Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

59 results about "Lathe center" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A lathe center, often shortened to center, is a tool that has been ground to a point to accurately position a workpiece on an axis. They usually have an included angle of 60°, but in heavy machining situations an angle of 75° is used.

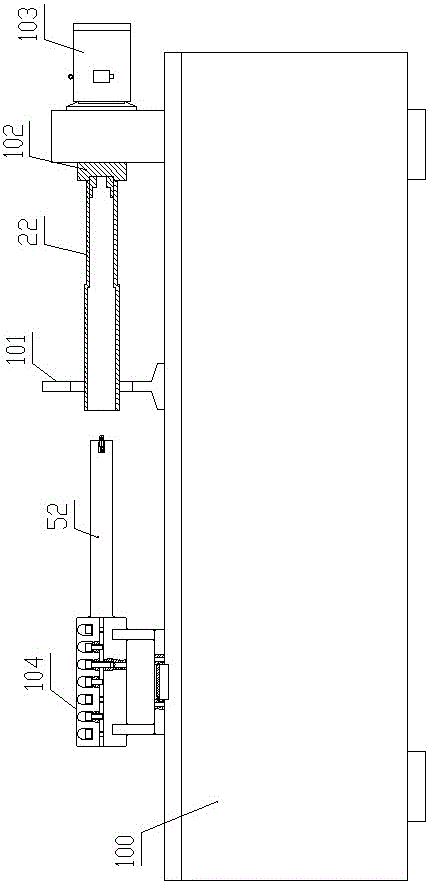

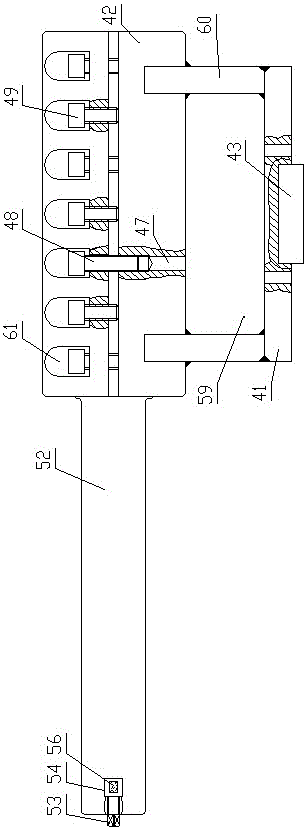

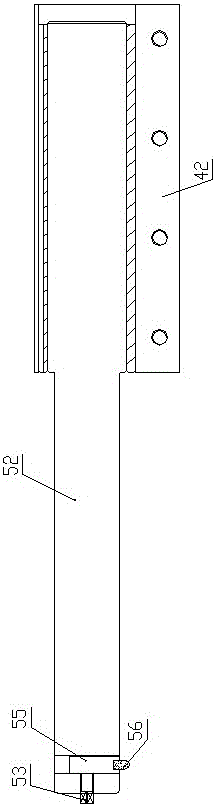

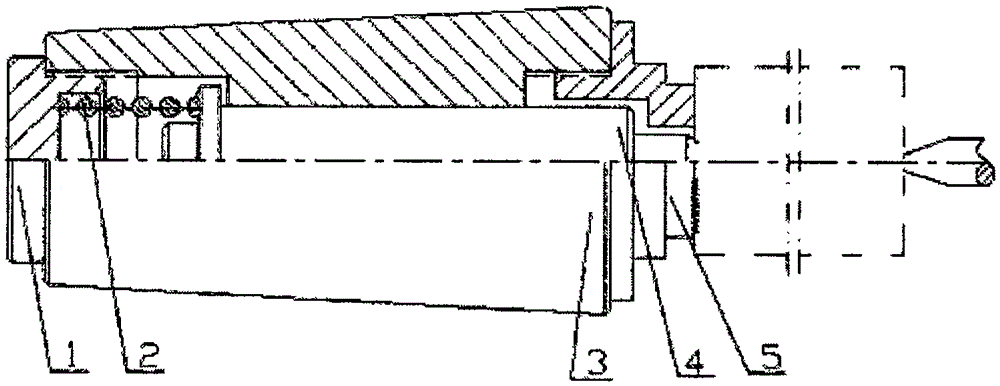

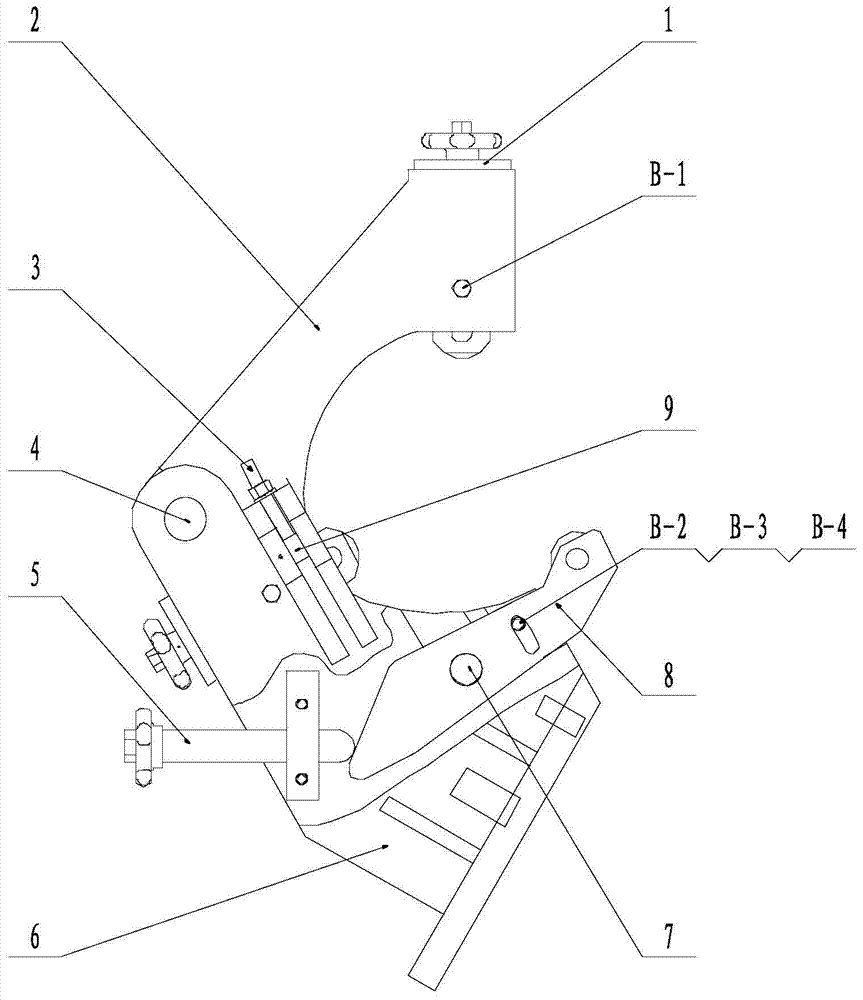

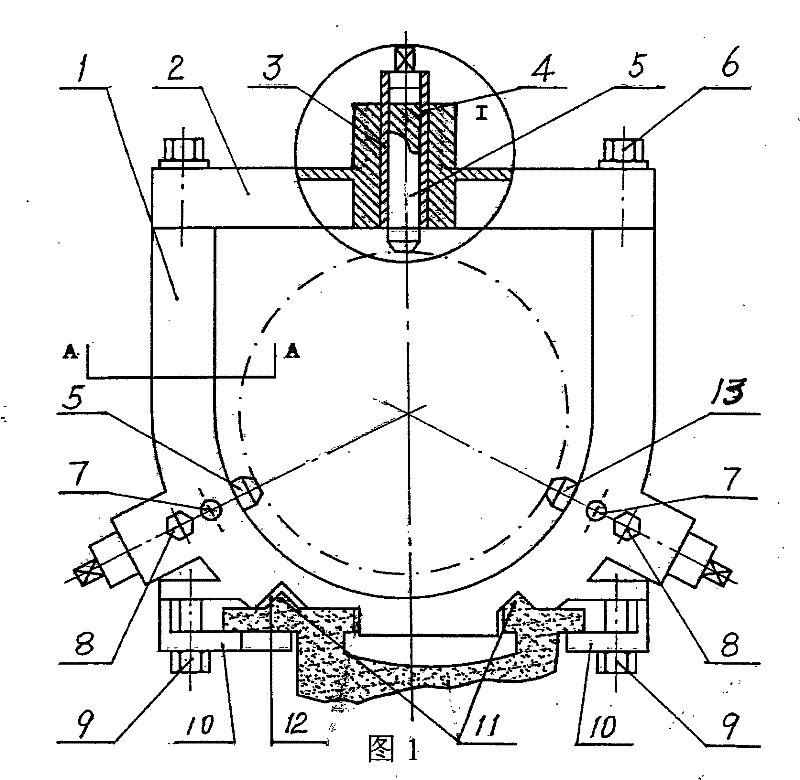

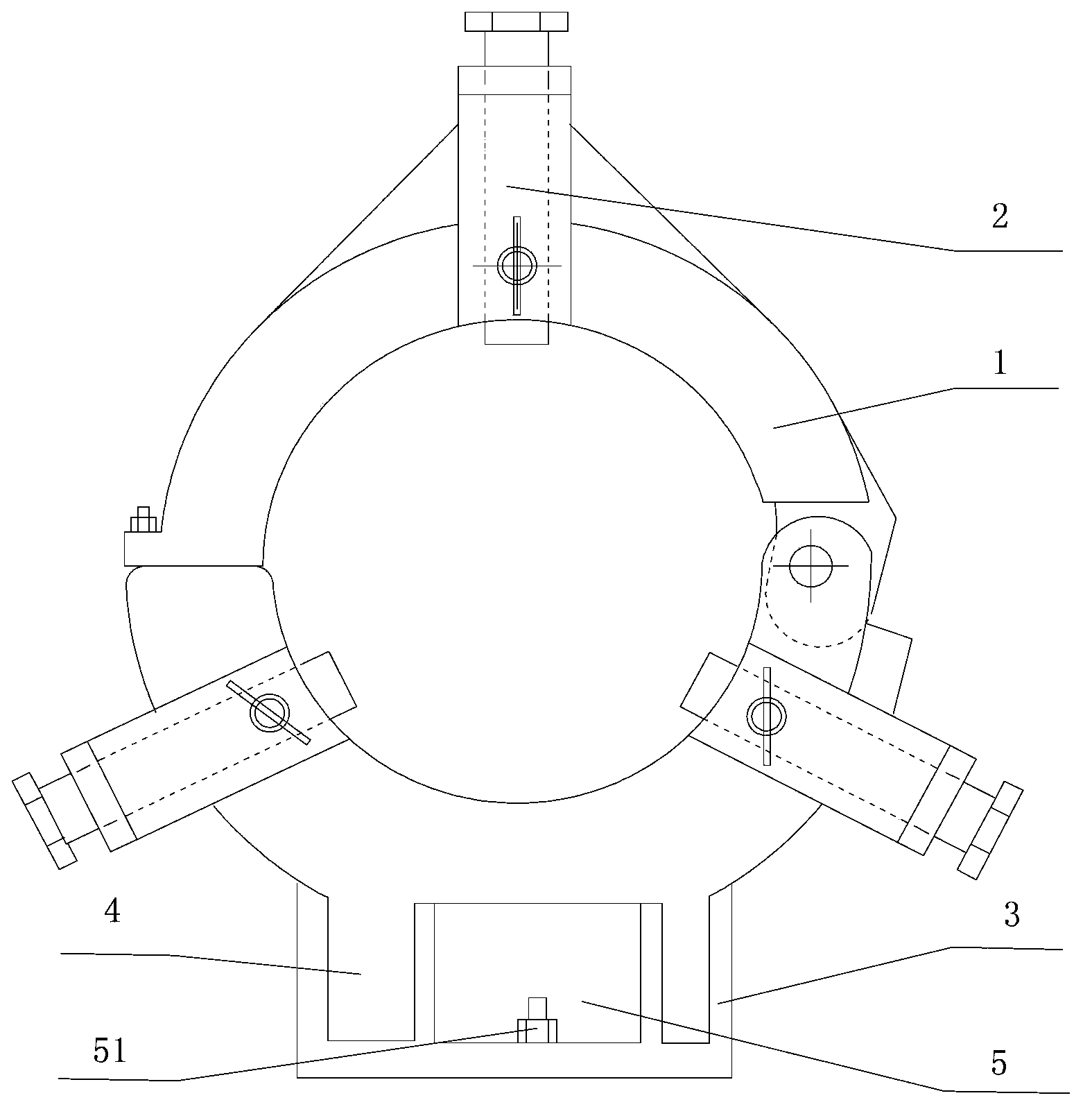

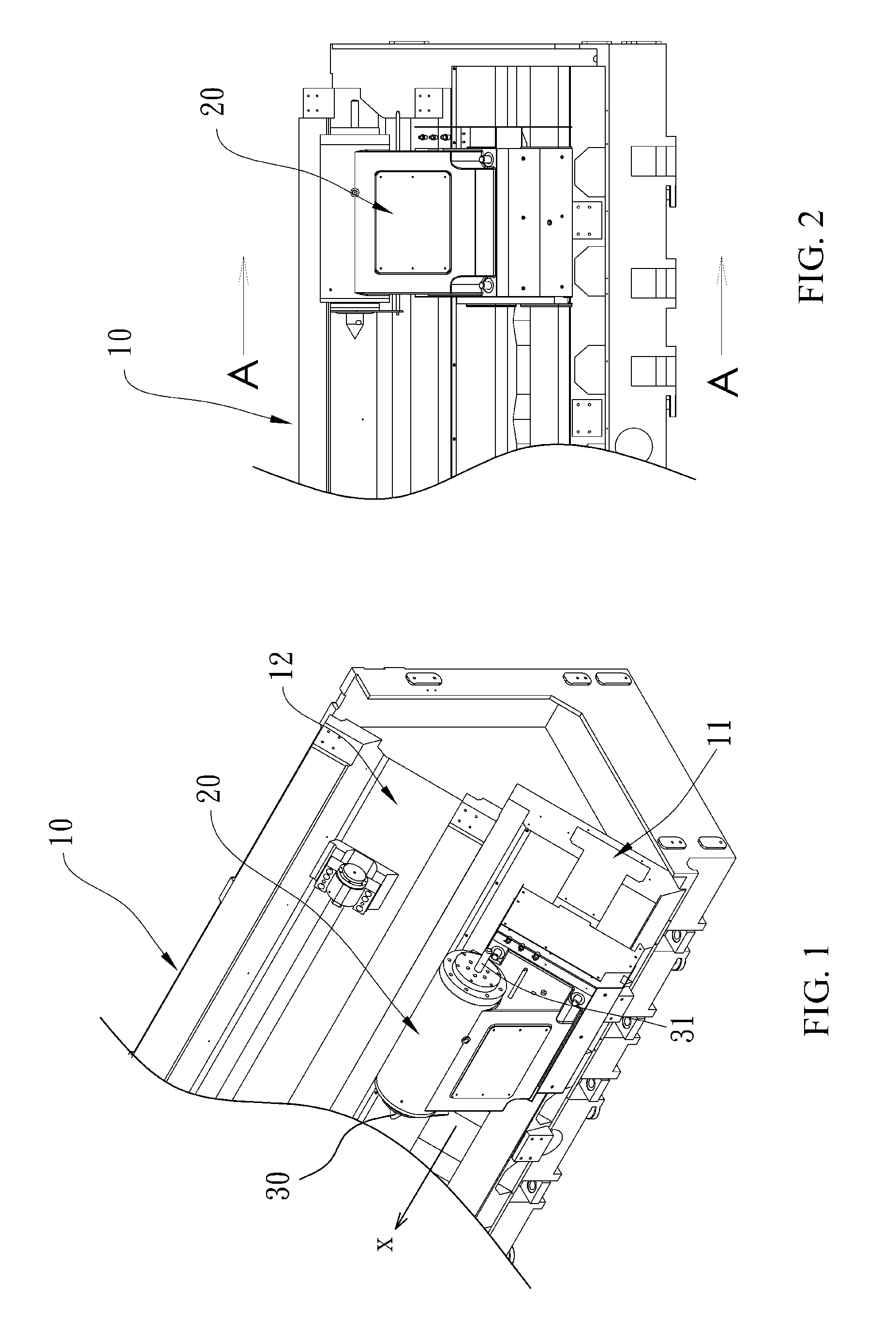

Lathe used for turning long rod class of parts

InactiveCN105880637ABe at easeEasy to holdTurning toolsTool holdersEngineeringMechanical engineering

