A guardrail welding method based on guardrail welding equipment

A welding equipment and welding method technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of high labor intensity, inconsistent welding seam height, low efficiency, etc., and achieve improved efficiency and welding effect. consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

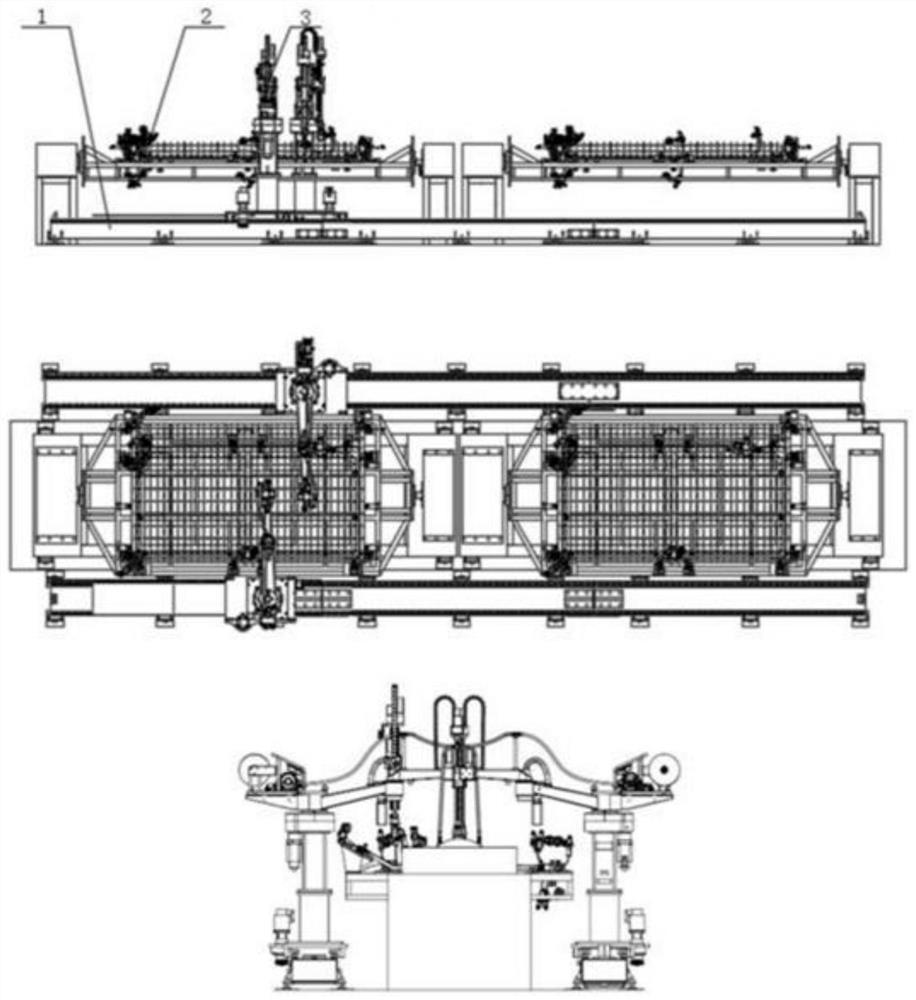

[0051] Such as figure 1 The schematic diagram of the overall structure of the guardrail welding equipment is shown. The structure of the equipment is mainly divided into three parts: slide rail mechanism 1, wire feeding mechanism 2, and welding mechanism 3.

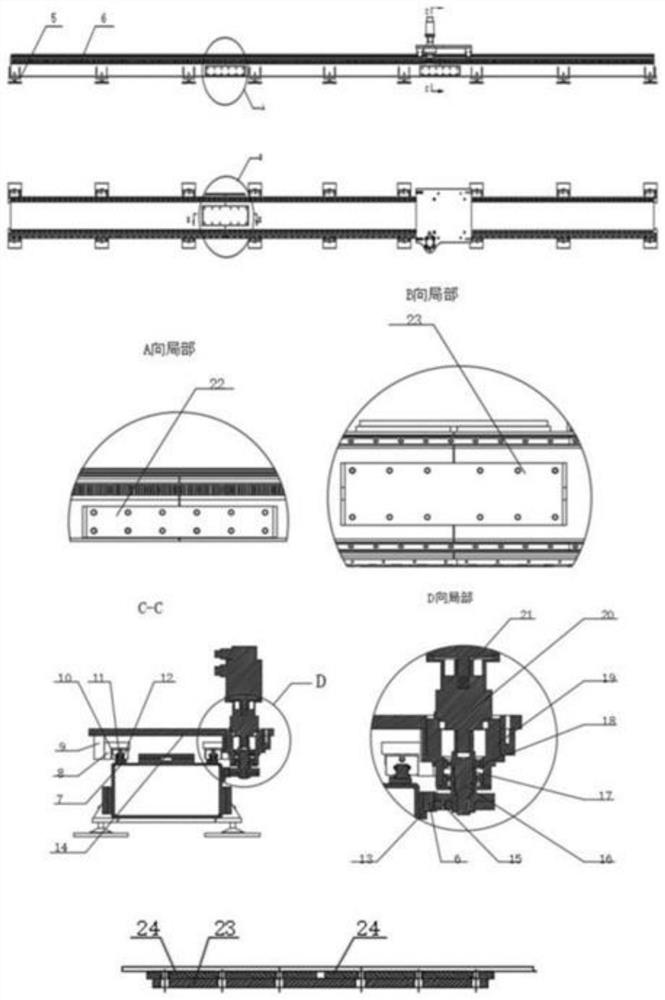

[0052] Such as figure 2 As shown, the slide rail mechanism 1 is horizontally divided into two slide rail mechanisms 1, which are symmetrically arranged on both sides of the welding mechanism 3 and 4 respectively, and three bases 10 are used on one side, and the base 10 adopts a square tube 400x200, three The connection between the segment bases 10 is welded on the upper part and the side of the fixing plate 24,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com