Machine vision detection method and system of boiler pipeline surface defect

A machine vision detection and pipeline technology, applied in the direction of instruments, computer components, image data processing, etc., to achieve the effect of protecting edge features and eliminating salt and pepper noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The present invention will be further described below in conjunction with drawings and embodiments.

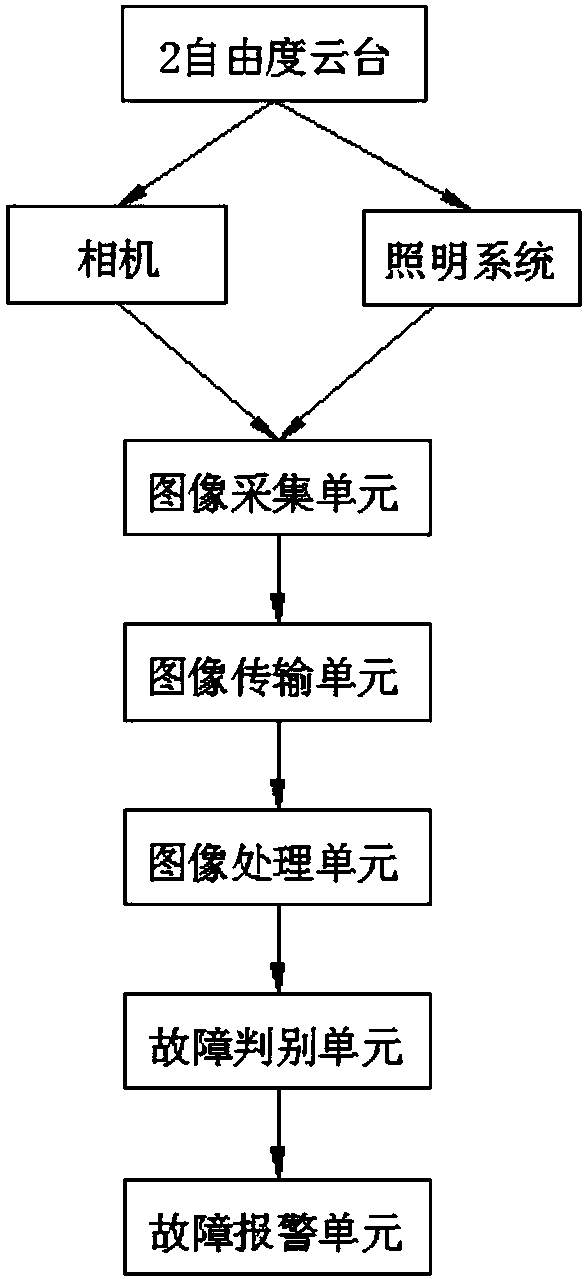

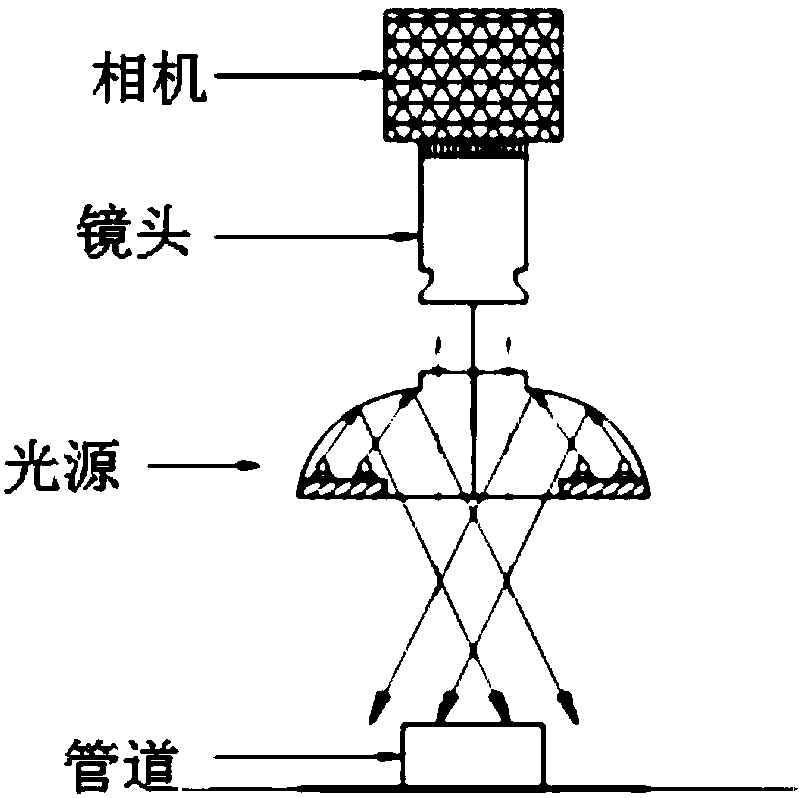

[0077] Such as figure 1 As shown, the machine vision detection system for boiler pipe surface defects disclosed in the present invention includes an image acquisition unit, an image transmission unit, an image processing unit, a fault judgment unit, and a fault alarm unit. Its specific structure is as figure 2 with 3 As shown, it includes an industrial camera 3, a two-degree-of-freedom platform 2, a lifting platform 1, an illumination system and a host computer; the industrial camera 3 and the illumination system are fixed on the lifting platform 1 through the two-degree-of-freedom platform 2, and the lifting platform 1 And the two-degree-of-freedom pan-tilt 2 drives the industrial camera 3 to move up and down, left and right, and is used to realize the continuous acquisition of boiler pipe surface images; the industrial camera 3 collects boiler pipe surface images ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com