Automatic heat-sealing plug screwing robot

A robot and automatic technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of high labor cost, low efficiency, and many operators, and achieve the effect of saving manpower and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

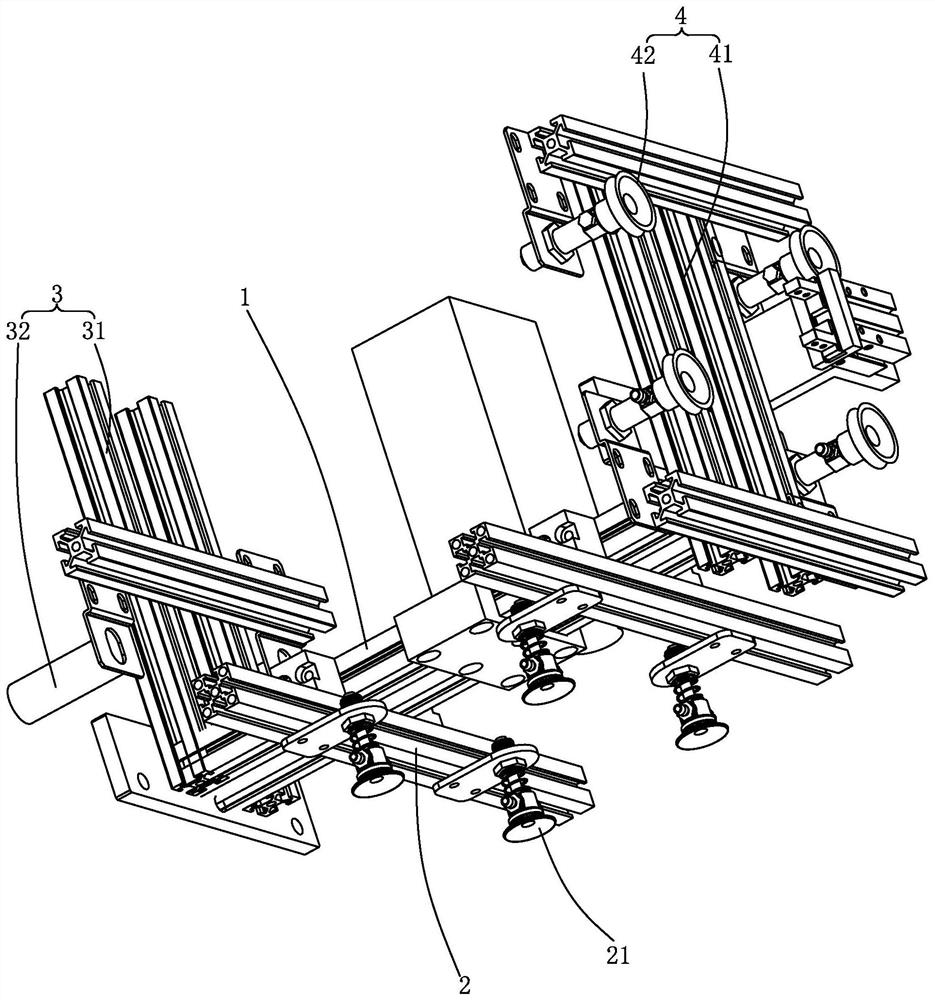

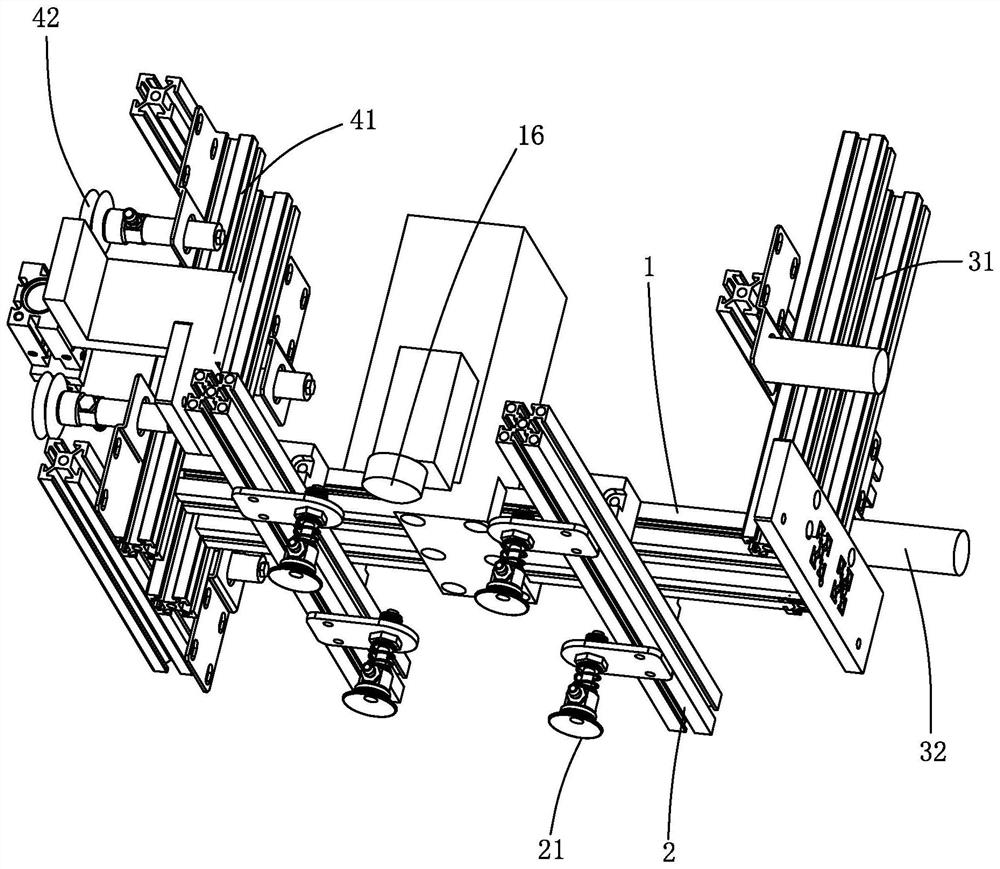

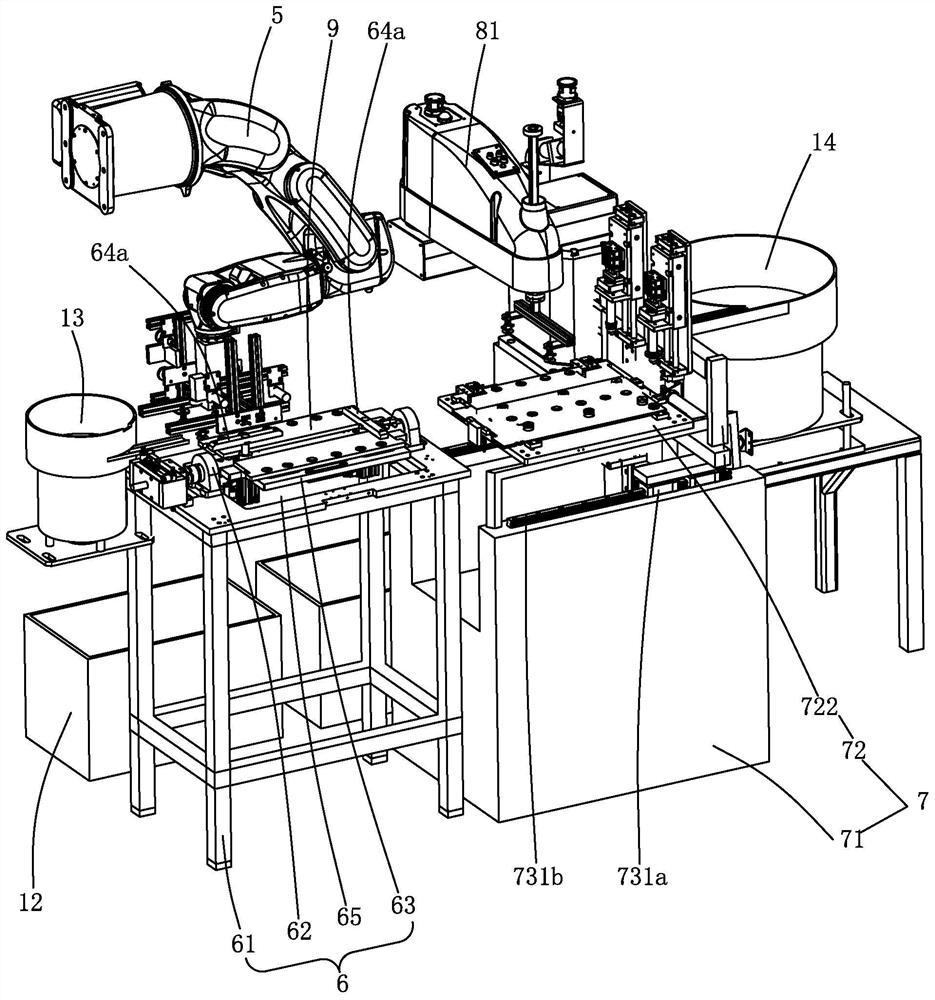

[0027] Example 1: See attached figure 1 to attach Figure 8 , the present embodiment provides an automatic heat-sealing plugging robot, including an injection molding robot for handling air filters and products and capable of hot-pressing air filters on products, and an air filter assembly machine for fixing products 6 1. The liquid injection plug assembly machine 7 that spins the liquid injection plug 10 on the product that has completed the hot-pressed air filter, and is located on one side of the liquid injection plug assembly machine 7 for providing the liquid injection plug or handling to complete the assembly of the liquid injection plug Product Planar Robot 8. The automatic heat-sealing plugging robot of the present invention realizes that the injection molding robot can automatically take the injection molding product and the air filter from the injection molding machine through the mutual cooperation among the injection molding robot, the filter sheet assembly machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com