Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

118results about "Float-controlled apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

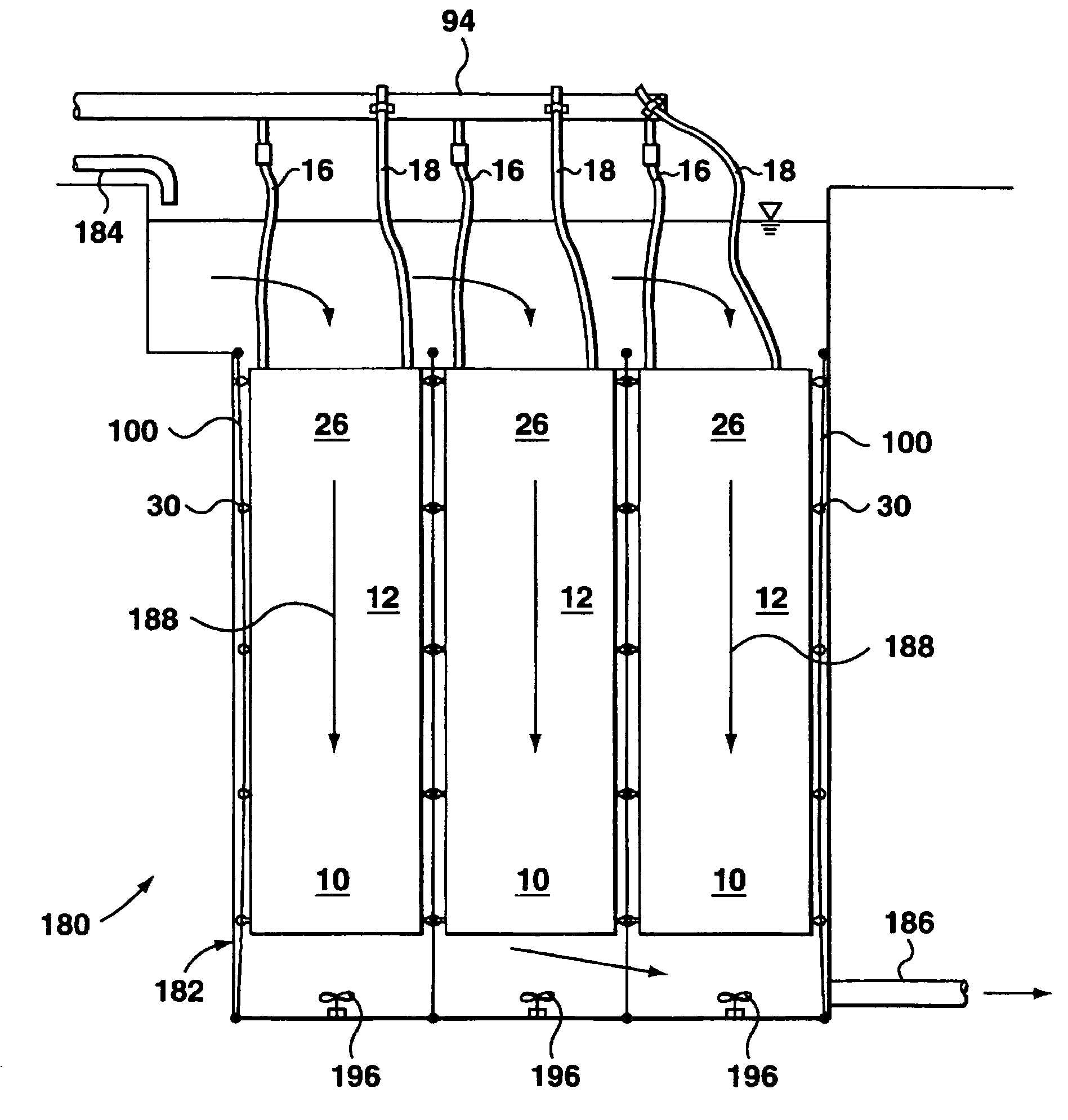

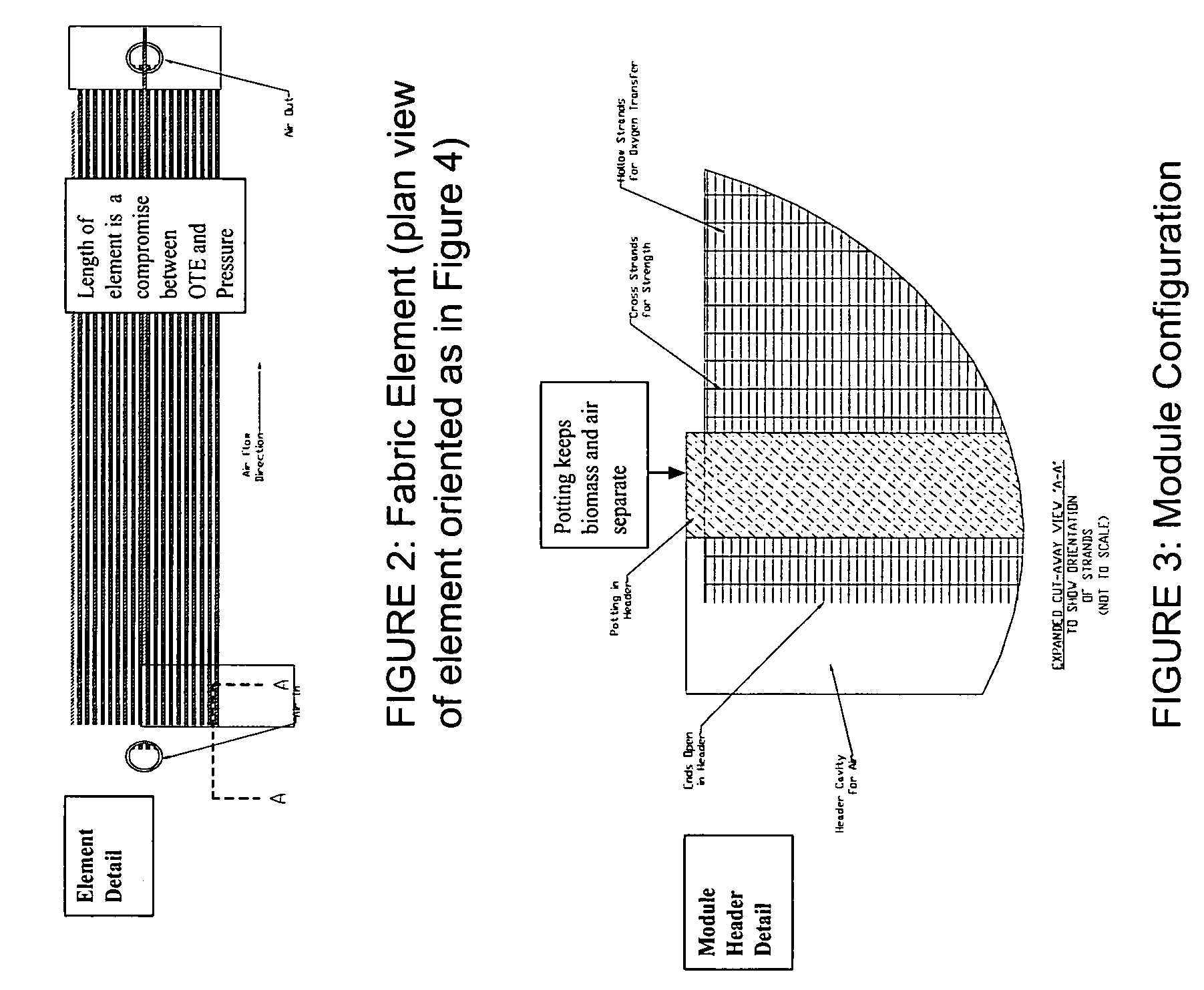

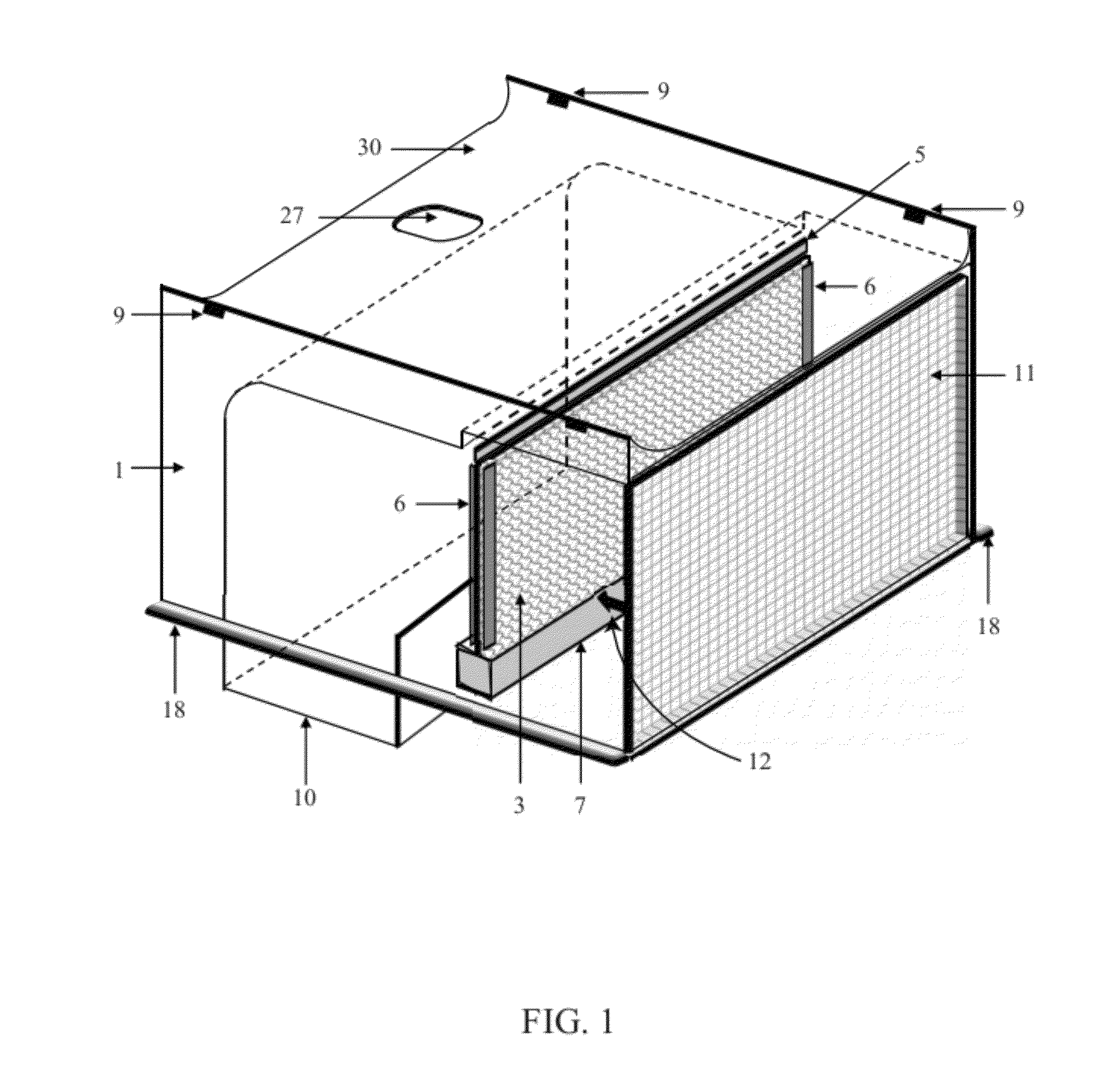

Membrane supported bioreactor for municipal and industrial wastewater treatment

ActiveUS7118672B2Reduce operating costsIncrease surface areaCarburetting airSemi-permeable membranesBiofilmFiber

A membrane supported biofilm reactor uses modules having fine, dense, non-porous hollow fibers made from Polymethyl pentene (PMP) formed into a fabric with the PMP as the weft. One or more sheets of the fabric are potted into a module to enable oxygen containing gas to be supplied to the lumens of the hollow fibers. Various reactors using such modules are described.

Owner:ZENON TECH PARTNERSHIP

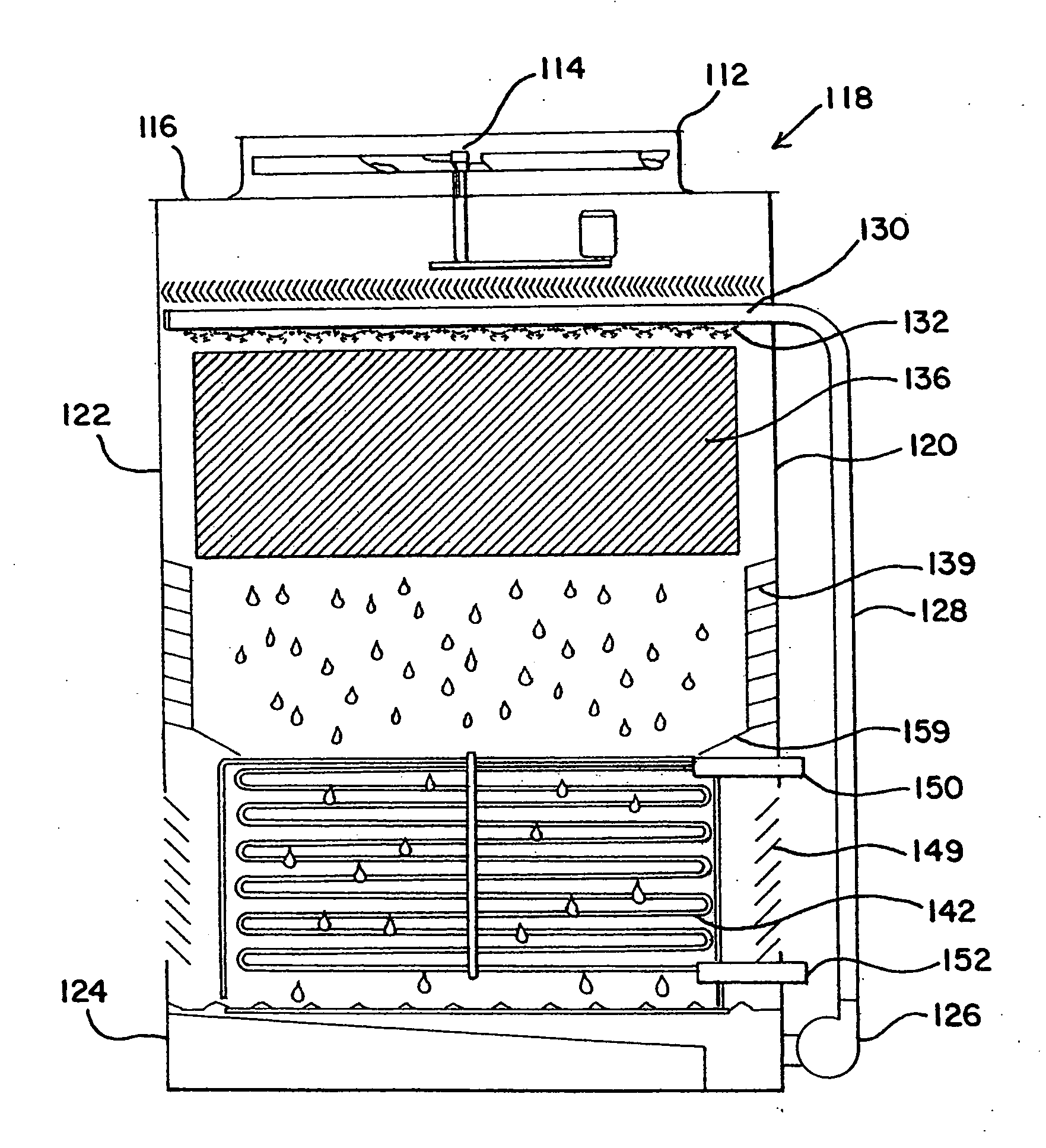

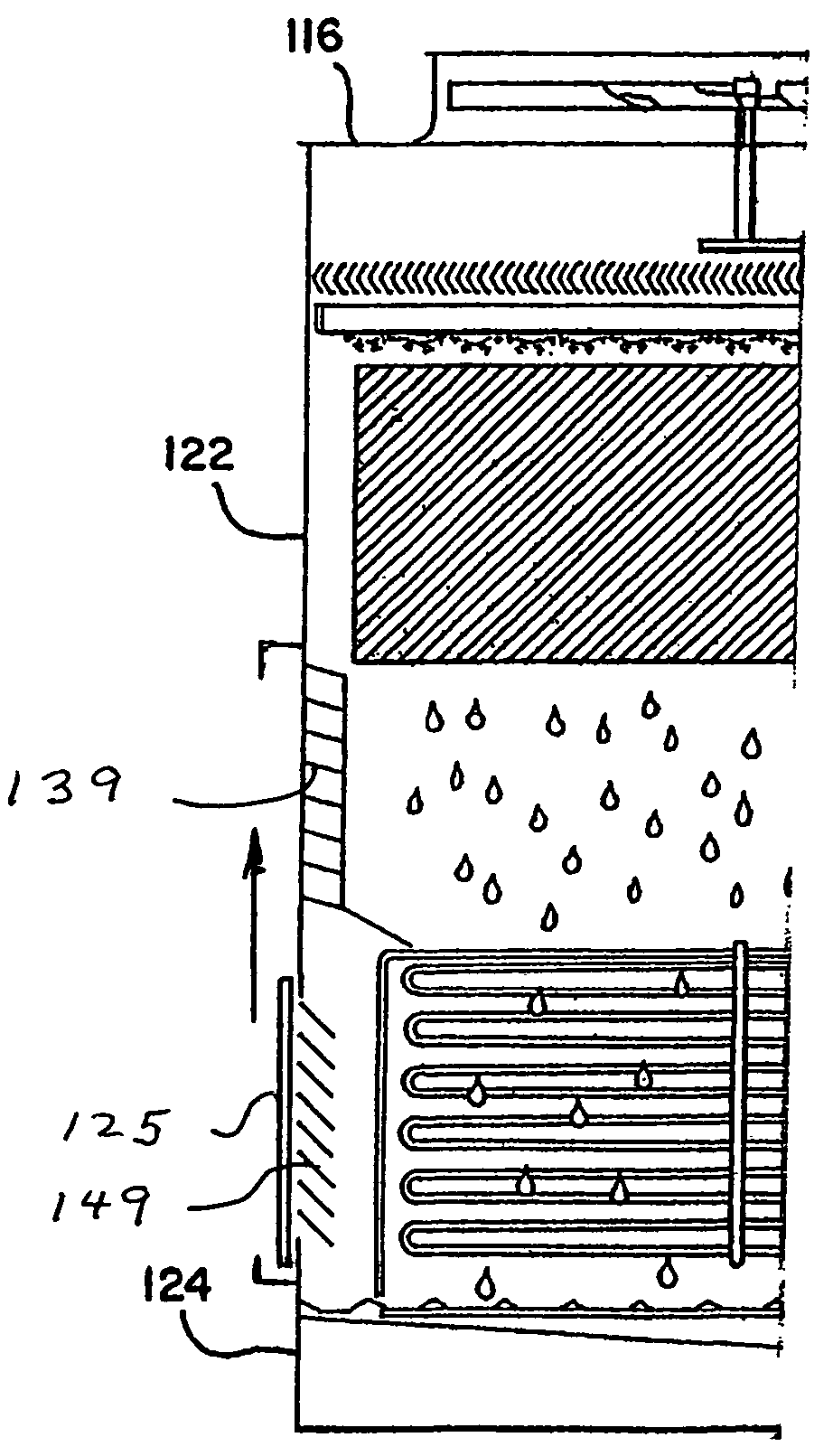

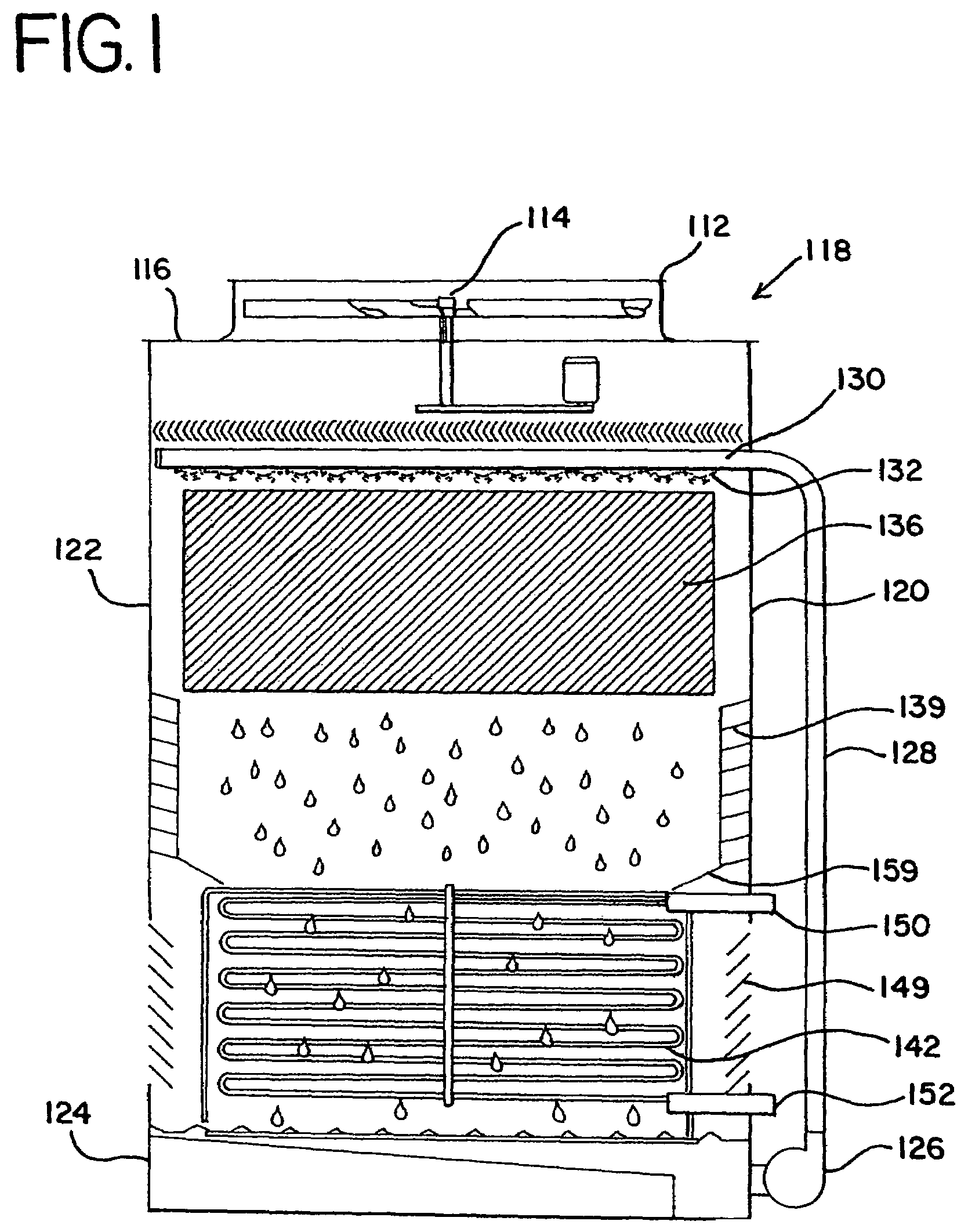

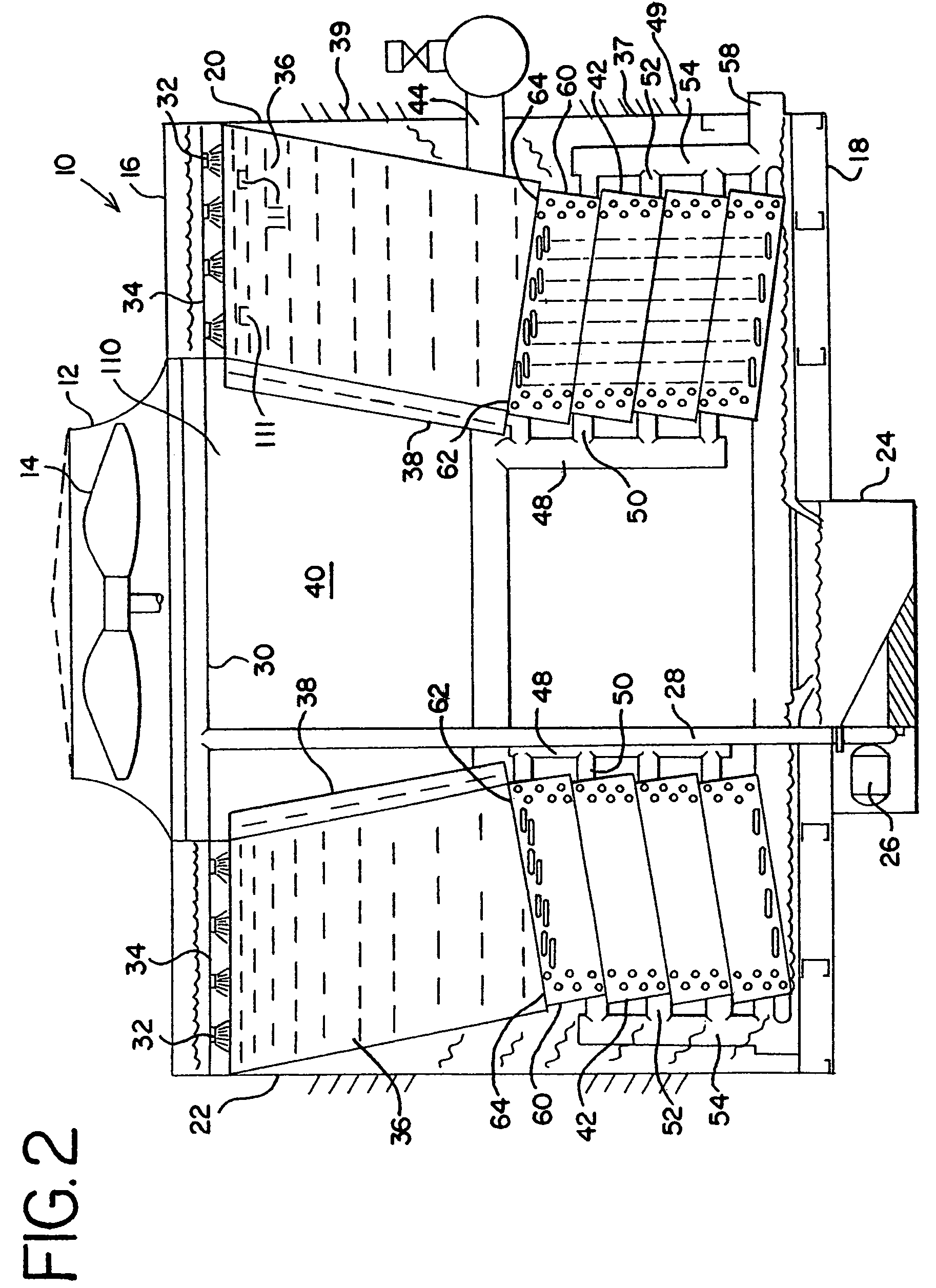

Cooling tower with direct and indirect cooling sections

ActiveUS20070187851A1Direct coolingLiquid degasificationMixing methodsCooling towerMechanical engineering

A mechanical draft cooling tower includes an air inlet and an air outlet. A liquid spray assembly is provided below the air outlet. A fill shell assembly is provided below the liquid spray assembly such that liquid can be sprayed onto the fill sheet assembly. An indirect heat exchange assembly is mounted beneath the fill sheet assembly. The indirect assembly usually comprises a series of coils through which a fluid to be cooled is circulated. A first air inlet is provided beneath the fill sheet assembly and includes a closing assembly. A second air inlet is provided beneath a top surface of the indirect assembly and includes a closing assembly.

