Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

283results about "Drilling without earth removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

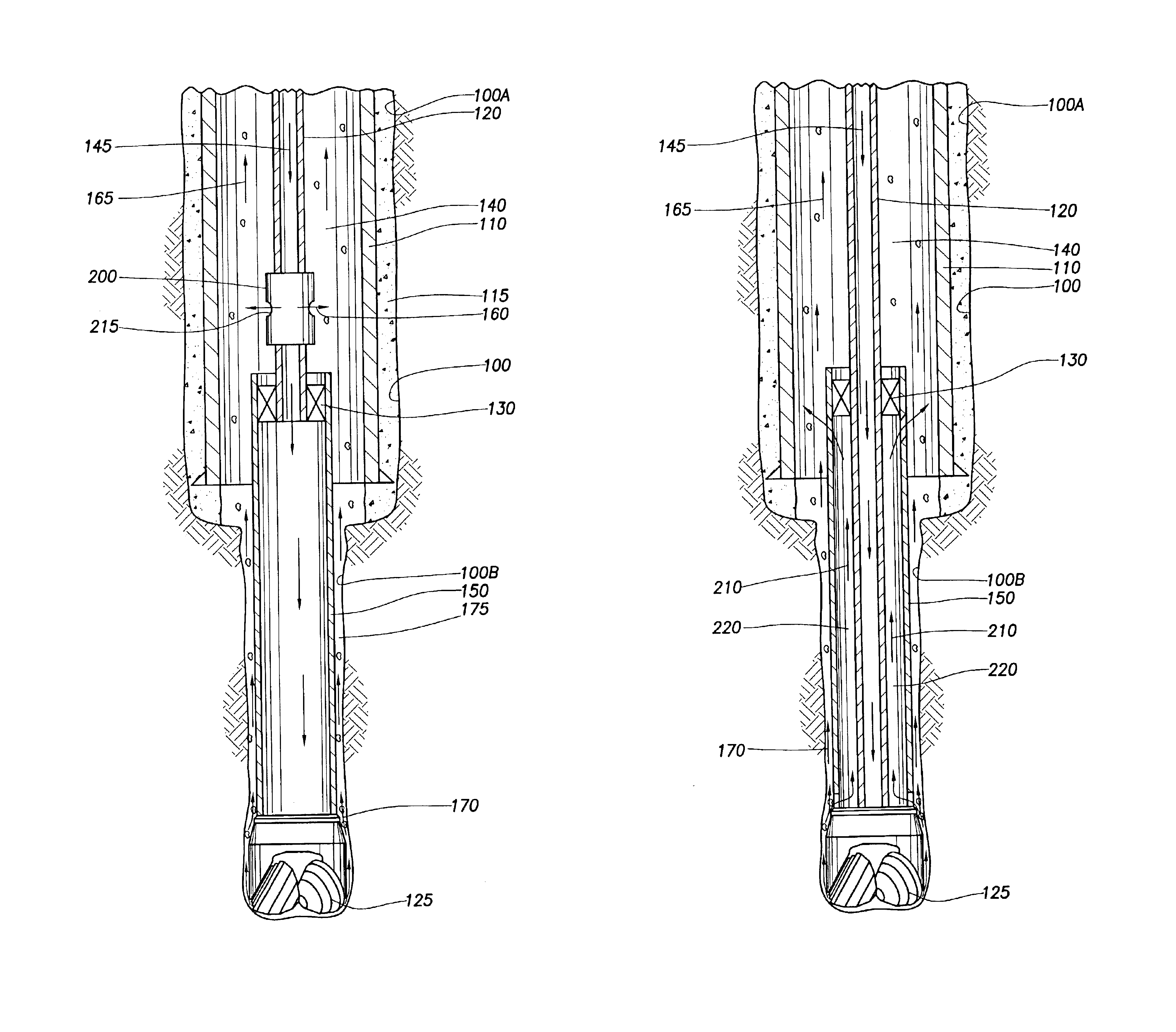

Drilling with concentric strings of casing

InactiveUS6857487B2Cost for assemblyReduce equipment costsEarth drilling toolsDrilling rodsWell drillingEngineering

The present invention provides a method and apparatus for setting concentric casing strings within a wellbore in one run-in of a casing working string. In one aspect of the invention, the apparatus comprises a drilling system comprising concentric casing strings, with each casing string having a drill bit piece disposed at the lower end thereof. The drill bit pieces of adjacent casing strings are releasably connected to one another. In another aspect of the invention, a method is provided for setting concentric casing strings within a wellbore with the drilling system. In another aspect of the invention, the releasably connected drill bit pieces comprise a drill bit assembly.

Owner:WEATHERFORD TECH HLDG LLC

Forming a wellbore casing while simultaneously drilling a wellbore

InactiveUS6892819B2Obstruct passageAvoid enteringEarth drilling toolsDrilling rodsBiomedical engineeringWellbore

An apparatus including a support member, the support member including a first fluid passage, a mandrel coupled to the support member, the mandrel including: a second fluid passage, a tubular member coupled to the mandrel, and shoe coupled to the tubular liner, the shoe including a third fluid passage, and a drilling assembly coupled to the shoe, wherein the first, second and third fluid passages and the drilling assembly are operably coupled.

Owner:ENVENTURE GLOBAL TECH LLC

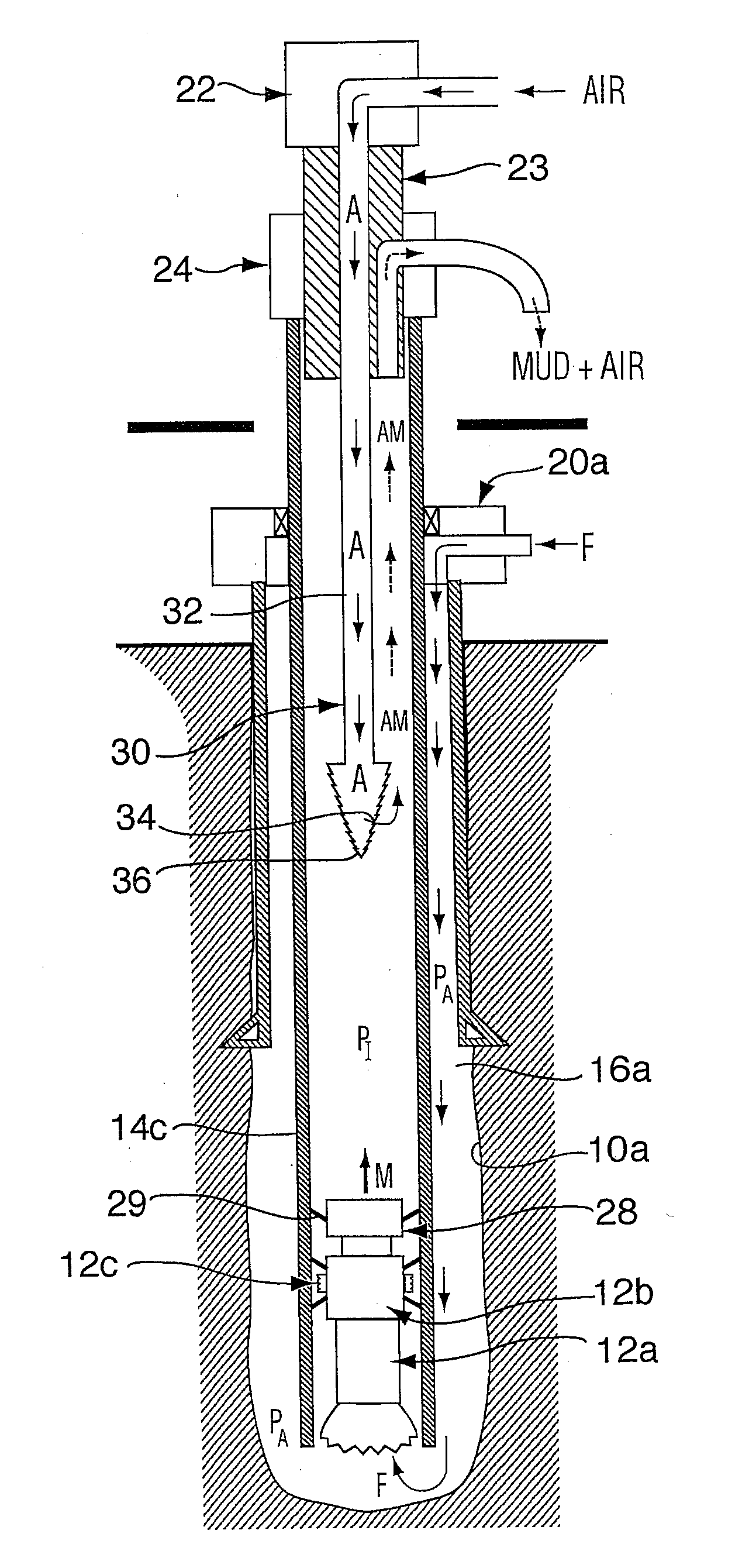

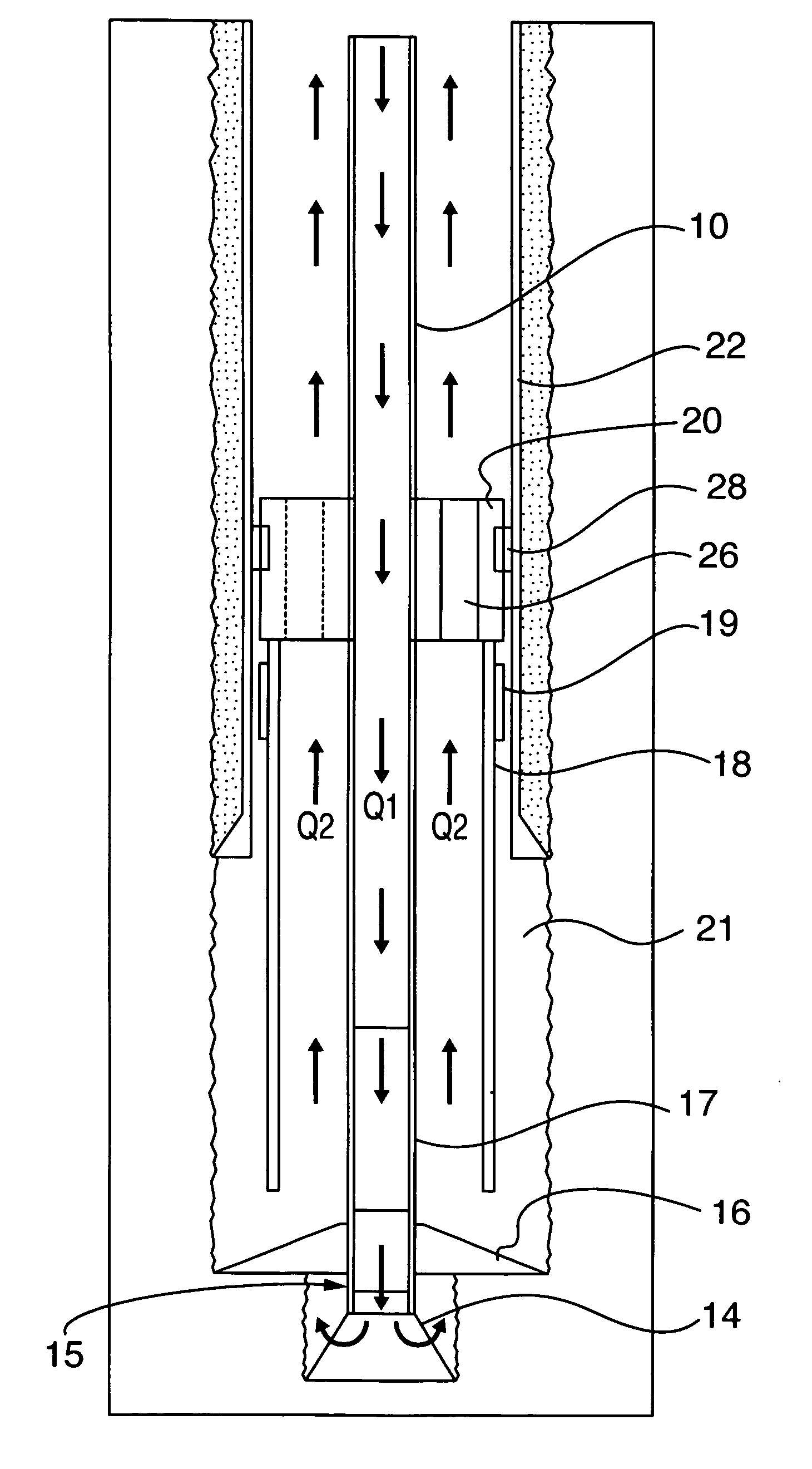

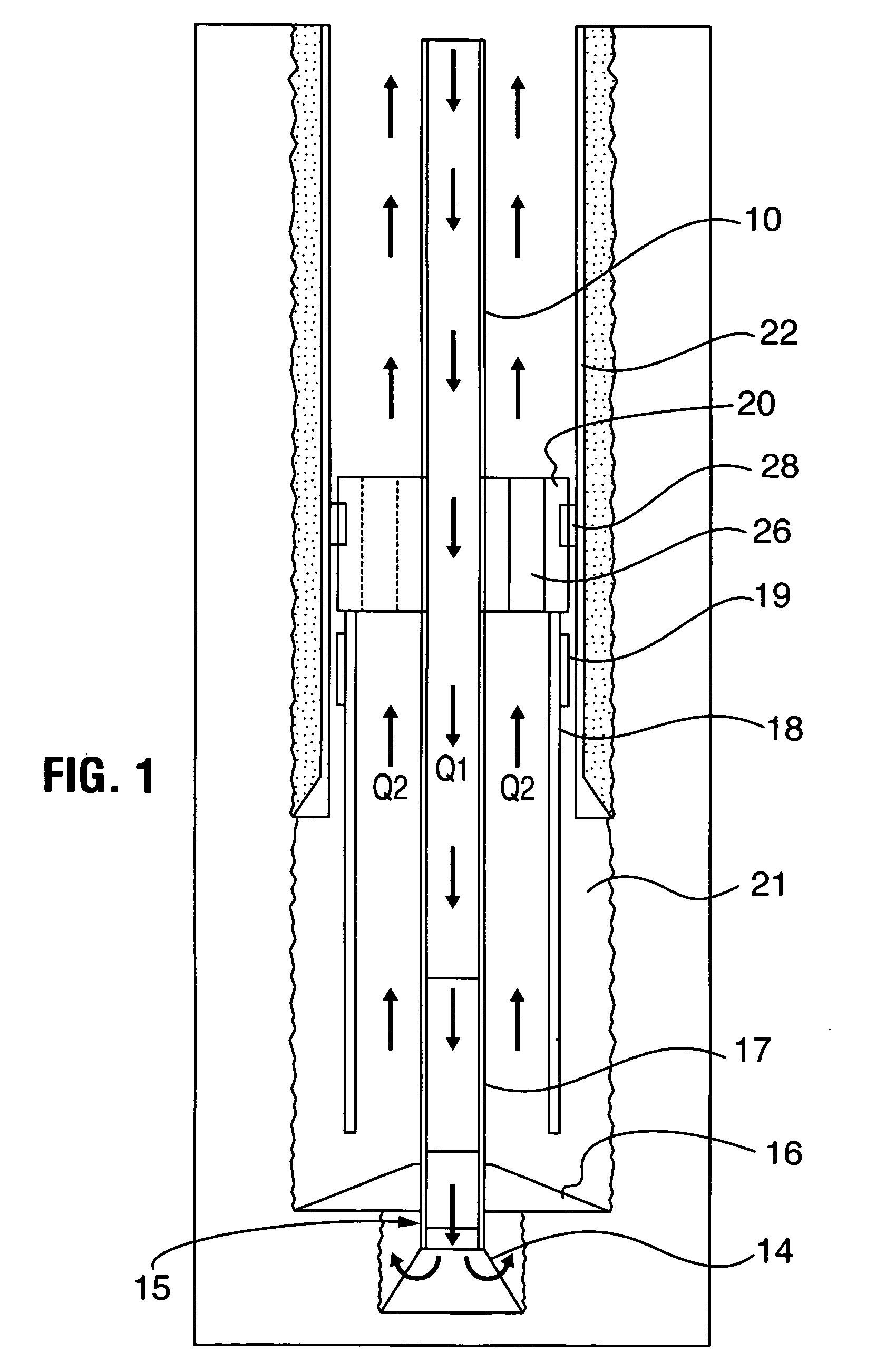

Method and apparatus for drilling a borehole with a borehole liner

A method for drilling a borehole includes; providing a drill string of drill pipe including a center bore, a distal end, a bit assembly at the distal end; hanging a liner from the drill string, thereby forming an annular space between the drill string and the liner and with the bit assembly extending from a lower end of the liner; positioning the drill string with the liner attached thereto in a borehole such that a second annular space is formed between the liner and the borehole wall; operating the bit assembly to proceed with drilling the borehole; and circulating drilling fluid down through the center bore of the drill string out through the bit assembly and down through the second annular space between the liner and the borehole wall, the drilling fluid returning up through the annular space between the drill string and the liner.

Owner:TESCO CORPORATION +1

Apparatus and method for drilling with casing

The present invention generally relates to a method and an apparatus for drilling with casing. In one aspect, a method of drilling a wellbore with casing is provided, including placing a string of casing with a drill bit at the lower end thereof into a previously formed wellbore and urging the string of casing axially downward to form a new section of wellbore. The method further includes pumping fluid through the string of casing into an annulus formed between the casing string and the new section of wellbore. The method also includes diverting a portion of the fluid into an upper annulus in the previously formed wellbore. In another aspect, a method of drilling with casing to form a wellbore is provided. In yet another aspect, an apparatus for forming a wellbore is provided. In still another aspect, a method of casing a wellbore while drilling the wellbore is provided.

Owner:WEATHERFORD TECH HLDG LLC

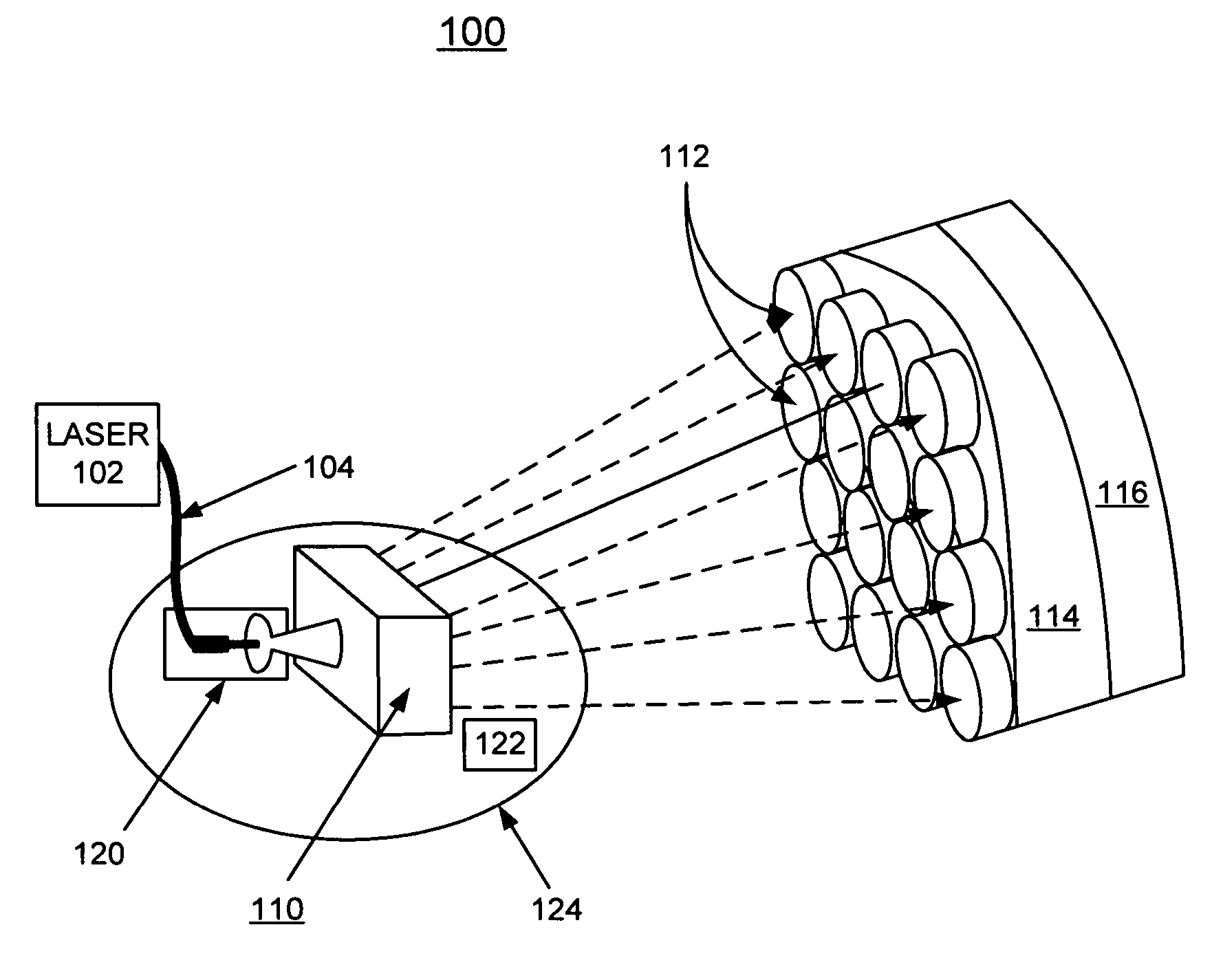

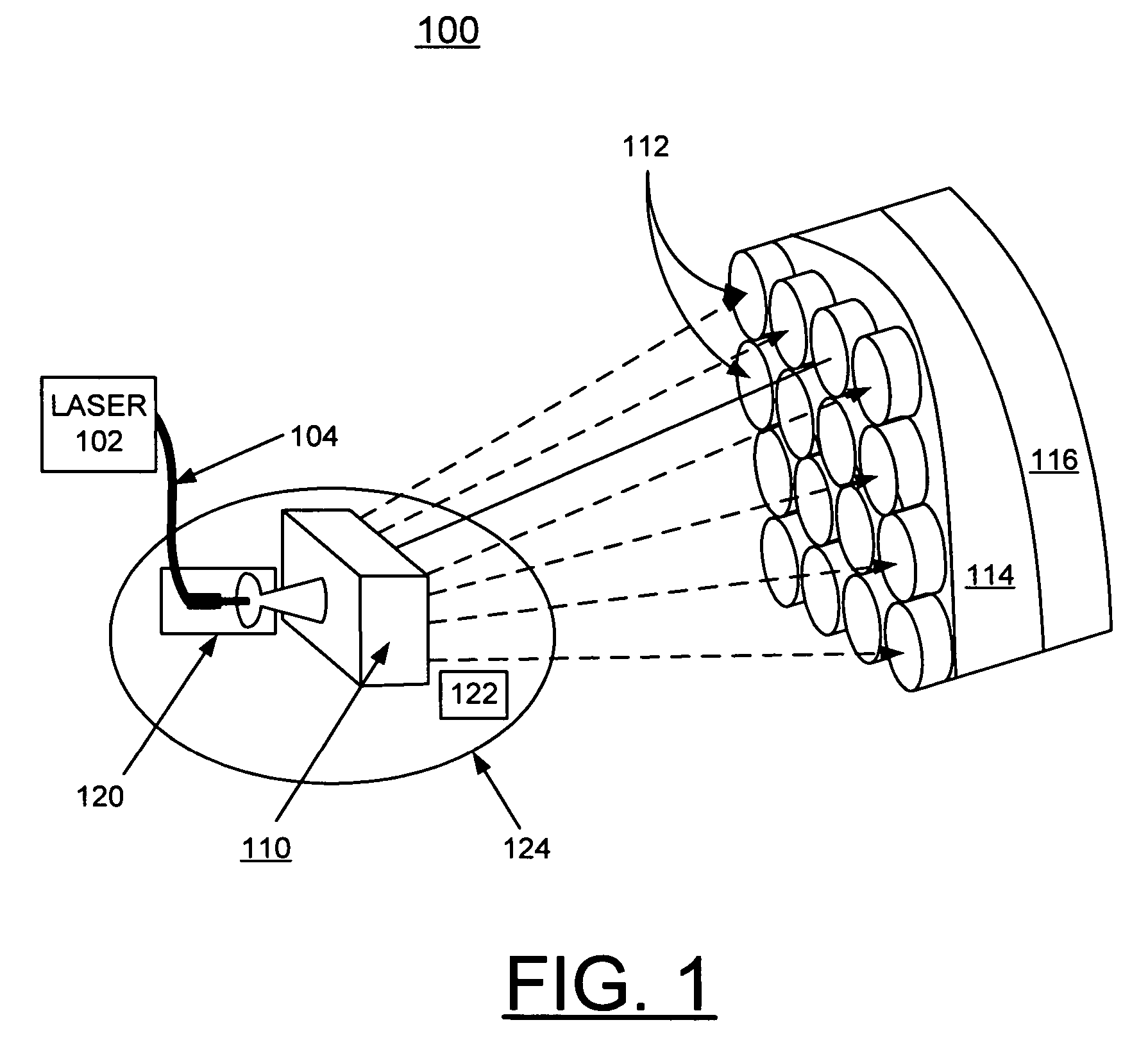

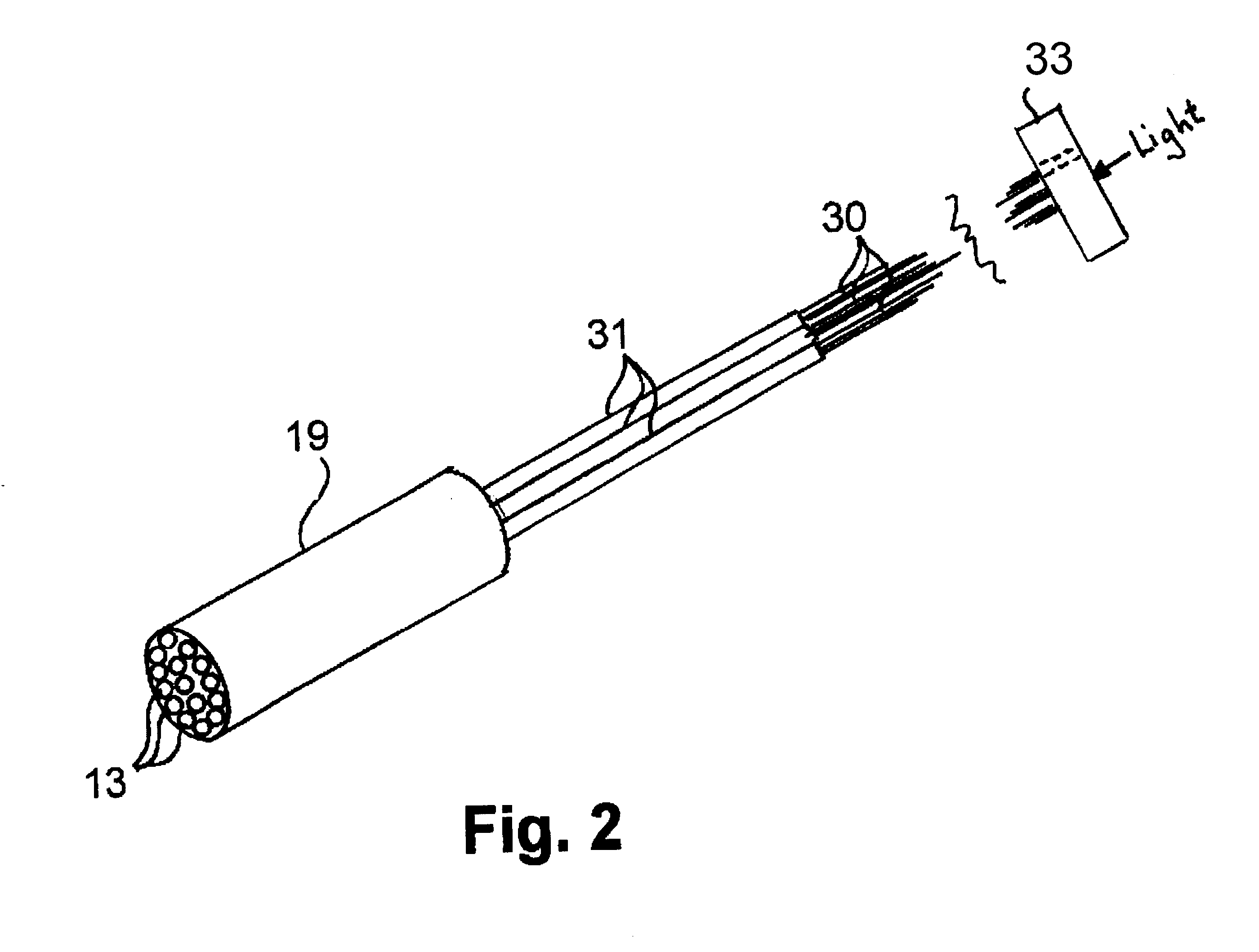

Downhole lens assembly for use with high power lasers for earth boring

InactiveUS6755262B2Difficult to controlRelative position is not easyEarth drilling toolsDisloding machinesFiberHigh power lasers

An earth boring apparatus at least partially locatable within a borehole. The apparatus includes a plurality of optical fibers, each of which has a proximal fiber light energy input end and a distal fiber light energy output end. At least one focal lens is disposed at the distal fiber light energy output end. The focal lens is made up of a plurality of focal elements, each of which corresponds to the distal fiber light energy output end of at least one optical fiber. The focal lens is arranged to receive light energy from the corresponding distal fiber light energy output end of the at least one optical fiber and focus it outwardly from the distal fiber light energy output end.

Owner:GAS TECH INST

Telescopic drilling method

A telescopic drilling method includes the steps of drilling an outer bore through a surface, inserting a hollow outer conduit into the outer bore, and at least partially inserting a first hollow inner conduit through the outer conduit. Next, the method includes the steps of preventing the first inner conduit from moving longitudinal with respect to the outer conduit engaging a rotatable inner drill bit with a ring drill bit and further drilling the outer bore using a unitary drill bit head to a successive depth. The inner drill bit is disengaged from the ring drill bit and a second end of a successive hollow inner conduit is attached to a first end of a preceding one, and the preceding inner conduit is unclamped.

Owner:SENSENIG FLOYD R

Laser liner creation apparatus and method

A method and apparatus for forming an in situ borehole liner in which a laser beam from a laser energy assembly disposed within a transparent drill head enclosure of a drill head assembly is directed into a rock formation to be drilled and a portion of the rock formation is melted, forming molten rock. The drill head assembly is directed into the molten rock forming a borehole having a borehole wall. At least one air stream from the drill head assembly is directed into the molten rock forming the molten rock against the borehole wall after which the molten rock against the borehole wall is cooled, forming a borehole liner.

Owner:GAS TECH INST

Laser liner creation apparatus and method

InactiveUS6851488B2Eliminate requirementsEarth drilling toolsDisloding machinesLaser beamsGeophysics

A method and apparatus for forming an in situ borehole liner in which a laser beam from a laser energy assembly disposed within a transparent drill head enclosure of a drill head assembly is directed into a rock formation to be drilled and a portion of the rock formation is melted, forming molten rock. The drill head assembly is directed into the molten rock forming a borehole having a borehole wall. At least one air stream from the drill head assembly is directed into the molten rock forming the molten rock against the borehole wall after which the molten rock against the borehole wall is cooled, forming a borehole liner.