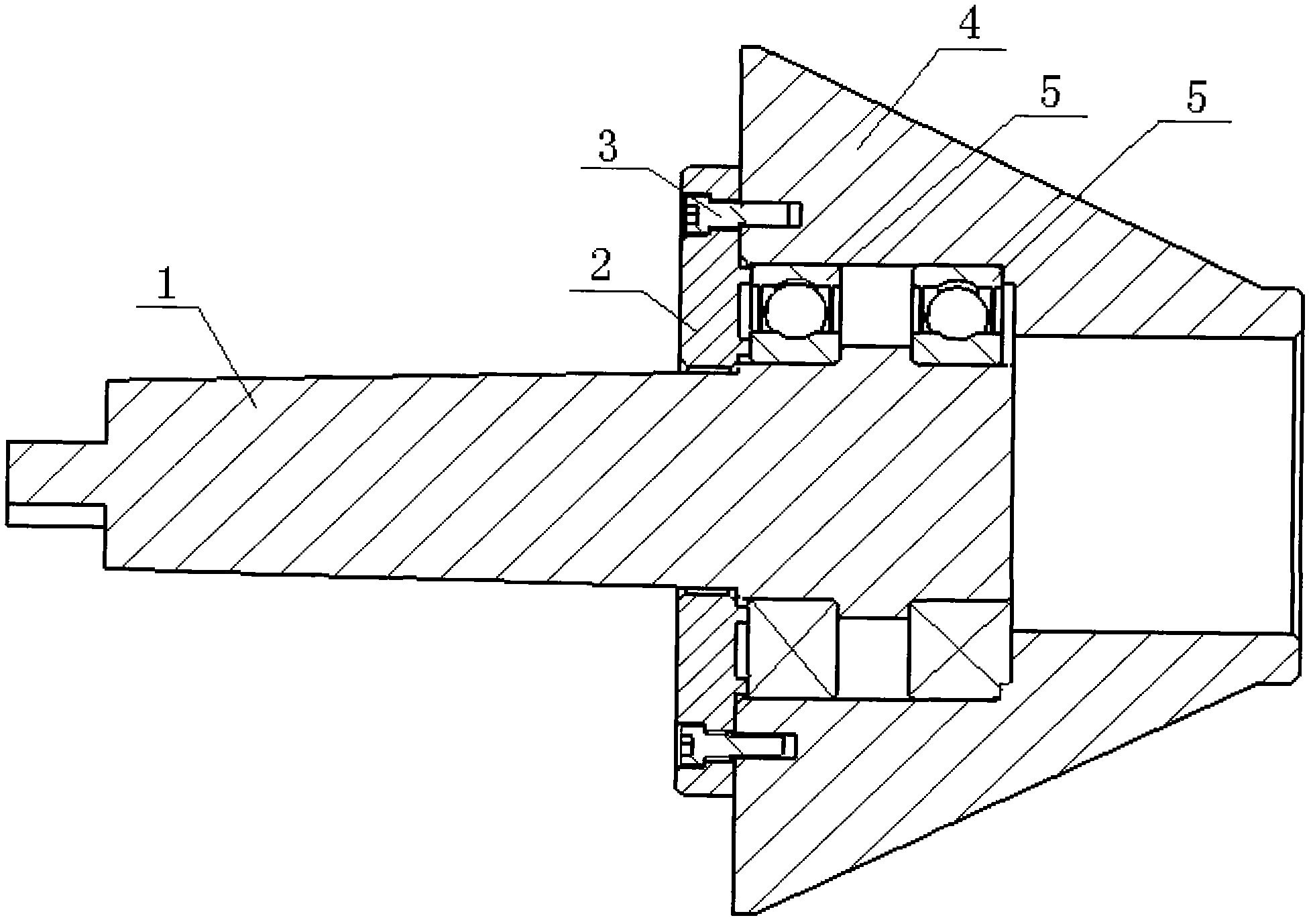

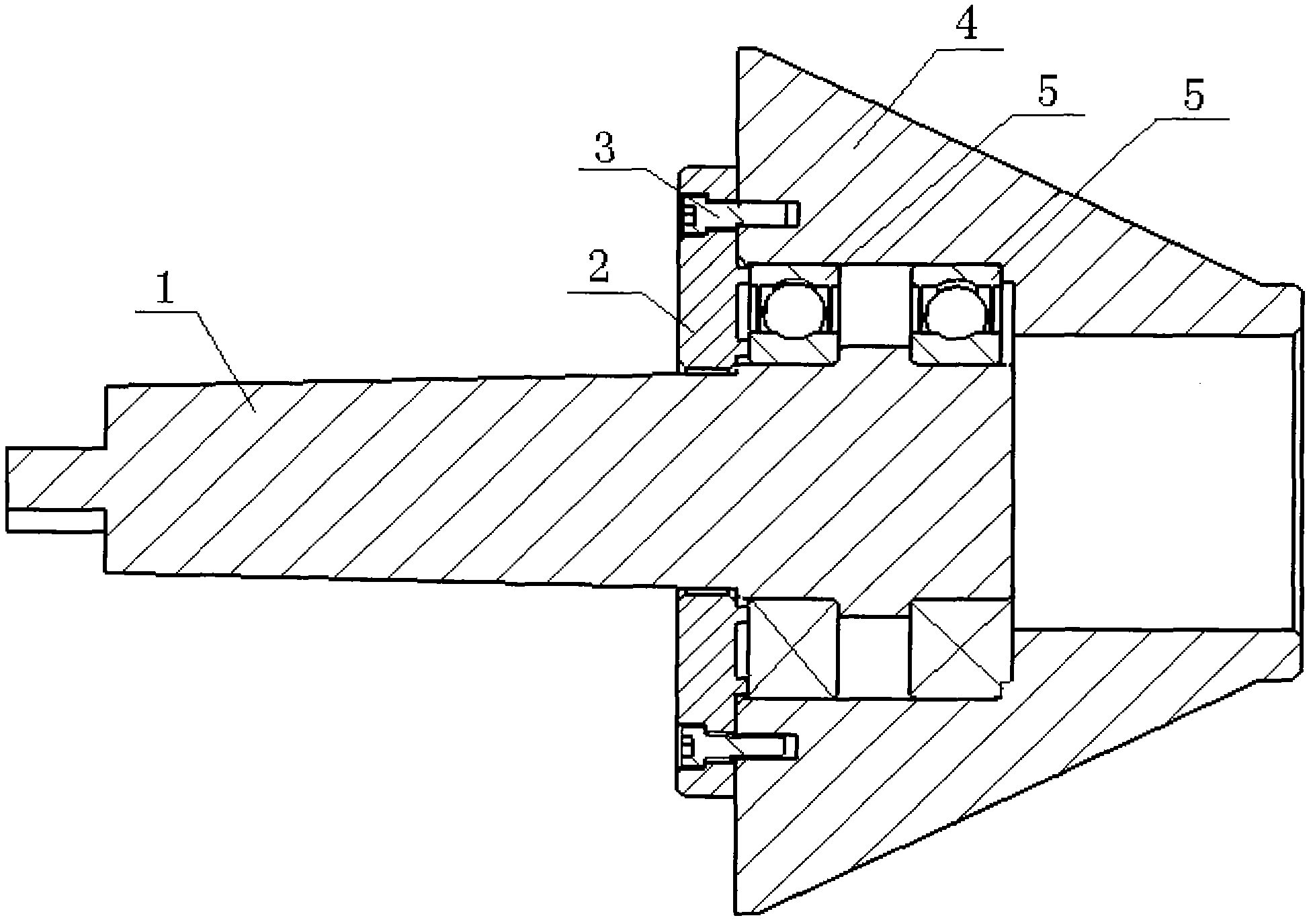

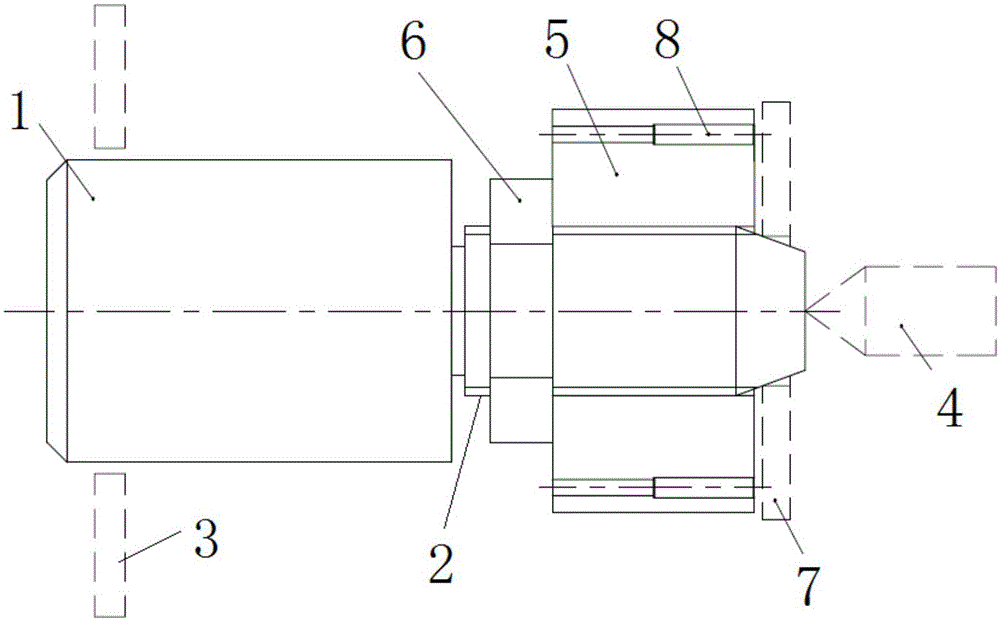

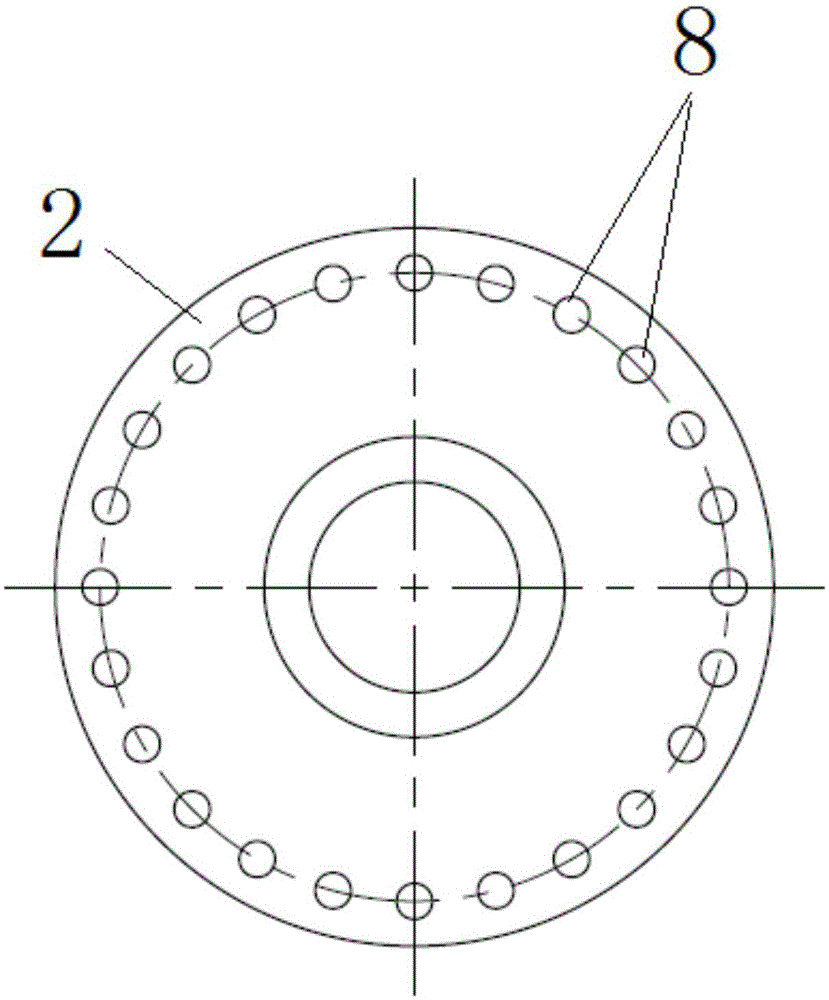

A lathe used for turning long rod class of parts comprises a lathe body, a cutter bar, a cutter bar clamping device, a clamping jaw type lathe center clamping device, a chuck and a motor, wherein the motor, the clamping jaw type lathe center clamping device and the cutter bar clamping device are fixed to the lathe body, and a main shaft of the motor is fixedly connected with the chuck; and the cutter bar clamping device comprises a horizontally arranged base, a cutter bar and a cutter bar sleeve, a positioning block protruding downwards out of the lower surface of the base is embedded in the bottom of the base, the base is fixedly connected with the cutter bar sleeve through a support base, the cutter bar sleeve is of a cylindrical structure, the central line of the cutter bar sleeve is horizontally arranged in the left and right direction, and a cylindrical mounting cavity is arranged in the cutter bar sleeve in the axial direction. The device is high in processing and turning precision, great in stability, low in defective rate and accurate in centering.

Owner:HUANGHE S & T COLLEGE

Lathe center frame

InactiveCN102441797AExtended service lifeReduce consumption costAuxillary equipmentLarge fixed membersBall bearingEngineering

The invention discloses a lathe center frame. A radial ball bearing is arranged in a slot at the middle of the front end of a clamping jaw which is used generally, and the radial ball bearing rotates around a workpiece under the action of a cutting force, thus abrasion of the clamping jaw is reduced. The invention has the advantages of prolonging the service life of a clamp and reducing the cost consumption through application.

Owner:陶晓明

Hot forming process for spoke

InactiveCN1721130AIncrease profitSave raw materialsOther manufacturing equipments/toolsPunchingEconomic benefits

This invention discloses thermoforming spoke technique and comprises steps: blanking, chamfering, rolling, welding, grinding, expanding, heating, forming, lathing center hole, punching screw hole, lathing surface and end face, trimming and packaging. It increases the utilization of steel material and economic benefit, decreases cost, enhances intensity of stretch-proofing and resistance to bending, and prolongs service life.