Owner:BALTIMORE AIRCOIL CO INC

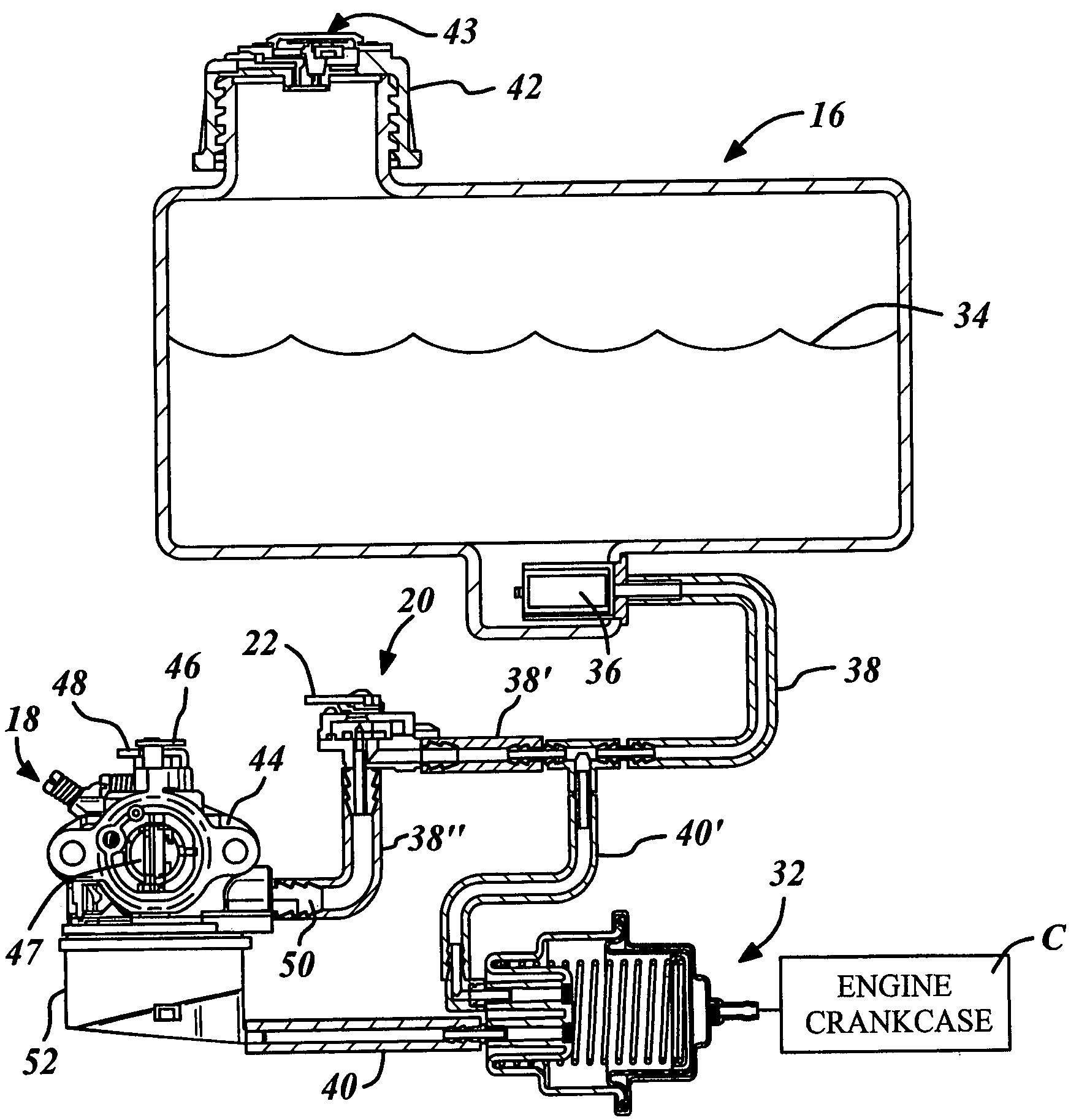

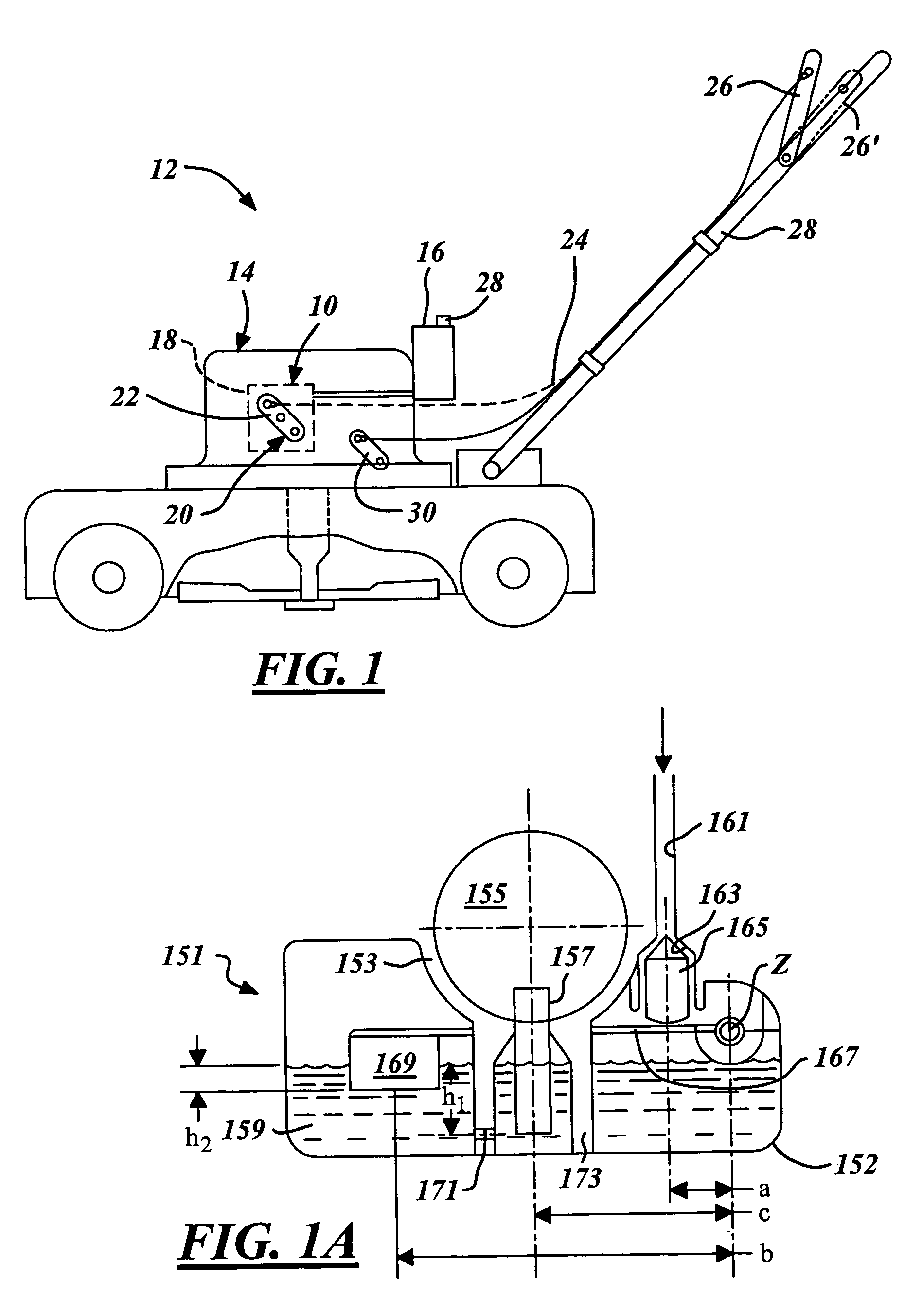

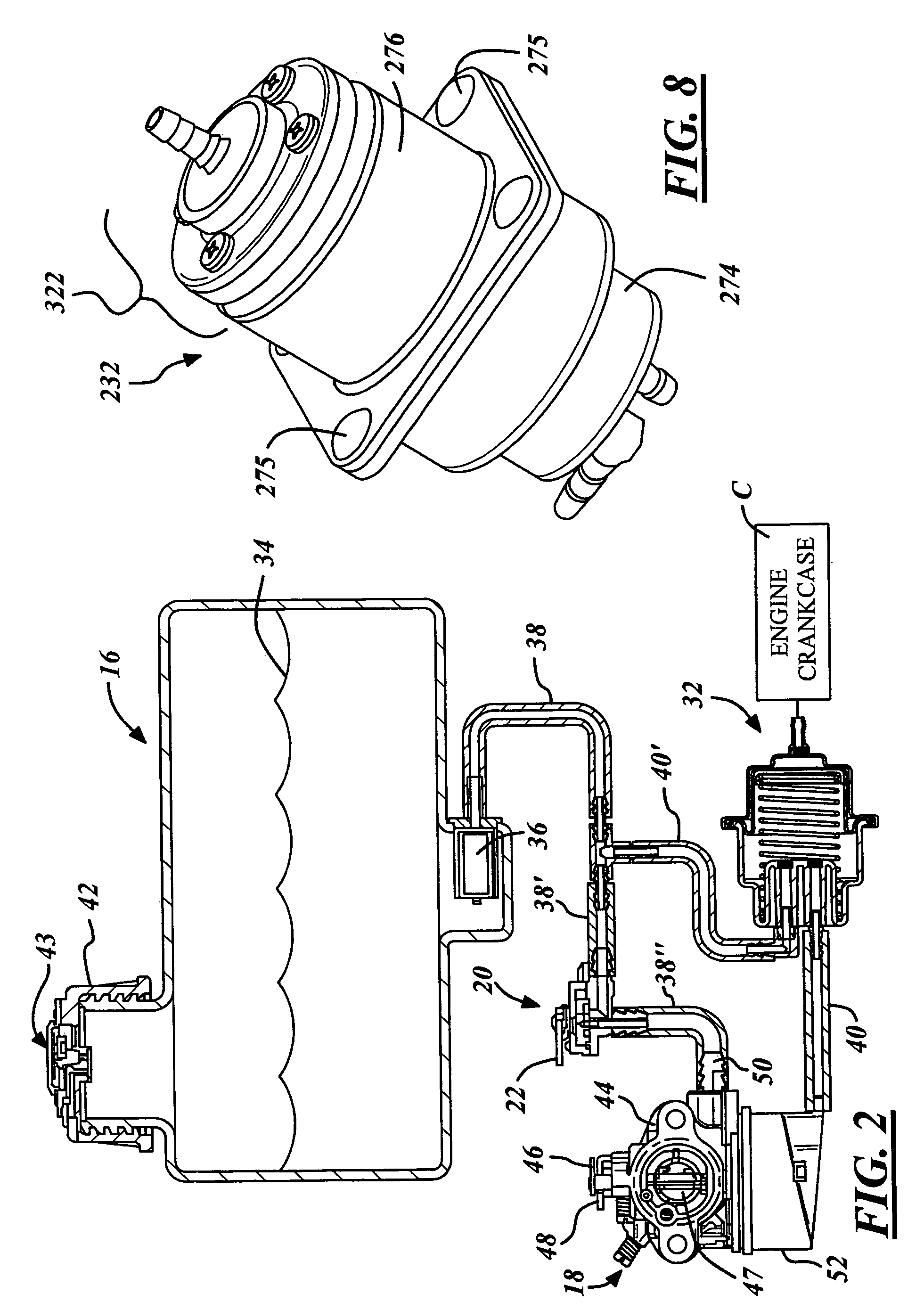

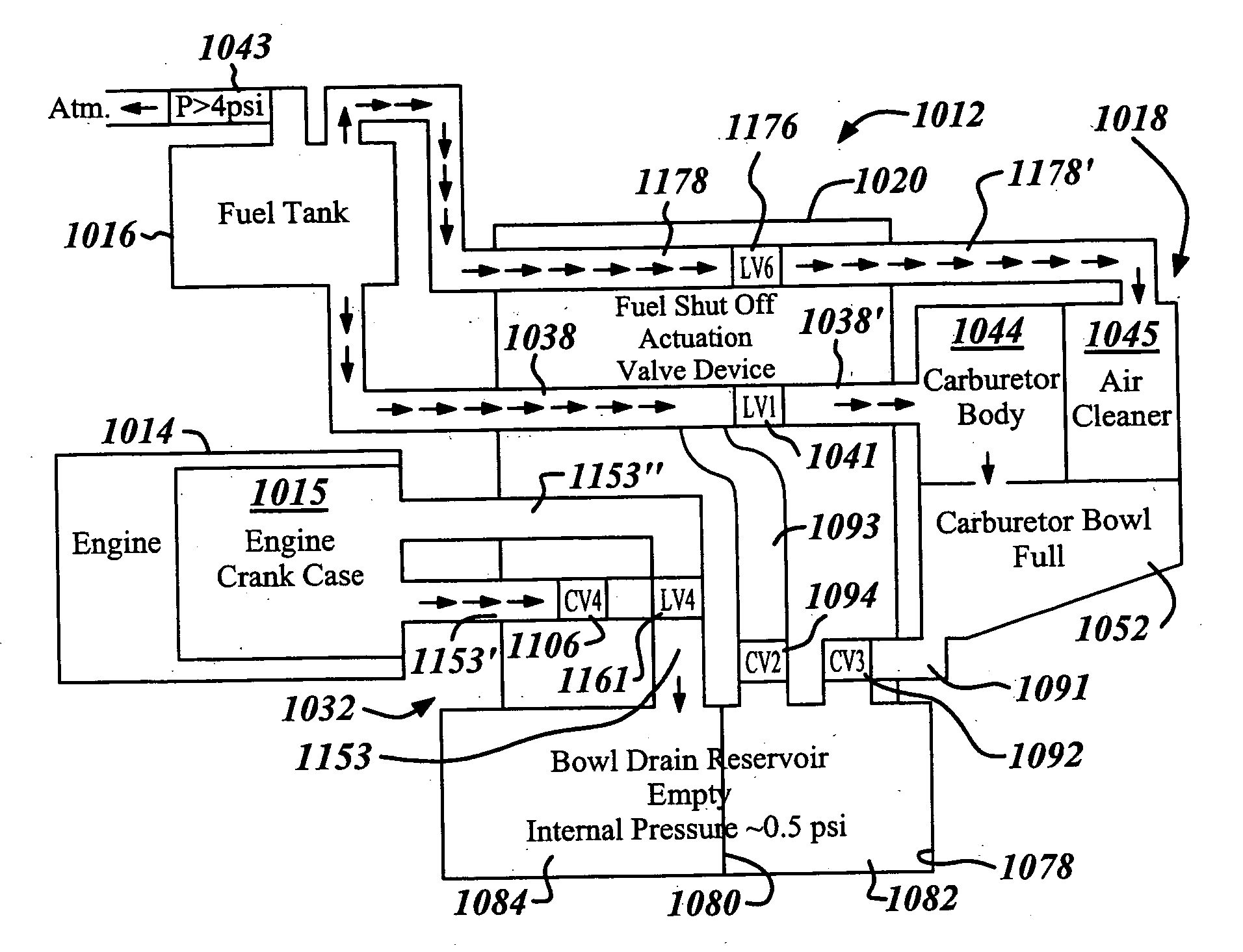

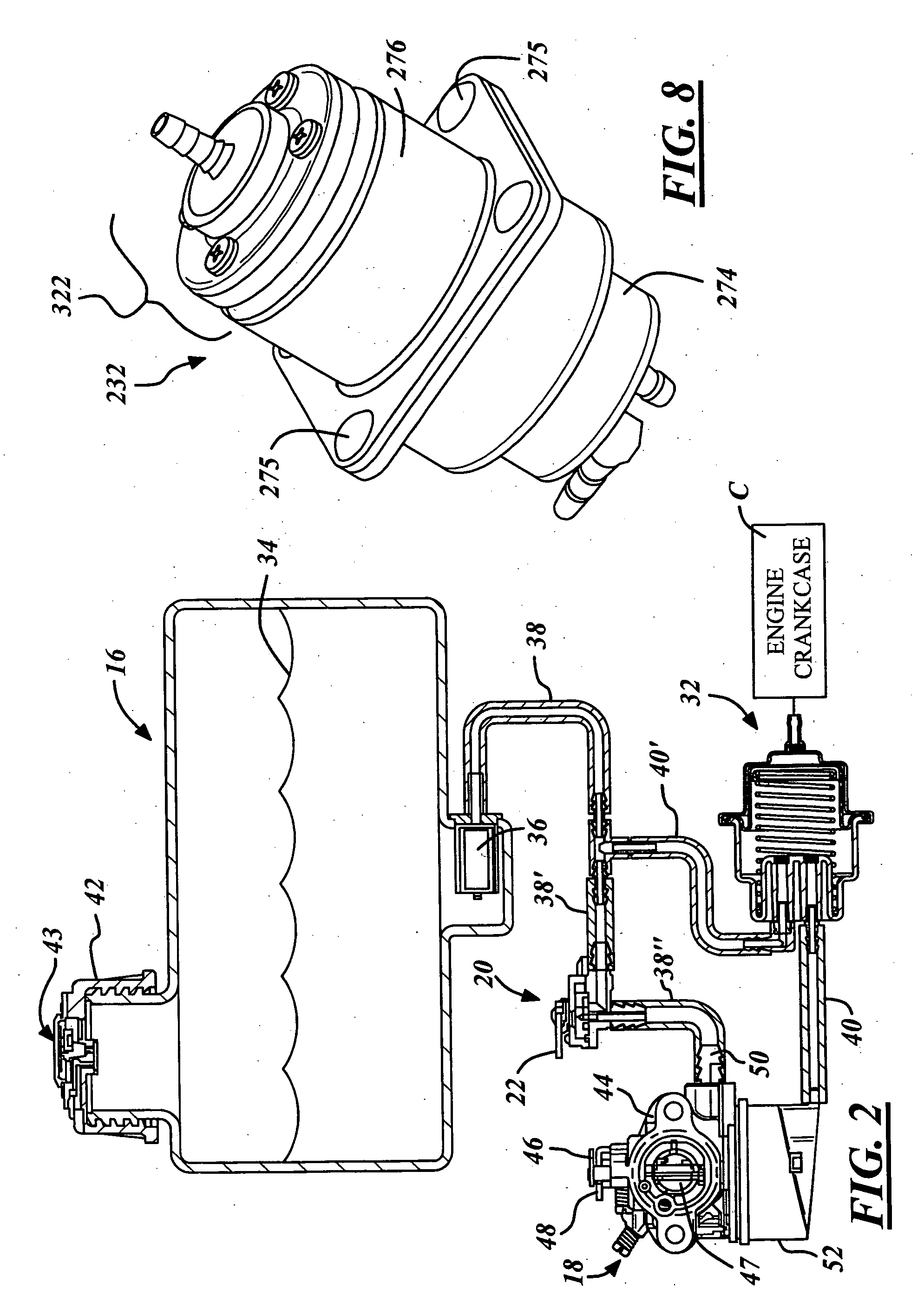

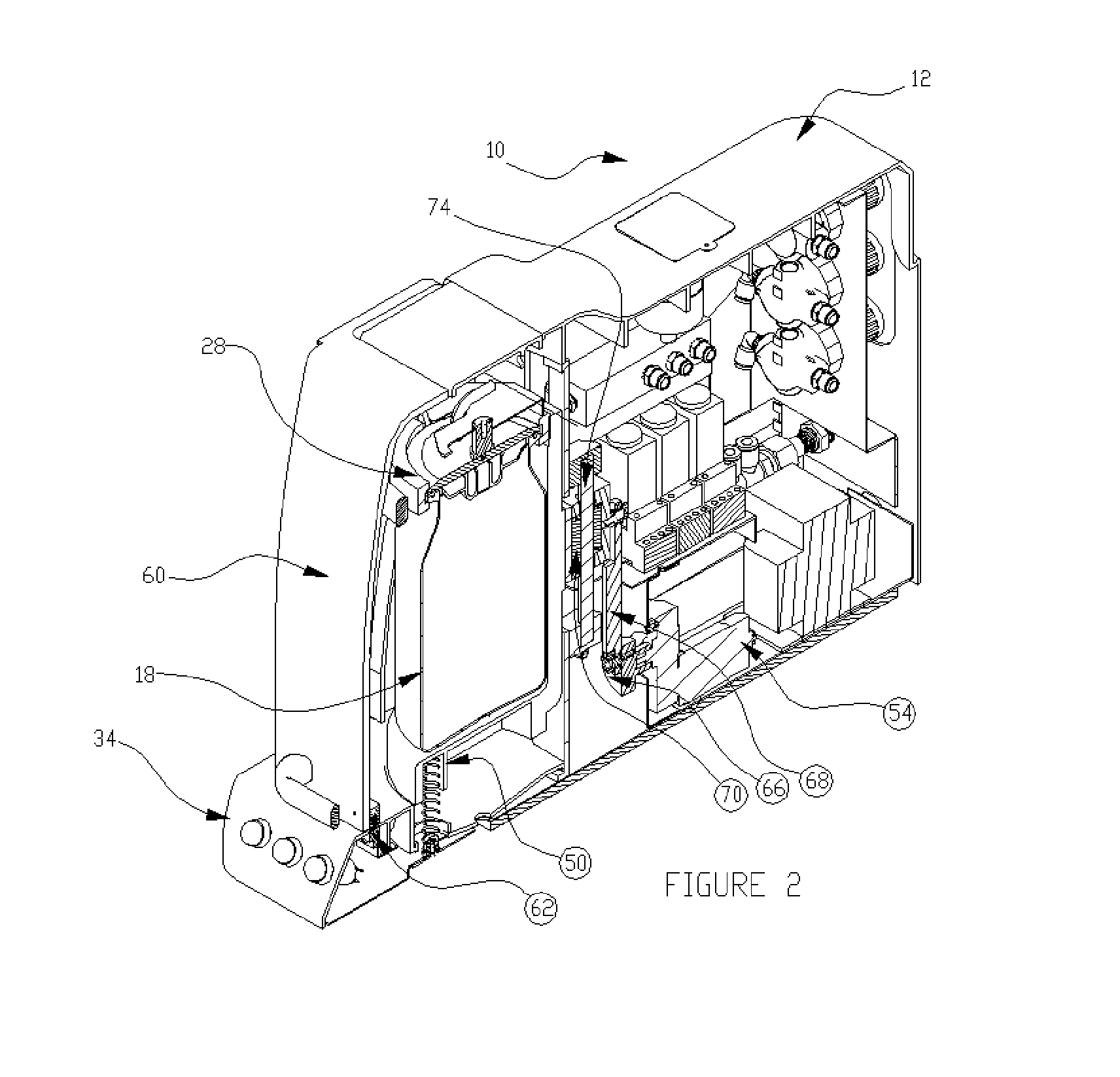

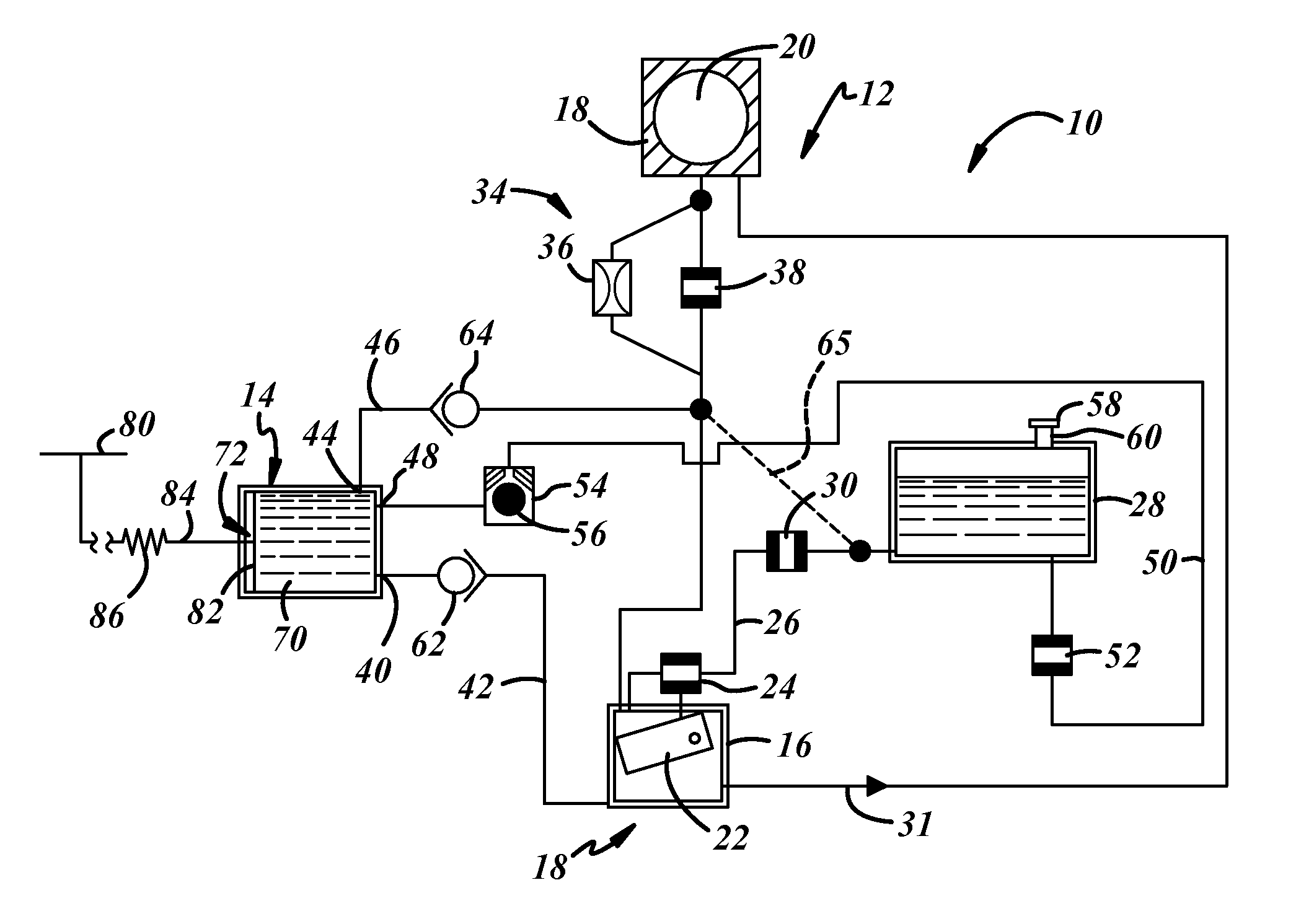

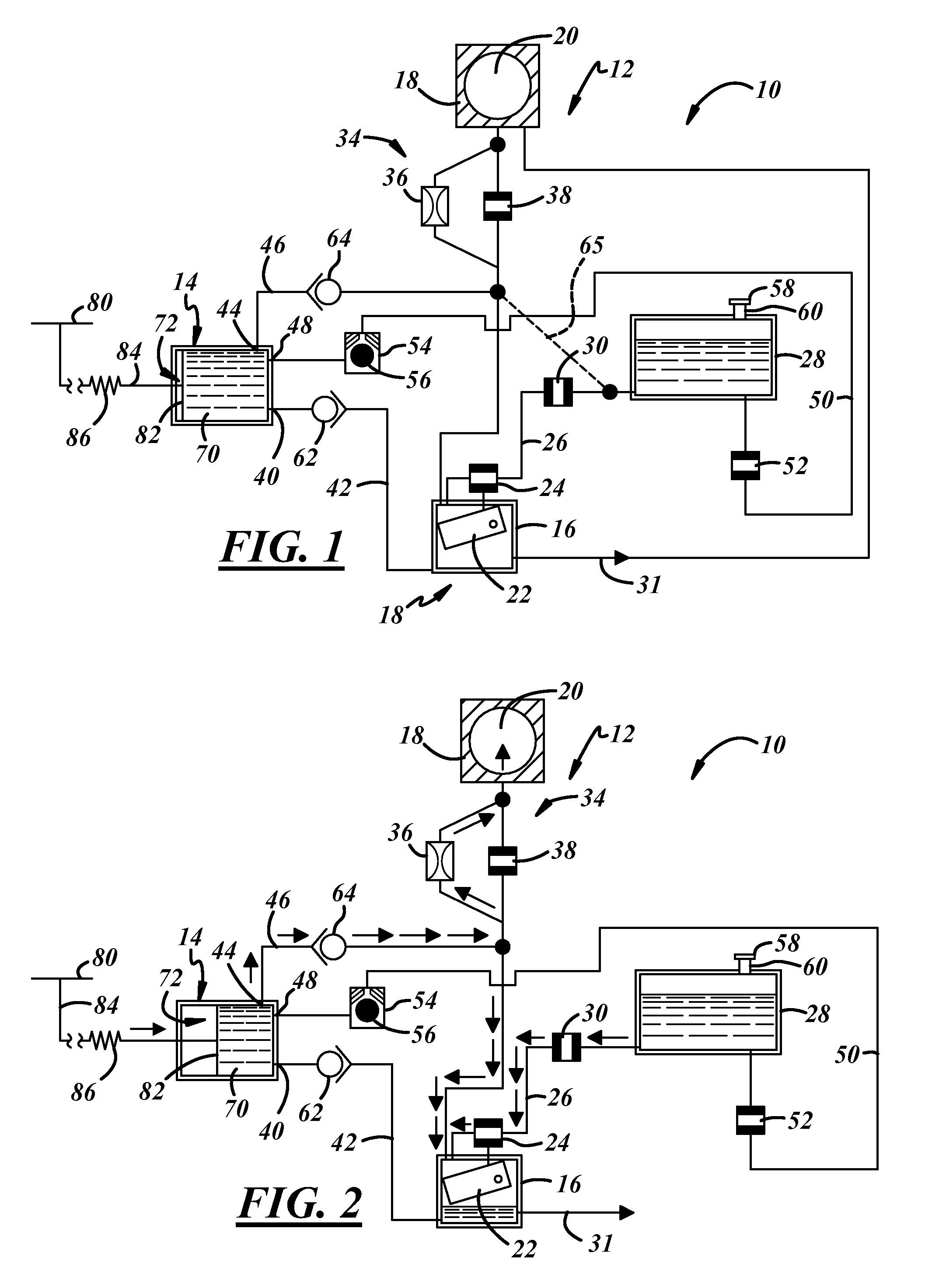

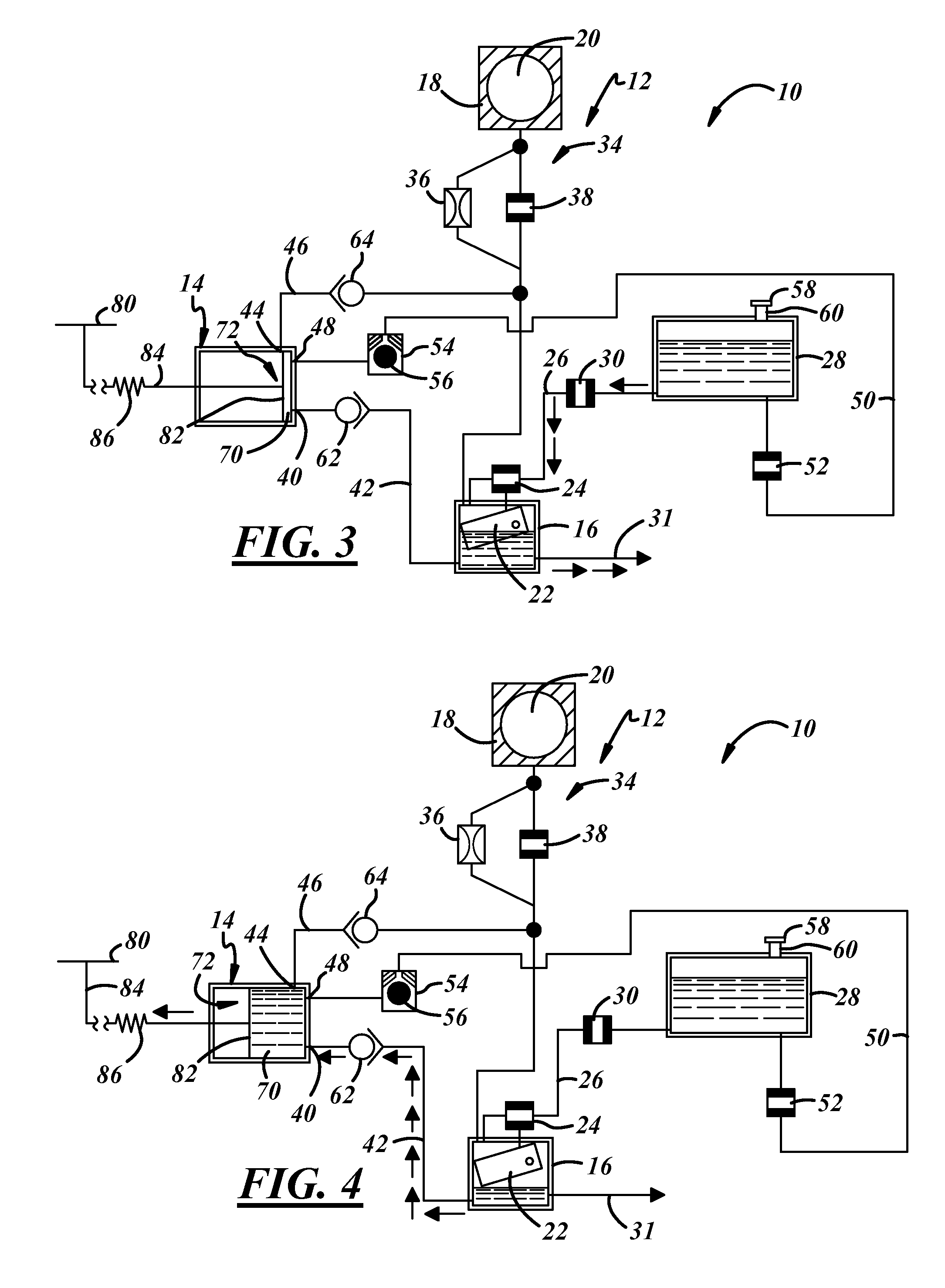

Controlling evaporative emissions in a fuel system

InactiveUS7263981B2Reduce and prevent emissionEmission controlNon-fuel substance addition to fuelFloat-controlled apparatusFuel tankCarburetor

Methods and fuel systems to reduce evaporative emissions of a volatile fuel. A fuel tank contains fuel, a carburetor mixes air with the fuel from the fuel tank, and a plurality of fluid paths route fuel amongst and / or between the fuel tank and the carburetor. A valve actuation device stops flow of fuel in one or more of the plurality of fluid paths and the carburetor is adapted to be drained of fuel during engine shutdown to reduce or prevent evaporative emissions from the fuel system. The carburetor is preferably designed so as to minimize a volume of fuel contained therein.

Owner:WALBRO ENGINE MANAGEMENT

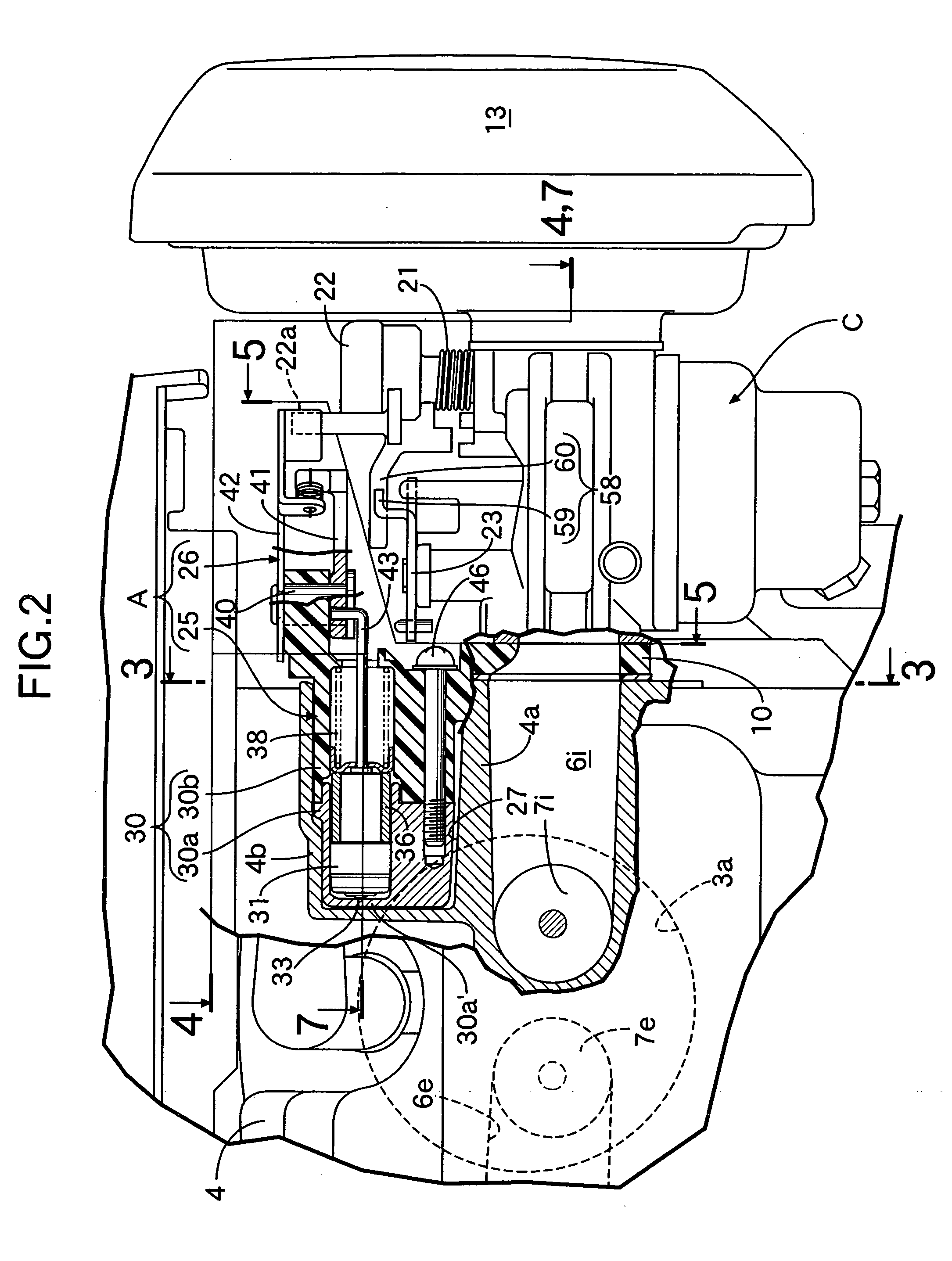

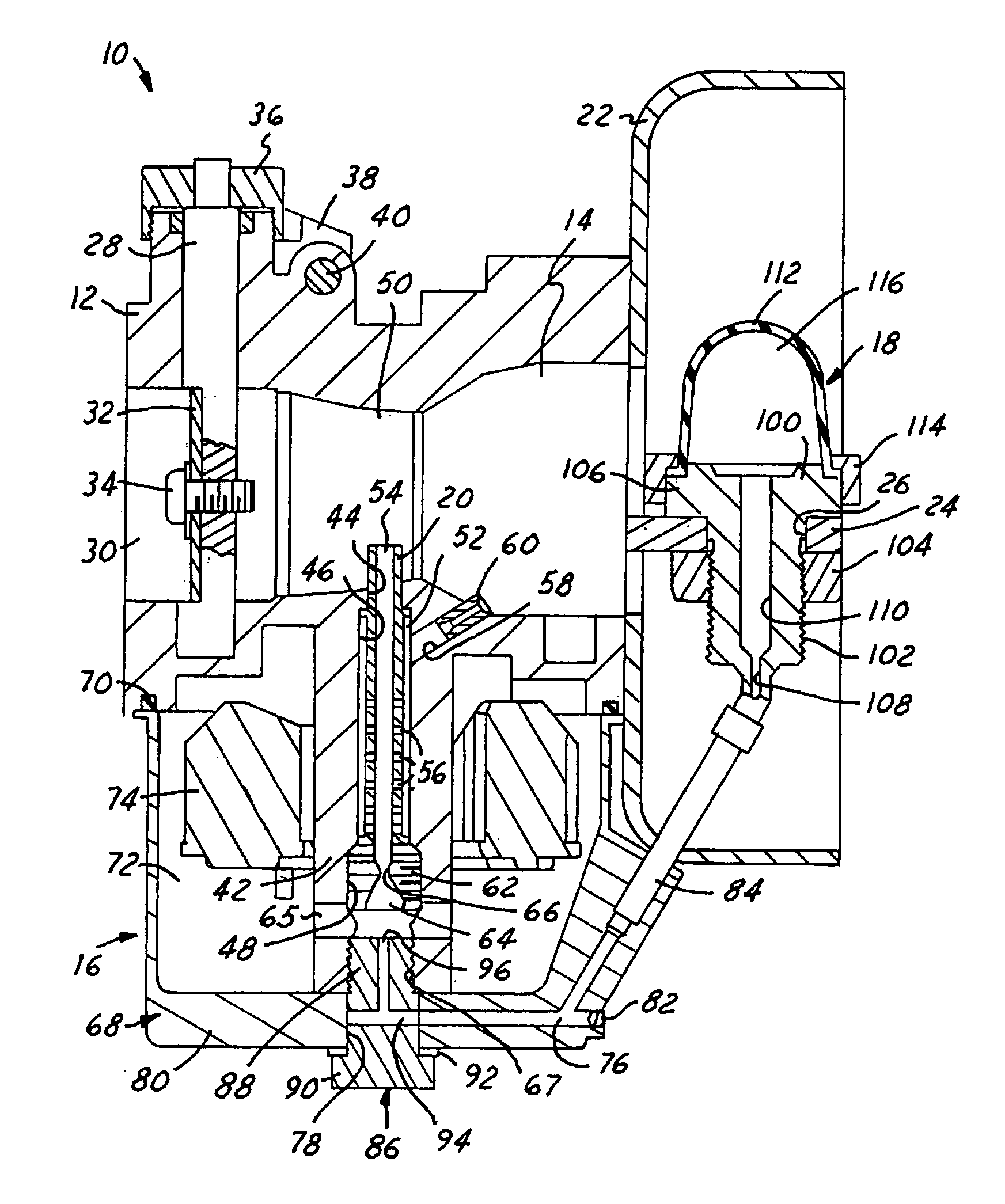

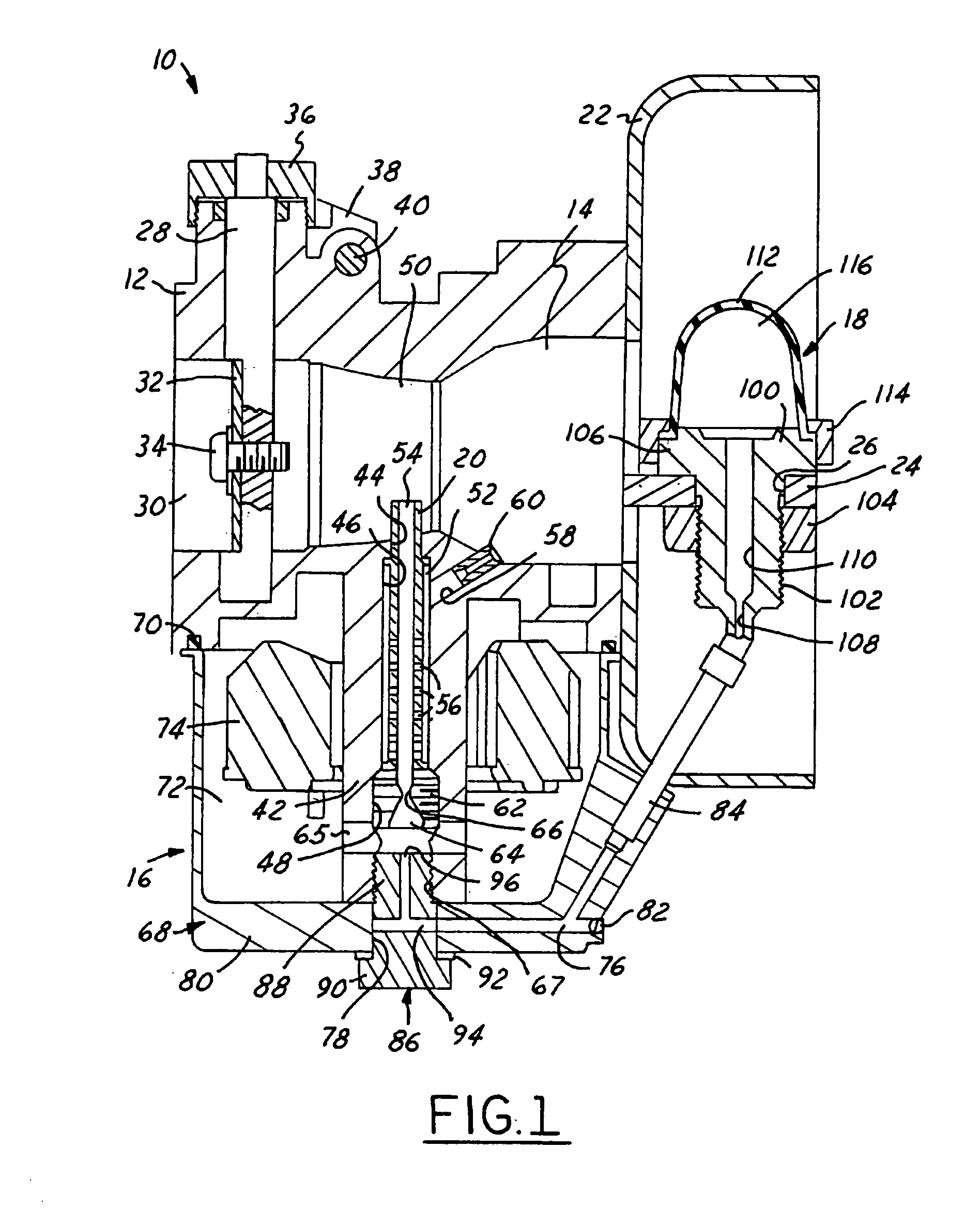

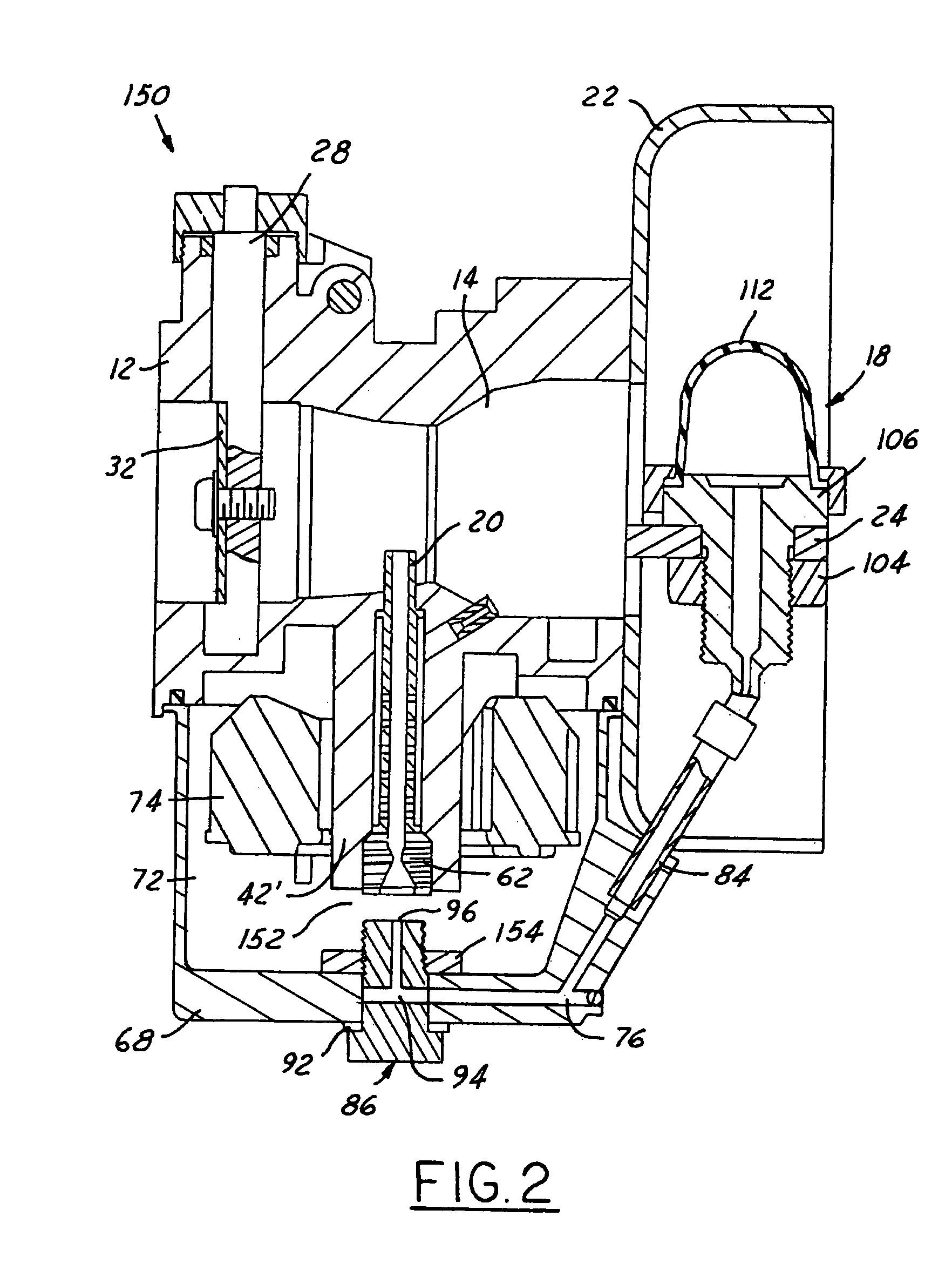

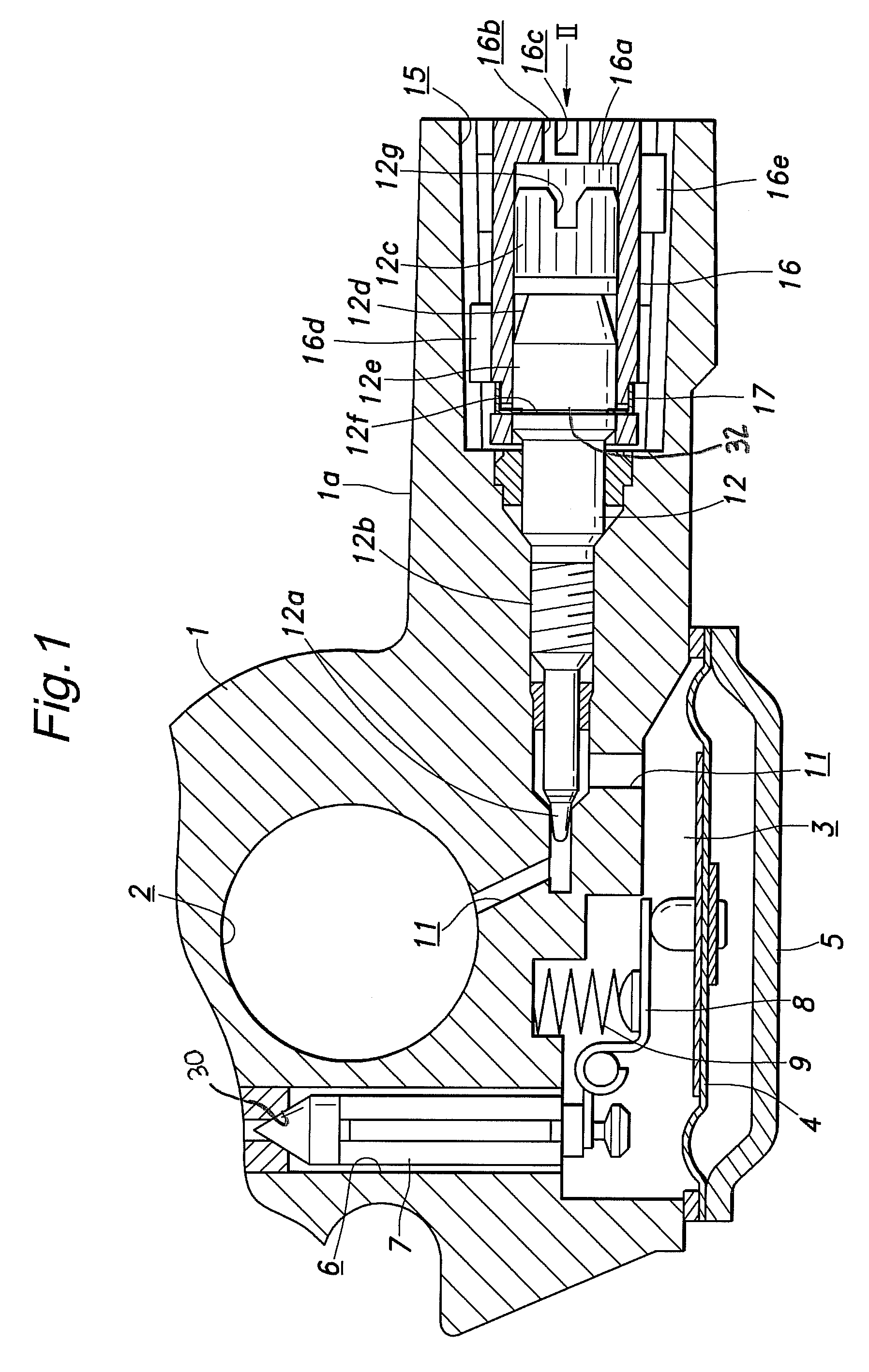

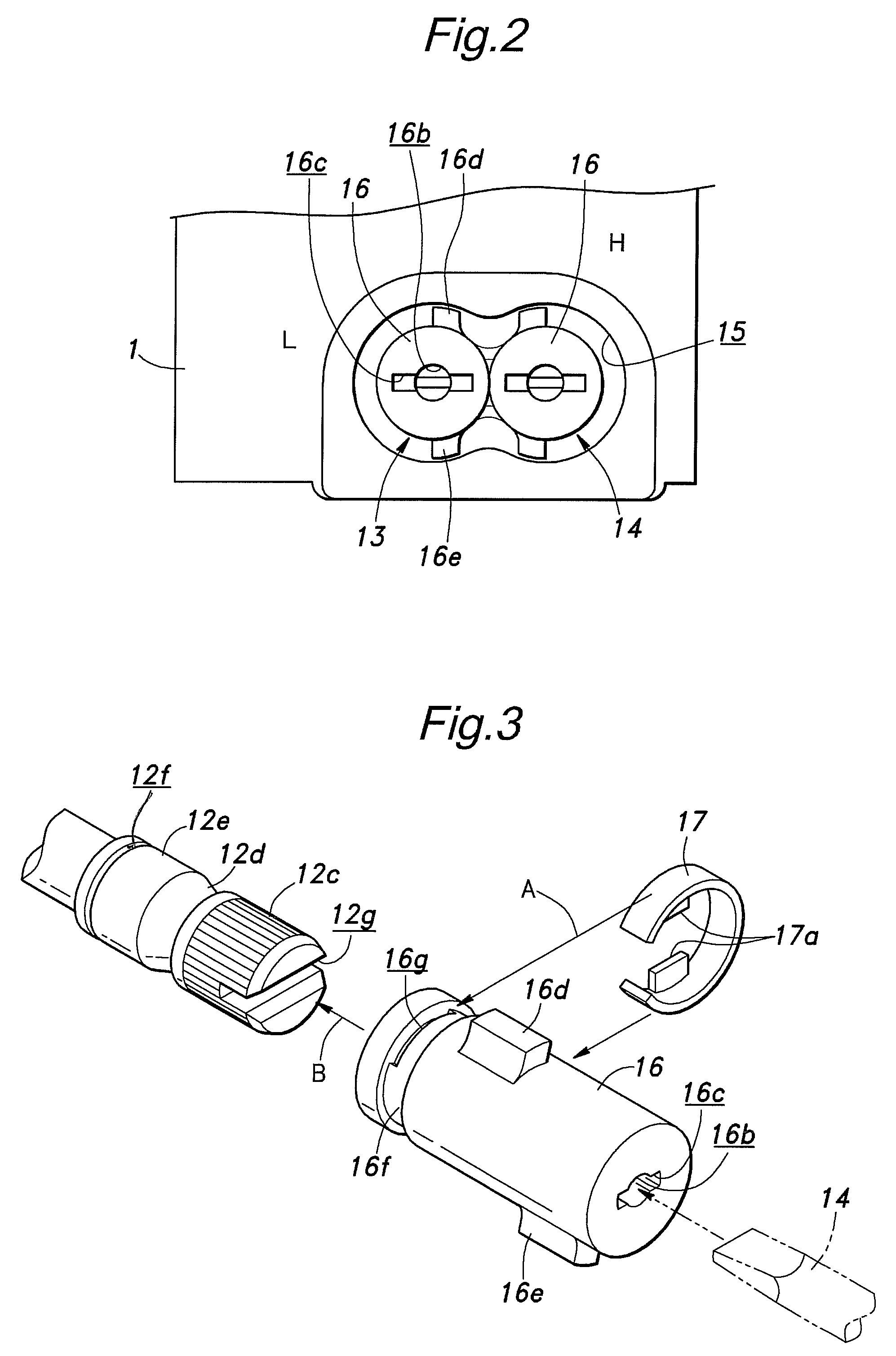

Carburetor

ActiveUS7261281B2Easy to useSmall sizeLighting and heating apparatusUsing liquid separation agentCarburetorThrottle