Owner:GAS TECH INST

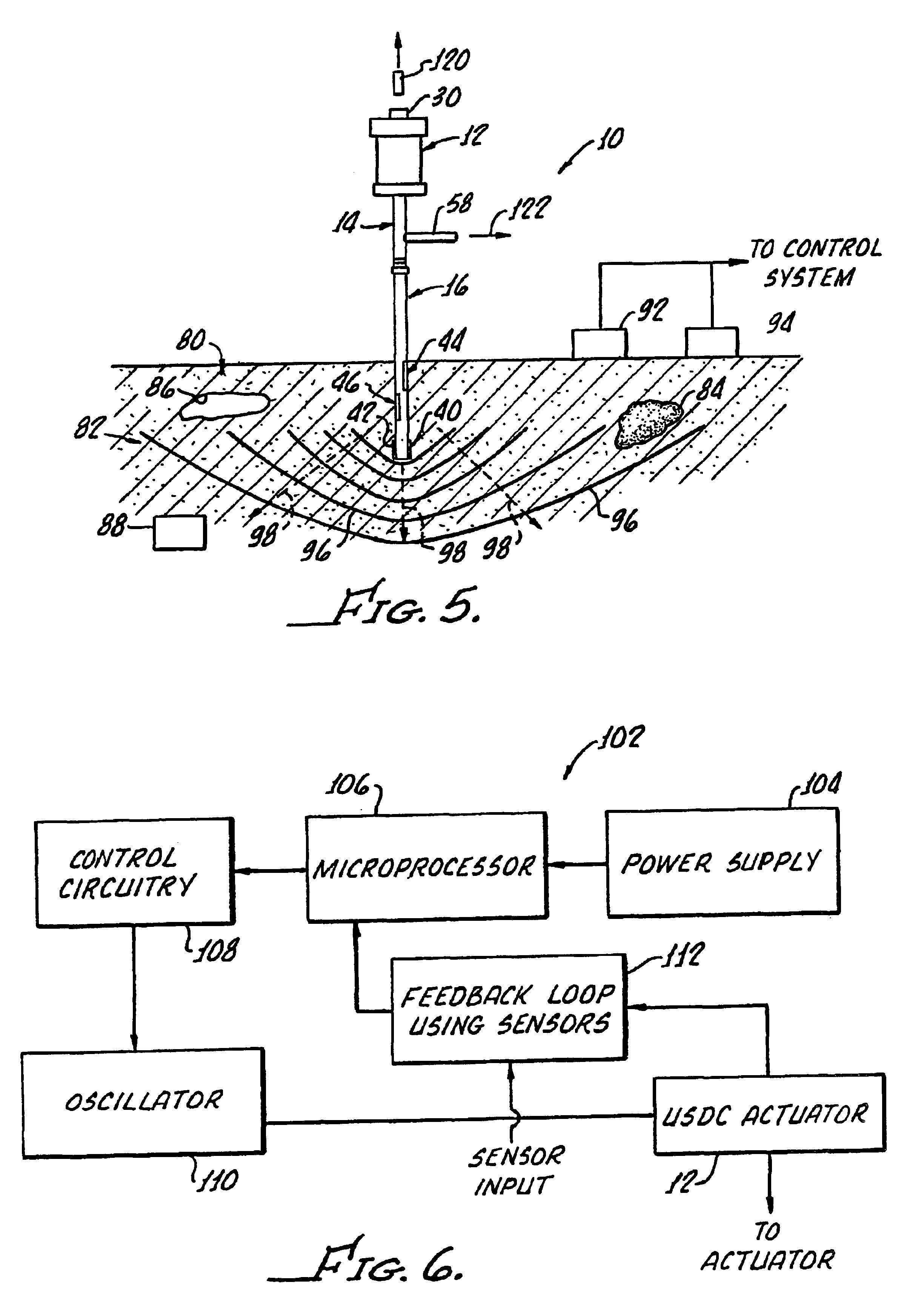

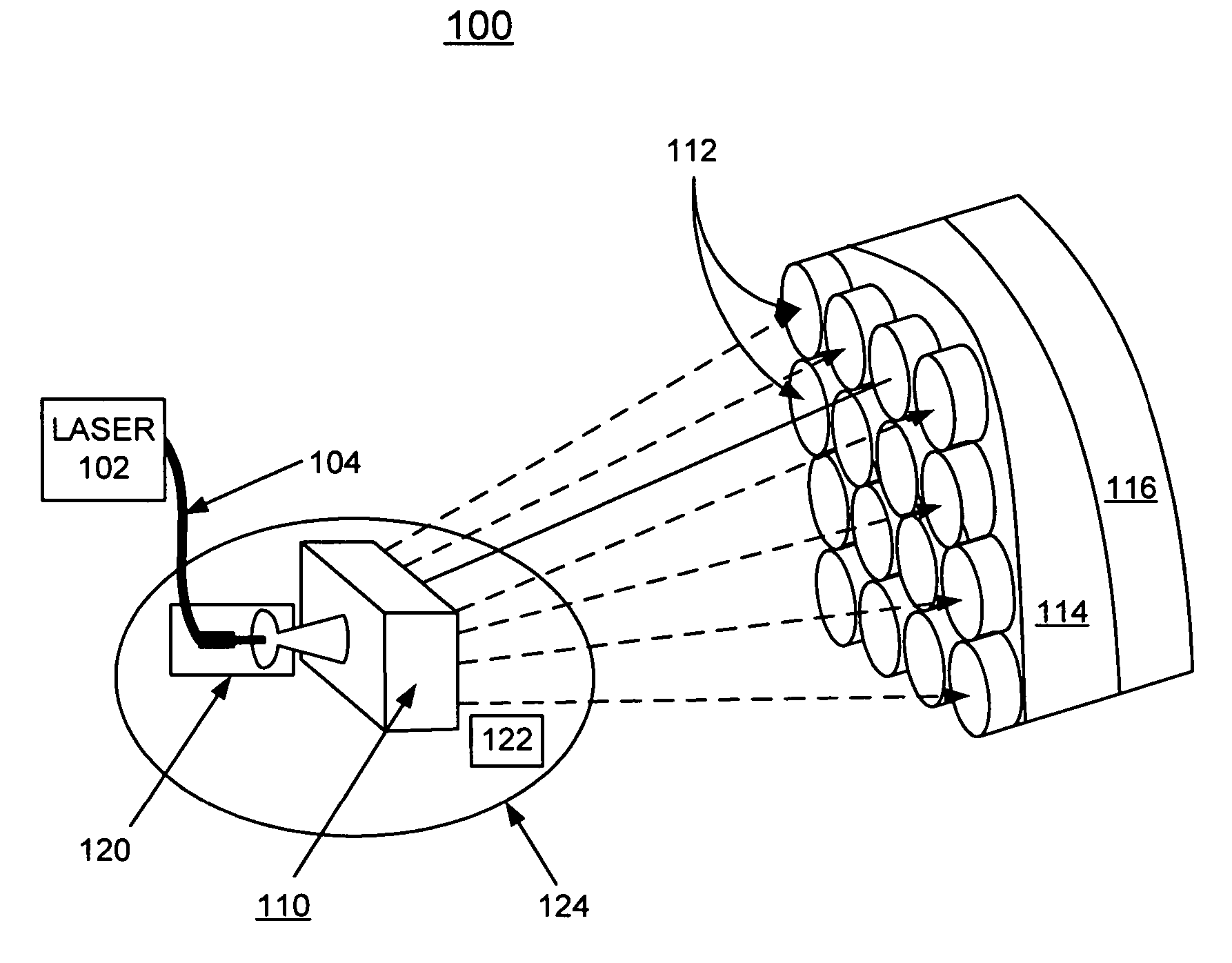

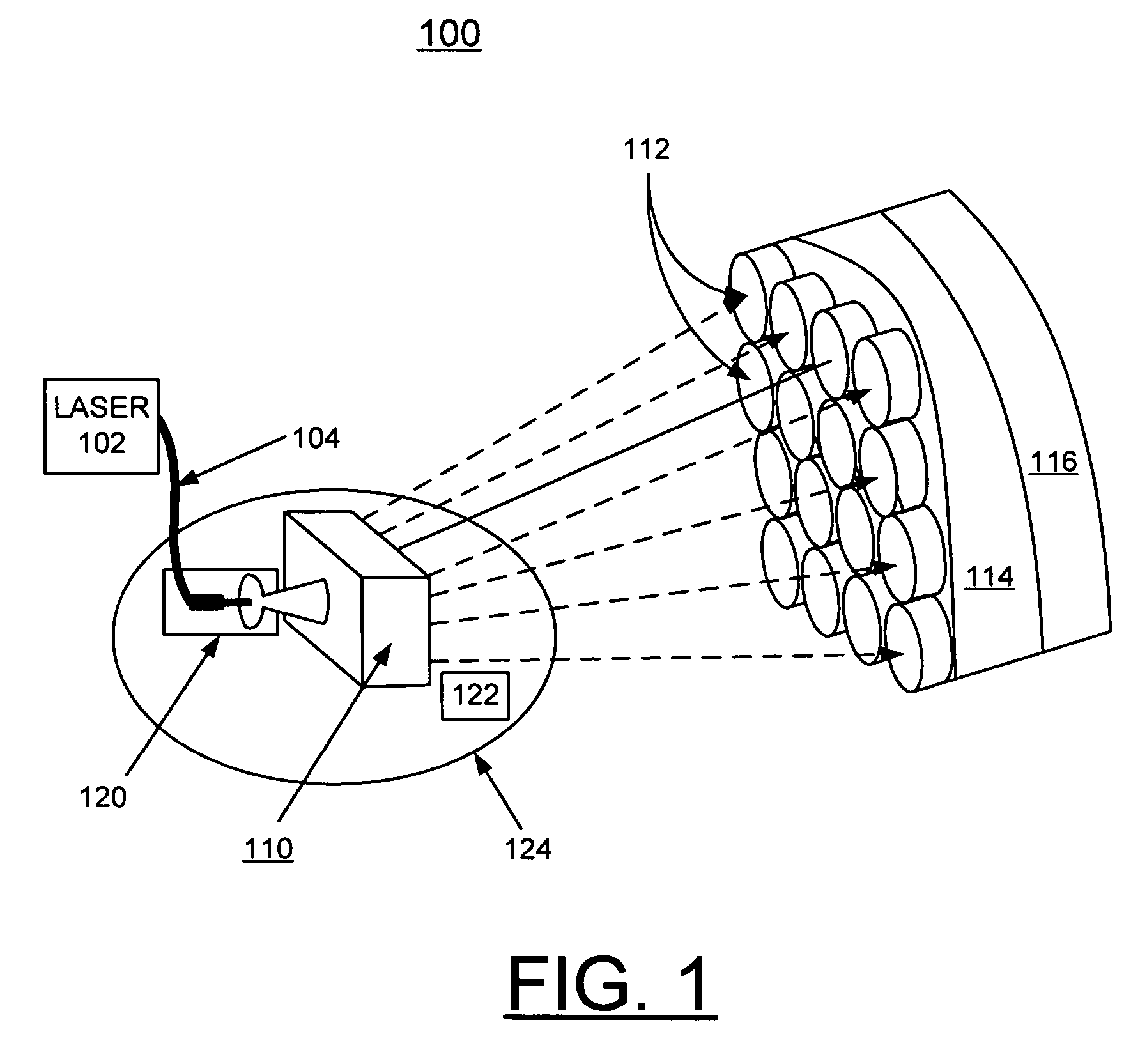

Methods of using a laser to spall and drill holes in rocks

ActiveUS20060237233A1Energy efficiencyProtection is necessaryEarth drilling toolsDisloding machinesSmall fragmentClassical mechanics

Apparatus and methods of using lasers are provided for spalling and drilling holes into rocks. A rock removal process is provided that utilizes a combination of laser-induced thermal stress and laser induced superheated steam explosions just below the surface of the laser / rock interaction to spall the rock into small fragments that can then be easily removed by a purging flow. Single laser beams of given irradiance spall rock and create holes having diameter and depth approximately equal to the beam spot size. A group of the single laser beams are steered in a controllable manner by an electro-optic laser beam switch to locations on the surface of the rock, creating multiple overlapping spalled holes thereby removing a layer of rock of a desired diameter. Drilling of a deep hole is achieved by spalling consecutive layers with an intermittent feed motion of the laser head perpendicular to the rock surface.

