Electronic device manufacturing apparatus and method for manufacturing electronic device

a manufacturing apparatus and electronic device technology, applied in the field of electronic device manufacturing apparatus, can solve the problems of insufficient size of the reaction region of the electronic device manufacturing apparatus suitable for the field of giant microelectronics, inability to control the generation inability to realize the production of structurally complex plasma, etc., to achieve the effect of improving the mass-productivity of the electronic device, improving the quality, and reducing the reaction region

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

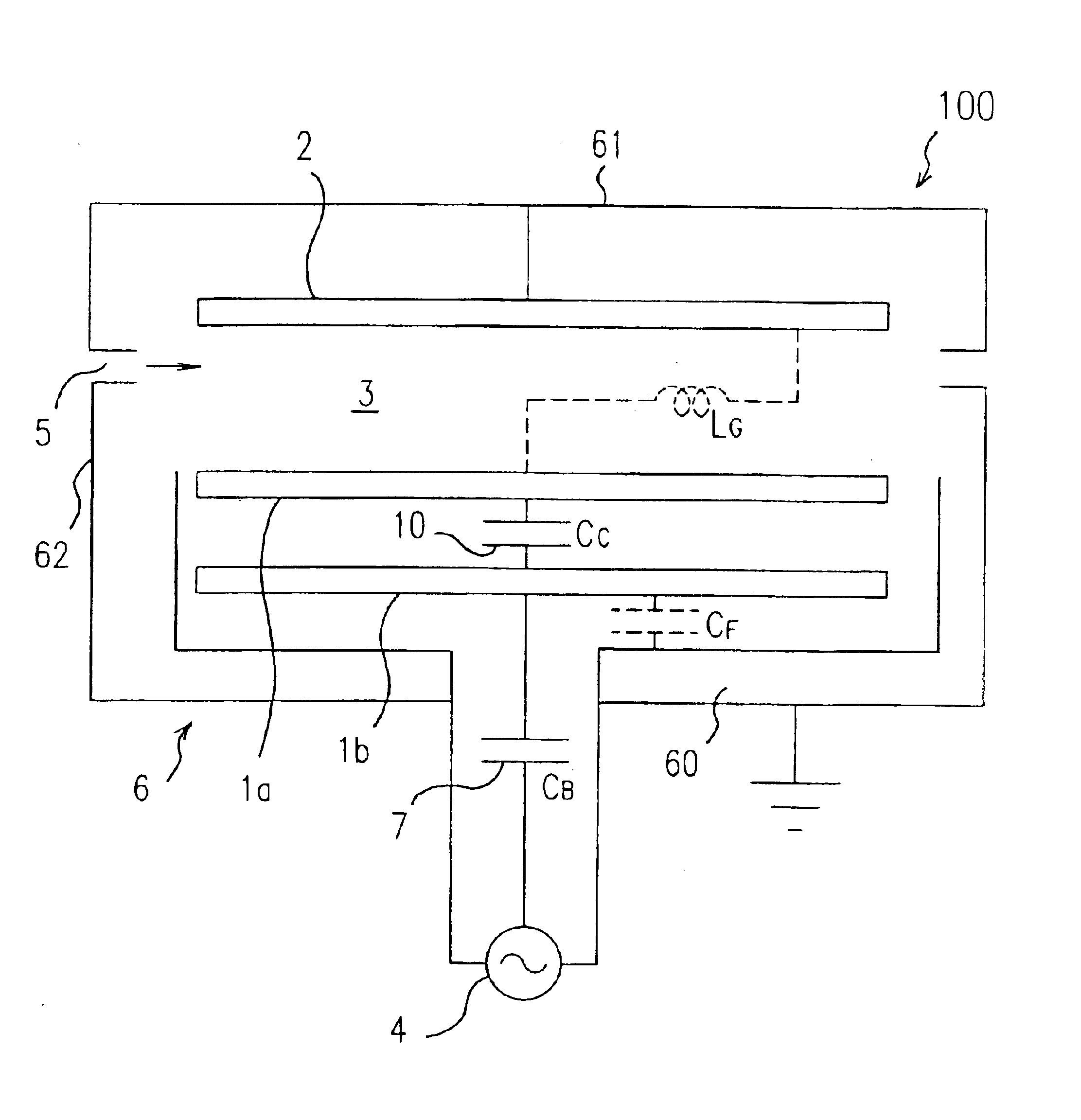

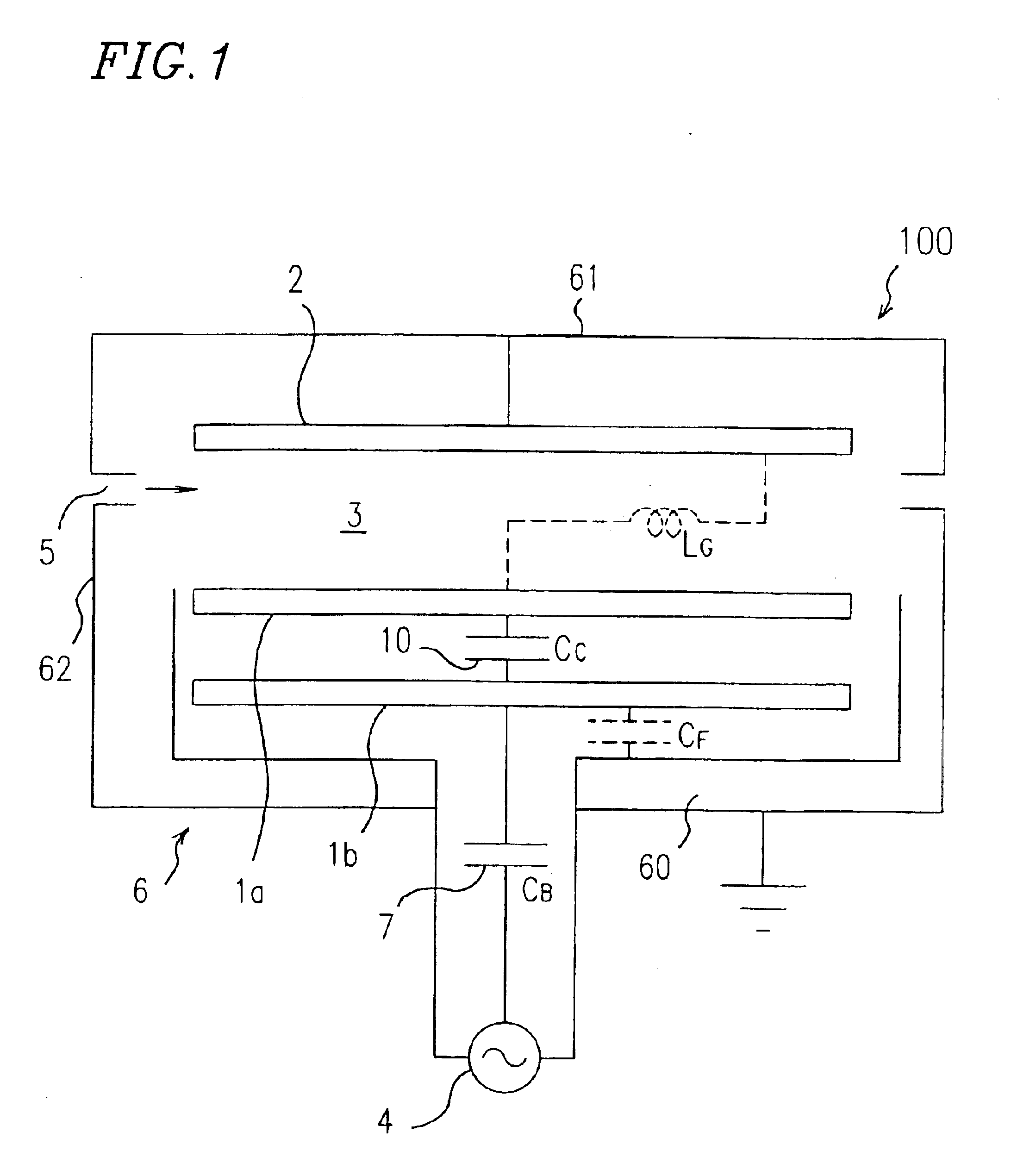

[0156]FIG. 1 illustrates an electronic device manufacturing apparatus 100 according to Example 1 of the present invention. The electronic device manufacturing apparatus 100 is implemented as a plasma CVD apparatus. The apparatus 100 includes a reaction chamber 6 which has a rectangular cross section. The anode electrode 2, the upper cathode electrode 1a and the lower cathode electrode 1b are provided within the reaction chamber 6. A bottom wall 60 of the reaction chamber 6 is grounded at some location in the right (in the figure) half thereof. The anode electrode 2 is electrically connected to an upper wall 61 of the reaction chamber 6, so as to be grounded.

[0157]The bottom wall 60 includes an opening in the middle of its length. The opening is insulated from the wall of the reaction chamber 6. A high frequency power generation source 4 is provided below the opening. The DC blocking capacitance element 7 (CB) formed of a capacitor is connected in series between the high frequency po...

example 2

[0169]FIGS. 3 and 4 are provided for illustrating an electronic device manufacturing apparatus 200 according to Example 2 of the present invention. The electronic device manufacturing apparatus 200 of Example 2 is also implemented as a plasma CVD apparatus. The difference from Example 1 is in the element that serves as the impedance adjusting capacitor having capacitance value CC. In Example 1, a capacitor is inserted to form the impedance adjusting capacitance CC. In Example 2, as shown in FIG. 3, a dielectric 11 (e.g., having a thickness of about 50 mm and a relative dielectric constant of about 3.0) is inserted to form the impedance adjusting capacitance CC between the cathode electrodes 1a and 1b. Components of the apparatus 200 of Example 2 shown in FIG. 3 which are also provided in the apparatus 100 of Example 1 are denoted by the same reference numerals and will not be described in detail below.