Owner:梁绪忠

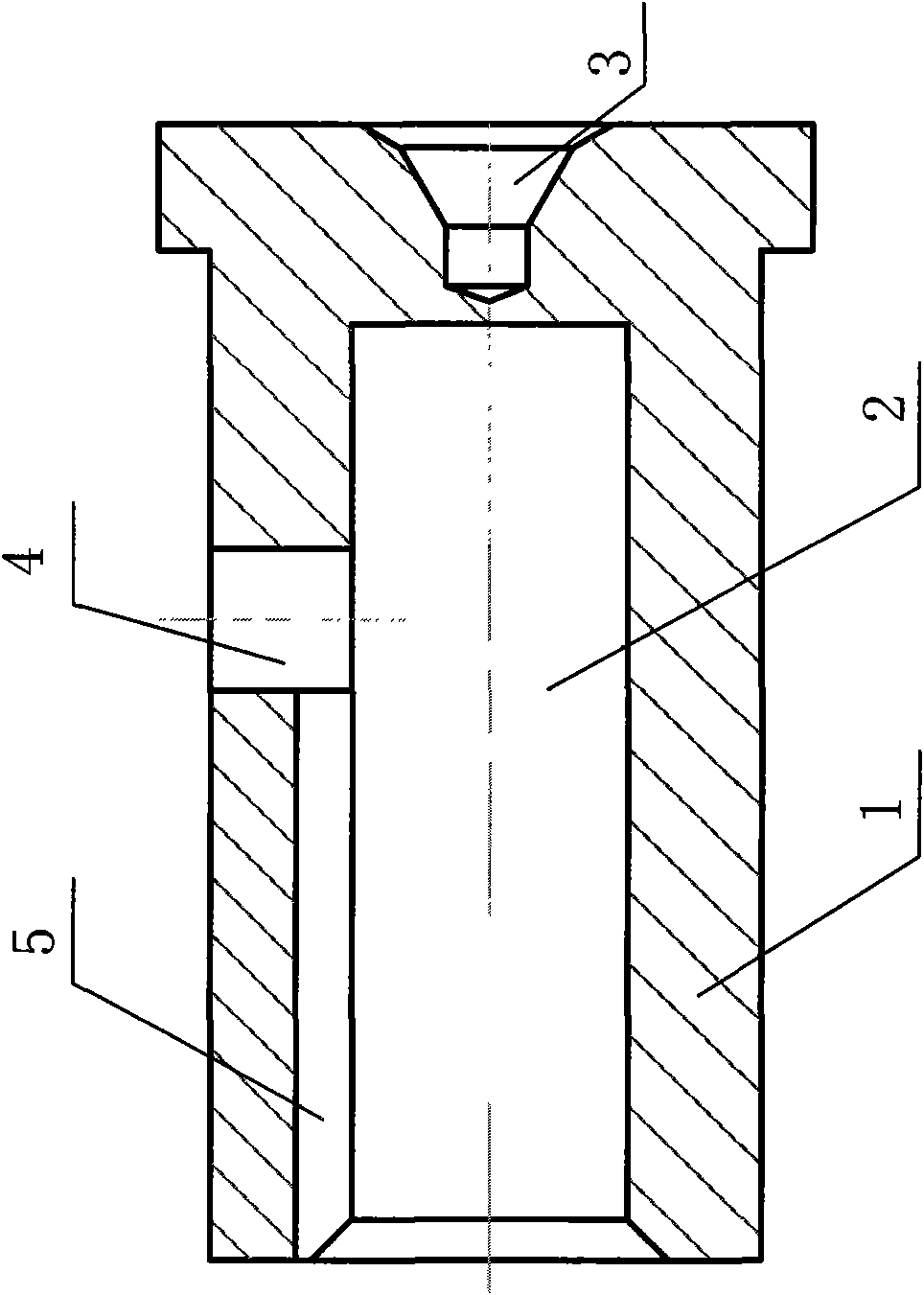

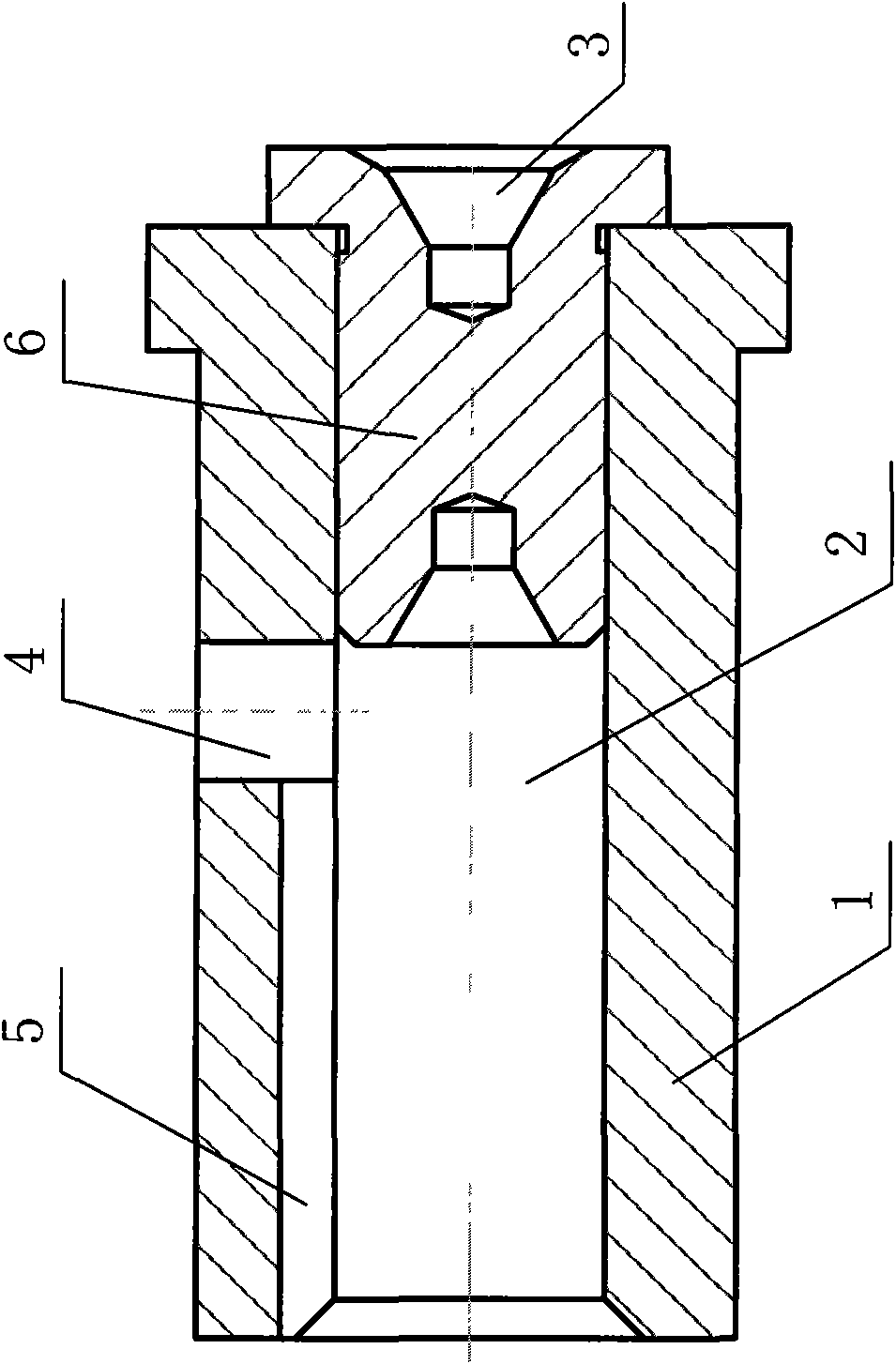

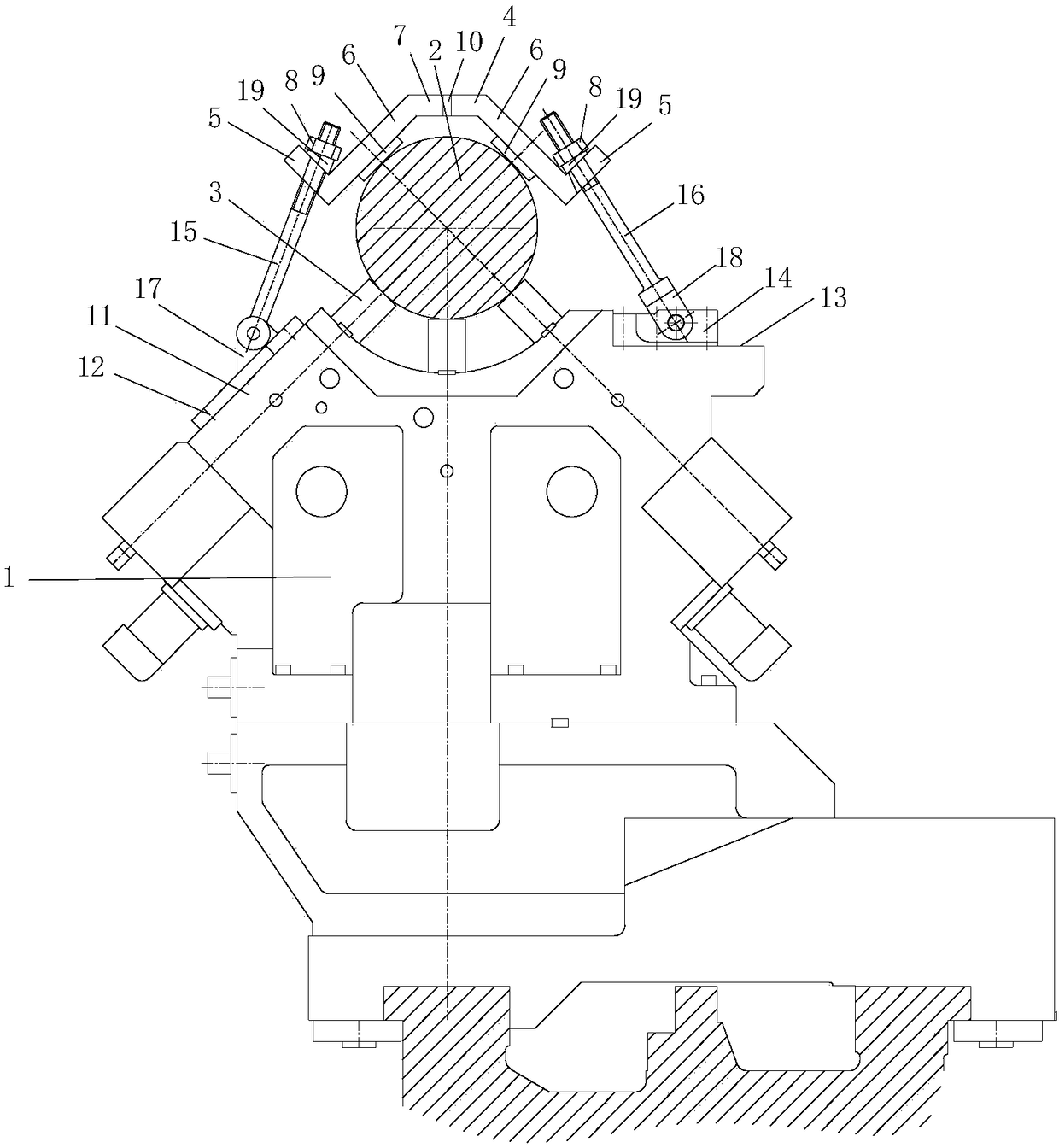

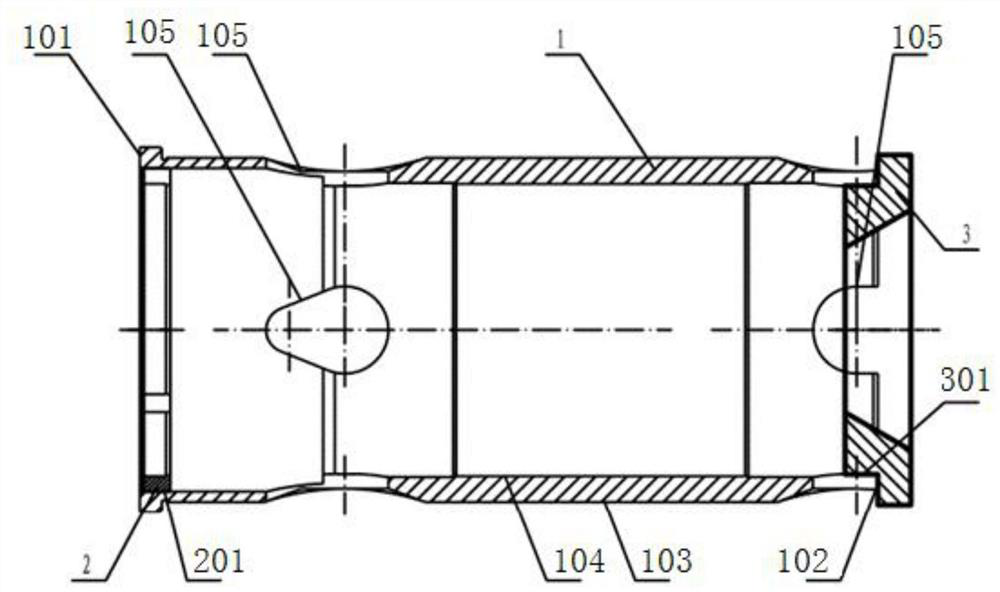

Lathe center

InactiveCN105414571AImprove processing speedImprove processing qualityTailstocks/centresEngineeringScrew thread

The invention discloses a lathe center. The lathe center comprises a plug screw, a spring, a Mohs taper, a mandrel center and an end face sharp tooth pusher dog; the plug screw is connected to the left end of the Mohs taper in a threaded manner, the end face sharp tooth pusher dog is connected to the right end of the Mohs taper in a threaded manner, and the diameter of the right end face of the end face sharp tooth pusher dog is 2 mm to 5 mm smaller than the diameter of a workpiece; sharp teeth are arranged on the end face of the end face sharp tooth pusher dog, and the mandrel center is arranged on an inner hole of the Mohs taper in a movable fit manner; and the spring is installed between the plug screw and a shaft shoulder of the mandrel center in a press fitting manner. By means of the lathe center, no-shutdown end face pulling is achieved, centering and pulling are combined, and the machining speed and quality are greatly improved.

Owner:张俊锋

Frock clamp for turning flange spigot of complete machine motor

InactiveCN101559567AImprove machining accuracySimple structurePositioning apparatusMetal-working holdersElectric machineryEngineering

The invention relates to a frock clamp used for turning a flange spigot of a complete machine motor which is assembled, comprising a fixed bushing with an inner hole; a key slot is opened on the wall of the inner hole at the socket joint end of the fixed bushing; the inner hole at the socket joint end is matched with the shaft extension of the motor to be turned; a center positioning hole which is coaxial with the inner hole of the bushing is arranged at the positioning end of the fixed bushing. The frock clamp uses the center positioning hole at the positioning end of the bushing instead of a center hole at the shaft extension end of the motor, uses keys to circumferentially fix the shaft extension of the motor with the key slot on the inner hole of the bushing and carries out turning on the flange spigot of the complete machine through fit of front and rear lathe centers with the center positioning hole of the bushing and a center hole at the non-shaft extension end of the motor. The frock clamp has the advantages of simple structure, reasonable design, low cost, easy operation, accurate positioning, high production efficiency and high processing precision of workpieces.

Owner:SHANDONG HUALI ELECTRIC MOTOR GRP

Center rest of horizontal lathe

InactiveCN106112575ASimple designEasy to useLarge fixed membersPositioning apparatusPetroleum engineeringLathe center

Owner:ANHUI RUIJIE FORGING

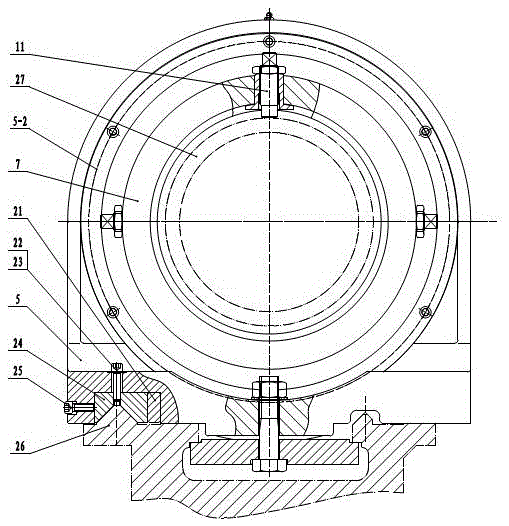

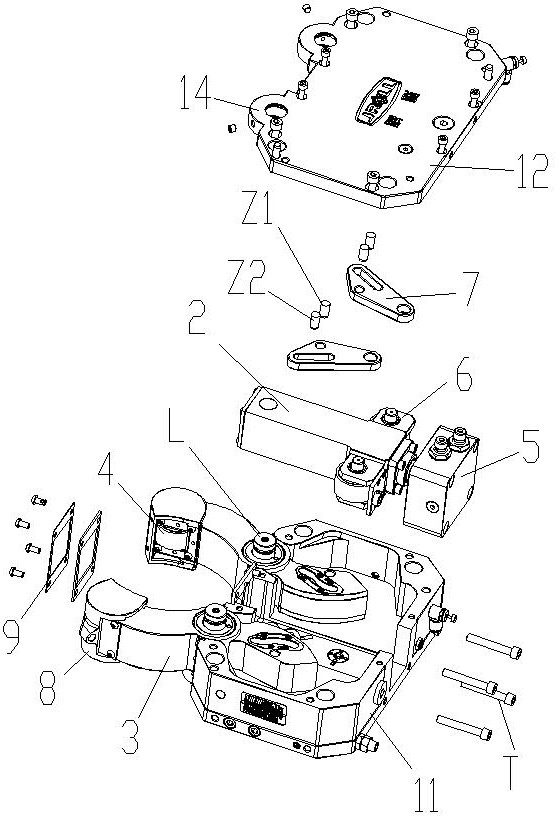

Semi-closed numerical control lathe center frame

ActiveCN103612128AMeet the requirements for clamping thin-walled cylindrical partsSolve clamping problemsLarge fixed membersNumerical controlEngineering

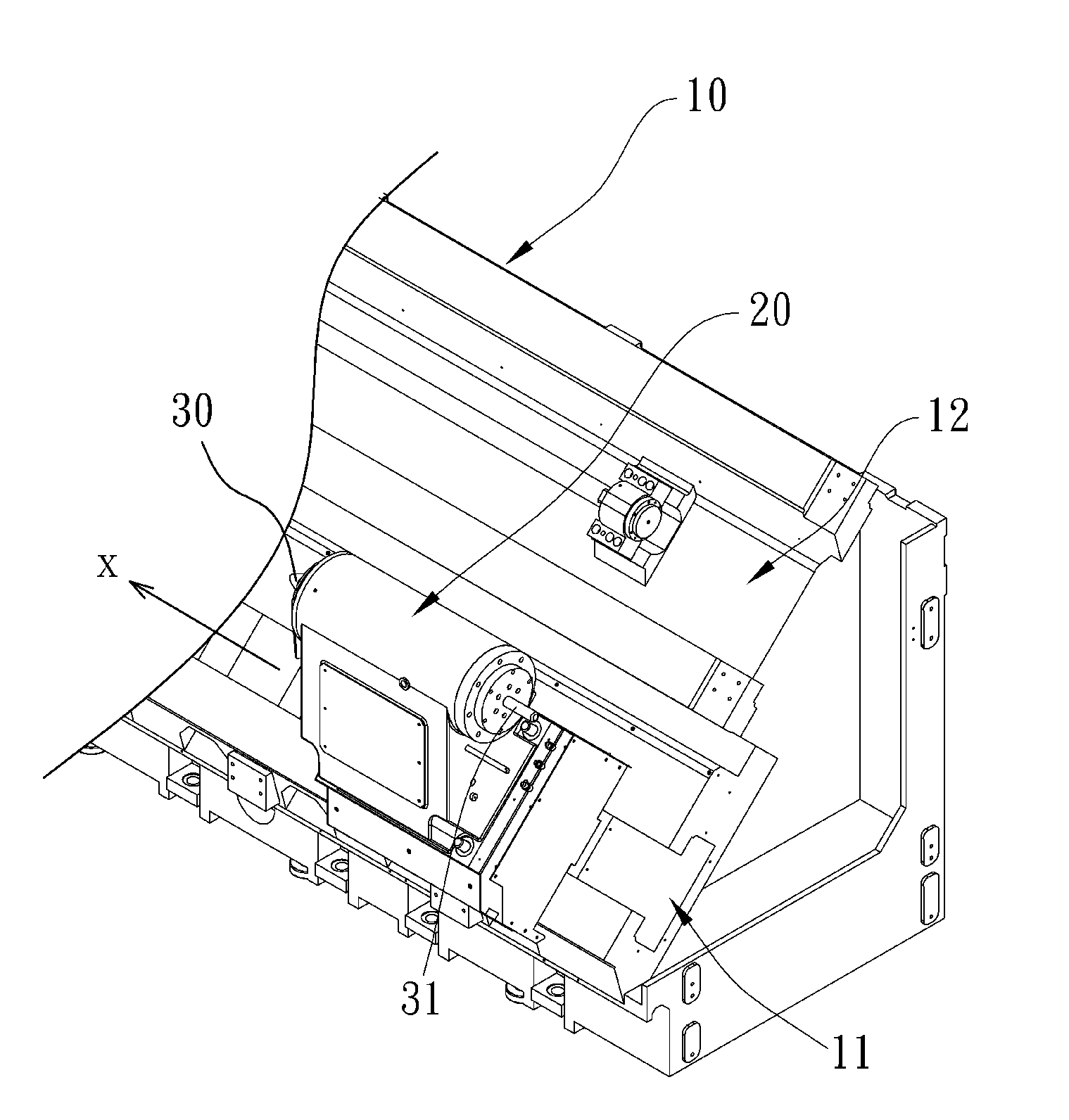

The invention discloses a semi-closed numerical control lathe center frame. A first guide block assembly is arranged at one end of a roll-over frame, and the other end of the roll-over frame is connected with a base through a roll-over frame rotary shaft and can rotate around the roll-over frame rotary shaft; a second guide block assembly is arranged on the base, and a fixing screw rod is arranged between the roll-over frame and the base; a rotary block assembly is connected with the base through a rotary block rotary shaft, and a rotary block adjusting screw rod is arranged on the base and abuts against the plane on one side of the rotary block assembly. By adjusting guide blocks and rotary blocks manually, the semi-closed numerical control lathe center frame achieves machining of thin-wall cylindrical elements, and solves the clamping problem of a numerical control lathe in machining thin, long and thin-wall parts. After the roll-over frame is opened, the parts are clamped on a three-jaw chuck of the numerical control lathe, and after primary clamping of the thin-wall cylindrical elements is finished, the roll-over frame is closed and fixed through a nut on the fixing screw rod; the guide blocks and the rotary blocks are adjusted, so that the middle portions of the thin-wall cylindrical elements are clamped. The semi-closed numerical control lathe center frame can meet the requirement that the numerical control lathe clamps the thin-wall cylindrical elements.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

Processing tooling for external circle of tube stock

InactiveCN104551729AStable supportImprove work efficiencyPositioning apparatusMetal-working holdersEngineeringCast iron pipe

The invention relates to a processing tooling for an external circle of a tube stock. The processing tooling comprises a disc and a stopping iron welded with the disc, wherein a cylinder and stretching rods are arranged in the disc; a plurality of through holes, through which the stretching rods can stretch, are uniformly distributed in a side wall of the disc; a central hole matched with the taper degree of the lathe center is formed in the center of the stopping iron; a lug boss is arranged on the middle part of the stopping iron; the lug boss is in a circle shape which is matched with the inner diameter of a centrifugal cast iron pipe; the quantity of the stretching rods is at least three and the original long baffle is changed into a circular baffle, so that the supporting force of the baffle for the end face of the centrifugal cast iron pipe is increased. An adjusting bolt is changed into a pneumatic stretching rod, so that the manual operation is reduced and the working efficiency is increased.

Owner:CHANGZHOU HAO RUI TOOLS

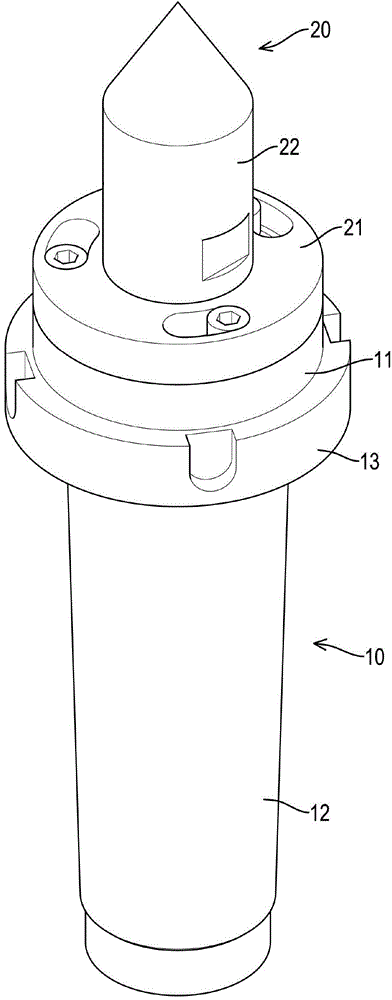

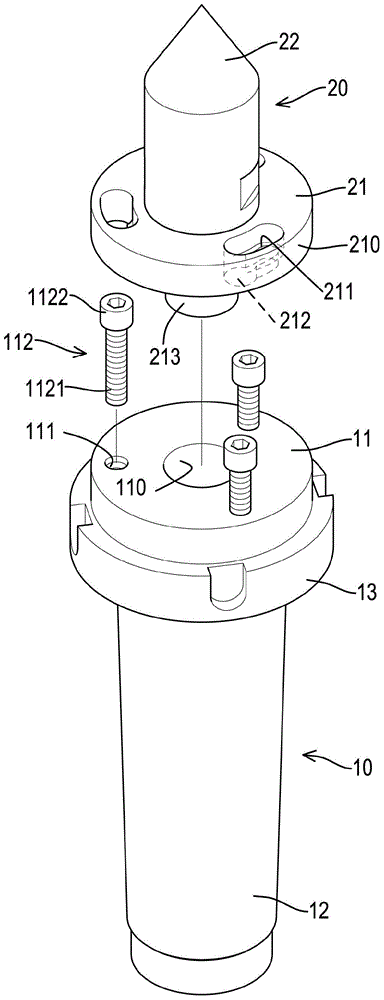

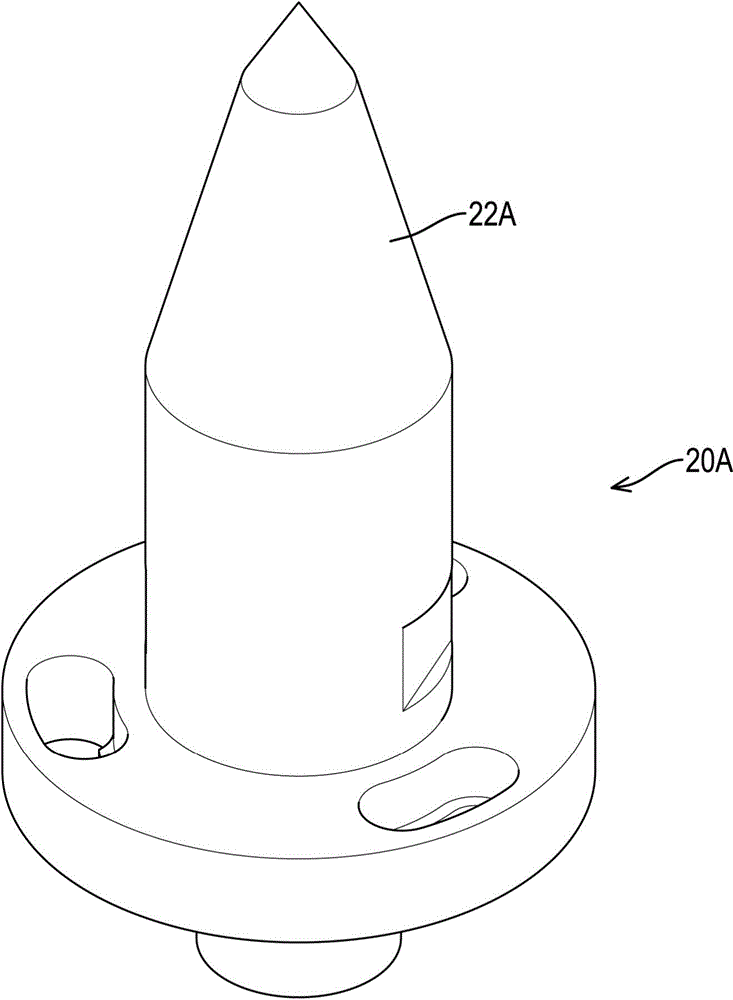

Centre device with various shapes of heads capable of being quickly replaced

The invention relates to a centre device with various shapes heads capable of being quickly replaced. The center device comprises a lathe center handle and a head replacing part, wherein the lathe center handle comprises a handle part and a head part formed at the top end of the handle part, the head part is provided with a containing part, the head replacing part comprises an abutting seat part and a mounting part arranged at the top end of the abutting seat part, and the head replacing part is detachably arranged at the containing part in a concave-convex corresponding manner by virtue of the mounting part; according to the centre device, the head replacing part with multiple different shapes can be replaced on the lathe center handle, by only unscrewing a locking piece and passing through a sliding hole and a through hole to lock and loosen the head replacing part in a rotating manner without completely removing the locking piece, the head replacing part can be used for processed objects of different shapes, and the aims of high applicability, low cost and quickly replacing are achieved.