Owner:UCHICAGO ARGONNE LLC

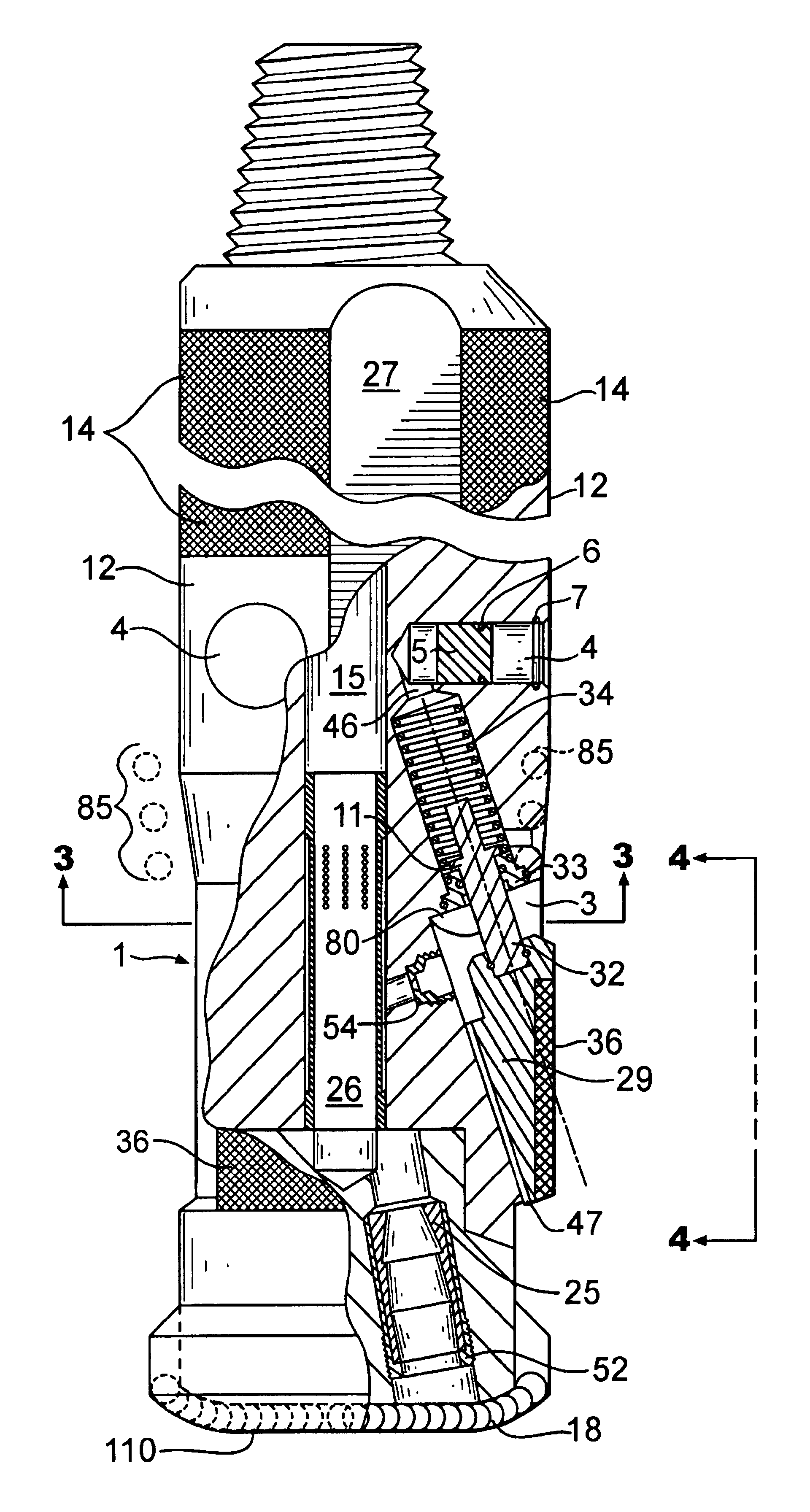

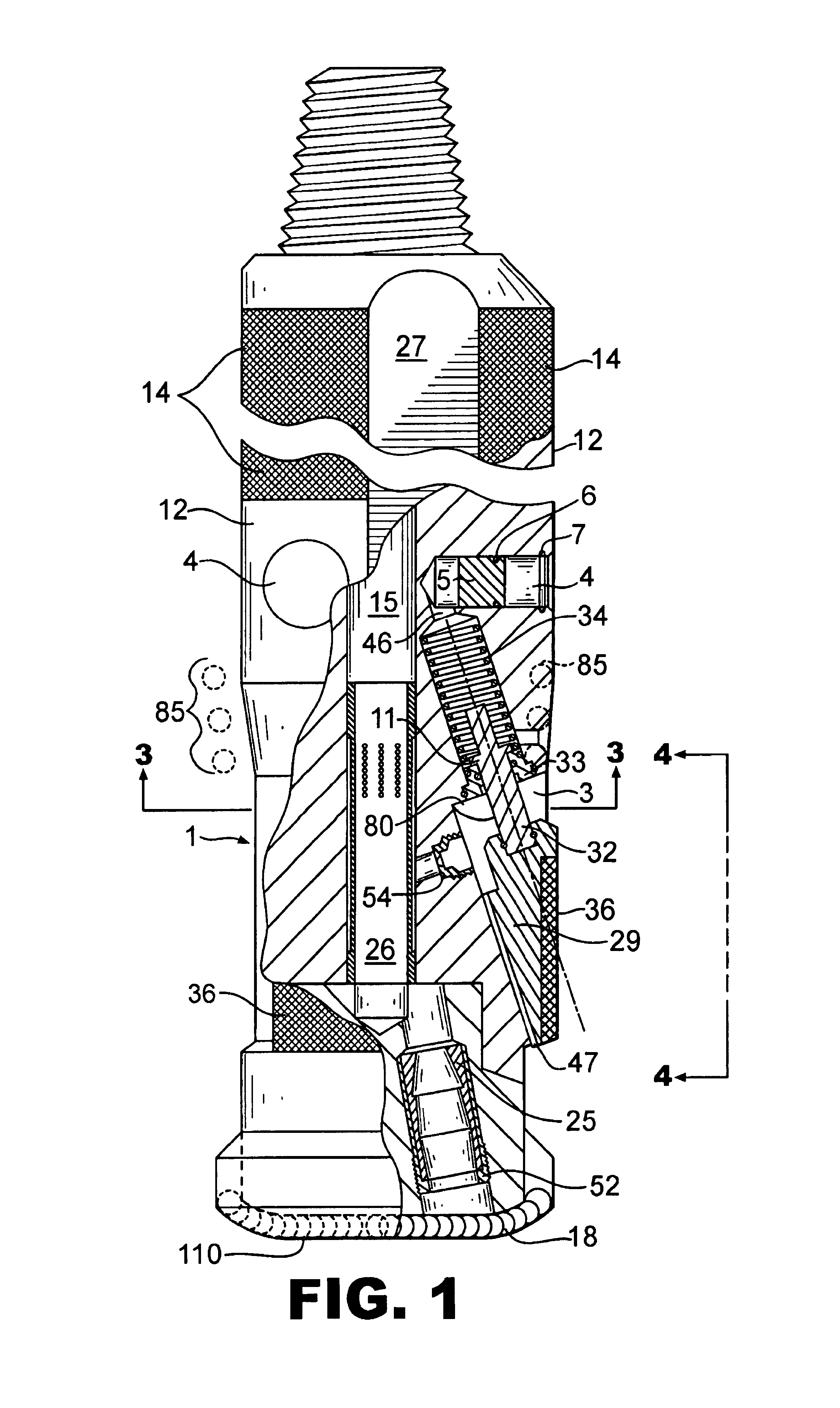

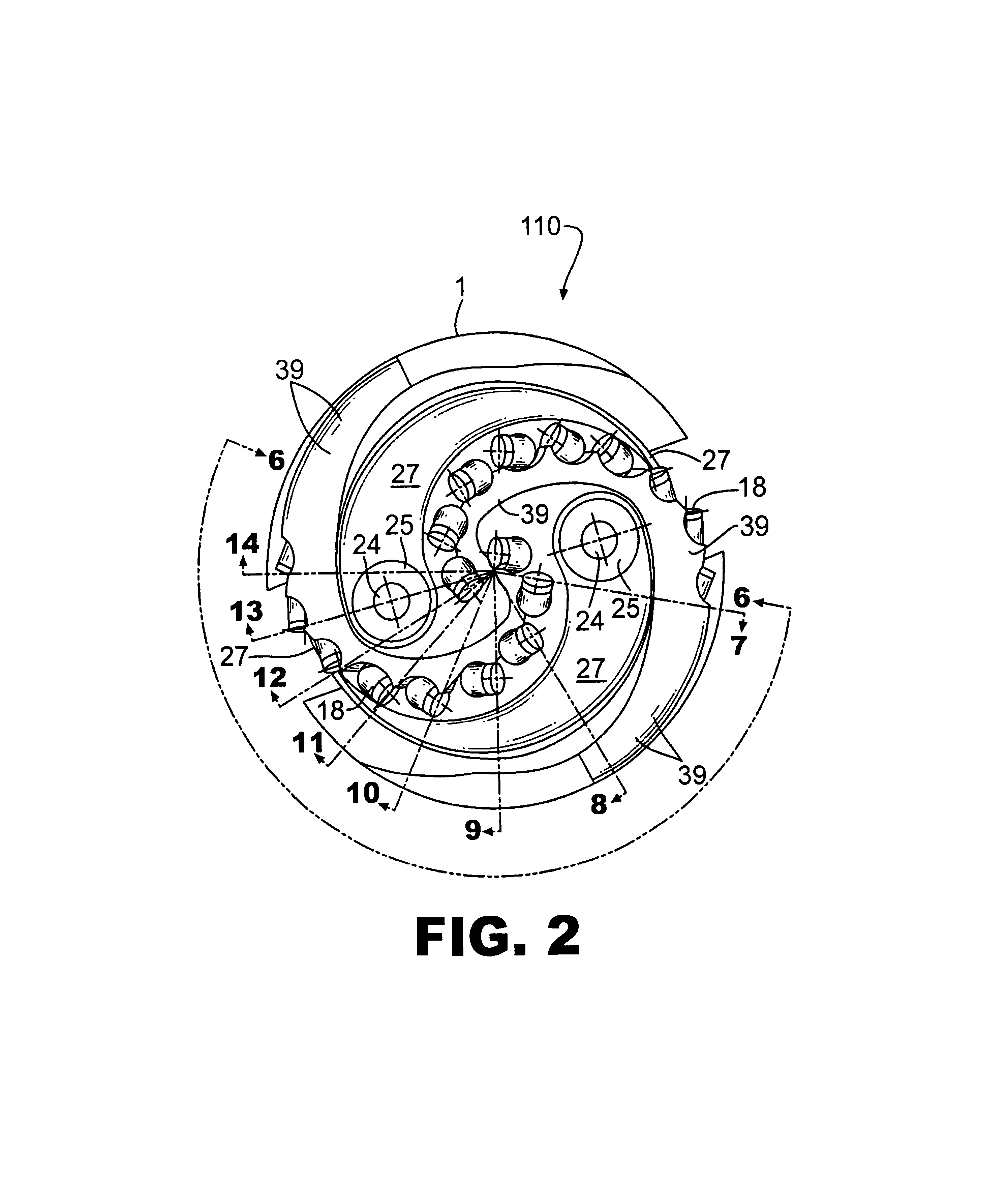

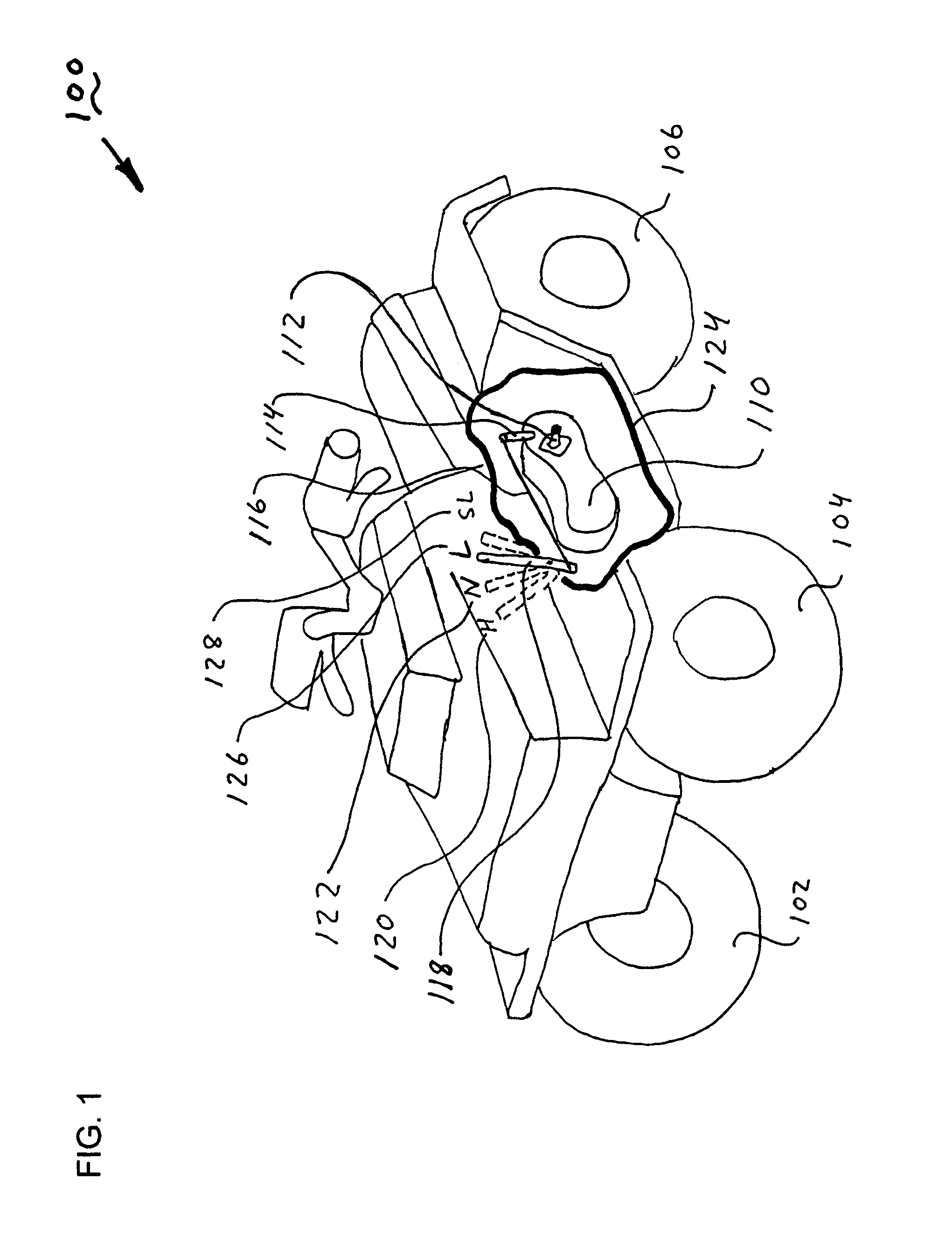

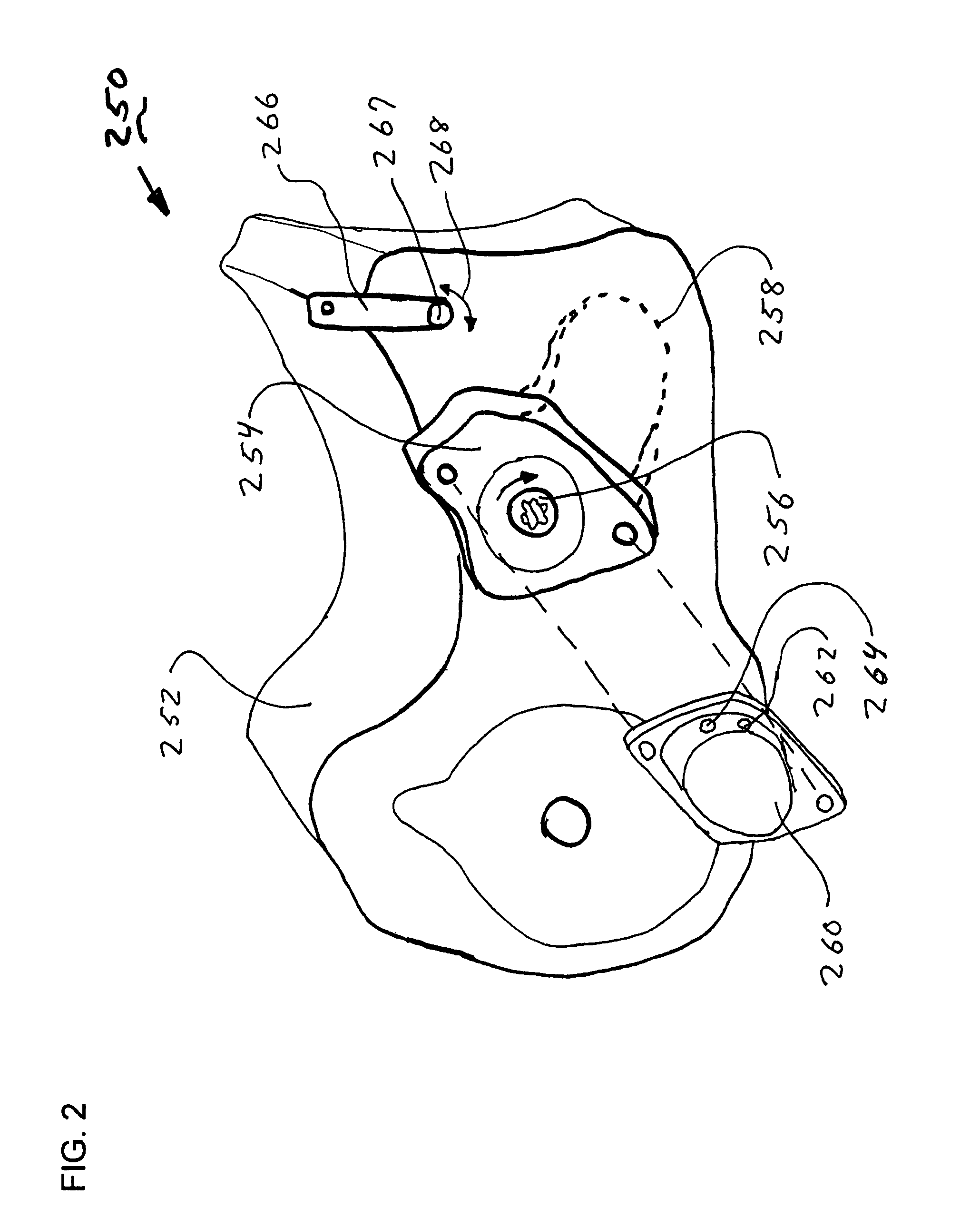

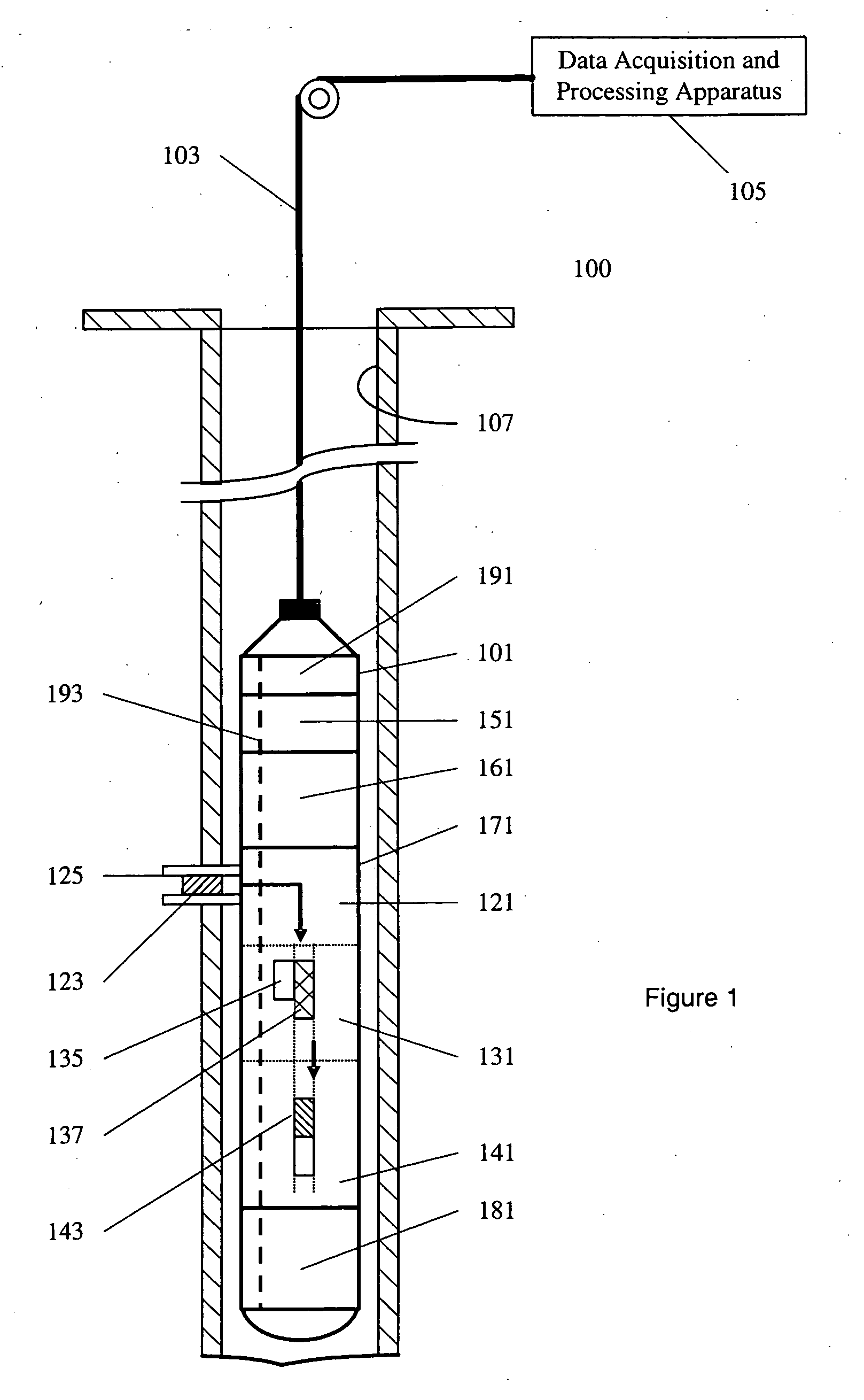

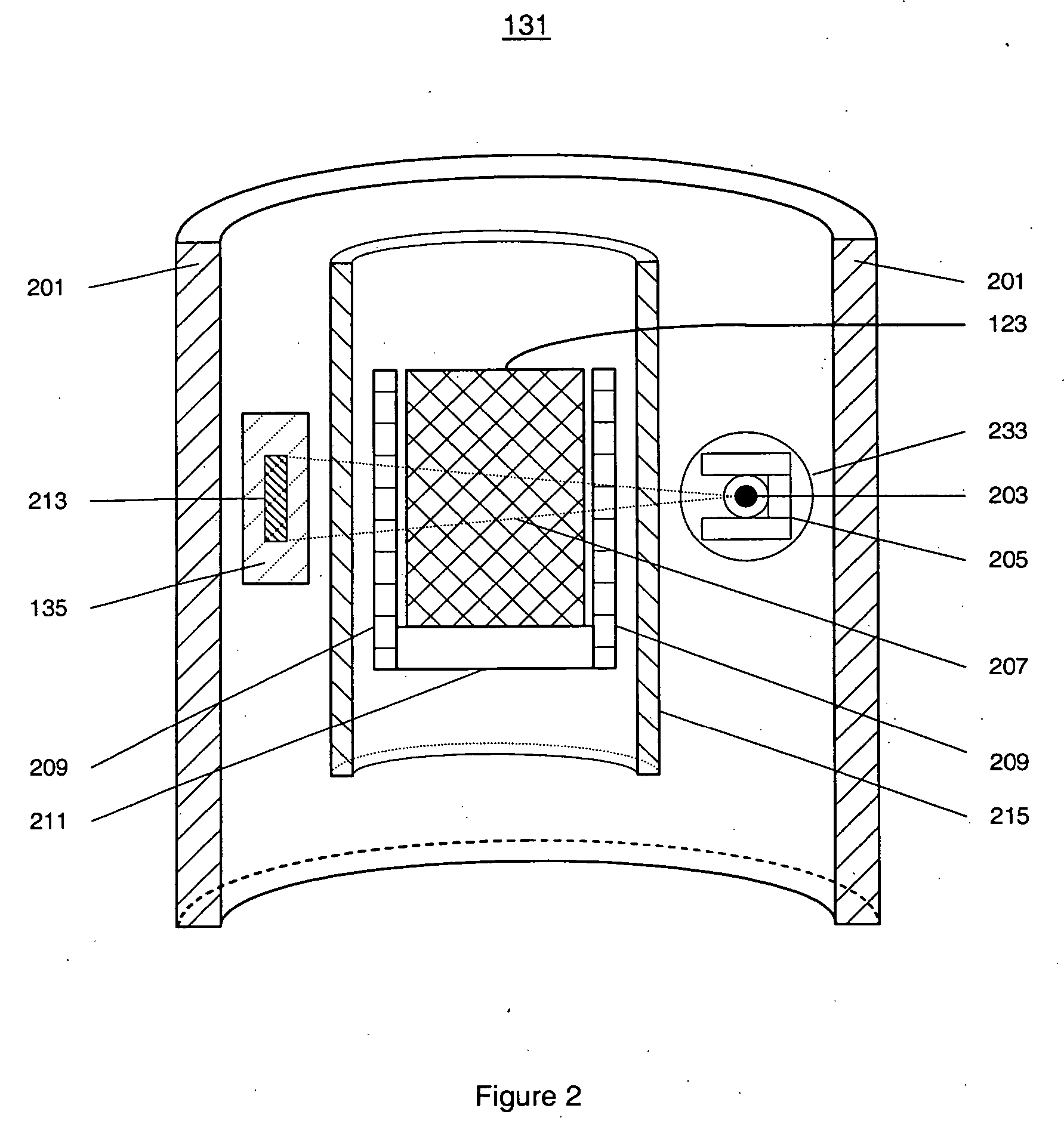

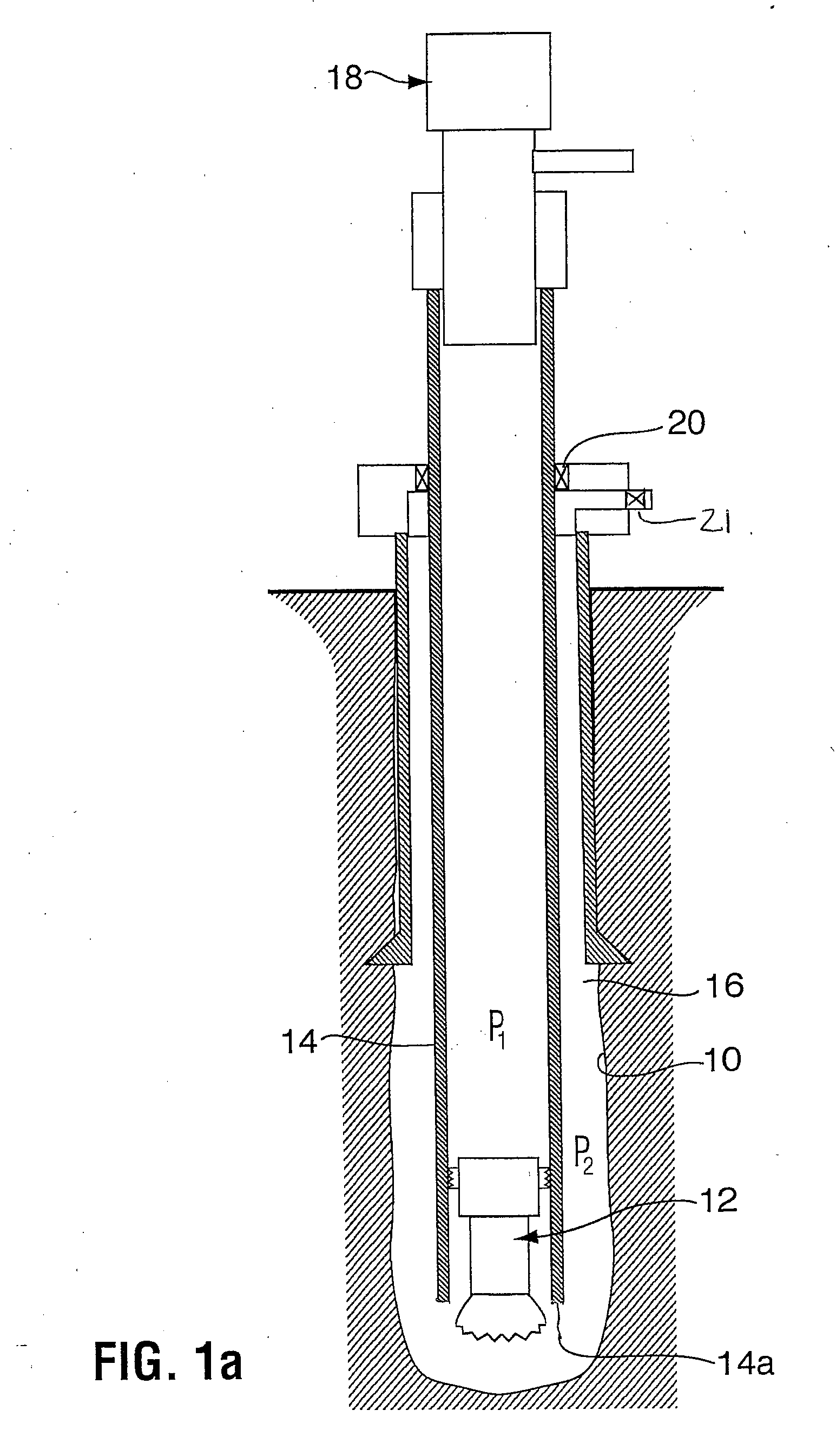

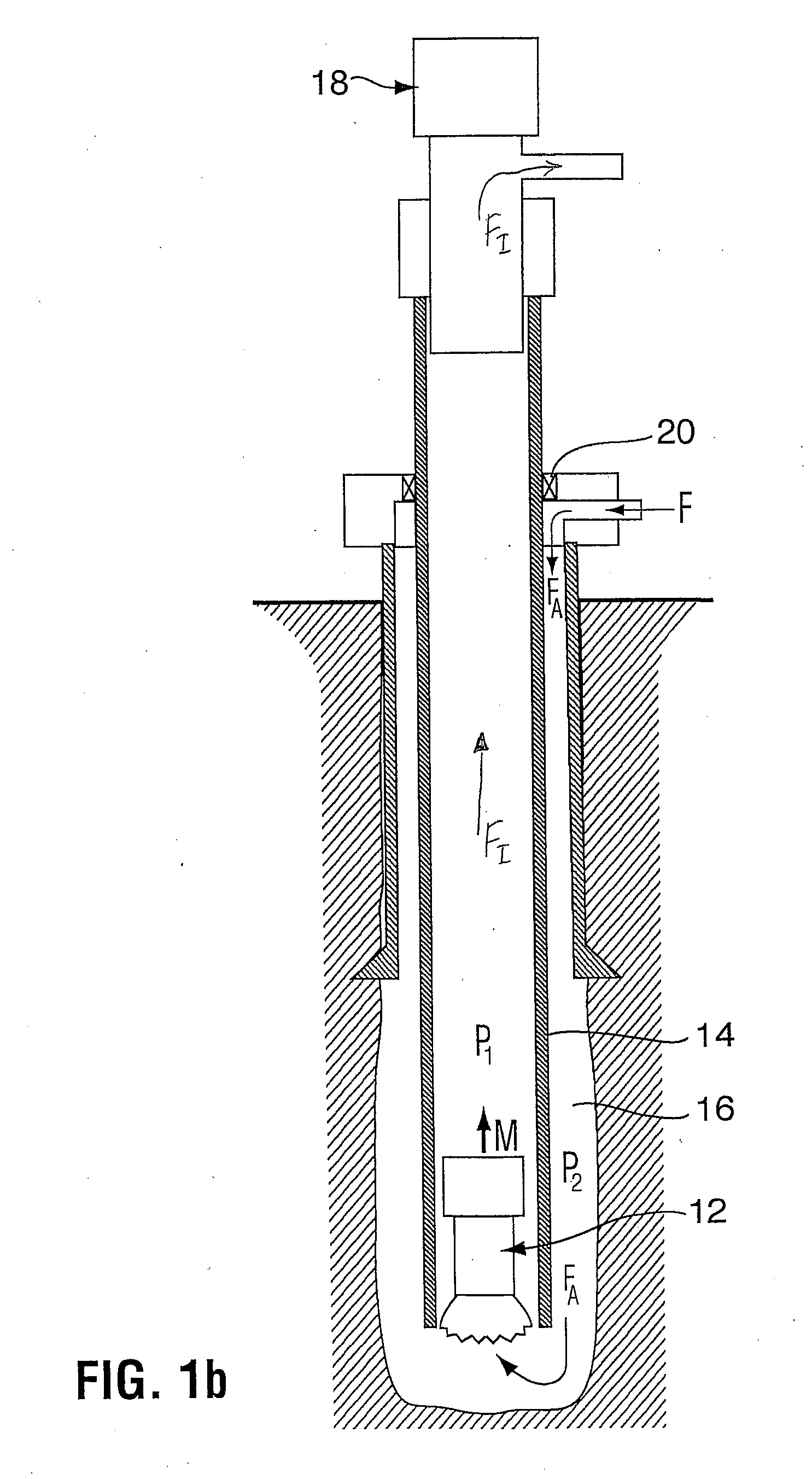

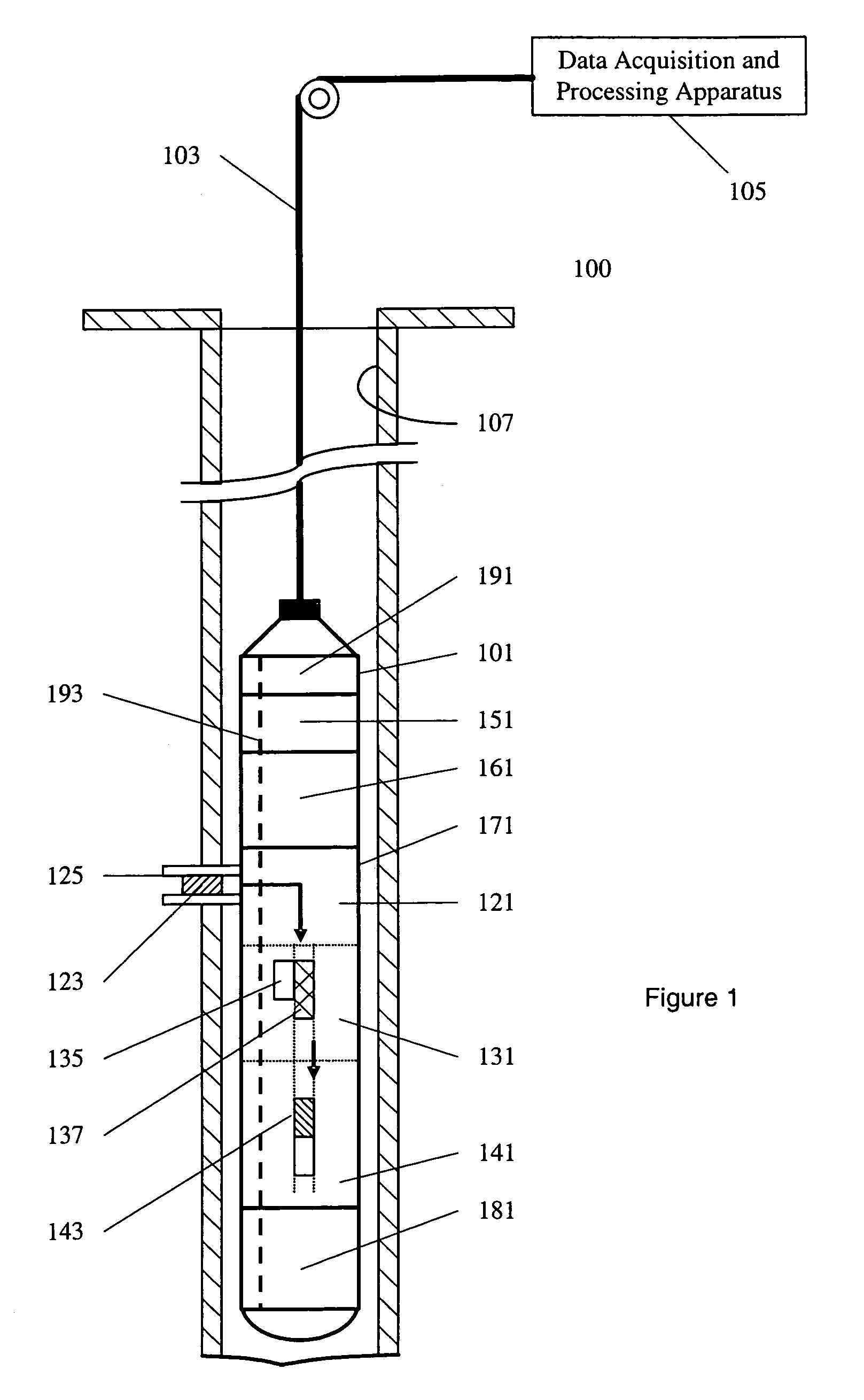

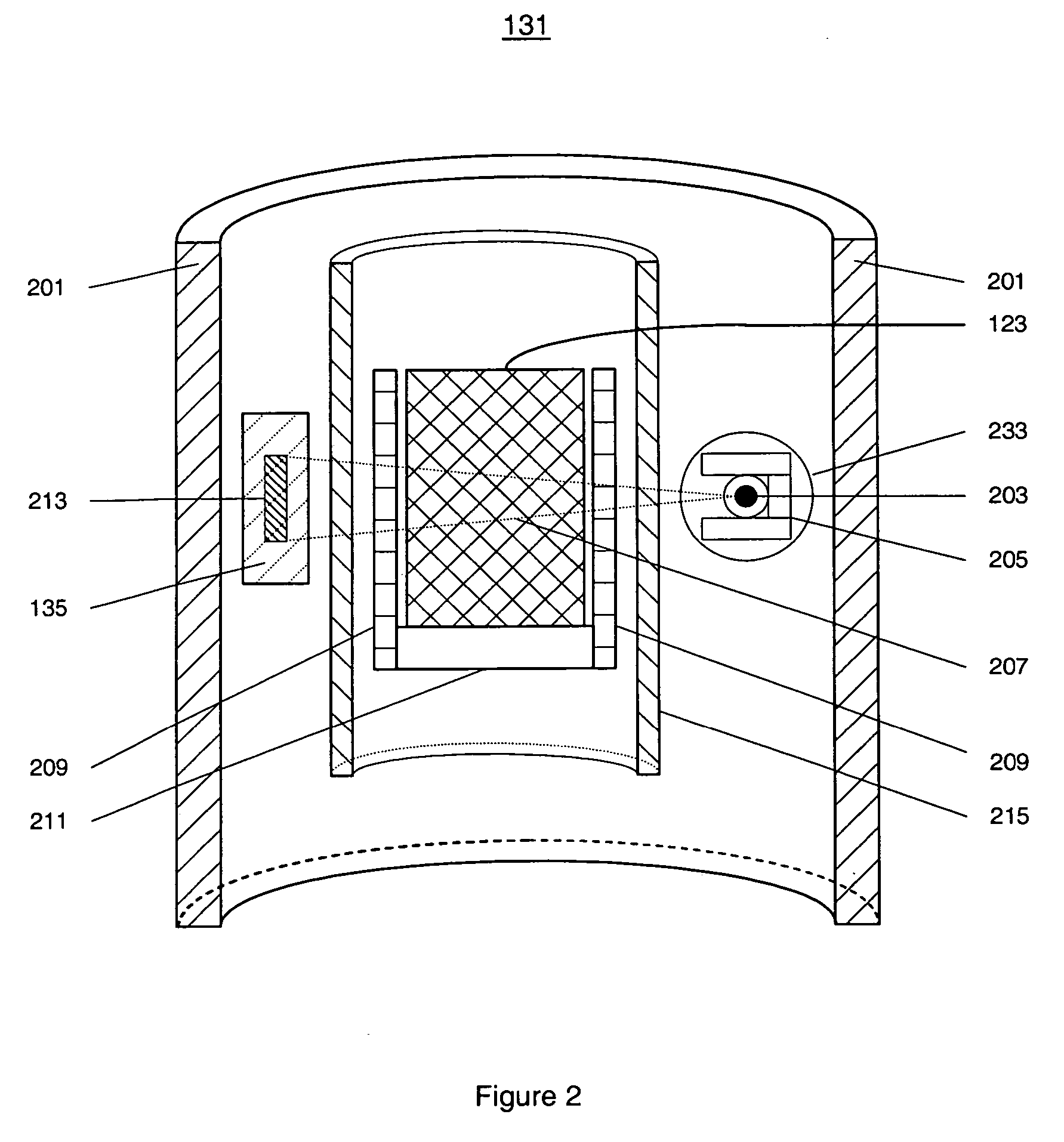

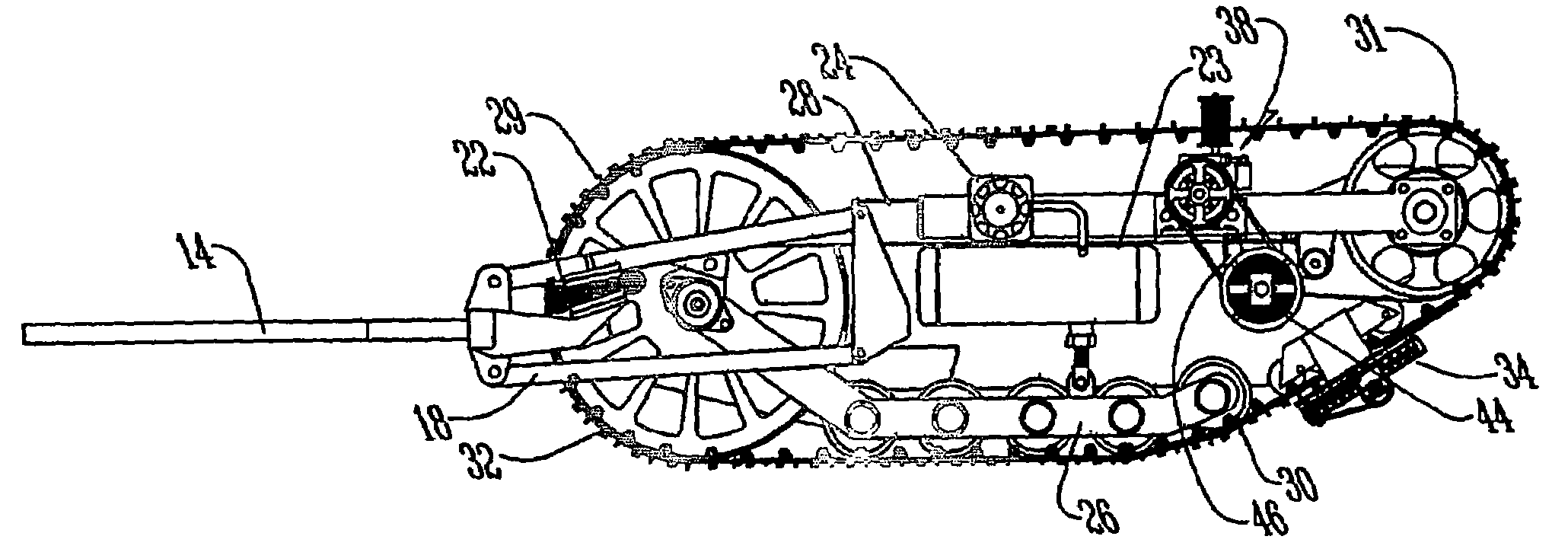

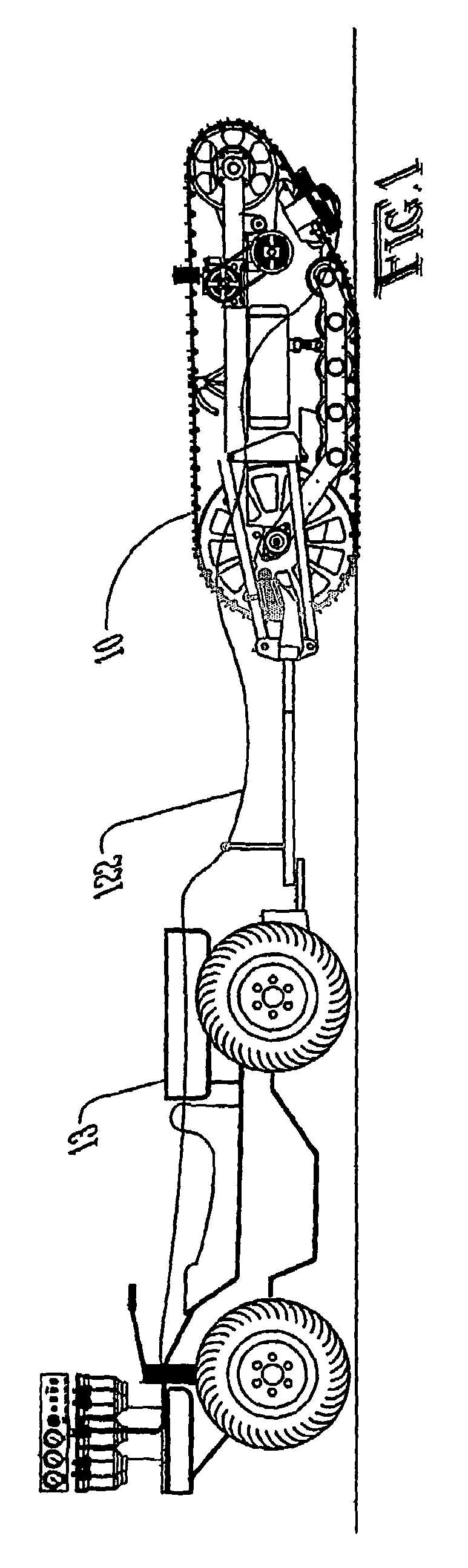

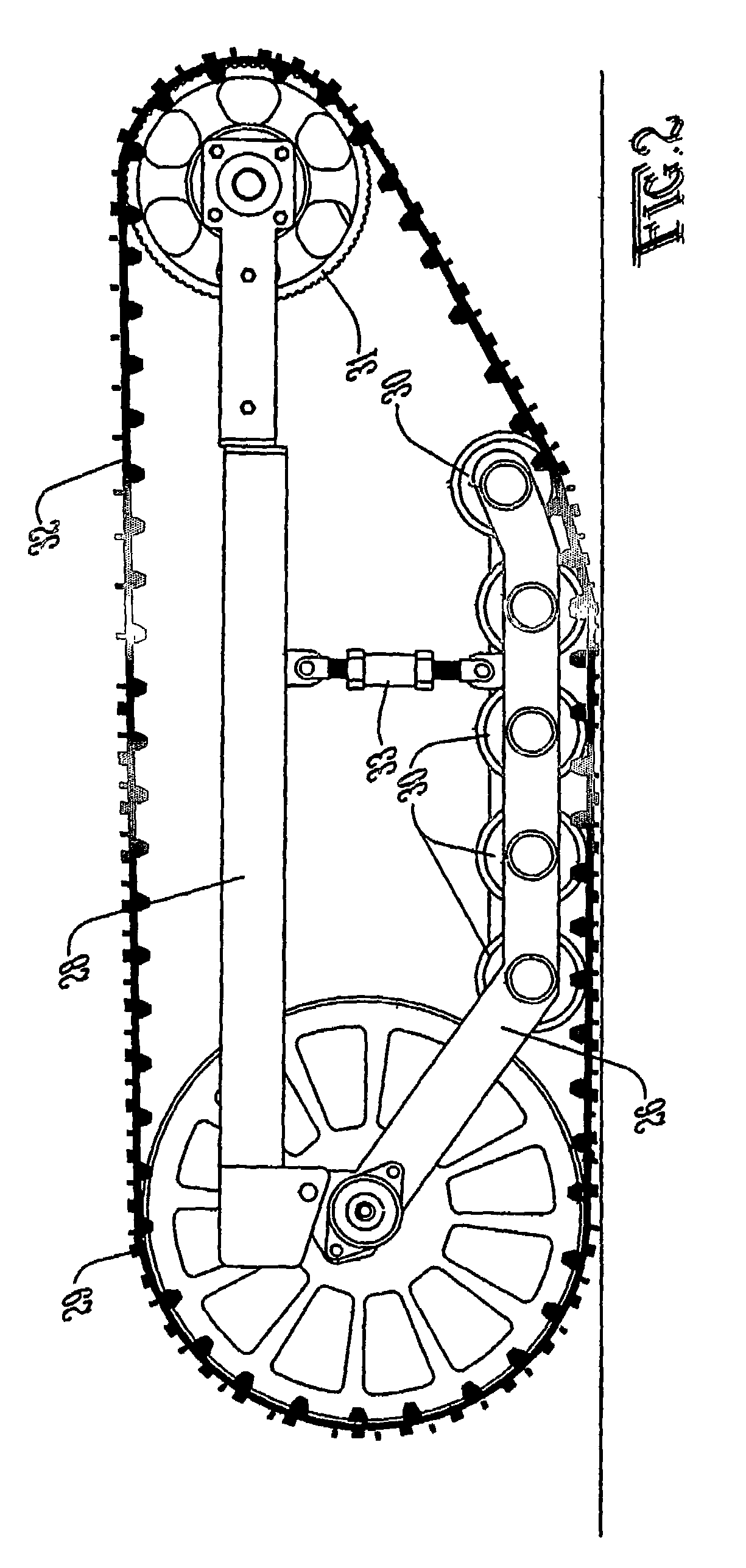

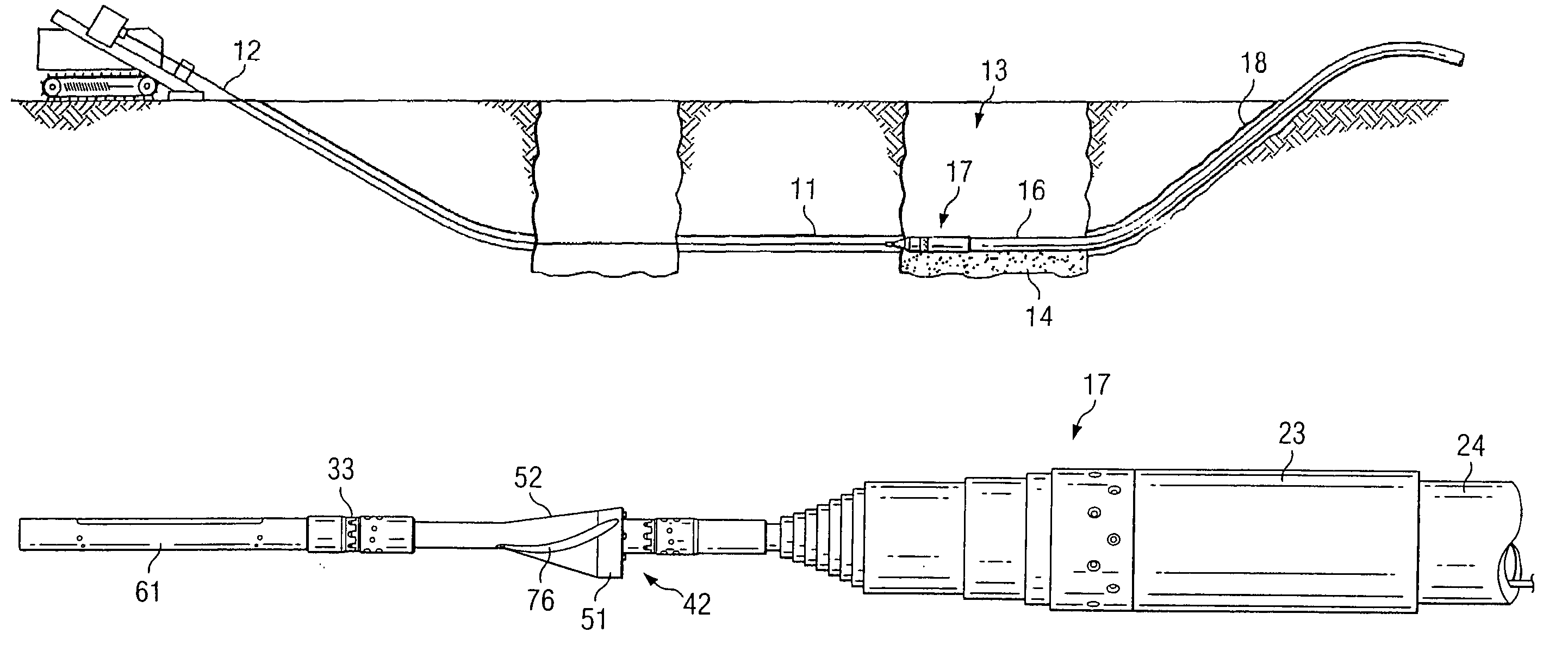

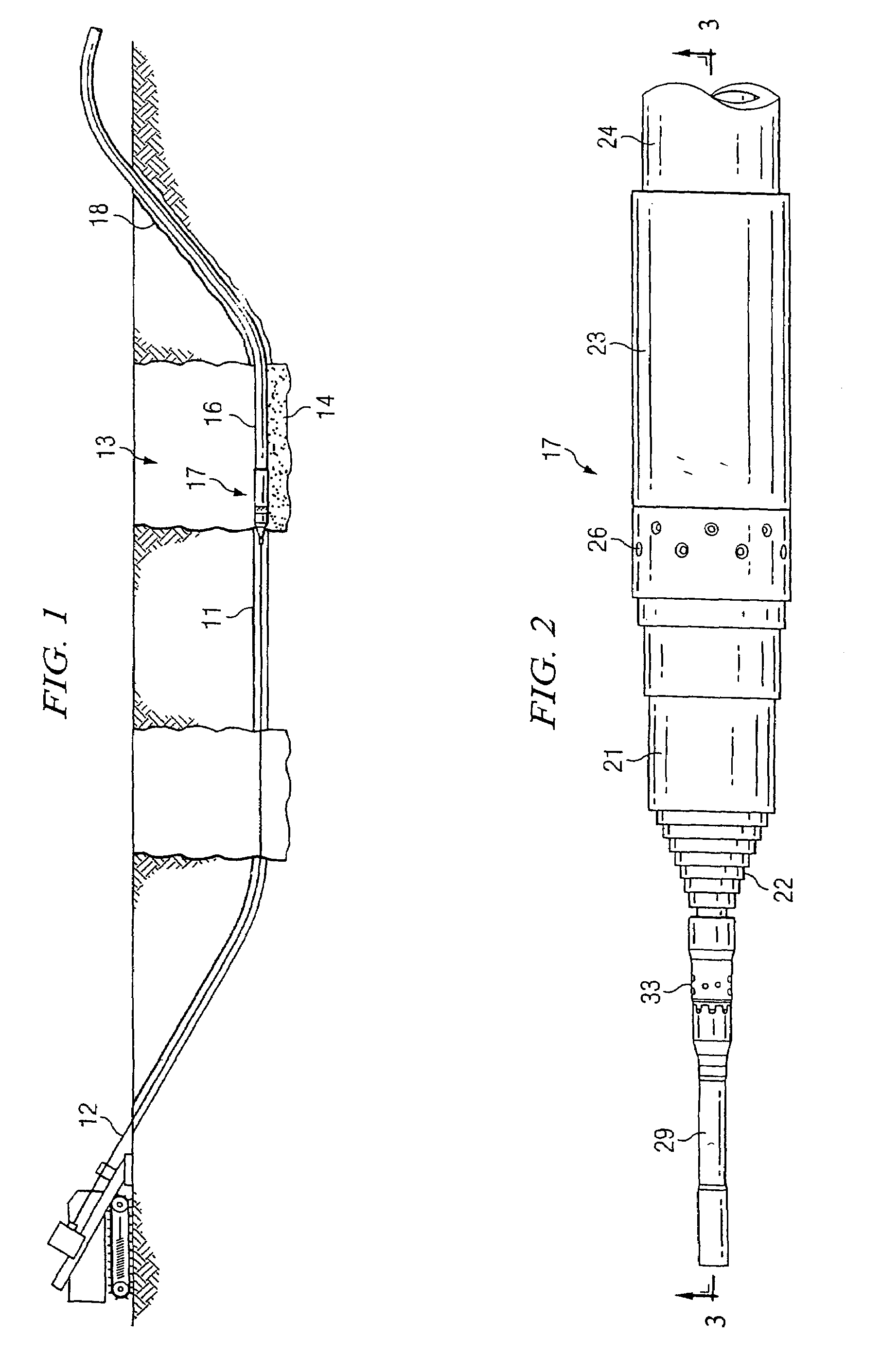

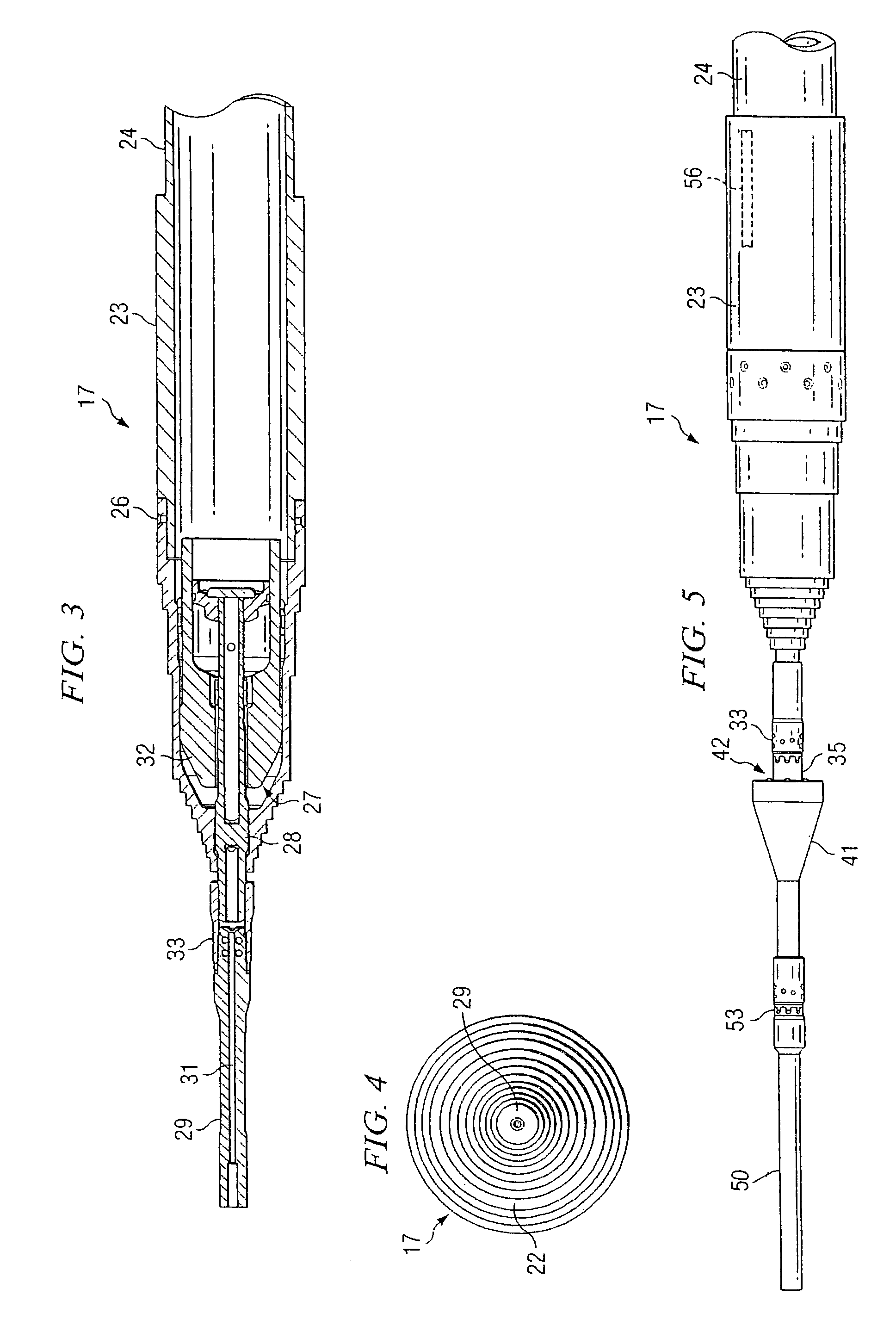

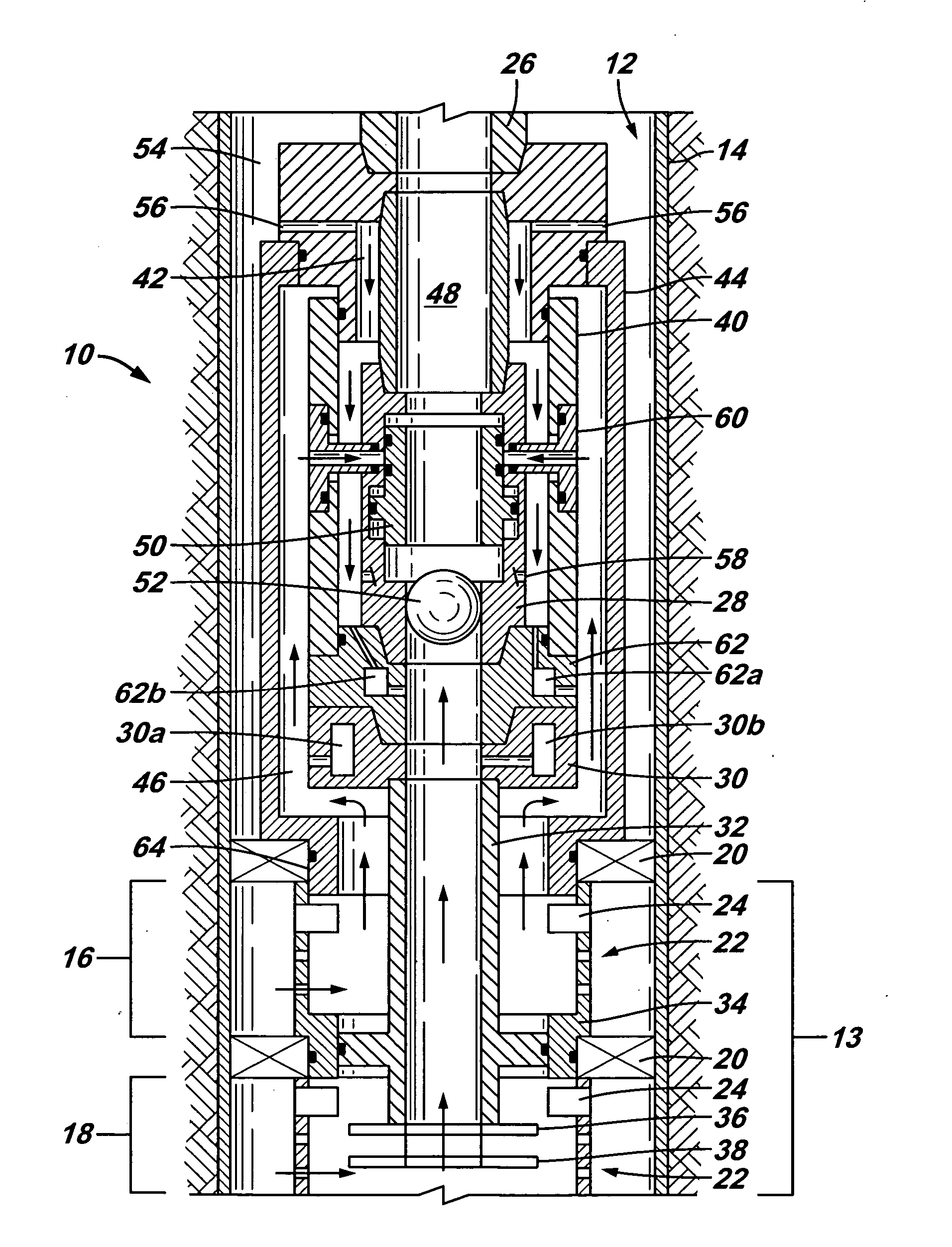

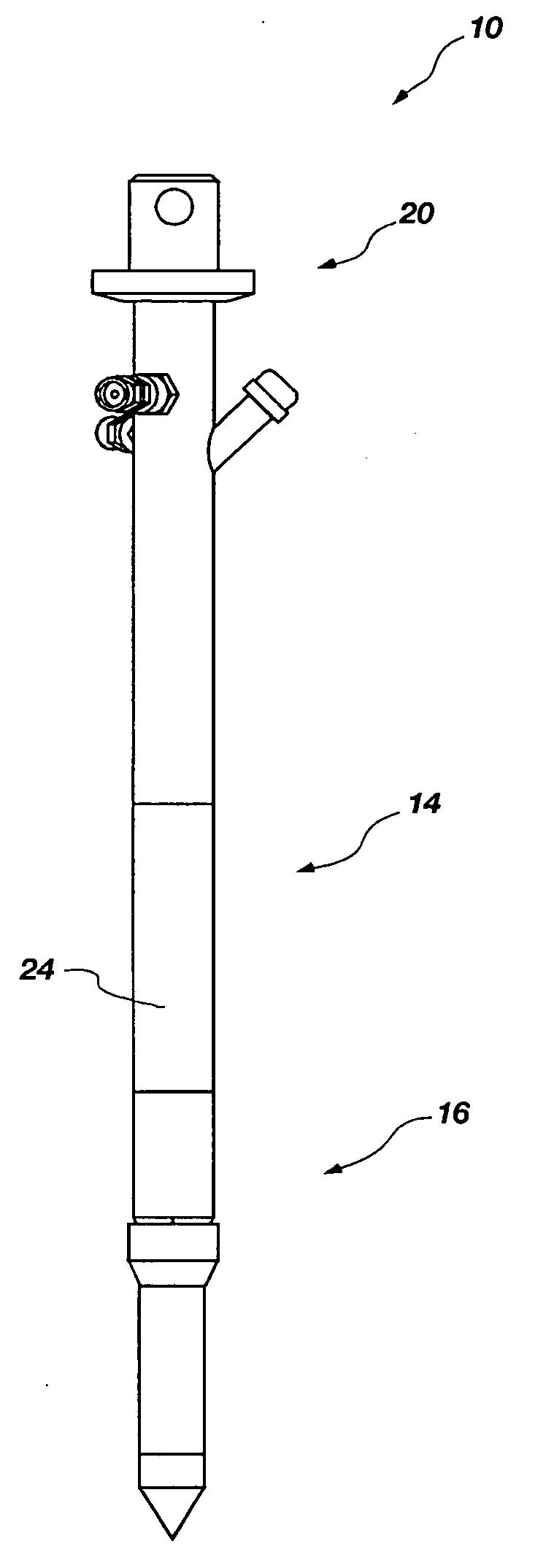

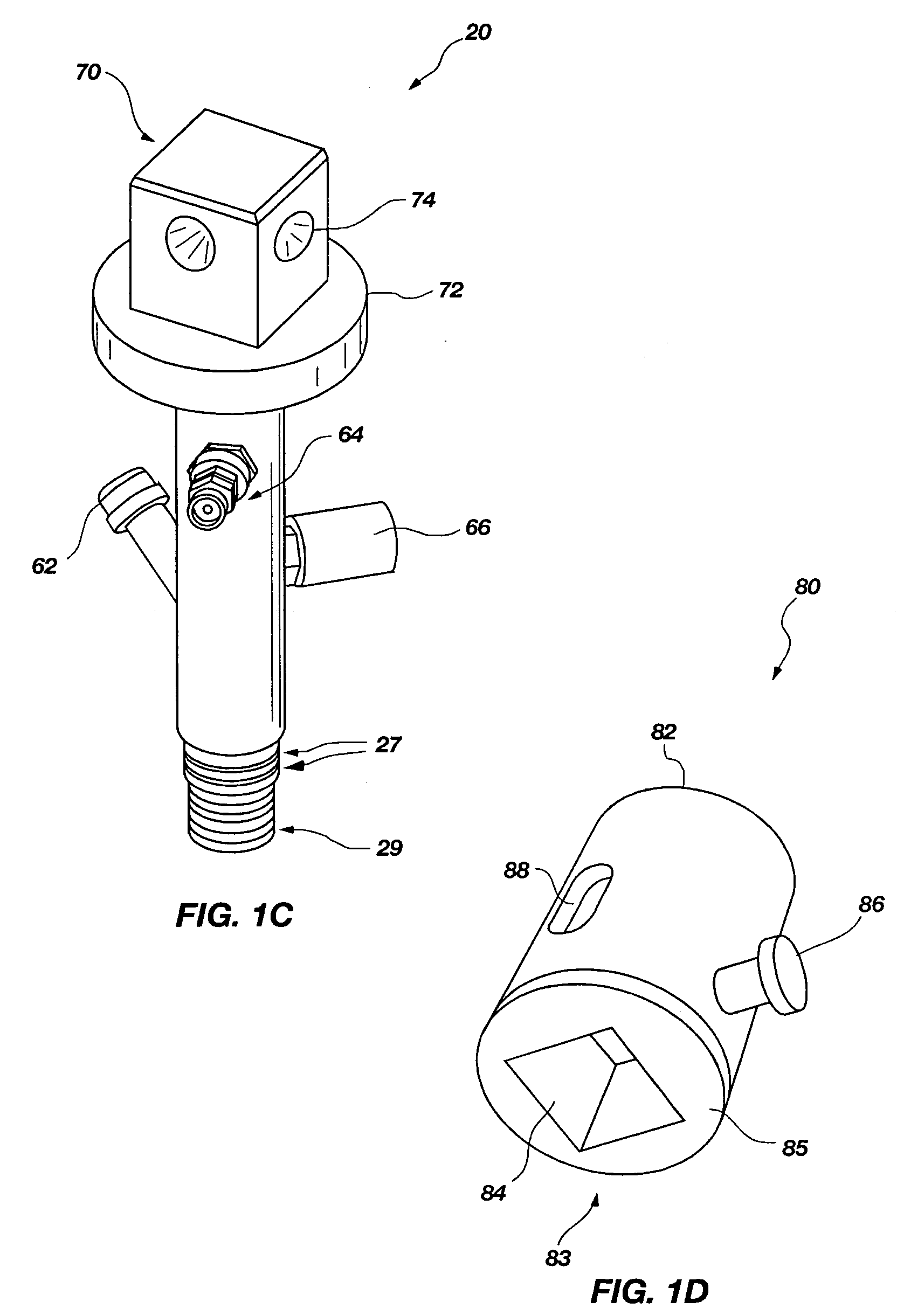

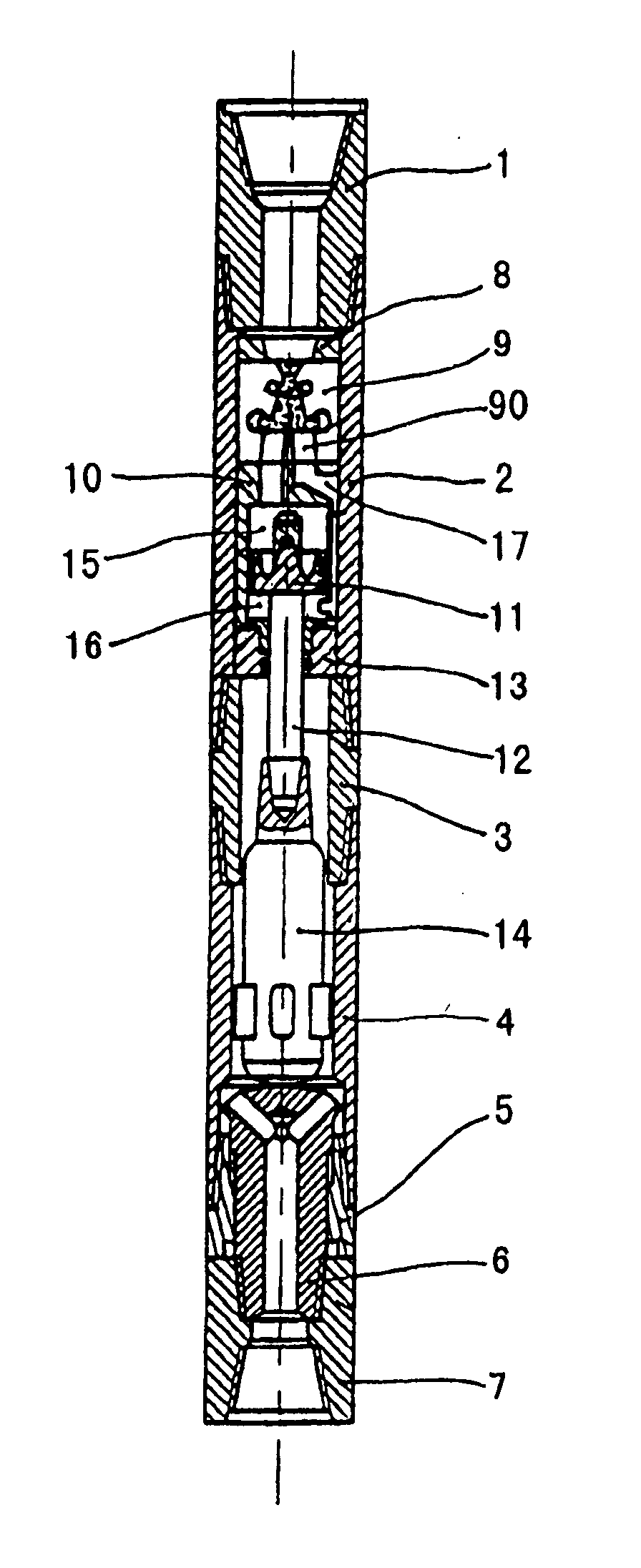

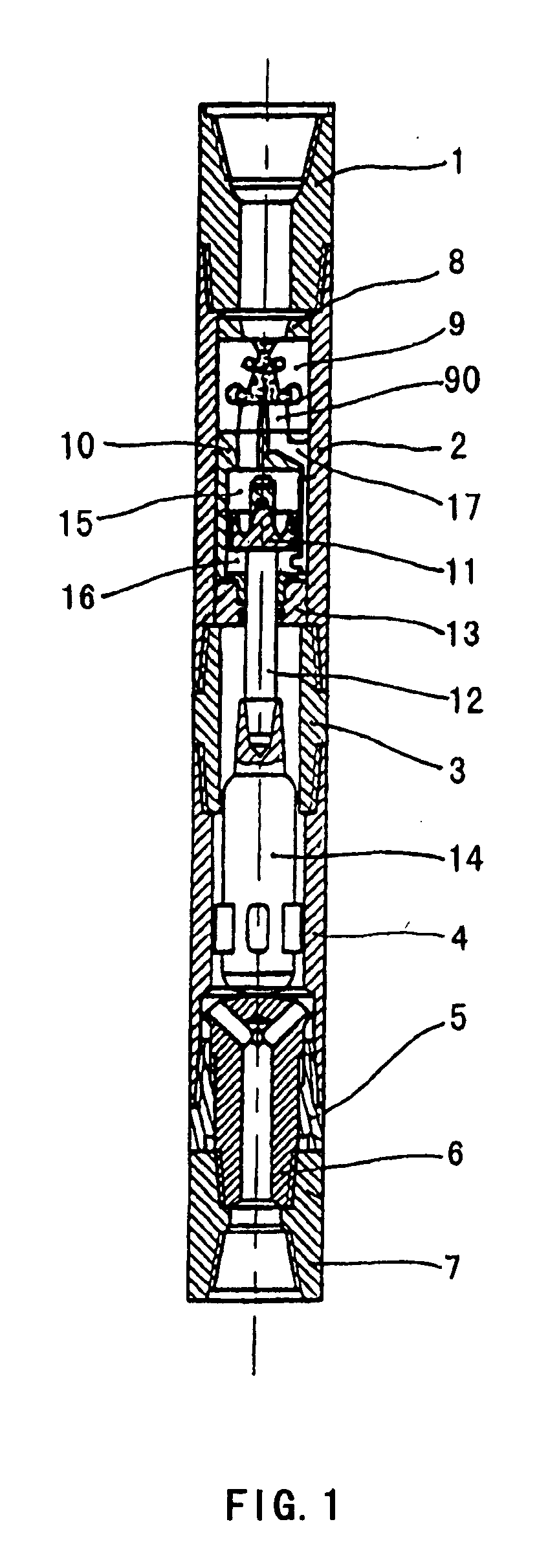

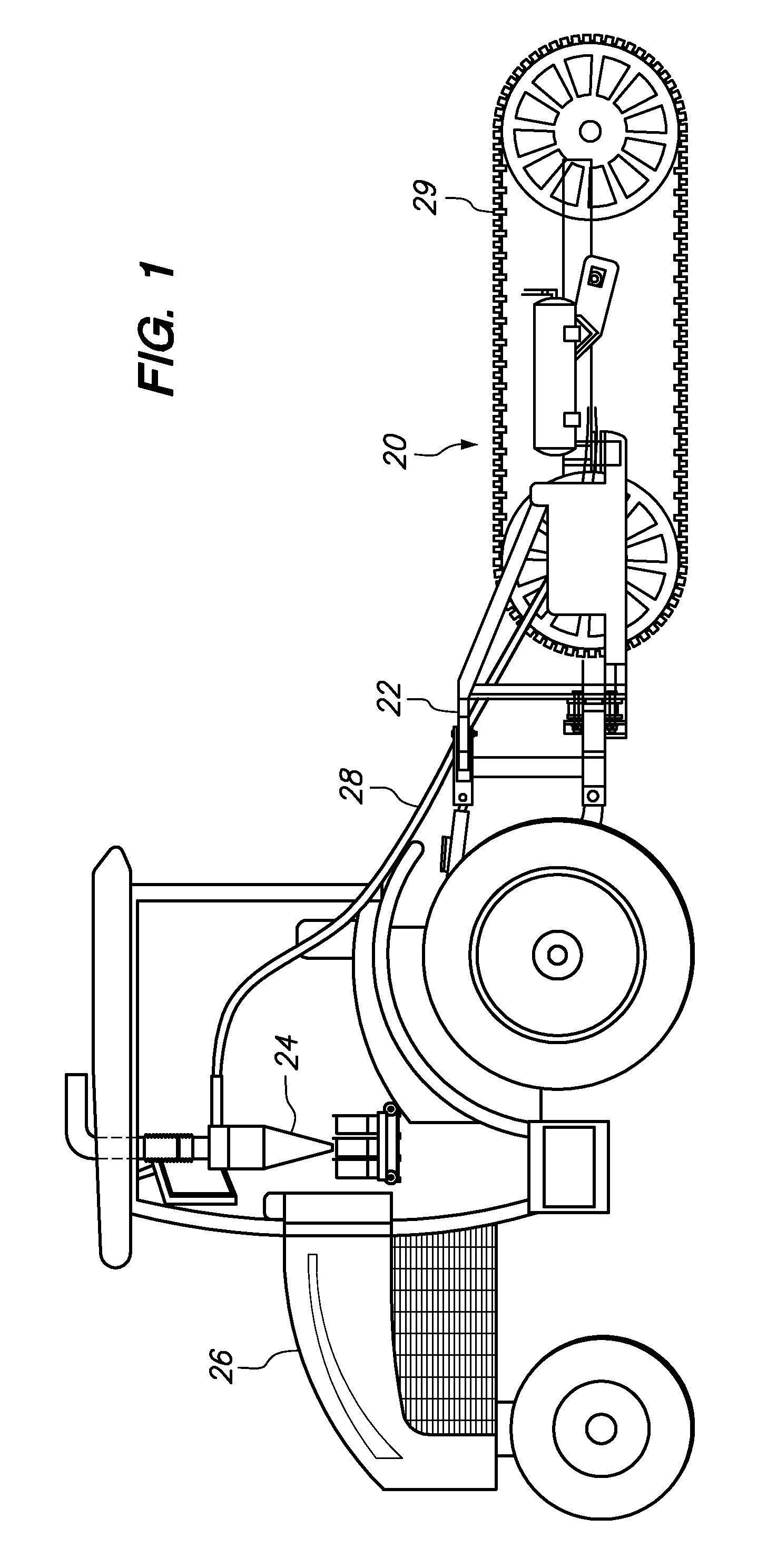

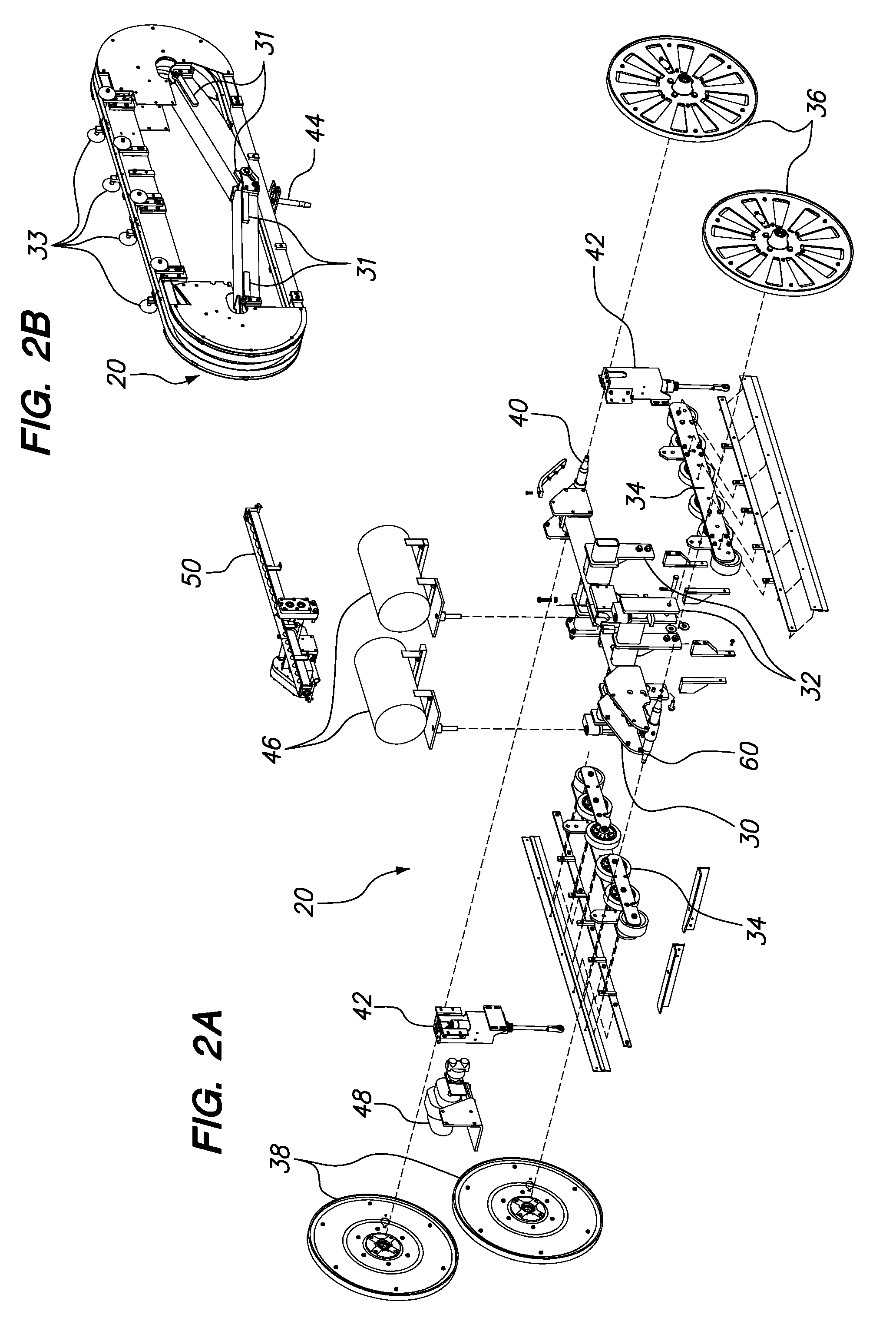

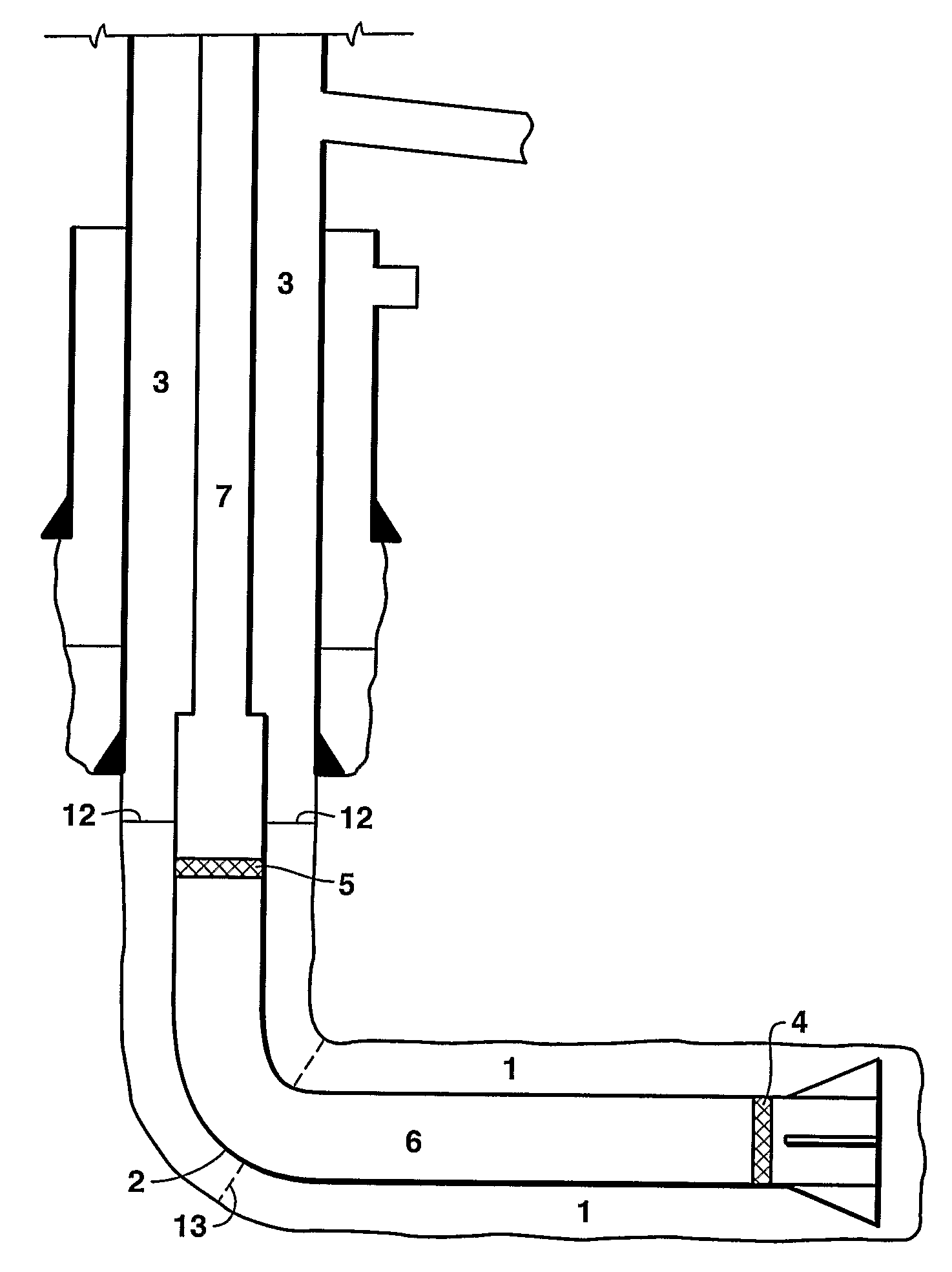

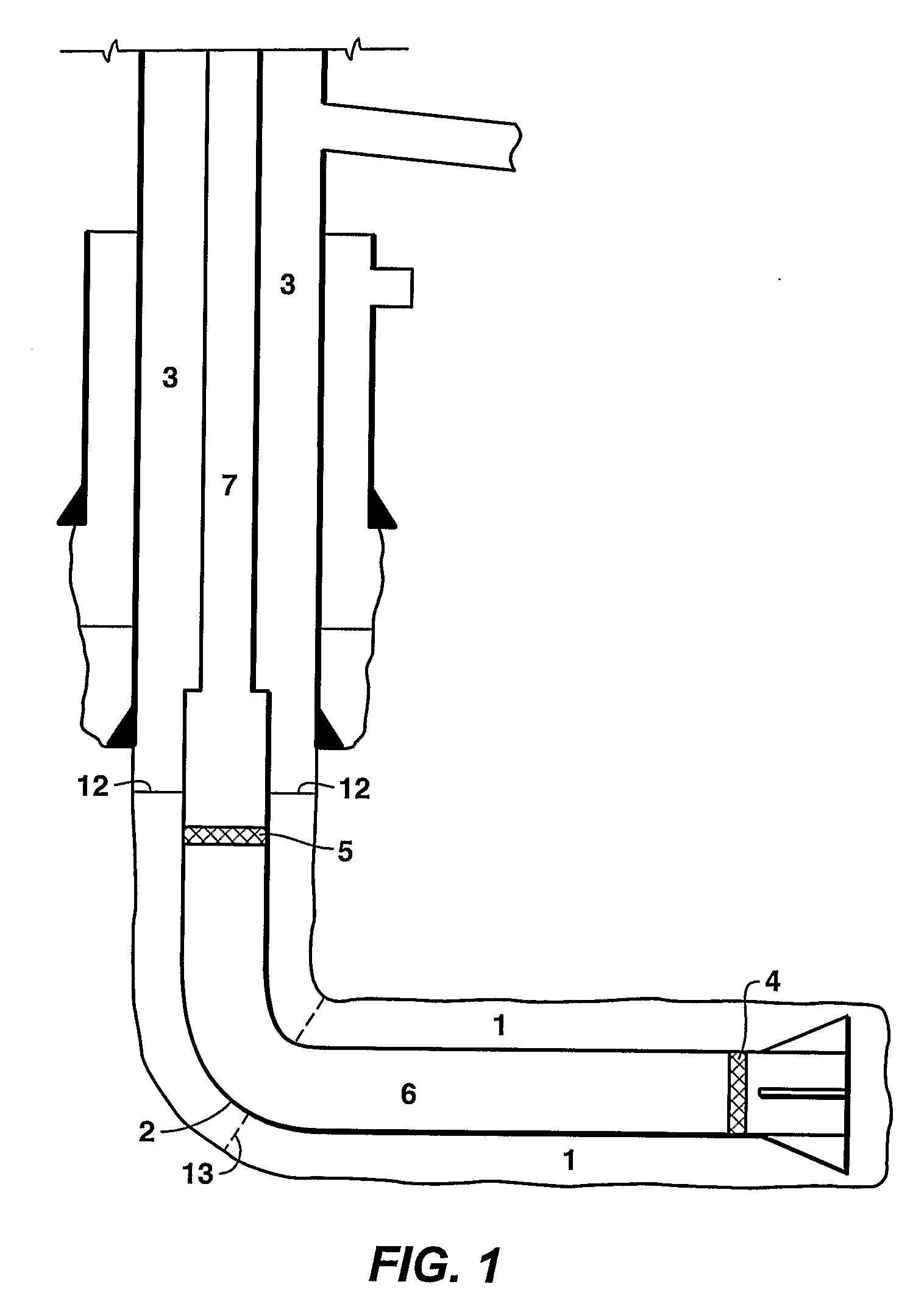

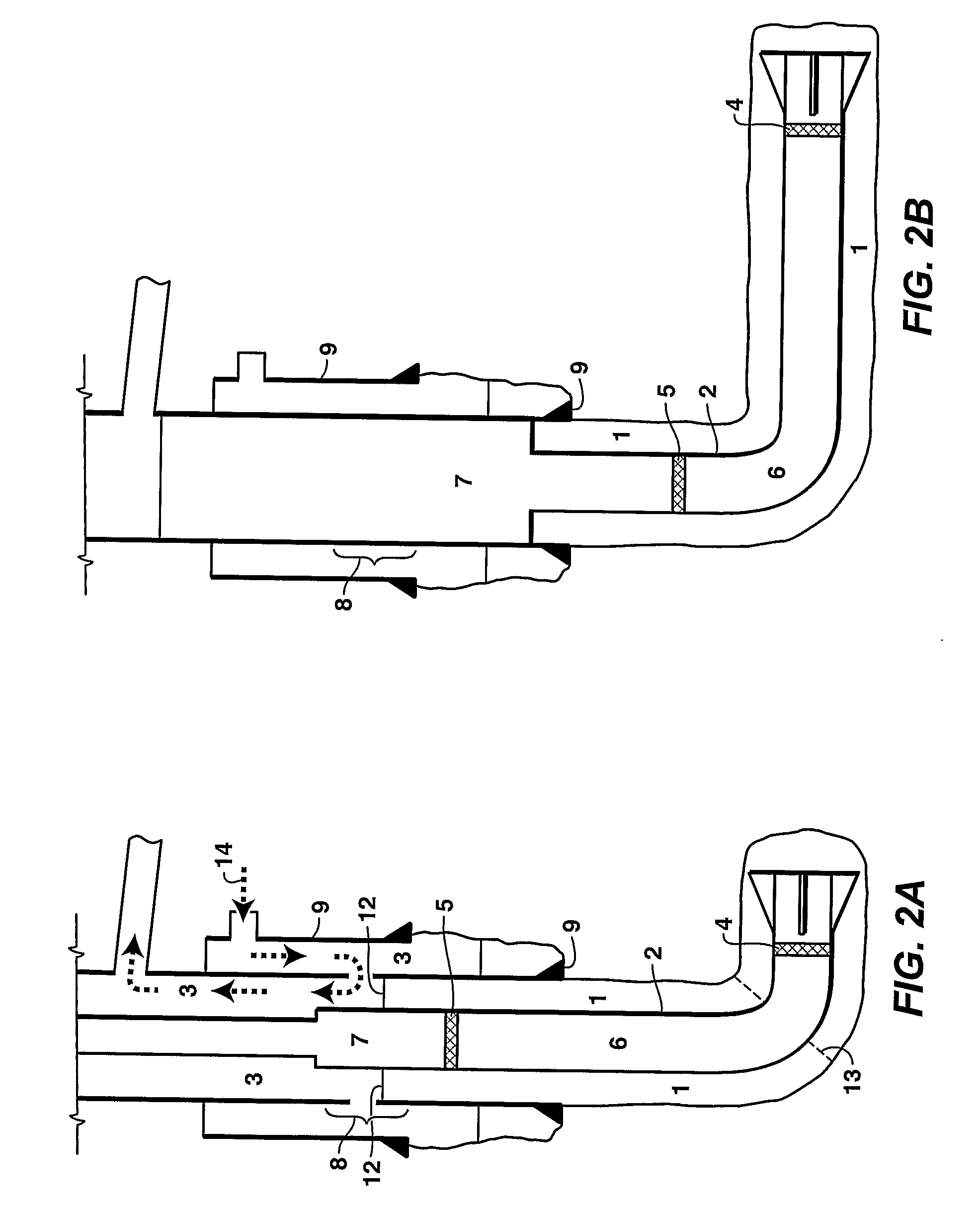

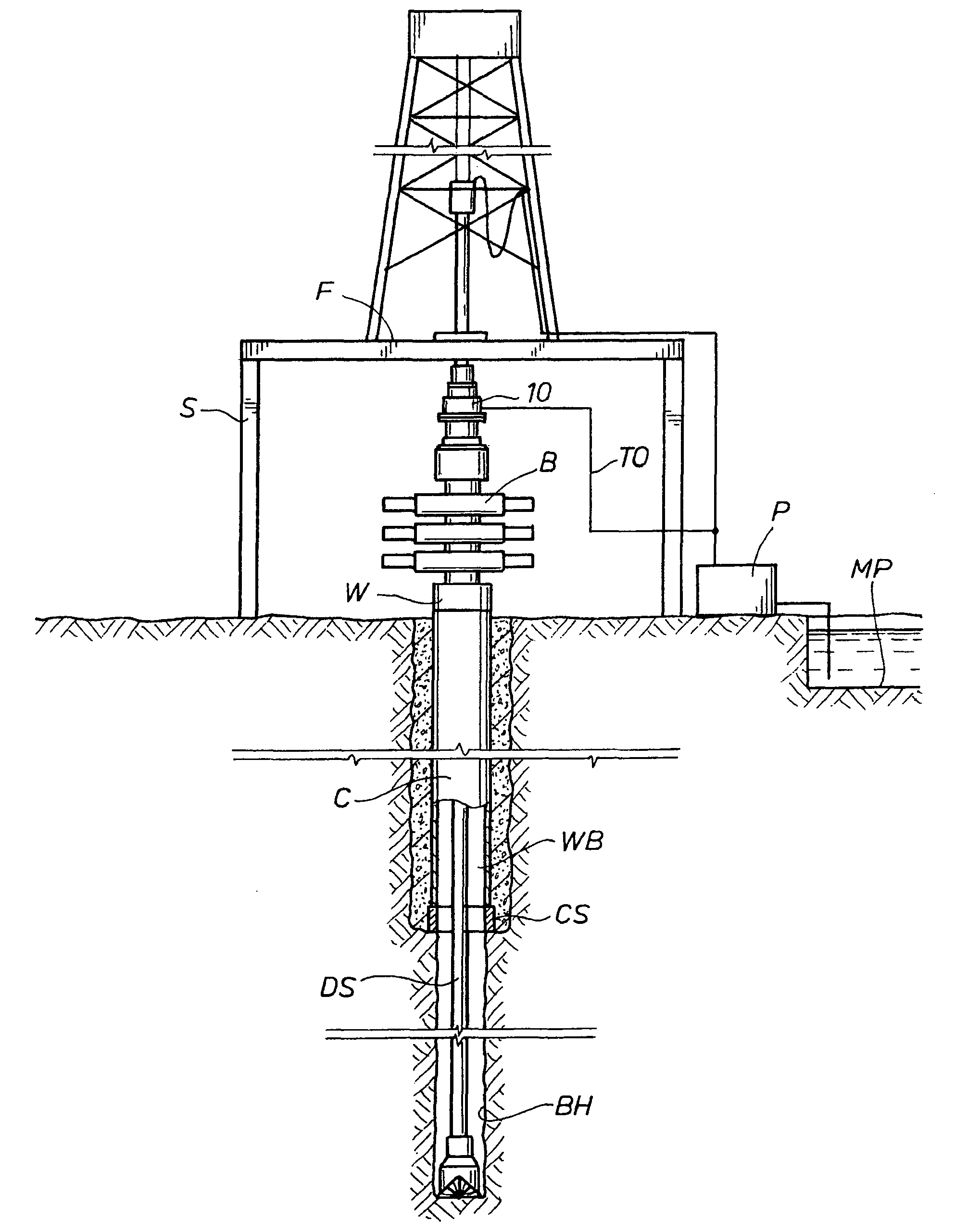

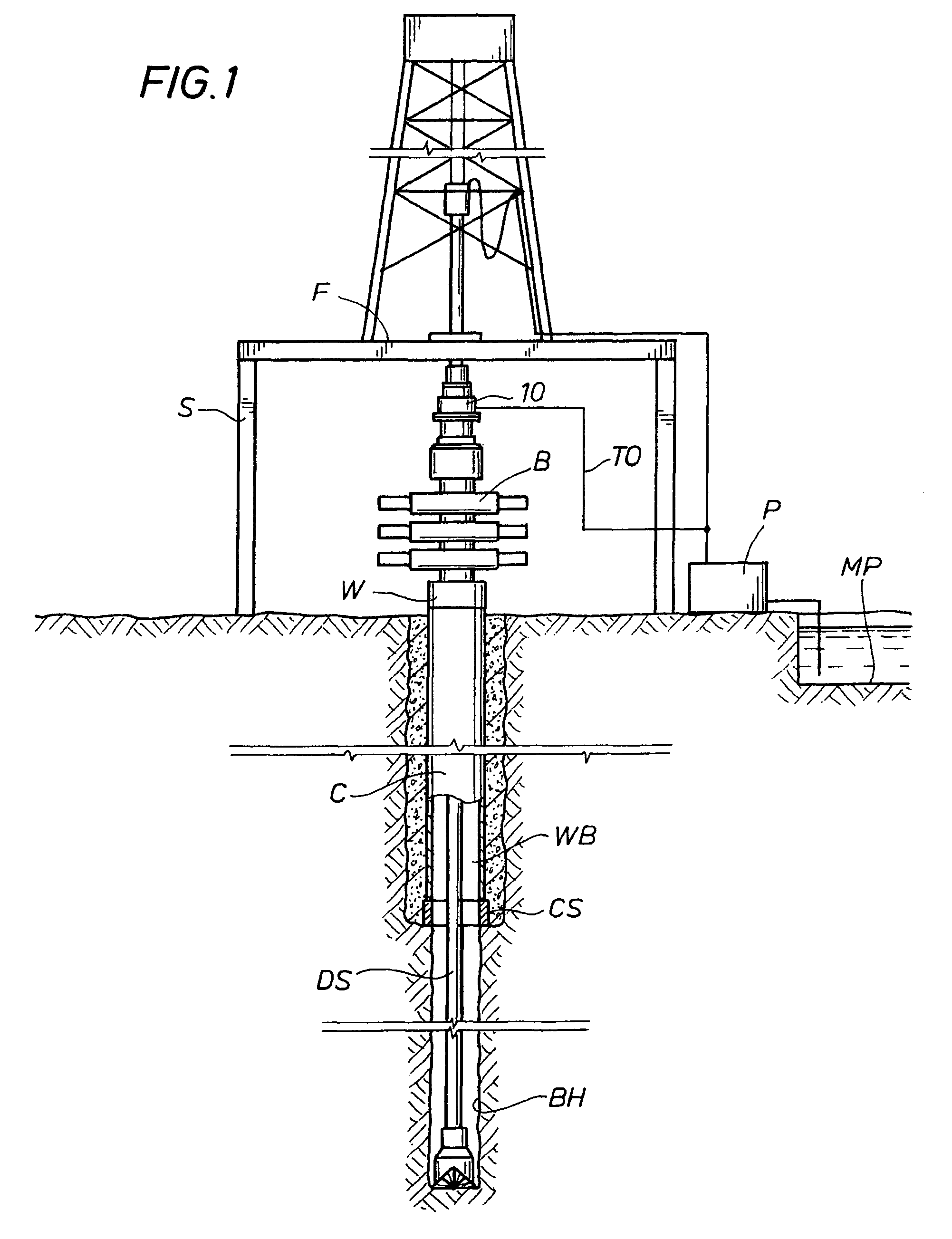

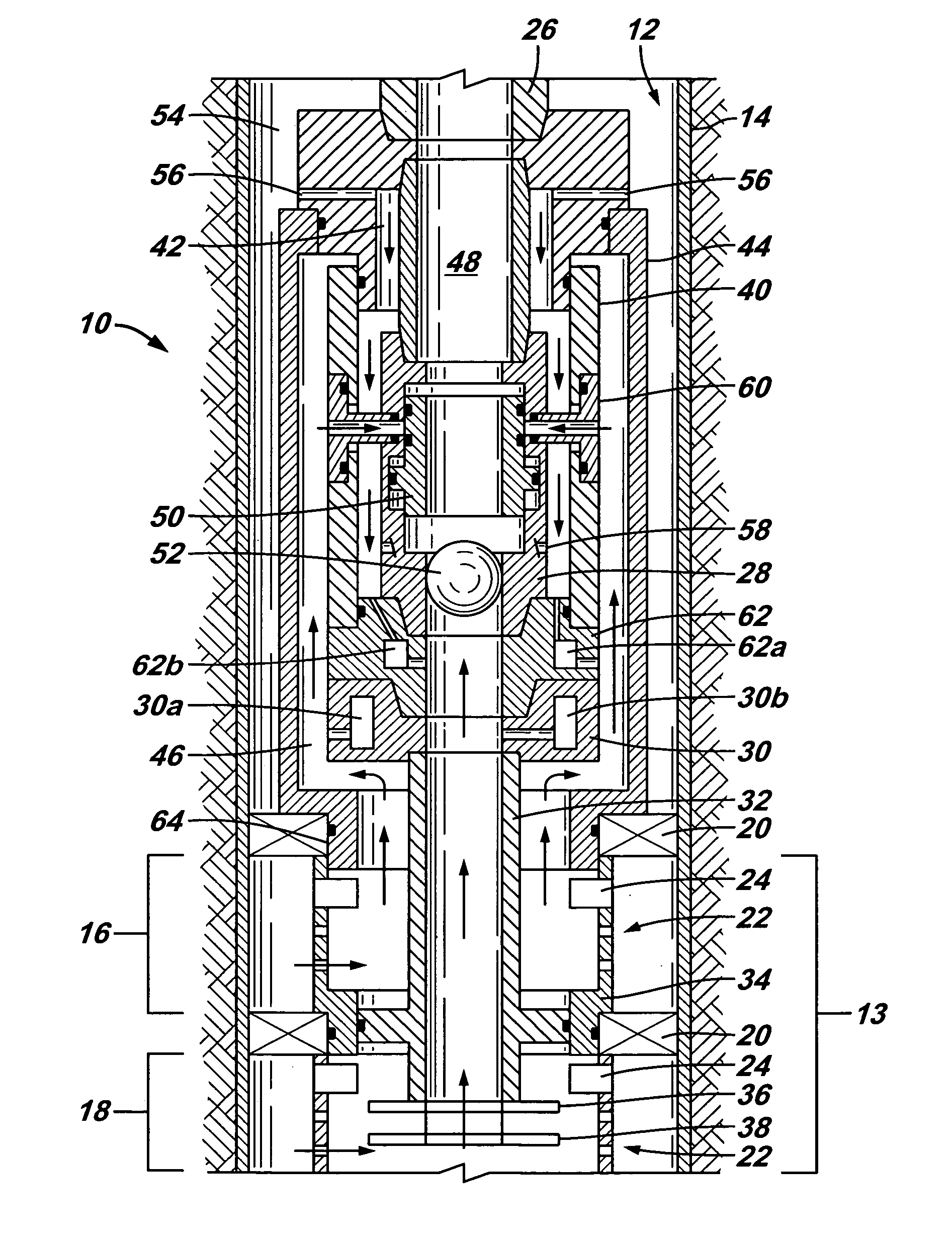

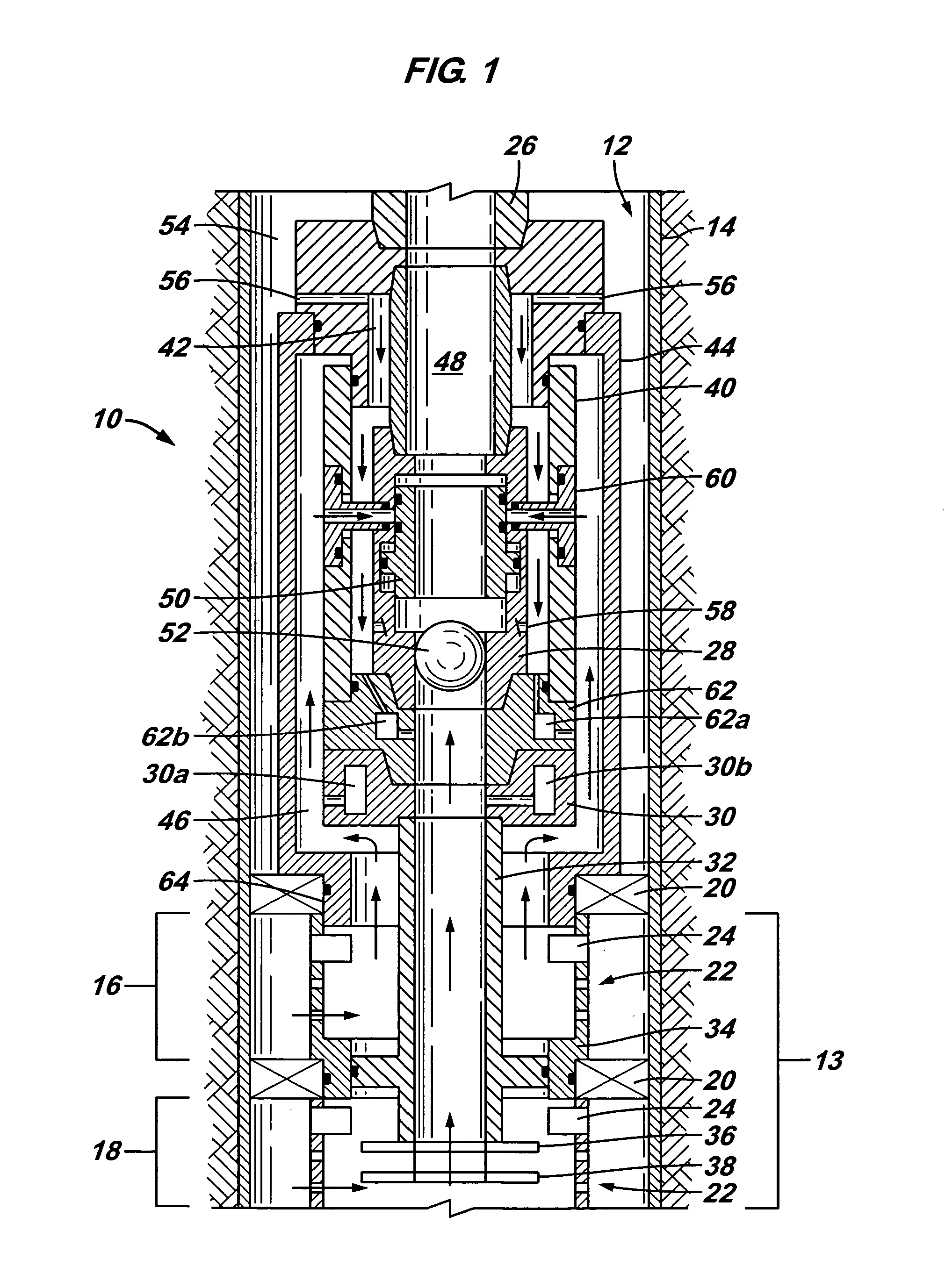

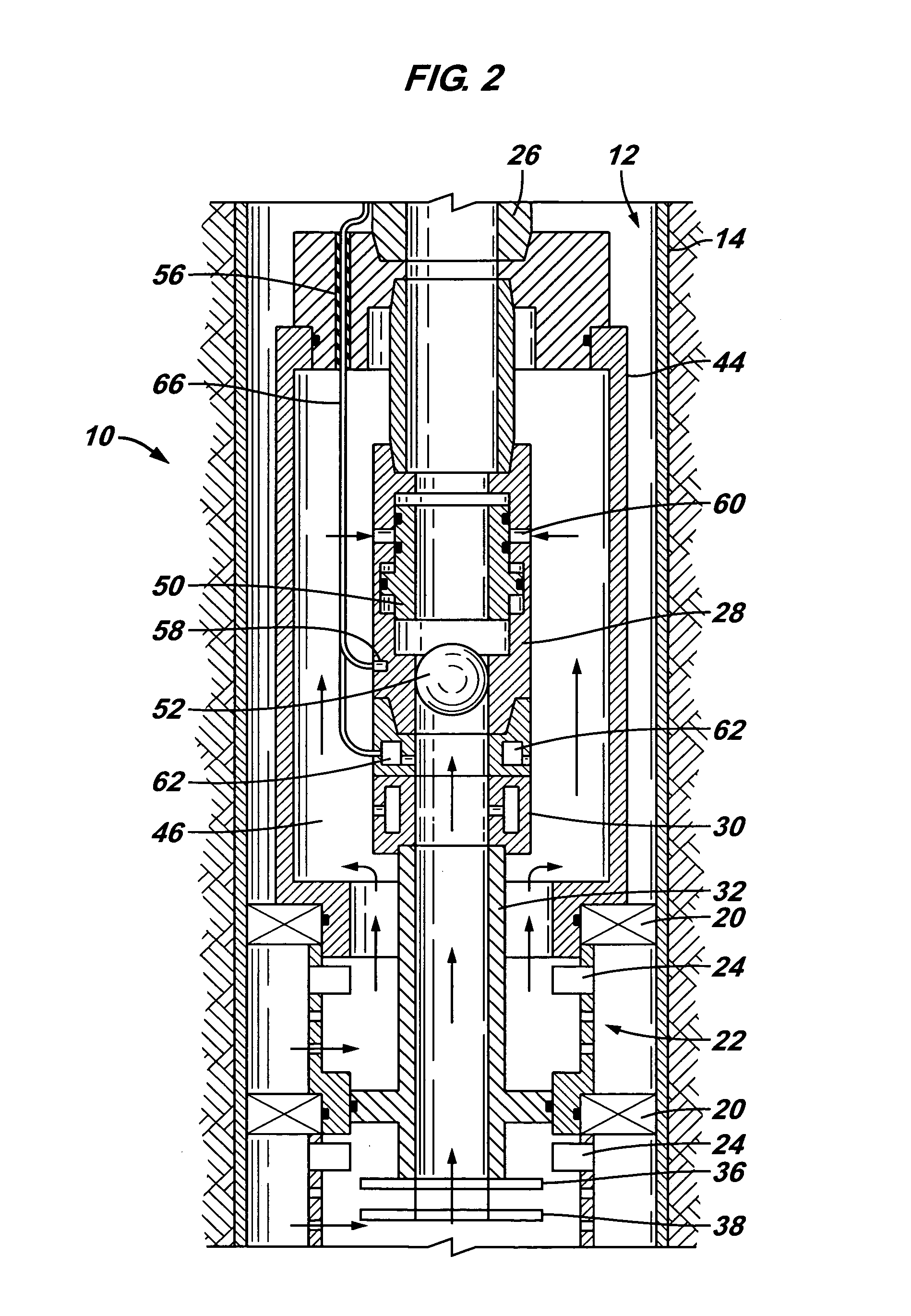

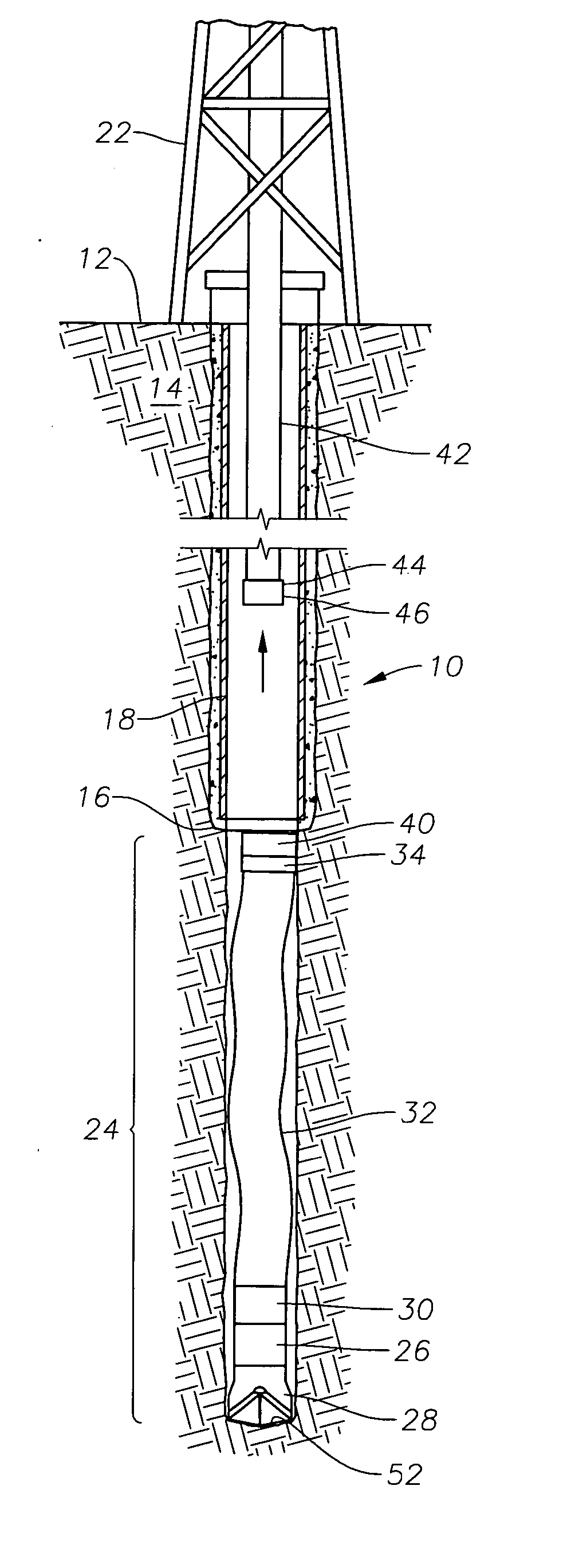

