Apparatus and method for reducing microorganisms on produce using chlorine dioxide gas

a technology of apparatus and produce, which is applied in the field of apparatus and method for reducing microorganisms on produce using chlorine dioxide gas, can solve the problems of limited effect of aqueous clone to decontaminate fruits and vegetables, ineffective in reducing pathogens on produce surfaces, and ineffective in reducing population

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

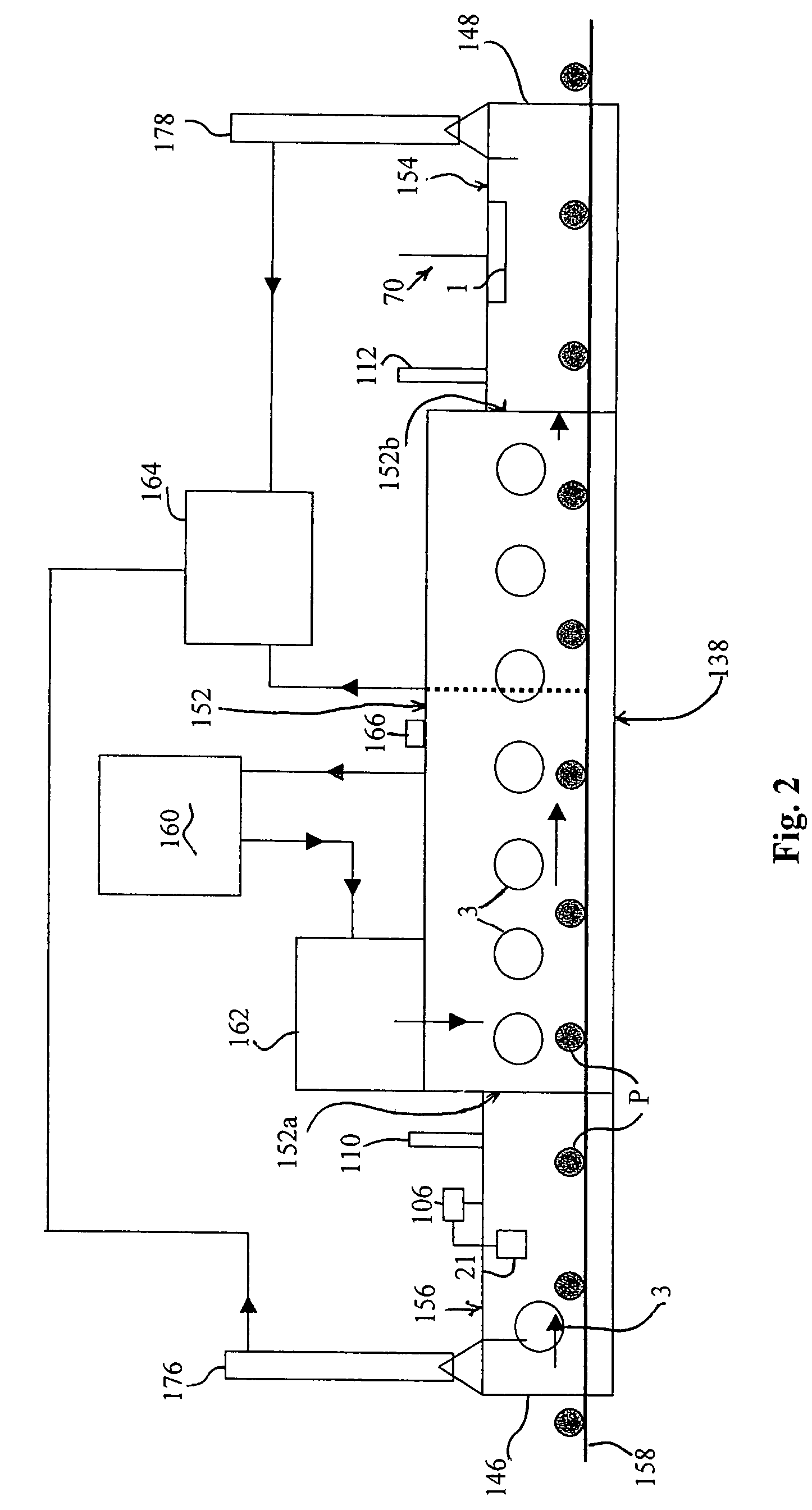

Image

Examples

example 1

Decontamination of Strawberries

[0042]Concerns have been raised about the microbial safety of strawberries because strawberries have been associated with three major outbreaks of hepatitis A, a virus spread by human feces, and a protozoan, Cyclospora cayetanensis. The source of contamination was thought to be from infected harvesters or contaminated irrigation water. It has been reported that foodborne pathogens, such as E. coli O157:H7 and Salmonella spp., can survive but not grow on the surface of fresh strawberries throughout the expected shelf life of the fruit and even survive in frozen strawberries for periods of greater than 1 month.

[0043]A cocktail mixture of E. coli O157:H7 strains (C7927, EDL933, 204P) and a mixture of L. monocytogenes strains (Scott A, F5069, LCDC 81-861) were utilized as target pathogens. Strawberries were spot-inoculated with 7-8 log cfu / strawberry of each pathogen (0.1 ml culture), stored for 1 day and 7 days at 4° C. Bacterial populations on the sample...

example 2

Decontamination of Cantaloupes

[0050]Salmonellosis is one of the most common forms of foodborne illness. In recent years, there have been three multistate outbreaks of Salmonelleosis caused by contaminated cantaloupes, all of which involved consumption from either salad bars or fruit salads. Cantaloupes can become tainted at any time during growth, harvest, distribution, processing, and handling due to frequent exposure to soil, insects, humans, or other contaminated products. The rough texture and hydrophobic nature of the surfaces of cantaloupes enable bacteria to readily attach—and can be difficult to remove. Although Salmonella cannot readily multiply on the outer surfaces of cantaloupes, the cells can be transferred to the flesh during slicing, making precut slices of fruit vulnerable to Salmonella growth. This may account for outbreaks of foodborne illness from salad bars or fruit salads that contain cantaloupes.

[0051]A cocktail mixture of 5 Salmonella strains (S. enteritidis, ...

example 3

Decontamination of Mushroom

[0058]Fresh uncut mushrooms were washed in tap water and allowed to air dry prior to inoculation with a cocktail containing five Salmonella strains (S. enteritidis, S. Poona, S. choleraesius, S. typhi, and S. anatum). Mushroom samples were spot inoculated with 0.1 ml of mixed 18-24 hr culture at two different locations (top of the cap and the underside of the cap). After the spot inoculation areas were allowed to dry. Mushrooms were then treated in an apparatus similar to FIG. 1 using a 10 L Irvine Plexiglass cylinder as the chamber and a stainless steel shelf therein as the produce receiver, where two inoculated mushrooms were laid on their side in the chamber. A wireless Thermo-Hygro recorder (RadioShack Corporation, Fort Worth, Tex.) was used to monitor relative humidity and temperature inside the treatment chamber. Gaseous ClO2 was produced using 0.5% chlorine gas in nitrogen using a laboratory chlorine dioxide generator (CDG Technology, Philadelphia, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com