Owner:ANDREAS STIHL AG & CO KG

Refrigerator haiving apparatus to produce carbonated water

ActiveUS20130309361A1Preventing intermixing therebetweenShorten the pathLighting and heating apparatusUsing liquid separation agentWater dischargeGas cylinder

A refrigerator having a carbonated water production module integrally provided with a carbon dioxide gas cylinder having carbon dioxide gas stored therein and a carbonated water tank to mix purified water with the carbon dioxide gas to produce carbonated water. The carbonated water production module is mounted to the rear surface of the door, and thus it may be cooled by cool air in the refrigeration compartment and be easy to access, and thereby repair and replacement thereof is facilitated. The dispenser includes a carbonated water discharge channel into which carbonated water from the carbonated water tank is discharged, and a purified water discharge channel into which purified water from the water tank is discharged. Since the purified water discharge channel does not pass through the carbonated water tank, a user is allowed to selectively dispense purified water or carbonated water anytime.

Owner:SAMSUNG ELECTRONICS CO LTD

Intake device

ActiveUS7011298B2Improve sealingEasy to assembleLighting and heating apparatusUsing liquid separation agentEngineeringButterfly valve

An intake device having an intake channel that includes an intake channel section is provided. A butterfly valve is pivotably mounted in the intake channel section. A dividing wall is disposed downstream of the butterfly valve and divides the intake channel section into an air duct and a mixture duct. The air duct has a flow cross-section that is greater than the flow cross-section of the mixture duct. A fuel jet opens into the mixture duct.

Owner:ANDREAS STIHL AG & CO KG

Cooling tower with direct and indirect cooling sections

A mechanical draft cooling tower includes an air inlet and an air outlet. A liquid spray assembly is provided below the air outlet. A fill shell assembly is provided below the liquid spray assembly such that liquid can be sprayed onto the fill sheet assembly. An indirect heat exchange assembly is mounted beneath the fill sheet assembly. The indirect assembly usually comprises a series of coils through which a fluid to be cooled is circulated. A first air inlet is provided beneath the fill sheet assembly and includes a closing assembly. A second air inlet is provided beneath a top surface of the indirect assembly and includes a closing assembly.

Owner:BALTIMORE AIRCOIL CO INC

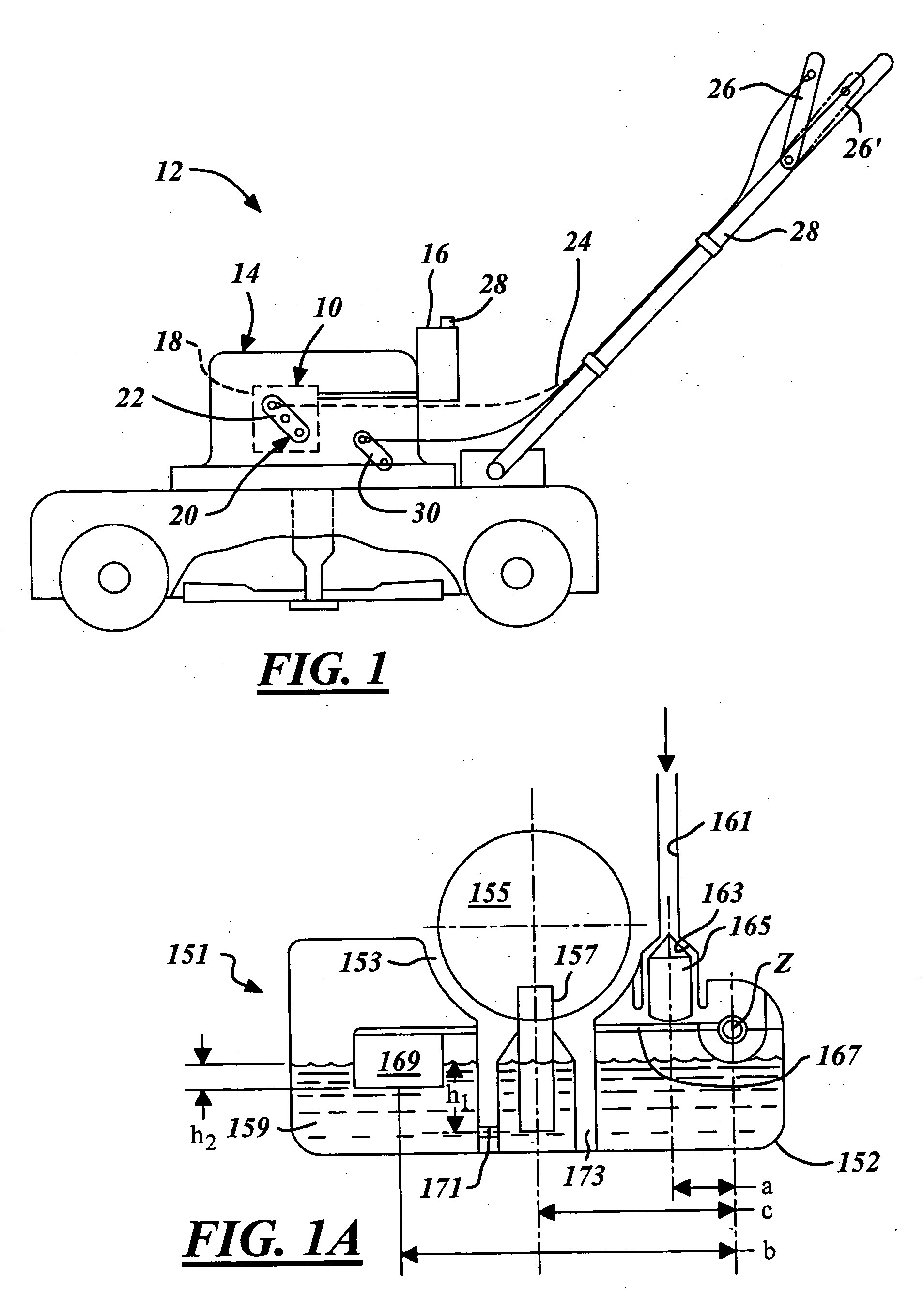

Controlling evaporative emissions in a fuel system

InactiveUS20060260587A1Reduce and prevent emissionEmission controlNon-fuel substance addition to fuelFloat-controlled apparatusFuel tankCarburetor

Methods and fuel systems to reduce evaporative emissions of a volatile fuel. A fuel tank contains fuel, a carburetor mixes air with the fuel from the fuel tank, and a plurality of fluid paths route fuel amongst and / or between the fuel tank and the carburetor. A valve actuation device stops flow of fuel in one or more of the plurality of fluid paths and the carburetor is adapted to be drained of fuel during engine shutdown to reduce or prevent evaporative emissions from the fuel system. The carburetor is preferably designed so as to minimize a volume of fuel contained therein.

Owner:WALBRO ENGINE MANAGEMENT

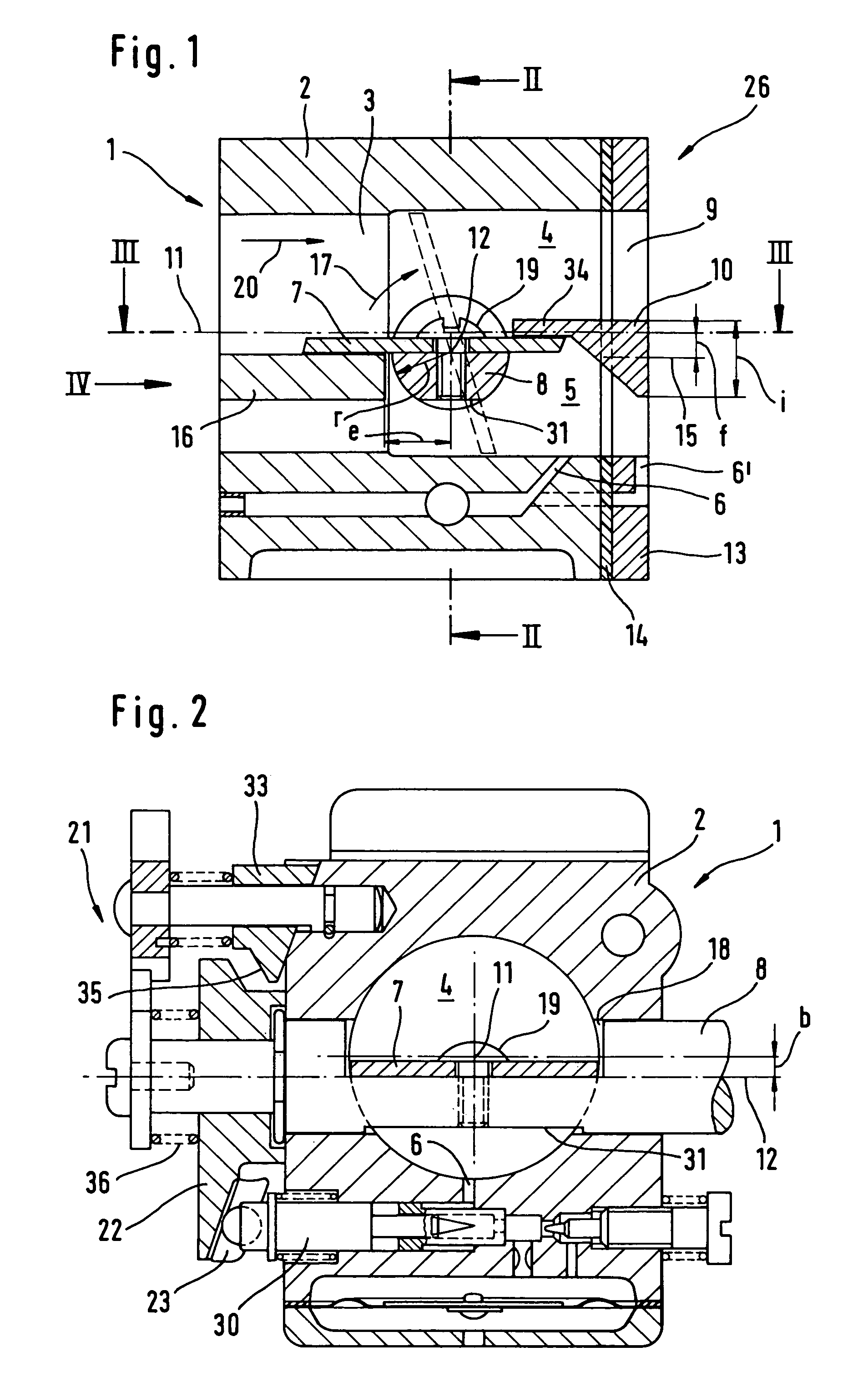

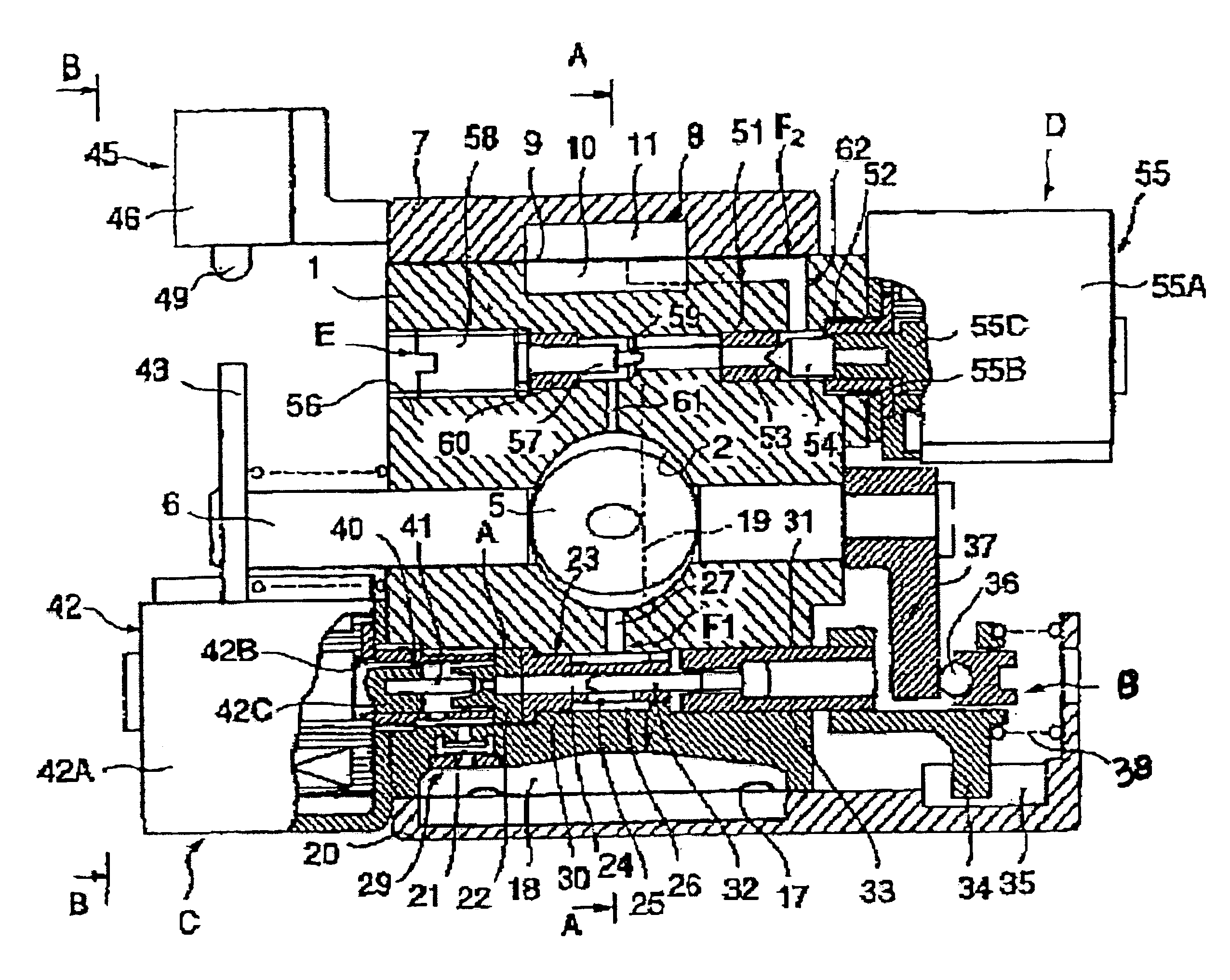

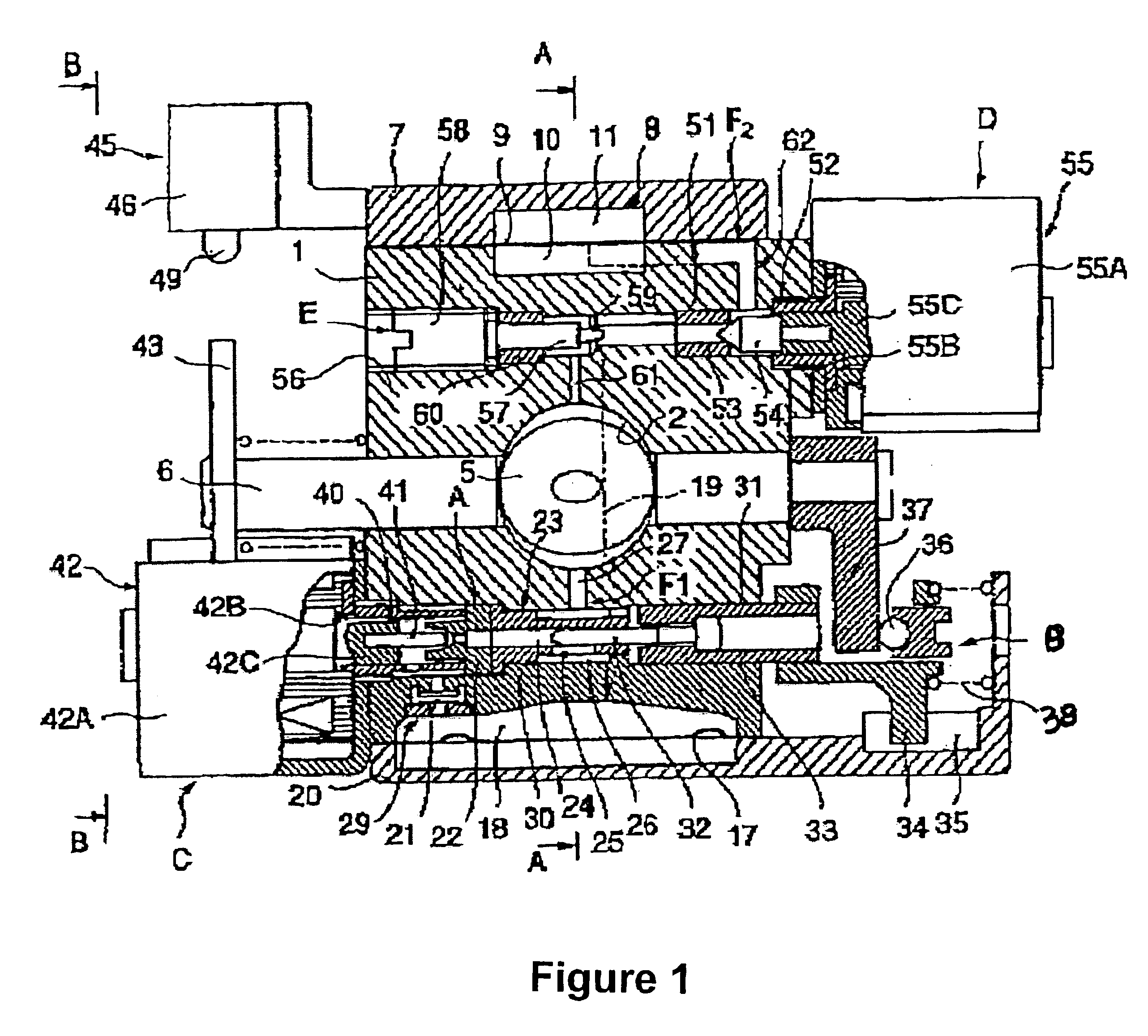

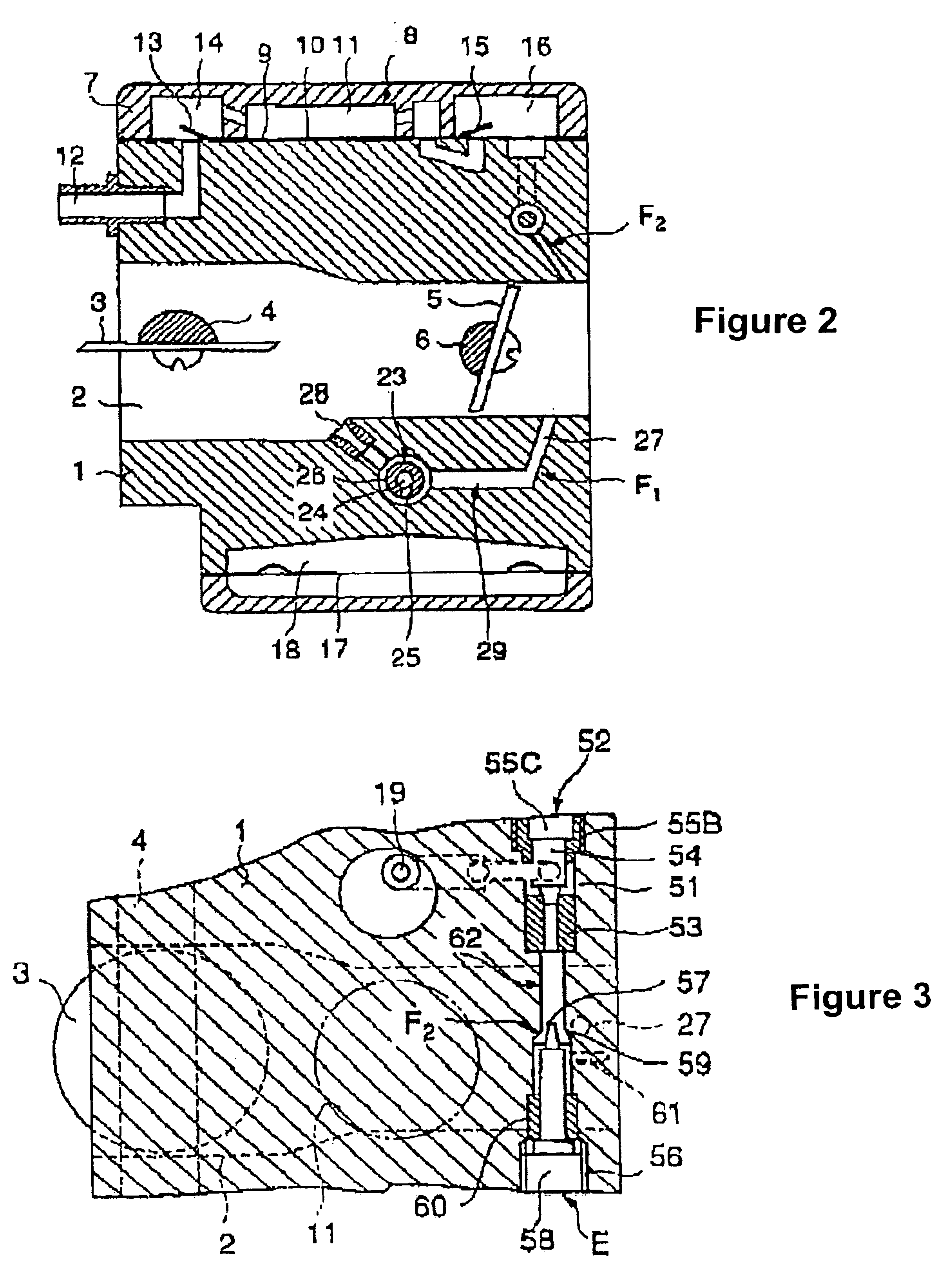

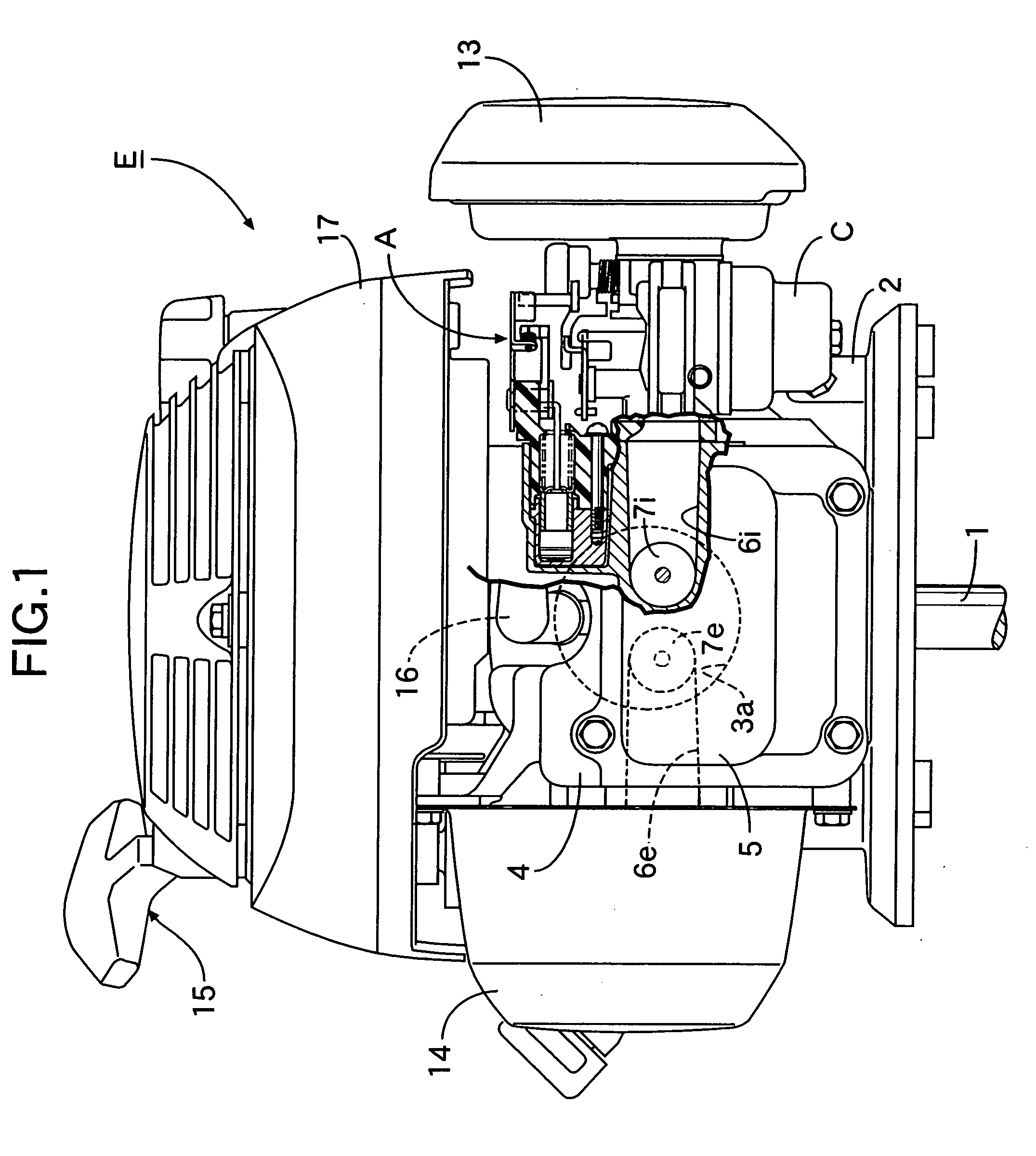

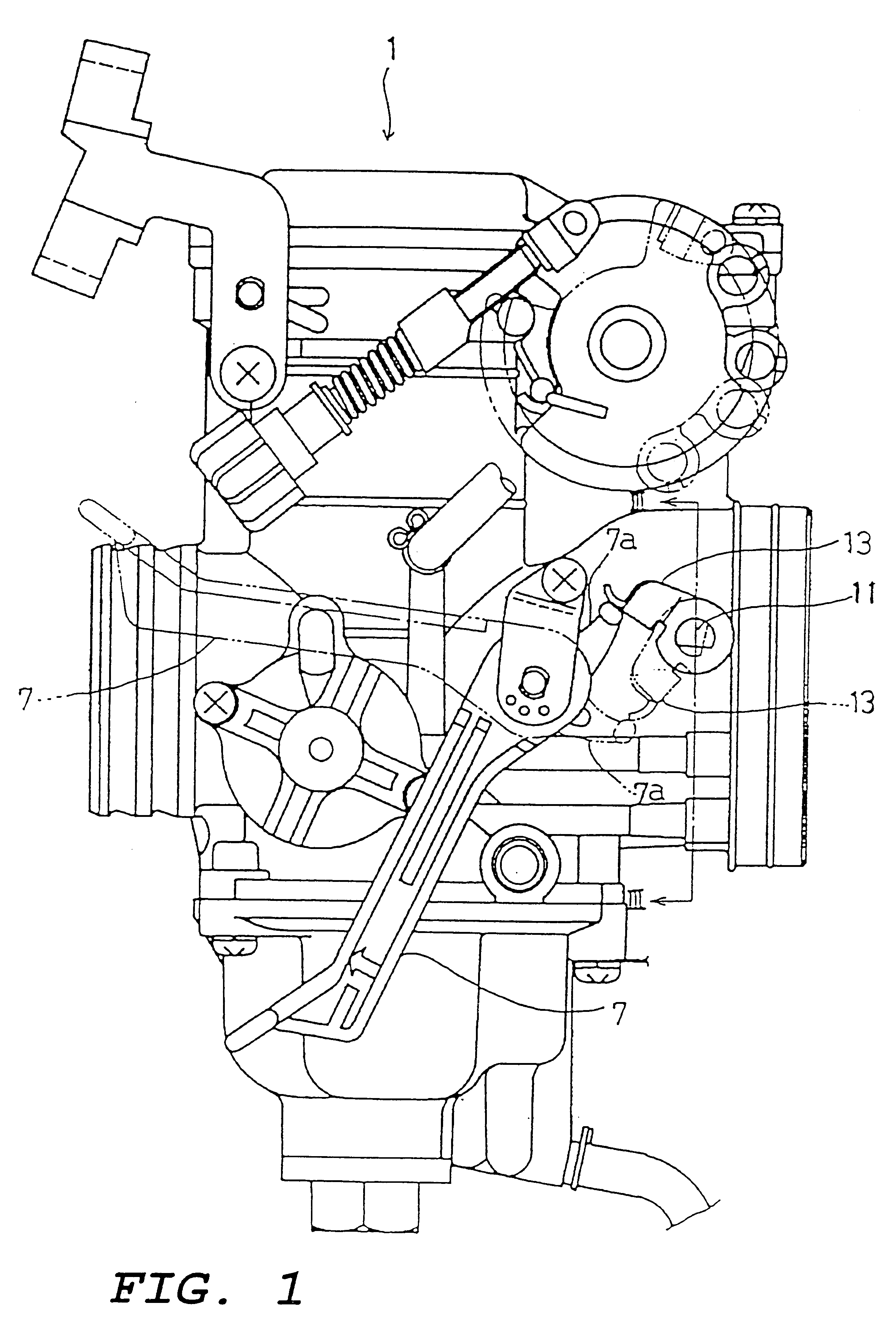

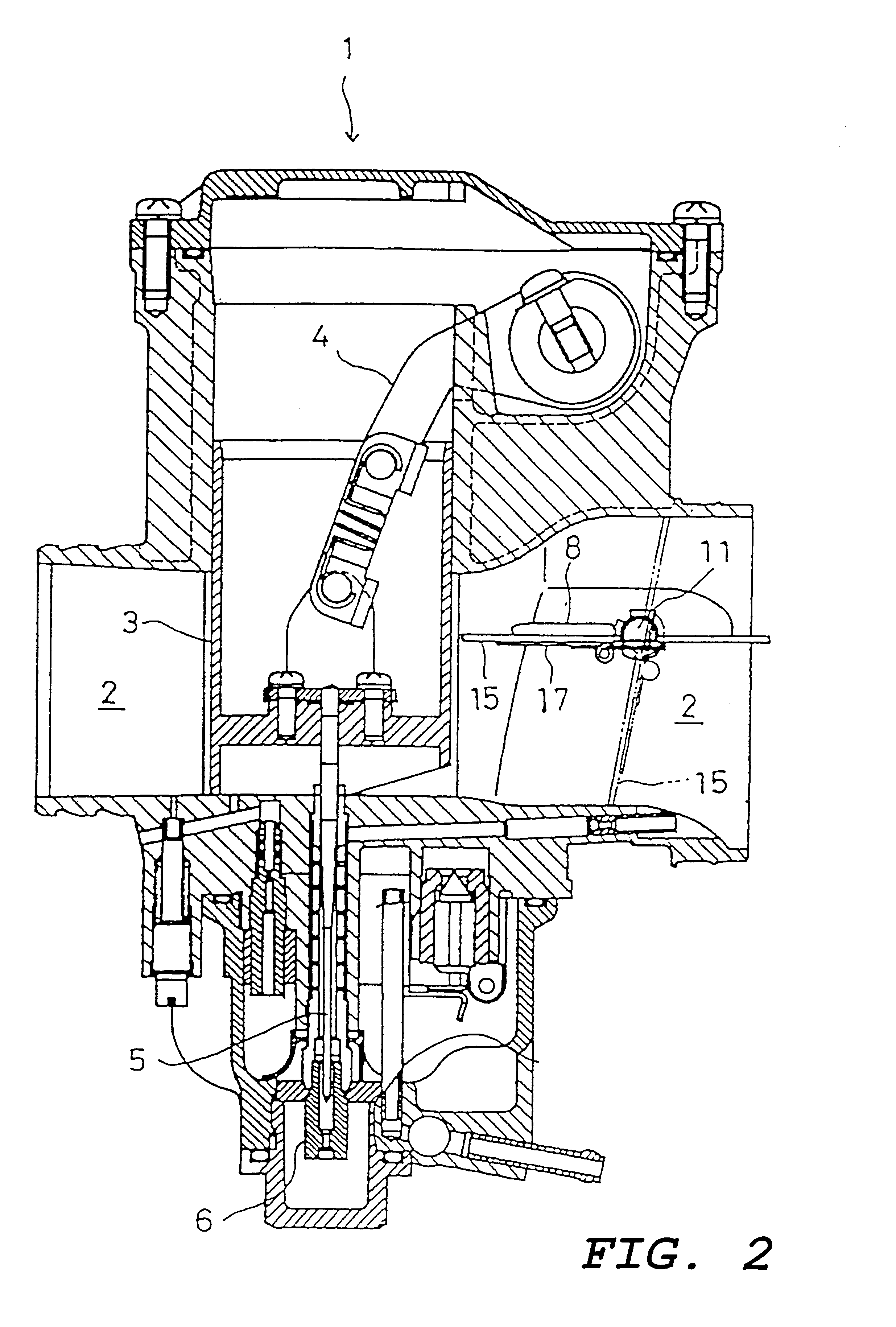

Carburetor

ActiveUS6880812B2Guaranteed uptimeLow range of rotationLighting and heating apparatusUsing liquid separation agentCarburetorEngineering

A carburetor is provided that supplies an appropriate amount of fuel at engine start-up and in a specific range of rotational speed, and allows stable engine operation at a target rotational speed. The carburetor comprises a first fuel system (F1) for metering fuel from the constant fuel chamber (18) with a metering needle (32) linked to a throttle valve (5), and delivering the fuel to an air intake passage (2); and a second fuel system (F2) for controlling fuel compressed by a fuel pump (8) with an electromagnetically driven control valve (52) and delivering the fuel to the air intake passage (2); by supplying pressured fuel controlled by the control valve (52) in a predetermined specific range of rotation and controlling the rotational speed during start-up and warm-up, a target rotational speed can be maintained.

