Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34 results about "Planar robot" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

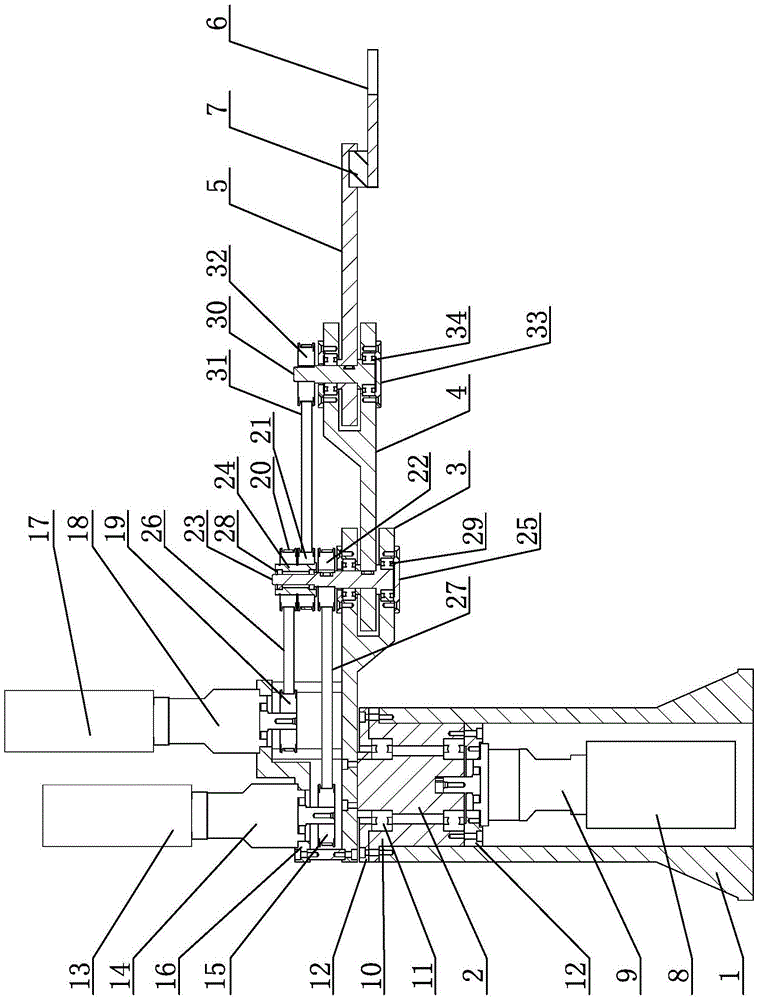

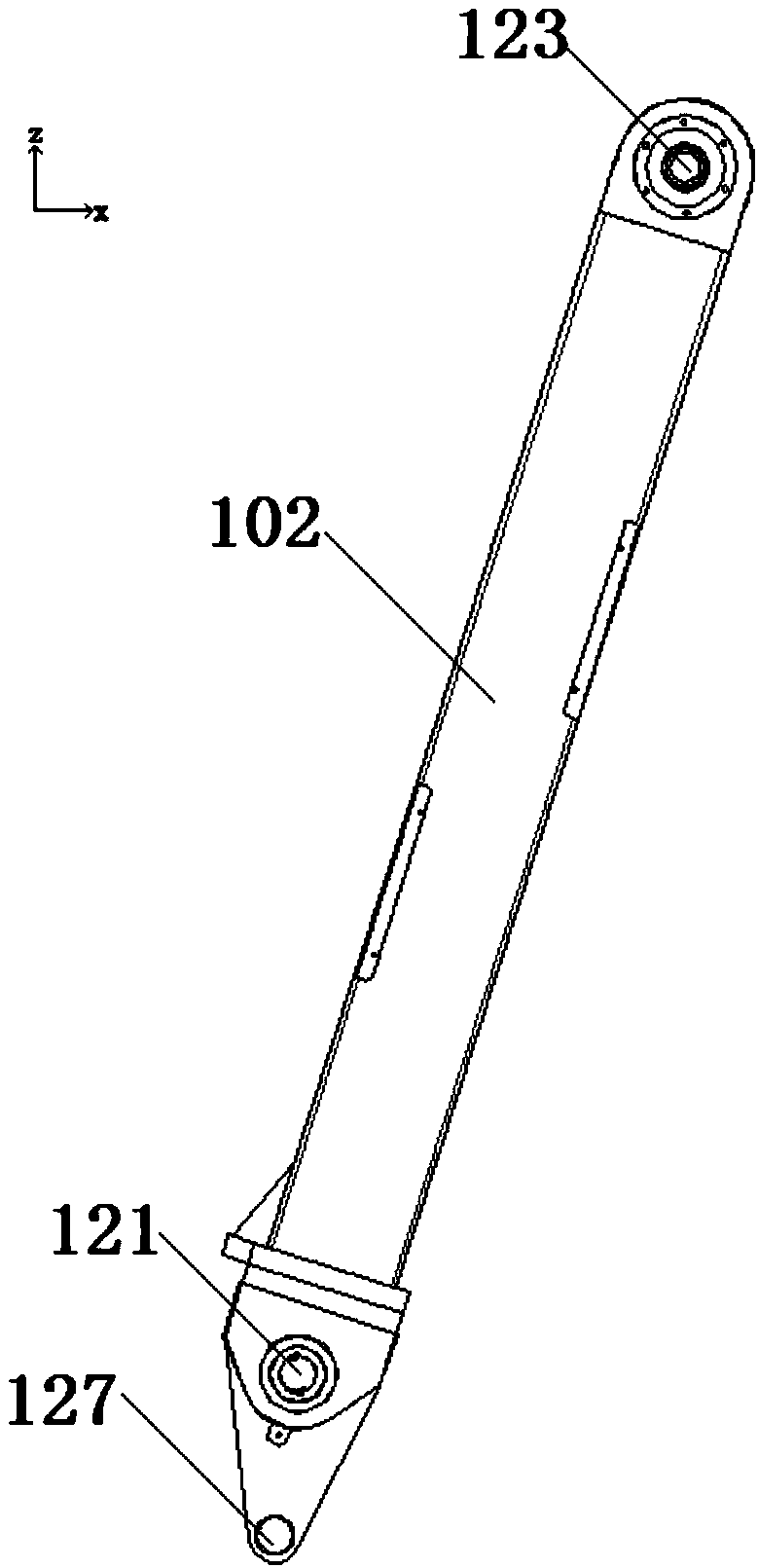

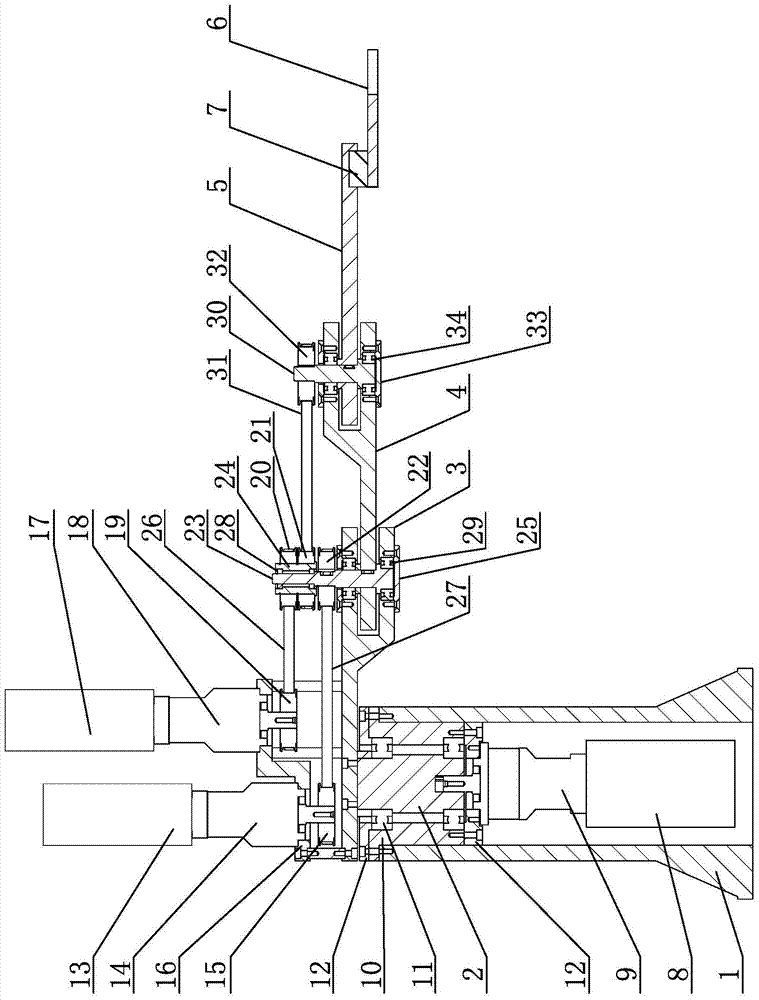

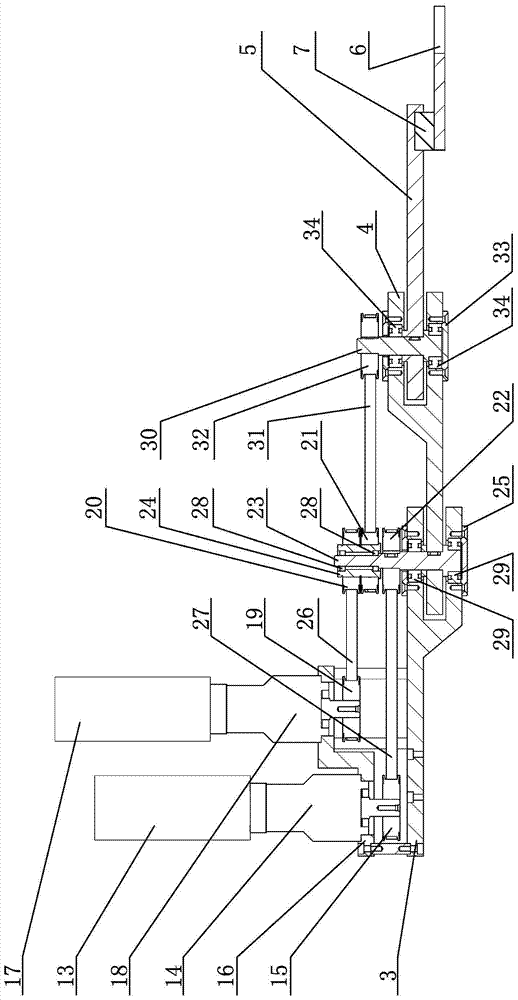

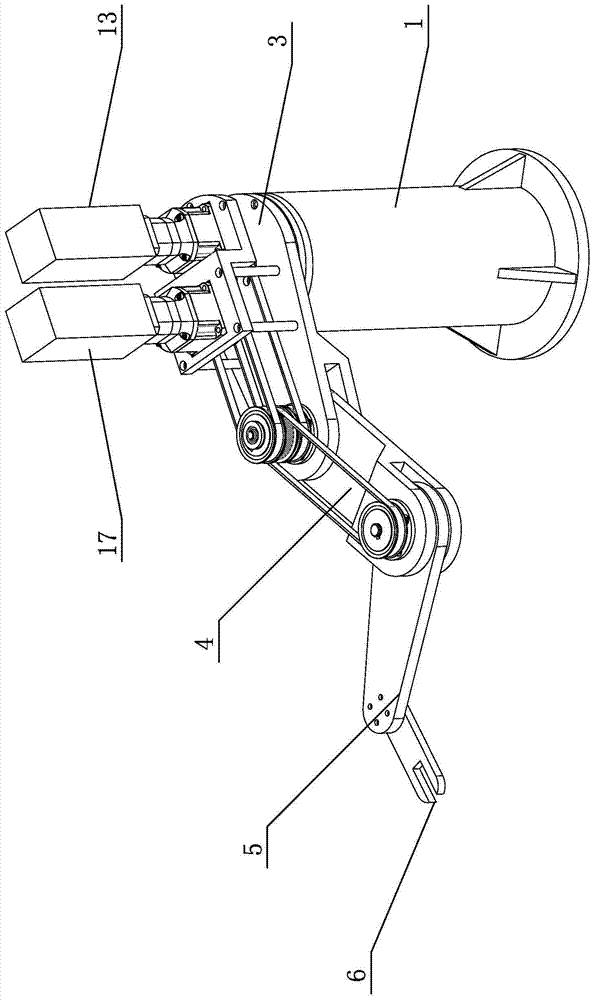

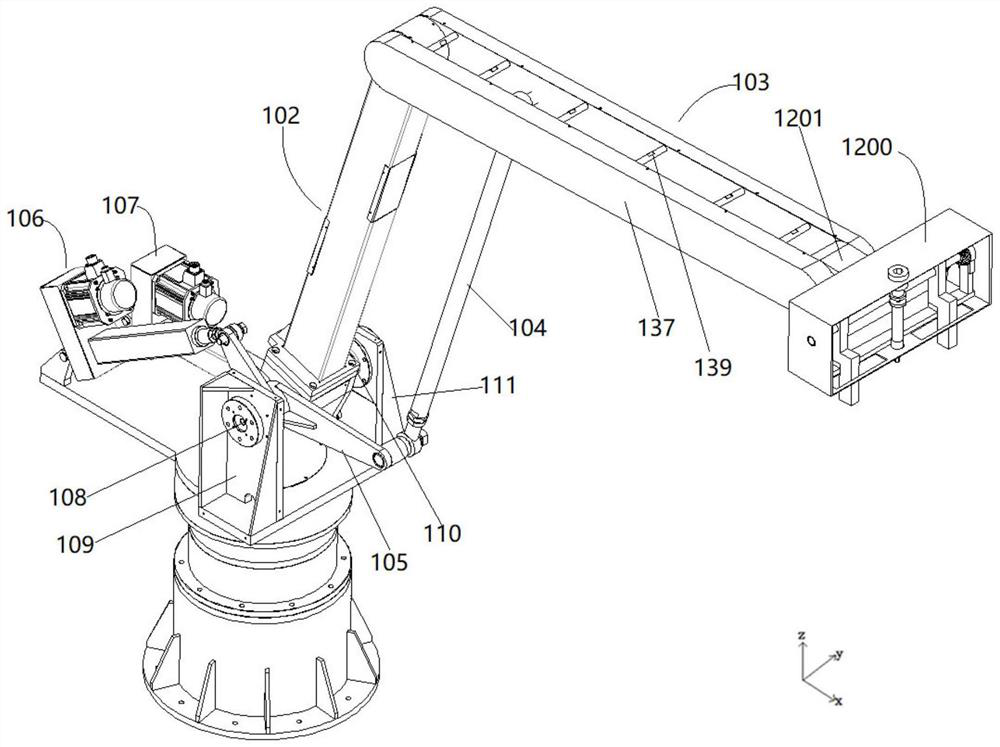

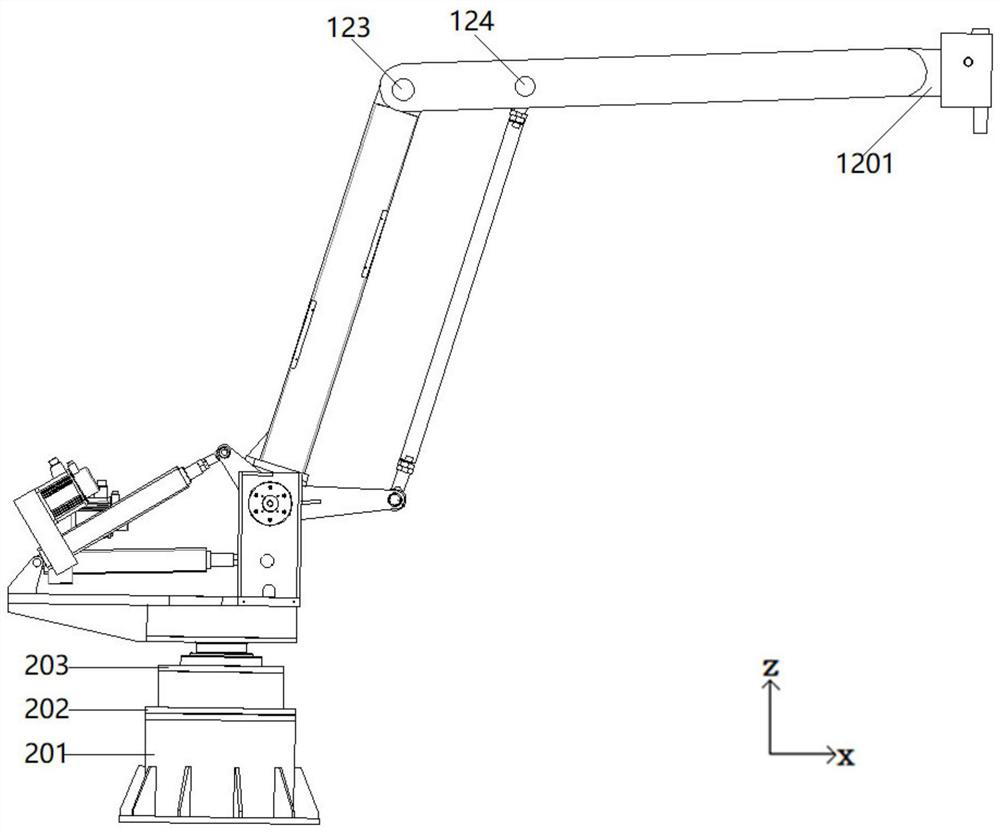

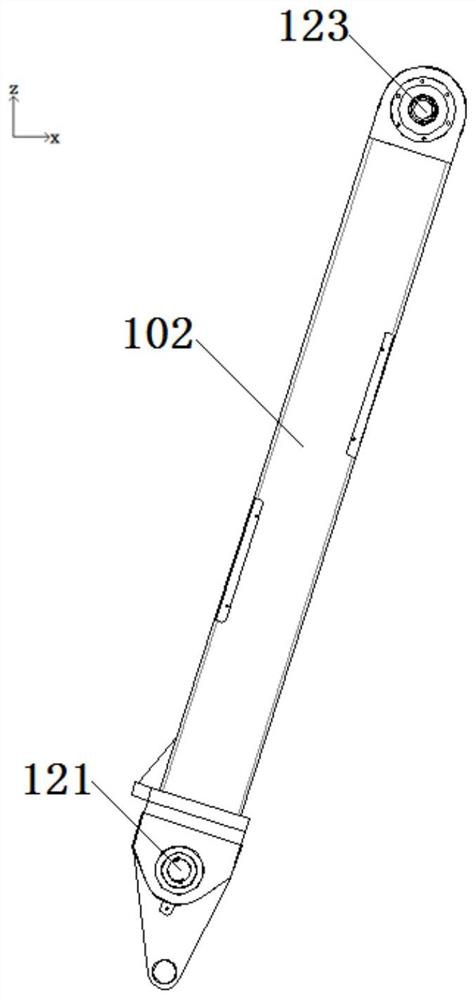

Artificial cochlea implanting operation system based on computer vision

ActiveCN103330616AGuaranteed accuracyShorten operation timeEar treatmentArtificial cochlea implantPlanar robot

The invention relates to an artificial cochlea implanting operation system based on computer vision. The artificial cochlea implanting operation system is characterized by comprising a computer, a head fixed support, a rough adjustment passive arm, a dual-plane rotor, a CT (Computed Tomography) scanner and photo-electric navigation equipment, wherein the computer is further internally provided with a VTK Platform rectification navigation platform; the VTK Platform rectification navigation platform comprises an image visualization unit, an image incision unit, a spatial rectification unit, a planning unit and a navigation unit, wherein the image visualization unit is used for reading, rebuilding and displaying the CT data of a patient, the image incision unit is used for incising the CT data of the patient and acquiring the data of an operative region, the spatial adjustment unit is used for combining a CT image space and an actual space so as to generate a rectification matrix, the planning unit is used for planning the operative pathway of an implanted artificial cochlea in the CT image space, and the navigation unit draws a model by combining the cochlea surface of the patient under the tracking of the photo-electric navigation equipment, and guides a doctor to finish the implanting operation of the artificial cochlea according to a planned path. The artificial cochlea implanting operation system based on computer vision can be extensively applied to artificial cochlea implanting operation.

Owner:PEKING UNIV THIRD HOSPITAL

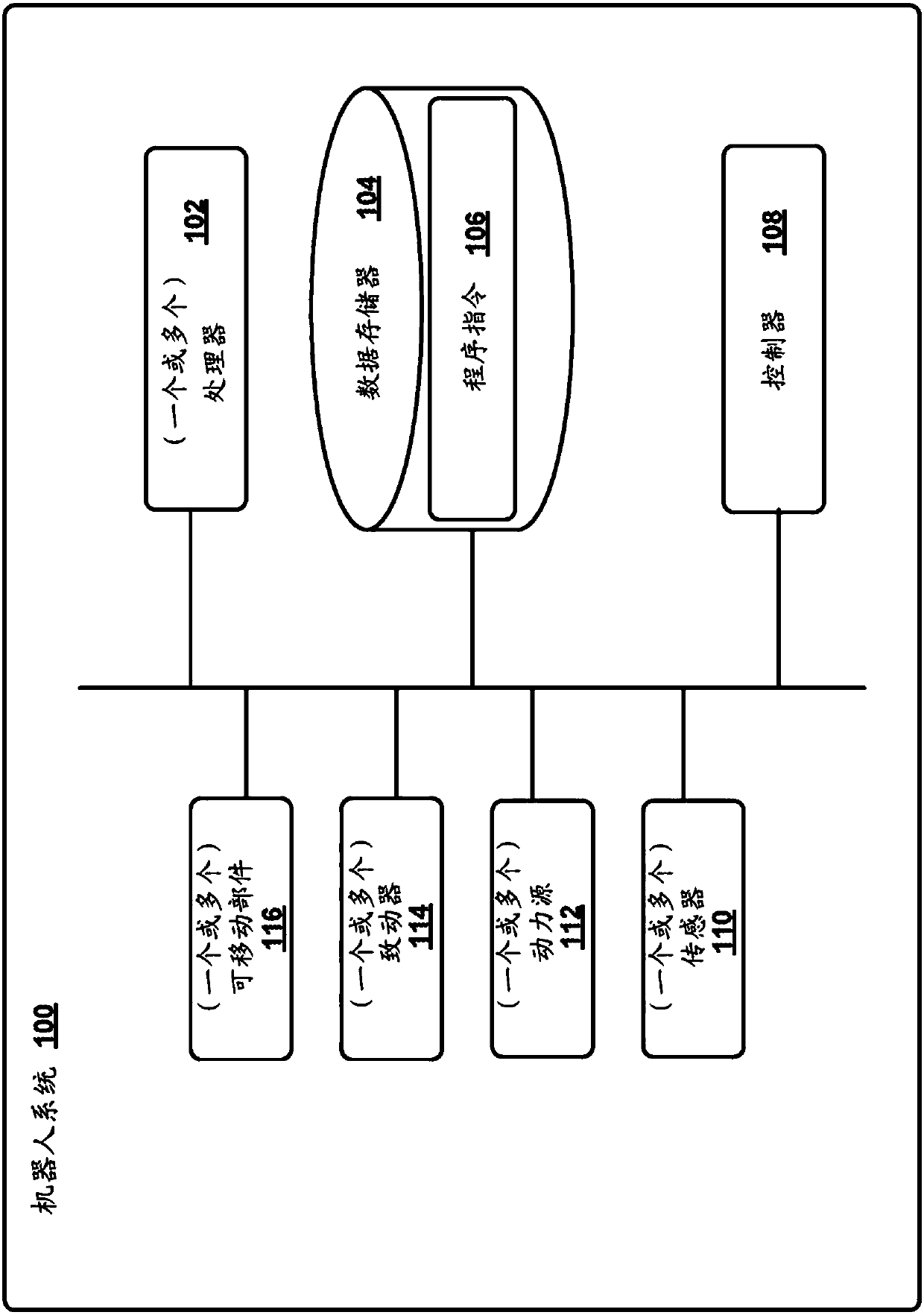

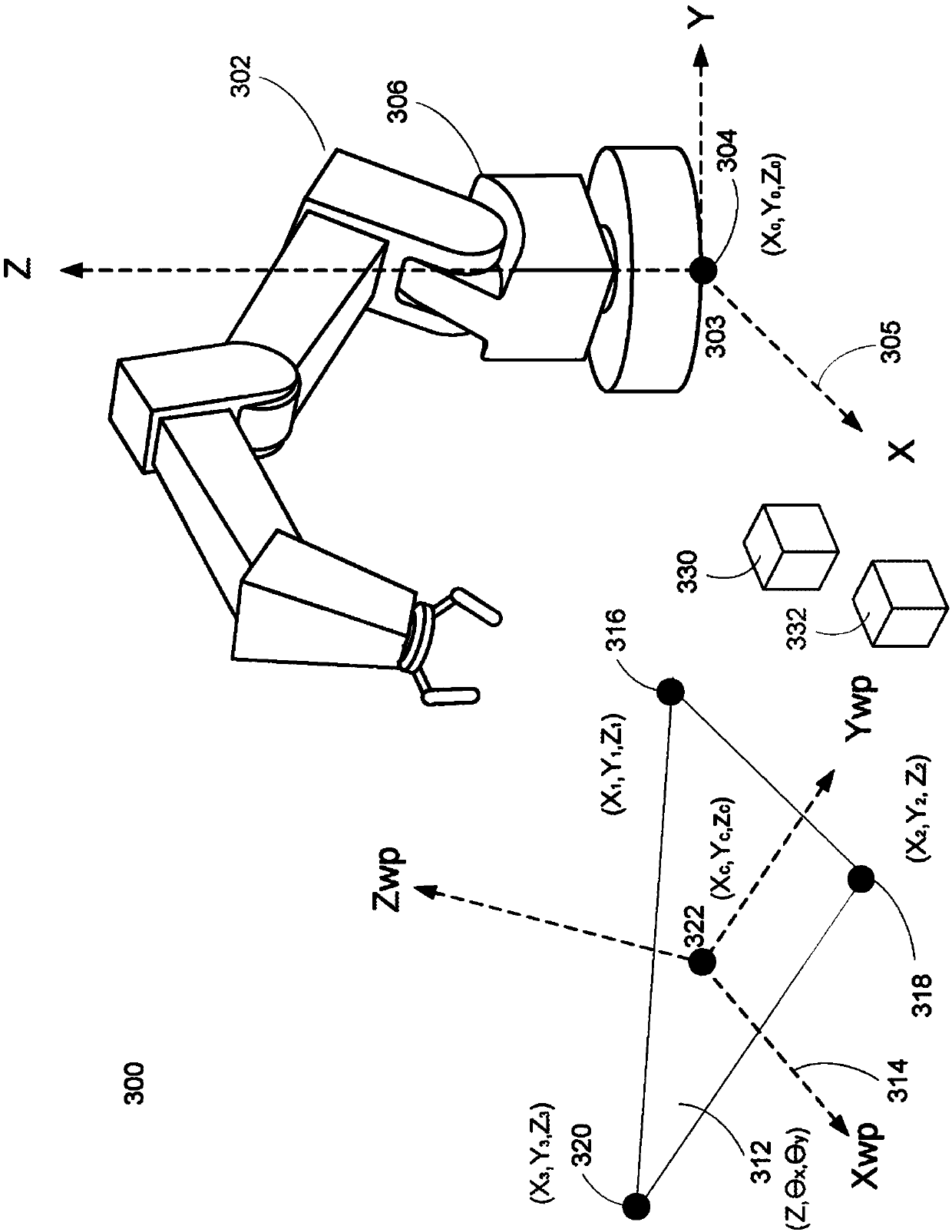

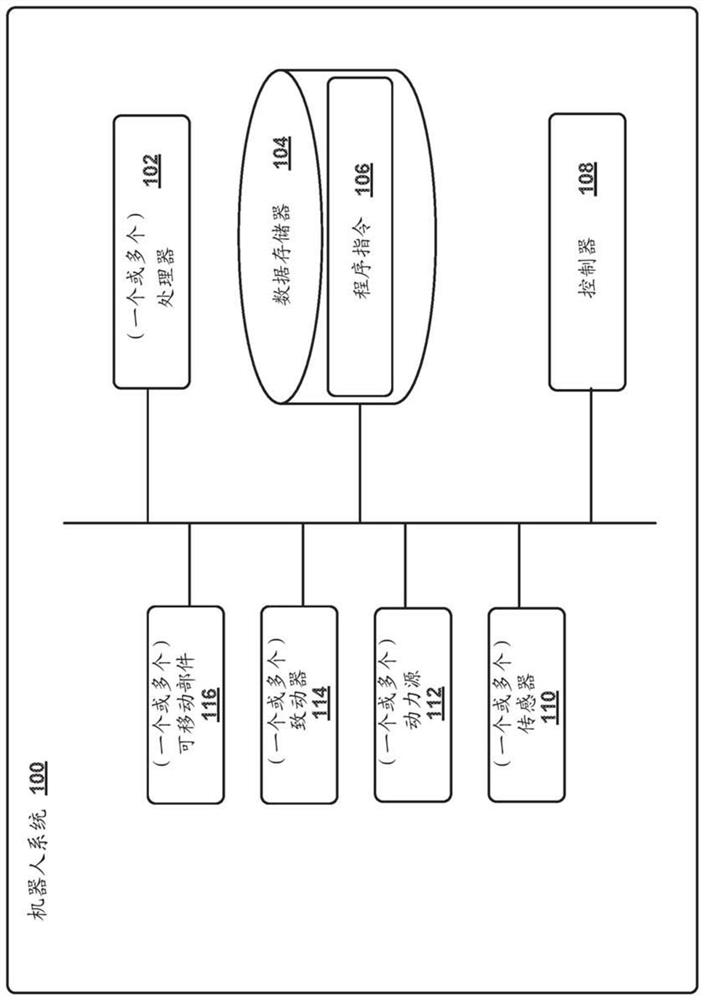

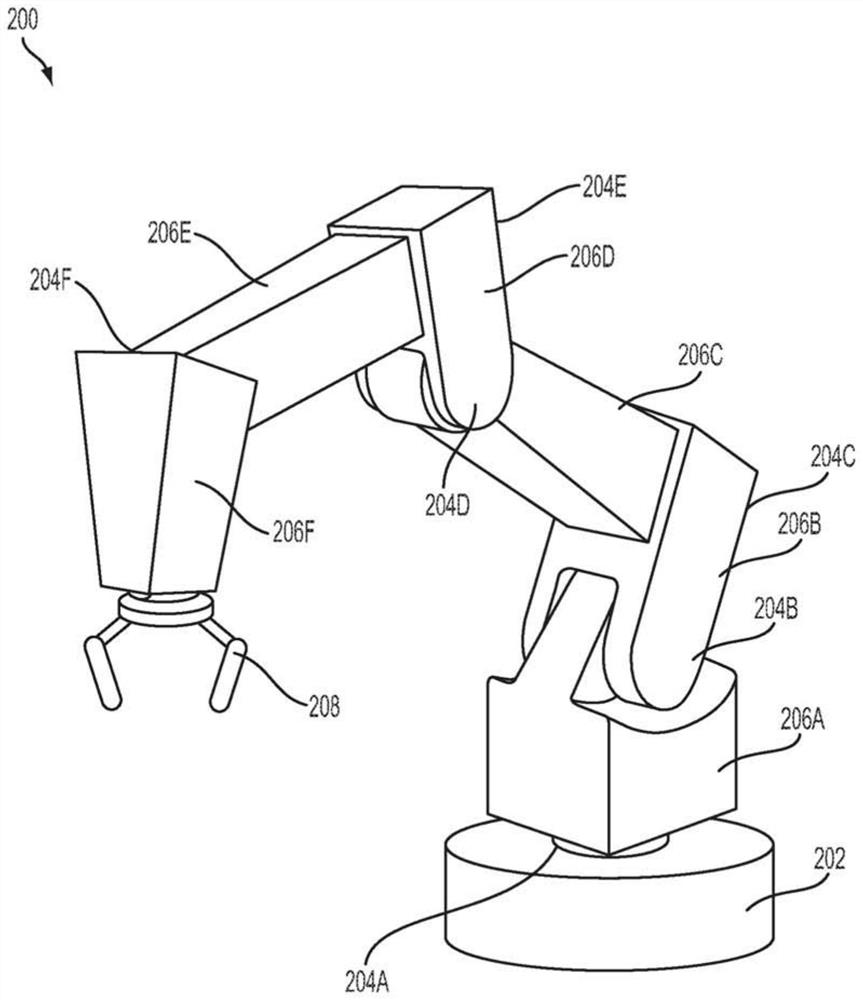

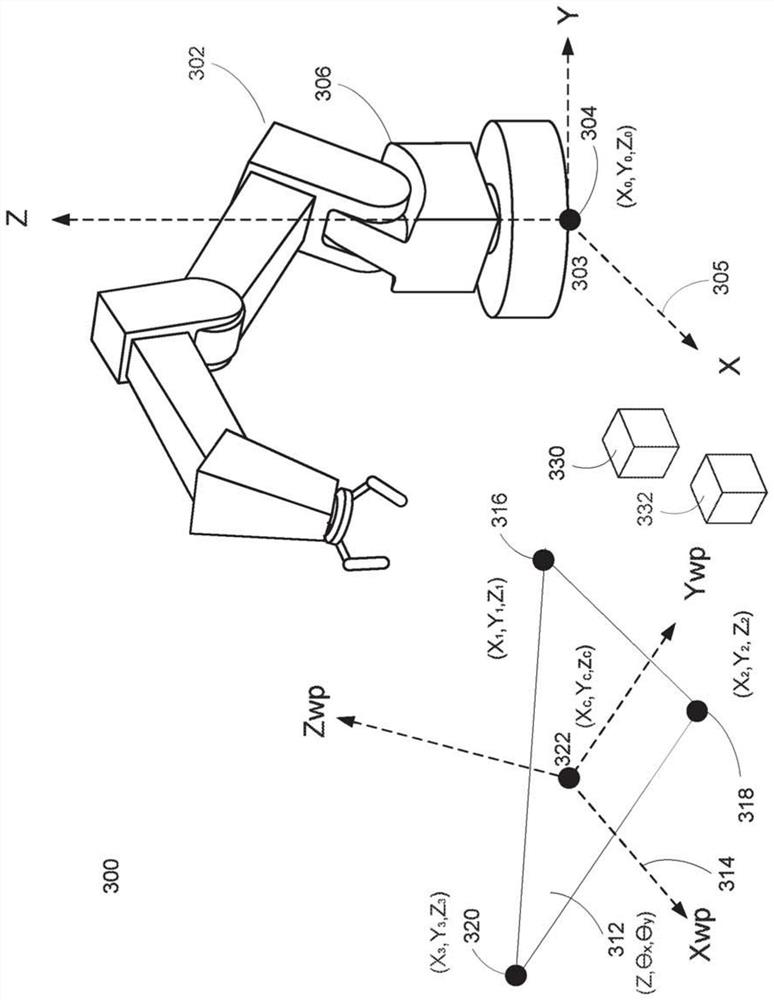

System and method for determining a work offset

ActiveCN107924175AObvious exampleObvious featuresProgramme controlProgramme-controlled manipulatorPlanar robotContact time

