Latent holographic media and method

a technology of holographic recording medium and holographic film, which is applied in the field of precursors, can solve the problems of limited the life of the developed emulsion, poor archival stability, and low dynamic range of silver halide materials, and achieve the effect of improving signal resolution and improving diffraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment a

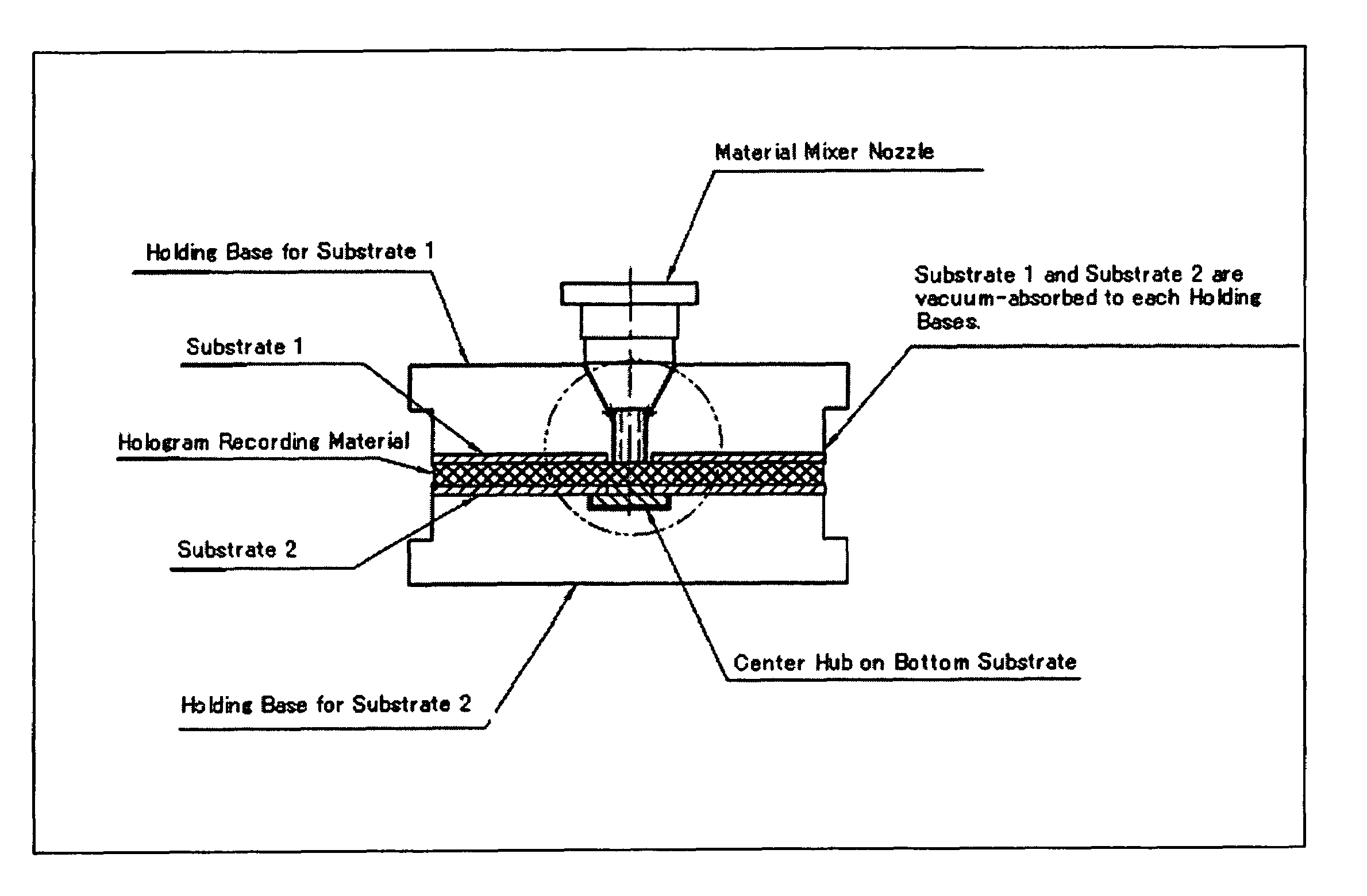

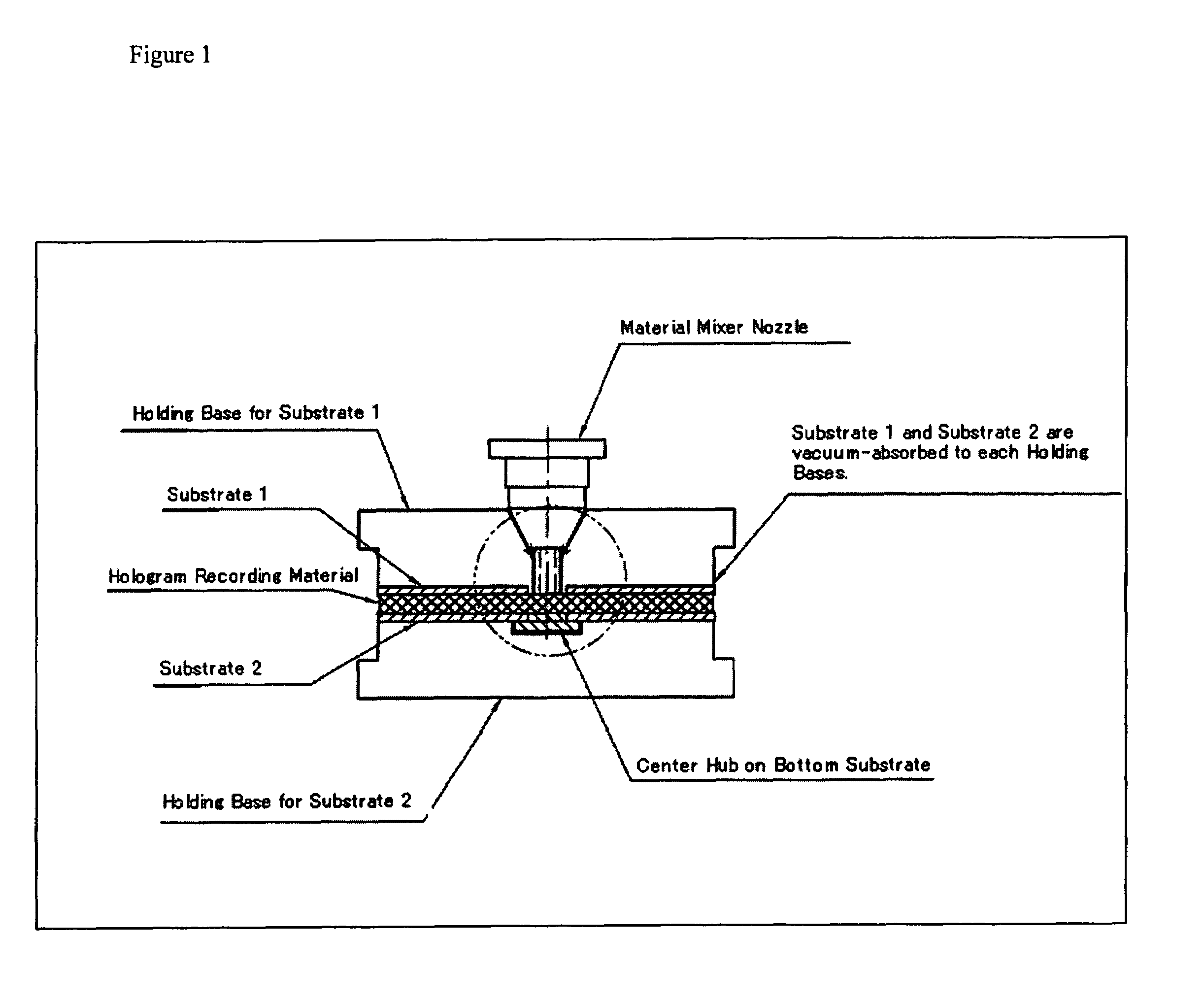

[0100]The preferred method used for making media of Embodiment A would be the following: Mix all chemical components (matrix or matrix precursor(s), monomer(s), photoinitiator(s), and developer(s)) together until homogeneous, then apply to substrate(s) or into mold(s). Optional packaging such as labeling, placing in a cartridge, etc. can then be performed. Substrates may already have antireflective coatings, labels, or tracking patterns already present.

[0101]The preferred method used for exposing media of embodiment A is the following: An article of media of Embodiment A, is exposed to light, to which it is sensitive. During this light exposure, photopolymerization occurs which chemically records the spatial light intensity distribution. A hologram capable of being read may or may not be present at this stage. Once the exposure schedule is completed (which may include a blanket irradiation step in which any unused monomer is reacted as much as possible), the recorded area is exposed...

embodiment b

[0110]In this embodiment, the media comprises at least one of each of the following components: a matrix, a photoactive chemical which contains functionality to which the developer attaches upon activation, and a developer. A preferred method to manufacture media of embodiment B is as follows. Mix all chemical components together until homogeneous, then apply to substrate(s) or into mold(s). Optional packaging such as labeling, placing in a cartridge, etc. can then be performed. Substrates may already have antireflective coating, labels, or tracking patterns present.