Owner:ZAMA JAPAN

Stratified two-stroke engine and dual passage fuel system

InactiveUS20120247435A1Emission reductionSimple designInternal combustion piston enginesLighting and heating apparatusHydrogenFour-stroke engine

Owner:MAVINAHALLY NAH S

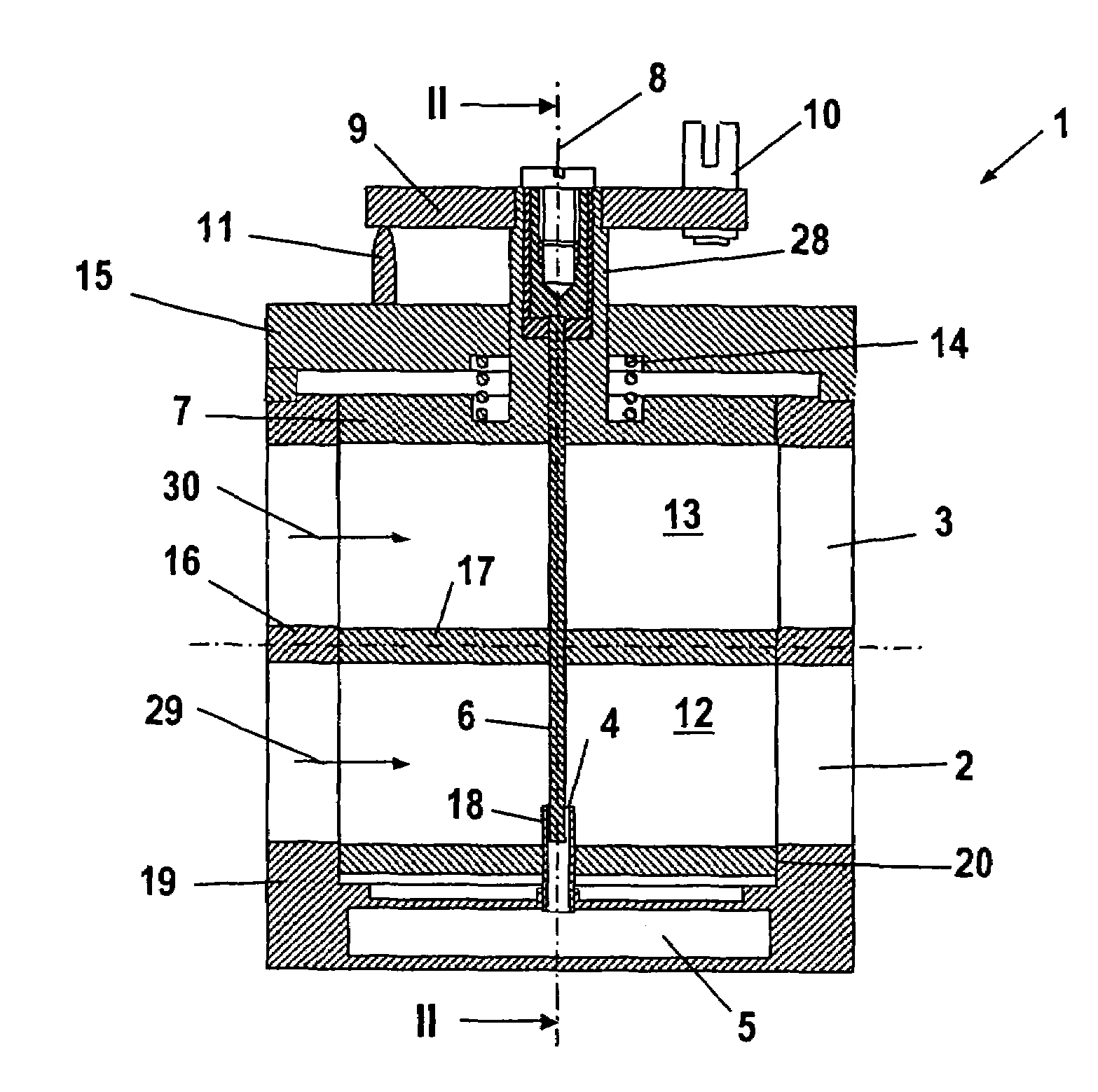

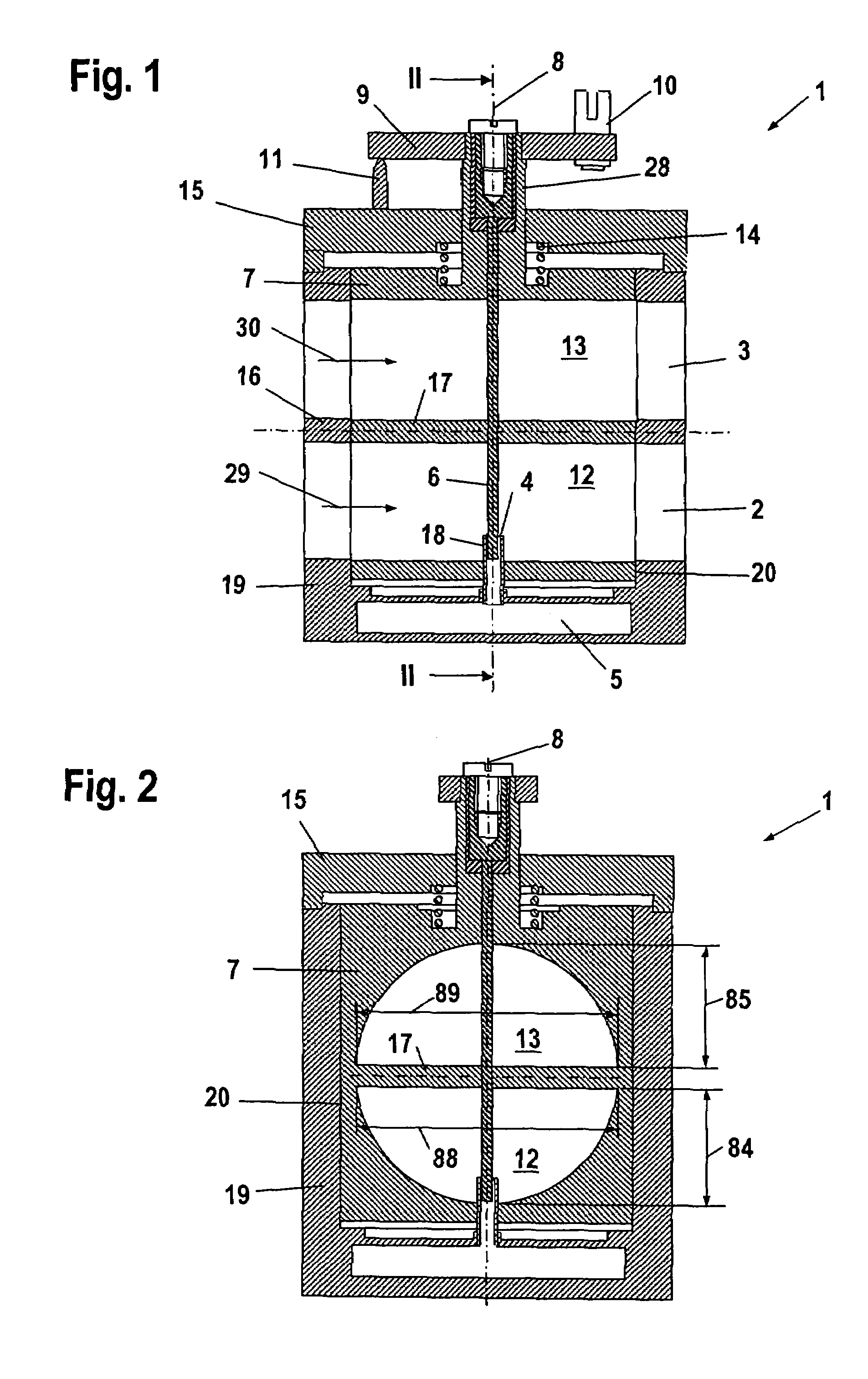

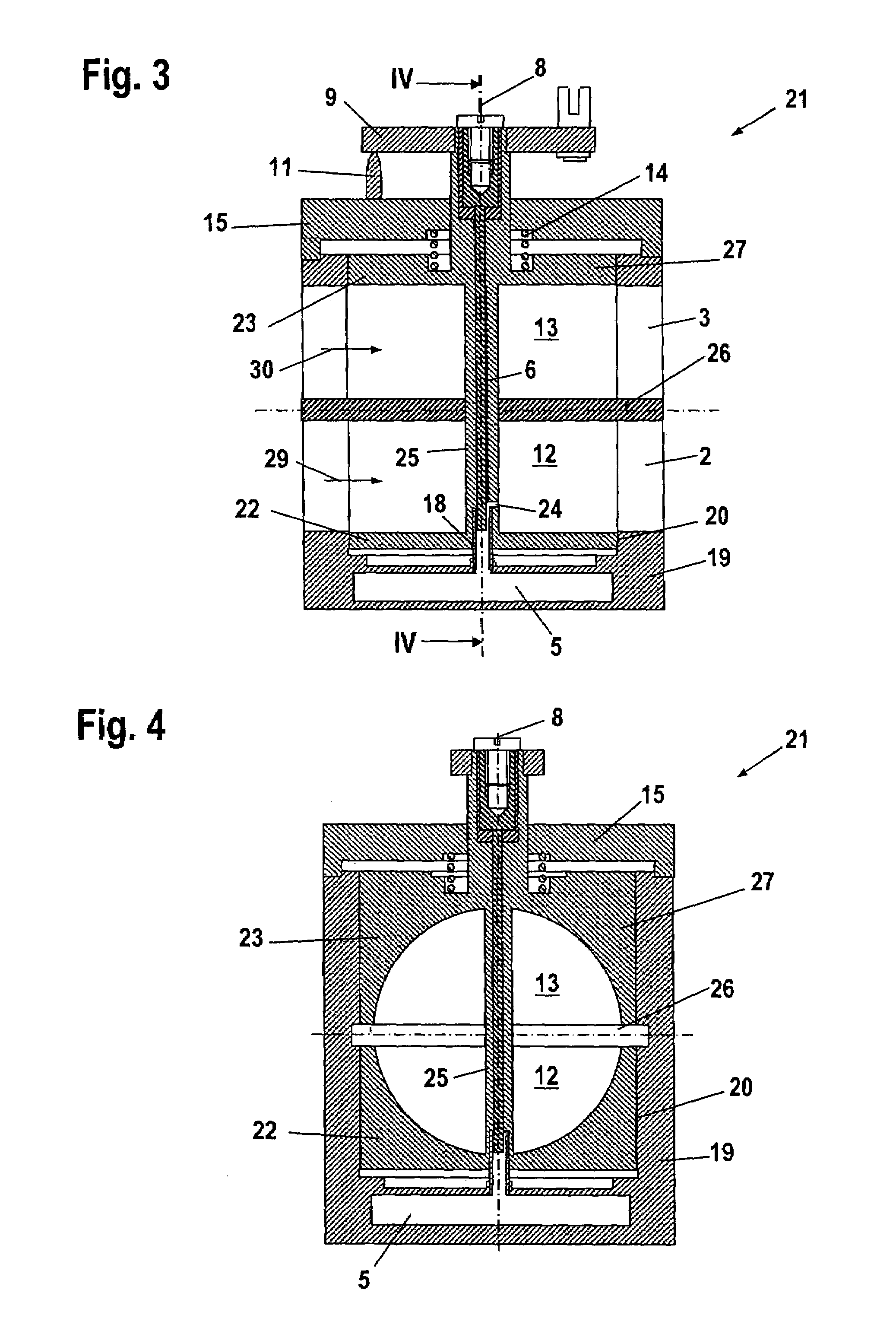

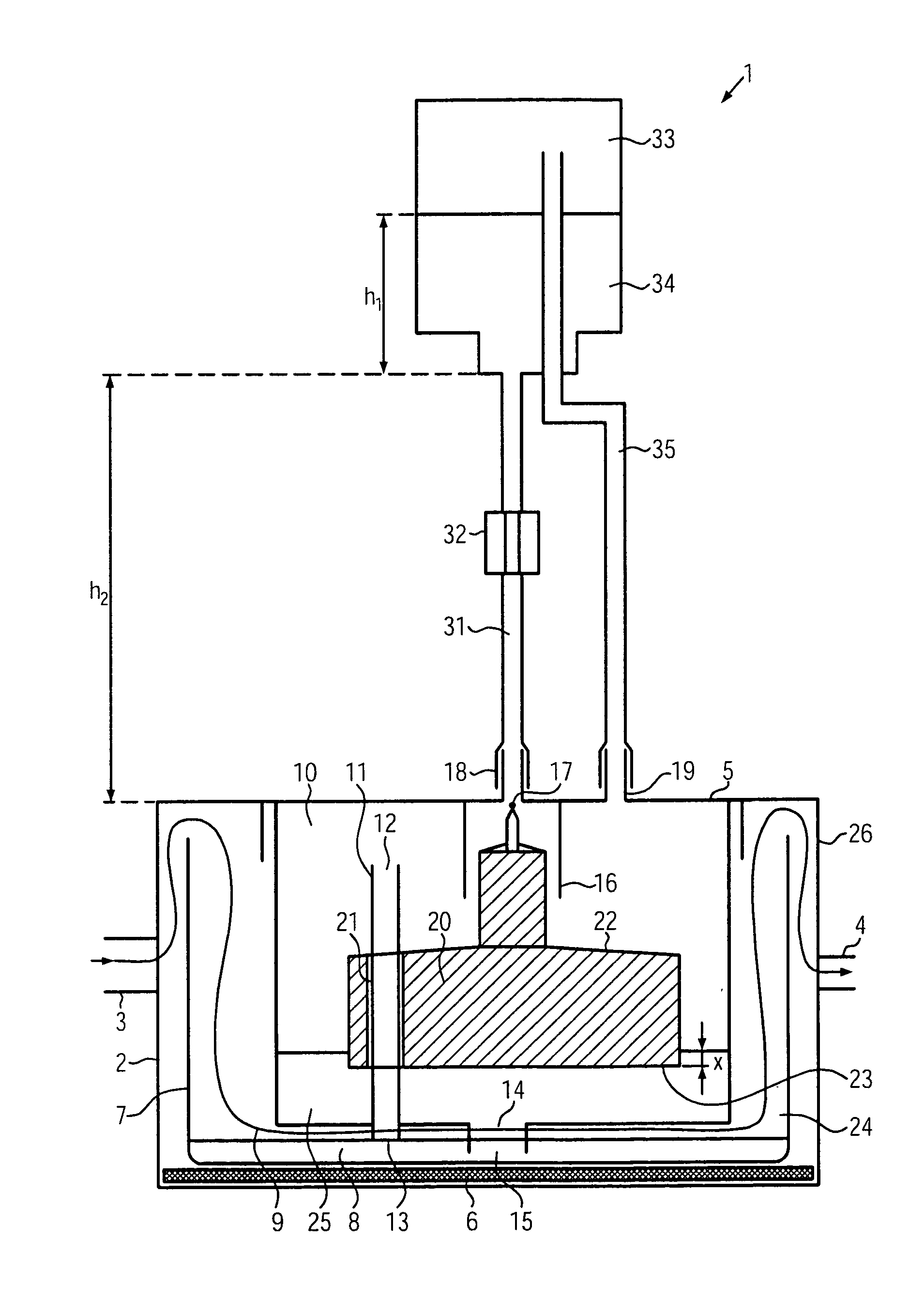

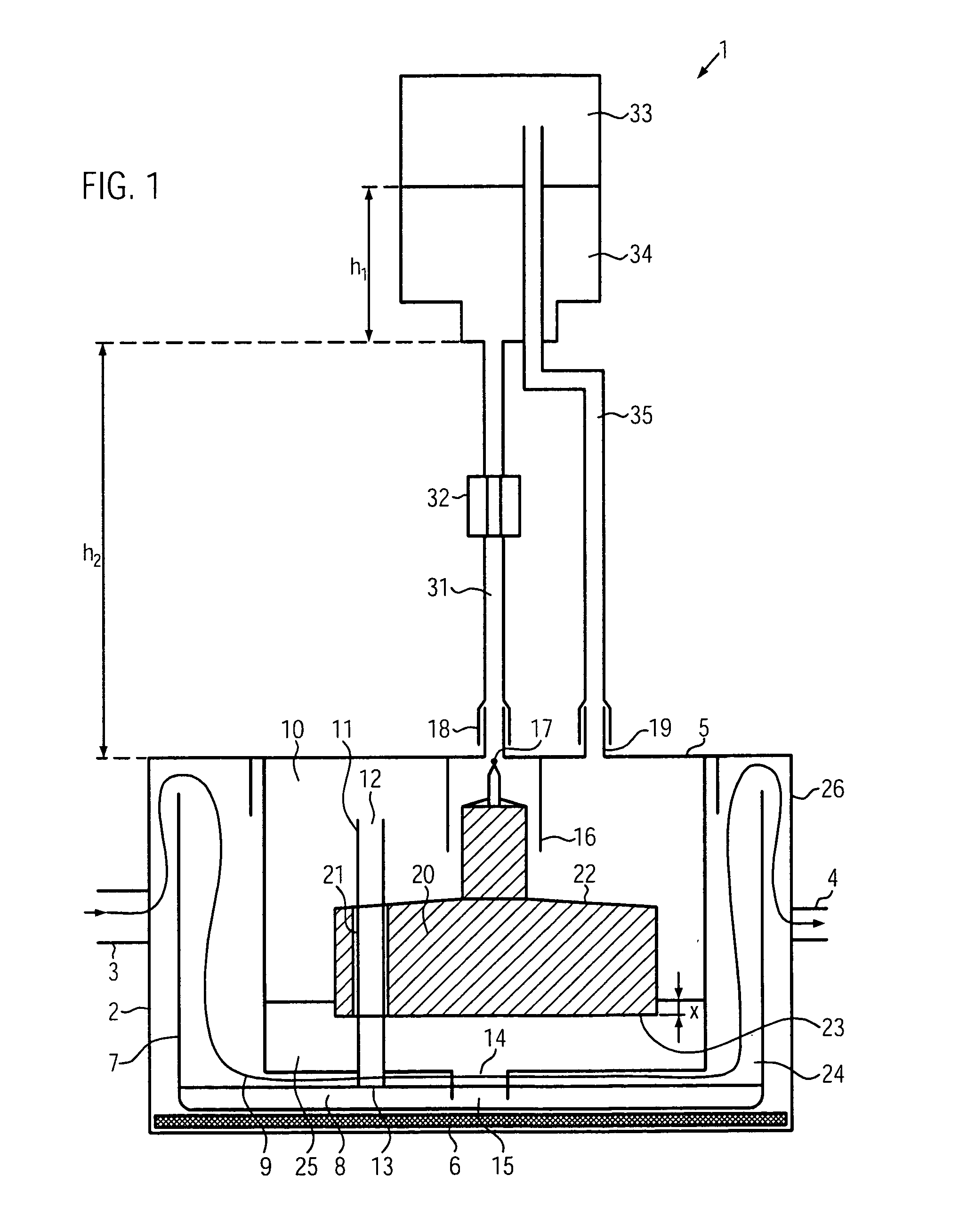

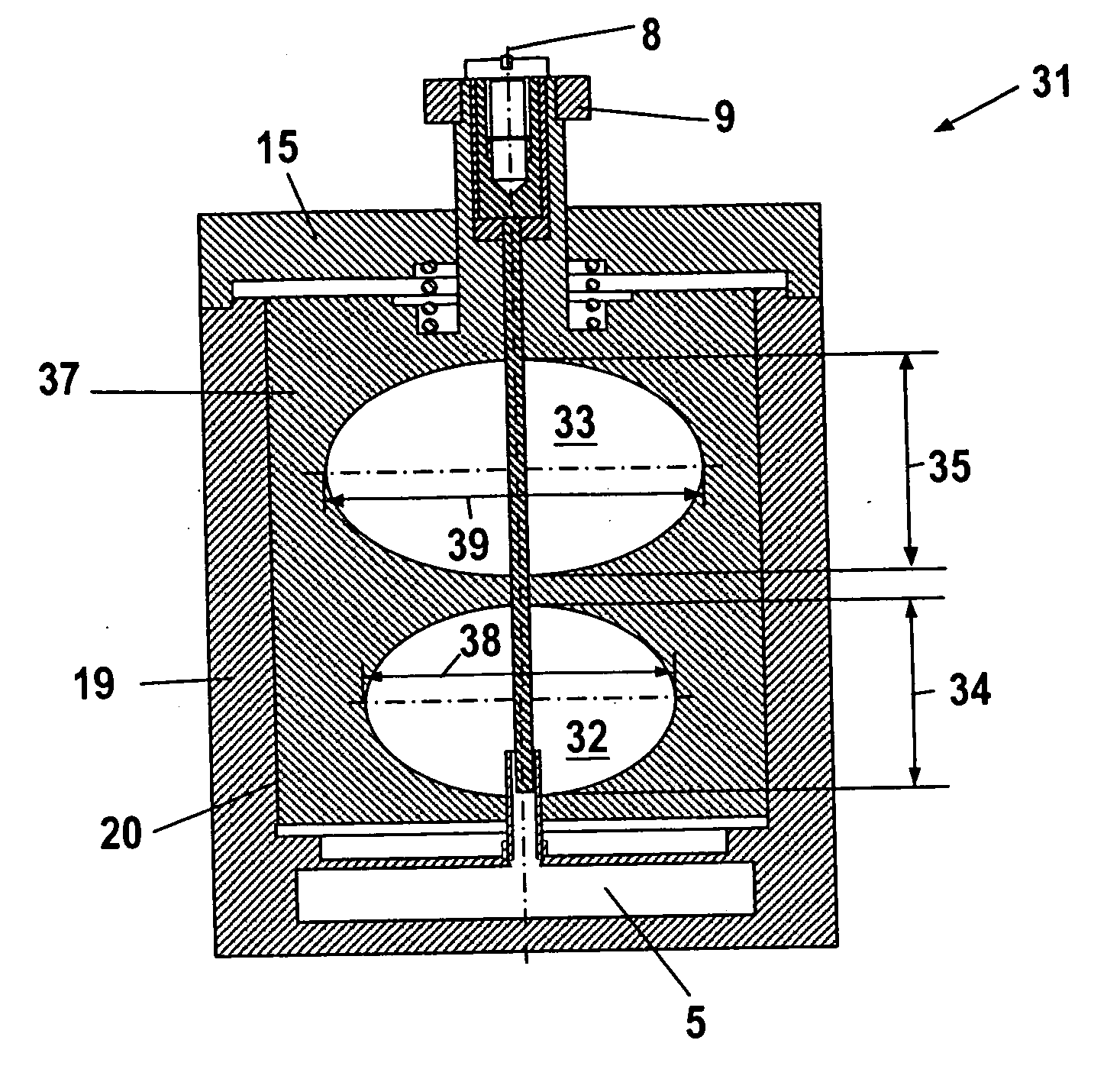

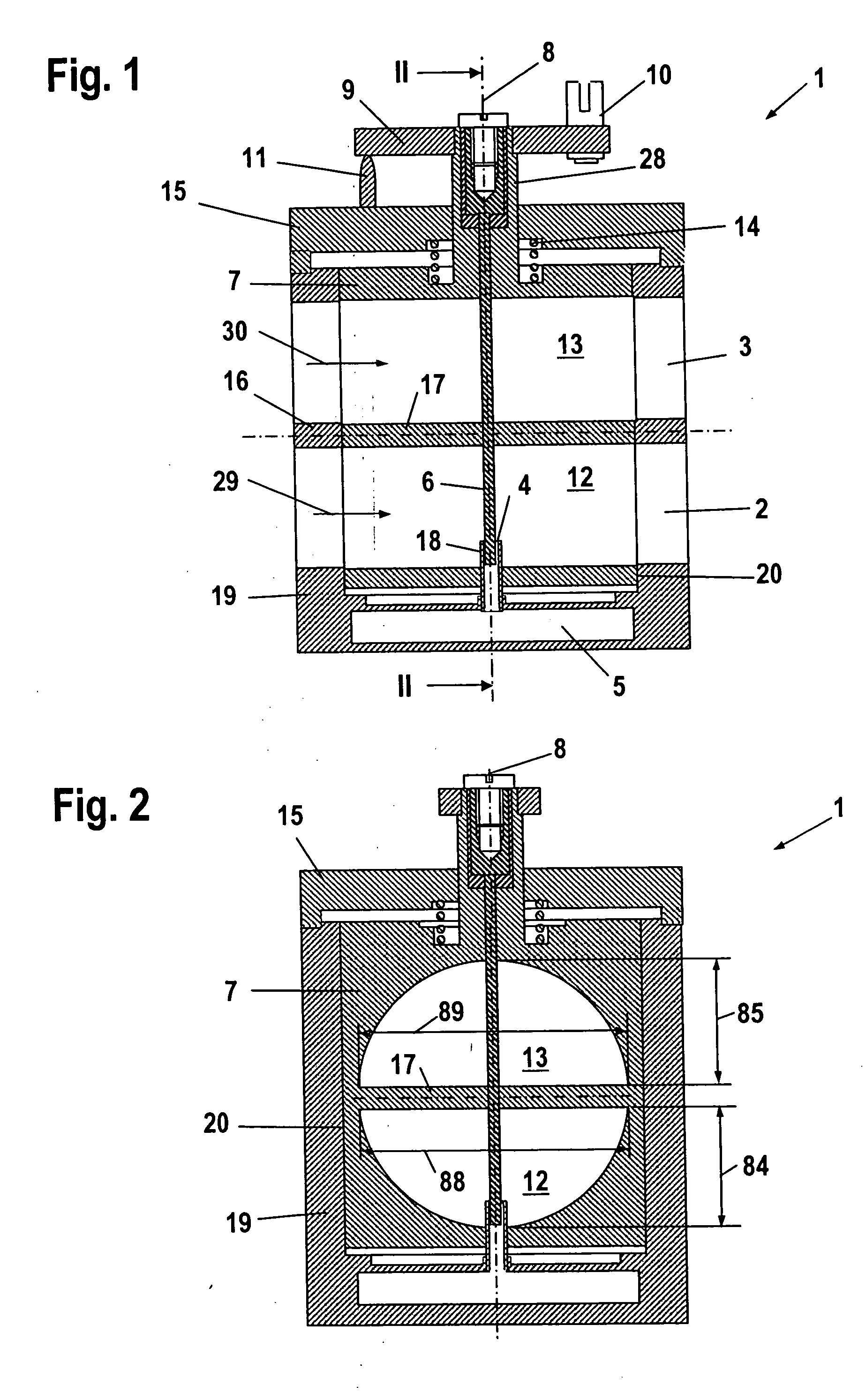

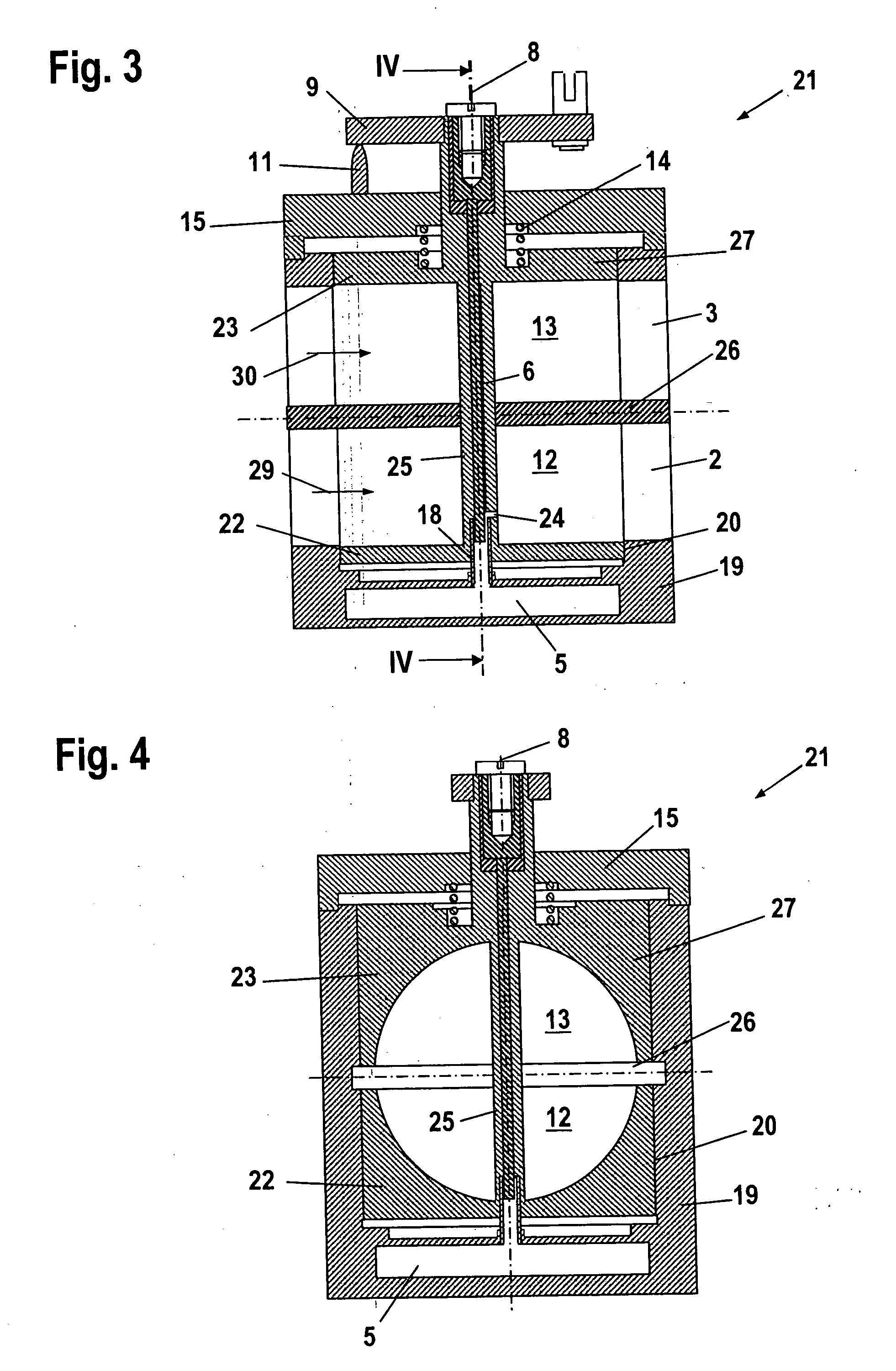

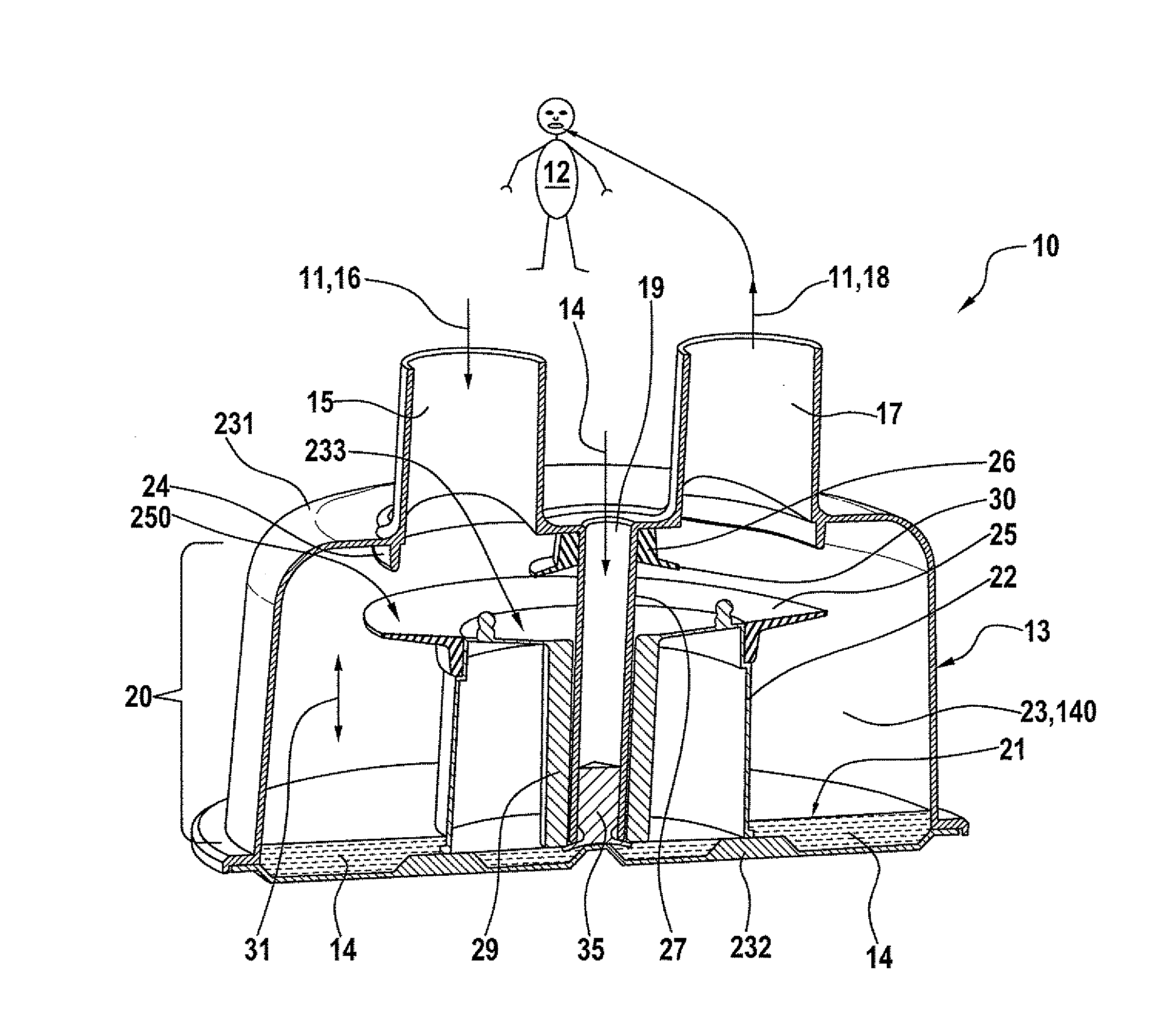

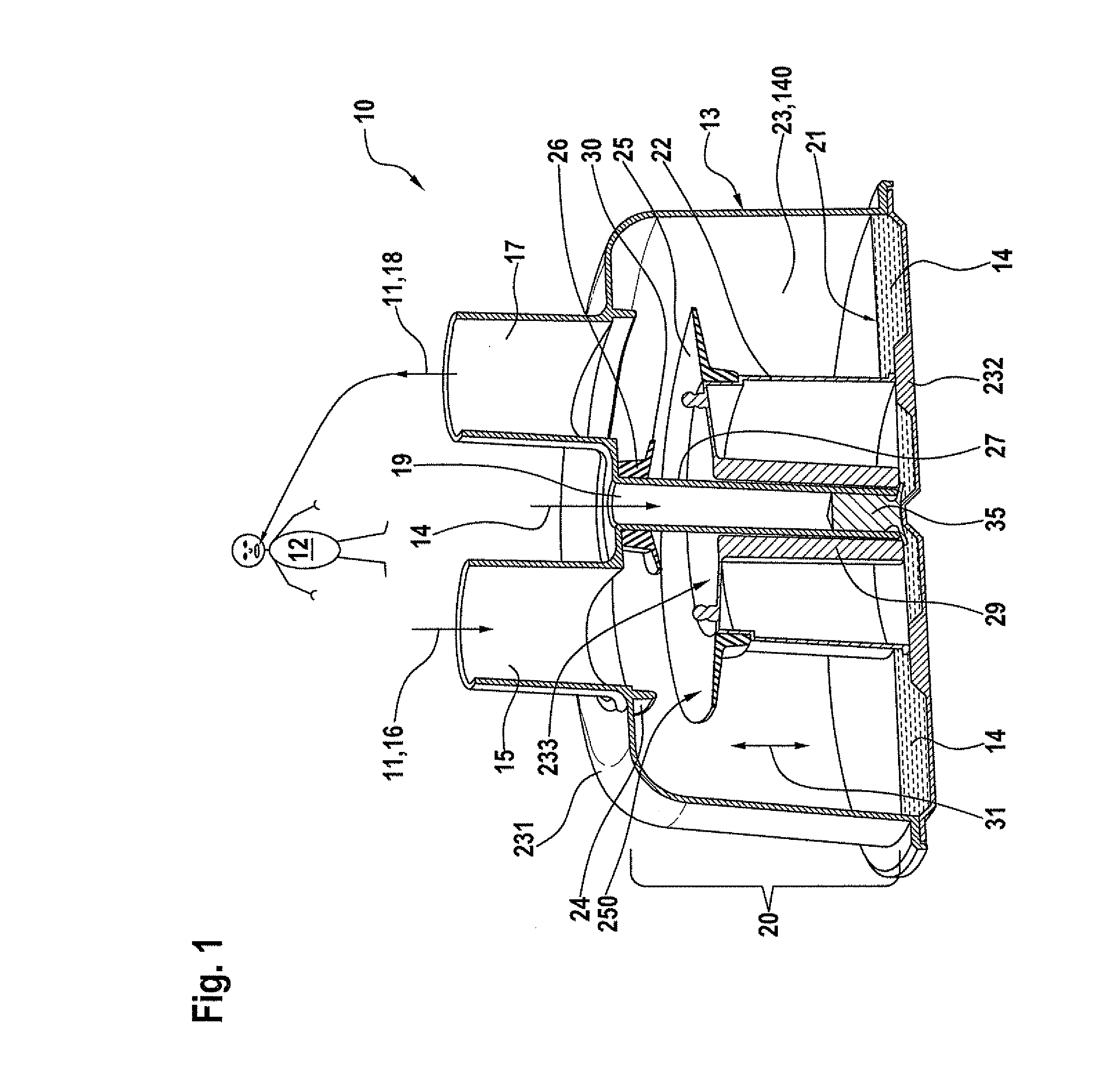

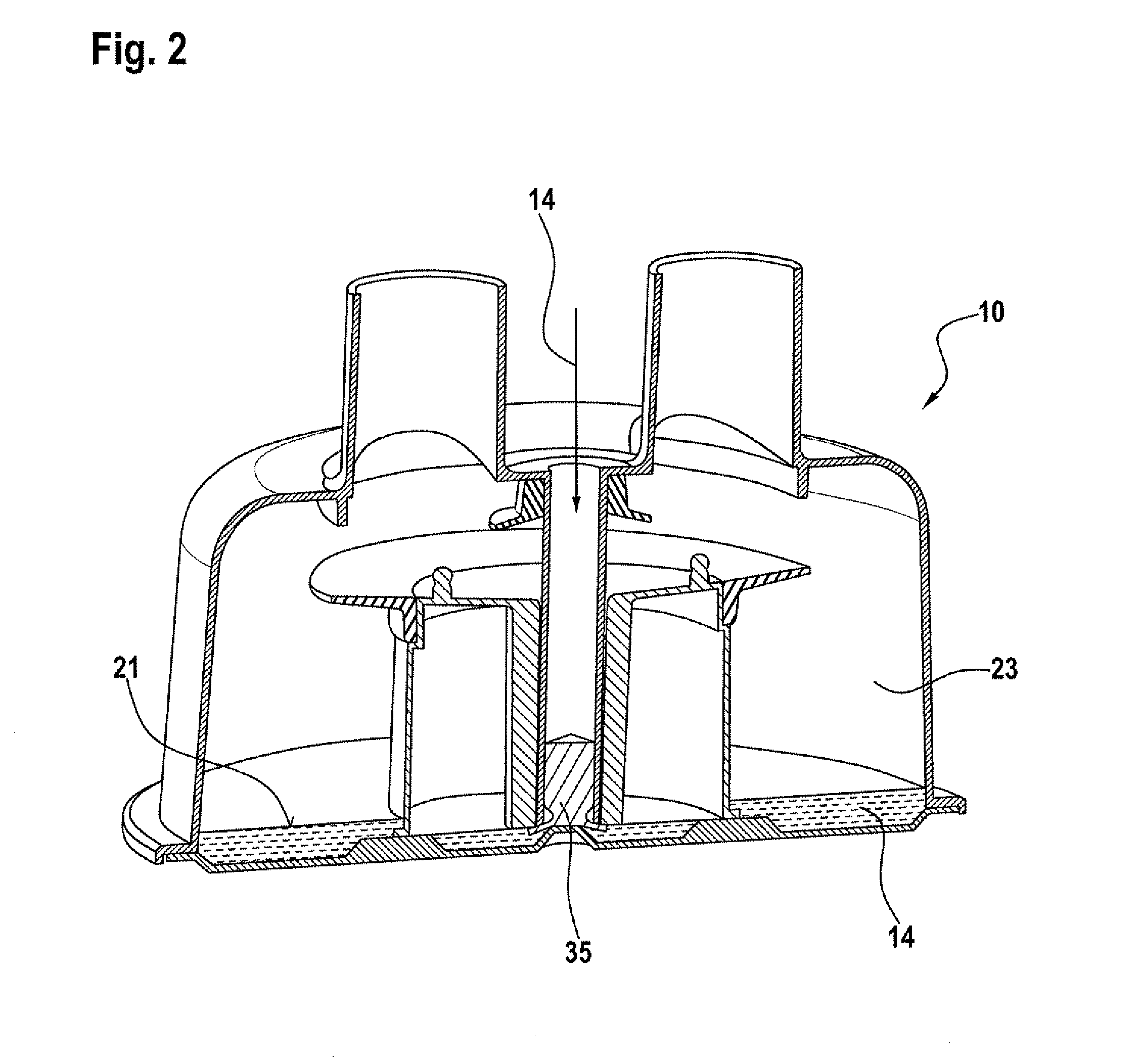

Evaporation chamber, intermediate chamber, and method

InactiveUS20120012186A1Easy to humidifyEasy to assembleLighting and heating apparatusUsing liquid separation agentMaximum levelEngineering

An evaporation chamber comprises a trough and an intermediate chamber disposed above the trough. The bottom of the intermediate chamber includes a liquid outlet through which liquid flows from the intermediate chamber into the trough. The intermediate chamber comprises a level valve, which allows a flow of liquid to follow from a liquid connection into the intermediate chamber so that the liquid level in the intermediate chamber is between a minimum level and a maximum level. The intermediate chamber has a liquid connection, a level valve, and a compensation connection. The liquid connection supplies a liquid. The level valve, allows a flow of liquid to follow from the liquid connection into the intermediate chamber so that the liquid level in the intermediate chamber is between a minimum level and a maximum level. The compensation connection is pneumatically connected to the gas space around the float.