Example systems and methods are disclosed for determining work offset data for a robot m a work environment. A robot operating in a work environment may receive an indication to determine a work offset. The work offset may describe the location and angular orientation of a working plane of the work environment relative to a base plane of the robot. In response to the indication, the robot may identify the working plane. The robot may be controlled to contact one or more points of the working plane. The robot may determine respective point locations of the contacted points relative to the baseplane based on the respective positions of the robot at respective times of contact. The robot may determine the location and angular orientation of the working plane relative to the base plane basedon the determined respective point locations of the contacted points.

Owner:X DEV LLC

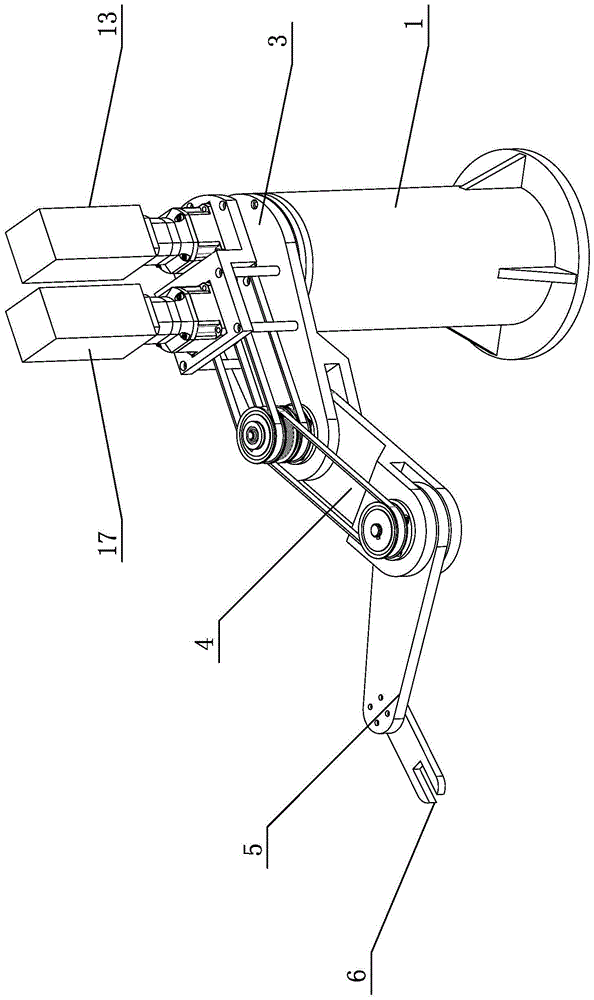

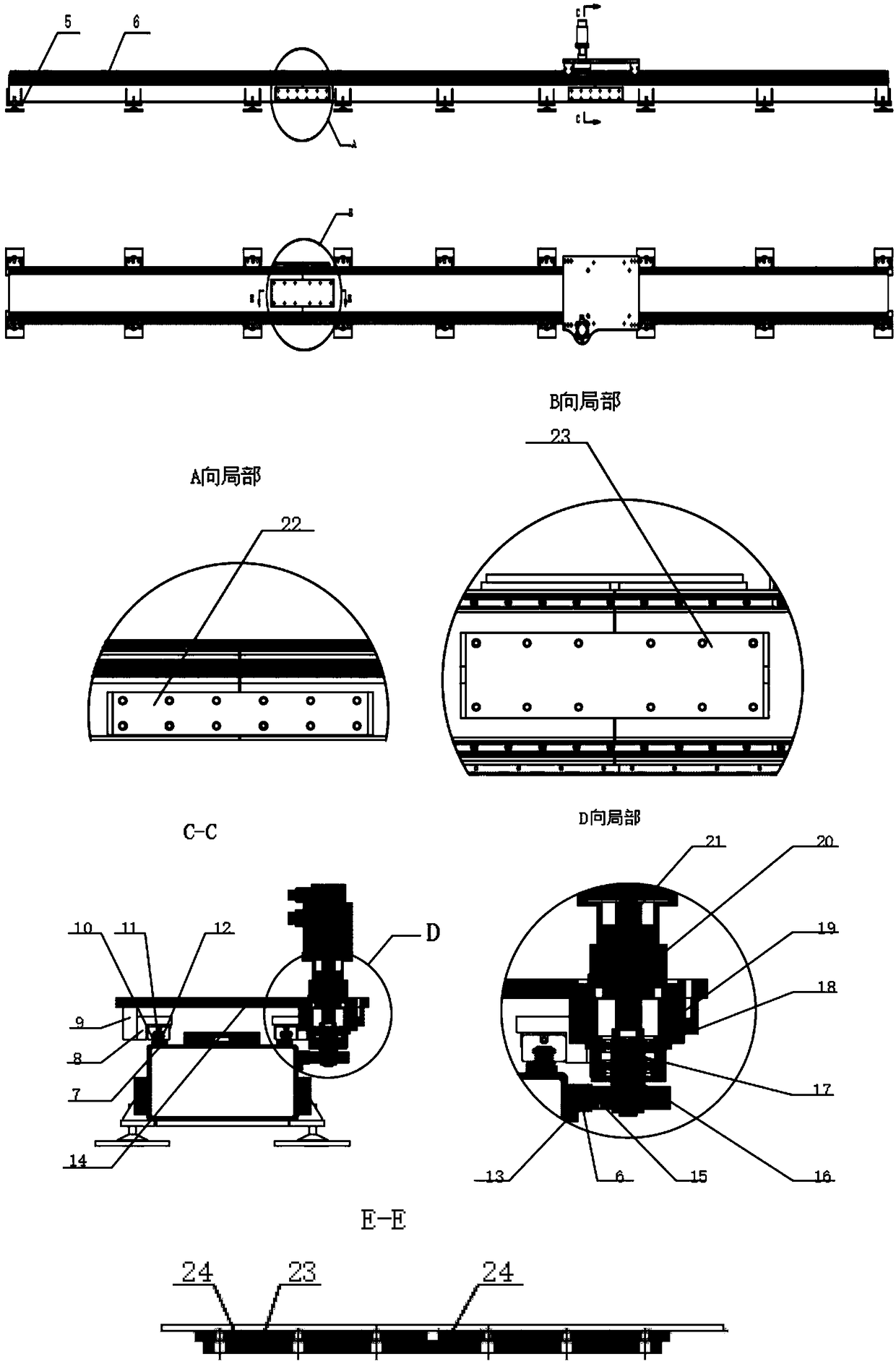

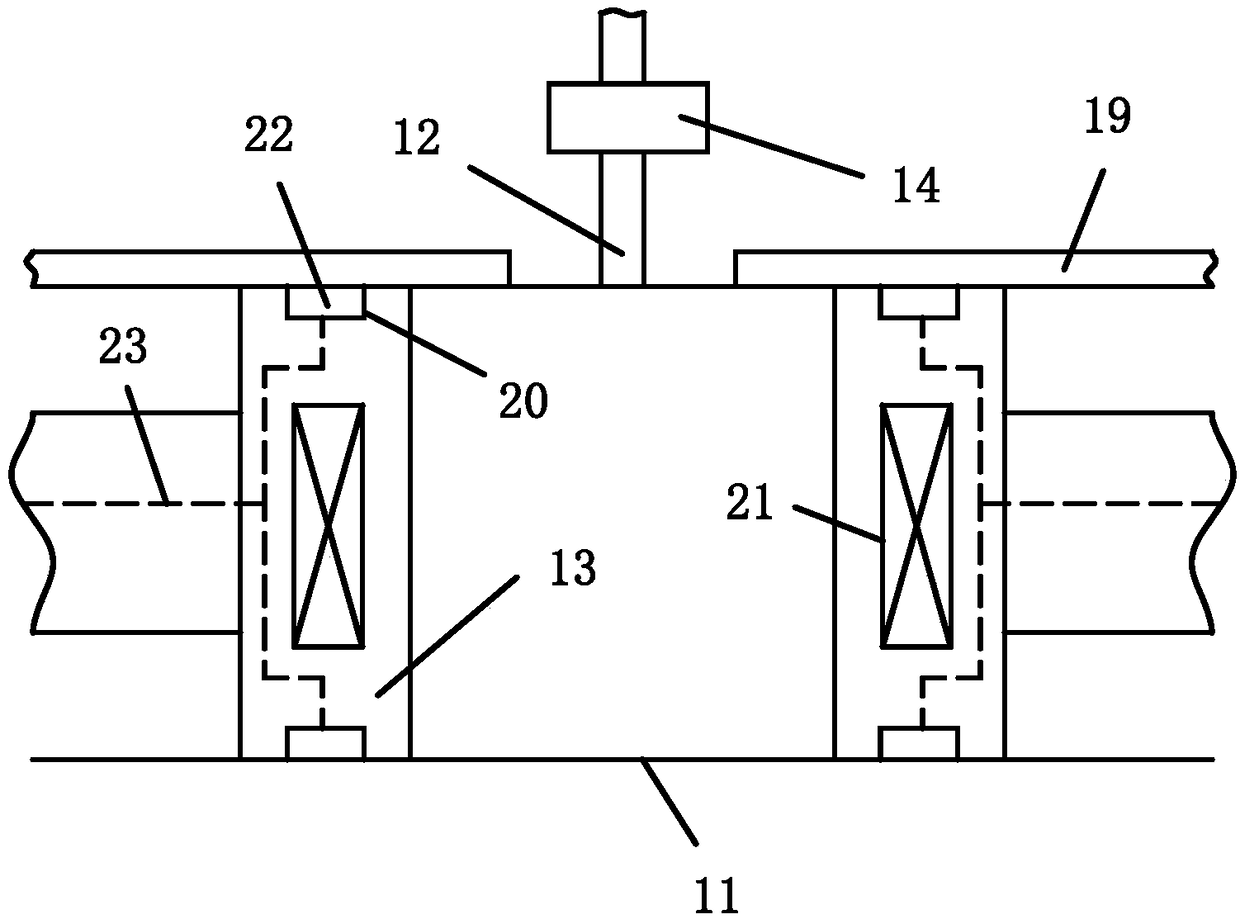

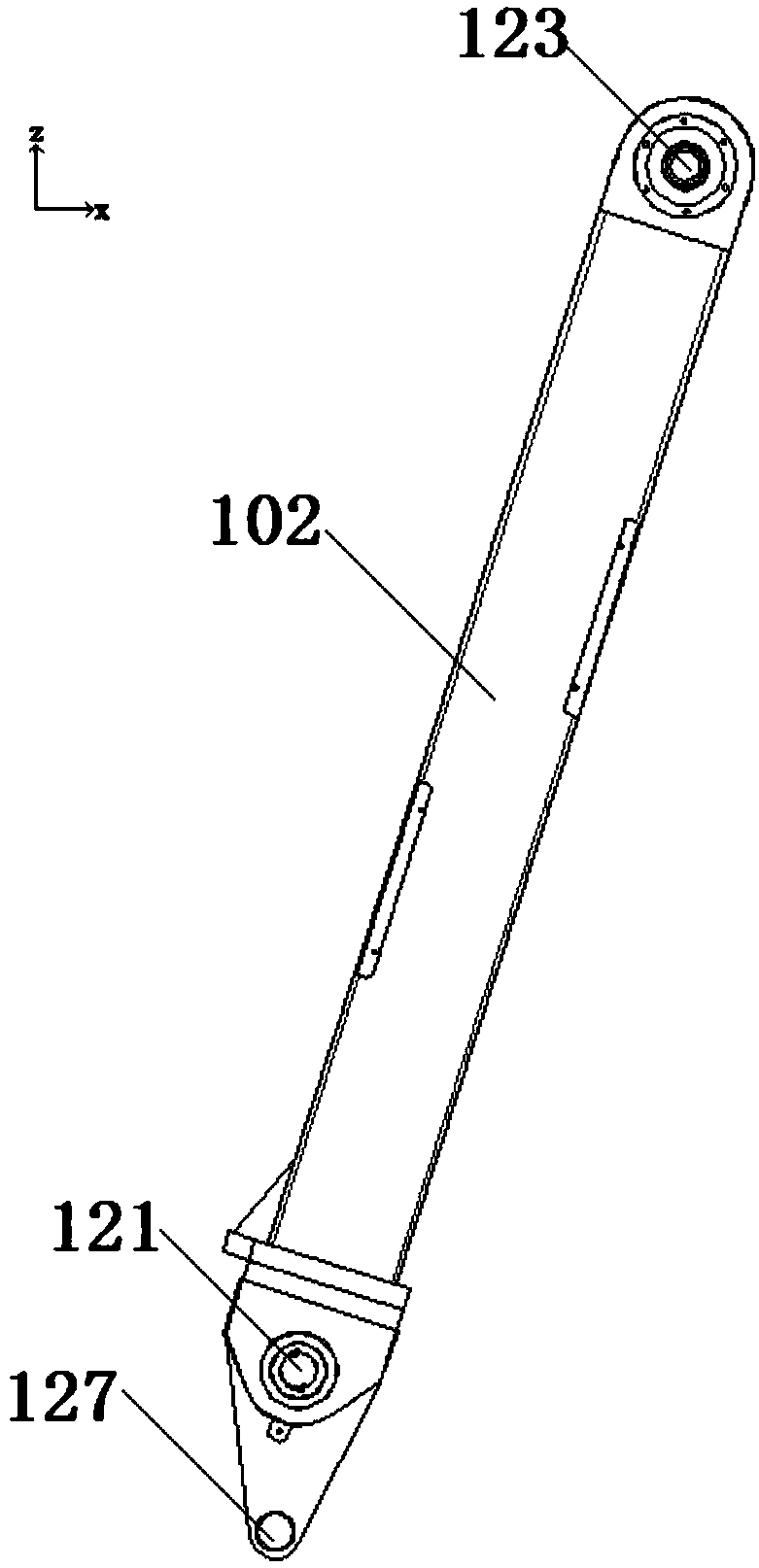

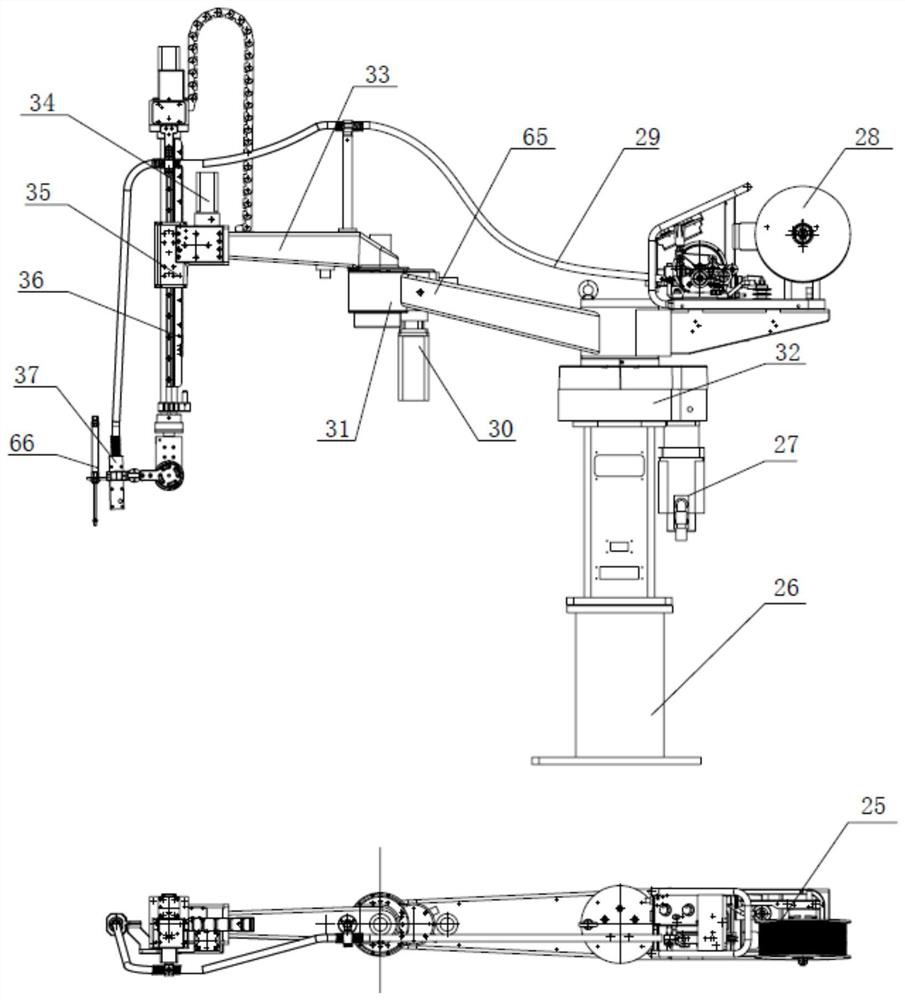

Planar redundant robot

ActiveCN105479451ASmall moment of inertiaImprove stabilityProgramme-controlled manipulatorPlanar robotAgricultural engineering

The invention discloses a planar redundant robot, relates to a robot, and specifically relates to a planar redundant robot. The invention aims at solving the problem of low location accuracy of the existing planar robot. The planar redundant robot disclosed by the invention comprises a base, a first drive unit, a joint shaft, a support mechanism, a first connection rod, a second connection rod, a third connection rod, a manipulator, a second drive unit, a third drive unit, a first transit mechanism, a second transit mechanism, a sensor and a drive unit support, wherein the first drive unit is installed in the base; the joint shaft is installed in the base through the support mechanism; the first drive unit is connected with the lower end of the joint shaft; the upper end of the joint shaft is connected with one end of the first connection rod; the other end of the first connection rod is connected with one end of the second connection rod through the first transit mechanism; and the other end of the second connection rod is connected with one end of the third connection rod through the second transit mechanism. The invention belongs to the field of robots.

