Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56 results about "Compression stockings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

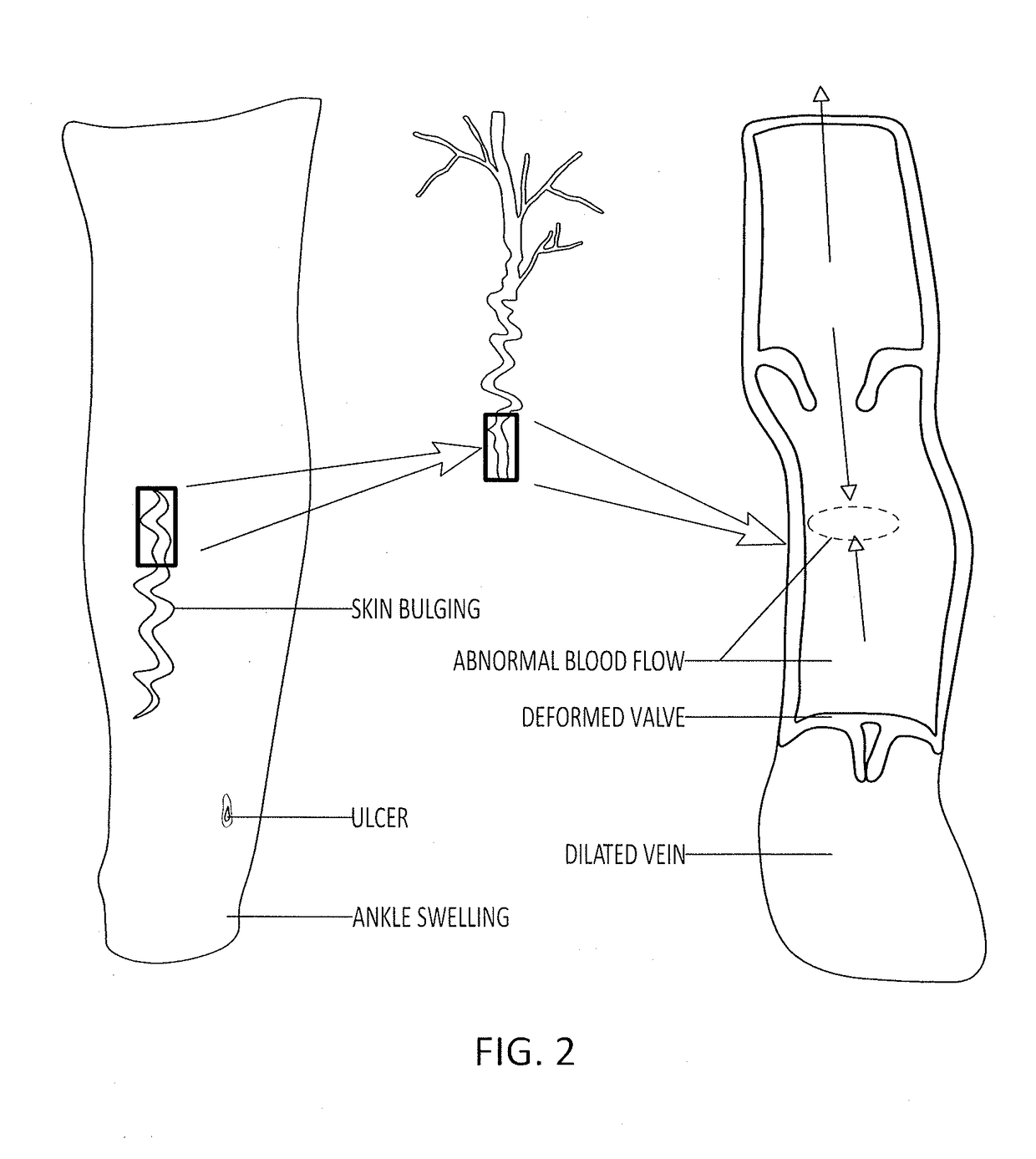

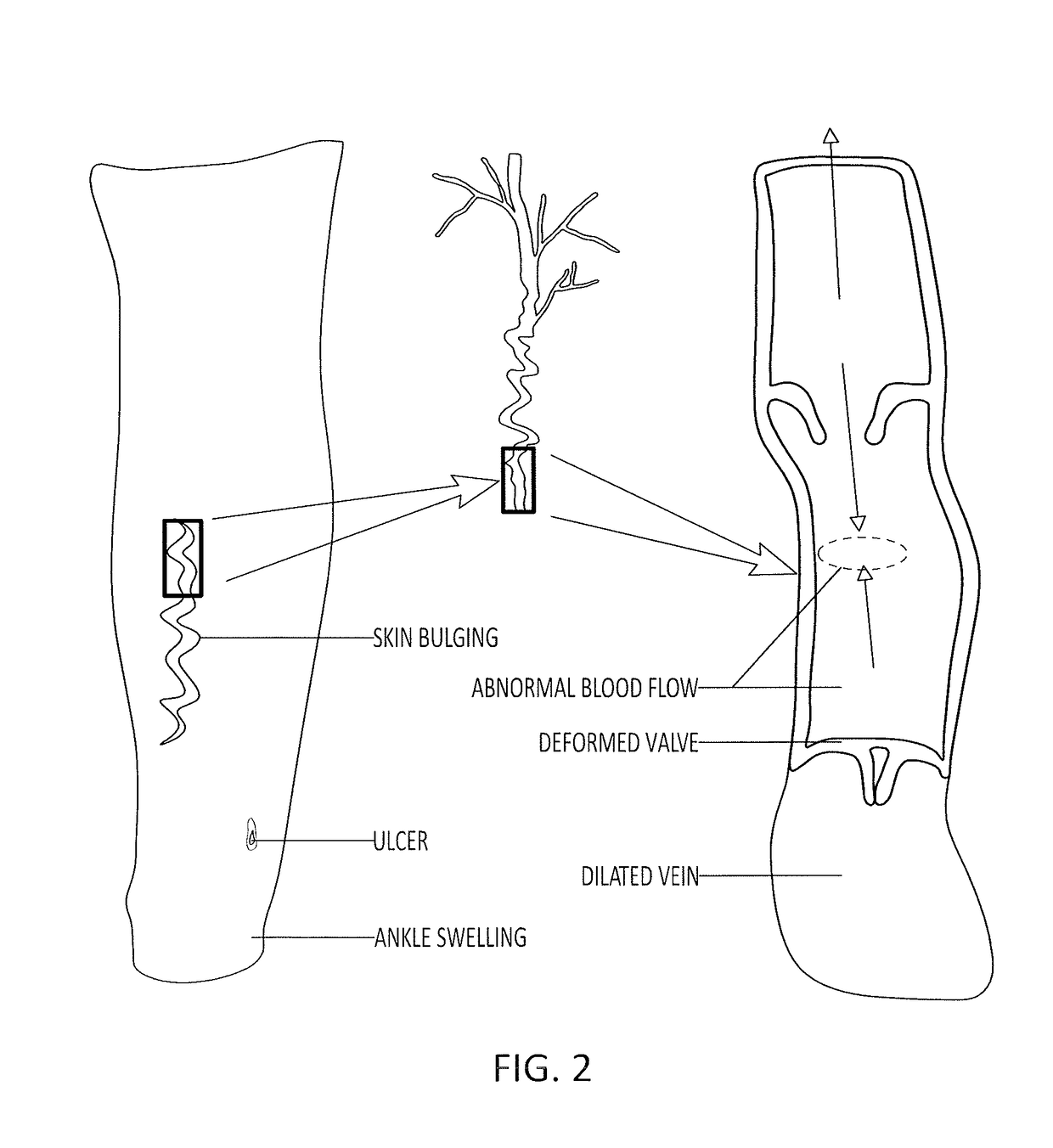

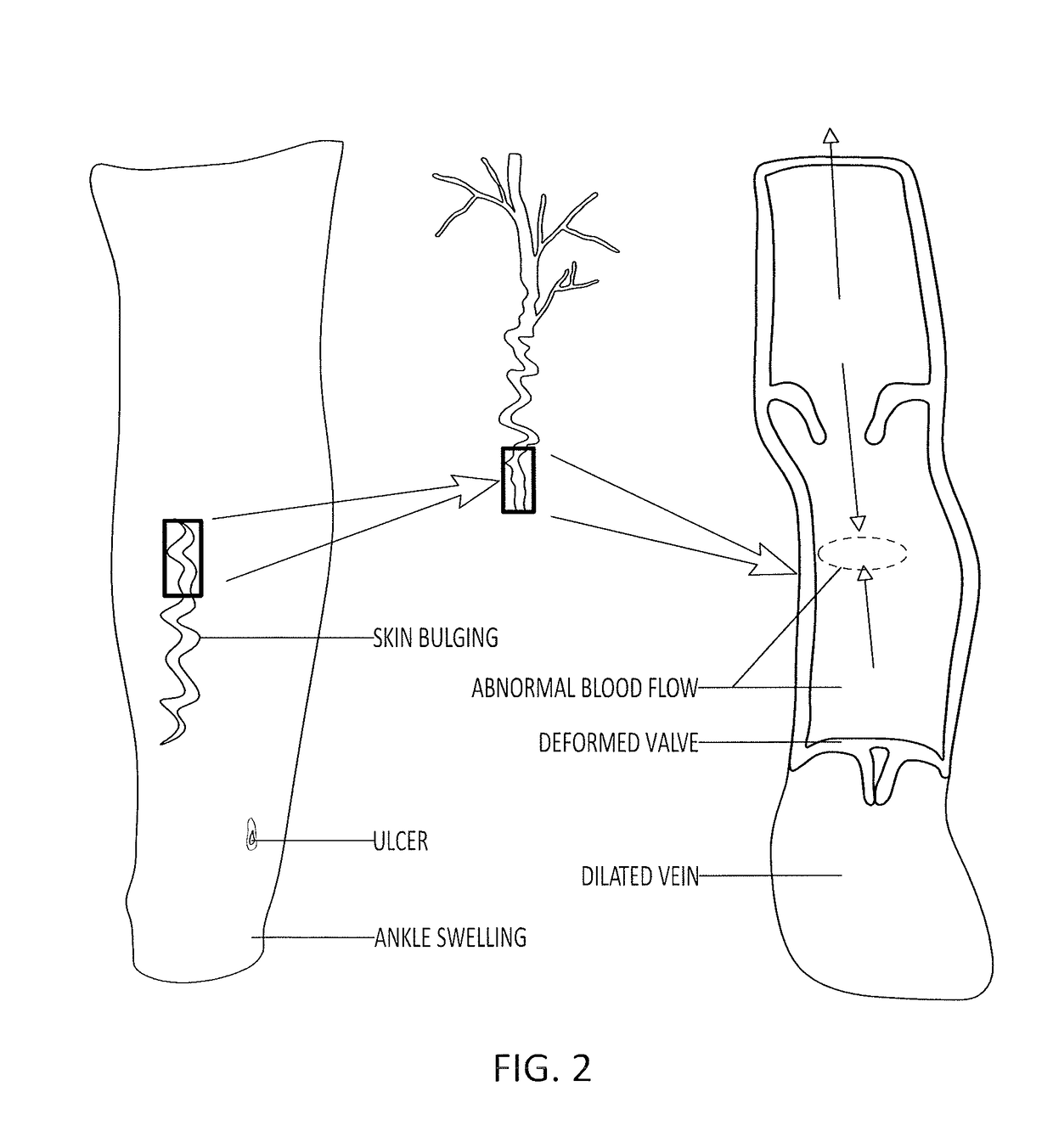

Compression stockings are a specialized hosiery designed to help prevent the occurrence of, and guard against further progression of, venous disorders such as edema, phlebitis and thrombosis. Compression stockings are elastic garments worn around the leg, compressing the limb. This reduces the diameter of distended veins and increases venous blood flow velocity and valve effectiveness. Compression therapy helps decrease venous pressure, prevents venous stasis and impairments of venous walls, and relieves heavy and aching legs.

Method and apparatus for treating wound using negative pressure therapy

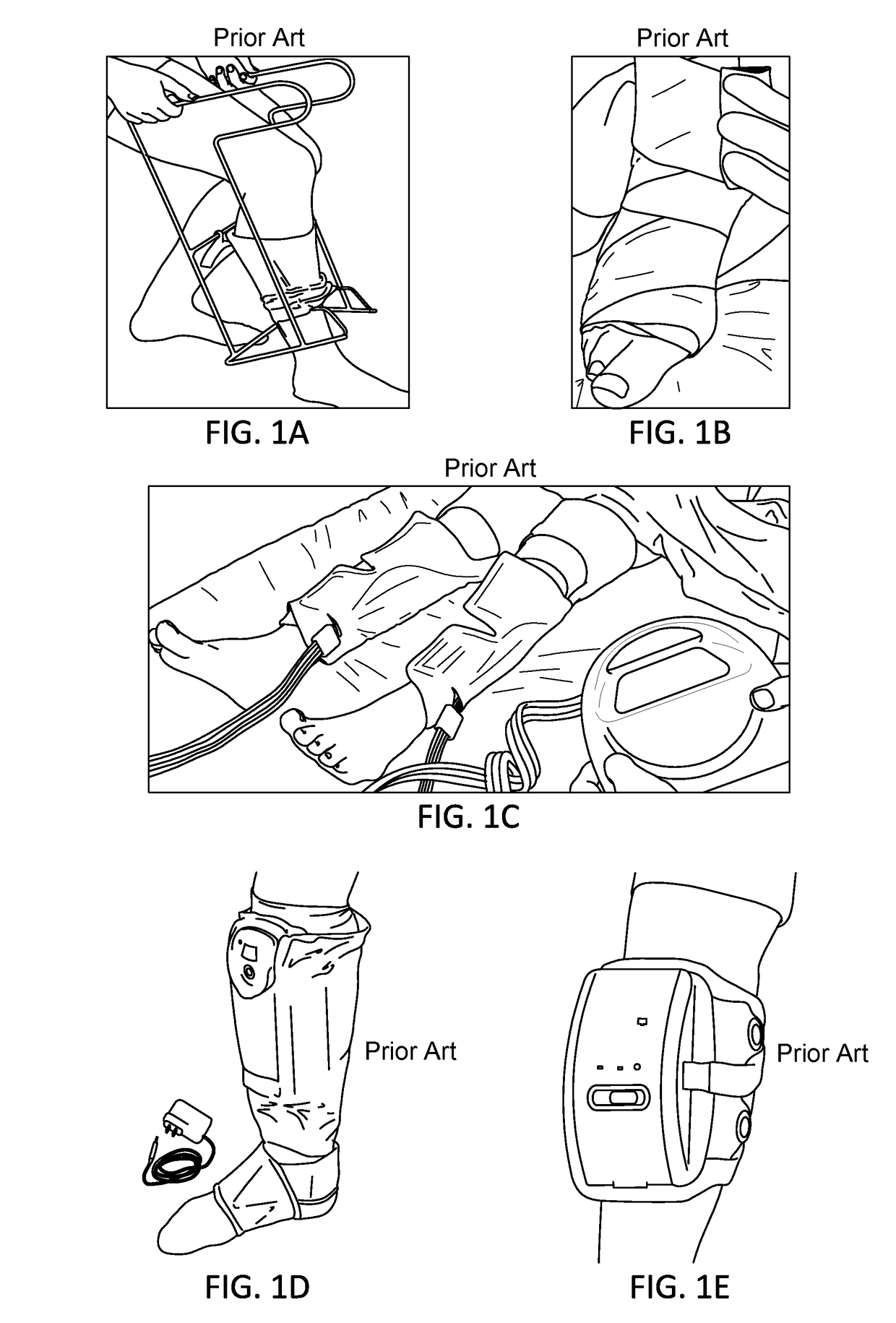

InactiveUS7896823B2Easy to returnReduce edemaBlood stagnation preventionPneumatic massageVacuum assistedThrombus

