High yield and enhanced performance fiber

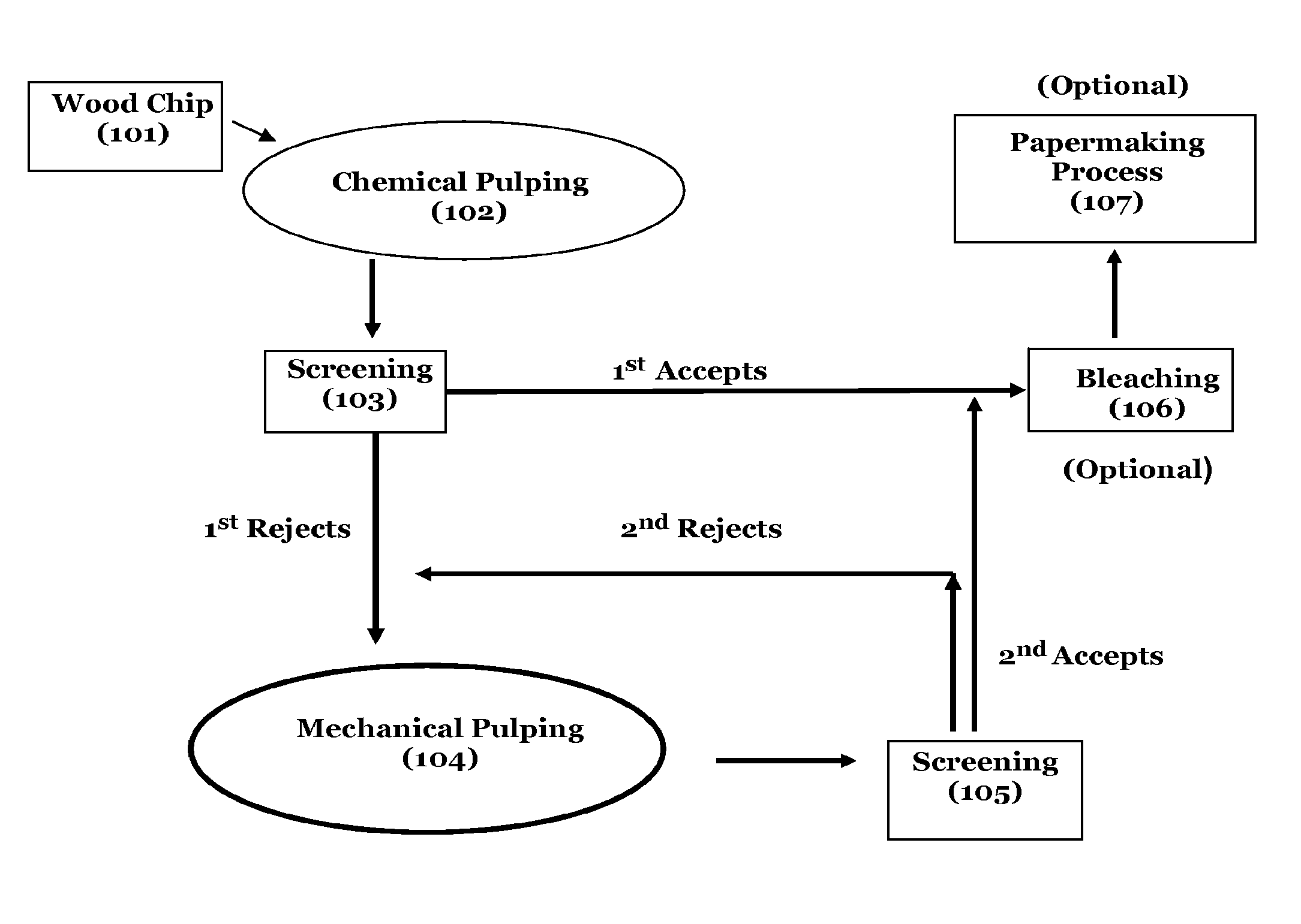

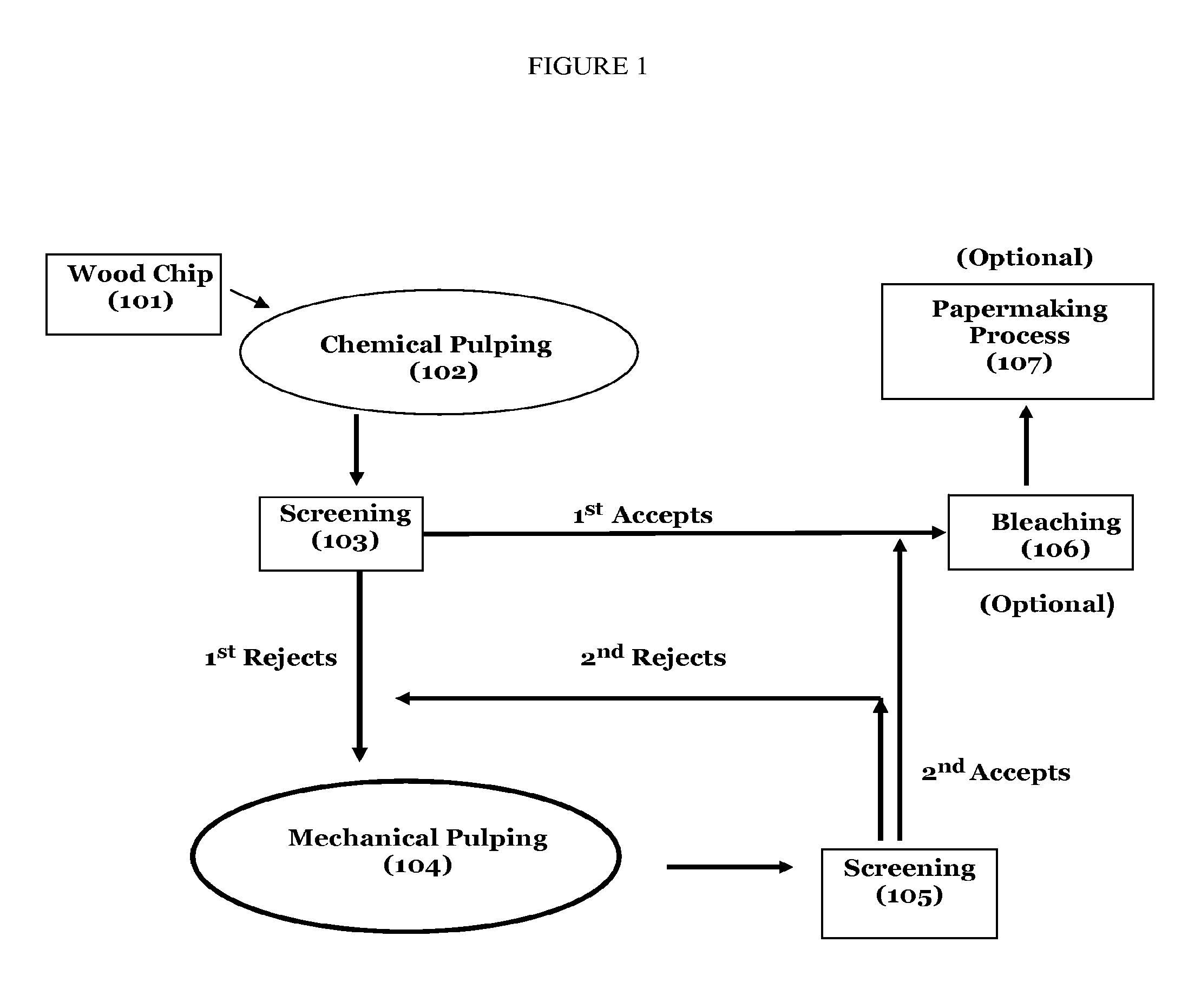

a fiber and high yield technology, applied in the multi-stage pulping process, papermaking, inorganic base pulverizing, etc., can solve the problems of high operational energy consumption of mechanical pulps, low fiber yield, and poor strength of mechanical pulps, so as to improve stiffness and strength, enhance properties, and increase yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