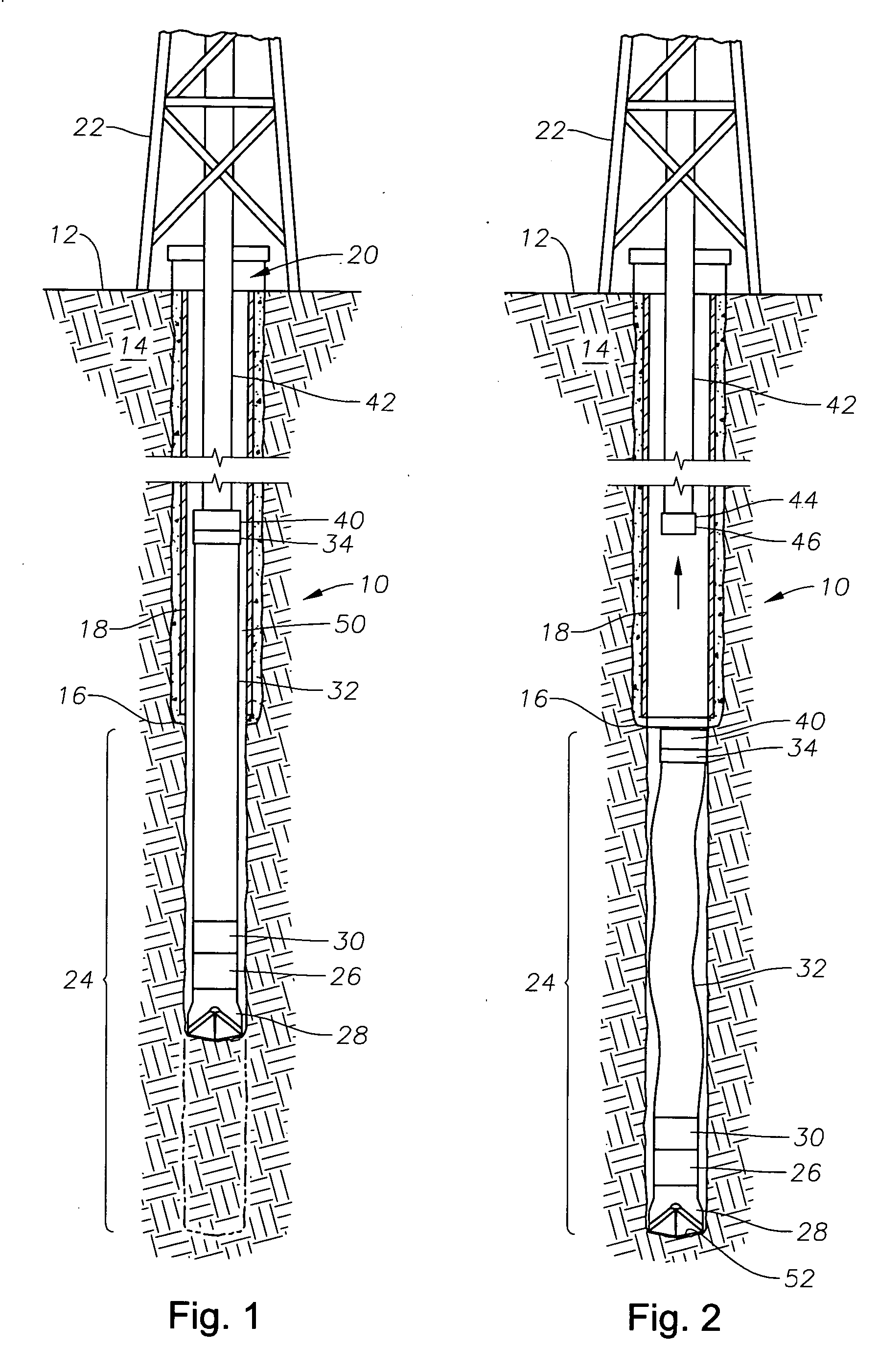

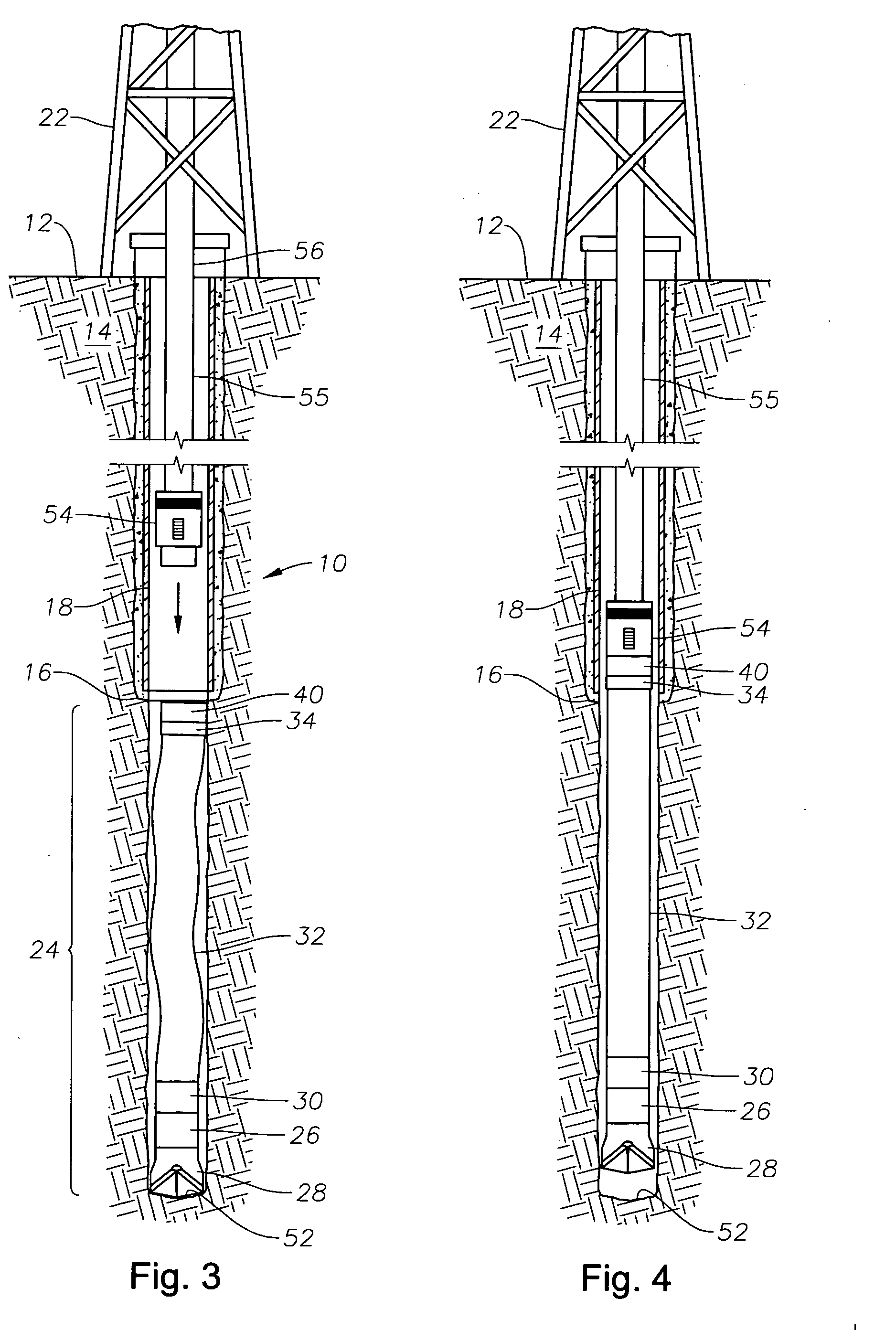

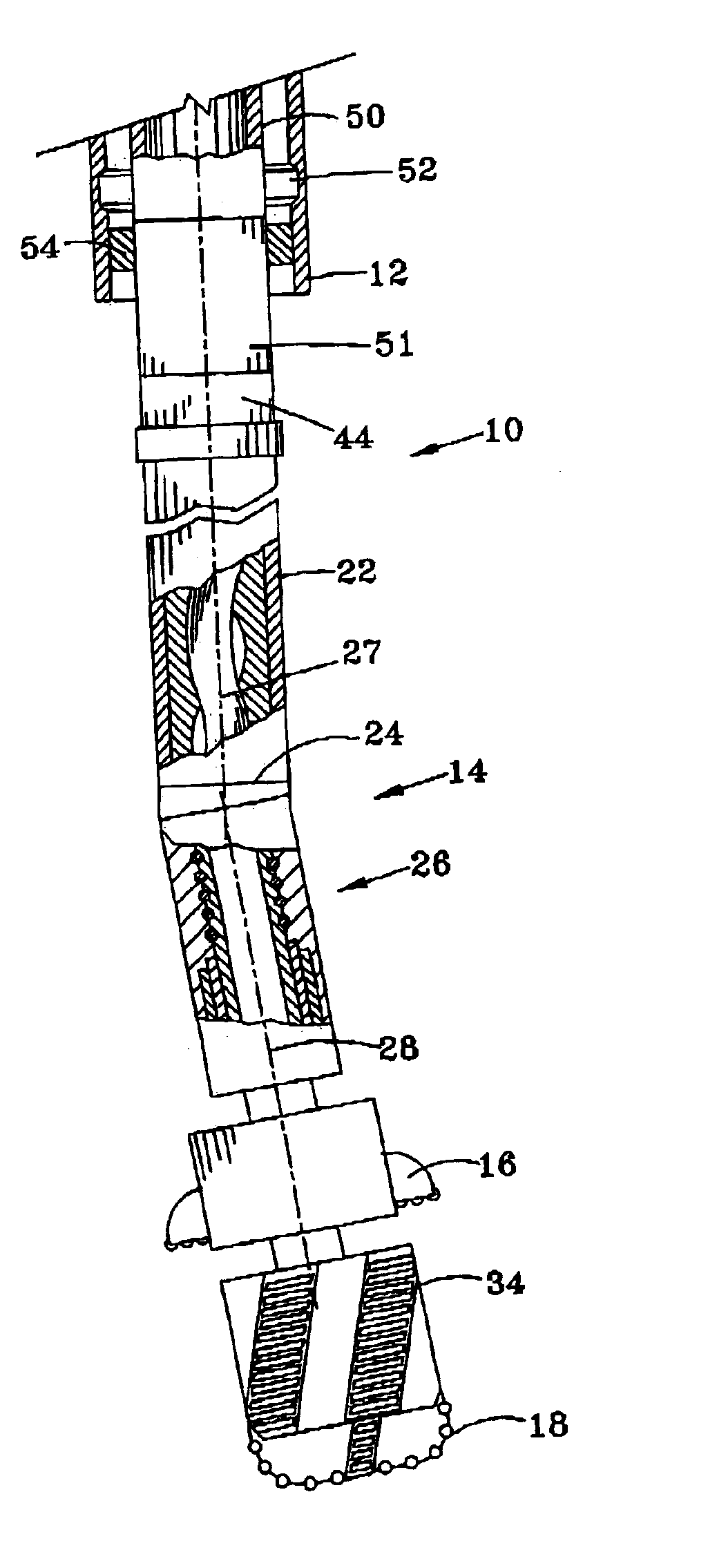

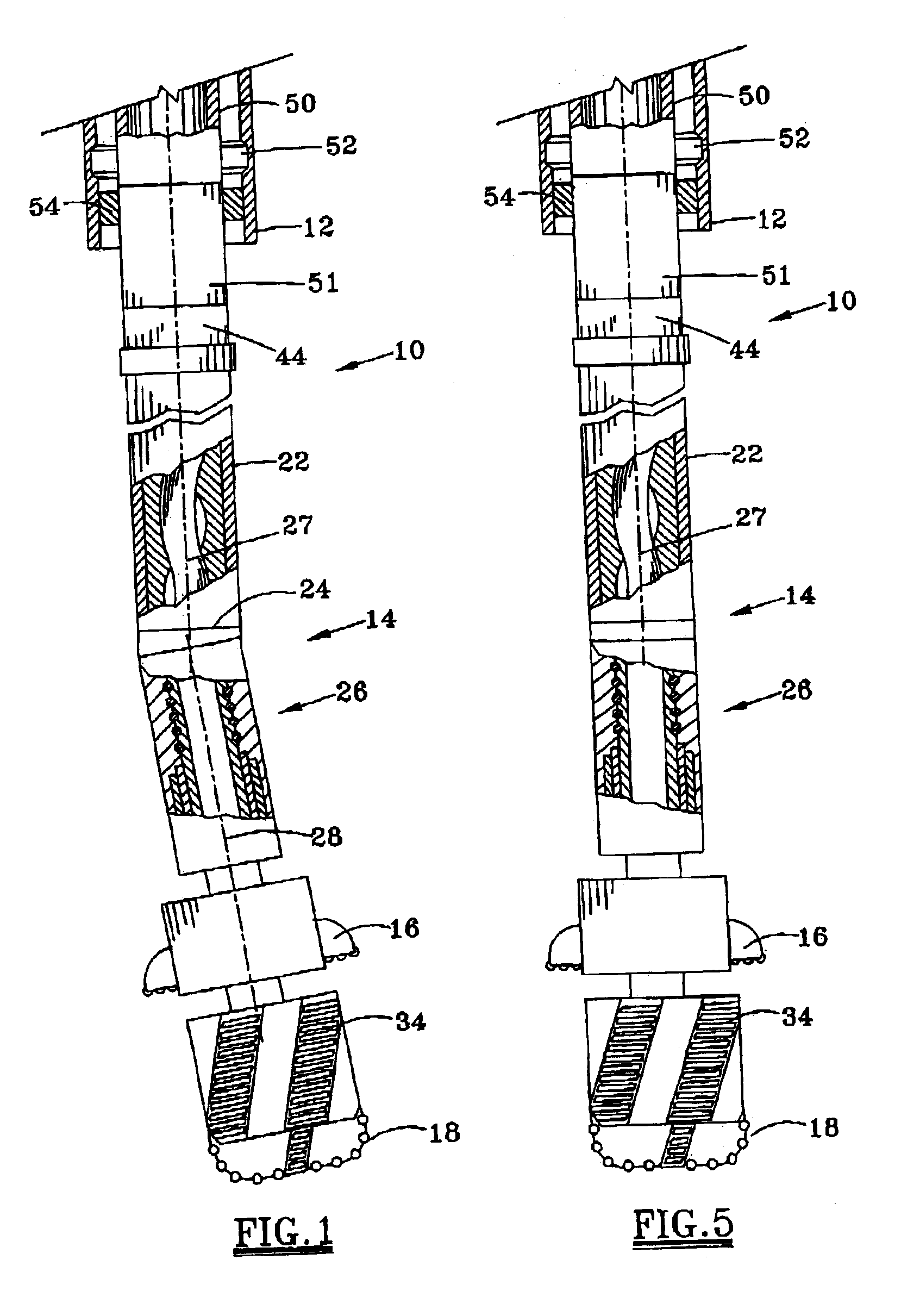

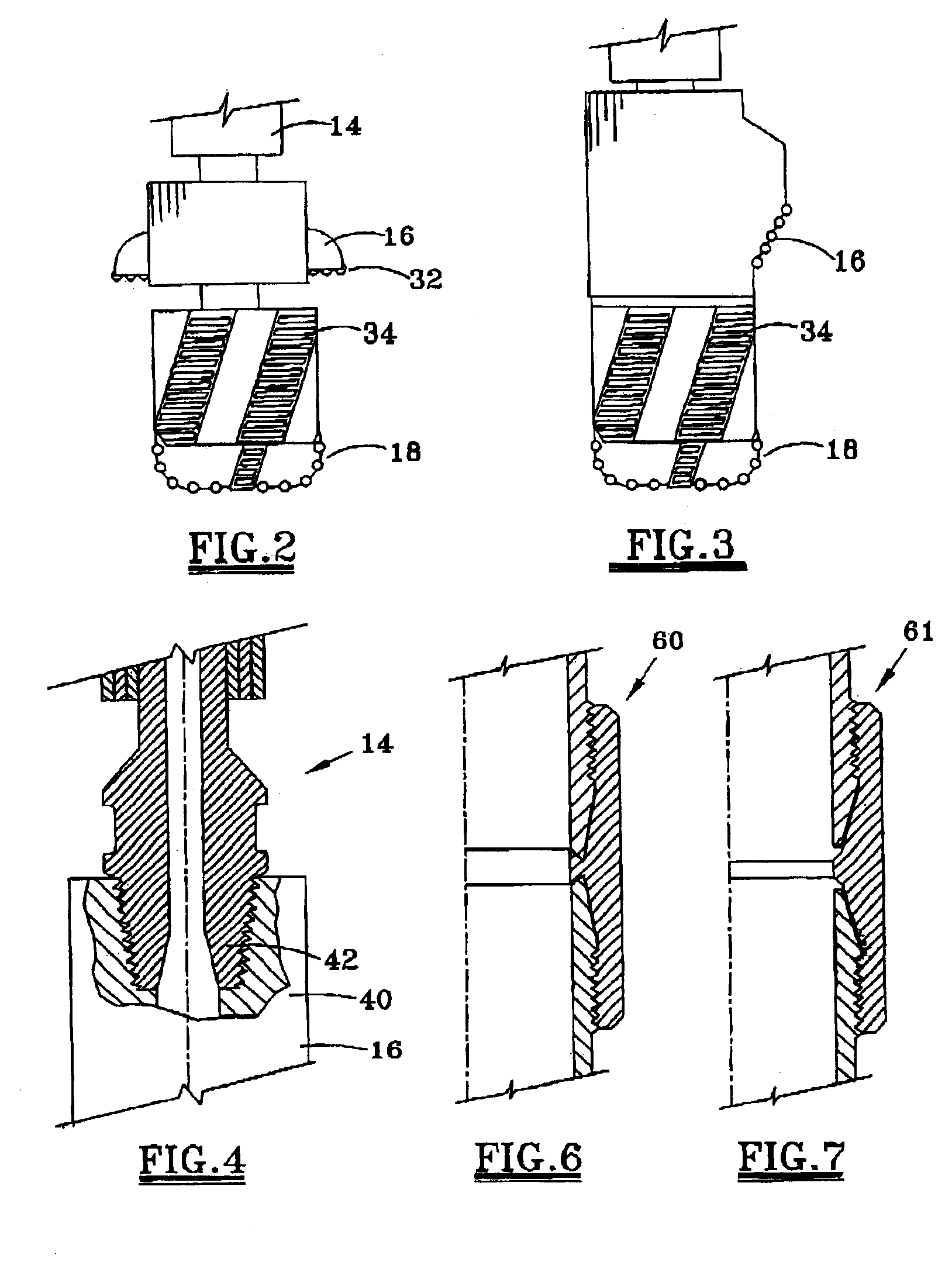

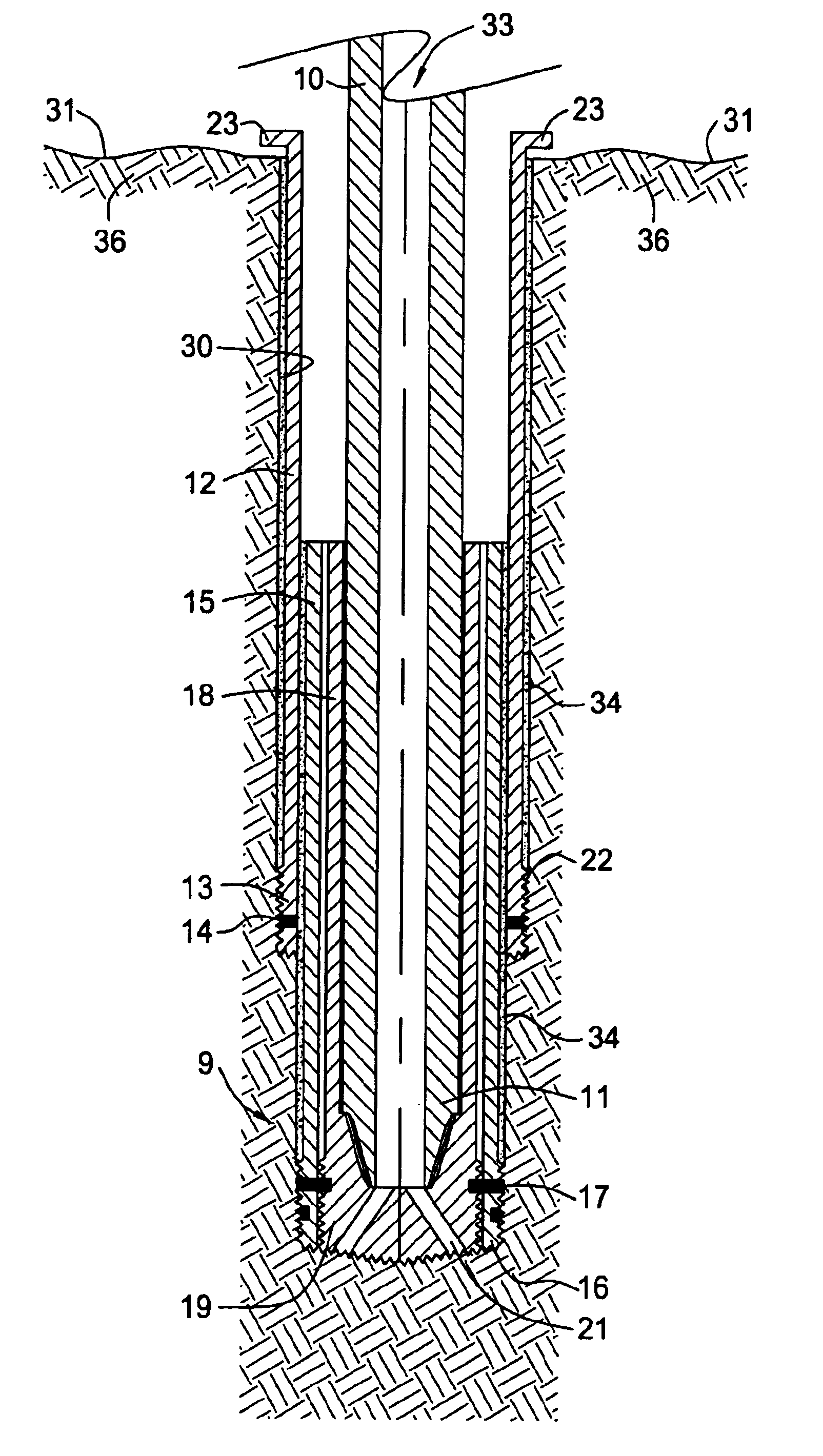

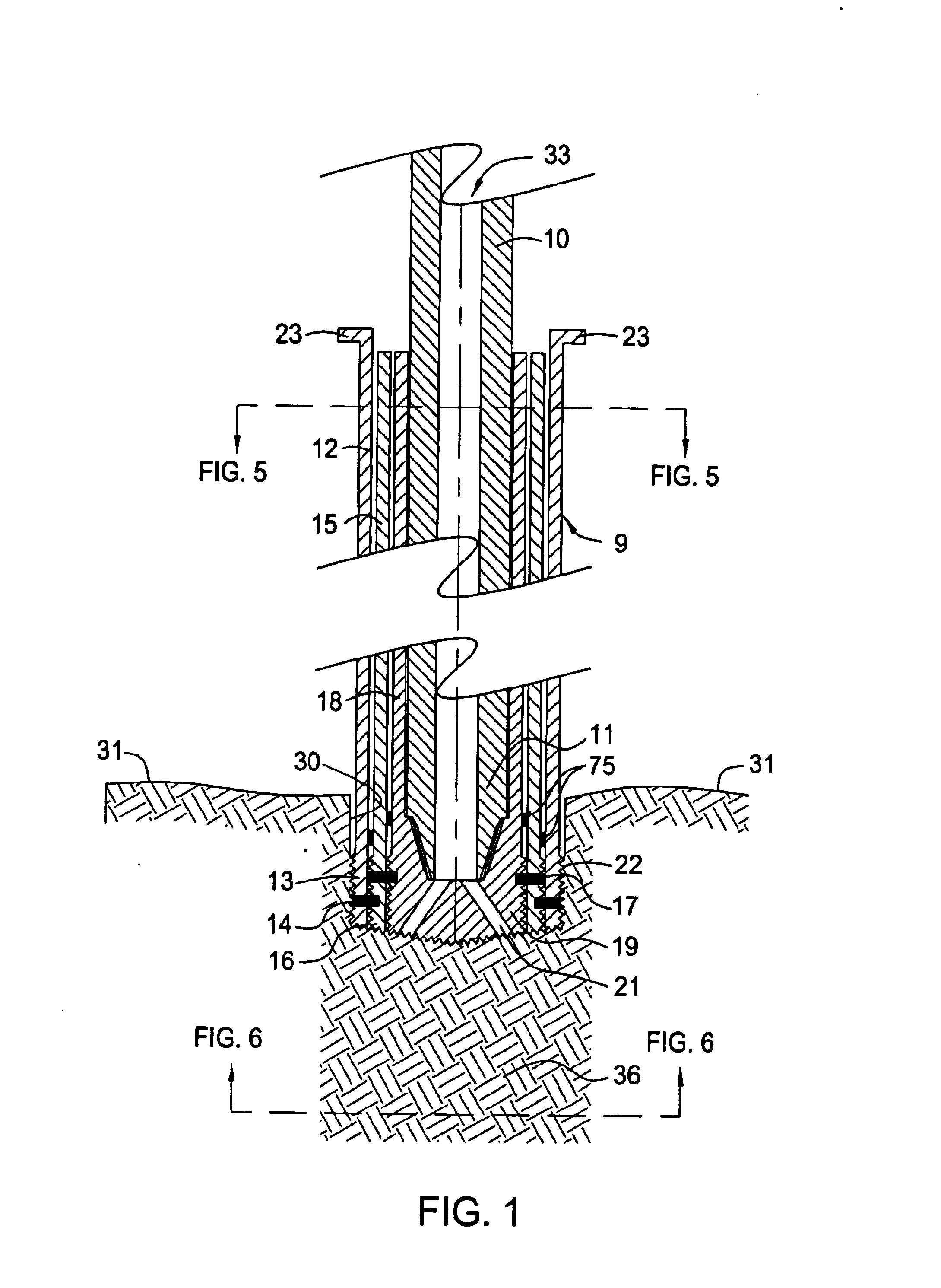

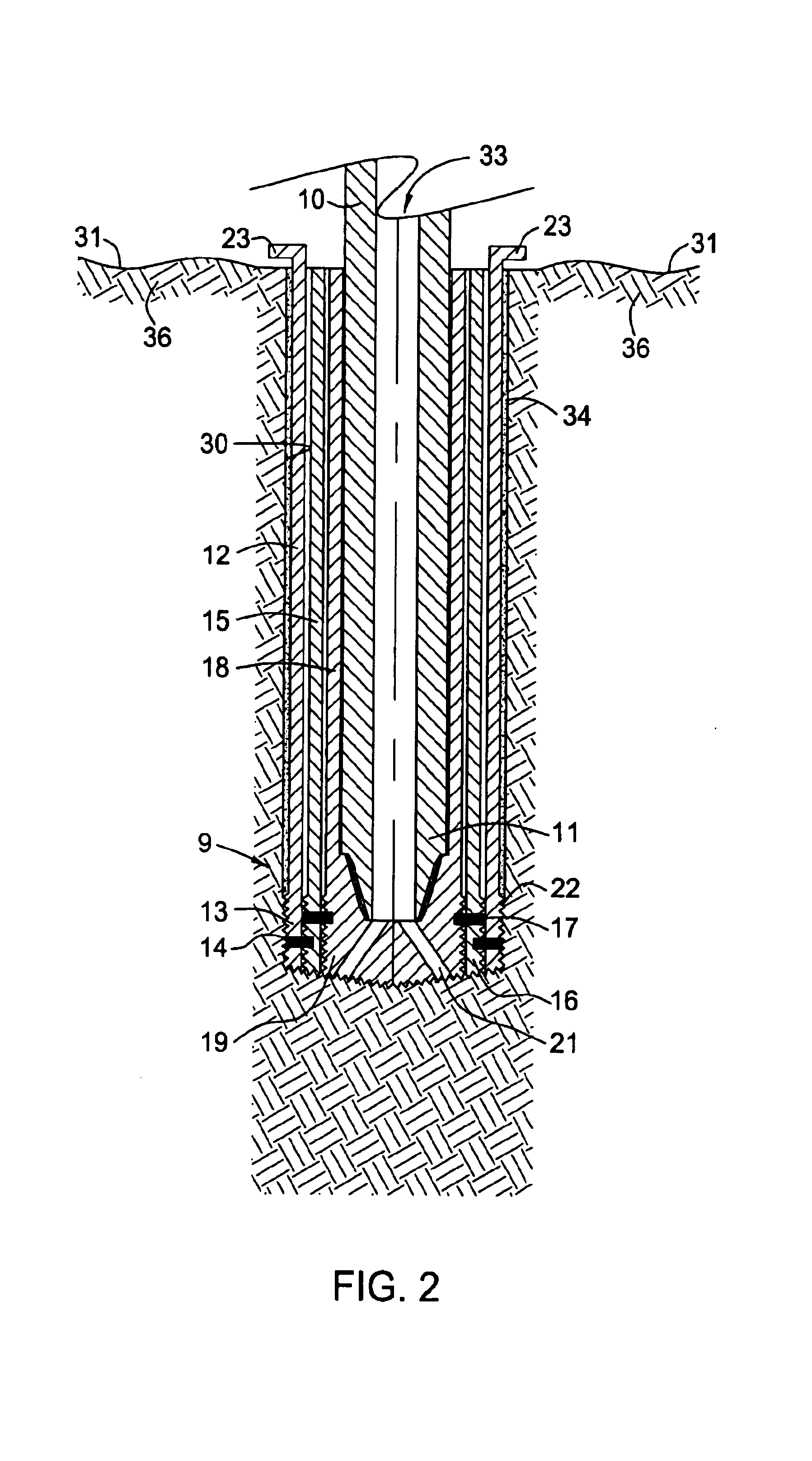

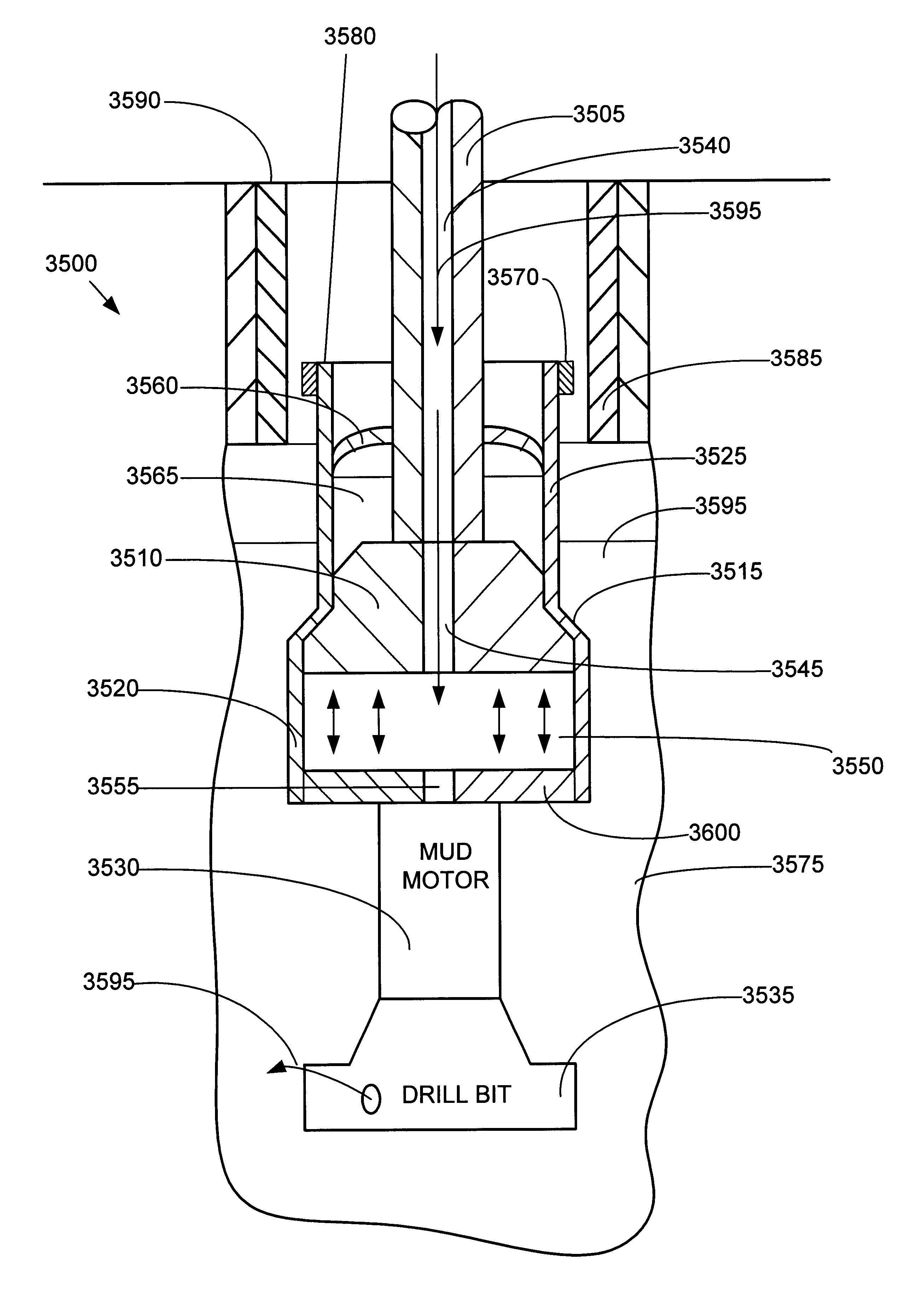

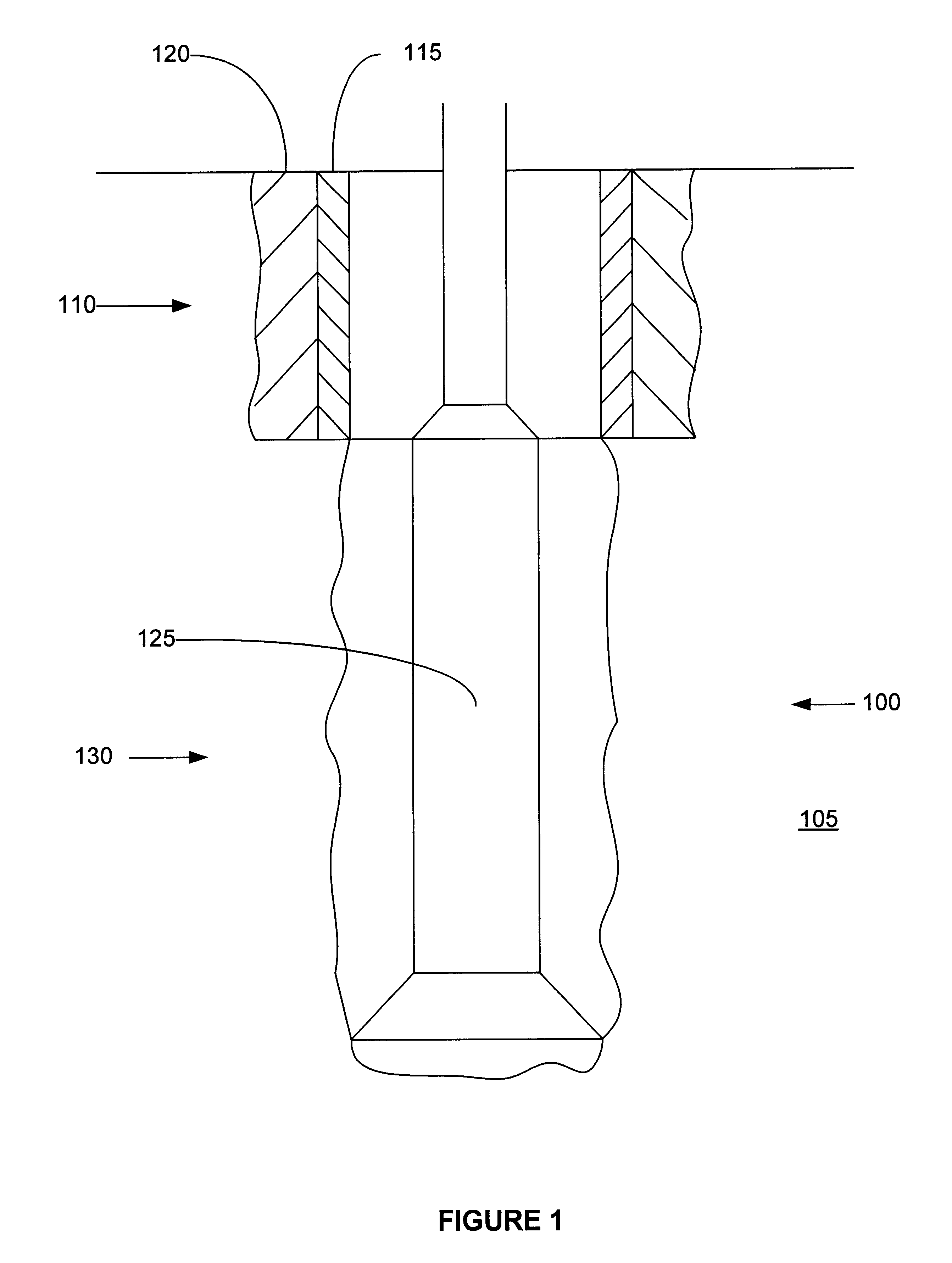

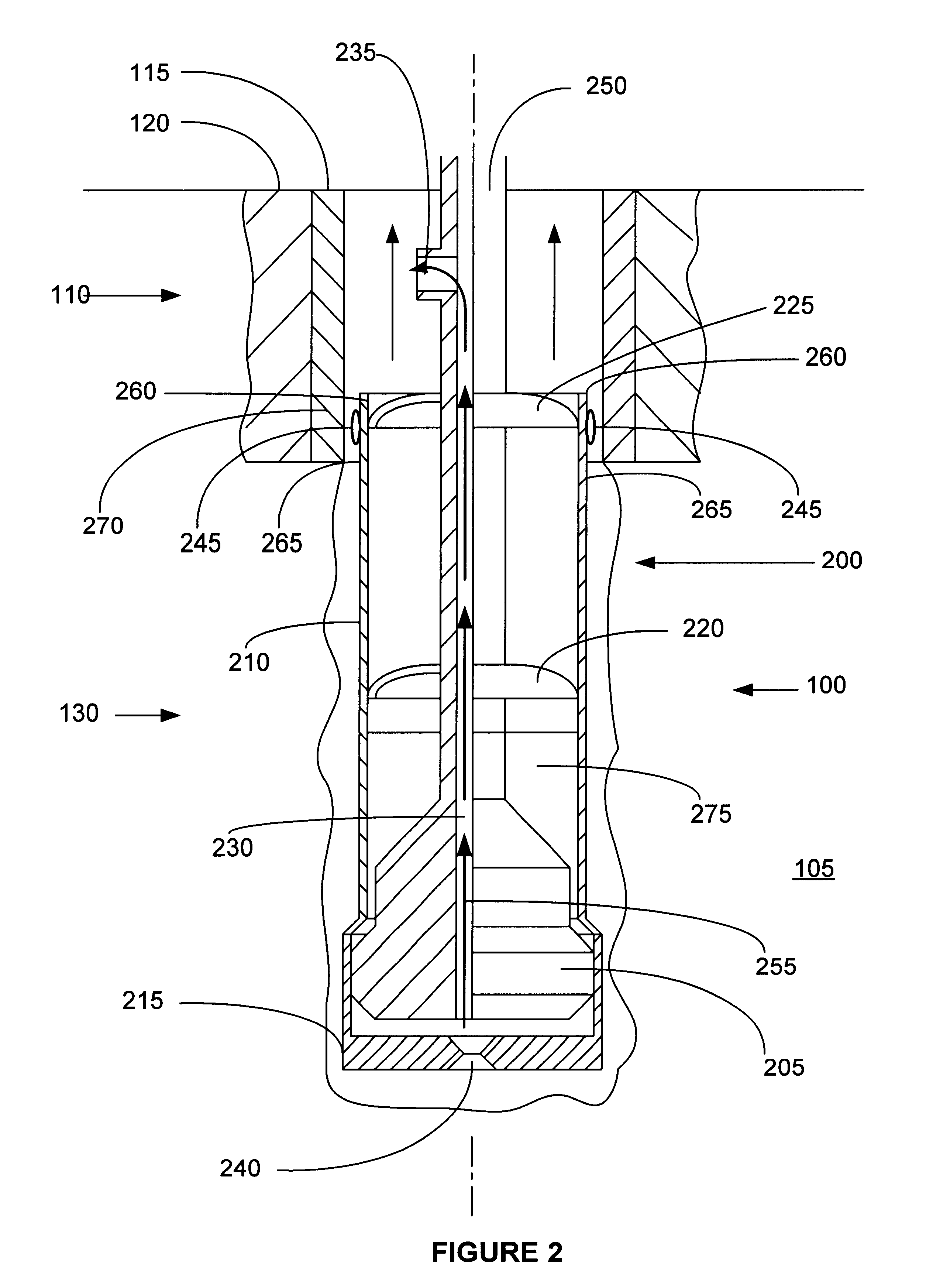

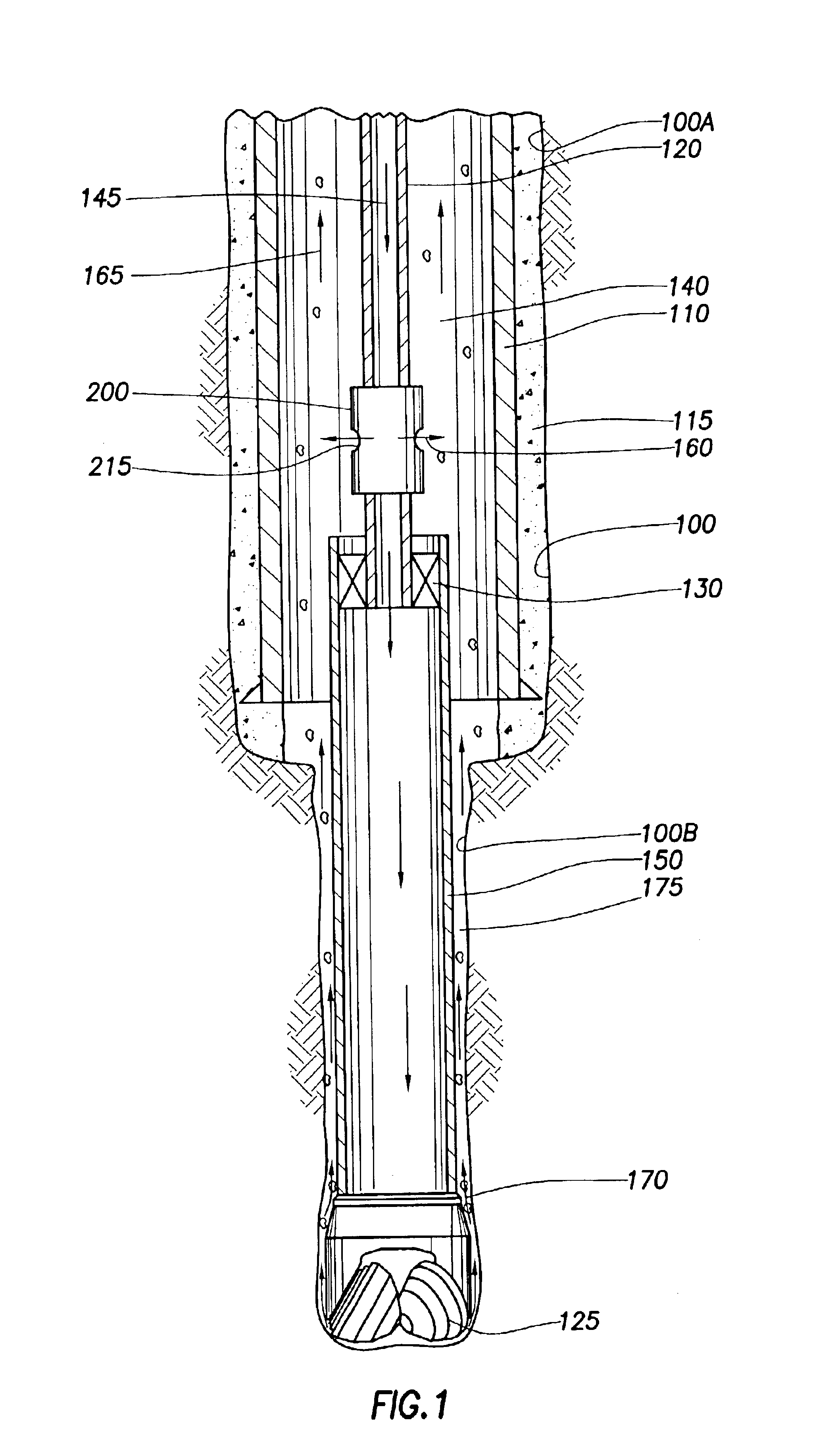

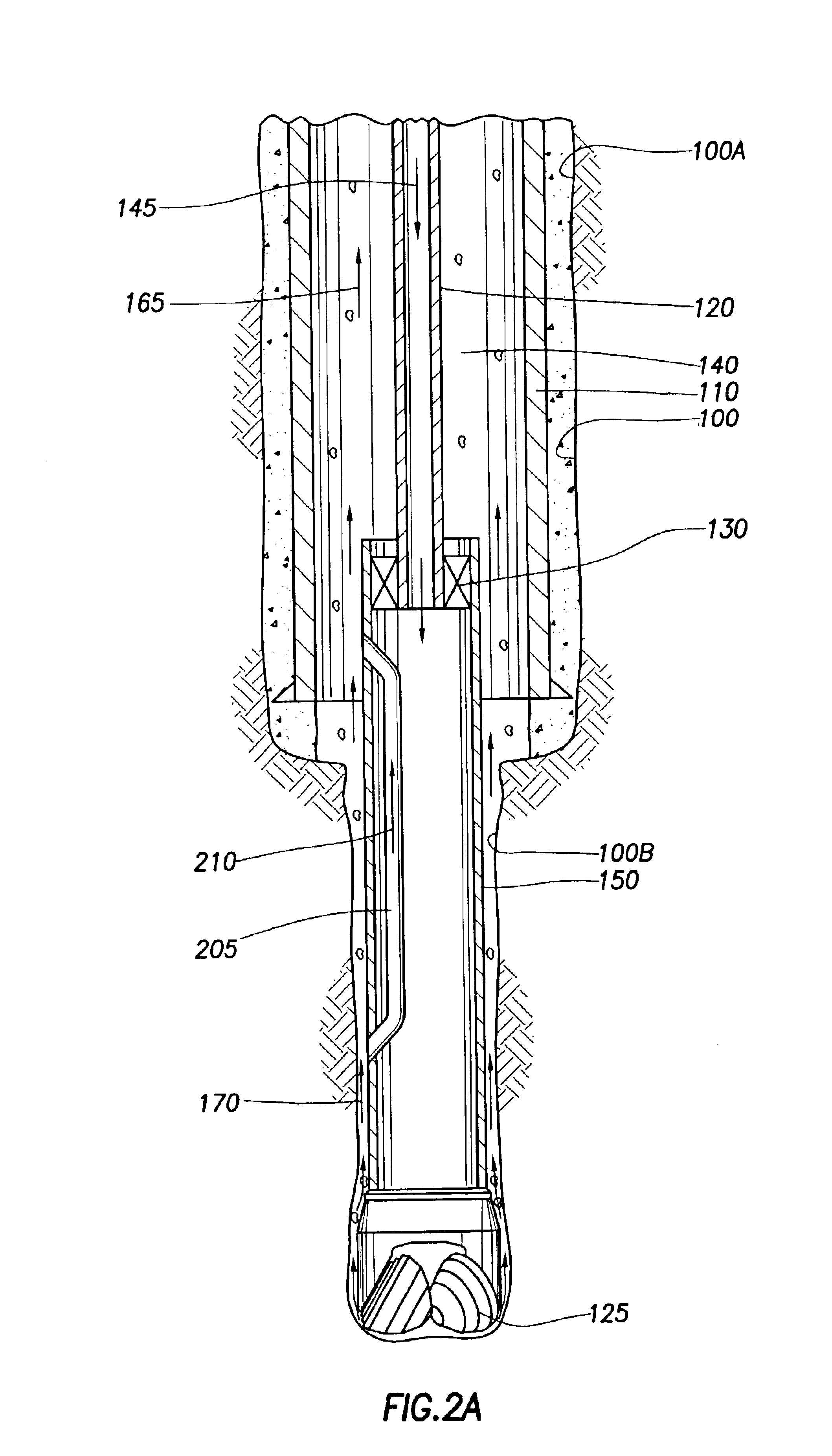

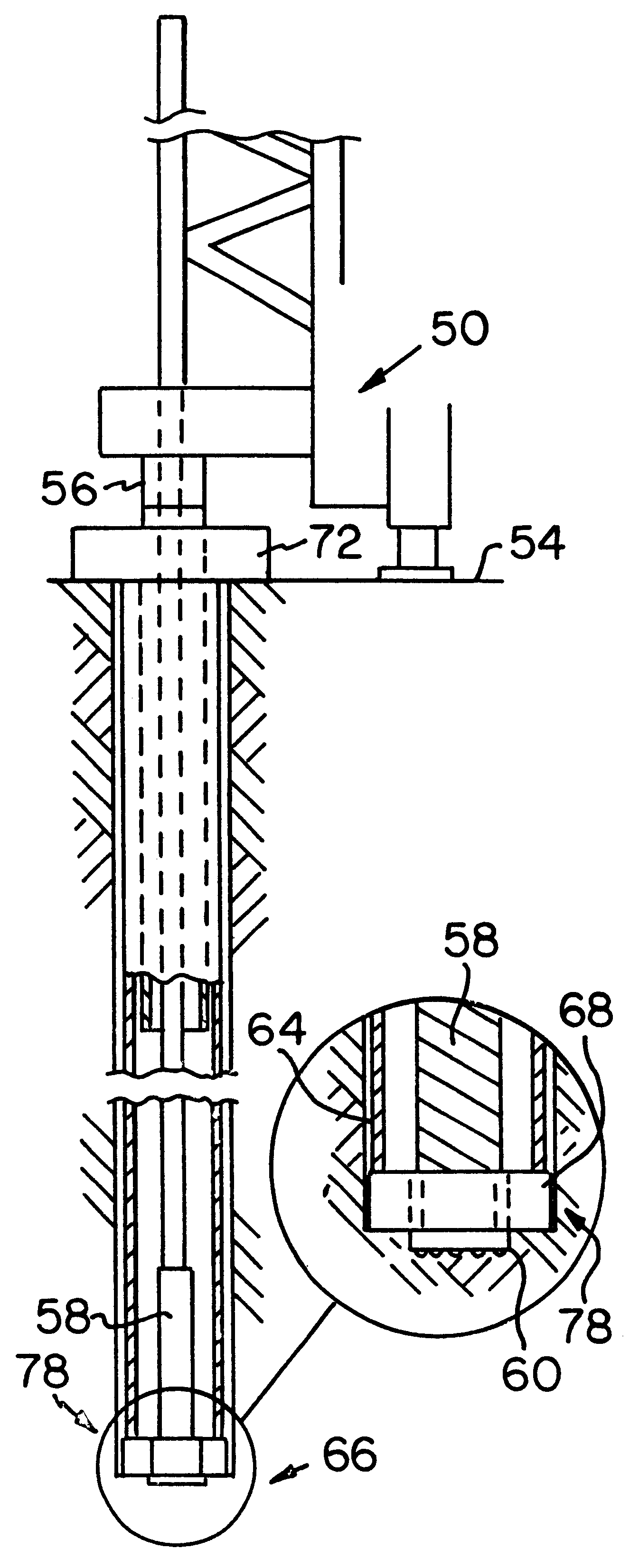

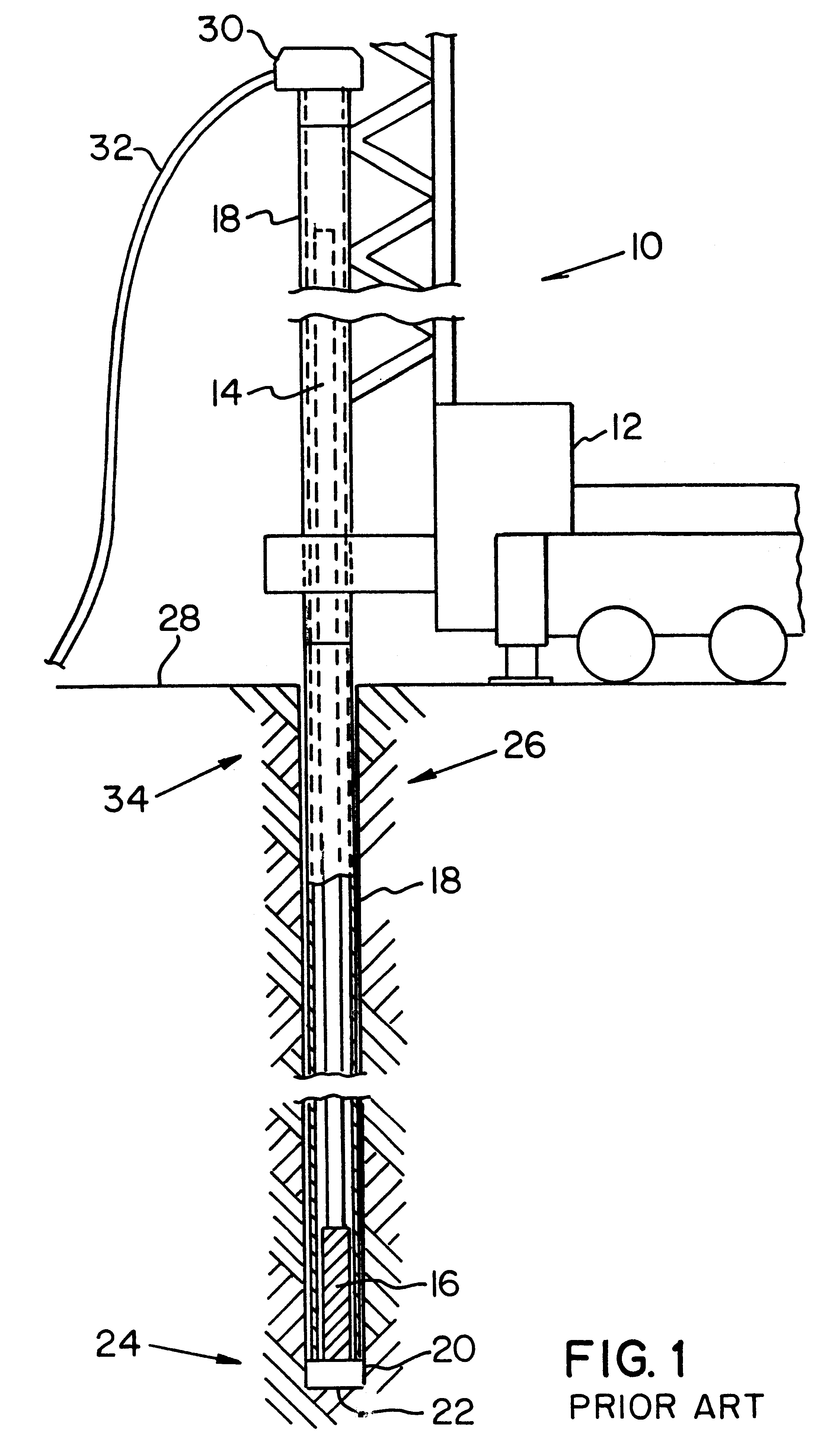

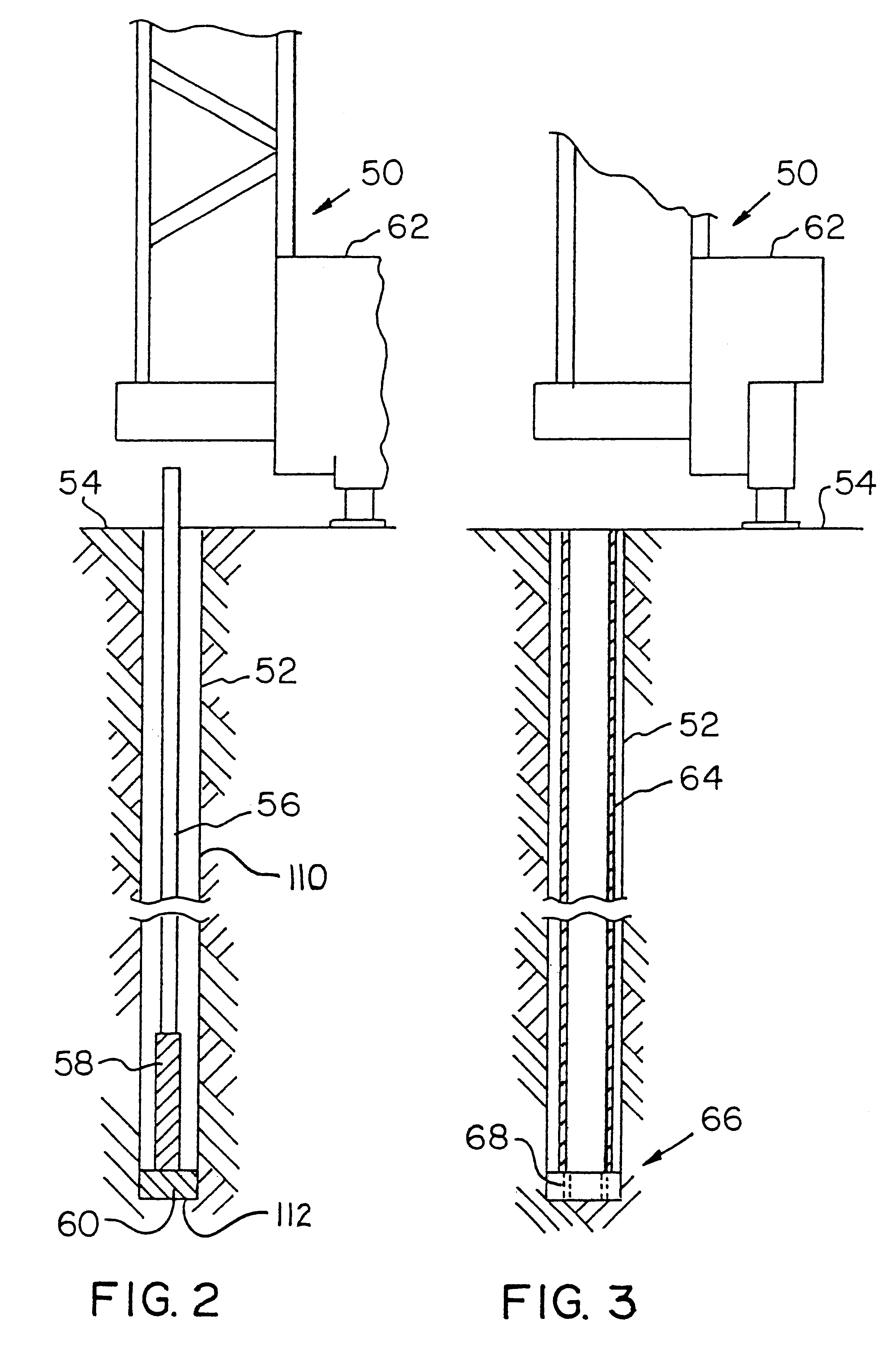

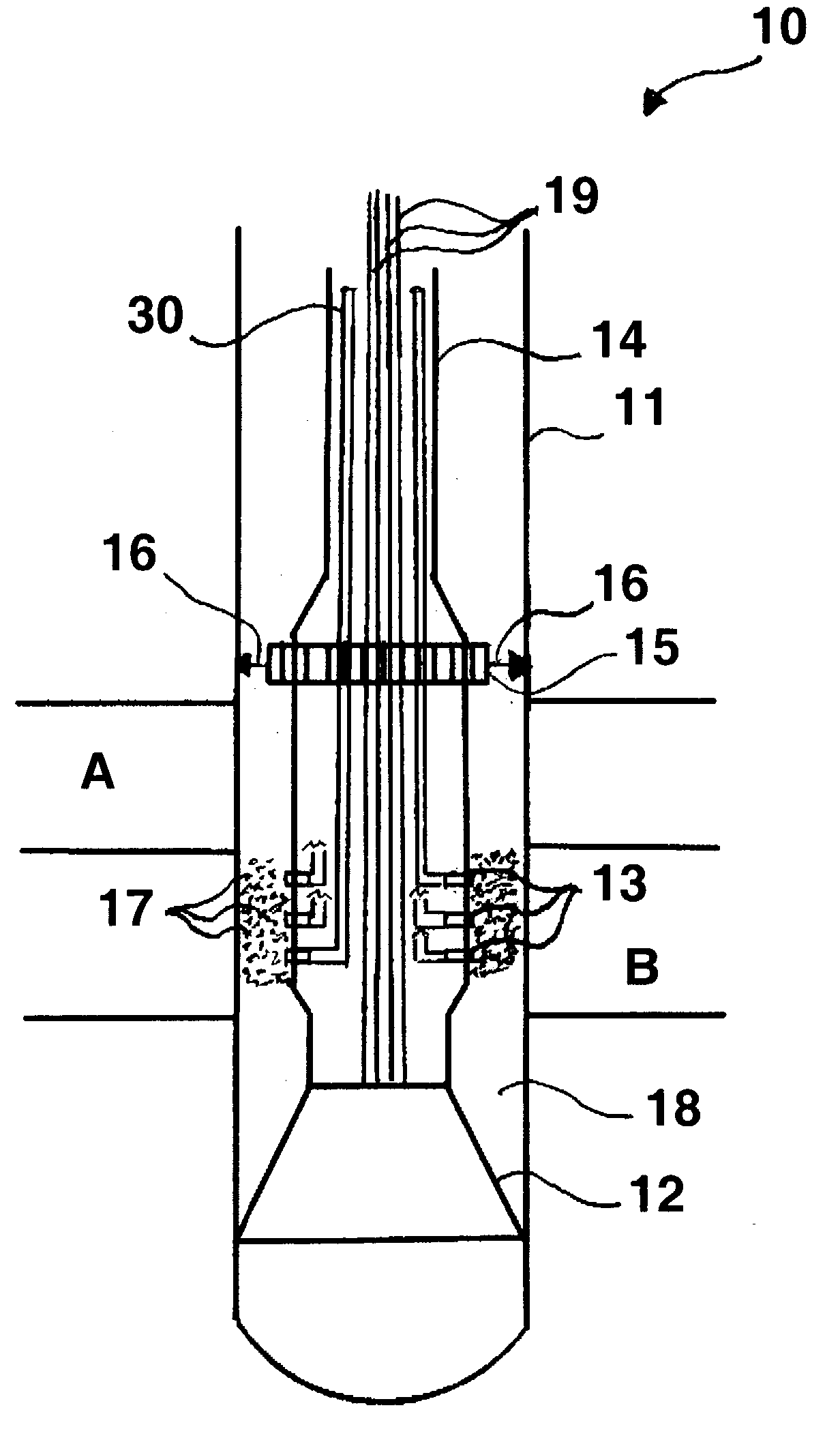

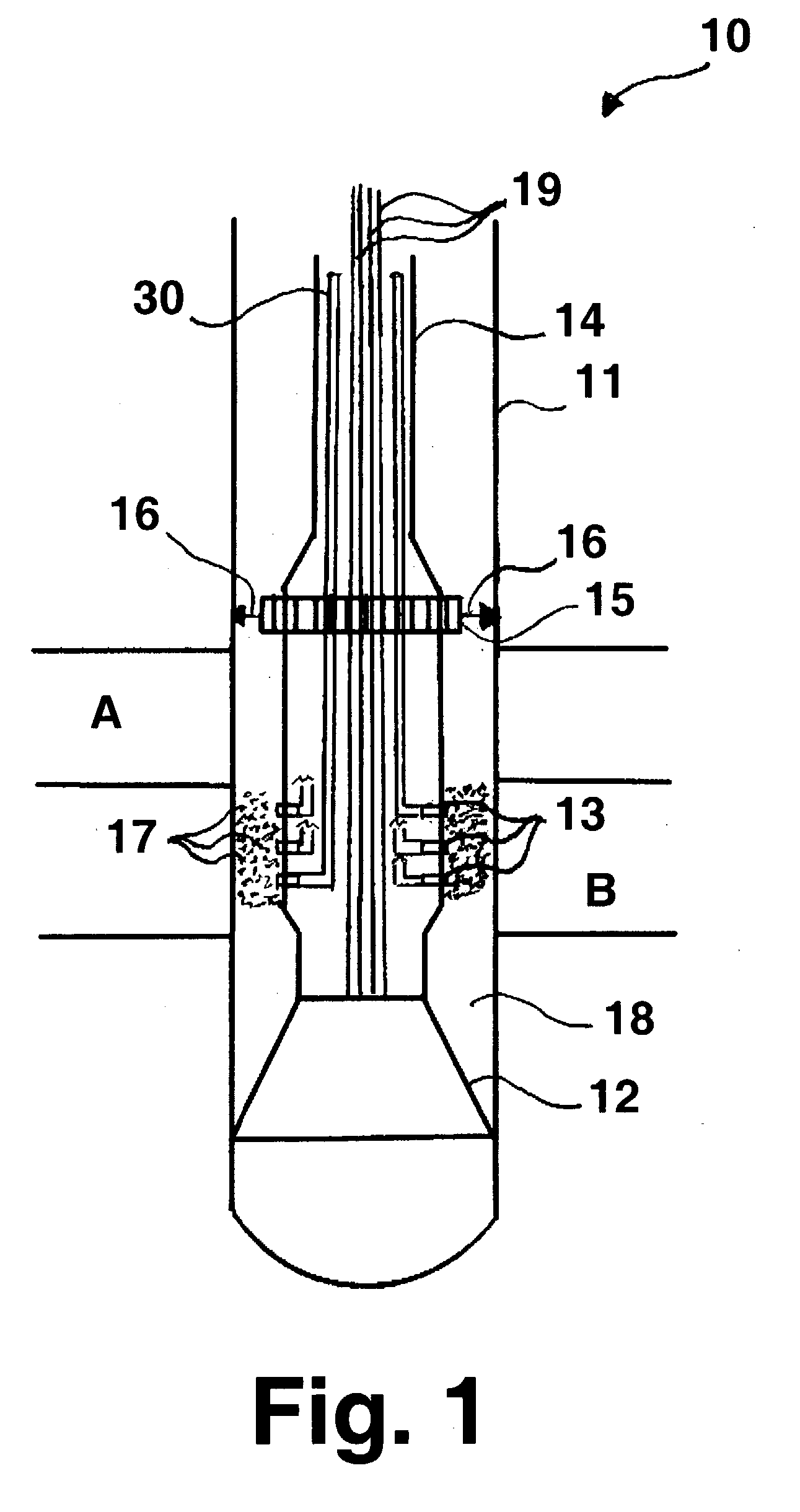

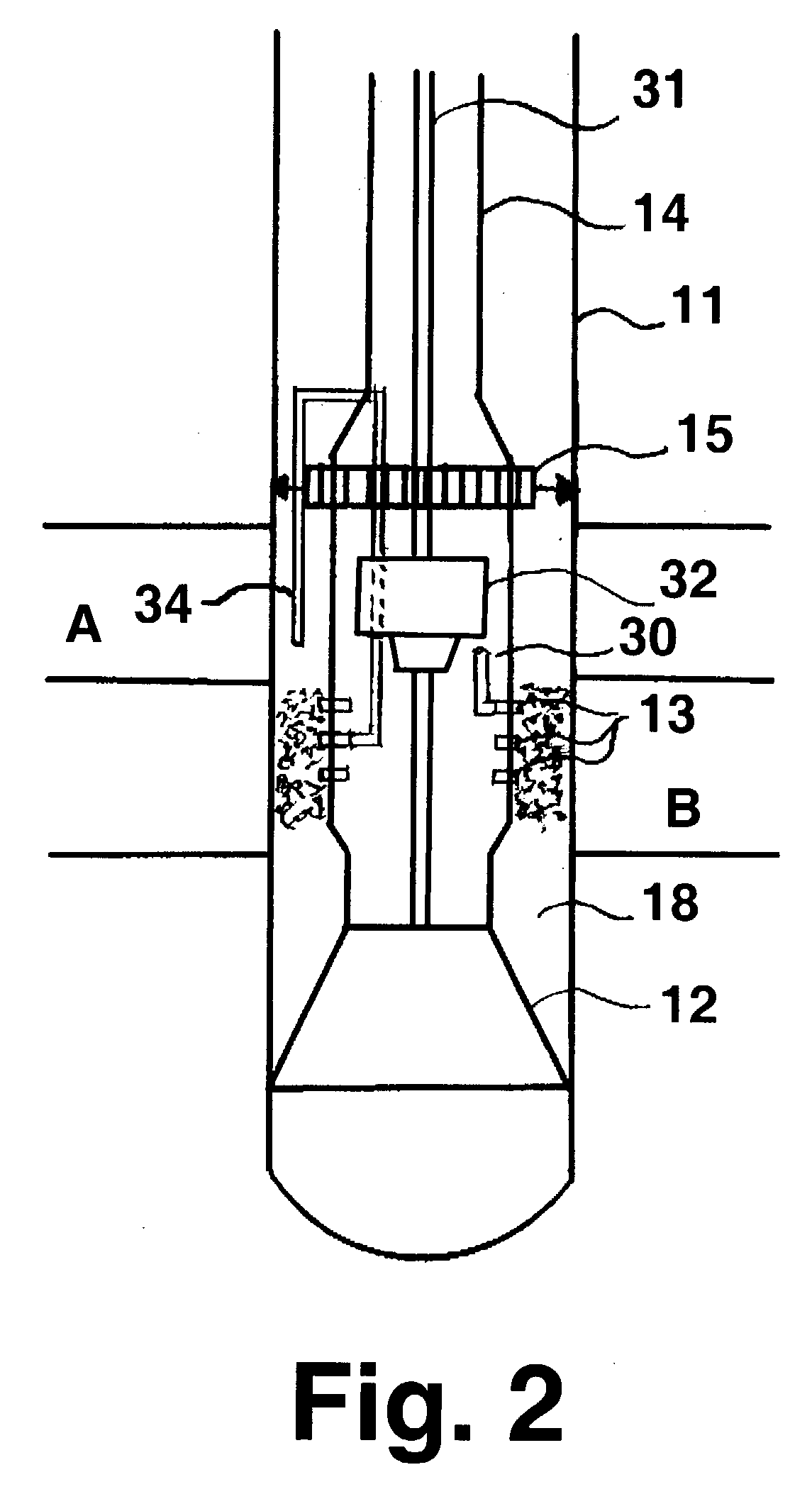

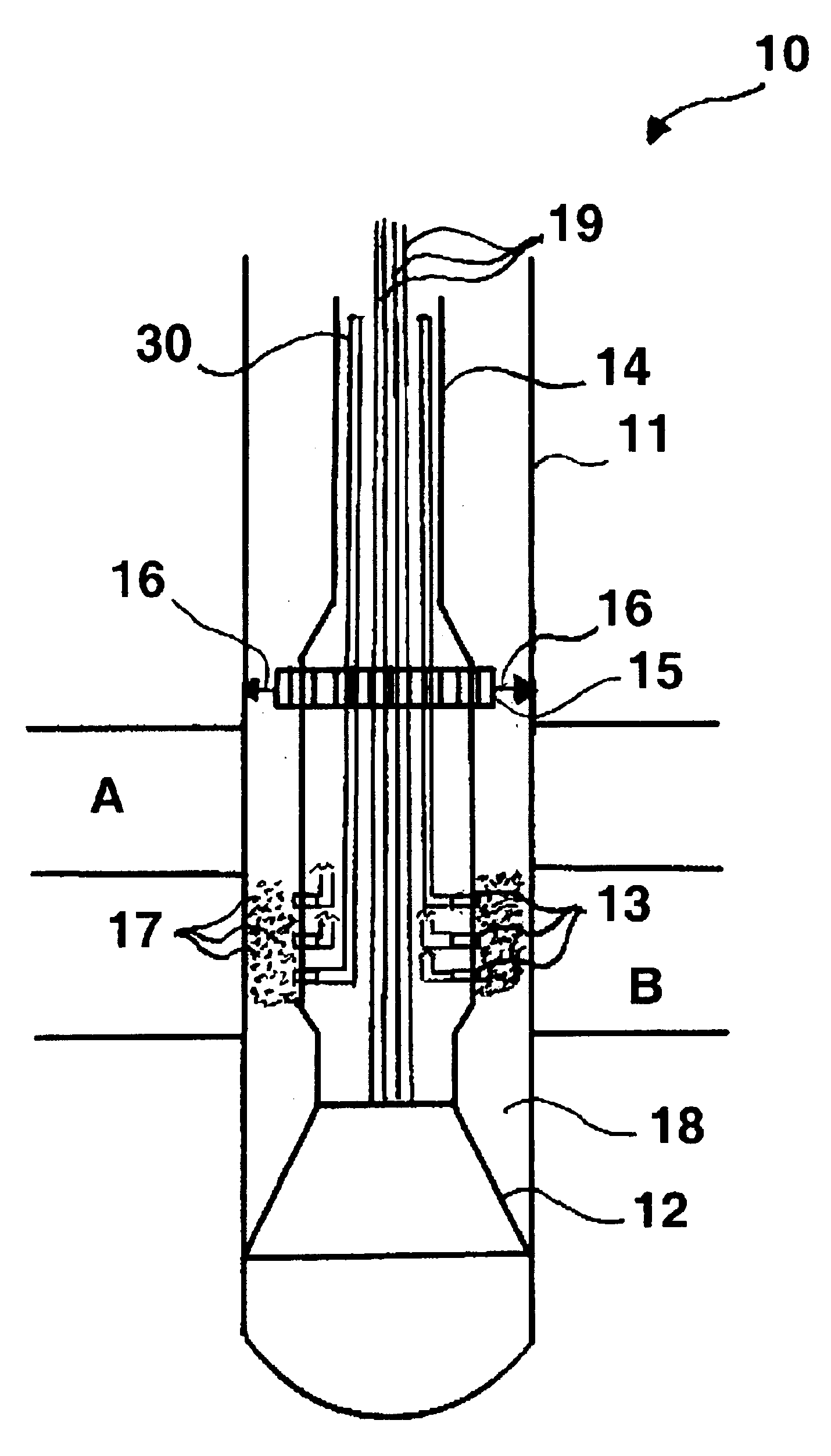

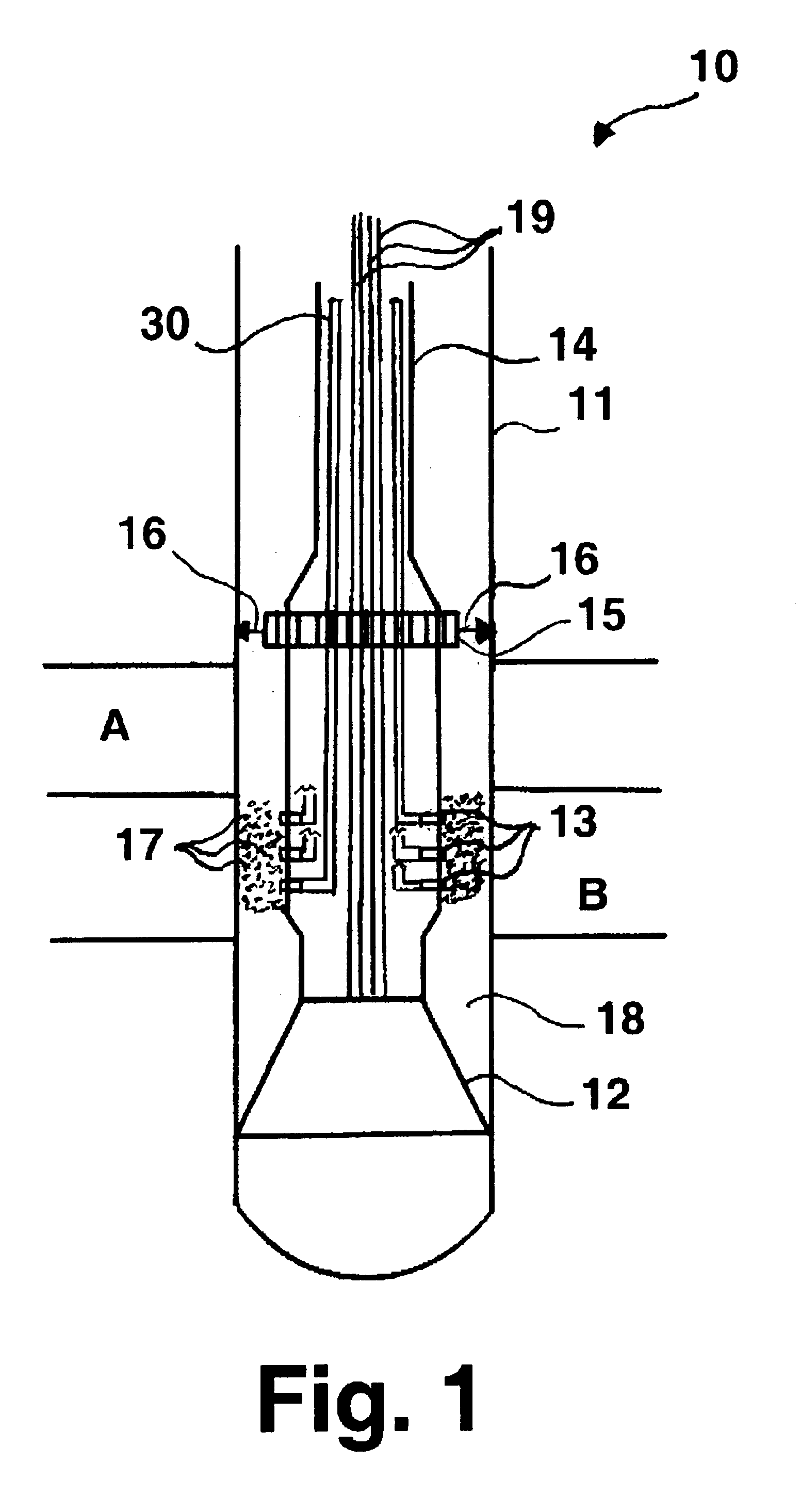

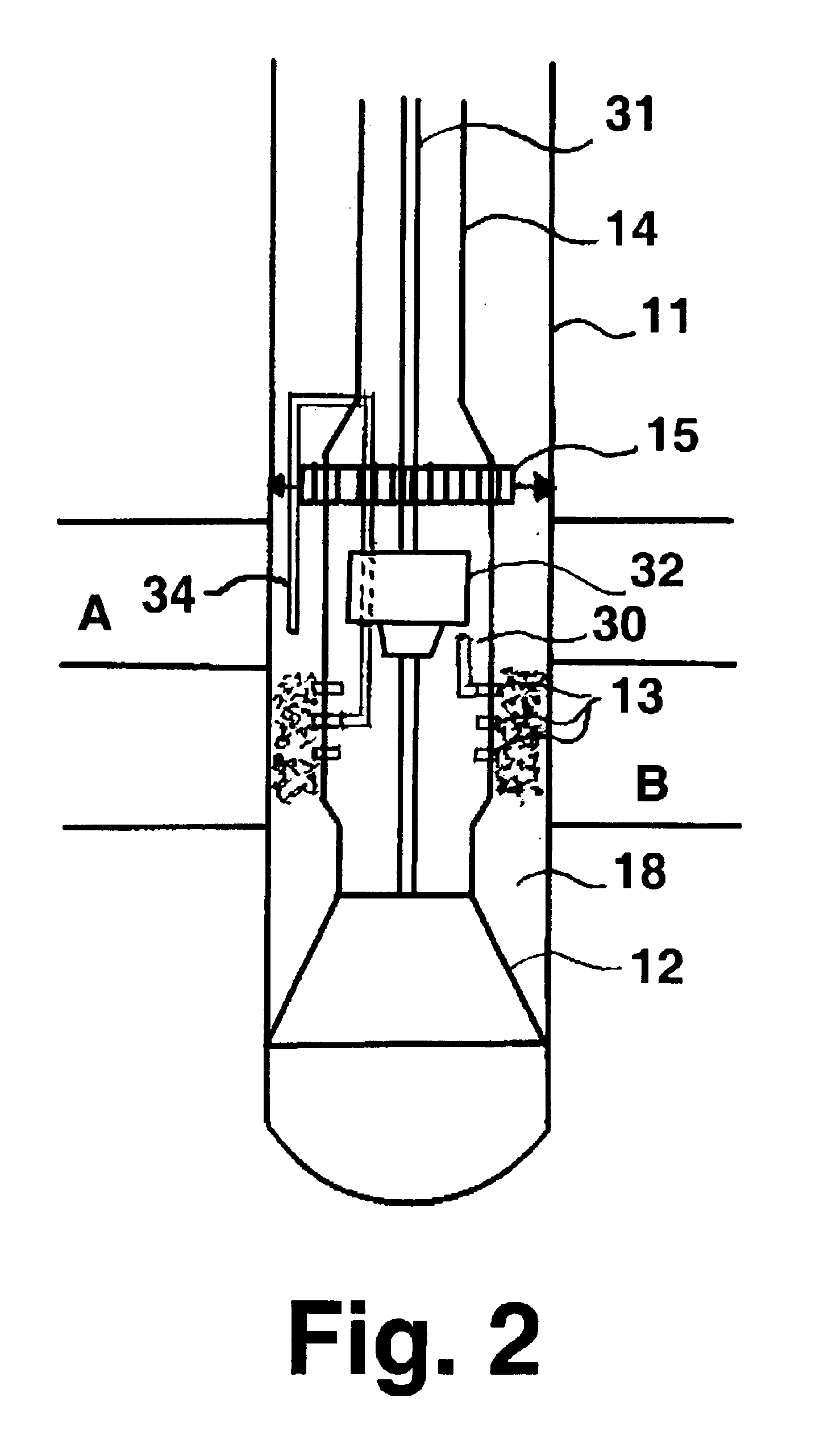

[apparatus and method for acquiring information while drilling]

ActiveUS20050109538A1Reduce the possibilityIncrease the outer diameterEarth drilling toolsSurveyBiomedical engineeringWellbore

An apparatus and method useful for acquiring information from a subsurface formation penetrated by a wellbore contemplate the use of a tubular body adapted for connection within a drill string disposed in the wellbore. The tubular body is equipped with one or more protuberances (e.g., ribs) defining