Owner:HARBIN INST OF TECH

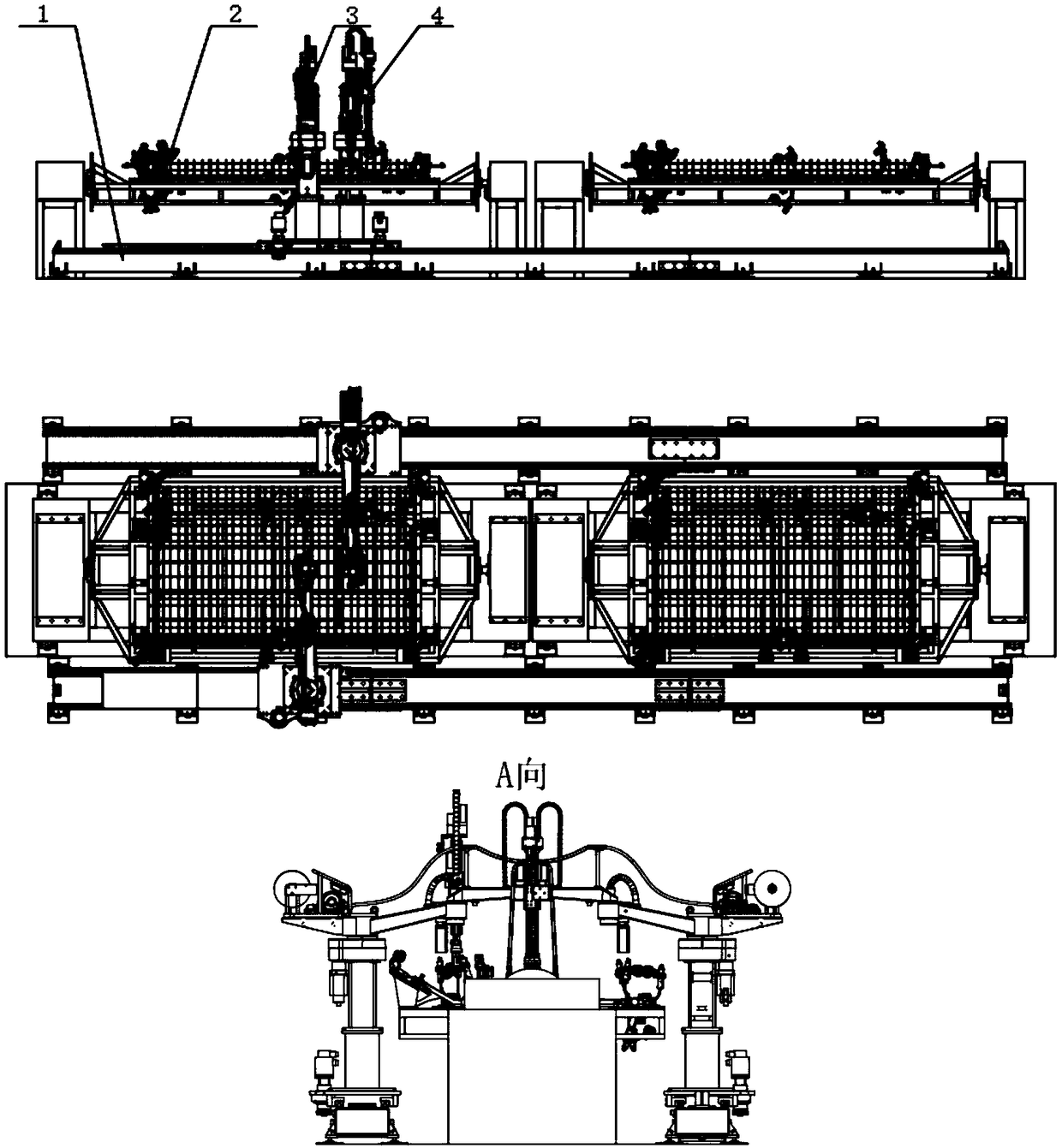

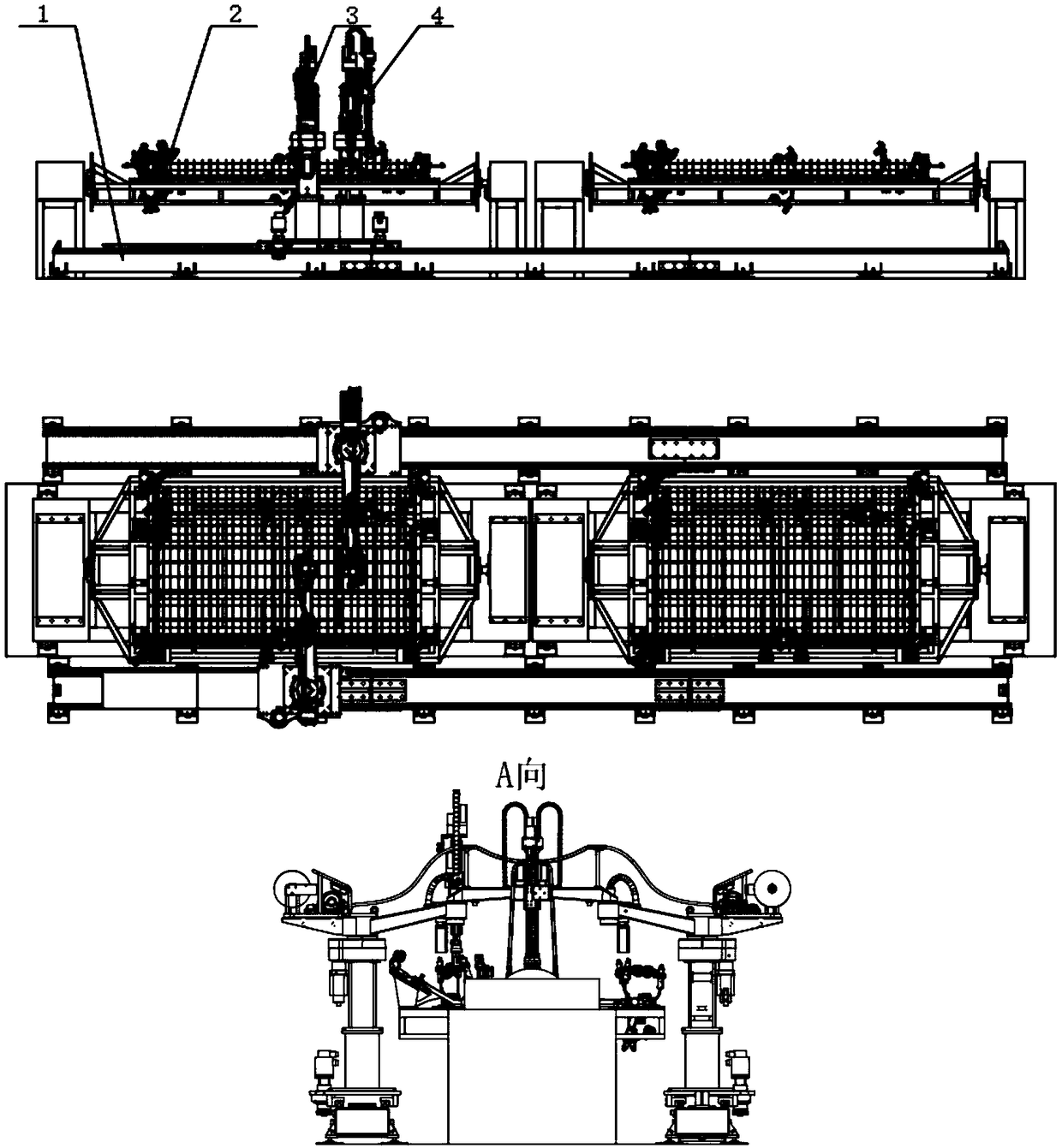

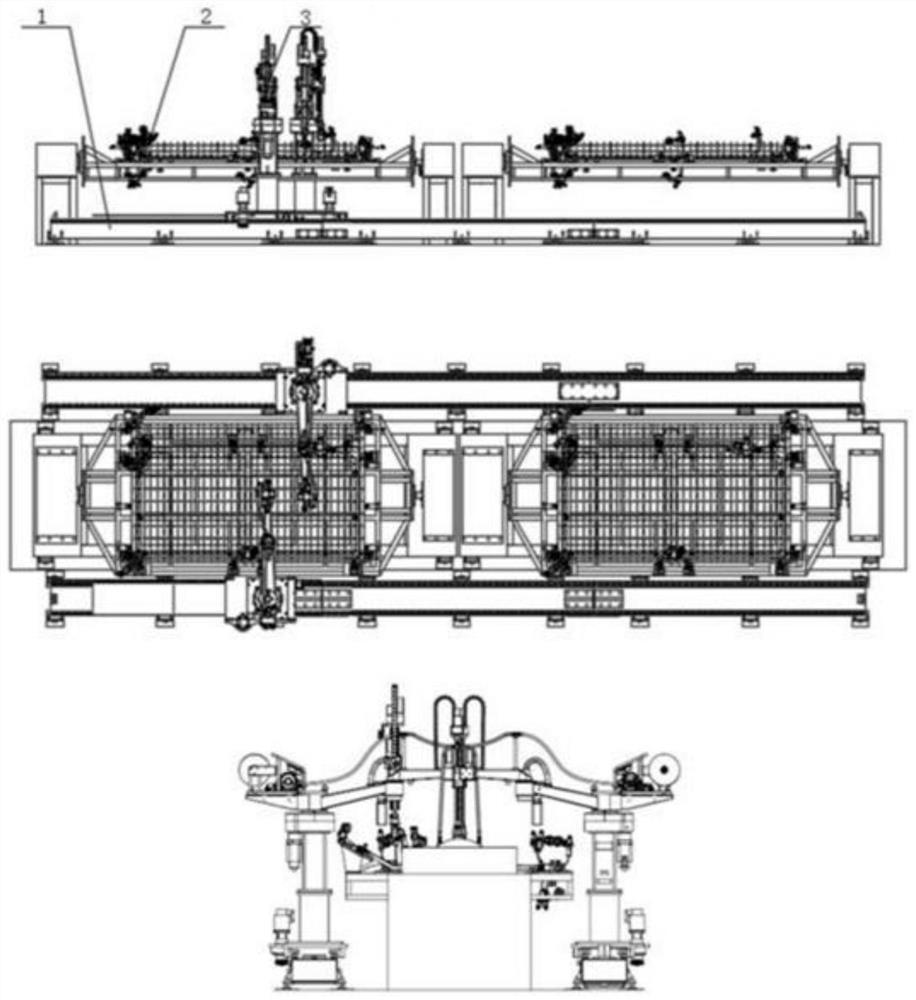

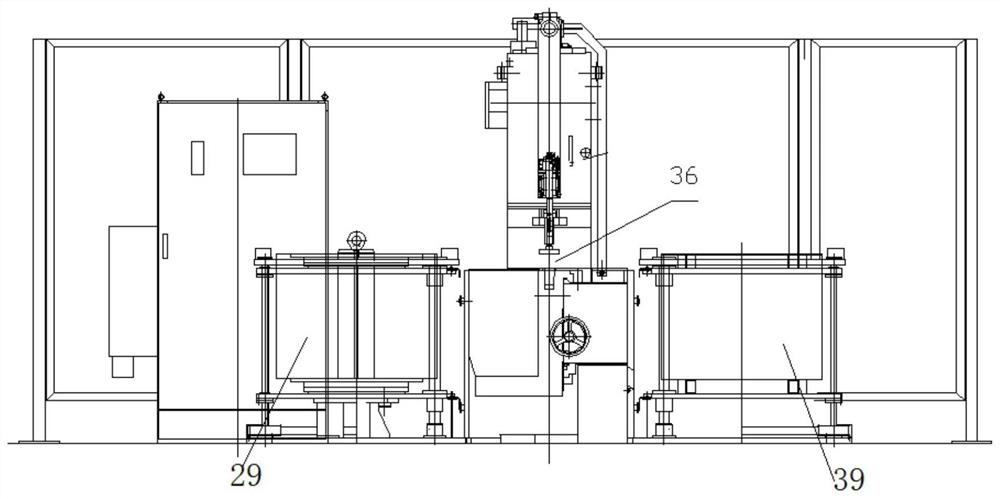

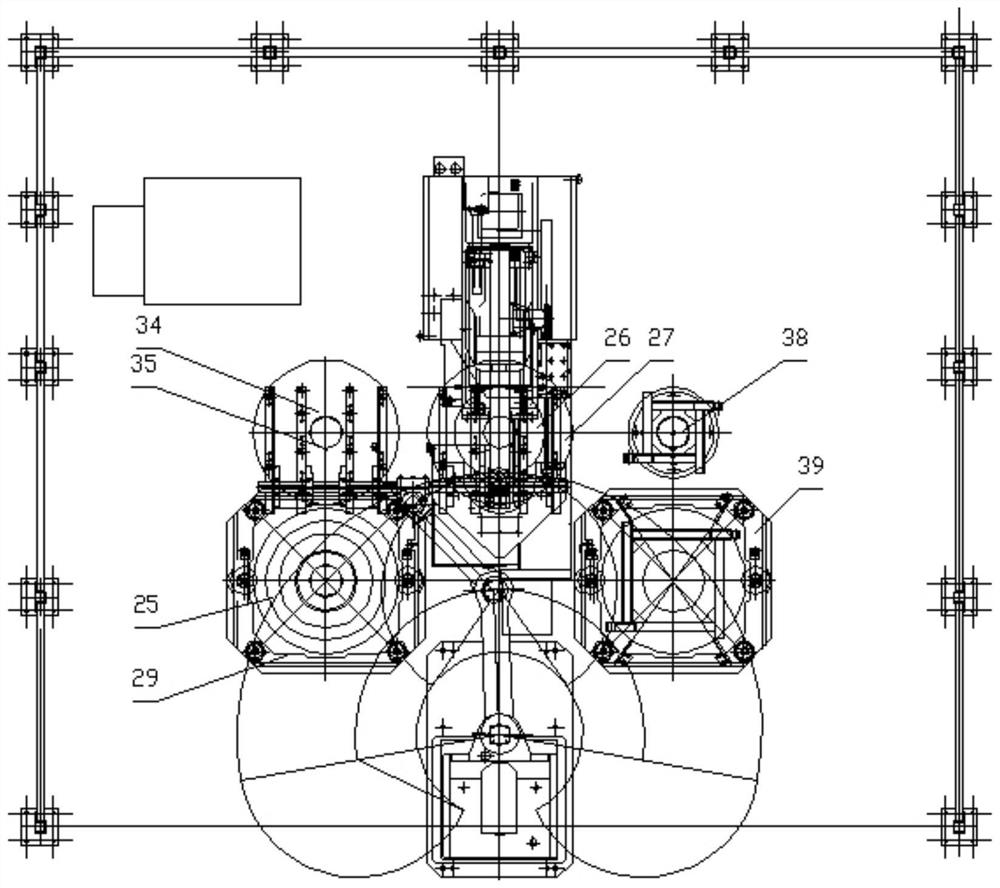

Protective guard welding equipment

ActiveCN108942023AAchieve weldingConsistent welding effectWelding/cutting auxillary devicesAuxillary welding devicesPlanar robotThree degrees of freedom

The invention relates to protective guard welding equipment which solves the problems of high labor intensity, low efficiency, irregular welding effect and ugly overall welding shape in manual weldingof protective guards with the same shapes and different sizes. The equipment is mainly divided into three parts: a slide rail mechanism, a wire feeding mechanism and a welding mechanism. The equipment is automatic equipment, and can realize welding of the protective guards through replacement of different tools for the protective guards with different sizes; as the protective guards generally usecarbon steel, and the welding mode uses gas shielded welding, in addition, a three-degree-of-freedom plane robot is used for realizing automatic feeding of welding wires to an appointed welding position, and welding guns arranged side by side weld the protective guards and master batches; and welding trajectories of the welding guns of the three-degree-of-freedom plane robot are controlled through programming procedures, so that the welding effect is consistent, and the efficiency is improved.

Owner:SUZHOU LVDIAN INFORMATION TECH CO LTD

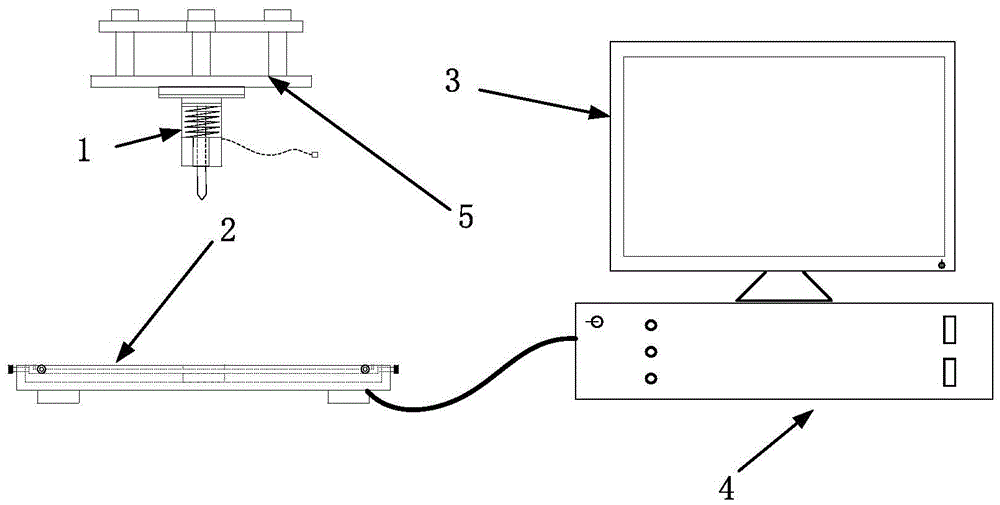

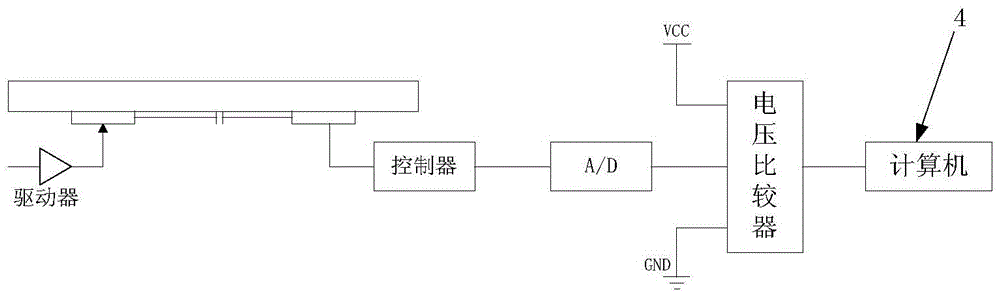

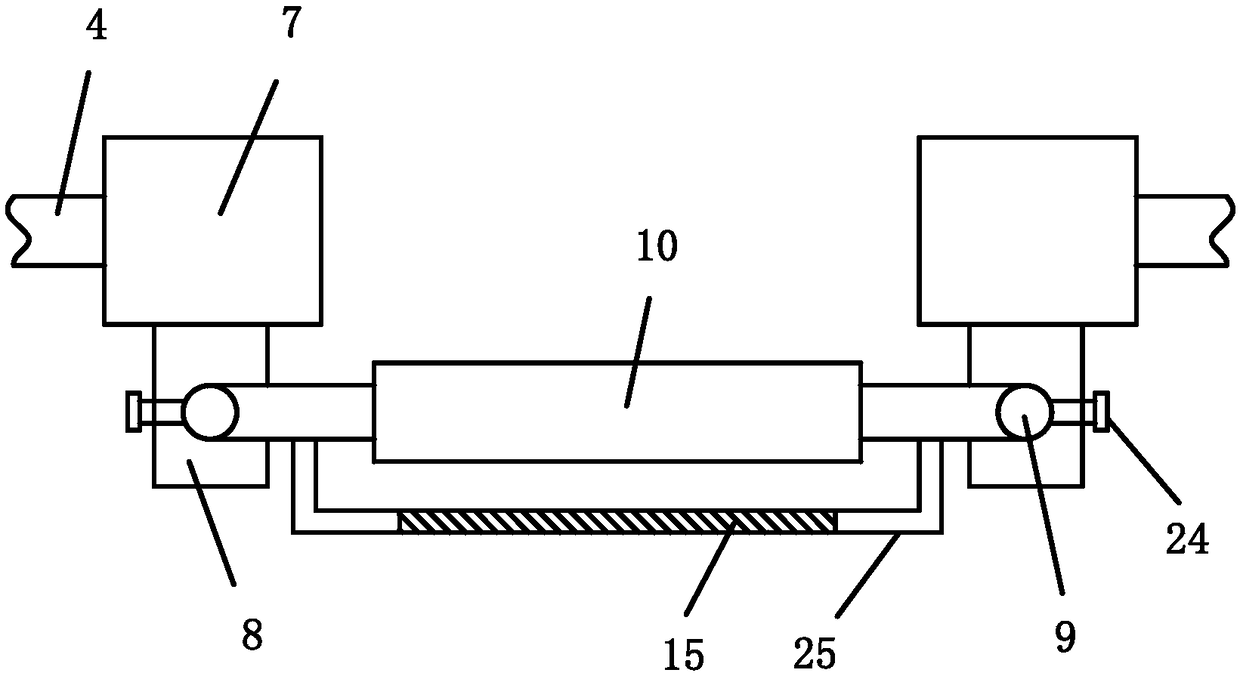

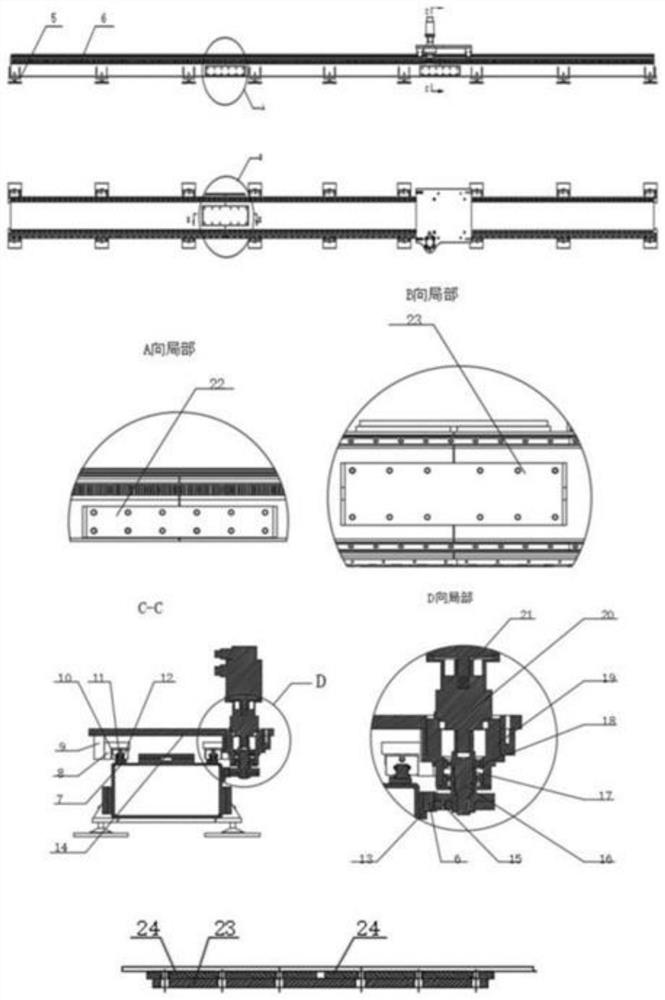

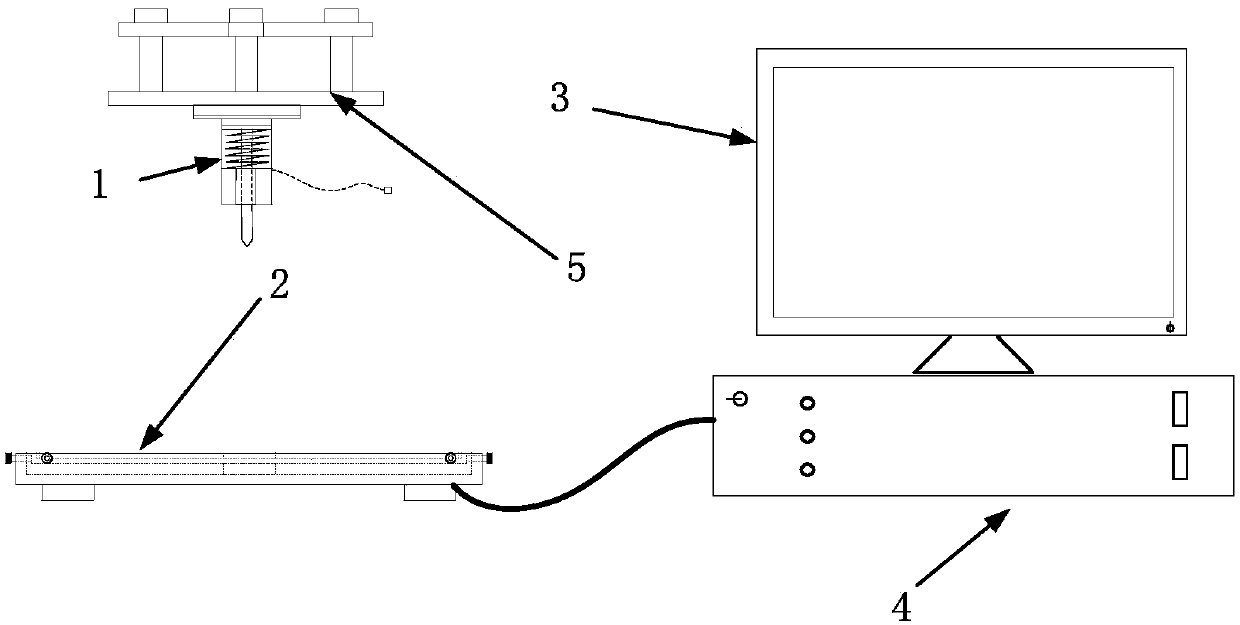

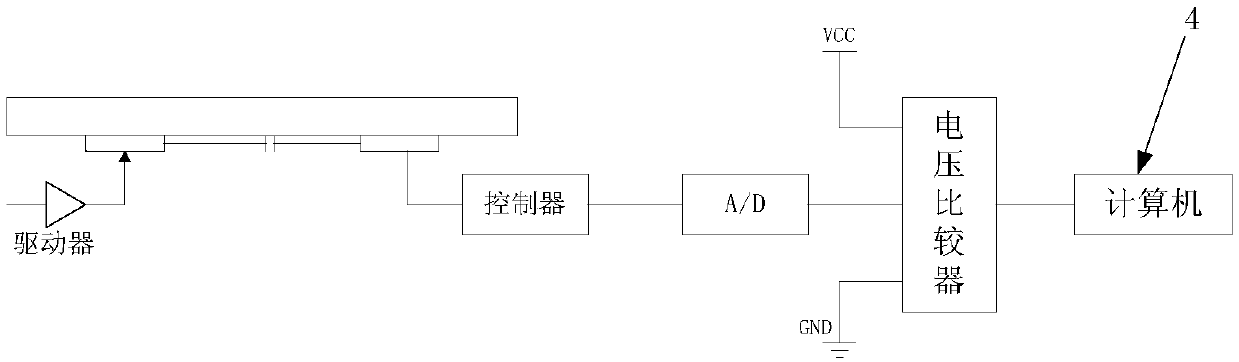

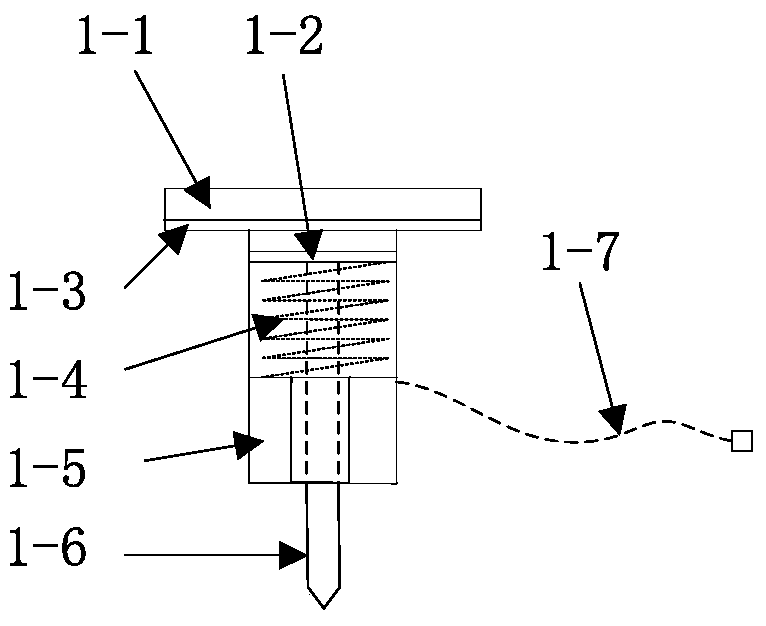

Plane robot position detection method and system based on capacitive touch screen

ActiveCN105547120AEasy to assembleImprove economyElectric/magnetic position measurementsUsing electrical meansCapacitancePlanar robot

The invention provides a plane robot position detection method and system based on a capacitive touch screen, belonging to a plane robot position detection method and system. The method and system are used for accurately detecting a plane robot end position coordinate. The system comprises a capacitive screen triggering device, a capacitive touch screen support device, a display screen, a computer, and an auxiliary fixing device, wherein the capacitive screen triggering device comprises a fixed magnet, a spring control board, a magnetic shield material, a reset spring, an electromagnet, a capacitive screen trigger, and an electromagnet connection wire. The capacitive touch screen support device comprises a support device base, an adjustment platform, an adjustment knob, anti-skid support legs, a rotation bearing, a capacitive touch screen, and a touch screen fixed pad. The auxiliary fixing device comprises a clamping base, a clamping plate and a clamping screw. The invention provides the plane robot position detection method and system based on a capacitive touch screen, and the problems of a complex measurement process, a long measurement time, limited measurement range and serious damage of a measuring instrument of an existing method are solved.

Owner:CHINA UNIV OF MINING & TECH

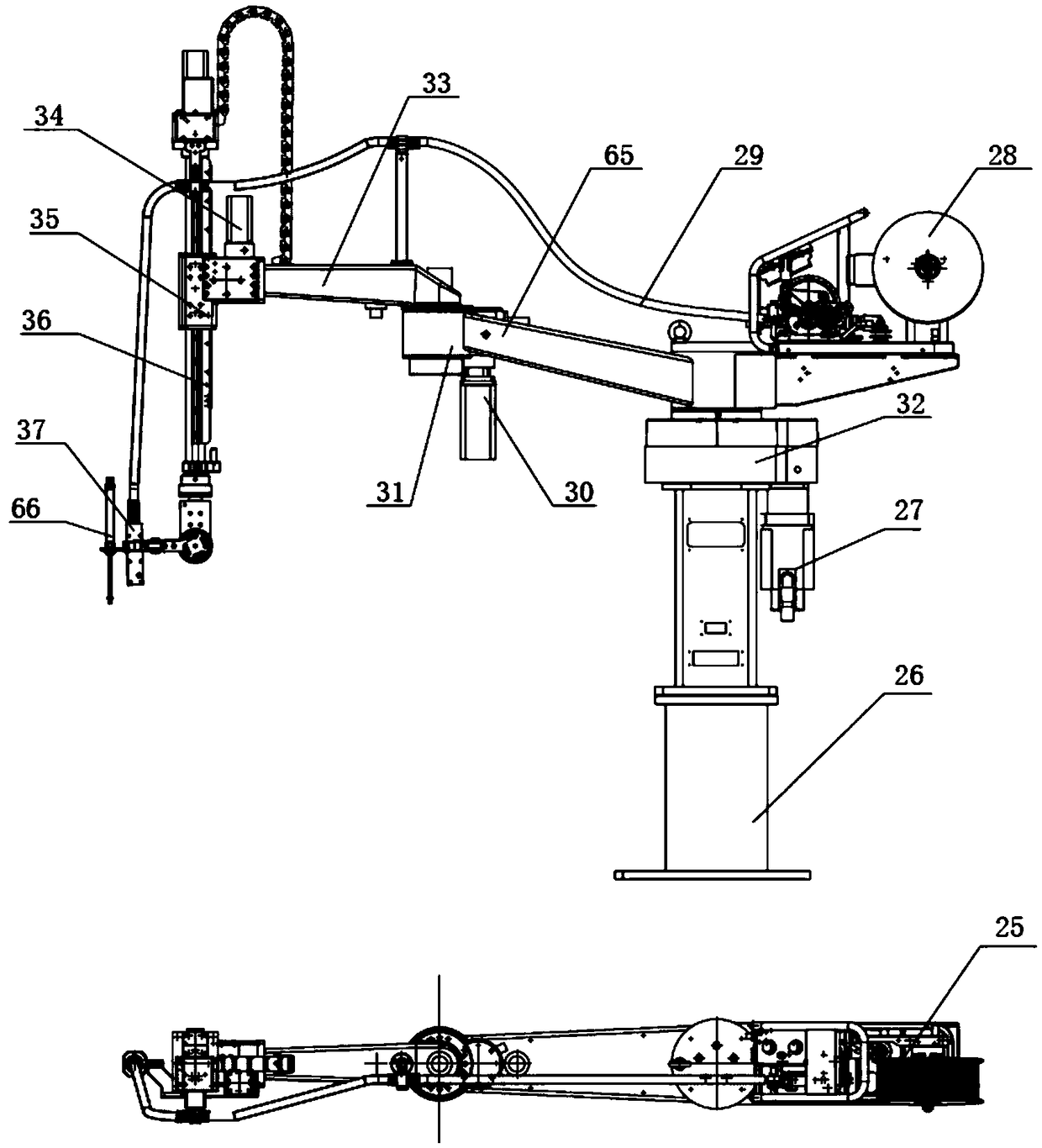

High-speed robot for positioning paint spraying

ActiveCN108177152ASmall moment of inertiaNot affected by exerciseProgramme-controlled manipulatorArmsPlanar robotEngineering

The invention discloses a high-speed robot for positioning paint spraying. The robot comprises a high-speed three-axis module, an electric clamping jaw and a paint spraying head. A plane robot for positioning paint spraying enables a driving element to be arranged at the bottom of a platform, a first arm and a second arm have no extra weight except the weight of the first arm, the weight of the second arm and a matched connecting rod, the moving speed of the tail end of the first arm and the second arm is high and rotating inertia of the rotating base of the first arm and the second arm is small; a driving element of the electric clamping jaw is arranged outside a joint arm, the tail end of the second arm only comprises a clamping jaw body, the load is light; the clamping jaw is driven inan electric mode, impact force is small, and the movement of a mechanical arm cannot be influenced; and the electric clamping jaw is adopted for clamping and positioning a workpiece to carry out the paint spraying operation, the operation efficiency is high.

