Middle/high carbon steel sheet and method for manufacturing same

a high carbon steel and middle/high carbon steel technology, applied in manufacturing tools, heat treatment equipment, furnaces, etc., can solve the problems of not always providing the desired effect, revealing anything about knowledge and techniques, and reducing the area of the reduction, so as to achieve excellent workability, favorable deep drawability, and excellent reduction in size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

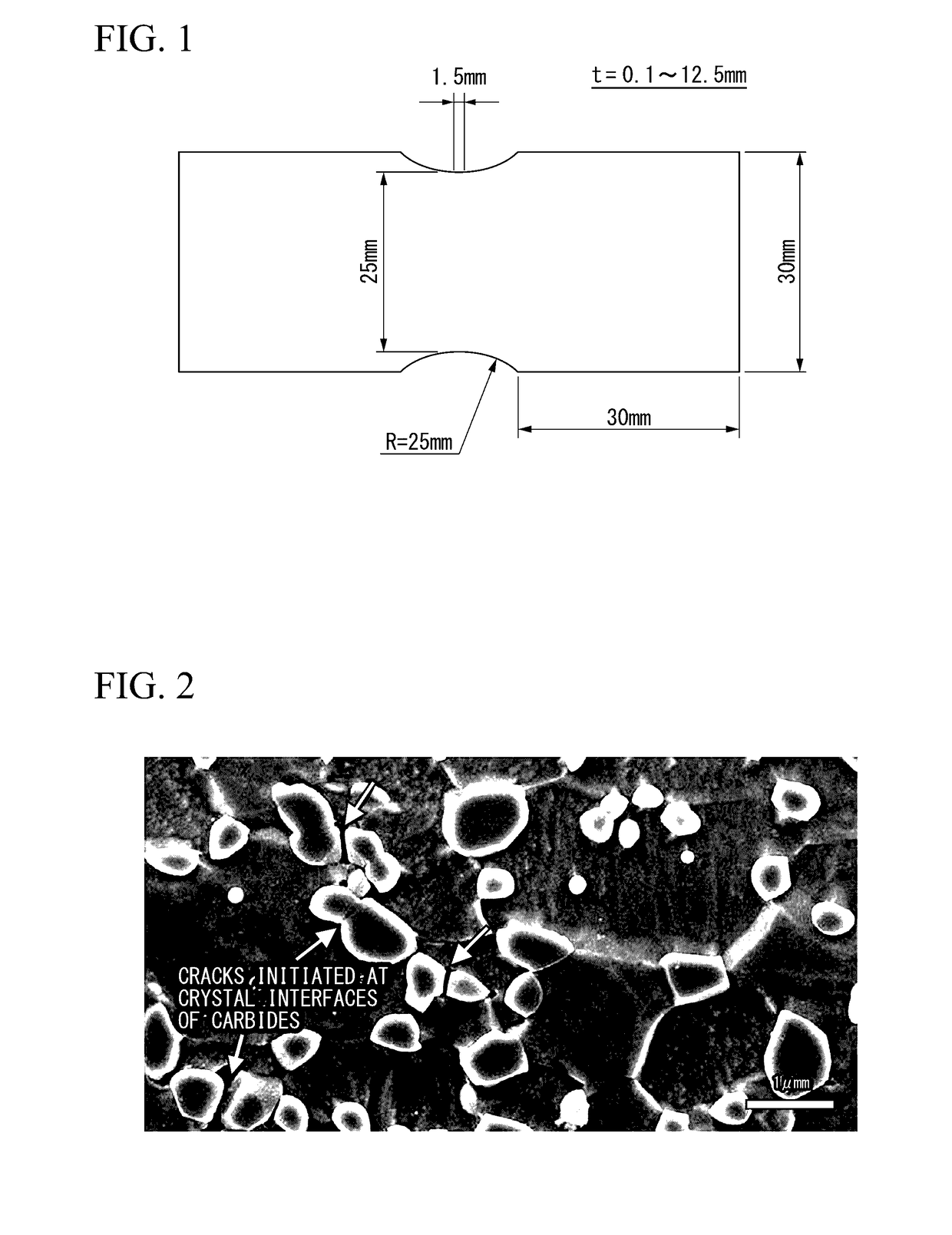

[0118]Next, the effects of the present invention will be described using examples.

[0119]The levels of the examples are examples of conditions for carrying out the present invention which were employed to confirm the feasibility and effects of the present invention, and the present invention is not limited to these condition examples. The present invention allows employment of a variety of conditions within the scope of the gist of the present invention as long as the object of the present invention is achieved.

[0120]Continuous cast pieces (steel ingots) having a composition shown in Table 1 were heated at 1,140° C. for 1.6 hours and then were hot-rolled, thereby obtaining 250 mm-thick slabs. The slabs were roughly hot-rolled to a thickness of 40 mm, rough bars, which are materials for finishing hot-rolling, were heated by 36° C. so as to initiate finish hot-rolling, the rough bars were finishing-hot-rolled at 880° C., then, were cooled to 520° C. on ROT at a cooling rate of 45° C. / s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com