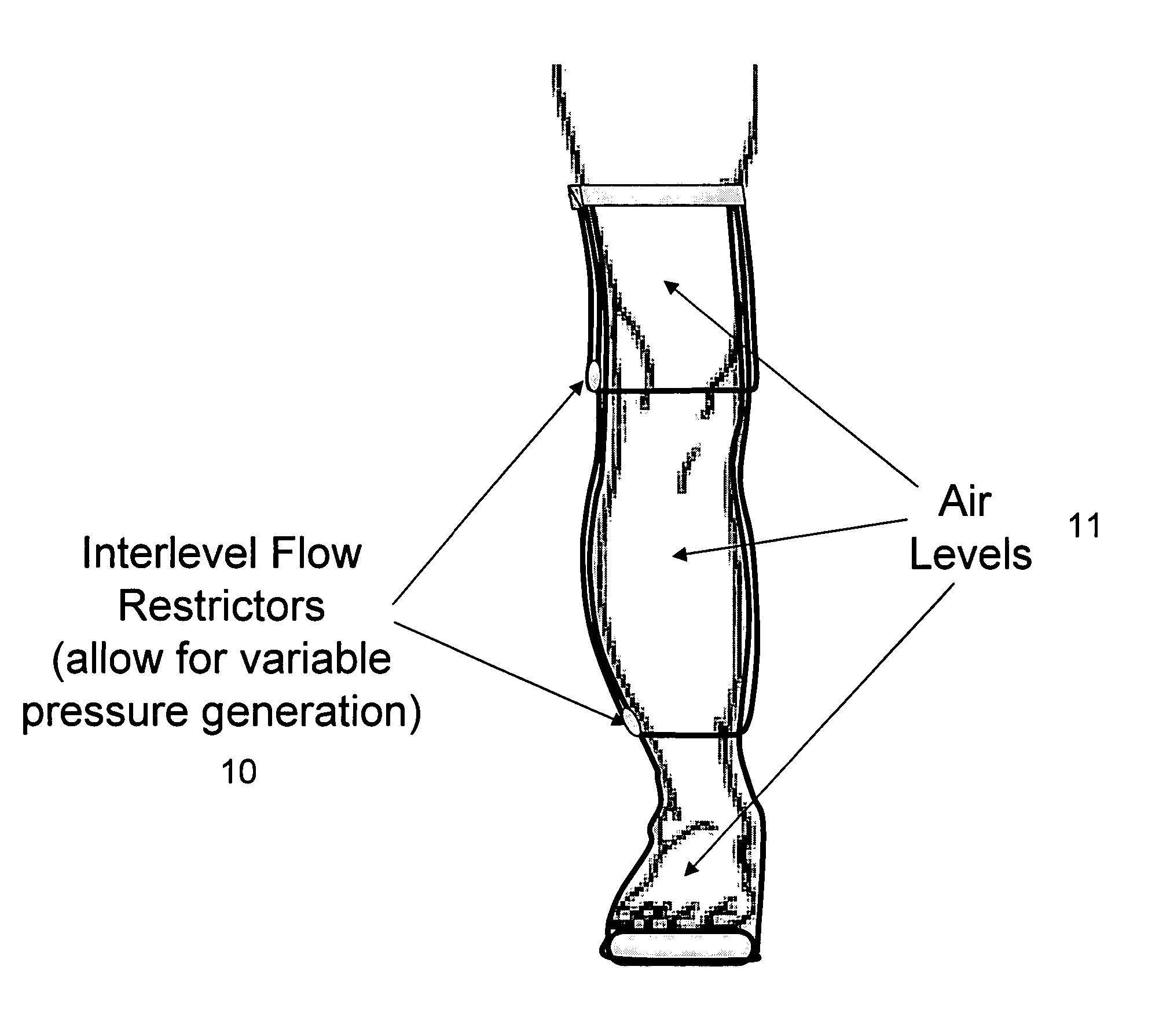

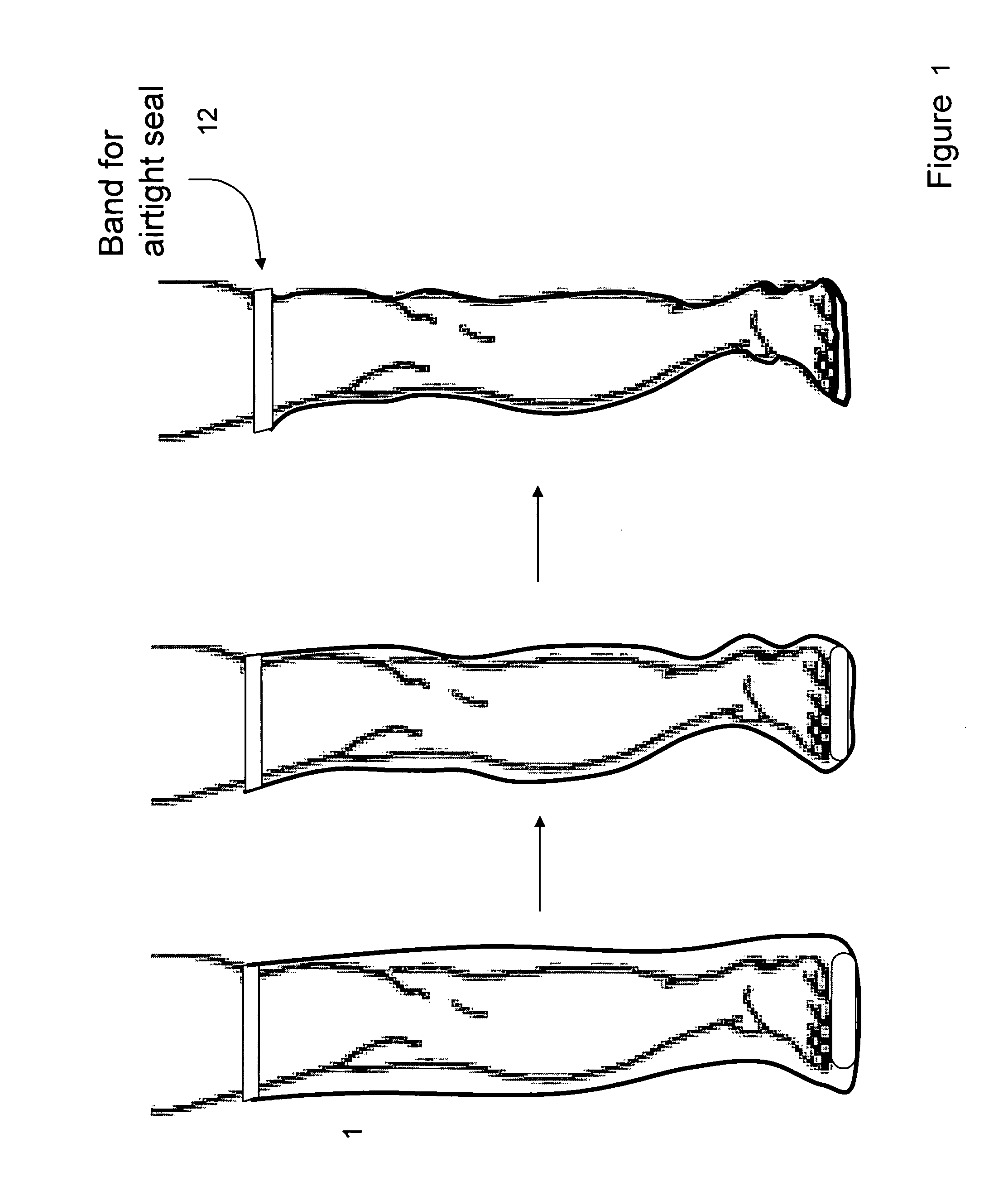

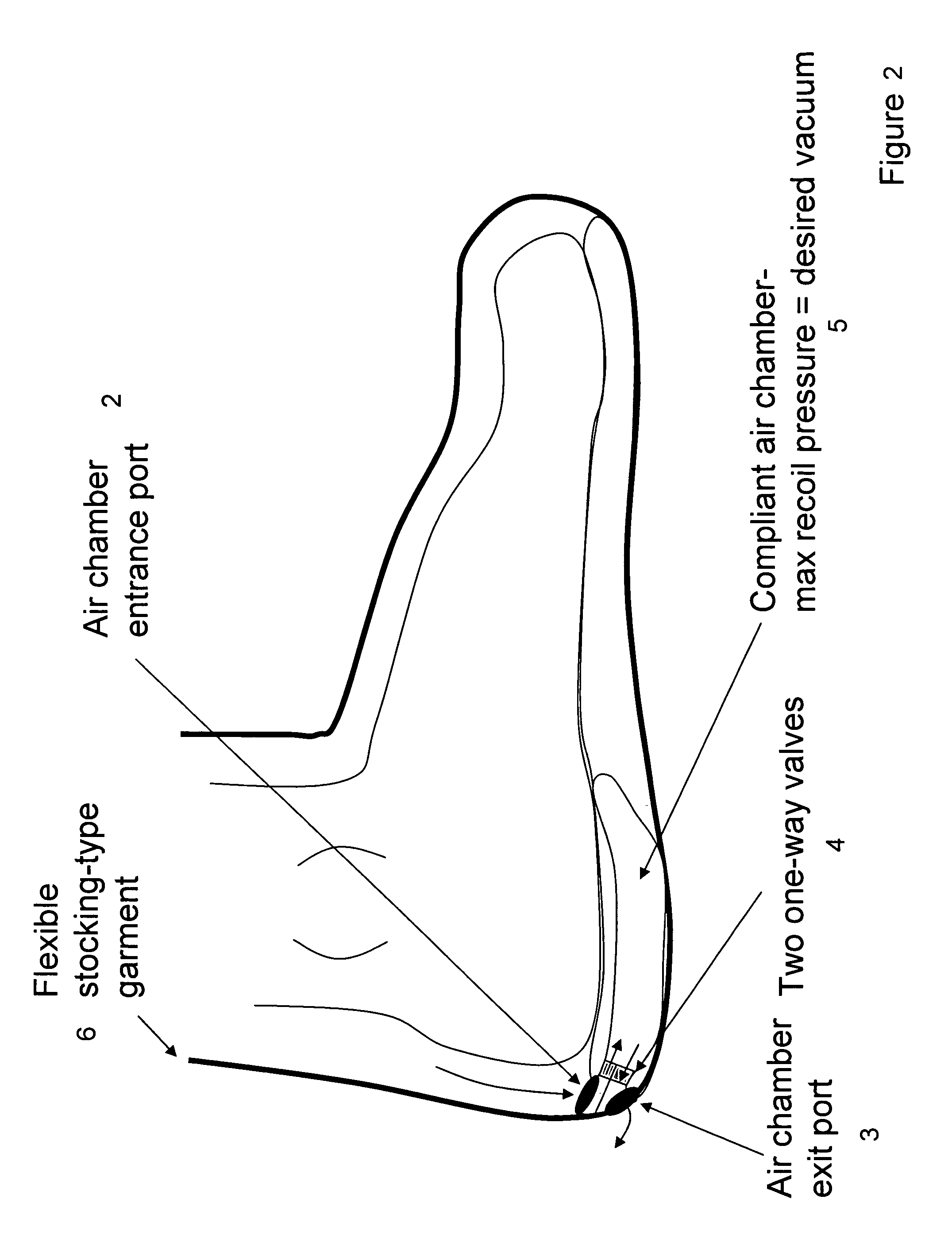

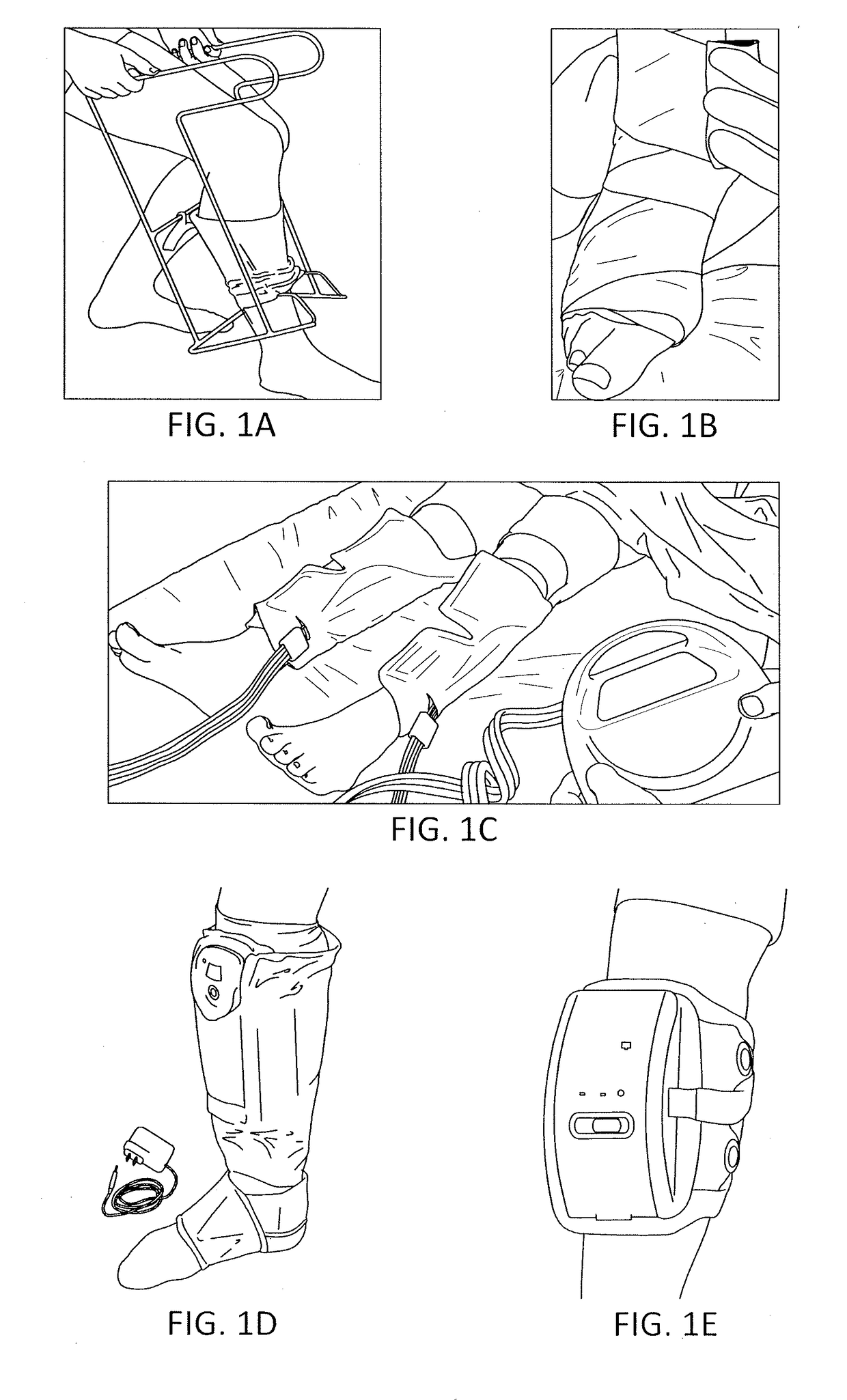

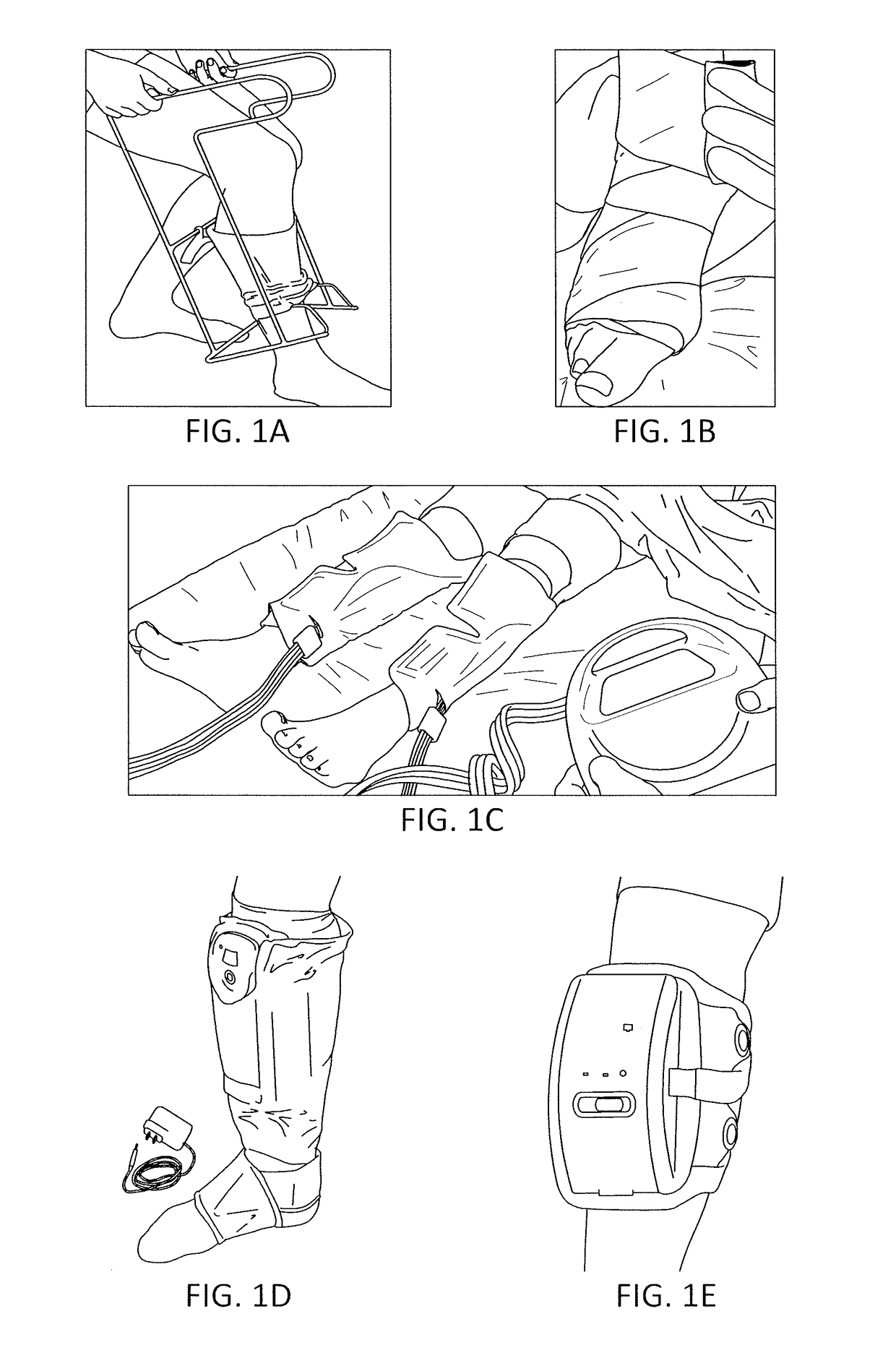

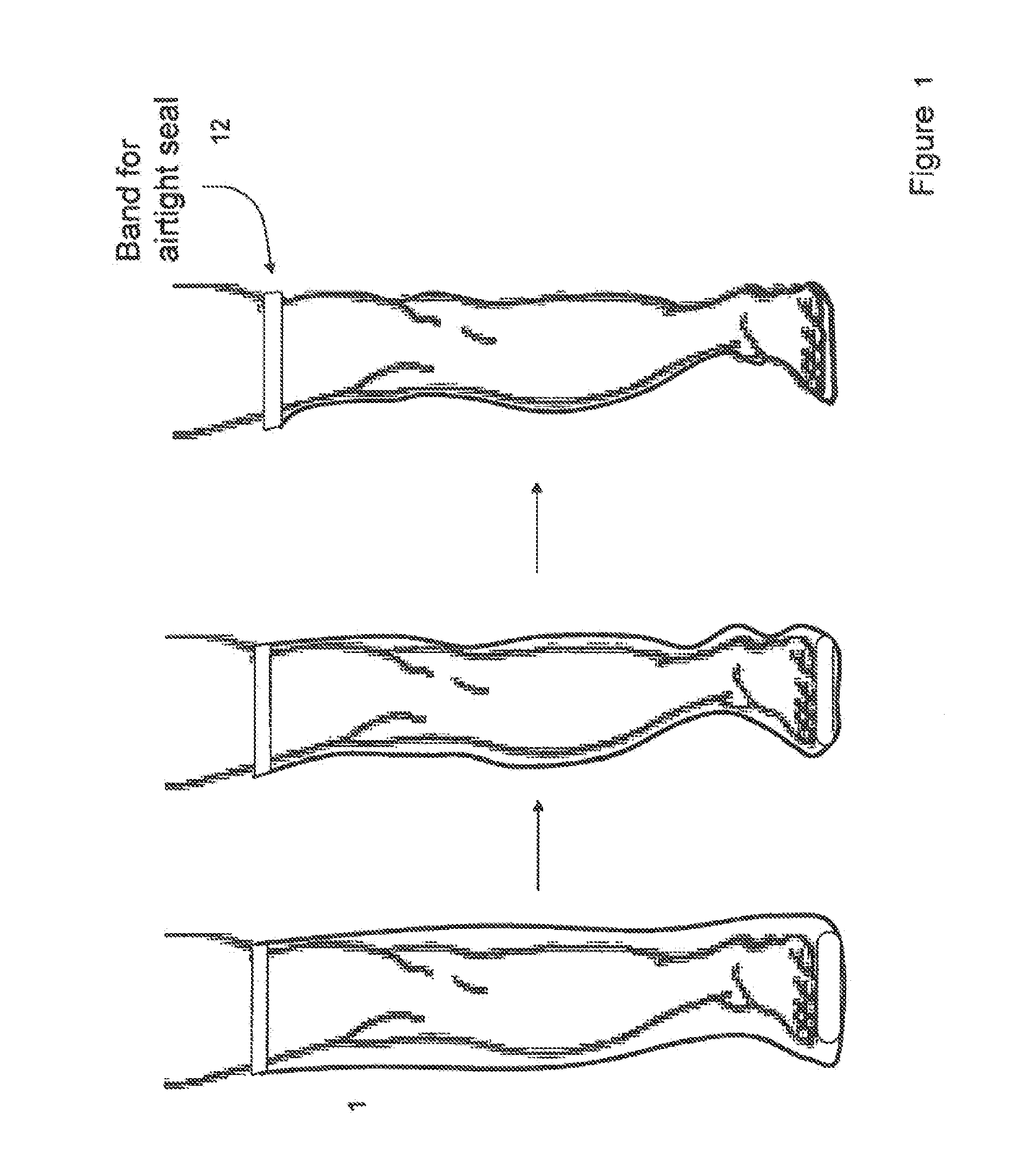

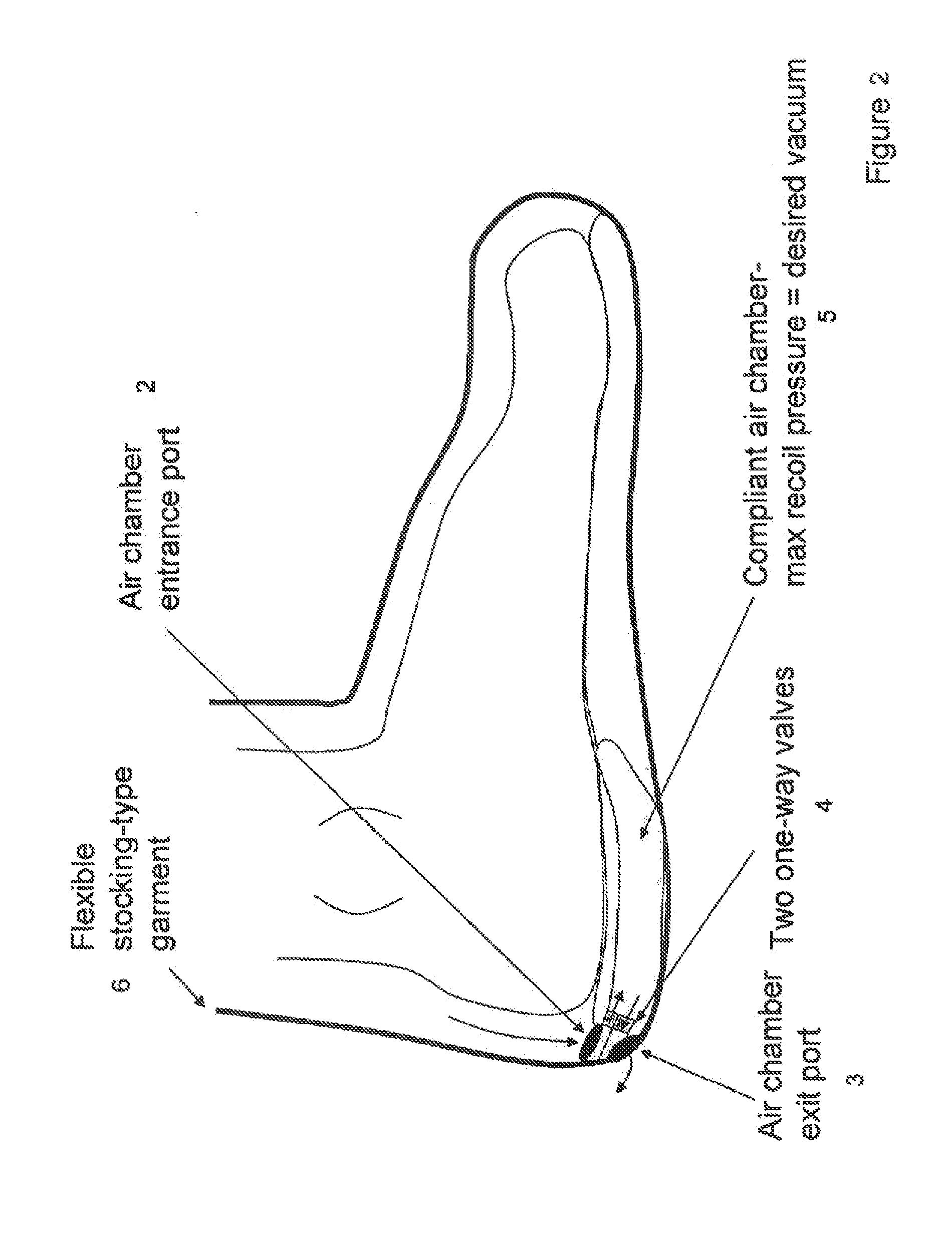

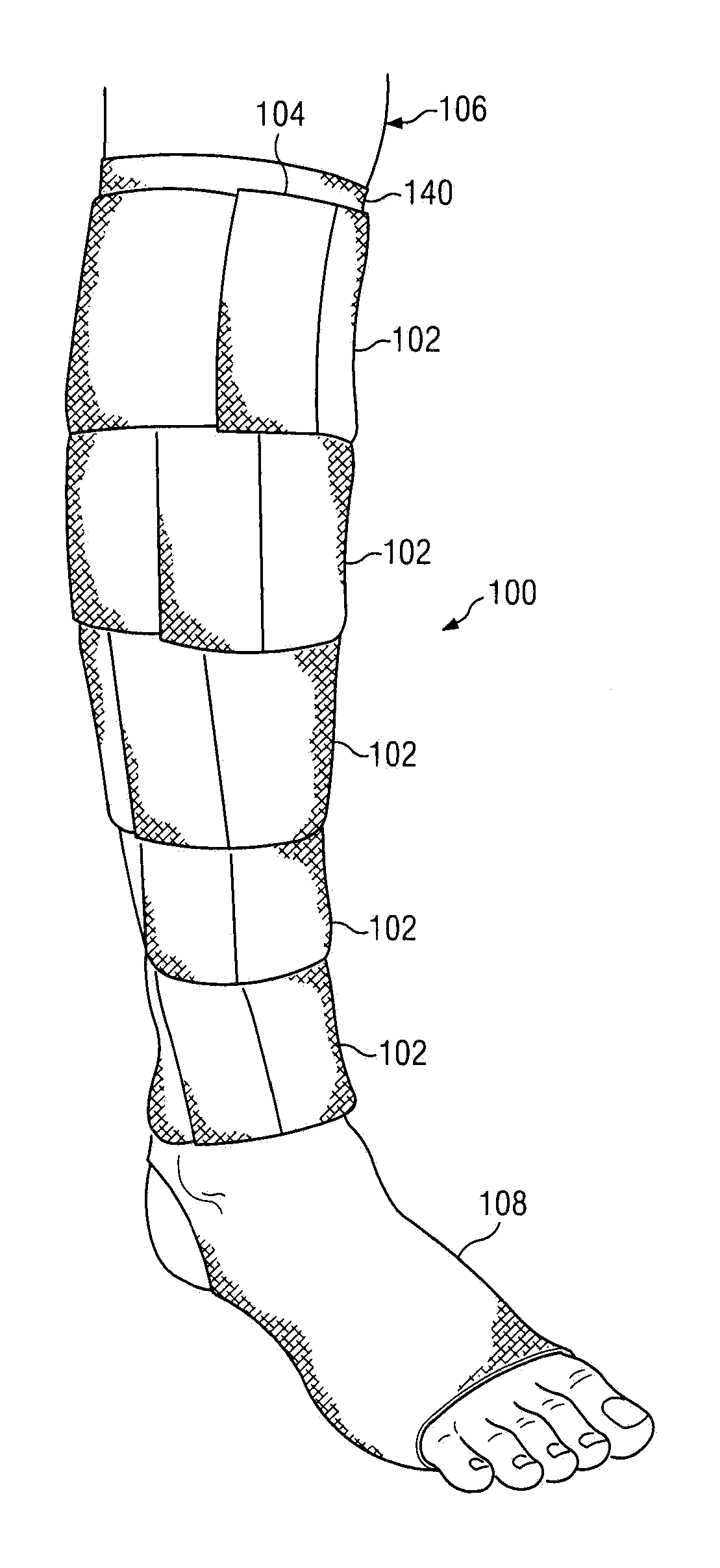

Devices that employ external compression stocking-type garments in the treatment of edema, chronic wounds, deep venous thrombosis prevention or claudication all share a number of significant limitations. These include the frequent need for custom fitting to assure an appropriate fit, vigilant maintenance to assure a continued “good fit,” limited compliance with proper use by patients and difficulty of application. There is a large body of evidence demonstrating that patients often decline to wear the