Method and device for manufacturing silicon rubber fire-cupping tool

A silicone rubber, liquid silicone rubber technology, applied in household appliances, suction equipment, other household appliances, etc., can solve problems such as difficulty in demoulding, prolong manufacturing time, increase labor intensity, etc., save time and personnel, and reduce electricity. waste and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

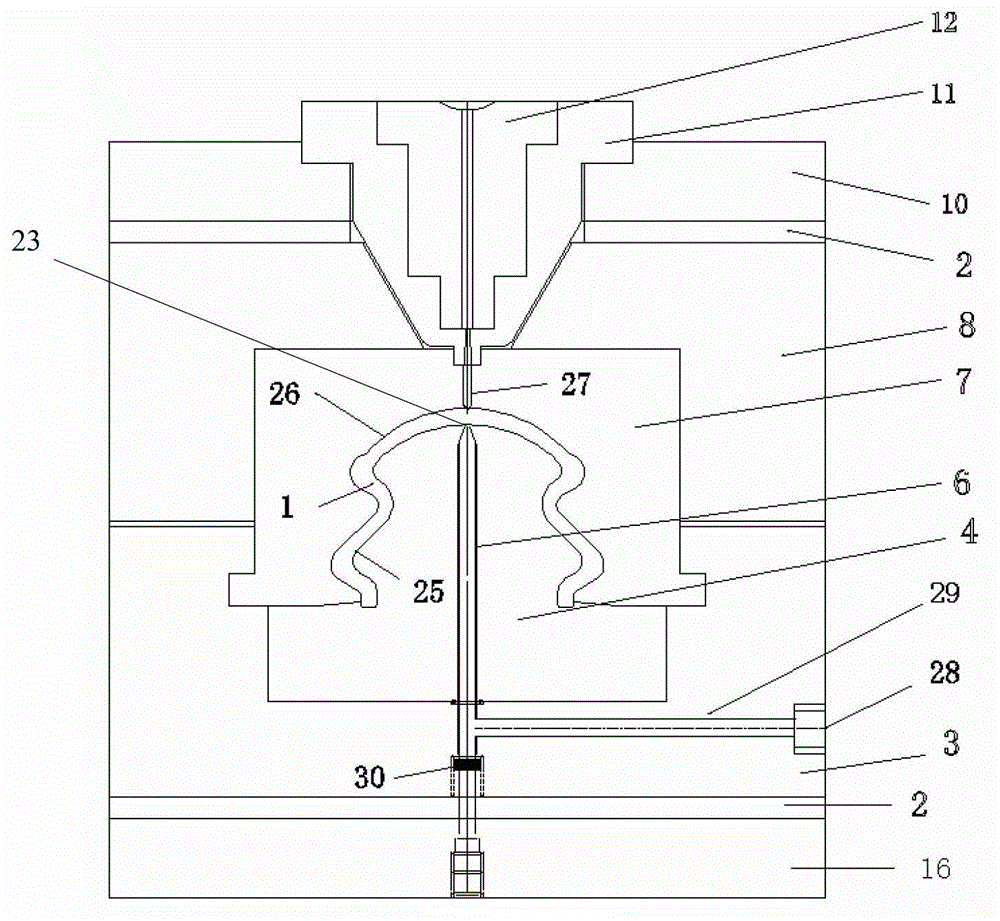

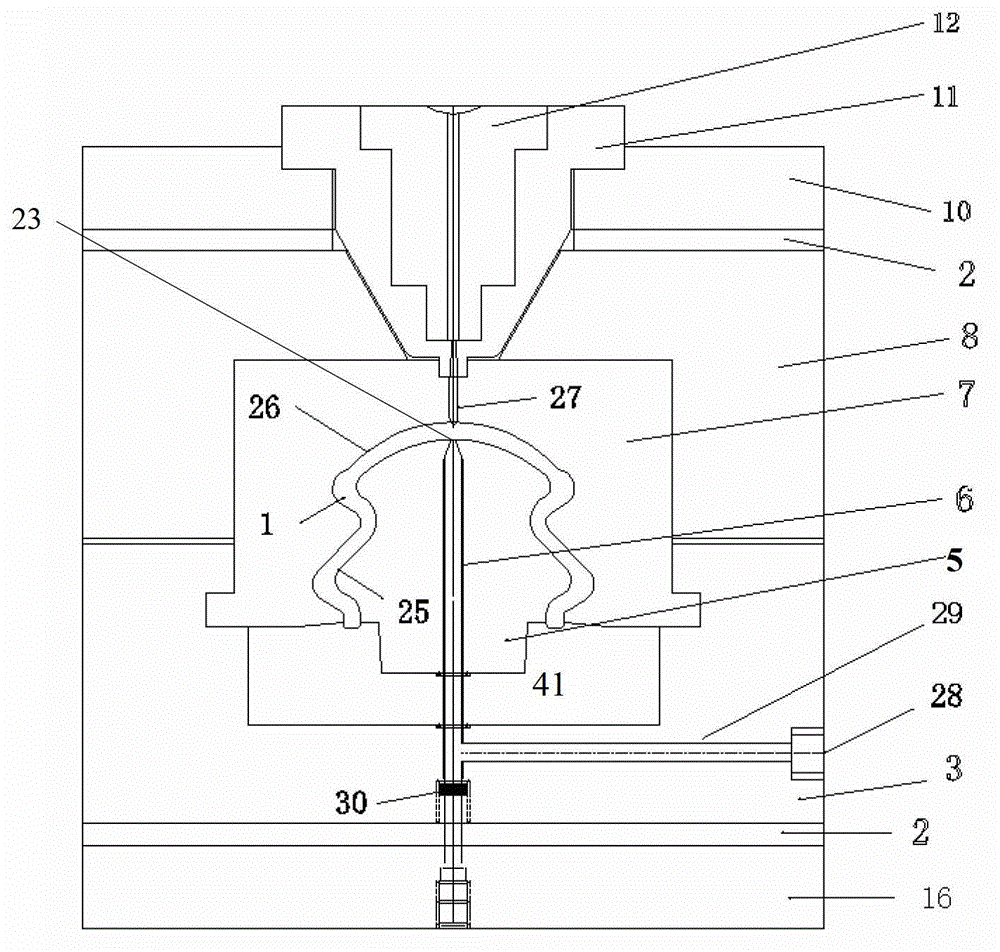

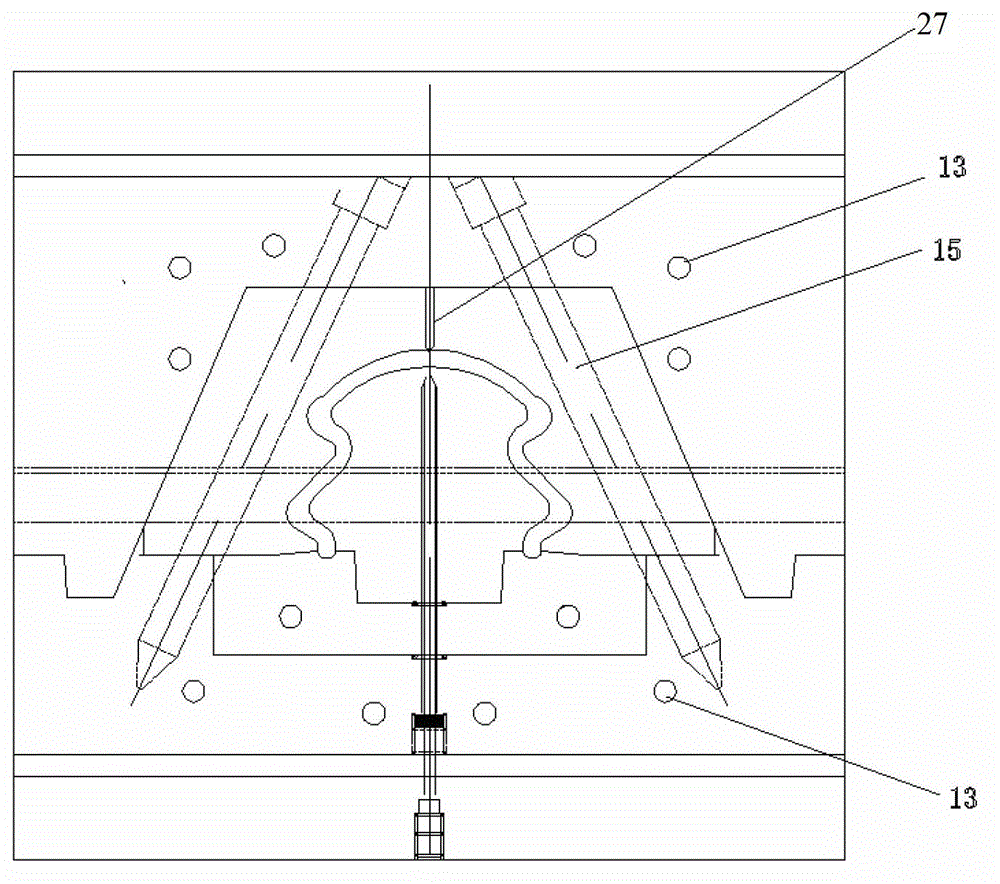

[0067] The specific implementation manners of the present invention will be described in detail below with reference to the accompanying drawings.

[0068] A device for making silicone rubber cupping utensils such as Figure 1a , Figure 1b and figure 2 As shown, it includes a nozzle 12 (also called a nozzle), an inner mold core 4, a separable row position 7 (also called a slider or a front mold or an outer mold), and a blowing demoulding device 6 . The blowing demoulding device 6 is used for blowing demoulding. The row position 7 has a concave shape, the row position is composed of at least two separable row block blocks, and the inner mold core has a convex shape. A mold cavity 1 for forming a silicone rubber cupping utensil is formed between the convex shape of the inner mold core 4 and the concave shape of the row position 7 . The blowing demoulding device 6 communicates with the mold cavity 1 through the blowing channel opening 23 provided at the junction of the inner...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com