Owner:SELEON

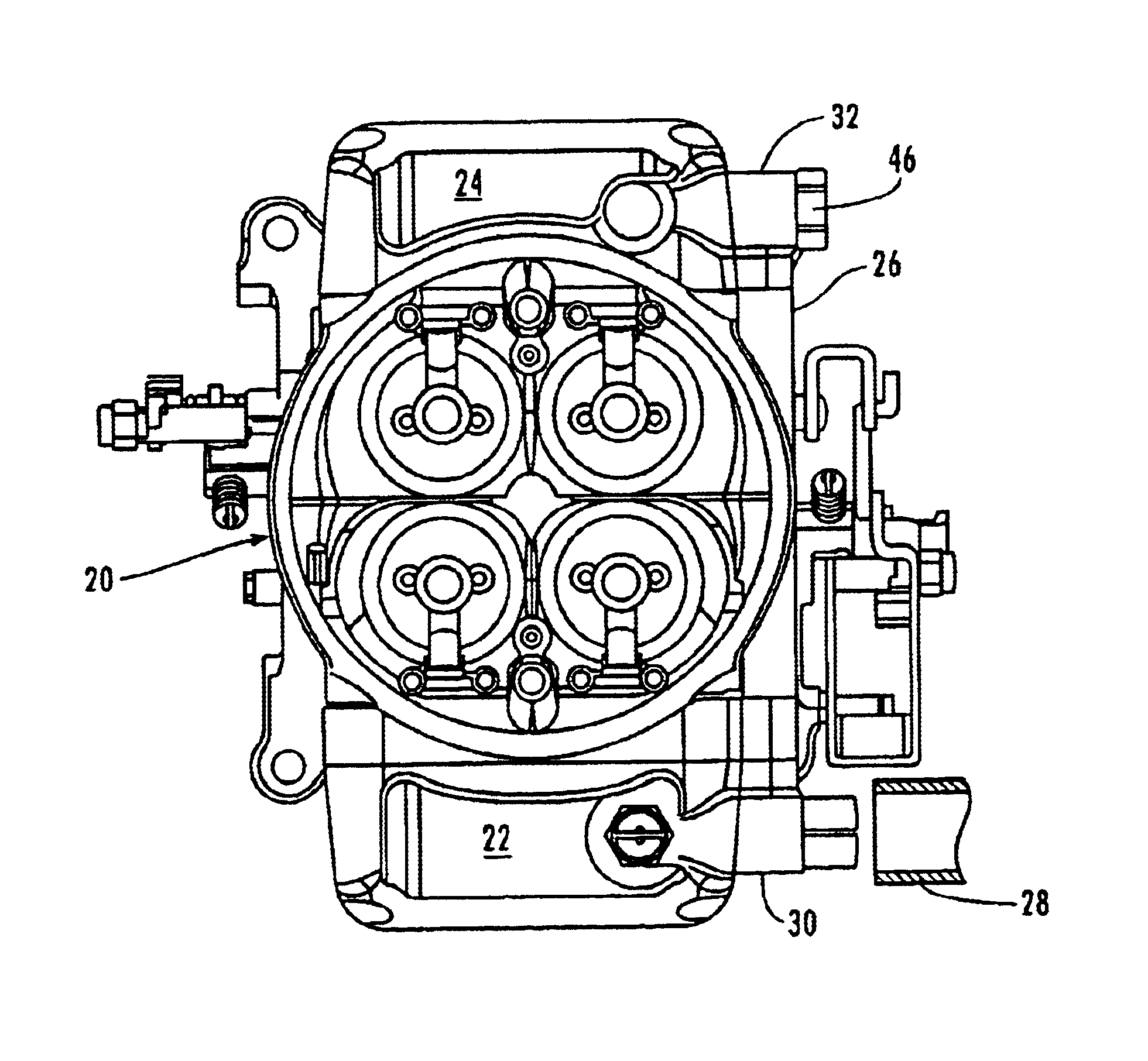

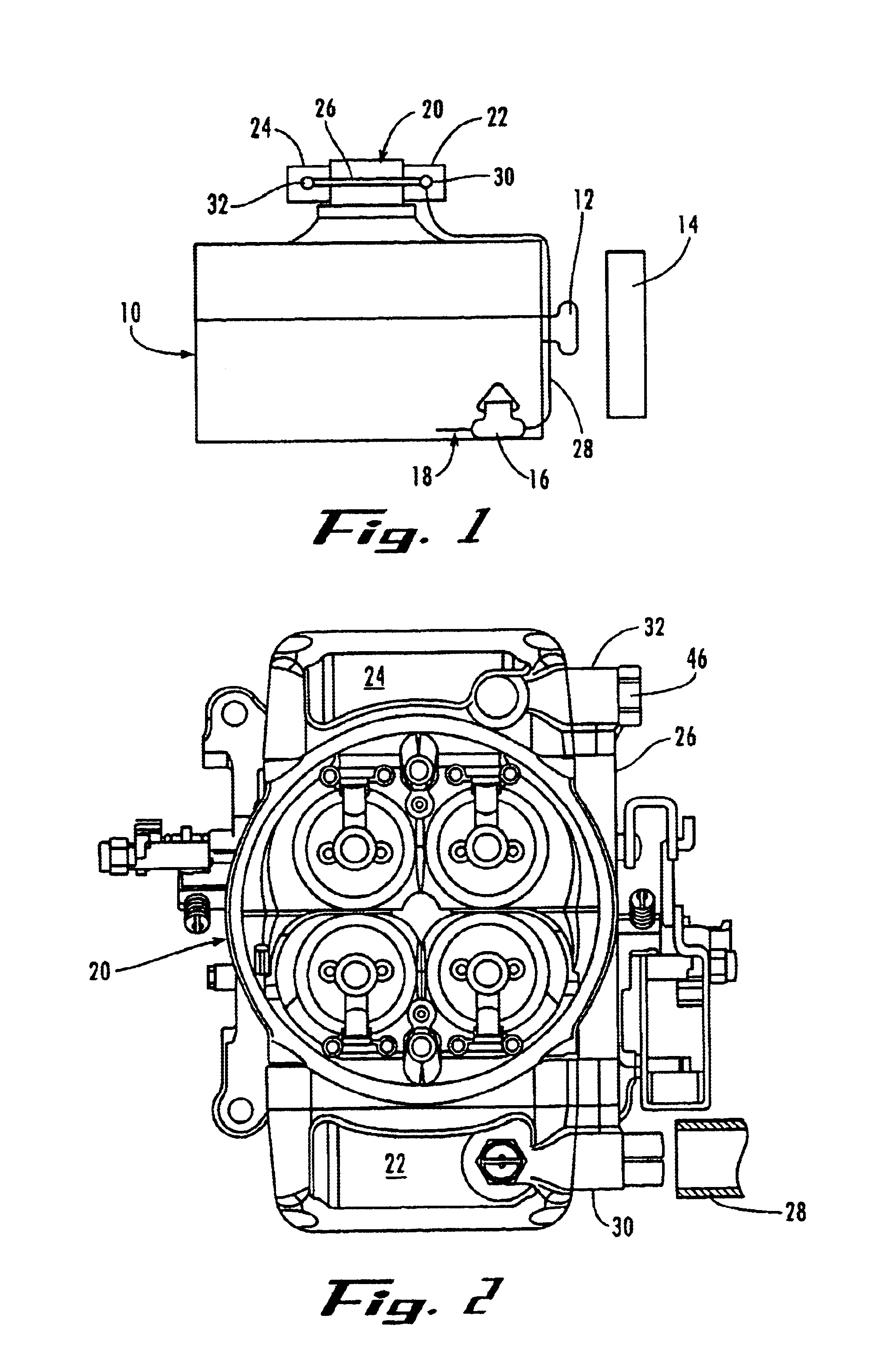

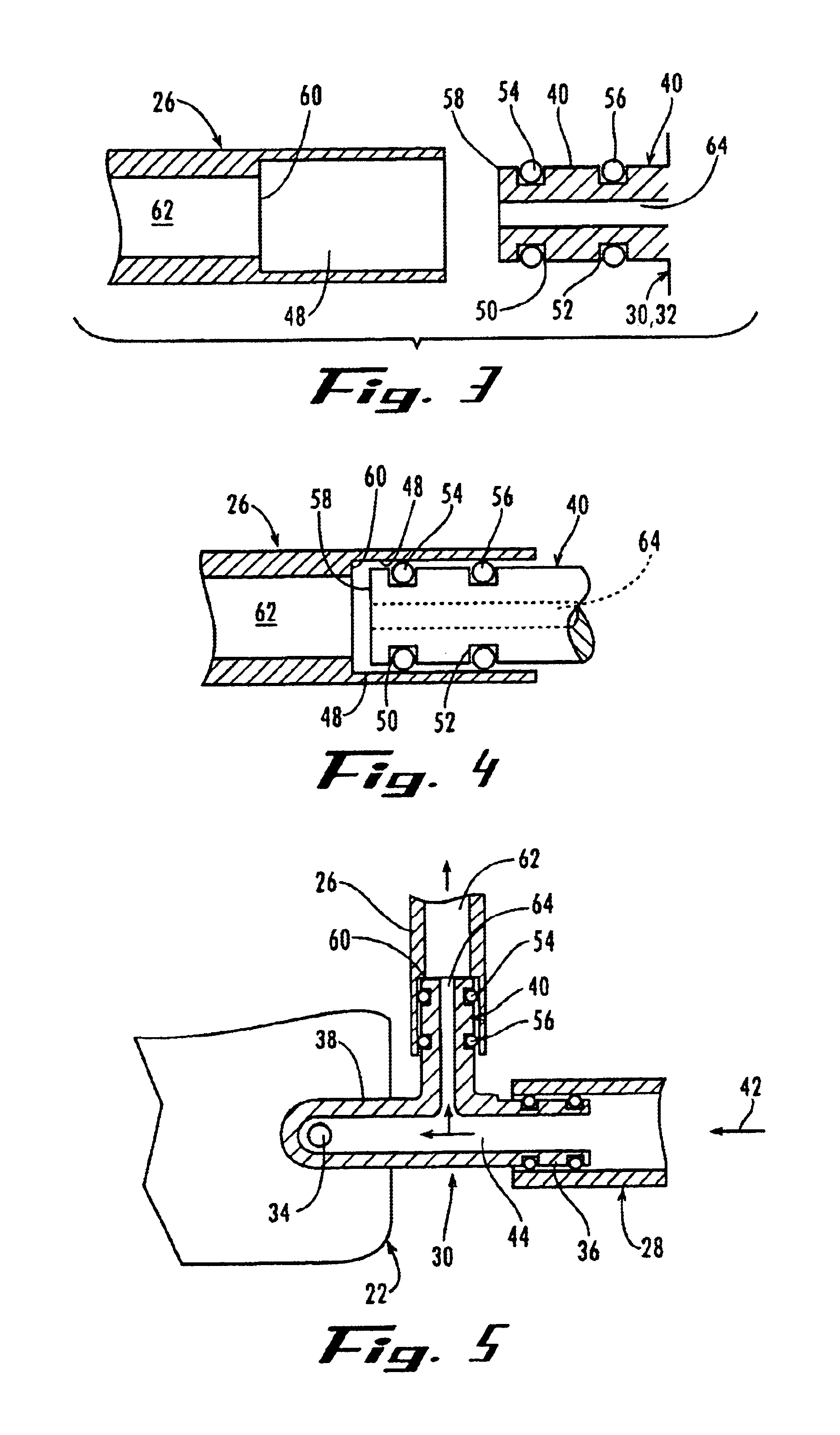

Transfer tube for carburetor fuel bowls

InactiveUS6874768B2Reduce the possibilityImproper installationLighting and heating apparatusUsing liquid separation agentCarburetorEngineering

Fuel bowls are placed on opposite sides of a carburetor, and a fuel transfer tube extends between the fuel bowls. External fuel receiving fixtures are mounted in fluid communication with the fuel bowls and have nipples facing each other. The fuel transfer tube is telescopically mounted at its ends to the nipples and O-rings seal the ends of the tubes to the nipples.

Owner:HOLLEY PERFORMANCE PRODUCTS

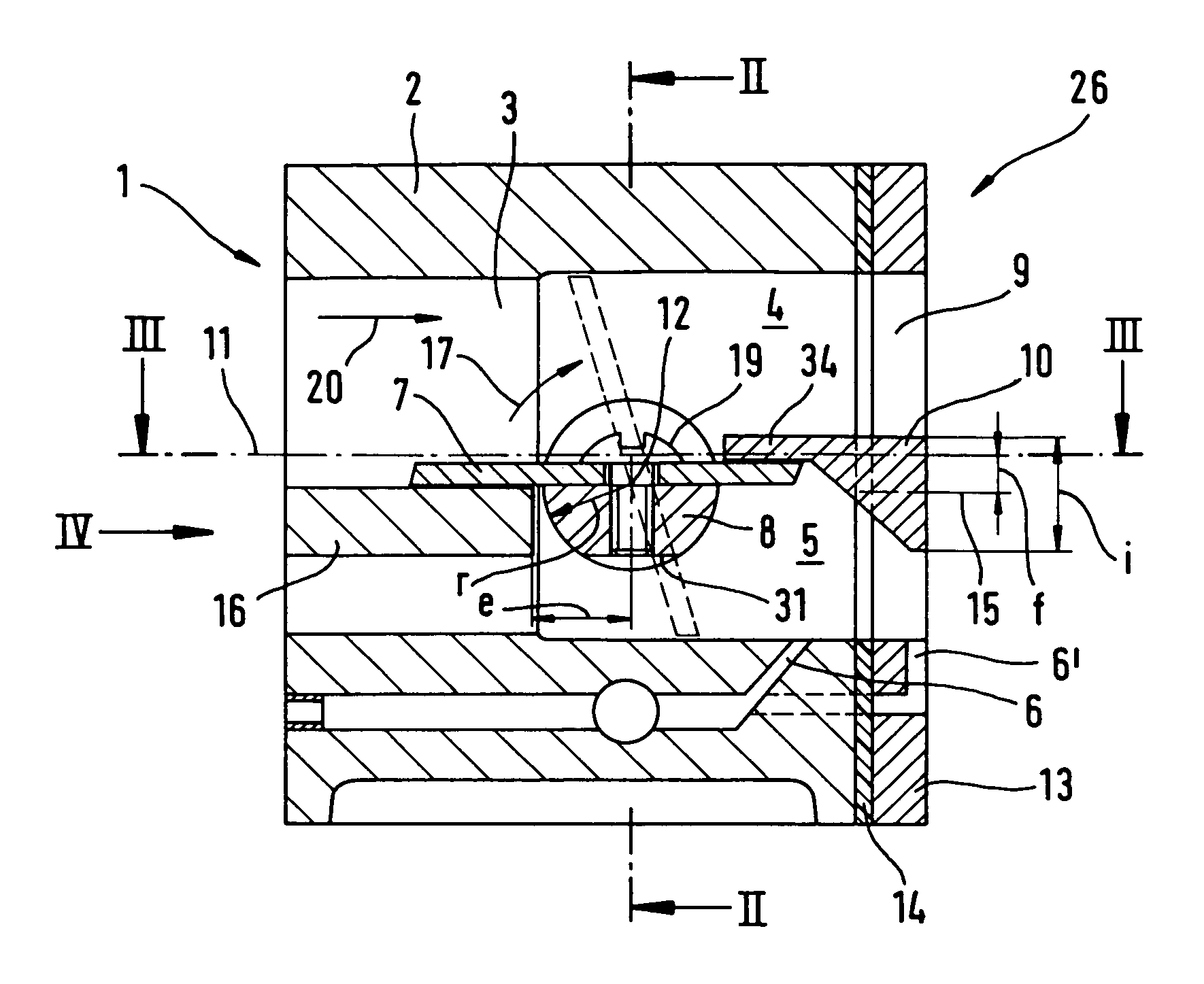

Carburetor

ActiveUS20060131763A1Easy to useSmall sizeLighting and heating apparatusUsing liquid separation agentEngineeringCarburetor

A carburetor comprising a mixture channel and an air channel that are separated from one another, wherein a fuel opening opens into the mixture channel. A throttle element is rotatable about an axis of rotation that extends transverse of the direction of flow in the mixture channel and in the air channel and extends through both channels. As a function of its position, the throttle element throttles a flow cross-section of the mixture channel and the air channel. The flow cross-section of a portion of the mixture channel and / or of the air channel has a non-circular shape in the vicinity of the throttle element.

Owner:ANDREAS STIHL AG & CO KG

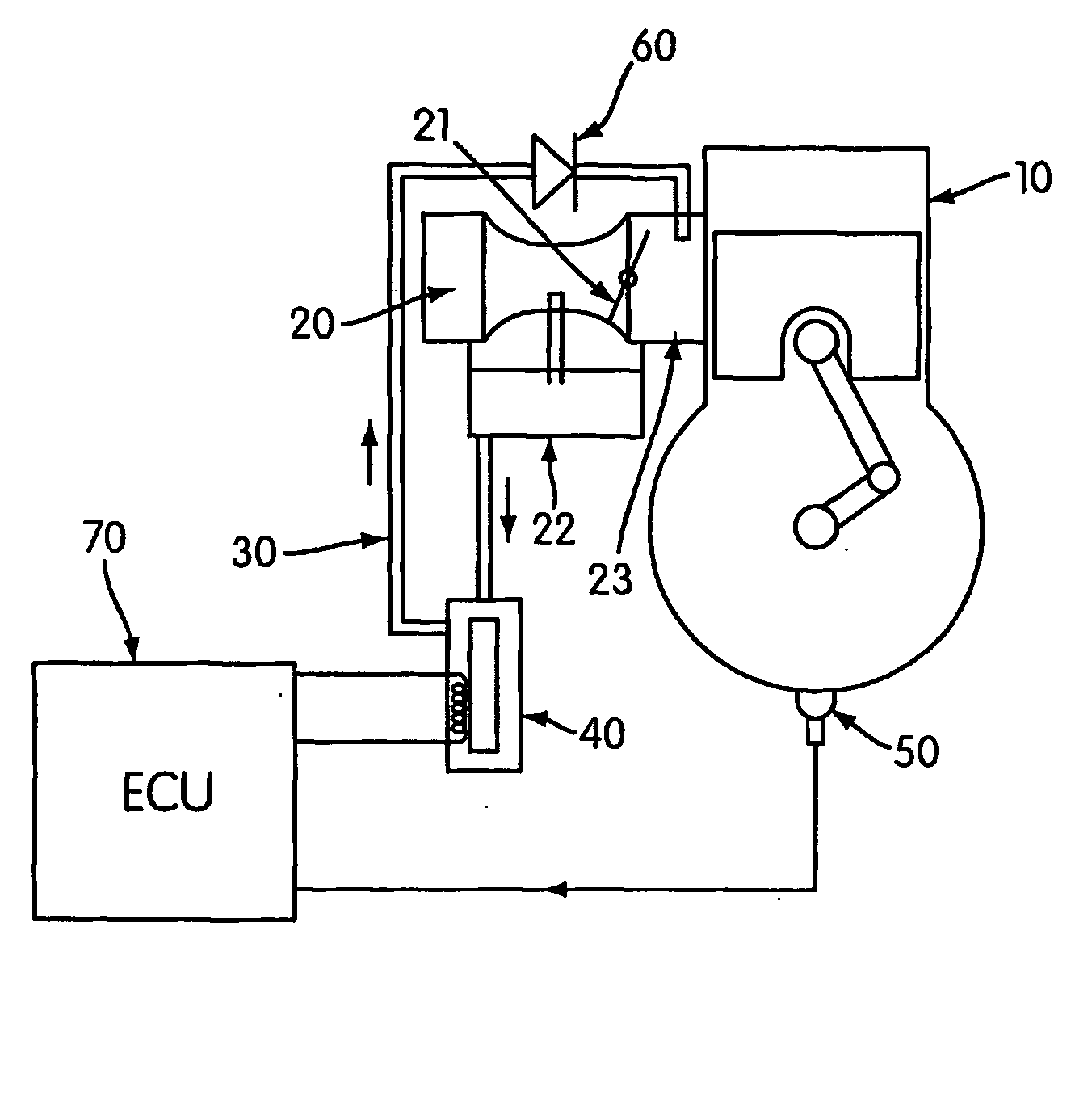

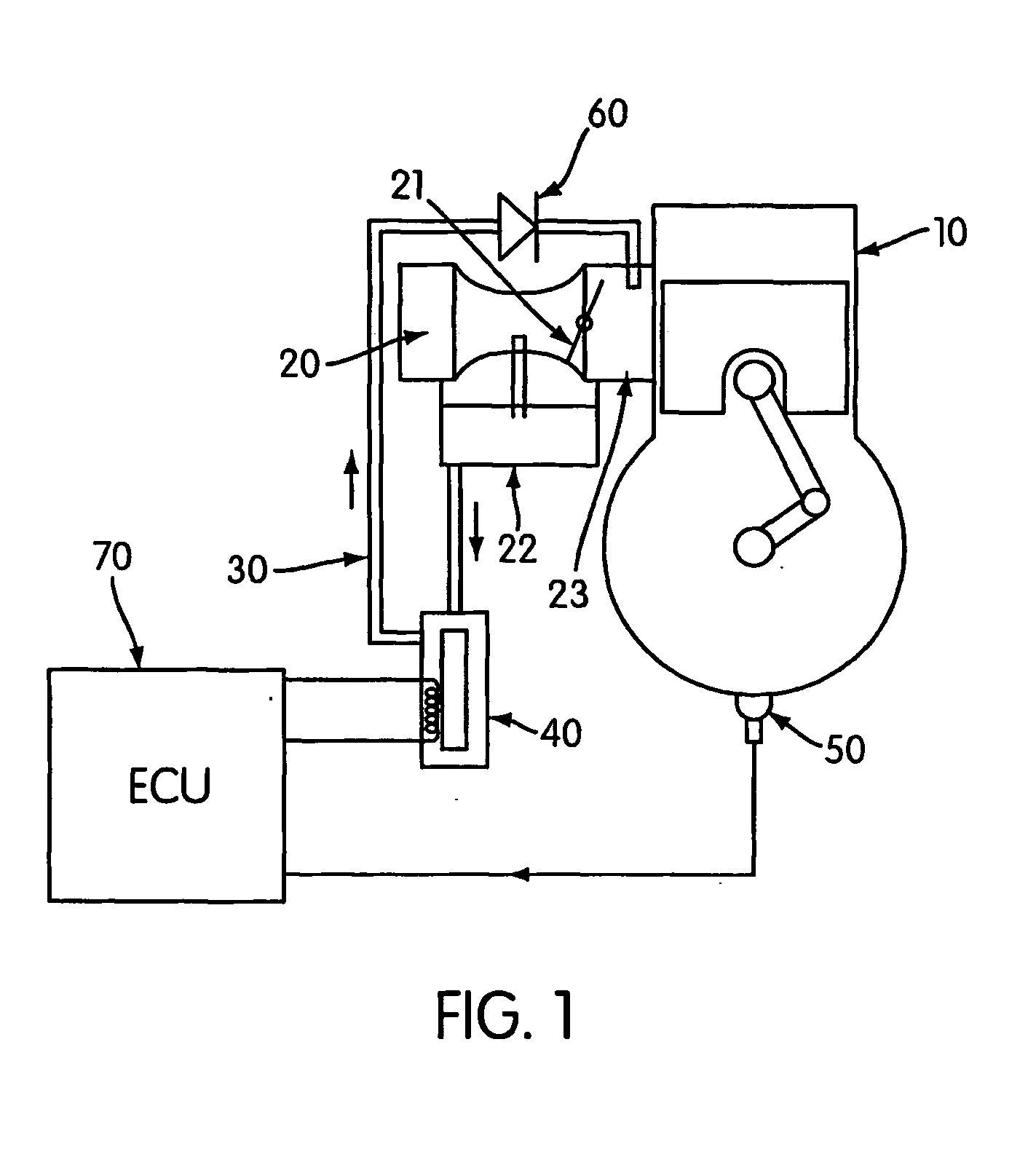

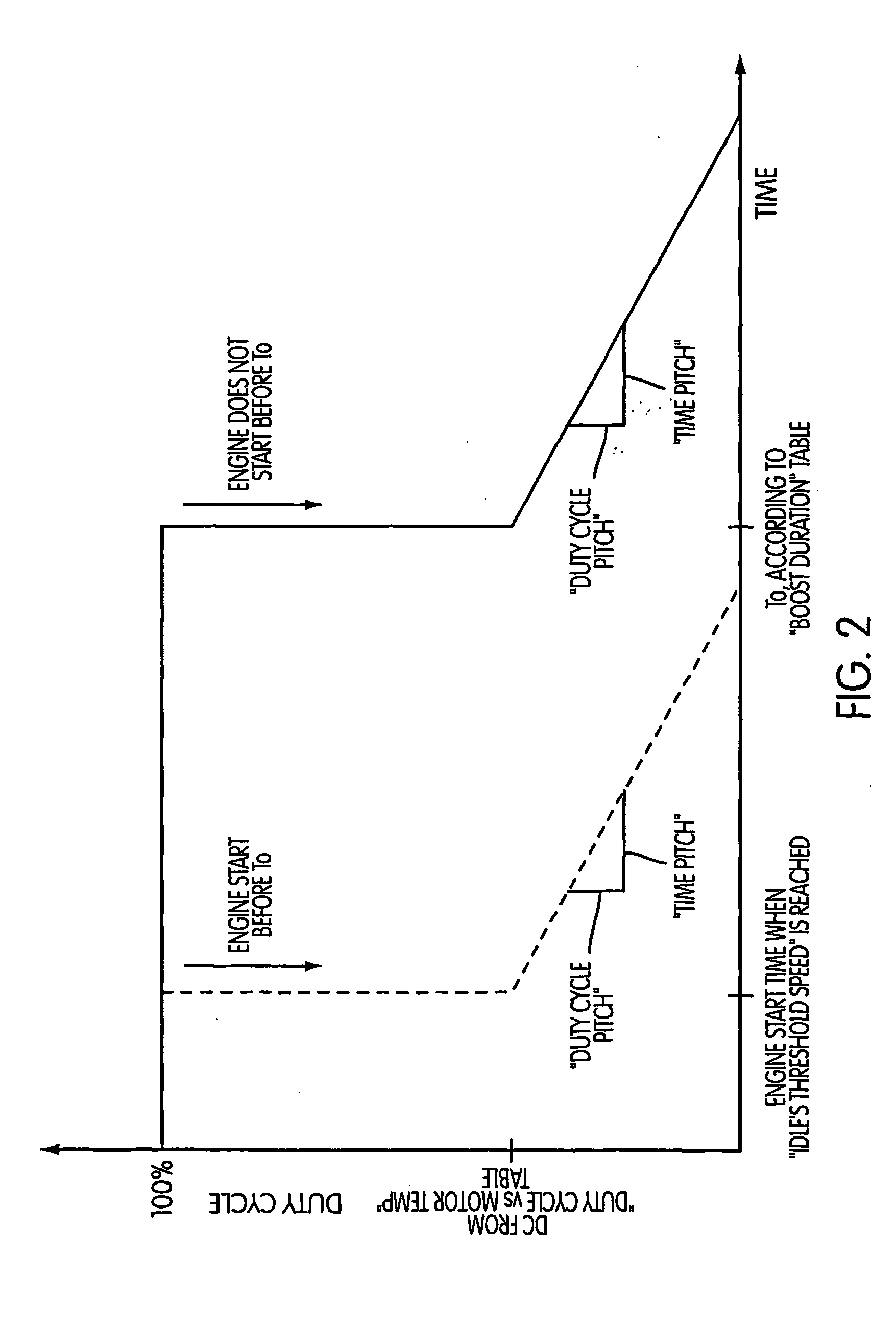

Systems and methods for automatic carburetor enrichment during cold start

InactiveUS20050098907A1Increase the air-fuel ratioElectrical controlFloat-controlled apparatusCost effectivenessDriver/operator

An automatic carburetor (20) enrichment system that controls the air-fuel mixture during cold start of an engine (10) having a carburetor including a fuel bowl (22) and an induction passage (23), includes a sensor (50) that provides a signal indicative of an engine temperature at engine start, a fuel line (30) connected between the fuel bowl (22) and the induction passage, a solenoid valve (40) disposed in the fuel line, and a controller (10) that receives the signal and sets a duty cycle of the solenoid valve associated with the engine temperature to increase the air-fuel ratio of the air-fuel mixture at engine start. The automatic carburetor enrichment system reduces cranking time during cold start, eliminates the need for driver input during cold start, prevents engine stalling without assistance from the operator during the warm up phase, provides a simpler, more cost effective and reliable carburetor enrichment, provides self-drowning protection without the use of an electronic idle switch and eliminates the risk of engine drowning when the engine is cranked with the choke ON and the ignition switches OFF.

Owner:BOMBARDIER RECREATIONAL PROD INC

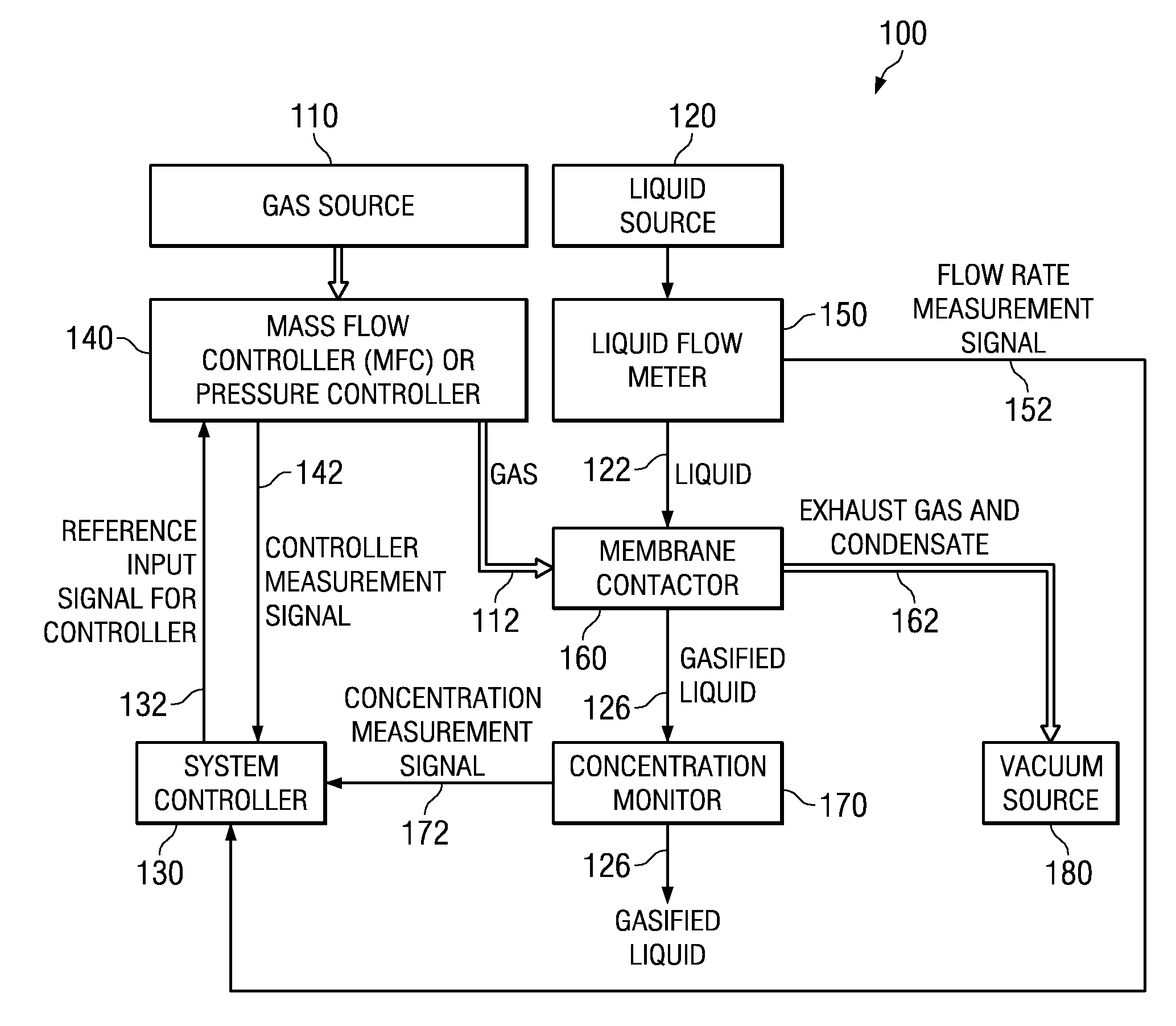

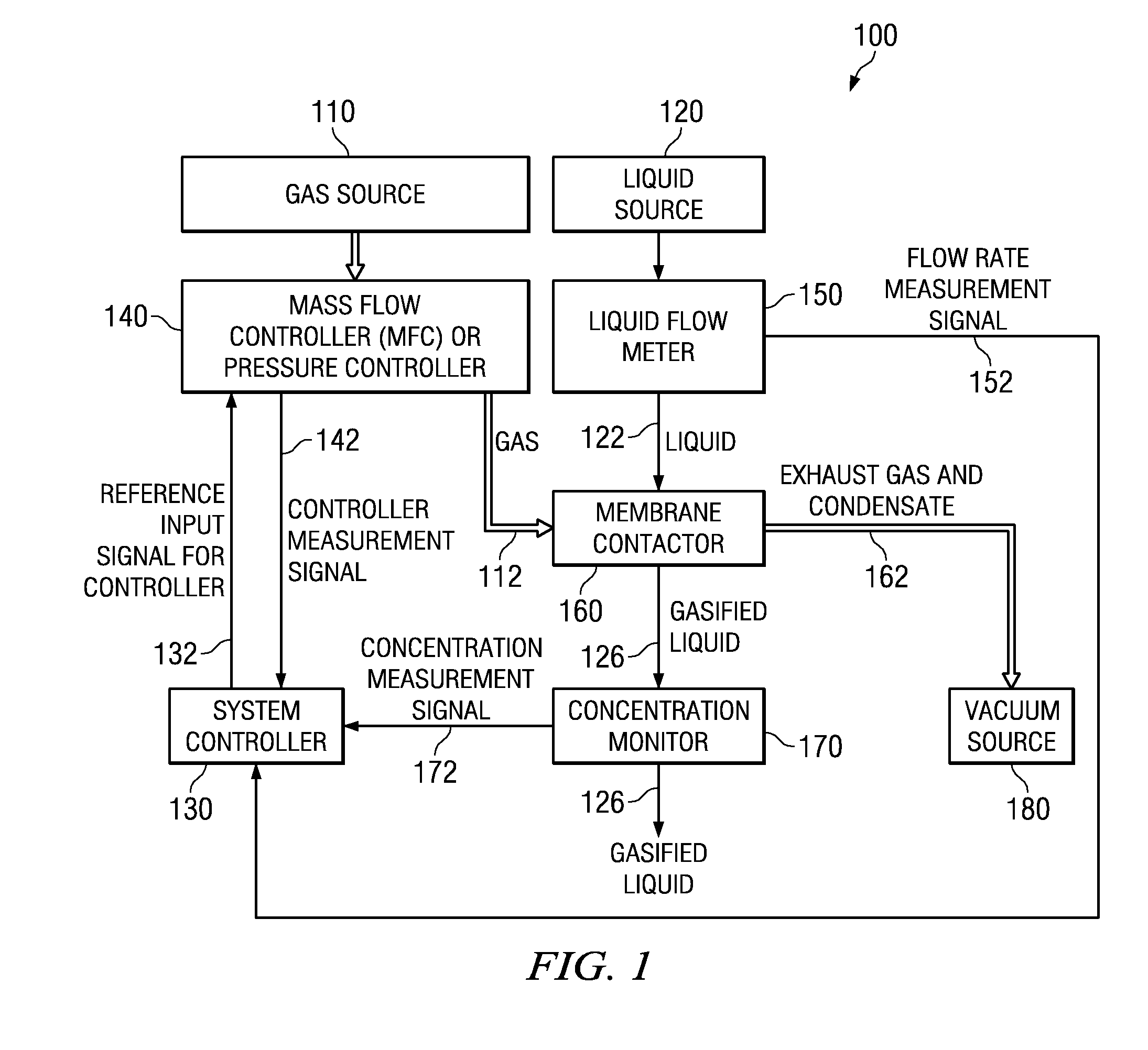

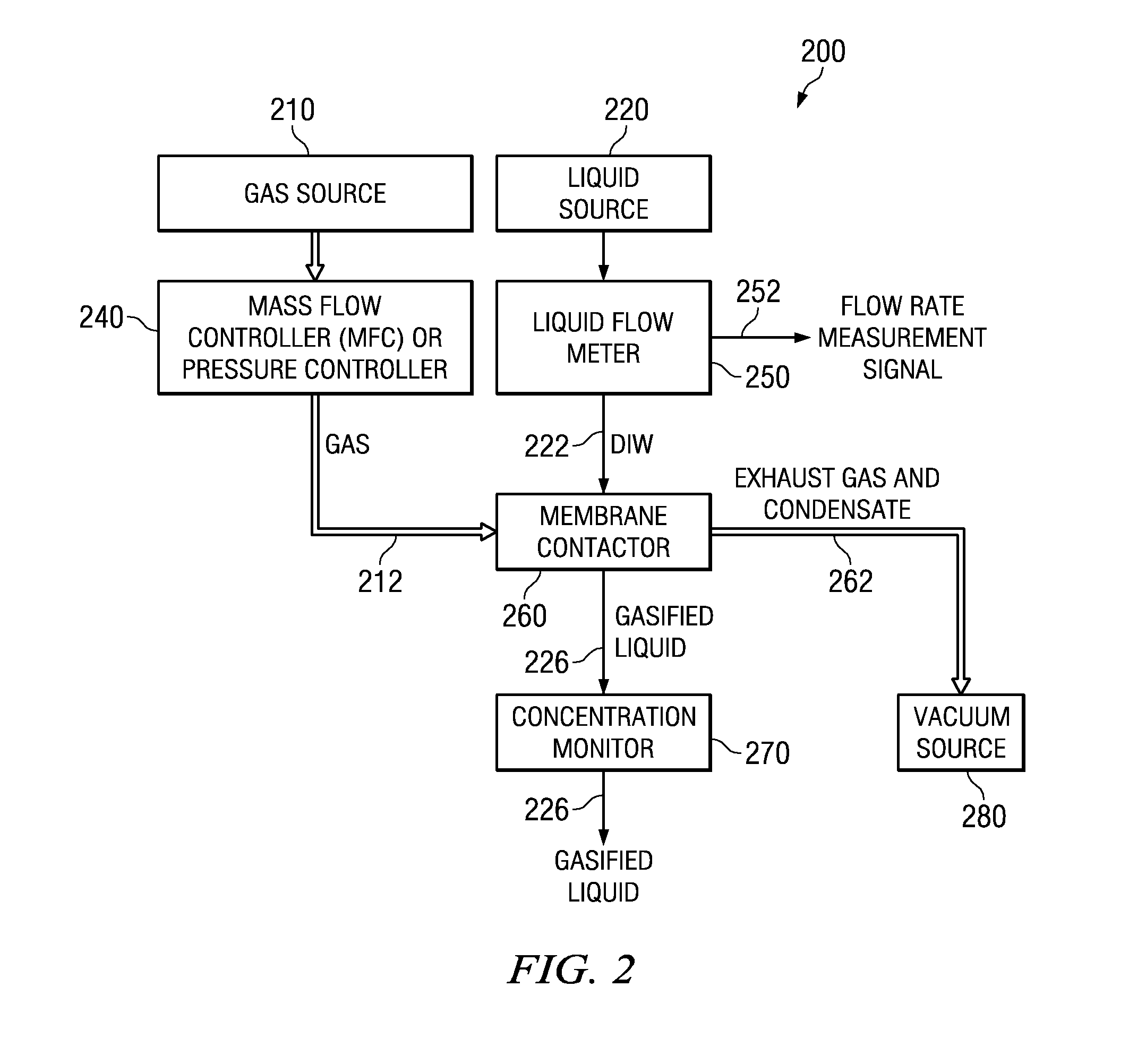

Gasification systems and methods for making bubble free solutions of gas in liquid

InactiveUS20110180148A1Low gas consumptionEliminate needLighting and heating apparatusMixing methodsFree solutionProduct gas

Embodiments disclosed herein can introduce low amounts of gas in a liquid with fast response time and low variation in concentration. In one embodiment, a gas is directed into an inlet on a gas contacting side of a porous element of a contactor and a liquid is directed into an inlet on a liquid contacting side of the porous element of the contactor. The liquid contacting side and the gas contacting side are separated by the porous element and a housing. The gas is removed from an outlet on the gas contacting side of the porous element at a reduced pressure compared to the pressure of the gas flowing into the inlet of the contactor. A liquid containing a portion of the gas transferred into the liquid is removed from an outlet on the liquid contacting side of the porous element, producing a dilute bubble free solution.