Owner:庄增信

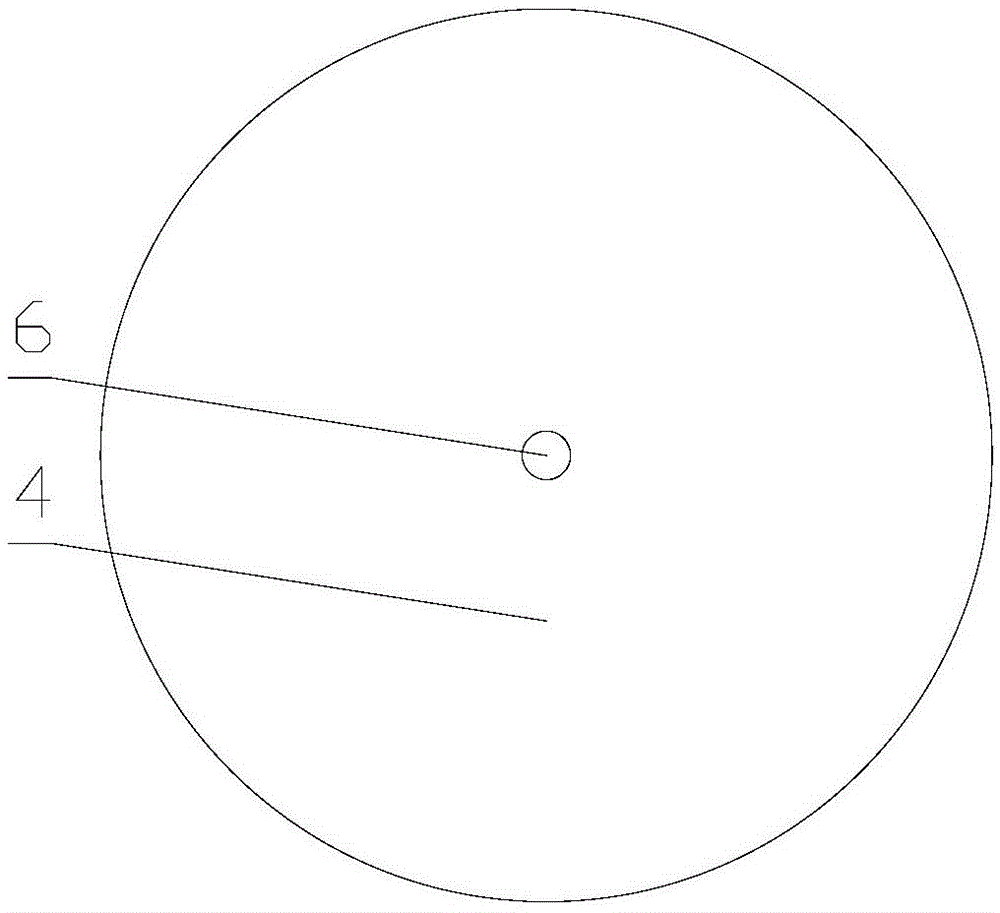

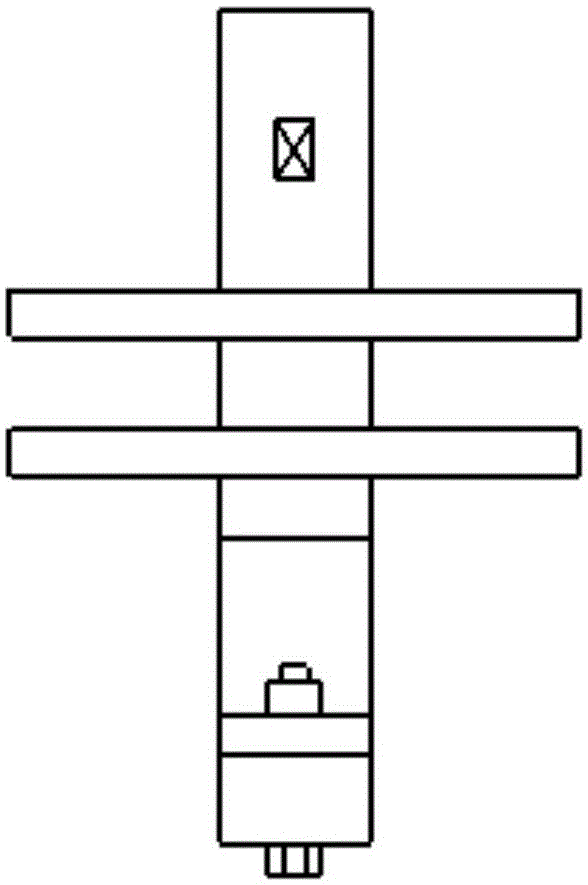

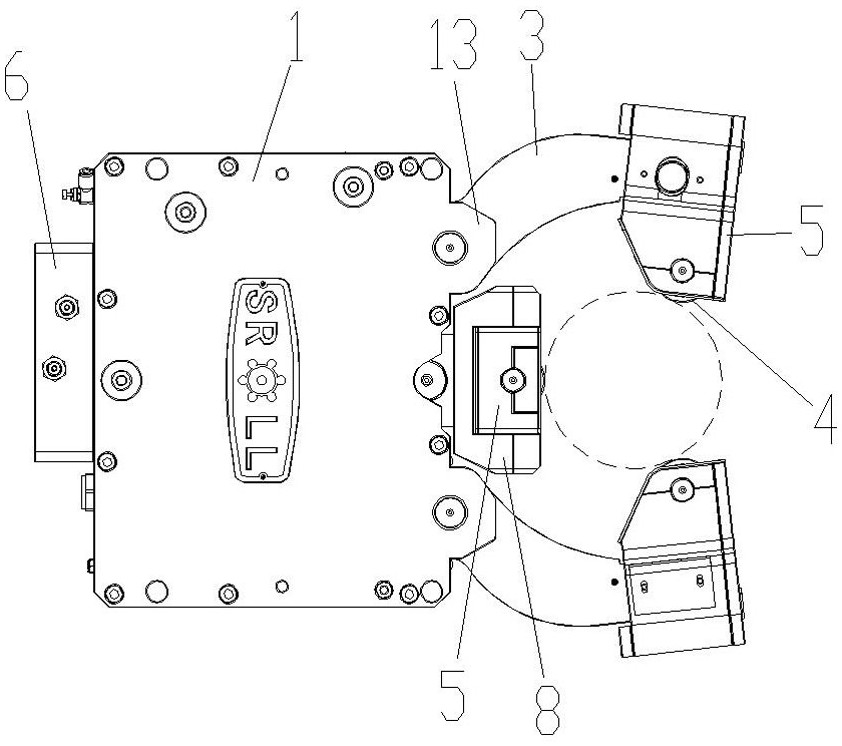

Lathe center frame and use method thereof

The invention discloses a lathe center frame and a use method thereof and belongs to the technical field of lathe equipment. The lathe center frame comprises a frame base, a bearing, an inner sleeve and compression screws for a machined workpiece, wherein the frame base comprises a base fixed to a lathe guide rail and an outer sleeve; the outer sleeve is fixed to the upper portion of the base; the inner sleeve extends into the middle of the outer sleeve; the inner sleeve and the outer sleeve are rotationally connected through the bearing; the front end of the inner sleeve extends out of the front end face of the outer sleeve; the sleeve wall of the front end of the inner sleeve is provided with at least three threaded holes in the radial direction; the threaded holes are evenly distributed in the circumference of the sleeve wall; the compression screws for the machined workpiece are installed inside the threaded holes. The use method of the lathe center frame comprises the steps that the compression screws are fastened to compress the machined workpiece, circular runout of the machine workpiece is detected through a dial indicator until the circular runout is the minimum, and the compression screws are fastened finally. The lathe center frame is especially suitable for machining thin and long workpieces, the rigidity of the workpieces is increased, deformation is reduced, the machining accuracy is improved, the working procedures are reduced, and the work efficiency is improved.

Owner:THE THIRD COAL MINE MACHINERY LTD OF ZHANGJIAGANG

Unblocked long roller claw lathe center rest

ActiveCN106312596AImprove rigidityEven by forceMachine tool componentsLarge fixed membersKnife holderPetroleum engineering

The invention provides an unblocked long roller claw lathe center rest. The center rest is an open-type rest which can ensure enough rigidity and opens toward a lathe saddle. Three long roller claw mechanisms are arranged on the center rest at an equal interval; one of the three long roller claw mechanisms is arranged under a central line of a lathe, which can ensure even stress on a slender shaft type work piece; during turning of the slender shaft type work piece, constant turning can be performed on the work piece on the center rest, unlike the common center rest, turning needs stopping due to block of the center rest during turning of the slender shaft type work piece on the center rest, after the work piece at one side of the center rest is machined, the center rest is moved, and turning of the work piece at the other side of the center rest is performed. The unblocked long roller claw lathe center rest has high working efficiency in turning of slender shaft type work pieces; through the long roller claw mechanisms, the support length of the slender shaft type work pieces is lengthened, the rigidity of the slender shaft type work pieces is greatly enhanced, and the turning quality of the slender shaft type work pieces is impoved.