an expanded axial portion. A probe is carried by the tubular body at or near a first location within the expanded axial portion of the body where the cross-sectional area of the expanded axial portion is a minimum. The probe is movable between retracted and extended positions. In another aspect, the inventive apparatus may further include a cover releasably-secured about the probe for protecting the probe while drilling. In a further aspect, the inventive apparatus may include a shearable backup support carried by the tubular body azimuthally opposite the probe permitting release of the apparatus from the wellbore in the event of a failure. In yet another aspect, the probe is at least partially carried within a debris-clearing channel formed in a protruding portion of the tubular body to promote fee movement of the probe within the wellbore.

Owner:SCHLUMBERGER TECH CORP

Stabilizing system and methods for a drill bit

InactiveUS6971459B2Promote lowerIncrease contact pressureEarth drilling toolsDrill bitsPilot holeEngineering

A drill bit stabilizing system comprising a body member having an axis and at least one recess formed in the body member housing at least one stabilizing member when in a first retracted position. The stabilizing member is positionable along a diagonal angle with the axis to a second extended operating position which extends downward and outward relative to the main body to selectively engage the surface of a pilot bore hole wall during a drilling operation so as to stabilize an under gauge drill bit used in association with the stabilizing system. The body member further comprises at least one fixed stabilizing surface positioned in an axially spaced relationship to the at least one movable stabilizing member. The body member further comprises a gauge cutter positioned above the moveable stabilizing member and below the fixed stabilizing surface to expand the pilot hole to the final gauge.

Owner:RANEY RICHARD C

Methods of using a laser to spall and drill holes in rocks

ActiveUS7416258B2Easy to disassembleProtection is necessaryEarth drilling toolsDisloding machinesSmall fragmentClassical mechanics

Apparatus and methods of using lasers are provided for spalling and drilling holes into rocks. A rock removal process is provided that utilizes a combination of laser-induced thermal stress and laser induced superheated steam explosions just below the surface of the laser / rock interaction to spall the rock into small fragments that can then be easily removed by a purging flow. Single laser beams of given irradiance spall rock and create holes having diameter and depth approximately equal to the beam spot size. A group of the single laser beams are steered in a controllable manner by an electro-optic laser beam switch to locations on the surface of the rock, creating