Owner:华南智能机器人创新研究院 +1

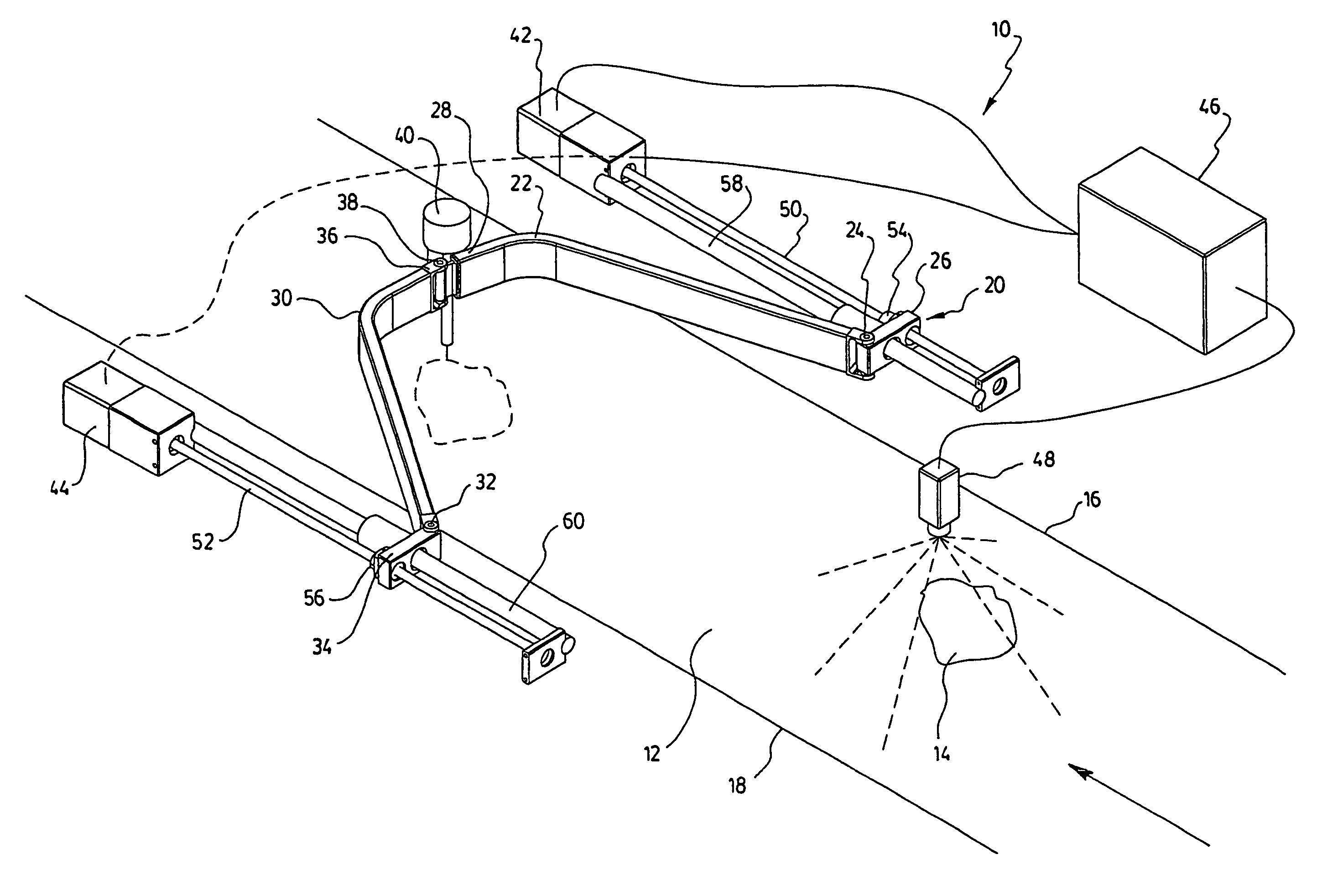

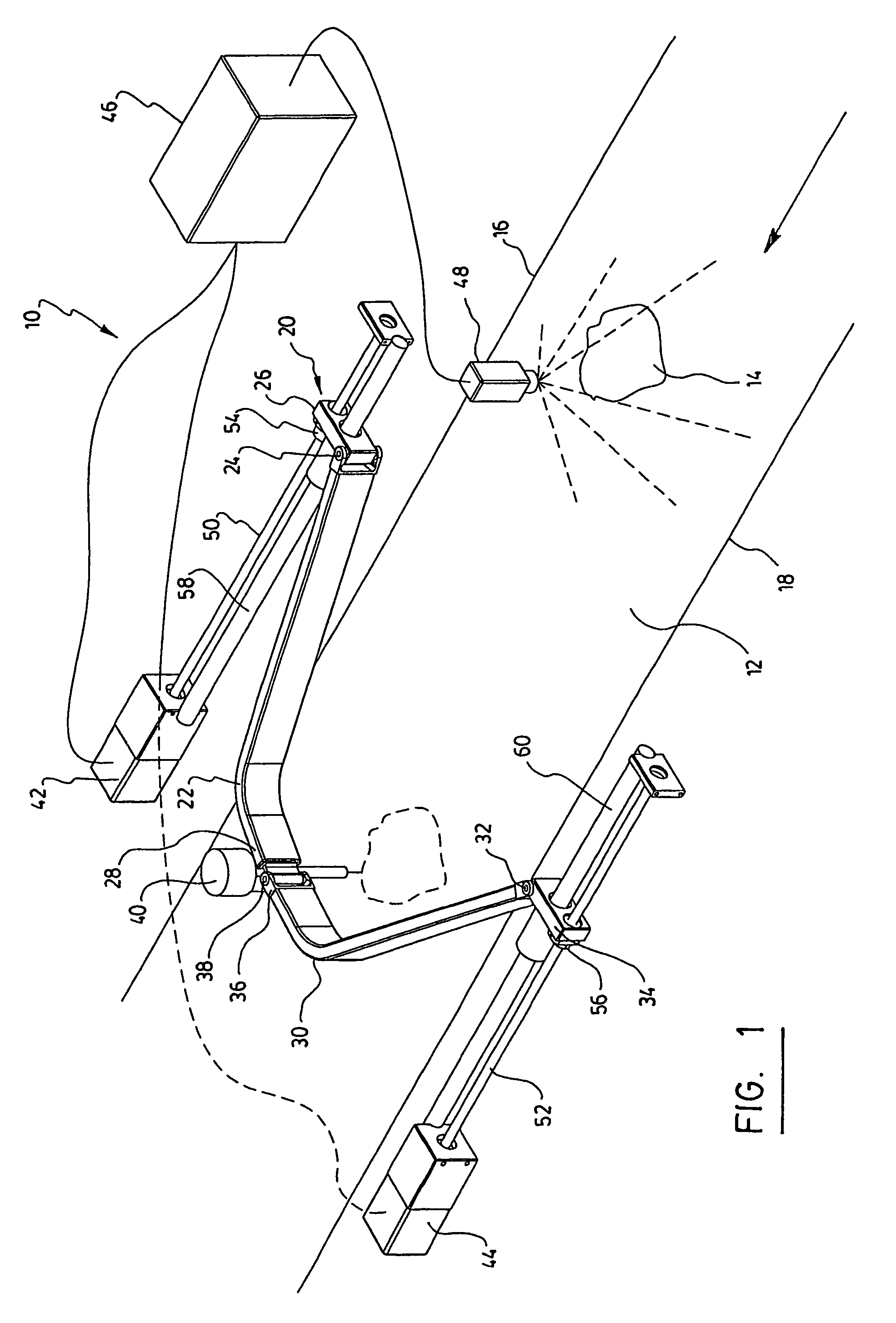

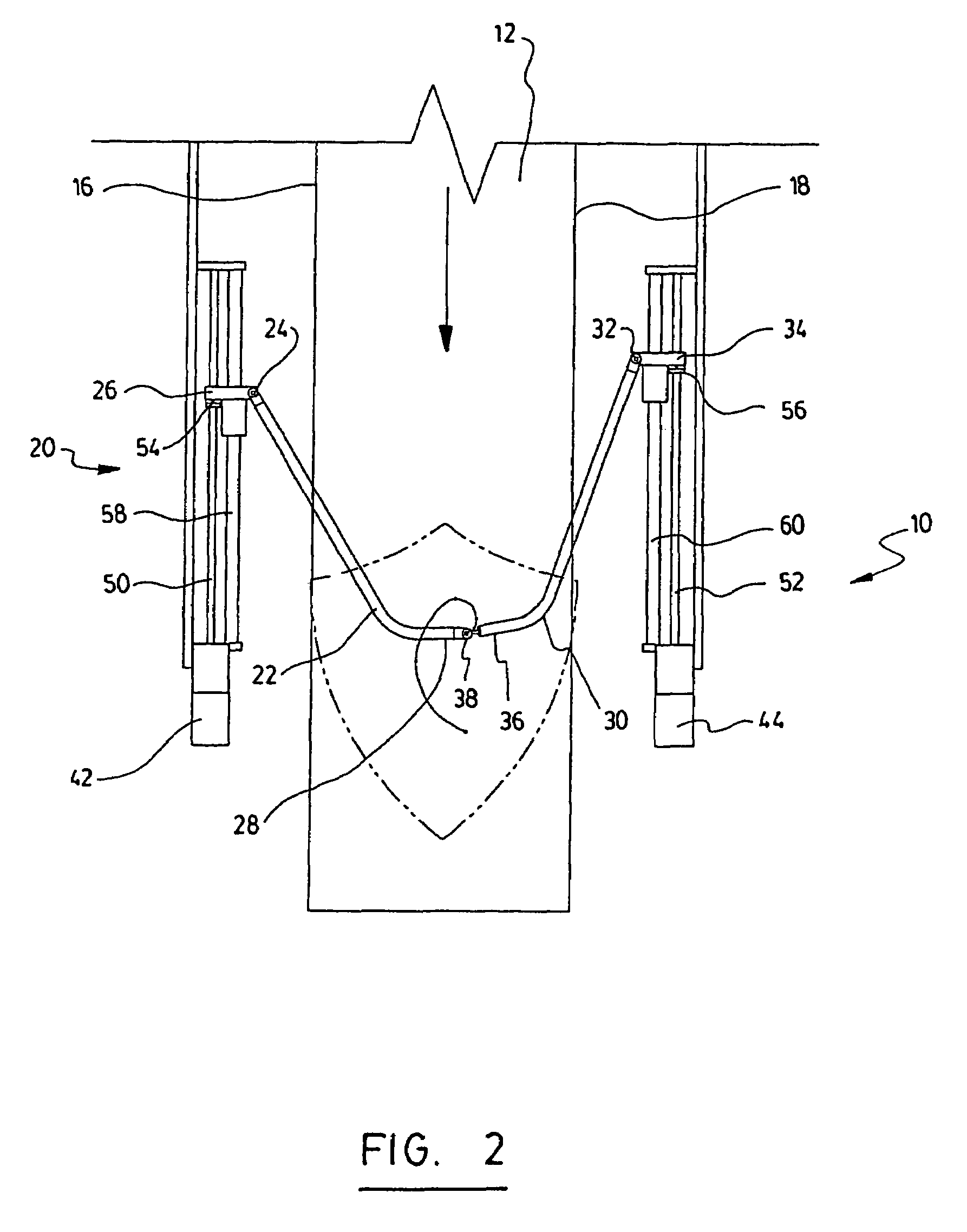

Planar robot with parallel axes and fixed motors for a water jet cutter

ActiveUS7448094B2Mechanically simpleReduce loadGang saw millsMetal working apparatusPlanar robotWater jet cutter

Owner:G E LEBLANC

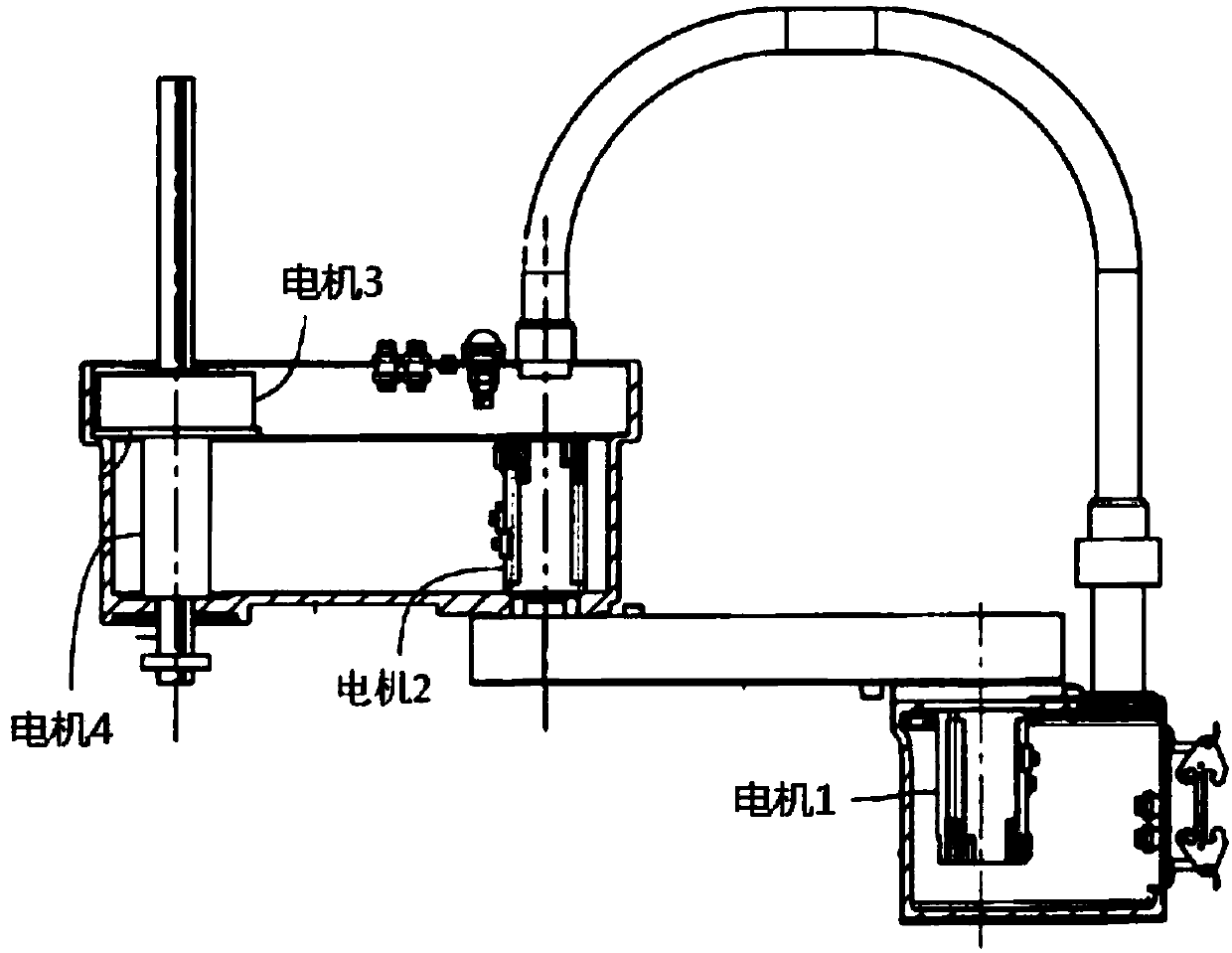

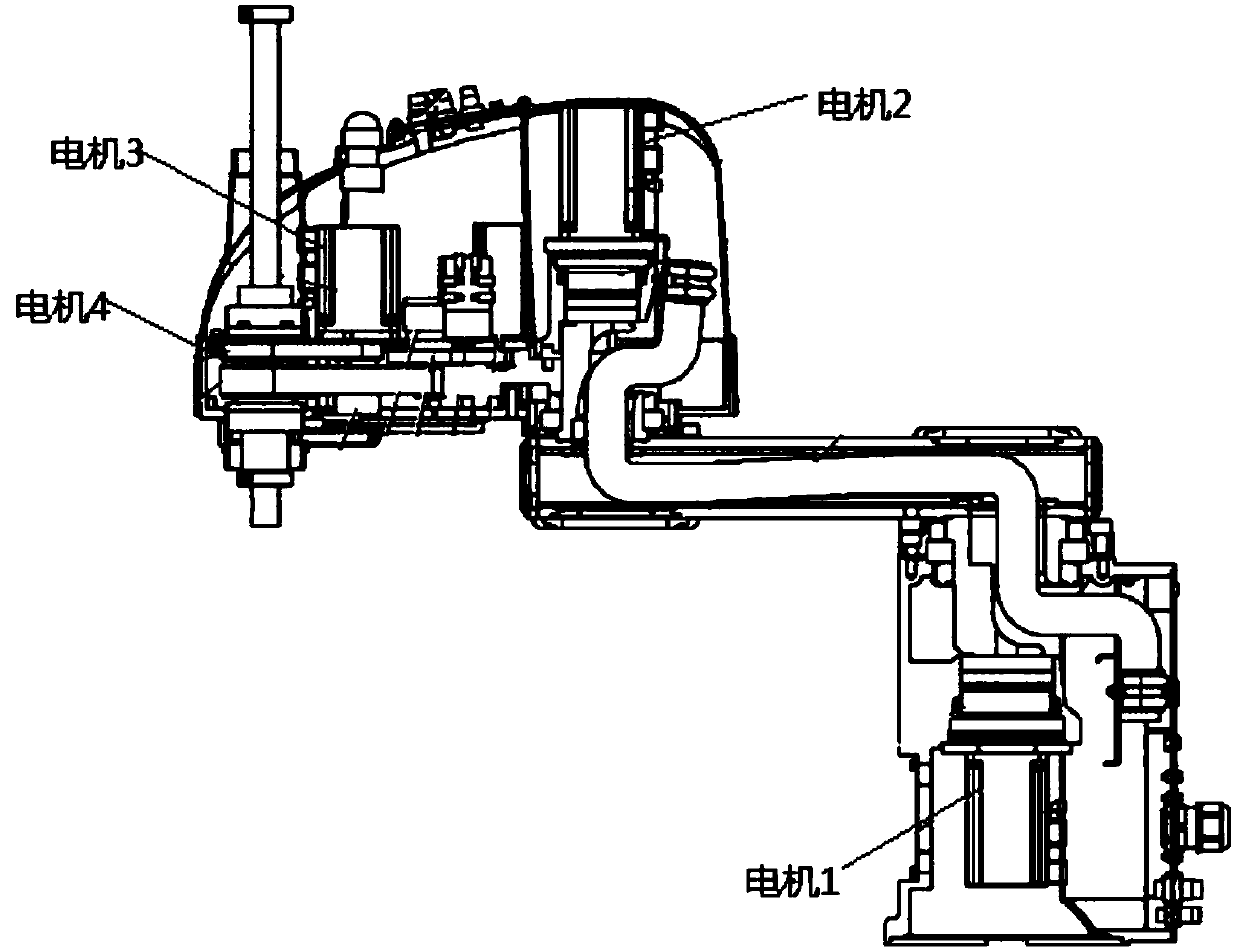

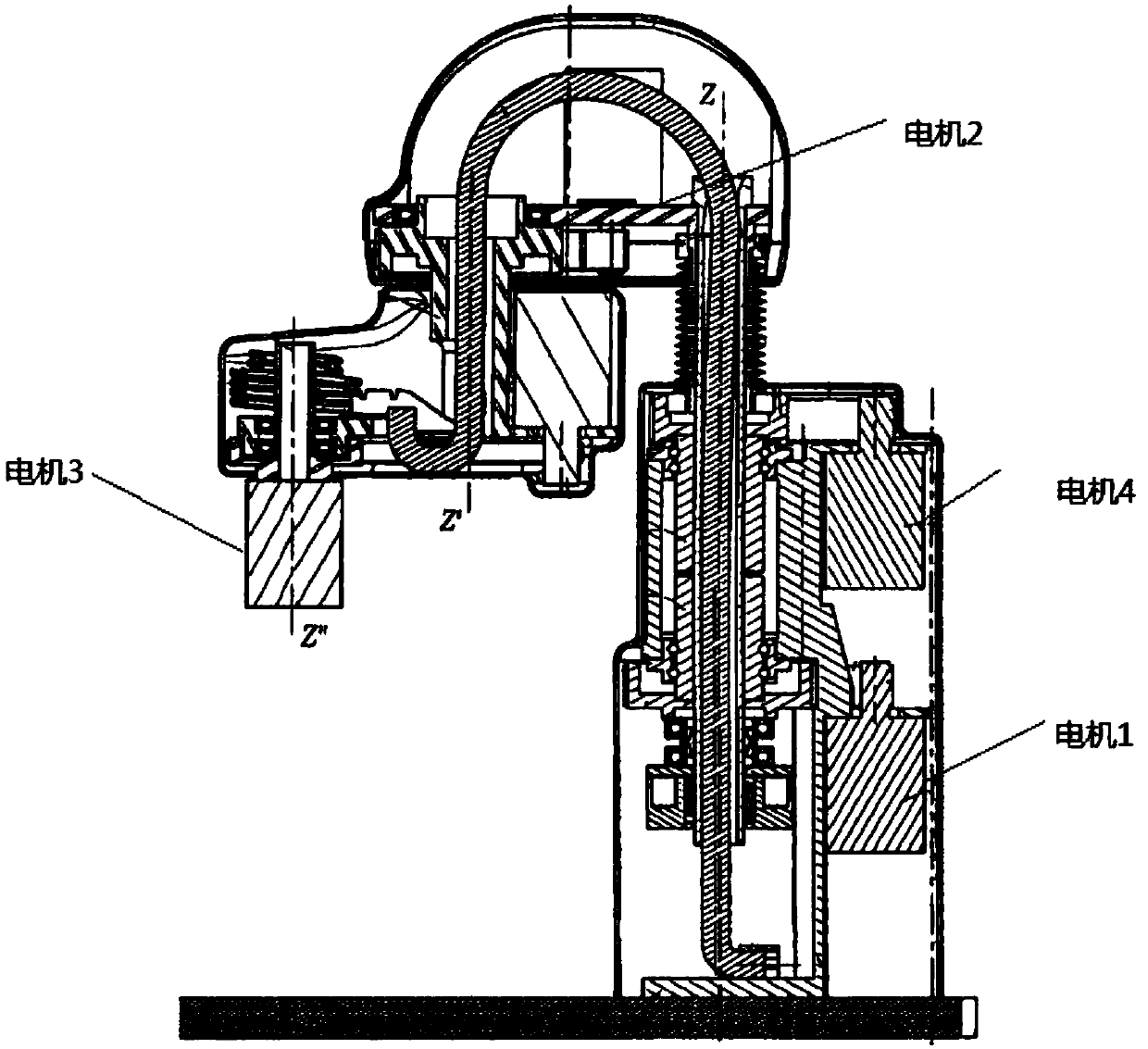

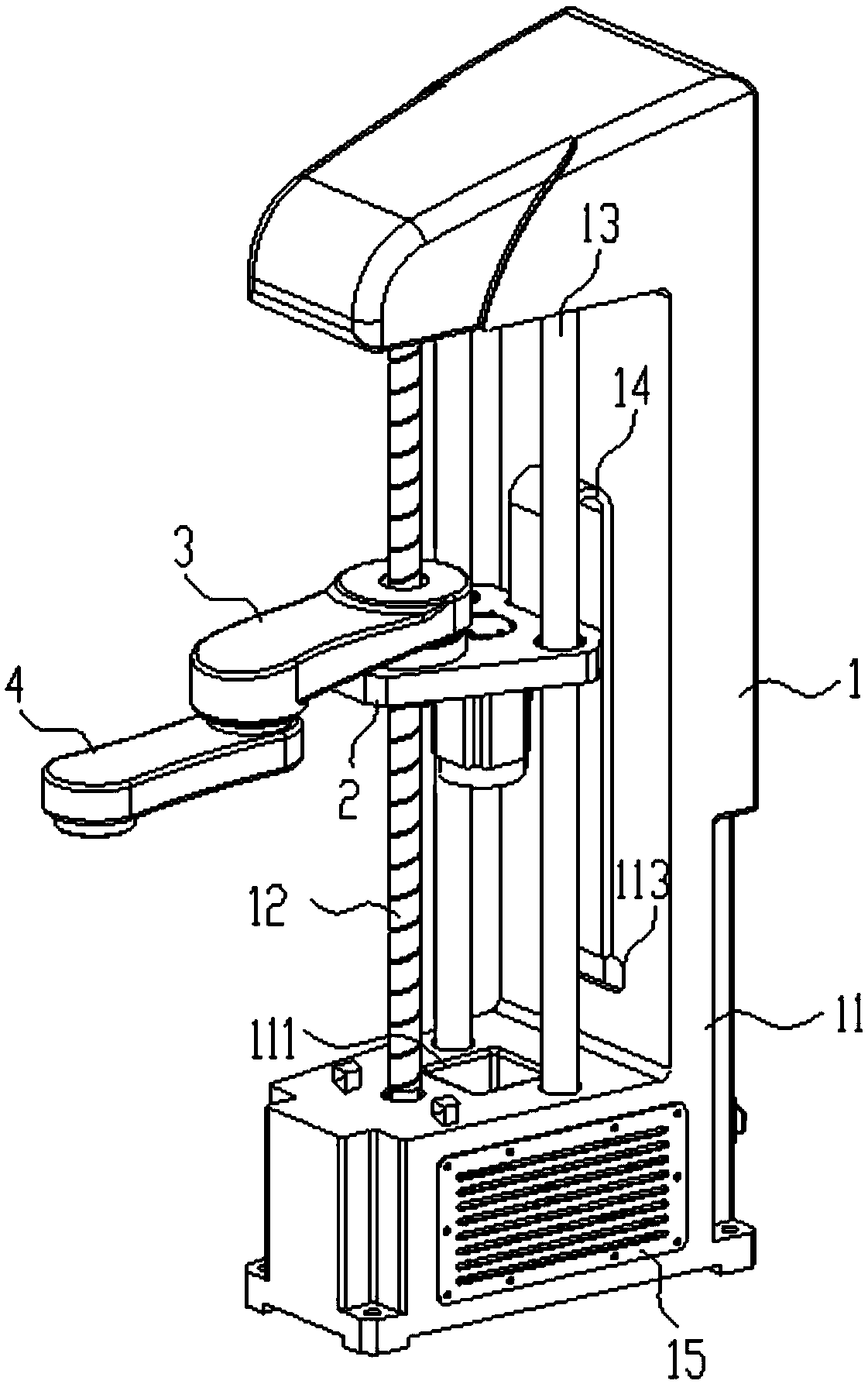

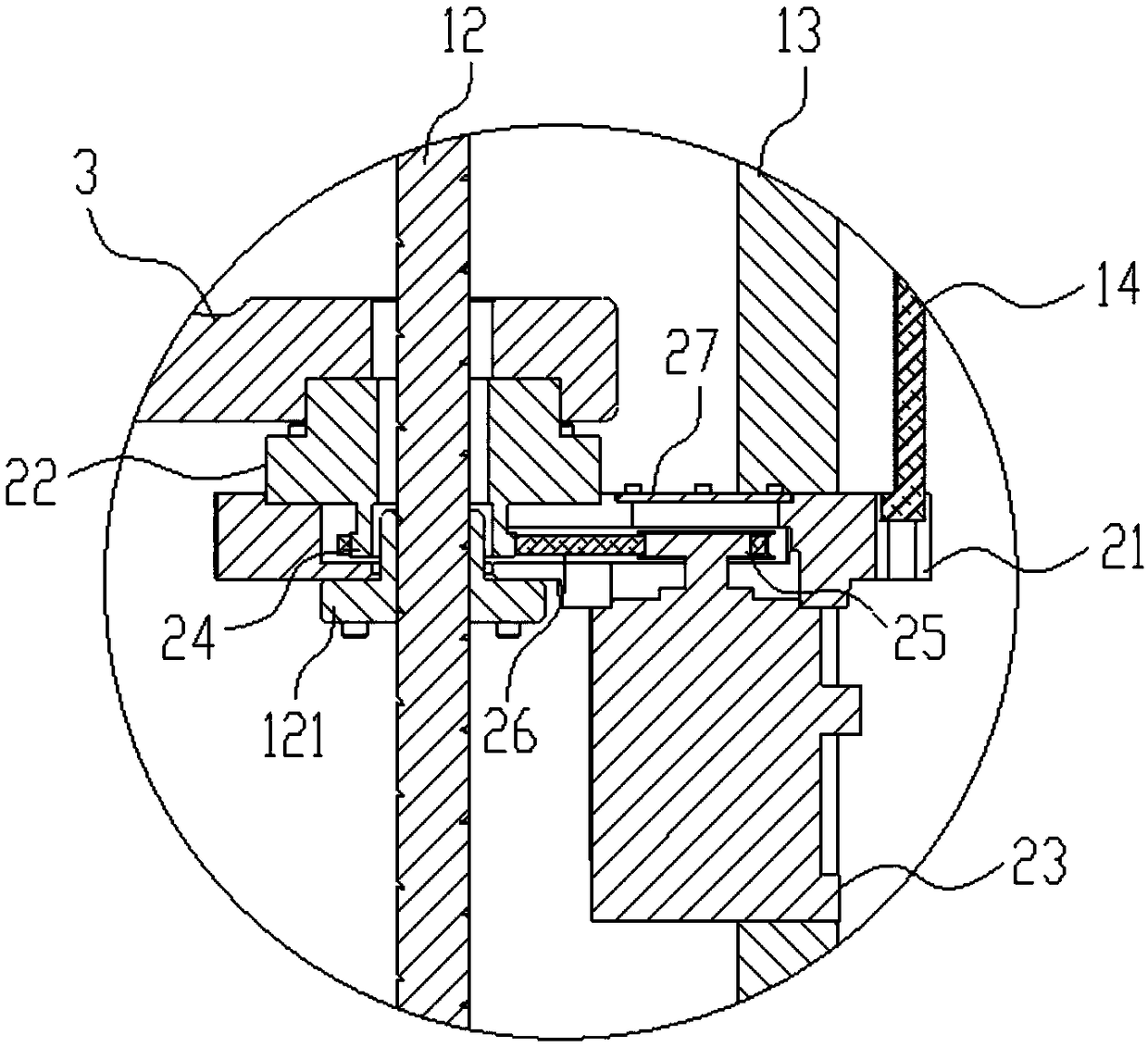

Planar joint robot

PendingCN107671836ASmall sizeReduce quality problemsProgramme-controlled manipulatorPlanar robotEngineering

The embodiment of the invention relates to the industrial field and discloses a planar joint robot. The planar joint robot comprises a base, a big arm, a front arm and a tool end, wherein the base isprovided with a concave structure; the big arm is located in a cavity of the base and connected with the base; the front arm is connected with the end, located outside the cavity of the base, of the big arm; and the tool end is arranged at the tail end of the front arm; and a first motor used for controlling rotation of the big arm in the horizontal direction and a second motor used for controlling rotation of the front arm in the horizontal direction are arranged in the base, a third motor used for controlling rotation of the tool end in the horizontal direction is arranged in the big arm, and a fourth motor used for controlling rotation of the tool end in the vertical direction is arranged in the front arm. According to the planar joint robot, part of motors in the front arm are arrangedon the rear portion, so that the dimension and movement inertia of the front arm are reduced; and in addition, when the planar joint robot moves vertically, only the tool end at the tail end of the front arm needs to be driven, the big arm and the front arm do not need to move vertically, and thus the response speed during movement and the stability during operation are improved.

Owner:上海新时达机器人有限公司

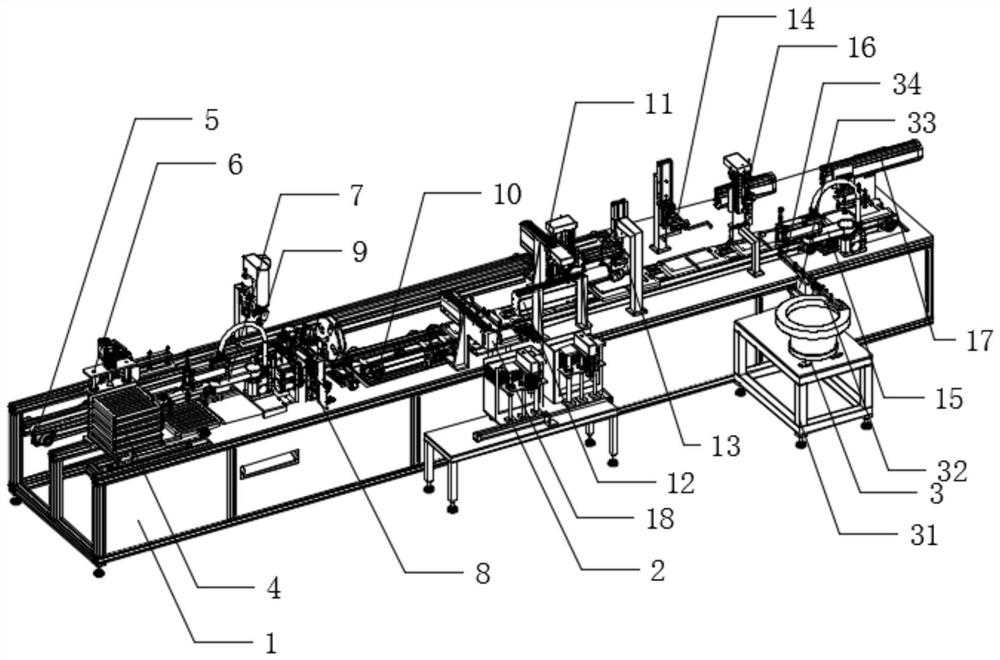

High-precision assembling system and assembling method

PendingCN112427911AHigh-precision assembly requirementsRealize location information measurementProgramme-controlled manipulatorUsing optical meansPlanar robotMeasurement device

The invention discloses a high-precision assembly system and an assembling method. The assembling system comprises a feeding module, an assembling module, an assembling operation module, a measurementand control module and an assembling information module, wherein the assembling operation module comprises a robot and a six-degree-of-freedom displacement table, the six-degree-of-freedom displacement table is arranged on a product assembling table, the six-degree-of-freedom displacement table is used for assembling products, the robot is used for grabbing the products to be assembled on the feeding module and moving the products to be assembled to the position right above the six-degree-of-freedom displacement table, the measurement and control module comprises a measurement module, two groups of same measurement devices of the measurement module are oppositely arranged, each measuring device comprises a linear laser sensor and a visual camera, and the linear laser sensor and the visualcamera are in communication connection with the six-degree-of-freedom displacement table. According to the system and the method, the products can be carried through the planar robot, and precise posture adjustment of the products in the assembling process is achieved through the six-degree-of-freedom displacement table; and the robot and the six-degree-of-freedom displacement table are matched with each other to realize a product assembling process with high-precision assembling requirements.