Owner:ENTEGRIS INC

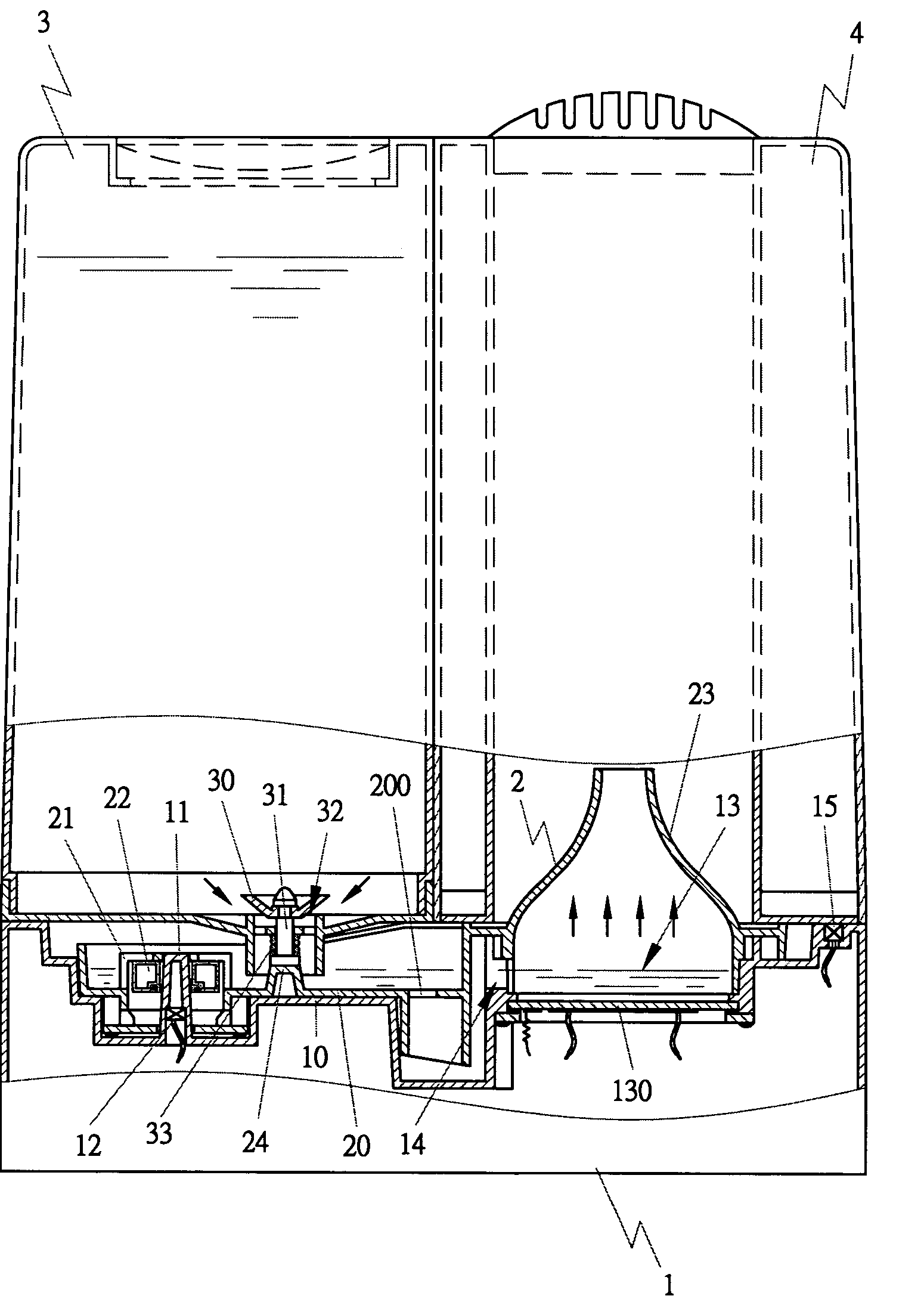

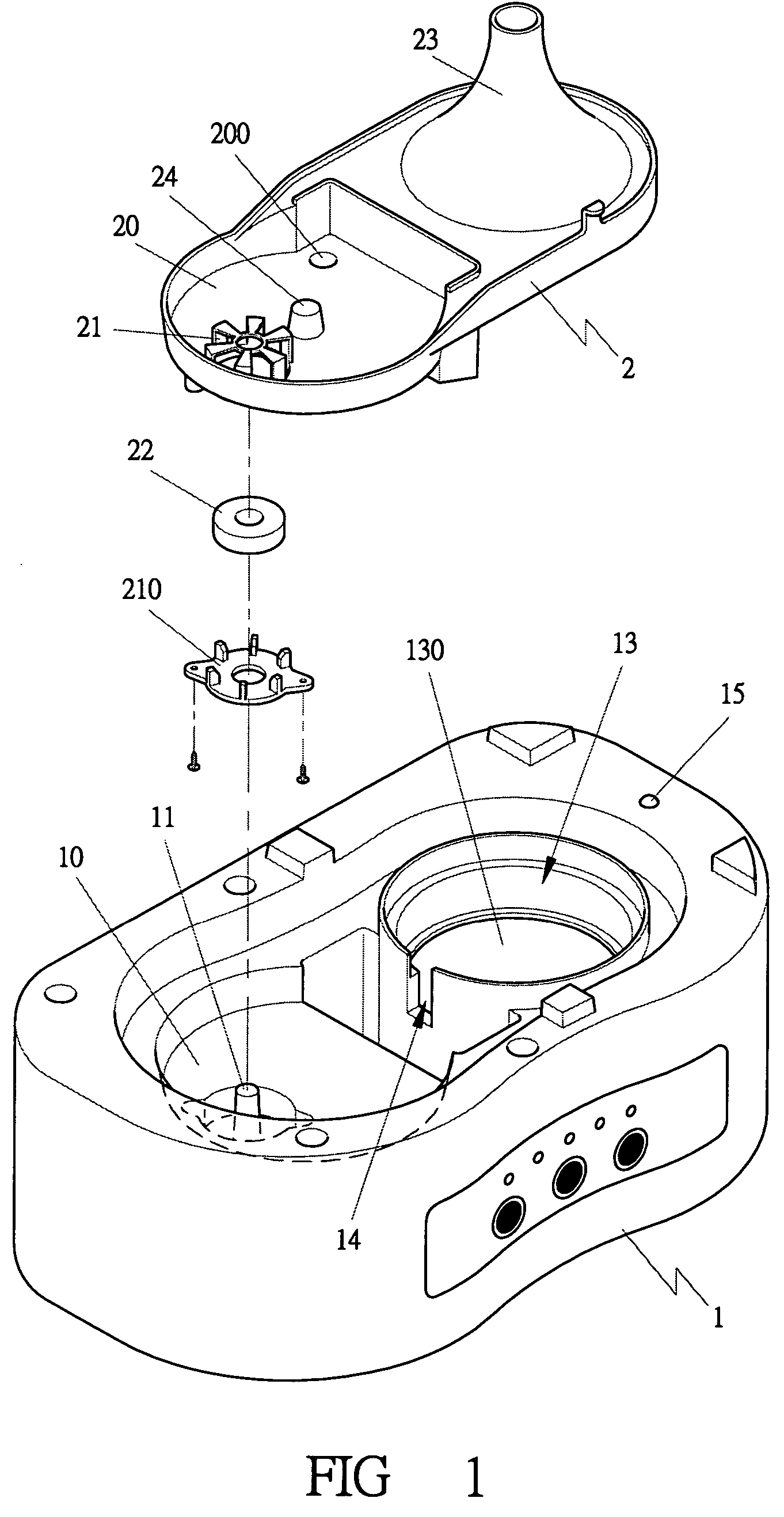

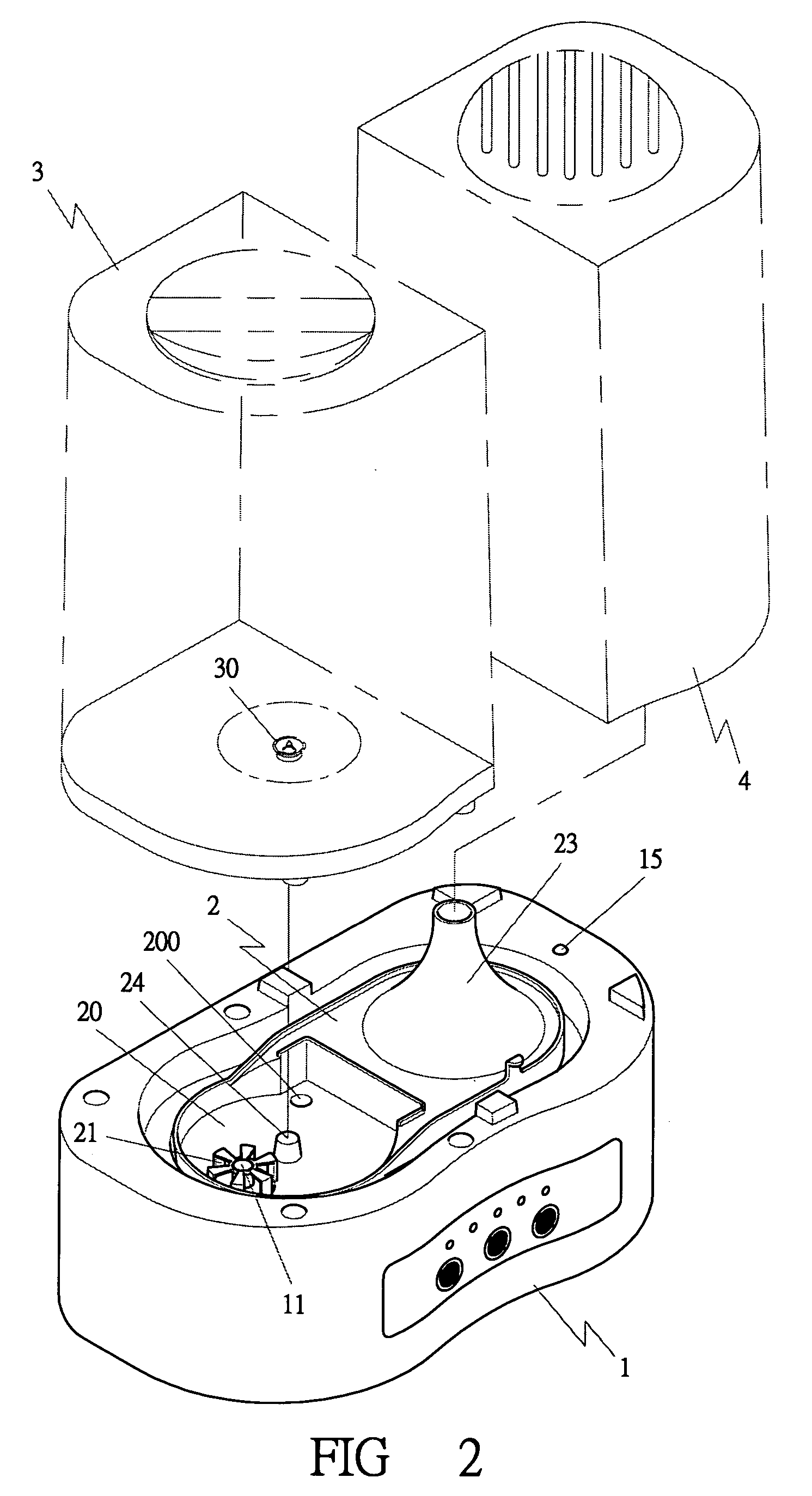

Safety device for a humidifier

InactiveUS7182321B2Preventing improper sensing of water levelRapid productionSpace heating and ventilation safety systemsLighting and heating apparatusElectricityEngineering

Owner:HUANG CHUAN PAN +1

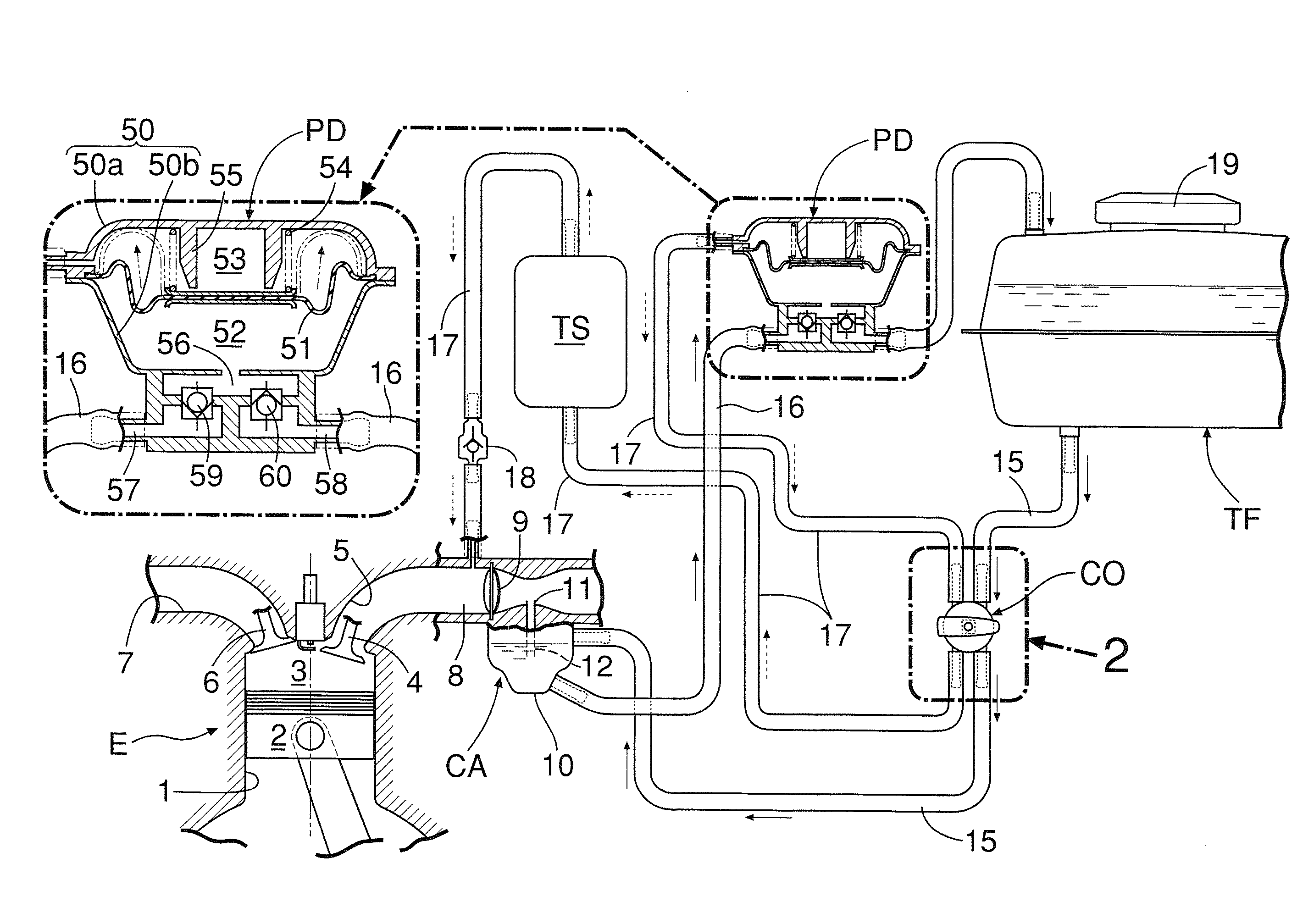

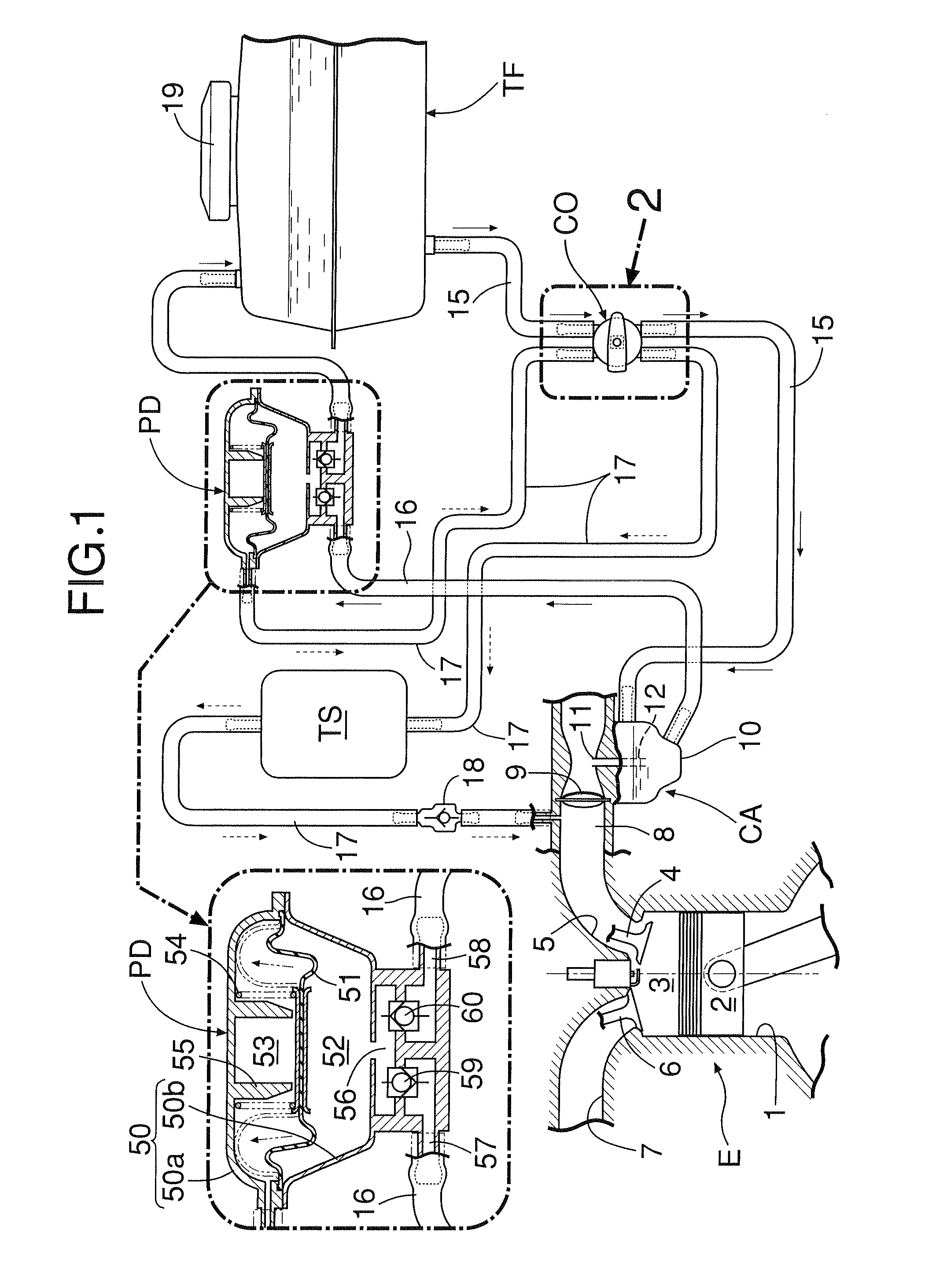

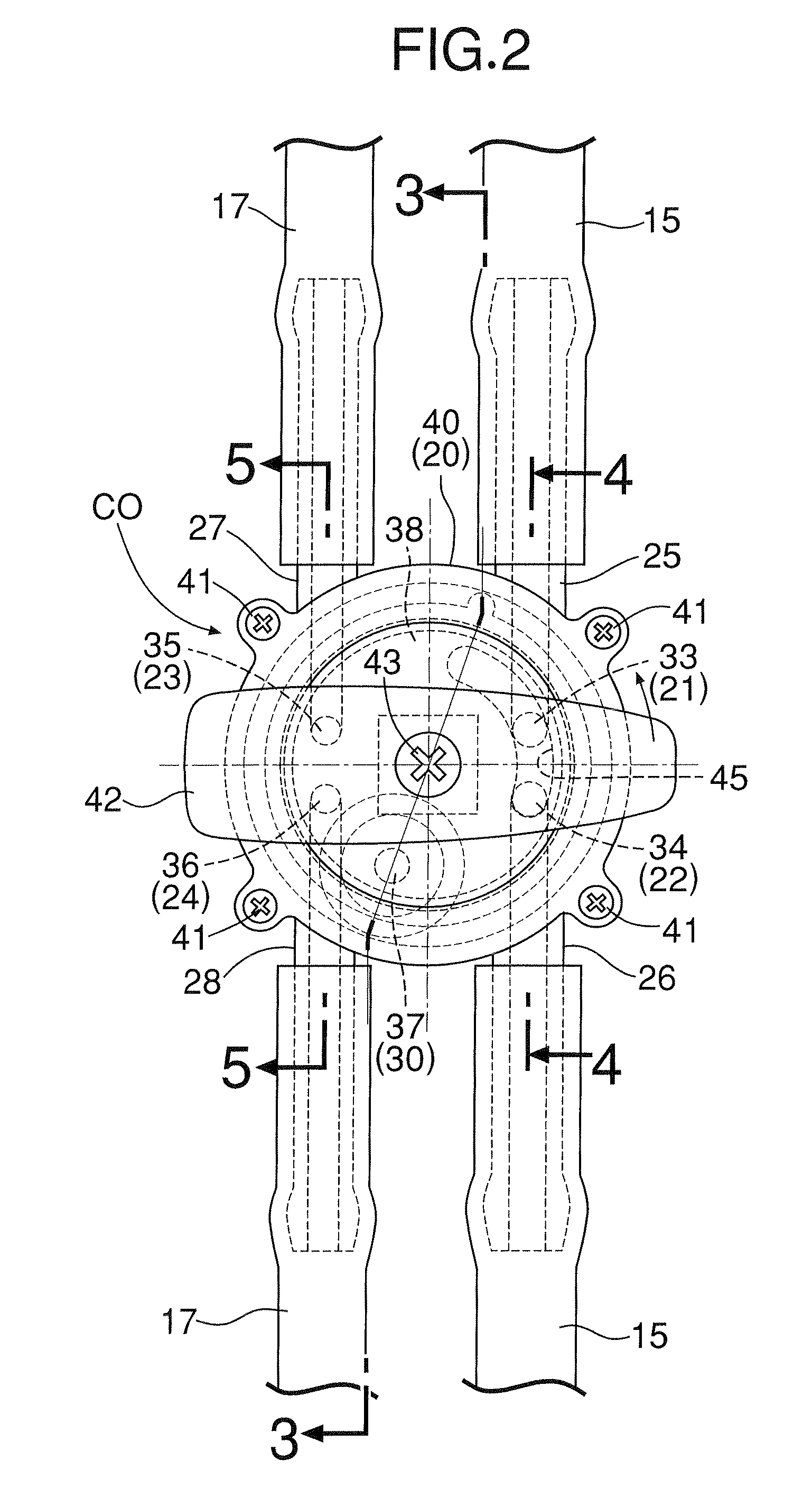

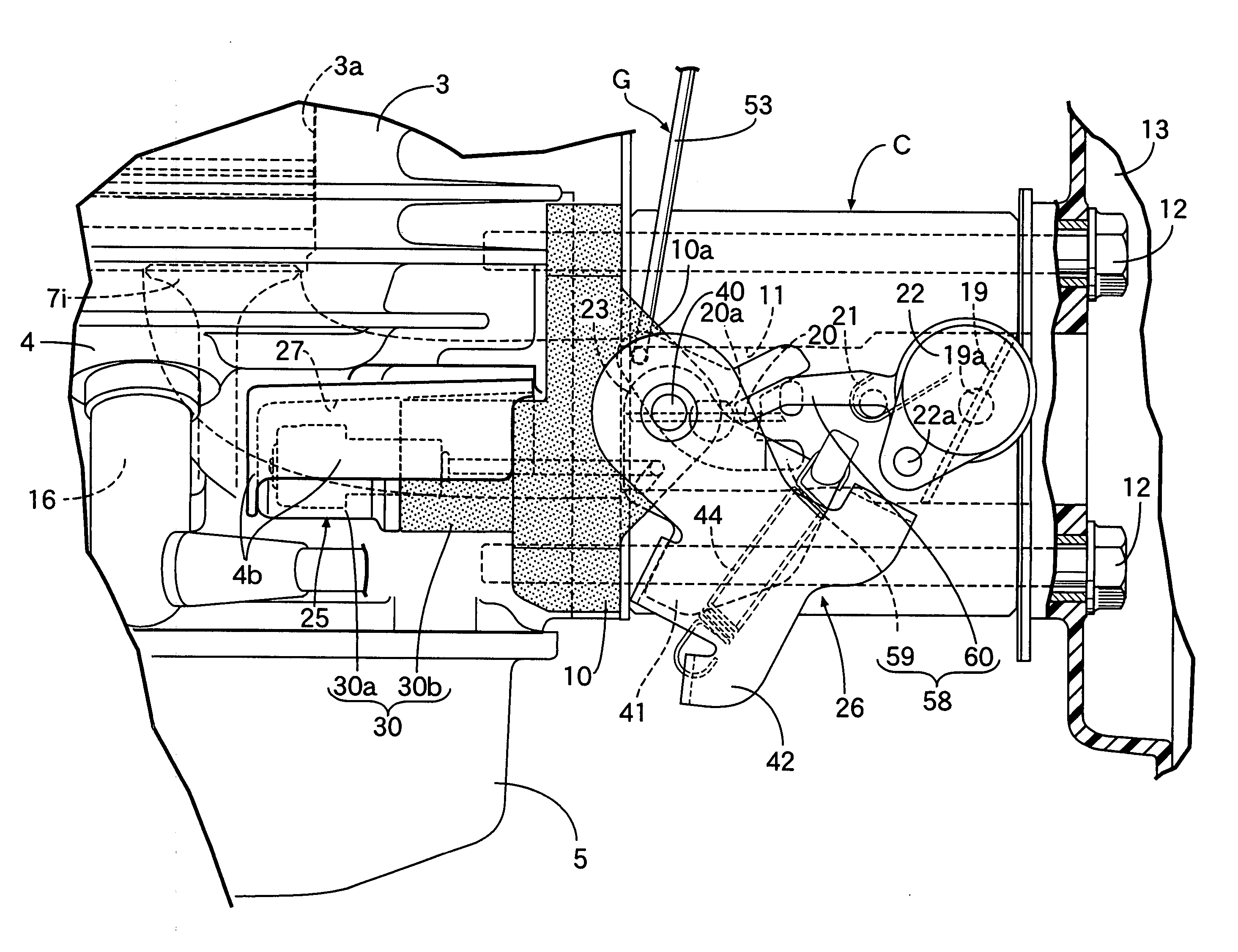

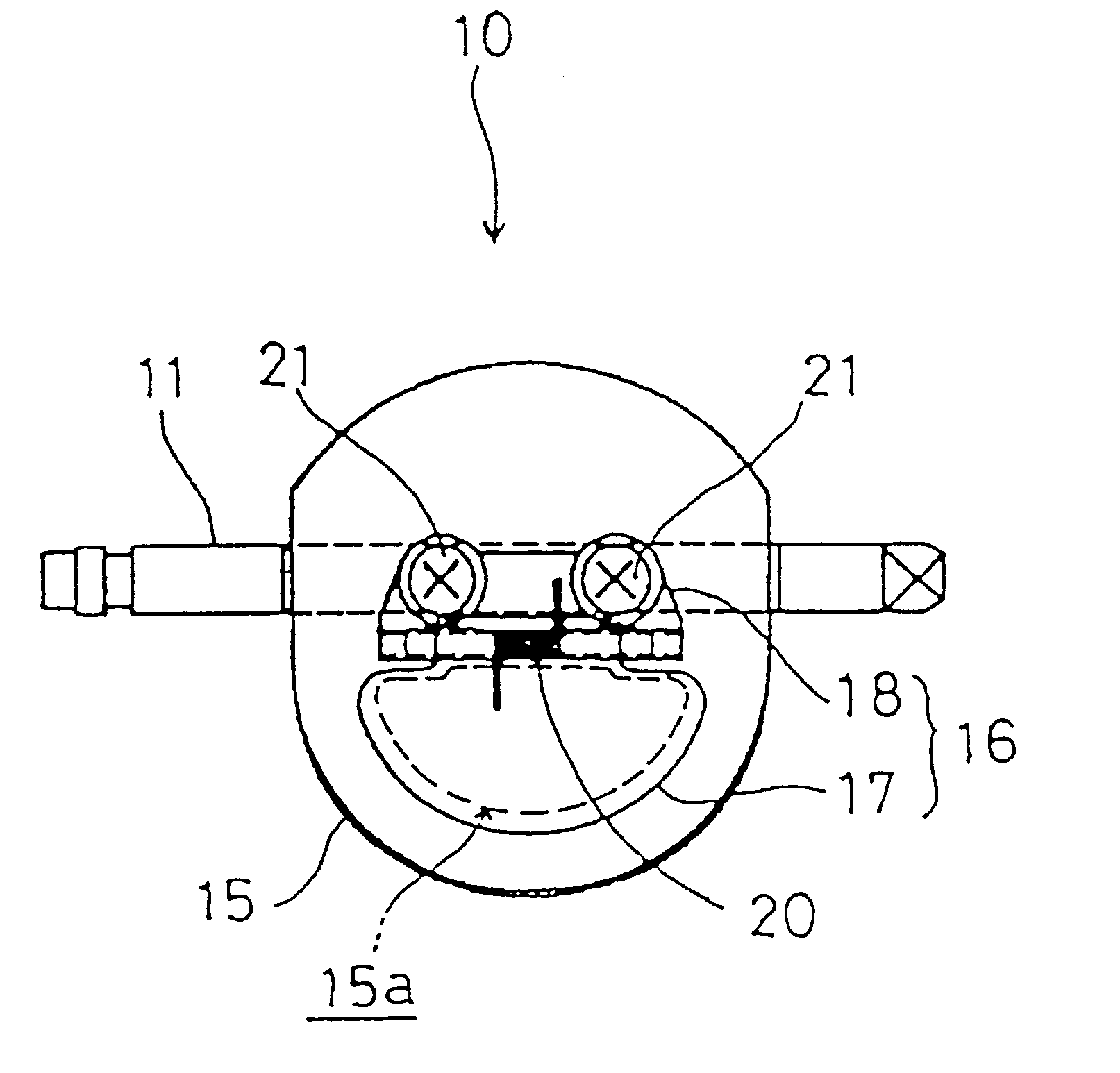

Automatic residual fuel vent device for carburetor

InactiveUS7775194B2Low costReduce component countFloat-controlled apparatusFuel injection apparatusDiaphragm pumpSurge tank

An automatic residual fuel vent device for a carburetor, the device including a fuel supply passage (15) connecting a fuel tank (TF) and a float chamber (10), a negative pressure passage (17) connecting an intake passage (8) and a negative pressure operating chamber (53) of a diaphragm pump (PD), a fuel vent passage (16) connecting the float chamber (10) and the fuel tank (TF), a single changeover cock (CO) provided so as to straddle the fuel supply passage (15) and the negative pressure passage (17), a negative pressure surge tank (TS) provided in the negative pressure passage (17), and the diaphragm pump (PD), which is connected to the fuel vent passage (16) and is operated by negative pressure of the negative pressure surge tank (TS), residual fuel of the float chamber (10) being returned to the fuel tank (TF) by the diaphragm pump (PD) operated by negative pressure from the negative pressure surge tank (TS) in accordance with the changing over of the changeover cock (CO). This enables residual fuel within the float chamber of the carburetor to be reliably returned to the fuel tank by intake negative pressure accumulated in the negative pressure surge tank and, furthermore, residual fuel can be vented by the changing over of a single changeover cock, thus enabling the number of components to be reduced and the device to be provided at a low cost.