compressive stockings as prescribed or in the form that would be most beneficial because they find these devices to be difficult to put on and take off.Building on the limitations of existing therapies, and distilled lessons learned from the field of prosthetics and wound healing, the present invention employs vacuum-assisted negative pressure to provide compression and help pump fluid from the tissues of affected limbs. The device is embodied in the form of a flexible stocking-like garment that will utilize a pumping mechanism to generate negative pressure around the limb and thus create vacuum compression that will mobilize fluid in a limb and increase venous return to the heart. Through the use of a circumferential wrap, the present invention provides a major advance in both the distribution of vacuum and the securing of the device over the limb.

Owner:THERANOVA LLC

Adaptive compression therapy systems and methods

InactiveUS20170312161A1Physical therapies and activitiesBlood stagnation preventionAdaptive compressionCompression therapy

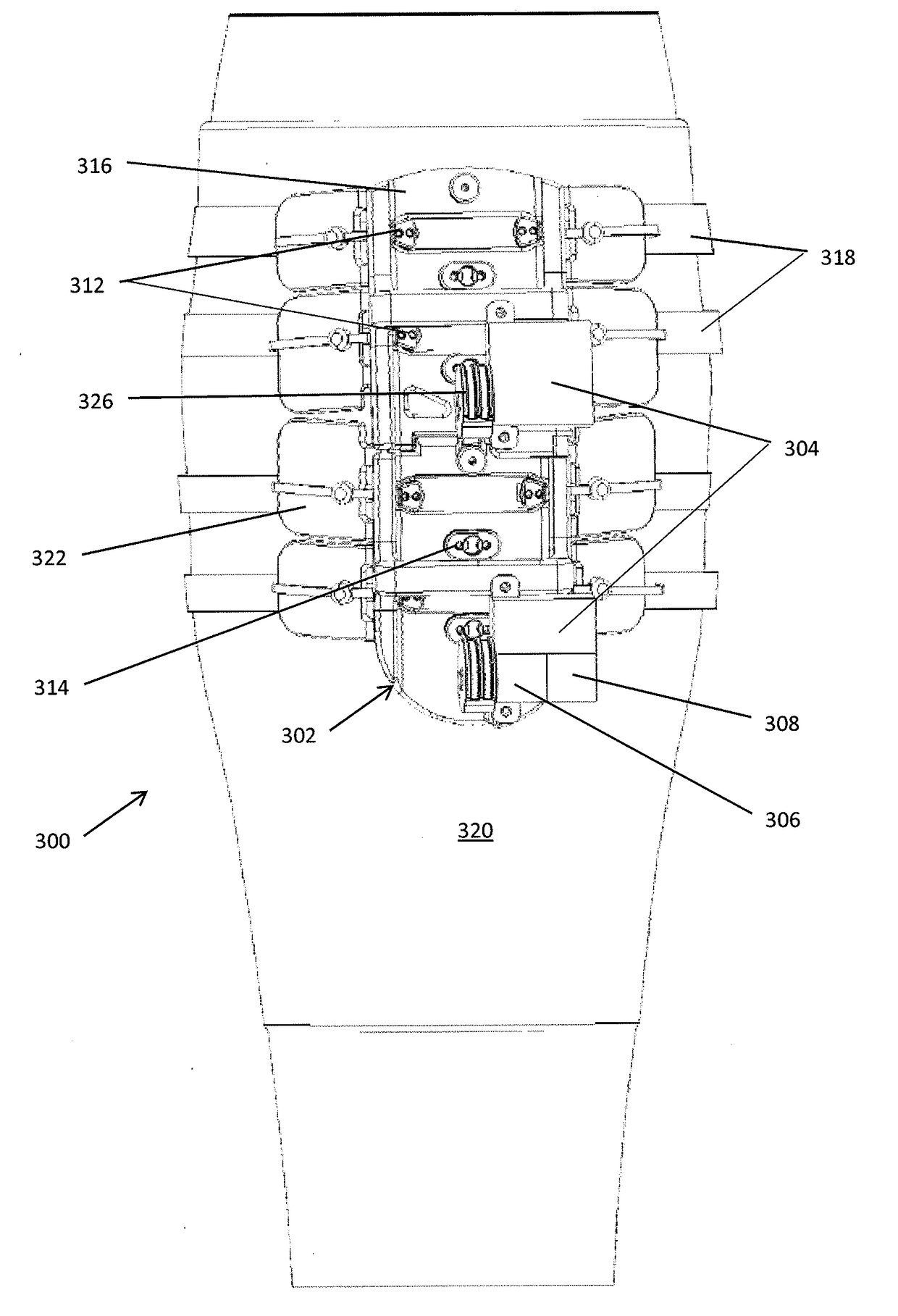

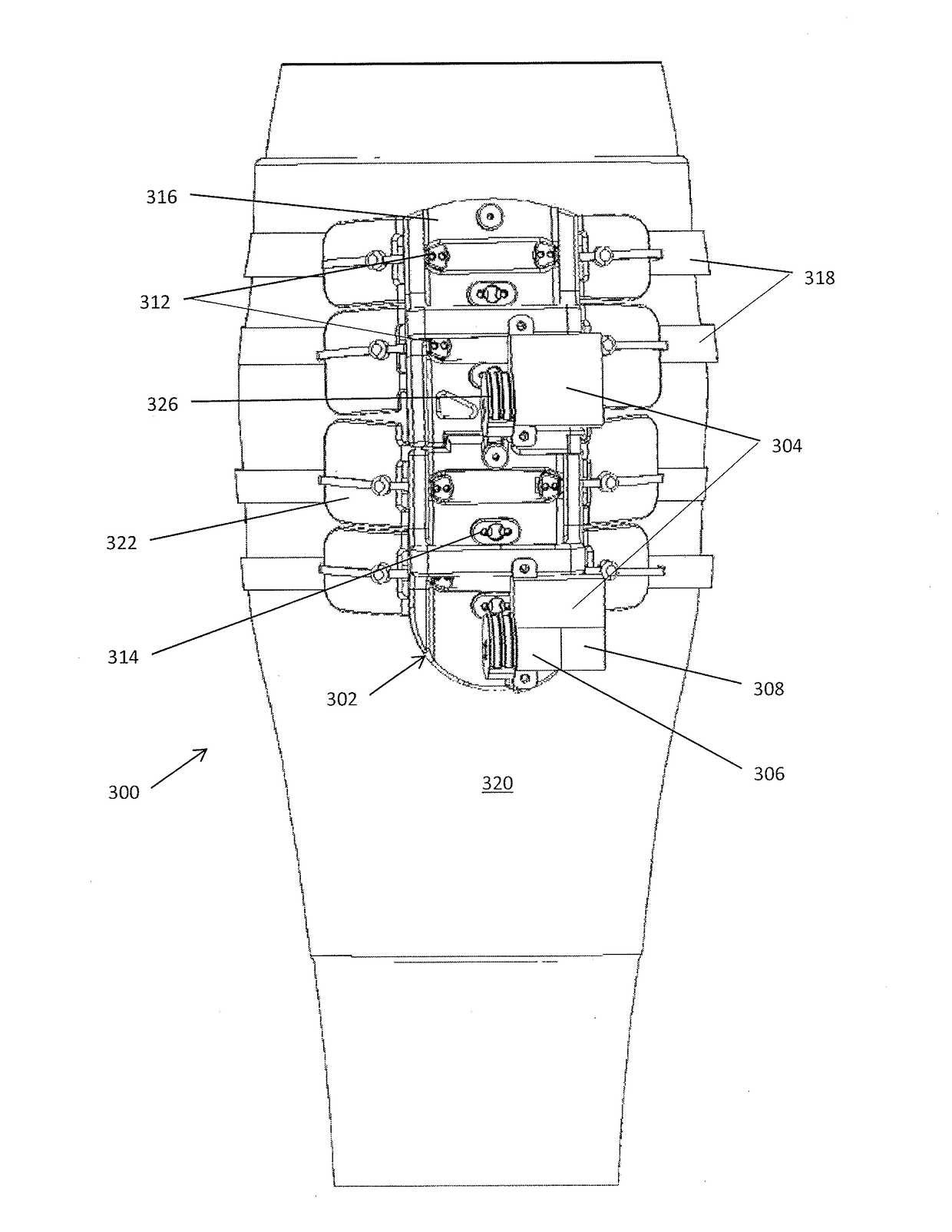

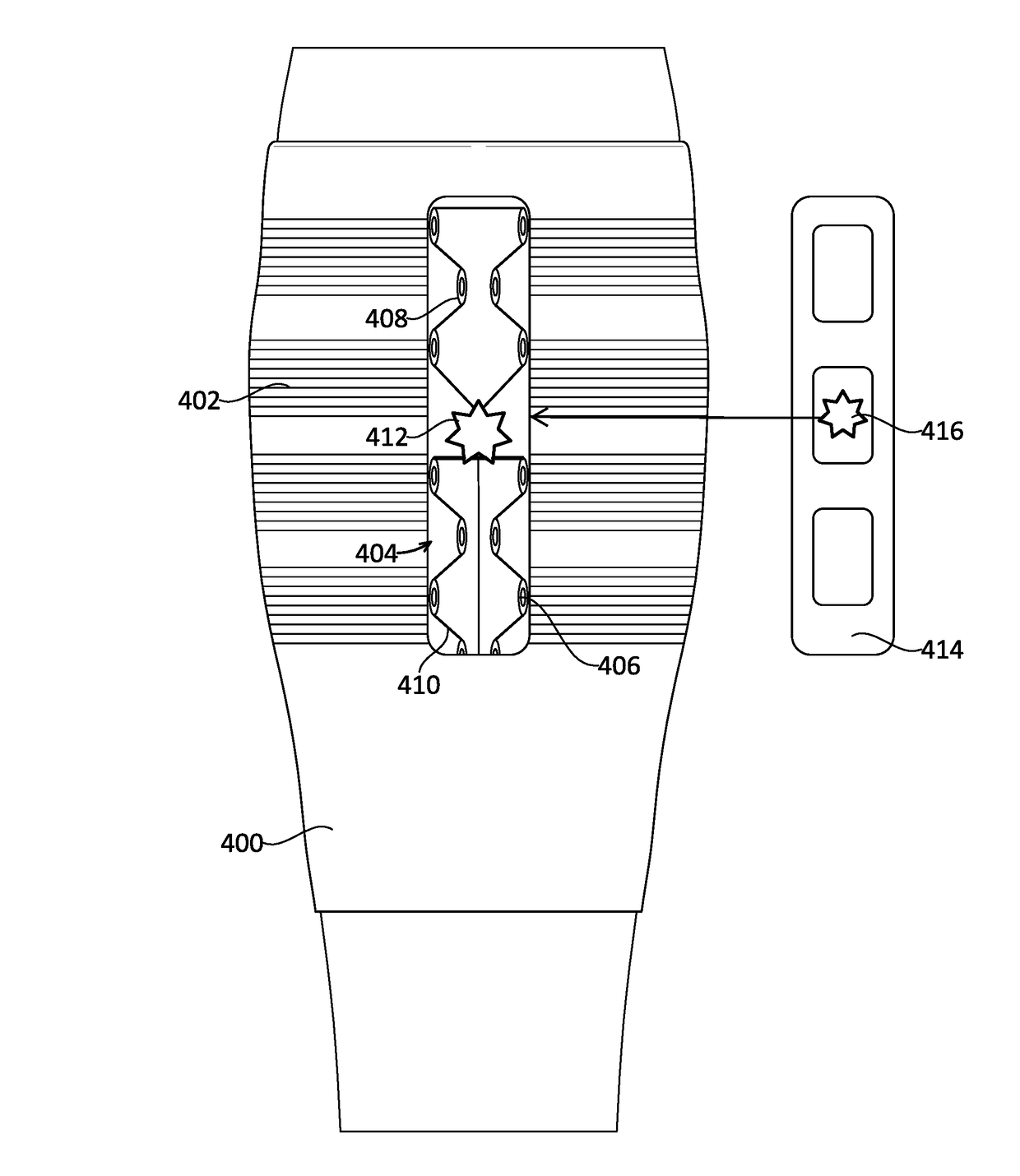

Systems, devices and methods for providing active and / or passive compression therapy to a body part can include a compression device worn over a compression stocking. The compression device can have a pulley based drive train that is driven by a motor to tighten and loosen compression elements, such as compression straps, in a precise, rapid, and balanced manner. Sensors can be used in the compression device and / or compression stockings to provide feedback to modulate the compression treatment parameters.