Owner:许飞

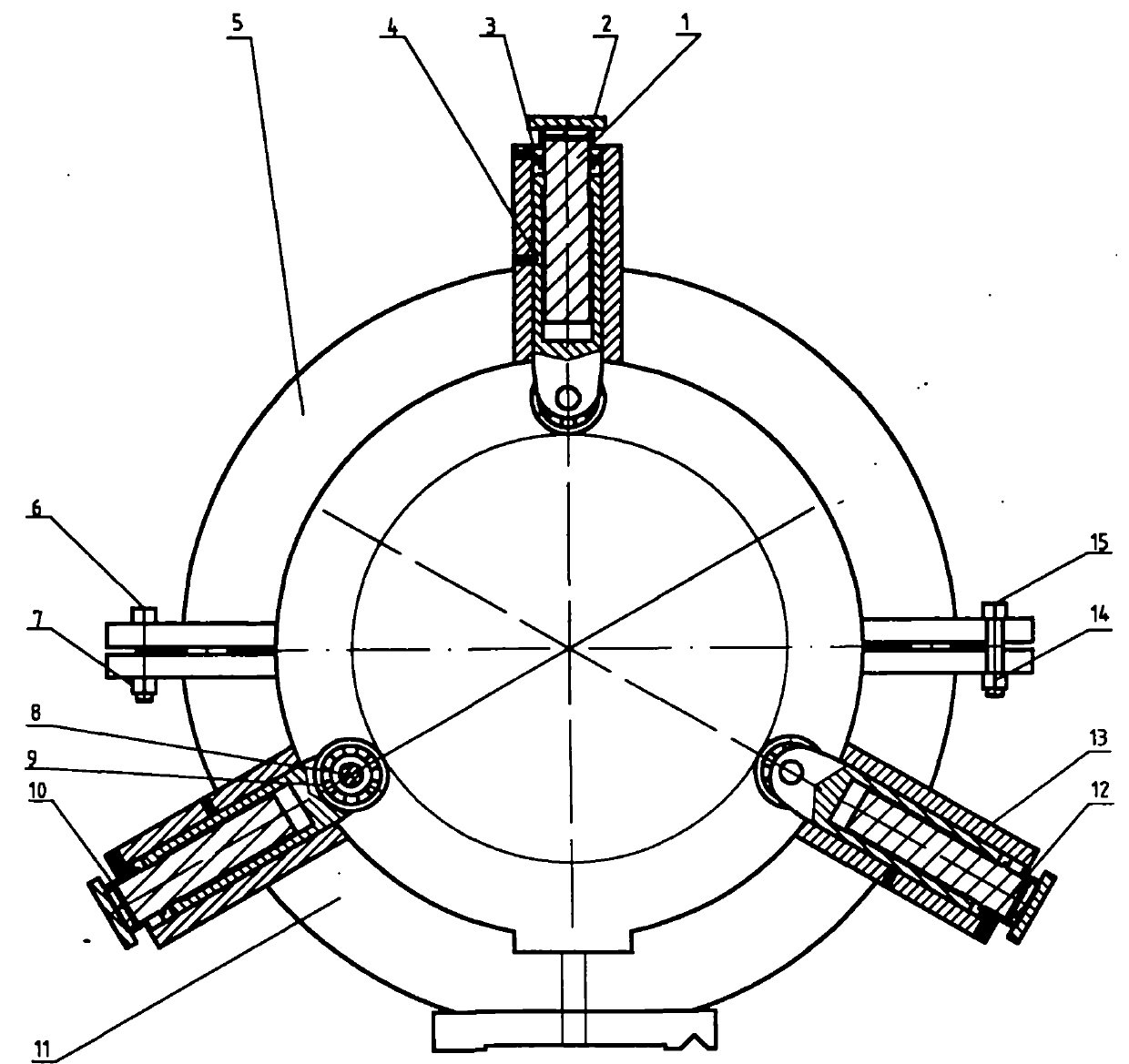

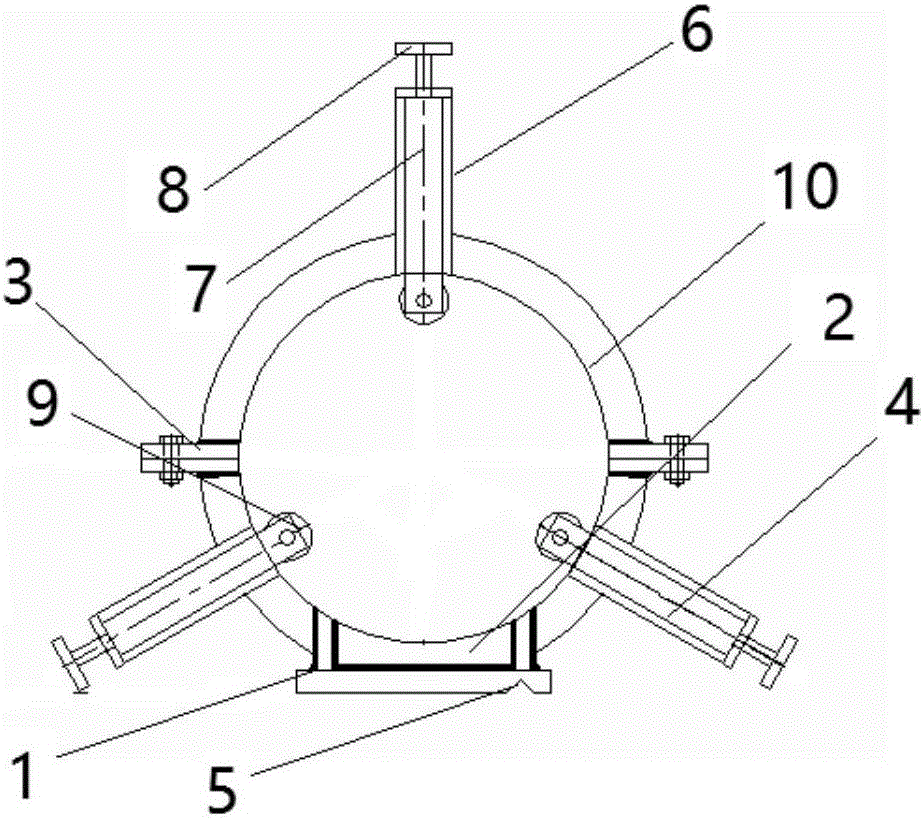

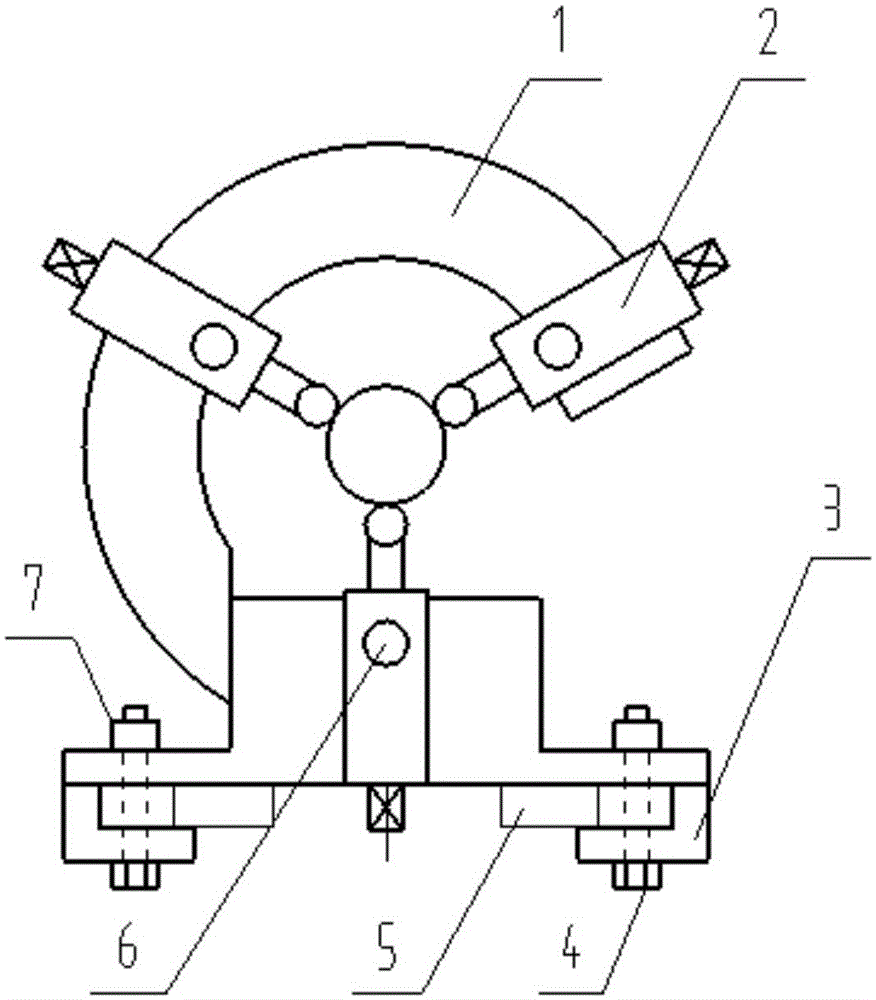

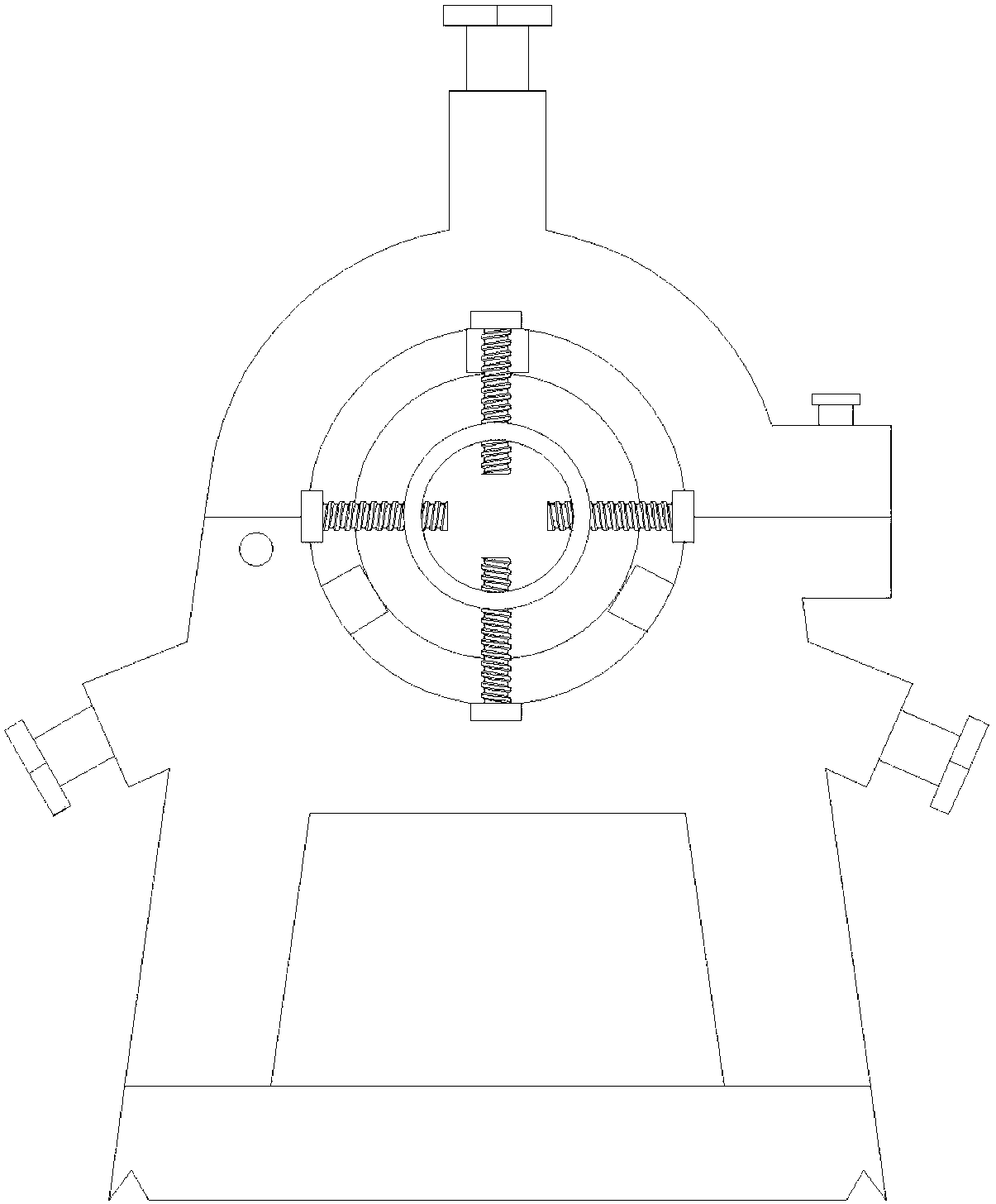

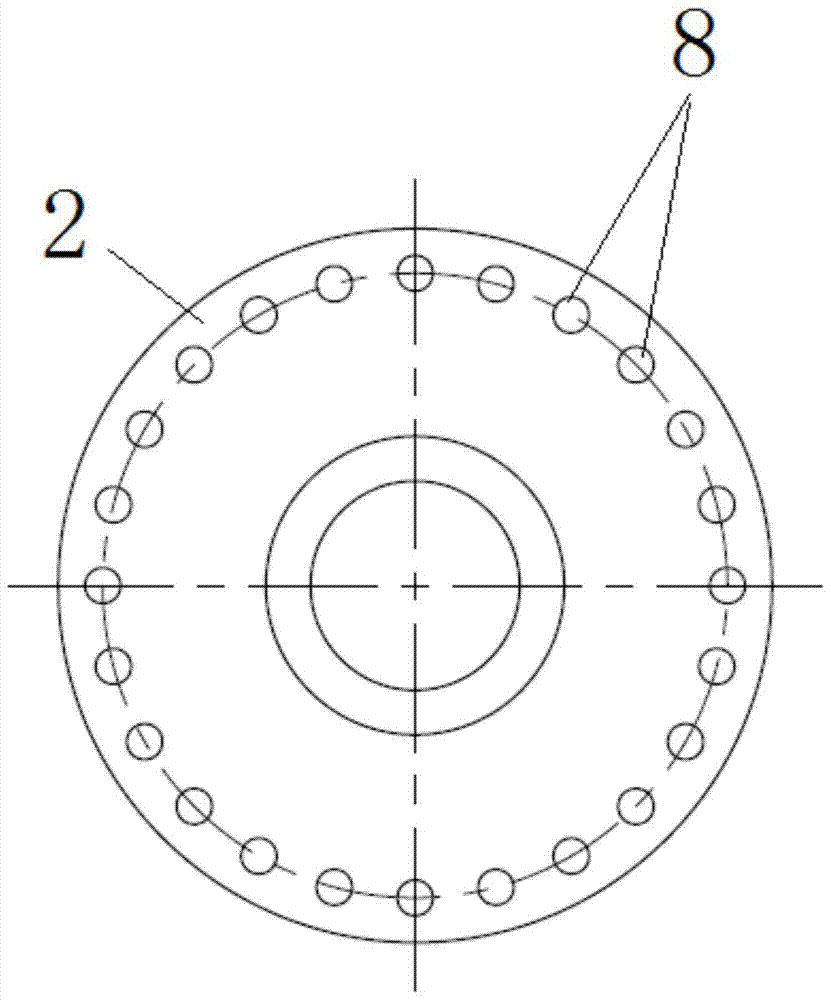

Horizontal lathe center frame

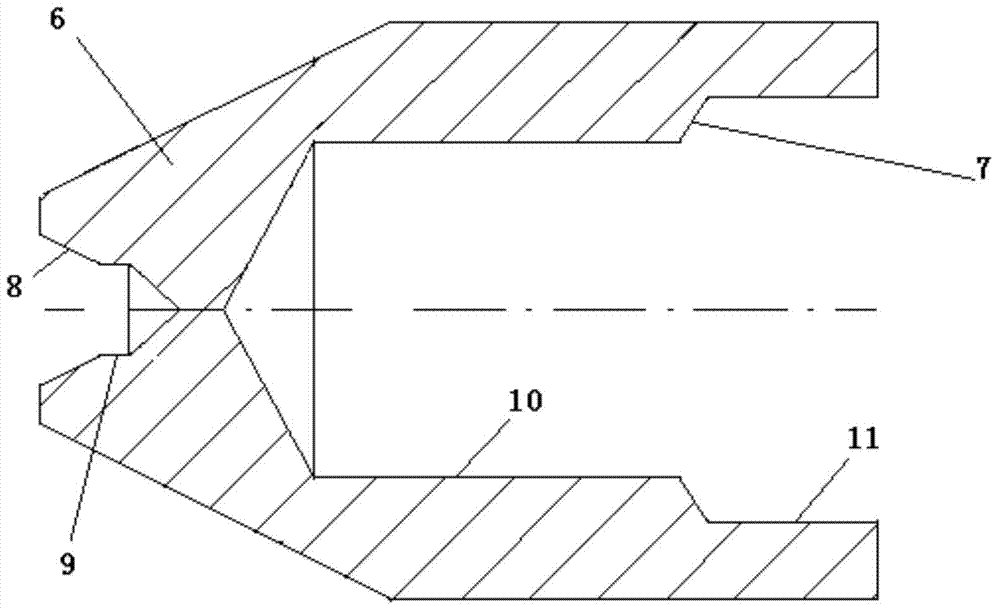

InactiveCN101456130AReasonable structural designExtended service lifeLarge fixed membersIsoetes triquetraMechanical engineering

The invention relates to a center frame of a horizontal lathe. The center frame comprises an upper frame body (2), a lower frame body (1), a fixing bolt (6) for connecting the two bodies, a pressing plate bolt (9) and a pressing plate (10), and is characterized in that the upper frame body (2) and the lower frame body (1) are U-shaped frames, a frame body adjusting mechanism is respectively arranged on the position of an equilateral triangle formed by two corresponding sides of the lower frame body (1) and the middle part of the upper frame body (2) centering on the incenters of the U-shaped frames, and simultaneously guide rail grooves (12) mounted to match a guide rail (11) of the lathe are arranged on the two sides of the U-shaped lower frame body (1) and are fixedly connected to the outside of the guide rail (11) of the lathe through the mounting pressing plate (10) and the pressing plate bolt (9). The center frame has the advantages of reasonable structure, long service life, safety and reliability, capability of processing long and large workpieces, large processing space, convenient use and adjustment, and the like.