Owner:HONDA MOTOR CO LTD

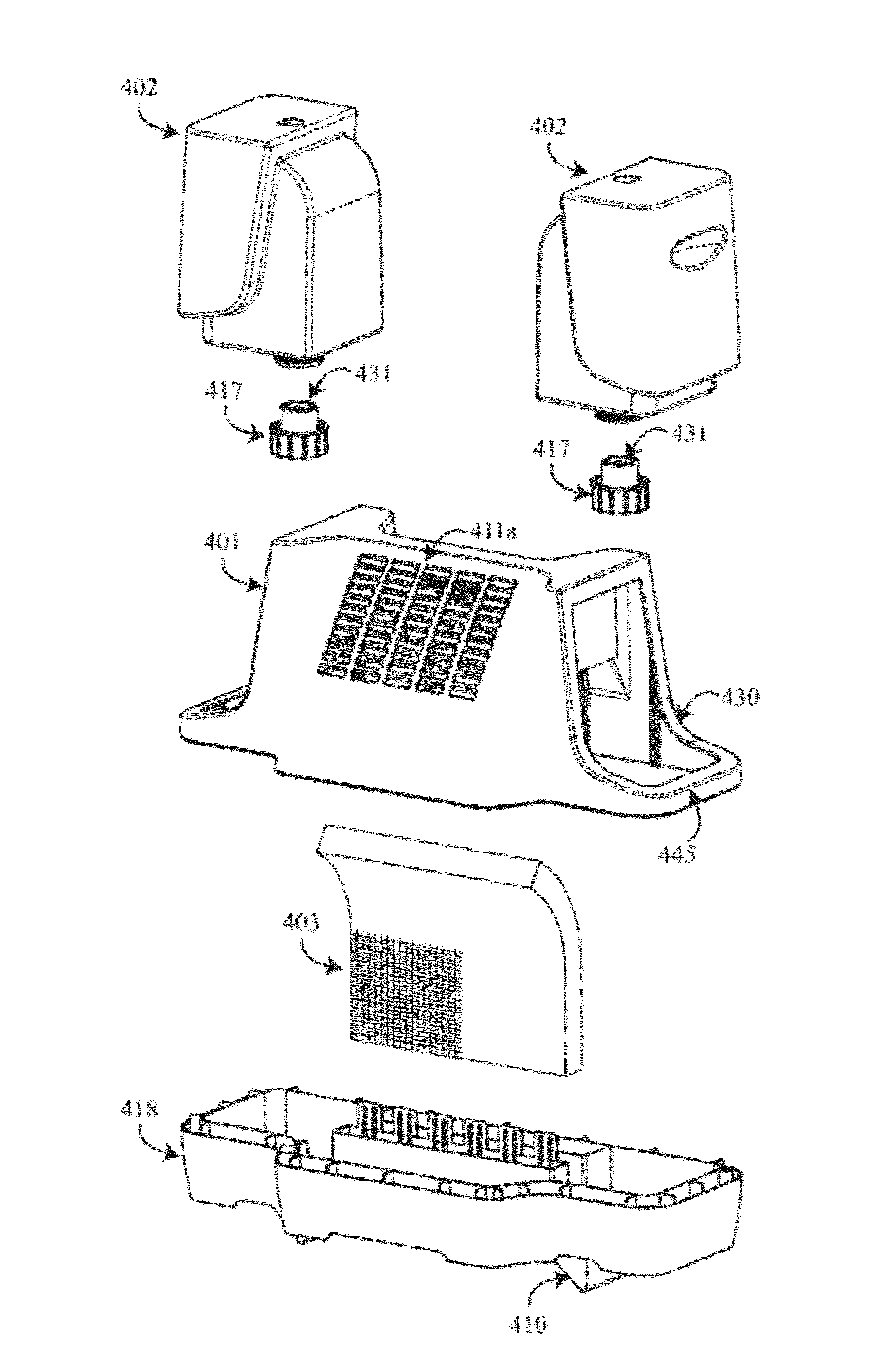

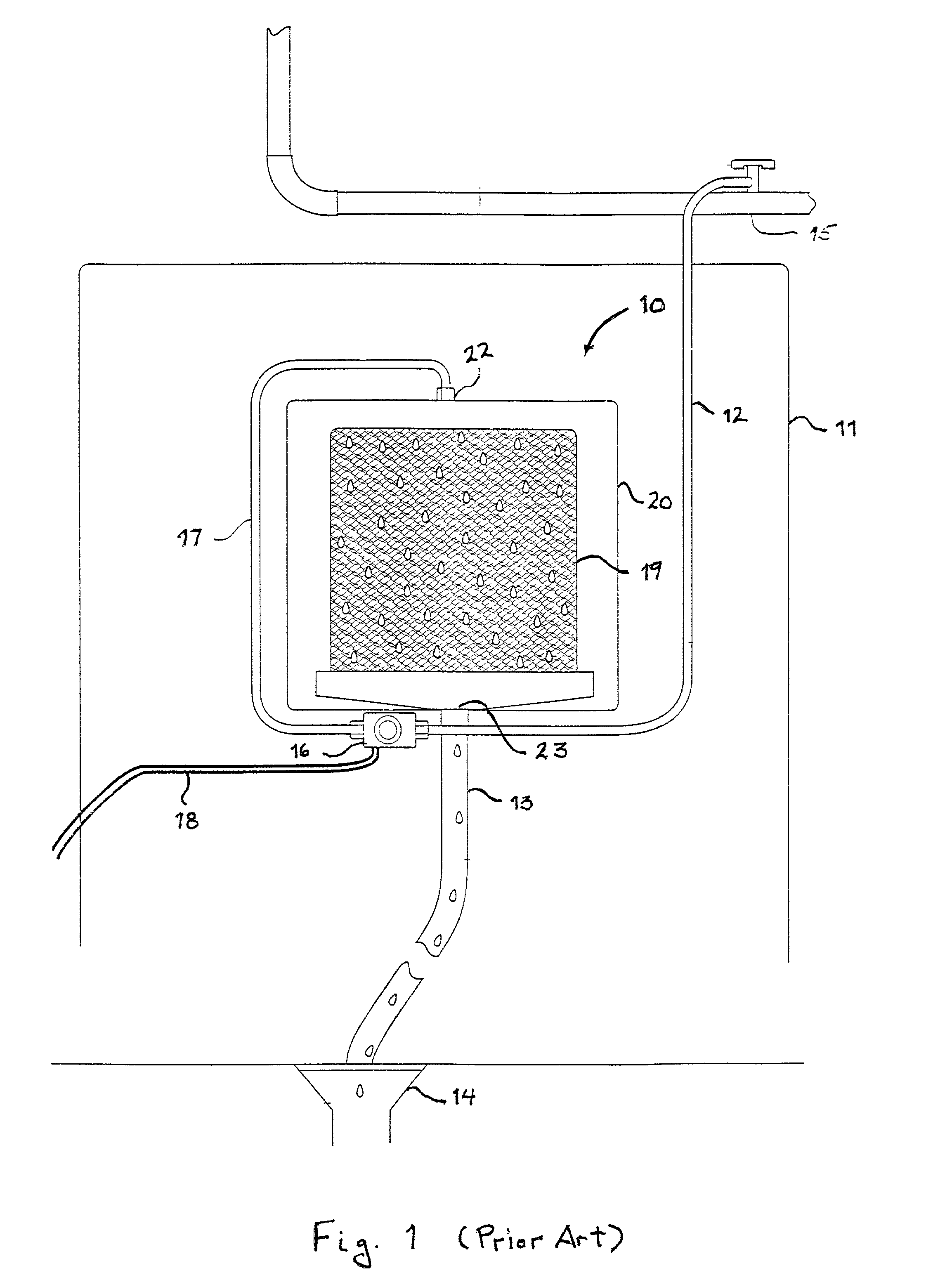

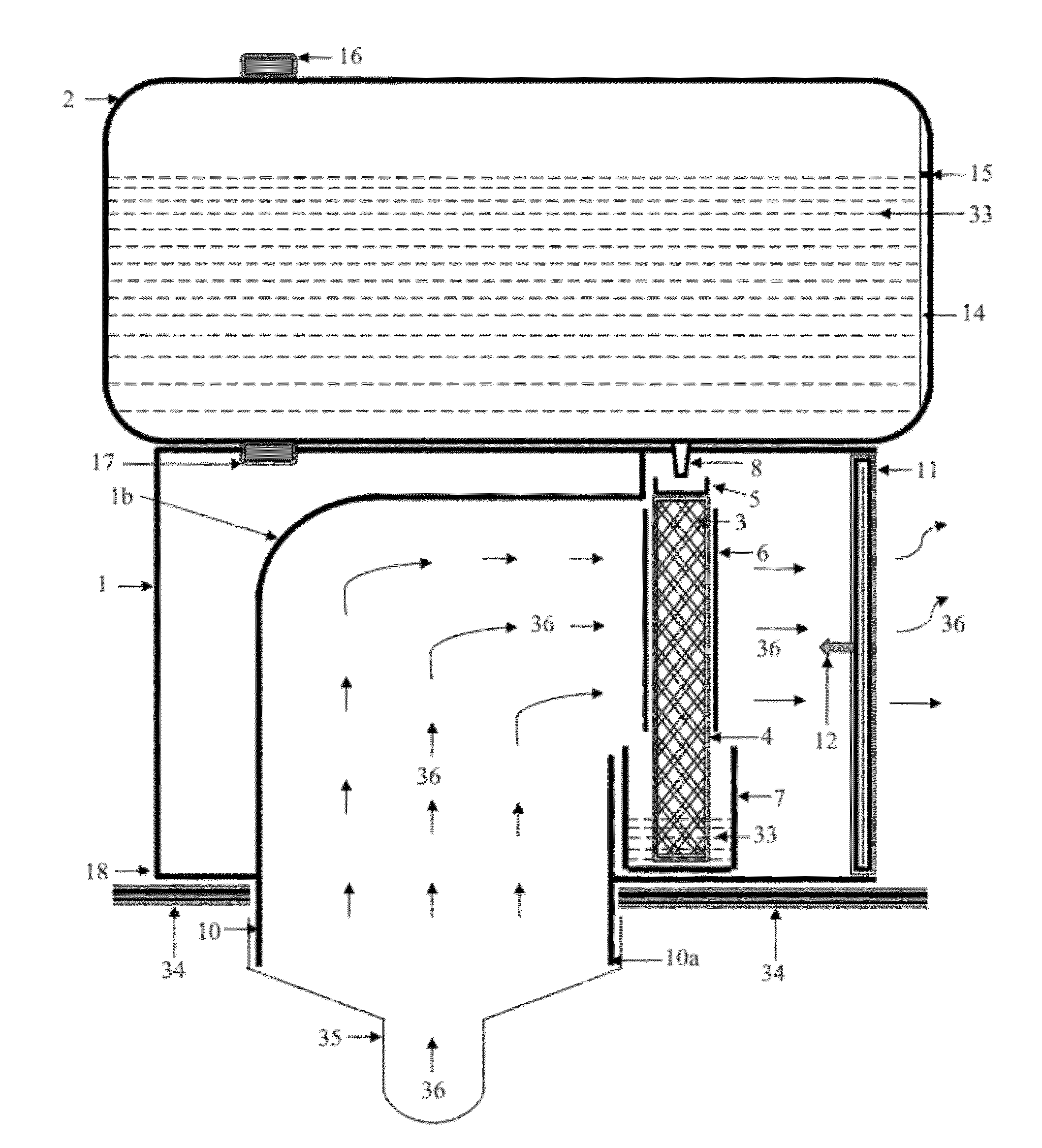

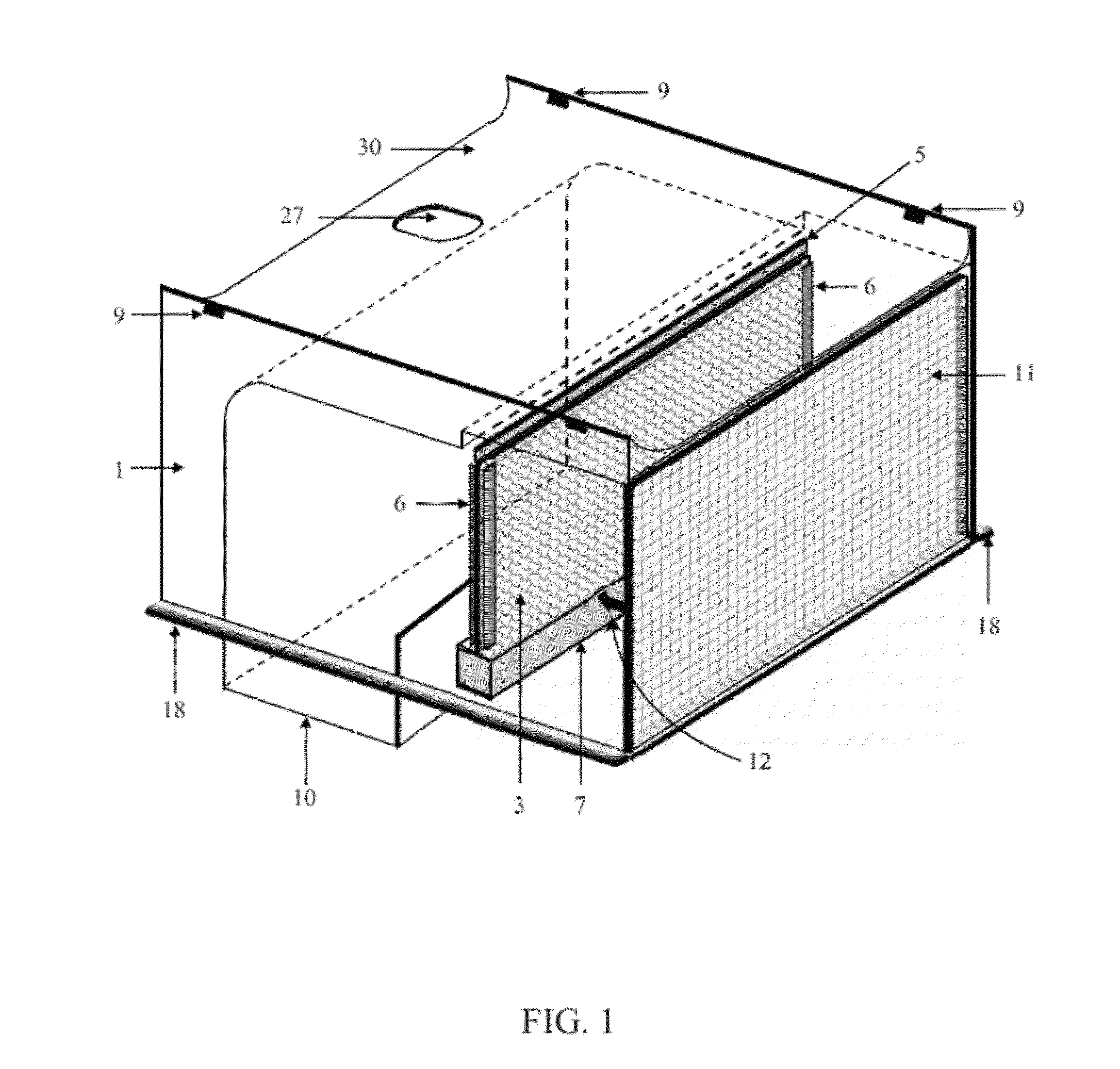

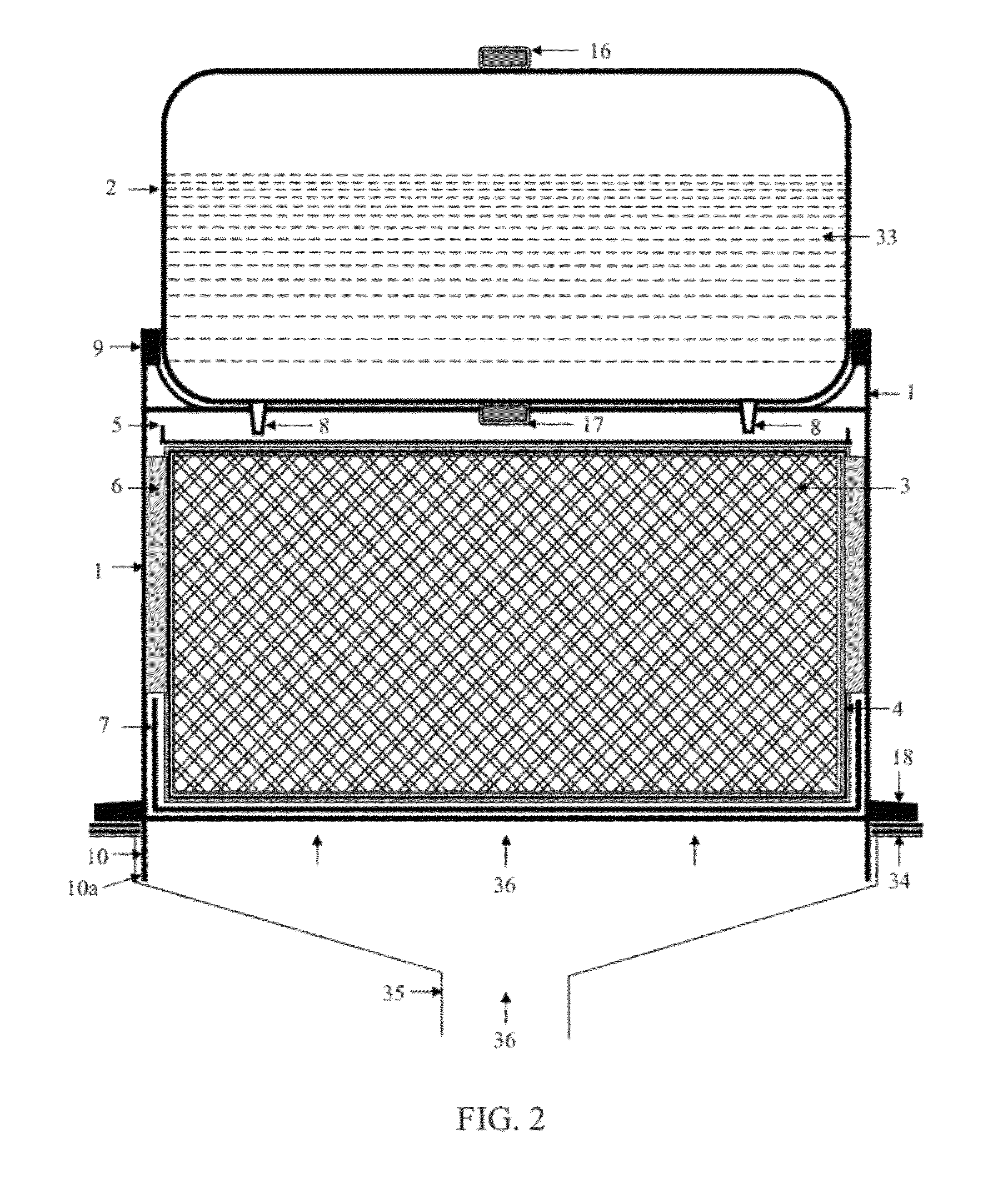

Room vent humidifier

InactiveUS20120267804A1Avoid external damageReduce evaporation rateLighting and heating apparatusMixing methodsFilter elementWaste management

A room humidifying apparatus is provided which operates with minimum cost and without any electrical power. The humidifier is located so as to make use of a stream of air coming from a register. The humidifier has a casing carrying a main water tank, a water pan and an evaporative filter element which are located in the casing. The tank drips water onto the filter element, which has a lower portion located in the water pan to collect any excess water dripping down the filter element and also to moisten it with capillary effect. Heated air from the register becomes humidified on passing through the filter element. The water tank can be filled manually from the top or be detachable and filled through a bottom refill opening. Alternatively, the water tank can be connected to a water source with a valve to regulate the flow of water into the water tank. The water tank may be balanced so as to displace, for example tilt, from a first position when it contains water to a second position when it is empty.

Owner:RODRIGS JERI

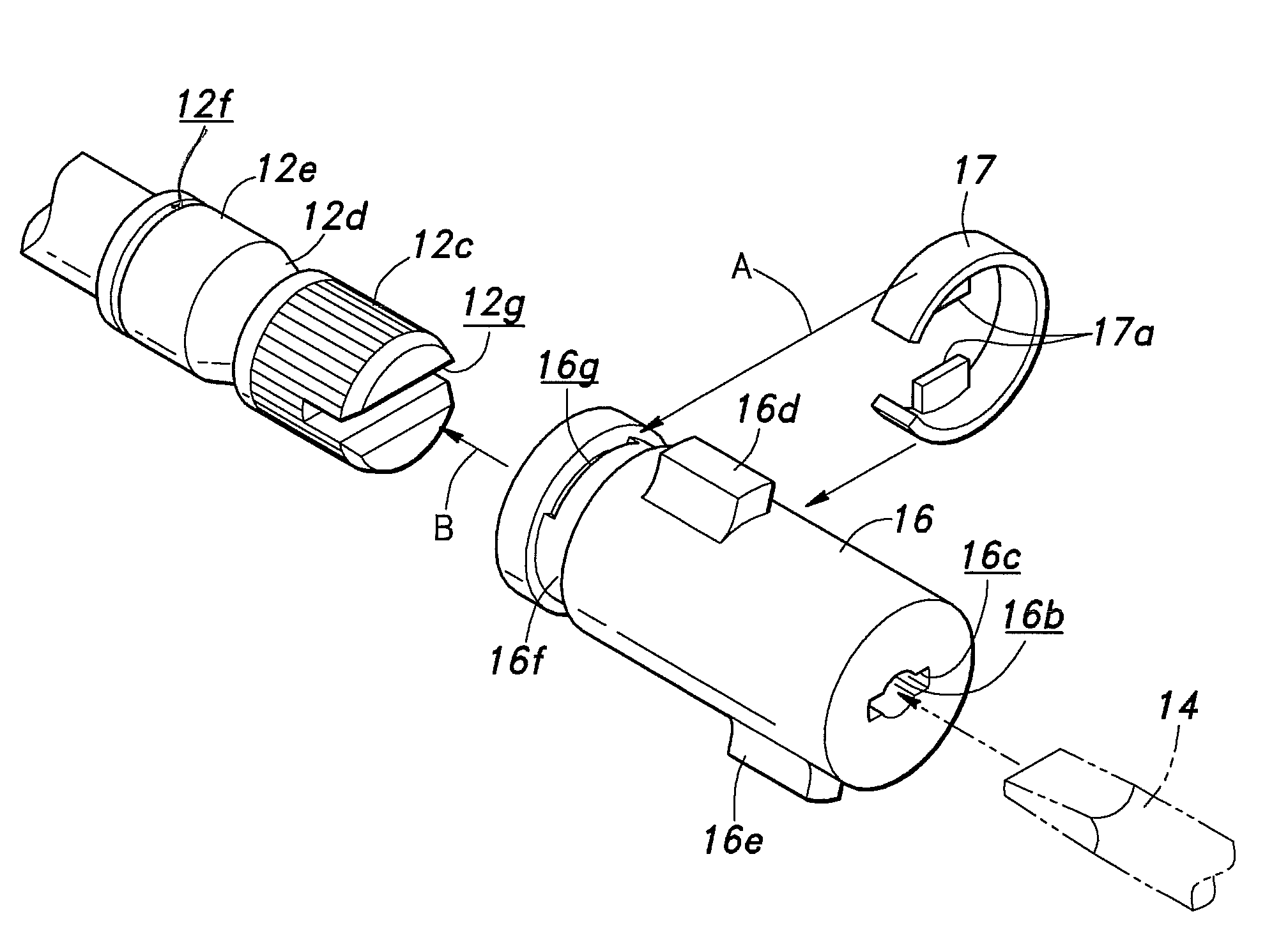

Automatic choke system for carburetor

ActiveUS20060022359A1Easy to controlEffectively suppress an excessively large concentration of fuelElectrical controlLighting and heating apparatusCarburetorEngineering

An automatic choke system includes: a wax-type temperature sensing section; and an output section which opens a choke valve of a carburetor in response to heat receiving operation of the temperature sensing section. Temperature sensing section includes: a bottomed cylindrical housing attached to an engine with its bottom portion directed to a high-temperature portion of the engine; a bottomed movable cylinder; a stationary piston slidably supported by the movable cylinder and having one end protruding out of the movable cylinder; and a wax contained in the movable cylinder in a sealed manner, and causing the movable cylinder and the stationary piston to move relative to each other in an axial direction. The movable cylinder is slidably housed in the housing in a state in which an outer end of the stationary piston abuts against an inner surface of the bottom portion of the housing. The output section is connected to the movable cylinder. Thus, the rate of opening of the choke valve can be increased immediately after the start of engine warming-up operation, and reduced as approaching the completion of engine warming-up operation.

Owner:HONDA MOTOR CO LTD

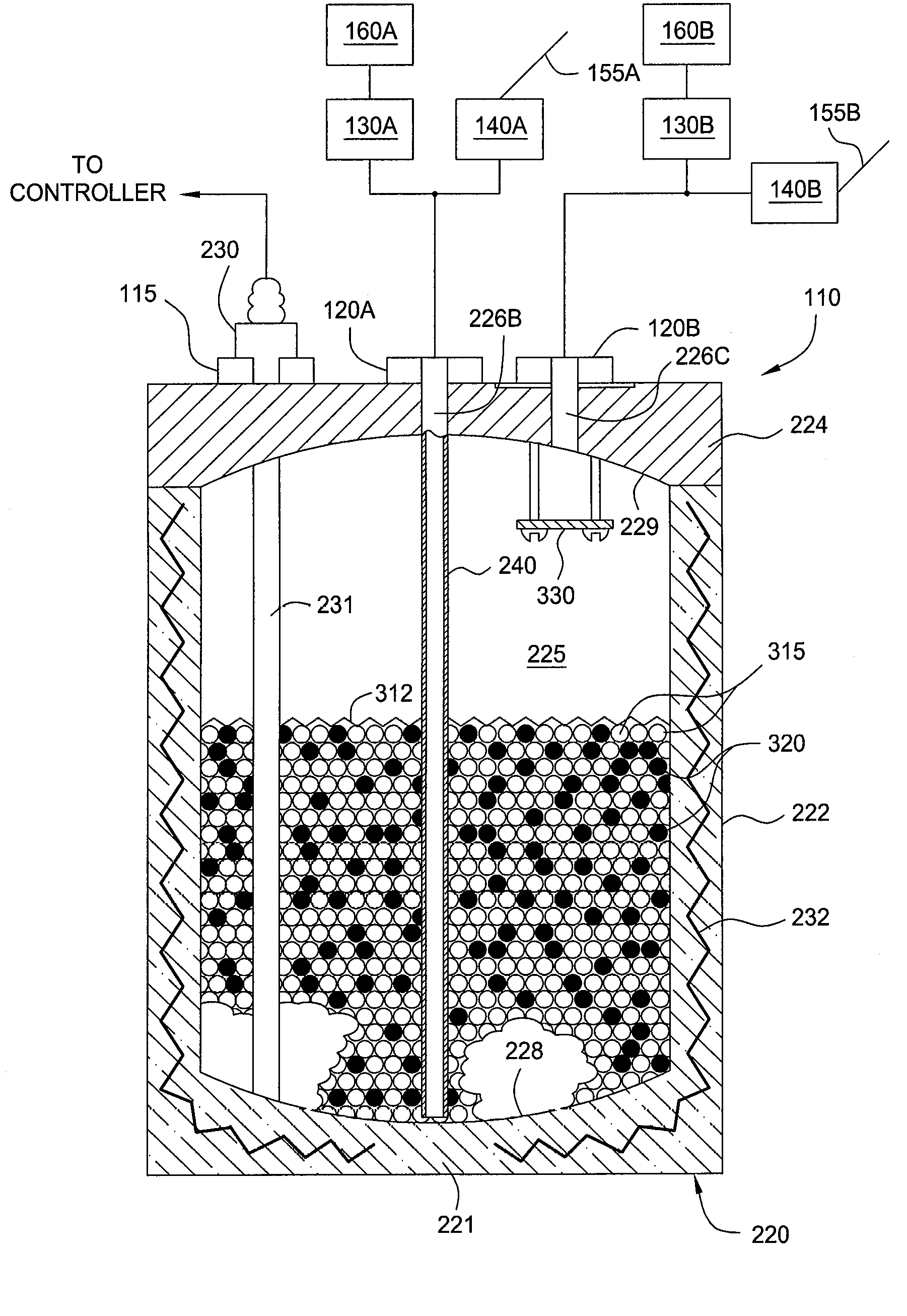

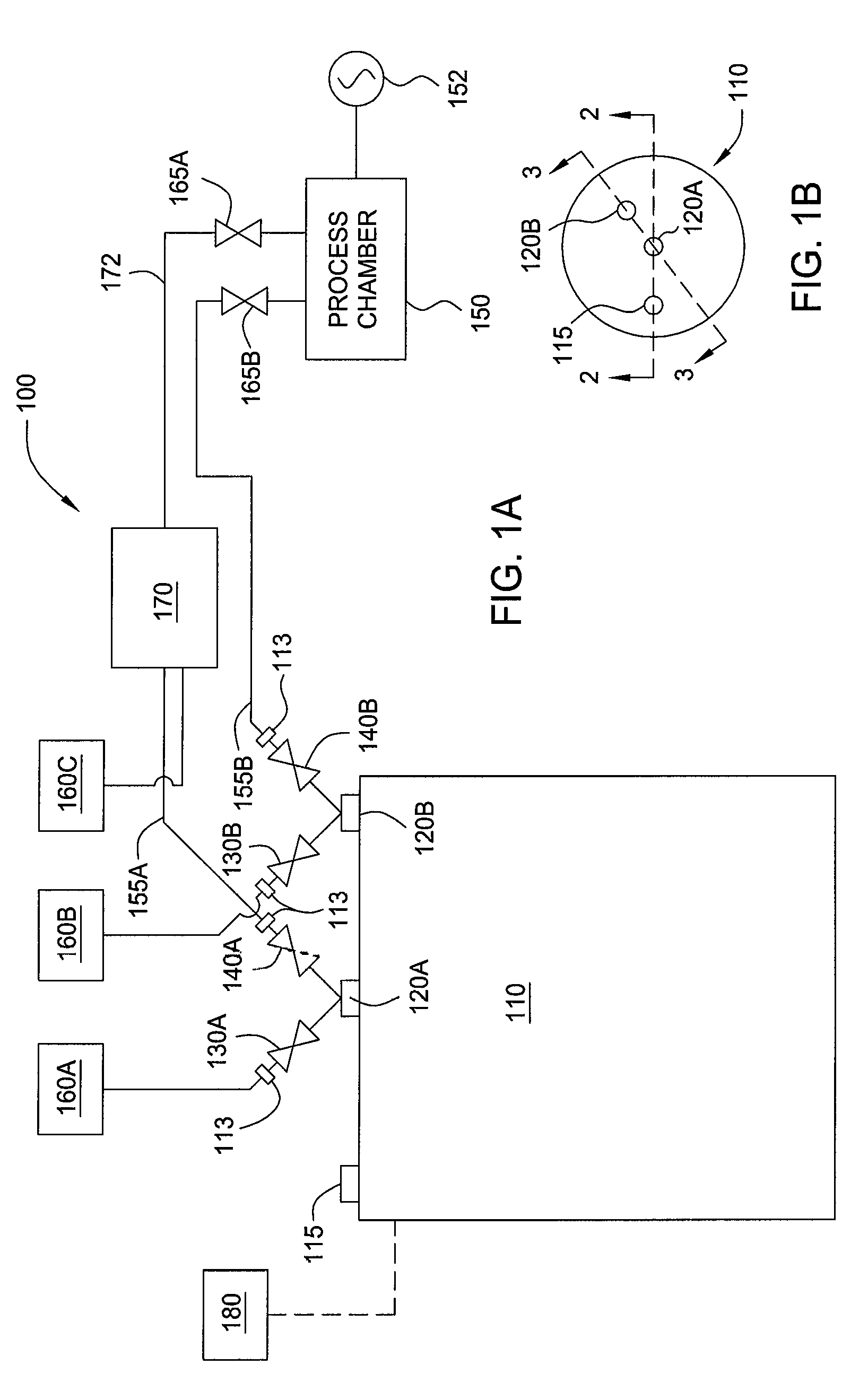

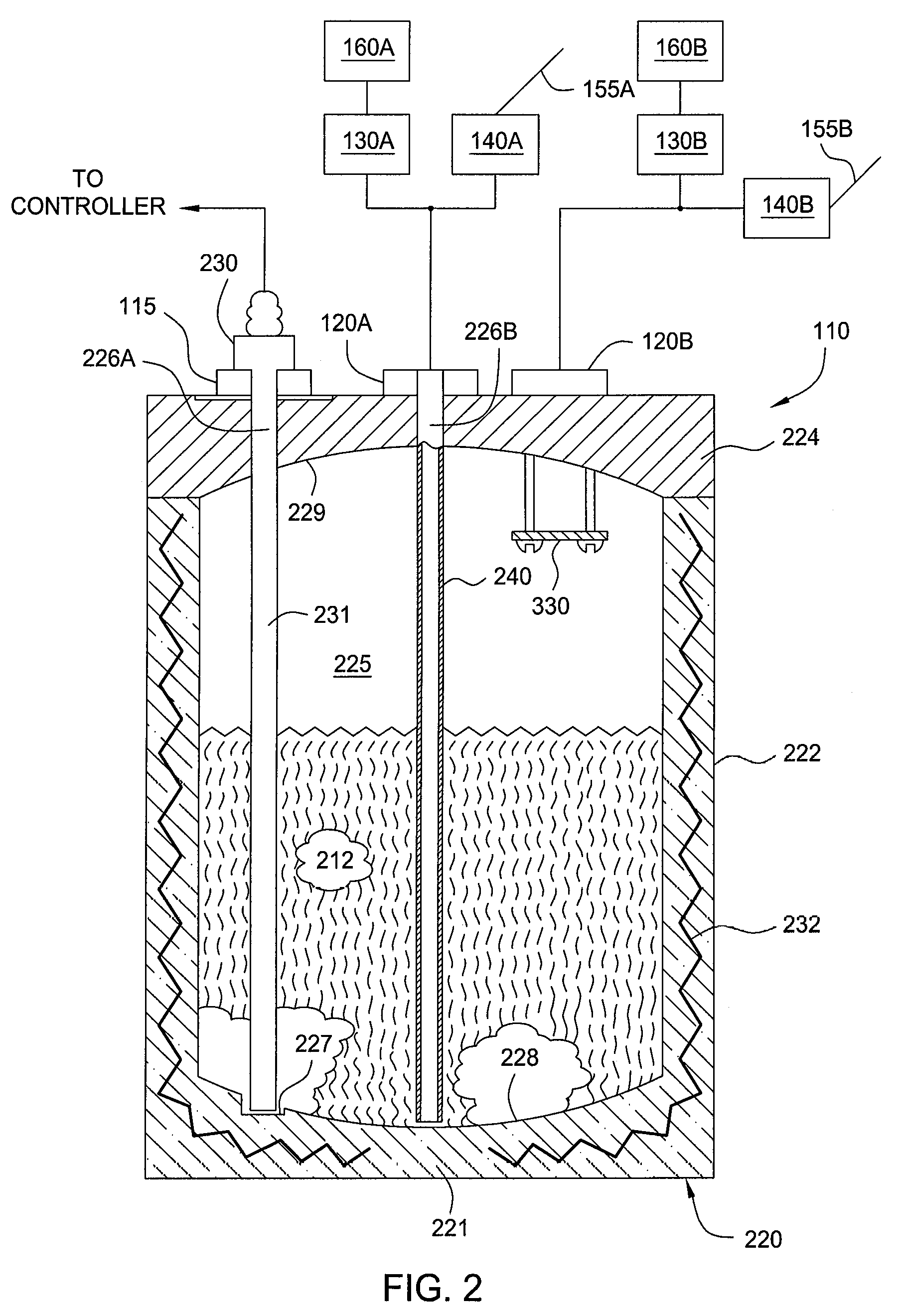

Ampoule for liquid draw and vapor draw with a continuous level sensor

A method and apparatus for providing a precursor to a process chamber is described. The apparatus comprises an ampoule capable of receiving either a liquid precursor source material or a solid precursor source material. The ampoule is capable of delivering either a liquid precursor material to a vaporizer coupled to the process chamber, or a vaporized or gaseous precursor material to the process chamber. The ampoule also includes a continuous level sensor to accurately monitor the level of precursor source material within the ampoule.

Owner:APPLIED MATERIALS INC

Priming system for a float bowl carburetor

InactiveUS7152852B1Facilitate delivery of fuelReduce stepsLighting and heating apparatusUsing liquid separation agentCarburetorFuel supply

A float bowl type carburetor has a fuel and air mixing passage extending therethrough, a float bowl assembly, a priming pump communicated with the float bowl assembly and a fuel supply pipe that is communicates fuel in the float bowl assembly with the fuel and air mixing passage. The priming pump is operable to deliver pressurized fluid into the float bowl assembly in the area of the fuel supply pipe. Preferably, the priming pump discharges fluid in line with the fuel supply pipe so that at least some of the fluid discharged from the priming pump flows directly into the fuel supply pipe to facilitate delivering a rich fuel and air mixture to the engine to facilitate starting the engine.

Owner:NIPPON WALBRO KK

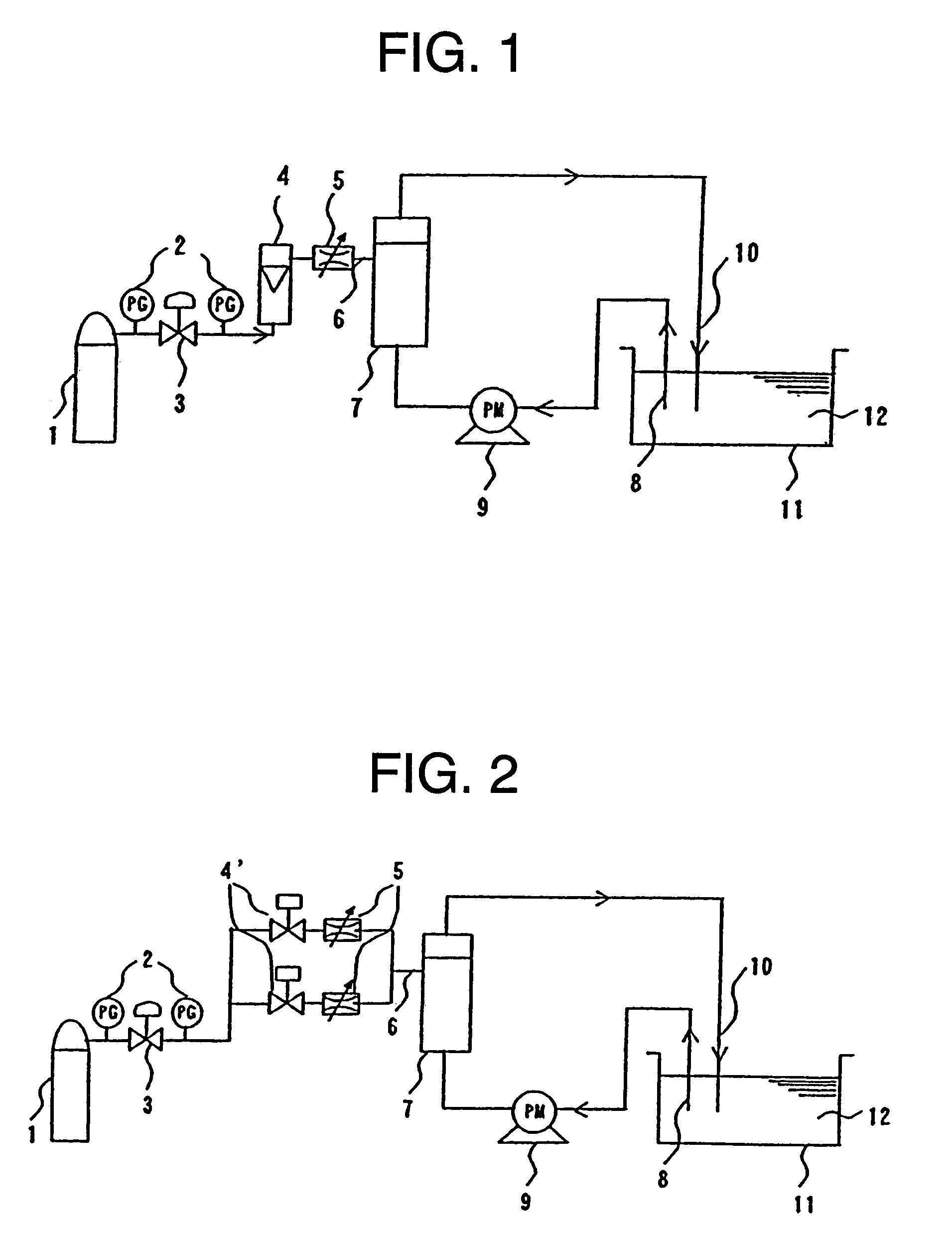

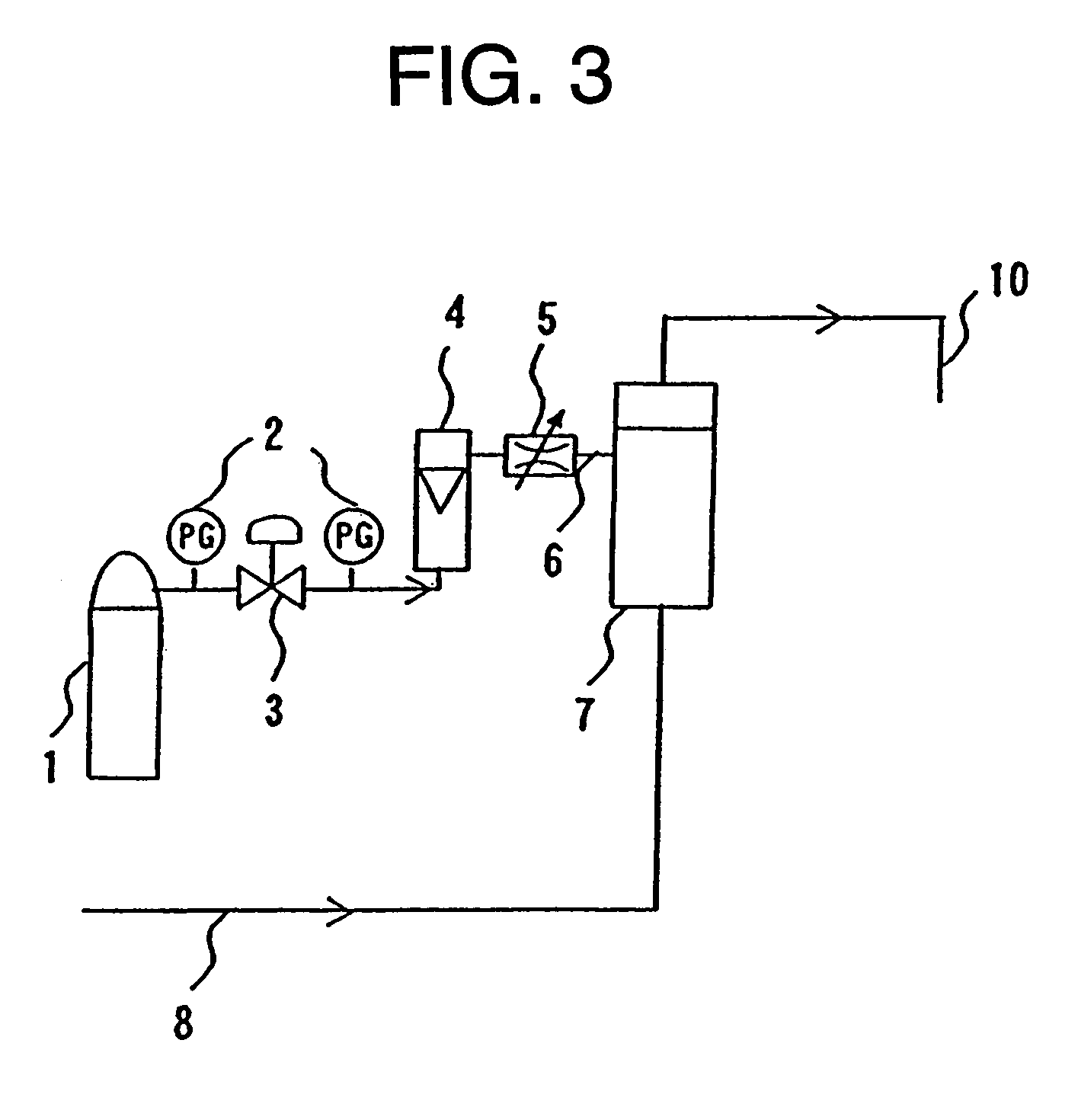

Device and method for manufacturing carbonated spring and carbonic water, control method for gas density applied thereto, and membrane module