multiple overlapping spalled holes thereby removing a layer of rock of a desired diameter. Drilling of a deep hole is achieved by spalling consecutive layers with an intermittent feed motion of the laser head perpendicular to the rock surface.

Owner:UCHICAGO ARGONNE LLC

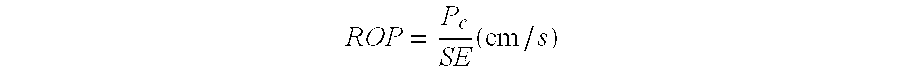

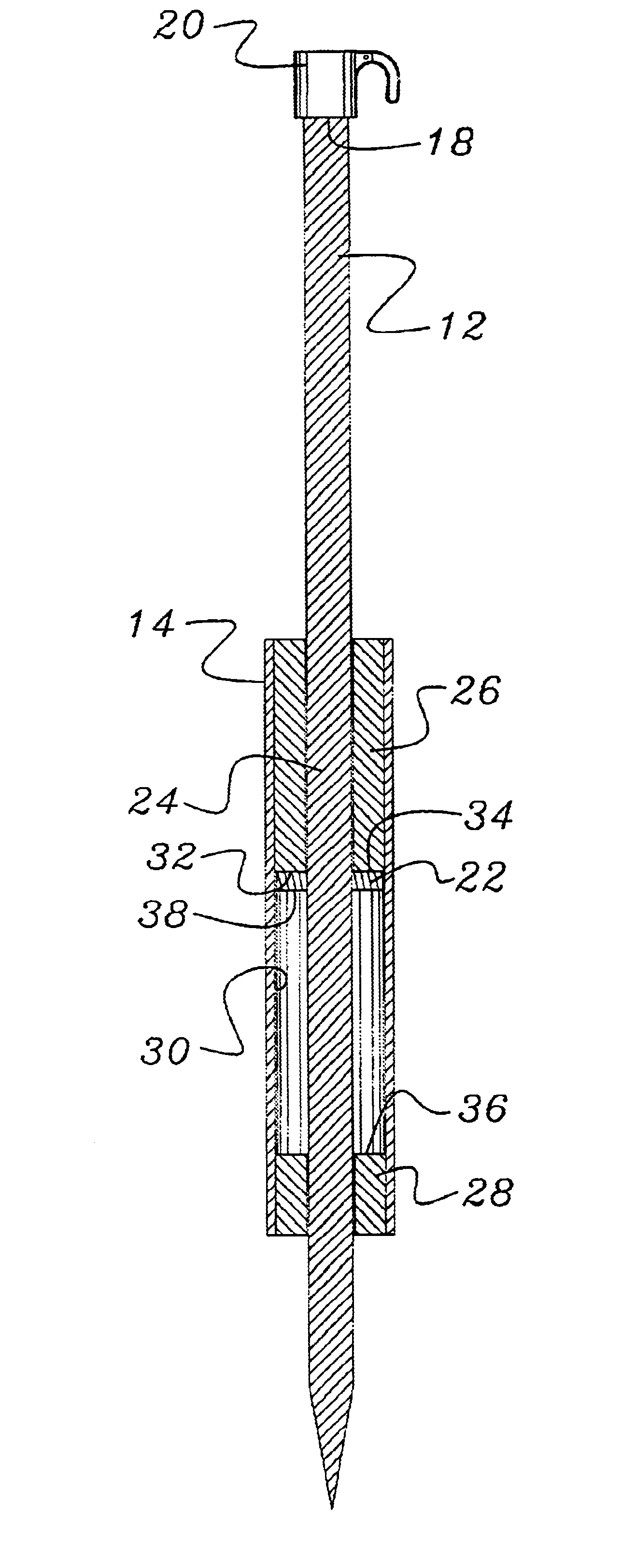

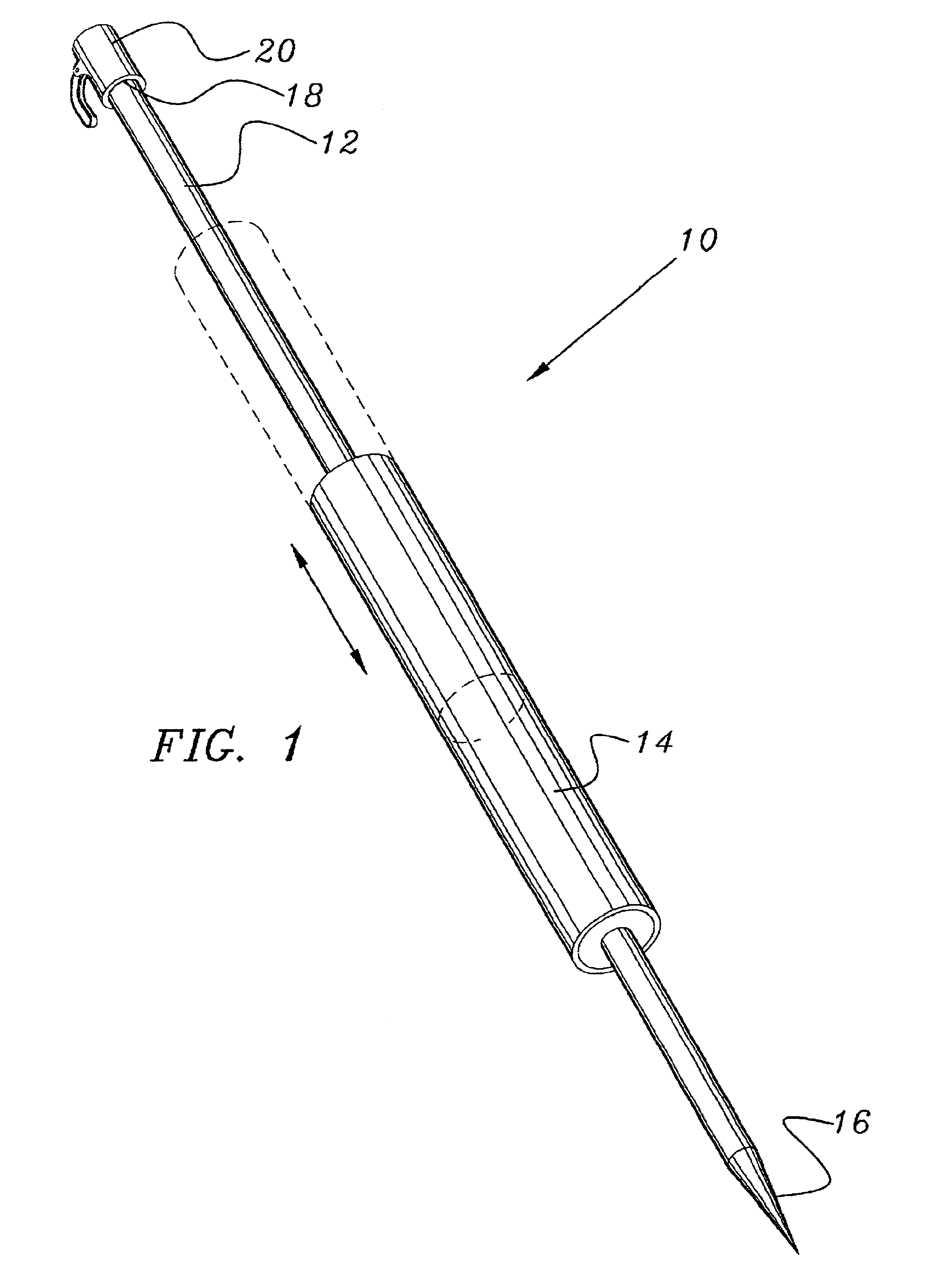

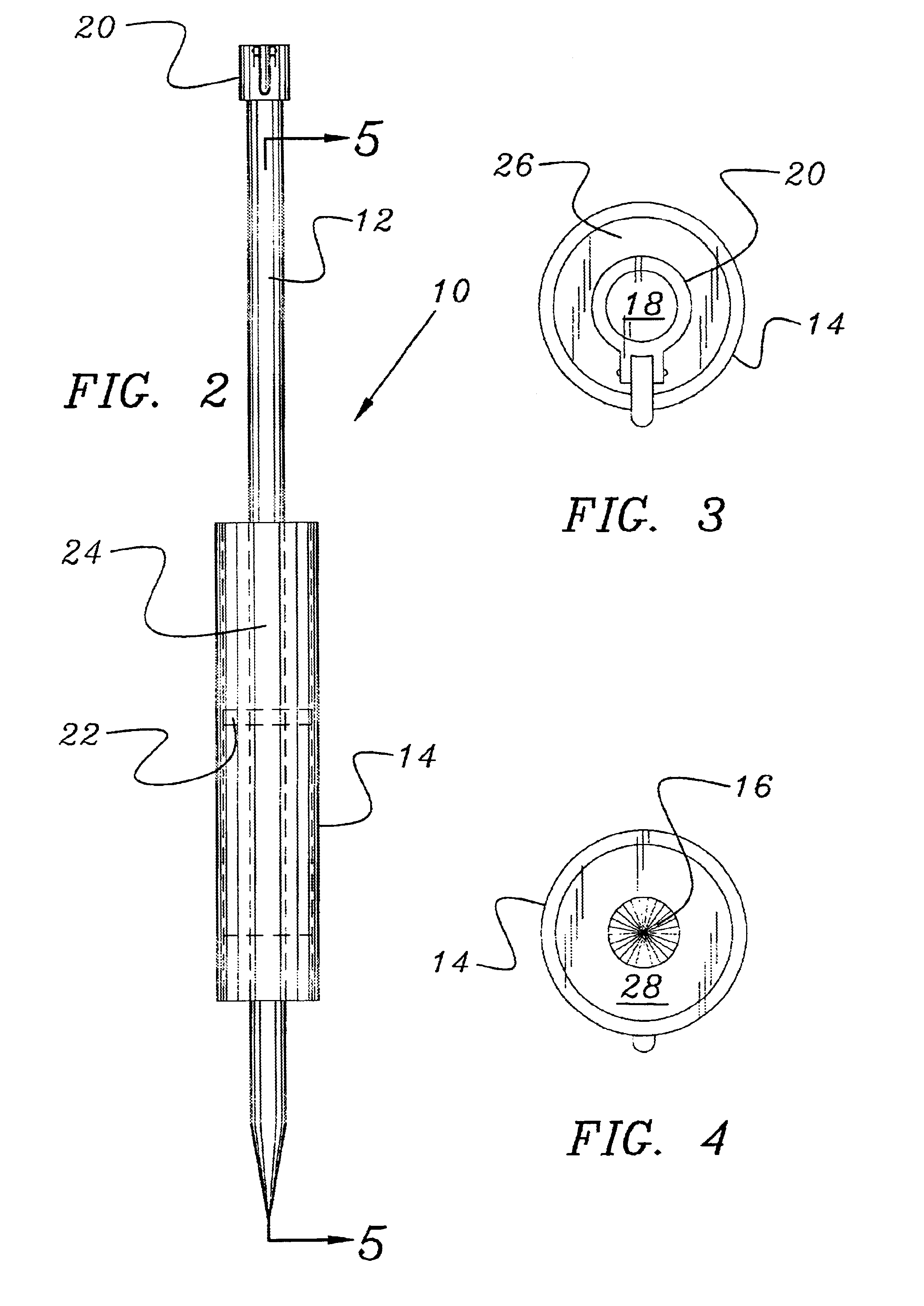

Smart-ultrasonic/sonic driller/corer

Apparatus for probing, sensing, testing penetrating and sampling a medium generally includes an actuator (12) for generating vibrations at ultrasonic frequencies and a horn (14) coupled to the actuator (12) for amplifying the actuator vibrations along with a non-rotating coring and drilling bit (16) for penetrating the medium. A bit (16) includes a drill stem (20) attached to the horn (14) and a bore (26) extends through the bit (16), horn (14) and actuator (12) for withdrawal of samples. A free mass (36) is disposed between the horn (14) and the drill stem (20) for oscillating therebetween in response to the actuator vibration for causing migration of medium debris around and through the actuator bore for effectively self-cleaning of the bit (16). The hammering action of the free mass (36) is used for penetration of the medium and for analysis of the medium though the use of spaced apart accelerometers (92 and 94).