Owner:李雨波

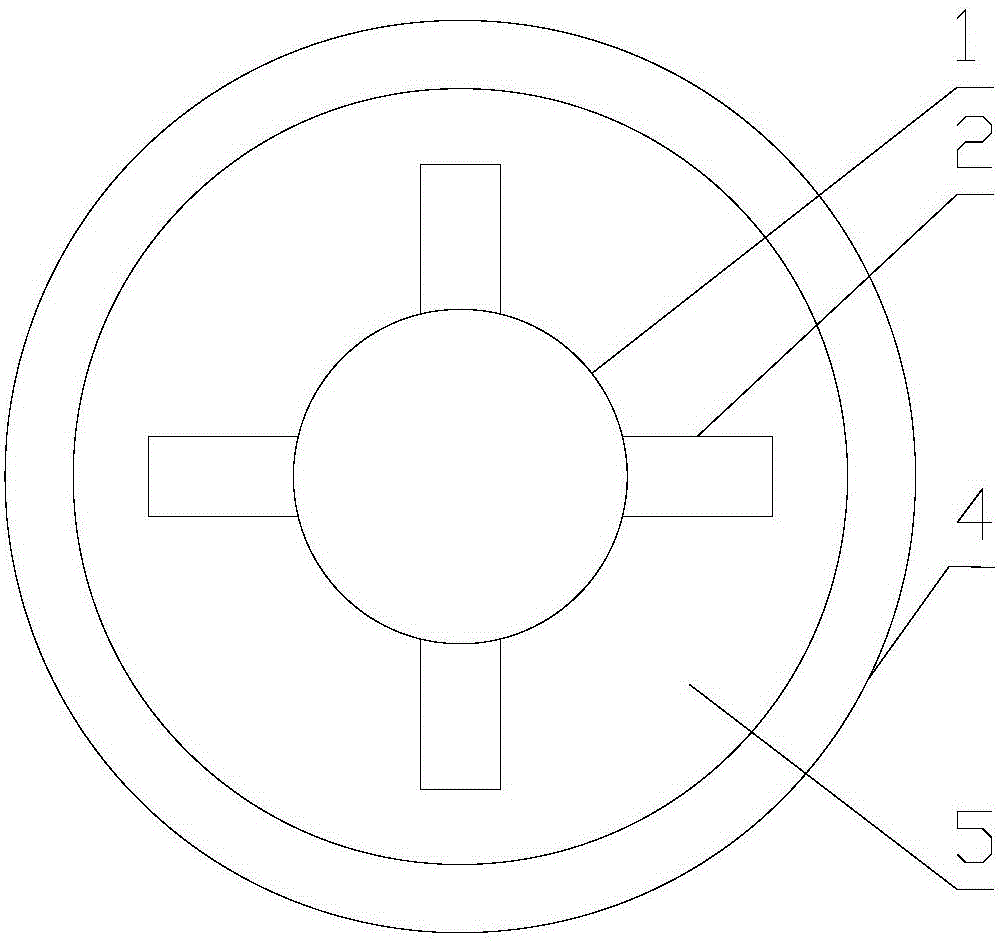

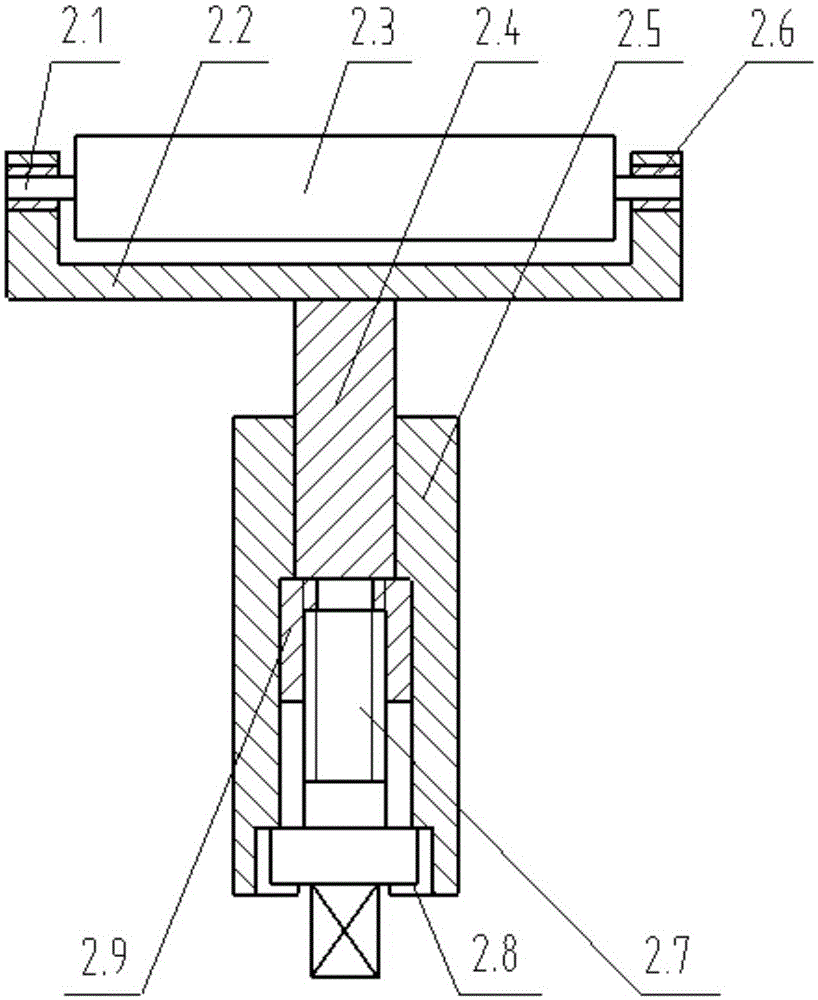

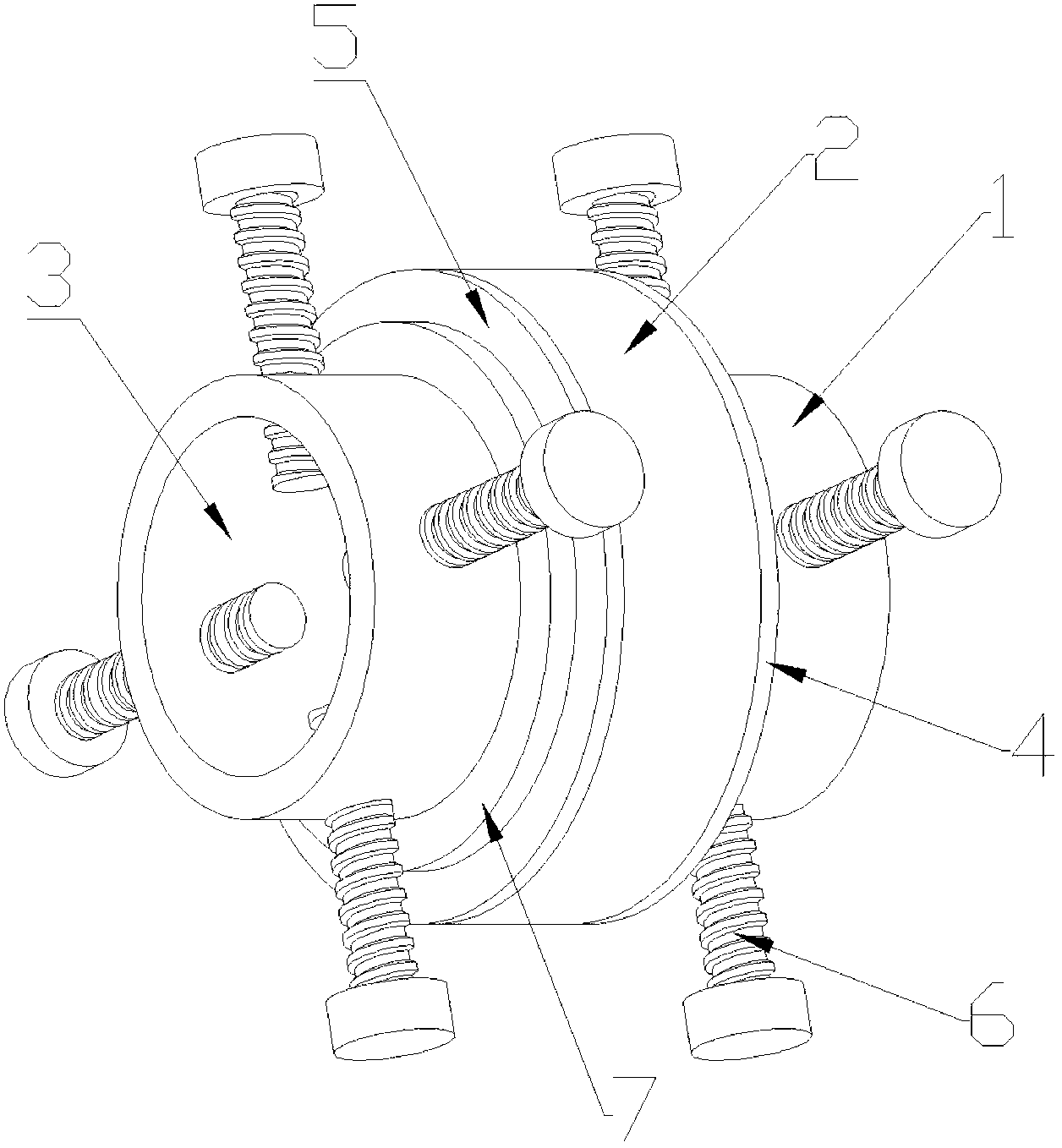

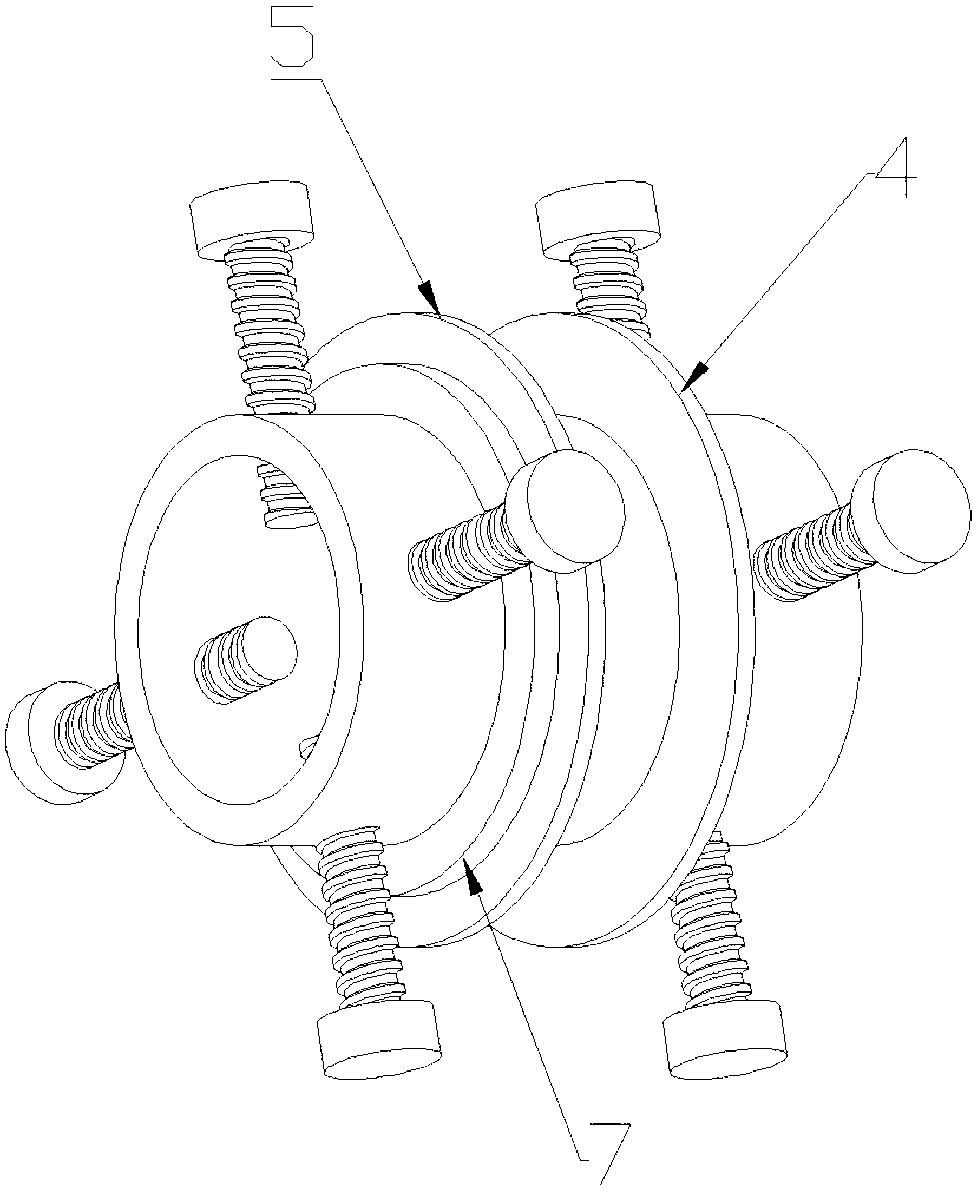

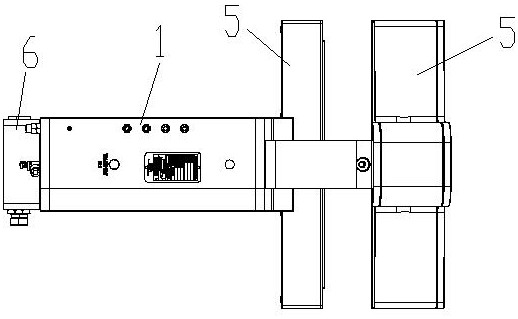

Lathe center frame auxiliary clamping mechanism

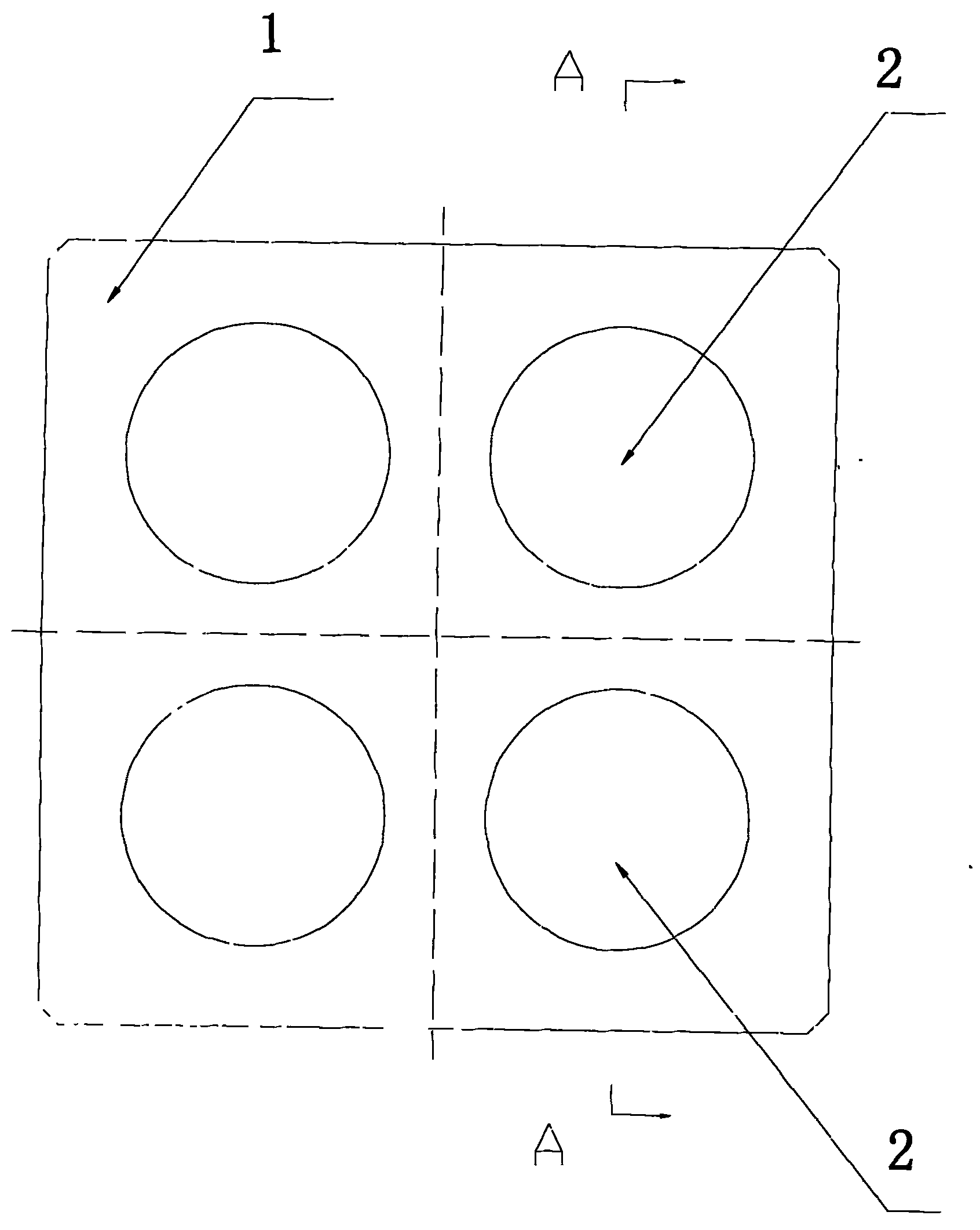

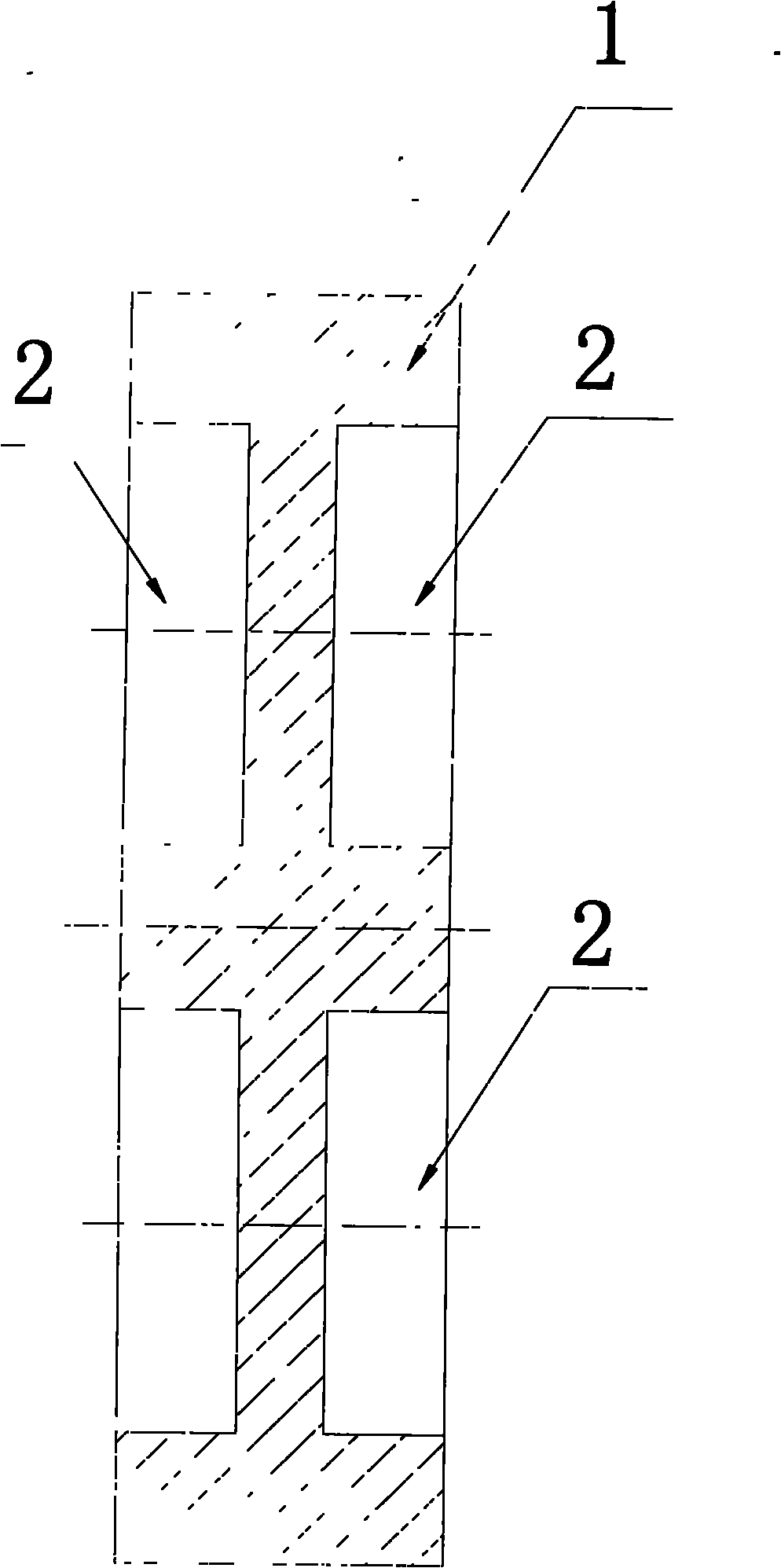

ActiveCN103286581APlay a supporting roleEasy to buyLarge fixed membersPositioning apparatusEngineeringMechanical engineering

The invention discloses a lathe center frame auxiliary clamping mechanism which comprises a clamping sleeve (1) and a rolling bearing (2), wherein a sleeve hole (3) used for installation of a machined moving bolt in a sleeved mode is formed in the clamping sleeve (1), the clamping sleeve (1) is at least provided with two pressing rods (6) with end faces pressing the outer circumferential face of the machined moving bolt, the rolling bearing (2) is axially installed on the clamping sleeve (1) in a limited mode, and the inner ring of the rolling bearing (2) is closely matched with the outer circumferential face of the clamping sleeve (1). The lathe center frame auxiliary clamping mechanism not only can support the machined moving bolt, but also enables the machined moving bolt to rotate, and can effectively guarantee lathing of the machined moving bolt.

Owner:宁波瑞亚紧固件制造有限公司

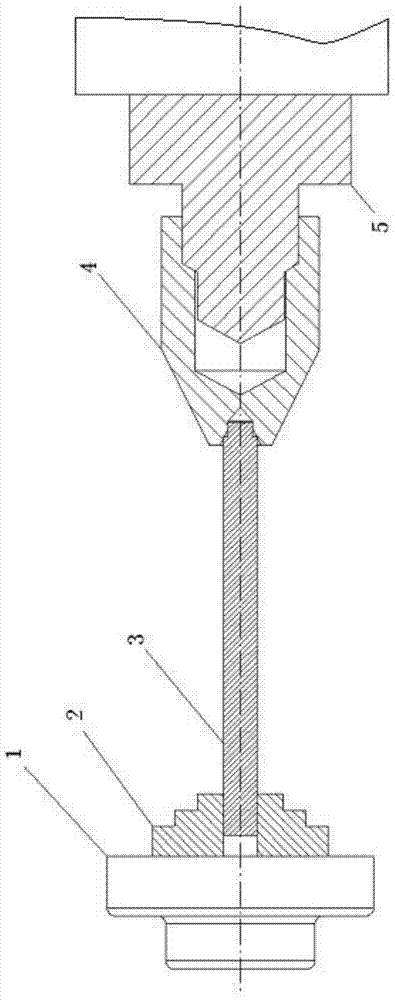

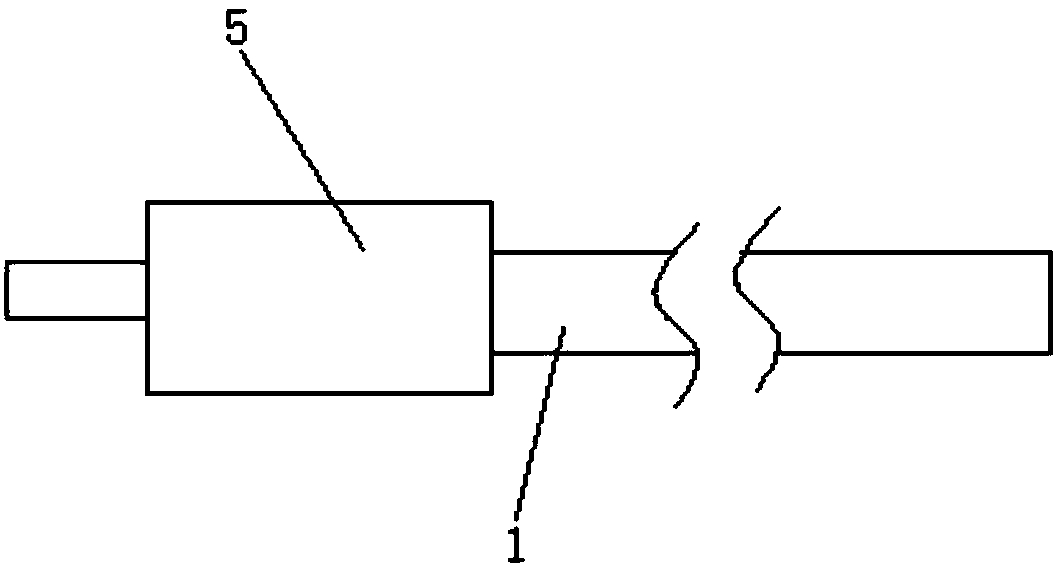

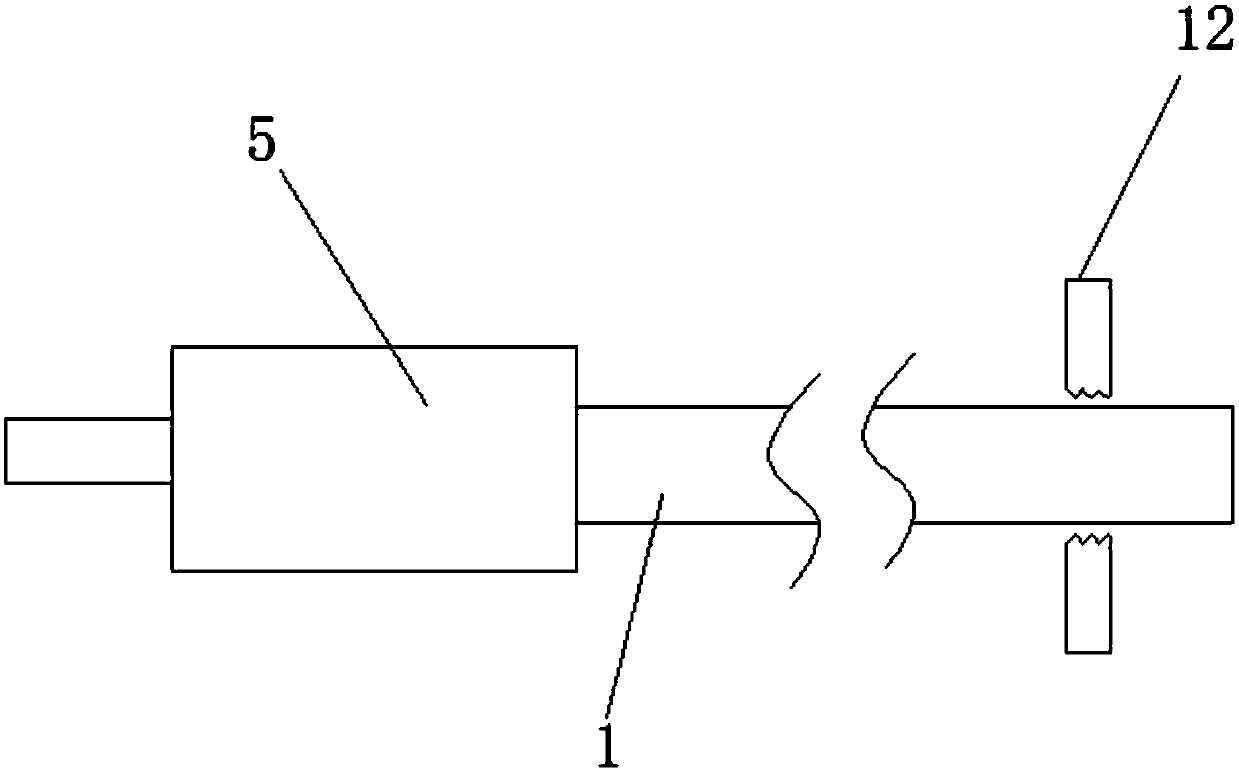

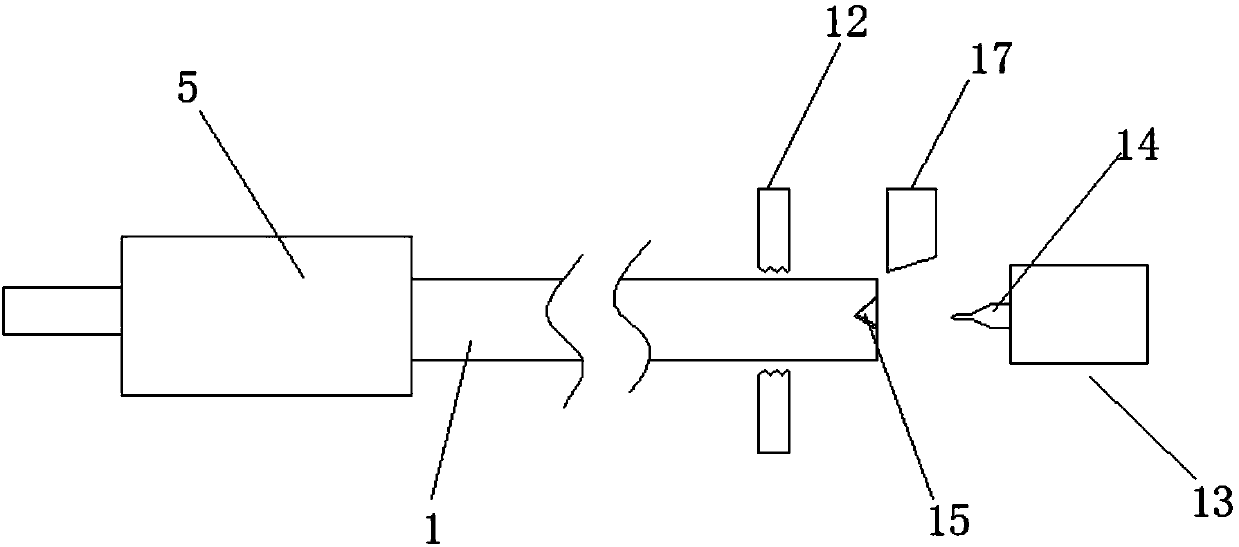

Lathe adapter used for fine bar processing

PendingCN104511756AEasy to fixImprove machining accuracyAutomatic conveying/guiding stockAuxillary equipmentEngineeringProcessing accuracy

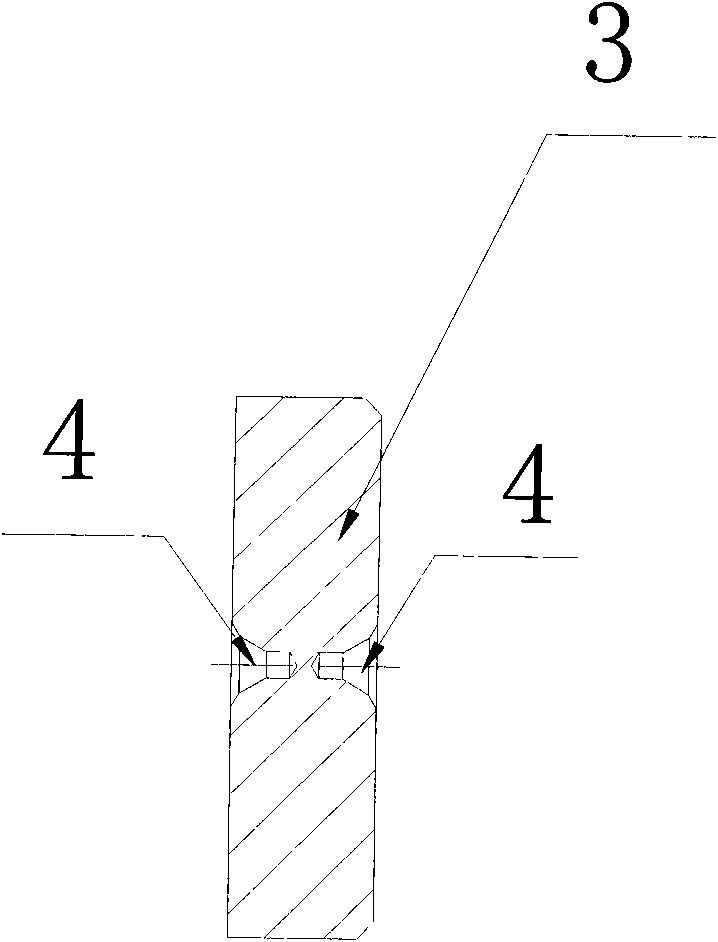

The invention relates to a lathe adapter used for fine bar processing, the left end of an adapter (4) is connected with an fine bar workpiece (3), the right end is connected with a lathe center (5), the left end of the adapter (4) is provided with a trapezoid bulge (6), the right end is provided with an inner stepped hole (10) and an outer stepped hole (11) which have unequal diameters, the surface of the trapezoid bulge (6) is provided with a cone-shaped groove (8), the bottom of the cone-shaped groove (8) is further provided with a cylindrical groove (9), and the joint of the inner stepped hole (10) and the outer stepped hole (11) is provided with a slope (7). Compared with the prior art, the adapter (4) is installed between the fine bar workpiece (3) and the lathe center (5), not only can more firmly fix the fine bar workpiece (3) but also can be skillfully connected with the lathe center (5), overcomes the vibrating problem during processing the fine bar workpiece (3) accordingly, and effectively improves the processing accuracy of the fine bar workpiece (3).

