Horizontal labeler

A labeling machine, horizontal technology, applied in the field of horizontal internal labeling equipment, can solve the problems of inability to label iron cans, small application range of labeling cans, high cost of mechanical production, etc., to achieve simple structure and practicality Strong, quality-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

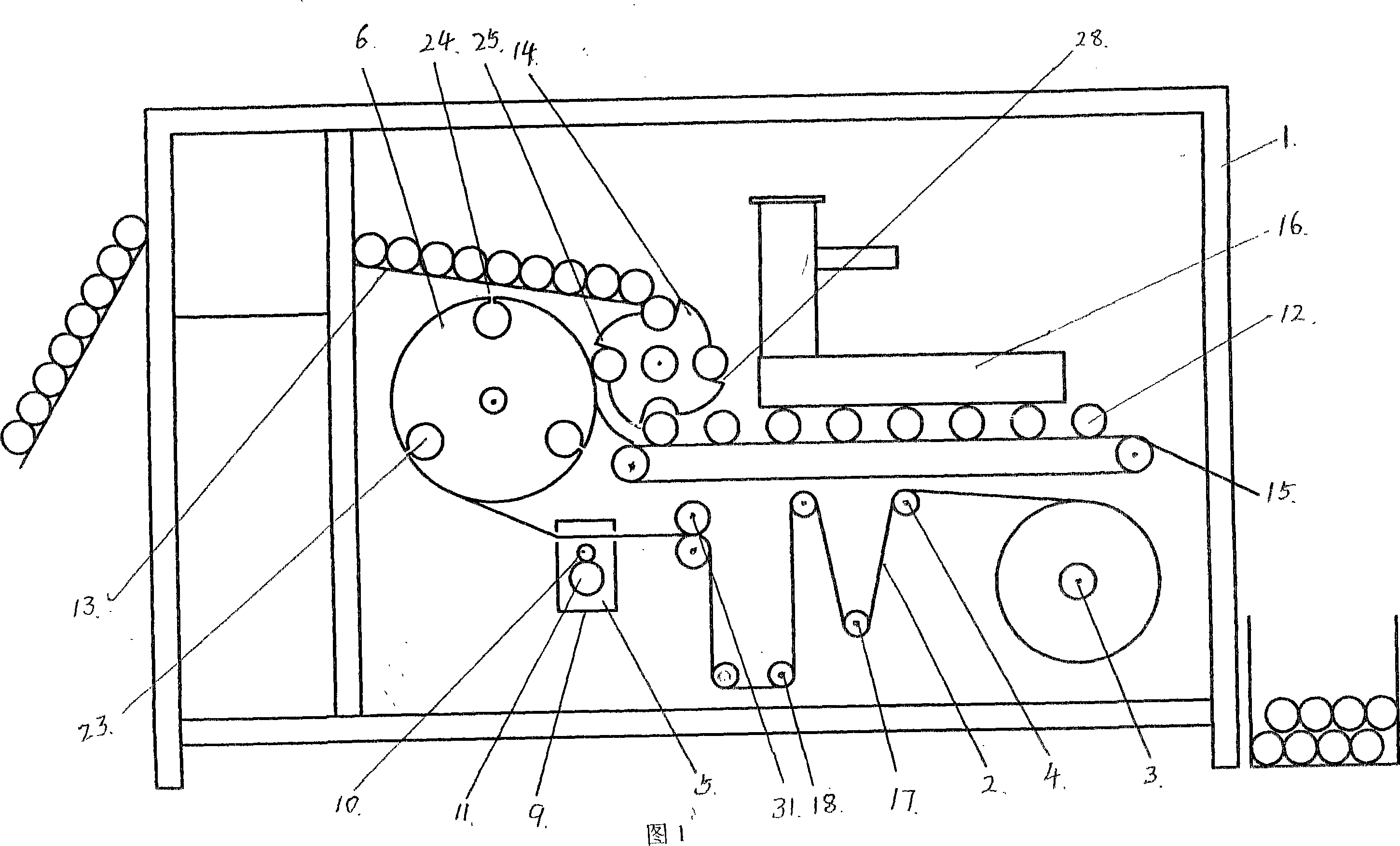

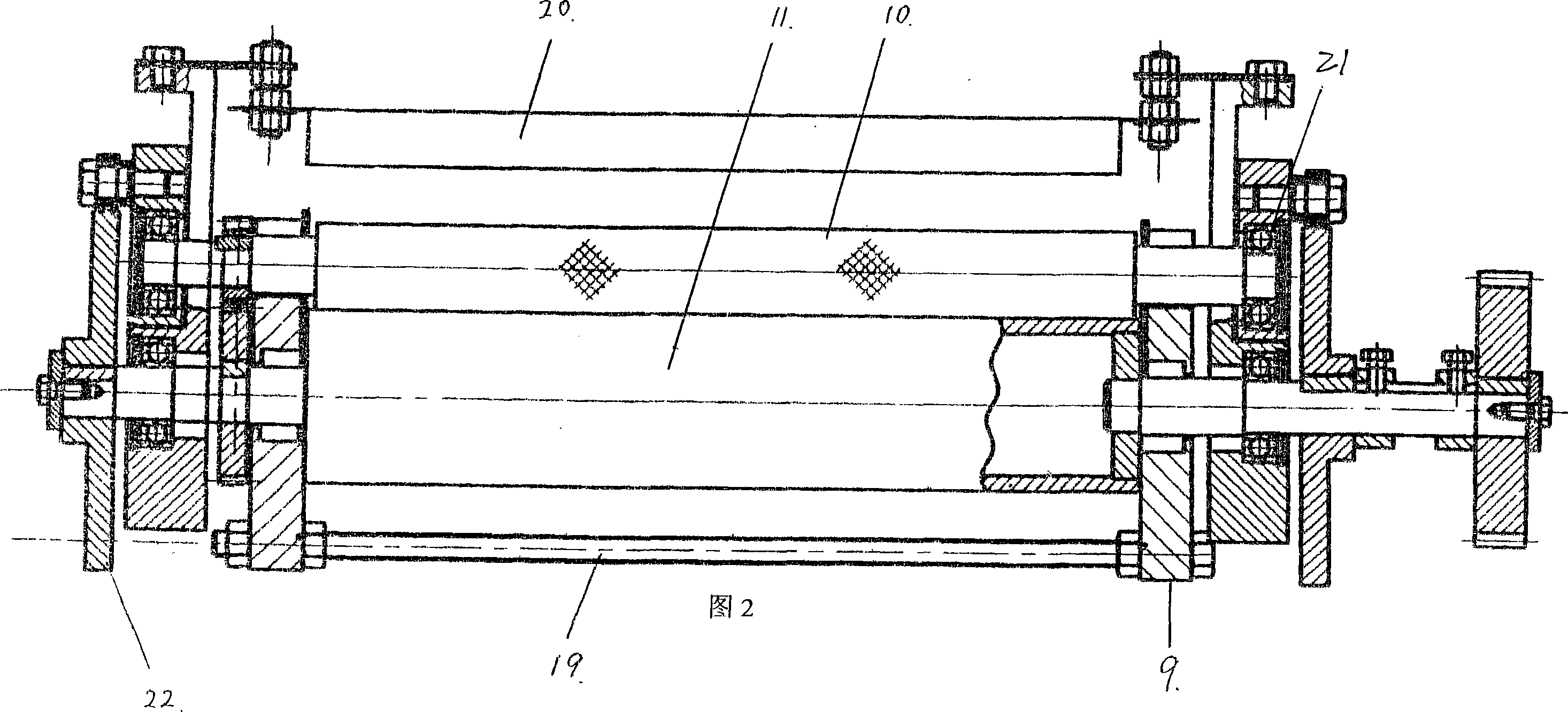

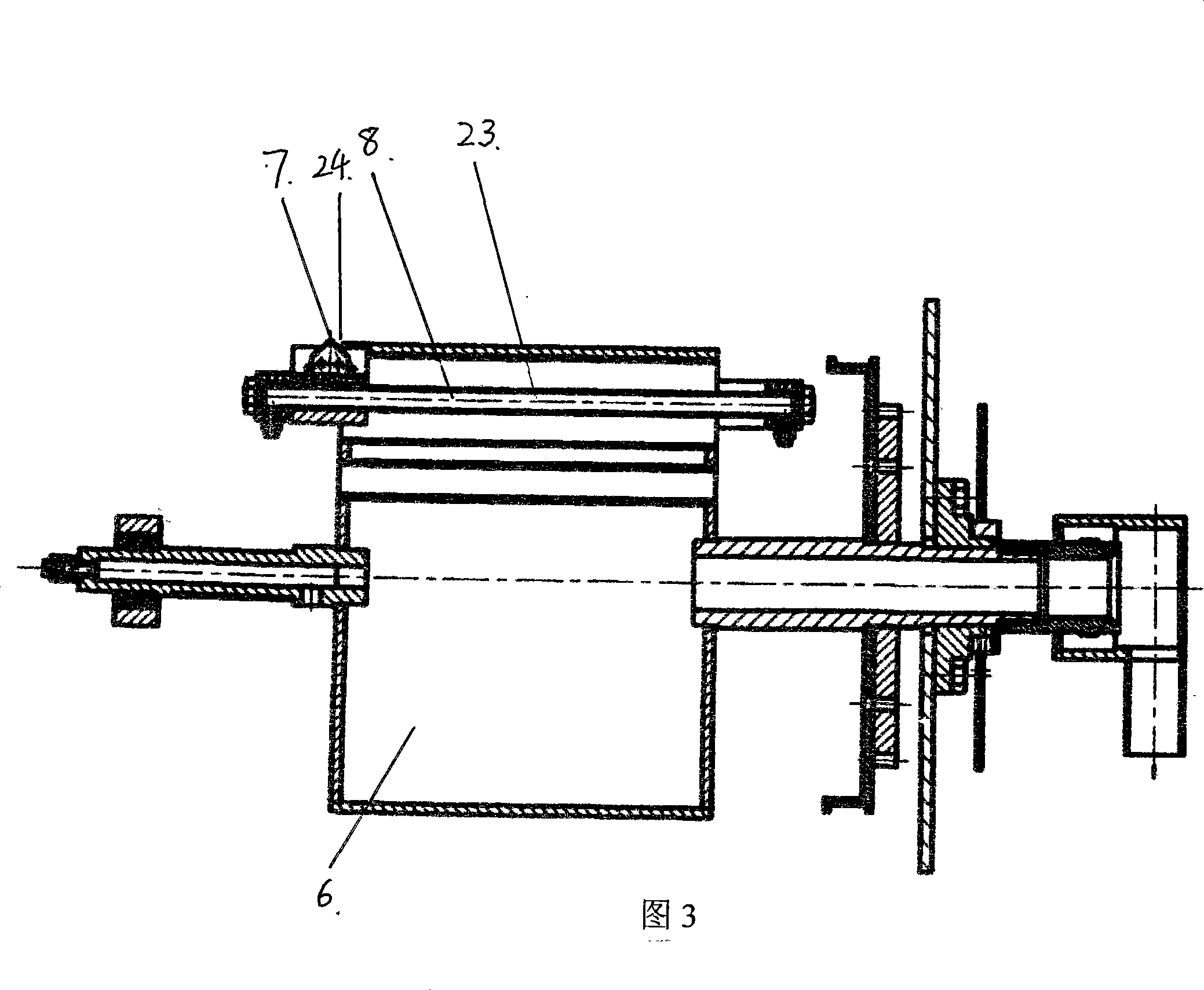

[0011] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0012] In the figure, 1 is the frame, 2 is the label, 3 is the labeling axis, 4 is the conveying shaft, 5 is the glue printer, 6 is the label suction roller, 7 is the cutter, 8 is the rodless cylinder, and 9 is the glue Box, 10 is a printing roller, 11 is a rubber hanging roller, 12 is a tank body, 13 is a tank box, 14 is a canister, 15 is a conveyor belt, 16 is a heat shrinker, 17 is a tension roller, 18 is Corrector, 19 is an electric heating tube, 20 is a top plate, 21 is a vertical guide rail, 22 is a cam, 23 is a guide groove, 24 is a knife slit, 25 is a canning plate, 26 is a canning main plate, and 27 is a sector The top block, 28 is the card slot, 29 is the pressure can assembly, 30 is the ejector rod, and 31 is the label feeding roller.

[0013] As shown in Figure 1, the present invention is an improved horizontal labeling machine, which is main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com