Owner:INST OF MACHINERY MFG TECH CHINA ACAD OF ENG PHYSICS

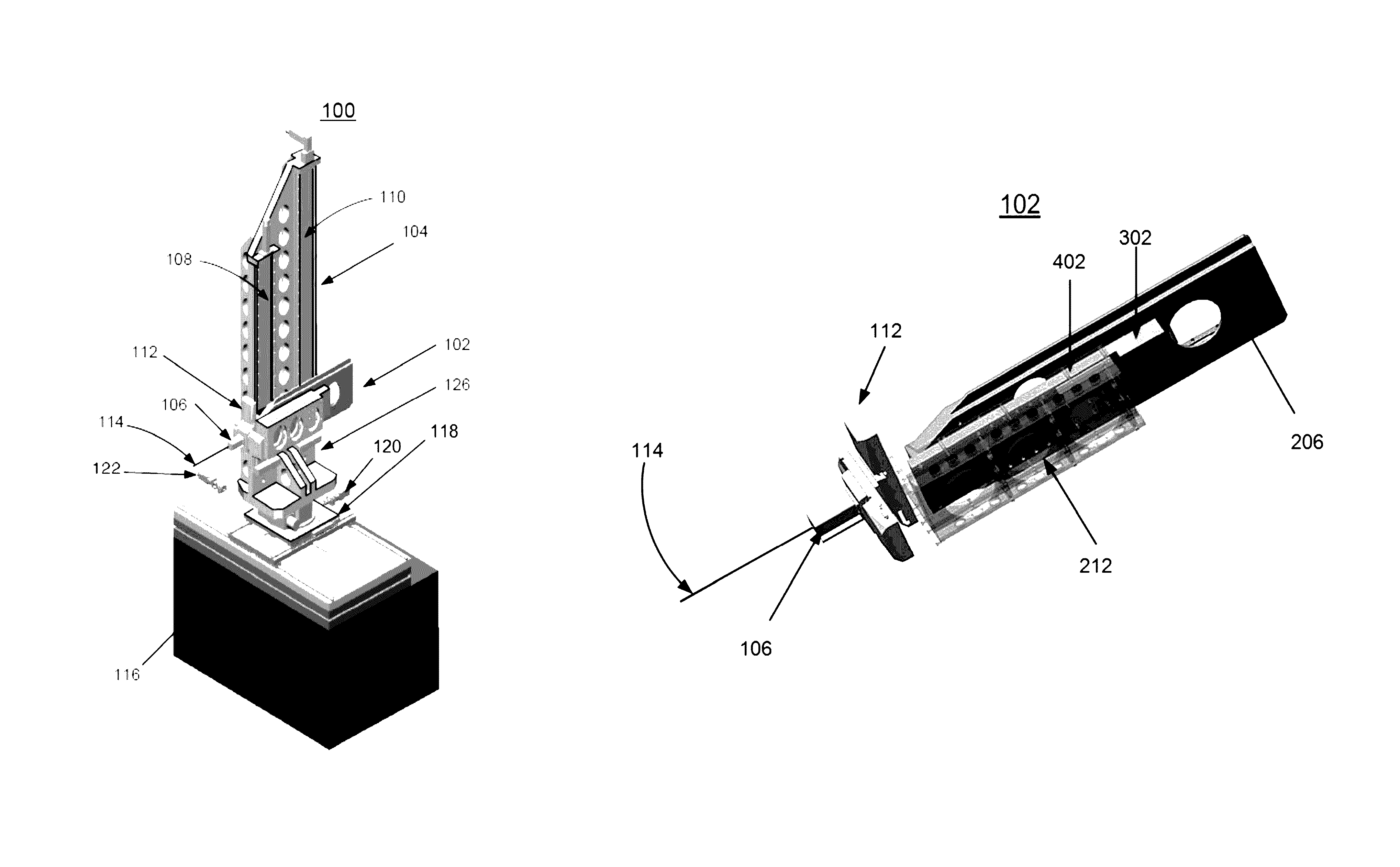

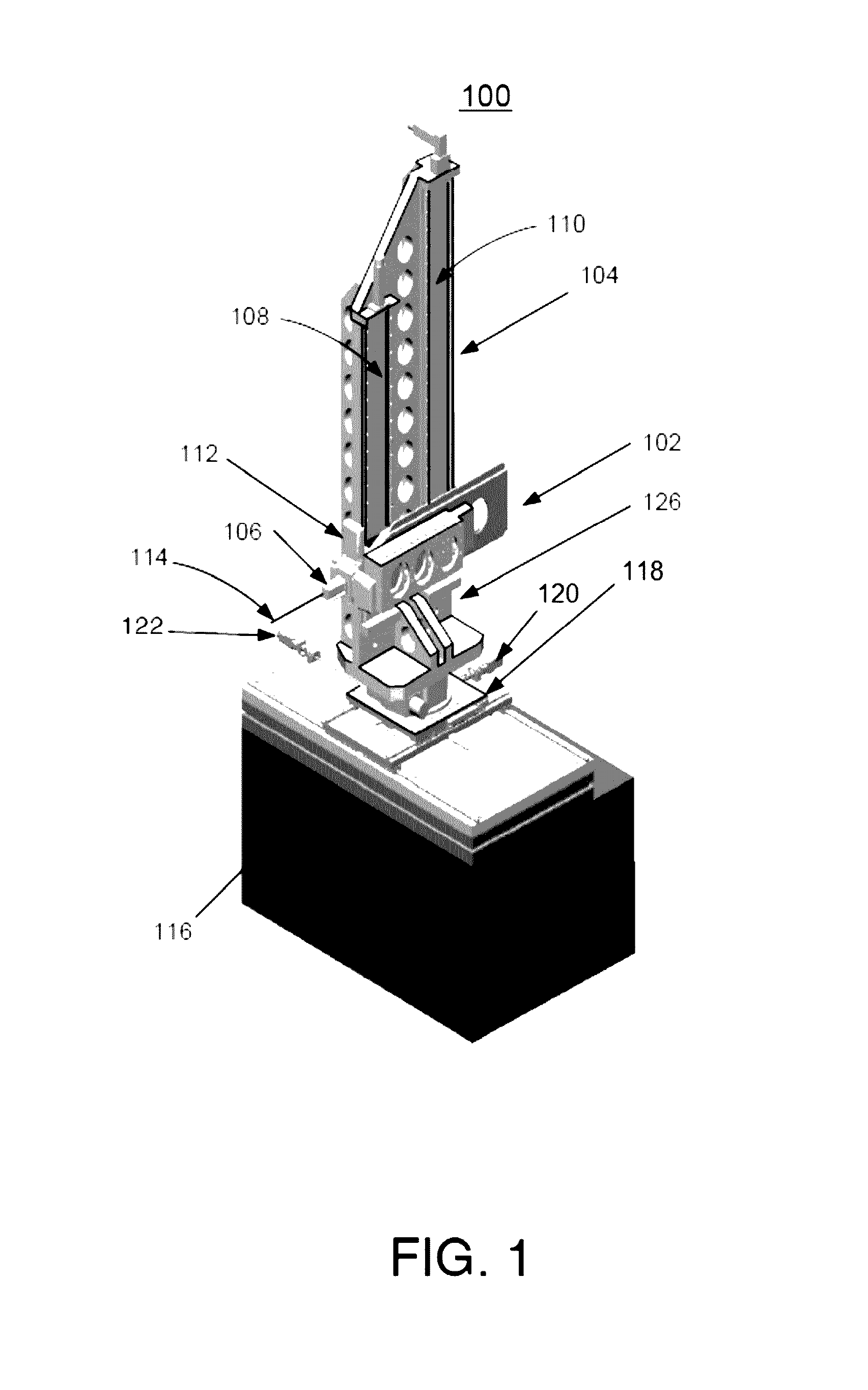

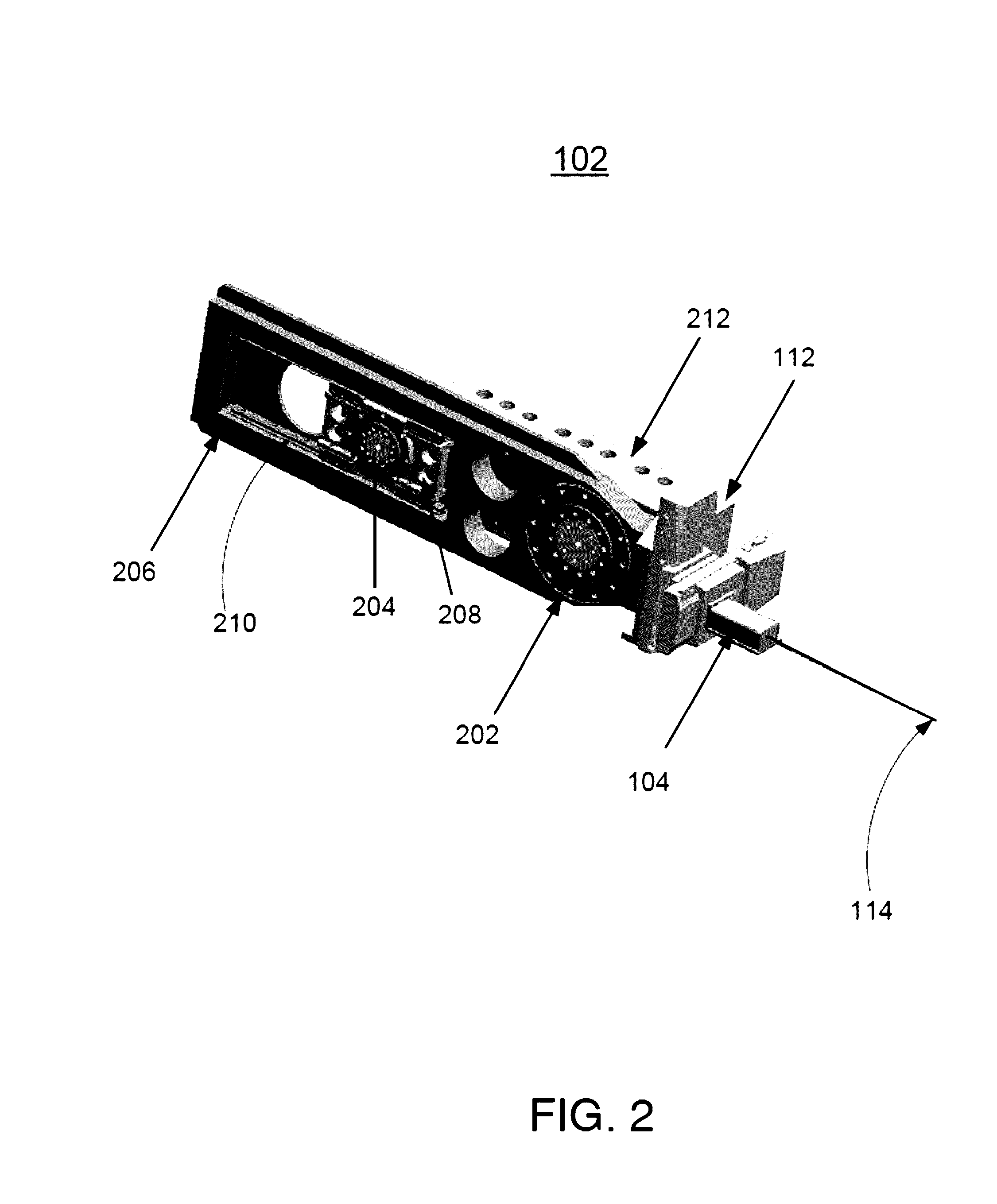

High precision detector robot arm system

InactiveUS9557282B1Effective positioning and manipulatingIncrease load capacityImaging devicesCathode ray tubes/electron beam tubesPlanar robotVertical plane

A method and high precision robot arm system are provided, for example, for X-ray nanodiffraction with an X-ray nanoprobe. The robot arm system includes duo-vertical-stages and a kinematic linkage system. A two-dimensional (2D) vertical plane ultra-precision robot arm supporting an X-ray detector provides positioning and manipulating of the X-ray detector. A vertical support for the 2D vertical plane robot arm includes spaced apart rails respectively engaging a first bearing structure and a second bearing structure carried by the 2D vertical plane robot arm.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

Guardrail welding method based on guardrail welding equipment

ActiveCN108942022AAchieve weldingConsistent welding effectWelding/cutting auxillary devicesAuxillary welding devicesPlanar robotThree degrees of freedom

The invention relates to a guardrail welding method based on guardrail welding equipment. When guardrails with the same shape but different specifications and sizes are manually welded, the manual labor intensity required is high, the efficiency is low, the welding effect is not regular, and the overall welding shape is not attractive. The guardrail welding method can realize welding of the guardrails by replacing different tools for the guardrails of the different specifications and sizes. Since the guardrails are generally made of carbon steel, gas shielded welding is used as the welding method, automatic feeding of welding wires to the specified welding position is realized by a three degree-of-freedom planar robot on the other hand, welding guns arranged in parallel are used for welding the guardrails and base metal, and welding tracks of the welding guns of the three degree-of-freedom planar robot is controlled by a programming program, so that the welding effect is consistent, and the efficiency is improved.