Owner:上海奥林汽车安全系统有限公司

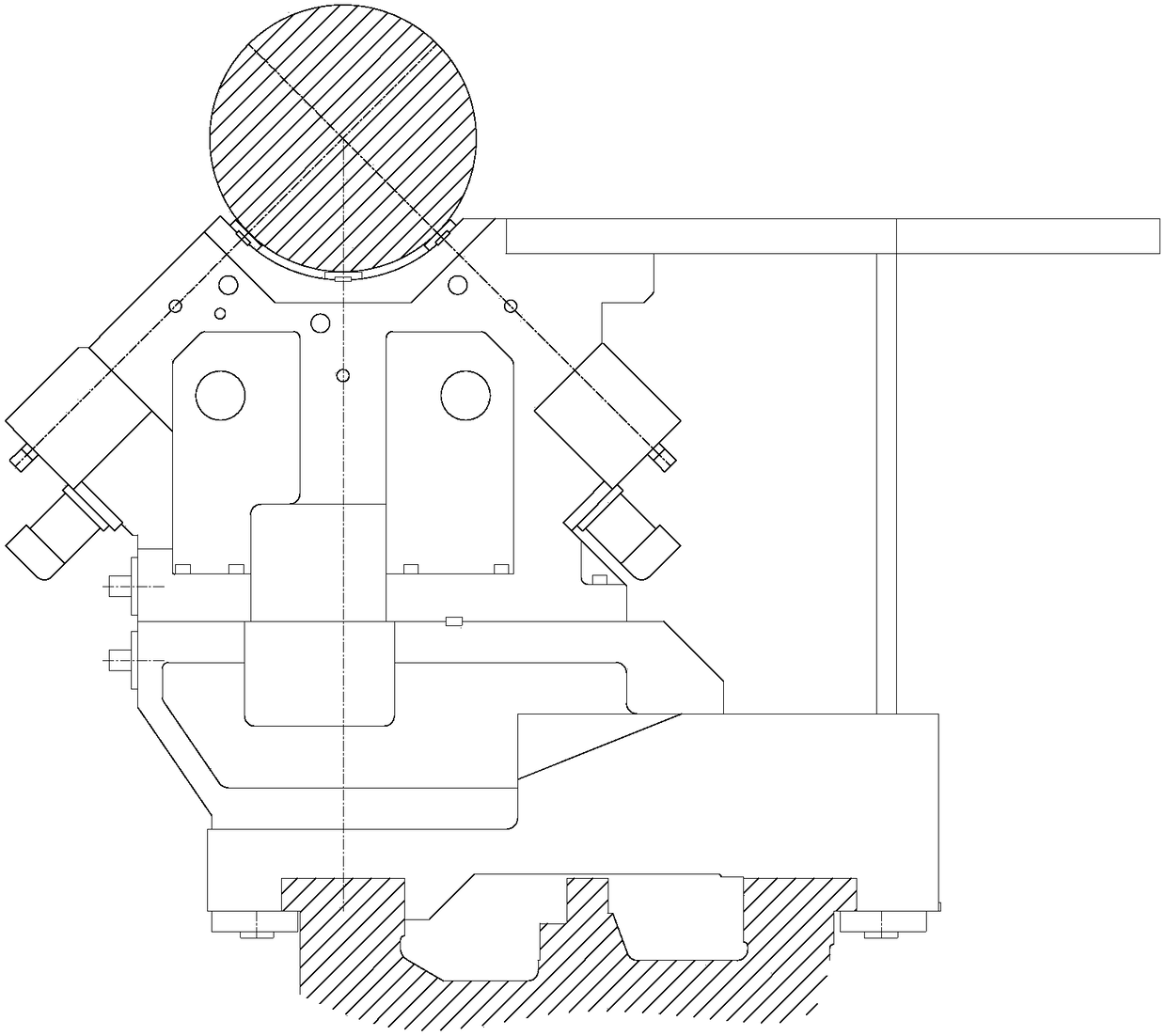

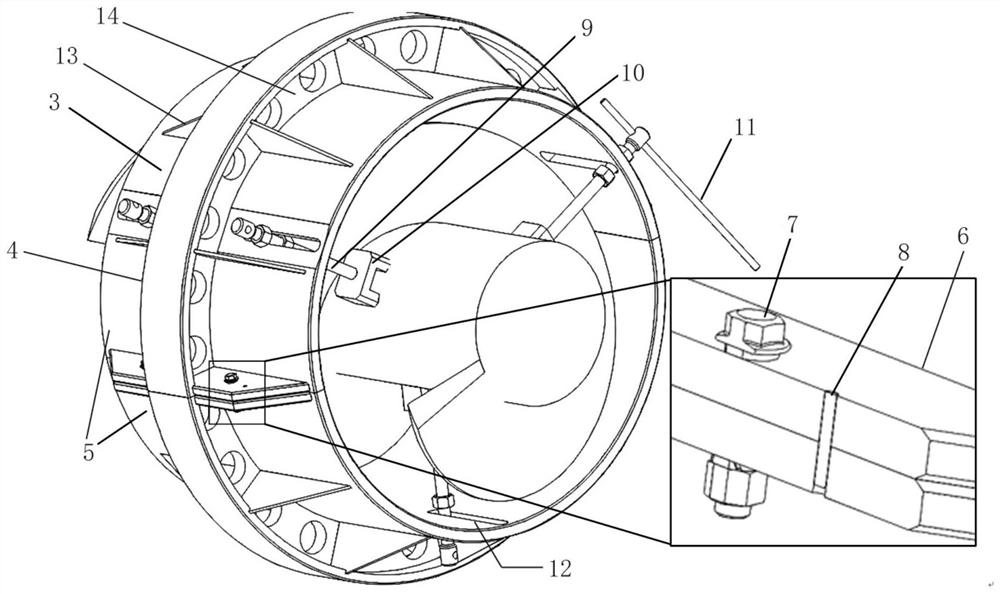

Crank shaft lathe center frame device

PendingCN108526925AGuaranteed stabilityQuality improvementAuxillary equipmentLarge fixed membersEngineeringMechanical engineering

The invention provides a crank shaft lathe center frame device which comprises a center frame. Multiple support pillars for supporting a main journal of a crank shaft are arranged in the center of thecenter frame; a cover plate structure capable of stably and tightly pressing on the upper part of the main journal is arranged on the center frame; the support pillars on the center frame support thelower part of the main journal; the cover plate structure stably and tightly press on the upper part of the main journal and comprises a pressing plate; movable pull rods are inclinedly connected totwo sides of the pressing plate; the lower ends of the movable pull rods are hinged onto the center frame; and the movable pull rods tightly press the main journal onto the center frame through the pressing plate. An oil groove is formed in a contact surface of a babbitt alloy block and the main journal, and when the crank shaft rotates, the main journal is lubricated, so that the friction betweenthe main journal and the pressing plate is reduced. The cover plate structure covers and presses on the main journal so as to prevent the crank shaft from upwards bouncing when the crank shaft rotates and is processed, so that the stability in processing the crank shaft is ensured, and the processing quality and the processing efficiency of the crank shaft are improved.

Owner:QINGDAO HAIXI HEAVY IND

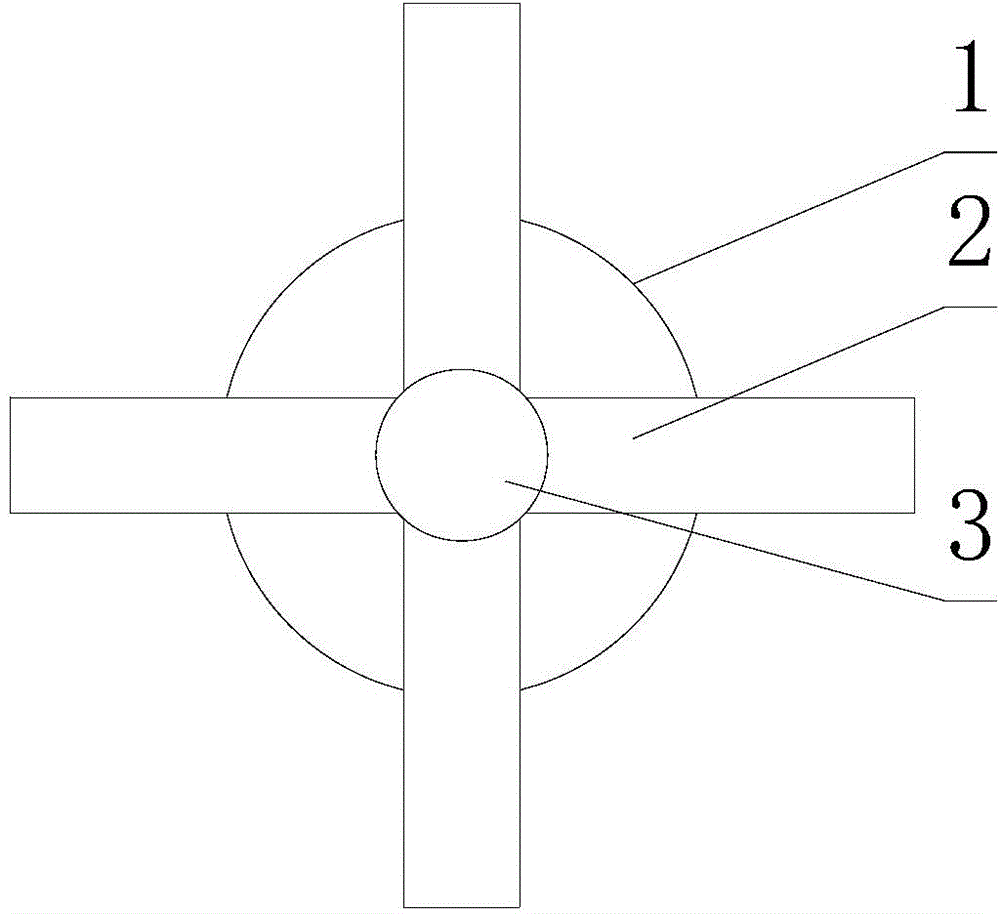

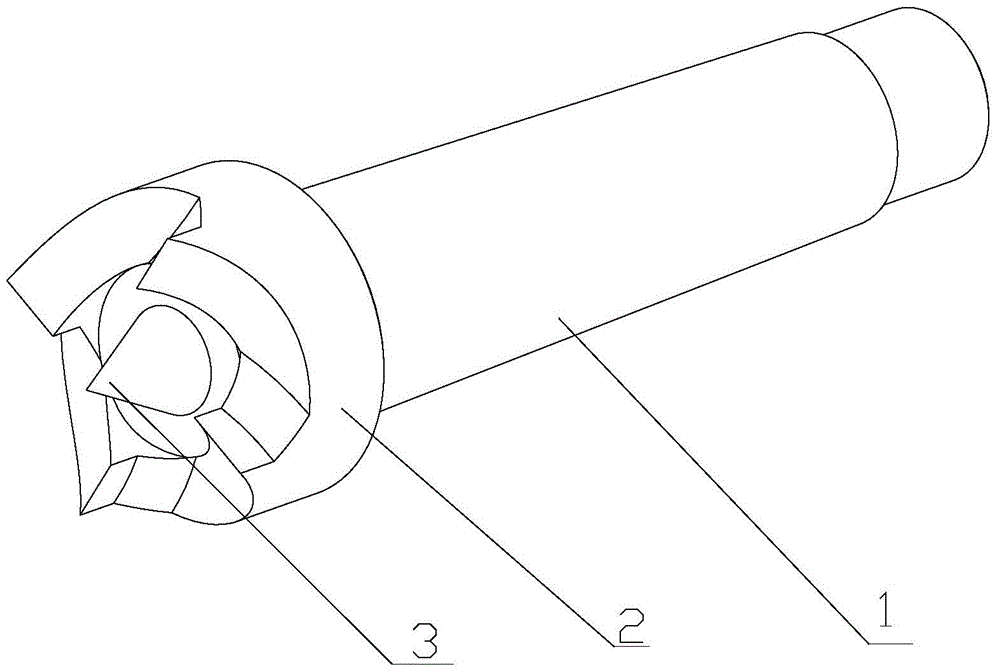

Wood lathe center

The invention discloses a wood lathe center. The wood lathe center is characterized in that the wood lathe center comprises a center handle and a center head connected to the center handle, the center head comprises a fixed ring and a fixed pointed end arranged in the center of the fixed ring and the edge of the fixed ring has a zigzag shape. Compared with the existing wood lathe center, the wood lathe center provided by the invention has the advantage that the fixed ring can completely fix a workpiece and does not easily fall off and slide down.

Owner:YANGZHOU XINGYI MACHINERY

Horizontal lathe center frame

InactiveCN101456130BReasonable structural designExtended service lifeLarge fixed membersIsoetes triquetraEngineering

The invention relates to a center frame of a horizontal lathe. The center frame comprises an upper frame body (2), a lower frame body (1), a fixing bolt (6) for connecting the two bodies, a pressing plate bolt (9) and a pressing plate (10), wherein the upper frame body (2) and the lower frame body (1) are connected by the fixing bolt (6), the lower frame body (1) is a U-shaped frame, an equilateral triangle is formed by taking a center of an inscribed circle of the U-shaped frame as a center, and the corresponding three vertices are respectively provided with frame regulating mechanisms, which is characterized in that the frame regulating mechanism is composed of a slide bushing (3), a slider (13), a frame claw (4), a regulating lead screw (5), a regulating lead screw handle (14), a baffle ring (15), a frame claw lock bolt (7) and a slide bushing lock bolt (8). The center frame has the advantages of reasonable structure, long service life, safety and reliability, capability of processing long and large workpieces, large processing space, convenient use and adjustment, and the like.

Owner:李雨波

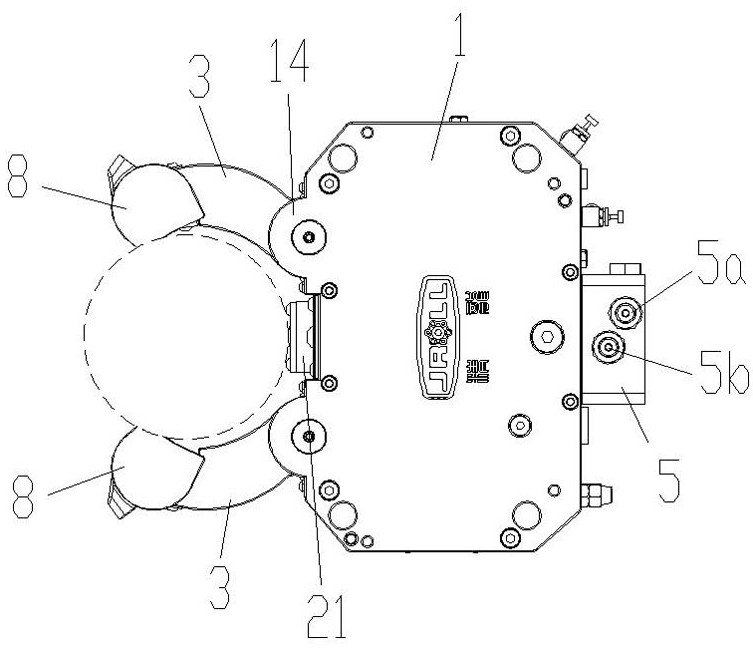

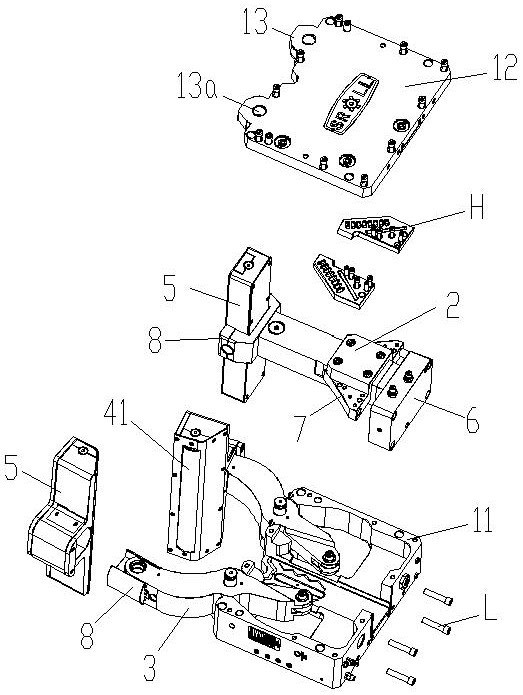

Self-centering lathe center frame

The invention discloses a self-centering lathe center frame. The self-centering lathe center frame comprises a shell, a center arm and two supporting arms; the front end of the center arm and the front ends of the two supporting arms are each provided with a supporting wheel set; the center arm is a cylinder body of an oil cylinder hidden in the shell, and a safety valve is assembled at the end ofa piston rod of the oil cylinder and installed on the rear end face of the shell; roller sets are symmetrically installed on the upper side face and the lower side face of the center arm, and outwards-protruding arc-shaped rolling faces in rolling contact fit with the roller sets are formed on the rear sections of the supporting arms; and the center arm moves forwards under the action of hydraulic pressure, meanwhile, the two supporting arms are pushed to synchronously move and fold through rolling force application of the roller sets to control a workpiece in a circle formed by supporting points of the three supporting wheel sets, and a return plate used for driving the supporting arms to be opened and reset when the center arm retreats is hinged to the center arm. According to the self-centering lathe center frame, by the adoption of the design of the built-in oil cylinder, the boundary dimension of the center frame is reduced, the clamping range is enlarged, reliability is high, using performance is good, and the self-centering lathe center frame is suitable for a machine tool with a small installation space and a large clamping range.

