Adhesive with tunable porosity and methods to support temporary bonding applications

- Summary

- Abstract

- Description

- Claims

- Application Information

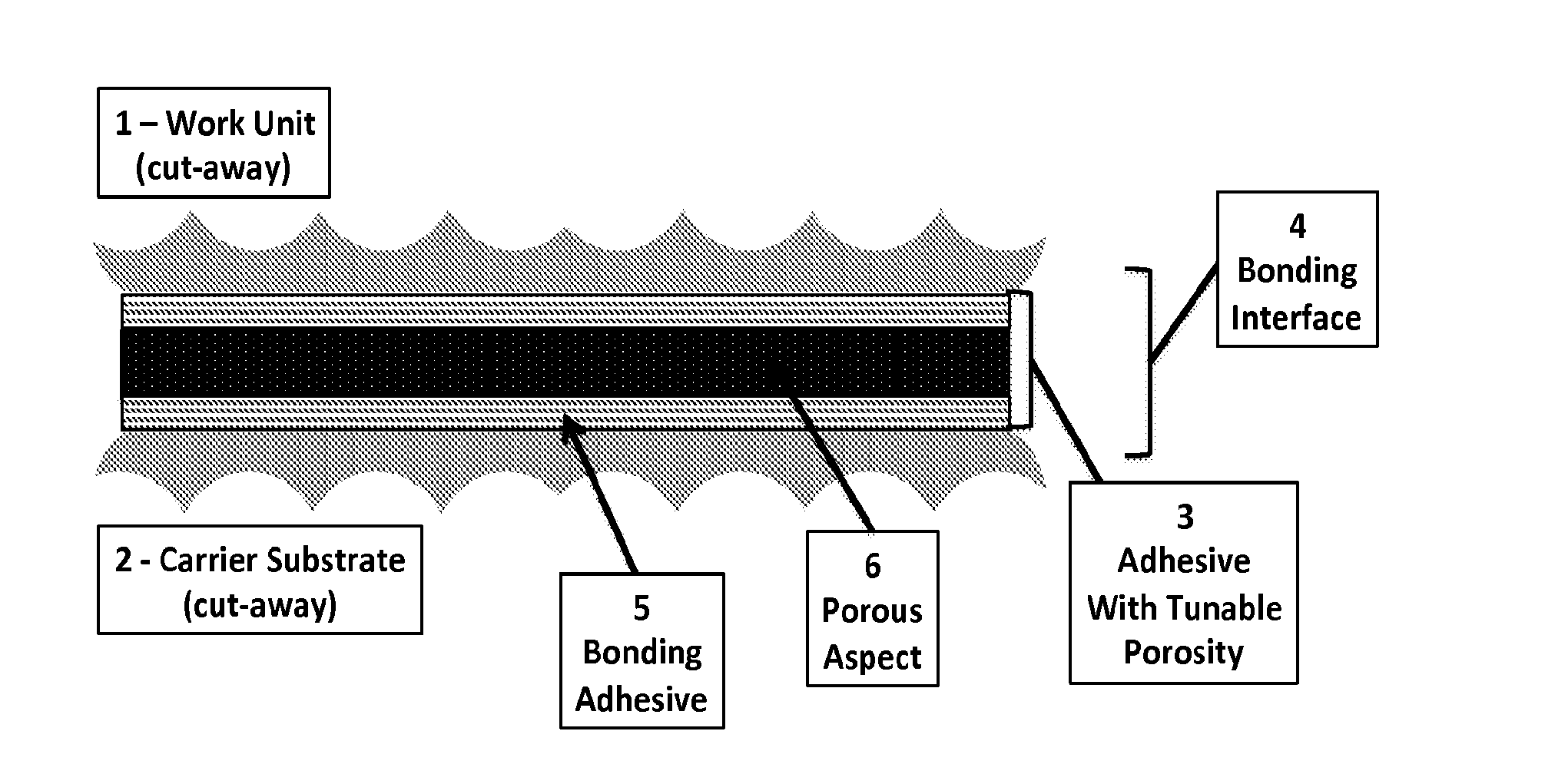

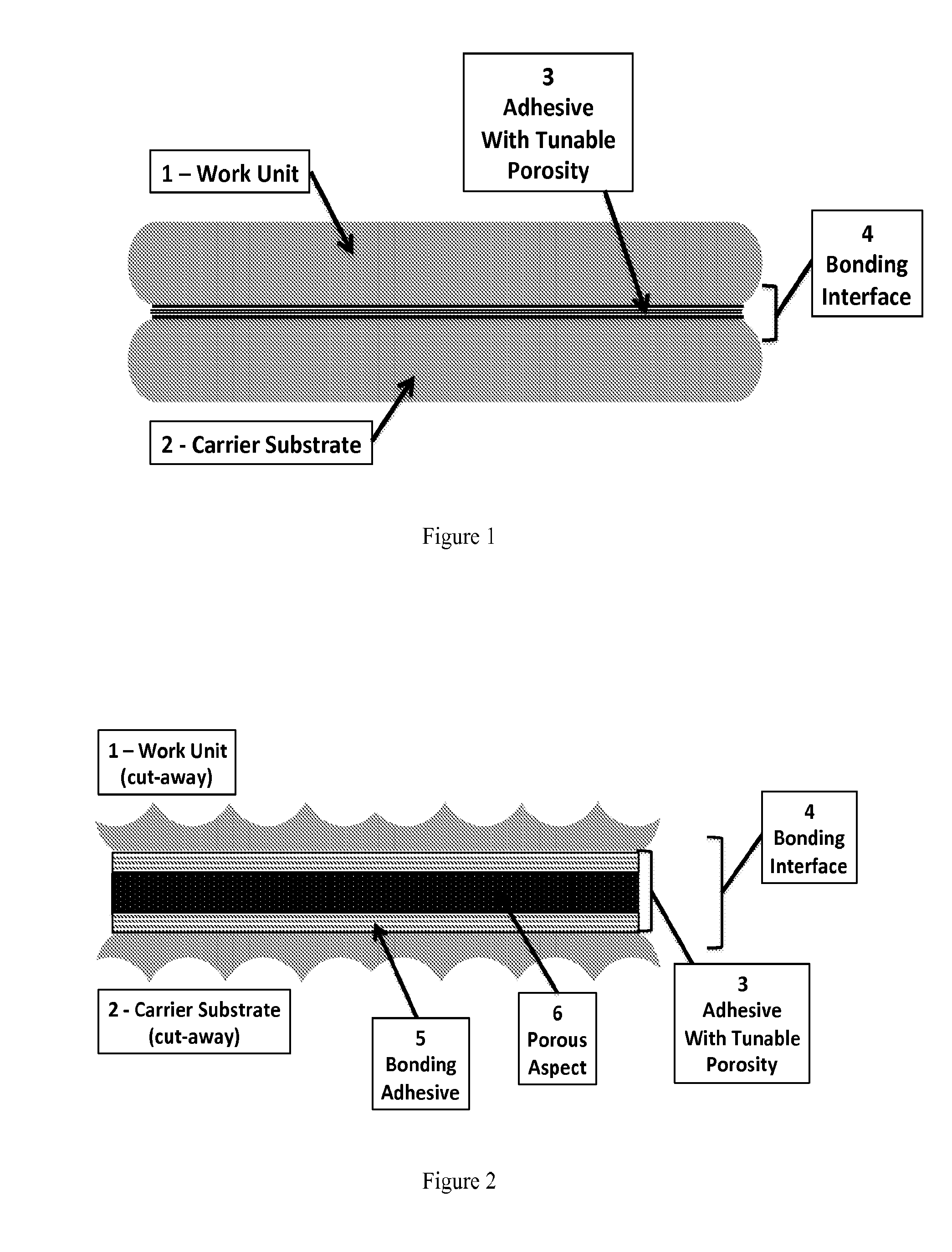

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

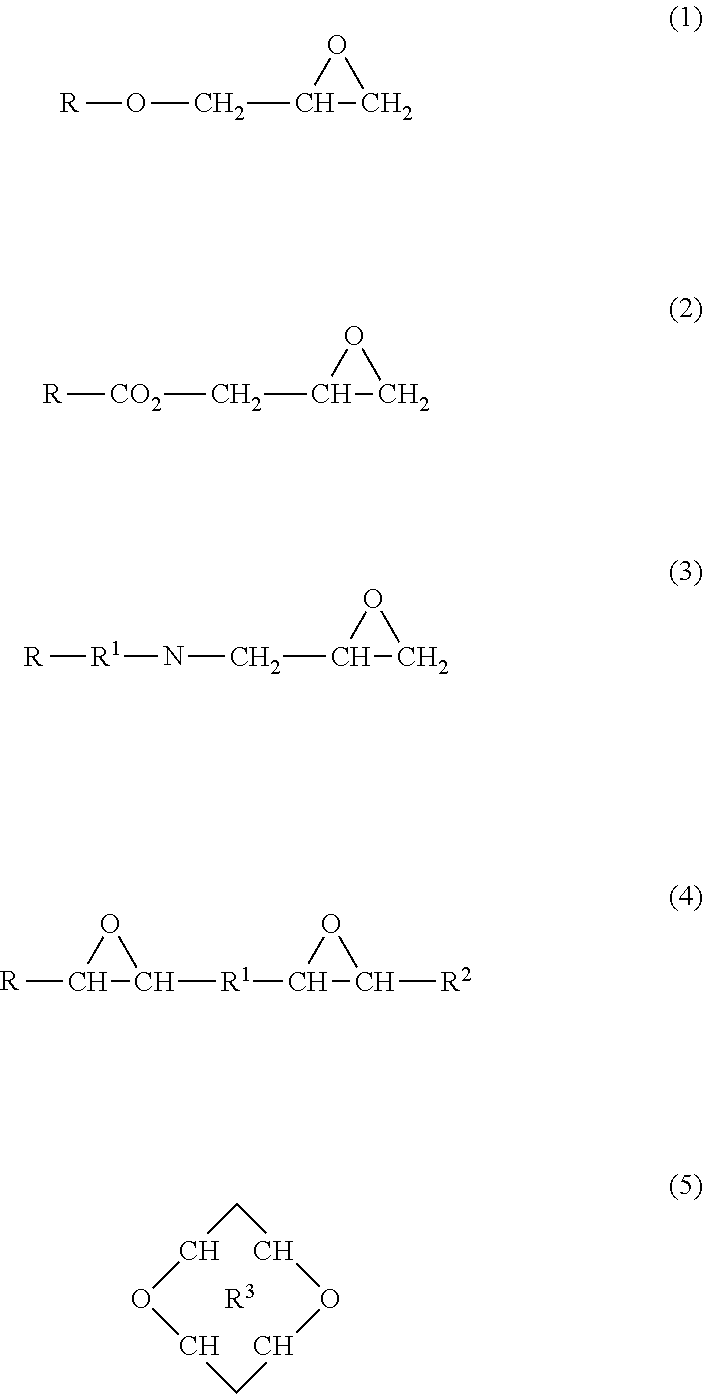

[0040]The compositions of the invention and the method of demonstrating the examples are described. It is understood, however, that the invention is not meant to be limited to the details described therein. In the examples, the percentages provided are percent (%) by weight unless otherwise stated. The invention is further illustrated, without limitation, by the following examples. The measurement of performance and selectivity of the invention is conducted using practices readily accepted by the industry.

[0041]Coatings are produced on a Brewer Science, Inc. CB-100 spin-coater, while spray and encapsulation uses custom tooling designed at Daetec. Metrology data is generated by a XP-1 stylus profiler, AFP-200 atomic