Owner:GUANGDONG XINFEI STEEL ART TECH CO LTD

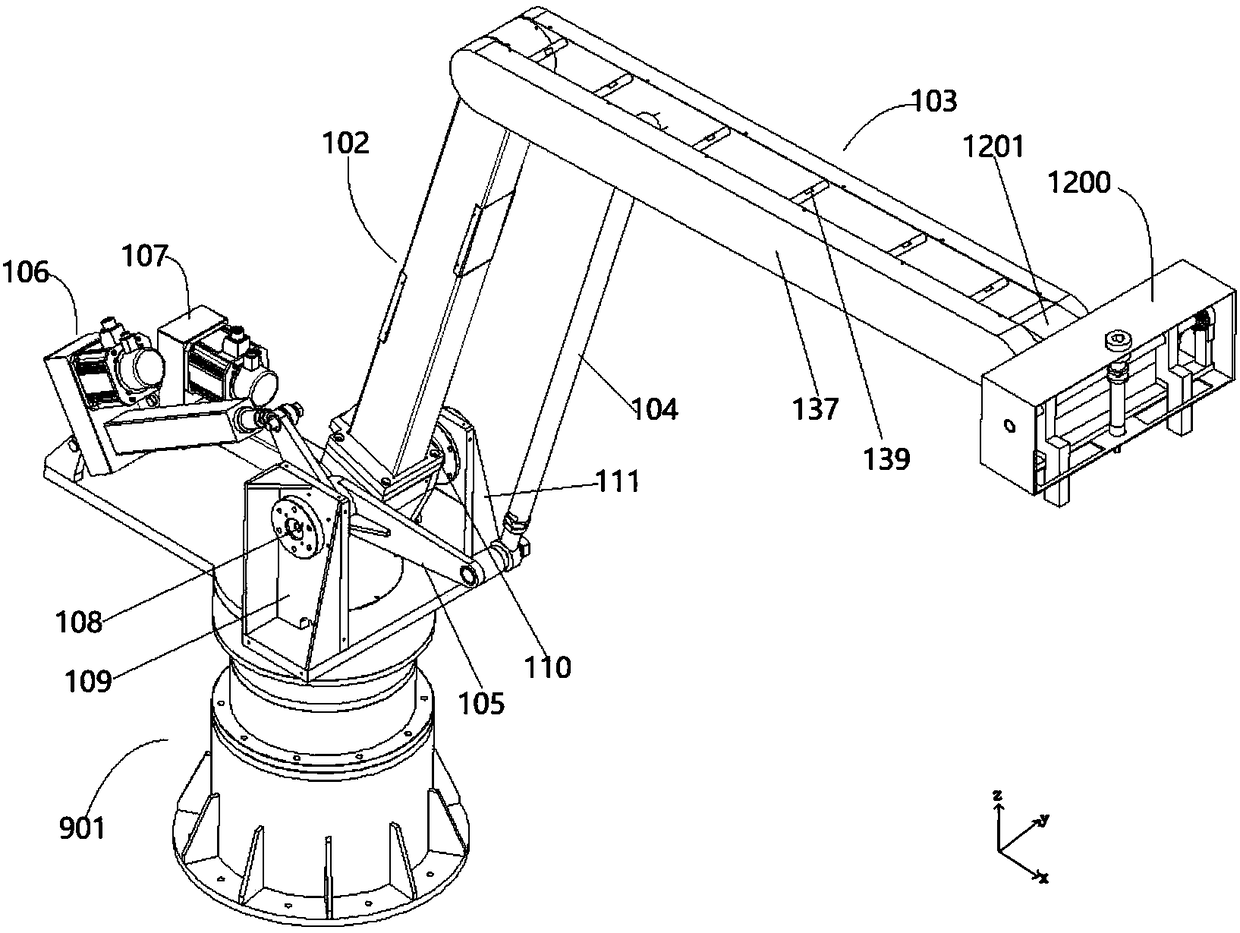

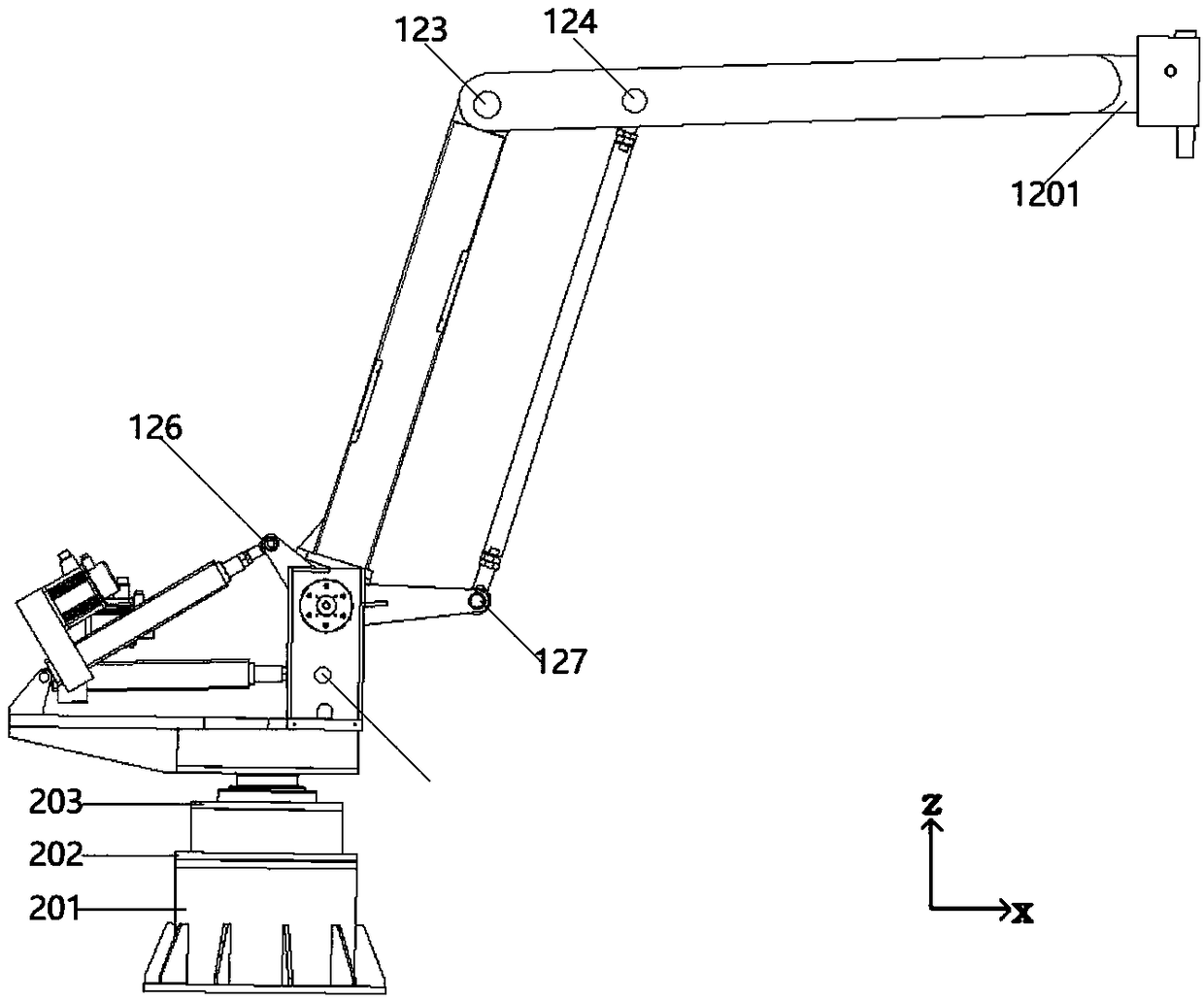

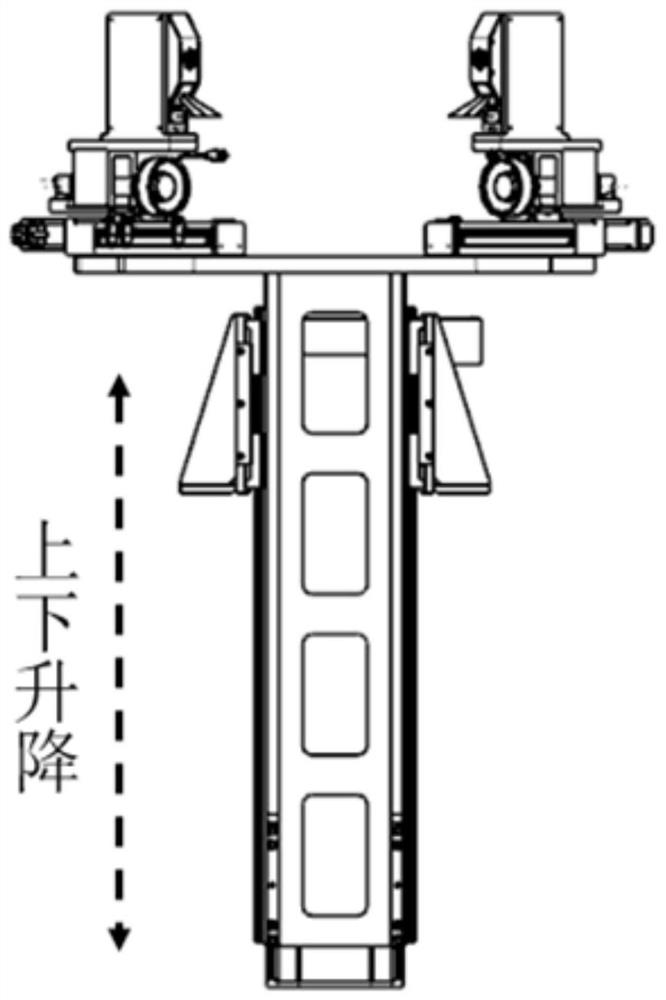

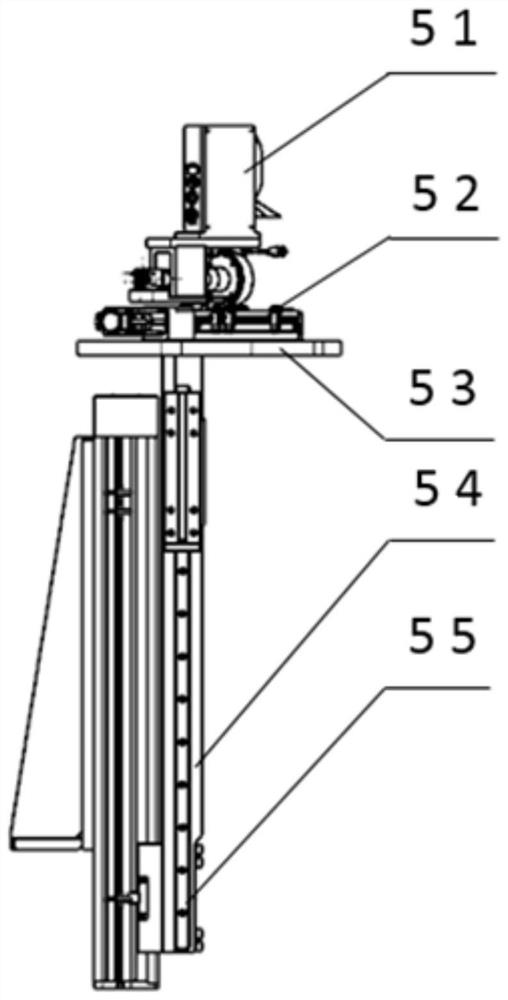

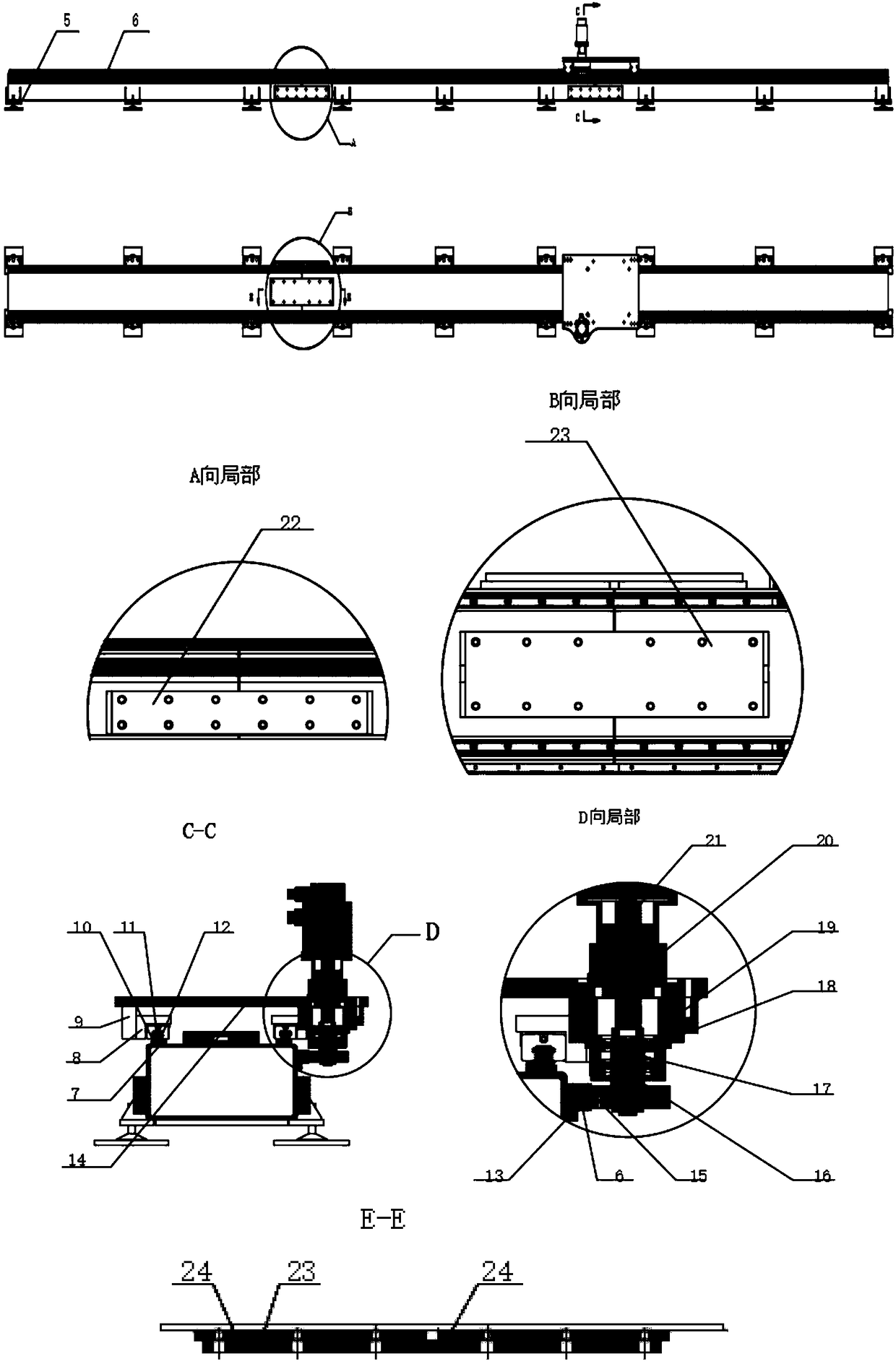

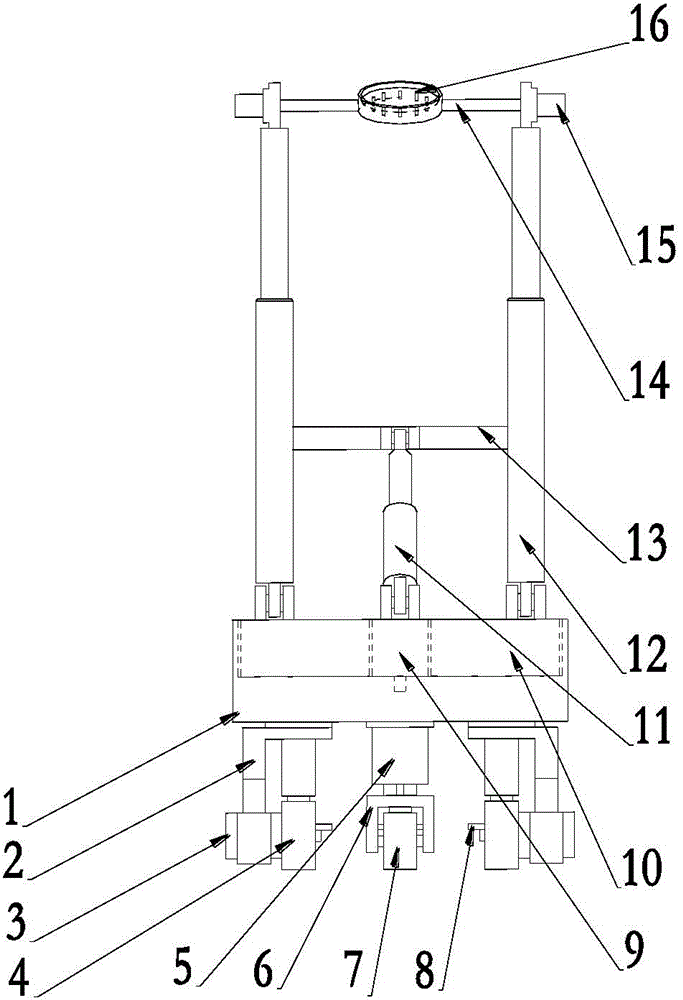

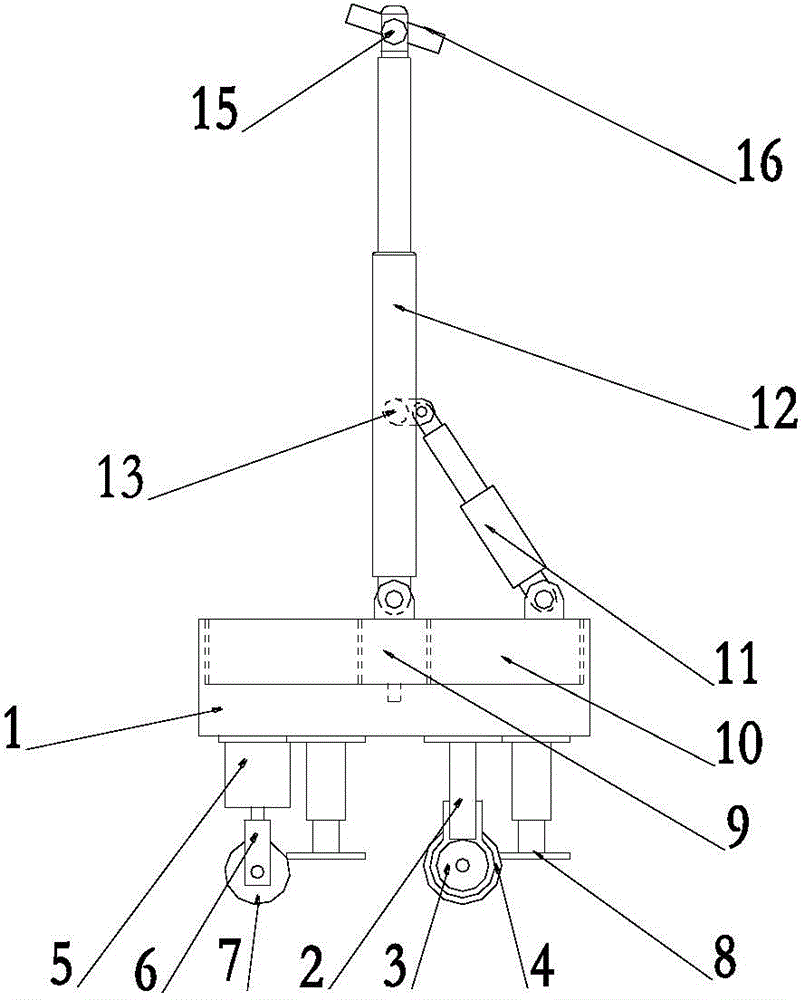

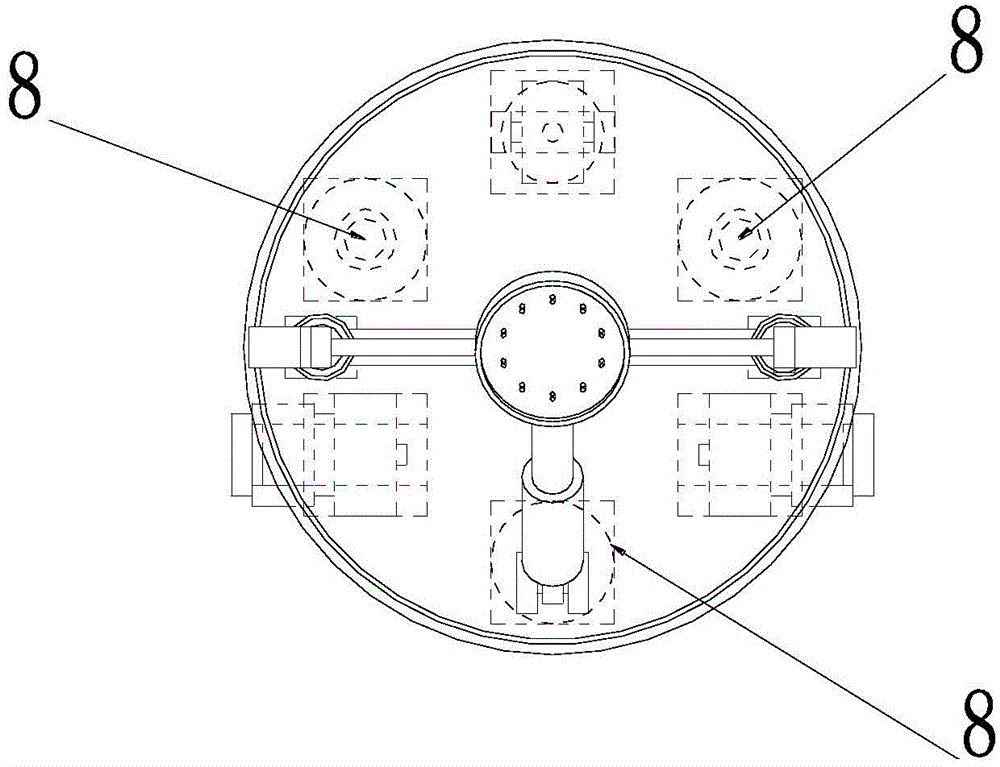

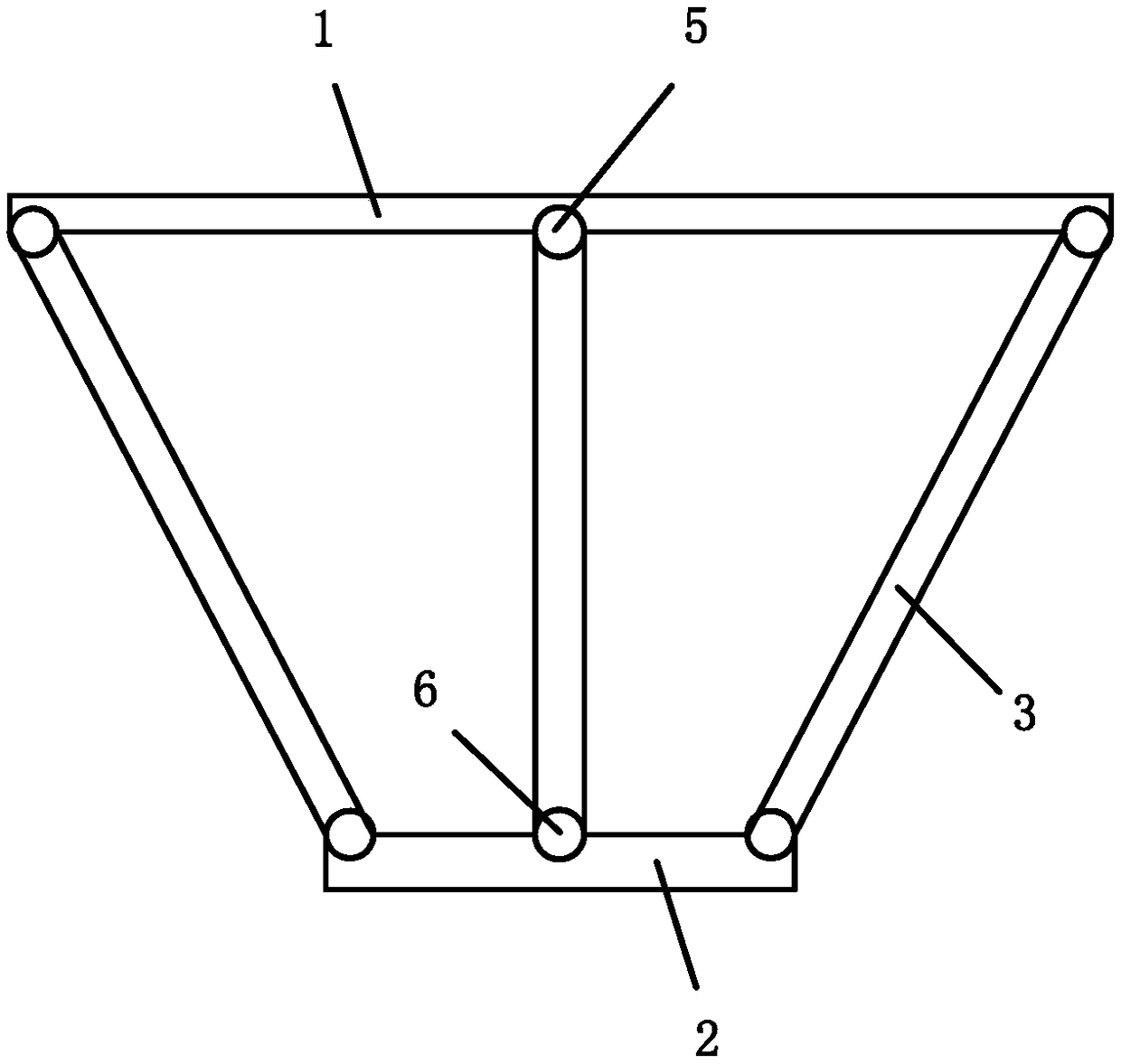

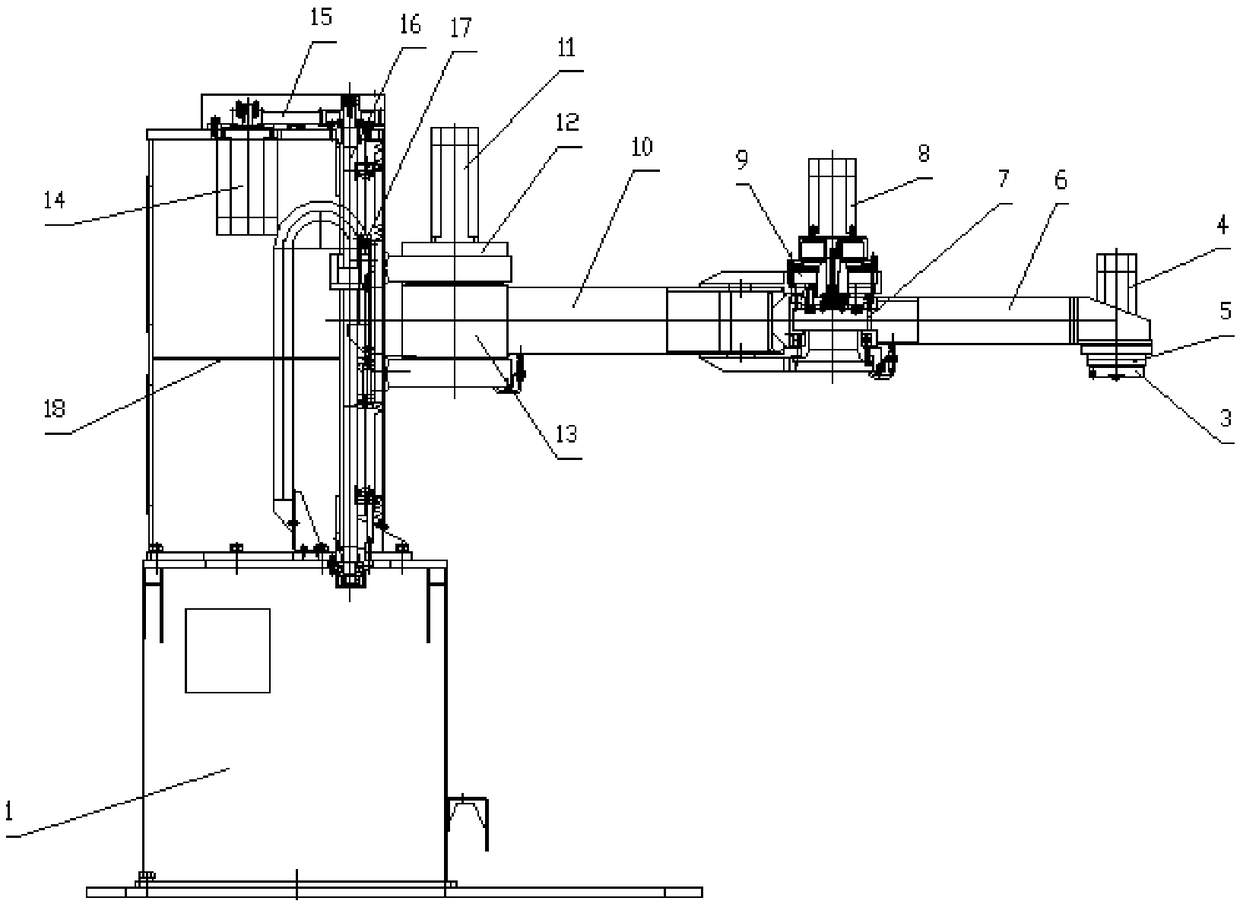

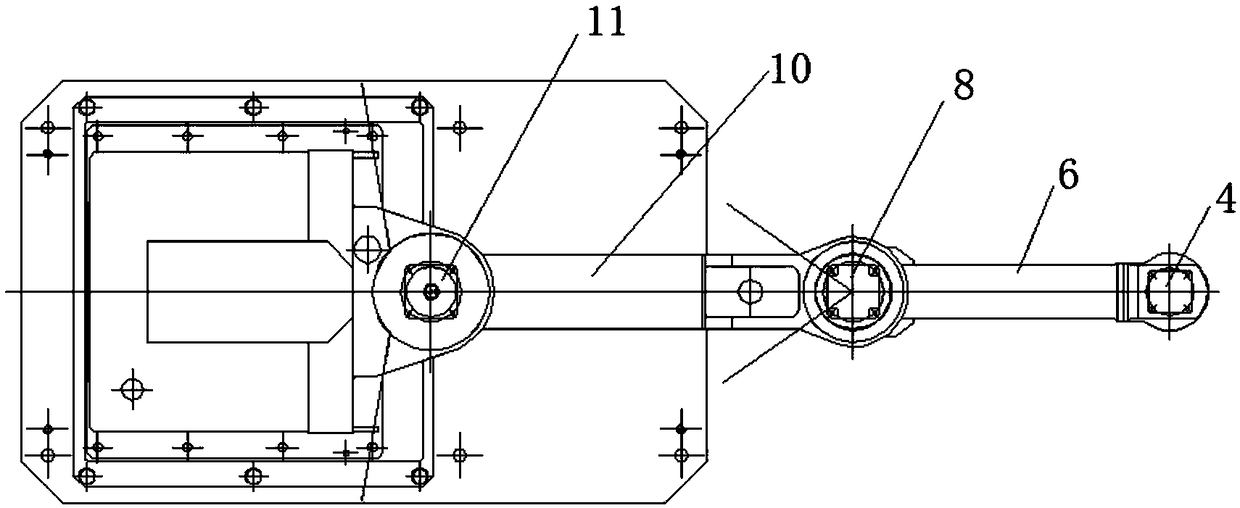

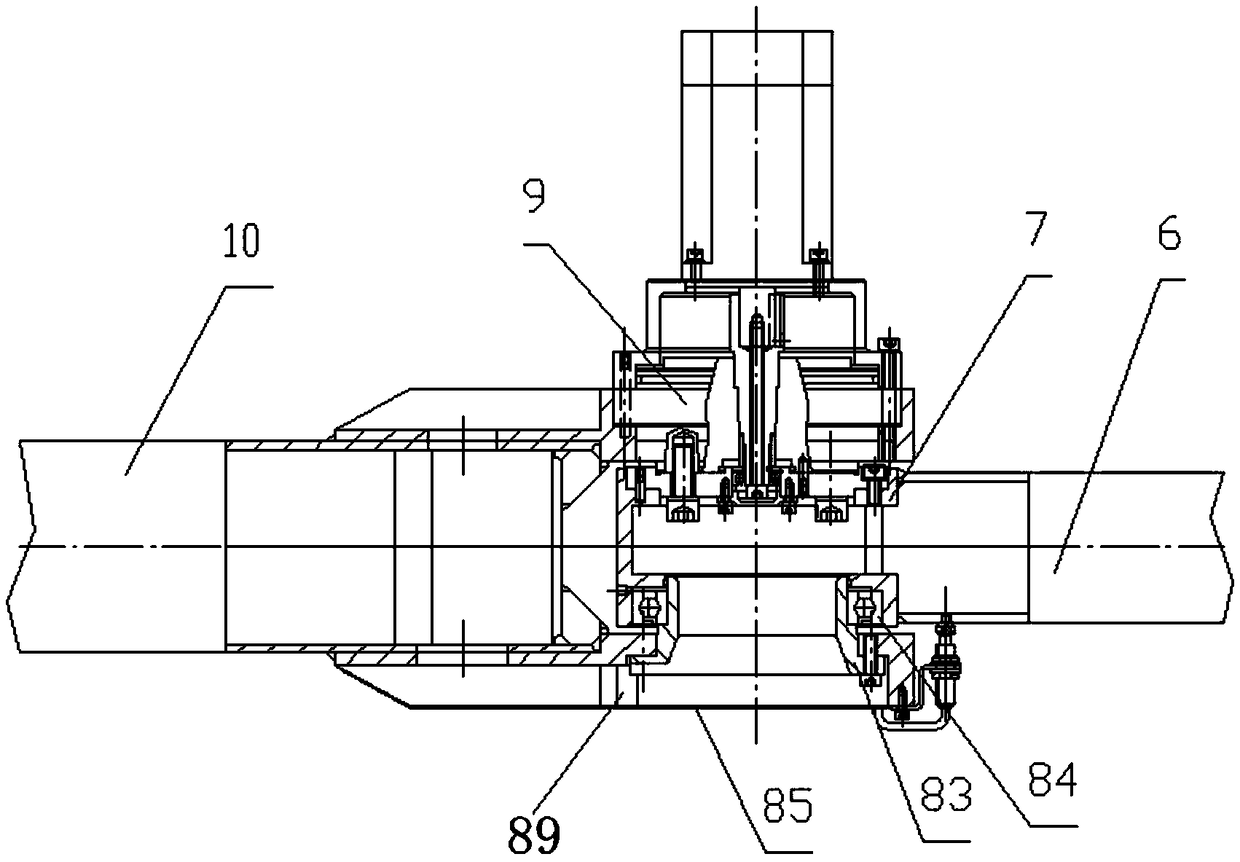

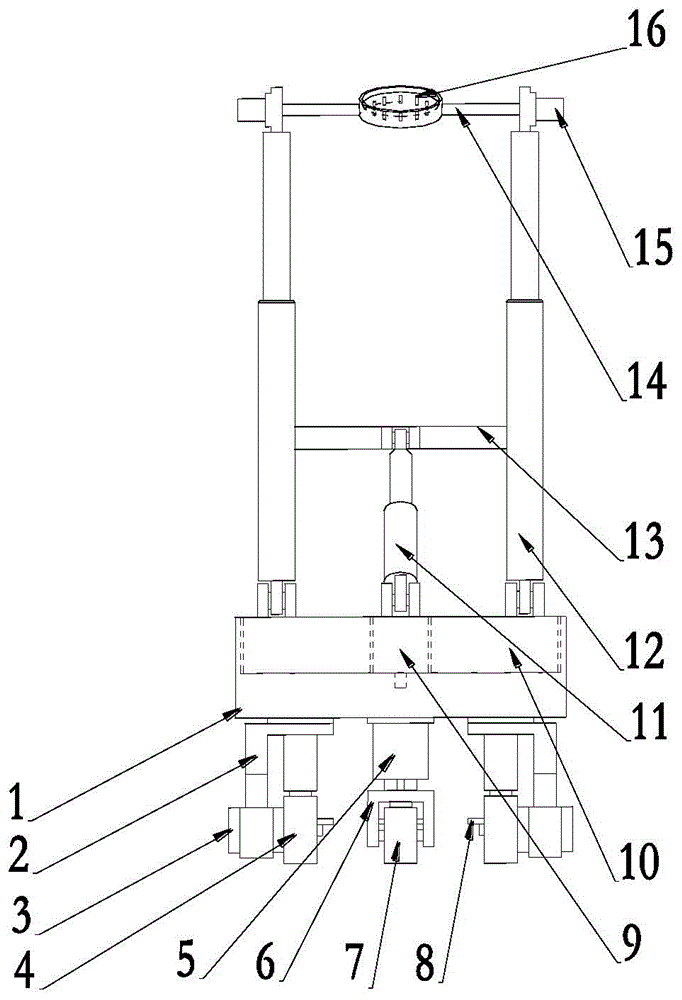

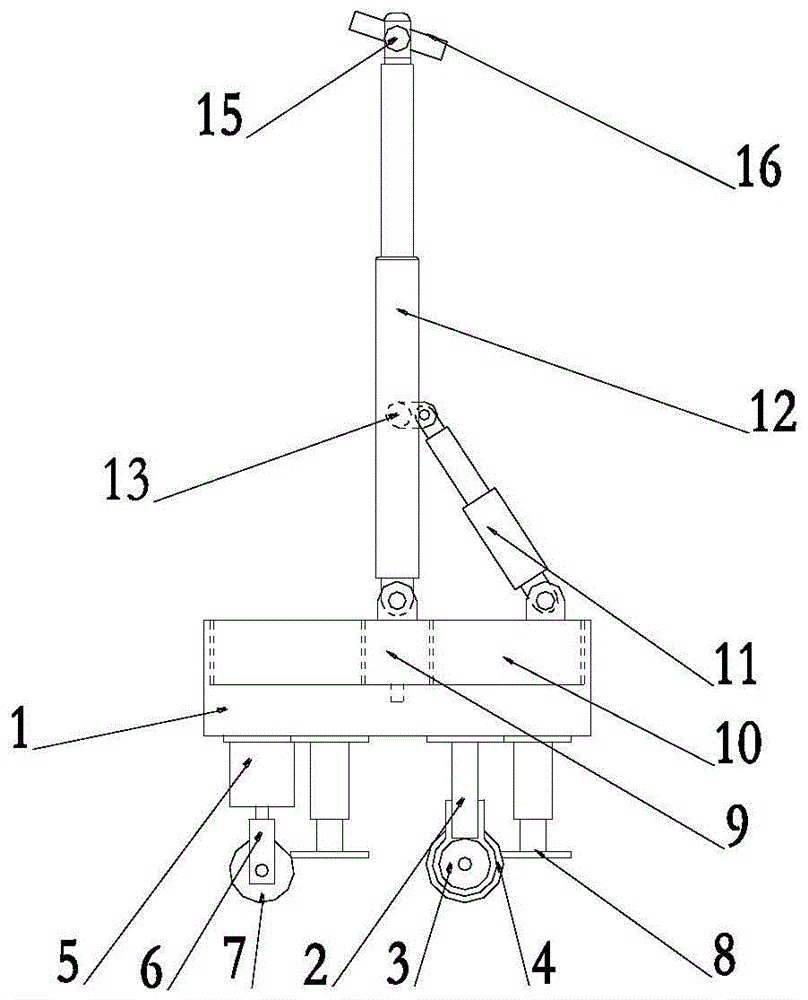

All-direction plane robot support device

ActiveCN104889969AExpand the scope of workRealize mobile operationsManipulatorHydraulic cylinderPlanar robot

The invention discloses an all-direction plane robot support device. The device comprises an advancing and turning mechanism, a base rotary turning mechanism and a lifting, moving and rotating mechanism, wherein the advancing and turning mechanism comprises advancing wheels (3) and a turning wheel (7); the base rotary turning mechanism comprises a rotating base (10), and a rotating base driving motor (9) for providing driving force; and the lifting, moving and rotating mechanism comprises a plane moving hydraulic cylinder (11), a vertical lifting hydraulic cylinder (12), a connecting rod (13), a rotating support frame (14) and a rotating support frame driving motor (15). The device is provided with the advancing and turning mechanism at the lower part of the base to realize the flowing operation according to the difference of working places; the base is provided with the base rotating mechanism to realize the rotation of the device for 360 degrees; and the lifting, moving and rotating mechanism is synchronously arranged above the rotating base mechanism to widen a working range of a plane robot.

Owner:CHINA UNIV OF MINING & TECH

Four-joint plane robot

PendingCN109291039ALarge range of motionSmall moment of inertiaProgramme-controlled manipulatorLinear motionPlanar robot

The invention discloses a four-joint plane robot. The four-joint plane robot comprises a first joint part, a second joint part, a third joint part and a fourth joint part, the first joint part comprises a base, a ball screw is arranged at the front end of the base, the rear end of the base is provided with auxiliary fixing columns which are symmetrically arranged, and a plastic drag chain is arranged on the outer wall of the base; and the second joint part comprises a lifting seat, a hollow speed reducer and a motor, wherein one end of the lifting seat penetrates through the ball screw and isarranged at a lead screw nut of the ball screw, the other end of the lifting seat penetrates through the auxiliary fixing columns, an output belt wheel is installed on the hollow speed reducer, an input belt wheel is installed on the motor, the output belt wheel and the input belt wheel transmit torque through a synchronous belt, and a sealing cover plate is arranged on the lifting seat. Accordingto the four-joint plane robot, by utilizing the position and structure relationships between the ball screw and the auxiliary fixing columns, the up-and-down linear motion of the robot and the improvement on the motion rigidity are achieved, the third joint part can rotate around the axis of the ball screw, the movement range of the robot is effectively enlarged, and the rotational inertia is reduced.

Owner:EFORT INTELLIGENT EQUIP CO LTD

Three-degree of freedom parallel planar robot

ActiveCN109434813AHigh precisionImprove stabilityProgramme-controlled manipulatorPlanar robotSolenoid valve

The invention discloses a three-degree of freedom parallel planar robot. The three-degree of freedom parallel planar robot comprises a fixed platform and a moving platform, wherein the fixed platformand the moving platform are movably connected by three groups of driving mechanisms, and the driving mechanisms comprise two cylinders arranged symmetrically. One ends of the cylinders are connected with the fixed platform through first rotation pairs, and the other ends of the cylinders are connected with the moving platform through second rotation pairs; the second rotation pairs comprise shaftsleeves and pin shafts which are movably connected in a sleeving mode, the shaft sleeves are connected with the moving platform, and limiting mechanisms are connected between the two pin shafts in thesame driving mechanism through universal joints; and the limiting mechanisms comprise air cylinders, air inlet and exhaust solenoid valves are connected to the side walls of the air cylinders throughfirst air pipes, pistons are arranged at the two ends of the air cylinders, and the pistons are connected with the universal joints. The three-degree of freedom parallel planar robot can improve thedeficiency of the prior art and improve the positioning speed.