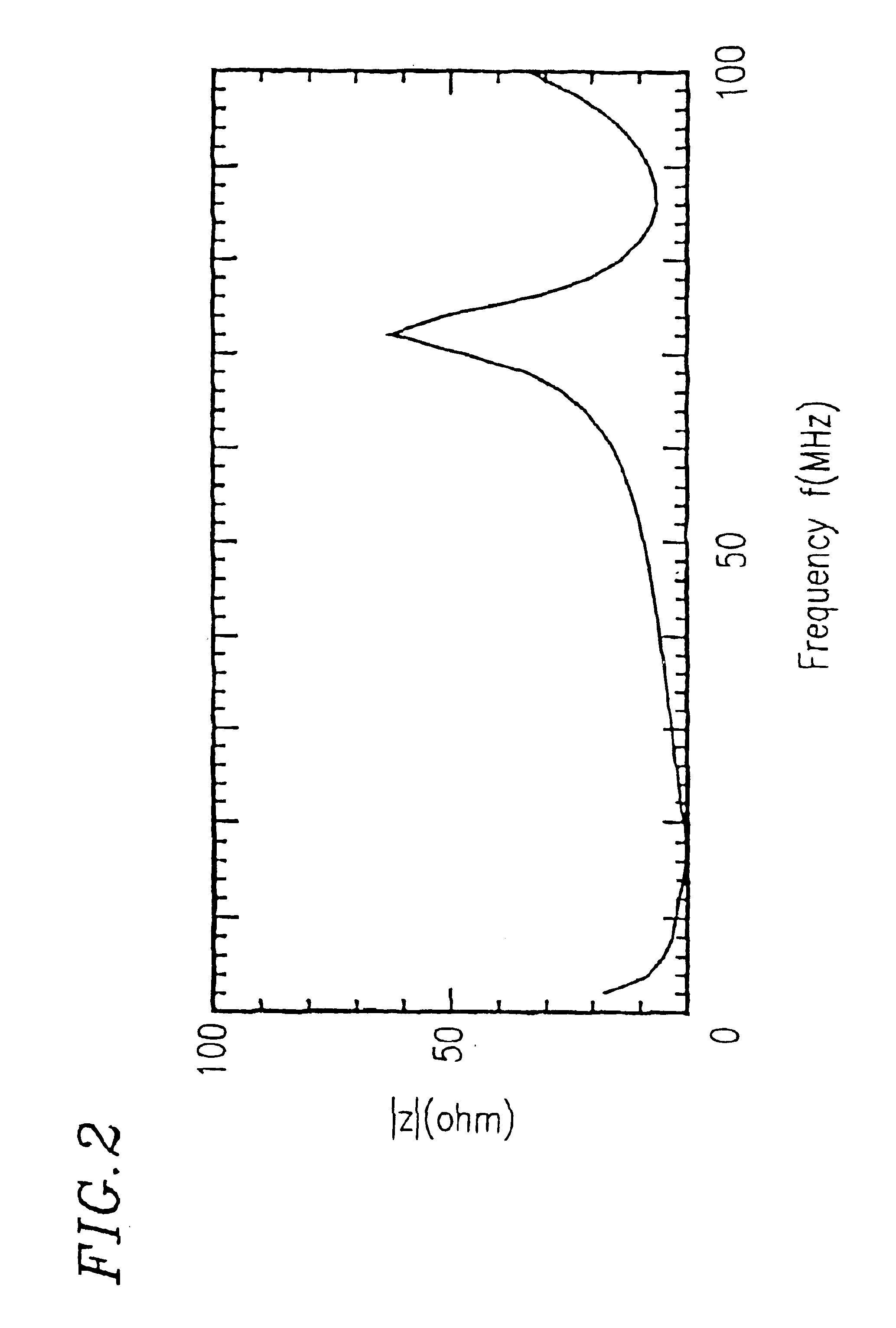

[0170]FIG. 4 shows the frequency dependency of the magnitude |Z| of the impedance ...

example 3

[0172]FIG. 5 illustrates an electronic device manufacturing apparatus 300 according to Example 3 of the present invention. The electronic device manufacturing apparatus 300 of Example 3 is also implemented as a plasma CVD apparatus. The difference from Examples 1 and 2 is as follows. In Example 3, as shown in FIG. 5, the dielectric 11 is provided on the cathode electrode 11 so as to form the impedance adjusting capacitor 11 having a capacitance value CC, while the electrode corresponding to the upper cathode electrode 1a, as in Examples 1 and 2, is eliminated. Components of the apparatus 300 of Example 3 shown in FIG. 5 which are also provided in the apparatuses of Examples 1 and 2 are denoted by the same reference numerals.

[0173]Herein, the dielectric 11 is formed of teflon having a relative dielectric constant of about 2.0 and a thickness of about 35 mm, and provides an impedance adjusting capacitance CC of about 250 pF.

[0174]In this structure, electrons in the plasma generated in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| excitation frequency | aaaaa | aaaaa |

| excitation frequency | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com