Owner:GYRUS ACMI INC (D B A OLYMPUS SURGICAL TECH AMERICA)

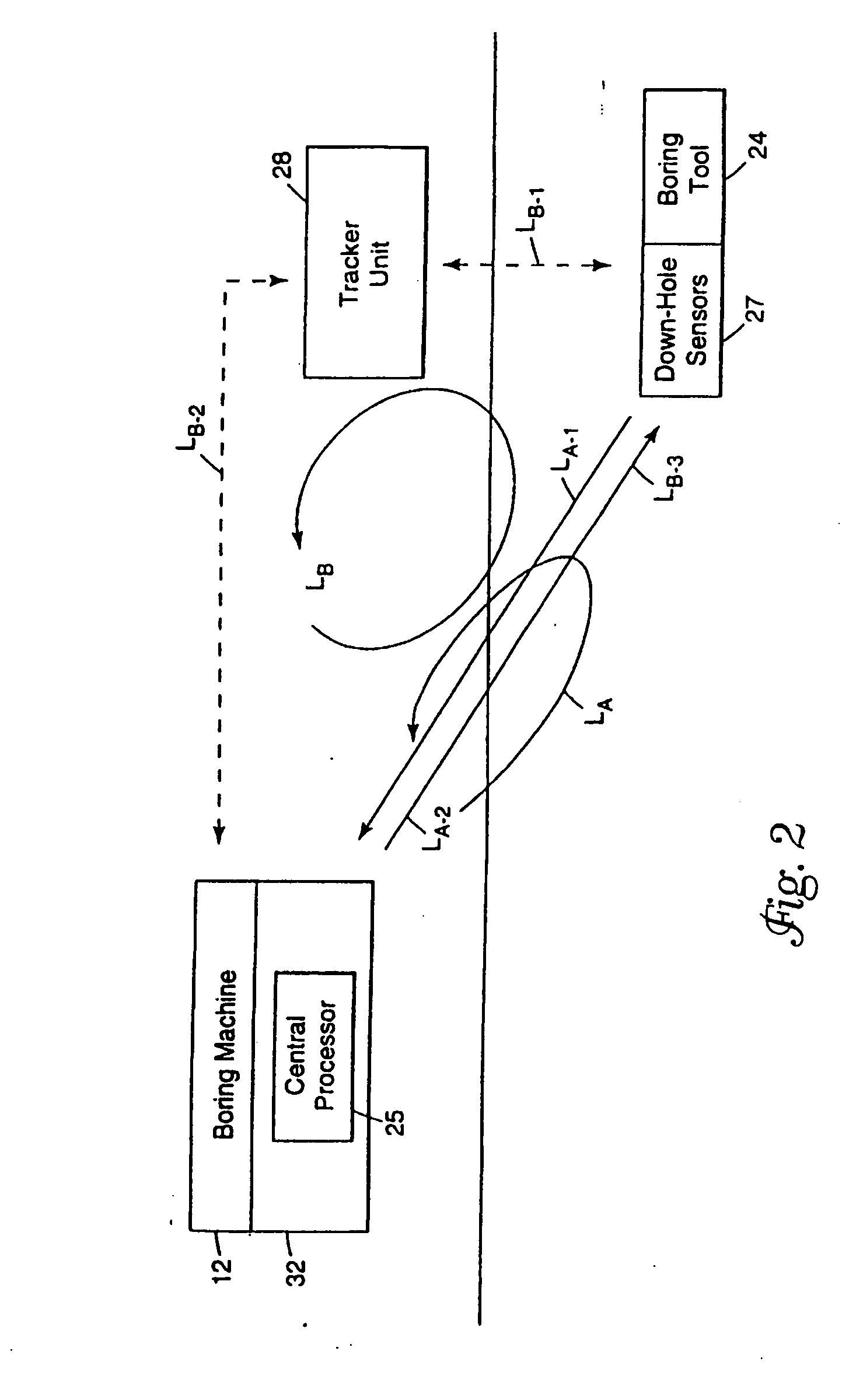

Underground drilling device employing down-hole radar

Devices for sensing at an underground drilling device in communication with an above-ground locator involve transmitting a radar probe signal from the underground drilling device. A radar return signal is received at the underground drilling device. The radar return signal is processed at the underground drilling device to produce sensor data. The sensor data is transmitted in a form suitable for reception by the above-ground locator.

Owner:VERMEER MFG CO

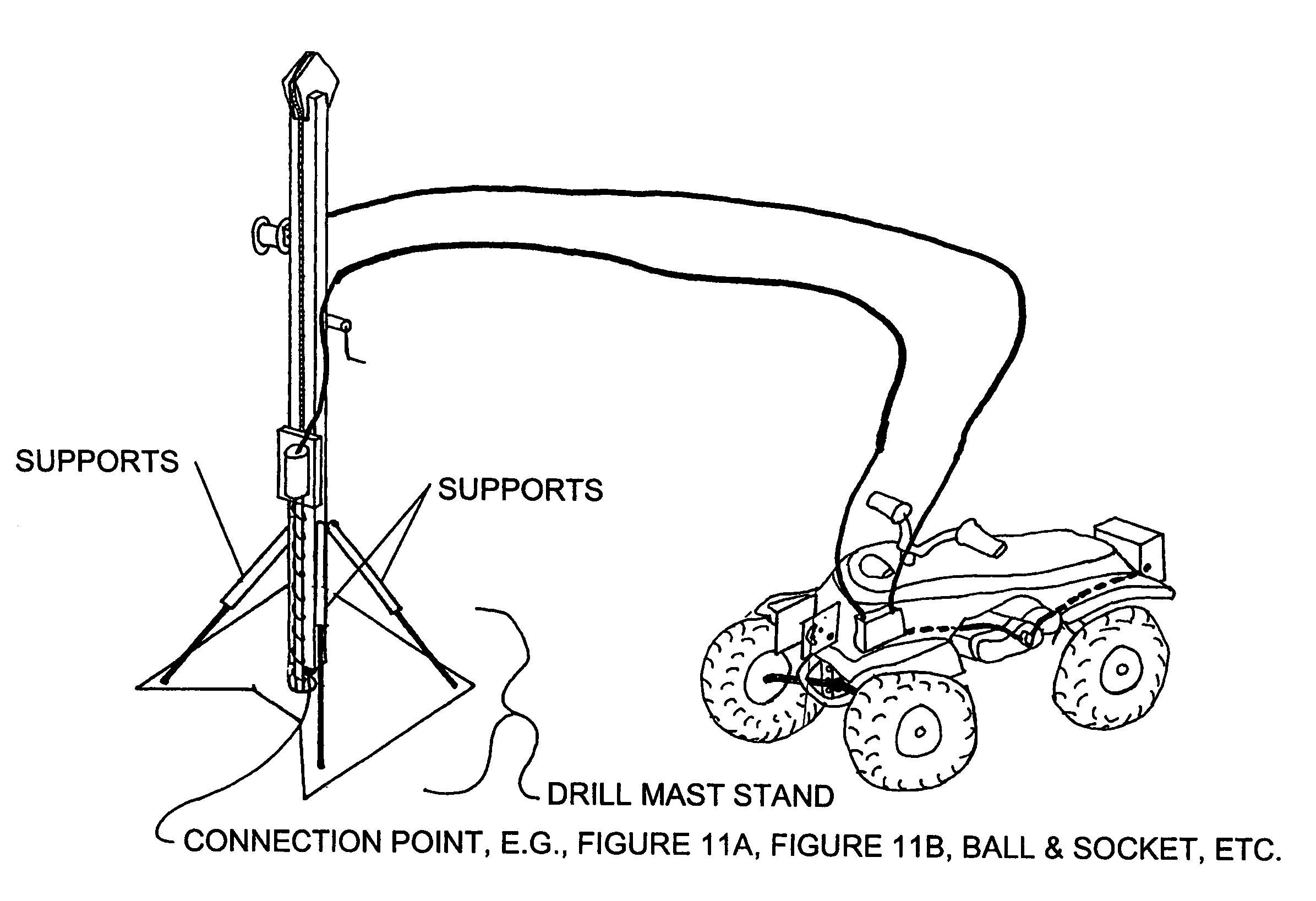

All terrain vehicle powered mobile drill

A method includes powering a drill motor with power derived from an all terrain vehicle (ATV) engine and controlling the drill motor. An apparatus includes a ATV with a power takeoff configured to deliver power from an ATV engine. A drill mast is moveably coupled to the ATV, a drill motor is configured to turn a drill bit and the drill motor is slidingly disposed on the drill mast. The drill motor is configured to be powered from the power takeoff; and a control is configured to operate the drill motor such that a hole can be drilled by the drill bit.

Owner:DAVIES JEFFREY D

Method and apparatus for in-situ side-wall core sample analysis

A wireline-conveyed side-wall core coring tool for acquiring side-wall core from a geological formation for performing in-situ side-wall core analysis. The coring tool has a core analysis unit operable to measure geophysical properties of an acquired side-wall core. The measured geophysical properties may be used to determine the success of the acquisition of side-wall cores by the coring tool. The core analysis unit is operable of performing an in-situ interpretation of measured geophysical property of the side-wall core and transmitting in near real-time the measurements or the interpretation results to surface data acquisition and processing apparatus.

Owner:SCHLUMBERGER TECH CORP

Casing bottom hole assembly retrieval process

InactiveUS20070068677A1Reduce hydrostatic pressureEarth drilling toolsDrill bitsHydrostatic pressureEngineering

A process for retrieving a bottom hole assembly through a casing string may include: installing a casing string in a borehole, the casing string including a bottom hole assembly releasably engaged thereto and moveable through an inner diameter of the casing string; releasing the bottom hole assembly from engagement with the casing string; reducing hydrostatic pressure in the casing string inner diameter above the bottom hole assembly so that the casing string inner diameter pressure above the bottom hole assembly is lower than a fluid pressure below the bottom hole assembly; permitting reverse circulation down through an annulus between the casing string and the borehole to permit the bottom hole assembly to rise up through the casing string toward the surface; and retrieving the bottom hole assembly from the casing string.

Owner:SCHLUMBERGER TECH CORP

Method and apparatus for in-situ side-wall core sample analysis

Owner:SCHLUMBERGER TECH CORP

Soil sampler apparatus and method

InactiveUS7255016B2Automatic collectionEasy to insertEarth drilling toolsWithdrawing sample devicesElectronic control systemControl system

Owner:AGROBOTICS LLC

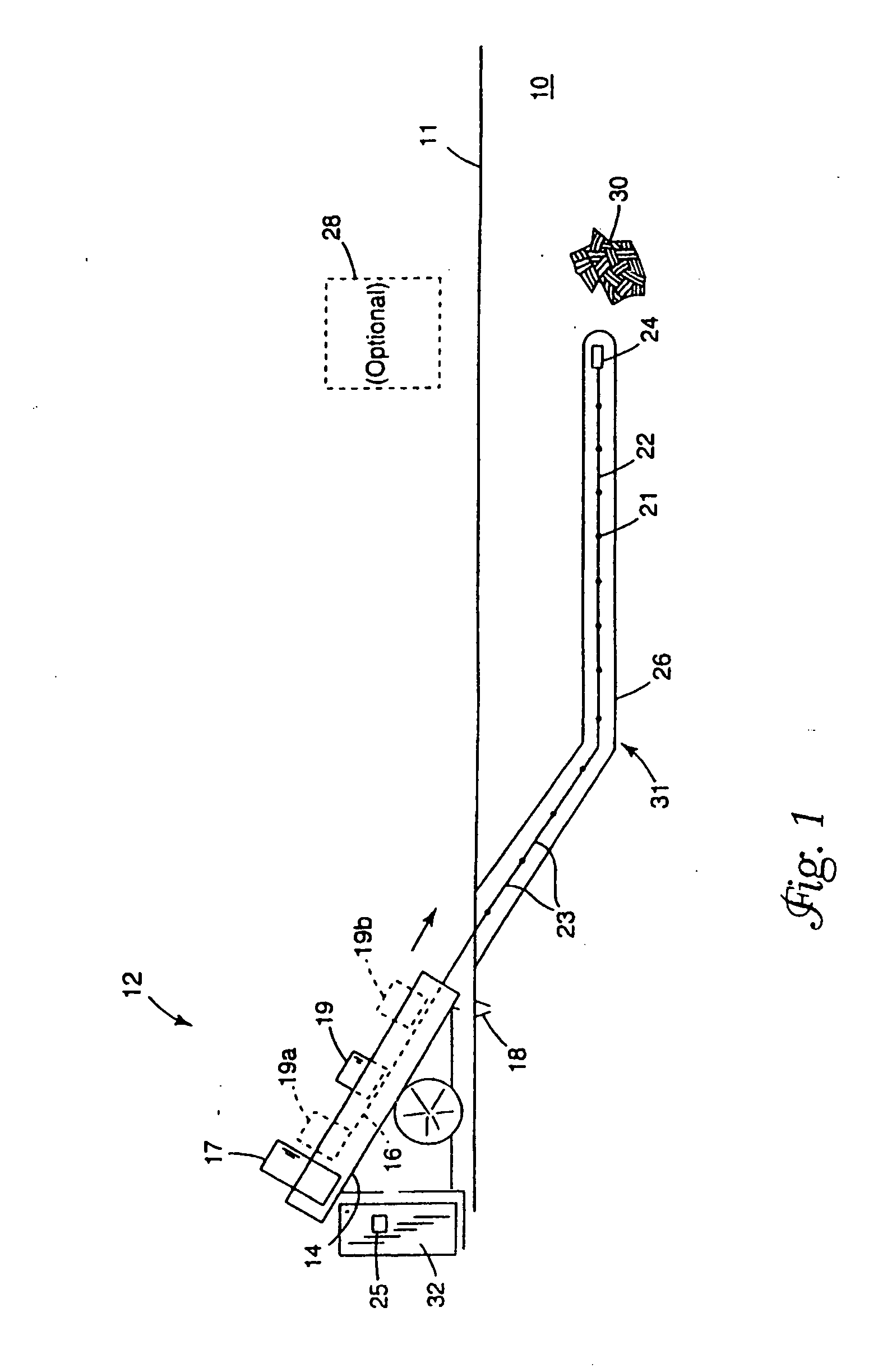

Method and apparatus for on-grade boring

A method for installation of an underground pipe includes an initial step of boring a pilot hole through the ground at a predetermined grade angle by extending a drill string having a steerable boring bit mounted thereon through the ground. Upon reaching an end location for the pilot hole, the bit is removed from the drill string, and an expander having a diameter greater than the pilot hole is attached to the drill string, which expander is backed by an impact device such as a pneumatic impactor including a striker that delivers repeated impacts to a rearwardly facing surface of the expander, and by a pipe drawn along behind the expander. The expander is pulled back through the pilot hole at the grade angle while the impactor is operated to aid progress of the expander through the ground and pull the pipe into place behind the expander. Typically in this method the replacement pipe is coupled to a rear end of the expander and the boring bit has a sonde housing containing a sonde attached thereto to indicate to an operator the orientation of a steering face on the boring bit.

Owner:EARTH TOOL L L C

Multiple zone testing system

InactiveUS20050077086A1Facilitates singular testingEasy to testEarth drilling toolsSurveyTester deviceIndustrial engineering

A method and system for drillstem testing multiple zones in a well with a single testing trip into the well. A multiple zone tester is landed in the lower completion to form separate controllable flow paths from each of the zones. The multiple zone testing system facilitates testing each zone singularly and performing commingled tests without pulling out of the well.

Owner:SCHLUMBERGER TECH CORP

Apparatuses for interaction with a subterranean formation, and methods of use thereof

An access casing assembly structured for placement at least partially within a subterranean formation by forcing the access casing assembly thereinto, comprising a plurality of casing sections operably coupled to form a central elongated cavity for providing access to the subterranean region is disclosed. Further, a tip portion of the access casing assembly may include a porous filter through which liquid or gas may communicate with the central elongated cavity. Also, a receiving member or at least one engagement hub may form a portion of the central elongated cavity and may include an engagement feature configured for selectively and lockingly engaging a locking structure of a device to be positioned within the access casing assembly. Methods of use are disclosed. A tensiometer is disclosed including a chamber structured for allowing at least partially filling with a fluid subsequent to contact therewith.

Owner:BATTELLE ENERGY ALLIANCE LLC

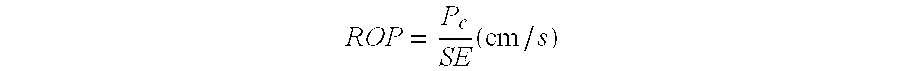

Power transmission unit of an impactor, a hydraulic jet impactor and the application thereof

InactiveUS20060011362A1Improve efficiencyAvoid long workEarth drilling toolsDrill bitsTransmitted powerWorking life

The invention discloses a fluid-driven impactor, a power transmission mechanism for the impactor and the use of the impactor. In the prior art, the working life of the impactor is short, since a rubber primary seal and an upper fluid-diverging lid for the fluid-driven impactor are both liable to erosion and the efficiency in transmitting power is low due to the complexity of the power transmission mechanism. In order to increase the drilling speed and / or extend the life of the impactor, the side cavity passage is formed in such a way that the inner wall of the outer pipe is isolated from the side cavity passage in a watertight manner without the use of the rubber primary seal. The loss in transmitting power is minimized by integrating the anvil of the power transmission mechanism and the lower joint. The problem of abrasion of the fluid-diverging hole is overcome and the nozzle can be used with different fluid flow by mounting a replaceable nozzle in the upper fluid-diverging lid, the nozzle selected from a series of nozzles with various inner diameters and made of a material more wearable than the material for diverging lid the upper fluid.

Owner:CHINA PETROCHEMICAL CORP +1

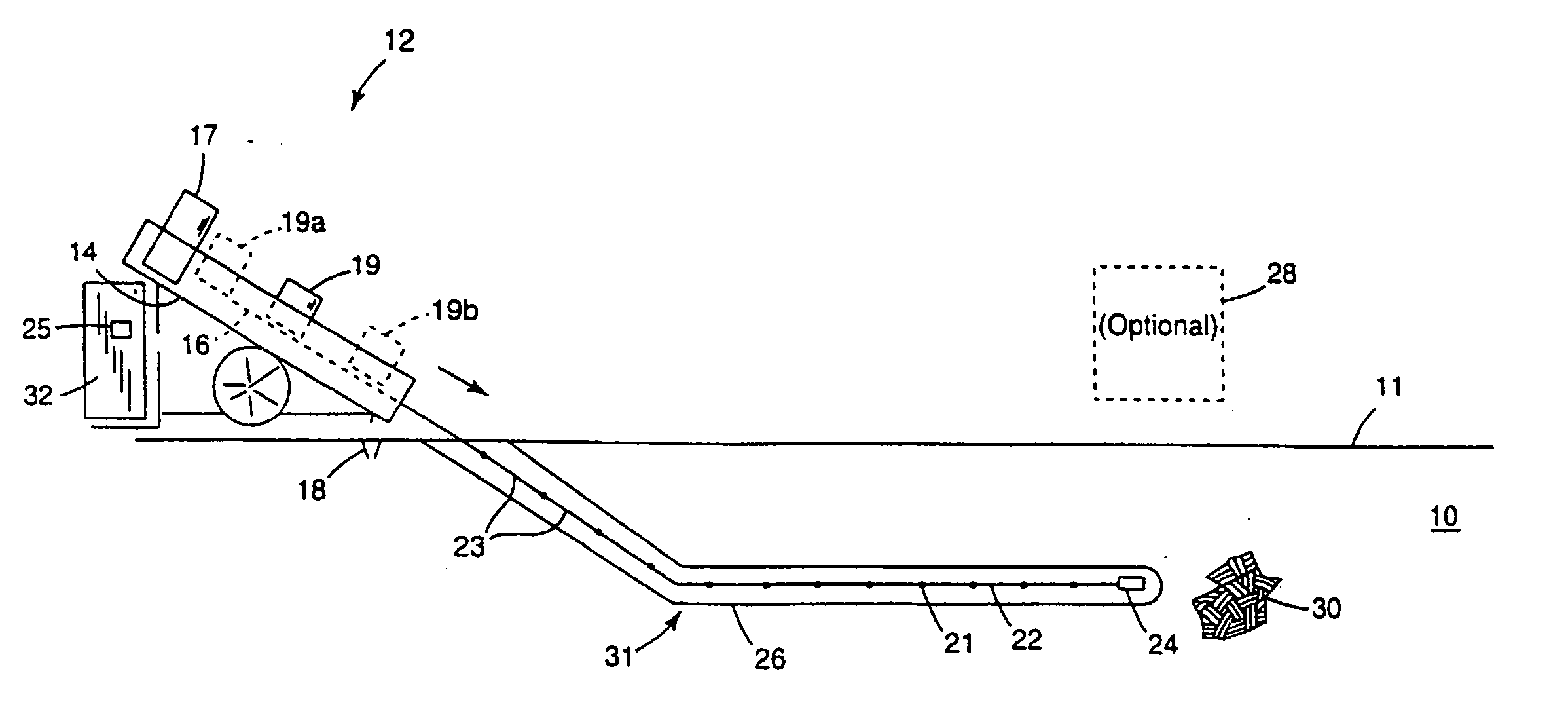

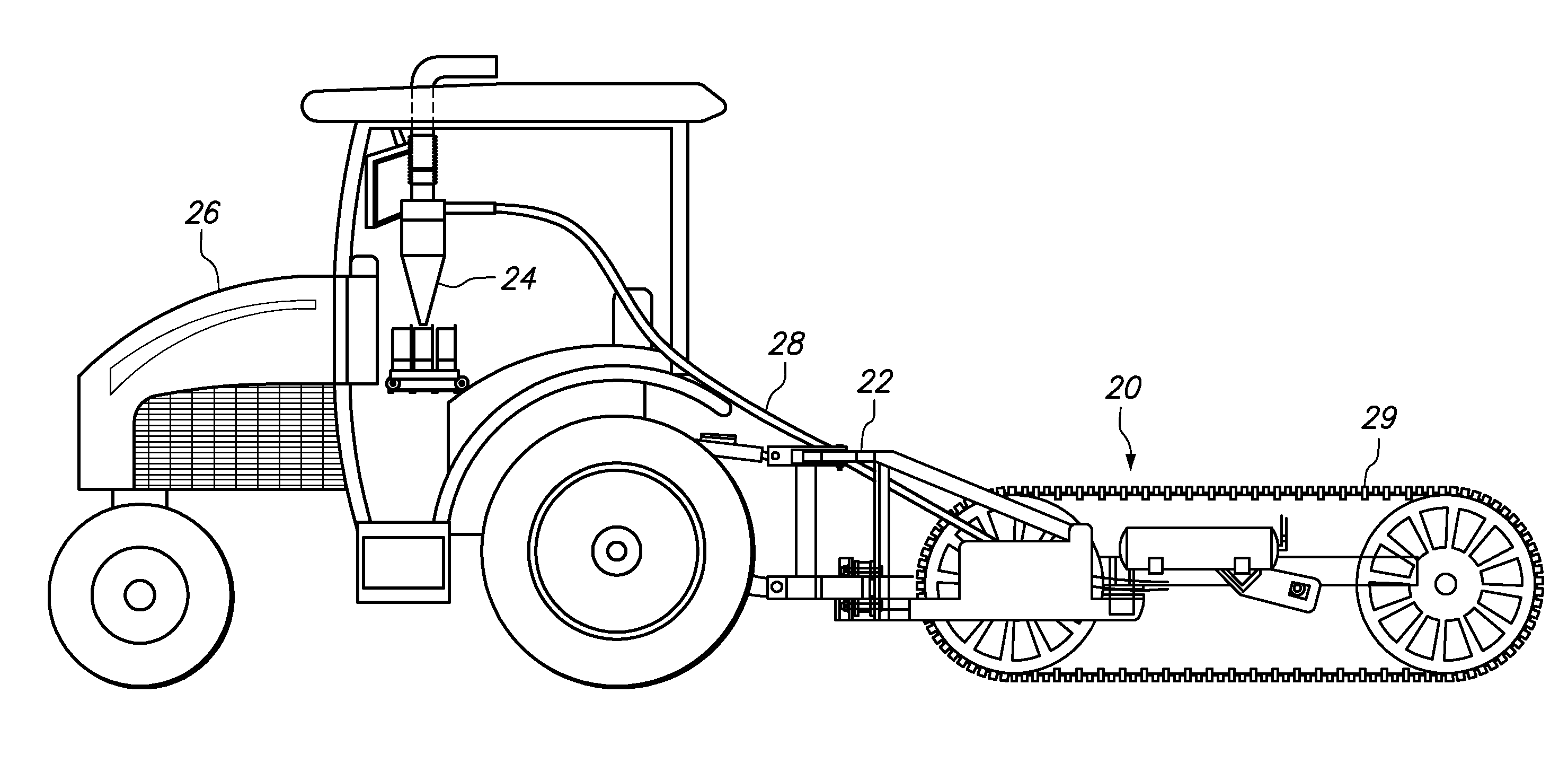

Soil Sampling Apparatus and Method

InactiveUS20100037712A1Automatic collectionEasy to insertEarth drilling toolsWithdrawing sample devicesEngineeringTractor

An apparatus automatically removes soil samples at intervals over a field of interest. The apparatus comprises a sampling assembly that rotates on a track. The probe of the sampler assembly is extended through the track and into the ground, then retracted on each revolution of the track. The sampler assembly is hinged and guided along a track in order to minimize soil compaction as the probe rotates around the rear wheel of the apparatus. Soil is ejected by means of a “rumble path” along the top of the track. The soil samples are pneumatically transferred to a bagging assembly located in the tractor pulling the apparatus.

Owner:AGROBOTICS LLC

Method for Running Tubulars in Wellbores

Methods for installing tubulars (for example, conduits, casing or liners) into a highly deviated wellbore are disclosed. In a first embodiment, the method comprises a) drilling the well to the planned total depth of the interval, b) placing a first fluid into the wellbore below a prescribed measured depth in the high-angle portion of the wellbore, said first fluid having a density that causes the portion of the tubular that extends into the first fluid to become substantially neutrally buoyant, c) placing a second fluid into the wellbore above the prescribed measured depth, said second fluid having a density less than said first fluid, d) plugging the distal portion of the tubular with a lower plug (or check valve) and an upper plug, e) as the tubular is run into the wellbore, placing a lightweight fluid into the plugged section of tubular and a heavy fluid above the plugged section of tubular, and f) running the tubular into the wellbore to the planned total depth.

Owner:EXXONMOBIL UPSTREAM RES CO

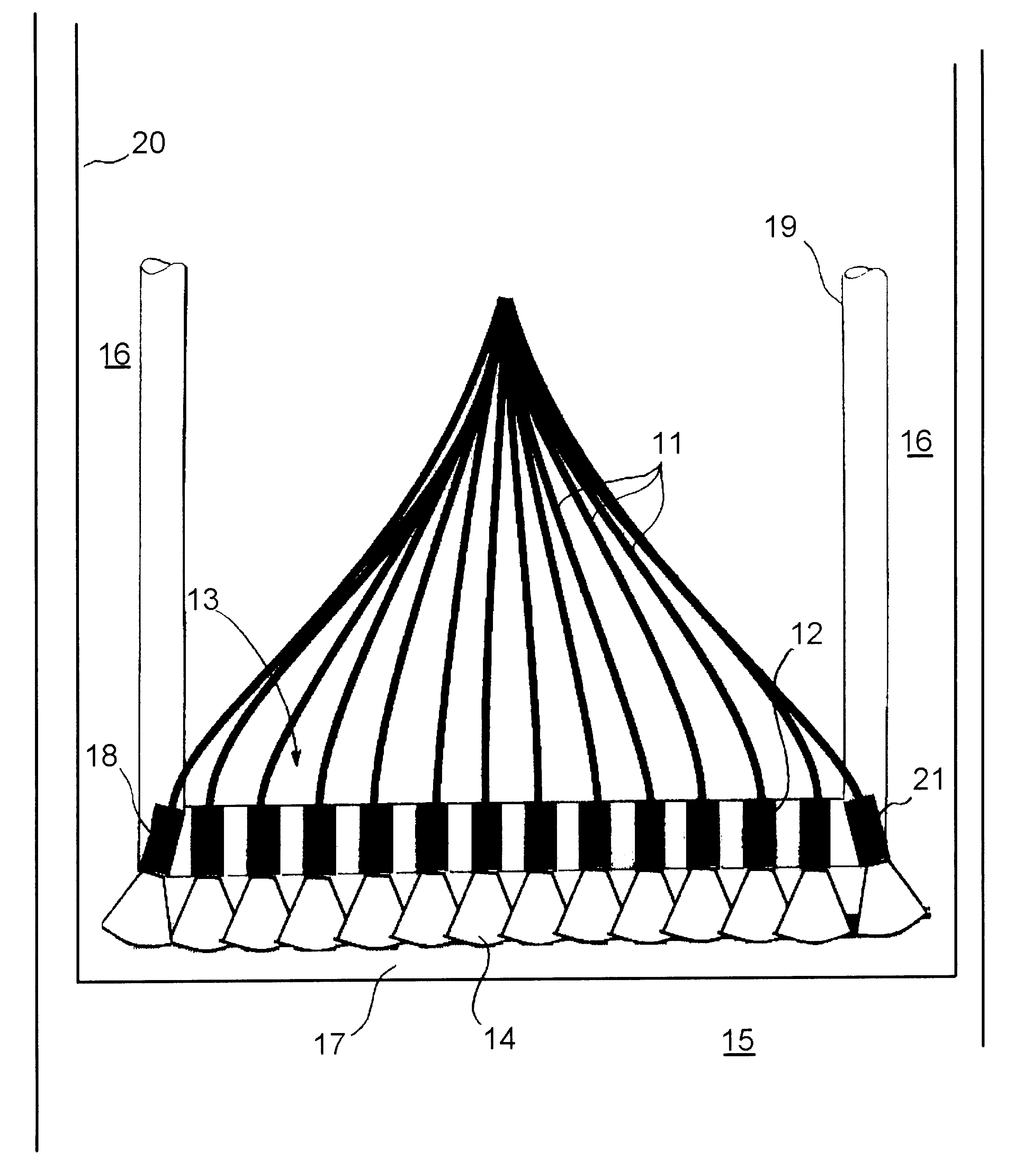

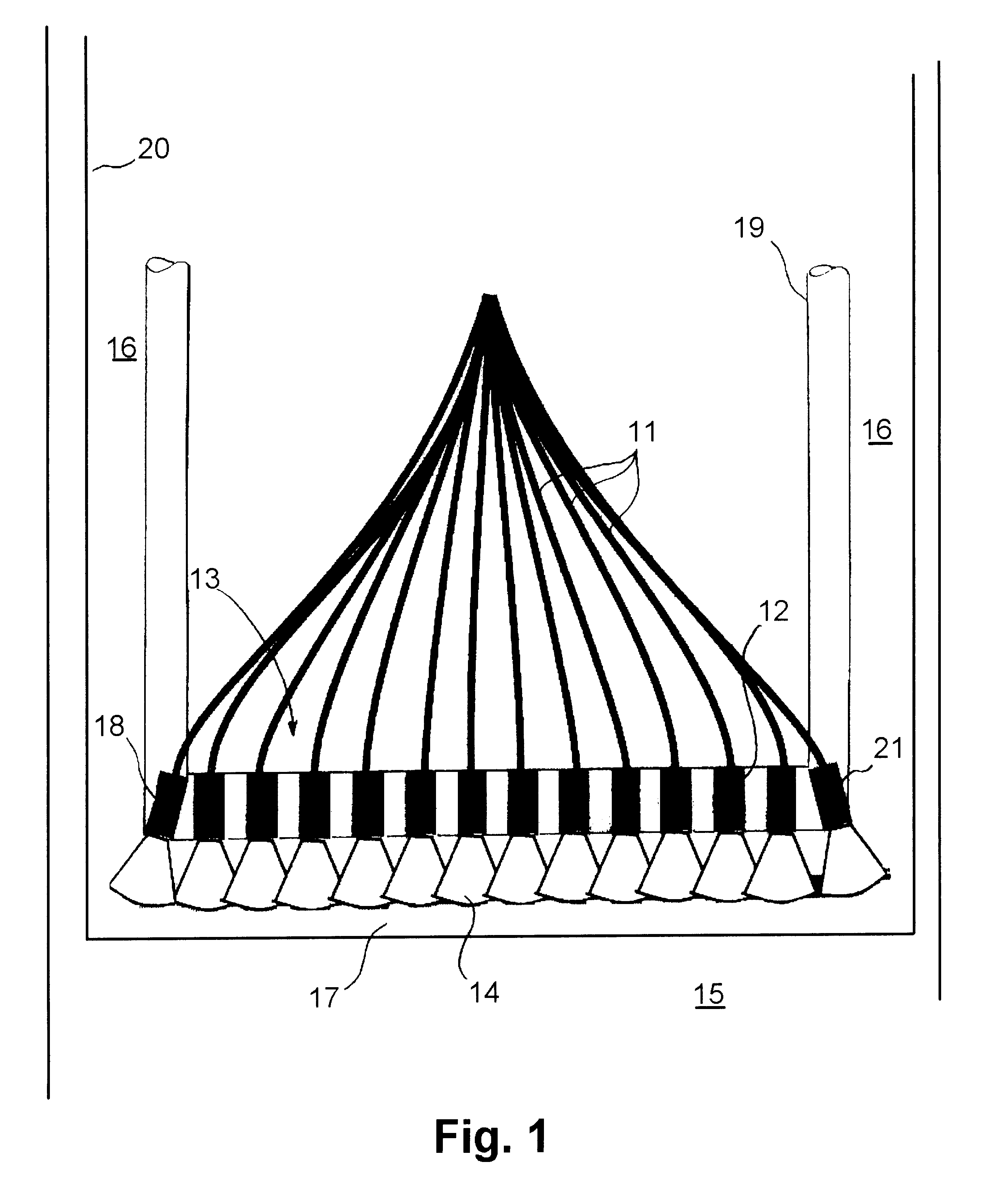

Hollow pole driver

InactiveUS6899187B1Avoid injuryNo pinching of the skin of the userEarth drilling toolsTents/canopiesLower limitMechanical engineering

A hollow pole has an open top end and a pointed bottom end; the open top end supports an additional pole. A ring member is permanently mounted about a mid-section of the hollow pole. A hammer sleeve having a length less than that of the hollow pole inserts over the hollow pole and around the ring member. A pair of weights are mounted within opposed ends of the hammer sleeve and surrounds the ring member. The ring member provides an upper and lower limit to the hammer sleeve. With the pointed bottom end of the hollow pole positioned on the ground, the hammer sleeve is pulled upward and slammed downward driving the pole into the ground. To remove the pole, the procedure is reversed whereby the hammer sleeve is slammed upwards away from the ground. The additional pole can support a plurality of different items, such as, for example, a beach umbrella or an attachment to a volley ball net.

Owner:TCB FLASH

Drilling with a high pressure rotating control device

A Drill-To-The-Limit (DTTL) drilling method variant to Managed Pressured Drilling (MPD) applies constant surface backpressure, whether the mud is circulating (choke valve open) or not (choke valve closed). Because of the constant application of surface backpressure, the DTTL method can use lighter mud weight that still has the cutting carrying ability to keep the borehole clean. The DTTL method identifies the weakest component of the pressure containment system, such as the fracture pressure of the formation or the casing shoe leak off test (LOT). With a higher pressure rated RCD, such as 5,000 psi (34,474 kPa) dynamic or working pressure and 10,000 psi (68,948 kPa) static pressure, the limitation will generally be the facture pressure of the formation or the LOT. In the DTTL method, since surface backpressure is constantly applied, the pore pressure limitation of the conventional drilling window can be disregarded in developing the fluid and drilling programs.

Owner:WEATHERFORD TECH HLDG LLC

Multiple zone testing system

InactiveUS7004252B2Facilitates singular testingEasy to testEarth drilling toolsSurveyTester deviceEngineering

A method and system for drillstem testing multiple zones in a well with a single testing trip into the well. A multiple zone tester is landed in the lower completion to form separate controllable flow paths from each of the zones. The multiple zone testing system facilitates testing each zone singularly and performing commingled tests without pulling out of the well.

Owner:SCHLUMBERGER TECH CORP

Latchable hanger assembly for liner drilling and completion

InactiveUS20070107911A1Minimize the numberUnrestricted returnEarth drilling toolsDrilling rodsWell drillingEngineering

Owner:BAKER HUGHES INC

Drilling with casing

A borehole may be drilled utilizing the bottom hole assembly 10, 50 with a downhole motor 14, which may offset at a selected bend angle. The motor housing is preferably run slick, and a gauge section 36 secured to the pilot bit 18 has a uniform diameter bearing surface along an axial length of at least 60% of the pilot bit diameter. The bit or reamer 16 has a bit face defining the cutting diameter of the drilled hole. The axial spacing between the bend and the bit face is controlled to less than fifteen times the bit diameter. The downhole motor, pilot bit and bit may be retrieved from the well while leaving the casing string in the well.

Owner:HALLIBURTON ENERGY SERVICES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![[apparatus and method for acquiring information while drilling] [apparatus and method for acquiring information while drilling]](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/f64a3a43-96cf-4e9d-9b44-73876b5e7bd2/US20050109538A1-20050526-D00000.png)

![[apparatus and method for acquiring information while drilling] [apparatus and method for acquiring information while drilling]](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/f64a3a43-96cf-4e9d-9b44-73876b5e7bd2/US20050109538A1-20050526-D00001.png)

![[apparatus and method for acquiring information while drilling] [apparatus and method for acquiring information while drilling]](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/f64a3a43-96cf-4e9d-9b44-73876b5e7bd2/US20050109538A1-20050526-D00002.png)