Owner:NORTH CHINA INST OF AEROSPACE ENG

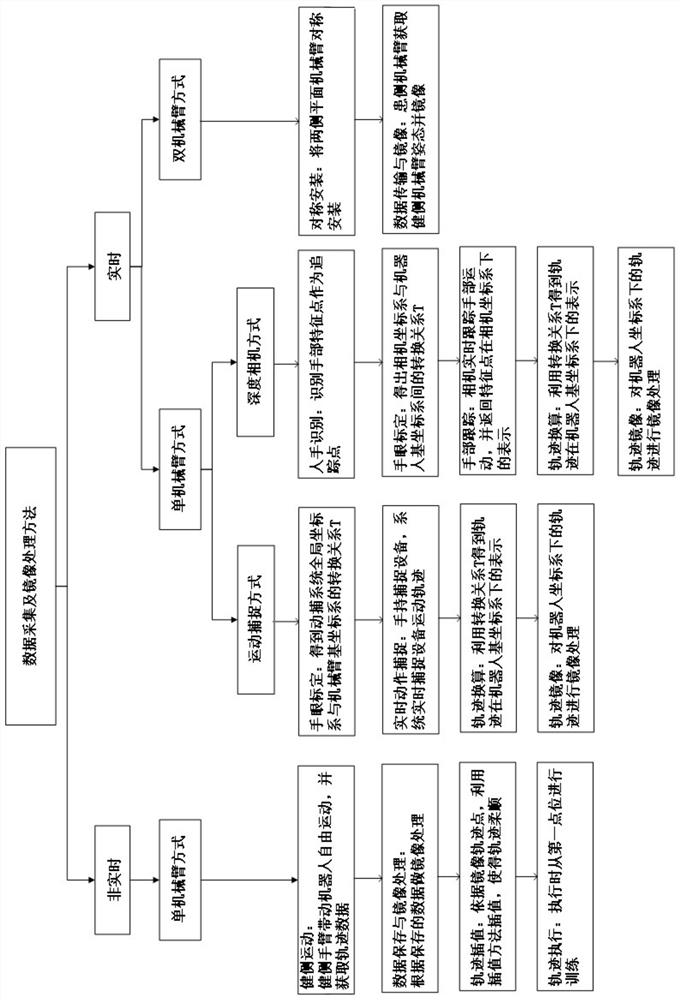

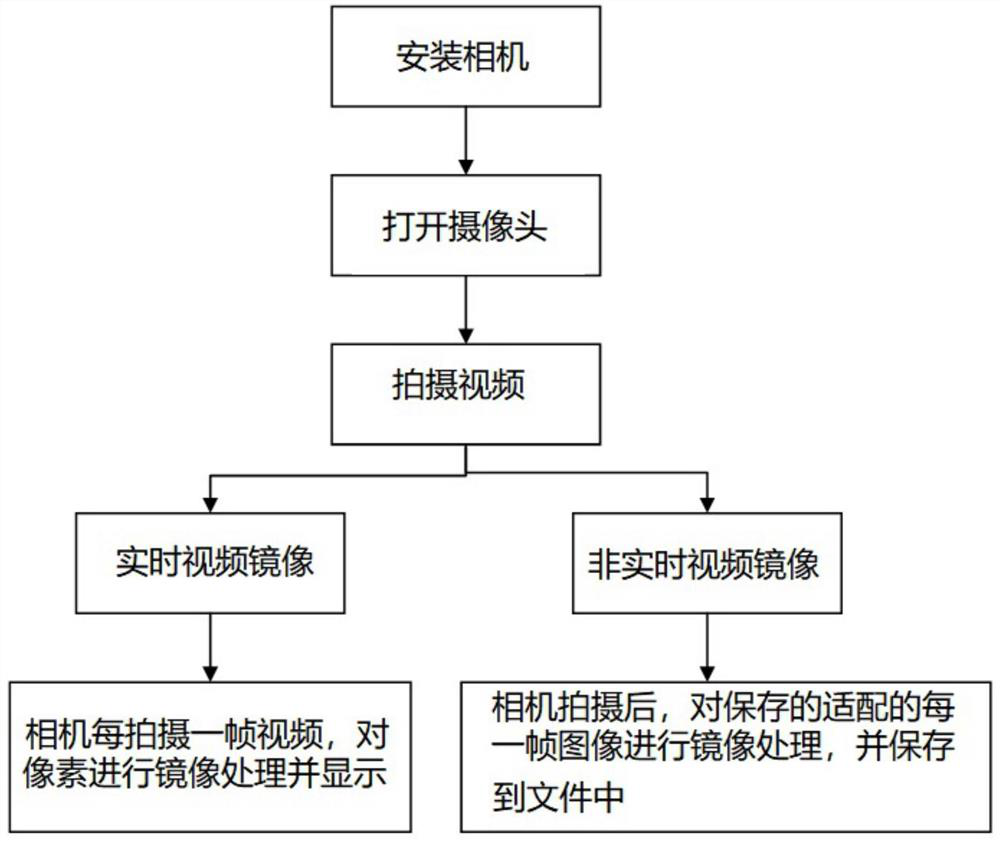

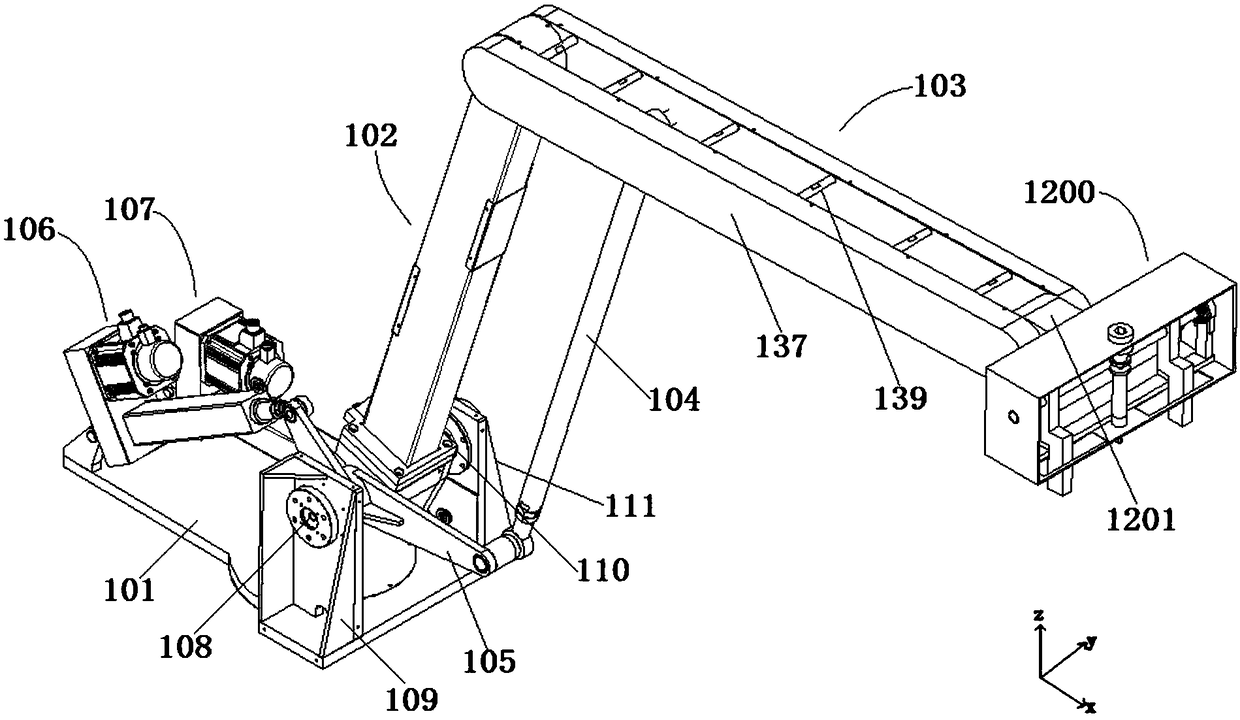

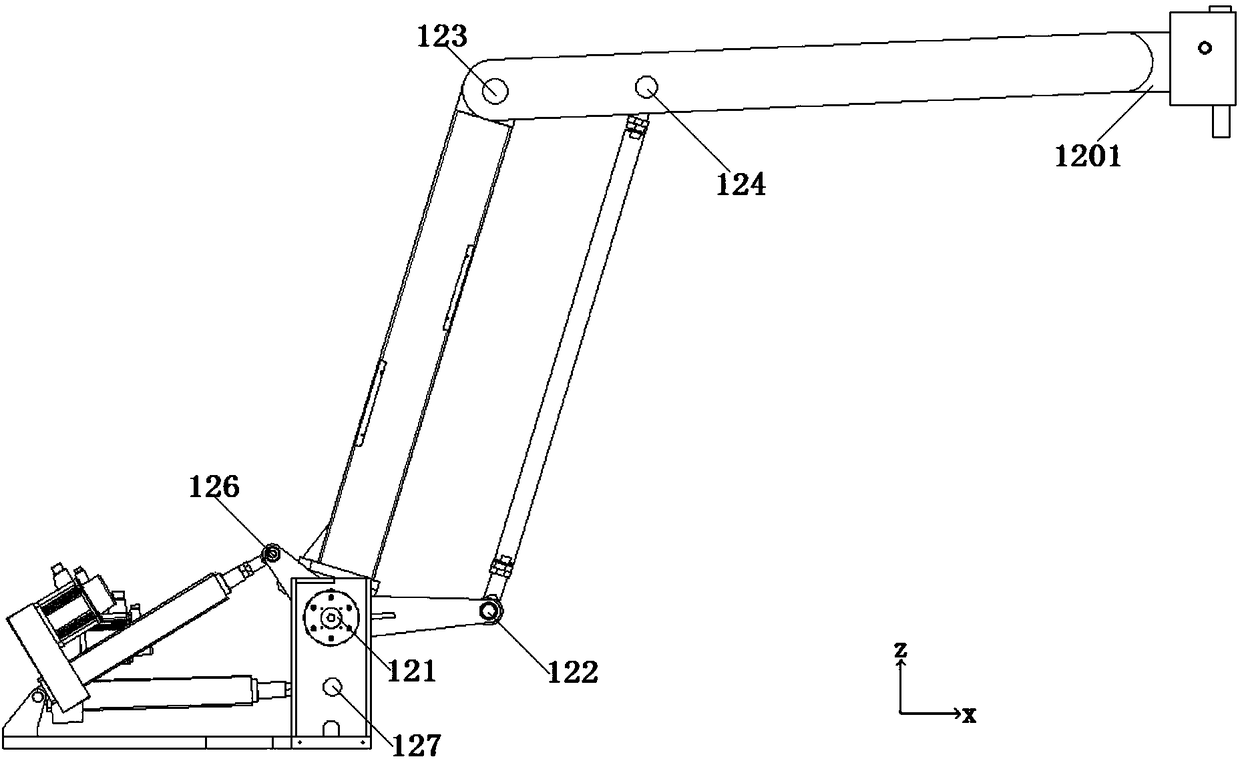

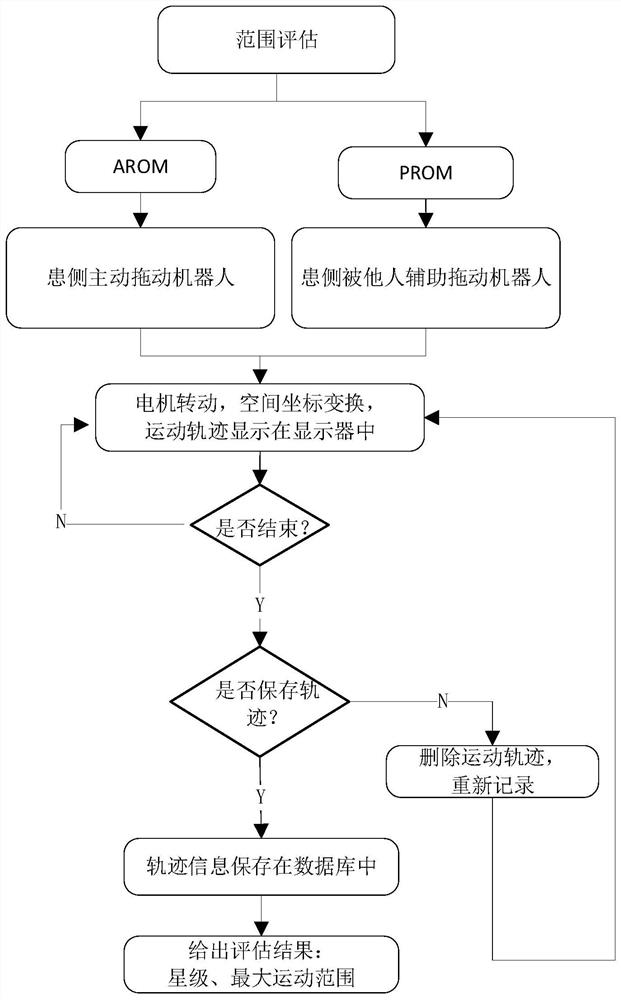

Acquisition and mirroring method for motion data of planar rehabilitation robot

PendingCN114010184AImprove recovery efficiencyImprove rehabilitation effectChiropractic devicesDiagnostic recording/measuringPlanar robotMirror therapy

The invention relates to an acquisition and mirroring method for motion data of a planar rehabilitation robot. According to the invention, motion data acquisition and mirroring processing are carried out through any one of a motion capturing and mirroring method, a depth camera acquisition and mirroring method and a video mirroring method, and a robot mechanical arm is combined for use to carry out mirroring therapy on a patient while the patient is driven to move through traction of the planar robot. According to the data acquired by the method, real-time mirror plane rehabilitation training (namely, simultaneous real-time mirroring of videos and motion tracks) and non-real-time mirror plane rehabilitation training (namely simultaneous non-real-time mirroring of videos and motion tracks) can be realized, force sense stimulation and visual stimulation are combined, and the rehabilitation efficiency and effect of patients are effectively improved.

Owner:SHANGHAI ROBOT IND TECH RES INST CO LTD

Planar robot for location and paint spraying

InactiveCN108161912AMove fastFast clamping workProgramme-controlled manipulatorGripping headsPlanar robotDriven element

The invention provides a planar robot for location and paint spraying. The planar robot includes a platform, a first arm, a second arm, a first connecting rod, a second connecting rod, a first arm driving assembly, a first connecting rod driving assembly and electric clamping jaws. According to the planar robot for the location and the paint spraying, drive elements are arranged at the bottom platform, the first arm and the second arm do not have extra weight except self-weight and the weight of the matched connecting rods, and the moving speed of tail ends is high; the driving elements of theelectric jaws are placed outside articulated arms, the tail end of the second arm only includes clamping jaw bodies, and the burden is lighter; the clamping jaws are driven in an electric mode, the impact is lower, so that the movement of mechanical arms is not affected; and paint spraying operation is carried out after the electric clamping jaws clamps and locates workpieces, so that the work efficiency is higher.

Owner:华南智能机器人创新研究院 +1

A Planar Redundancy Robot

ActiveCN105479451BSmall moment of inertiaImprove stabilityProgramme-controlled manipulatorPlanar robotAgricultural engineering

The invention discloses a planar redundant robot, relates to a robot, and specifically relates to a planar redundant robot. The invention aims at solving the problem of low location accuracy of the existing planar robot. The planar redundant robot disclosed by the invention comprises a base, a first drive unit, a joint shaft, a support mechanism, a first connection rod, a second connection rod, a third connection rod, a manipulator, a second drive unit, a third drive unit, a first transit mechanism, a second transit mechanism, a sensor and a drive unit support, wherein the first drive unit is installed in the base; the joint shaft is installed in the base through the support mechanism; the first drive unit is connected with the lower end of the joint shaft; the upper end of the joint shaft is connected with one end of the first connection rod; the other end of the first connection rod is connected with one end of the second connection rod through the first transit mechanism; and the other end of the second connection rod is connected with one end of the third connection rod through the second transit mechanism. The invention belongs to the field of robots.

Owner:HARBIN INST OF TECH

A high-speed robot for positioning spray paint

ActiveCN108177152BSmall moment of inertiaNot affected by exerciseProgramme-controlled manipulatorArmsPlanar robotEngineering

The invention provides a high-speed robot for positioning and painting, which includes a high-speed three-axis module, electric grippers and a painting head. The planar robot used for positioning and spraying sets the driving element on the platform at the bottom. The first arm and the second arm have no additional weight except their own weight and the weight of the supporting connecting rod. The end moves faster and the rotation of the base The rotational inertia is small; the driving element of the electric gripper is placed outside the articulated arm, and the end of the second arm only includes the gripper body, and the load is light; the gripper is driven by electric mode, the impact force is small, and it will not affect the movement of the mechanical arm The impact is caused; the electric gripper is used to clamp and position the workpiece and then carry out the painting operation, and the operation efficiency is high.

Owner:华南智能机器人创新研究院 +1

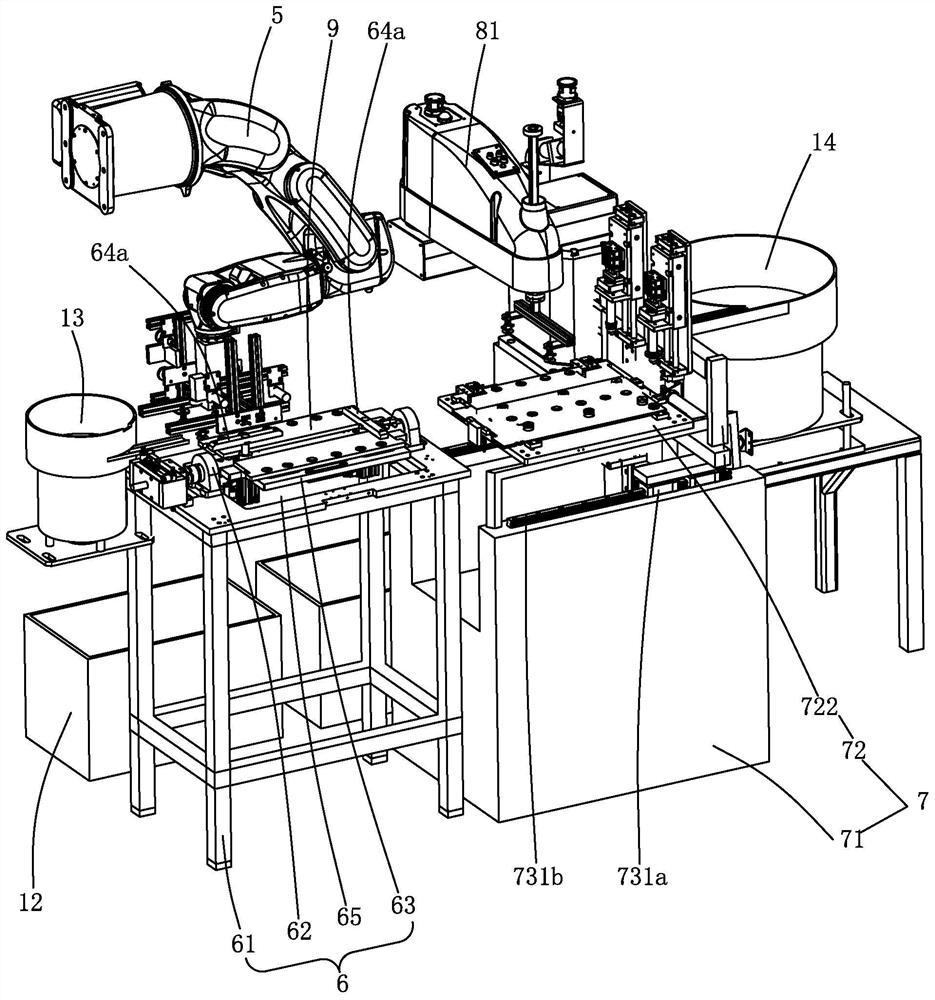

Automatic assembling mechanism for reverse boards of indication boards

PendingCN114406675AContinuous productionImprove assembly efficiencyAssembly machinesMetal working apparatusPlanar robotRobot hand

The invention discloses an indication board reverse panel automatic assembling mechanism which comprises an operation table, a reverse panel feeding device and a power line fixing seat feeding device. A circuit board servo feeding platform is arranged on one side of the upper end of the operation table; a first clamping speed chain lifting circulation device and a lead screw module feeding mechanical arm are arranged on the upper end face of the operation table and located on one side of the circuit board servo feeding platform, and a first plane robot, an automatic wire stripping machine and a double-shaft automatic wire welding machine are arranged on the upper end face of the operation table. The automatic assembling machine is simple in structure and reasonable in design, automatic operation is adopted, the processes of feeding, wire stripping, wire welding and the like of the circuit board can be automatically completed, the assembling efficiency is effectively improved, the labor cost is reduced, meanwhile, automatic feeding of the reverse panel can be completed, manual placement is not needed, and the working efficiency is further improved.