Owner:宁波市精恒凯翔机械有限公司

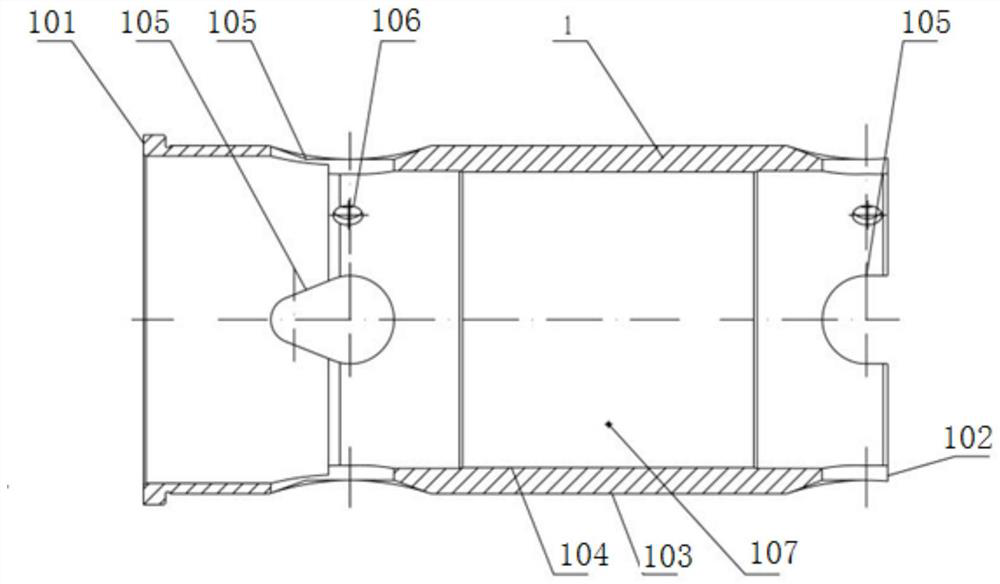

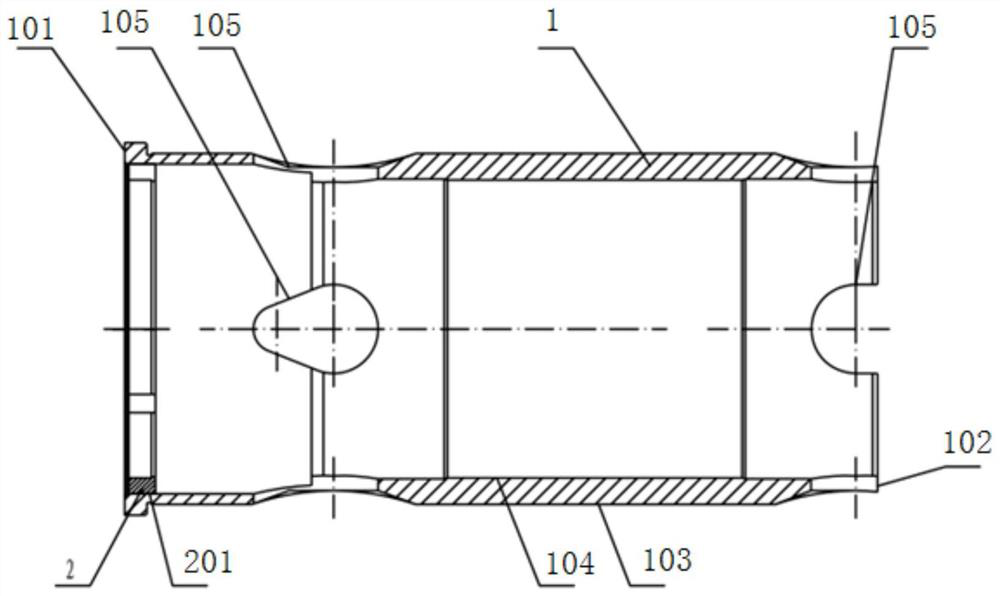

Lathe center

InactiveCN102319911AImprove general performanceNo axial playTailstocks/centresEngineeringMachine tool

The invention discloses a lathe center, which comprises an assembly shaft, a jacking head and a gland, wherein the jacking head is a cone, the top of the jacking head is a flat end face, one end of the assembly shaft is inserted into a step hole at the large end of the jacking head and connected with the jacking head through a bearing, the other end of the assembly shaft is arranged on a lathe, and the gland is arranged at the outer side of the bearing; as a preferably scheme, the jacking head is connected with the assembly shaft through two bearings arranged in interval; and the step hole in the jacking head is a through hole. The lathe center is convenient for installation and easy to realize and has strong generality; and the general center of the lathe is replaced by using the conical jacking head with planar top, the jacking head is connected with the assembly shaft through the two bearings, and the jacking head is matched with a chuck of the lathe, so that effective clamping of steel pipes of multiple specification is realized, and the production efficiency and the product quality are improved.

Owner:WUXI DAJIN HIGH PRECISION COLD DRAWN STEEL TUBE

Method for turning counterbores at two ends

The invention relates to a method for turning counterbores at two ends. In order to solve the problem that coaxiality of counterbores at two ends can not be ensured, the method for turning the counterbores at two ends provided by the invention has the following steps: 1) turning a counterbore in one end surface of a processed part; 2) processing a circular tooling part in accordance with the diameter of the counterbore, processing a center bore in the circle center of the tooling part, and forming interference fit by matching the diameter of the tooling part with the diameter of the counterbore; and 3) assembling the processed tooling part and the processed counterbore as a whole in a manner of little interference, and turning the counterbore in the other end of the part by using a lathe center to hold the center bore of the tooling part. In the method for turning the counterbores at two ends provided by the invention, the self-made tooling part is adopted, the processing position of each counterbore is located by the center bore, and the counterbores at two ends of the processed part can be ensured to be on the same axis, thereby meeting the drawing requirements.

Owner:SHANDONG HUALI ELECTRIC MOTOR GRP

Positioning fixture for lathe machining

ActiveCN105108515AAxialAchieve positioningPositioning apparatusMetal-working holdersEngineeringMagnet

The invention discloses a positioning fixture for lathe machining. The positioning fixture includes an aligning positioning rod which includes a positioning rod and an adjusting rod, wherein the positioning rod and the adjusting rod are connected. The positioning rod is connected to a three-jaw chuck of a lathe. A side at an end portion of the adjusting rod is provided with a lathe center. The adjusting rod of the aligning positioning rod has one end connected to the positioning rod and the other end which has a side wall shaped in a conical surface. The adjusting rod is sleeved with a rotary positioning disc. An inner end surface of the rotary positioning disc and the positioning rod are provided therebetween with a locking nut which sleeves the adjusting rod. The outer end surface of the rotary positioning disc is provided thereon with a magnet which attracts a workpiece. According to the invention, with the structure, the positioning fixture has the following advantages: 1. the rotation of the rotary positioning disc drives the workpiece to displace on the conical surface of the adjusting rod, the center of the workpiece is adjusted to a rotation center of the lathe, and accurate positioning is performed on annular parts; 2. the rotary positioning disc is locked by the locknut so as to achieve axial positioning and radial positioning of the workpiece and prevent part deformation caused by the positioning of the three-jaw chuck of the lathe, and thus parts are convenient to machine.

Owner:WUHU HENGLONG AUTO STEERING SYST

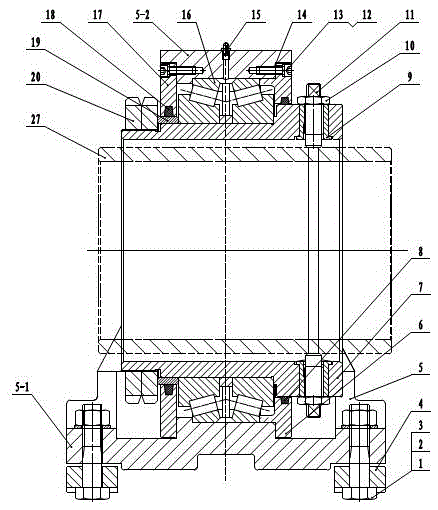

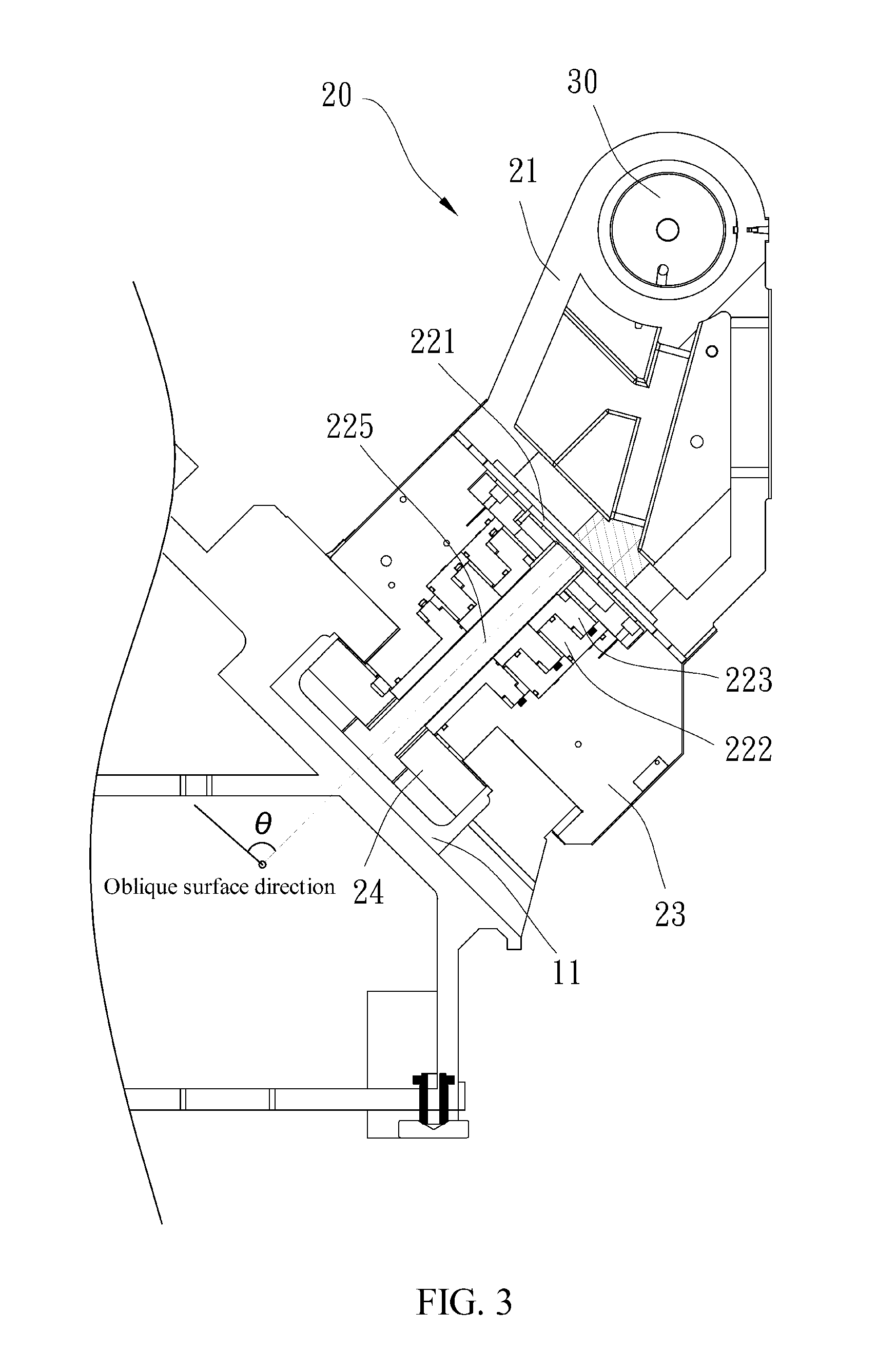

Tailstock for machine tools

ActiveUS20160184901A1Increase clamping forceChange appearanceTailstocks/centresLarge fixed membersEngineeringTailstock

A tailstock includes a main body, a lathe center unit arranged in a hollow hole of the main body, a sliding base coupled with the main body and having a slider configured at a side thereof for pairing a slide rail, and a clamping unit configured in the sliding base. The clamping unit for increasing clamping force of the tailstock further includes a connection plate having at least one positioning hole to connect the main body, at least one hydraulic rod bridging the slider and the main body, a plurality of loading devices ring-set about the hydraulic rod, and a plurality of sleeves ring-set with the corresponding loading devices.

Owner:TAIWAN TAKISAWA TECH

Roller lathe center frame

InactiveCN103659303AEnsure load carrying capacityReduce weightLarge fixed membersArchitectural engineeringLoad bearing

The invention discloses a roller lathe center frame which comprises an annular frame. An inner ring of the annular frame is provided with three supporting rods which are telescopic in the radial direction in a trisection mode. The roller lathe center frame further comprises a base. The base is fixedly connected with the lower end face of the annular frame. A reinforcement rib is fixedly connected between the base and the annular frame. By means of a groove of the base and the reinforcement rib of the roller lathe center frame, the load bearing capacity of the base is ensured and meanwhile, the weight of the base is reduced. Meanwhile, the center frame and a lathe can be conveniently detached and installed.

Owner:JIANGSU DONGYE ROLL

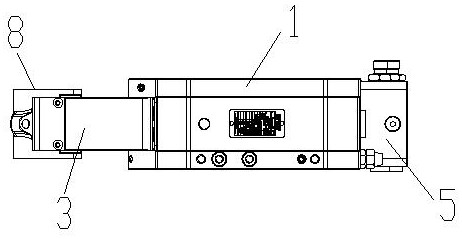

Lengthened roller type lathe center frame

PendingCN112318153AIncrease contact areaImprove machining accuracyLarge fixed membersCylinder blockSupport point

The invention discloses a lengthened roller type lathe center frame. The lengthened roller type lathe center frame comprises a center arm arranged in an installation base and two supporting arms hinged to the installation base, and the front end of the center arm and the front ends of the supporting arms are each provided with a roller; the rollers are lengthened rollers, lengthened roller supports are installed at the front end of the center arm and the front ends of the supporting arms, and the lengthened rollers are installed in the lengthened roller supports; the central arm is a cylinderbody of an oil cylinder hidden in the installation base, a safety valve is installed on the rear end surface of the installation base, and a piston rod of the oil cylinder is connected with the safetyvalve; and the two supporting arms are symmetrically arranged, pressure-bearing wheels are installed at the rear ends of the supporting arms, wedge-shaped plates are installed on the upper side faceand the lower side face of the center arm, thrust slopes in rolling contact with the pressure-bearing wheels are formed on the wedge-shaped plates, the center arm pushes the pressure-bearing wheels through the thrust slopes to drive the two supporting arms to move synchronously to be closed while advancing under the hydraulic action, so that a workpiece is controlled in a circle formed by supporting points of the three rollers, and return plates used for pulling the supporting arms to be opened and reset are installed on the wedge-shaped plates.

Owner:宁波市精恒凯翔机械有限公司

Tailstock for machine tools

A tailstock includes a main body, a lathe center unit arranged in a hollow hole of the main body, a sliding base coupled with the main body and having a slider configured at a side thereof for pairing a slide rail, and a clamping unit configured in the sliding base. The clamping unit for increasing clamping force of the tailstock further includes a connection plate having at least one positioning hole to connect the main body, at least one hydraulic rod bridging the slider and the main body, a plurality of loading devices ring-set about the hydraulic rod, and a plurality of sleeves ring-set with the corresponding loading devices.

Owner:TAIWAN TAKISAWA TECH

A Machining Technology of Thin Wall and Deep Hole Cylinder Liner

Owner:CHINA PETROCHEMICAL CORP +1

Three-pin fork machining process

The invention discloses a three-pin fork machining process. The machining process comprises the following steps that 1) an initially machined three-pin fork is transversely placed on a lathe, a positioning tool is arranged at one end, away from a handle part, of the three-pin fork, the positioning tool comprises a containing part with a containing cavity, wherein a transmission mechanism is arranged inside the containing cavity, a positioning rib is arranged on the inner wall of the containing cavity, the three-pin fork is inserted into the containing cavity of the containing part, and the position of the three-pin fork in the containing cavity is corrected through the positioning rib; 2) the three-pin fork is clamped from the circumferential surface of the handle part of the three-pin fork bu using a first central frame; 3) a cutter head of the lathe is provided with a a center drill tool, a center drill is equipped with the the center drill tool, and a center hole is drilled in the end surface by using the center drill; 4) a lathe center extends into the center hole and abuts against the three-pin fork, and the first center frame is loosened; 5) the positioning tool drives the three-pin fork to rotate around an axis, and a turning tool is used for turning the outer peripheral surface of the handle part of the three-pin fork; and 6) after the turning is completed, the lathe center returns to an original position. According to the three-pin fork machining process, the precision of the machined three-pin fork is high, and the consistency is good.

Owner:上海伟奕传动轴配件有限公司

A positioning fixture for lathe processing

ActiveCN105108515BAchieve positioningAvoid deformationPositioning apparatusMetal-working holdersEngineeringMagnet

The invention discloses a positioning fixture for lathe machining. The positioning fixture includes an aligning positioning rod which includes a positioning rod and an adjusting rod, wherein the positioning rod and the adjusting rod are connected. The positioning rod is connected to a three-jaw chuck of a lathe. A side at an end portion of the adjusting rod is provided with a lathe center. The adjusting rod of the aligning positioning rod has one end connected to the positioning rod and the other end which has a side wall shaped in a conical surface. The adjusting rod is sleeved with a rotary positioning disc. An inner end surface of the rotary positioning disc and the positioning rod are provided therebetween with a locking nut which sleeves the adjusting rod. The outer end surface of the rotary positioning disc is provided thereon with a magnet which attracts a workpiece. According to the invention, with the structure, the positioning fixture has the following advantages: 1. the rotation of the rotary positioning disc drives the workpiece to displace on the conical surface of the adjusting rod, the center of the workpiece is adjusted to a rotation center of the lathe, and accurate positioning is performed on annular parts; 2. the rotary positioning disc is locked by the locknut so as to achieve axial positioning and radial positioning of the workpiece and prevent part deformation caused by the positioning of the three-jaw chuck of the lathe, and thus parts are convenient to machine.

Owner:WUHU HENGLONG AUTO STEERING SYST

Improved vertical lathe centering clamp

InactiveCN104889760AImprove accuracyCentral positioning structure is simpleWork clamping meansPositioning apparatusHydraulic cylinderMachine tool

The invention discloses an improved vertical lathe centering clamp comprising a powered chuck body (1), a central disk spring (2), a compressing head (3), a telescopic claw (4), a small chuck pulling claw (5), a small chuck pulling plate (6), a telescopic head (7), and a machine tool pull rod head (8); the powered chuck body (1) is fixed on a machine tool clamp base through bolts; the telescopic head (7) is connected with a machine tool hydraulic cylinder pull rod; the telescopic claw (4) is connected with the small chuck pulling claw (5); the small chuck pulling claw (5) is connected with the small chuck pulling plate (6); the small chuck pulling plate (6) is connected with a clamp radial sliding seat; the compressing head (3) is connected with the telescopic head (7); and the central disk spring (2) is installed inside the telescopic head. Being simple in center locating structure, and with most connectors of the original clamp being saved, the purpose of stabilizing the accuracy of the clamp can be achieved by the improved vertical lathe centering clamp; and the simplification of the spare parts of the clamp allows the maintenance of the clamp to be done with fewer people and allows the clamp to be easily restored.

Owner:CITIC DICASTAL

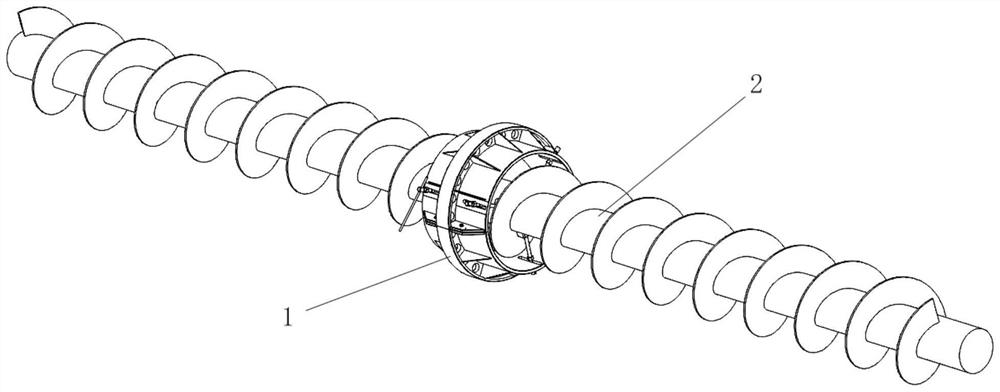

Universal long screw shaft diameter machining supporting device

InactiveCN113927320AAvoid unusable situationsQuick assembly and disassemblyLarge fixed membersClassical mechanicsEngineering

A universal long screw shaft diameter machining supporting device comprises a supporting assembly and a fixing mechanism. A sliding groove is formed in the supporting assembly, and the two ends of the fixing mechanism are fixed to the sliding groove and a long screw to be machined respectively. A flange is arranged at the outer end of the supporting ring, and a stiffening plate is further arranged between the flange and a sleeve. The supporting assembly comprises an upper arc section and a lower arc section. According to the supporting device, the fixing mechanism slides to a proper position in the axial direction in the assembling process, and therefore interference between the fixing mechanism and a spiral structure on the screw can be avoided. The combined structure of the flange and the stiffening plate can greatly increase the contact area between the supporting device and a lathe center frame roller, and vibration generated between the supporting assembly and a lathe center frame is avoided. The supporting device is divided into two detachable parts, frequent shaft penetrating operation during assembly and disassembly of the integral supporting device can be avoided, assembly and disassembly are fast, operation is easy, welding is not needed, universality and durability are good, long screws of various specifications can be machined through one supporting device, and the production efficiency is greatly improved.

Owner:XUZHOU NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com