquisition restarting unit which restarts acquisition of signals from the sensor unit 1 when the pressing member detection unit D does not detect the pressing member P.

Owner:ORMON CORP

Device for measuring the shoulder joint position of continuously conveyed poultry carcasses, arrangements for filleting poultry carcasses and corresponding methods

ActiveUS11503834B2Reliable measurementPermanent magnetsMechanical width measurementsAnimal scienceMedicine

An apparatus for measuring the shoulder joint position of continuously conveyed poultry bodies has a measuring station, arranged along a conveying line, which is adapted to detect the shoulder joint position. Also provided is an arrangement for filleting poultry bodies having such an apparatus for measuring, and to corresponding methods.

Owner:NORDISCHER MASCHINENBAU RUD BAADER GMBH CO KG

Mechanical width detection unit and shape detection device

ActiveCN105606010BEasy to operateLow costMechanical width measurementsMechanical thickness measurementsEngineeringLight hole

The invention disclose a mechanical width detection unit. The detection unit comprises a basic installation part, a detection collision rod hinged to the basic installation part, a limiting part limiting rotation of the collision rod, an elastic force part which acts a radial elastic force on the collision rod and a light shield which is arranged on the collision rod and includes a light hole. The mechanical width detector and the appearance detector are characterized by low cost and simple operation.

Owner:ZHEJIANG DAMON TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com