Owner:湖北匠远智能科技有限公司

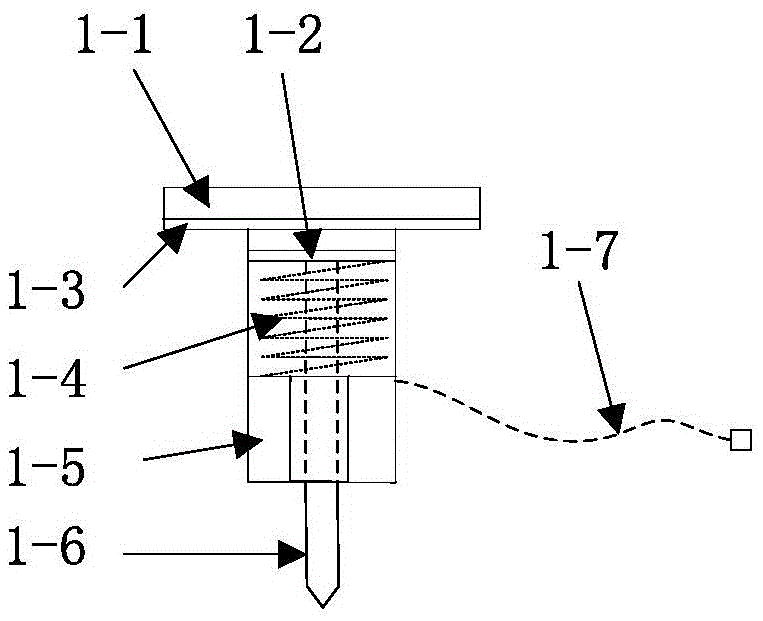

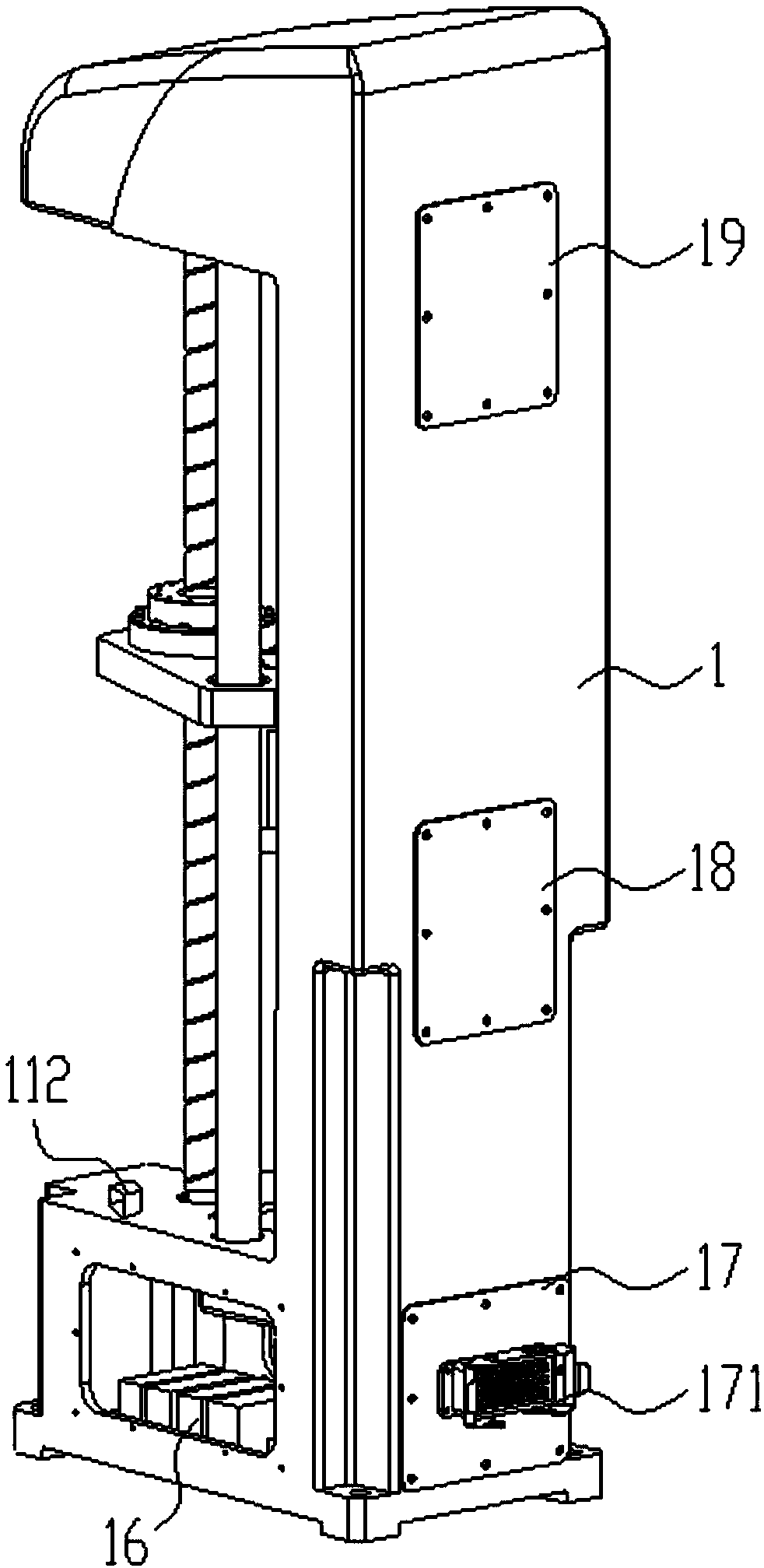

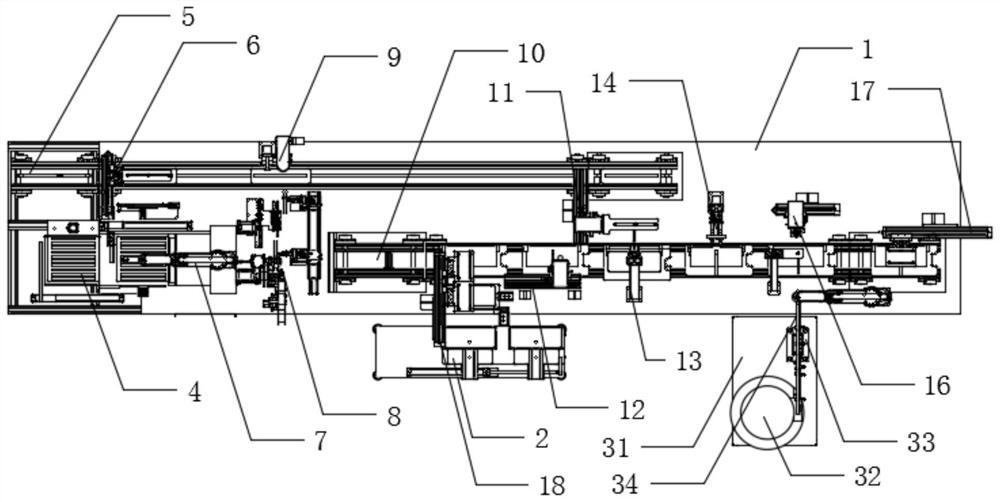

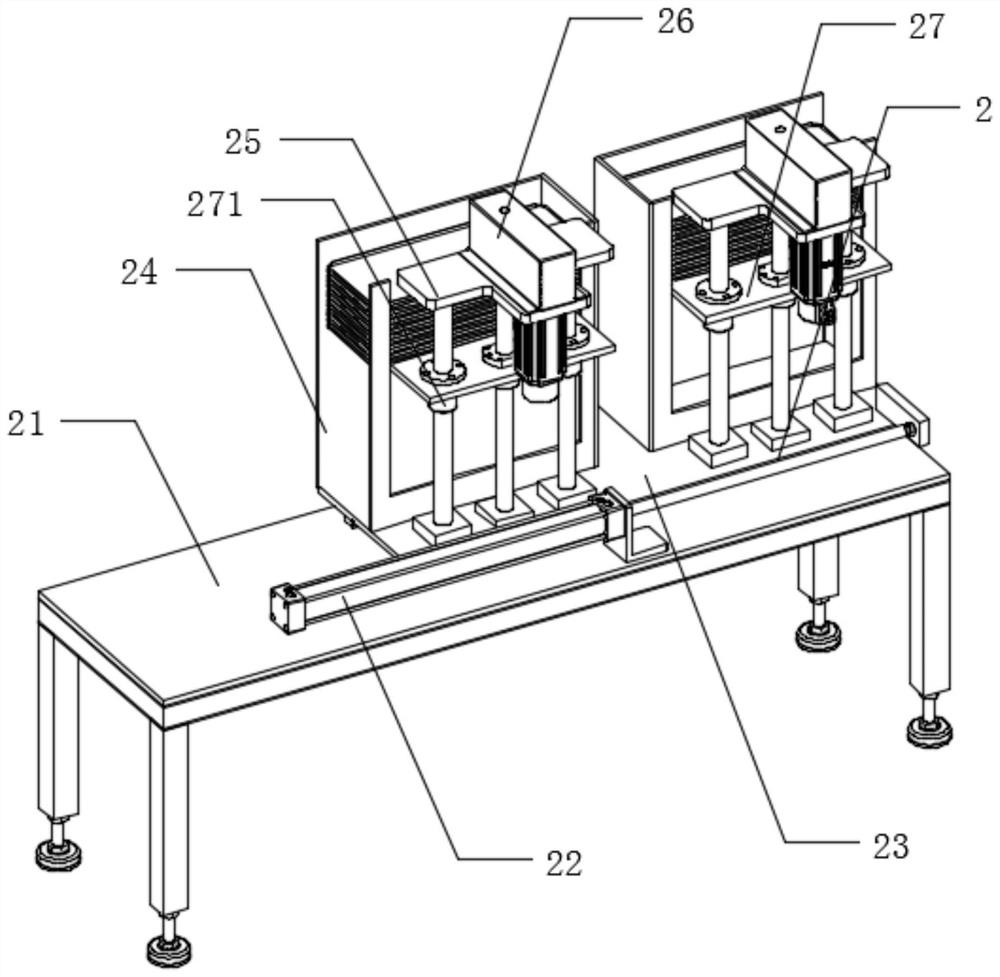

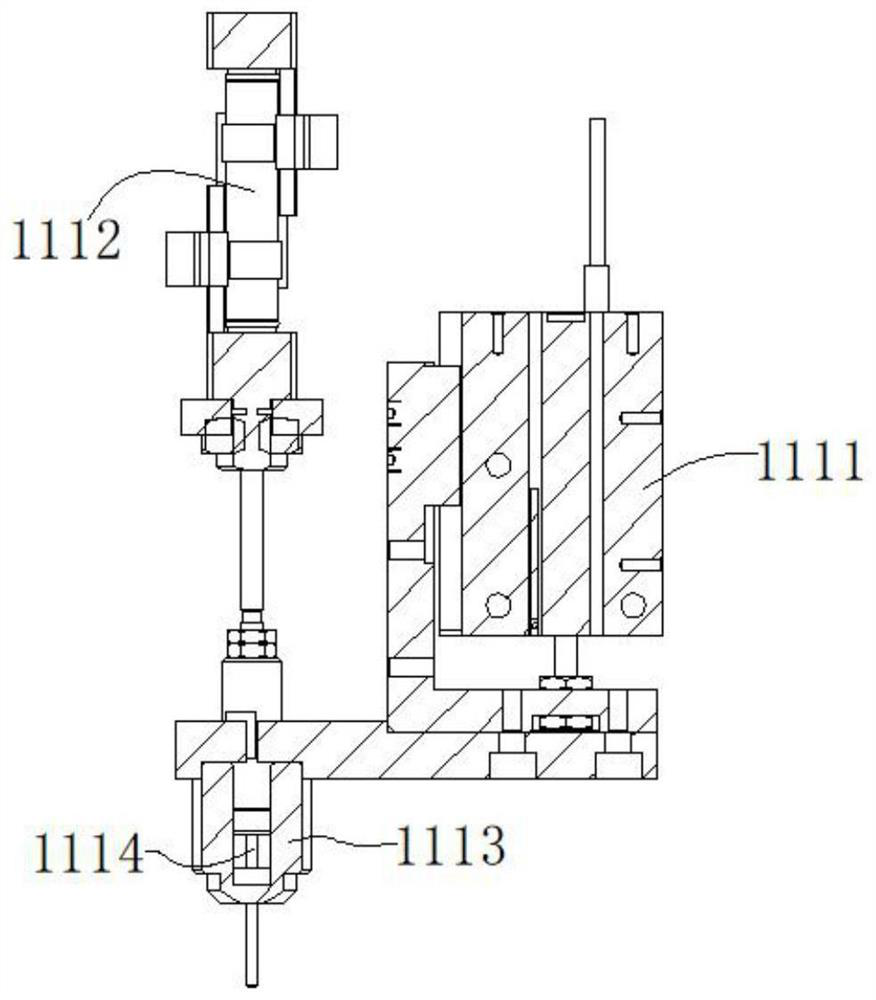

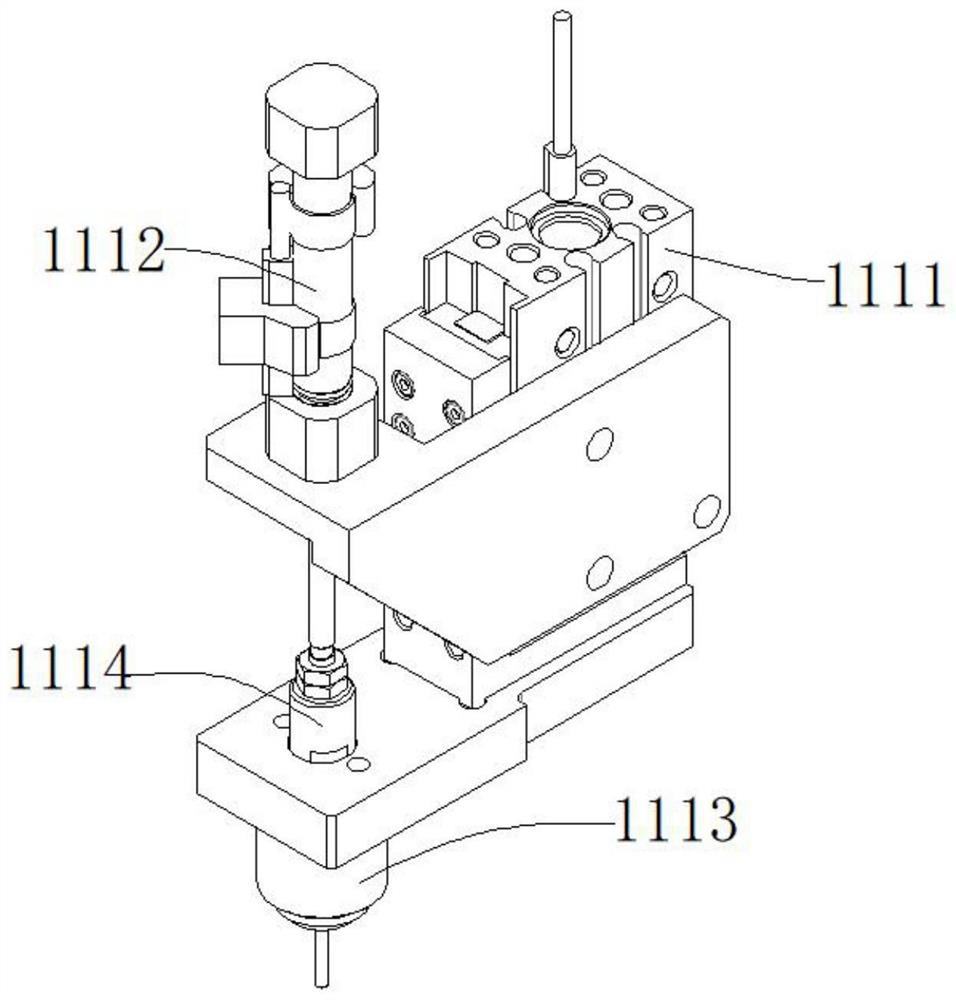

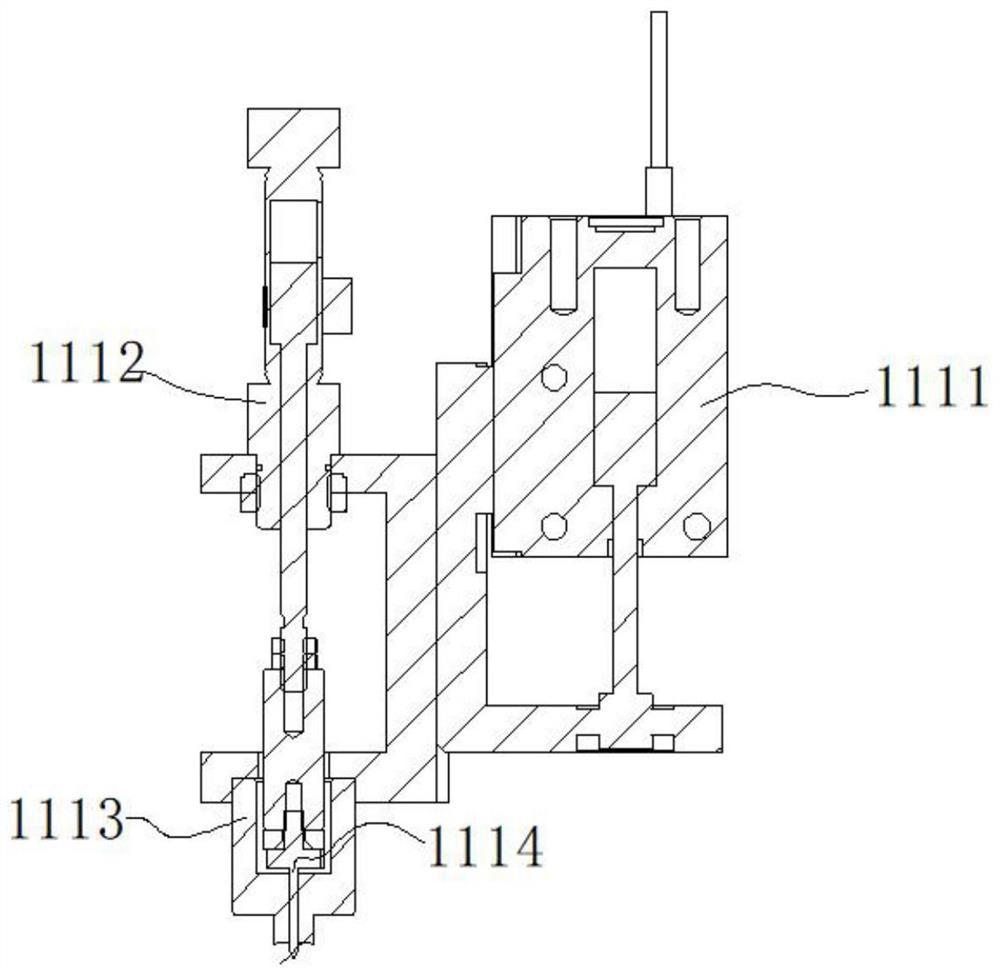

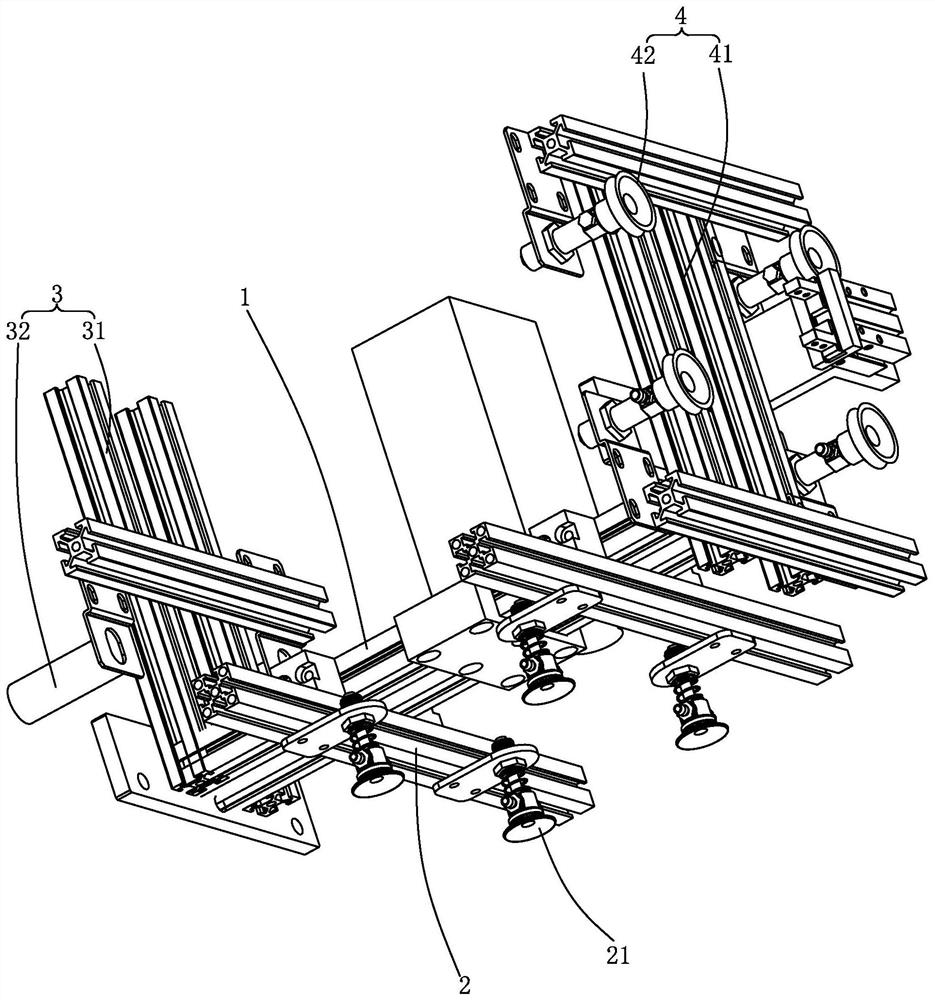

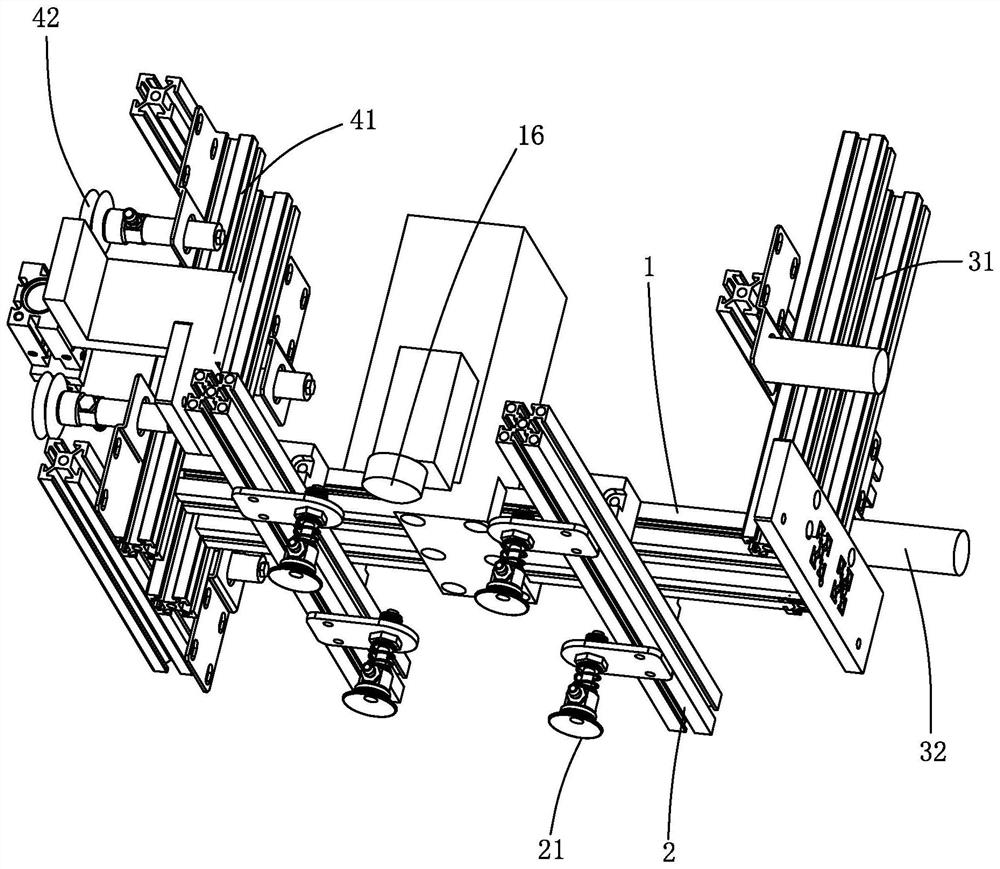

Rivet taking and placing mechanism, planar robot, rivet pressing device and rivet pressing system

The invention discloses a rivet taking and placing mechanism, a planar robot, a rivet pressing device and a rivet pressing system. The rivet taking and placing mechanism comprises a first telescopic part, a second telescopic part, a sleeve and a stand rod, wherein the sleeve is vertically arranged, a through hole which vertically penetrates through the sleeve is arranged in the middle, the stand rod is vertically arranged and penetrates into the through hole from top to bottom, the first telescopic part is in drive connection with the sleeve, the second telescopic part is in drive connection with the stand rod, and the first telescopic part and / or the second telescopic part are / is used for driving the stand rod to move relative to the sleeve in the vertical direction to enable the lower end of the stand rod to extend out of the sleeve or be retracted into the sleeve; when a rivet is a hollow rivet, the lower end of the stand rod is magnetic, and the lower end of the sleeve is made of anon-magnetic material; and when the rivet is a solid rivet, the lower end of the sleeve is magnetic, and the lower end of the stand rod is made of the non-magnet material. The rivet taking and placing mechanism is simple in structure and high in degree of automation.

Owner:重庆智能机器人研究院

Systems and methods for determining operating offset

Example systems and methods of determining work offset data for a robot in a work environment are disclosed. A robot operating in a work environment may receive instructions to determine a work offset. A work offset may describe the position and angular orientation of the work plane of the work environment relative to the robot's reference plane. In response to the indication, the robot can identify the work plane. The robot can be controlled to touch one or more points of the work plane. The robot may determine corresponding point positions of the contact points relative to the reference plane based on the corresponding positions of the robot at the corresponding contact times. The robot may determine the position and angular orientation of the work plane relative to the reference plane based on the determined corresponding point positions of the contact points.

Owner:X DEV LLC

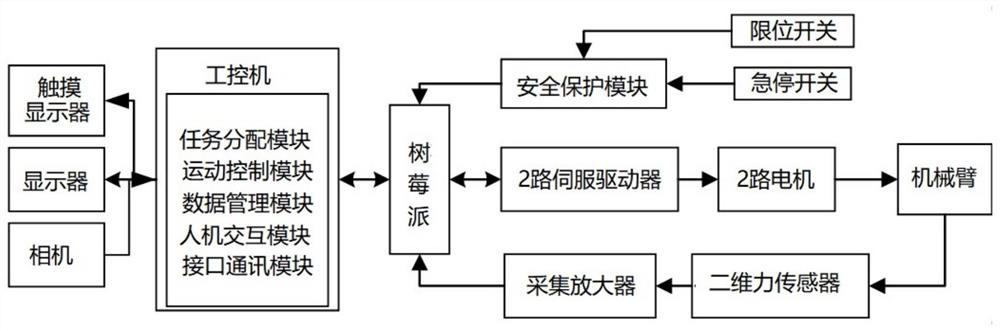

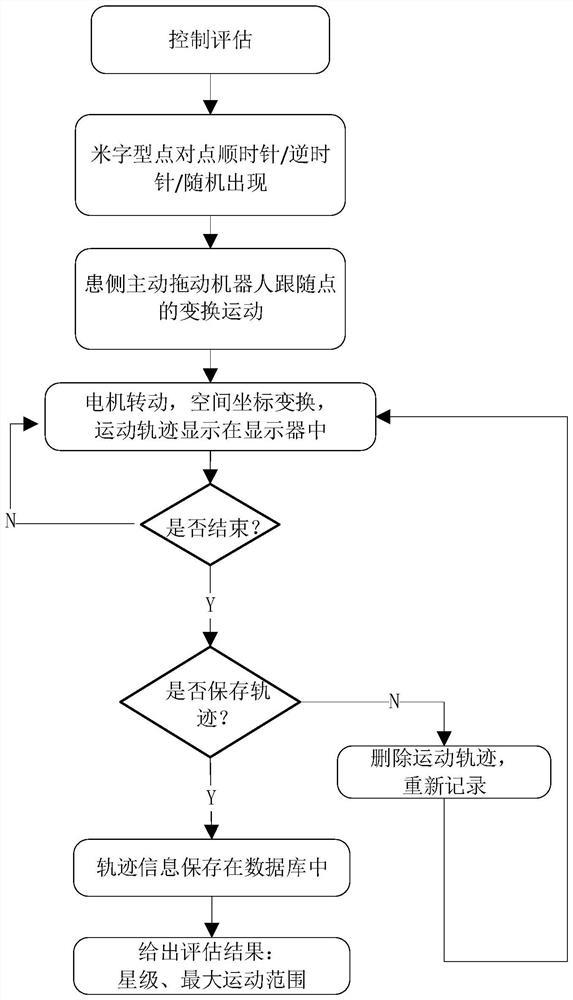

Plane rehabilitation mirror image robot control system and training mode implementation method

PendingCN113996025ASolving the inability to efficiently stimulate motor neuronsImprove recovery efficiencyGymnastic exercisingChiropractic devicesPlanar robotEngineering

The invention relates to a plane rehabilitation mirror image robot control system and a training mode implementation method. The plane rehabilitation mirror image robot control system comprises a robot control module, a mirror image control module, an industrial personal computer and a Raspberry Pi. The robot control module collects force and motion data of a robot and sends the data to the Raspberry Pi, the Raspberry Pi converts the data and then sends the data to the industrial personal computer, the mirror image control module captures the motion data of the robot and sends the data to the industrial personal computer, and the industrial personal computer controls the robot control module and the mirror image control module to work cooperatively in a set training mode. An upper limb plane rehabilitation robot and a mirror image device are combined together, the problems that a traditional mirror image therapy is not provided with a traction device, and a plane robot cannot effectively stimulate motor neurons are solved, and a patient is driven to move through traction of the plane robot when the patient is subjected to mirror image therapy. And force sense stimulation and visual stimulation are combined, so that the rehabilitation efficiency and effect of the patient are effectively improved.

Owner:SHANGHAI ROBOT IND TECH RES INST CO LTD

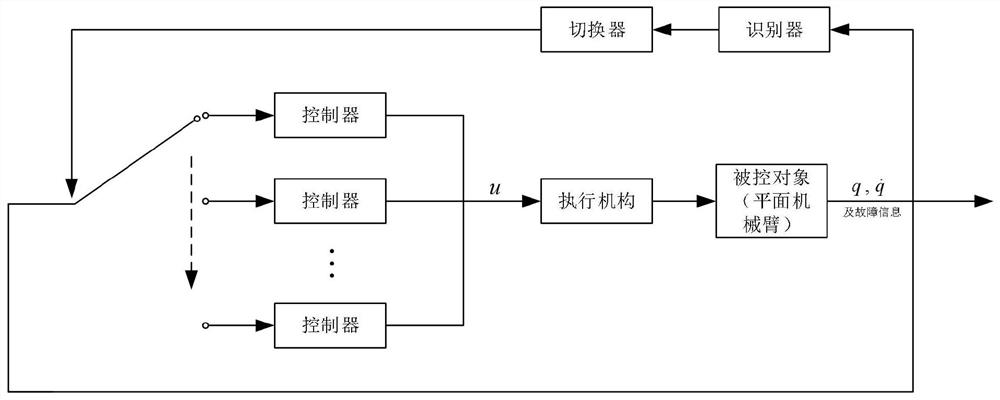

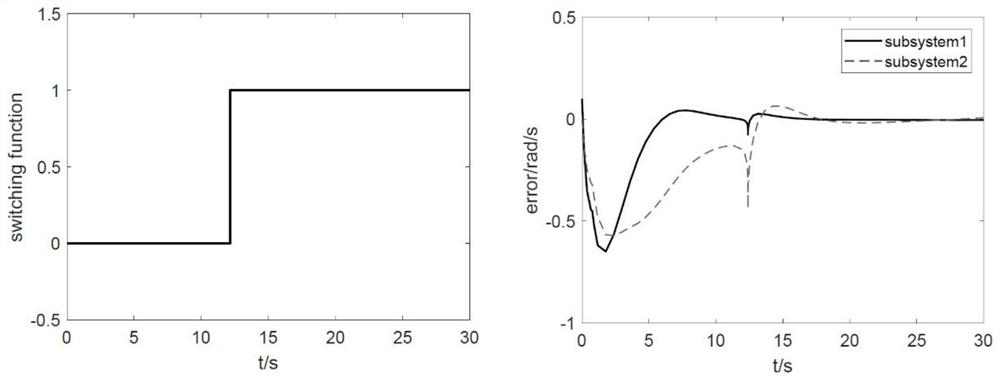

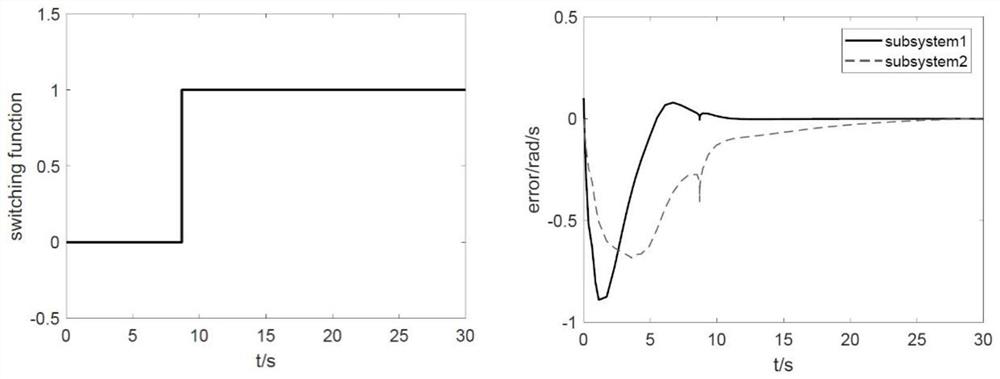

A planar manipulator system and its distributed fault-tolerant control method

ActiveCN109986562BImprove reliabilitySimple designProgramme-controlled manipulatorPlanar robotNonlinear model

The invention discloses a plane manipulator system and a distributed fault-tolerant control method thereof, belonging to the field of plane manipulator fault-tolerant control. According to different angular positions, a series of linear models are constructed to approximate the original nonlinear model, so that the coupling relationship between each sub-manipulator can be obtained, and then the corresponding distributed fault-tolerant control law is designed for each linear model, including two types of execution A switching law is proposed to make the system stable under the condition of controller switching. The invention overcomes the limitation of reduced tracking efficiency of the planar manipulator when the actuator or the sensor fails during the tracking process, and improves the operating reliability of the planar manipulator system.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Automatic heat-sealing plug screwing robot

InactiveCN112606308ARealize full automationSave human effortProgramme-controlled manipulatorPlanar robotAir filter

The invention discloses an automatic heat-sealing plug screwing robot. The automatic heat-sealing plug screwing robot comprises an injection molding robot used for carrying an air filter and a product and capable of pressing the air filter onto the product in a hot pressing manner, an air filter assembling machine used for fixing the product, a liquid injection plug assembling machine used for spinning a liquid injection plug onto the product with air filter hot pressing completed and a planar robot arranged on one side of the liquid injection plug assembling machine and used for providing the liquid injection plug or carrying the product with liquid injection plug assembling completed. According to the automatic heat-sealing plug screwing robot, through mutual cooperation of the injection molding robot, the filter assembling machine, the liquid injection plug assembling machine and the planar robot, the injection molding robot can take the injection molding product from an injection molding machine and achieve heat sealing of the air filter and automatic assembling of the liquid injection plug, automation of the whole process is achieved, manpower is saved, production efficiency is improved, and the problems of high labor cost and low efficiency due to the fact that existing injection molding equipment needs many operators are solved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA ZHONGSHAN INST

A guardrail welding method based on guardrail welding equipment

ActiveCN108942022BAchieve weldingConsistent welding effectWelding/cutting auxillary devicesAuxillary welding devicesPlanar robotStructural engineering

The invention relates to a guardrail welding method based on guardrail welding equipment. When guardrails with the same shape but different specifications and sizes are manually welded, the manual labor intensity required is high, the efficiency is low, the welding effect is not regular, and the overall welding shape is not attractive. The guardrail welding method can realize welding of the guardrails by replacing different tools for the guardrails of the different specifications and sizes. Since the guardrails are generally made of carbon steel, gas shielded welding is used as the welding method, automatic feeding of welding wires to the specified welding position is realized by a three degree-of-freedom planar robot on the other hand, welding guns arranged in parallel are used for welding the guardrails and base metal, and welding tracks of the welding guns of the three degree-of-freedom planar robot is controlled by a programming program, so that the welding effect is consistent, and the efficiency is improved.

Owner:GUANGDONG XINFEI STEEL ART TECH CO LTD

Artificial cochlea implanting operation system based on computer vision

ActiveCN103330616BGuaranteed accuracyShorten operation timeEar treatmentArtificial cochlea implantPlanar robot

The invention relates to an artificial cochlea implanting operation system based on computer vision. The artificial cochlea implanting operation system is characterized by comprising a computer, a head fixed support, a rough adjustment passive arm, a dual-plane rotor, a CT (Computed Tomography) scanner and photo-electric navigation equipment, wherein the computer is further internally provided with a VTK Platform rectification navigation platform; the VTK Platform rectification navigation platform comprises an image visualization unit, an image incision unit, a spatial rectification unit, a planning unit and a navigation unit, wherein the image visualization unit is used for reading, rebuilding and displaying the CT data of a patient, the image incision unit is used for incising the CT data of the patient and acquiring the data of an operative region, the spatial adjustment unit is used for combining a CT image space and an actual space so as to generate a rectification matrix, the planning unit is used for planning the operative pathway of an implanted artificial cochlea in the CT image space, and the navigation unit draws a model by combining the cochlea surface of the patient under the tracking of the photo-electric navigation equipment, and guides a doctor to finish the implanting operation of the artificial cochlea according to a planned path. The artificial cochlea implanting operation system based on computer vision can be extensively applied to artificial cochlea implanting operation.

Owner:PEKING UNIV THIRD HOSPITAL

Four-axle planar robot for high-speed grooving machine

InactiveCN109366498AIncrease stiffnessGood lookingProgramme-controlled manipulatorPlanar robotEnvironmental noise

The invention discloses a four-axle planar robot for a high-speed grooving machine. The four-axle planar robot for the high-speed grooving machine comprises a robot main body; the robot main body is provided with shoulder parts, large arms, elbow parts, small arms and wrist parts corresponding to human arms in sequence; and the robot wrist parts are used for mounting robot grippers. The four-axleplanar robot for the high-speed grooving machine has the characteristics of high rigidity, high precision, high reliability, high speed and simple and beautiful arm shape, and liberates human from monotonous complicated physical labor with weak safety and high environmental noise to engage in the work rich in creativity.

Owner:WUHU ELECTROTECHN MACHINERY

A method and system for position detection of planar robot based on capacitive touch screen

ActiveCN105547120BEasy to assembleImprove economyElectric/magnetic position measurementsUsing electrical meansCapacitancePlanar robot

The invention provides a plane robot position detection method and system based on a capacitive touch screen, belonging to a plane robot position detection method and system. The method and system are used for accurately detecting a plane robot end position coordinate. The system comprises a capacitive screen triggering device, a capacitive touch screen support device, a display screen, a computer, and an auxiliary fixing device, wherein the capacitive screen triggering device comprises a fixed magnet, a spring control board, a magnetic shield material, a reset spring, an electromagnet, a capacitive screen trigger, and an electromagnet connection wire. The capacitive touch screen support device comprises a support device base, an adjustment platform, an adjustment knob, anti-skid support legs, a rotation bearing, a capacitive touch screen, and a touch screen fixed pad. The auxiliary fixing device comprises a clamping base, a clamping plate and a clamping screw. The invention provides the plane robot position detection method and system based on a capacitive touch screen, and the problems of a complex measurement process, a long measurement time, limited measurement range and serious damage of a measuring instrument of an existing method are solved.

Owner:CHINA UNIV OF MINING & TECH

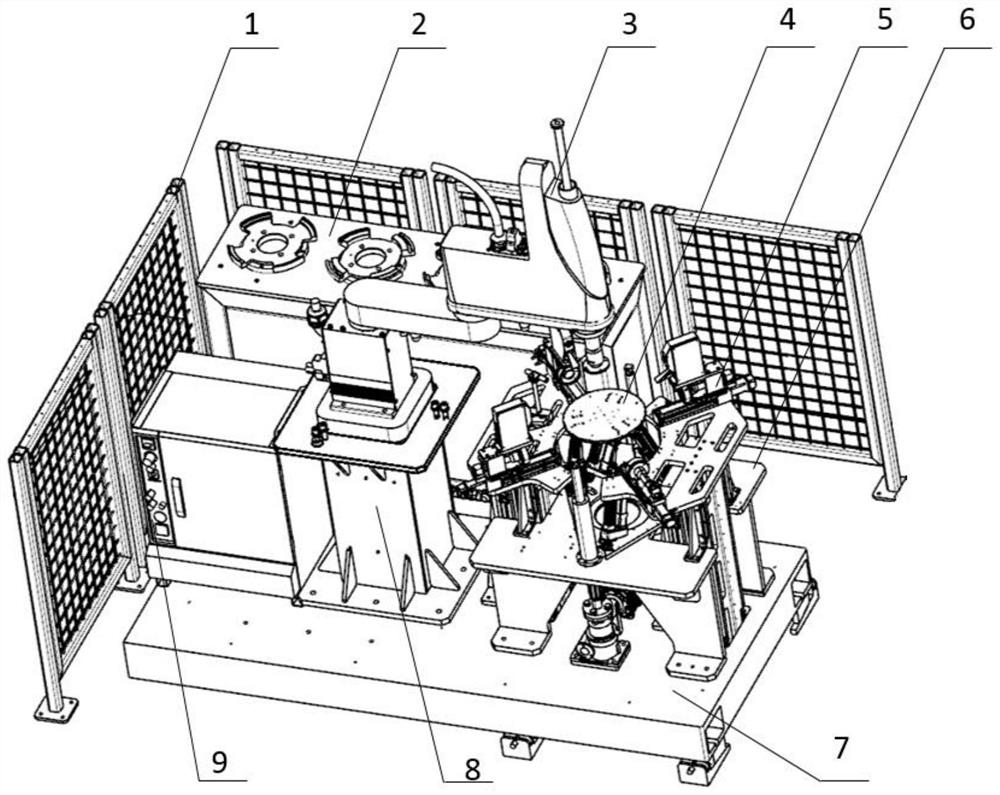

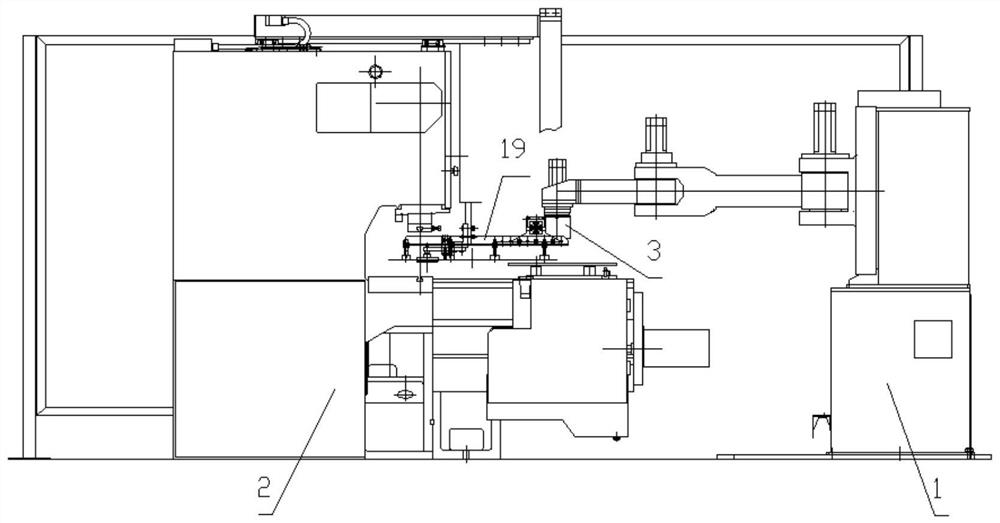

Four-axis planar robot integrated system for automatic loading and unloading of high-speed notching machines

ActiveCN109848285BRealize automatic loading and unloadingHigh precisionMetal-working feeding devicesPositioning devicesPlanar robotElectric machinery

The invention discloses a four-axis planar robot integrating system used for automatic feeding and discharging of a high-speed notching press. The system comprises the high-speed notching press and afour-axis planar robot located in front of the high-speed notching press. A robot gripper is installed on a robot waist portion of the four-axis planar robot. Motor blank piece vacuum chucks, stator piece electromagnetic chucks and rotor piece electromagnetic chucks are installed on the robot gripper. A blank table and a piece sorting device are installed on one side of the high-speed notching press, and a rotor piece table and a stator piece table are installed on the other side of the high-speed notching press. The four-axis planar robot integrating system has the characteristics of high precision, high reliability, high speed, convenient operation and maintenance and the like, a manual feeding and discharging mode of a current high-speed notching press is changed, and the human beings are liberated from monotonous and sundry physical labor and are engaged in more creative work.

Owner:WUHU ELECTROTECHN MACHINERY

An all-round planar robot support device

ActiveCN104889969BExpand the scope of workRealize mobile operationsManipulatorHydraulic cylinderPlanar robot

The invention discloses an all-direction plane robot support device. The device comprises an advancing and turning mechanism, a base rotary turning mechanism and a lifting, moving and rotating mechanism, wherein the advancing and turning mechanism comprises advancing wheels (3) and a turning wheel (7); the base rotary turning mechanism comprises a rotating base (10), and a rotating base driving motor (9) for providing driving force; and the lifting, moving and rotating mechanism comprises a plane moving hydraulic cylinder (11), a vertical lifting hydraulic cylinder (12), a connecting rod (13), a rotating support frame (14) and a rotating support frame driving motor (15). The device is provided with the advancing and turning mechanism at the lower part of the base to realize the flowing operation according to the difference of working places; the base is provided with the base rotating mechanism to realize the rotation of the device for 360 degrees; and the lifting, moving and rotating mechanism is synchronously arranged above the rotating base mechanism to widen a working range of a plane robot.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com