Owner:RADIAL MEDICAL INC

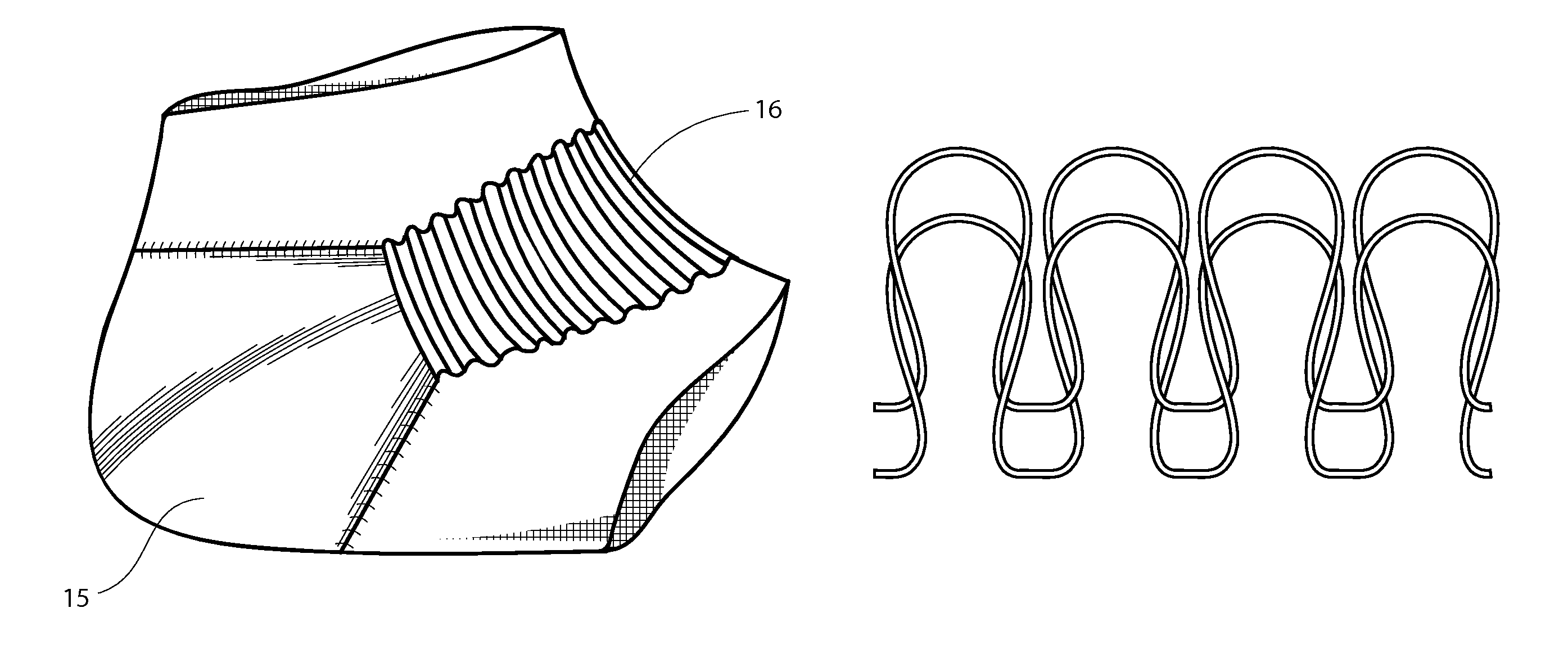

Therapeutic stockings

A knitted therapeutic medical compression stocking made from courses of bi-component fibers inlaid courses of spandex yarn. The use of bi-component yarns, in particular, crimped yarns having an elastomeric core preferably of a polyurethane and a thermoplastic sheath preferably of a polyamide when knit with inlaid courses of bare spandex, covered spandex, or spandex covered with a bi-component yarn forms therapeutic medical stockings that provide excellent compression control. In addition, these therapeutic stockings are more transparent than conventional therapeutic stockings. The therapeutic stockings of the present invention may be knit on a conventional circular hosiery knitting machine.

Owner:BSN MEDICAL INC

Compression stocking, compression stocking weaving process and seamless hosiery machine

ActiveCN103564666AGradient CompliantPerformance requirements to achieve the same ambient pressure differenceFeet bandagesHandkerchiefsEngineeringCompression stockings

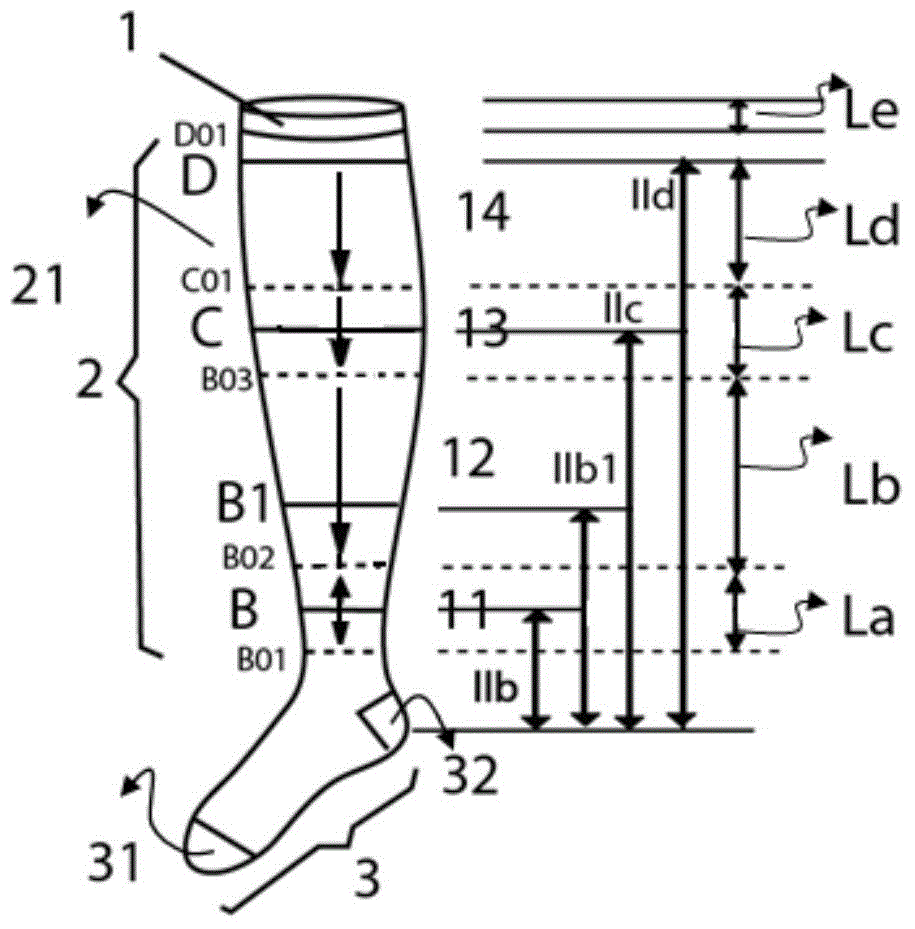

The invention discloses a compression stocking, a compression stocking weaving process and a seamless hosiery machine applied to the compression stocking weaving process. A stocking body of the compression stocking comprises a stable area, compression gradually-changing areas and a compression difference area. The stable area is connected with a stocking foot, the length parameters of the stable area and the girth parameters of the middle portion of the stable area are set corresponding to the length parameters of an ankle and the girth parameters of the thinnest part of the ankle respectively, and the interface compression in the stable area is kept consistent. The plurality of compression gradually-changing areas are located between the stable area and a welt, the stable area, the compression gradually changing areas and the welt are sequentially connected from bottom to top, the interface compression in each compression gradually-changing area gradually decreases from bottom to top, the interface compression of the joint of every two adjacent compression gradually-changing areas is kept successive, and each compression gradually-changing area has a preset compression gradually-decreasing gradient. The compression difference area is located in a local area defined by the stable area and / or the compression gradually-changing areas, and the interface compression in the compression difference area can be distributed in a gradient mode or in an even mode. The compression stocking can meet the requirements for the specific compression magnitude and the distribution of different parts of a lower limb.

Owner:AC CARPI APPL COMPANY

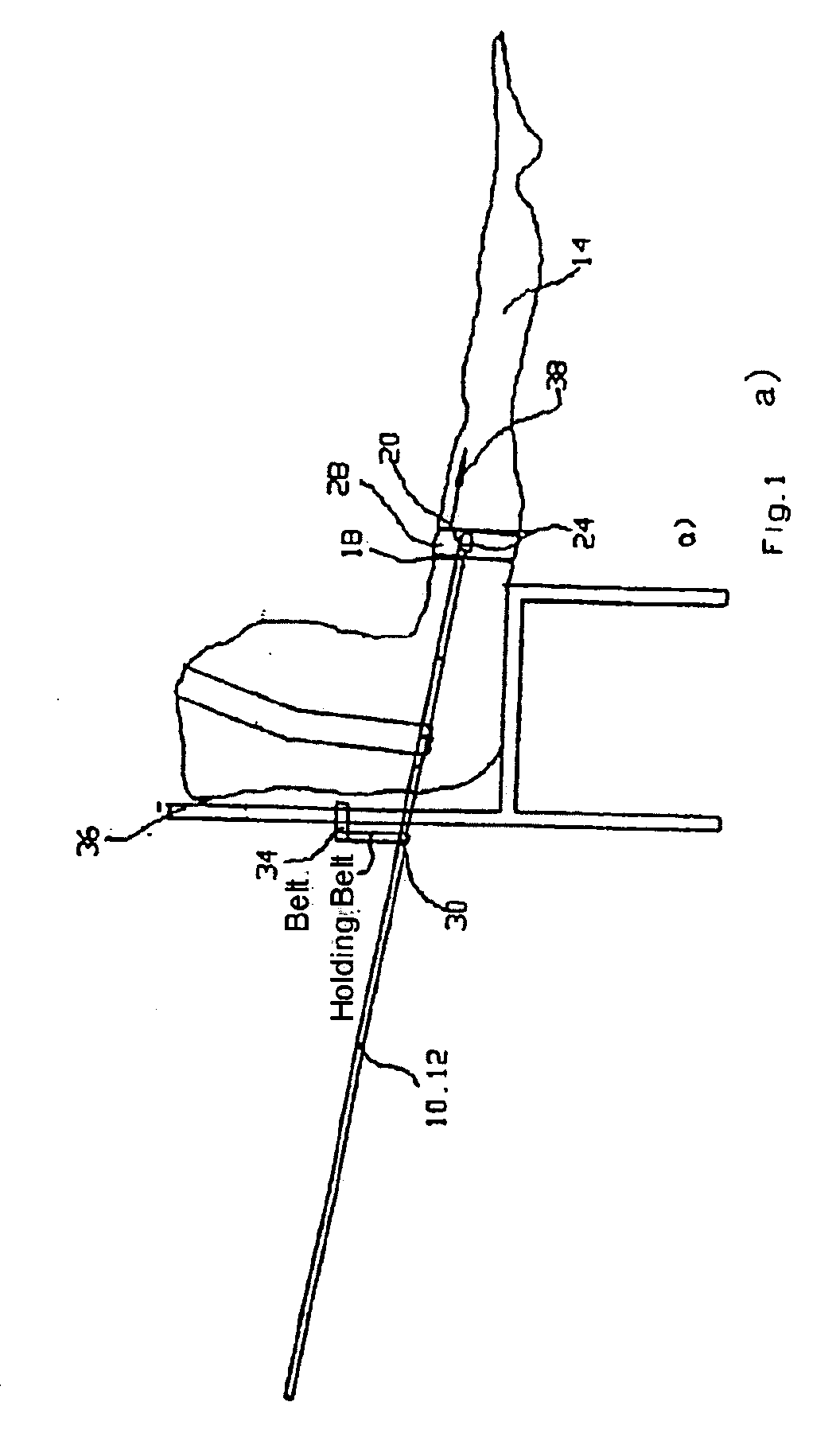

Adaptive compression therapy systems and methods

InactiveUS20170312165A1Physical therapies and activitiesMassage combsAdaptive compressionCompression therapy

Systems, devices and methods for providing active and / or passive compression therapy to a body part can include a compression device worn over a compression stocking. The compression device can have a pulley based drive train that is driven by a motor to tighten and loosen compression elements, such as compression straps, in a precise, rapid, and balanced manner. Sensors can be used in the compression device and / or compression stockings to provide feedback to modulate the compression treatment parameters.

Owner:RADIAL MEDICAL INC

Adaptive compression therapy systems and methods

InactiveUS10076462B2Physical therapies and activitiesMassage combsAdaptive compressionCompression therapy

Systems, devices and methods for providing active and / or passive compression therapy to a body part can include a compression device worn over a compression stocking. The compression device can have a pulley based drive train that is driven by a motor to tighten and loosen compression elements, such as compression straps, in a precise, rapid, and balanced manner. Sensors can be used in the compression device and / or compression stockings to provide feedback to modulate the compression treatment parameters.