force profiler, and a Xi-100 optical profiler (www.kla-tencor.com), using equipment settings 5 mg stylus load, minimum 4 mm distance, and a speed of 0.5 mm / sec. Modified thermogravimetric test methodology for outgas is conducted by typical laboratory scales (+ / −0.1 mg). U...

example # 1

Example #1

[0043]The following experiments demonstrate the relationship of liquid penetration by capillary activity through an adhesive matrix prepared with a specific amount of binder and filler. Experiment #1 indicates the trend of faster penetration and release as thickness is reduced. Experiment #2 suggests improved penetration and release as the filler:binder ratio is increased. For both experiments, the polymer binder is a thermoplastic polyurethane (TPU), identified as Estane 5715 TPU, exhibiting a glass transition (Tg) and softening point of 23 C and 55 C, respectively, produced by Lubrizol Advanced Materials, Inc. (www.estane.com). The chosen filler for these experiments is a milled glass fiber identified as Microglass 3082, which includes fiber diameters and length of 16 um and 120 um, respectively, as manufactured by Fibertec (www.fibertecinc.com). Appearance of the milled glass is a powder. The TPU is dissolved into n,n-dimethylacetamide (DMAC) at approximately 25% solids...

example # 2

Example #2

[0045]A series of bonded glass pairs are prepared with a binder:filler ratio measured over a range between 0.4 and >2.0. Thickness of each adhesive composite is maintained constant at approximately 1.0 mm. The time to achieve full penetration and release of the bonded glass pair in AA7:DMSO is measured and reported in Table 2.

TABLE 2Penetration and release in AA7:DMSO of thebonded pair adhesive composite film prepared as binderEthane 5715 TPU with filler Microglass 3082, exhibitinga filler:binder ratio of 1.0. Thickness are varied as stated.Penetration &ThicknessFiller:Binderrelease time#(mm)ratio(sec)11.00.490021.01.030031.02.430

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ratio | aaaaa | aaaaa |

| Adhesivity | aaaaa | aaaaa |

| Porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com