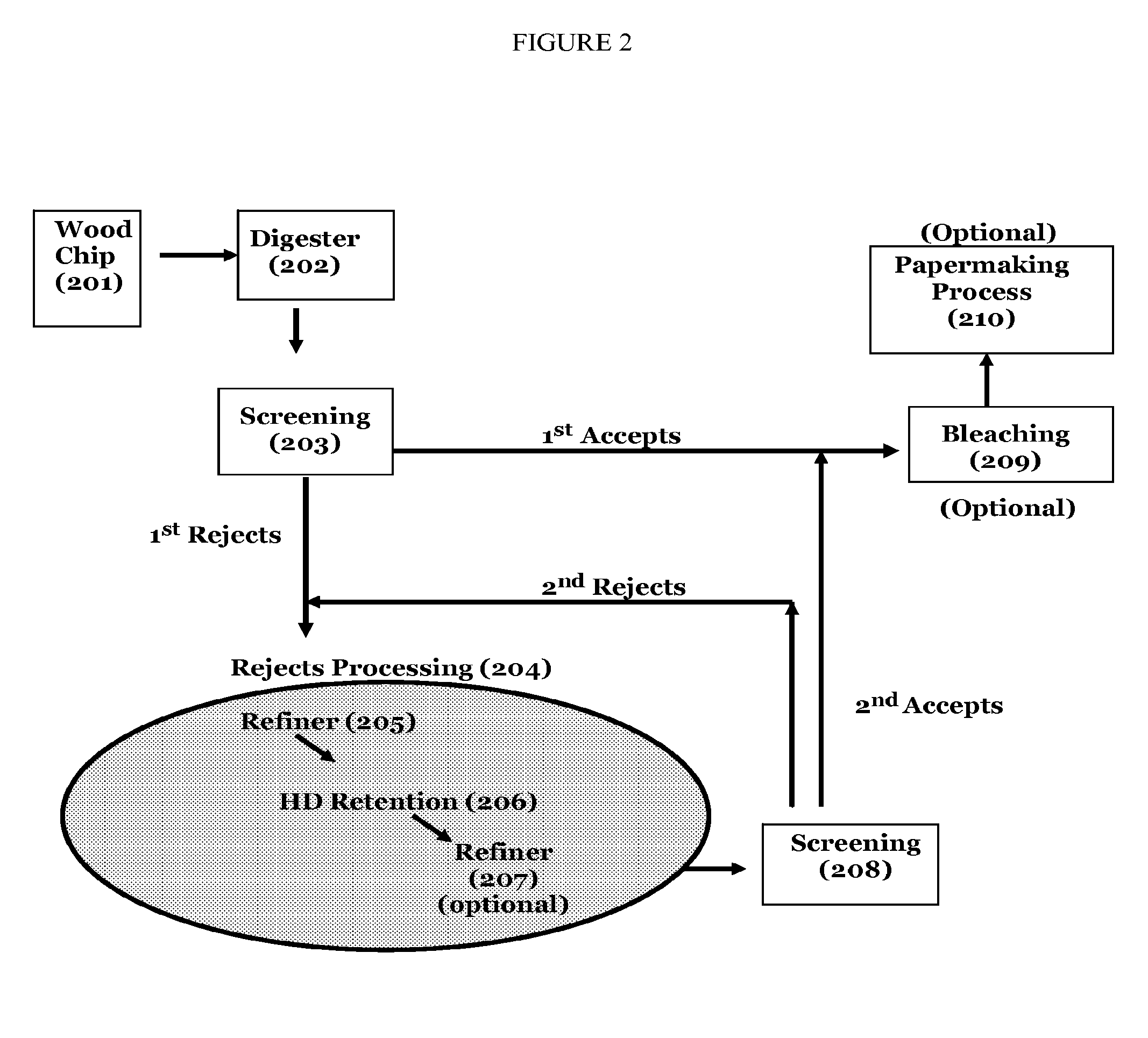

[0043]Hardwood chips were Kraft pulped in a digester to a kappa number of 50 to provide a first amount of pulp containing a first accepts component and a first rejects component. The first accepts component was separated from the first rejects component using a 0.085″ hole screen followed by a 0.008″ slotted screen. The first rejects component was then thickened to 30% consistency, and then refined and pre-bleached by an APMP type alkaline pulping process using alkaline peroxide in a high consistency refiner to generate a second amount of pulp containing a second accepts component and a second rejects component. The second accepts component was separated from the second rejects component and shives using a 0.008″ slotted screen, and then from the smaller fiber bundles that passed the 0.008″ screen using a 0.006″ slotted screen.

[0044]The resulting second accepts component was added back to a stream of the first accepts component. The resulting fiber blend, comprising 70% by weight of...

example 2

[0055]Hardwood chips were Kraft pulped in a digester to a kappa number of 70 to provide a first amount of pulp containing a first accepts component and a first rejects component. The first accepts component was separated from the first rejects component using a 0.110″ hole screen followed by a 0.008″ slot screen. The first rejects component was then thickened to 30% consistency, and then refined with an APMP type alkaline pulping process using caustic or alkaline peroxide in a high consistency refiner to generate a second amount of pulp containing a second accepts component and a second rejects component. The second accepts component was separated from the second rejects component and shives using a 0.008″ slotted screen, and then from the smaller fiber bundles that passed the 0.008″ screen using a 0.006″ slotted screen. A portion of the first accepts was retained as an independent fiber. The remainder of the first accepts fiber was used to produce fiber blends.

[0056]A portion of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| kappa number | aaaaa | aaaaa |

| kappa number | aaaaa | aaaaa |

| kappa number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com