Owner:RADIAL MEDICAL INC

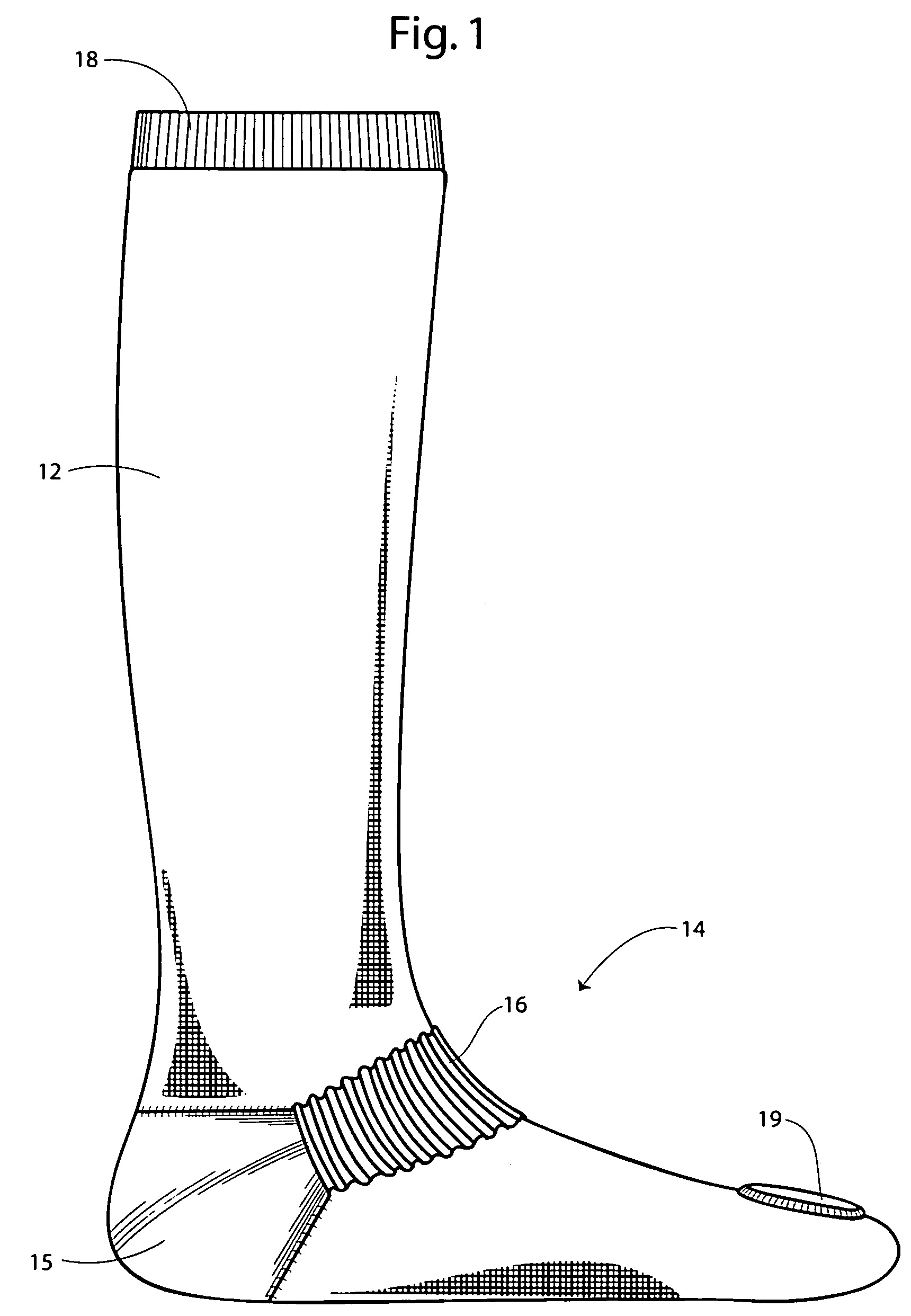

Therapeutic stocking

ActiveUS7775069B1Reduce compressionOrnamental textile articlesFeet bandagesPhysical medicine and rehabilitationCompression stockings

A therapeutic compression stocking is knitted in an integrated knit format to have an oversized heel pocket from which an ankle arch portion extends that is knitted in a rib stitch format that is free of wrinkles when donned. The foot portion has a constant compression force while the leg portion has a graduated compression force. The leg portion compression force being less than the foot portion compression force.

Owner:ALBAHEALTH

Hosiery donning device, in particular for compression hosiery

ActiveUS20110049201A1Simple and cost-effectiveOvercomes drawbackApparel holdersHeel strikeEngineering

A hosiery donning device, in particular for compression hosiery, has a support, a front end portion of which is inserted into the hosiery to be donned; the support defines a downwardly-facing cavity so that a foot can be inserted into the sock or stocking by making the support slide over the upper surface and instep of the foot; a handle is joined to the rear of the support, it is fixed and faces upwards in relation to the support; the cavity is defined by a saddle-shaped portion, on which at least a portion of the hosiery is gathered; the saddle-shaped portion accompanies a portion of the hosiery over the heel of the foot, when the handle is tilted forwards while the saddle-shaped portion remains in contact with the instep of the foot.

Owner:BERTINOTTI SILVIA

Method and apparatus for negative pressure therapy

InactiveUS20110295168A1Easy to returnReduce edemaBlood stagnation preventionPneumatic massageVacuum assistedVenous thrombosis

Devices that employ external compression stocking-type garments in the treatment of edema, chronic wounds, deep venous thrombosis prevention or claudication all share a number of significant limitations. These include the frequent need for custom fitting to assure an appropriate fit, vigilant maintenance to assure a continued “good fit,” limited compliance with proper use by patients and difficulty of application. There is a large body of evidence demonstrating that patients often decline to wear the compressive stockings as prescribed or in the form that would be most beneficial because they find these devices to be difficult to put on and take off. Building on the limitations of existing therapies, and distilled lessons learned from the field of prosthetics and wound healing, the present invention employs vacuum-assisted negative pressure to provide compression and help pump fluid from the tissues of affected limbs. The device is embodied in the form of a flexible stocking-like garment that will utilize a pumping mechanism to generate negative pressure around the limb and thus create vacuum compression that will mobilize fluid in a limb and increase venous return to the heart. Through the use of a circumferential wrap, the present invention provides a major advance in both the distribution of vacuum and the securing of the device over the limb.

Owner:THERANOVA LLC

Therapeutic stocking

ActiveUS20080132822A1Efficient productionReduce compressionOrnamental textile articlesFeet bandagesWrinkle skinPhysical therapy

Owner:ALBAHEALTH

Human body lower limb automatic measuring device and method

ActiveCN102763923ARealize automatic measurementEasy to operateClothes making applicancesHuman bodyDisplay device

The invention relates to a human body lower limb automatic measuring device and a human body lower limb automatic measuring method. The device comprises an image collecting device and an image processor, wherein the image collecting device comprises a pair of special measuring trousers and a measuring work table, the front side and the left side of the measuring work table are respectively provided with a camera machine case, the camera machine case is connected with the measuring work table through a metal rod, a camera and a flash lamp are arranged on the camera machine case, the image processor consists of a computer host machine and a display, and the image collecting device and the image processor are connected through a USB (universal serial bus) data wire. The device and the method provided by the invention have the beneficial effects that a front side image and a lateral side image are collected through a camera, the automatic measurement on the lower limb dimension of the human bodies is realized, all dimensions required by the medical compression stockings can be simply, fast and accurately obtained, the defects of time waste, labor waste and the like the manual measurement in the prior art are avoided, the device and the method can also be used for realizing the application to other leg dimension requiring occasions, the cost is low, and the operation is simple and convenient.

Owner:ZHEJIANG SCI-TECH UNIV +1

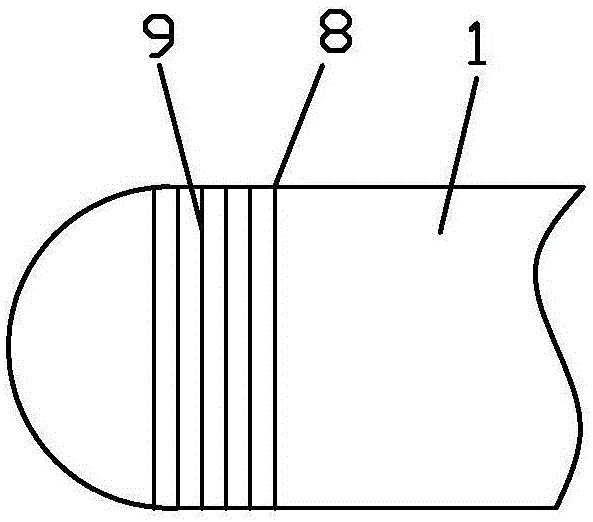

Compression Article, Particularly A Compression Stocking With A Surface Pattern

The invention relates to a compression article, particularly a compression stocking or compression tights, made of an elastic knitted fabric (1) with a base knitted fabric (2), which is made from a knitting thread (S) and inside of which compression-imparting compression threads (K) are deposited. In order to obtain a surface pattern, the manner in which the compression threads (K) are deposited alternates area by area.

Owner:JULIUS ZORN

Adaptive compression therapy systems and methods

InactiveUS20200268592A1Therapeutic applicationMassage combsBlood stagnation preventionPhysical medicine and rehabilitationCompression therapy

Systems, devices and methods for providing active and / or passive compression therapy to a body part can include a compression device worn over a compression stocking The compression device can have a pulley based drive train that is driven by a motor to tighten and loosen compression elements, such as compression straps, in a precise, rapid, and balanced manner. Sensors can be used in the compression device and / or compression stockings to provide feedback to modulate the compression treatment parameters.

Owner:RADIAL MEDICAL INC

Universal chap-style compression stocking

InactiveUS20050177927A1High pressureProviding openingStockingFeet bandagesPhysical medicine and rehabilitationThigh musculature

There is provided a chap-styled therapeutic gradient compression stocking that includes a foot portion, a leg portion having a lower leg portion extending from the foot portion upward above the knee to an upper leg portion, a waist support and a hip portion extending between the waist support and the upper leg portion may be made with stretchable yarn to provide a compressive force against the lower leg and thigh of a patient and constructed so as to be worn on either leg. The hip portion is formed between the thigh portion and the waist support and covers the area below the waist of the patient to the upper leg portion. The hip portion is formed around the lower waist of the patient and has cutouts on each side of the hip portion, sized to accommodate the crotch area of the patient so that the stocking may be worn on either leg. The therapeutic stocking is held in place on the patient's leg by a waist support or waistband that includes a strap-engaging loop formed at the top of the hip portion. The strap-engaging loop extends around that portion of the circumference the hip portion at the front and rear of the portion but not above the cutouts. Through the strap-engaging loop is waist strap. The strap has Velcro®-type fasteners on either side so that the strap may be easily opened and closed from either side depending upon which leg the stocking is being worn.

Owner:BSN MEDICAL INC

Compression stocking

InactiveUS20120172922A1Less amount of dexterityLess amount of strengthSurgeryFeet bandagesConstant stressEngineering

A compression stocking includes a foot portion that is adapted to matingly removably receive at least a portion of a foot. A closable and openable leg portion extends upwardly from a top of the foot portion, is adapted to removably receive at least a portion of a corresponding leg, and defines adjoining edges of the leg portion. A fastening device extends a length of the leg portion and is adapted to fasten the adjoining edges to and unfasten the adjoining edges from each other and, in turn, close and open the leg portion. In this way, the compression stocking can secure and apply continuous pressure to the foot and leg.

Owner:SESI NASRIN

Assist device for doffing stockings

InactiveUS20080277432A1Completely sliding the stocking over the foot is simplifiedEasy to operateApparel holdersFeet bandagesEngineeringCompression stockings

In order to ensure easy handling as well as cost-effective production of an assist device for doffing stockings, in particular compression stockings, it is proposed to configure the assist device with two rod-shaped sliding elements, where a front end of each rod-shaped sliding elements is connected to a top circular border of the stocking at diametrically opposite positions in a form-fitting and force-fitting manner, and where the stocking can be rolled off and / or slid off the leg and / or foot by sliding the sliding elements in the direction of the foot and over the foot.

Owner:HORCHER WILLI

Removable Sleeve for Facilitating the Application of Compression Stockings

InactiveUS20100089954A1Broaden applicationEasy to useApparel holdersEngineeringCompression stockings

An inexpensive sleeve and method of use are disclosed for easing application of a compression stocking onto a foot and leg. By reducing the friction usually encountered when applying a compression stocking or sock, the sleeve protects the foot and leg from injury, and helps to avoid the need for sophisticated stocking or sleeve manipulation. The sleeve is made from a low friction material, such as plastic, silk, Tyvec, or nylon, and therefore is easy to pull over the foot and leg while closely conforming thereto so as to avoid folding and bunching. The sleeve can be disposable and / or closed at one end. The method of use includes pulling the sleeve over the foot and leg, pulling the stocking over the sleeve, and then removing the sleeve through an open stocking toe or through the top of the stocking, leaving the stocking in place.

Owner:RONDEAU ROGER E +2

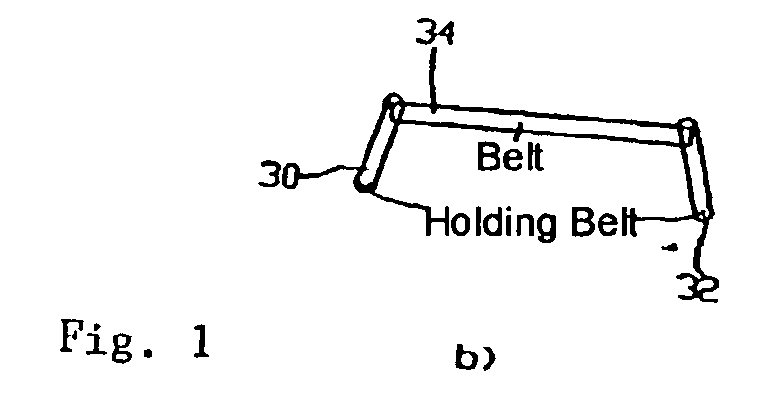

Compression Stocking Donning Aid

Embodiments of the Compression Stocking Donning Aid are comprised of a handle assembly, a bracket assembly, and a sock applicator assembly. The handle assembly is comprised of two, mirror image handles that are covered by handle grips. The handles are essentially linear elongated cylinders that allow the user of the Aid to grasp the Aid and apply the necessary leverage to open the compression stocking for application. The sock applicator assembly is comprised of two sock applicators. The bracket assembly is comprised of a back plate, a front plate, a ratcheting plate, a ratcheting dog, a pivot fastener, a ratcheting dog fastener, and padding. The ratcheting plate forms ratcheting teeth that engage with the ratcheting dog while the handles are moved inward.