InactiveUS7152850B2Easy to adjustEasy to manufactureFlow mixersLighting and heating apparatusHigh concentrationGas cylinder

Owner:MITSUBISHI RAYON CO LTD

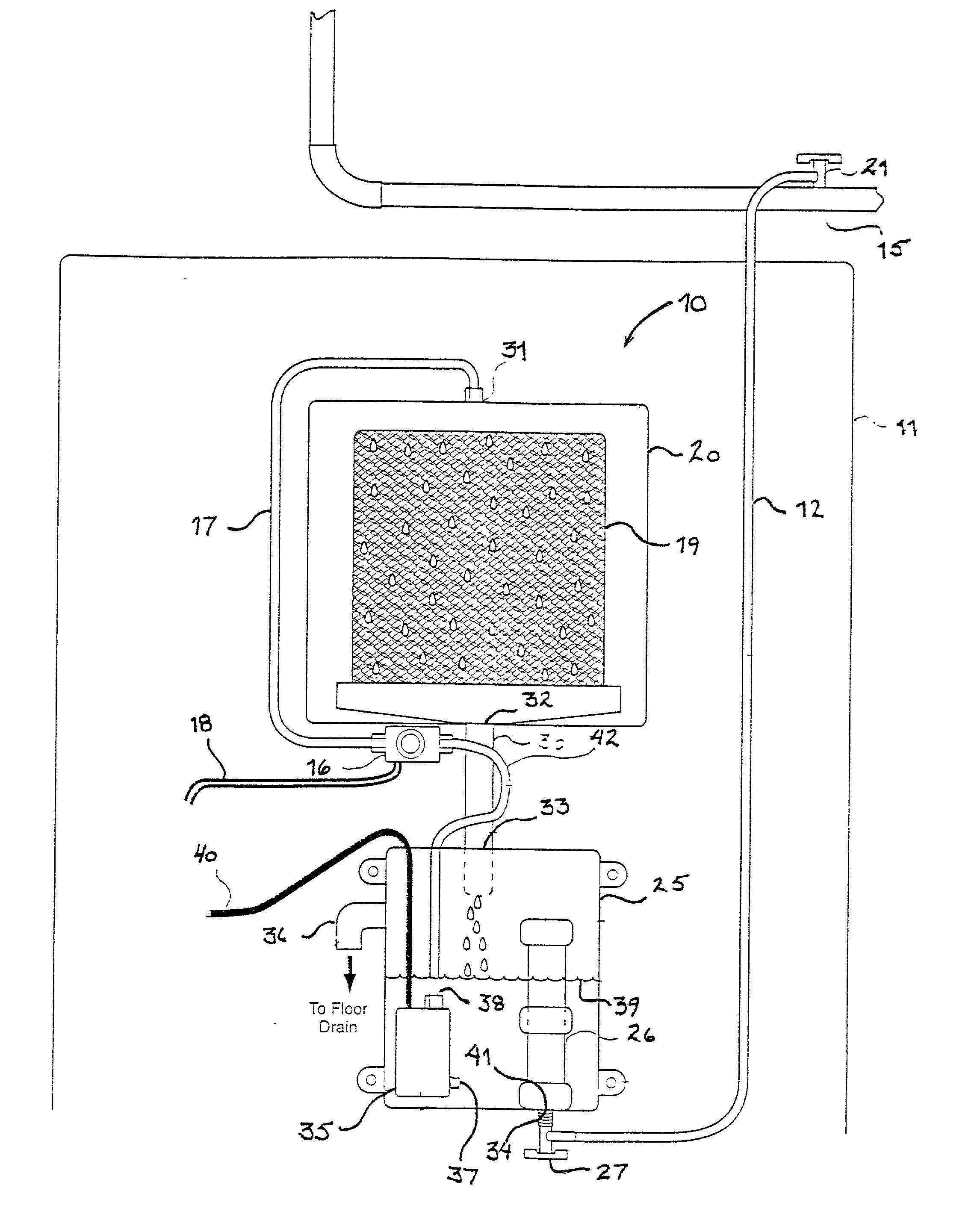

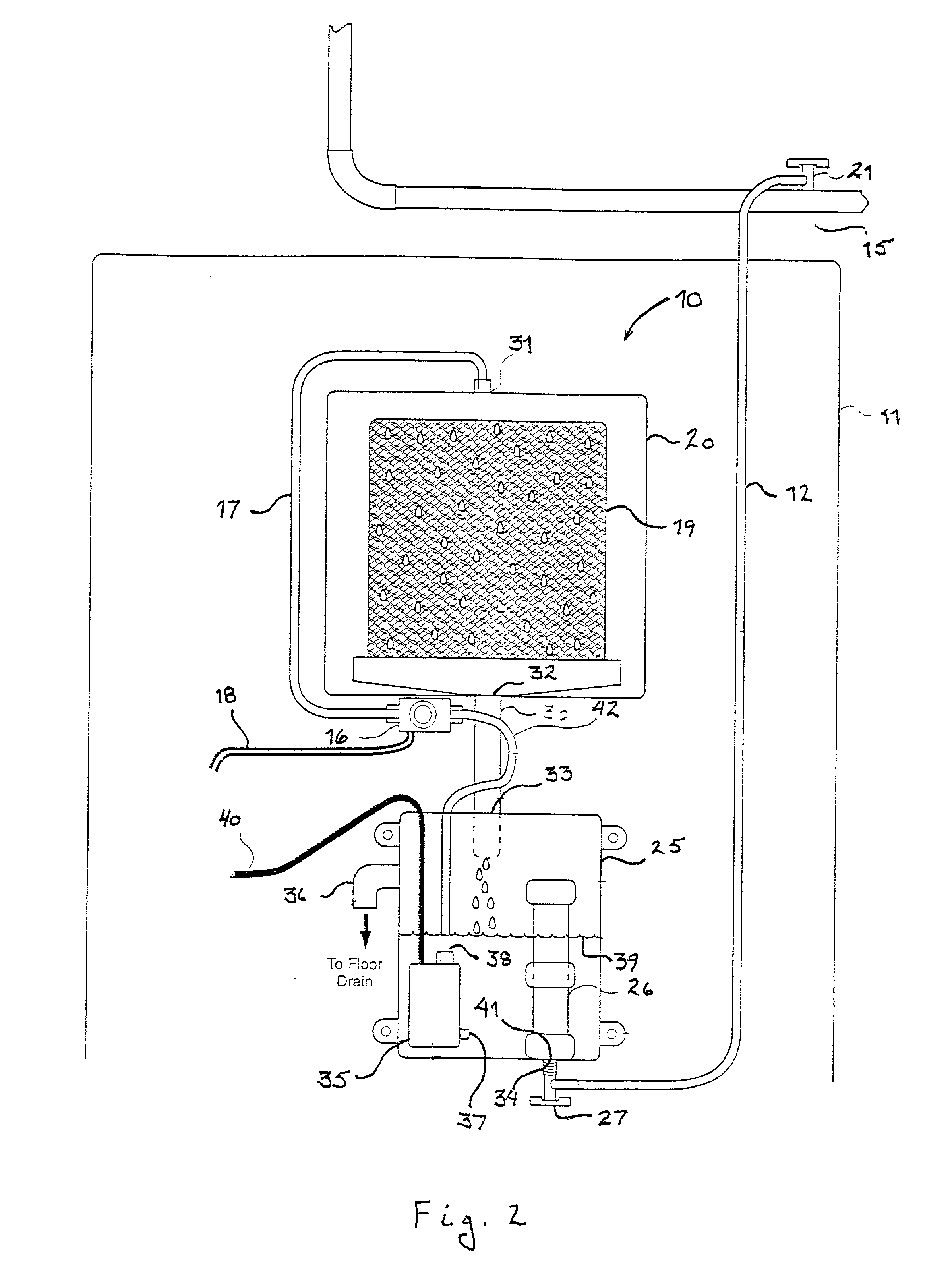

Water conservation system for humidifiers

A humidification system having a humidifier housing having a supply water inlet and an excess water outlet, which excess water outlet is in fluid communication with a water reservoir vessel. A pump is provided by way of which water in the water reservoir vessel is circulated to the supply water inlet of the humidifier housing.

Owner:TRIODYNE WANGLER CONSTR SPECIALTIES

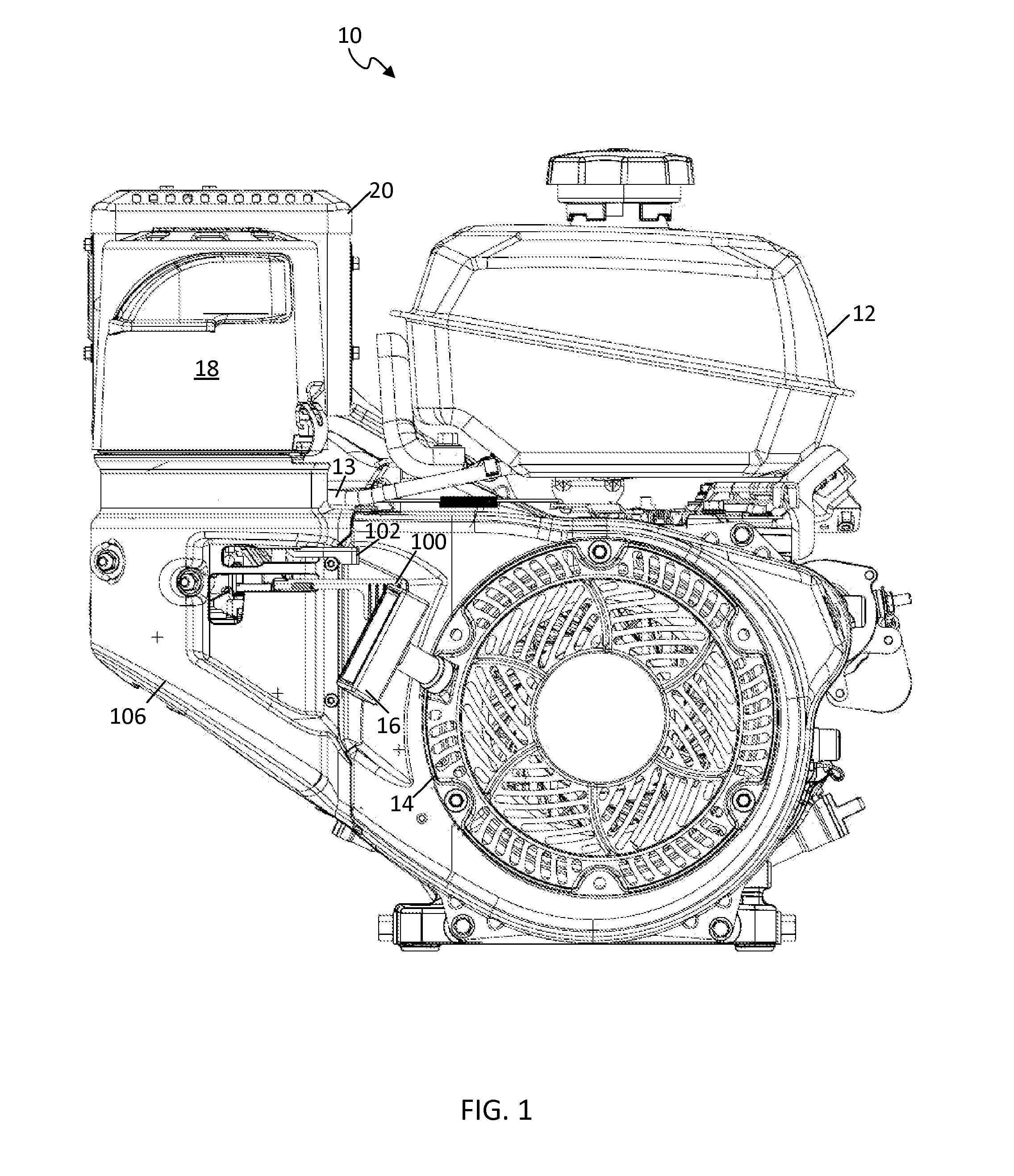

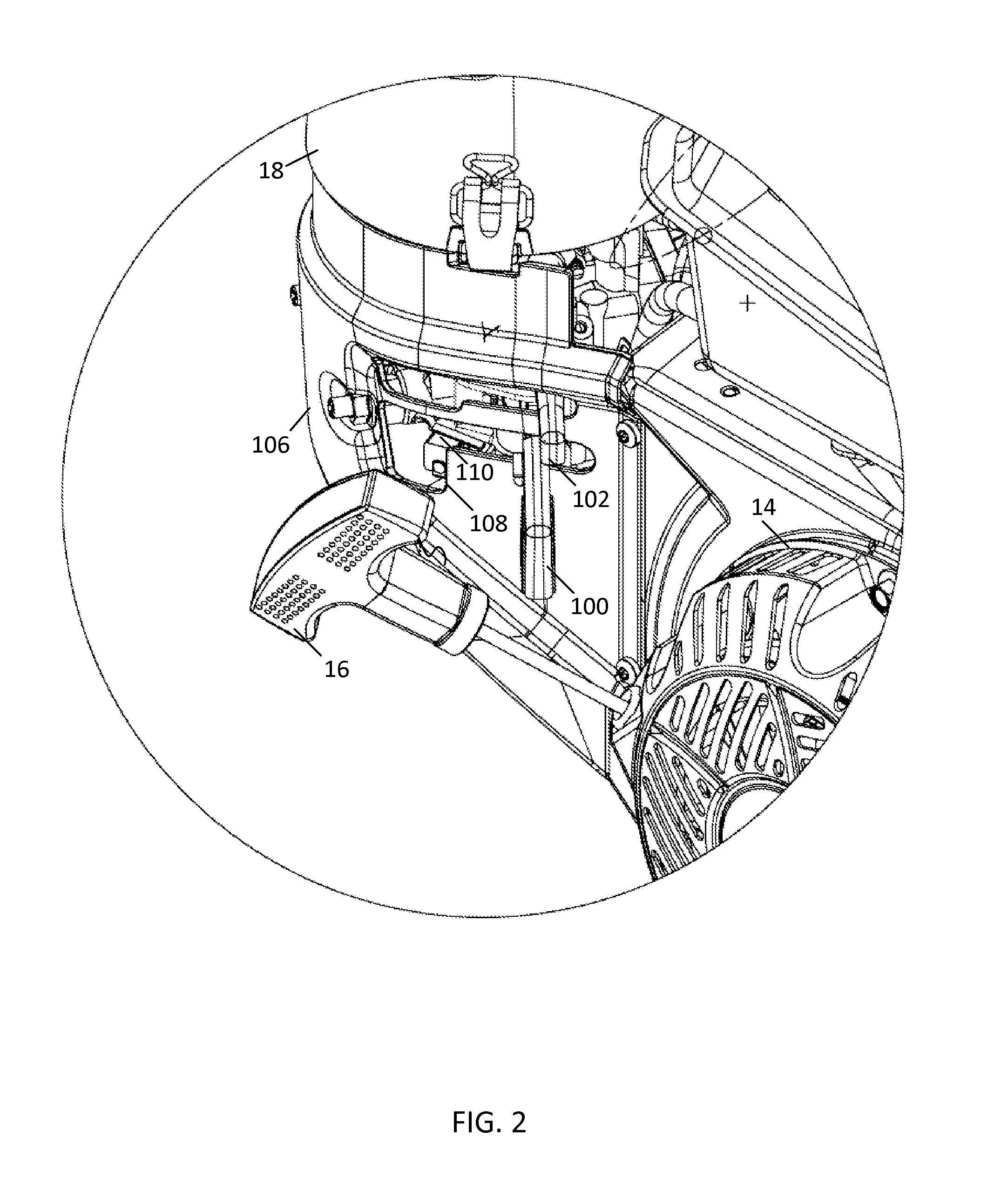

Automatic Fuel Shutoff

A combination lever for a carburetor is an integrated shutoff lever and fuel valve. The combination lever includes a longitudinal portion for a handle and a cylindrical portion including a fuel path for the fuel valve. A carburetor casing is shaped to form a valve chamber and a carburetor chamber. The valve chamber supports the cylindrical portion. A directional cavity formed in the cylindrical portion of the combination lever regulates a flow of fuel to the carburetor chamber according to a rotation of the combination lever. At one position the directional cavity opens the fuel path so that fuel flows into the carburetor chamber. At another position the directional cavity closes the fuel path so that the flow of fuel is blocked. The combination lever may also include an abutment portion to engage a switch for completing an electrical shutoff path to an engine coupled to the carburetor.

Owner:KOHLER CO

Device for humidifying breathing air for artificial respiration

A device for humidifying breathing air for artificial respiration of mammals, in particular human beings, includes at least one essentially closed container for receiving water, a first opening for letting in the non-humidified air and a second opening for letting out humidified air, and an inlet for supplying the water to the container. The inlet is located in the upper part of the container, which is adjoined by a tube essentially crossing through the container interior, and on the free end of the tube, a valve is disposed, which limits the level of the water supplied via the tube in such a way that the container bottom in the container interior is essentially covered with water.

Owner:ARTA PLAST

Room vent humidifier

InactiveUS8905384B2Avoid external damageReduce evaporation rateLighting and heating apparatusUsing liquid separation agentWater sourceStreamflow

A room humidifying apparatus is provided which operates with minimum cost and without any electrical power. The humidifier is located so as to make use of a stream of air coming from a register. The humidifier has a casing carrying a main water tank, a water pan and an evaporative filter element which are located in the casing. The tank drips water onto the filter element, which has a lower portion located in the water pan to collect any excess water dripping down the filter element and also to moisten it with capillary effect. Heated air from the register becomes humidified on passing through the filter element. The water tank can be filled manually from the top or be detachable and filled through a bottom refill opening. Alternatively, the water tank can be connected to a water source with a valve to regulate the flow of water into the water tank. The water tank may be balanced so as to displace, for example tilt, from a first position when it contains water to a second position when it is empty.

Owner:RODRIGS JERI

Carburetor choke valve

InactiveUS6186482B1Excellent relief functionReduce component countLighting and heating apparatusUsing liquid separation agentCarburetorRelief valve

To provide a lightweight choke valve that has a reduced number of components and is easy to assemble, despite being provided with a relief valve. A carburetor choke valve provided in an intake passageway of a carburetor includes a plate shaped choke valve body having a relief opening. A base end side of a plate shaped relief valve for opening and closing the relief opening is jointly fastened to a rotatably supported choke shaft crossing the intake passage of the carburetor.

Owner:HONDA MOTOR CO LTD

Carburetor limiter cap device

InactiveUS8286614B2Restrict movementPrevent removalLighting and heating apparatusUsing liquid separation agentCarburetorCap device

An adjustment limiting device for a carburetor including a fuel adjustment valve rotatable to adjust a supply of fuel in or delivered from the carburetor includes an adjustment limiting cap and a connector. The adjustment limiting cap is adapted to be disposed over a portion of the fuel adjustment valve and includes a rotary connection feature adapted to limit relative rotational movement between the adjustment limiting cap and the fuel adjustment valve, and a rotation limiter to limit rotational movement of the adjustment limiting cap. The connector may be carried by the adjustment limiting cap to maintain the adjustment limiting cap on the fuel adjustment valve. The connector may be concealed by the carburetor body, permit the adjustment limiting cap to be fitted onto the fuel adjustment valve, and prevent the adjustment limiting cap from being removed from the fuel adjustment limiting valve.

Owner:WALBRO ENGINE MANAGEMENT

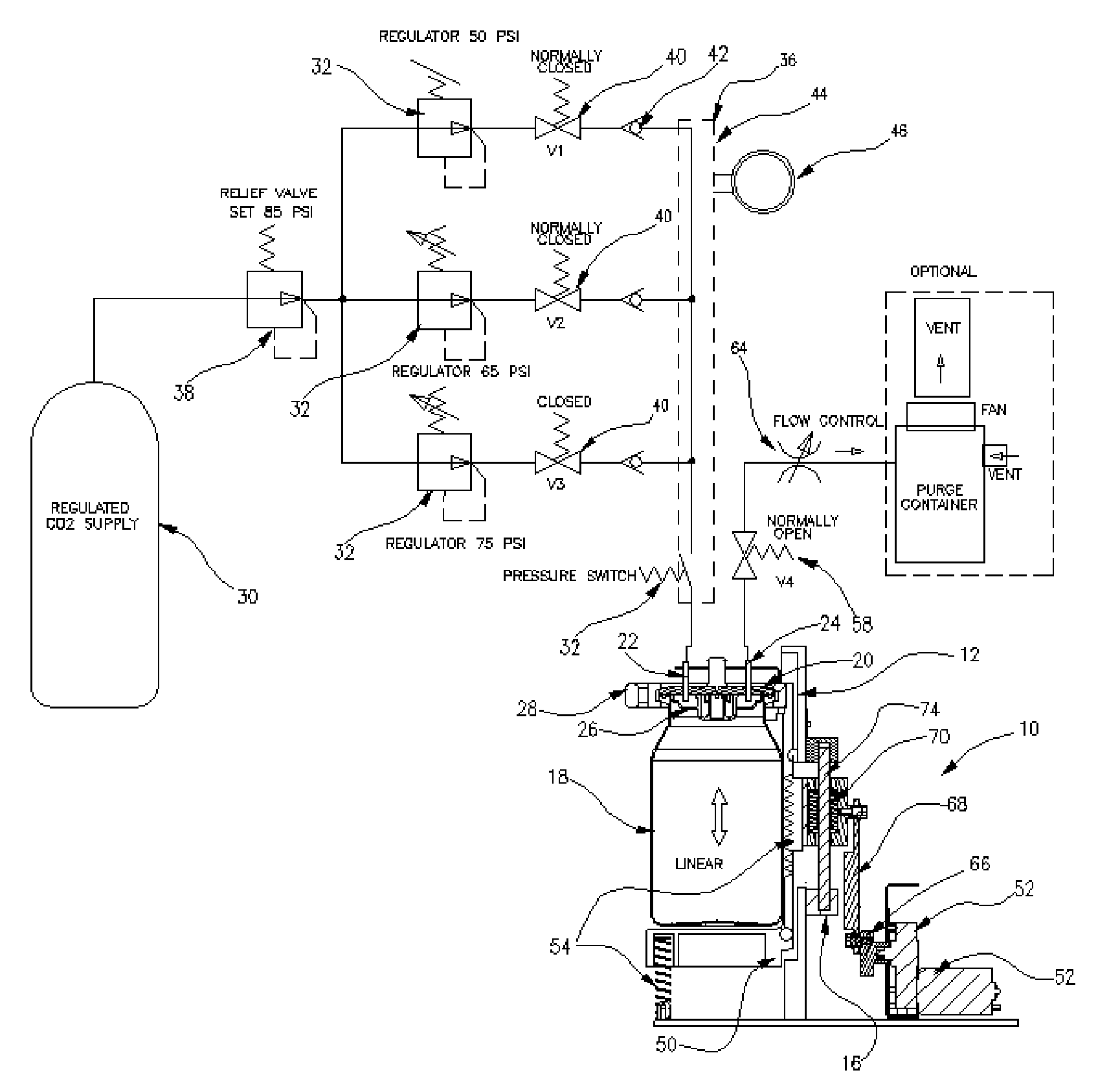

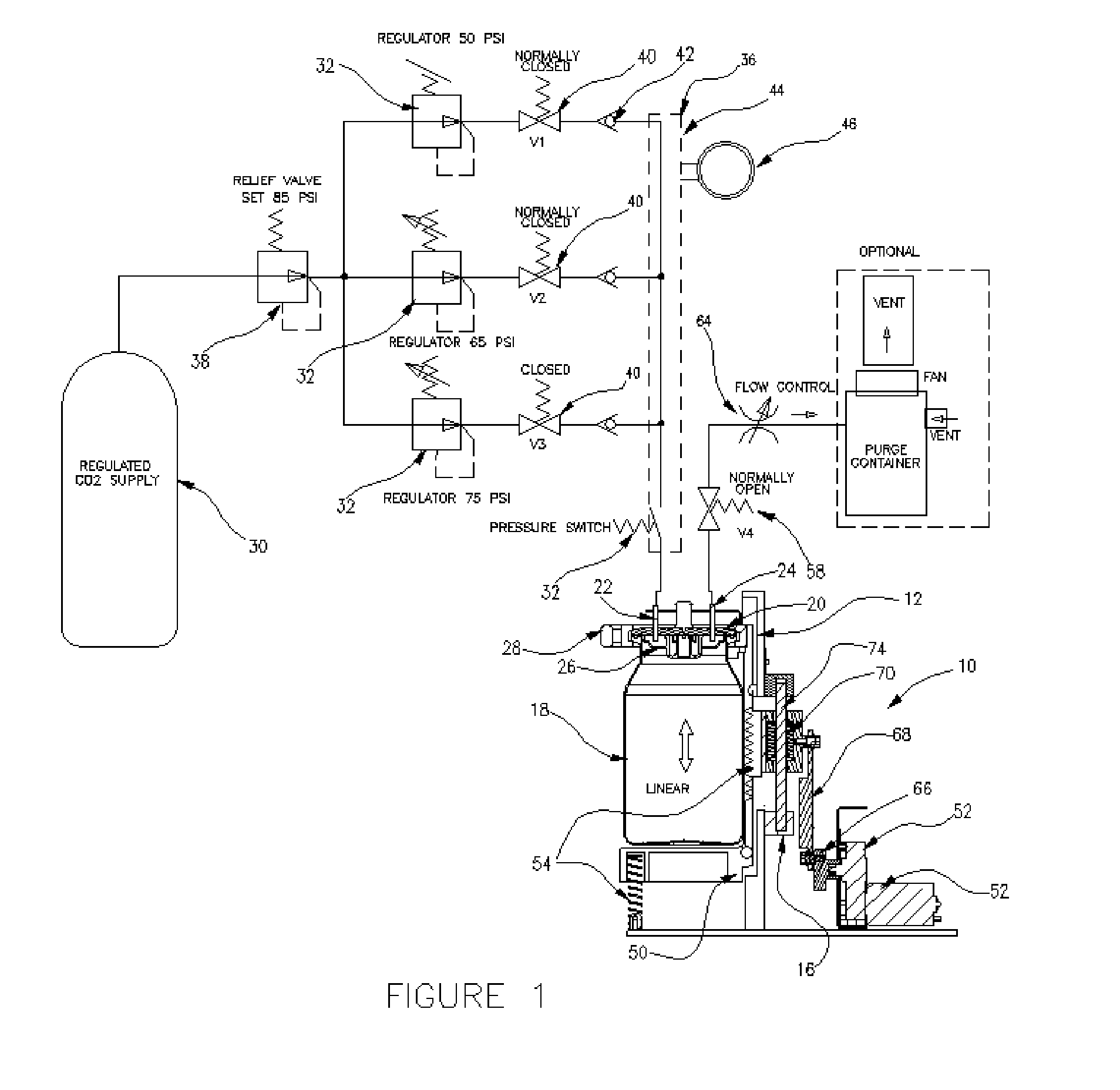

Batch carbonator and method of forming a carbonated beverage

ActiveUS20140255574A1Shaking/oscillating/vibrating mixersLighting and heating apparatusLocking mechanismEngineering

A batch carbonation apparatus includes a housing defining a vessel cavity. The housing includes an agitation mechanism. The pressure vessel includes a cap that has a CO2 inlet and a CO2 outlet is provided. The pressure vessel also includes a seal. The pressure vessel is moveable into an out of the vessel cavity. A locking mechanism is provided and is attached to the agitation mechanism to removably lock the cap and seal relative to the pressure vessel. A CO2 source is connected to a plurality of valves where each valve has a differing pressure. A selection toggle is attached to the housing. A control mechanism is coupled to the plurality of valves. A user selects a desired carbonation level using the selection toggle and CO2 is introduced to the pressure vessel at a specified pressure wherein the agitation mechanism agitates liquid within the pressure vessel forming a carbonated beverage having a selected carbonation level. Also disclosed is a process of forming a carbonated beverage in a batch.

Owner:MARMON FOODSERVICE TECH INC

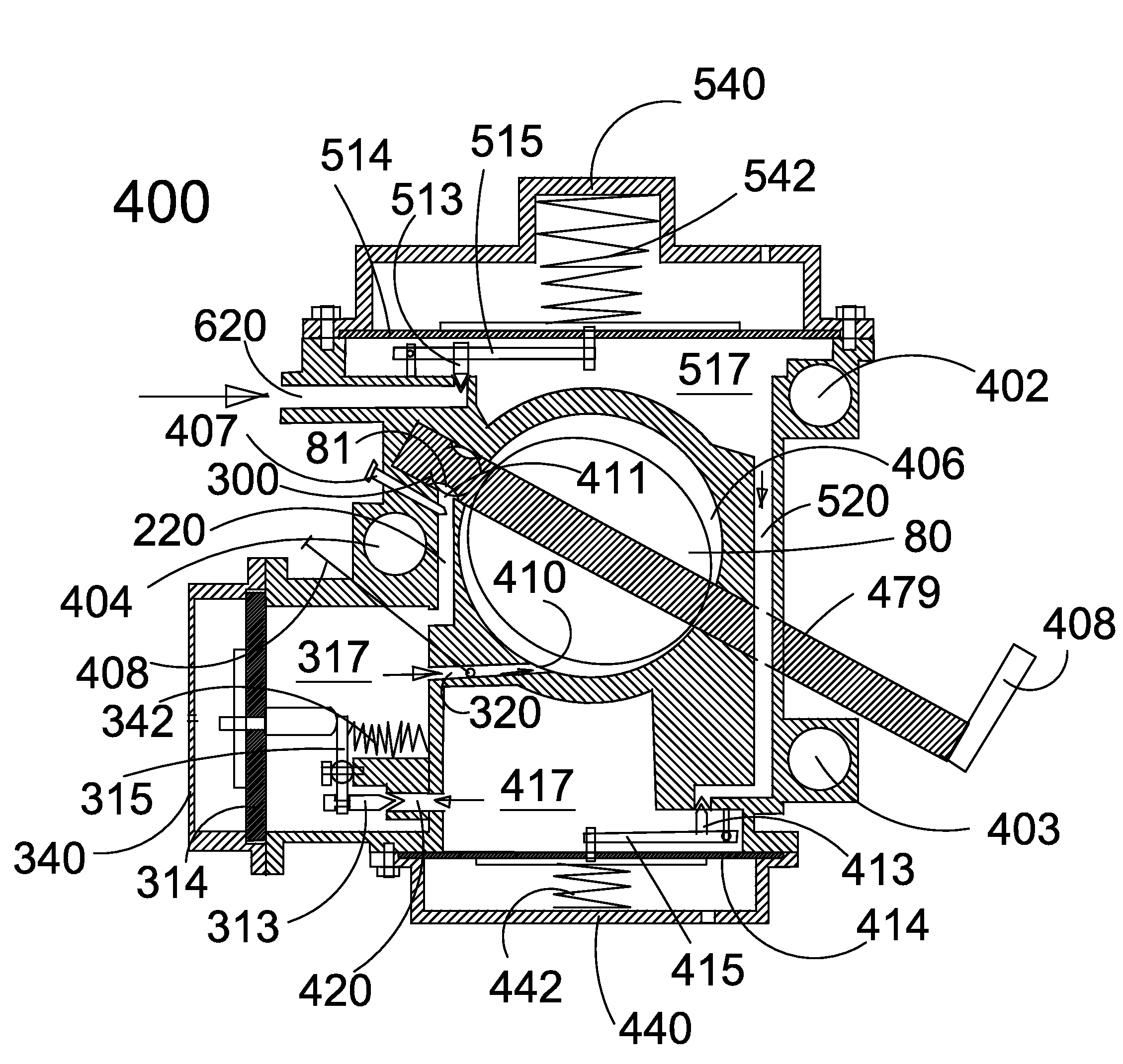

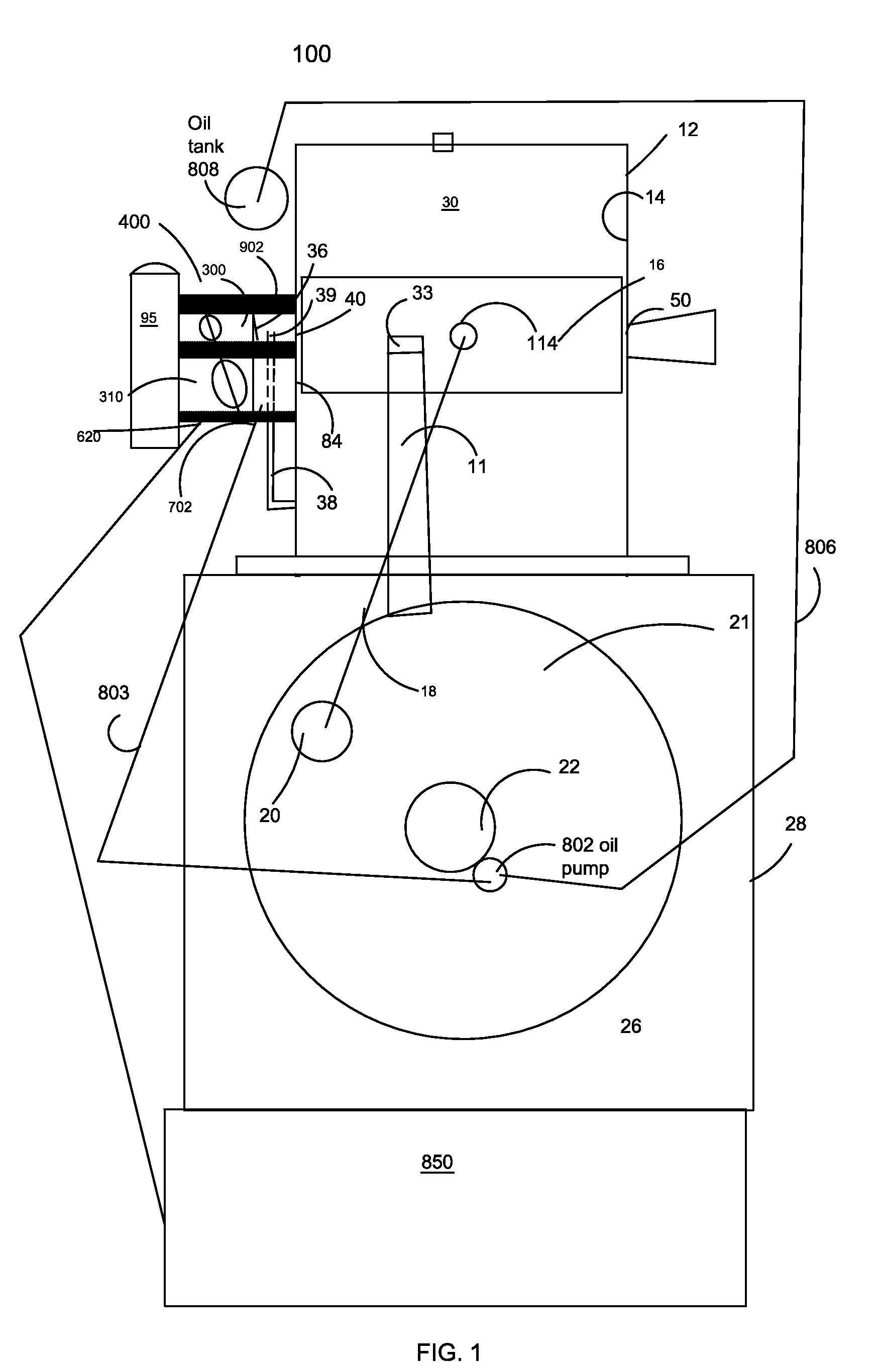

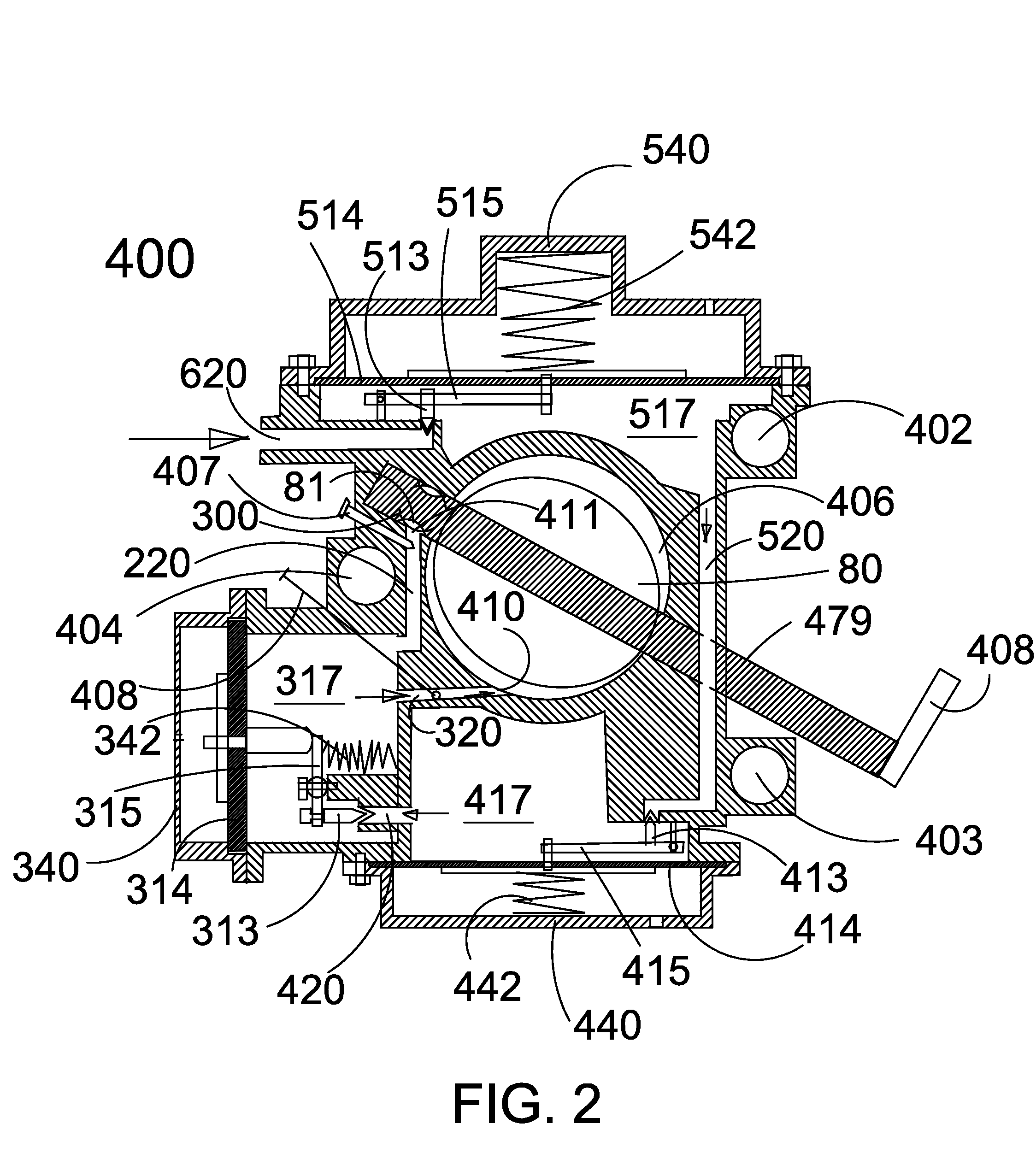

Fuel system with drain unit

InactiveUS7775189B2Hydrocarbon emissionElectrical controlFloat-controlled apparatusCarburetorActuator

A fuel system for a carburetor that supports operation of an engine includes a body with a bore, a fuel source communicated with the bore and from which fuel is supplied to the bore for delivery to the engine, a drain unit and a control. The drain unit is communicated with the fuel source to selectively receive fuel from the fuel source and has a fuel chamber and an actuator operable to vary the volume of the fuel chamber. The control is communicated with the actuator to permit fuel flow from the fuel source to the fuel chamber when the engine is shut down and to cause fuel to flow from the fuel chamber to the fuel source prior to starting the engine.

Owner:WALBRO ENGINE MANAGEMENT

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com