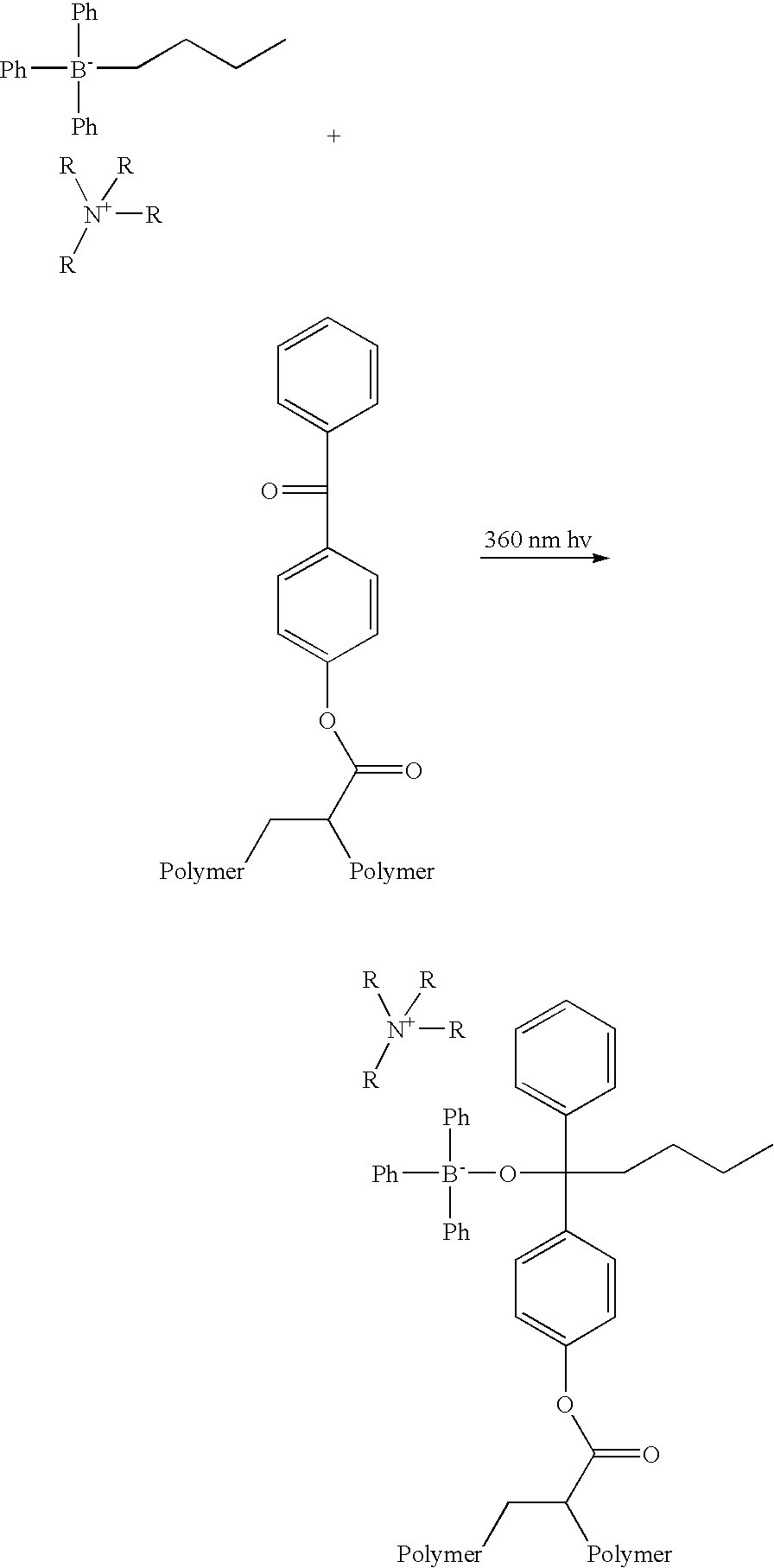

[0111]A preferred method for exposing media of embodiment B is as follows. An article of media of Embodiment B is exposed to light, to which it is sensitive. During this light exposure, the photoactive chemical bonds to the matrix to chemically record the spatial light intensity; a hologram capable of being read may or may not be present at this stage. Once the exposure schedule is completed (which may include a blanket ...

embodiment c

[0118]In this embodiment, the media comprises at least one of each of the following components: a photoactive matrix and a developer. A preferred method to manufacture media of embodiment C is as follows. Mix all chemical components together until homogeneous, then apply to substrate(s) or into mold(s). Optional packaging such as labeling, placing in a cartridge, etc. . . . can then be performed. Substrates may already have antireflective coating, labels, or tracking patterns already present.

[0119]A preferred method for exposing media of embodiment C is as follows. An article of media of Embodiment C, is exposed to light, to which it is sensitive. During this light exposure, the photoactive matrix records the spatial light intensity by forming active attachment sites; a hologram capable of being read may or may not be present at this stage. Once the exposure schedule is completed then the area recorded to is exposed to an energy source (as the activation step) such that the develope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com