Owner:BARKER LOREN CHARLES MR

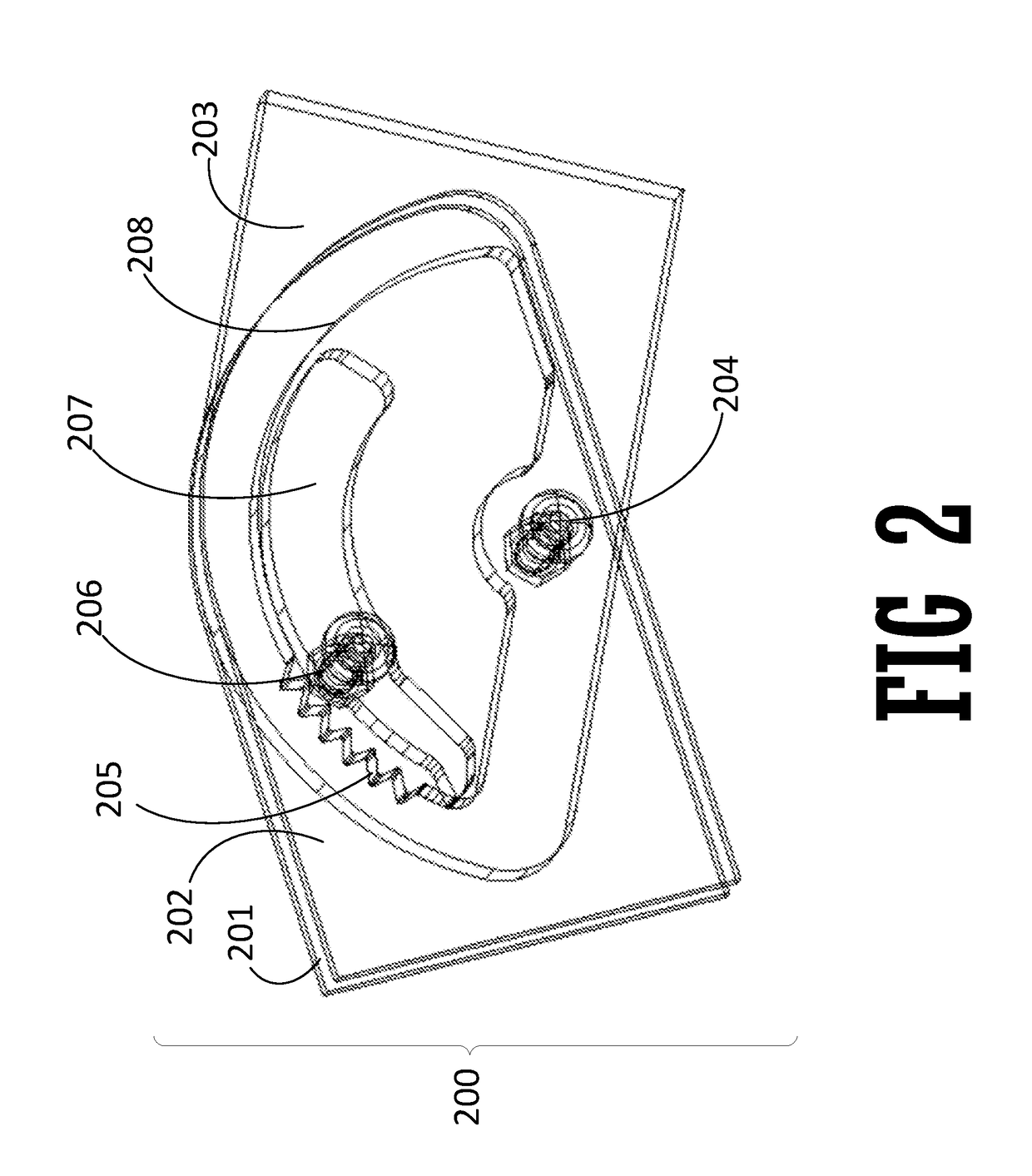

Medical Support and Compression Stocking

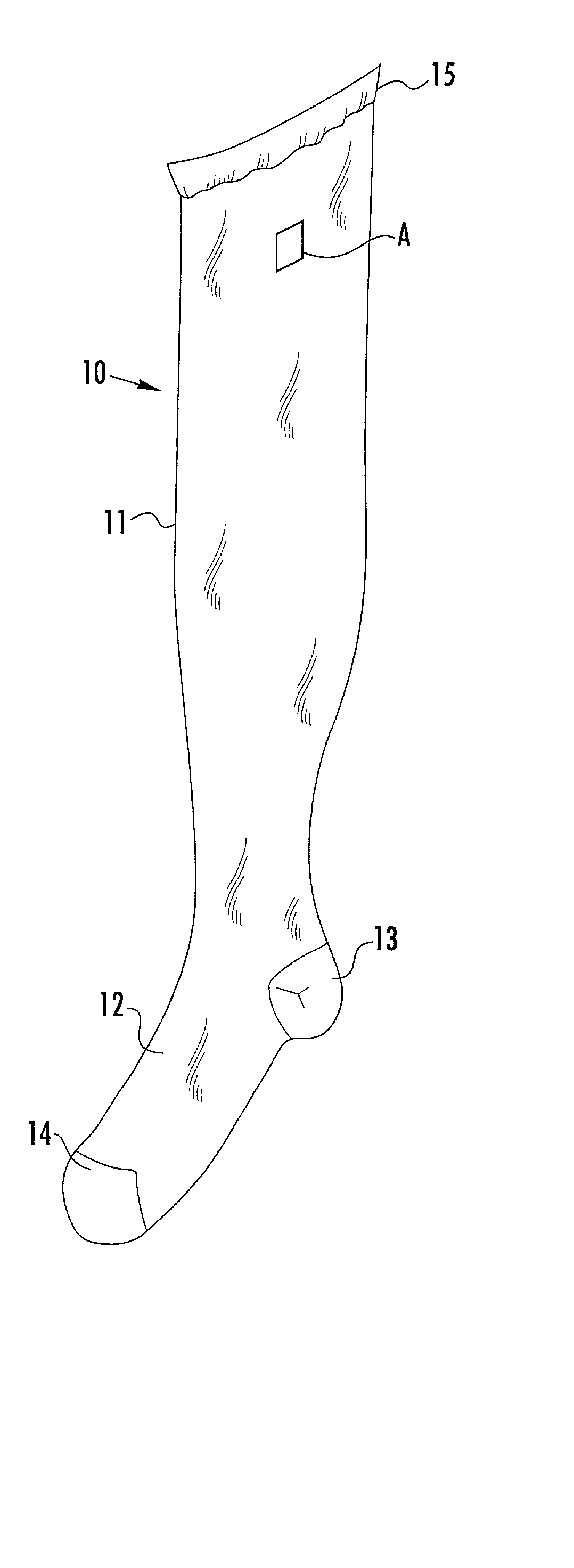

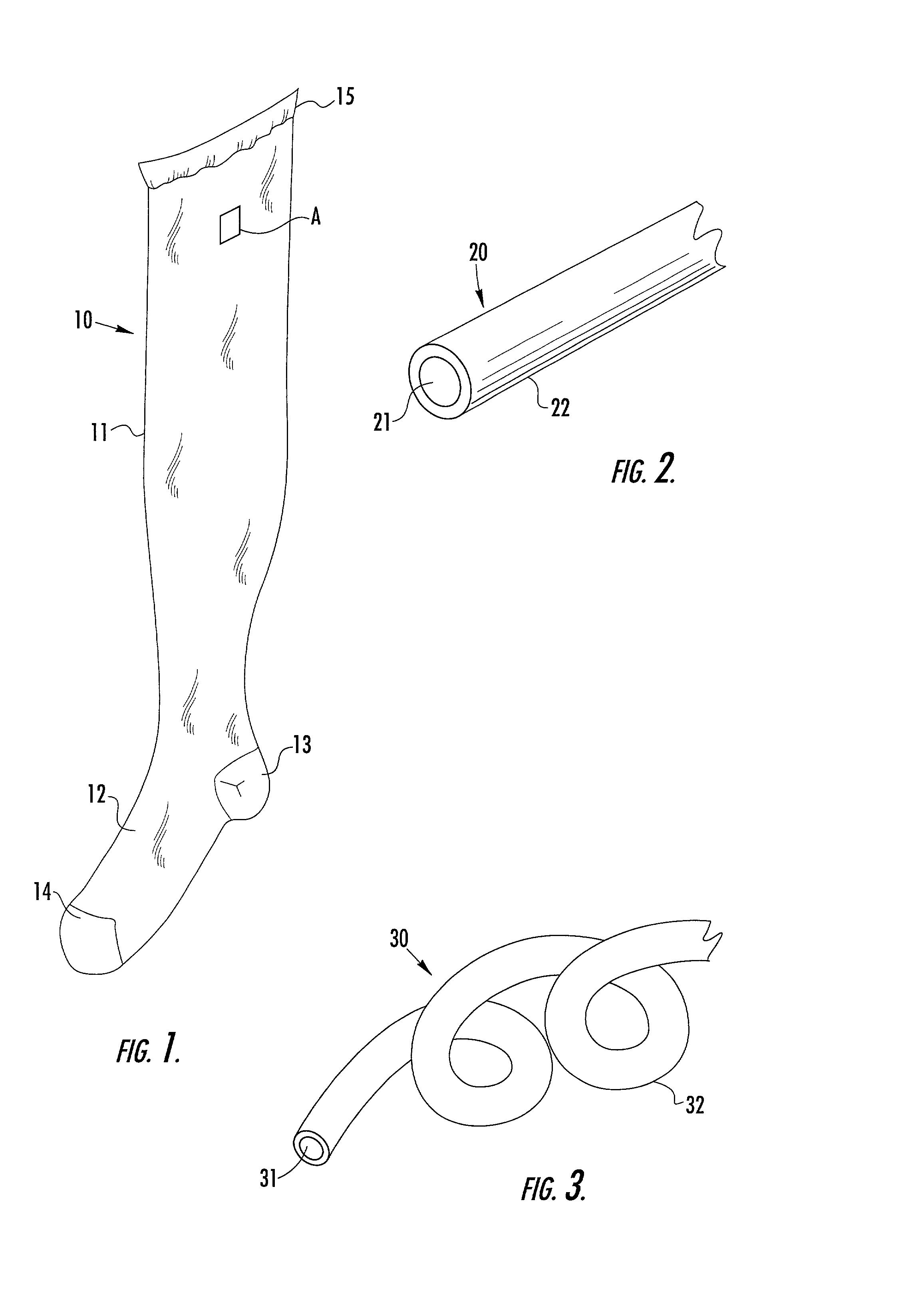

InactiveUS20140323934A1Pleasant compression pressureEasy to disassemblePneumatic massageChiropractic devicesEngineeringCompression stockings

In order to improve the use of a medical support and compression stocking, it is proposed that the stocking (10) shall comprise a woven- or knitted-fabric-type base element (20) that is substantially tubular and that can be pulled over the lower leg of the wearer. Moreover, the stocking comprises at least one air chamber (30) that can be filled with air. The air chamber (30) is designed in a tubular shape along the length of the support and compression stocking. The stocking further comprises an electronic unit that is equipped with a micropump and a valve for the air supply, the micropump being provided with a valve, a current source, preferably a rechargeable battery and control electronics including a wireless data transfer unit. The pressure values of the at least one air chamber can be regulated by means of the data transfer unit and a software stored in the electronic unit.

Owner:EMPA EIDGENOESSISCHE MATERIALPRFUNGS & FORSCHUNGSANSTALT +3

Hybrid compression stocking

ActiveUS20110218473A1Simple, but very reliable,Maximal augmentationPneumatic massageChiropractic devicesDistal portionTransition line

A compression stocking for compressing a limb is disclosed. The stocking may include a proximal tube, a distal tube, and an transition line or zone. The proximal tube may have a distal end and a proximal end and be configured to compress a proximal portion of a limb. The distal tube may have a distal end and a proximal end and be configured to compress a distal portion of the limb. The transition line or zone may provide a location where the distal end of the proximal tube connects to the proximal end of the distal tube. The transition line or zone may correspond to an abrupt change in magnitude between compression provided by the proximal tube and compression provided by the distal tube.

Owner:FARROW INNOVATIONS

Compression stocking meeting requirements of human body pressure and pressure distribution law and knitting method thereof

PendingCN108301110AMeet changing needsEliminate or reduce stressWeft knittingHandkerchiefsPhysical medicine and rehabilitationDistribution law

The invention discloses a compression stocking meeting the requirements of human body pressure and pressure distribution law and a knitting method thereof. According to the method, adjusting coils arearranged at intervals between normal coils of the compression stocking, and the normal coils and the adjusting coils cooperate to form an organ structure. When the stocking body surface is not stretched or shrunk, the adjusting coils are extruded by the normal coils and suspended on the surface of the compression stocking, and an upper and a lower normal coils are closely cooperated, when the stocking body surface is stretched, the normal coils are stretched to form gaps, and the gaps are filled with the adjusting coils. The compression stocking meeting the requirements of human body pressureand pressure distribution law and the knitting method thereof have the advantages that when the size of the stocking body surface is changed for adapting to changes in the bones, muscles and the likein daily activities of a human body, the compression stocking automatically adjusts the size of the stocking body to meet the changing needs of the human body surface during exercise, and thereby eliminating or reducing the problem of unreasonable pressure and pressure distribution caused by changes in the bones, muscles and the like under different active conditions of the human body.

Owner:JIANGSU HUAJIA SILK +1

Compression stocking donning aid

Embodiments of the Compression Stocking Donning Aid are comprised of a handle assembly, a bracket assembly, and a sock applicator assembly. The handle assembly is comprised of two, mirror image handles that are covered by handle grips. The handles are essentially linear elongated cylinders that allow the user of the Aid to grasp the Aid and apply the necessary leverage to open the compression stocking for application. The sock applicator assembly is comprised of two sock applicators. The bracket assembly is comprised of a back plate, a front plate, a ratcheting plate, a ratcheting dog, a pivot fastener, a ratcheting dog fastener, and padding. The ratcheting plate forms ratcheting teeth that engage with the ratcheting dog while the handles are moved inward.

Owner:BARKER LOREN CHARLES MR

Compression support stocking with a compression support body

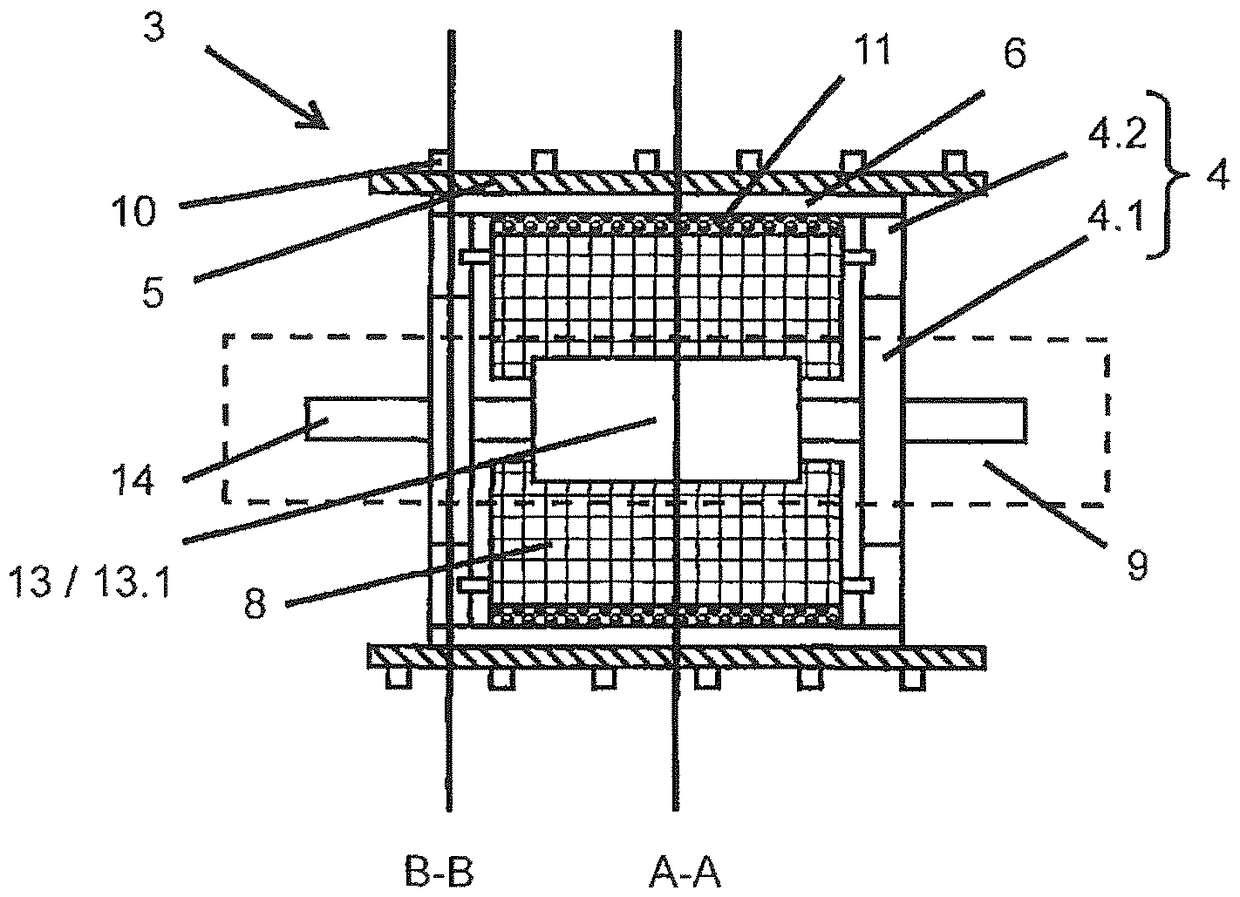

InactiveUS7028690B2Improved force transmissionAccurate adaptationRestraining devicesFeet bandagesTissue fluidKnee Joint

A compression stocking (1) made of a knit or woven elastic fabric provided with a compression body (6) which can be attached to the compression stocking (1) such that the compression body is positioned at a knee joint (5). The compression stocking (1) of the invention can be used, for example, after surgery in the area of the knee joint (5). To get rid of the wound secretion, blood and tissue fluid that occurs during surgery from the soft tissue surrounding the joint, a defined pressure is applied by the compression stocking (1) and the compression body (6) to the soft tissue of the knee joint (5). To this end, the compression body (6) has a recess (7) to accommodate the patella of the knee joint (5). The recess (7) and the compression body (6) each have an elliptical shape, which is approximately adapted to the shape of the patella, i.e., the joint soft tissue. To accommodate the wound suture and associated wound clamps, the compression body (6) has a groove-shaped recess (11) on the surface facing the soft tissue of the knee joint (5).

Owner:SCHNEIDER THOMAS +2

Compression stocking, compression stocking weaving process and seamless hosiery machine

ActiveCN103564666BGradient CompliantPerformance requirements to achieve the same ambient pressure differenceFeet bandagesHandkerchiefsEngineeringCompression stockings

A compression stocking, a weaving process of the compression stocking, and a seamless hosiery machine applied in the process. A stocking body (2) of the compression stocking comprises a stable region (11), compression gradually-changing regions (12, 13, 14), and a compression difference region. The stable region (11) is connected to a stocking foot (3). A length parameter (LA) and a middle girth parameter (B) of the stable region (11) are set separately according to a length parameter (LA) of an ankle and a girth parameter (cB) of a thinnest part of the ankle. The interface compression in the stable region (11) is kept consistent. The compression gradually-changing regions (12, 13, 14) are located between the stable region (11) and a welt (1), the stable region (11), the compression gradually changing regions (12, 13, 14) and the welt (1) are sequentially connected from bottom to top. The interface compression in each of the compression gradually-changing regions (12, 13, 14) gradually decreases from bottom to top, the interface compression of the joint of the neighboring compression gradually-changing regions (12, 13, 14) is kept successive, and each of the compression gradually-changing regions (12, 13, 14) has a preset compression gradually-decreasing gradient. The compression difference region is located in a local region surrounded by the stable region (11) and / or the compression gradually-changing regions (12, 13, 14). The interface compression in the compression difference region may be distributed in a gradient manner or in an even manner. The compression stocking can meet requirements for the specific compression magnitude and the distribution of different parts of a lower limb.

Owner:AC CARPI APPL COMPANY

Anti-varicose veins compression stocking

The invention discloses an anti-varicose veins compression stocking. The anti-varicose veins compression stocking comprises a stocking body, at least two parallel soft magnetic stripes are arranged onthe outer side of the stocking body, and every two adjacent soft magnetic stripes are mutually attracted. By adopting the structure, when blood flows to the foot from the heart, the blood flows intothe foot so that the stocking body is expanded by a distance, because the attractive force between the magnetic stripes can be sharply reduced after the magnetic stripes are separated by a distance, the overall pressure of the stocking can be reduced, and the blood more easily flows to the foot; while the blood backflows, the stocking is shrunk by a distance, the attractive force between the magnetic stripes can be sharply increased after the magnetic stripes get close by a distance, the overall pressure of the stocking is greatly increased, accordingly, the blood more easily backflows, and itis ensured that that blood flows more smoothly.

Owner:浙江拓臻医疗科技有限公司

Donning aid for compression stockings

The invention relates to a donning aid 1 for compression stockings 2, comprising a carrier element 7 which is able to enclose a body part at least to some extent. The donning aid 1 is characterized bycomprising at least one motor designed to set the carrier element 7 or parts thereof moving, the movement being able to at least aid in rolling a compression stocking 2 up or down.

Owner:乔治赫兹格

Compression stocking

InactiveUS9610199B2Donning and doffing of it is relatively easyLess amountSurgeryFeet bandagesCompression therapyConstant stress

A stocking for a compression-therapy patient comprises a foot portion matingly removably receiving and surrounding a foot. A closable / openable leg portion extends from the foot portion, removably receives a leg, defines adjoining edges of the leg portion, and includes a band defining an uppermost area of the leg portion and material of which is more compressive / supportive than a remainder thereof. A fastening device extends along the leg portion and continuously fastens / unfastens the edges to / from each other and closes / opens the leg portion such that the stocking can secure and apply continuous pressure to the foot / leg. The device includes a zipper and an enfoldment connected and secured along a continuous inner edge of the zipper, including material that is different than the band and / or remainder of the leg portion, and disposed between the zipper and skin and contacting the skin such that the enfoldment prevents the zipper from contacting the skin.

Owner:SESI NASRIN

Graded compression stocking

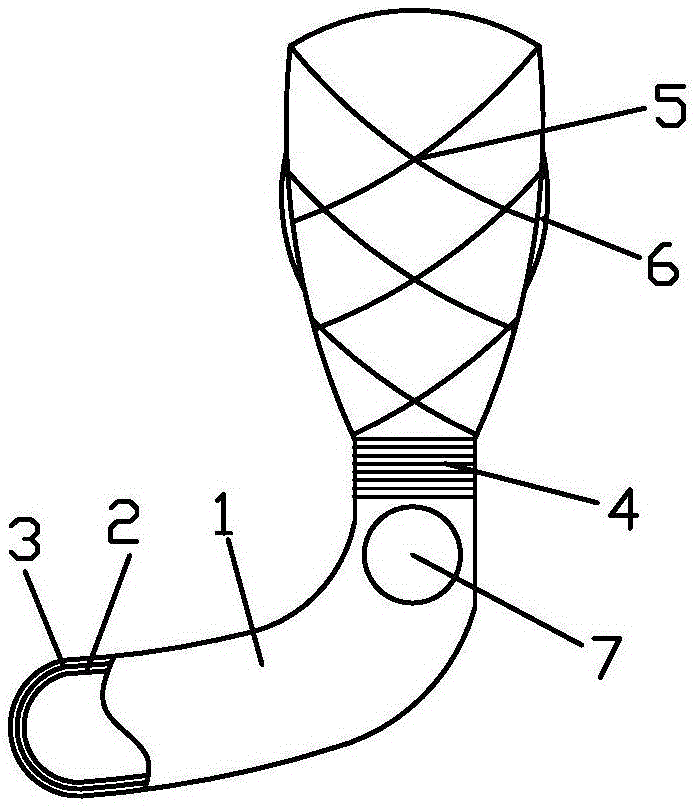

Provided in the invention is a graded compression stocking comprising a stocking body, an elastic inner layer, a ventilating layer, an ankle elastic ring, a graded elastic band, and a plurality of shank elastic plates. The ventilating layer is arranged at the inner side of the stocking body; the elastic inner layer is arranged at the inner side of the ventilating layer; and the stocking body, the elastic inner layer and the ventilating layer are processed by hot pressing to form an integrated compression stocking body. The ankle elastic ring is arranged at the ankle of the compression stocking body; and the graded elastic band is arranged at the shank of the compression stocking body, wherein the internal diameter of the shank part of the compression stocking body is larger than the internal diameter of the ankle elastic ring. The graded elastic band is formed by intersection of a plurality of elastic band bodies arranged at intervals; and the elastic band bodies are inclined at 45 degrees based on the horizontal plane. The multiple shank elastic plates are uniformly distributed on the compression stocking body and are located at the shank part of the compression stocking body. According to the invention, the leg pressure can be reduced in a stepped mode; the foot and the leg can be effectively protected; and thus various foot problems containing an artery varicose problem, a flat foot problem, a big toe valgus problem, and an ankle sprain problem and the like can be solved.

Owner:HAINING HAD SOCKS

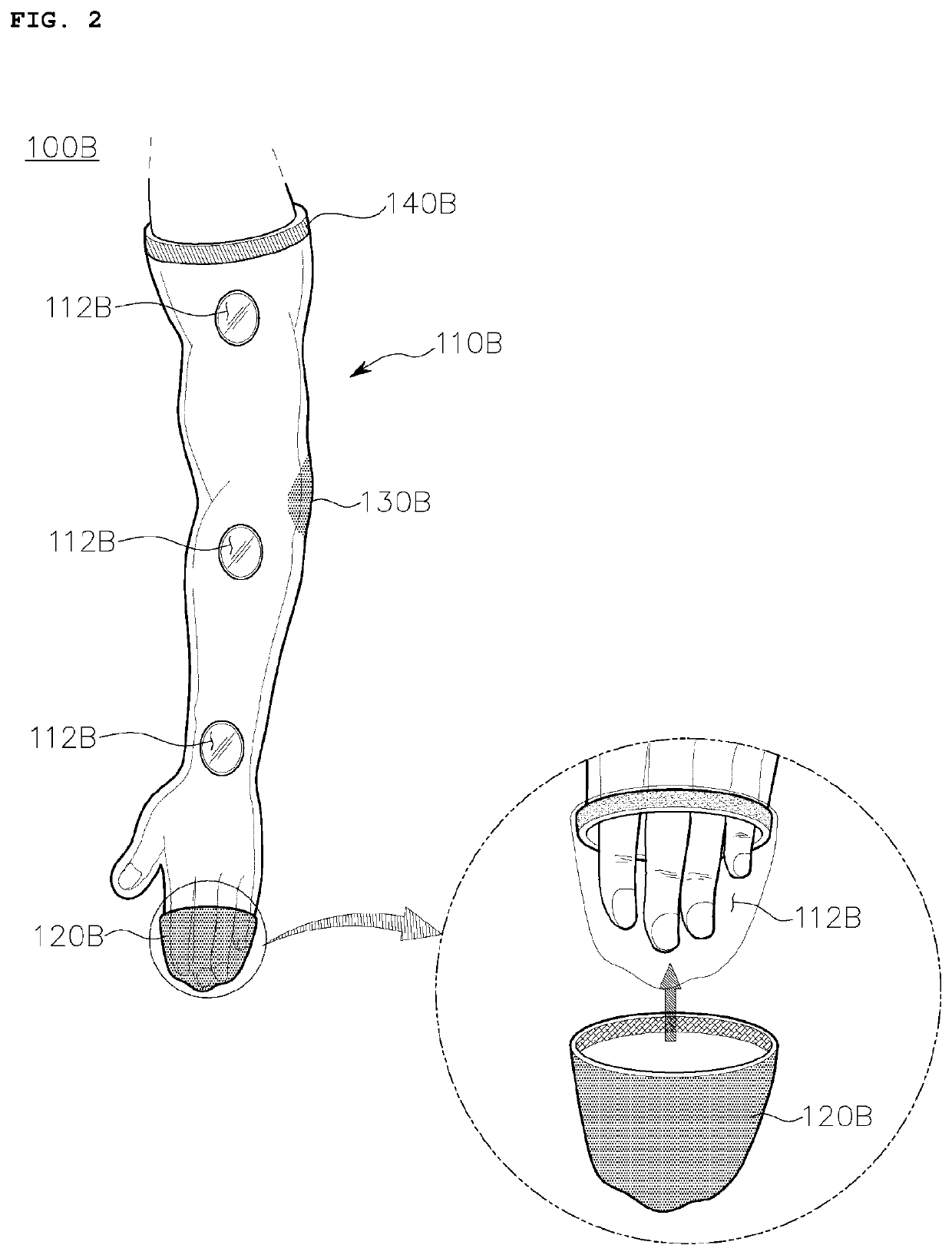

Compression stocking for hemiplegia patient

PendingUS20210315741A1Problem is particularly acutePrevent looseningFinger bandagesPlastersPhysical medicine and rehabilitationThrombus

A According to the present disclosure, there is provided a compression stocking for a hemiplegia patient worn on the hemiplegia patient's arm or leg, including: a main body having an observation portion configured to observe a corresponding body portion so as to check a vascular lesion of the patient, in which the main body has different compression degrees depending on portions of the arm or the leg. According to the present disclosure, it is possible to correct and treat the acute unilateral limb problem by wearing the compression stocking on the arm or leg requiring treatment of the hemiplegia patient, prevent thrombus by compressing the arm or leg with different pressures in a state where the compression stocking for a hemiplegia patient is worn on the hemiplegia patient's arm or leg, and check the vascular lesion of the patient through the observation portion formed at the end thereof in a state where the compression stocking for a hemiplegia patient is worn on the hemiplegia patient's arm or leg.

Owner:AJOU UNIV IND ACADEMIC COOP FOUND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com